Mid-Term Building Material Planning

The LLEN

設計主題DESIGN THEME

Project Introduction

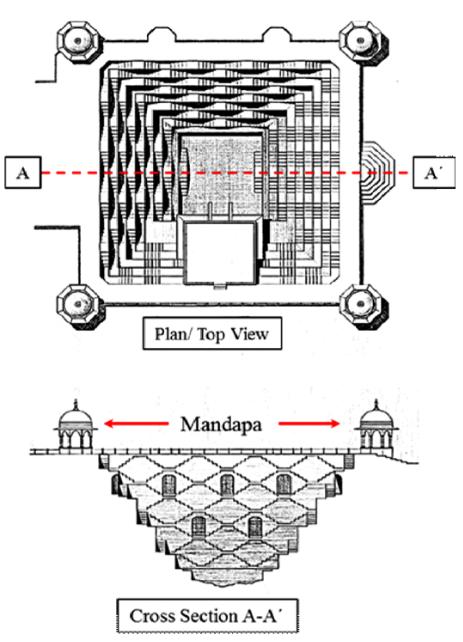

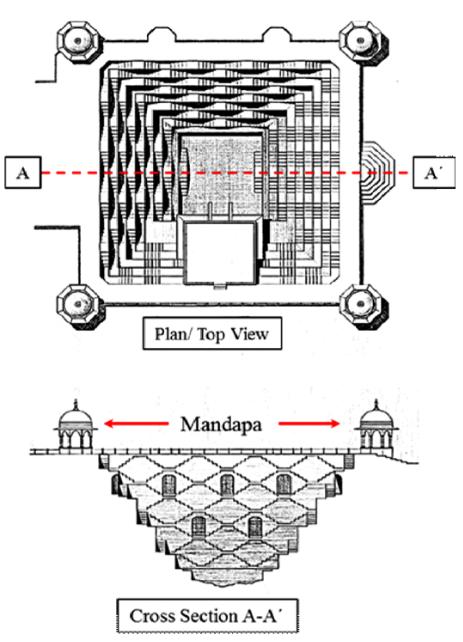

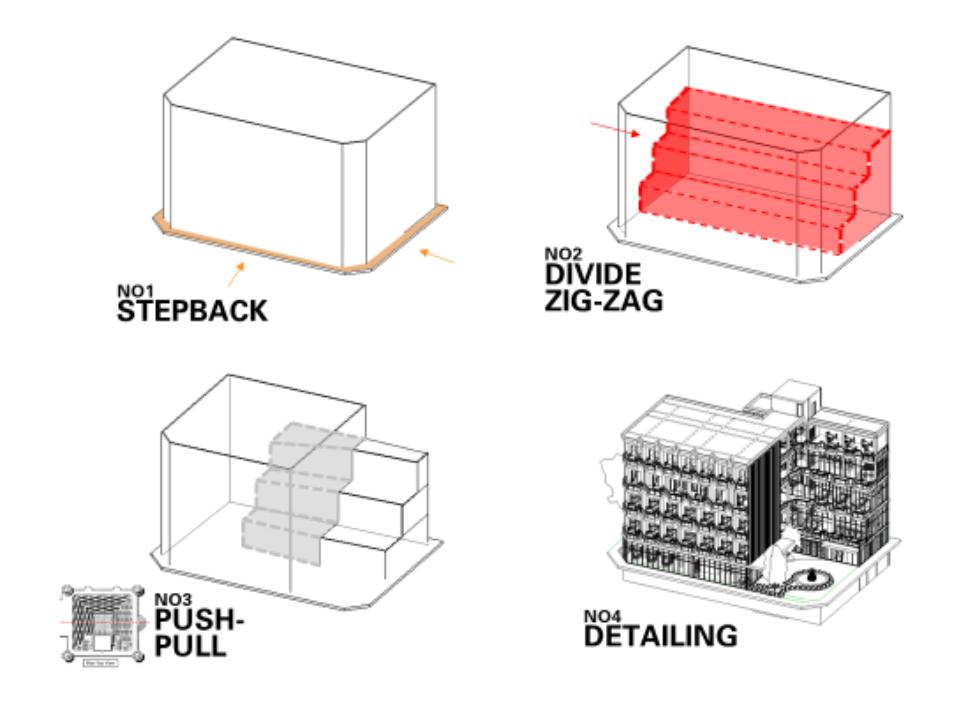

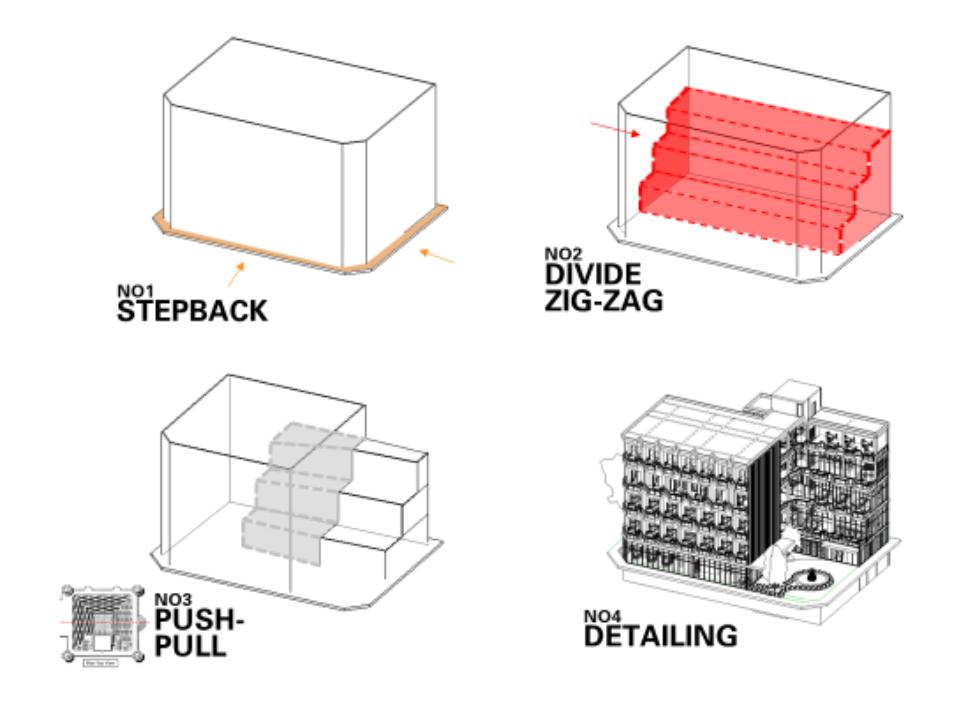

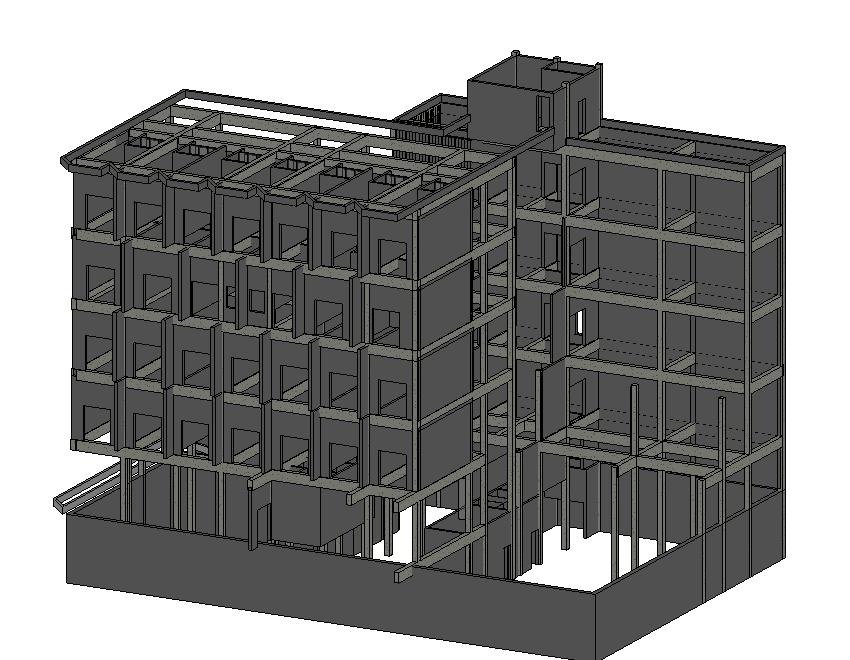

The LLEN is a visionary project that seeks to revitalize the Zhongshan district, once known as the most luxurious district in Taipei during the Japanese occupation period. Inspired by the geometric intricacies of Indian Stepwells, this concept incorporates their design elements to create a stunning architectural masterpiece.

We see that it is available at every height, and each level has interconnected stairs, offering the opportunity to people at any level to have interaction. The design includes both vertical and horizontal connections to encourage socializing and interaction among guests. Suitable for a hostel where people around the world gather and talk not just for staying in their hotel room and sleepin

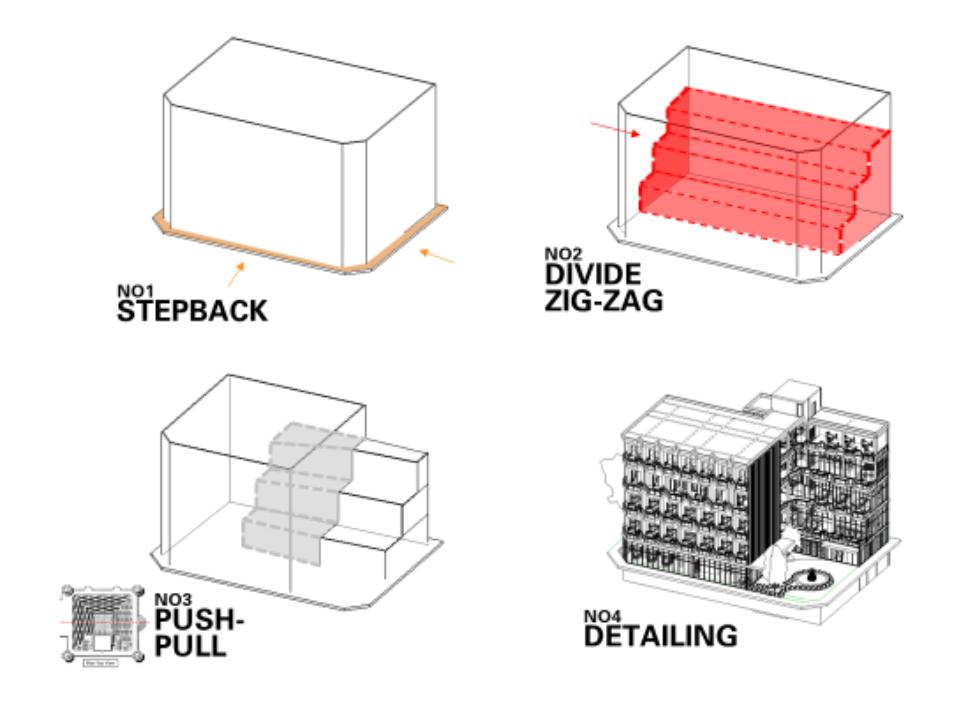

規模發展 MASS DEVELOPMENT

The LLEN

材料審核MATERIAL REVIEW

Project Introduction

The LLEN was constructed using sustainable methods and materials, prioritizing environmentally conscious practices. Throughout the construction process, careful consideration was given to minimize the environmental impact by employing energy-efficient systems, reducing waste generation, and utilizing renewable resources. Sustainable building materials, such as recycled or locally sourced materials, were chosen to promote resource conservation and reduce carbon emissions.

Additionally, wood was selected as the primary material for the hostel due to its ability to create a comfortable and inviting atmosphere. Wood has a natural warmth and aesthetic appeal that can evoke a sense of coziness and relaxation, which aligns well with the desired ambiance of a hostel.

Curtain Wall and Windows

Door & Windows

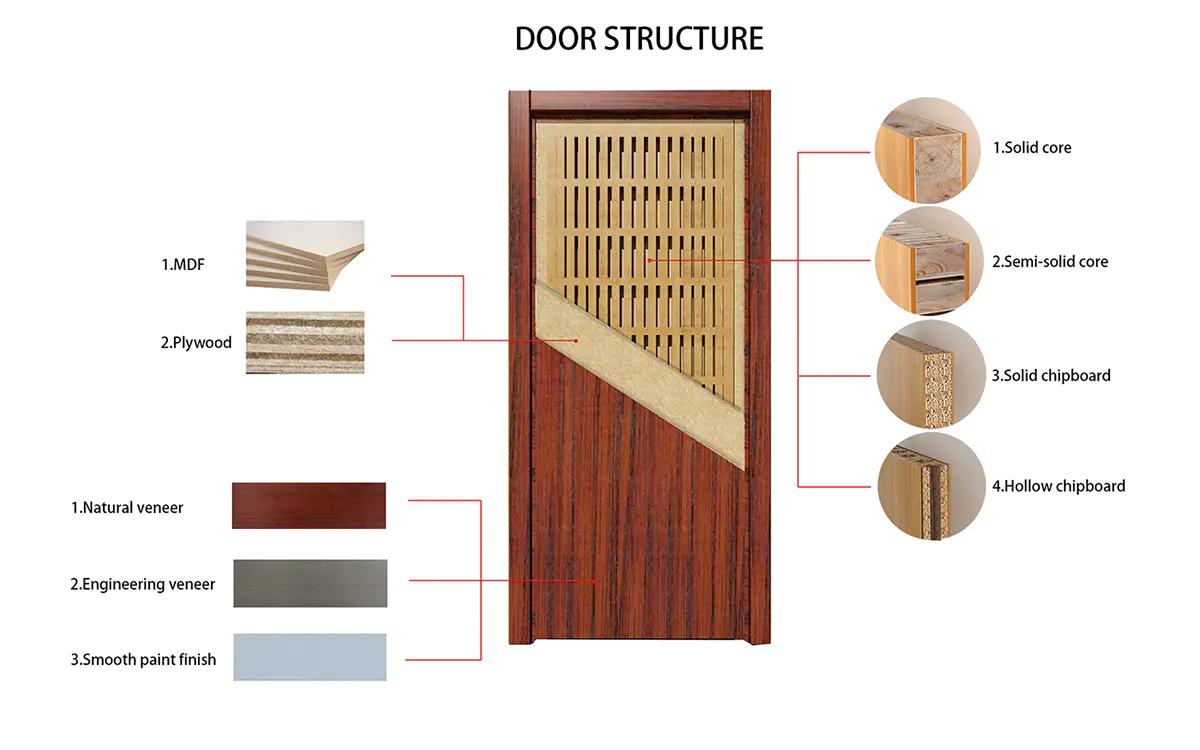

Plywood, Natural Venner

High Performance Glazing

Autoclaved Aerated Concrete Structural

Wainscoting

The LLEN

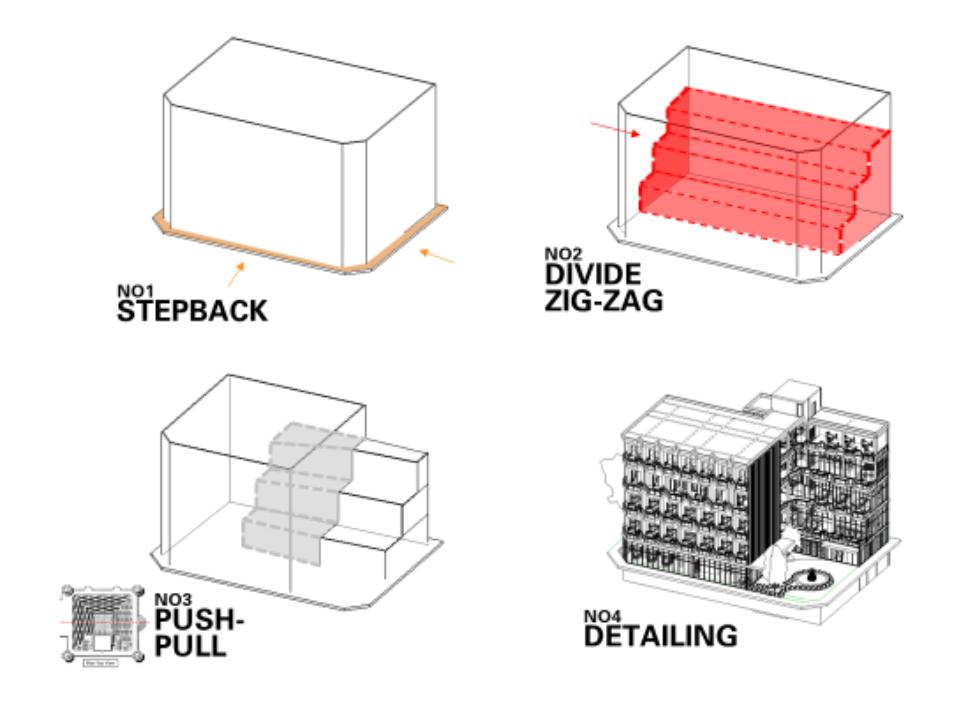

Outdoor Flooring

Permeable Pavers

Permeable pavers, also referred to as “porous pavement systems” or “permeable interlocking concrete pavements” (PICP), reduce the need to rebuild storm sewers in the face of new building though effective storm water management Non-porous paved surfaces result in significant run off, land erosion, and silt formation in service bodies of water As Southern California and many areas of the country pave over more and more land to meet the demand for housing and highways, storm water management becomes an increasingly large problem, resulting in the growing number of ordinances and regulations around the use of permeable pavements in land development.

Material Introduction

The LLEN

Permeable Pavers

Characteristics

Usability

Safety

Maintenance, Ease of Cleaning, Replacement

Outdoor Flooring Permeable Pavers

Permeable pavers have a wide range of uses and can be employed in different locations and situations. Permeable pavers can be designed to withstand freezing and thawing cycles, making them suitable for regions with cold weather. Permeable pavers can be utilized in various settings such as residential driveways, parking lots, pedestrian walkways, patios, plazas, and even heavy-duty applications like roadways. Additionally, permeable pavers offer design flexibility and aesthetic versatility.

Slip Resistance: Permeable pavers are often designed with textured surfaces or patterns that improve traction This helps to reduce the risk of slips and falls, especially in wet or icy conditions

Stormwater Management: One significant safety benefit of permeable pavers is their ability to manage stormwater effectively By allowing water to infiltrate through the surface, permeable pavers help to prevent the formation of puddles and reduce the risk of hydroplaning accidents They also minimize runoff, which can contribute to flooding and hazardous road conditions

Reduced Heat Island Effect: Traditional non-porous surfaces, such as concrete or asphalt, can absorb and radiate heat, leading to the formation of heat islands in urban areas Permeable pavers, on the other hand, have a higher albedo (reflectivity) and allow water to evaporate, reducing surface temperatures This can help create a more comfortable and safer environment, particularly in hot climates, by mitigating the risk of overheating and heat-related incidents

Durability: Permeable pavers are often constructed from durable materials like concrete or interlocking grids that can withstand heavy loads and traffic This durability ensures that the pavers maintain their structural integrity over time, reducing the risk of tripping hazards or surface failures

Permeable pavers generally require less maintenance compared to non-porous materials like concrete or asphalt The porous nature of permeable pavers allows water to pass through, reduces the likelihood of water-related issues such as puddling, ponding, or water damage Routine maintenance typically involves inspecting the paver surface for any clogging or debris and removing it to ensure proper drainage

Cleaning permeable pavers is relatively straightforward Regular sweeping or using a leaf blower can remove loose debris, leaves, or dirt that may accumulate on the surface For deeper cleaning, pressure washing with water can be effective in removing stubborn stains or grime

If a permeable paver becomes damaged or worn out, it can be relatively easy to replace individual pavers without disturbing the entire surface The interlocking or modular design of permeable pavers allows for easy removal and replacement of specific units

The LLEN

Permeable Pavers Characteristics

Outdoor Flooring Permeable Pavers

Fire Resistant & Impact Resistance

In terms of fire resistance, permeable pavers made of concrete can provide some level of fire resistance due to the nature of the material. However, their fire resistance is generally lower compared to non-porous materials like solid concrete or asphalt. The porosity of permeable pavers may allow flames to penetrate the surface or create potential weak points where fire can spread.

Regarding impact resistance, permeable pavers made of durable materials like concrete or interlocking grids can withstand light to moderate impacts, such as foot traffic or light vehicle loads. However, they may not be as resilient as solid non-porous materials when subjected to heavy loads or concentrated impacts.

Universality

Consideration of the at Each Stage of Building's Life Cycle

Permeable pavers are becoming increasingly common and available in many countries, including Taiwan As a result, the demand for permeable pavers has been growing, and suppliers and manufacturers have responded by making them more accessible in the market

Design and Planning: During the design and planning stage, it is crucial to assess the specific needs and requirements of the project Factors such as site conditions, anticipated water runoff, load-bearing capacity, and aesthetic preferences should be taken into account Proper design and planning will optimize the functionality and long-term performance of the permeable paver system

Construction and Installation: The construction and installation stage involves proper implementation of the permeable pavers It is essential to follow manufacturer guidelines, industry best practices, and local regulations to ensure correct installation

Use and Maintenance: During the use and occupancy stage, regular maintenance is crucial to preserve the performance and effectiveness of the permeable paver system Regular inspections should be conducted to check for any clogging, debris accumulation, or surface damage Maintenance activities may include cleaning the surface, removing debris, and addressing any necessary repairs promptly

Renovation and Expansion: In the event of renovation or expansion, permeable pavers offer flexibility and adaptability They can be easily removed, replaced, or extended to accommodate changes in the building's footprint or landscaping requirements

End-of-Life Considerations: When reaching the end of their life cycle, permeable pavers can be recycled or repurposed Materials such as concrete or plastic pavers can be crushed and used as aggregate in new construction projects, reducing waste and environmental impact Proper disposal methods should be followed to ensure compliance with local regulations and promote sustainability

The LLEN

Permeable Pavers Comparison

Outdoor Flooring Permeable Pavers

Permeable Pavers Asphalt, Brick

Water Manage ment

Environm ental Impact

Permeable pavers excel in water management by allowing water to infiltrate through the joints or porous surface, reducing surface runoff and promoting groundwater recharge

Permeable pavers have a significantly lower environmental impact compared to asphalt They help mitigate the heat island effect, reduce water pollution by filtering pollutants, and support natural water infiltration

In contrast, both asphalt and traditional brick surfaces are impermeable, leading to increased runoff and potential drainage issues

Asphalt production contributes to carbon emissions, and its impermeable surface exacerbates stormwater runoff and urban heat island effects Traditional brick, while more environmentally friendly than asphalt, is still impervious and can contribute to surface runoff

Durability and Loadbearing Capacity

Maintena

nce and Repairs

Permeable pavers can also withstand heavy loads when designed properly, making them a viable alternative for driveways and parking areas

Permeable pavers generally require lower maintenance compared to asphalt and traditional brick While periodic cleaning and inspections are necessary, permeable pavers do not require regular sealing or resurfacing like asphalt

Asphalt is known for its high load-bearing capacity and durability, making it suitable for heavy traffic areas such as roads and parking lots

Traditional brick may require occasional resealing and repairs to maintain its appearance and structural integrity Traditional brick is durable but may have limitations in load-bearing capacity and is more commonly used in pedestrian areas

Aesthetic s and Design Flexibility

Cost Consider ations

Permeable pavers offer a wide range of design options, shapes, colors, and patterns, allowing for creative and visually appealing installations. They can be used to create intricate designs or blend with existing architectural styles.

While the upfront cost of permeable pavers may be higher than asphalt, the long-term benefits, such as reduced maintenance and stormwater management, can offset the initial investment

Asphalt has limited design flexibility, primarily offering a uniform and utilitarian appearance. Traditional brick provides a classic and timeless aesthetic but may have fewer design options compared to permeable pavers.

Traditional brick may have higher upfront costs and similar long-term maintenance requirements to permeable pavers

The LLEN

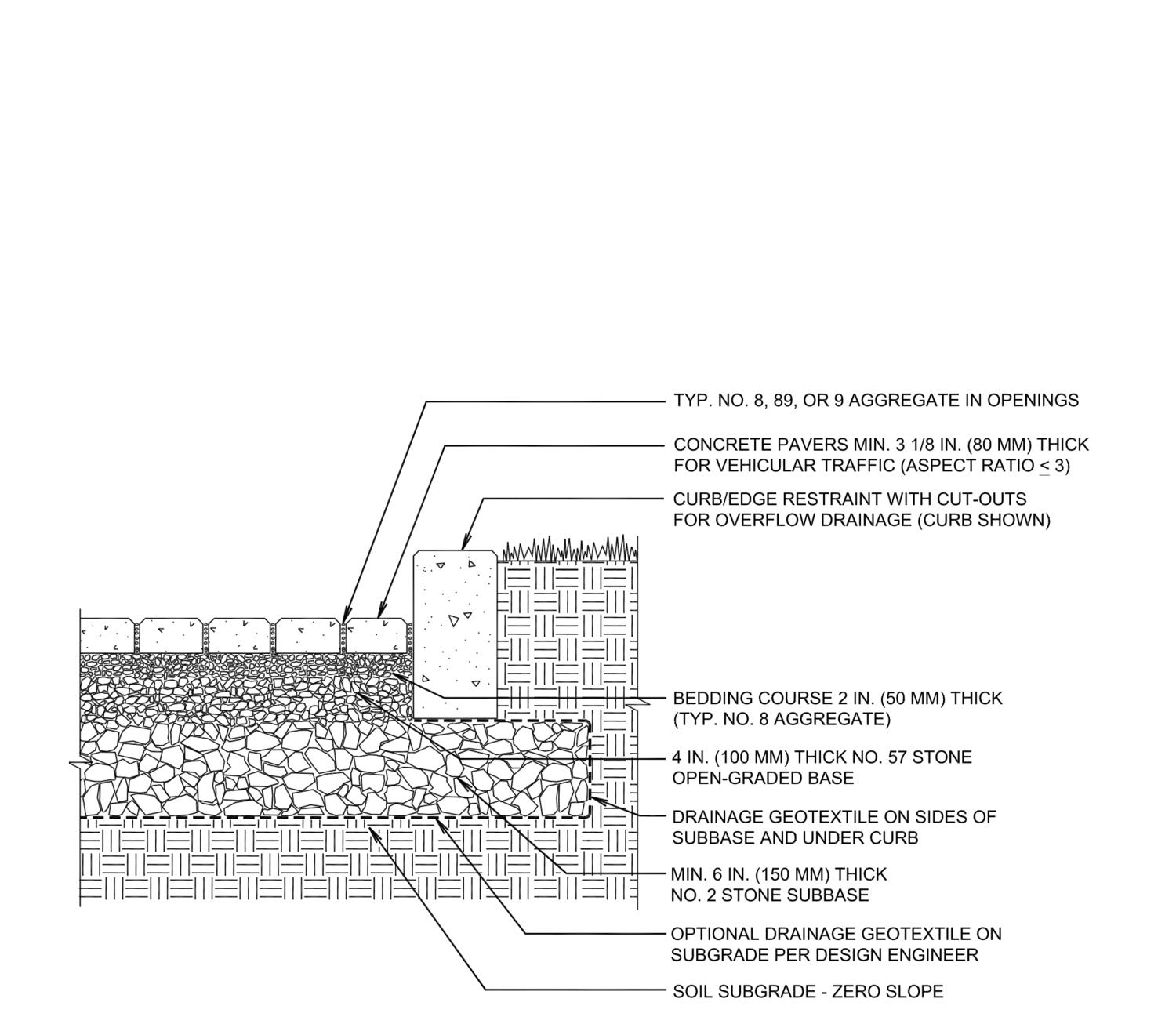

Structural

RC (Reinforced Concrete)

Permeable pavers, also referred to as “porous pavement systems” or “permeable interlocking concrete pavements” (PICP), reduce the need to rebuild storm sewers in the face of new building though effective storm water management Non-porous paved surfaces result in significant run off, land erosion, and silt formation in service bodies of water As Southern California and many areas of the country pave over more and more land to meet the demand for housing and highways, storm water management becomes an increasingly large problem, resulting in the growing number of ordinances and regulations around the use of permeable pavements in land development.

Material

Introduction

The LLEN

Structural RC (Reinforced Concrete)

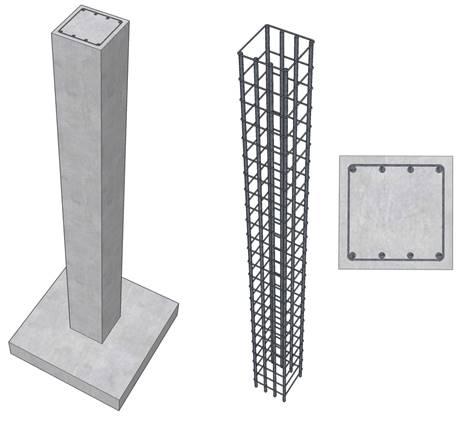

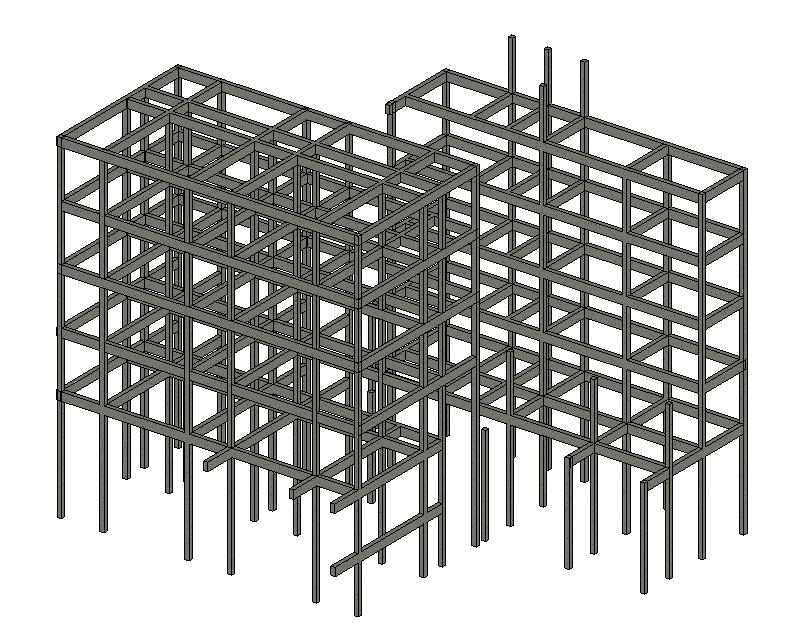

RC (Reinforced Concrete)

Characteristics

Usability

Safety

Maintenance, Ease of Cleaning, Replacement

Reinforced Concrete (RC) have wide-ranging applicability and suitability for various construction projects. RC is a versatile and widely used construction material that offers numerous benefits. RC is known for its exceptional strength and durability. It is suitable for a wide range of applications, including buildings, bridges, dams, roads, and other infrastructure projects.

RC structures are designed to provide structural integrity and stability. The combination of concrete's compressive strength and steel reinforcement's tensile strength creates a robust and resilient framework This structural integrity ensures that RC structures can withstand various loads, including vertical loads from the building's weight and horizontal loads from factors like wind, earthquakes, or other dynamic forces RC construction is governed by rigorous building codes and standards that focus on safety and structural performance These codes prescribe minimum design requirements, construction practices, and material specifications to ensure that RC structures meet safety standards and withstand anticipated loads and environmental conditions

Visual Inspections: Regular visual inspections should be conducted to assess the condition of the RC structure This includes inspecting the concrete surfaces, looking for cracks, spalling, corrosion stains, or any signs of distress Visual inspections can help identify areas that require further investigation or maintenance

Repairing Cracks and Spalling: Cracks and spalling (surface deterioration) are common issues in RC structures Small cracks should be sealed or repaired promptly to prevent water infiltration and further deterioration Larger cracks or areas of spalling may require more extensive repairs, such as removing damaged concrete, applying repair mortars or patching compounds, and ensuring proper bonding to the existing structure

Corrosion Protection: Steel reinforcement within RC structures is susceptible to corrosion, which can weaken the structure over time Adequate corrosion protection measures should be in place, such as ensuring sufficient concrete cover over the reinforcement and using corrosion-inhibiting admixtures or coatings where necessary Regular inspection and maintenance of corrosion protection measures are essential to prevent or address any corrosion issues

Waterproofing: Waterproofing measures are crucial to protect RC structures, especially those exposed to moisture or water infiltration This may involve applying waterproofing membranes, sealants, or coatings to vulnerable areas, such as basements, roofs, or joints Regular inspection and maintenance of waterproofing systems help ensure their effectiveness and prevent water-related damage

The LLEN

Structural RC (Reinforced Concrete)

RC (Reinforced Concrete)

Characteristics

Fire Resistant & Impact Resistance

RC has excellent fire resistance compared to many other construction materials. Concrete is non-combustible and does not contribute to the spread of fire. It retains its strength and stability even under high temperatures, providing a reliable level of fire protection. This is crucial for ensuring the safety of occupants and preventing the rapid spread of flames within a building.

RC has inherent impact resistance, making it suitable for areas prone to impact loads, such as industrial facilities or structures close to transportation routes. RC structures can withstand accidental impact from vehicles, machinery, or other external forces without significant damage, ensuring the safety of the structure and its occupants.

Universality

Consideration of the at Each Stage of Building's Life Cycle

Reinforced Concrete (RC) is a widely used construction material in Taiwan It has been extensively employed in various types of buildings, infrastructure projects, and residential properties throughout the country Taiwan has established comprehensive building codes and standards that govern the design, construction, and maintenance of RC structures These regulations ensure that RC buildings meet safety requirements and withstand seismic activity, which is important due to Taiwan's location in a seismically active region

Planning and Design Stage: The RC structure should be designed to meet the intended purpose, anticipated loads, and design codes and standards Careful selection of high-quality concrete, appropriate reinforcement, and supplementary materials to ensure durability and performance

Construction Stage: Implementing rigorous quality control measures to ensure proper placement, curing, and compaction of concrete, as well as correct installation of reinforcement Regular inspections and testing to verify compliance with design specifications and identify any construction defects or deviations

Operation and Maintenance Stage: Conducting periodic inspections to identify any signs of deterioration, such as cracks, spalling, or corrosion, and addressing them promptly

Renovation and Retrofit Stage: Conducting thorough assessments of the existing structure to identify any deficiencies, deterioration, or structural weaknesses

Implementing structural retrofitting techniques, such as strengthening the RC elements, adding new reinforcement, or upgrading structural systems to meet current standards

Demolition and End-of-Life Stage: Identifying opportunities for reusing or recycling RC materials from the demolished structure to reduce waste and promote sustainability

The LLEN

Structural RC (Reinforced Concrete)

RC (Reinforced Concrete) Comparison

RC (Reinforced Concrete)

Strength and Durability

Fire Resistance

Aesthetics and Design Flexibility

RC structures offer high compressive strength and can withstand heavy loads

RC structures provide inherent fire resistance due to the concrete's noncombustible nature

RC structures generally require less maintenance than steel structures.

RC (Reinforced Concrete)

Strength and Durability

Fire Resistance

Longevity

Steel Structures

Steel structures, on the other hand, have high tensile strength, making them ideal for long-span structures

Steel structures require additional fire protection measures to maintain their structural integrity in the event of a fire

Steel structures are susceptible to corrosion and may require periodic inspections, protective coatings, and maintenance of connections.

Timber Structures

RC structures have higher load-bearing capacity and can support heavier loads compared to timber structures Lower loads

RC structures provide better fire resistance than timber structures, as concrete does not combust.

Timber structures require additional fire protection measures, such as fireresistant coatings or treatments.

With proper maintenance and protection against moisture and pests, RC structures have a longer lifespan compared to timber structures, which may be susceptible to rot, decay, and insect damage

Maintenance

In general, RC (Reinforced Concrete) structures tend to be easier to maintain compared to timber structures

The LLEN

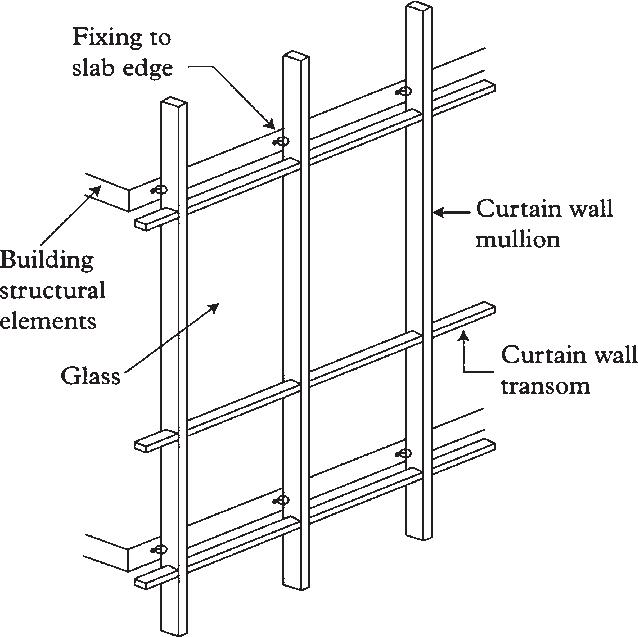

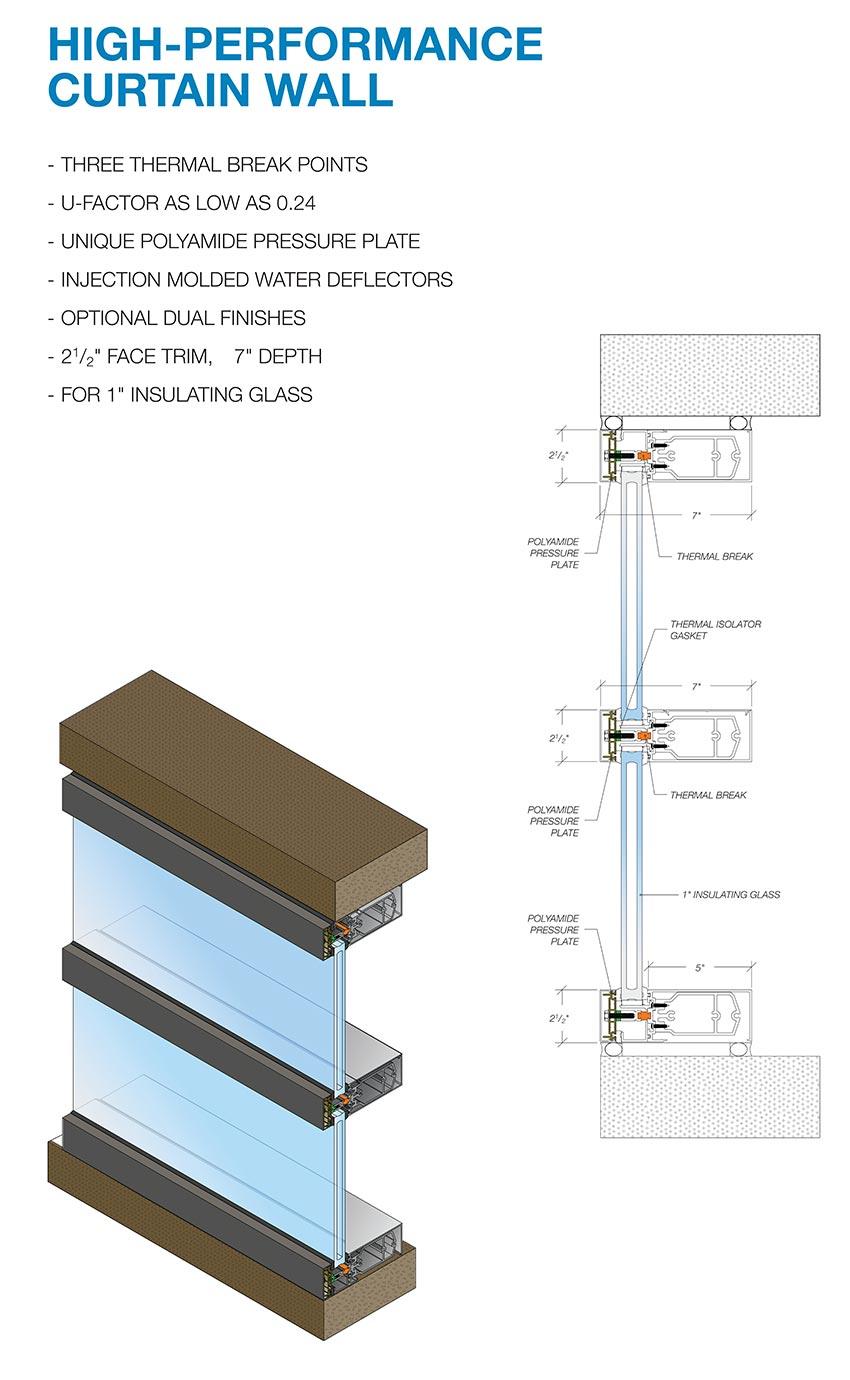

Curtain Wall and Windows

High-Performance Glazing

Permeable pavers, also referred to as “porous pavement systems” or “permeable interlocking concrete pavements” (PICP), reduce the need to rebuild storm sewers in the face of new building though effective storm water management Non-porous paved surfaces result in significant run off, land erosion, and silt formation in service bodies of water As Southern California and many areas of the country pave over more and more land to meet the demand for housing and highways, storm water management becomes an increasingly large problem, resulting in the growing number of ordinances and regulations around the use of permeable pavements in land development.

The LLEN

Curtain Wall and Windows High-Performance Glazing

High-Performance Glazing Characteristics

Usability

Safety

Maintenance, Ease of Cleaning, Replacement

High-performance glazing have broad applicability and suitability for various architectural and building projects. High-performance glazing allows ample natural light to enter indoor spaces while minimizing glare and maintaining visual comfort, benefits different building types, such as offices, schools, hospitals, and residential structures. It also can provide enhanced sound insulation, beneficial in urban areas, near transportation hubs, or in buildings that require a quieter indoor environment, such as educational or healthcare facilities. High-performance glazing contributes to sustainable building practices by reducing energy consumption and reliance on artificial lighting. It supports green building certifications and sustainability goals, making it applicable to projects that seeking environmentally friendly solutions.

High-performance glazing systems are engineered to provide structural stability and support They are designed to withstand wind loads, seismic activity, and other environmental forces, ensuring the overall safety and stability of the building envelope

1. 2. 3. 4 5 6

Regular Inspections: Conduct routine inspections of high-performance features, such as glazing systems, to identify any signs of damage, wear, or deterioration. Inspections can help identify issues early on and prevent further damage or performance degradation.

Cleaning and Maintenance Guidelines: Follow the manufacturer's cleaning and maintenance guidelines specific to the high-performance features installed in your building. These guidelines may include recommended cleaning agents, techniques, and frequencies to preserve the performance and appearance of the features.

Cleaning Procedures: Use appropriate cleaning methods to avoid damaging highperformance features. For high-performance glazing, consider using non-abrasive cleaners and soft lint-free cloths to prevent scratching the glass surface Avoid using harsh chemicals that may degrade coatings or seals

Sealant and Gasket Maintenance: High-performance features often rely on effective seals and gaskets to maintain their performance Regularly inspect and replace worn or damaged seals and gaskets to ensure proper functionality and prevent air or water infiltration

Performance Testing: Periodically assess the performance of high-performance features to ensure they continue to meet the desired performance criteria This may involve conducting tests for air leakage, water penetration, or thermal efficiency to verify that the features are functioning as intended

Repairs and Replacements: Address any identified issues promptly by conducting necessary repairs or replacements This may include replacing damaged glass panes, repairing seals, or upgrading components to maintain the performance of the high-performance features

The LLEN

High-Performance Glazing Characteristics

Fire Resistant & Impact Resistance

High-performance glazing can be manufactured with fire-rated glass or incorporate fire-resistant coatings. This enhances the fire safety of buildings by providing a barrier against the spread of flames, smoke, and heat. Fire-rated glazing can also help maintain safe evacuation routes and provide fire compartmentalization in critical areas.

High-performance glazing is designed to withstand external impacts, reducing the risk of breakage or shattering. It is often manufactured using tempered or laminated glass, which are more resistant to breakage than standard annealed glass. This helps prevent potential injuries from flying glass shards in the event of impact.

Universality

Consideration of the at Each Stage of Building's Life Cycle

In Taiwan, high-performance glazing has gained popularity in modern architectural designs and building projects It is commonly used in commercial buildings, residential complexes, educational institutions, and other structures With Taiwan's focus on energy efficiency and sustainable building practices, high-performance glazing plays a significant role in improving thermal performance, daylighting, and overall energy efficiency in buildings

Design and Planning Stage: Evaluate the energy performance goals of the building and incorporate high-performance glazing solutions that help achieve desired energy efficiency targets Analyze the building's orientation and shading strategies to optimize solar heat gain and select appropriate glazing coatings and technologies Consider the building's interior lighting requirements and integrate high-performance glazing that maximizes natural daylight while minimizing glare and heat gain

Construction Stage: Follow proper installation practices for high-performance glazing to ensure proper sealing, alignment, and integration with the building envelope

Operation and Maintenance Stage: Develop a regular cleaning and maintenance program for high-performance glazing to preserve its performance and appearance

Follow manufacturer guidelines for cleaning methods and products Monitor the performance of high-performance glazing over time, including factors like energy efficiency, thermal performance, and daylighting levels Address any performance issues promptly

Renovation and Retrofit Stage: Assess the potential for energy upgrades in existing buildings by retrofitting or replacing glazing systems with higher performance alternatives to improve energy efficiency

End-of-Life Stage: When high-performance glazing reaches the end of its life cycle, explore recycling options to minimize waste and environmental impact

Follow local regulations and guidelines for proper disposal

The LLEN

Curtain Wall and Windows High-Performance Glazing

High-Performance Glazing Comparison

High-Performance Glazing

Thermal Performance

Solar Control

Daylighting and Visual Comfort

Sound Insulation

Condensatio n Control

Durability and Longevity

Traditional Glazing

High-performance glazing offers significantly better thermal insulation compared to conventional glazing It incorporates advanced technologies such as low-emissivity (lowe) coatings, multiple glazing layers, and gas-filled spaces, resulting in reduced heat transfer and improved energy efficiency This helps to minimize heat loss in winter and heat gain in summer, enhancing indoor comfort and reducing heating and cooling energy requirements

High-performance glazing includes specialized coatings and glazing configurations that provide excellent solar control It can selectively block or reflect solar radiation while allowing natural light to pass through, thereby minimizing unwanted heat gain and reducing the need for excessive cooling systems This helps maintain a comfortable indoor environment and reduces reliance on artificial lighting

High-performance glazing is designed to maximize daylight penetration while minimizing glare and maintaining visual comfort. It offers superior light transmittance properties, disperses light evenly, and reduces the need for artificial lighting during daylight hours. This enhances occupant well-being, productivity, and reduces energy consumption related to lighting.

High-performance glazing can significantly improve sound insulation compared to conventional glazing By incorporating multiple layers of glass and acoustic interlayers, it helps reduce external noise transmission, creating a quieter indoor environment This is particularly beneficial in urban areas or near high-noise sources

High-performance glazing systems are designed to minimize condensation on the glass surface With improved thermal insulation, the interior surface temperature of the glazing remains closer to room temperature, reducing the likelihood of condensation forming This helps maintain a dry and comfortable indoor environment and prevents potential damage caused by condensation

High-performance glazing is engineered to be durable and resistant to various environmental factors It undergoes rigorous testing to ensure it can withstand wind loads, thermal stress, and impact resistance This results in a longer service life and reduced maintenance requirements compared to conventional glazing

The LLEN

Wall

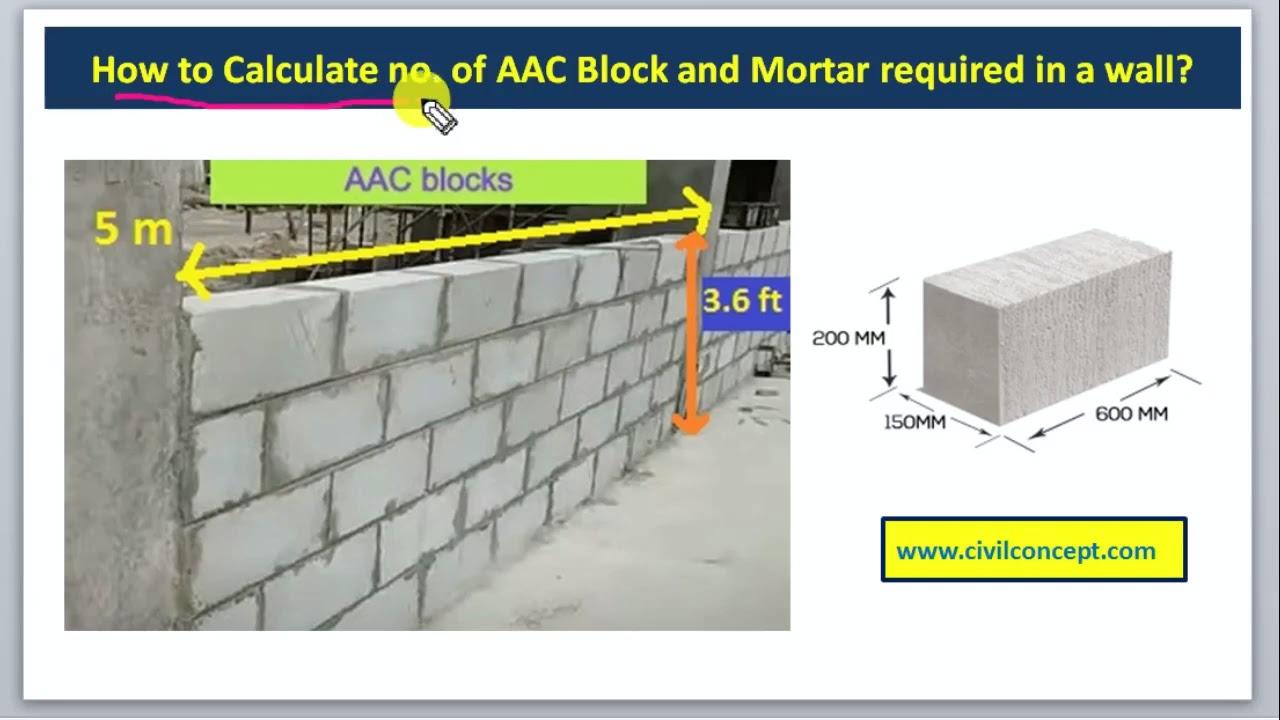

Autoclaved Aerated Concrete

Autoclaved Aerated Concrete (AAC) is a lightweight, precast, foam concrete building material that is known for its excellent thermal insulation, strength, and durability. It is produced by mixing finely ground sand or fly ash with cement, lime, water, and a small amount of aluminum powder. The mixture is then poured into molds and undergoes a process called autoclaving, which involves steam curing under high pressure and temperature. AAC was developed in 1924 by a Swedish architect, who was looking for alternate building material with properties similar to that of wood – good thermal insulation, solid structure and easy to work with – but without the disadvantage of combustibility, decay and termite damage

Material

Introduction

The LLEN

Wall

Autoclaved Aerated Concrete

Autoclaved Aerated Concrete (ACC)

Characteristics

Usability

AAC can be used in various types of buildings, including residential, commercial, industrial, and institutional structures. It is suitable for both low-rise and high-rise constructions, making it a versatile choice for different building projects. AAC can be utilized in various structural elements, such as walls, floors, roofs, and partitions. Its lightweight nature makes it easy to handle and install, and its excellent load-bearing capacity allows for efficient structural designs. It is important to note that while AAC provides safety benefits, proper design, construction, and adherence to building codes and regulations are essential to ensure the overall safety of the building.

Safety

Maintenance, Ease of Cleaning, Replacement

AAC offers excellent structural stability and strength It has a high load-bearing capacity, making it suitable for constructing durable and stable buildings AAC structures are resistant to various external forces such as wind, earthquakes, and impacts, enhancing the overall safety of the building

Maintenance:

Regular Inspections: Periodic visual inspections are recommended to check for any signs of damage, cracks, or deterioration This helps identify any maintenance needs early on

Moisture Control: Proper moisture management is crucial to prevent the accumulation of moisture within the AAC Adequate waterproofing measures should be in place, such as applying appropriate sealants or coatings to exposed surfaces, especially in areas prone to moisture intrusion

Ease of Cleaning:

Surface Cleaning: AAC surfaces can be easily cleaned using mild detergents and water Regular cleaning helps maintain the aesthetics and cleanliness of AAC walls or other surfaces

Stain Removal: For stubborn stains, gentle scrubbing with non-abrasive cleaners can be effective However, it is recommended to test any cleaning products on a small, inconspicuous area before applying them to the entire surface

Efflorescence Prevention: Efflorescence, a white crystalline deposit, may occasionally appear on AAC surfaces due to the migration of salts Preventive measures, such as proper sealing and effective moisture control, can help minimize efflorescence formation

Replacement:

In cases where individual AAC units are damaged or need replacement, they can be easily removed and replaced without affecting the entire structure This modularity allows for targeted repairs and reduces the time and cost associated with replacement

The LLEN

Fire Resistant & Impact Resistance

Universality

Consideration of the at Each Stage of Building's Life Cycle

Wall

Autoclaved Aerated Concrete

Autoclaved Aerated Concrete (ACC)

Characteristics

AAC is highly fire-resistant due to its inorganic composition and the presence of noncombustible materials. It does not release toxic gases when exposed to fire, contributing to enhanced fire safety in buildings.

AAC has good impact resistance, making it less prone to damage from accidental impacts or collisions. This adds to the overall safety and durability of AAC structures.

AAC has gained significant popularity in Taiwan's construction industry It is commonly used for various applications, including residential buildings, commercial structures, industrial facilities, and infrastructure projects

AAC also has gained widespread acceptance worldwide due to its numerous advantages, such as its lightweight nature, thermal insulation properties, fire resistance, and sustainability

Design Stage:

AAC's lightweight nature allows for efficient structural designs, reducing the load on the foundation and overall construction costs

Construction Stage:

Construction Efficiency: AAC blocks are lightweight, making them easy to handle, transport, and install, leading to faster construction times and reduced labor costs

Compatibility with Other Materials: AAC can be easily integrated with other building materials, such as steel or timber, allowing for flexible construction options

Operation Stage:

Energy Efficiency: AAC's thermal insulation properties contribute to reduced energy consumption for heating and cooling, resulting in cost savings and environmental benefits

Durability: AAC structures have a long lifespan and require minimal maintenance, reducing operational costs

Indoor Air Quality: AAC is an inert material, free from harmful emissions, contributing to a healthy indoor environment for occupants

End-of-Life Stage:

Reusability and Recycling: AAC can be recycled and used as an aggregate in new AAC production or other construction applications, reducing waste and promoting sustainable practices

Demolition: AAC structures can be demolished and the blocks can be salvaged for reuse, minimizing waste generation

The LLEN

Weight

Thermal Insulation

Sound Insulation

Fire Resistance

Construction Speed

Thermal Insulation

Construction Speed

Sound Insulation

Fire Resistance

Wall

Autoclaved Aerated Concrete

Autoclaved Aerated Concrete (ACC) Comparison

Autoclaved Aerated Concrete (ACC)

Conventional Concrete

AAC is significantly lighter than conventional concrete, making it easier to handle, transport, and install

AAC provides better thermal insulation properties than conventional concrete, leading to energy savings and improved comfort

AAC offers superior sound insulation compared to conventional concrete, reducing noise transmission between rooms and from external sources

AC has excellent fire-resistant properties, providing enhanced safety compared to conventional concrete

AAC construction can be faster due to the use of lightweight blocks and panels, leading to shorter construction timelines.

Autoclaved Aerated Concrete (ACC)

AAC offers better thermal insulation than clay bricks, resulting in energy efficiency and reduced heating and cooling requirements

AAC blocks are larger and lighter than clay bricks, allowing for faster construction progress

AAC provides superior sound insulation compared to clay bricks, creating quieter indoor environments.

AAC has higher fire resistance than clay bricks, contributing to improved safety in case of fire incidents.

The LLEN

Indoor Flooring

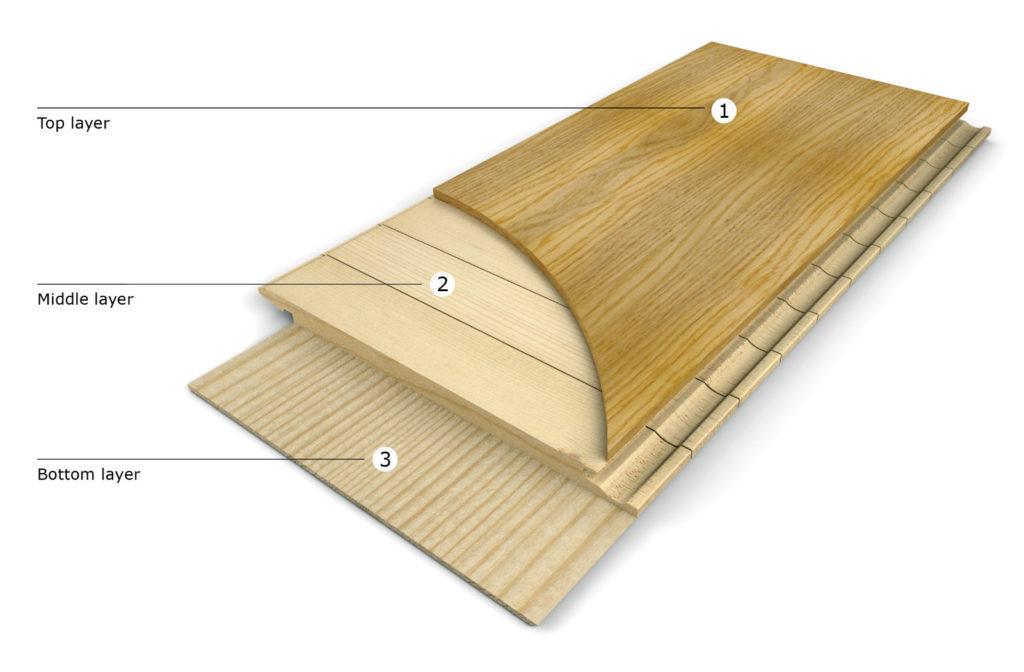

Hardwood Flooring

Hardwood flooring is made of solid wood, and it’s one of the most popular flooring options. It is usually made of hardwood species like maple, oak or walnut. And it has a significantly longer lifespan that allows for sanding and refinishing over and over Hardwood flooring, also referred to as solid wood flooring, is often made of a hardwood species Popular species include maple, walnut, oak and cherry. Solid flooring comes from a solid piece of milled wood, hence the name. Hardwood flooring installation involves nailing the wood planks to the subfloor, a project that requires some skills. Because it is solid wood, it can easily be sanded and refinished several times over its lifespan to maintain its appearance.

The LLEN

Hardwood Flooring Characteristics

Usability

Safety

Maintenance, Ease of Cleaning, Replacement

Indoor Flooring Hardwood Flooring

Hardwood floors are renowned for their durability and longevity. They can withstand heavy foot traffic, resist wear and tear, and maintain their beauty for decades. This makes them suitable for both residential and commercial applications, including homes, offices, retail spaces, and public buildings. Hardwood flooring works well in rooms of various sizes. It can make small spaces appear larger and create a sense of openness, while also adding warmth and coziness to larger rooms. Its versatility in adapting to different room sizes contributes to its universality.

Slip Resistance: Hardwood flooring, when properly maintained, provides a reasonably slip-resistant surface The natural texture of the wood, combined with the application of appropriate finishes, can help prevent slips and falls, making it safer for occupants

Hygiene and Allergen Control: Hardwood floors are less prone to trapping dust, allergens, and other particles compared to carpets This feature improves indoor air quality and reduces the risk of respiratory issues and allergies, making it a healthier flooring option, particularly for individuals with sensitivities

Maintenance:

Hardwood floors require routine cleaning to remove dust, dirt, and debris This can be done using a soft broom, vacuum with a hardwood floor attachment, or a microfiber mop Periodically, hardwood floors may require refinishing or resealing to restore their original luster and protect against wear This process typically involves sanding the surface and applying a new finish

Ease of Cleaning:

Hardwood floors are relatively easy to clean due to their smooth and non-absorbent surface Regular sweeping or vacuuming can remove loose dirt and debris For deeper cleaning, use a hardwood floor cleaner recommended by the manufacturer or a pHneutral cleaning solution diluted with water Avoid using harsh chemicals or abrasive cleaners that can damage the finish

Replacement:

Over time, hardwood floors may show signs of wear, scratches, or damage that cannot be easily repaired In such cases, replacement of individual boards or sections may be necessary Professional installation is recommended for replacement, especially when matching the existing flooring's species, color, and finish Skilled craftsmen can ensure a seamless and uniform appearance

The LLEN

Hardwood Flooring Characteristics

Indoor Flooring Hardwood Flooring

Fire Resistant & Impact

Resistance

Universality

Fire Resistance: While hardwood flooring is combustible, it has inherent fireresistant properties. Solid hardwood tends to burn slowly, giving occupants more time to evacuate in case of a fire. However, it is essential to note that fire safety measures, such as smoke detectors and fire-resistant coatings, should be in place to enhance overall safety.

Hardwood flooring is susceptible to damage from heavy impacts, such as dropping heavy objects or furniture on the floor. Large and sharp objects can dent or gouge the wood surface, and in some cases, repairs or replacement may be necessary.

Hardwood flooring has a long-standing tradition and is highly sought after in many parts of the world In Taiwan, hardwood flooring is a common choice for residential and commercial properties It is valued for its natural beauty, warmth, and elegance Taiwanese consumers appreciate the aesthetic appeal and durability of hardwood flooring The most popular hardwood species used in Taiwan include oak, teak, maple, and walnut Local manufacturers and suppliers offer a wide range of hardwood flooring options to cater to different design preferences and budgets

Design and Planning:

Choose the appropriate hardwood species, grade, and finish that align with the design vision, functional requirements, and expected foot traffic in different areas of the building

Construction and Installation:

Consideration of the at Each Stage of Building's Life Cycle

Hire experienced flooring professionals who have expertise in hardwood flooring installation techniques Improper installation can lead to issues like buckling, warping, or gaps in the flooring

Occupancy and Use:

Implement a routine cleaning and maintenance schedule to keep the hardwood flooring in optimal condition This includes sweeping, vacuuming, and periodic damp mopping using manufacturer-recommended cleaning products

Renovation and Replacement:

Over time, hardwood floors may show signs of wear and minor damage Consider refinishing the surface to restore its original appearance and protect the wood This process typically involves sanding, staining, and applying a new finish If specific sections of the hardwood flooring are severely damaged or worn, individual boards can be replaced to maintain a consistent look

The LLEN

Hardwood Flooring Comparison

Hardwood Flooring

Material

Appearance

Durability

Value

Material

Appearance

Maintenance

Moisture Resistance

Authenticity

Indoor Flooring Hardwood Flooring

Laminate Flooring

Hardwood flooring is made of natural wood, while laminate flooring consists of a composite core covered with a printed layer that resembles wood

Hardwood flooring offers an authentic, timeless look with natural variations and grains, whereas laminate flooring may have a more uniform appearance

Hardwood flooring is generally more durable and long-lasting, as it can be sanded and refinished multiple times Laminate flooring is less resistant to scratches and cannot be refinished

Hardwood flooring tends to add more value to a property and is often seen as a premium option compared to laminate flooring

Flooring

Hardwood flooring is made of natural wood, while vinyl flooring is made of synthetic materials

Hardwood flooring has a warm, natural look, while vinyl flooring can mimic various materials, including wood, stone, or tile

Hardwood flooring requires regular maintenance, such as refinishing and occasional polishing. Vinyl flooring is low-maintenance and easy to clean.

Hardwood flooring is susceptible to water damage and is not recommended for highmoisture areas. Vinyl flooring is more water-resistant and suitable for areas prone to moisture.

Hardwood flooring offers an authentic, organic feel, while vinyl flooring may lack the same level of authenticity

The LLEN

Indoor WallMDF Wainscoting

Material Introduction

Medium-density fiberboard is a wood-like option, and it’s close to the real thing But, it is a more cost-effective option and comes with a number of benefits. It is created from a combination of wood chips, sawdust, and plant fibers, and provides additional insulation against sound or noise and extreme temperatures. It is created by compressing wood fibers under high pressure and temperature to form a dense and uniform panel MDF is known for its smooth surface, stability, and ease of machining It is widely used in the construction industry for various applications. It, however, has downsides: it is weaker and a lot easier to damage in comparison to real wood This wainscoting material will cost you somewhere in the range of USD$2-4 per linear foot.

The LLEN

Usability

Safety

Maintenance, Ease of Cleaning, Replacement

Indoor Wall MDF Wainscoting

Medium Density Fiberboard (MDF)

Characteristics

Construction and Furniture: MDF is commonly used in the construction industry and furniture manufacturing. MDF panels are used for interior trim, cabinetry, shelving, and other structural components in buildings and furniture.

Interior Design and Decor: MDF offers a smooth and consistent surface, making it ideal for painting, veneering, or laminating. It is often used for decorative purposes, such as wall paneling, molding, baseboards, and doors.

Retail Fixtures and Displays: MDF is widely used in the retail industry for building store fixtures, display units, and stands. Its versatility allows for custom designs, and it can be easily painted or laminated to match branding or aesthetic preferences.

Exhibition and Event Structures: MDF's lightweight nature and ease of fabrication make it suitable for temporary structures used in exhibitions, trade shows, and events.

Soundproofing and Acoustic Applications: It is commonly used in creating sound barriers, speaker enclosures, and acoustic panels for controlling noise in recording studios, home theaters, and commercial spaces.

To ensure safety when using MDF, it is advisable to choose products from reputable manufacturers that meet safety standards and guidelines Proper ventilation, dust control measures, and safe handling practices should be followed during installation and construction By taking these precautions, the potential risks associated with MDF can be minimized, allowing for its safe use in various applications

Maintenance:

MDF is generally low-maintenance and requires minimal upkeep Regular dusting or light cleaning with a soft, dry cloth is usually sufficient to keep the surface clean

Ease of Cleaning:

MDF surfaces are smooth and non-porous, making them relatively easy to clean Dust and dirt can be easily removed using a soft cloth or duster

It's important to dry the MDF surface thoroughly after cleaning to prevent water penetration and potential damage

Replacement:

If a section of MDF needs to be replaced due to damage or wear, it is possible to remove and replace the affected area However, the ease of replacement depends on the specific application and the manner in which the MDF is installed or integrated into the structure

In some cases, replacing a damaged MDF panel may require dismantling or disassembling certain components, such as cabinetry or furniture

When replacing MDF, ensure that the new panel matches the thickness, dimensions, and finish of the existing material for a seamless appearance

The LLEN

Fire Resistant & Impact Resistance

Universality

Consideration of the at Each Stage of Building's Life Cycle

Indoor Wall MDF Wainscoting

Medium Density Fiberboard (MDF)

Characteristics

MDF is considered to be a combustible material, and it can ignite and contribute to the spread of fire. When exposed to high heat, MDF can release toxic gases and smoke. It is important to note that MDF does not have inherent fire-resistant properties. However, there are fire-resistant coatings and treatments available that can be applied to MDF to enhance its fire resistance. These coatings can help delay the ignition and spread of fire, providing additional time for evacuation and fire suppression efforts.

MDF is generally less impact resistant compared to materials like solid wood or plywood. It has a relatively low density, and its composition consists of wood fibers compressed together with a resin binder.To improve the impact resistance of MDF, additional measures can be taken, such as reinforcing the structure with internal supports or adding protective coatings.

MDF (medium-density fiberboard) is a widely used material in both Taiwan and worldwide It is known for its versatility and is commonly used in various applications, including furniture, cabinetry, interior trim, and construction In Taiwan, MDF is readily available and commonly used in the woodworking industry It is used in the production of furniture, kitchen cabinets, shelves, and other interior components On a global scale, it is widely used in the construction and furniture industries as an alternative to solid wood MDF manufacturers can be found in many countries worldwide, including China, the United States, Germany, Malaysia, Brazil, and others

Design and Planning Stage:

Assess the specific requirements of the project and determine if MDF is suitable for the desired applications Consider the structural requirements, load-bearing capabilities, and potential environmental conditions to ensure proper use of MDF

Material Procurement and Installation Stage:

Source MDF from reputable suppliers or manufacturers who adhere to quality standards and sustainability practices Verify that the MDF meets regulatory requirements for formaldehyde emissions and other environmental considerations

Use and Maintenance Stage:

Educate occupants and users about the characteristics and limitations of MDF to promote proper care and maintenance Implement preventive measures to protect MDF surfaces from excessive moisture, heat, and physical damage

Renovation or Replacement Stage:

Assess the condition of existing MDF components and determine if they can be salvaged, repaired, or need replacement Consider the environmental impact and sustainability of disposal methods if MDF needs to be replaced

The LLEN

Cost

Strength and Durability

Surface Finish

Machinability

Environment al Impact

Aesthetics

Applications

Longevity

Indoor Wall MDF Wainscoting

Medium Density Fiberboard (MDF) Comparison

Medium Density Fiberboard (MDF)

Other

MDF is generally more affordable compared to solid wood or other engineered wood products It offers a cost-effective option for projects where budget is a concern

While MDF is not as strong as solid wood, it still provides good strength and stability for many applications However, it is more susceptible to moisture damage and should be protected from prolonged exposure to water

MDF has a smooth and uniform surface, making it ideal for painting, laminating, or veneering It allows for a consistent finish and can achieve a seamless appearance

MDF is easy to work with and can be cut, drilled, and shaped with standard woodworking tools It has uniform density, reducing the risk of splitting or splintering during cutting or shaping

MDF is typically made from recycled wood fibers and resin binders, making it a sustainable choice. However, the manufacturing process often involves the use of adhesives containing formaldehyde, which can emit low levels of volatile organic compounds (VOCs). It is important to choose low-emission or formaldehyde-free MDF to minimize environmental impact.

MDF offers a smooth and consistent surface, making it suitable for a range of finishes and decorative treatments It can be painted, stained, or coated to achieve various looks and styles

MDF is commonly used in furniture, cabinetry, shelving, molding, and interior trim It is less suitable for outdoor applications or areas prone to moisture exposure

Properly maintained, MDF can have a long lifespan However, it is more susceptible to moisture damage compared to materials like solid wood or plywood

The LLEN

Door & Windows

Plywood, Natural Venner

Doors and windows constructed using plywood with a natural veneer finish. Plywood is a type of engineered wood made by bonding multiple layers of thin wood veneers together using adhesives The layers are stacked in alternating grain directions, which adds strength and stability to the panel. Plywood is known for its structural integrity, durability, and versatility. A thin layer of real wood than applied to the surface of the plywood panel to provide a natural and aesthetic appearance The veneer is typically bonded to the plywood using adhesives and then finished with protective coatings. constructing doors and windows with plywood and natural veneer provides a combination of strength, durability, versatility, and aesthetic appeal.

Material Introduction

The LLEN

Door & Windows Plywood, Natural Venner

Plywood

Characteristics

Usability

Plywood is extensively used in the construction industry for various purposes. It is commonly employed for structural sheathing, subflooring, roof decking, wall paneling, and formwork. Its strength and stability make it suitable for providing structural support in buildings. Plywood is a popular choice for furniture and cabinetry due to its strength, durability, and versatility. It can be used to construct cabinet boxes, shelves, drawers, tables, chairs, and other furniture components.

Safety

Maintenance, Ease of Cleaning, Replacement

To ensure plywood safety, it is recommended to select plywood that complies with relevant industry standards and certifications, such as those related to formaldehyde emissions, structural integrity, or fire resistance It is also crucial to follow proper handling, installation, and maintenance practices to minimize potential risks associated with plywood use

Maintenance:

Routine cleaning of plywood surfaces can be done using a soft cloth or mop dampened with water or a mild, non-abrasive cleaning solution Avoid using harsh chemicals or abrasive cleaners that can damage the surface

Ease of Cleaning:

Smooth Surface: Plywood generally has a smooth surface that is easy to clean Dust, dirt, or spills can be easily wiped or mopped away with a damp cloth or mop

Stain Removal: For stubborn stains, it is important to promptly clean them using appropriate methods and cleaning agents recommended for the specific type of stain Always test any cleaning product on a small, inconspicuous area of the plywood before applying it to the entire surface

Replacement:

Damage Assessment: In the event of severe damage, such as extensive water damage, significant impact, or structural deterioration, the plywood may need to be replaced Assess the extent of the damage to determine if replacement is necessary

Professional Assistance: For complex replacement tasks or structural components, it is recommended to seek the assistance of a professional contractor or carpenter who has experience working with plywood

Proper Installation: When replacing plywood, ensure that it is properly installed, adhering to recommended installation guidelines and using appropriate fasteners and adhesives

The LLEN

Fire Resistant & Impact

Resistance

Universality

Consideration of the at Each Stage of Building's Life Cycle

Door & Windows

Plywood, Natural Venner

Plywood

Characteristics

Plywood is a combustible material and can contribute to the spread of fire. However, certain types of plywood, such as fire-rated or fire-resistant plywood, are available and designed to offer increased fire resistance. It is crucial to consider the fire safety requirements of the specific application and select plywood accordingly.

Plywood offers good impact resistance compared to some other building materials. The layered construction of plywood, with alternating grain directions in each layer, provides inherent strength and resilience.

Plywood is widely used in Taiwan and around the world due to its versatility, affordability, and structural properties

Design and Planning Stage:

Structural Integrity: Plywood's strength and load-bearing capabilities make it suitable for structural applications such as walls, floors, and roofs. Consider the specific design requirements and consult with engineers or architects to determine the appropriate plywood grade, thickness, and layout.

Construction Stage:

Ensure that the plywood being used meets relevant industry standards and certifications. Check for proper grading, adhesive quality, and absence of defects or damage that may affect its performance.

Occupancy Stage:

Implement regular cleaning and maintenance practices to keep the plywood surfaces clean and in good condition Follow the manufacturer's guidelines for cleaning agents, avoiding abrasive cleaners that can damage the surface

Renovation or Demolition Stage:

Reusability: Evaluate the condition of the plywood during renovation or demolition projects Depending on its condition, plywood may be salvaged, reused, or recycled if it meets the necessary quality standards

Responsible Disposal: If the plywood cannot be reused or salvaged, ensure proper disposal following local waste management regulations and environmental guidelines

The LLEN

Door & Windows Plywood, Natural Venner

Plywood Comparison

Plywood

Strength and Durability

Moisture Resistance

Cost

Surface Finish

Environment al Impact

Machinability

Applications

Longevity

Aesthetics

Other

Plywood is known for its strength and durability, making it a reliable choice for structural applications Compared to materials like particleboard or MDF (medium-density fiberboard), plywood offers higher strength and load-bearing capacity

Plywood can vary in moisture resistance depending on the type of adhesive used and the presence of exterior-grade or marine-grade options It generally offers better moisture resistance compared to materials like solid wood, making it suitable for use in areas prone to humidity or occasional moisture exposure

Plywood is typically more affordable than solid wood or other engineered wood products It provides a cost-effective option for various construction projects

Plywood surfaces are generally smooth and consistent, making it suitable for painting, veneering, or laminating It allows for a wide range of surface finishes and decorative treatments

Plywood can be sourced from sustainably managed forests and certified for its environmental performance. However, it is important to consider the sourcing and production practices of the specific plywood product to ensure its sustainability.

Plywood is relatively easy to work with and can be cut, drilled, and shaped using standard woodworking tools It offers good dimensional stability and resistance to splitting or cracking during fabrication

Plywood has a wide range of applications across various industries It is commonly used in construction for structural sheathing, subflooring, roofing, and wall paneling It is also popular in furniture making, cabinetry, packaging, and DIY projects

Properly maintained, plywood can have a long lifespan However, its durability may vary dependingon the grade and exposure to moisture or environmental factors

Plywood can have a natural wood grain appearance, which can be enhanced with the use of veneers or surface treatments It provides a warm and natural look that can be incorporated into interior design and decorative applications