very compact, highly accurate

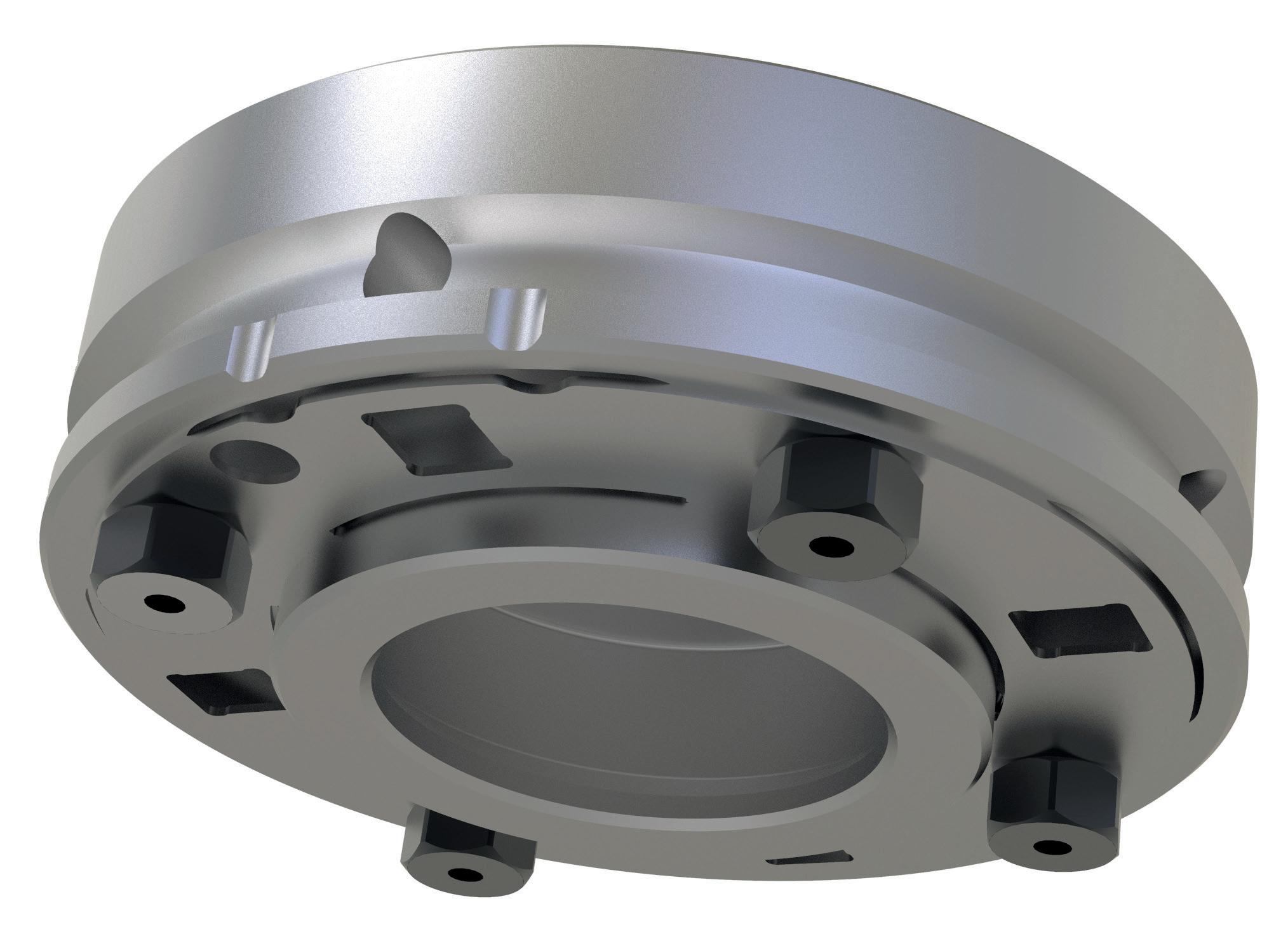

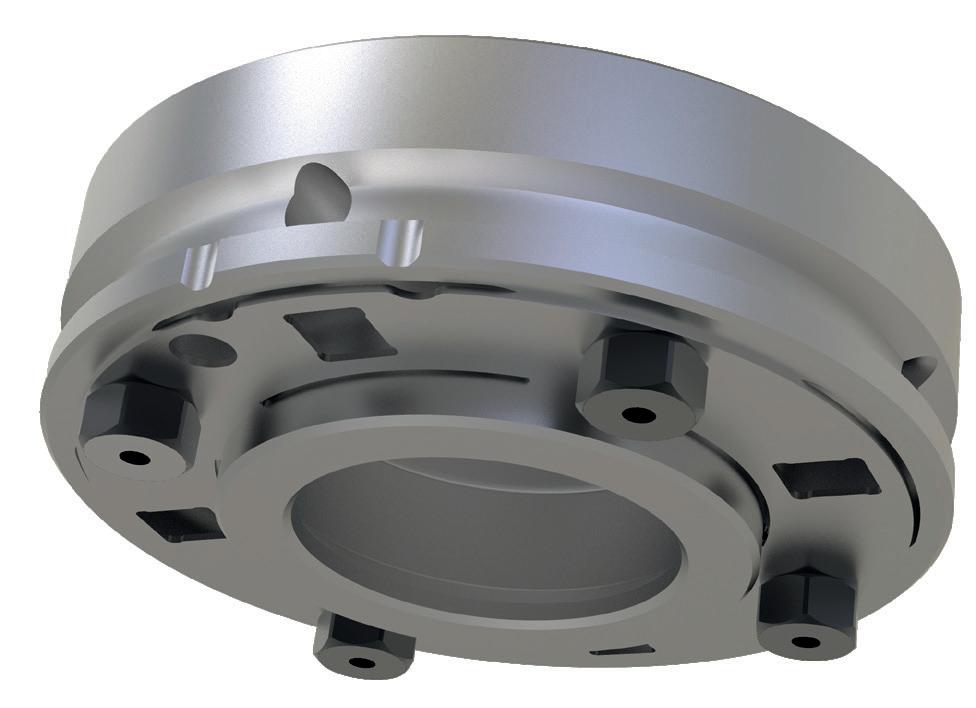

EROWA CMT

for micromechanics

Well-designed clamping solutions for micro manufacturing

The new EROWA CMT Compact Micro Tooling adds another innovation to the successful EROWA clamping system portfolio and takes micro high-precision manufacturing to a whole new level.

Specially developed energy-efficient micro-machining machines in detail-critical industries – ranging from watchmaking and jewelry to medical technology and microtechnology – the CMT clamping system delivers exceptional quality, precision, and efficiency in an ultra-compact design.

Micro and precision mechanics require specialized, precisely coordinated solutions. Particularly in demanding sectors such as the watchmaking and jewelry industry, medical technology and microtechnology, maximum precision, efficiency and sustainability is required.

The industry has been undergoing change for some time now. The trend is clearly moving towards compact, energy-efficient, and high-precision micro-manufacturing systems that are perfectly tailored to the resource-saving requirements of the future.

Thanks to the minimal space requirements, the space saved can be used to increase productivity in manufacturing. Additionally, its significantly lower energy consumption compared to conventional machines allows for more cost-effective and sustainable production of workpieces.

EROWA clamping technology as a factor for success

In order to unleash the full potential of micromachines, the machine must also be equipped with equally efficient workpiece handling. As a pioneer in the field of highprecision clamping systems, we have taken on this task. The newly developed EROWA CMT (Compact Micro Tooling) combines a high degree of quality and precision, as is already known from established EROWA products.

Developed for the next generation of micro-machining machines – suitable for both manual and automated production – the clamping system, with a diameter of just 45 mm, delivers maximum efficiency and functionality in the most compact form.

For comparison: The CMT chuck easily fits on a conventional business card – it could hardly be more compact.

Precise clamping technology in the smallest of spaces

The CMT system stands for versatile functionality and accuracy in an ultra-compact design.

• The clamping system is designed for workpiece sizes up to 50 x 50 x 50 mm. For optimum efficiency in the production of small parts and workpieces.

• Clamping is performed using spring force and the chuck is released pneumatically. The chuck remains mechanically locked in the unpressurized state.

• Similar to other EROWA products, positioning is performed using a backlash-free centering plate for maximum repeatability and system accuracy.

• The reference supports with integrated media feed-throughs also allow direct control of pneumatic clamping elements on the pallet.

• A central feed allows the use of a plunger to activate clamping elements , such as collets, mounted directly on the pallet. For higher demands, the clamping force can be further increased through optional retensioning, enabling the plunger to handle greater operating forces.

We would be happy to advise you personally

EROWA

- Manufacturing automation at its best

EROWA AG, founded in Switzerland in 1971, is now a globally operating organization specializing in the development, production, consulting, and distribution of state-of-the-art manufacturing technology for tool and mold making, as well as for production and precision engineering. With their headquarters located in central Switzerland, EROWA ranks among the world‘s leading companies in clamping technology and automation. Having 13 subsidiaries and 22 representatives, EROWA offers international points of contact and worldwide customer service.

Empowering Your Production

The next step towards greater efficiency, precision and productivity starts now. With EROWA, you have a partner who will optimize your production holistically - from clamping technology to automation and process control. Our innovative solutions adapt flexibly to your requirements and grow with you - for production that is ready for tomorrow. Get in touch with us - we will be happy to assist you.