P O R T F O L I O E

C

K

S M A

E T I N

A Y A

E S U M E SKILLS AND SOFTWARE PROFIENCY

.Communication and Time Management Skills

.Task oriented

.Adaptability and Flexibility

.Teamwork and Collaboration Skills

EDUCATION

. SketchUp

. Twinmotion

. Illustrator

. Revit

. AutoCad

.

Photoshop

.

Ms PowerPoint

Ms Office

.

REXPERIENCE

.

ADVANCED DIPLOMA PROGRAM IN ARCHITECTURAL TECHNOLOGY

George Brown College| 2022 - 2024

Architectural Technology Program

.

DEGREE PROGRAM IN URBAN PLANNING

Suleyman Demirel University | 2019 - 2021

City and Urban Planning Program

UNIVERSITY VOLUNTARY WORK

Suleyman Demirel University - 2020

Attended evaluation of existing neighborhood parks in terms of “need-based equity”

UNIVERSITY VOLUNTARY WORK

Suleyman Demirel University - 2020

Attended renovation and transformation project of Başköy School

UNIVERSITY VOLUNTARY WORK

Suleyman Demirel University - 2019

Attended foundation organization improvement of life environments for the development and care of children.

UNIVERSITY VOLUNTARY WORK

Suleyman Demirel University - 2019

Attended renovation and transformation project of İnönü Primary School

Turkish . English

.

I am a motivated and detail-oriented architectural technologist with an Advanced Diploma in Architectural Technology. My proficiency in AutoCAD, Revit, and other design softwares, combined with a strong understanding of building codes, construction methods, and materials, enables me to deliver exceptional results in my work.

My ability to communicate effectively and work well in a team environment is a testament to my collaborative approach to projects. Additionally, I have a passion for continuing education and professional development, as I believe that learning never stops and there is always room for improvement.

With my experience and expertise, I am confident in my ability to contribute to any architectural project and bring a high level of dedication and commitment to every task at hand.

Esmanurctnk98@gmail.com 416-820-4851 48 Lawnside Dr. North York / ON A B O U T M E

“Architecture is not based on concrete and steel, and the elements of the soil. It’s based on wonder. It’s based on a sense of adventure and a desire to create something beautiful and timeless.”

- Daniel Libeskind`

C O N T E N T AUTOMOTIVE DEALERSHIP PORSCHE - 2023 pg. 18 02 THE HILLCREST COMMUNITY NATURE CETRE - 2022 pg. 26 03 WAREHOUSE PROJECT - 2023 pg. 34 04 pg. 6 01 HIGH RISE CONDOMINIUM PROJECT - CURVALUX - 2023 URBAN HAVEN MIXED BUILDING PROJECT - 2022 05 pg. 46 06 POINT CLOUD PROJECT - 2023 pg. 58

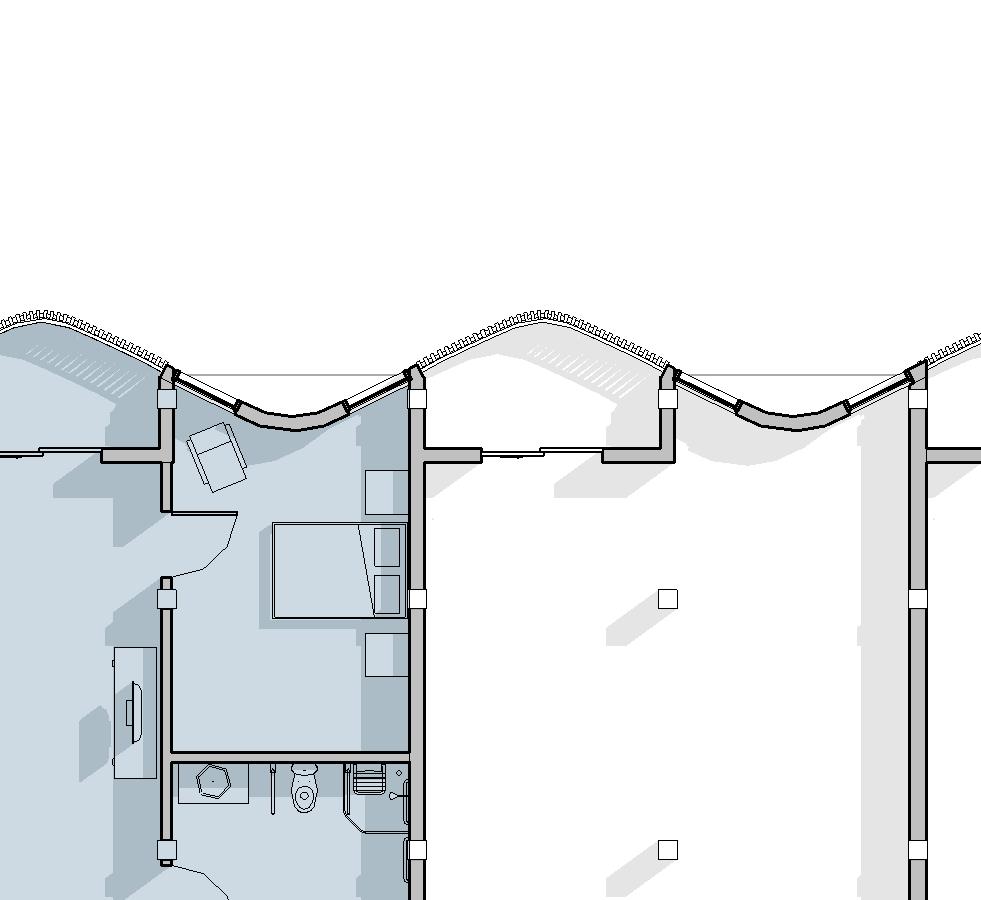

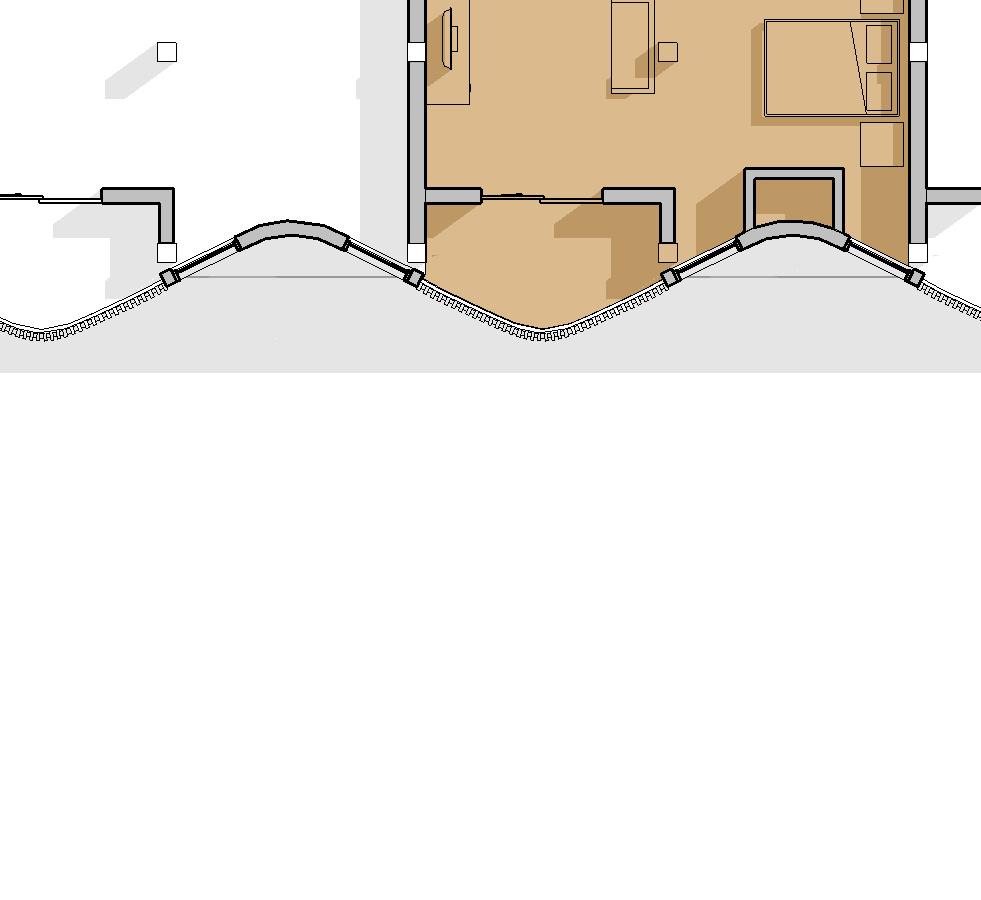

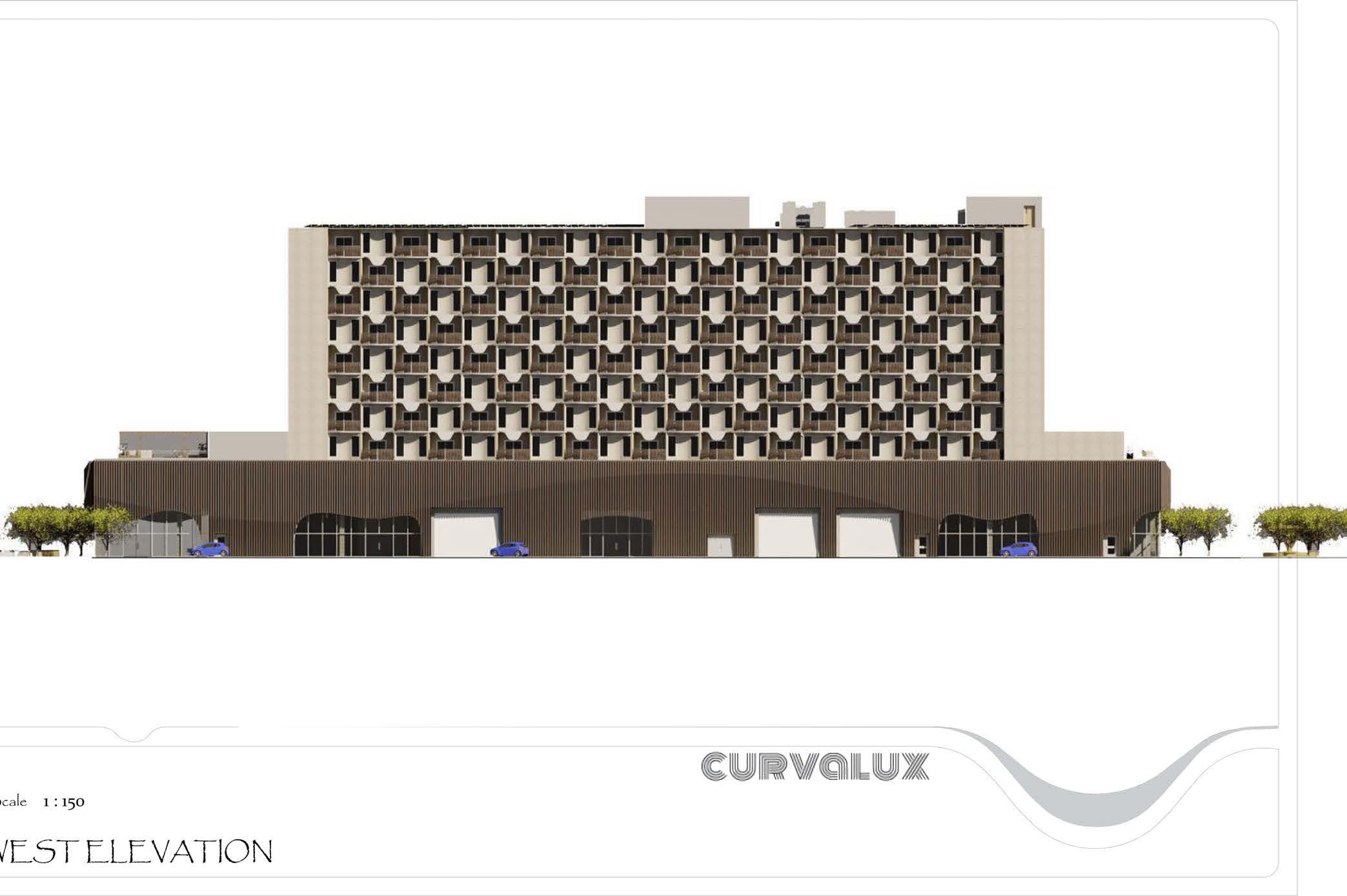

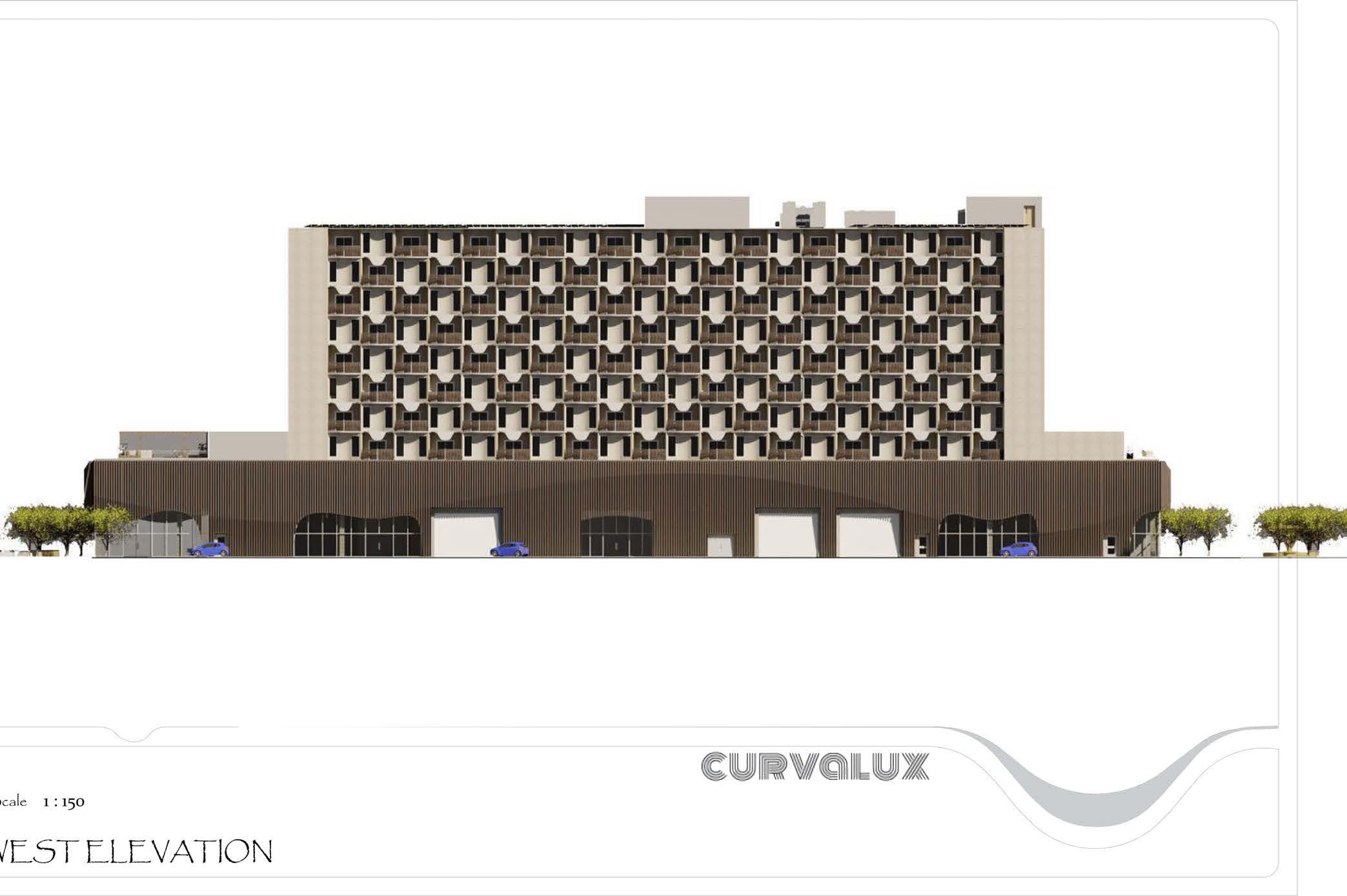

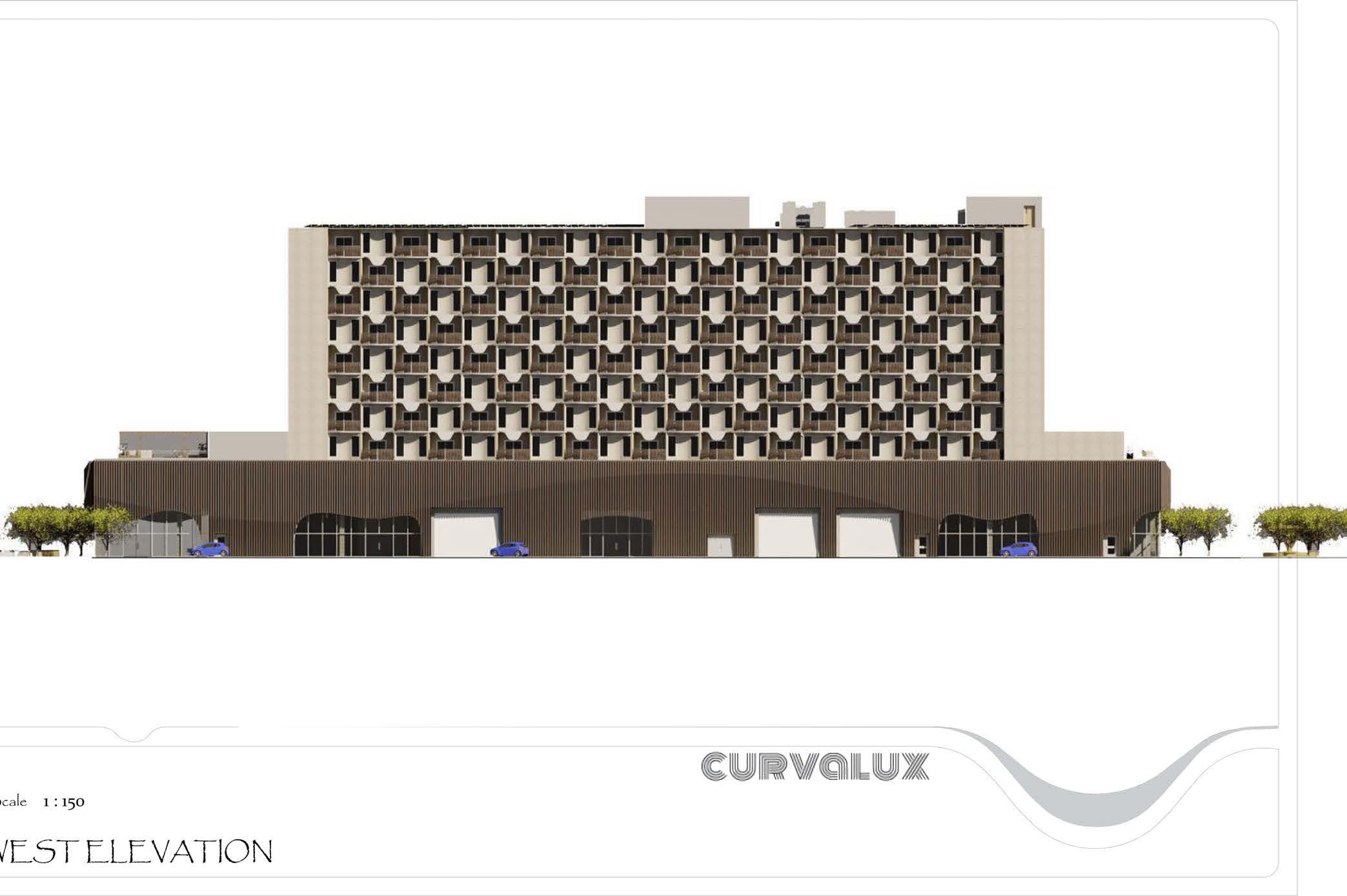

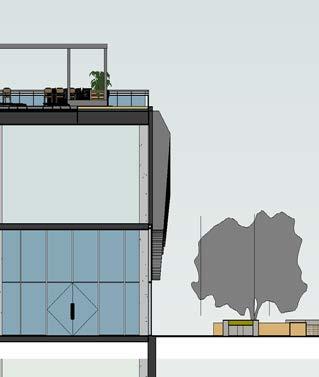

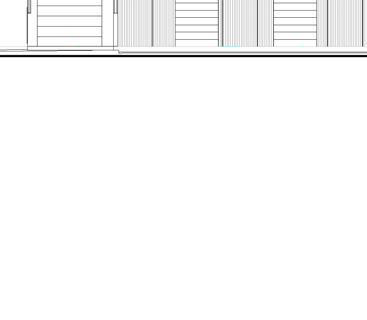

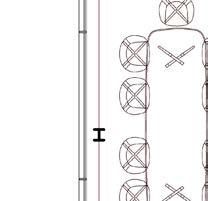

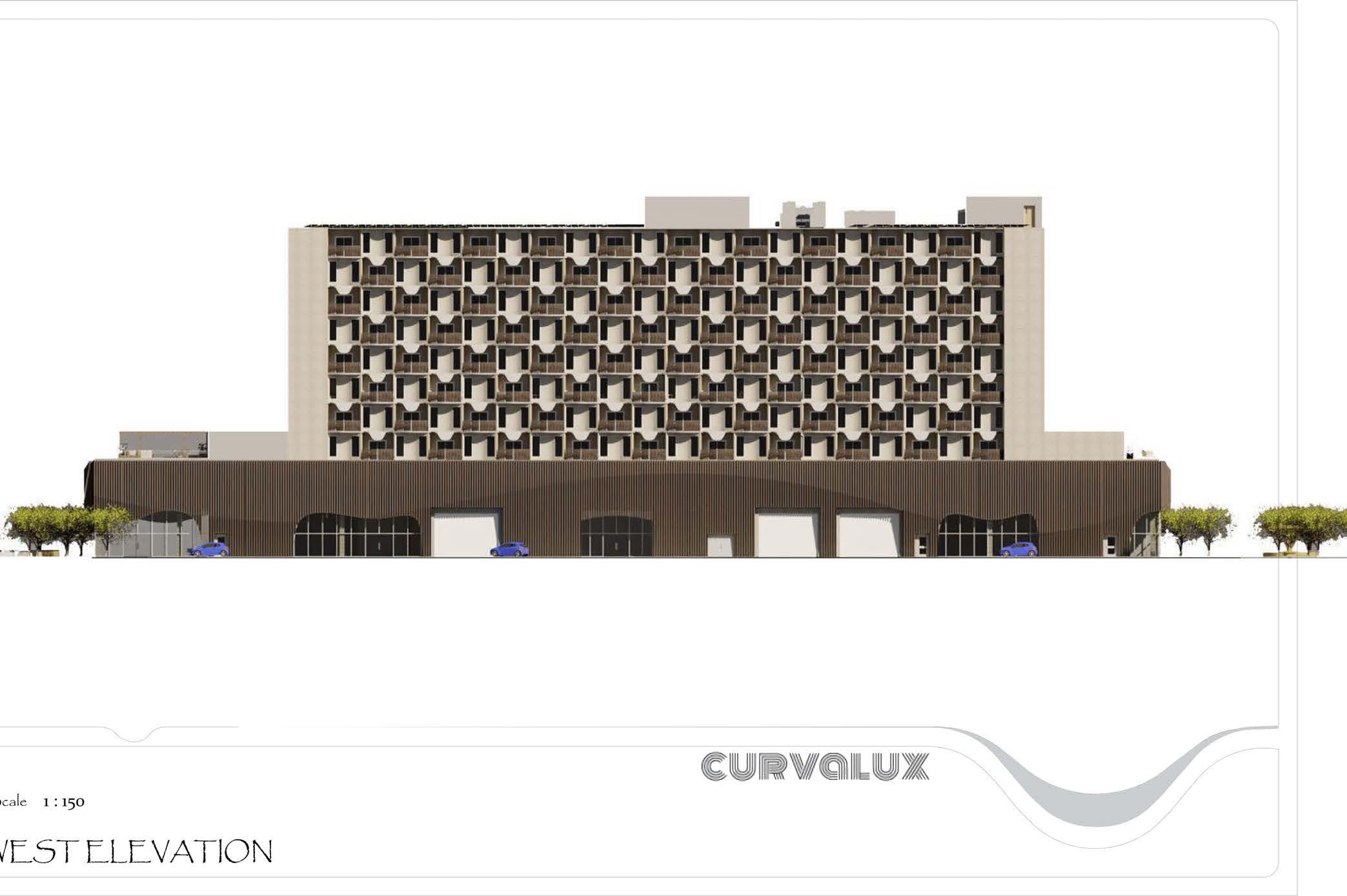

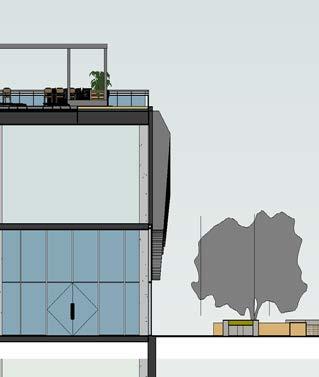

HIGH RISE CONDOMINIUM PROJECT CURVALUX - 2023

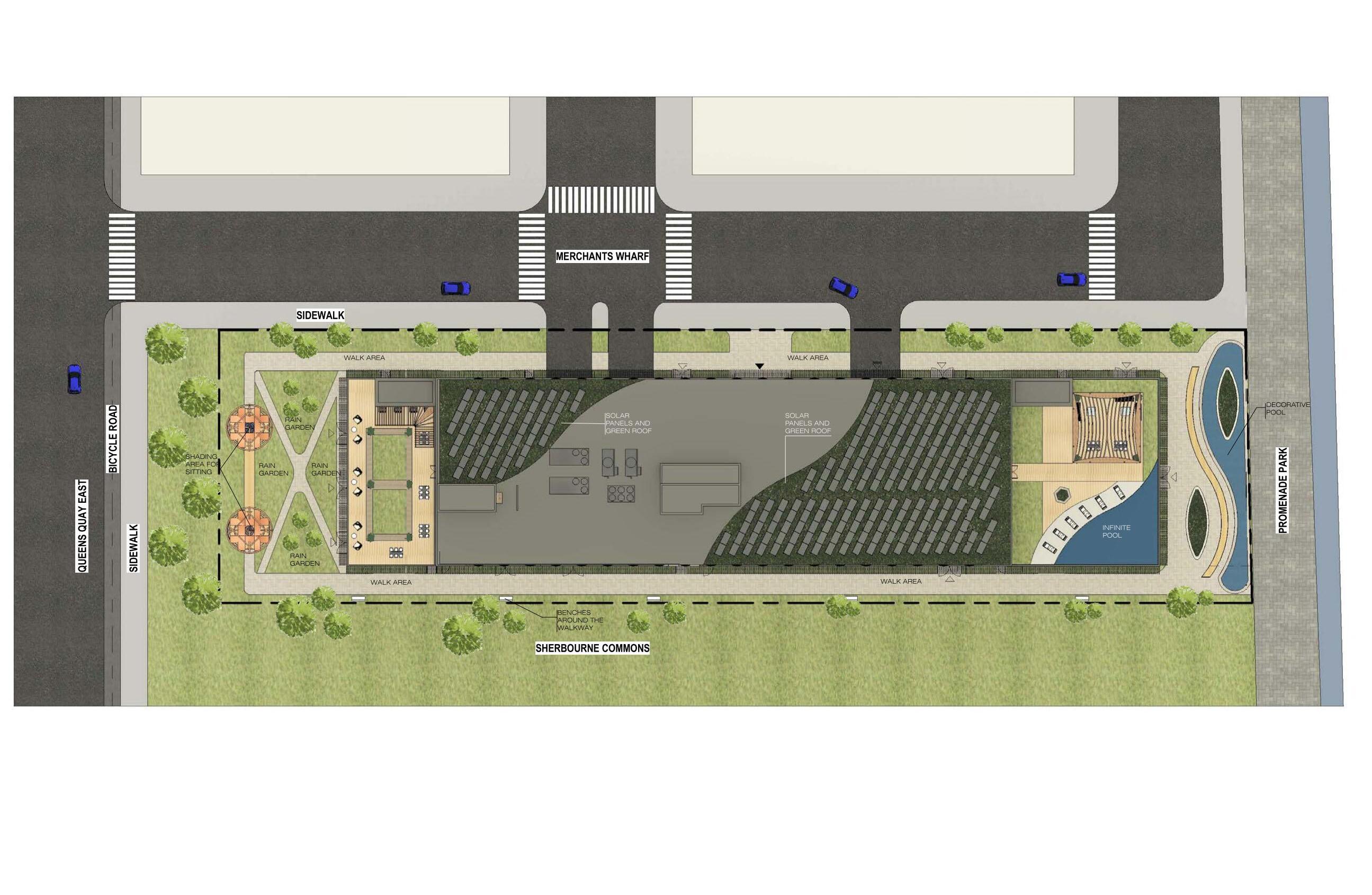

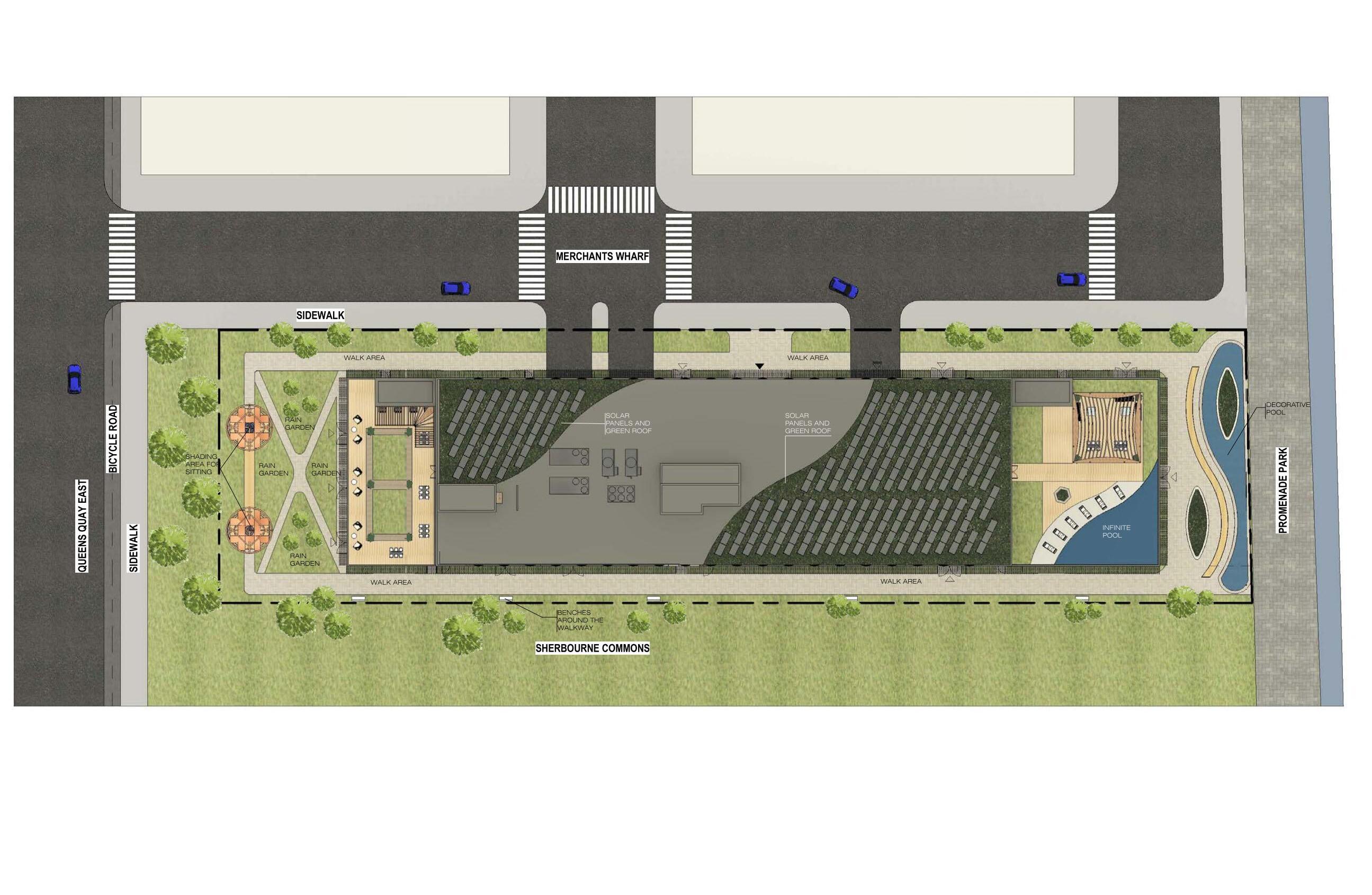

A mid-rise mixed-use building near Queen’s Quay and Merchant’s Wharf, offering lake views. With 10 stories, the first two are made of concrete and the remaining eight are from cross-laminated wood. The ground floor features rentable retail spaces, while the second-floor is for amenities.

By : Esma Cetinkaya, Umesh Chauhan Jim Kwan

01

HIGH RISE CONDOMINIUM PROJECT - CURVALUX - 2023

01 I

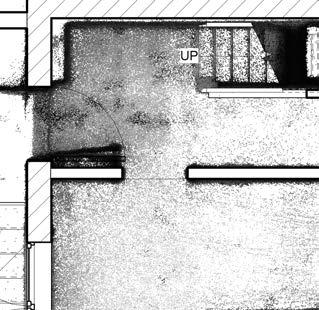

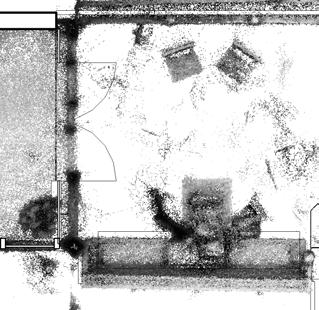

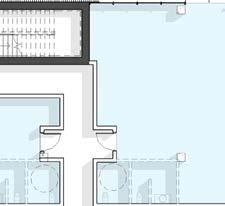

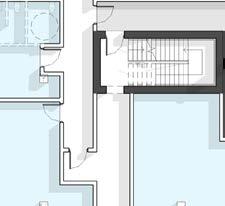

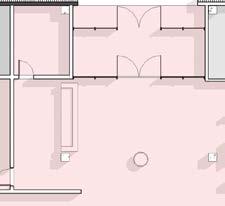

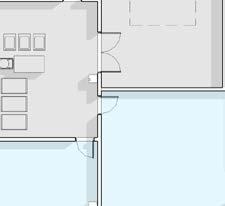

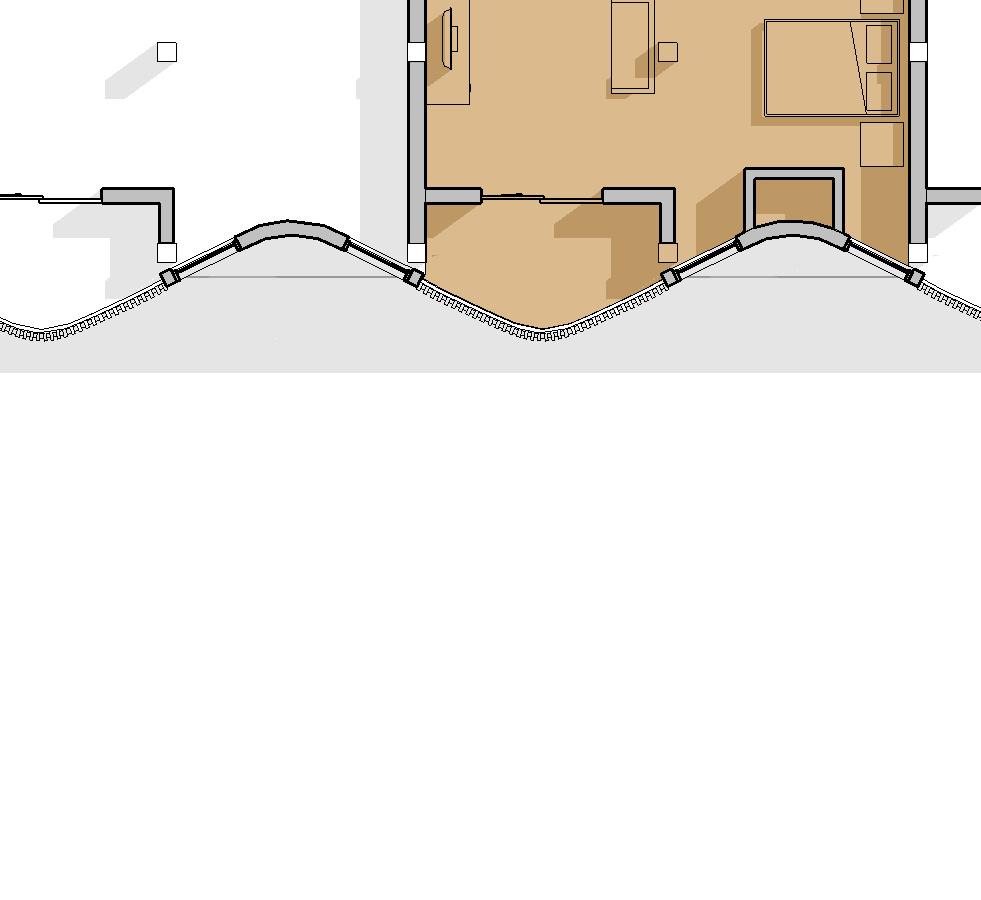

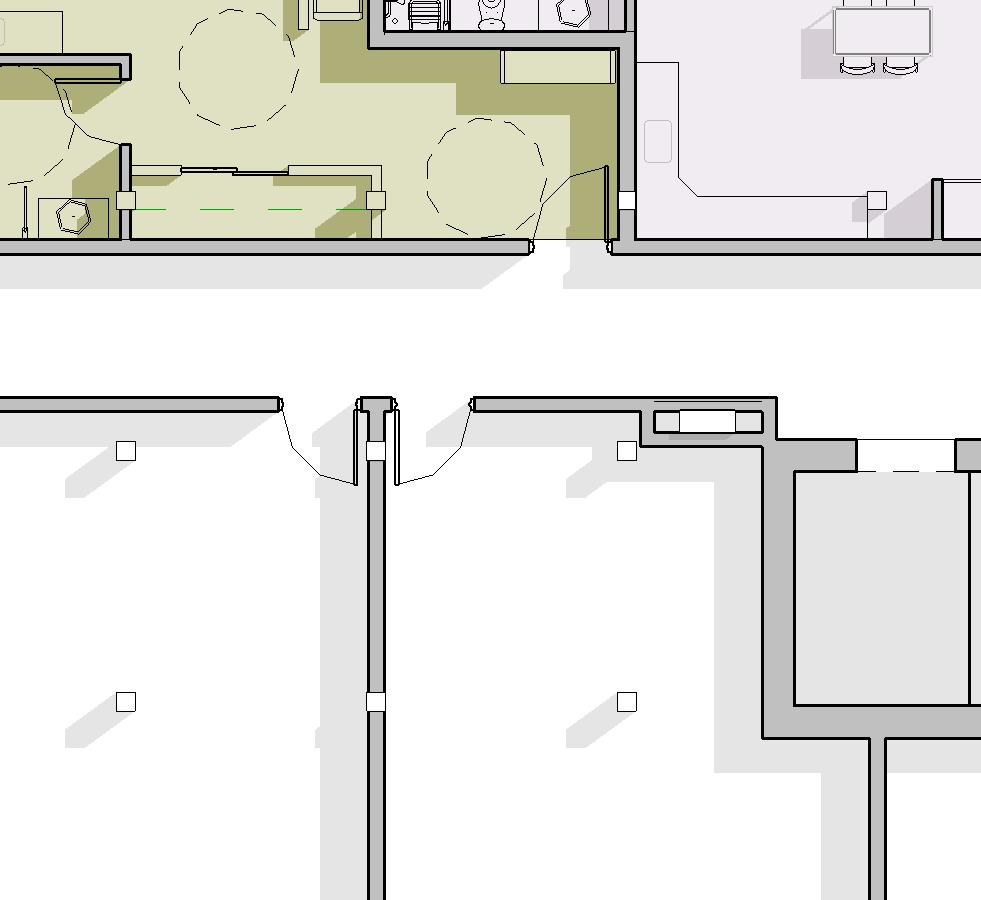

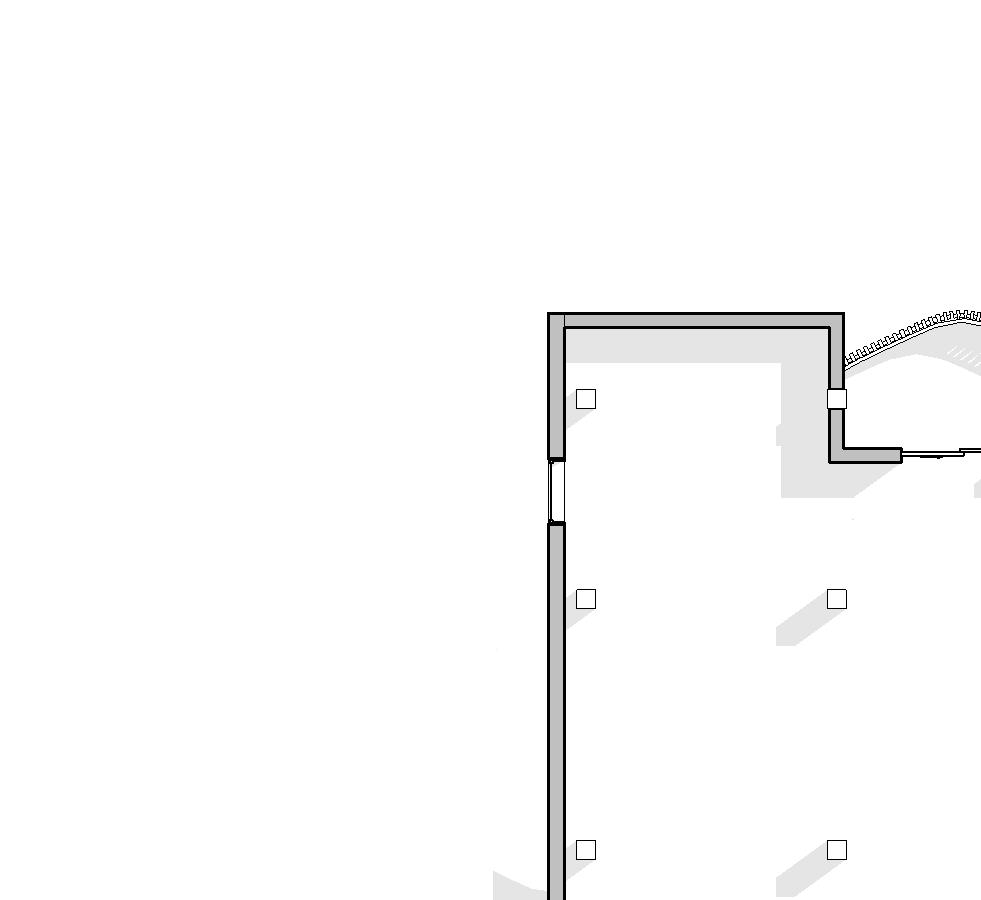

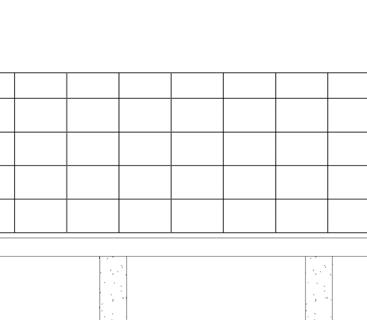

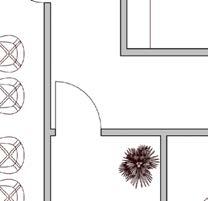

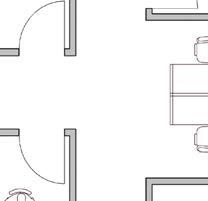

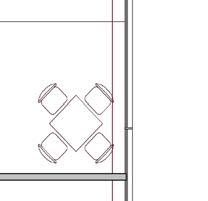

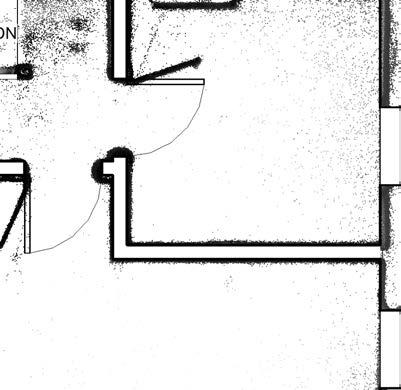

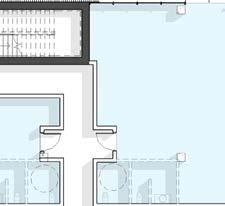

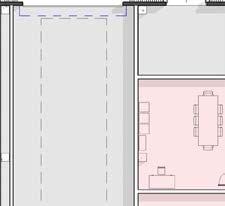

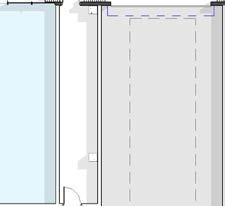

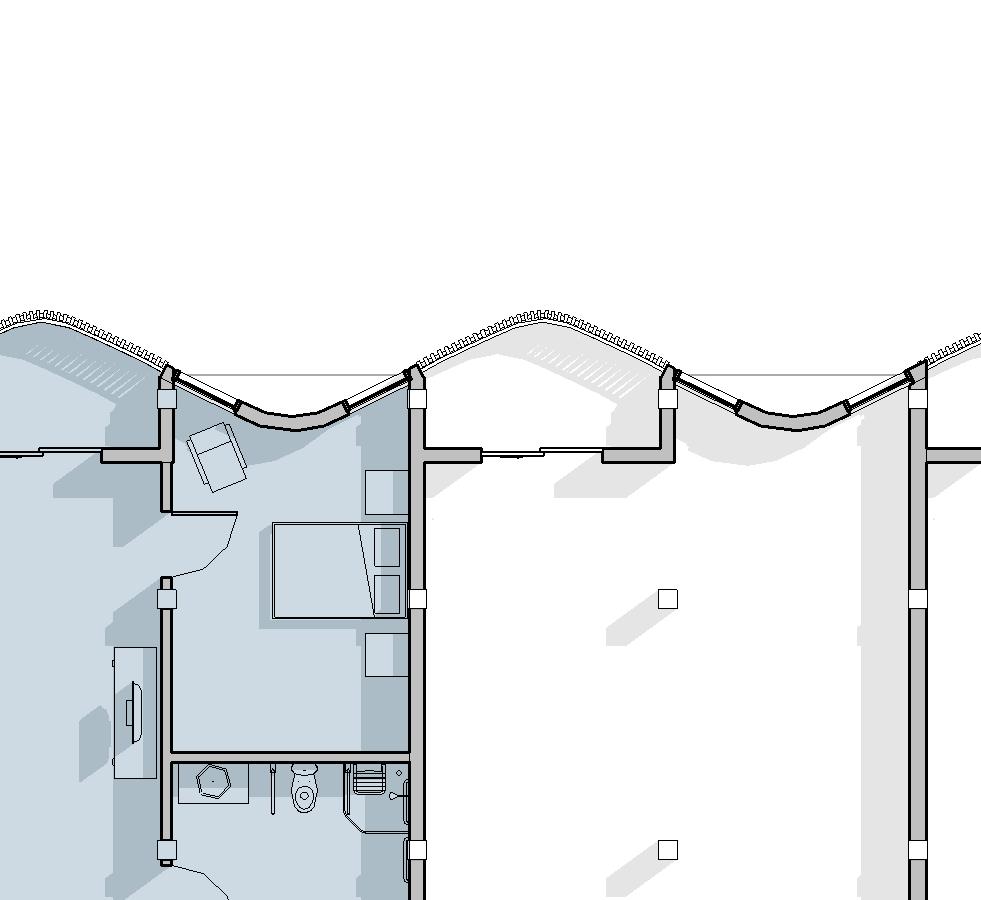

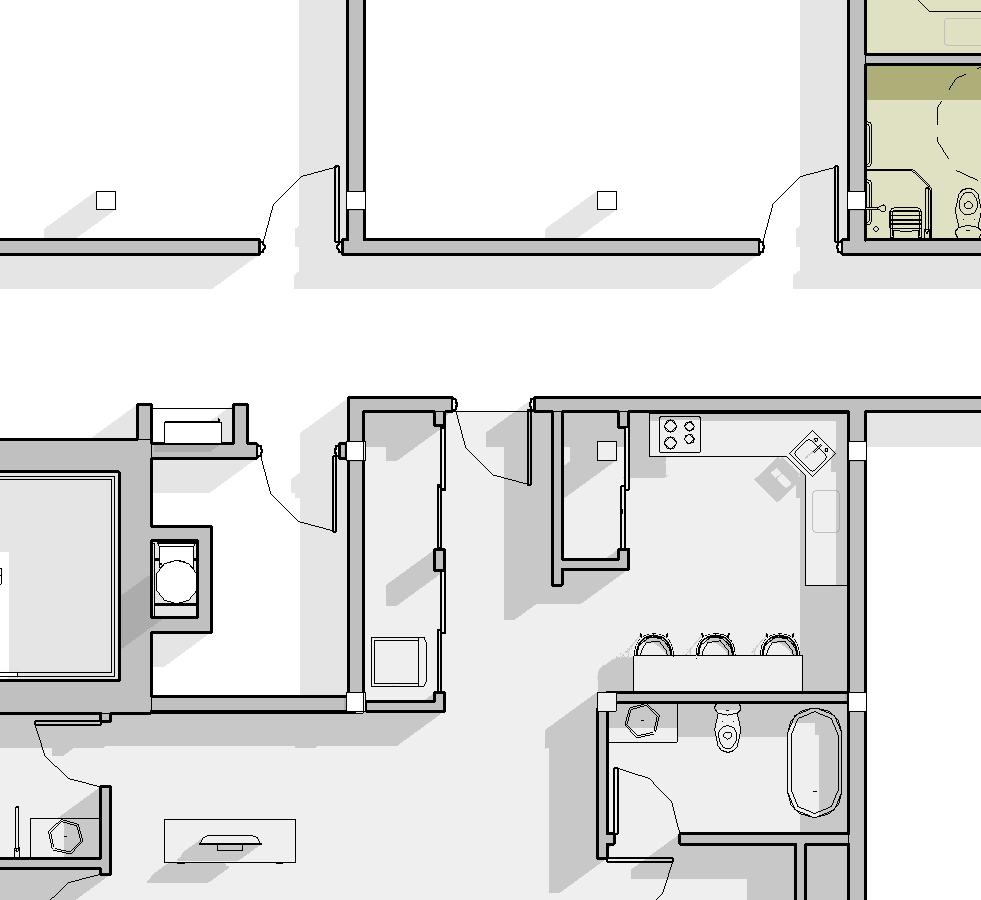

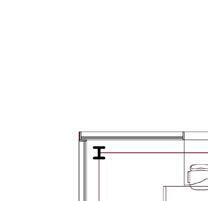

FIRST FLOOR PLAN

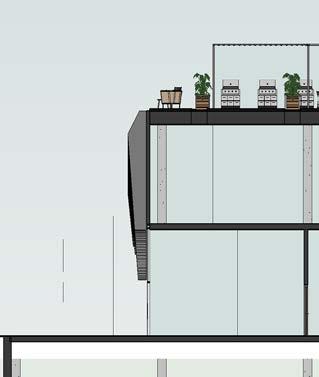

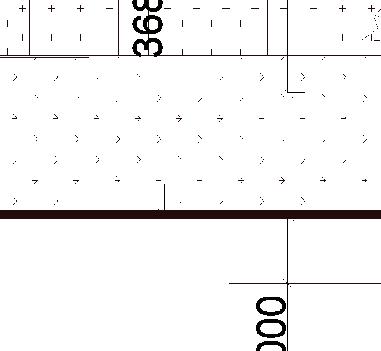

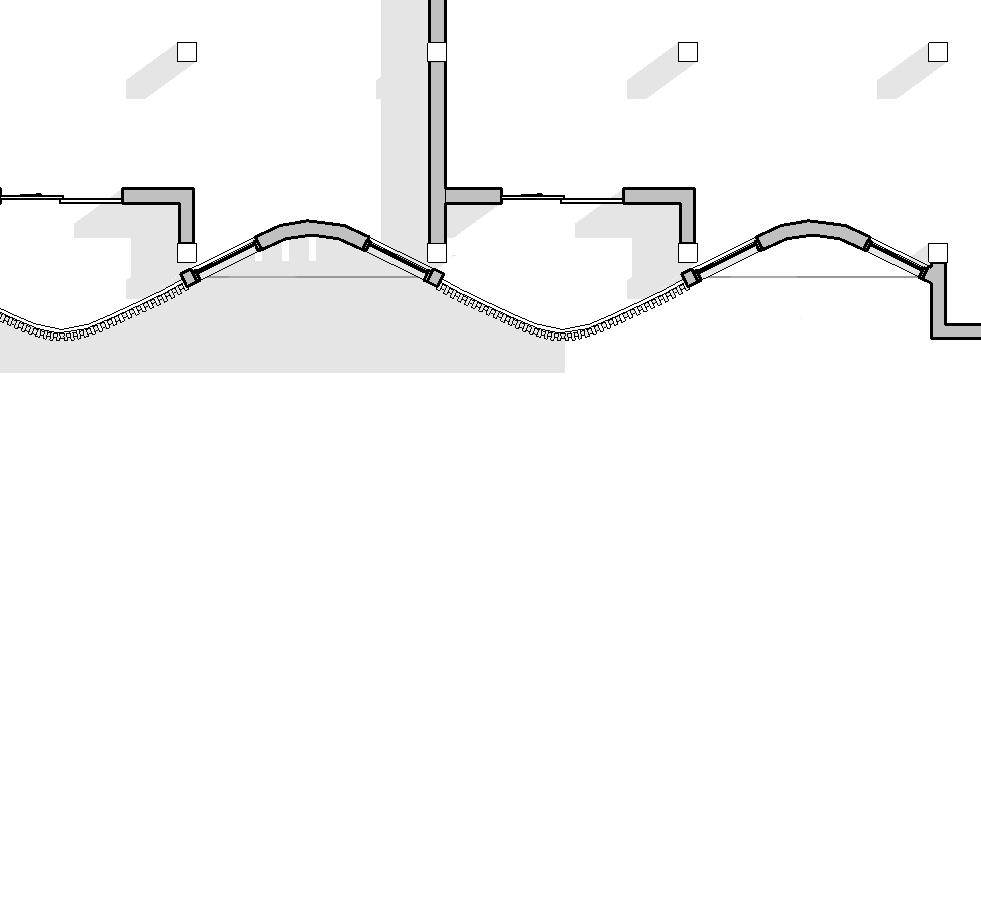

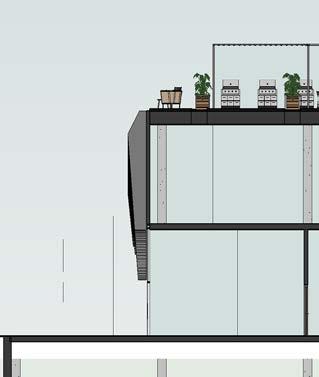

We seek to maximize the production of renewable energy, improve stormwater management, and reduce the ecological footprint of the building through the integration of solar panels, a green roof, rain gardens, and permeable pavement on the site.

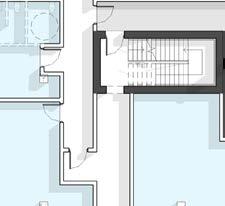

SECOND FLOOR PLAN

Permeable pavement: A sustainable solution that allows water to naturally infiltrate the ground, reducing stormwater runoff and promoting groundwater recharge.

Rain gardens: Nature’s sustainable sponge, absorbing and filtering rainwater runoff, preventing pollution in waterways, replenishing groundwater, and creating habitats for diverse plant and animals

Solar panels: Harnessing the power of the sun to generate clean and renewable energy, reducing carbon emissions and promoting a sustainable future.

Green roofs: Nature’s sustainable blanket, providing insulation, reducing energy consumption, and mitigating urban heat island effect while fostering biodiversity and improving air quality.

9

arch.technology & studio 4 [101395020] | |

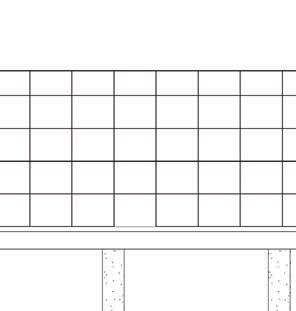

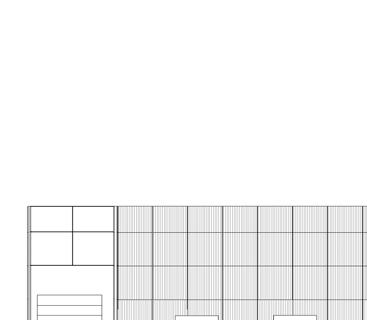

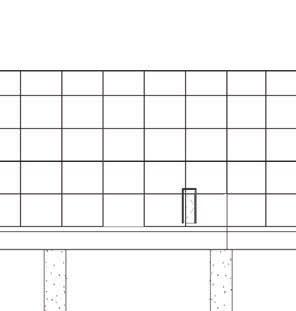

EAST ELEVATION SOUTH ELEVATION

SHADING AREA FOR SITTING DECORATIVE POOL

INFINITE POOL FOR RESIDENTS

HIGH RISE CONDOMINIUM PROJECT - CURVALUX - 2023

GROUND

The ground floor design resident access, in accordance design aimed to optimize comply with safety regulations. for the main facade,on

10 SERVICE CORRIDOR EXIT CORRIDOR OPTIONAL W/C OPTIONAL W/C OPTIONAL 71 m² RETAIL 56 m² RETAIL 82 m² RETAIL

Scale 1 : 150

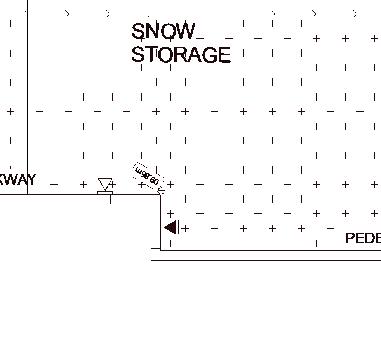

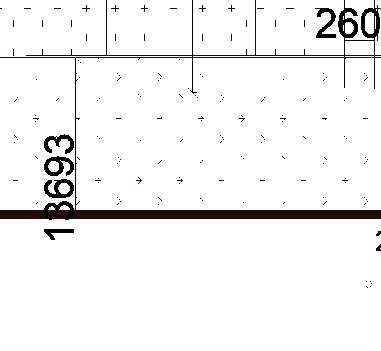

FLOOR PLAN UP UP SERVICE CORRIDOR RETAIL RETAIL RETAIL EXIT CORRIDOR 18.9M 7.1M

FLOOR PLAN 01 I

FLOOR GROUND

GROUND

/ SCALE: 1:150

OBC / SCALE: 1:150

design focused on maximizing the retail area while providing easy accordance with Ontario Building Code (OBC) requirements. The optimize retail space utilization, ensure convenient pathways, and regulations. In the interior we also kept wave pattern that we used facade,on the walls and ceilings.

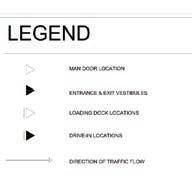

11 MOVING ELEVATOR ELEVATOR ELEVATOR LOBBY ELEVATOR MOVING ELEVATOR EXIT CORRIDOR RAMP DOWN TO P1 SLOPE 15% RAMP DOWN TO P1 SLOPE 15% SERVICE CORRIDOR OPTIONAL W/C OPTIONAL W/C OPTIONAL W/C OPTIONAL W/C 135 m² RETAIL 32 m² GARBAGE ROOM (RESIDENTIAL) 32 m² GARBAGE ROOM (RETAIL) 129 m² MOVING ROOM 8 m² JANITOR'S CLOSET 40 m² PROPERTY MANAGEMENT OFFICE 25 m² ELECTRICAL ROOM 14 m² PARCEL ROOM 12 m² MAIL ROOM 167 m² RETAIL 447 m² RETAIL 104 m² RETAIL 44 m² LOADING AREA (RESIDENTIAL) 24 m² VESTIBULE 26 m² CONCIERGE Redundant Room LOBBY 118 m² DRIVE-IN (TYPE G) RESIDENTIAL RETAIL STORAGE/MEC/MOVING 65 m² RETAIL 94 m² RETAIL SERVICE CORRIDOR 28 m² LOADING AREA (GARBAGE) 13 m² UNIVERSAL W/C 17 m² CACF 58 m² LOUNGE 102 m² DRIVE-IN (TYPE G)

DN UP UP UP DN DN MOVING ELEVATOR ELEVATOR LOBBY 24 HR CONCIERGE ELEVATOR CACF MOVING ROOM LOADING AREA GARBAGE ROOM UNIVERSAL WASHROOM PROPERTY MANAGEMENT OFFICE PARCEL ROOM MAIL ROOM LOADING AREA TYPE G TYPE LOBBY RETAIL EXIT CORRIDOR JANITOR'S CLOSET RETAIL RETAIL RETAIL 2658 13.9M 21.0M 21.1M 15.9M 21.6M 26.7M 12.3M 15.0M 15.8M SERVICE CORRIDOR 1 HR FRR 2 HR FRR 7.1M ELECTRICAL ROOM RETAIL RETAIL 20.9M 21.8M 9.9M

01 I HIGH RISE CONDOMINIUM PROJECT - CURVALUX - 2023

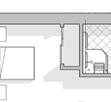

SUITE FLOOR PLAN / SCALE: 1:150

Our design accessibility assistance. imity to ity challenges any hindrance. commitment environment dents, enhancing

12 66 m² STUDIO 89 m² 2 BEDROOM 59 m² STUDIO 66 m² 1 BEDROOM ASSISTED LIVING UNIT: 2 BEDROOM ELEV BALCONY HVAC HVAC HVAC ELEV ELEVELEV JANITOR'S CLOSET ELEC.CLOSET GARBAGE ROOM 121 m2 ASSISTED LIVING UNIT: 2 BEDROOM 122 m2 ASSISTED LIVING UNIT: STUDIO 75 m2 FHC FHC STAIR 3 BEDROOM 2 BEDROOM 121 m2 120 m2 PLANT PLANT PLANT PLANT PLANT PLANT PLANT PLANT PLANT PLANT PLANT PLANT PLANT PLANT BALCONY BALCONY BALCONY BALCONY BALCONY BALCONY BALCONY BALCONY BALCONY BALCONY BALCONY BALCONY BALCONY CORRIDOR CORRIDOR

LOBBY

RECEPTION

design approach for the assisted living unit prioritized accessibility and convenience for the residents who require assistance. By strategically locating the units in close proxthe elevator, we ensured that individuals with mobilchallenges could easily access their apartments without hindrance. This thoughtful consideration reflects our commitment to providing a professional and efficient living environment that caters to the unique needs of the resienhancing their overall quality of life.

13 67 m² STUDIO 66 m² STUDIO 77 m² 2 BEDROOMS 75 m² 1 BEDROOM+DEN STUDIO 64 m2 2 BEDROOM 98 m2 FHC STAIR PLANT PLANT PLANT PLANT PLANT PLANT BALCONY BALCONY BALCONY BALCONY BALCONY BALCONY CORRIDOR m² WALK-IN CLOSET 13 m² BEDROOM CLOSET FOYER BALCONY BALCONY HVAC D/W m² WASHROOM 20 m² BEDROOM 27 m² LIVING ROOM 26 m² KITCHEN/DINING m² FOYER m² CLOSET m² WASHROOM 15 m² BEDROOM 1 PLANT PLANT 2 BEDROOM ASSISTED LIVING UNIT 121 m2 1:50 STUDIO UNIT / SCALE: 1:50 2 BR ASSISTED LIVING UNIT / SCALE: 1:50 15 m² BEDROOM 18 m² BEDROOM m² WASHROOM 13 m² BEDROOM m² WASHROOM 14 m² KITCHEN 38 m² LIVING ROOM DINING HVAC BALCONY BALCONY STORAGE CLOSET CLOSET CLOSET CLOSET D/W 600 W/D 12 m² LIVING ROOM 11 m² KITCHEN/DINING m² WASHROOM BALCONY Scale As indicated 3 BEDROOM AND ASSISTED LIVING STUDIO KEY PLAN 3 BEDROOM UNIT 120 m2 ASSISTED LIVING STUDIO 1:50 3 BR LIVING UNIT / SCALE: 1:50 ASSISTED LIVING STUDIO / SCALE: 1:50 HVAC STORAGE m² WALK-IN BATHROOM F W/D STORAGE HVAC 17 m² BEDROOM (ASSISTED LIVING) 30 m² LIVING 16 m² BEDROOM m² BATHROOM 19 m² DINNER m² KITCHEN 11 m² FOYER m² ENSUITE Scale As indicated 2 BEDROOM ASSISTED LIVING UNIT AND 2 BEDROOM 2 BEDROOM ASSISTED LIVING UNIT 122 m2 2 BEDROOM ASSISTED LIVING UNIT KEY PLAN 1:50 2 BR ASSISTED LIVING UNIT / SCALE: 1:50 2 BR LIVING UNIT / SCALE: 1:50

W/D F D HVAC STORAGE 15 m² LIVING m² KITCHEN 17 m² DINNING 18 m² MASTER BEDROOM m² WALK-IN m² ENSUITE 15 m² BEDROOM 1 m² BATHROOM m² FOYER F W/D STORAGE HVAC 17 m² BEDROOM (ASSISTED LIVING) 30 m² LIVING 16 m² BEDROOM m² BATHROOM 19 m² DINNER m² KITCHEN 11 m² FOYER m² ENSUITE Scale As indicated 2 BEDROOM ASSISTED LIVING UNIT AND 2 BEDROOM 2 BEDROOM ASSISTED LIVING UNIT 122 m2 2 BEDROOM ASSISTED LIVING UNIT KEY PLAN 1:50 15 BEDROOM 3 18 BEDROOM 2 m² WASHROOM 13 BEDROOM 1 m² WASHROOM 14 m² KITCHEN 38 m² LIVING ROOM DINING HVAC BALCONY BALCONY KITCHEN STORAGE CLOSET CLOSET CLOSET CLOSET D/W 600 W/D HVAC 12 m² LIVING ROOM KITCHEN/DINING m² WASHROOM m² CLOSET m² FOYER m² CLOSET 14 m² BEDROOM BALCONY PLANT

As indicated

BEDROOM AND ASSISTED LIVING STUDIO KEY PLAN 3 BEDROOM UNIT 120 m2 ASSISTED LIVING STUDIO 75 m2 1:50 1:50 3 CLOSET m² WAHROOM HVAC W D BALCONY 13 m² KITCHEN/DINING 12 m² LIVING ROOM m² BEDROOM m² PLANT BALCONY BALCONY D/W WASHROOM 20 m² ROOM 26 2 CLOSET 15 m² PLANT 2 BEDROOM ASSISTED UNIT 121 m2 STUDIO UNIT 64 m2 1:50

Scale

3

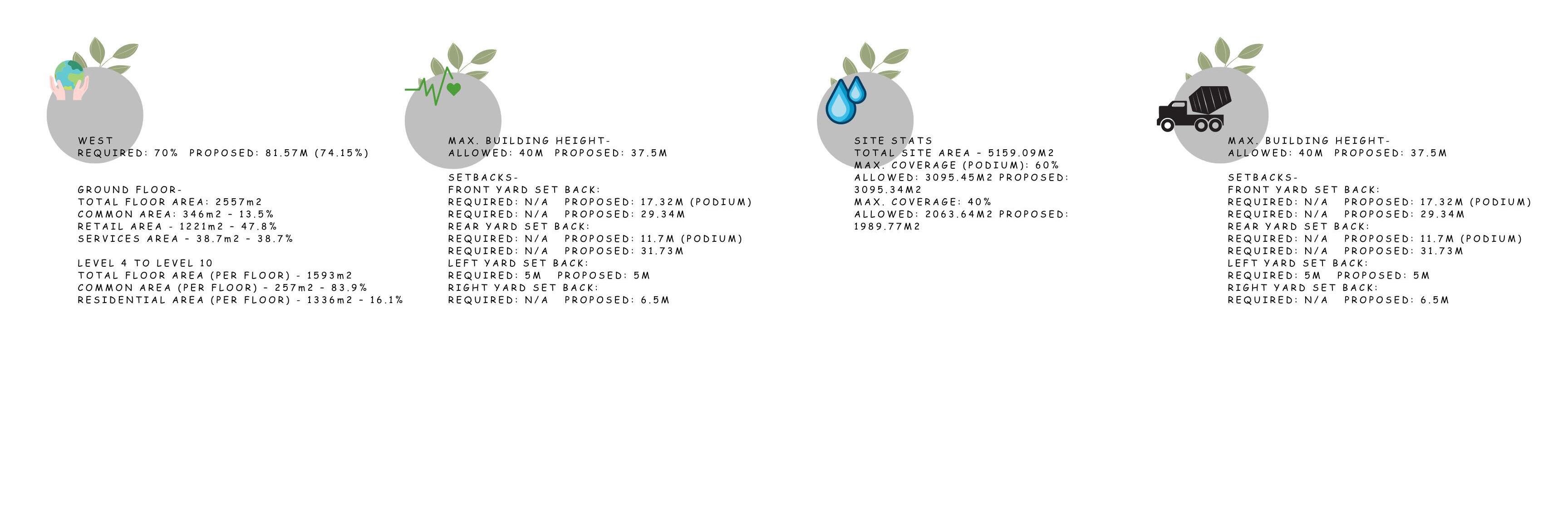

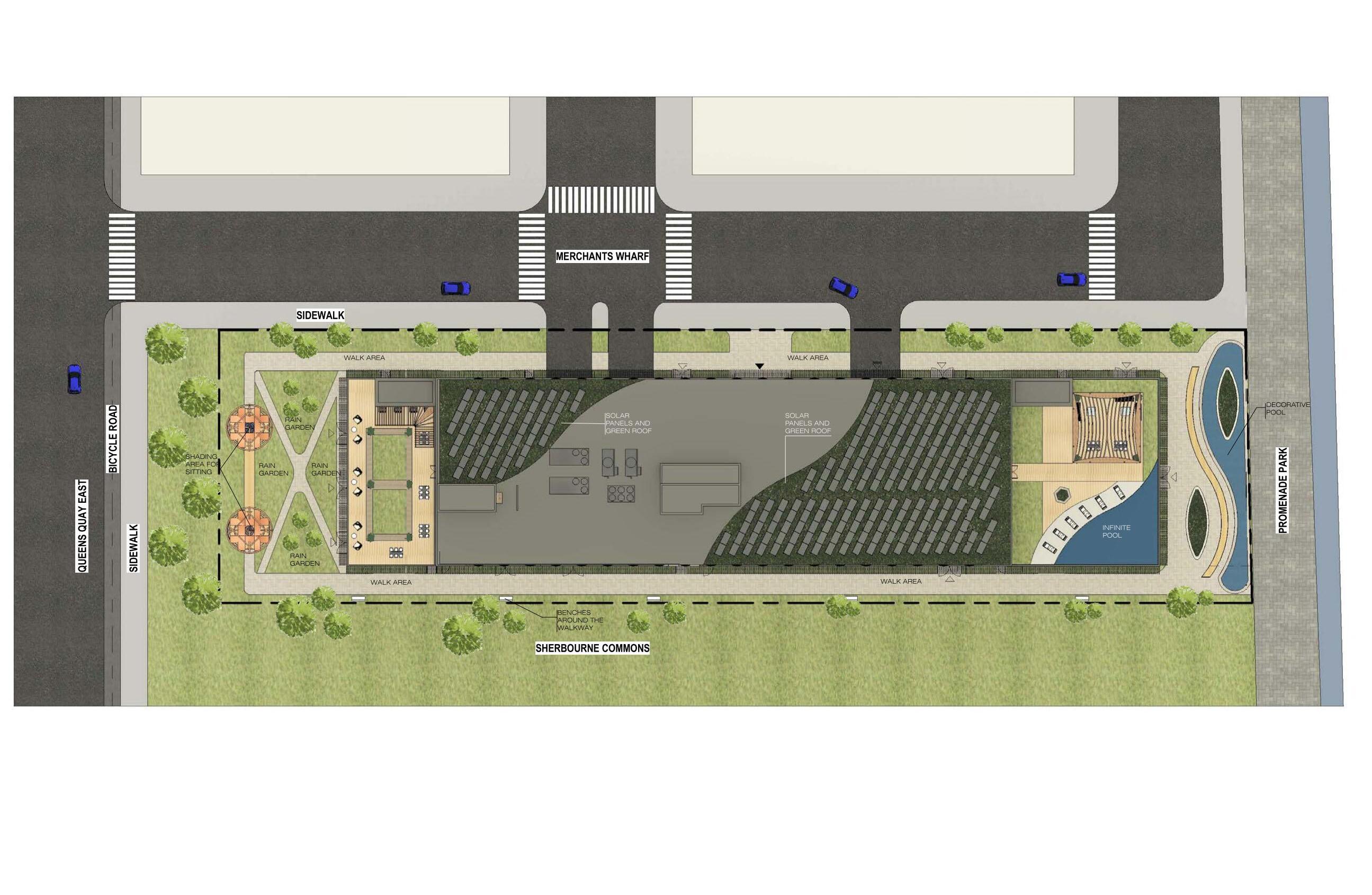

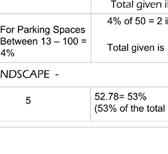

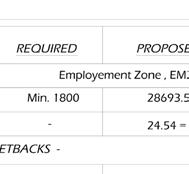

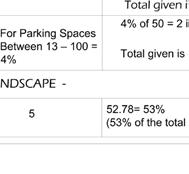

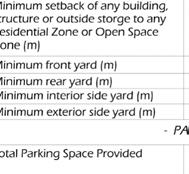

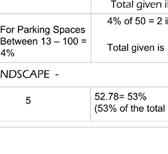

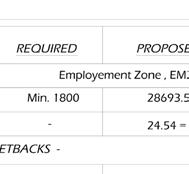

REQUIRED N/A

PROPOSED 17.32M

LEFT YARD SETBACK:

REQUIRED: 5M PROPOSED:5M

01 I HIGH RISE CONDOMINIUM PROJECT - CURVALUX - 2023

REQUIRED N/A

PROPOSED:29.34M

REQUIRED:5M PROPOSED 11.7M (PODIUM)

REQUIRED N/A PROPOSED 31.73M

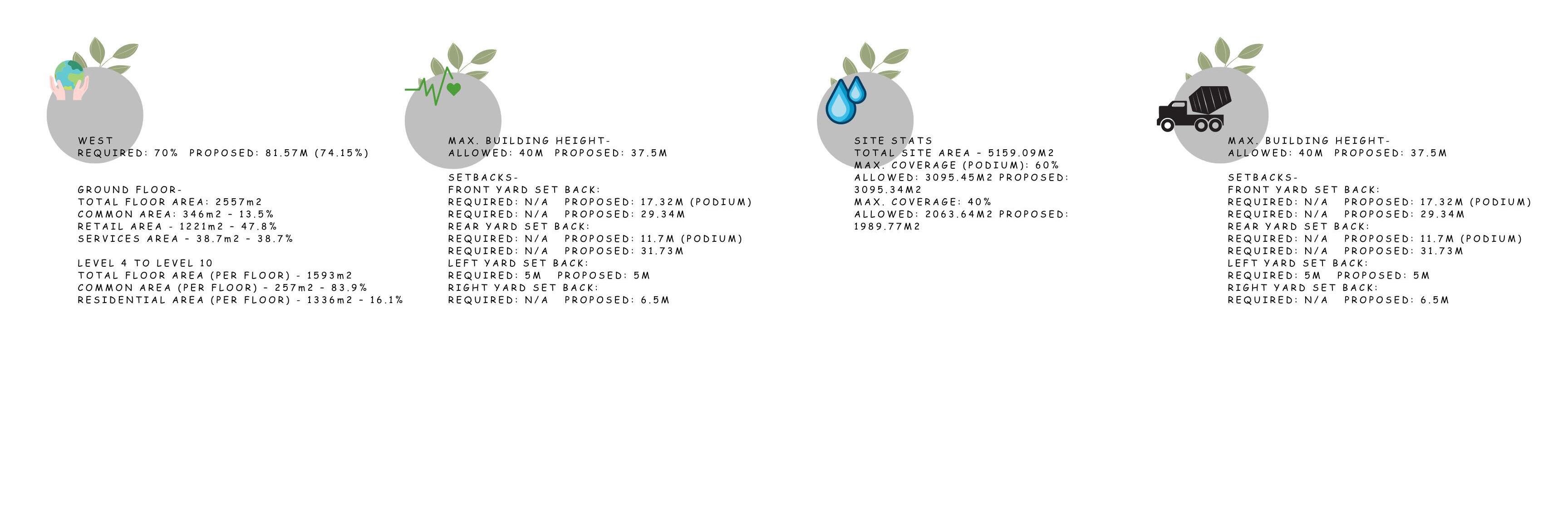

WEST

REQUIRED: 70% PROPOSED :81.57M (74.15%)

RIGHT YARD SETBACK: REQUIRED N/A PROPOSED:6.5M

GROUND FLOOR:

TOTAL FLOOR AREA: 2557m2

COMMON AREA: 346m2 - 13.5%

RETAIL AREA: 1221m2 - 47.8%

SERVICES AREA 38.7m2 - 38.7%

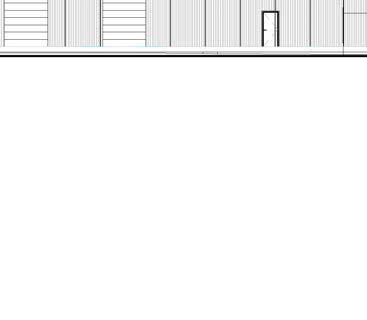

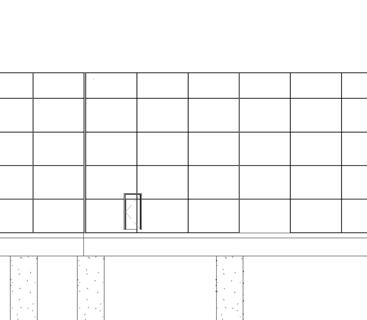

WEST ELEVATION / SCALE: 1:150

WEST ELEVATION WEST ELEVATION

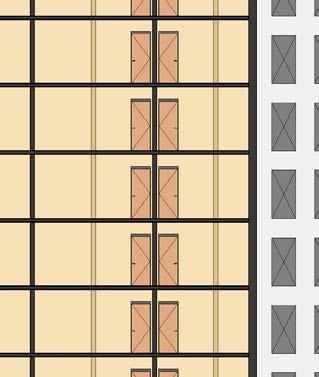

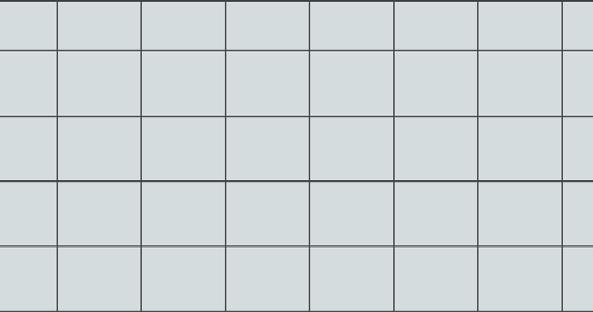

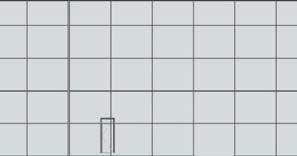

The elevations of the project feature wave patterns in both the main bottom facade and balconies, utilizing corten steel to create a distinct look that sets it apart from typical downtown buildings. The wave patterns were chosen to align with the waterfront location and evoke a sense of fluidity. By incorporating these design elements, we aimed to create a visually captivating and unique architectural presence that embraces the natural vibes of the waterfront.

MARMOLEUM HIGHTRAFFIC CARPETING RESIDENTIAL

TYPICAL STUDIO UNIT TYPICAL 2 BD UNIT

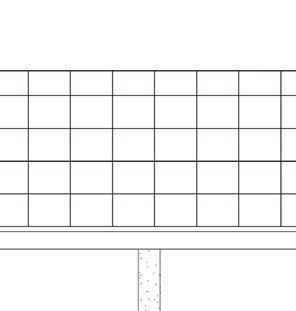

NORTH ELEVATION NORTH ELEVATION

durable, weatherresistant, and visually striking.

Corten steel: where sustainability meets style. With its weathered look and durability, it offers eco-friendliness and aesthetic appeal. The steel develops a protective layer, reducing upkeep and environmental impact. Its raw texture and industrial charm enhance spaces, unlocking design possibilities. Corten steel showcases our dedication to sustainability and elegant design.

Precast Concrete: Sustainable strength and timeless elegance. Its off-site manufacturing reduces waste and environmental impact. With clean lines and durability, it brings a sense of permanence to architectural designs. Precast concrete embodies sustainability and enduring beauty.

To promote electric vehicle adoption, 15% of available parking spots will be designated as electric vehicle charging stations.

To promote electric vehicle adoption, 15% of available parking spots will be designated as electric vehicle charging stations.

through effective sustainable water

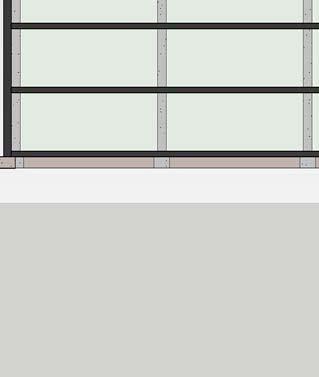

Energy-efficient Fibertec windows feature triple-glazed, kryptonfilled glass for optimal insulation

RECEPTION DESIGN LOBBY DESIGN

NORTH ELEVATION / SCALE: 1:150

ENERGY STAR™ appliances: efficient, eco-friendly, and cost-saving.

Ventilation: backup to natural airflow, ensuring comfortable indoor conditions.

Wool carpets are a flooring option that embraces natural fibers, providing a renewable, biodegradable, and energy-efficient choice for a healthier indoor environment and a more sustainable planet.

Energy-efficient Fibertec windows feature triple-glazed, krypton-filled glass for optimal insulation and sustainability.

Low flow aerators: A sustainable solution that reduces water consumption by limiting flow rates without compromising performance, conserving resources and promoting water efficiency for a greener future.

Low VOC paint: A sustainable choice that minimizes harmful emissions, improving indoor air quality and promoting a healthier environment for both occupants and the planet.

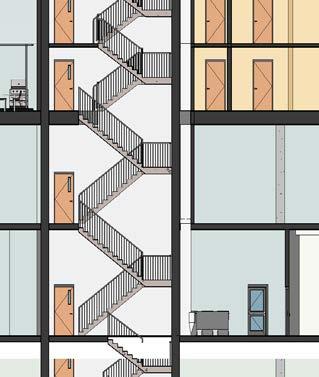

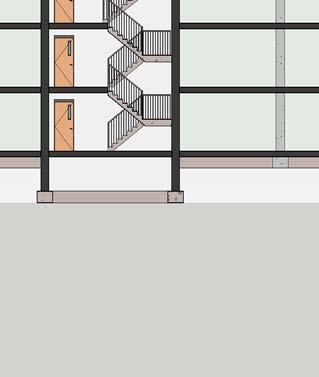

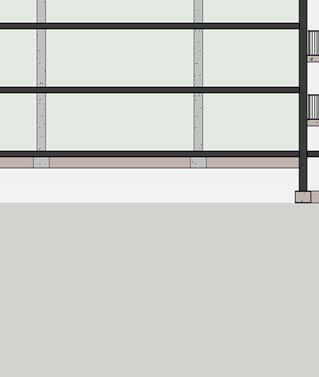

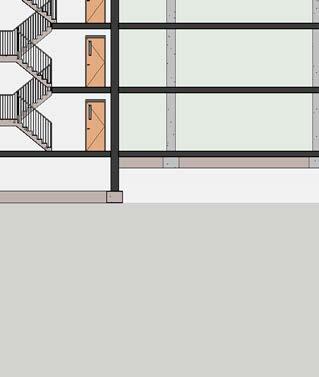

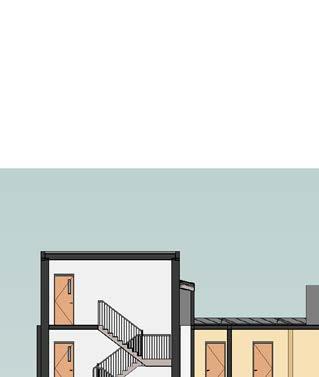

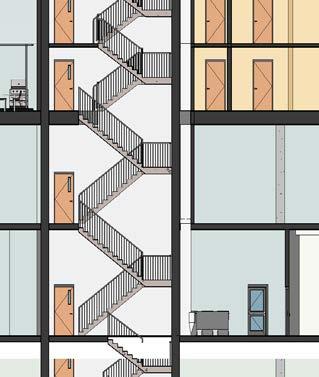

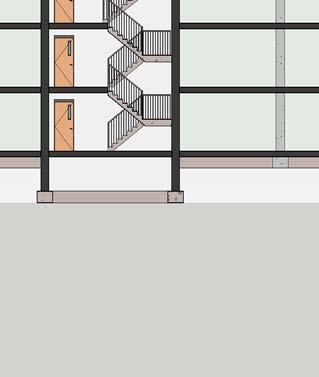

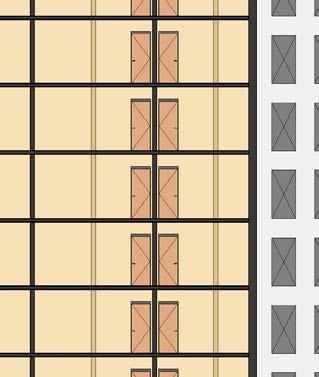

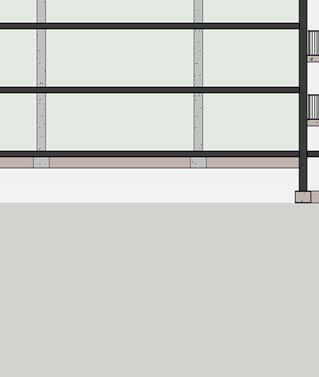

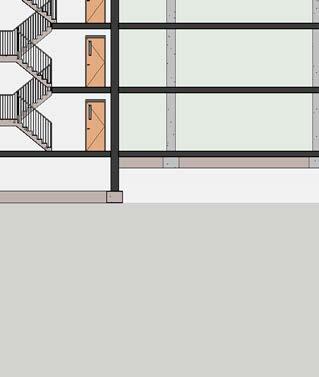

BUILDING SECTION / SCALE: 1:150

16 GARBAGE ROOM DRIVE-IN (TYPE G) AMENITIES FLOOR AMENITIES FLOOR RETAIL AMENITIES FLOOR BARBEQUE AREA 3 BD SUITE GARBAGE ROOM GARBAGE ROOM GARBAGE ROOM GARBAGE ROOM GARBAGE ROOM GARBAGE ROOM GARBAGE ROOM GARBAGE ROOM 1 BD PARKING PARKING PARKING PARKING PARKING PARKING PARKING PARKING PARKING PARKING PARKING PARKING 3 BD SUITE1 BD 3 BD SUITE1 BD 3 BD SUITE1 BD 3 BD SUITE1 BD 3 BD SUITE1 BD 3 BD SUITE1 BD 3 BD SUITE1 BD STAIRCASE CORE STAIRCASE CORE STAIRCASE CORE STAIRCASE CORE STAIRCASE CORE STAIRCASE CORE

01 I HIGH

RISE CONDOMINIUM PROJECT - CURVALUX - 2023

Level 1 0 Level 2 5000 Level 3 10000 Level 4 13000 Level 5 16000 Level 6 19000 Level 7 22000 Level 8 25000 Level 9 28000 Level 10 31000 Roof 34000 P1 -2850 P2 -5700 P3 -8550 Roof - MEC 36900 DRIVE-IN (TYPE G) LOBBY LOUNGE PARKING ENTRY OPTIONAL W/C RETAIL AMENITIES FLOOR AMENITIES FLOOR AMENITIES FLOOR AMENITIES FLOOR AMENITIES FLOOR AMENITIES FLOOR AMENITIES FLOOR TERRACE SUITESTUDIO PARKING PARKING PARKING PARKING PARKING PARKING PARKING PARKING PARKING PARKING PARKING PARKING PARKING PARKING PARKING PARKING PARKING PARKING PARKING PARKING STUDIO STUDIO 2 BD SUITE 2 BD SUIT STUDIO SUITESTUDIO STUDIO STUDIO 2 BD SUITE 2 BD SUIT STUDIO SUITESTUDIO STUDIO STUDIO 2 BD SUITE 2 BD SUIT STUDIO SUITESTUDIO STUDIO STUDIO 2 BD SUITE 2 BD SUIT STUDIO SUITESTUDIO STUDIO STUDIO 2 BD SUITE 2 BD SUIT STUDIO SUITESTUDIO STUDIO STUDIO 2 BD SUITE 2 BD SUIT STUDIO SUITESTUDIO STUDIO STUDIO 2 BD SUITE 2 BD SUIT STUDIO SUITESTUDIO STUDIO STUDIO 2 BD SUITE 2 BD SUIT STUDIO ELEVATOR CORE STAIRCASE CORE ELEVATOR CORE ELEVATOR CORE ELEVATOR CORE ELEVATOR CORE ELEVATOR CORE

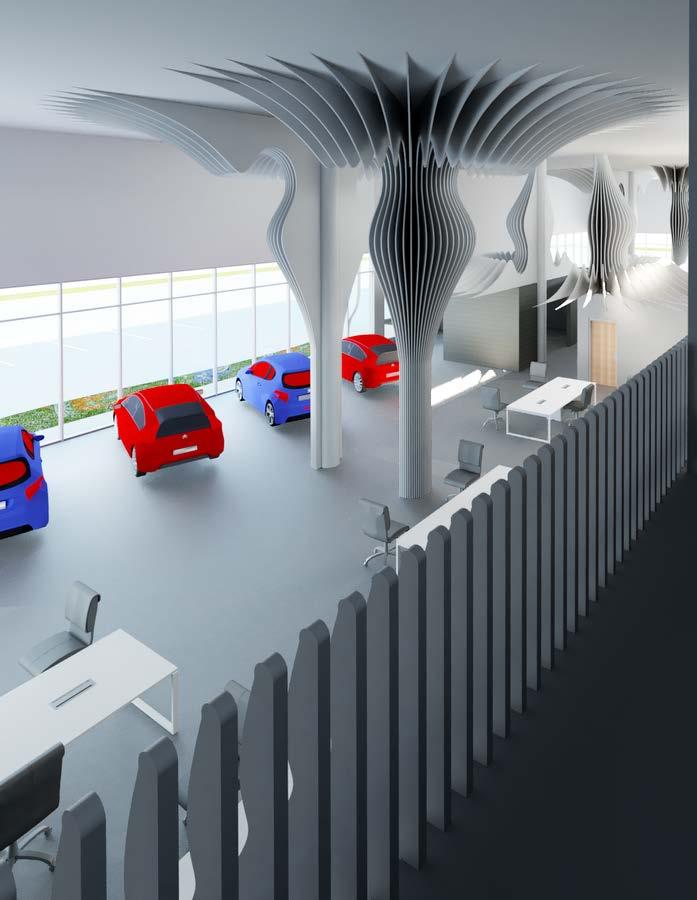

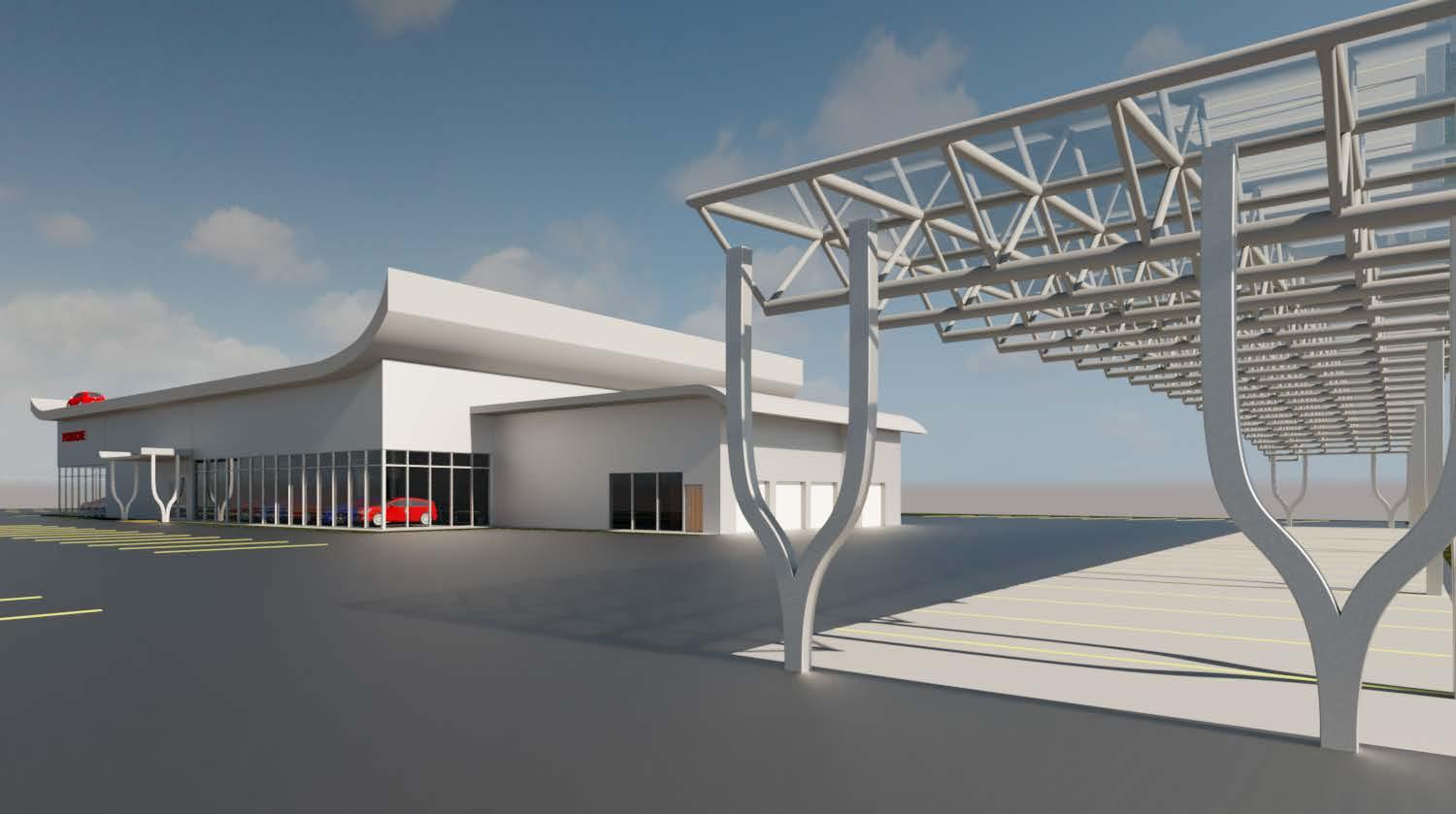

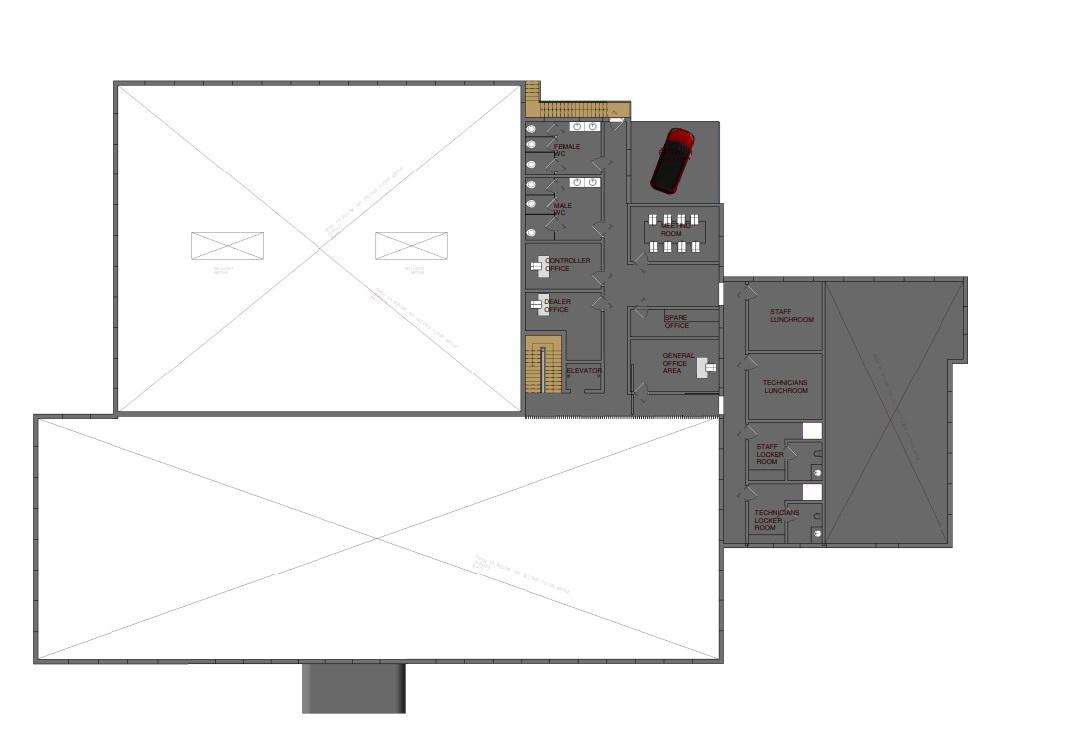

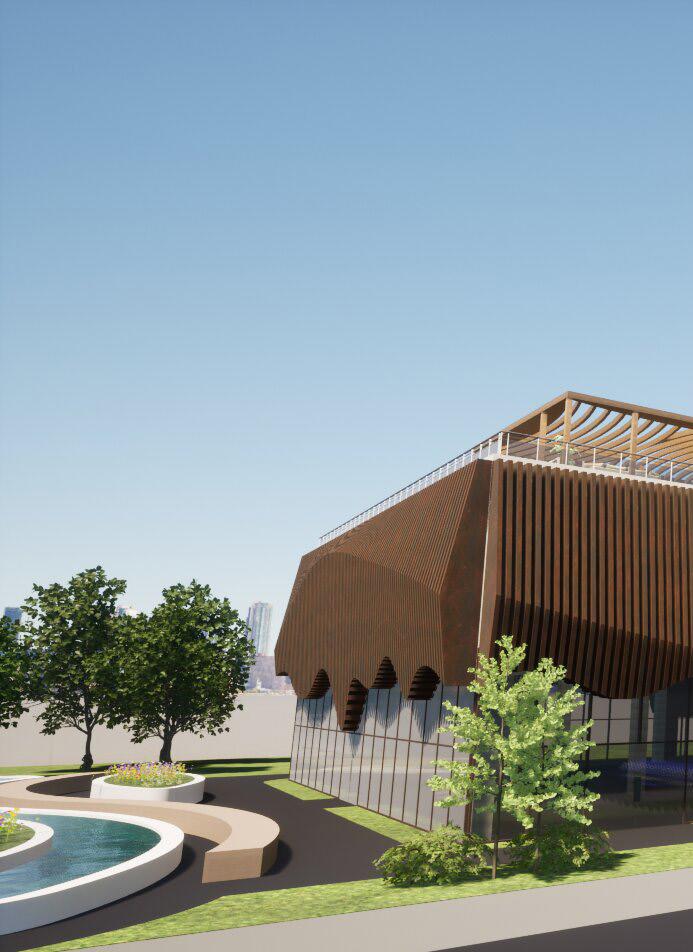

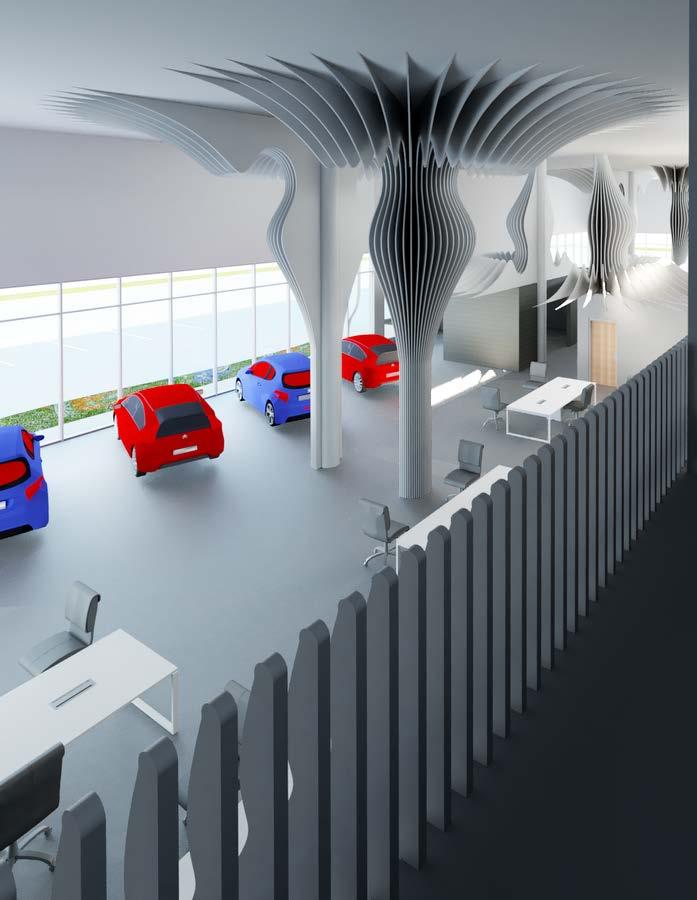

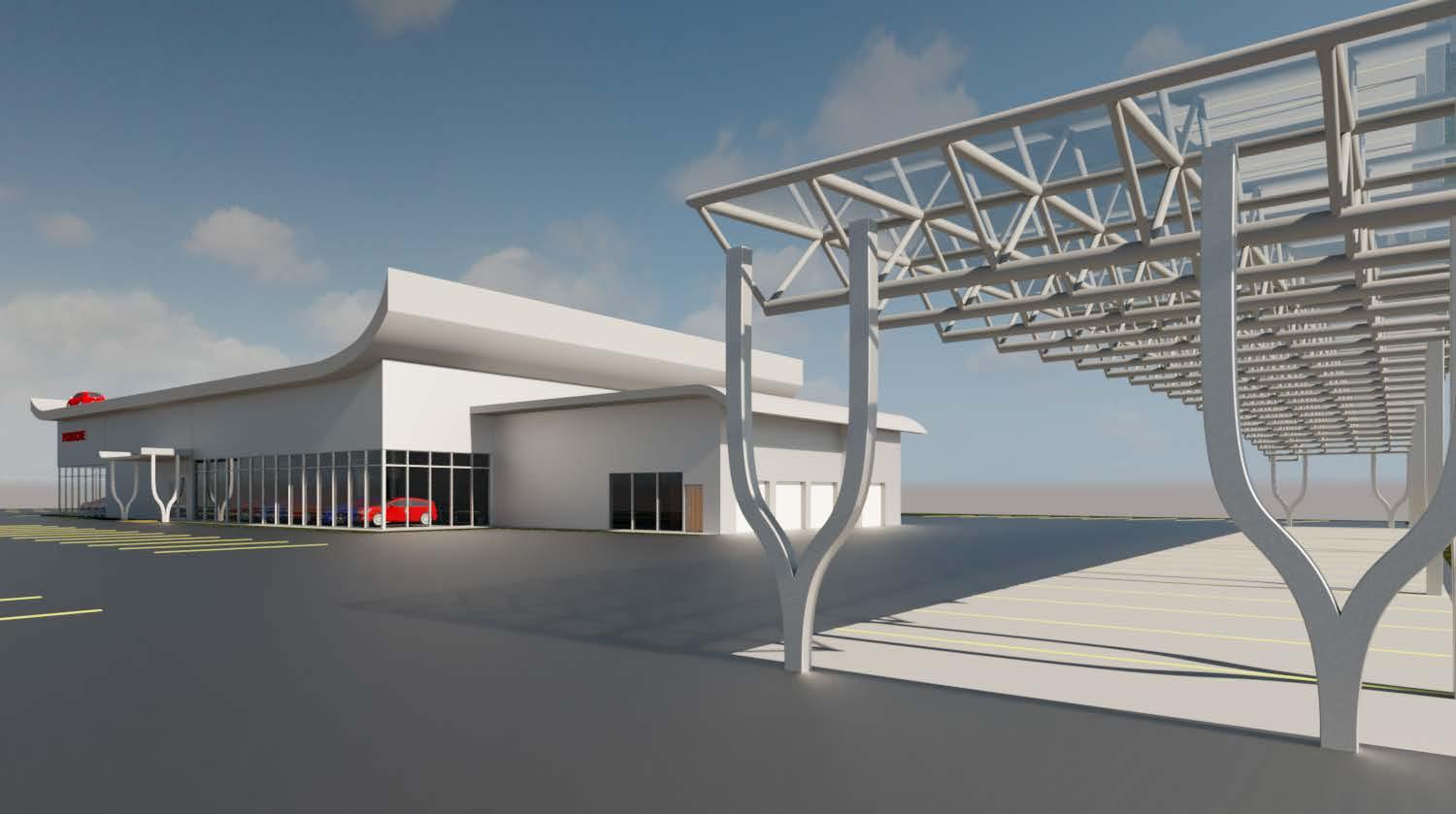

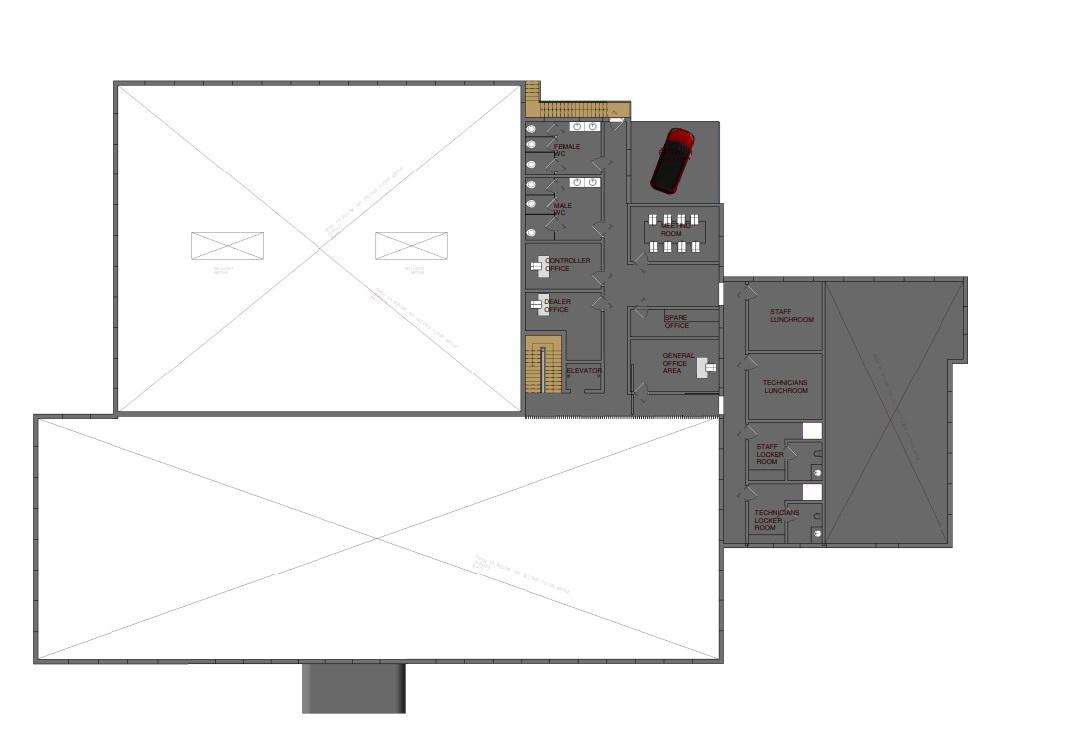

AUTOMOTIVE DEALERSHIP PORSCHE -

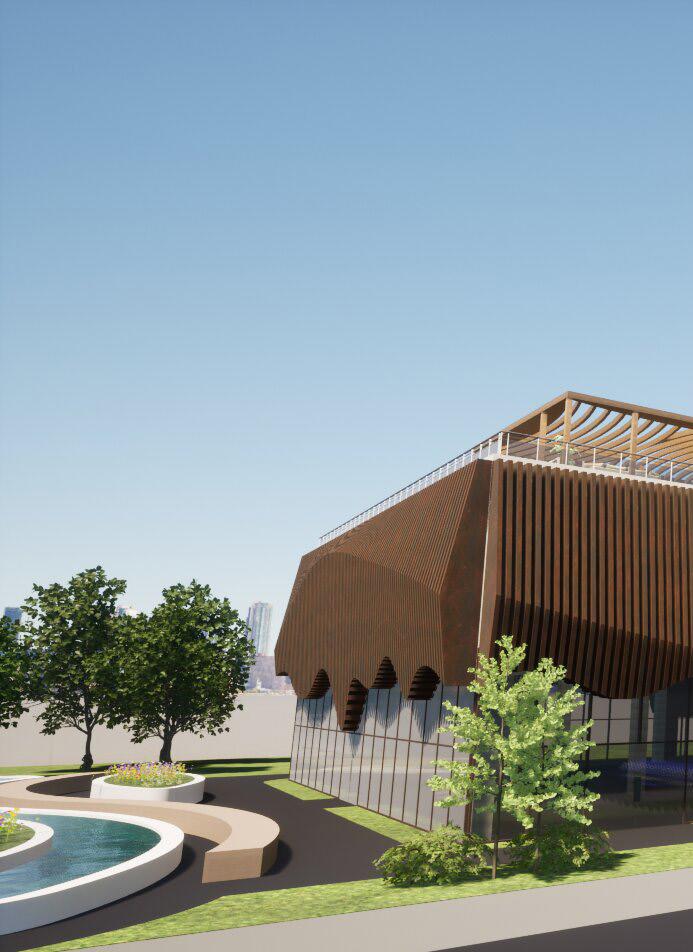

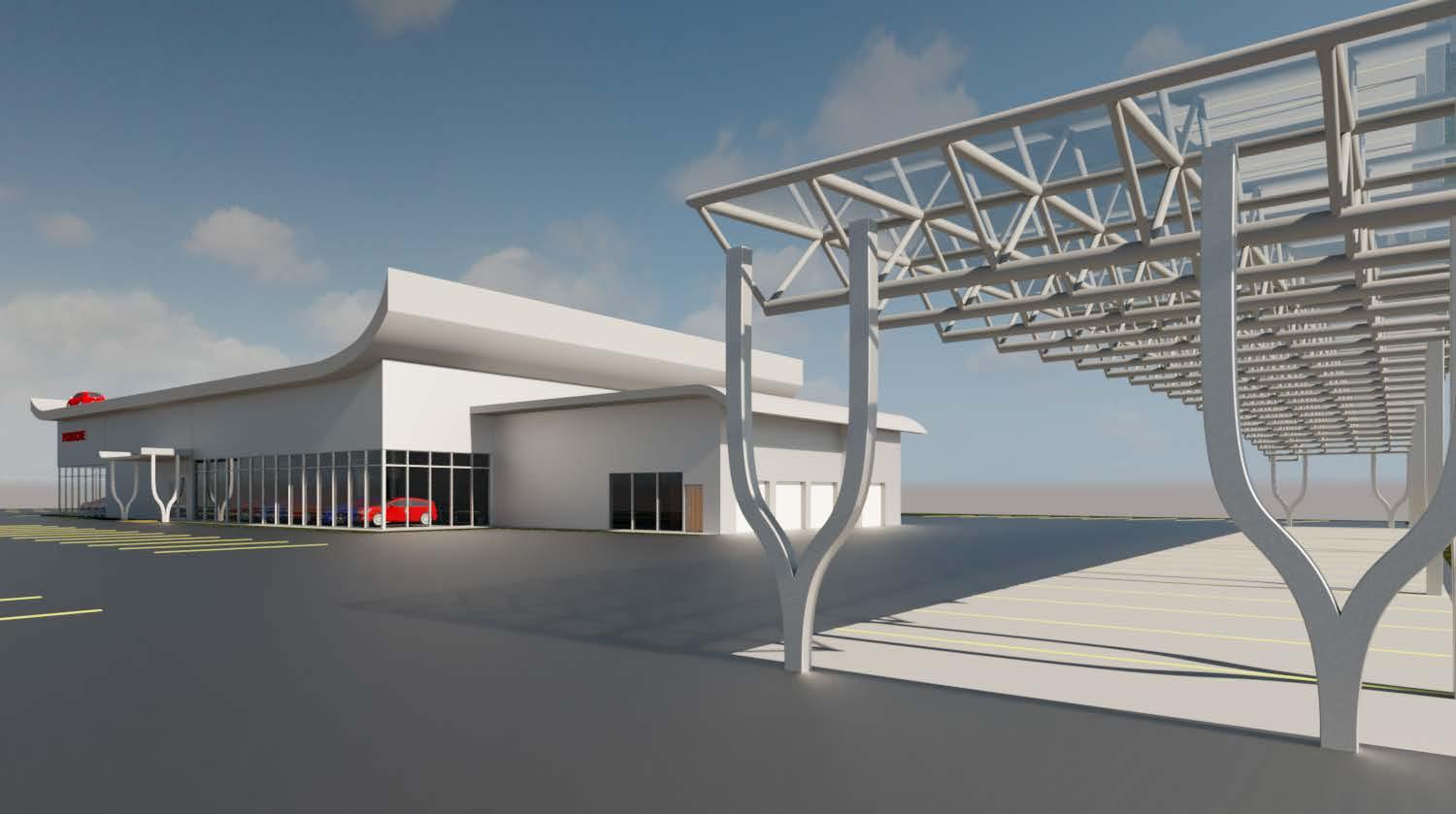

This project showcases an automated Porsche dealership store, designed to provide a cutting-edge and immersive experience for car enthusiasts. The store’s design not only captures the essence of the Porsche brand but also incorporates advanced automation technologies to enhance customer engagement. With a sleek and modern aesthetic, the store seamlessly integrates with its surroundings, creating a visually appealing and inviting atmosphere. a functional piece into materials.

By : Esma Cetinkaya, Umesh Chauhan

By : Esma Cetinkaya, Umesh Chauhan

AUTOMOTIVE DEALERSHIP - PORSCHE

The focus on sustainability is evident through the implementation of energy-efficient systems and eco-friendly materials, aligning with Porsche’s commitment to environmental responsibility. Through the seamless integration of automation, aesthetics, and sustainability, this project sets a new standard for automotive retail experiences.

concept statement

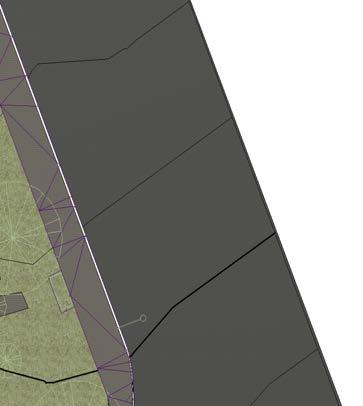

The design of this building not only focuses on integrating with the natural surroundings but also prioritizes sustainability. Recycled materials were incorporated into the construction, reducing the environmental impact and promoting responsible building practices. The use of recycled materials, along with the organic and flowing design of the curving roof, creates a seamless and harmonious connection between the structure and the environment.

Incorporating recycled materials into our charging station design not only aligns sustainability goals but also creates a sleek and modern look. The use and metal provides a visually appealing element that enhances the aesthetic of the space.

DealershipPORSCHE

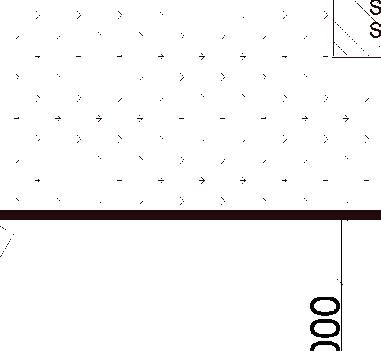

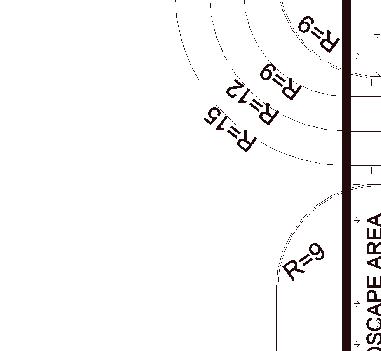

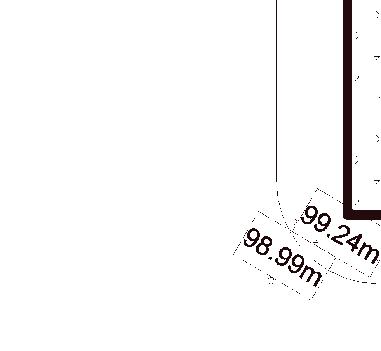

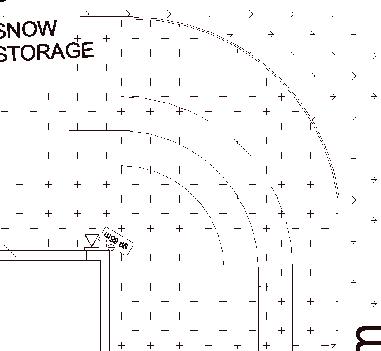

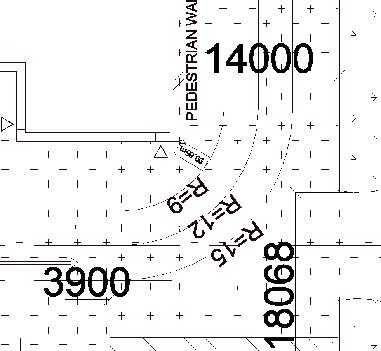

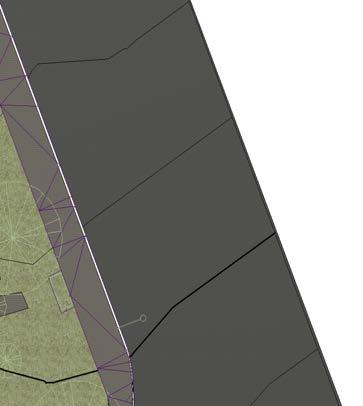

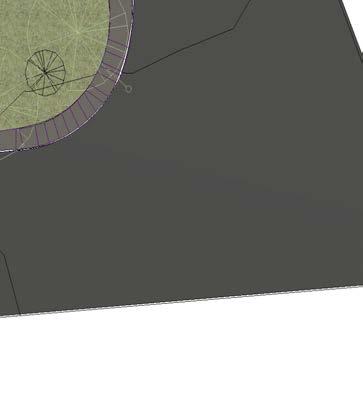

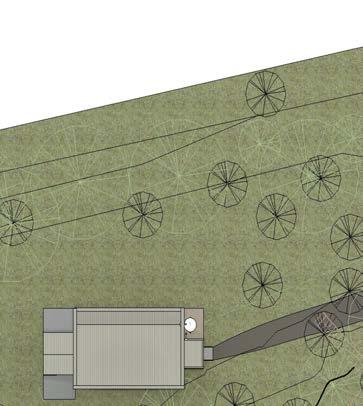

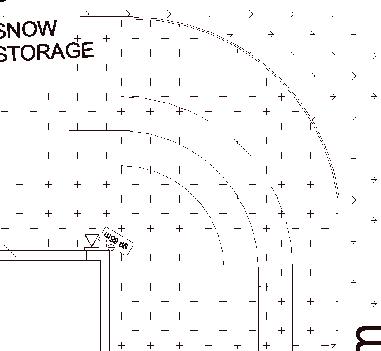

SITE PLAN

The incorporation of recycled materials into the charging station design aligns with their sustainability goals and creates a sleek and modern look. By utilizing glass and metal, we have successfully introduced visually appealing elements that enhance the overall aesthetic of the space. The use of these recycled materials not only highlights our commitment to sustainability but also showcases our dedication to creating a charging station that seamlessly blends modernity with environmental consciousness. The result is a charging station that not only serves its purpose but also stands as a testament to their innovative and eco-friendly approach to design.

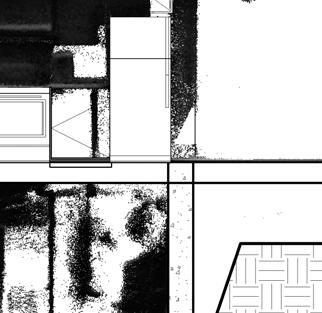

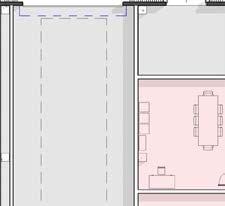

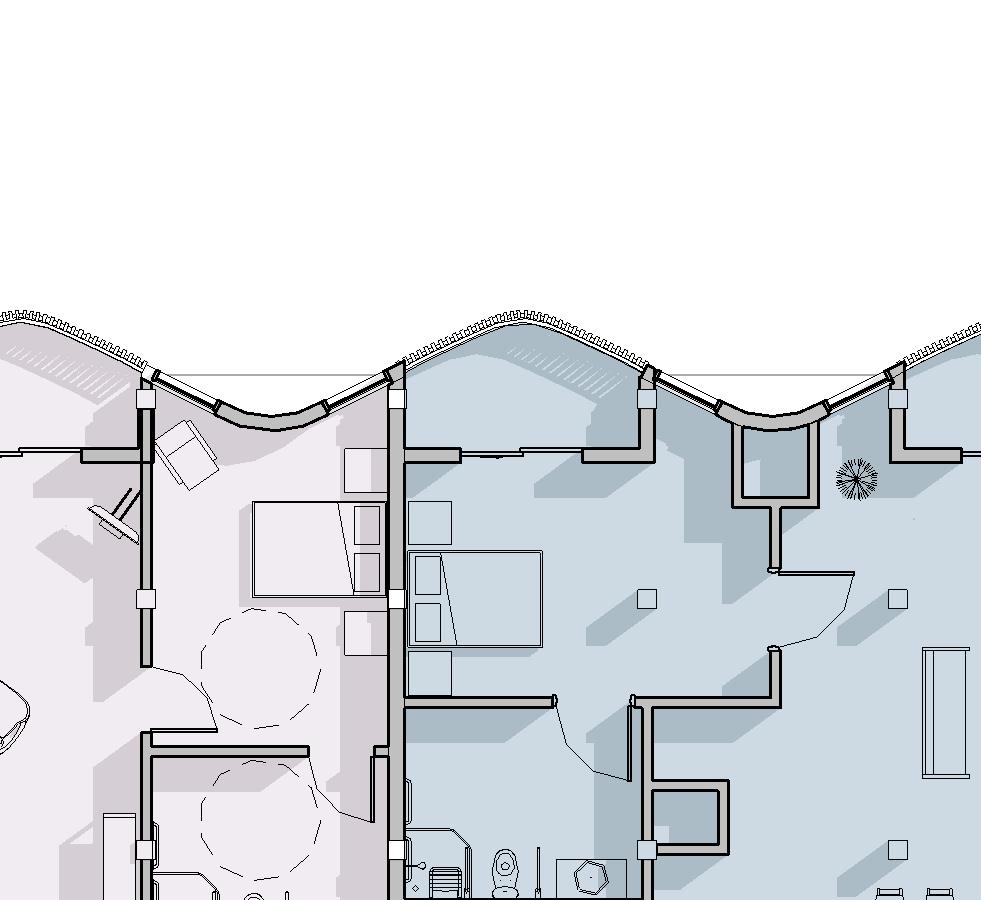

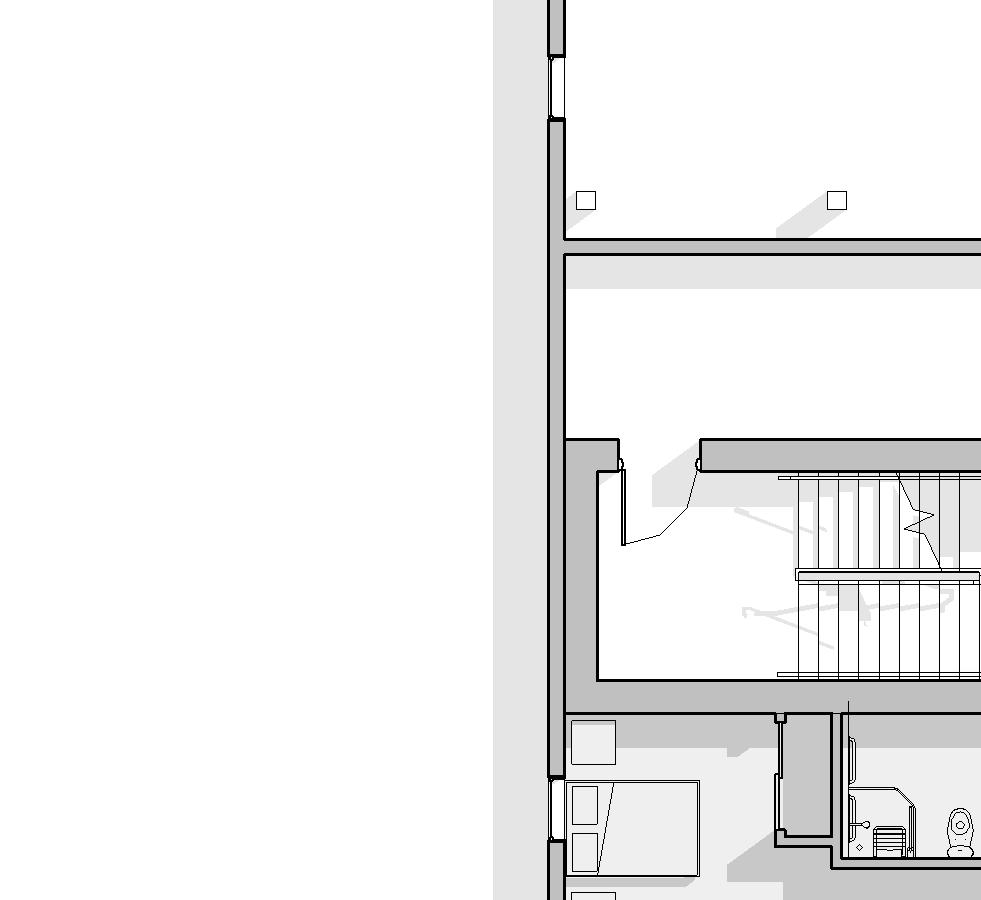

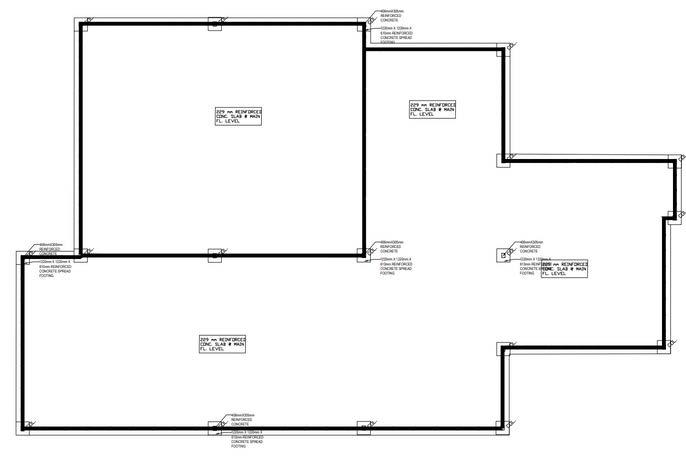

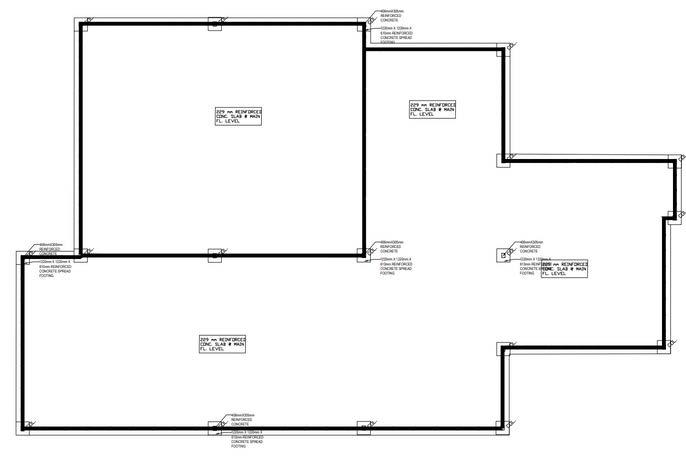

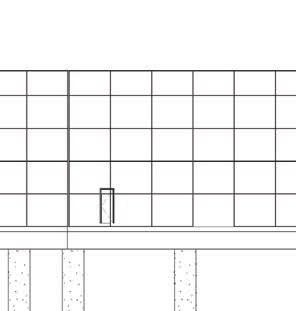

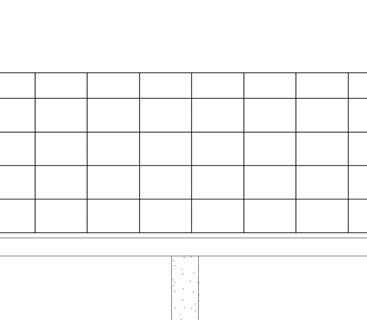

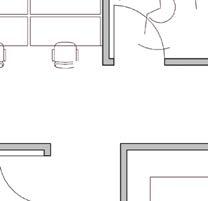

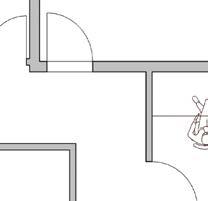

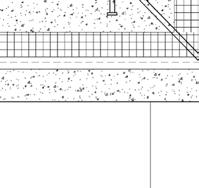

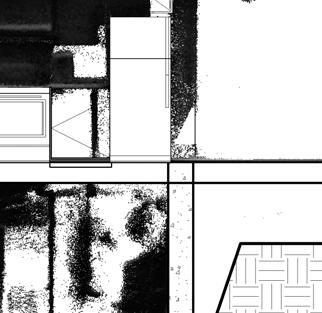

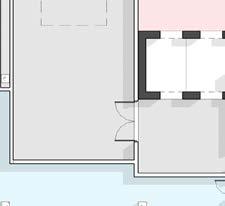

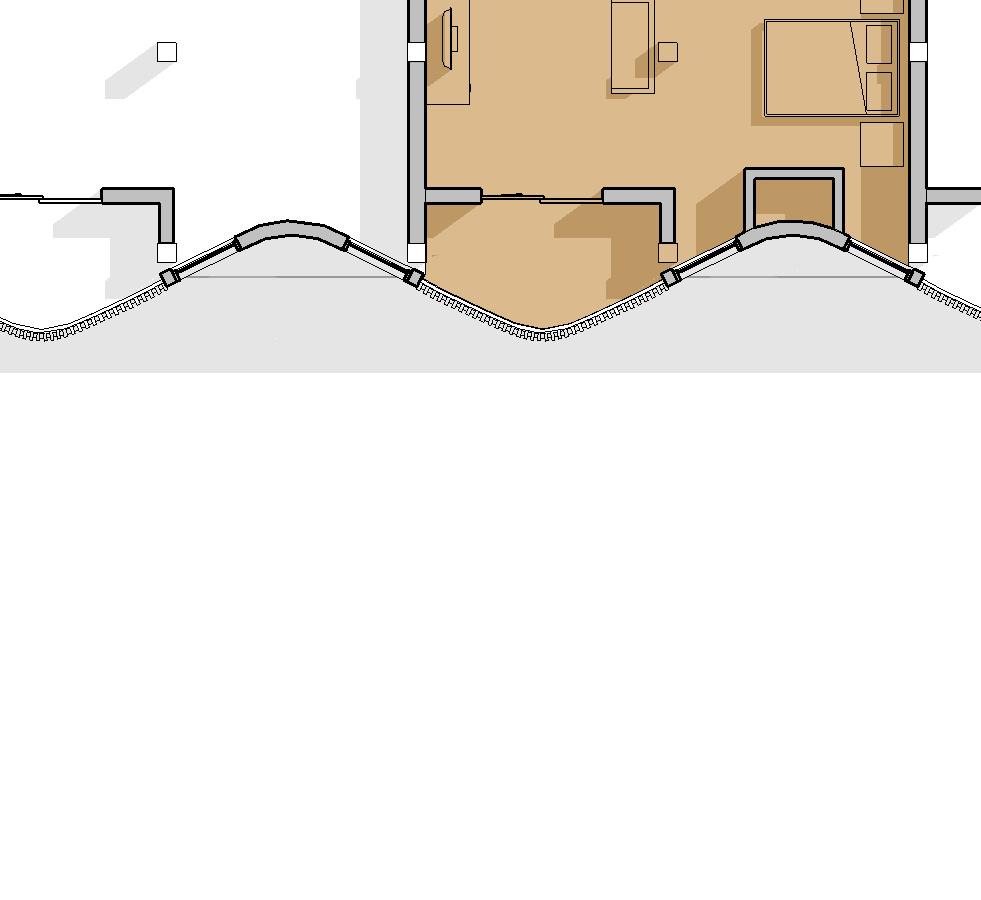

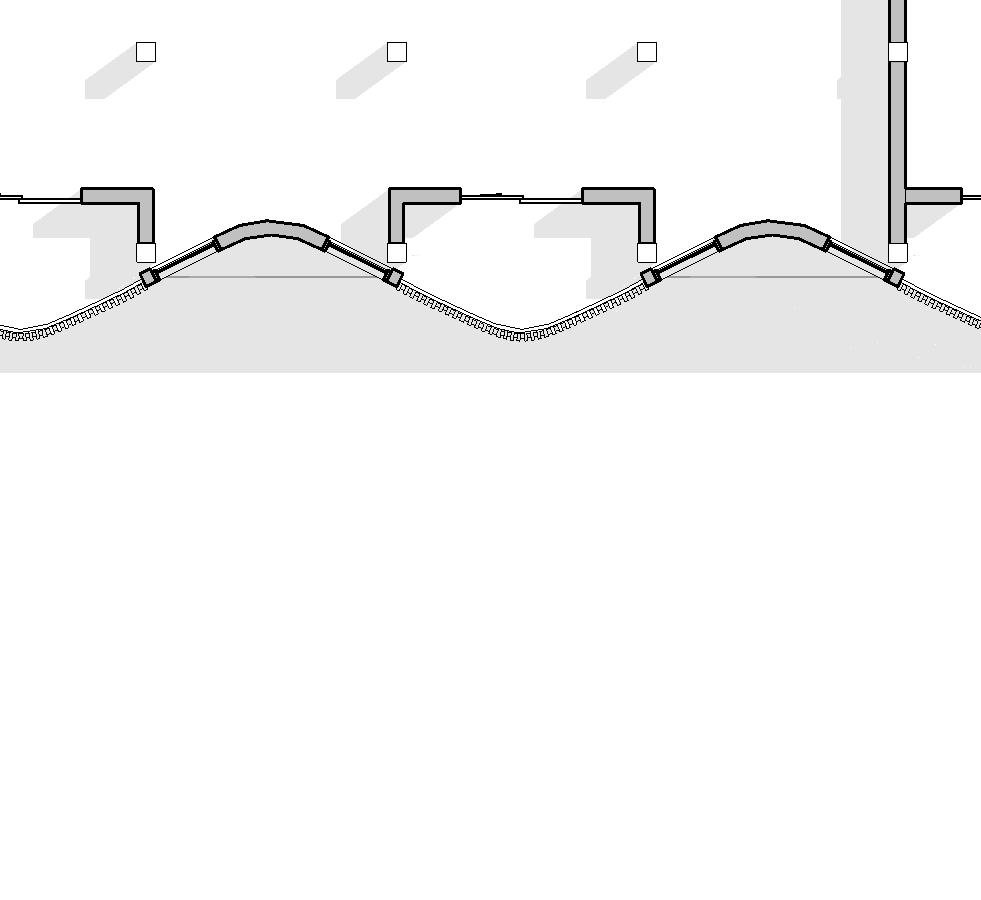

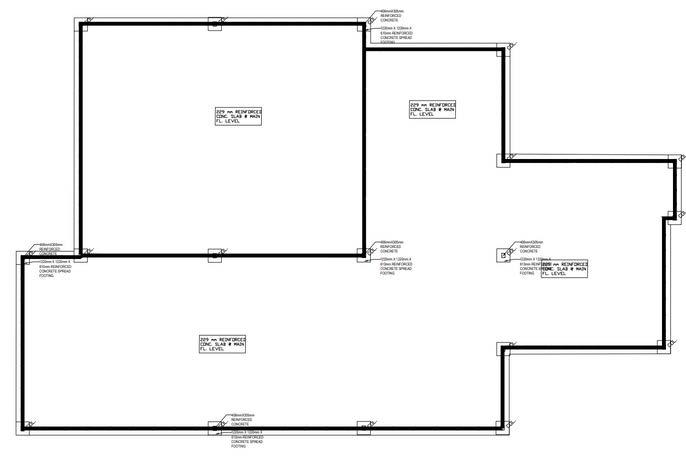

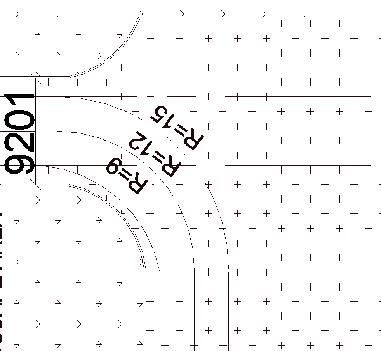

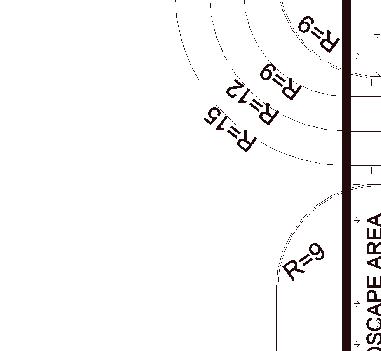

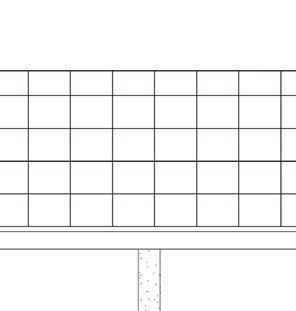

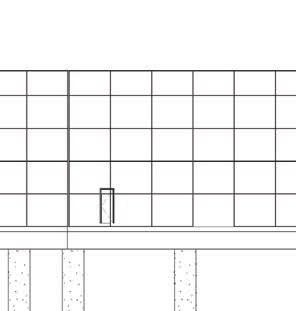

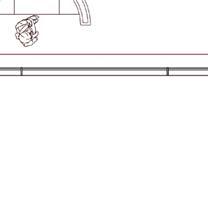

FOUNDATION PLAN

02 I

SITE PLAN / SCALE: 1:100

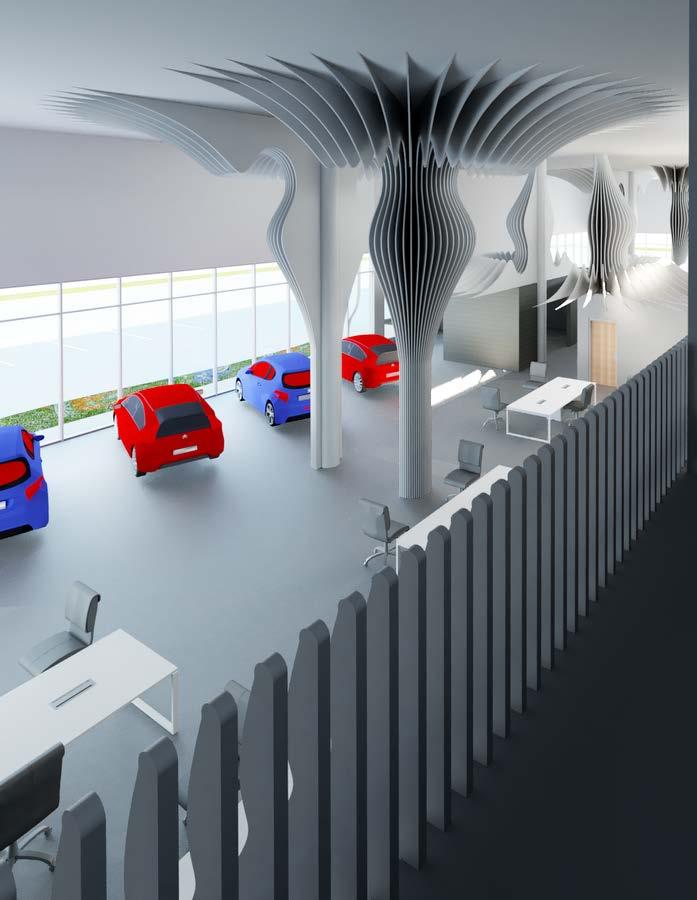

Our design incorporates an exquisite column element, showcasing addition not only enhances the visual appeal but also serves the team's ingenuity as they serve a dual function, doubling forts, we have successfully created a design that showcases

Incorporating recycled materials into our charging station design not only aligns with our sustainability goals but also creates a sleek and modern look. The use of glass and metal provides a visually appealing element that enhances the overall aesthetic of the space.

FOUNDATION PLAN

MATERIALS

Insulated metal panels with aluminum sustainable and long-lasting solution for modern construction, with easy installation and custom sizing options. They offer good insulation and are

- PORSCHE

seamless and harmonious

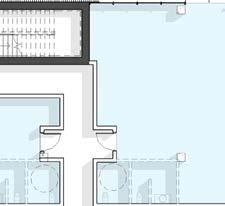

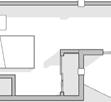

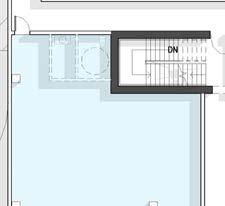

FIRST FLOOR PLAN SECOND

harmonious connection between the structure and the environment.

showcasing our collective effort to improve the space's aesthetics while elegantly concealing the structural columns. This serves a practical purpose, making it both useful and eye-catching. Notably doubling as a unique and striking ceiling feature that further enhances the space's visual appeal. Through our collaborative ef showcases our shared vision and skills, resulting in an impressive and visually captivating charging station.

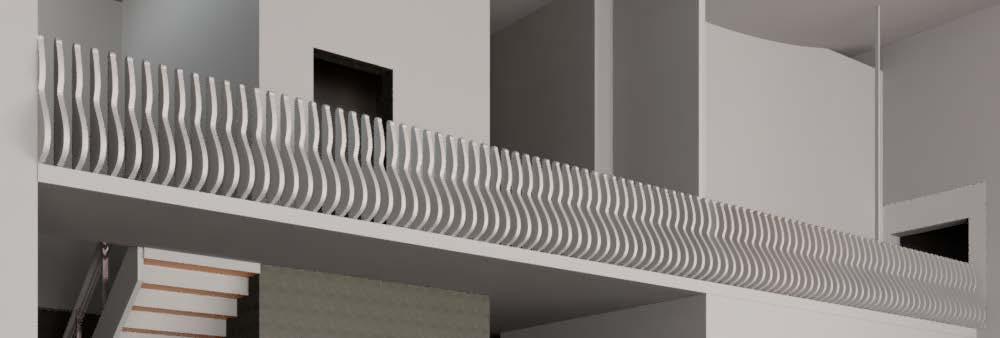

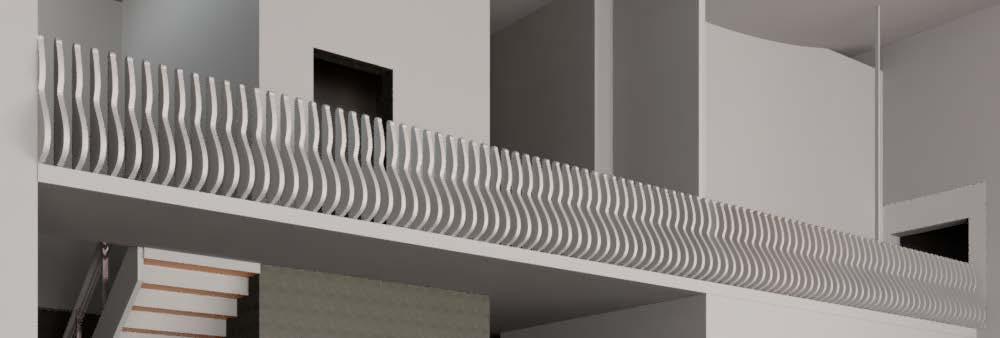

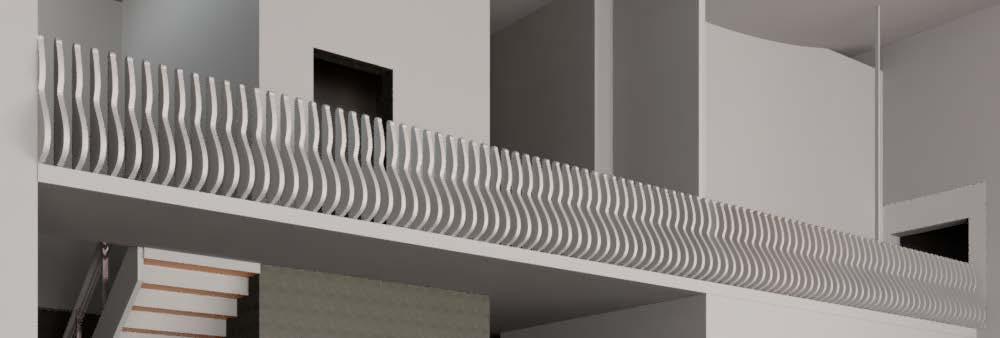

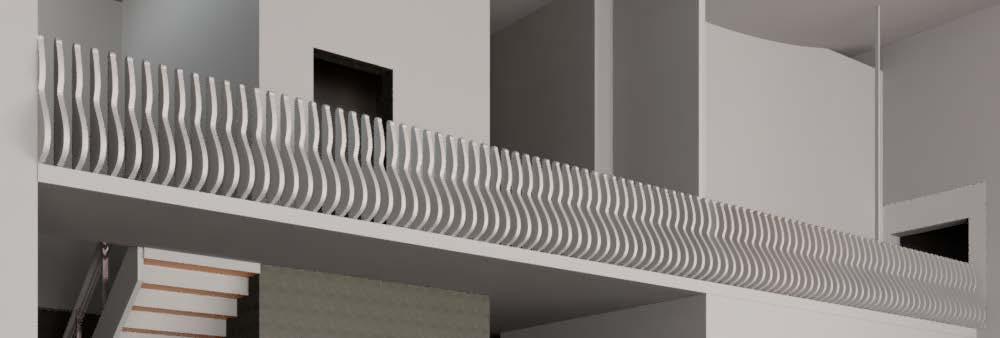

We improved the look of our railings to create a more elegant and visually appealing showroom. an eye-catching feature that adds to the overall visual appeal of the space by adding unusual

name-umesh

[101392618]ESMA

SECOND FLOOR PLAN / SCALE: 1:50

Our focus on enhancing the aesthetics of their showroom led to a remarkable transformation of the railings. By reimagining these functional elements, they successfully elevated them into eye-catching features that contribute to the overall visual appeal of the space. This achievement was accomplished through the thoughtful incorporation of unique and high-quality materials, which added a touch of elegance and sophistication. Our dedication to refining even the smallest details resulted in a showroom that not only showcases their attention to design but also captivates visitors with its visually stunning railings. [101395020] |

–FINAL

Automotive Dealership Project 2

22 02 I AUTOMOTIVE DEALERSHIP - PORSCHE EAST ELEVATION SECTION 2 Automotive DealershipPORSCHE –| FINAL FIRST FLOOR PLAN EAST ELEVATION SECTION 2 SOUTH ELEVATION –| FINAL FIRST FLOOR PLAN SECOND FLOOR PLAN NORTH ELEVATION / SCALE: 1:150 SOUTH ELEVATION / SCALE: 1:150 SECOND FLOOR PLAN / SCALE: SECTION 1 name-umesh [101392618]ESMA Automotive Project 2 –

WEST ELEVATION DealershipPORSCHE FIRST FLOOR NORTH ELEVATION arch.technology & studio 4 studio proffesor-BRENTWOOD | arch.technology & studio [101392618]ESMA [101395020] | | EAST ELEVATION / SCALE: 1:150 WEST ELEVATION / SCALE: 1:150

02 I

AUTOMOTIVE DEALERSHIP - PORSCHE

SECTION 2

Incorporating recycled materials into our charging station design not only aligns with our sustainability goals but also creates a sleek and modern look. The use of glass and metal provides a visually appealing element that enhances the overall aesthetic of the space.

INSULATED METAL PANELS WITH ALUMINUM

MATERIALS

Insulated metal panels with aluminum sustainable and long-lasting solution for modern construction, with easy installation and custom sizing options. They offer good insulation and are made from recycled materials.

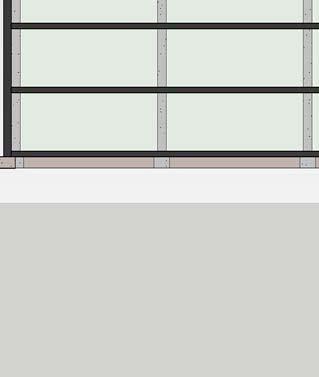

GLAZED WALL PANELS

Glazed walls offer numerous benefits for modern buildings, including natural light, energy efficiency, and design versatility. When incorporating glass walls into a project, proper orientation, shading, and glazing choices are critical concerns.

FOUNDATION PLAN

Sustainable and long-lasting solution for modern construction, with easy installation and custom sizing options. They offer good insulation and are made from recycled materials.

We improved the look of our railings to create a more elegant and visually appealing showroom. We transformed a functional piece into an eye-catching feature that adds to the overall visual appeal of the space by adding unusual and high-quality materials.

name-umesh [101392618]ESMA [101395020]

SECTION 1

MATERIALS

Insulated metal panels with aluminum sustainable and long-lasting solution for modern construction, with easy

DealershipPORSCHE

Incorporating with our sustainability of glass and overall aesthetic

GLAZED WALL PANELS

Our design incorporates an exquisite column element that not only improves the space's aesthetics but also elegantly conceals the structural columns. This addition adds an aesthetically attractive aspect that is useful as well as eye-catching. Additionally, the middle columns of the charging station also serve a dual function by working as a unique and striking ceiling feature, further enhancing the visual appeal of the space.

studio proffesor-BRENTWOOD | |

Glazed walls offer numerous benefits for modern buildings, including natural light, energy efficiency, and design versatility. When incorporating glass walls into a project, proper orientation, shading, and glazing choices are critical concerns.

arch.technology & studio 4

Project 2 –FINAL

installation and custom sizing options. They offer good insulation and

are

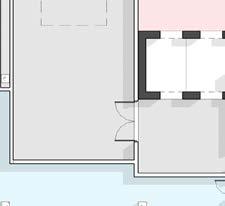

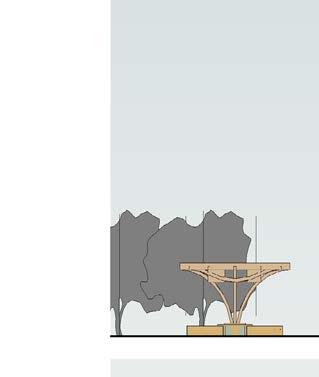

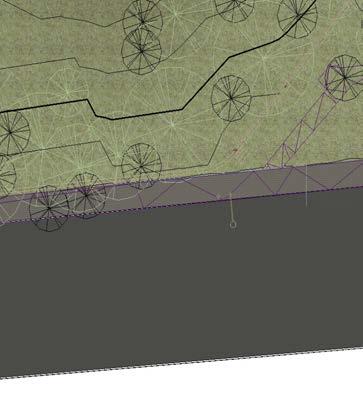

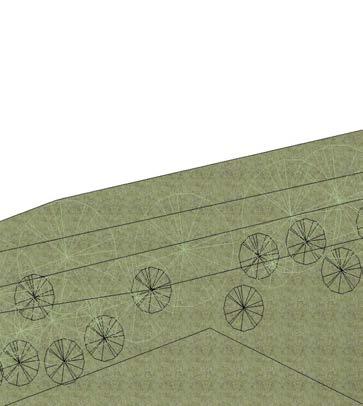

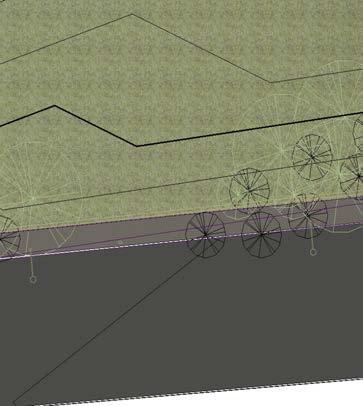

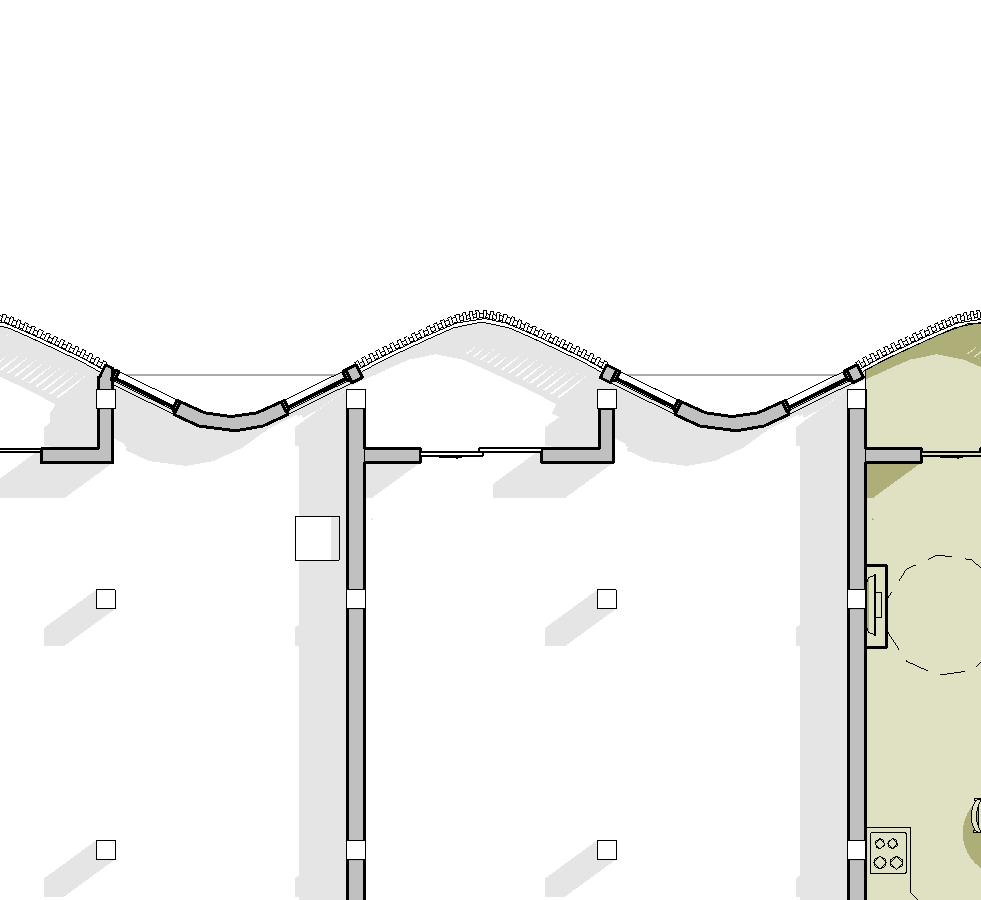

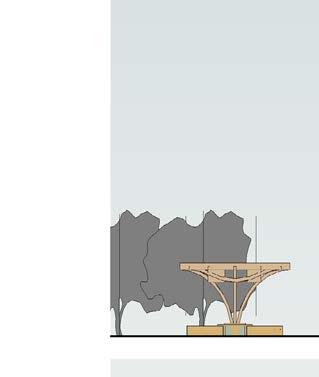

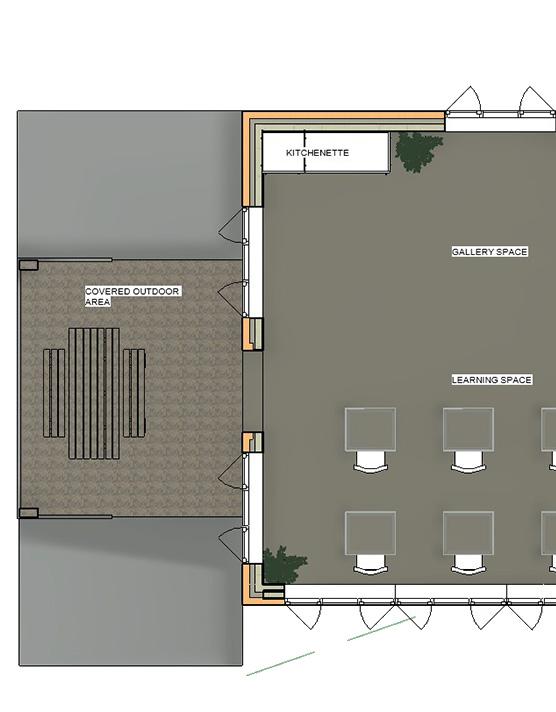

THE HILLCREST COMMUNITY NATURE

CETRE-2022

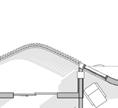

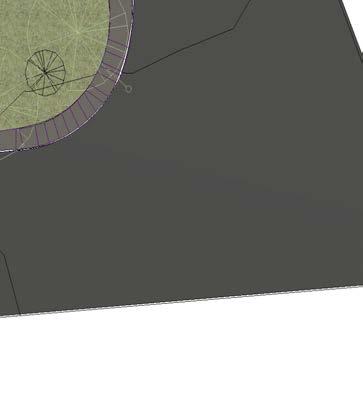

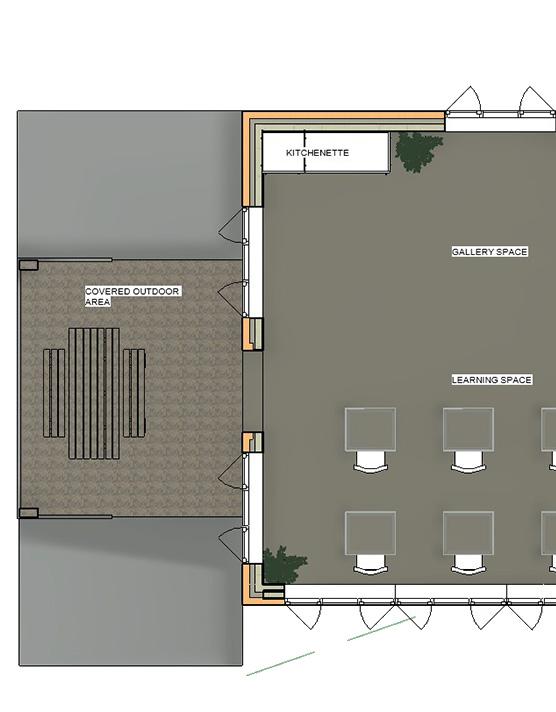

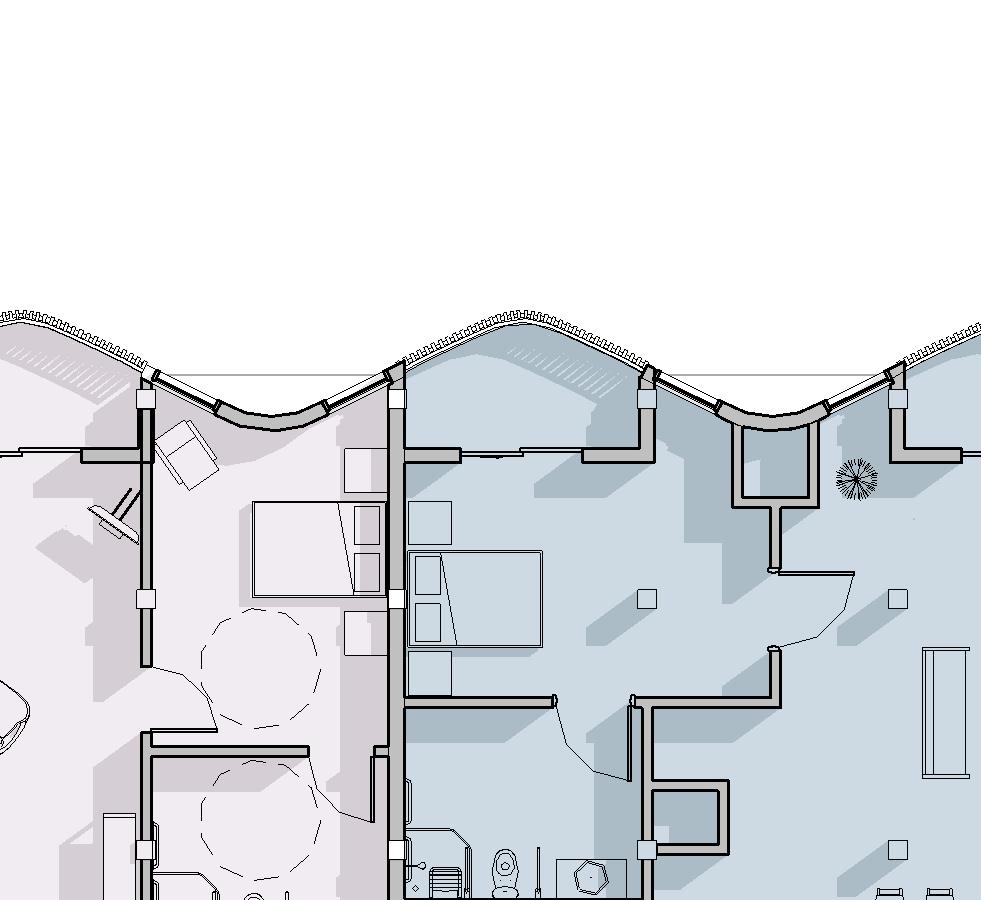

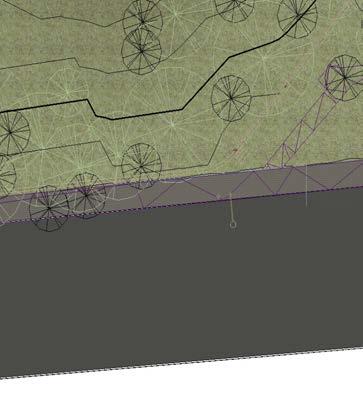

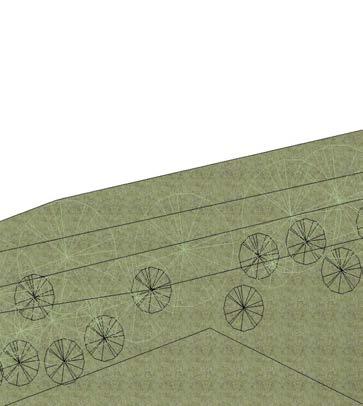

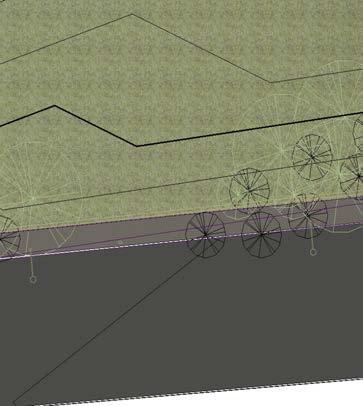

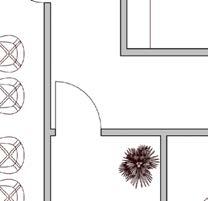

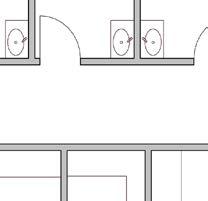

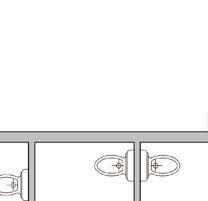

In my third semester, I worked on designing a sustainable community center with a strong focus on eco-friendly features. Sustainability has become a critical aspect of modern-day building design, and I wanted to ensure that my design was not only functional but also environmentally responsible. After research, I decided to make rainwater harvesting the primary sustainable design concept for my project. To achieve this, I incorporated a sloped roof and water collection tank in my design. These features allow us to collect and filter rainwater, making it usable for washroom needs and reducing our dependence on potable water.

By : Esma Cetinkaya

By : Esma Cetinkaya

03

In my project, I prioritized sustainability by utilizing native trees to minimize the carbon footprint. By incorporating these indigenous species into the site, I not only enhanced the natural beauty of the area but also promoted environmental balance and reduced carbon emissions. This conscious decision reflects the commitment to creating designs that harmonize with the environment and contribute to a greener future.

To minimize water consumption, I incorporated low-pressure dual aerators in the interior fixtures, ensuring efficient water usage without sacrificing performance. Furthermore, energy-efficient lighting fixtures were carefully selected to reduce energy consumption and minimize the project’s environmental impact.

1

PROPOSED BUILDING 1 150 Site

EXISTING BUILDING

03 I THE HILLCREST COMMUNITY CENTRE - 2022

SITE PLAN / SCALE: 1:150

Also in the interior I integrated various eco-friendly elements to create a truly sustainable space. The use of reclaimed wood flooring not only added character and warmth but also reduced the demand for new timber, contributing to forest conservation efforts. Additionally, I employed low VOC paint to enhance indoor air quality, prioritizing the health and well-being of occupants.

03 I THE HILLCREST COMMUNITY CENTRE - 2022 FLOOR PLAN / SCALE: 1:100 18 W/D HVAC STORAGE LIVING KITCHEN DINNING 18 m² 4 m² ENSUITE 15 m² BEDROOM BATHROOM FOYER W/D STORAGE BEDROOM (ASSISTED LIVING) BEDROOM FOYER ENSUITE Scale As indicated 2 BEDROOM ASSISTED LIVING UNIT AND 2 BEDROOM 2 BEDROOM ASSISTED LIVING UNIT 122 m 2 BEDROOM ASSISTED LIVING UNIT 98 m 2 KEY PLAN 1:50 1:50 GALERY SPACE LIVING m² KITCHEN m² F D W/D STORAGE 17 m² BEDROOM (ASSISTED LIVING) 30 m² LIVING BEDROOM BATHROOM DINNER m² KITCHEN 11 m² FOYER m² ENSUITE Scale As indicated 2 BEDROOM ASSISTED LIVING UNIT AND 2 BEDROOM 2 BEDROOM ASSISTED LIVING UNIT 122 m 2 2 BEDROOM 98 m 2 KEY PLAN 1:50 1:50 LEARNING SPACE W/D F STORAGE 15 m² LIVING m² KITCHEN MASTER BEDROOM WALK-IN BEDROOM m² BATHROOM D W/D STORAGE HVAC BEDROOM (ASSISTED LIVING) 30 m² 16 m² BEDROOM BATHROOM DINNER m² Scale As indicated 2 BEDROOM ASSISTED LIVING UNIT AND 2 BEDROOM 2 BEDROOM ASSISTED LIVING UNIT 122 m 2 2 BEDROOM ASSISTED LIVING UNIT 98 m 2 KEY PLAN 1:50 1:50 KITCHENETTE HVAC STORAGE LIVING KITCHEN 17 m² DINNING m² m² ENSUITE 15 m² BEDROOM BATHROOM m² FOYER D W/D STORAGE HVAC 17 m² BEDROOM (ASSISTED LIVING) LIVING BEDROOM BATHROOM KITCHEN FOYER ENSUITE Scale As indicated 2 BEDROOM ASSISTED LIVING UNIT AND 2 BEDROOM 2 BEDROOM ASSISTED LIVING UNIT 122 m 2 2 BEDROOM ASSISTED LIVING UNIT 98 m 2 KEY PLAN 1:50 1:50 COVERED OUTDOOR AREA

19 MASTER BEDROOM m² ENSUITE 15 m² m² FOYER F D W/D STORAGE 17 m² BEDROOM (ASSISTED LIVING) 30 m² LIVING BEDROOM 1 BATHROOM DINNER 9 m² KITCHEN 11 m² FOYER m² ENSUITE Scale As indicated 2 BEDROOM ASSISTED LIVING UNIT AND 2 BEDROOM 2 BEDROOM ASSISTED LIVING UNIT 122 m 2 2 BEDROOM ASSISTED LIVING UNIT 98 m 2 KEY PLAN 1:50 1:50 UTILITY ROOM D 15 m² MASTER BEDROOM WALK-IN ENSUITE BEDROOM 1 W/D HVAC BEDROOM (ASSISTED LIVING) 16 m² BEDROOM 1 m² BATHROOM 19 m² DINNER FOYER ENSUITE Scale As indicated 2 BEDROOM ASSISTED LIVING UNIT AND 2 BEDROOM 2 BEDROOM ASSISTED LIVING UNIT 122 m 2 2 BEDROOM ASSISTED LIVING UNIT KEY PLAN 1:50 UNIVERSAL WASHROOM D 15 m² FOYER W/D HVAC BEDROOM (ASSISTED LIVING) LIVING 16 m² m² BATHROOM 19 m² FOYER ENSUITE Scale As indicated 2 BEDROOM ASSISTED LIVING UNIT AND 2 BEDROOM 2 BEDROOM ASSISTED LIVING UNIT 122 m 2 2 BEDROOM 98 m 2 KEY PLAN 1:50 1:50 ENTRY FOYER F D W/D STORAGE HVAC BEDROOM (ASSISTED LIVING) LIVING KITCHEN FOYER ENSUITE Scale As indicated 2 BEDROOM ASSISTED LIVING UNIT 2 BEDROOM ASSISTED LIVING 122 m 2 KEY PLAN 1:50 GENERAL CLOSET F W/D STORAGE 17 m² BEDROOM (ASSISTED LIVING) 9 m² KITCHEN 11 m² FOYER m² ENSUITE Scale As indicated 2 BEDROOM ASSISTED LIVING 2 BEDROOM ASSISTED 122 m 2 KEY PLAN 1:50 SHOE/COAT CLOSET D 15 m² FOYER W/D HVAC BEDROOM (ASSISTED LIVING) LIVING 16 m² m² BATHROOM 19 m² FOYER ENSUITE Scale As indicated 2 BEDROOM ASSISTED LIVING UNIT AND 2 BEDROOM 2 BEDROOM ASSISTED LIVING UNIT 122 m 2 2 BEDROOM ASSISTED 98 m 2 KEY PLAN 1:50 1:50 UP

I incorporated a water collection tank, specifically designed for rainwater harvesting, into my project to effectively collect and store rainwater for sustainable use.

As a part of my project, I integrated triple-glazed windows which offer enhanced insulation performance, reduced heat loss, and minimized noise levels to provide a comfortable and energy-efficient environment.

To promote inclusivity and accessibility in my professional project, I incorporated a ramp for the outdoor area, allowing individuals with mobility impairments to navigate the space with ease and convenience.

32

03 I THE HILLCREST COMMUNITY CENTRE - 2022

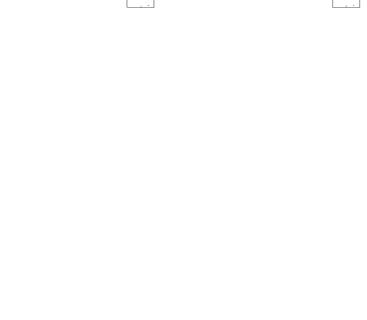

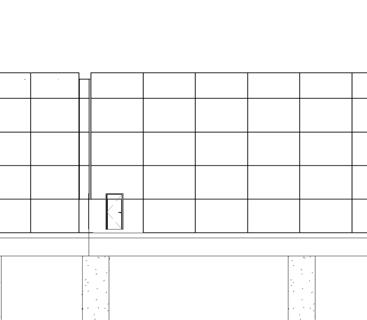

EAST ELEVATION / SCALE: 1:100

NORTH ELEVATION / SCALE: 1:100

As part of my project, I designed a sloped roof to facilitate rainwater harvesting, allowing for the efficient collection and storage of rainwater for sustainable use.

I added a water collection tank to my project, designed to collect and store rainwater for sustainable use. This eco-friendly feature allows for the reduction of water usage and lowers costs, contributing to the overall sustainability of the building.

As part of my sustainable design approach, I incorporated LED lighting in my project to promote energy efficiency and reduce the overall carbon footprint of the buildig.

33

SOUTH ELEVATION / SCALE: 1:100

WEST ELEVATION / SCALE: 1:100

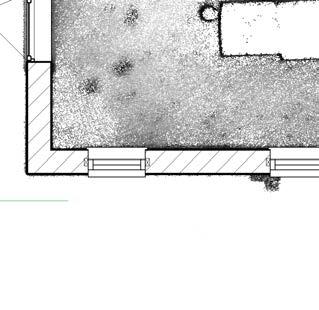

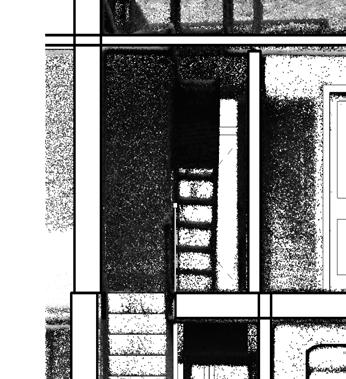

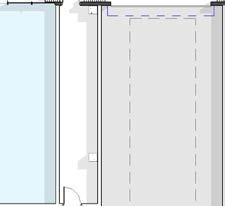

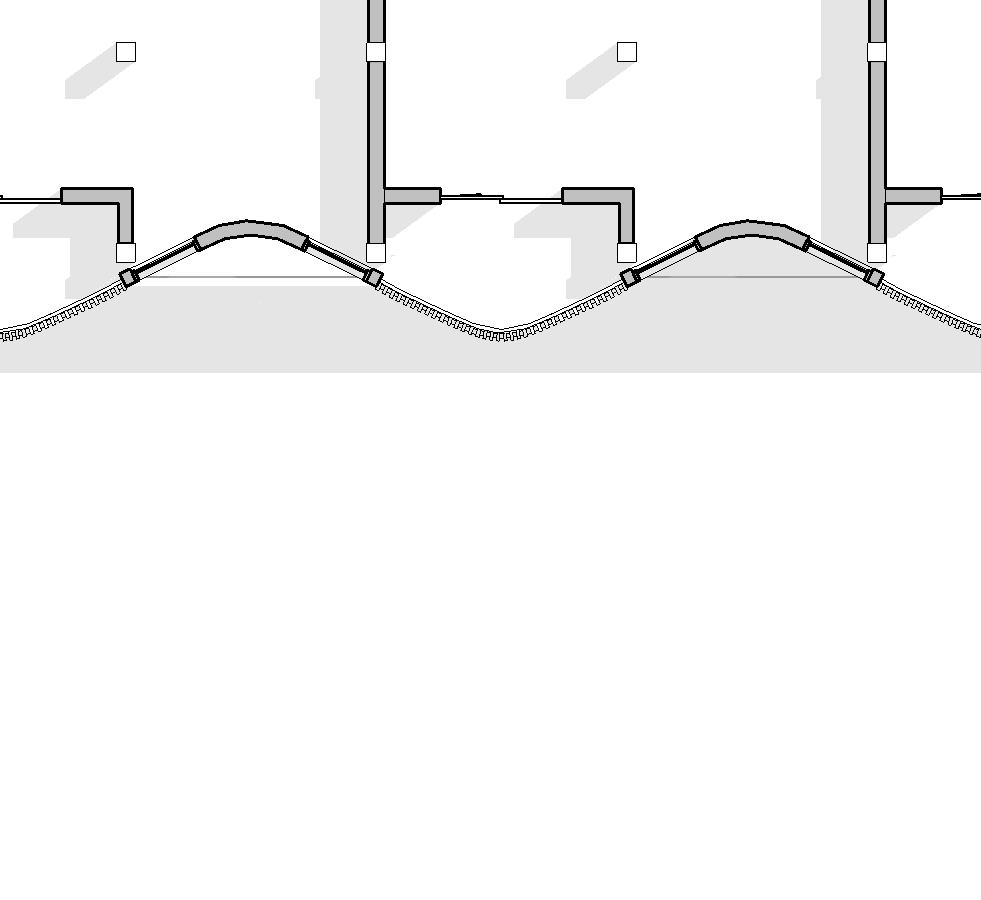

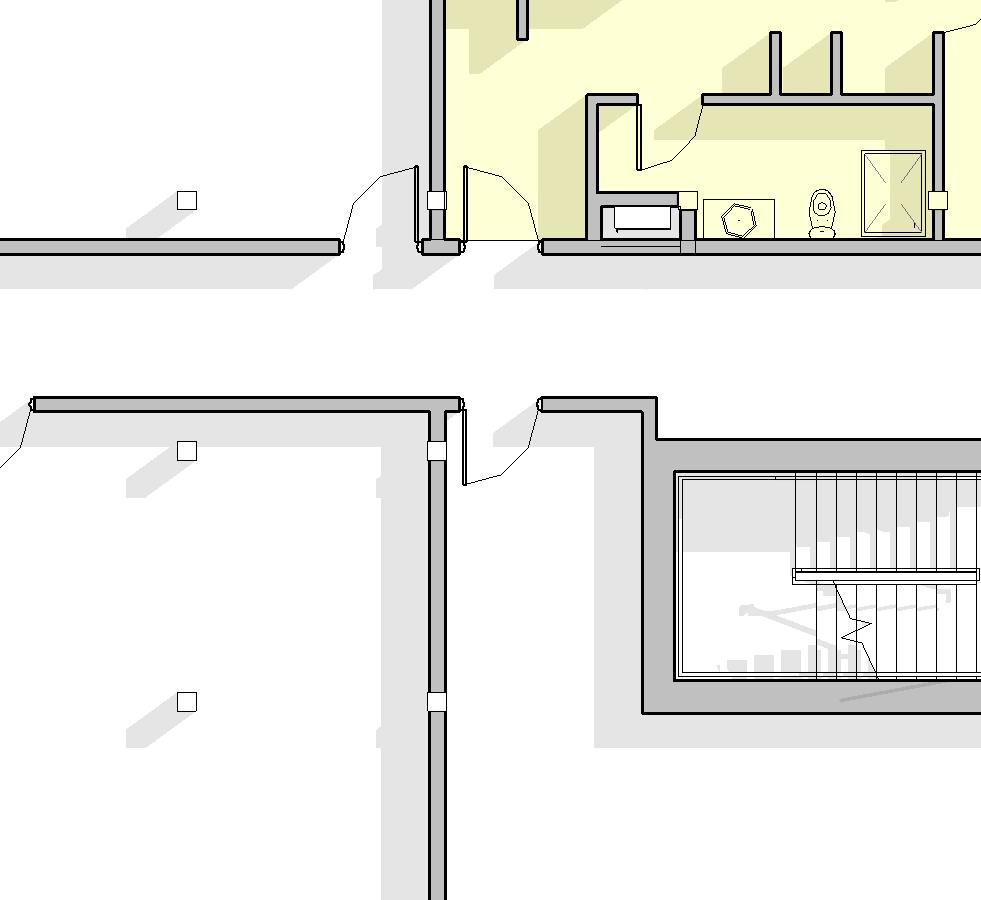

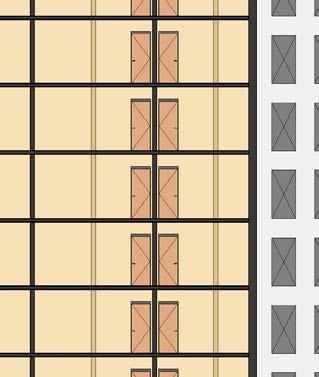

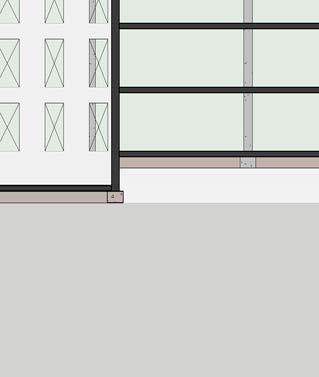

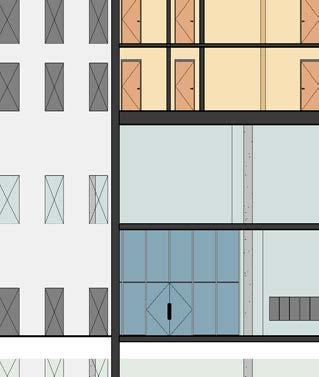

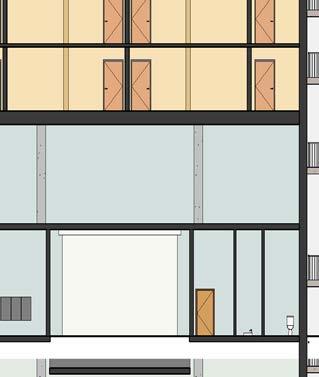

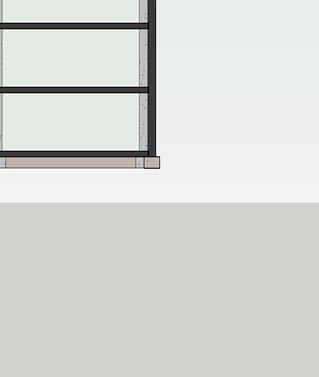

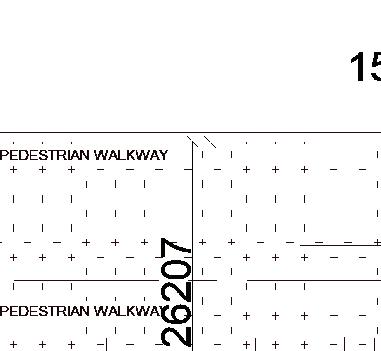

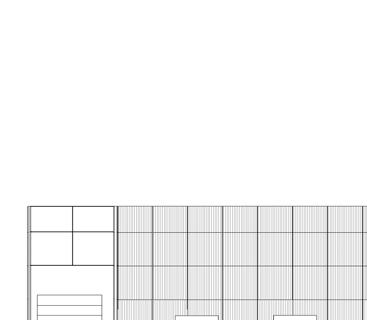

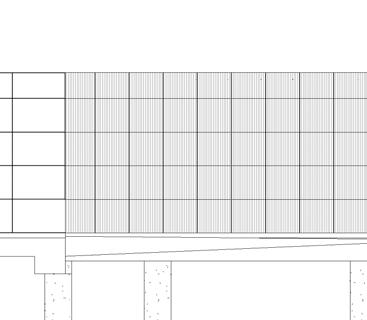

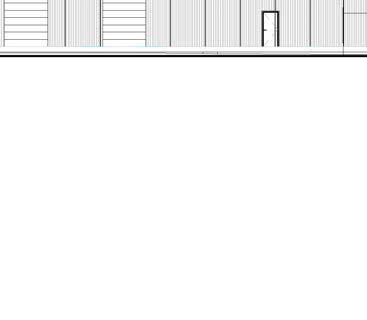

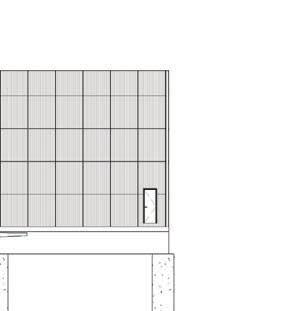

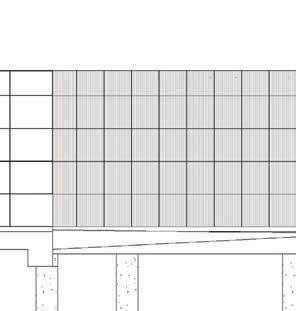

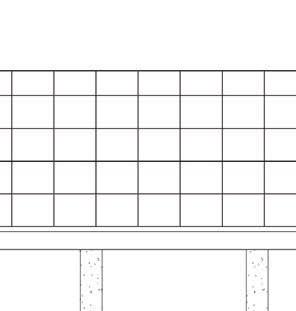

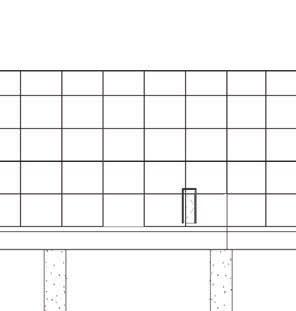

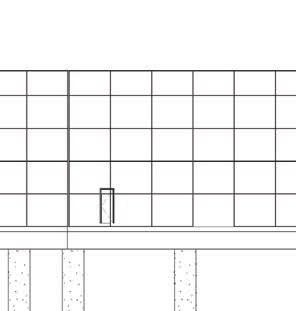

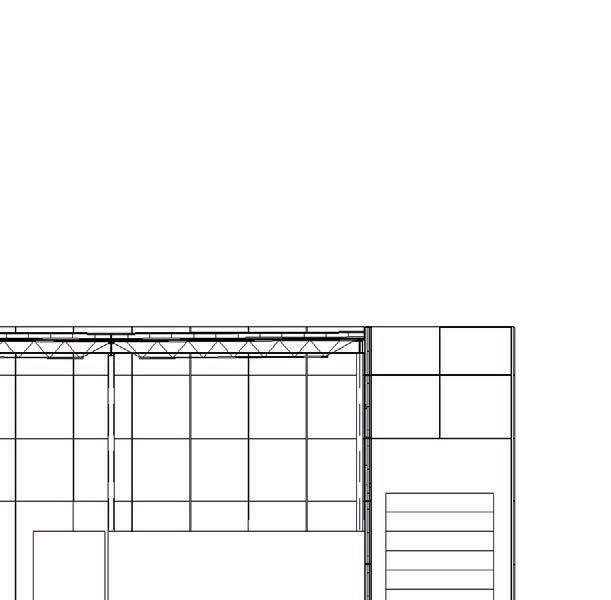

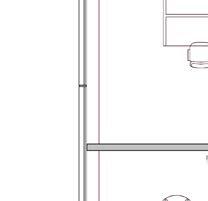

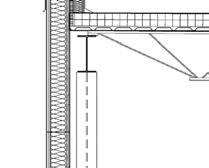

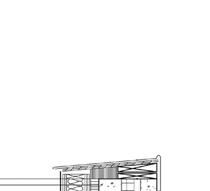

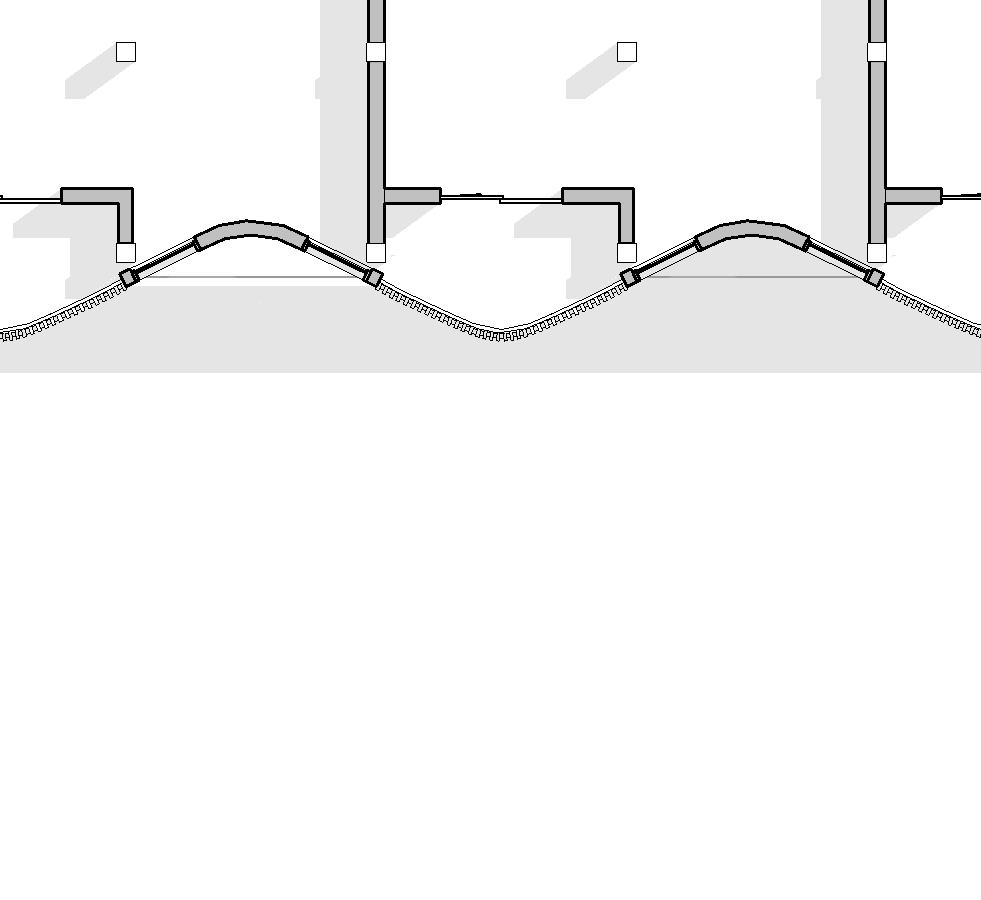

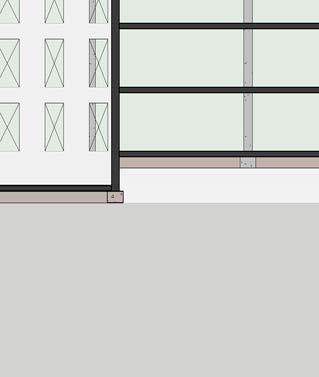

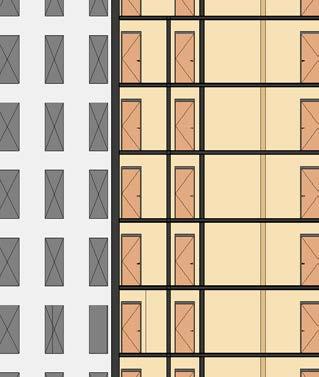

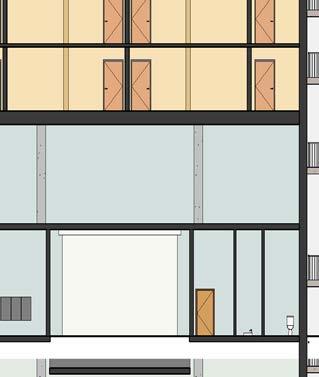

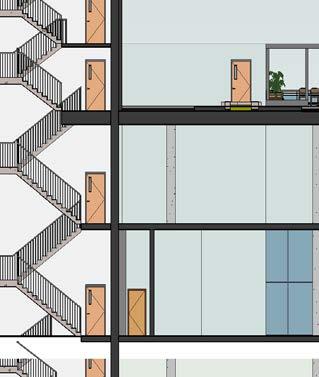

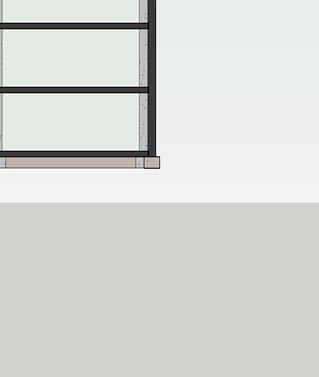

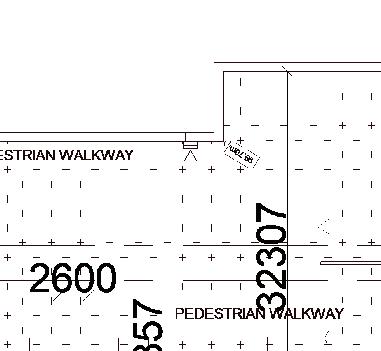

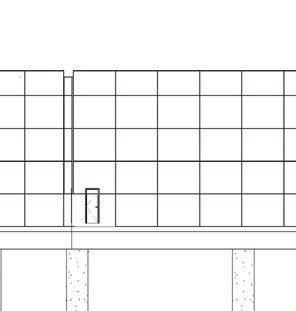

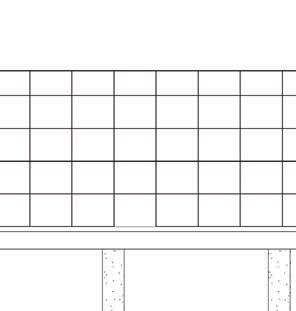

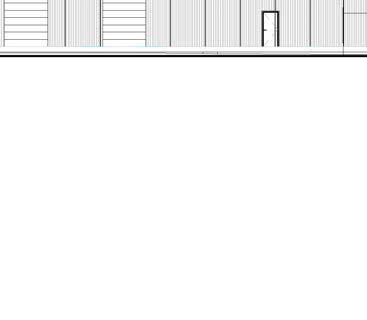

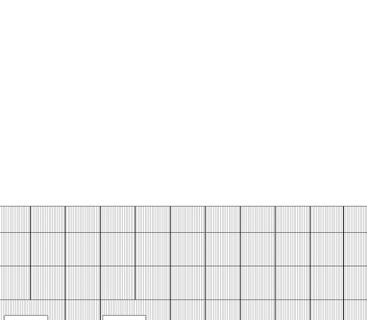

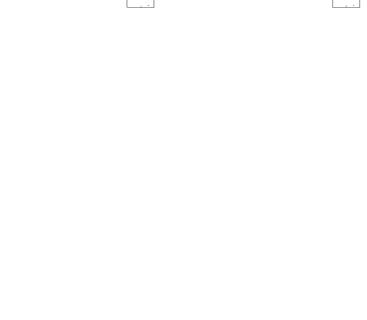

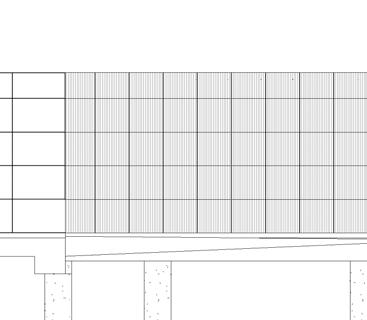

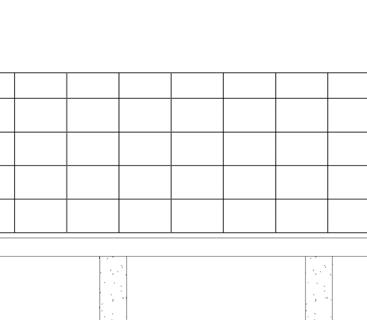

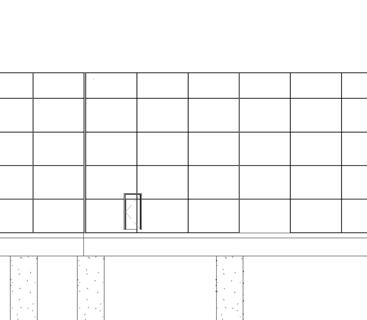

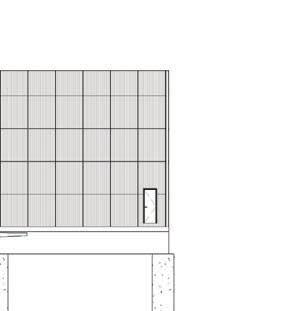

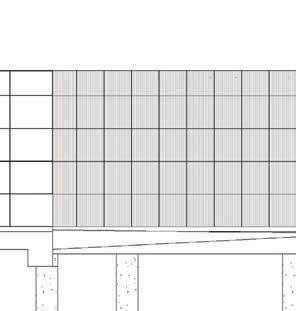

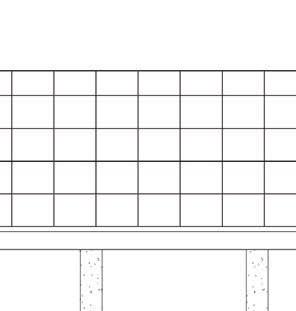

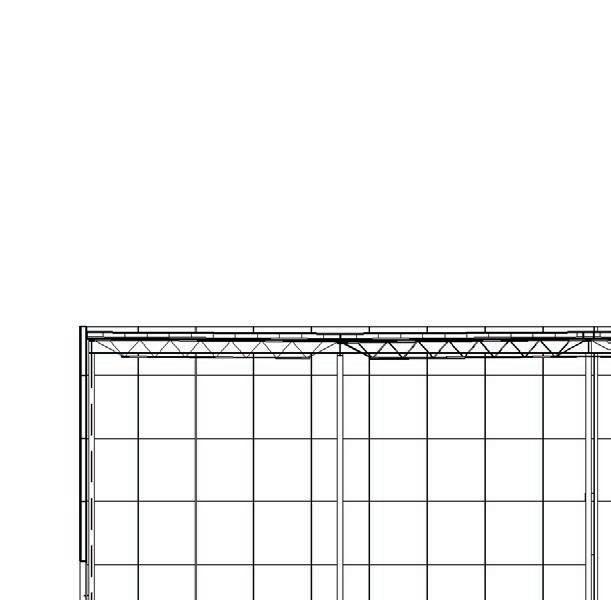

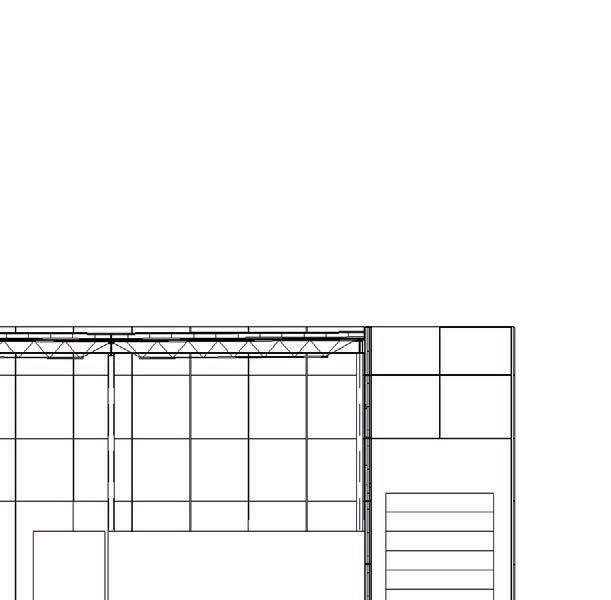

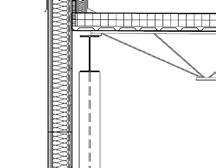

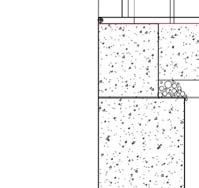

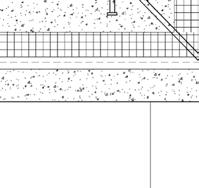

WAREHOUSE PROJECT 2023

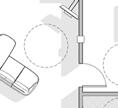

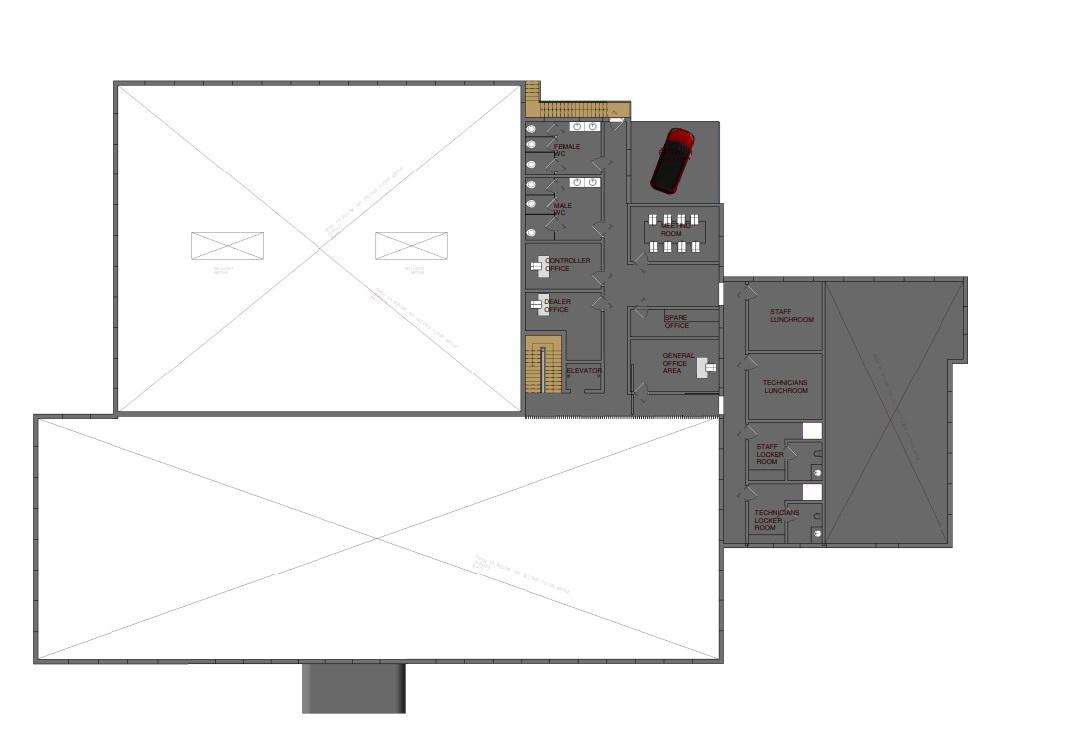

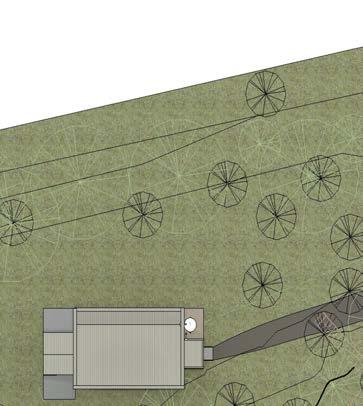

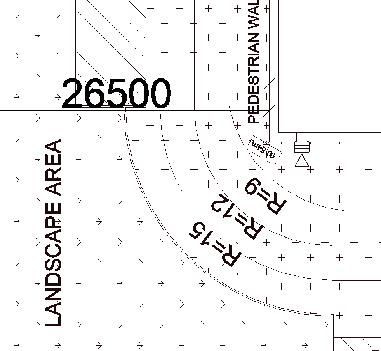

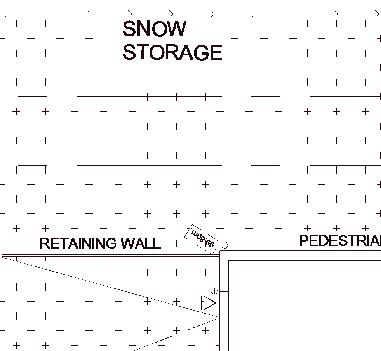

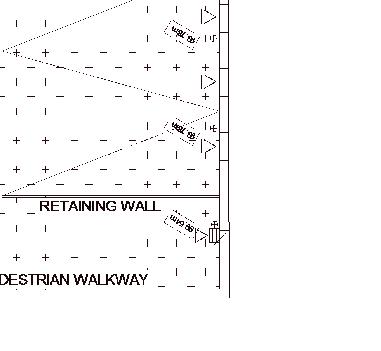

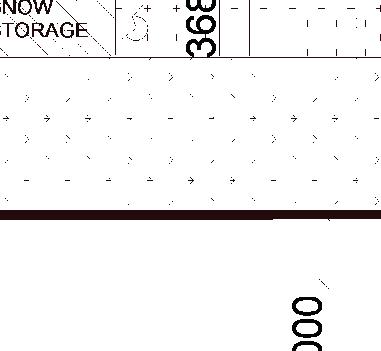

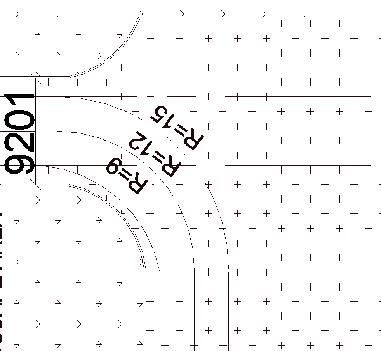

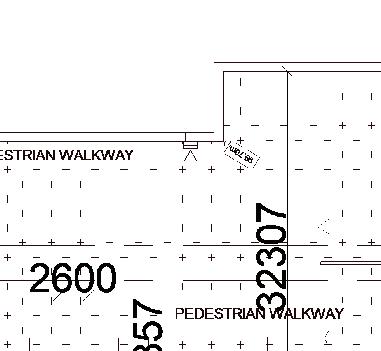

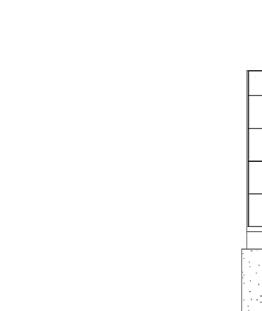

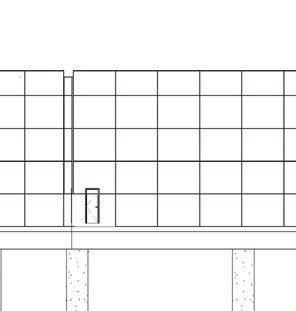

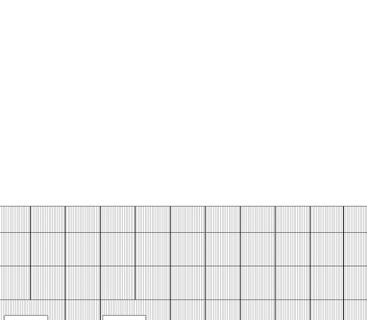

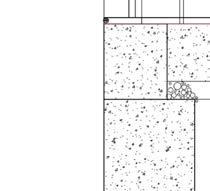

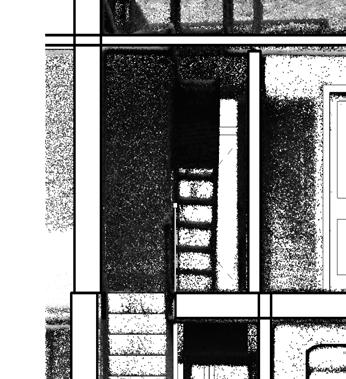

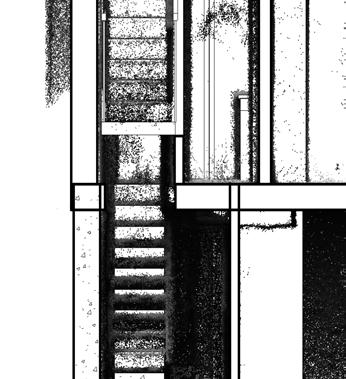

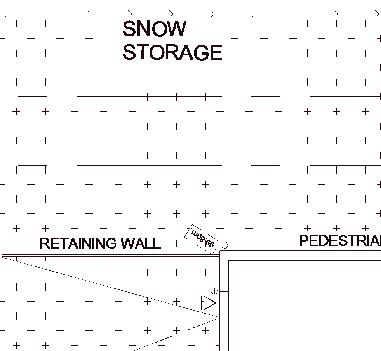

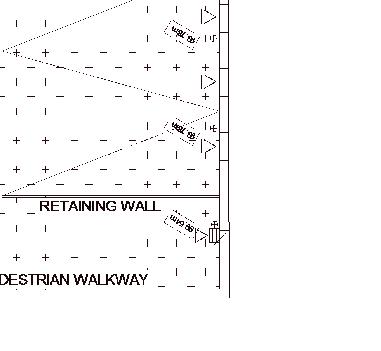

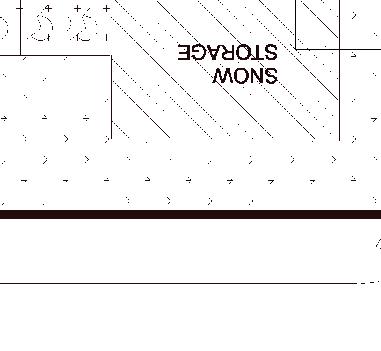

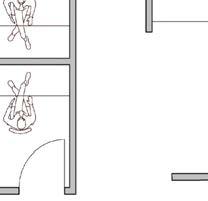

For our fourth-semester project, we designed a warehouse with a two-story office area to accommodate 45 employees. Our challenge was to maximize the use of space while incorporating three different wall materials. Our design concept was to create a functional warehouse with three main sections: receiving, storage, and shipping. We used metal panel walls with a horizontal pattern for the receiving and shipping areas, concrete block walls with a rough finish for the storage area, and glass walls for the two-story office area to create a sense of openness. We also created section drawings to showcase the details of the design. Overall, we successfully designed a warehouse that meets the requirements of limited space and incorporates interesting wall materials.

By : Esma Cetinkaya, Umesh Chauhan

By : Esma Cetinkaya, Umesh Chauhan

04

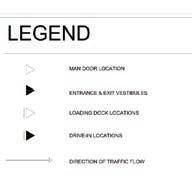

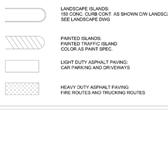

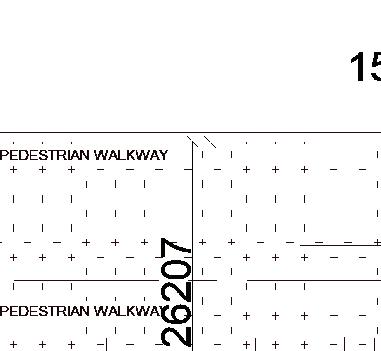

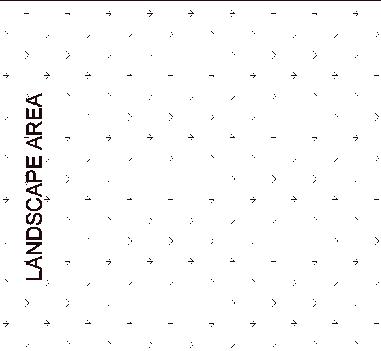

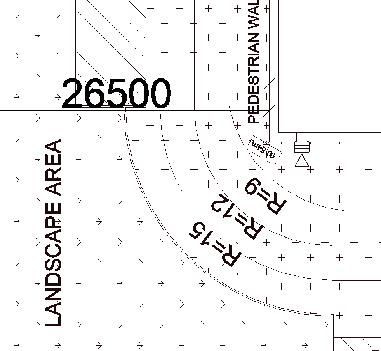

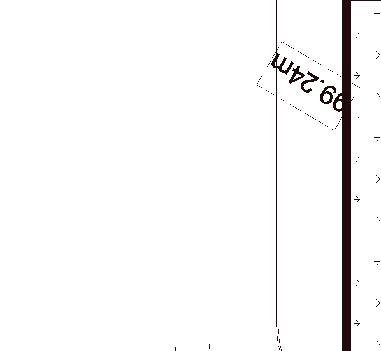

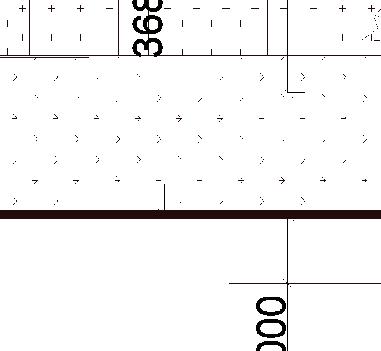

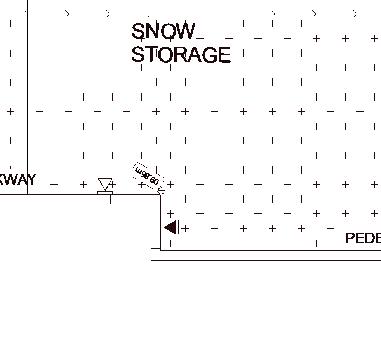

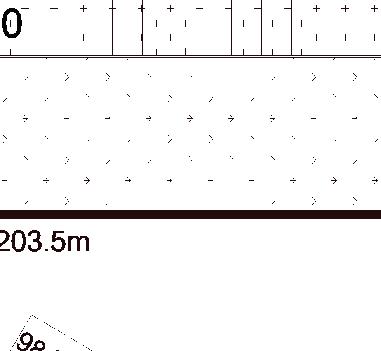

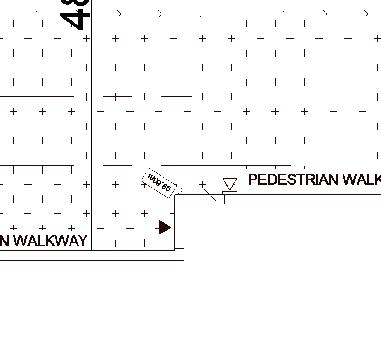

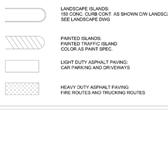

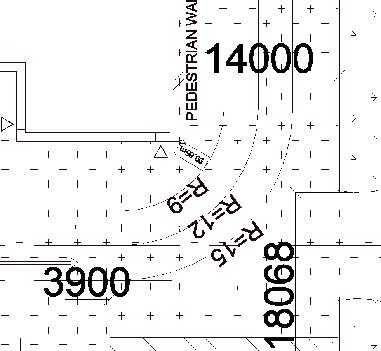

1 : 400 SITE PLAN 1 SITE PLAN AND NOTES / SCALE: 1:400

WAREHOUSE PROJECT - 2023

DOOR SCHEDULE

COSTRUCTION NOTES

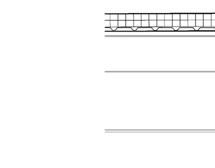

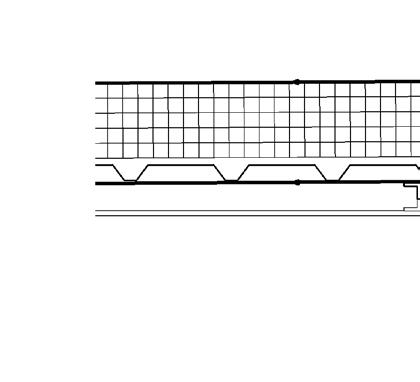

ROOF CONSTRUCTION

• BUILD-UP ROOF FIBERBORD C/W SBS ACKING RIGID INSULATION SINGLE-PLY FELT IN ASPHAL GYPSUM BOARD METAL DECKING ROOF STRUCTURE

RIGID INSULATION SINGLE-PLY FELT IN STRUCTURE

20mm

SHEATING 158mm INSULATION 16mm AIR

PANEL CURTAIN WALL

CURTAIN WALL "SANDWHICH PANEL" 25mm INSULATION 65mm THICK PRECAST CONCRETE

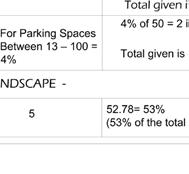

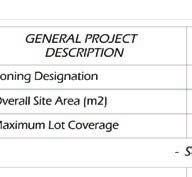

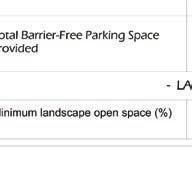

SITE AND PROJECT DATA

EXTERIOR WALL CONSTRUCTION

• GLAZED CURTAIN WALL 20mm CLADDING 20mm SHEATING 158mm INSULATION 16mm AIR INFILTRATION

• 16mm GYPSUM BOARD PRECAST CONCRETE PANEL CURTAIN WALL

• 90mm THICK PRECAST CONCRETE WALL CURTAIN WALL "SANDWHICH PANEL" 25mm AIR INFILTRATION BARRIER 50mm RIGID INSULATION 65mm THICK PRECAST CONCRETE PANEL CURTAN WALL "SANDWHICH PANEL"

INTERIOR WALL CONSTRUCTION

• 125mm METAL STUD WALL

• 200mm CONCRETE BLOCK

FOUNDATION WALL/FOOTINGS

5'-0" DIAMETER REINFORED CONCRETE CAISSING ON FOUNDATION EXTEND 14 THICK POURED CONCRETE TRENCH WALL BELOW GRADE AT PERIMETER, EXTENDING MINIMUM 6" ABOVE FINISHED EXTERIOR GRADE AND MINIMUM 5 BELOW FINSHED EXTERIOE GRADE.

SLAB

CAISSING ON FOUNDATION EXTEND 14 THICK GRADE AT PERIMETER, EXTENDING MINIMUM MINIMUM 5 BELOW FINSHED EXTERIOE GRADE. ON GRADE. MUST REST ON COMPACTED

400mm FROM EXTERIOR FACE OF

2 WALL SECTIONS

230mm THICK REINFORCED CONCRETE SLAB ON GRADE. MUST REST ON COMPACTED GRAVEL.

A.7.1 - 2 WALL SECTIONS

CONVENTIONAL STEEL FRAM

200mm x 200mm WIDE FLANGE I-COLUMN @ 400mm FROM EXTERIOR FACE OF PERIMERTER WALL OF THE BUILDING

A.8.0 - 2 PLAN DETAILS & 2 SECTION DETAILS

200mm x 200mm HSS INTERNAL STEEL COLUMNS

A.8.1 - 2 PLAN DETAILS & 2 SECTION DETAILS

DOORS

LOADING DOOCK DOOR 8'-0"WIDE BY 10'-0" HIGH

DEIVE-IN DOOR 12'-0' WIDE x 14'-0" HIGH

PEDESTRIAN DOOR MINIMUM 3'-0" WIDE

35 04 I

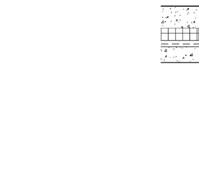

SHEET NAME SHEET NUMBER

th CLIENT PROJECT DRAWN BY DATE SCALE: - Project 1 Final Construction Drawings Brentwood ESMA 02/25/23

SITE AND PROJECT DATA

DOOR 1 2 3 4 5 6 7 WALL W1 W2 W3 W1 W2 FINAL

COLUMNS

1 2 3 4 5 6 7 910mm X 2110mm INTERIOR DOOR 1010mm X 2110mm INTERIOR DOOR 810mm X 2110mm INTERIOR DOOR 915mm X 2320 EXTERIOR DOOR 2440mm X 3050mm LOADING DOOR 3660mm X 4270mm DRIVE-IN DOOR EXTERIOR CURTAIN WALL DOOR WALL SCHEDULE W1 W2 W3 GLAZED CURTAIN WALL PRECAST CONCRETE PANEL CURTAIN WALL PRECAST CONCRETE PANEL CURTAIN WALL W1 125mm METAL STUD WALL 200mm CONCRETE BLOCK INDEX A.1.0 - COVER PAGE A.2.0 - SITE PLAN A.3.0 - FOUNDATION PLAN A.3.1 - GROUND FLOOR PLAN A.3.2 - SECOND FLOOR PLAN A.3.3 - ROOF PLAN A.4.0 - ELEVATIONS A.4.1 - ELEVATIONS A.5.0 - BUILDING CROSS SECTIONS A.5.1 - BUILDING CROSS SECTIONS A.6.0 - CALL-OUT PLANGROUND FLOOR OFFICE A.6.1 - CALL-OUT PLAN SECOND FLOOR OFFICE A.7.0 -

PROJECT 1FINAL CONSTRUCTION DRAWINGS COSTRUCTION NOTES ROOF CONSTRUCTION • BUILD-UP ROOF FIBERBORD C/W SBS ACKING RIGID INSULATION S PLY FELT IN ASPHAL GYPSUM BOARD METAL DECKING ROOF STRUCTURE EXTERIOR WALL CONSTRUCTION •GLAZED CURTAIN WALL 20mm CLADDING 20mm SHEATING 158mm INSULATION 16mm AIR INFILTRATION •16mm GYPSUM BOARD PRECAST CONCRETE PANEL CURTAIN WA •90mm THICK PRECAST CONCRETE WALL CURTAIN WALL "SANDWHICH PANEL" 25mm AIR INFILTRATION BARRIER 50mm RIGID INSULATION 65mm THICK PRECAST CONCRETE PANEL CURTAN WALL "SANDWHICH PANEL" INTERIOR

CONSTRUCTION

METAL STUD WALL •200mm CONCRETE BLOCK 910mm X 2110mm INTERIOR DOOR 1010mm X 2110mm INTERIOR DOOR 810mm X 2110mm INTERIOR DOOR 915mm X 2320 EXTERIOR DOOR 2440mm X 3050mm LOADING DOOR 3660mm X 4270mm DRIVE-IN DOOR EXTERIOR CURTAIN WALL DOOR PRECAST CONCRETE PANEL CURTAIN WALL INDEX A.1.0 - COVER PAGE A.2.0 - SITE PLAN A.3.0 - FOUNDATION PLAN A.3.1 - GROUND FLOOR PLAN A.3.2 - SECOND FLOOR PLAN A.3.3 - ROOF PLAN A.4.0 - ELEVATIONS A.4.1 - ELEVATIONS A.5.0 - BUILDING CROSS SECTIONS A.5.1 - BUILDING CROSS SECTIONS A.6.0 - CALL-OUT PLANGROUND FLOOR OFFICE A.6.1 - CALL-OUT PLAN SECOND FLOOR OFFICE A.7.0 - 2 WALL SECTIONS

WALL

•125mm

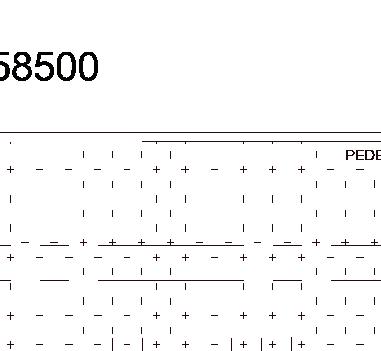

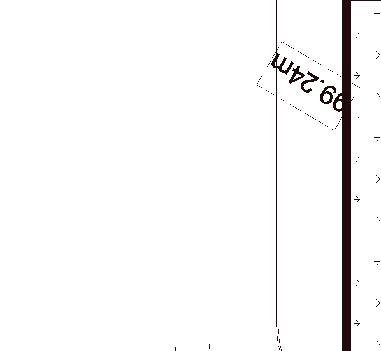

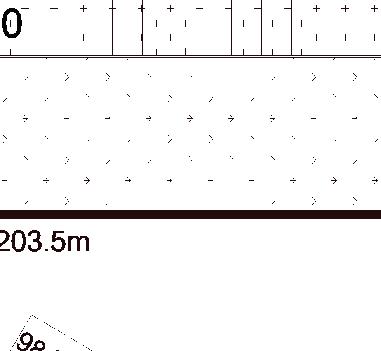

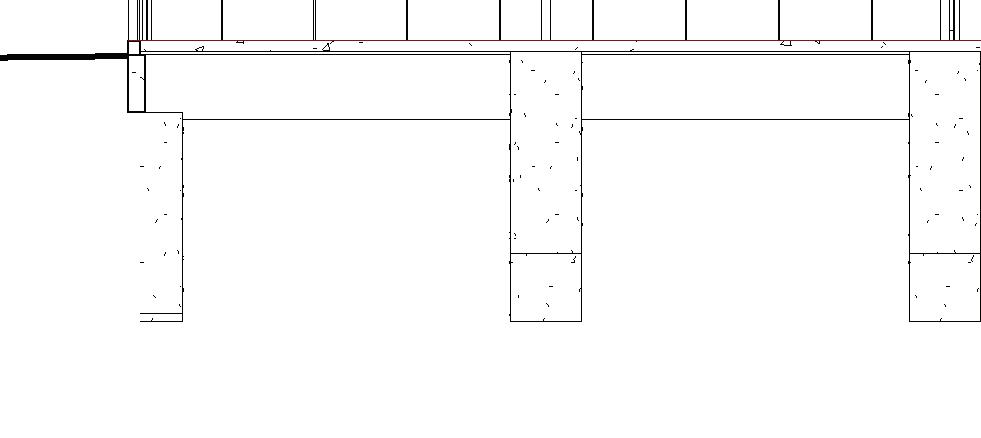

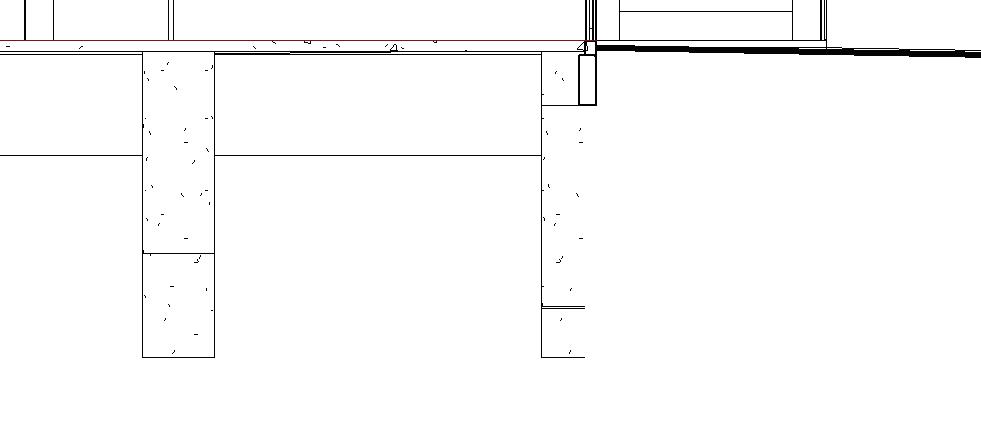

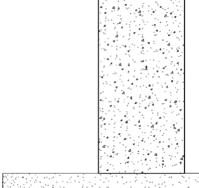

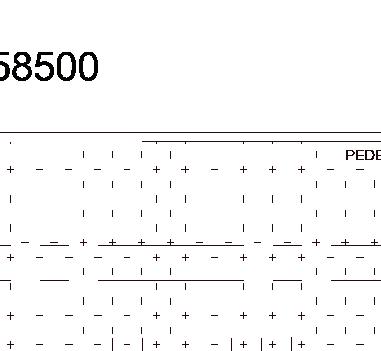

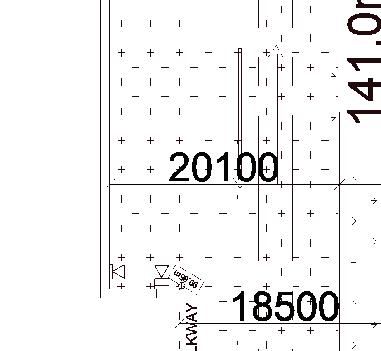

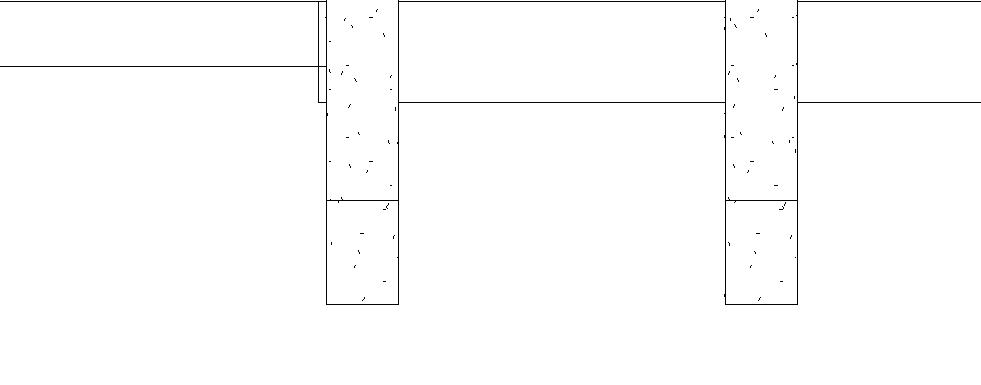

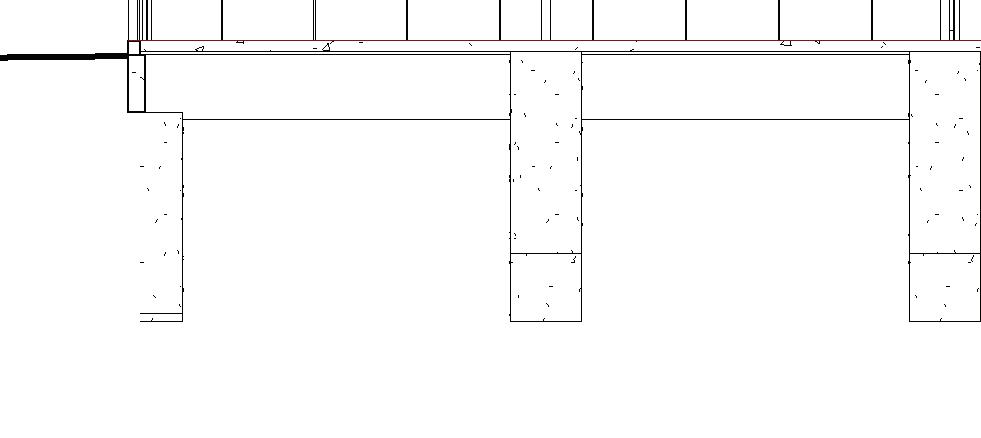

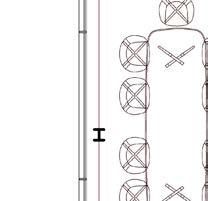

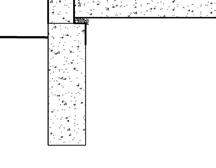

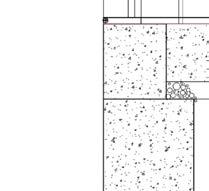

G Fx F E D C B A 1 2 3 3x 4 5 6 7 8 8x 10 11 12 13 13x 14 14x 9 1 A.5.0 A.7.1 2 A.7.0 2 A.7.1 1 A.7.0 Ax REINFORCED CAISSON REINFORCED CAISSON REINFORCED CAISSON REINFORCED CAISSON REINFORCED CAISSON REINFORCED CAISSON REINFORCED CAISSON REINFORCED CAISSON REINFORCED CAISSON REINFORCED CAISSON REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CAISSON REINFORCED CAISSON REINFORCED CAISSON REINFORCED CAISSON REINFORCED CAISSON REINFORCED CAISSON REINFORCED CAISSON REINFORCED CAISSON REINFORCED CAISSON CAISSON CAISSON CAISSON CAISSON CAISSON CAISSON CAISSON CAISSON CAISSON REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CAISSON REINFORCED CAISSON REINFORCED CAISSON REINFORCED CAISSON REINFORCED CAISSON REINFORCED CAISSON REINFORCED CAISSON REINFORCED CAISSON REINFORCED CAISSON REINFORCED CONCRETE REINFORCED CAISSON REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE CAISSON REINFORCED CAISSON REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE CAISSON CONCRETE CAISSON CONCRETE CAISSON CONCRETE CAISSON REINFORCED CAISSON REINFORCED CONCRETE CAISSON REINFORCED CONCRETE CAISSON CONCRETE CAISSON REINFORCED CAISSON REINFORCED CAISSON REINFORCED CAISSON REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE REINFORCED CONCRETE 28960 6100 7283 4378 11662 11662 11662 11662 3785 7877 11662 11662 11662 11662 6025 5637 11662 11662 158500 8852 129074 3978 8452 8452 8452 8452 8452 8452 56390 6100 7283 4378 11662 11662 11662 11662 3785 7877 11662 11662 11662 11662 6025 5637 11662 11662 158500 17303 400 33807 56390 6100 2352 8452 8452 8452 8452 8452 CLIENT PROJECT DRAWN BY DATE SCALE: SHEET NAME SHEET NUMBER 1:250 Project 1 Final Foundation Plan A.3.0 1 : 250 FOUNDATION PLAN 1 EC North

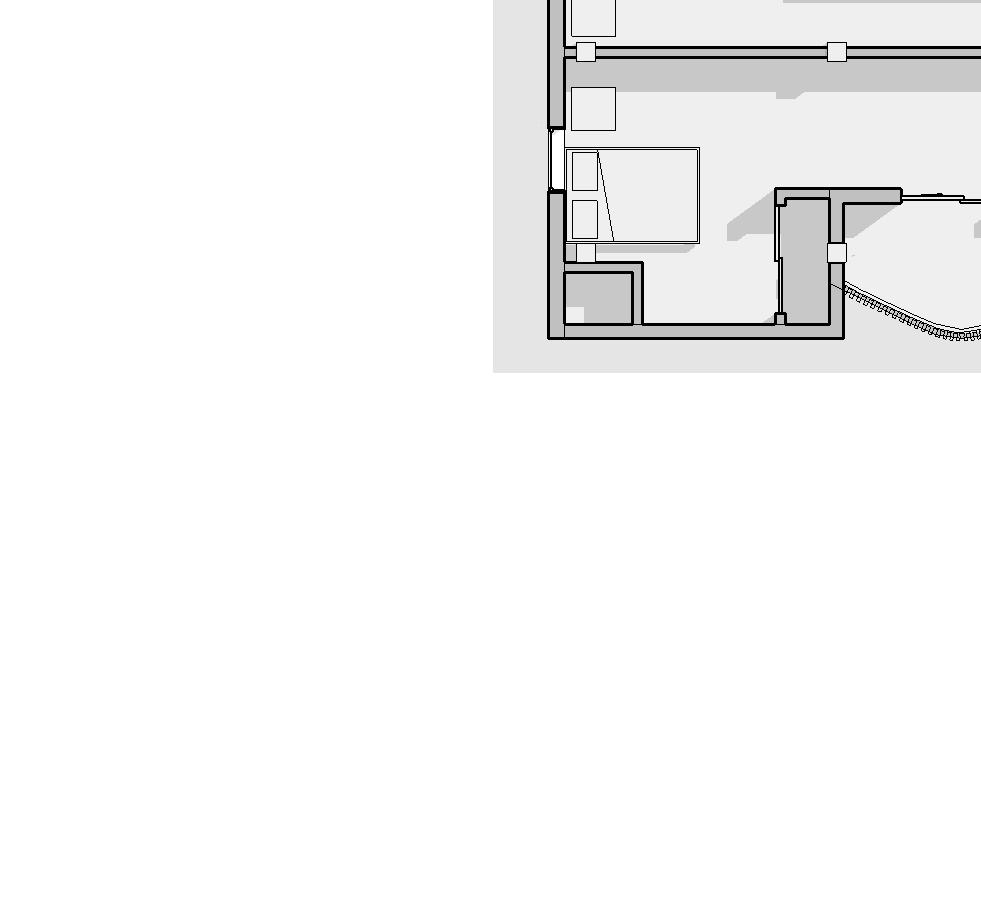

PLAN /

04 I

FOUNDATION

SCALE: 1:250

WAREHOUSE PROJECT - 2023

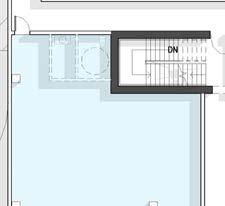

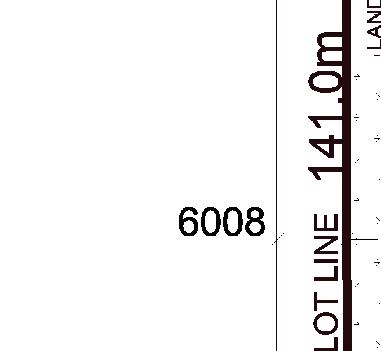

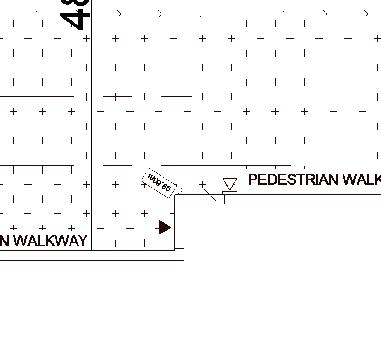

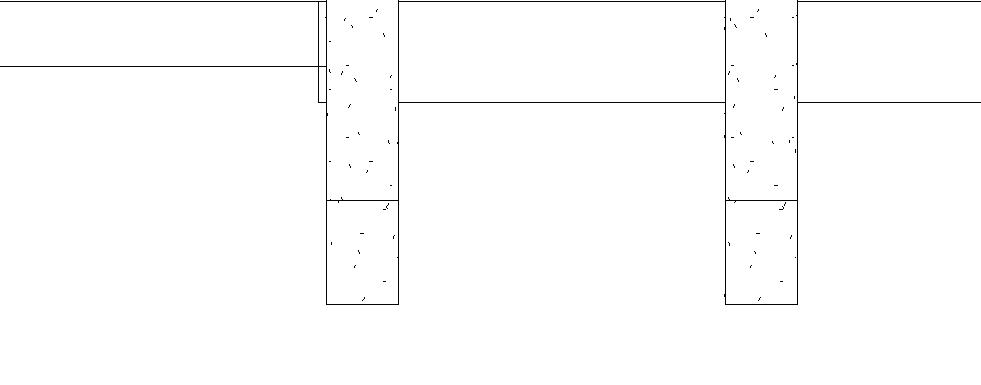

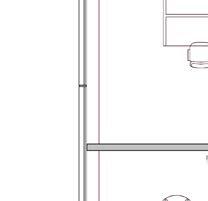

SECOND FLOOR PLAN / SCALE: 1:250

SECOND FLOOR PLAN

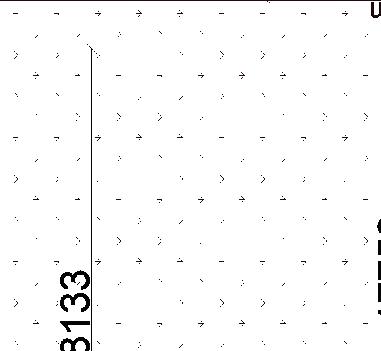

DN A.4.1 1 G Fx F E D C B A 1 2 3 3x 4 5 6 7 8 8x 10 11 12 13 13x 14 14x 9 A.4.0 1 A.4.0 A.4.1 2 2 1 A.5.0 1 A.7.1 2 A.7.0 A.7.1 A.7.0 1 A.6.1 W1 W2 W1 W1 W1 W1 W1 W1 W1 W1 W1 W1 6058 6445 5025 33882 17504 33906 8777 8452 8452 8452 8452 8452 51435 62092 32000 29348 33807 17678 6100 2352 8452 8452 8452 8452 8452 51510 28960 6100 7283 4378 11662 11662 11662 11662 3785 7877 11662 11662 11662 11662 6025 5637 11662 11662 152400 128677 400 15340 13984 6100 7283 4378 11662 11662 11662 11662 3785 7877 11662 11662 11662 11662 6025 5637 11662 11662 158400 200mm 200mm HSS 200mm 200mm HSS 200mm 200mm HSS COLUMNS COLUMNS COLUMNS 200mm 200mm HSS 200mm 200mm HSS SHAPE COLUMNS 200mm X 200mm SHAPE COLUMNS SHAPE COLUMNS 200mm 200mm SHAPE COLUMNS 200mm 200mm SHAPE COLUMNS Ax PROJECT SCALE: SHEET NAME SHEET NUMBER 1:250 Project 1 Final Second Floor Plan A.3.2 1 250

1 EC r th

38 04 I WAREHOUSE

2023 Level 4000 GROUND FLOOR PLAN 0 D C B A SECOND FLOOR PLAN 4270 TOP OF ROOF 9181 TOP OF PARAPET WALL 9560 Ax 1 : 250 East 1 1 : 250 NORTH 2 EC EC

PROJECT -

SECOND FLOOR

GROUND FLOOR

GROUND 7 SECONDFLOO P OF PARAPE Level 1 4000

G Fx F E

TOP OF ROOF TOP OF PARAPET

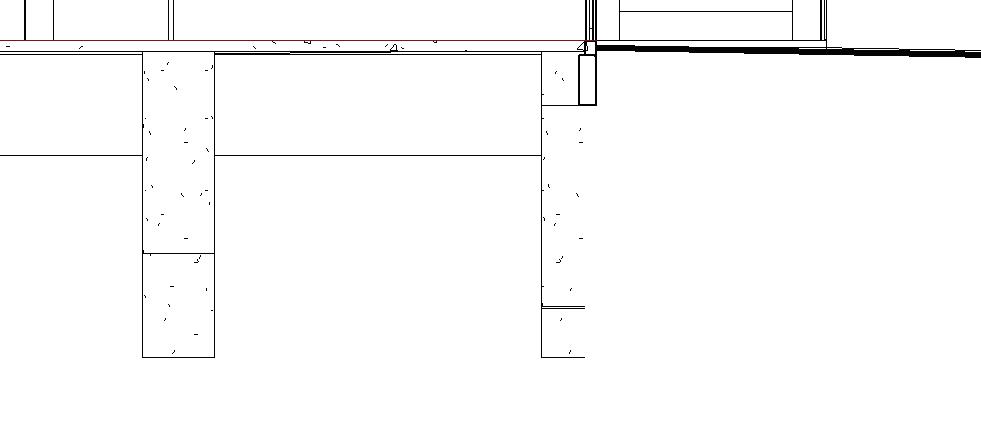

WAREHOUSE PROJECT - 2023

40

SCALE: 1:250 04 I

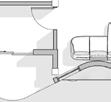

TOP OF GROUND FLOORS LAB 0 G Fx F E D TOPOF SECOND FLOOR SLAB 4270 TOPOFROOF 9181 TOP OF PARAPE T WA LL 9560 REINFORCED CONCRETE CAISSON CONCRETE SLAB SEE SECT IONDETAILFOR ROOF CONSTRUCTION REINFORCED CONCRETE CAISSON REINFORCED CONCRETE CAISSON REINFORCE CONCRETE CAISSON 360 mm THICK TRENCH WALL 2 00 mm X 200 m HSS COL UMN 2 00 mm X 20 0mm HSS COL UMN 2 00 mm X 20 0mm HSS COL UM N OPEN WEB STEEL JOIST 2 4K7 @ 1 830 mm O C FROM G RDER TO GIRDER OPEN WEB 1 83 0mm O G RDER 2 00 mm X 2 00 mm W DE FL ANGE I SHAPE COL UMN WAREHOUSE AREA WAREHOUSE AREA

BUILDING CROSS SECTION /

TOP OF GROUND FLOORS LAB 0 C

A TOPOFSECOND FLOORSLAB 4270 TOPOFROOF 9181 TOP OF PARAPE T WA LL 9560 SEESECTION DETAIL FORROOFCONSTRUCTION 4 A.8.1 WAREHOUS RCED TE REINFORCED CONCRETE CAISSON REINFORCED CONCRETE CAISSON REINFORCED CONCRETE CAISSON 360 mm THICK TRENCH WALL Ax m 2 00 mm X 20 0mm HSS COL UM N 2 00 mm X 20 0mm HSS COL UMN ST EEL JO ST 24 K7 @ C FROM G RDER TO OPEN WEB ST EEL JOIST 24 K7 @ 1 83 0mm O C F ROM G RDER T O G RDER 2 00 mm X 2 00 mm W DE FL ANGE I SHAPE COL UMN WAREHOUSE AREA

B

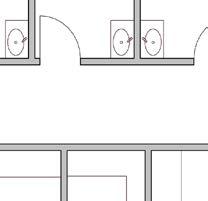

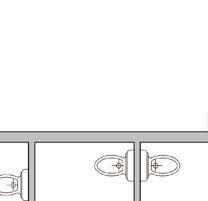

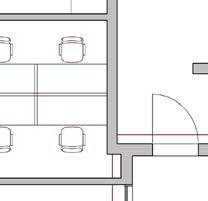

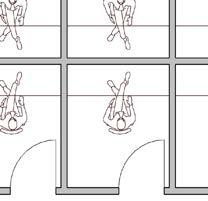

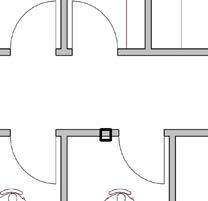

42 13x 14 14x UNIVERSAL WASHROOM MALE WASHROOM FEMALE WASHROOM PRINTING ROOM PRIVATE OFFICE PRIVATE OFFICE PRIVATE OFFICE PRIVATE OFFICE PRIVATE OFFICE PRIVATE OFFICE PRIVATE OFFICE KITCHENETTE OFFICE FOR 2 STORAGE ROOM CONFERENCE ROOM RECEPTION 2 A.8.1 1 : 50 CALLOUT PLAN 1 -GROUND FLOOR OFFICE 1 EC SECOND FLOOR OFFICE CALLOUT PLAN / `SCALE: 1:50 04 I WAREHOUSE

PROJECT - 2023

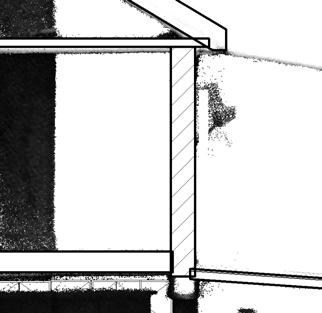

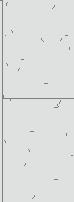

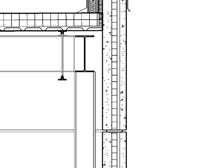

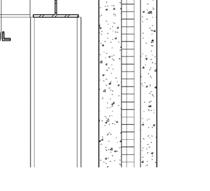

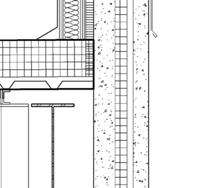

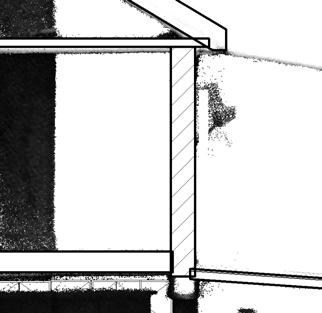

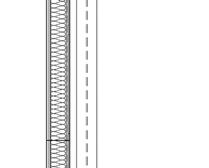

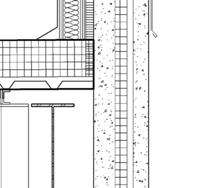

SECTION 1

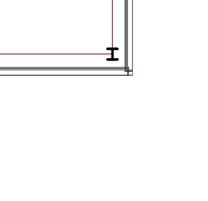

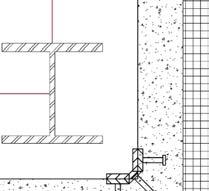

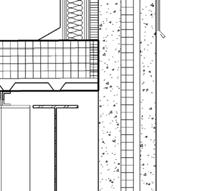

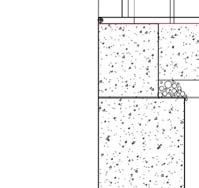

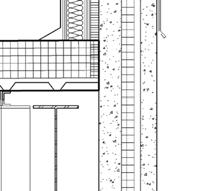

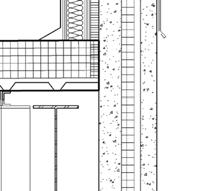

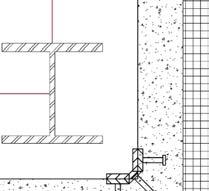

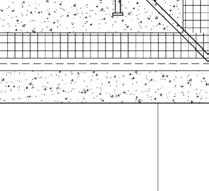

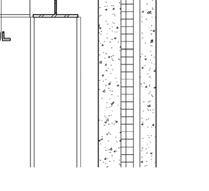

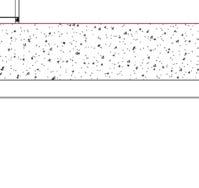

WALL SECTION 1 / SCALE: 1:25

TOP OF PARAPET WALL 9560.00

TOP OF ROOF 9150.00

16mm GYPSUM BOARD 20mm SHEATING

20mm CLADDING

158mm BATT INSULATION 16mm AIR INFILTRATION

TOP OF SECOND FLOOR SLAB 4270.00

TOP OF GROUND FLOOR SLAB 0.00

WALL SECTION 1

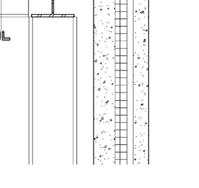

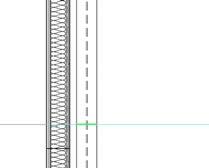

WALL SECTION 2 / SCALE: 1:25

200mm X 200mm WIDE FLANGE I SHAPE COLUMN 400mm FROM EXTERIOR FACE OF WALL

250 mm THICK PERITEMER BEAM

230 mm REINFORCED CONCRETE FLOOR SLAB

410 x 60mm WIDE FLANGE SHAPE STEEL BEAM STEEL JOIST GRAVEL

360mm THICK TRENCH WALL

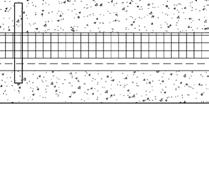

TOP OF GROUND TOP OF SECOND TOP OF PARAPET 9560.00 200mm X 200mm WIDE FLANGE I SHAPE COLUMN 400mm FROM EXTERIOR FACE OF WALL 65mm THICK PRECAST CONCRETE PANEL CURTAIN WALL "SANDWICH 25mm AIR INFILTRATION BARR 50mm RIGID INSULATION 410 x 60mm WIDE SHAPE STEEL BEAM 360mm THICK TRENCH WALL 90mm THICK PRECAST CONCRETE PANEL CURTAIN WALL "SANDWICH PANEL" 50mm RIGID INSULATION BELOW GRADE 3660mm X 4270mm DRIVE TOP OF GROUND FLOOR SLAB 0.00 E

4270.00

OF ROOF 9150.00

9560.00

20mm SHEATING

16mm AIR INFILTRATION 20mm CLADDING

FLANGE I SHAPE

400mm FROM EXTERIOR

OF

360mm THICK TRENCH WALL

250

x 60mm WIDE FLANGE I SHAPE STEEL BEAM GRAVEL SCALE: 1:25 Project 1 Final Wall Sections(EC)

SECTION 2 1 : 25 WALL

1

TOP OF SECOND FLOOR SLAB

TOP

TOP OF PARAPET WALL

16mm GYPSUM BOARD

158mm BATT INSULATION

200mm X 200mm WIDE

COLUMN

FACE

WALL

230 mm REINFORCED CONCRETE FLOOR

mm THICK PERITEMER BEAM 410

WALL

E

PROJECT SCALE: 1:25 Project 1 Final 1 : 25

1 EC

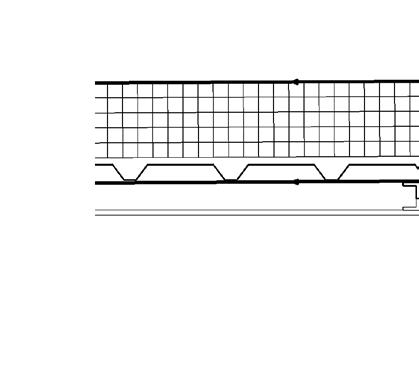

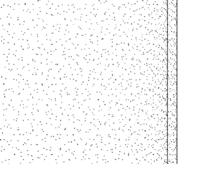

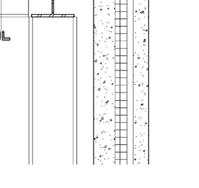

90mm THICK PRECAST CONCRETE PANEL CURTAIN WALL "SANDWHICH PANEL" 25mm AIR INFILTRATION BARRIER

200mmX200mm WIDE FLANGE STEEL COLUMN ( SHAPE COLUMN) AT PERIMETER OF THE BUILDING

CONNECTORS TO MANUFACTURERS SPECIFICATION

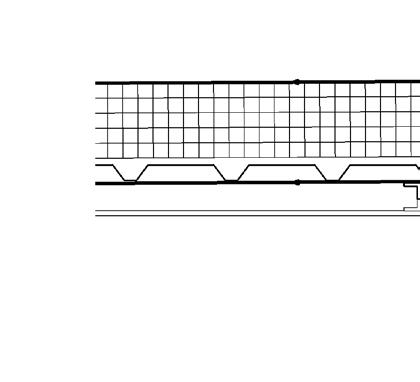

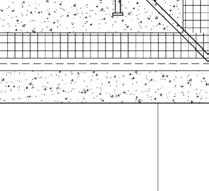

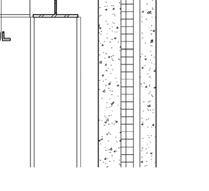

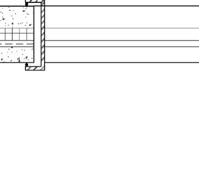

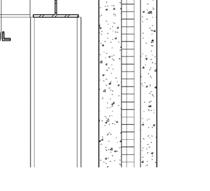

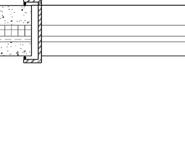

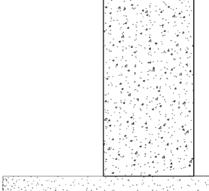

PLAN DETAIL 1 / SCALE: 1:5

PLAN DETAIL 1-Exterior corner where 2 precast concrete panels meet

(Exterior corner where 2 precast concrete panels meet.)

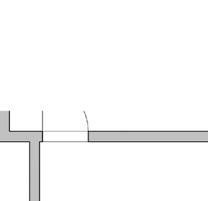

PLAN DETAIL 2 / SCALE: 1:10 (The jamb of the drive-in doors meets precast concrete panel.)

PLAN DETAIL 2-The jamb of the drive-in doors meets precast concrete panel.

65mm THICK PRECAST CONCRETE PANEL CURTAIN WALL "SANDWHICH PANEL"

GROUT

SEALANT CONTINUOUS, ALL VERTICAL AND HORIZONTAL JOIST TO BE SEALED

PLAN DETAIL 2-The jamb of the drive-in doors meets precast concrete panel.

STOREFRONT CURTAIN WALL 200MM DEEP PREFINISHED ALUMINIUM FRAME

SECTION DETAIL 1 -Precast 4 SECTION DETAIL 2 / SCALE: 1:10 (Precast Concrete Panel Parapet)

REINFORCED CONCRETE CAISSON TO REST ON UNDISTURBED

BEAM

14

A

50mm RIGID INSULATION

8x

HORIZONTAL WALL PANEL STEEL FRAME

HORIZONTAL WALL PANEL

SOIL 250 mm THICK PERITEMER

SEALANT 8x PRECAST

25mm AIR INFILTRATION BARR CONCRETE PANEL CURTAIN WALL CONTINUOUS CLEAT MOISTURE BARRIER FULL

CONCRETE PANEL CURTAIN WALL "SANDWICH PANEL"

CAVITIES WITH SEMI RIGID INSULATION 1 : 5

1

1 : 10

2 EC

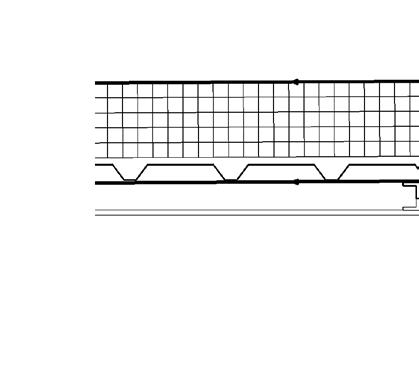

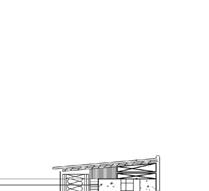

8x 200mm X 200mm WIDE FLANGE I SHAPE COLUMN 400mm FROM EXTERIOR FACE OF WALL 410 x 60mm WIDE FLANGE -SHAPE STEEL BEAM WOOD CURB C/W PLYWOOD FACE ALL WOOD TO BE P/T FULL CAVITY WITH BATT INSULATION BUILT-UP ROOF RIGID INSULATION GYPSUM BOARD METAL DECKING ROOF STRUCTURE PROJECT Project Construction 1 : 5 1 1

10

:

8x GROUT SEALANT CONTINUOUS, ALL VERTICAL AND HORIZONTAL JOIST TO BE SEALED HORIZONTAL WALL PANEL STEEL FRAME 65mm THICK PRECAST CONCRETE PANEL CURTAIN WALL "SANDWHICH PANEL" 90mm THICK PRECAST CONCRETE PANEL CURTAIN WALL "SANDWHICH PANEL" 50mm RIGID INSULATION 25mm AIR INFILTRATION BARRIER HORIZONTAL WALL PANEL 14x STOREFRONT CURTAIN WALL 200MM DEEP PREFINISHED ALUMINIUM FRAME 200mm X 200mm WIDE FLANGE SHAPE COLUMN 1 : 10

2 EC

04 I WAREHOUSE

PROJECT - 2023

PLAN DETAIL 2-The jamb of the drive-in doors meets precast concrete panel.

STOREFRONT CURTAIN WALL 200MM DEEP PREFINISHED ALUMINIUM FRAME

SECTION DETAIL 2 -Glass curtain wall meets the foundation wall.

Plan Details & Section Details

-Precast Concrete Panel Parapet

SECTION DETAIL 1 / SCALE: 1:10

(Glass curtain wall meets the foundation wall)

SECTION DETAIL 2 -Glass curtain wall meets the foundation wall.

1

Brentwood Jolley

Plan Details & Section Details

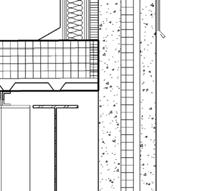

45 230 mm REINFORCED CONCRETE FLOOR SLAB ON 360mm THICK TRENCH WALL PERITEMER BEAM BACKER ROAD STEEL PLATE CONNECTOR 65mm THICK PRECAST CONCRETE PANEL CURTAIN WALL "SANDWICH PANEL" 25mm AIR INFILTRATION BARR 50mm RIGID INSULATION 90mm THICK PRECAST CONCRETE PANEL CURTAIN WALL "SANDWICH PANEL" METAL CAP WITH CONTINUOUS CLEAT ASPHALT FELT MOISTURE BARRIER FULL CAVITIES WITH SEMI DRAWN BY VARIES Project 1 Final Construction Drawings Brentwood Jolley

-Precast Concrete Panel Parapet EC 1:10 MANUFACTURERS PANEL" 25mm AIR INFILTRATION BARRIER TOP OF GROUND FLOOR SLAB 0.00 14x 230 mm REINFORCED CONCRETE FLOOR SLAB

REINFORCED CONCRETE CAISSON TO REST ON UNDISTURBED SOIL 360mm THICK TRENCH WALL 250 mm THICK PERITEMER BEAM GRAVEL BACKER ROAD SEALANT STEEL PLATE CONNECTOR 200mm X 200mm

FLANGE I SHAPE COLUMN 400mm FROM EXTERIOR FACE OF WALL TOP OF ROOF 9150.00 TOP OF PARAPET WALL 9560.00 65mm THICK PRECAST CONCRETE PANEL CURTAIN WALL "SANDWICH PANEL" 25mm AIR INFILTRATION BARR 50mm RIGID INSULATION 90mm THICK PRECAST CONCRETE PANEL CURTAIN WALL "SANDWICH PANEL" METAL CAP WITH CONTINUOUS CLEAT ASPHALT FELT MOISTURE BARRIER FULL CAVITIES WITH SEMI-RIGID INSULATION CLIENT DRAWN BY DATE SCALE: SHEET NAME SHEET NUMBER VARIES

Construction

WIDE

Project 1 Final

Drawings

ESMA 02/25/23

: 10

corner where 2 precast 1

2

: 10

3

EC EC EC EC

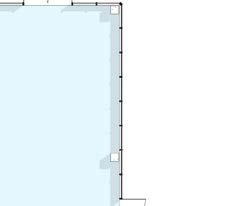

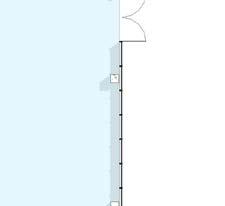

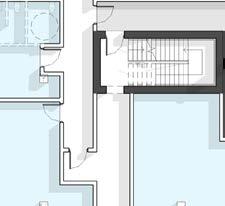

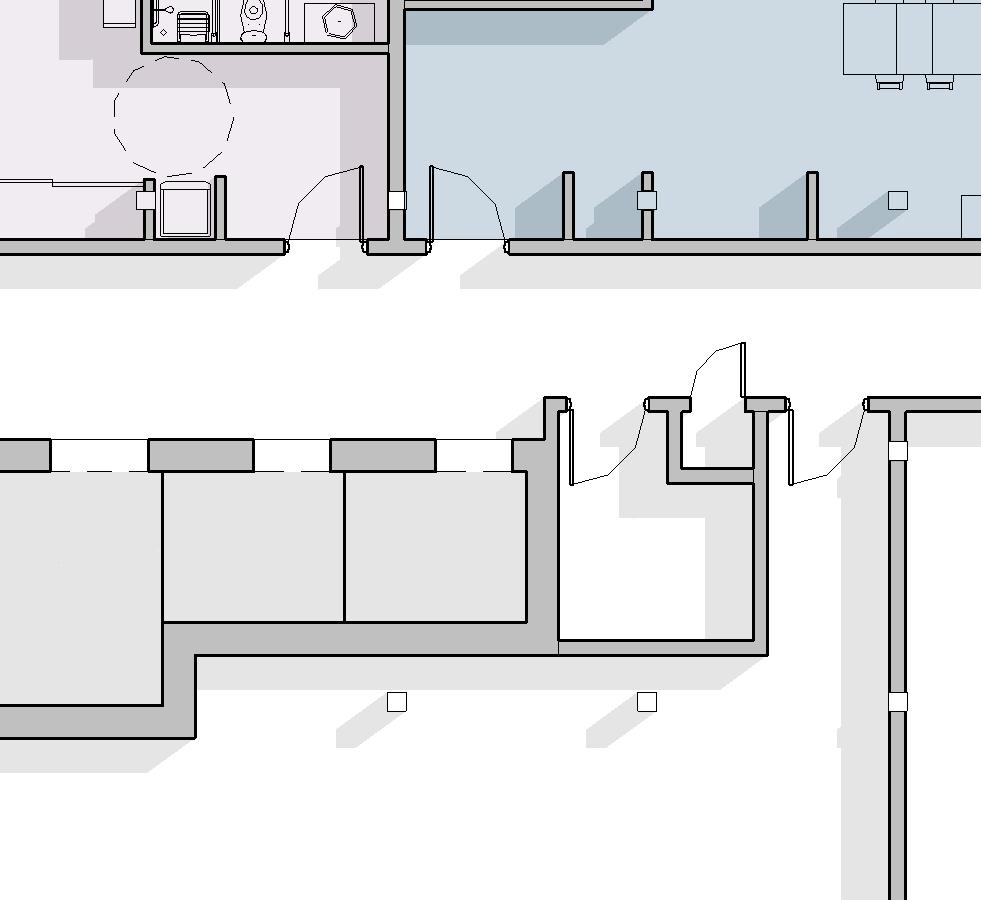

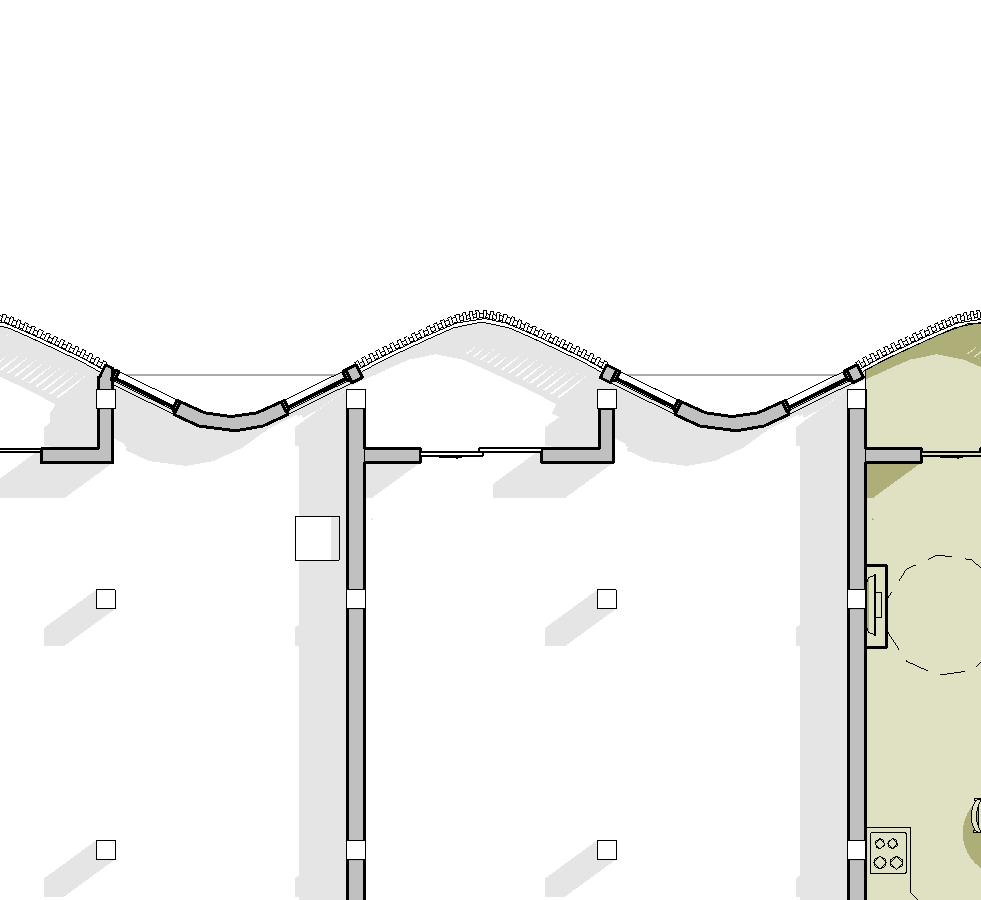

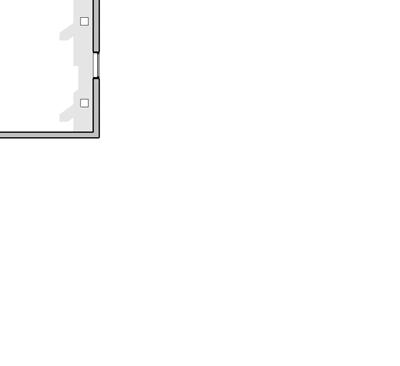

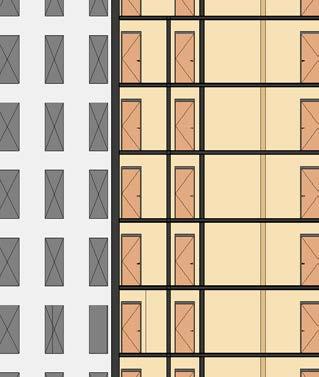

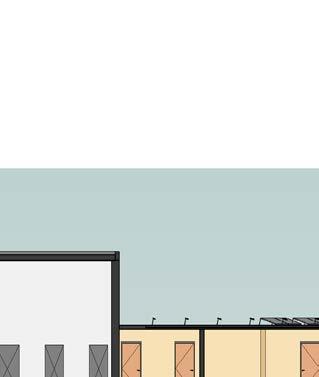

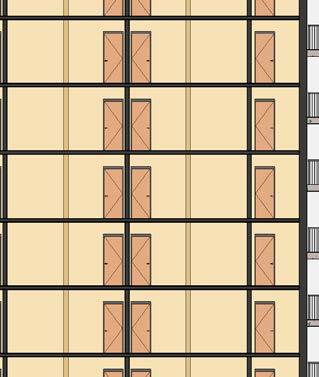

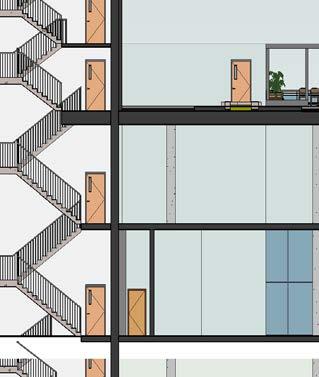

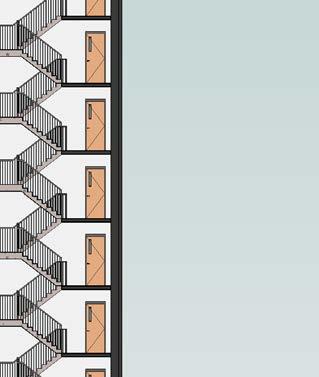

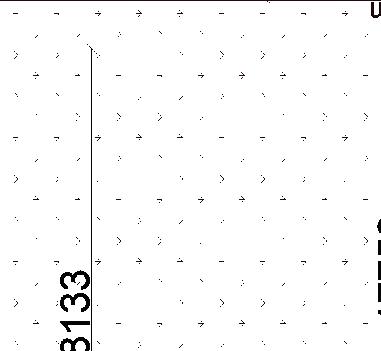

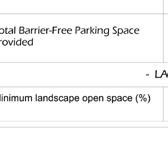

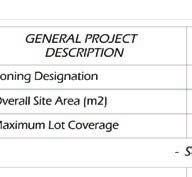

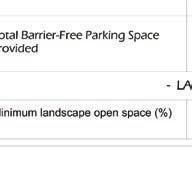

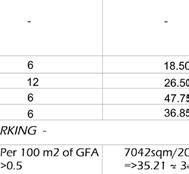

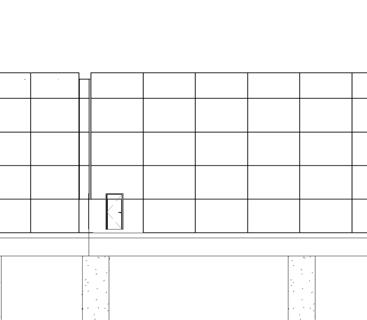

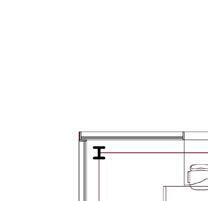

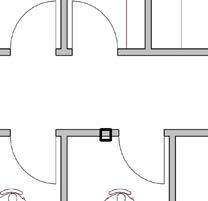

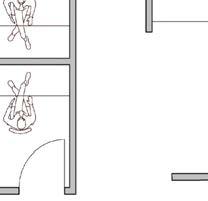

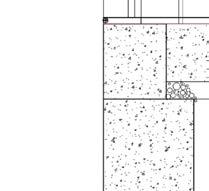

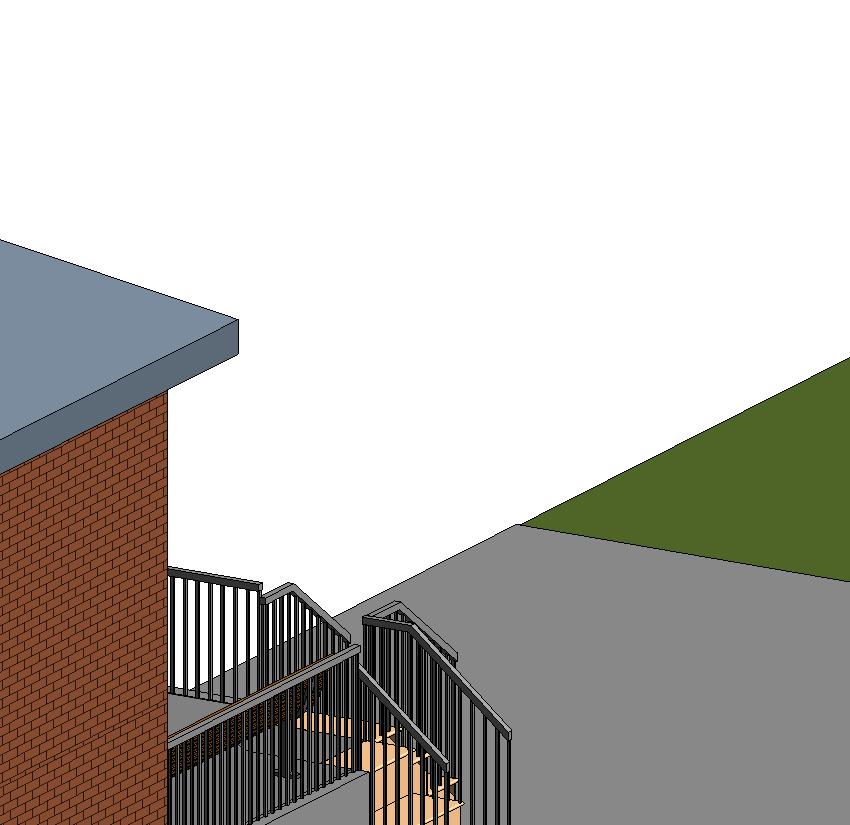

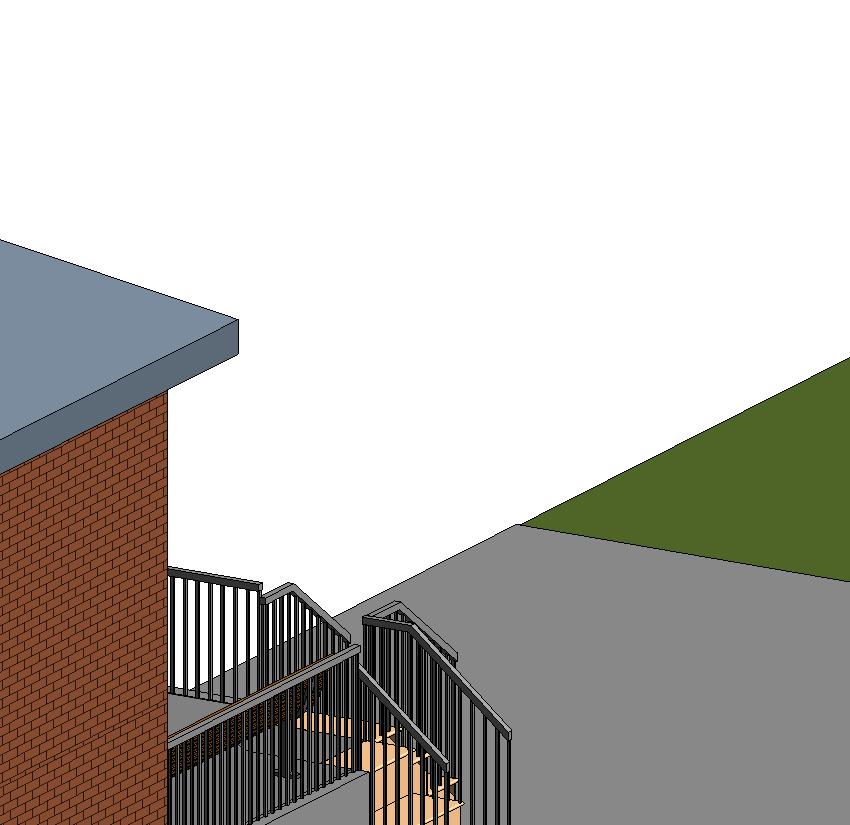

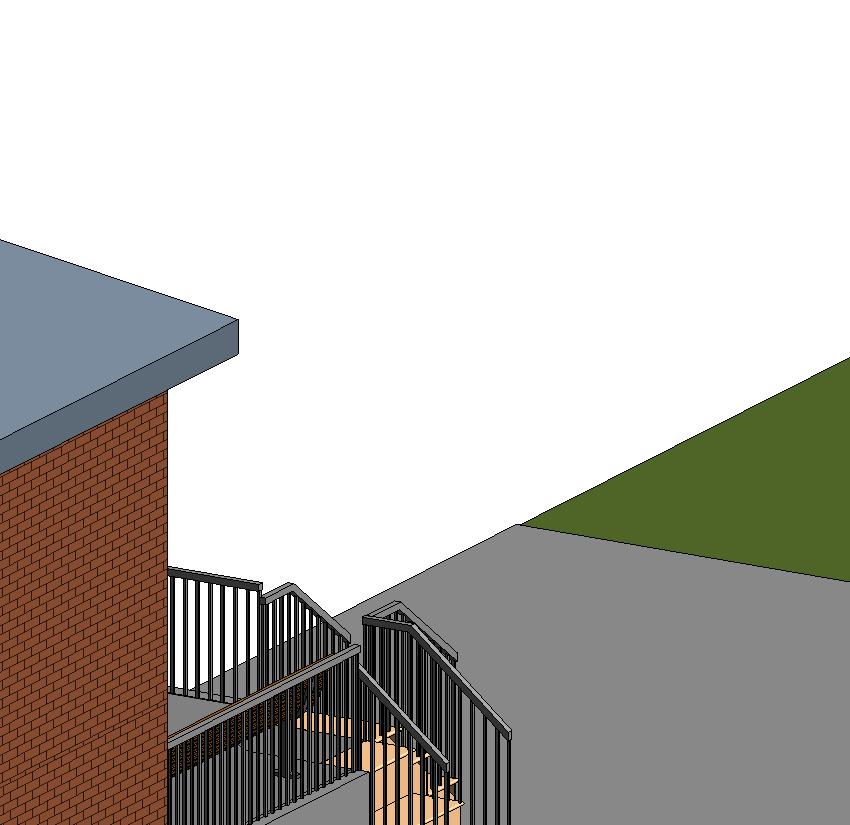

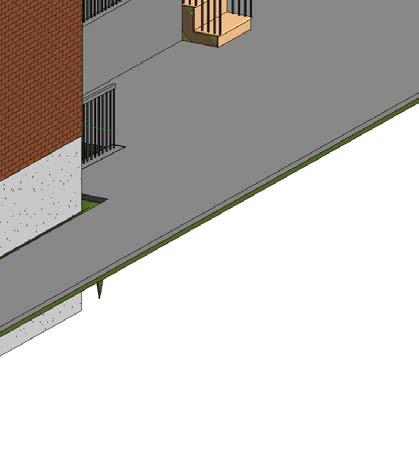

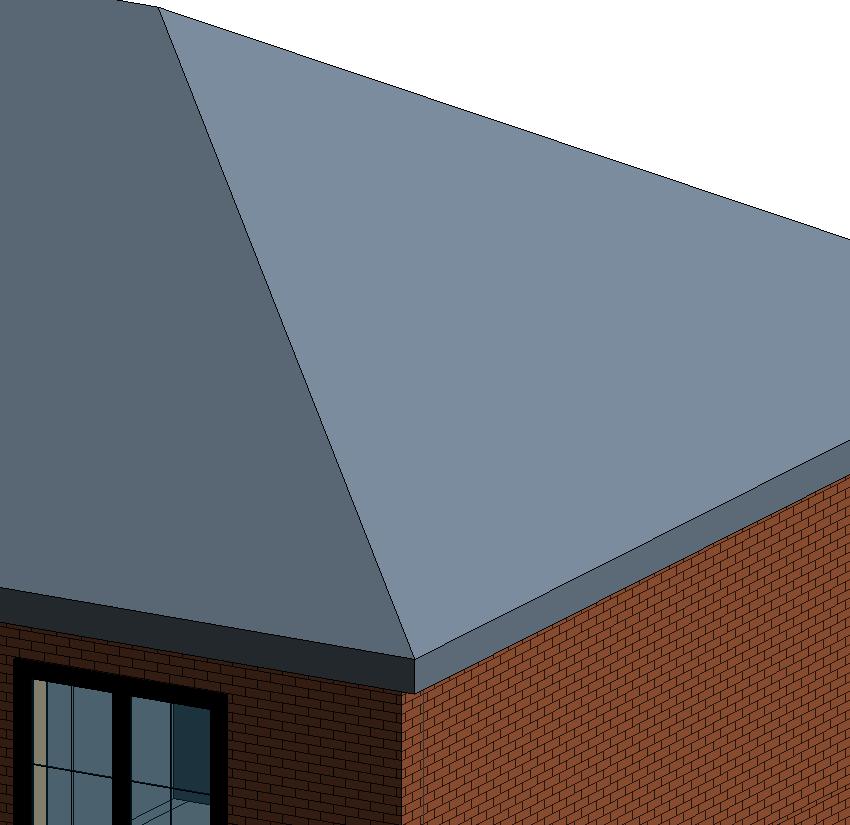

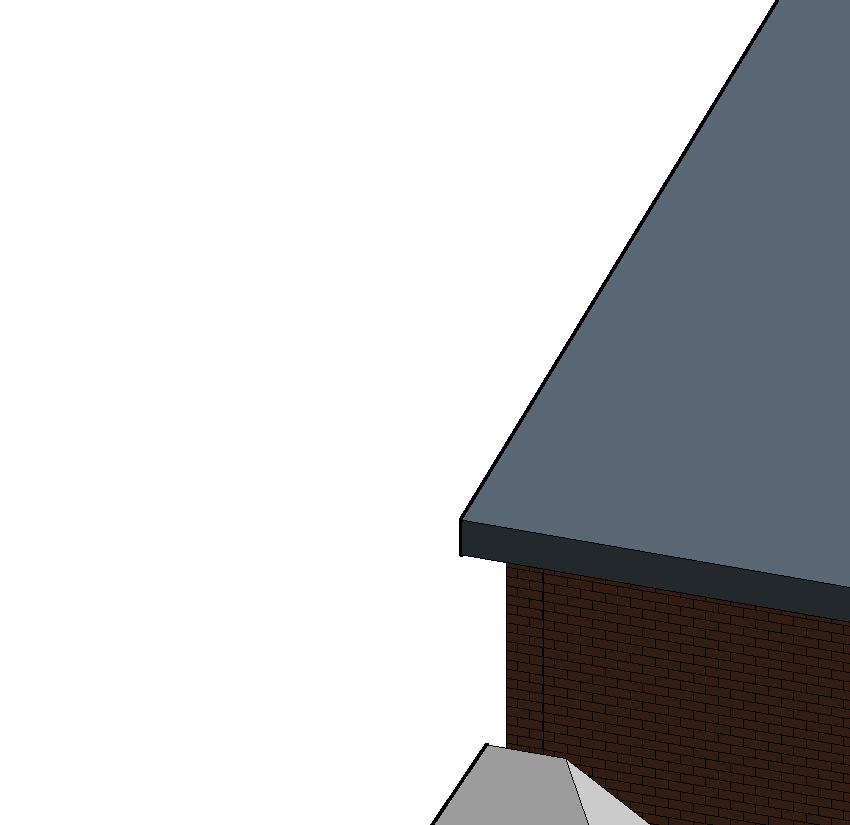

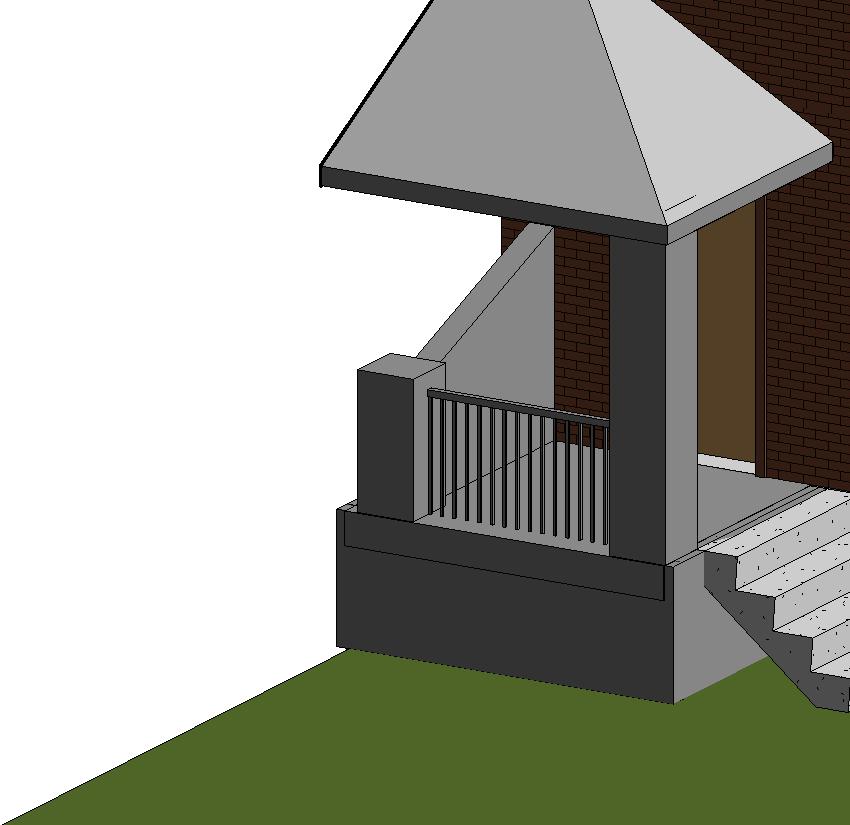

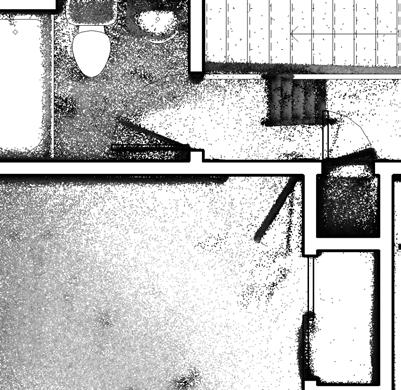

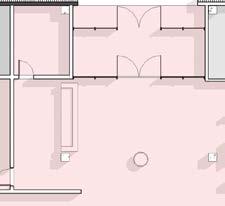

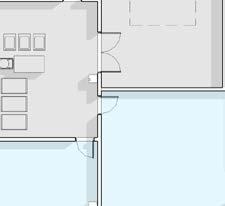

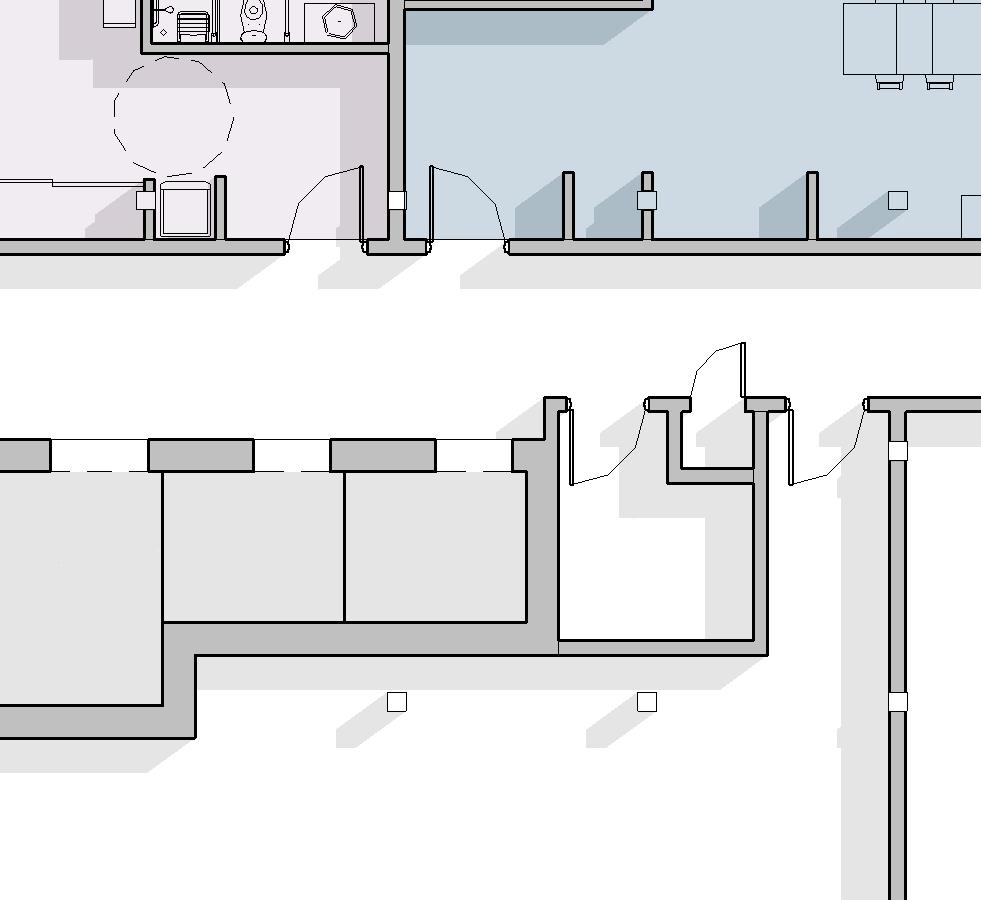

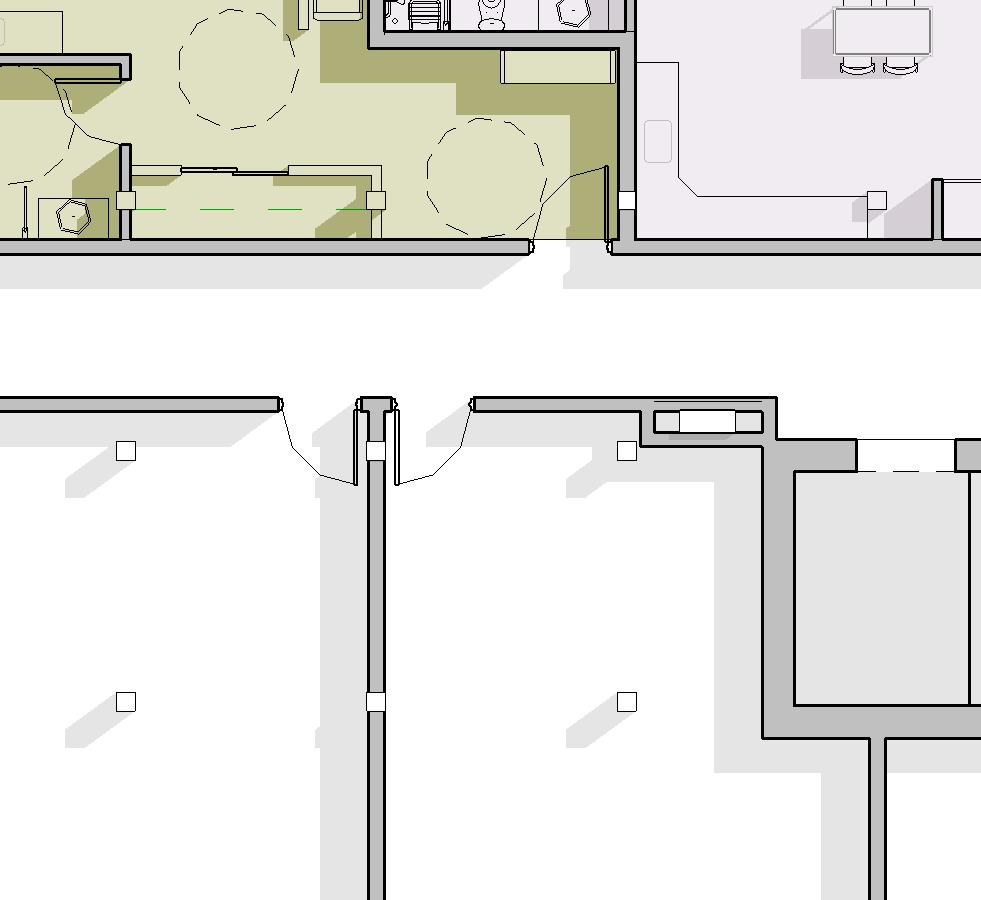

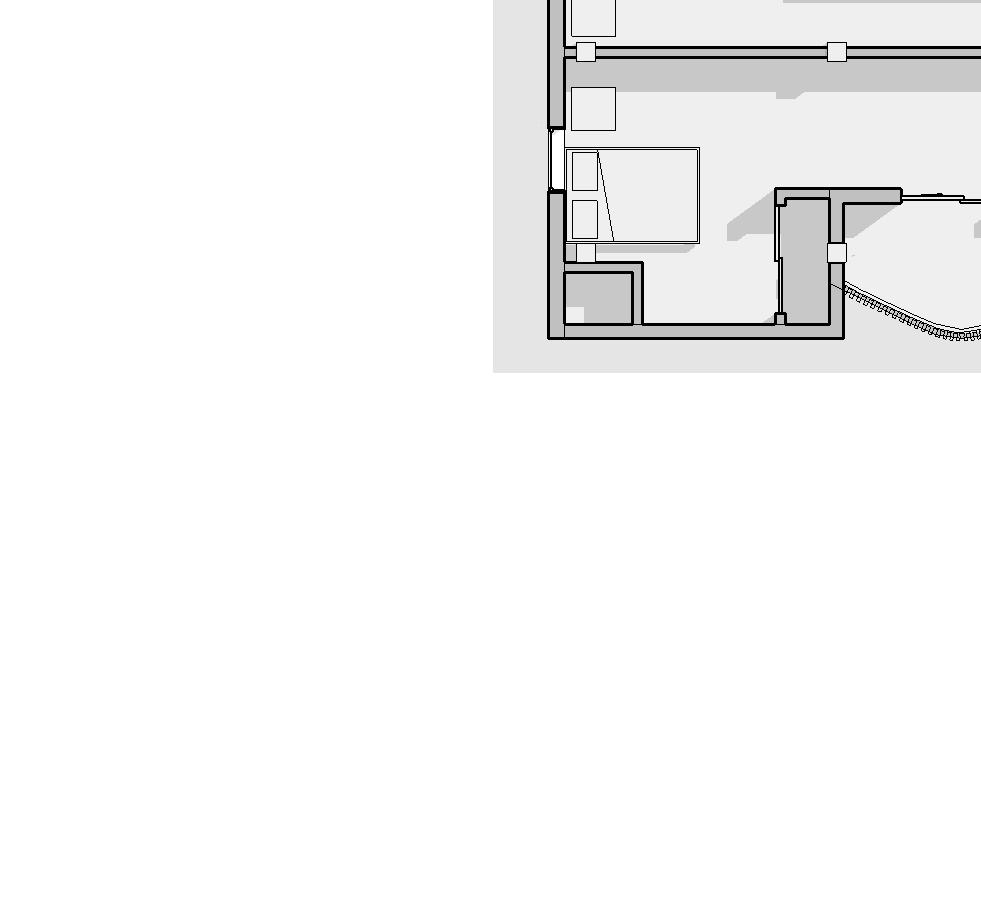

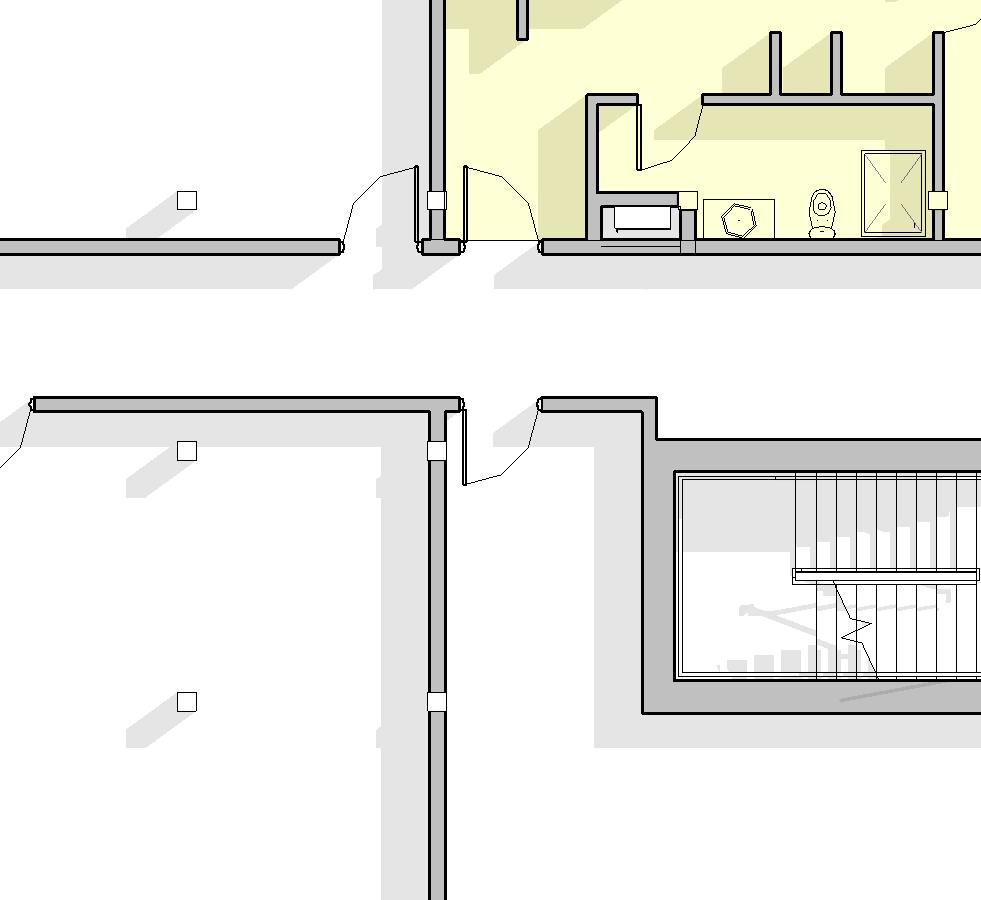

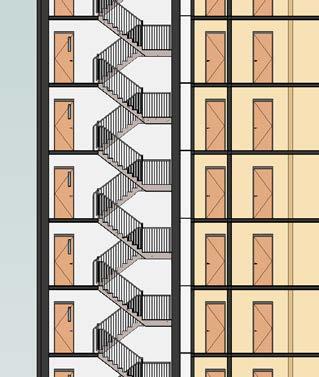

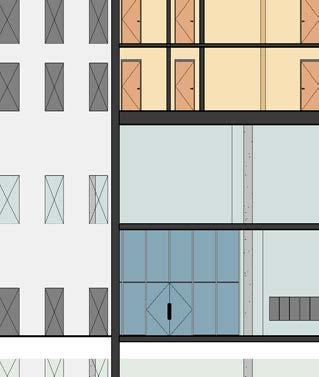

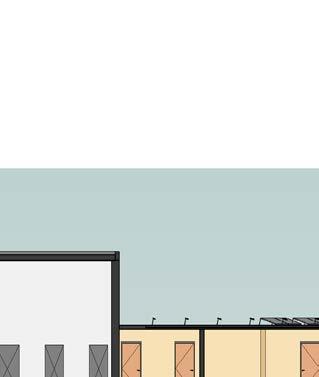

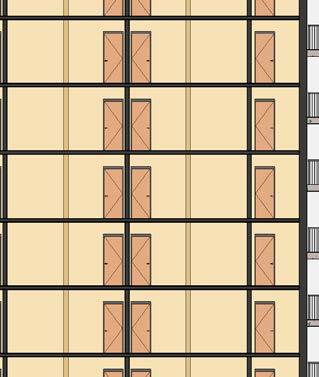

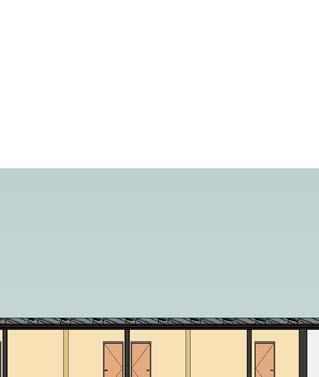

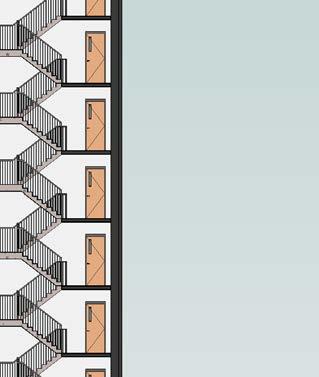

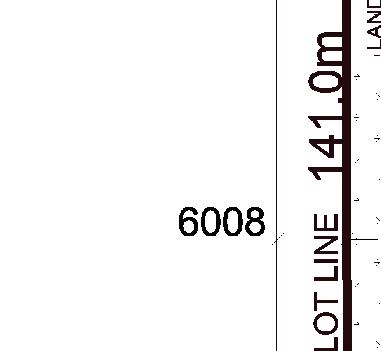

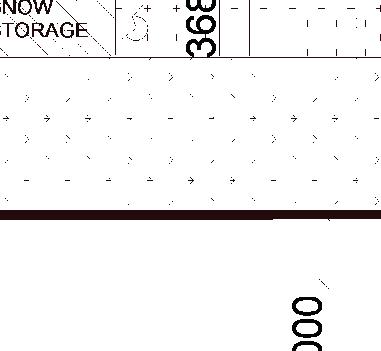

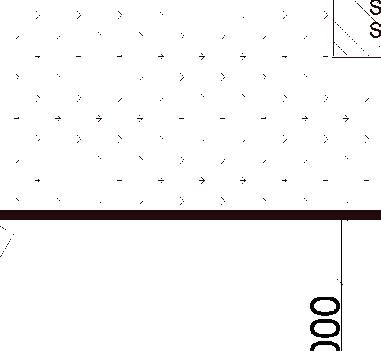

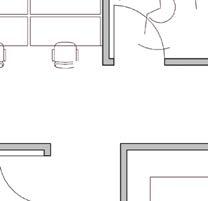

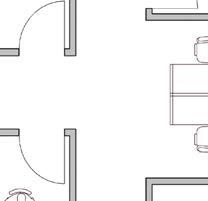

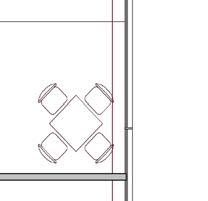

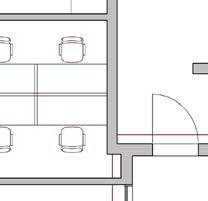

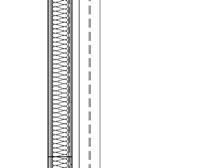

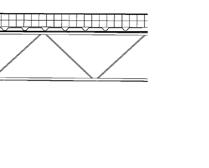

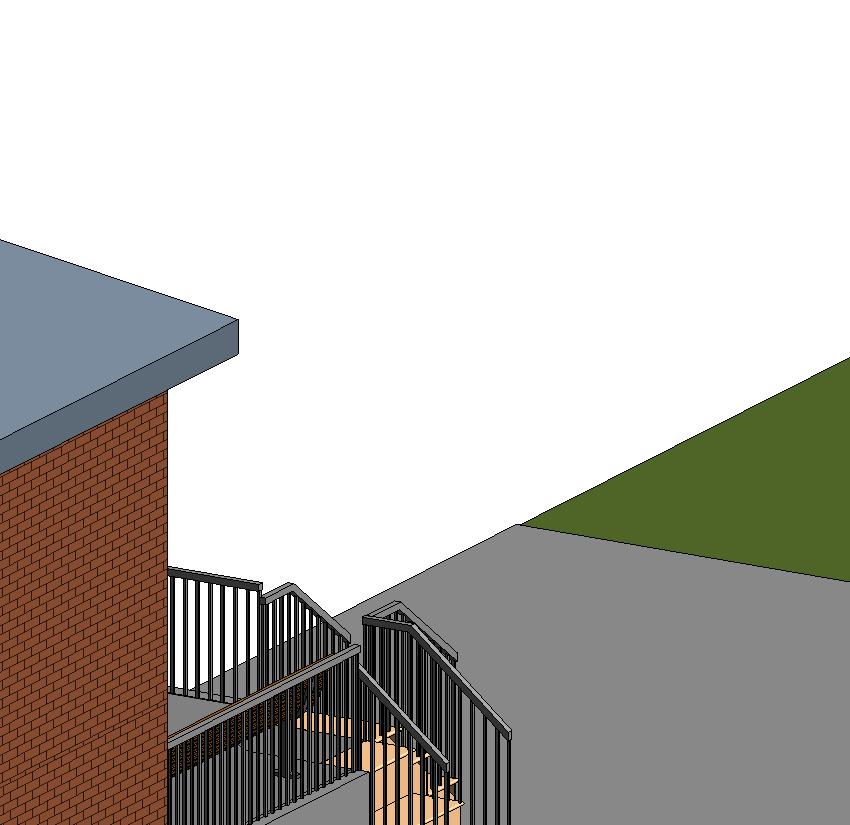

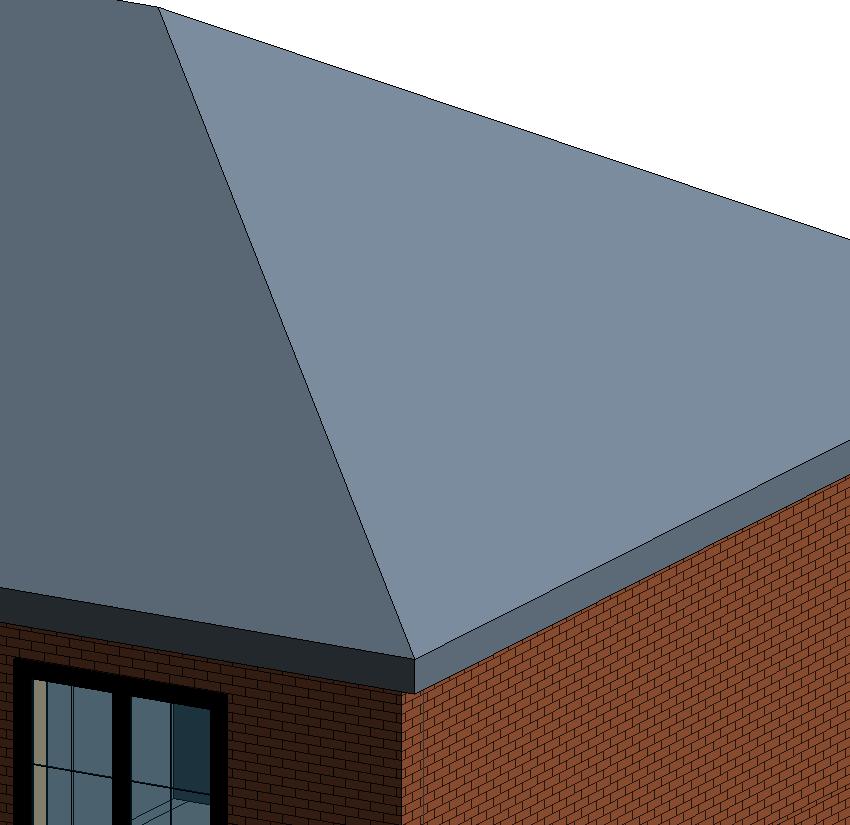

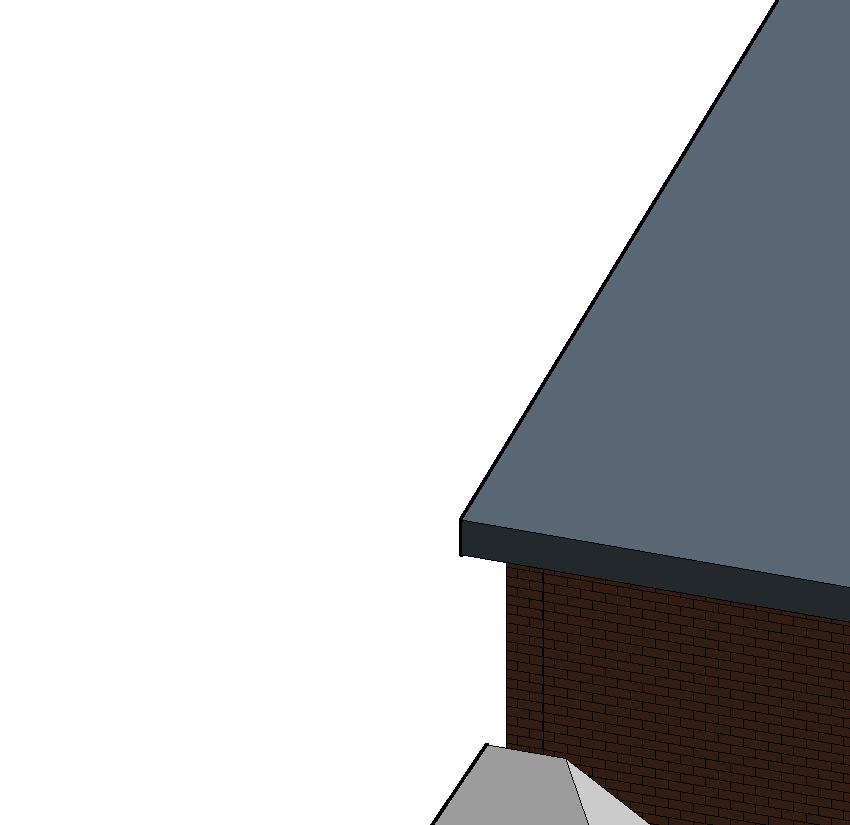

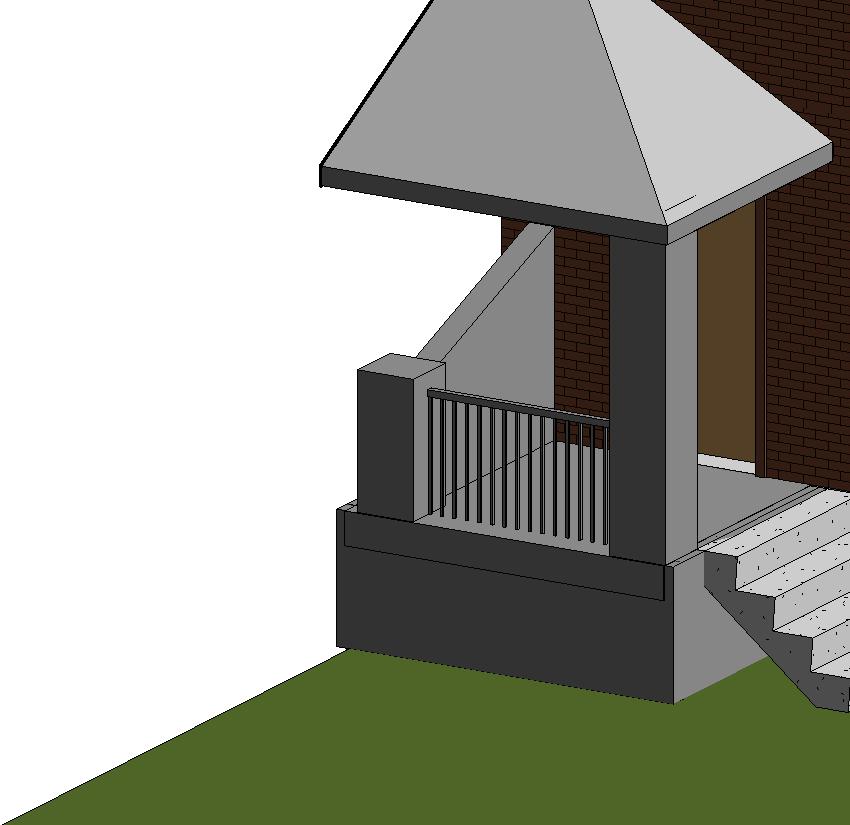

URBAN HAVEN MIXED BUILDING PROJECT -2022

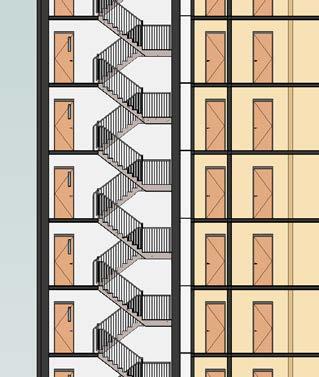

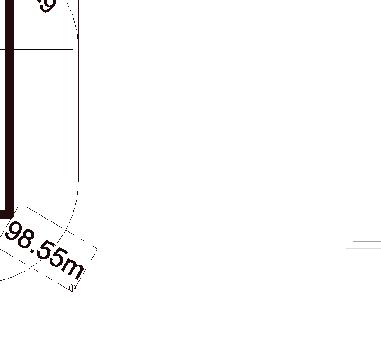

In my third semester, I worked on a group project where we designed a multiple storey mixed building according to the OBC. Our design process involved conceptual sketches, detailed plans, and 3D models. Key considerations included accessibility, safety, and functionality. We worked collaboratively as a team, leveraging each other’s strengths to create a functional and aesthetically pleasing design. This project taught me valuable technical skills, knowledge of the Ontario Building Code, and the importance of teamwork. Overall, this project was an excellent opportunity to apply the skills and knowledge that I had gained in my program. It helped me to develop my technical skills in design software and my understanding of the Ontario Building Code. It also taught me the importance of teamwork and collaboration in achieving a common goal.

By : Esma Cetinkaya, Umesh Chauhan Fazra Fahim Dhruvi Rathod

04

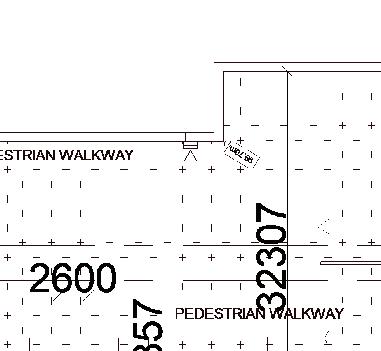

02 I URBAN HAVEN MIXED BUILDING PROJECT - 2022 THIRD FLOOR PLAN / SCALE: 1:150 C B D E F A 1 2 3 4 5 BALCONY BALCONY BALCONY UNIT 200/201/202 UNIT203 UNIT221 UNIT220 UNIT219 UNIT218 BALCONY BALCONY BALCONY UNIT222 COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. 2001 2001 2001 3951 6000 6000 6000 6000 6000 962 1875 6125 2095 6994 4727 3951 4886 914 1627 3951 1383 914 1764 3951 1519 914 8248 7875 14477 6000 6000 6000 6000 6600 30804 12102 6000 6000 6000 6000 6000 6000 6000 6000 26014 12177 1 A-4.0 1 A-4.2 A-4.1 1 1 A-5.3 A-4.1 1 A-5.2 1 3725 3597 914 350 914 741 1600 3951 3926 3951 914 914 914 914 914 914 2 2 2 2 4 4 4 4 4 4 4 4

47 6 7 8 9 10 11 12 13 14 15 UNIT203 UNIT204 UNIT 205 LAUNDRY ROOM UNIT206 UNIT 206/207/208 UNIT 209/210 BALCONY BALCONY BALCONY STAIR #2 UNIT211 UNIT212 UNIT213 UNIT218 UNIT217 UNIT215 UNIT214 UNIT216 BALCONY BALCONY BALCONY BALCONY BALCONY BALCONY CORRIDOR BALCONY BALCONY BALCONY BALCONY ELEVATOR 1 ELEVATOR D W COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. 3951 2001 3951 3951 2001 4200 4200 6000 6000 6000 6000 6000 6000 6000 6000 6000 84204 7204 1959 887 5232 7782 7921 962 6000 6000 6000 6000 7025 3951 1127 5796 10221 1983 6000 6000 6000 6000 6000 6000 6000 6000 6000 84204 4427 3951 3209 914 2903 6124 3951 4109 914 304 18202 12500 6600 6000 6000 6000 6000 30804 31800 4200 4200 16002 47850 6177 10221 5796 A-4.3 1 A-4.3 1 1 A-4.2 1 A-4.0 A-5.2 1 2125 2125 3597 2498 1398 3718 3597 3597 2125 2125 1553 1954 1553 1954 1650 932 932 4275 534 914 350 914 3951 3951 3951 3951 914 914 914 914 914 914 2599 1048 914 1530 4398 914 914 914 914 6000 2 2 2 2 2 2 2 2 2 2 2 3 3 3 3 3 3 4 4 4 4 4 4 4 4 4 4 4 4

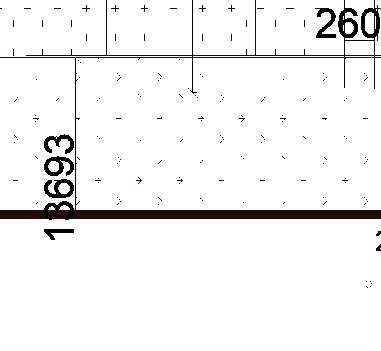

48 ROOF PLAN / SCALE: 1:150 02

C B D E F A 1 2 3 4 5 6 7 RD 6000 6000 6000 6000 6000 6000 6000 6000 6000 6000 6000 6000 6600 6000 6000 6000 6000 30396 31212 N C B D E F A 1 2 3 4 5 6 7 RD 6000 6000 6000 6000 6000 6000 6000 6000 6000 6000 6000 6000 6600 6000 6000 6000 6000 30396 31212

I URBAN HAVEN MIXED BUILDING PROJECT - 2022

F.U.D.E. DESIGN

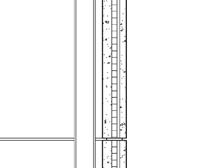

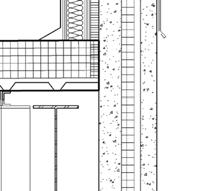

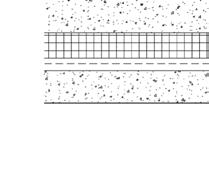

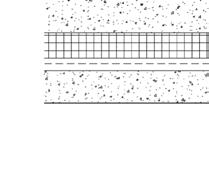

WALL TYPE SPECIFICATIONS:

90mm (4') FACE BRICK 25mm (1") AIR SPACE. 22X180X0.76mm (7/8"X7"X0.03") GALV. METAL TIES @400mm (16") O/C, HORIZONTAL 600mm (24") O/C VERTICAL APPROVED RIGID INSULATION RSI 1.4 (R8) EXT.RIGID INSUL. DB., 38X89 (2"X4") STUDS @ 400mm (16") O/C WITH APPROVED DIAGONAL WALL BRACING, RSI 2.1 (R12) INSUL. AND APPROVED VAP. BARRIER WITH APPROVED CONT. AIR BARRIER, 13mm (1/2") INT. DRYWALL FINISH. PROVIDE WEEP HOLES @ 800mm (32") O/C BOTTOM COURSE AND OVER OPENINGS. PROVIDE BASE FLASHING UP MIN. 150mm (6")

90mm (4') STONE 25mm (1") AIR SPACE. 22X180X0.76mm (7/8"X7"X0.03") GALV. METAL TIES @400mm (16") O/C, HORIZONTAL 600mm (24") O/C VERTICAL APPROVED RIGID INSULATION RSI 1.4 (R8) EXT.RIGID INSUL. DB., 38X89 (2"X4") STUDS @ 400mm (16") O/C WITH APPROVED DIAGONAL WALL BRACING, RSI 2.1 (R12) INSUL. AND APPROVED VAP. BARRIER WITH APPROVED CONT. AIR BARRIER, 13mm (1/2") INT. DRYWALL FINISH. PROVIDE WEEP HOLES @ 800mm (32") O/C BOTTOM COURSE AND OVER OPENINGS. PROVIDE BASE FLASHING UP MIN. 150mm (6")

METAL SIDING 1"X2" STRAPPING AT 16" O/C ON TYVEK. 9.5mm (3/8") EXTERIOR TYPE PAPER, 9.5mm (3/8") EXTERIOR TYPE SHEATHING, 38X140 STUDS @ 400mm (16") O/C. R24 WALL INSULATION AND APPROVED VAPOUR BARRIER AND APPROVED CONT. AIR BARRIER, 13mm (1/2") INT. DRYWALL FINISH.

STUCCO FINISH COAT ON FIBERGLASS/METAL MESH EMBEDDED INTO BASECOAT 2" STYROFOAM RIGID INSULATION BOARD WITH DUREX FLEXCRETE ADHESIVE ON DUREX GREEN GUARD BARRIER ON 1/2" PLYWOOD SHEATHING 2'X6" STUDS @ 16" O/C W/ R24 WALL INSULATION 6mil VAP. BARRIER, 1/2" INT. DRYWALL FINISH.

COL. : STRUCTURAL COLUMN

L.B : LOAD BEARING WALL

PROJECT 1 : FINAL

SCALE - 1:150

CONSTRUCTION DRAWINGS

DUE DATE : 2022-11-17

DRAWN BY : UMESH CHAUHAN ESMA

THE CONTRACTOR MUST VERIFY AND ACCEPT RESPONSIBILITY FOR

SUPPLIED INFORMATION. XXXXXXXXXXXXXXXXXX ARCHITECT IS NOT

RESPONSIBLE FOR THE ACCURACY OF THE SURVEY, STRUCTURAL, MECHANICAL, ETC., ENGINEERING INFORMATION SHOWN ON THESE DRAWINGS. REFER TO THE APPROPRIATE ENGINEERING DRAWINGS

1

3 4 2

8 9 10 11 12 13 14 15 RD RD 6000 6000 6000 6000 6000 6000 6000 6000 83796 84612 6600 6000 6000 6000 6000 30396 31212 6000 6000 6000 6000 6000 6000 6000 6000 83796 84612 6204 2603 1305 801 8 9 10 11 12 13 14 15 RD RD 6000 6000 6000 6000 6000 6000 6000 6000 83796 84612 6600 6000 6000 6000 6000 30396 31212 6000 6000 6000 6000 6000 6000 6000 6000 83796 84612 6204 2603 1305 801

CETINKAYA

02 I URBAN HAVEN MIXED BUILDING PROJECT - 2022

50 C/W D.A.C 3 4 PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C 3 4 PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C 3 4 PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C 3 4 PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C 3 4 PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C 3 PLY SUBF. AS PER MANUFACTURER C/W D.A.C 3 4 PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C 3 4 PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C 3 4 PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C 3 4 PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. C B D E F A 1 2 3 4 5 6 7 Bx Cx 26014 4200 32202 6000 6000 6000 6000 6000 6000 6000 12177 4836 914 350 914 9822 914 350 914 9822 6150 5850 6150 5850 6000 12027 6000 6000 6000 6000 6000 6000 6000 13563 914 6961 914 7234 914 8352 7875 14577 6000 6000 1760 4240 4500 1500 6600 30804 ROOF FRAMING PLAN / SCALE: 1:150

BFBA91

MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C 3 PLY SUBF. AS PER MANUFACTURER C/W D.A.C 4 PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C 3 PLY SUBF. AS PER MANUFACTURER C/W D.A.C 4 PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C 3 4 PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C 3 PLY SUBF. AS PER MANUFACTURER C/W D.A.C 4 PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C 3 PLY SUBF. AS PER MANUFACTURER C/W D.A.C 4 PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C PLY SUBF. AS PER MANUFACTURER C/W D.A.C AS PER MANUFACTURER C/W D.A.C AS PER MANUFACTURER C/W D.A.C AS PER MANUFACTURER C/W D.A.C AS PER MANUFACTURER COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. COL. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. LB. 204 mm REINFORCED CONC. LB. LB. 8 9 10 11 12 13 14 15 9x 31800 4200 14019 16002 4300 31700 6000 3898 2102 6000 6000 6000 6000 6000 11586 12600 6600 914 350 914 9822 914 350 914 27030 12204 5796 6177 5850 6150 5850 6000 6000 6000 6000 6000 6000 84204

I URBAN HAVEN MIXED BUILDING PROJECT - 2022

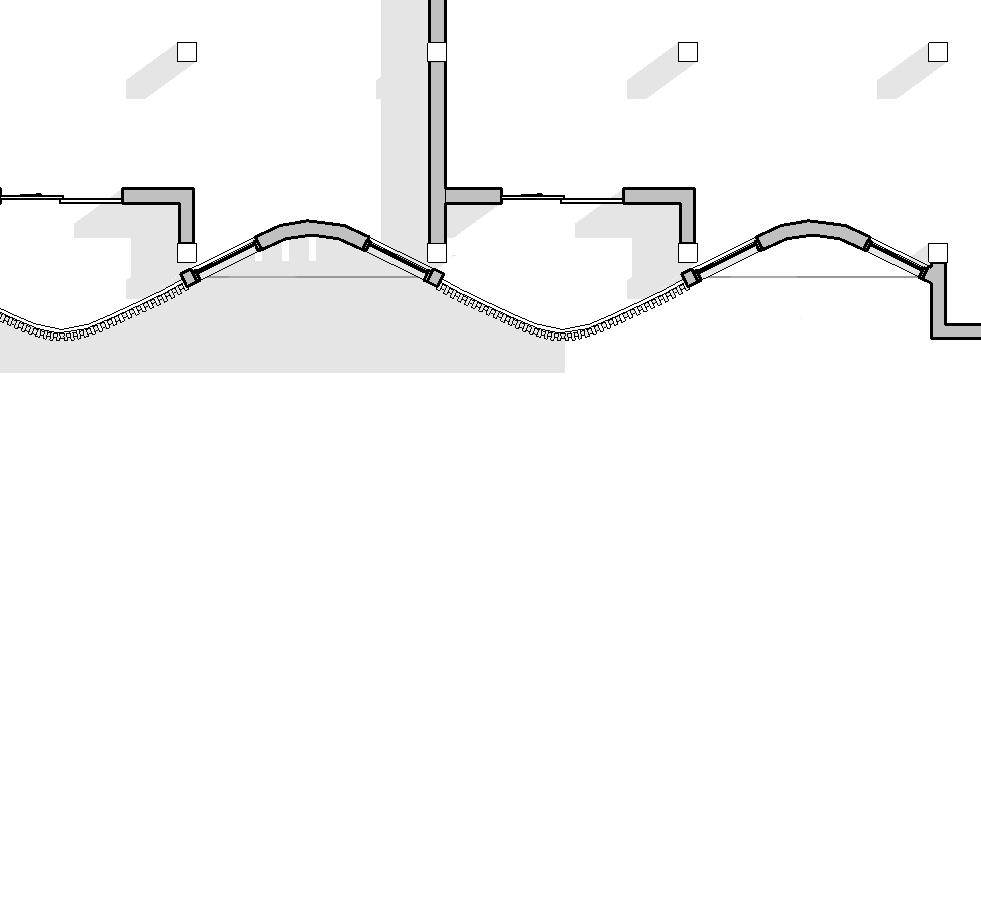

52 WEST ELEVATION / SCALE: 1:150

8

9x TOP OF PARKING FLOOR SLAB TOP OF GROUND FLOOR SLAB TOP OF SECOND FLOOR SLAB TOP OF THIRD FLOOR SLAB TOP OF ROOF SLAB 1.47 m 1.20 1.47 m 1.20 F.G 1.01 m X 1.20 1.47 m X 1.20 1.47 m 1.20 1.01 m X 1.20 m 1.47 m 1.20 m 1.47 1.20 m 1.01 m 1.20 m 1.47 m 1.20 1.47 m 1.20 m 1.01 m 1.20 1.47 m X 1.20 1.47 m X 1.20 1.01 m X 1.20 1.47 m X 1.20 m 1.47 m X 1.20 1.01 m X 1.20 m 1.47 1.20 m 1.47 m X 1.20 m 1.01 m 1.20 m 1.47 1.20 m 1.47 m 1.20 m F.G 1.01 1.20 m 1.47 m X 1.20 m 1.47 m X 1.20 F.G 1.01 m X 1.20 1.47 m 1.20 1.47 m 1.20 F.G 1.01 m X 1.20 2.0 m 1.20 2000 1200 3951 1200 1200 3951 1200 3951 1200 3951 1200 3951 3951 1200 1200 3951 1200 3951 914 2200 3000 3660 302 302 610 2896 3356 3353 3353 ELEVATOR SHAFT GARBAGE CHUTE

02

9 10 11 12 13 14 15

2 3 4 5 6 7

8 1.47 m 1.20 m 1.47 1.20 m 1.01 m 1.20 m 1.47 m 1.20 1.47 m 1.20 m 1.01 m 1.20 1.47 m X 1.20 1.47 m 1.20 1.01 m X 1.20 1.47 m X 1.20 m 1.47 m X 1.20 1.01 m X 1.20 m 1.47 m X 1.20 1.47 m 1.20 1.01 m X 1.20 1.47 m 1.20 m 1.47 1.20 m F.G 1.01 m 1.20 m 1.47 m 1.20 m 1.47 1.20 m F.G 1.01 m 1.20 1200 2.0 m 1.20 m 2.0 m X 1.20 m 2.0 m 1.20 m 2000 3951 1200 1200 2000 1200 3951 3951 1200 1200 3951 3951 1200 1200 3951 1200 3951 2 STONE FINISH 2 STONE FINISH 1 BRICK VENEER FINISH 1200 700 1900

1

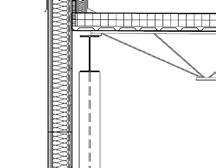

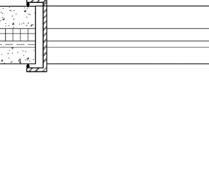

54 BUILDING CROSS SECTION / SCALE: 1:150 02 I URBAN

TOP OF SUBFLOOR ROOF TOP OF SUBFLOOR THIRD FLOOR TOP OF SUBFLOOR SECOND FLOOR TOP OF SUBFLOOR GROUND FLOOR TOP OF SUBFLOOR PARKING FLOOR UNIT #C8 SHIPPING AND RECEIVING COVERED TRUCK BAY UNIT 107 UNIT 112/113 UNIT 213 UNIT 206/207/208 BALCONY BALCONY SIDEWALK PARKING PARKING PARKING PARKING CORRIDOR CORRIDOR 410 3353 3353 3734 2896 204 610 13950 2 A-6.2 4 4 4 4 3 A-6.2 B E F C D A Bx Cx

HAVEN MIXED BUILDING PROJECT - 2022

TOP OF SUBFLOOR ROOF

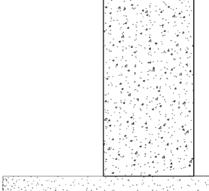

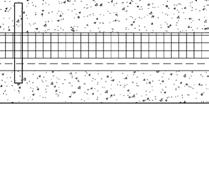

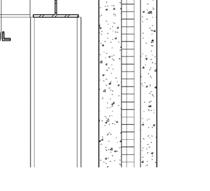

STUCCO/VENEER CLADDING FINISH COAT ON FIBERGLASS/METAL MESH EMBEDDED INTO BASECOAT

2" STYROFOAM RIGID INSULATION BOARD WITH DUREX FLEXCRETE ADHESIVE ON DUREX GREEN GUARD BARRIER ON 1/2" PLYWOOD SHTG

2"x6" STUDS @ 16" 0/C W/ R24 WALL INSULN

6mil VAP. BARR. 13mm (1/2") INT. DRYWALL FINISH.

HANDRAIL

FINISHED RAILING

STUCCO/VENEER CLADDING FINISH COAT ON FIBERGLASS/METAL MESH EMBEDDED INTO BASECOAT

2" STYROFOAM RIGID INSULATION BOARD WITH DUREX FLEXCRETE ADHESIVE ON DUREX GREEN GUARD BARRIER ON 1/2" PLYWOOD SHTG

2"x6" STUDS @ 16" 0/C W/ R24 WALL INSULN 6mil VAP. BARR. 13mm (1/2") INT. DRYWALL FINISH.

TOP OF SUBFLOOR THIRD FLOOR

2" x 4"

FINISHED RAILING

90mm (4') FACE BRICK 25mm (1") AIR SPACE. 22X180X0.76mm (7/8"X7"X0.03") GALV. METAL TIES @400mm (16") O/C, HORIZONTAL 600mm (24") O/C EXT.RIGID INSUL. DB., 38X140 (2"X6") STUDS @ 400mm (16") O/C WITH APPROVED DIAGONAL WALL BRACING, RSI 2.1 (R12) INSUL. AND APPROVED VAP. BARRIER WITH APPROVED CONT. AIR BARRIER, 13mm (1/2") INT. DRYWALL FINISH. PROVIDE WEEP HOLES @ 800mm (32") O/C BOTTOM COURSE AND OVER OPENINGS. PROVIDE BASE FLASHING UP MIN. 150mm (6")

406mm, 25MPA POURED CONCRETE FOUNDATION

100mm DIA, WEEPING TILE WITH MIN. 150mm CLEAR COVER STONE

WALL SECTION / SCALE: 1:30

TOP OF SUBFLOOR SECOND FLOOR

POURED CONC. 25 MPa

TOP OF SUBFLOOR GROUND FLOOR

55

410 3353 3353 3658 2896 14479 000

BASEMENT SLAB 204mm

PRE-ENG FLOOR SYSTEM

PRE-ENG FLOOR SYSTEM

TOP OF SUBFLOOR PARKING FLOOR HANDRAIL

229 mm SLAB 25MPA CONC.

2" x 4"

STUCCO/VENEER CLADDING FINISH FIBERGLASS/METAL MESH EMBEDDED INTO 2" STYROFOAM RIGID INSULATION WITH DUREX FLEXCRETE ADHESIVE GREEN GUARD BARRIER ON 1/2" PLYWOOD 2"x6" STUDS @ 16" 0/C W/ R24 6mil VAP. BARR. 13mm (1/2") INT. DRYWALL

PRE-ENG FLOOR SYSTEM

STUCCO/VENEER CLADDING FINISH FIBERGLASS/METAL MESH EMBEDDED INTO 2" STYROFOAM RIGID INSULATION WITH DUREX FLEXCRETE ADHESIVE GREEN GUARD BARRIER ON 1/2" PLYWOOD 2"x6" STUDS @ 16" 0/C W/ R24 6mil VAP. BARR. 13mm (1/2") INT. DRYWALL

3 SECTION SCALE - 1:30

56 CONCRETE CURB RESIDENTIAL ENTRY STAIR #1 1 C 4 5 6 Bx Cx 1246 1214 1513 1246 1214 143 86 1375 506 351 418 736 319 1282 522 522 506 351 2434 1910

1047 SECTION AND PLAN DETAILS / SCALE: 1:30 02 I URBAN HAVEN MIXED BUILDING PROJECT - 2022

A-6.4 1 DETAIL PLAN 4 SCALE - 1:30 (E.C)

A-6.4 DETAIL PLAN 4

- 1:30 (E.C)

A-6.4

SCALE

A

FINISH COAT ON INTO BASECOAT INSULATION BOARD ADHESIVE ON DUREX PLYWOOD SHTG WALL INSULN DRYWALL FINISH.

4

TYPICAL ROOF CONSTRUCTION: GRAVEL AND FLOOD COAT ON 4 PLY ROOFING FELT ON 13mm FIBERBOARD OVERLAY ON 100 RIGID INSULATION RSI 3.52 (R20) VAPOUR BARRIER ON PRE-ENGINEERED JOIST

5%

PREFINISHED METAL COPING WITH FR40 FLEXIBLE MEMBRANE UNDERLAYMENT ON 19mm PLYWOOD BACKING

BATT INSULATION PACKED IN-BETWEEN SHEATHING BOARDS.

MINIMUM RSI 3.52 (R20) MINIMUM.

FINISH COAT ON INTO BASECOAT INSULATION BOARD

ADHESIVE ON DUREX PLYWOOD SHTG WALL INSULN DRYWALL FINISH.

CONTINUOUS SEALANT AND BACKER ROD. 1

DETAIL 8 WHERE THE EXTERIOR WALL MATERIAL TRANSITIONS FROM ONE TO ANOTHER (

- 1:30

7

DETAIL

SCALE

(E.C)

A-6.4 2 SECTION

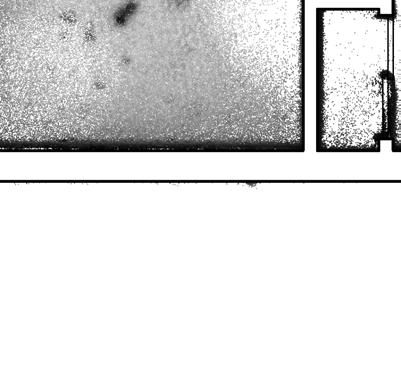

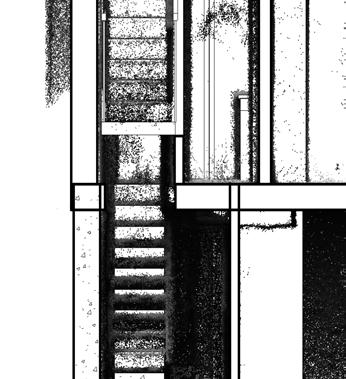

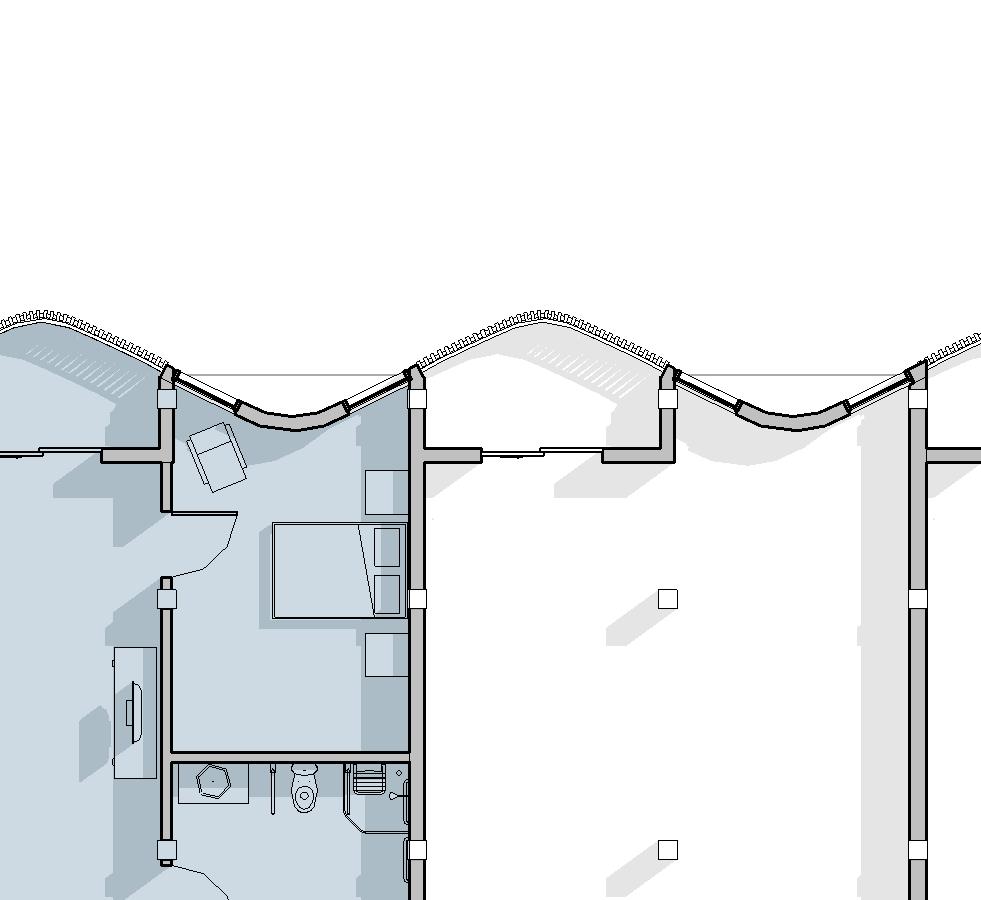

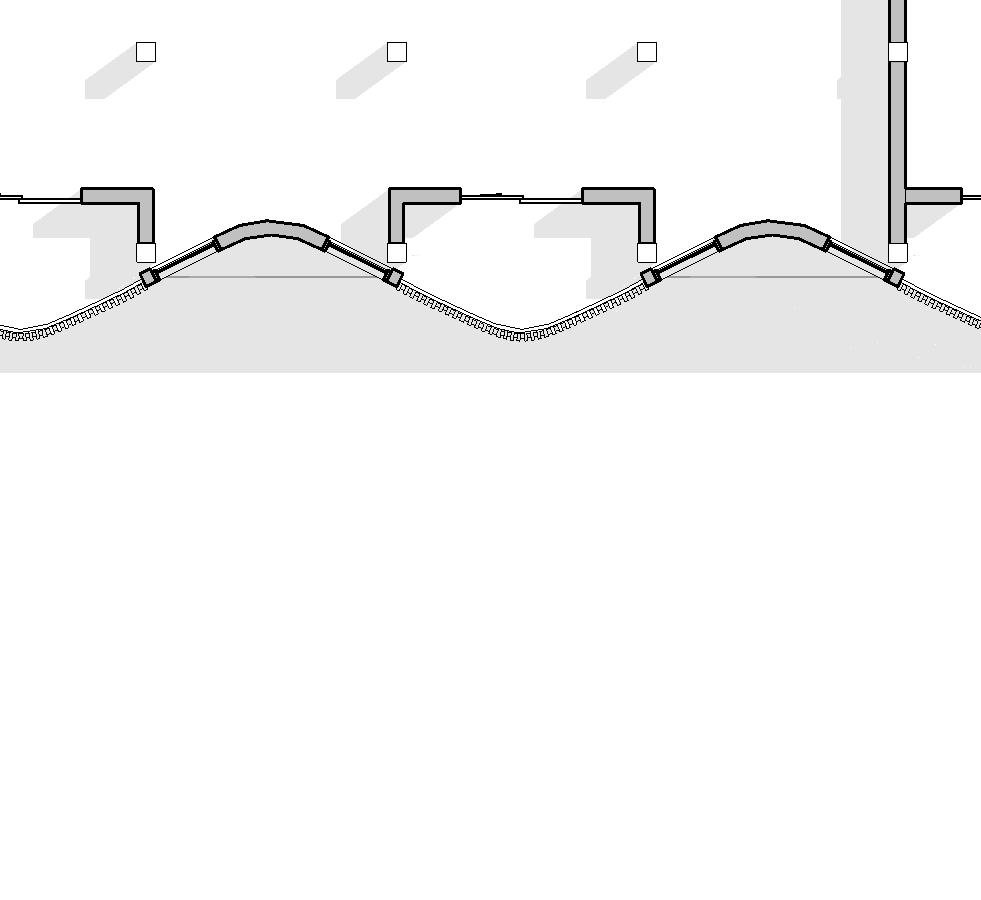

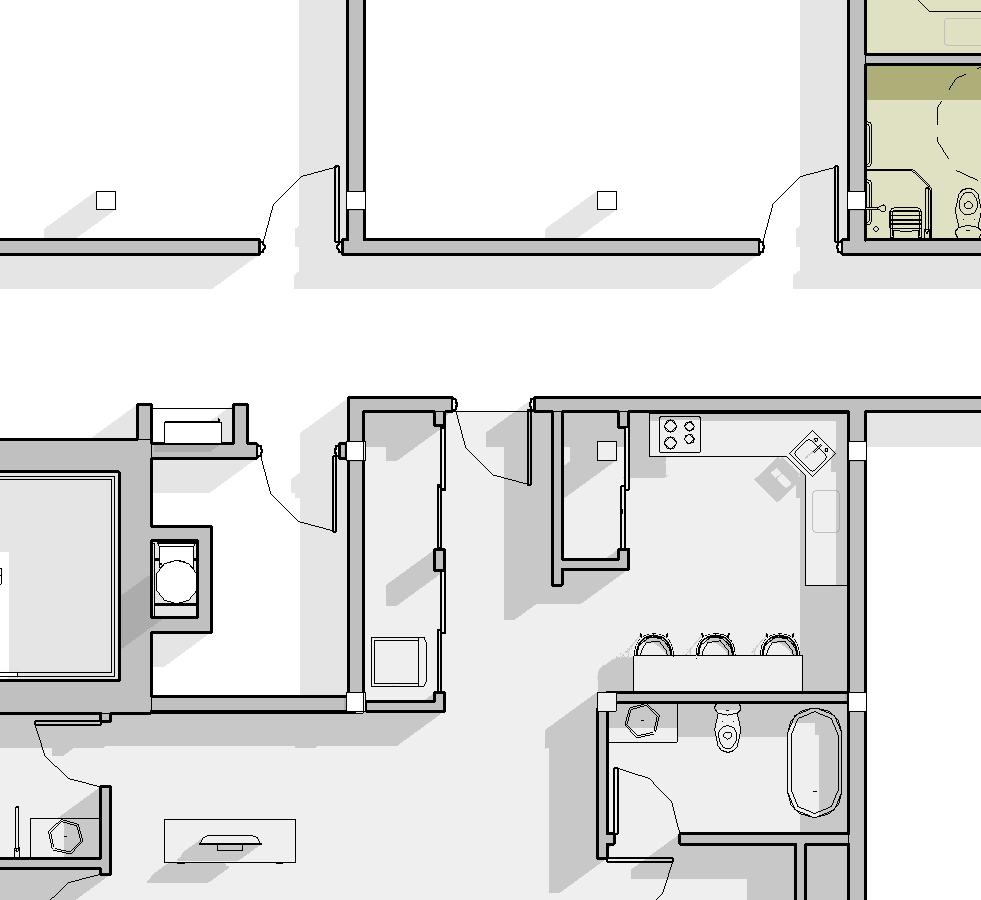

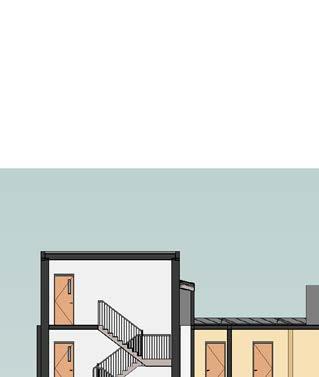

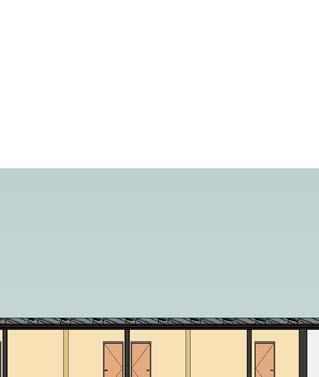

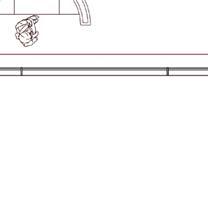

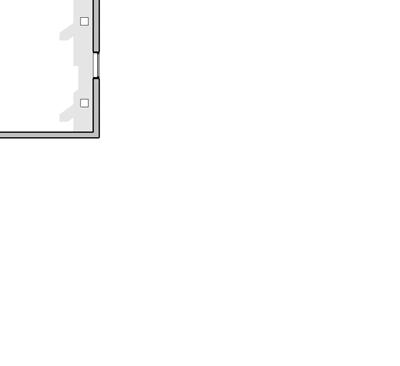

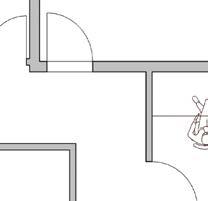

POINT CLOUD PROJECT SMALL HOUSE 2023

By : Esma Cetinkaya,

By : Esma Cetinkaya,

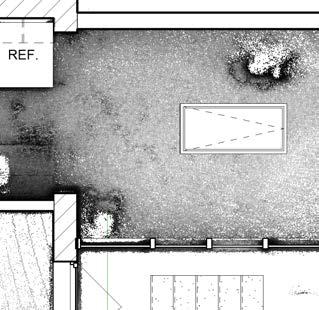

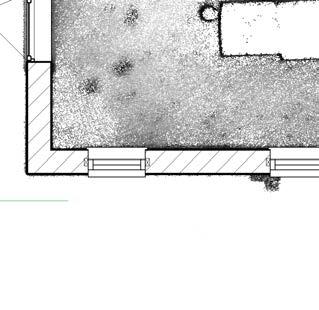

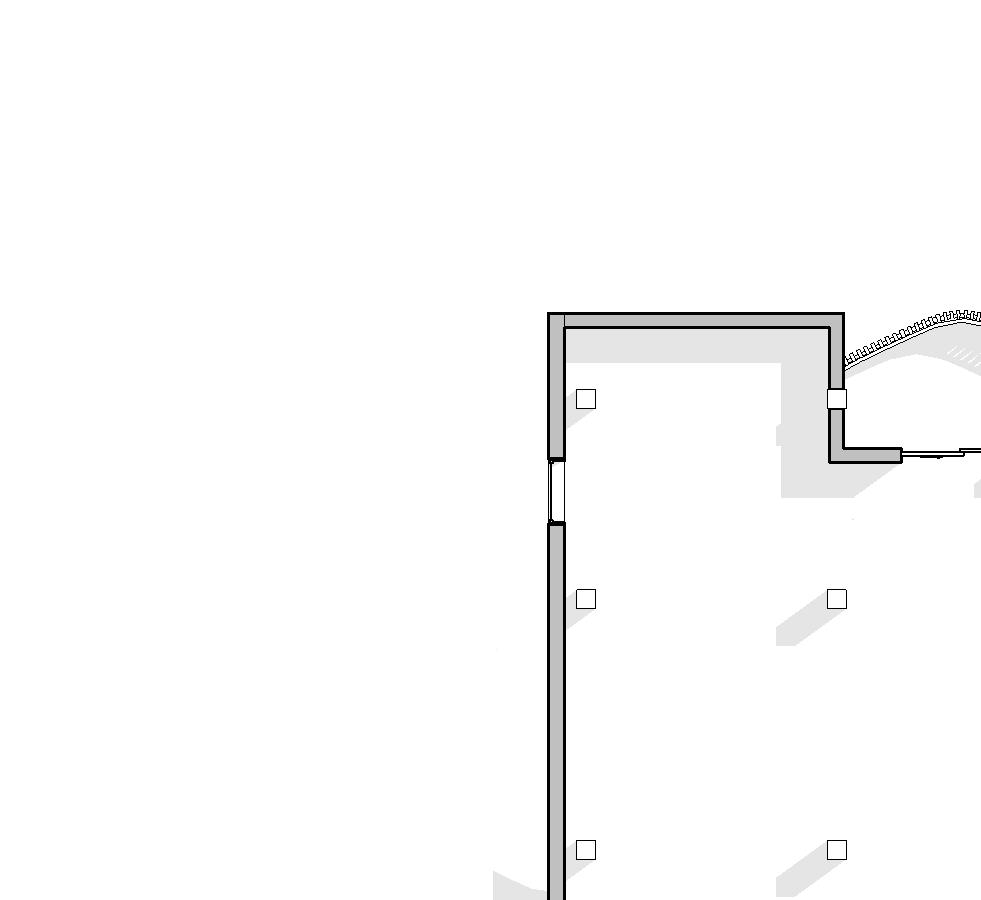

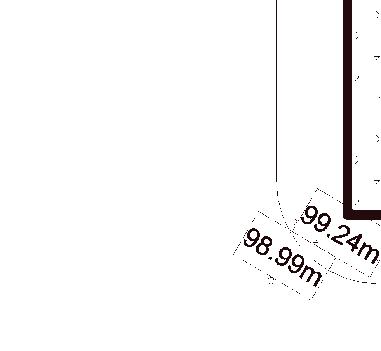

HORVATH CONCENTRATION IN DIGITAL TECHNOLOGIES 01 7:59:25 PM Cover Page 1 : 150 1 Site Plan SITE PLAN / SCALE: 1:150 06

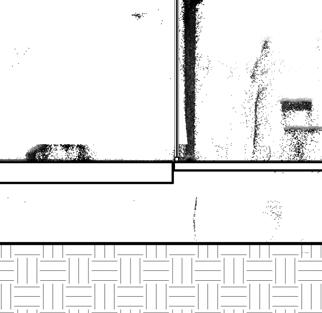

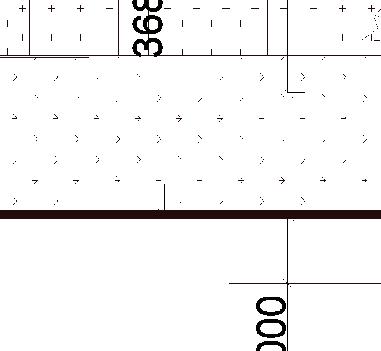

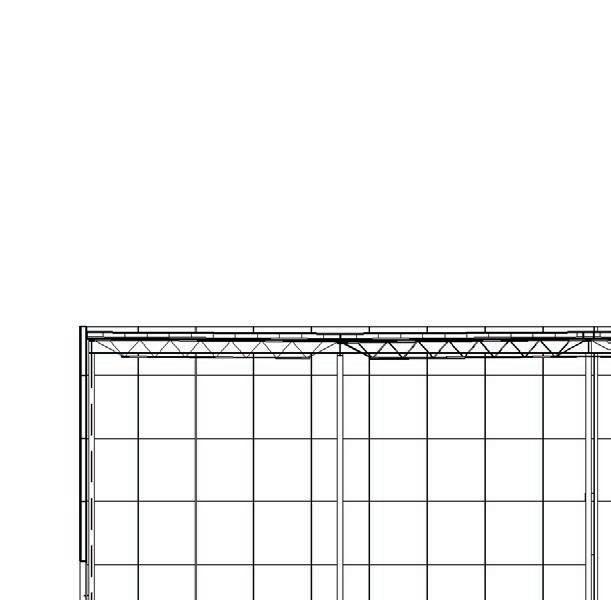

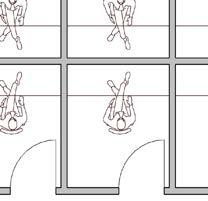

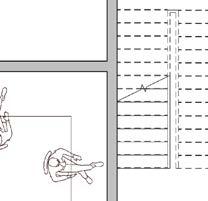

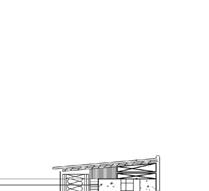

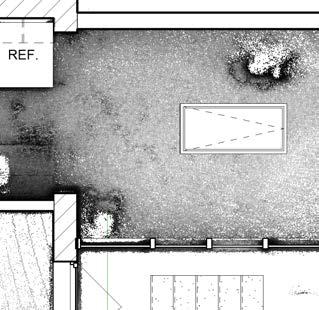

During my co-op semester, I had the privilege of contributing to a remarkable building project. My primary focus was on utilizing cutting-edge technologies such as scanning and Recap software to clean point cloud files and generate precise Revit drawings. This experience proved instrumental in expanding my skill set and proficiency with industry-leading tools.

59 REF. DN DN DN BACKYARD DRIVEWAY FRONT YARD EXISTING BUILDING 41.00 7.80 7.22 7.81 1.45 22.55 15.03 3.35 3.77 7.80 1:150

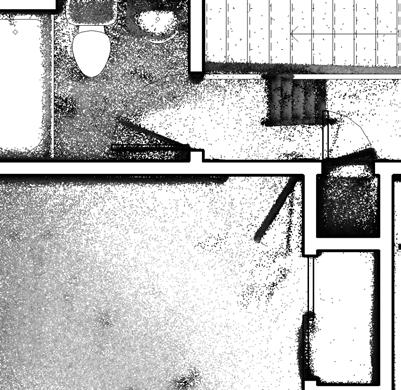

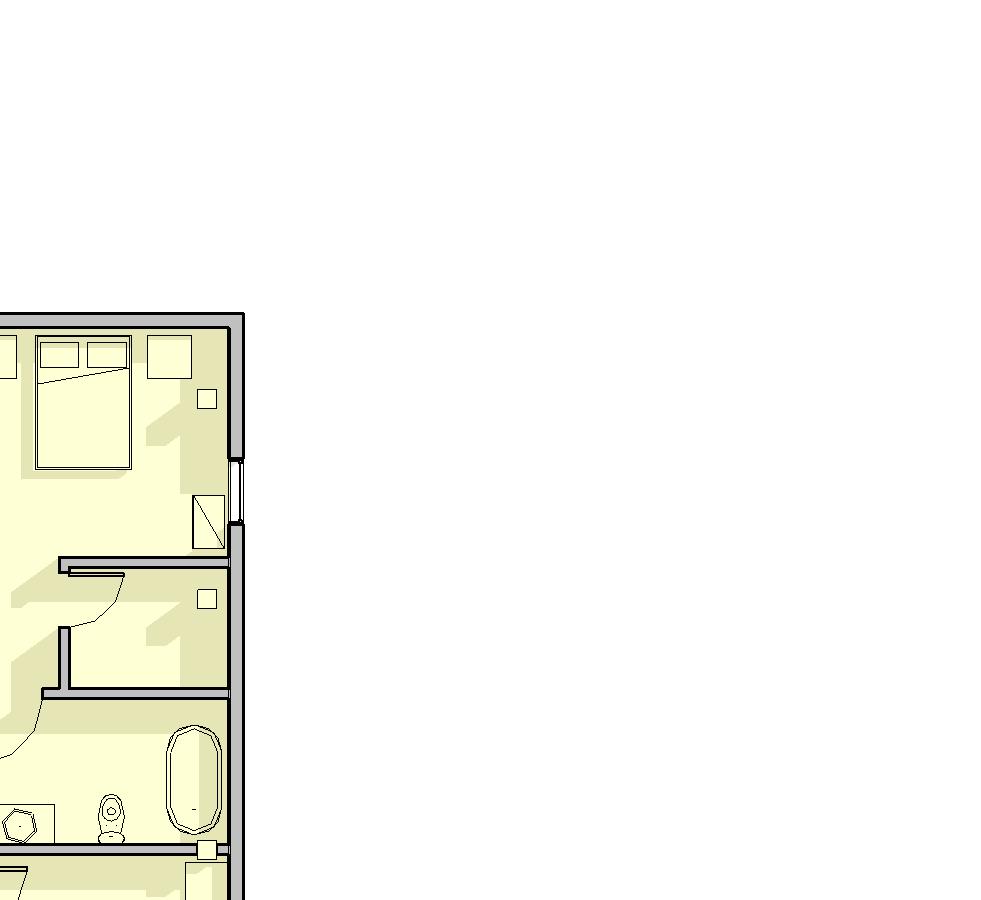

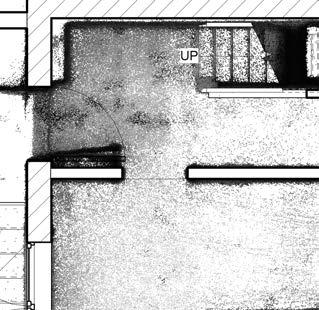

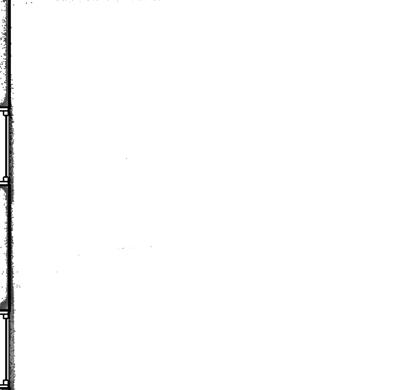

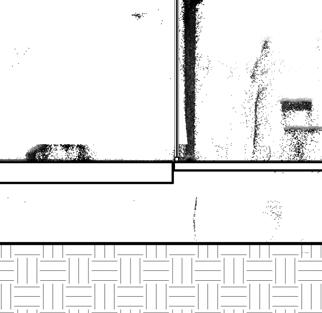

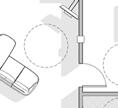

BASEMENT PLAN / SCALE: 1:50

Basement Plan

1

Using Recap, I processed and refined large sets of point cloud data. I carefully removed errors and inconsistencies to ensure the final results were precise. By organizing and tidying up the point cloud files, I produced high-quality Revit drawings, which served as a foundation for the project’s design and construction phases.

1 : 50

60 UP UP 9 m² Bedroom 17 m² Open Area 2 m² Bathroom Basement Entry 0.63 0.86 2.83 1.67 0.86 0.30 0.39 1.58 0.10 0.62 0.50 0.61 0.79 0.10 8.50 0.50 1.48 0.59 0.71 0.79 1.33 0.76 3.79 6.04 1.60 0.30 7.92 0.30 8.52 0.30 0.30 5.43 0.30 2.83 0.100.54 0.61 3.80 0.30 0.30 1.03 0.85 0.10 1.40 0.10 1.18 0.30 6.04 1.09 0.76 1.26 Project number Basement Project Esma Cetinkaya

No. Description Date

06 I POINT CLOUD PROJECT - 2023

1 Basement W/ Point Cloud BASEMENT PLAN W/ POINT CLOUD/ SCALE: 50

1 : 50

No. Description Date

BATHROOM BEDROOM OPEN AREA 0.30 7.92 0.30 8.52 0.30 1.18 0.10 1.40 0.10 0.85 0.76 1.03 0.30 6.04 0.30 2.83 0.10 4.96 0.30 8.50 0.30 1.48 0.10 3.84 0.30 6.02 1.57 0.86 0.76 0.59 1.58 0.62 0.50 0.61 0.79 1.60 1.09 1.26 1.18 Project number Date Drawn by www.autodesk.com/revit

Project Esma Cetinkaya

Issue Author

Basement Plan

Project 3B

2023

Esma Cetinkaya

The project provided me with invaluable hands-on experience and a deep understanding of the intricacies involved in transforming raw data into comprehensive architectural models. Through my involvement, I not only enhanced my technical abilities but also enhanced my problem-solving skills and attention to detail.

Project 3B

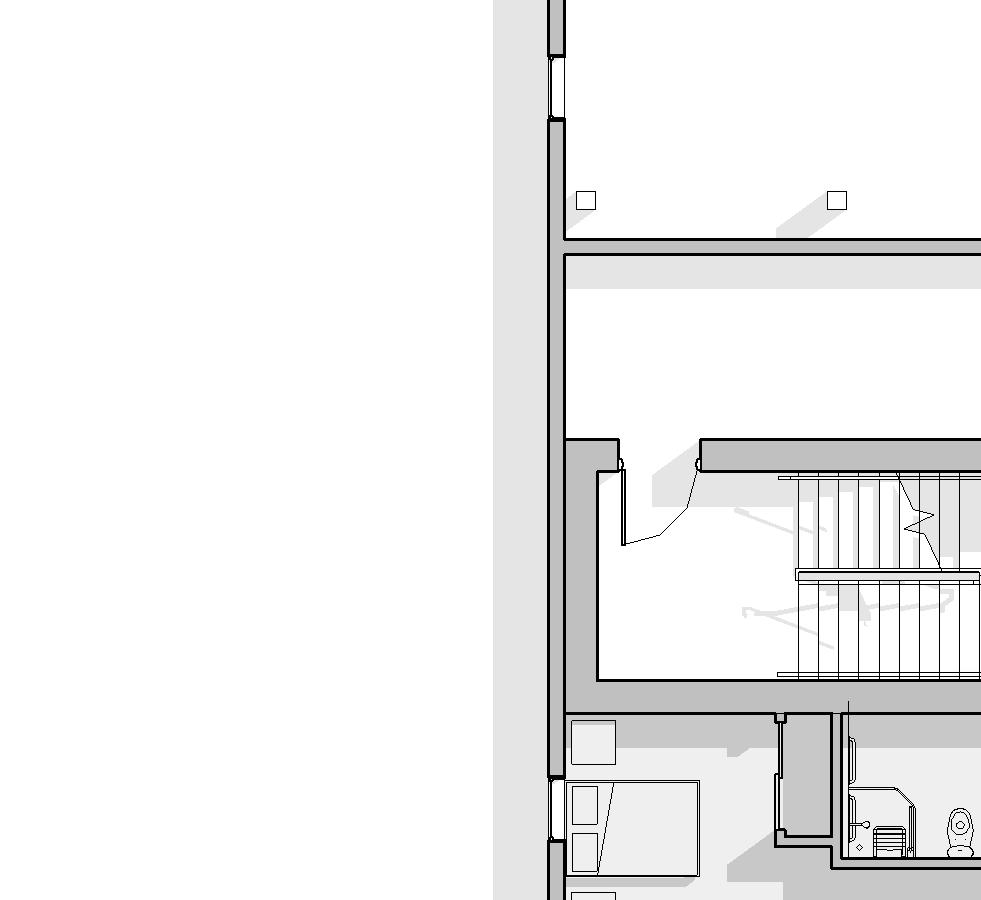

62 DN REF. UP DN 10 m² SUN/MUD ROOM 9 m² KITCHEN 7 m² FOYER 14 m² DINING ROOM 12 m² LIVING ROOM 8.54 1.15 0.91 1.01 1.60 1.39 8.54 0.47 1.99 0.85 1.60 1.15 0.20 0.13 0.30 0.14 0.30 0.20 0.30 0.30 1.24 3.70 0.70 0.81 2.70 0.38 0.40 0.79 0.14 0.30 0.91 0.41 2.18 0.63 1.60 0.85 0.45 1.59 0.45 0.14 3.80 0.30 1.09 7.94 12.24 6.07 1.99 0.46 0.71 1.55 0.71 0.58 Scale Project number Date Drawn by Checked by www.autodesk.com/revit 1 : 50 A1 First Floor Plan Project Number

Issue Date Author Checker 1 : 50 1 First Floor Plan No. Description Date FIRST FLOOR PLAN / SCALE: 1:50

06

I POINT CLOUD PROJECT -

KITCHEN FOYER DINING ROOM LIVING ROOM SUN/MUD ROOM 0.30 7.94 0.30 3.70 12.24 8.54 3.70 0.91 0.30 1.09 1.60 1.01 0.72 0.20 6.07 0.30 4.00 0.14 1.60 1.99 0.70 0.79 0.81 2.70 0.14 1.46 www.autodesk.com/revit Esma Cetinkaya Project 3B 1 : 50 1 First Floor Plan W/ Point Cloud FIRST FLOOR PLAN W/ POINT CLOUD / SCALE: 1:50

SECOND FLOOR PLAN / SCALE: 1:50

1 : 50 1 Second Floor Plan

Through this project, I gained expertise in Recap and scanning technologies, which I am excited to apply to future endeavors. I look forward to contributing to innovative solutions and advancing the field of architecture.

Esma Cetinkaya

64 DN 0.61 0.61 8.54 6.03 0.76 0.76 0.30 0.30 0.14 2.51 0.76 0.76 0.32 2.50 0.88 0.87 3.22 1.17 1.60 0.83 0.14 1.69 0.76 0.82 0.11 0.60 0.50 0.51 3.83 3.60 1.59 6.03 0.30 0.30 0.14 0.30 2.10 3.07 2.50 1.16 0.14 0.59 1.51 3.22 0.30 12 m² BEDROOM 3 m² BATHROOM 12 m² BEDROOM 6 m² BEDROOM CL CL LI 0.14 8.54 0.14 0.61 0.14 3.83 Second Floor Plan

No. Description Date

06 I POINT

CLOUD PROJECT - 2023

3.22 0.30 3.22 0.14 0.61 0.14 3.83 0.30 8.54 0.30 1.51 0.76 0.51 0.14 0.59 0.76 1.16 0.30 0.30 2.10 0.14 3.07 0.14 2.50 0.30 8.54 0.30 1.17 1.60 0.83 0.14 1.49 0.14 0.30 6.03 2.50 2.78 1.40 0.61 0.61 0.61 0.50 0.76 0.76 0.87 0.88 0.76 1.32 0.14 0.14 0.14 BEDROOM BEDROOM BEDROOM BATHROOM 6.03 Project number Date Drawn by Second Floor W/ Point Cloud Project Number Esma Cetinkaya Project 3B Issue Date Author No. Description Date 1

: 50 1 Second Floor W/ Point Cloud SECOND FLOOR PLAN W/ POINT CLOUD / SCALE:

66 First Floor Plan 0.00 First Floor Plan 0.00 Second Floor Plan 2.74 Second Floor Plan 2.74 Roof 5.19 Roof 5.19 Foundation -0.38 Foundation -0.38 5 12 2.77 0.25 0.62 1.85 0.64 2.11 1.24 8.24 TO Roof 8.24 TO Roof 8.24 1.01 0.72 1.54 0.49 0.56 1.54 0.38 0.25 2.77 9.25 12 5 Scale Project number Date Drawn by Checked by www.autodesk.com/revit 1 : 50 A6 East/West Elevations Project Number

Issue Date Author Checker No. Description Date 1 : 50 1 West Elevation 1 : 50 2 East Elevation WEST ELEVATION / SCALE: 1:50 EAST ELEVATION / SCALE: 1:50

Esma Cetinkaya Project 3B

06 I POINT CLOUD PROJECT - 2023

67 Plan 0.00 Plan 2.74 Roof 5.19 Foundation 0.38 Roof 8.24 2023-06-25 7:13:57 PM First Floor Plan 0.00 Second Floor Plan 2.74 Roof 5.19 Foundation -0.38 12 5 5 12 0.25 2.77 2.47 2.74 0.24 9.24 0.24 TO Roof 8.24 Scale Project number Date Drawn by Checked by www.autodesk.com/revit 1 : 50 A7-1 North Elevation Project Number Esma Cetinkaya Project 3B Issue Date Author Checker No. Description Date 1 : 50 1 North Elevation NORTH ELEVATION / SCALE: 1:50

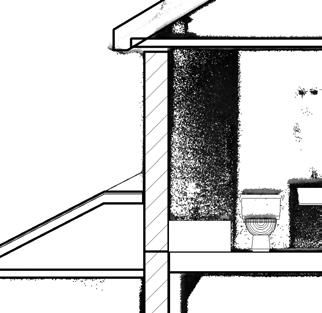

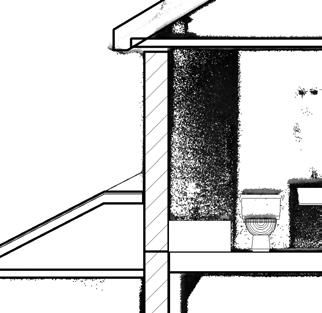

68 First Floor Plan 0.00 Second Floor Plan 2.74 Roof 5.19 Basement Plan -2.12 T.O. Footing -2.22 Foundation -0.38 2.89 0.10 2.61 0.25 2.49 0.25 1.99 0.11 0.30 10.90 BASEMENT KITCHEN BEDROOM BATHROOM FOYER SUN/MUD ROOM 12 5 TO Roof 8.24 Scale Project number Date Drawn by Checked by www.autodesk.com/revit 1 : 50 A8

Section Project Number Esma

Issue Date Author Checker No. Description Date LONGITUDINAL SECTION / SCALE: 1:50 06 I POINT CLOUD

Long.

Cetinkaya Project 3B

PROJECT - 2023

69 First Floor Plan 0.00 Second Floor Plan 2.74 Roof 5.19 Basement Plan -2.12 T.O. Footing -2.22 B.O. Footing -2.53 Foundation -0.38 TO Roof 8.24 Scale Project number Date Drawn by Checked by www.autodesk.com/revit 1 : 50 A8-1

Section W/Cloud Project Number Esma Cetinkaya Project 3B Issue Date Author Checker No. Description Date LONGITUDINAL SECTION W/ POINT CLOUD / SCALE: 1:50

Long.

70 First Floor Plan 0.00 Second Floor Plan 2.74 Roof 5.19 Basement Plan -2.12 T.O. Footing -2.22 Foundation -0.38 3.05 2.47 0.25 2.49 0.25 1.99 10.58 TO Roof 8.24 Project number Date Lat. Section Project Number Esma Cetinkaya Project 3B Issue Date No. Description Date LATITUDINAL SECTION / SCALE: 1:50

TO Roof 8.24

Roof 5.19

Second Floor Plan 2.74

First Floor Plan 0.00

Foundation -0.38

Basement Plan -2.12

T.O. Footing -2.22

3.05 2.47 0.25 2.49 0.25 1.99 10.58

Project number Date 2023-06-25 7:14:05 PM A10 Lat Section W/ Cloud Project Number Esma Cetinkaya Issue Date No. Description Date LATITUDINAL SECTION W/ POINT CLOUD / SCALE: 1:50

T H A N K Y O U esmanurctnk98@gmail.com 416-820-4851 48 Lawnside Dr. North York / ON

To promote electric vehicle adoption, 15% of available parking spots will be designated as electric vehicle charging stations.

To promote electric vehicle adoption, 15% of available parking spots will be designated as electric vehicle charging stations.

By : Esma Cetinkaya, Umesh Chauhan

By : Esma Cetinkaya, Umesh Chauhan

By : Esma Cetinkaya

By : Esma Cetinkaya

By : Esma Cetinkaya, Umesh Chauhan

By : Esma Cetinkaya, Umesh Chauhan

By : Esma Cetinkaya,

By : Esma Cetinkaya,