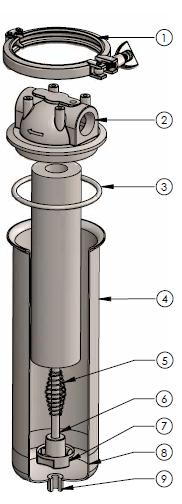

ERE INC manufactures the SampsonTM High Pressure Filter Housings that are made of a high quality 304 or 316 stainless steel. Great for many industrial applications. Also available in a custom made sanitary finish for pharmaceutical and food grade applications. ERE INC also manufactures filter bags which are sold separately.

Features

• Available in a 90 GPM and a 180 GPM

• Available in 304 and 316 Stainless Steel

• Operating Temperature 750C

• Operating Pressure 150 PSI

• Design Pressure 225 PSI

Applications

• Petrochemical

• Construction

• Cosmetic

• Medical

• Textile

• Food

• Pharmaceutical

• Waste water

• Beverage

• Etc...

Accessories

1. What are you filtering?

2. How large are the particles?

3. What is your desired flow rate?

4. What are the conditions (flow, pressure, temperature) of the process?

5. What is the quality of filtration required?

6. Will you require treatment of the liquid?

Both models come in standard with Note

• 2" In & Outlet

• FNPT

• Side in and bottom out

• EPDM O-Rings

• Acid wash interior finish

• Electrolyzed exterior finish

• Other configurations available upon request

Handle

Vent

O-Ring

Top Cover

Shell Flange

Eye Bolt 7. Filter Bag Plate

8. Port Inlet 9. Shell

Basket 11. Port Outlet

Support Leg

• Compatible with all filter bags (all micron sizes and materials)

• Max operating temperature is 75º C

• Size of pressure gauge holes on cover is ¼"

• Polypropylene

• Nylon

• Polyester

• 0.5 - 2000 micron sizes

1440,

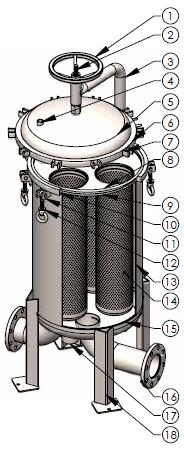

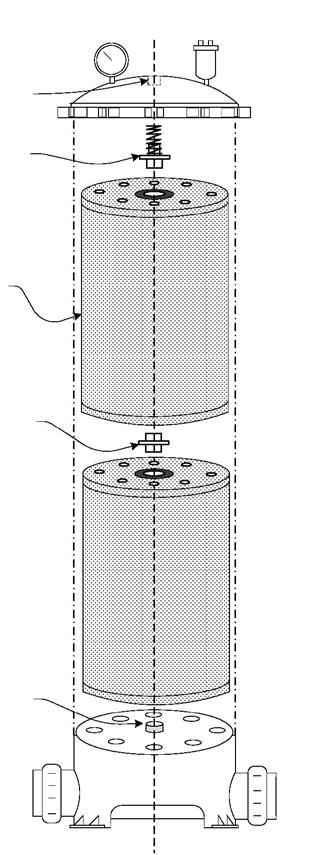

ERE INC manufactures the SampsonTM Stainless Steel Multi-Bag Filter Housings. Great for sediment filtration in high pressure applications up to 150 PSI Constructed of high quality stainless steel. ERE INC also offers manufactures Bages which are sold separately.

Features

• Available in a standard 540 (3 bags) , 720 (4bags) and 1080 (6 bags) GPM

• Available in 304 and 316 Stainless Steel All models come standard with: 4" (540 & 720 GPM) 6" (1080 GPM) In & outlet ANSI

• Bottom in and bottom out

• EPDM O-rings

• Acid wash interior finish

• Electrolyzed exterior finish

• Side entry designs and other configurations are available upon request

Note

• Compatible with all filter bags (all micron sizes and materials)

• Max operating temperature is 75°C

• Size of pressure gauge holes on cover is ¼"

Applications

• Petrochemical

• Construction

• Cosmetic

• Chemical

• Textile

• Food

• Pharmaceutical

• Waste Water

• Etc...

1. What are you filtering?

2. How large are the particles?

3. What is your desired flow rate?

4. What are the conditions (flow, pressure, temperature) of the process?

5. What is the quality of filtration required?

6. Will you require treatment of the liquid?

ERS-720-BB-SS304-6F 22" Ø- 61" 7" x 32" (Bag #2)(4) 4"

ERS-720-BB-SS316-6F 22" Ø- 61" 7" x 32" (Bag #2)(4) 4"

ERS-900-BB-SS304-6F 24" Ø- 66" 7" x 32" (Bag #2)(5) 6" Flange

ERS-1080-BB-SS304-6F 24" Ø- 66" 7" x 32" (Bag #2)(6) 6"

24" Ø- 66" 7" x 32" (Bag #2)(6) 6

ERS-1100-BB-SS304-6F 24" Ø- 66" 7" x 32" (Bag #2)(6)

ERS-1100-BB-SS316-6F 24" Ø- 66" 7" x 32" (Bag #2)(6)

ERS-1260-BB-SS304-6F 30" Ø- 70" 7" x 32" (Bag #2)(7)

(Bag #2)(7) 6"

ERS-1440-BB-SS316-6F 30" Ø- 74" 7" x 32" (Bag #2)(8) 6"

32" Ø- 78" 7" x 32" (Bag #2)(9)

ERS-1660-BB-SS316-8F 32" Ø- 78" 7" x 32" (Bag #2)(9)

ERS-1900-BB-SS304-8F 34" Ø- 79" 7" x 32" (Bag #2)(10) 8" Flange

ERS-1900-BB-SS316-8F 34" Ø- 79" 7" x 32" (Bag #2)(10) 8"

ERS-2160-BB-SS304-8F 38" Ø- 81" 7" x 32" (Bag #2)(12) 8" Flange

ERS-2160-BB-SS316-8F 38" Ø- 81" 7" x 32" (Bag #2)(12) 8" Flange 150

* Side entry designs are available upon request.

1. Turntable 2. Screw rod

Davit

Vent

Top cover 6. Top cover flange

Eye nut socket 8. O-ring

Filter bag plate

Shell flange

Eye bolt socket 12. Eye bolt

Shell

Basket

Bottom cover 16. Port (Inlet/outlet)

Drain

Support leg

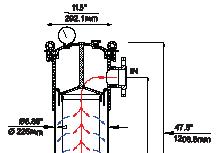

SampsonTM’s Bag Filter Housings are characterized with high precision, high flow capacity, easy installation and maintenance. Their unique body design made of uPVC makes them ideal for corrosive environments and processes.

Features Applications

• Most parts of this filter are made of uPVC

• uPVC material is resistant to corrosion

• Light weight design and very easy to install

• Side entry and bottom outlet

• The distribution system is from top (side entry) to bottom

• The lid and the body are connected using flanges to ensure the housing can withstand higher pressure

• Petrochemical

• Construction

• Cosmetic

• Chemical

• Medical

• Textile,

• Food (waste water)

• Etc...

• Compatible with most filter bags

• Max. operating temperature is 45°C

• Size of pressure gauge holes on cover is ¼"

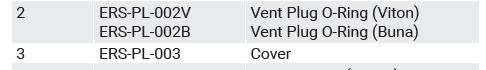

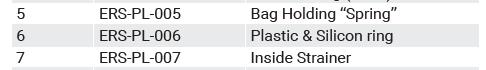

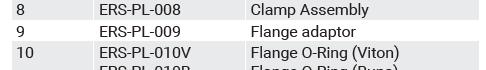

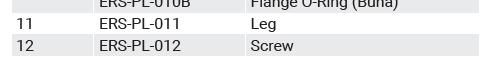

Part Number

Description

OBS-GO-0-030PP 0-30 PSI Pressure Gauge ¼" Connection

OBS-GO-0-060PP 0-60 PSI Pressure Gauge ¼" Connection

OBS-GO-0-100PP 0-100 PSI Pressure Gauge ¼" Connection

WA-FV-4M1-1/4

Automatic Air Vent ¼" Connection

ERS-PL-004S Silicone O-ring

ERS-PL-004B Buna O-ring

ERS-PL-005 Filter Holder

ERS-PL-006 Plastic & Silicon Ring

ERS-PL-007 Inside Filter Basket

ER-SAMPLEPORT Sampling Port Assembly (Pressure Gauge Required)

ERS-180-SE-PL

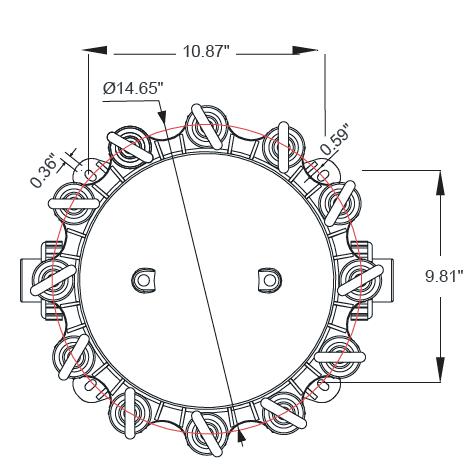

Flow Diagram

Mechanical drawing

PE = FELT POLYESTER

MICRONS = 1, 5, 10, 25, 50, 75, 100, 200

PO = FELT POLYPROPYLENE

MICRONS = 1, 3, 5, 10, 25, 50, 75, 100, 200

PEM = MESH, POLYESTER

MULTIFILAMENT

MICRONS = 100, 150, 200, 250, 300, 400, 500, 600, 800, 1000, 1500, 2000

NMO = MESH NYLON

MONOFILAMENT

MICRONS = 1, 5, 10, 25, 50, 75, 100, 150, 175, 200, 250, 300, 400, 500, 600, 800, 1000, 1200

POMB = OIL REMOVAL

MATERIAL

POXL = FELT POLYPROPYLENE EXTENDED LIFE

MICRONS = 1, 5, 10, 25, 50, 100

NX = NOMEX ARAMID FIBERS

MICRONS = 1, 5, 10, 25, 50

Determine the type of contaminants to be removed

Select the micron size of the bag according to the size of the particles to be filtered out

P = NONE

C = CEREX

PEM = POLYESTER

MULTIFILAMENT COVER

NMO = NYLON

MONOFILAMENT COVER

Flow rate, Pressure & Temperature

Choose filter according to flow rate, pressure and temperature of the system

S = CARBON STEEL RING

SS = STAINLESS STEEL

P = POLY

DS = DRAWSTRING

OTHER OPTIONS AVAILABLE

W = WELDED SIDE + BOTTOM

SS = STICHED SIDE + BOTTOM (SPECIAL ORDER)

Chemical Compatability and Viscosity

Base final selection of the filter on chemical compatability and viscosity of the influent

Determine if single stage or multi stage filtration needed

Base final selection on type of liquid to be filtered

* To verify compatibility, immersion tests should be conducted

Sampson™’s PLATINUM Polypropylene needle felt filter media is surface treated to prevent downstream fibre migration. Standard felts can be used in a multitude of industrial processes and are silicone free for automotive and paint appllications. In addition, our polypropylene felts are made from FDA and EU compliant materials for food contact applications.

Features Applications

• FDA and EU compliant materials for food applications

• Surface treated prevents fiber migration

• Size 1-4 bags (other sizes also available)

• Micron Rating, 1, 3, 5, 10, 25, 75, 50, 100, 200

• Available with steel , stainless steel, plastic ring or no ring

• Welded sides and bottom prevents unnecessary fluid by pass

• Sewn also available upon request

• Embossed media and micron

• Pharmaceutical and cosmetics

• Food & beverage

• Paint, costing, ink and adhesives

• Industrial wastewater

• Oil and gas

• Groundwater

• Etc...

* All above part numbers include handles and plastic ring (other models and sizes available upon request)

* See page 8 for more options

Sampson™’s PLATINUM Polyester filter bags are filtration components made from polyester fibers. These bags are designed to capture and filter particles from various fluids, such as liquids or gases, in industrial processes. The polyester material offers durability and resistance to abrasion, making these filter bags suitable for challenging environments. Known for their efficient particle retention capabilities, polyester filter bags are commonly used in applications where fine filtration is essential. They are employed in diverse industries, including water treatment, chemical processing, and manufacturing, to ensure effective separation of impurities and contaminants from the process fluids.

Features Applications

• FDA and EU compliant materials for food applications

• Surface treated prevents fiber migration

• Size 1-4 bags (other sizes also available)

• Micron Rating 0.5, 1, 5, 10, 25, 75, 50, 100, 200

• Available with steel or plastic ring

• Welded sides and bottom prevents unnecessary fluid by pass

• Embossed media and micron

• Food Industries

• We can also customize your bag

• Pharmaceutical and cosmetics

• Food & beverage

• Paint, costing, ink and adhesives

• Industrial wastewater

• Oil and gas

• Groundwater

• Chemical

• Water Treatment

• Etc...

* All above part numbers include handles and plastic ring (other models and sizes available upon request)

* See page 8 for more options

SampsonTM’s PLATINUM Nylon Monofilament (NMO) precision woven filtration media offers enhanced removal characteristics and improved strength and durability. Each filament in the weave has been extruded with a consistent yarn diameter enabling the filtration structure to deliver exact pore openings. As well, the smooth extruded surface allows the filter to be cleaned and reused in certain applications.

Features Applications

• Size 1-4 bags (other sizes also available)

• Micron Rating 1 to 1200

• Silicone free thread and double stitched for maximum strength

• Raised integral handles make bag change-out quick and easy

• Available with steel, stainless steel or plastic ring

• We can also customize your bag

• Paint

• Coating

• Ink

• Adhesives

• Automotive

• Industrial wastewater

• Oil & gas

• Etc...

NMO-25-P4P-P

50 NMO-50-P1P-P NMO-50-P2P-P NMO-50-P3P-P NMO-50-P4P-P

75 NMO-75-P1P-P NMO-75-P2P-P

NMO-100-P1P-P NMO-100-P2P-P NMO-100-P3P-P NMO-100-P4P-P

125 NMO-125-P1P-P NMO-125-P2P-P NMO-125-P3P-P NMO-125-P4P-P

150 NMO-150-P1P-P NMO-150-P2P-P NMO-150-P3P-P NMO-150-P4P-P

175 NMO-175-P1P-P NMO-175-P2P-P NMO-175-P3P-P NMO-175-P4P-P

200 NMO-200-P1P-P NMO-200-P2P-P NMO-200-P3P-P NMO-200-P4P-P

250 NMO-250-P1P-P NMO-250-P2P-P NMO-250-P3P-P NMO-250-P4P-P

300 NMO-300-P1P-P NMO-300-P2P-P NMO-300-P3P-P NMO-300-P4P-P

400 NMO-400-P1P-P NMO-400-P2P-P NMO-400-P3P-P NMO-400-P4P-P

500 NMO-500-P1P-P NMO-500-P2P-P NMO-500-P3P-P NMO-500-P4P-P

600 NMO-600-P1P-P NMO-600-P2P-P NMO-600-P3P-P NMO-600-P4P-P

800 NMO-800-P1P-P NMO-800-P2P-P NMO-800-P3P-P NMO-800-P4P-P

1000 NMO-1000-P1P-P NMO-1000-P2P-P NMO-1000-P3P-P NMO-1000-P4P-P

1200 NMO-1200-P1P-P NMO-1200-P2P-P NMO-1200-P3P-P NMO-1200-P4P-P

* All above part numbers include handles and plastic ring (other models and sizes available upon request)

* See page 8 for more options

SampsonTM’s PLATINUM Polyester multifilament mesh series provides an economical alternative to monofilament mesh. Multifilaments are woven from yarns where each strand within the yarn is comprised of many smaller filaments twisted together to create strong, but economical media. Available with a full range of sizes and retainer options, the polyester mesh media provides good dirt removal capacity in a wide range of micron ratings.

Features Applications

• Size 1-4 bags (other sizes also available)

• Micron Rating 100 to 2000

• Strong, but economical filter

• Silicone free thread and double stitched for maximum strength

• Raised integral handles make bag change-out quick and easy

• Available with steel, stainless steel or plastic ring

• We can also customize your bag

• Automotive

• Food and beverage

• Petrochemical

• Paint and ink

• Coatings

• Adhesives

• Oil and gas

• Etc...

100 PEM-100-P1P-P PEM-100-P2P-P PEM-100-P3P-P

PEM-100-P4P-P

150 PEM-150-P1P-P PEM-150-P2P-P PEM-150-P3P-P PEM-150-P4P-P

200 PEM-200-P1P-P PEM-200-P2P-P PEM-200-P3P-P PEM-200-P4P-P

250 PEM-250-P1P-P PEM-250-P2P-P PEM-250-P3P-P PEM-250-P4P-P

300 PEM-300-P1P-P PEM-300-P2P-P PEM-300-P3P-P PEM-300-P4P-P

400 PEM-400-P1P-P PEM-400-P2P-P PEM-400-P3P-P PEM-400-P4P-P

500 PEM-500-P1P-P PEM-500-P2P-P PEM-500-P3P-P PEM-500-P4P-P

600 PEM-600-P1P-P PEM-600-P2P-P PEM-600-P3P-P PEM-600-P4P-P

800 PEM-800-P1P-P PEM-800-P2P-P PEM-800-P3P-P PEM-800-P4P-P

1000 PEM-1000-P1P-P PEM-1000-P2P-P PEM-1000-P3P-P PEM-1000-P4P-P

1500 PEM-1500-P1P-P PEM-1500-P2P-P PEM-1500-P3P-P PEM-1500-P4P-P

2000 PEM-2000-P1P-P PEM-2000-P2P-P PEM-2000-P3P-P PEM-2000-P4P-P

* All above part numbers include handles and plastic ring (other models and sizes available upon request)

* See page 8 for more options

SampsonTM’s PLATINUM Polypropylene oil adsorbing filters has multi-layer construction makes use of the dirt loading attributes of needle felt media combined with the oil adsorbing capabilities of polypropylene microfibre. This combination creates a double-duty filter by removing both particulate and traces of non-emulsified oils from process streams.

Polypropylene microfibre is well known for its ability to adsorb oil. Its chemical composition and unique pore structure serve as a magnet to non-emulsified oils. Oils are drawn to, and trapped within, the multitude of void in the microfibre media. As a result, microfibre media can hold up to 7 times its weight in oil, dependent upon process variables such as the oil viscosity and process flow rate.

Features Applications

• Filters particulate and oils

• Available from 1 to 100 micron

• Can hold up to 7 times its weight in oil depending on viscosity and flow rate

5 POMB-5-P1SH-P

10 POMB-10-P1SH-P

25 POMB-25-P1SH-P

50 POMB-50-P1SH-P

100 POMB-100-P1SH-P

POMB-5-P2SH-P

POMB-10-P2SH-P

POMB-25-P2SH-P

POMB-50-P2SH-P

POMB-100-P2SH-P

• Industrial parts manufacturing

• Chemical process

• Industrial process water

• Etc..

POMB-5-P3SH-P

POMB-10-P3SH-P

POMB-25-P3SH-P

POMB-50-P3SH-P

POMB-100-P3SH-P

POMB-5-P4SH-P

POMB-10-P4SH-P

POMB-25-P4SH-P

POMB-50-P4SH-P

POMB-100-P4SH-P

* All above part numbers include handles and plastic ring (other models available upon request)

* See page 8 for more options

SampsonTM’s PLATINUM PSORB filter bags contain a specially constructed blend of media creating an engineered core of virgin shredded microfibre. The unique design of the PSORB bag channels the flow of the process fluid through the oil adsorbing core for greater adsorption. The PSORB filter is manufactured with an internal impermeable media layer, which channels the process fluid through the microfibre core, thereby increasing contact time and opportunity for adsorption.

The PSORB filter bag is designed for maximum flows of 5 to 10 GPM (1.13m3/hr to 2.27m3/hr) to allow for optimum extraction of non-emulsified oil from a fluid stream. Residence time and increased surface area of the microfiber core allow for peak performance.

Features

• PSORB filter bags contain a specially constructed blend of media creating an engineered core of virgin shredded microfibre

• Increased available surface area for oil adsorption

• Felt media has outer surface treatment to prevent loose fibres and downstream migration

• The best performance for the PSORB filter bag is in a low flow application with flows of 5 to 10 GPM

• Retainer is made from chemically resistant FDA compliant polypropylene resin and offers a unique four-point positive seal

• Polypropylene felt filter bag series is available in 1, 5, 10, 25, 50, 100, and 200 microns

PSORB-1-P1SH-P

Applications

• Industrial Parts Manufacturing

• Chemical Process

• Industrial Process Water

• Metal Casting

• Etc...

PSORB-1-P2SH-P 5

PSORB-5-P1SH-P

PSORB-10-P1SH-P

PSORB-25-P1SH-P

50

100

200

PSORB-50-P1SH-P

PSORB-100-P1SH-P

PSORB-200-P1SH-P

* All above part numbers include handles and steel ring

PSORB-5-P2SH-P

PSORB-10-P2SH-P

PSORB-25-P2SH-P

PSORB-50-P2SH-P

PSORB-100-P2SH-P

PSORB-200-P2SH-P

The SampsonTM filter series offers a broad spectrum of oil adsorbing options from light duty adsoptions to the most critical applications. Designed to remove a full range of non-emulsified oil and dirt from process streams the series includes the POMB, PSORB, OWS and 500 series configurations.

OWS Series

OWS bags (oil water separator) are manufactured with a granular activated carbon core making it the most effective of the oil adsorbing filter bag.

For maximum retrieval of trace amounts of oil, the OWS activated carbon filter bag offers the best performance of all the oil adsorbing filter bags. OWS filters are designed for low flow applications where residence time and expanded surface area allow for superior retention. Using the latest in manufacturing technology, the OWS filters feature an impermeable inner liner which channels fluid through the centre core filled with oil adsorbing activated granular carbon.

Granular activated carbon is a form of carbon specially processed to be riddled with small, low-volume pores that increase the surface area available for oil adsorption. The result is increased oil adsorption capacity of up to 12.9L.

The OWS bags can be custom made in configurations to fit a variety of systems and processes. In addition, OWS bags can be purchased pre-filled with activated carbon or carbon ready so that the end user can fill the bags on-site with the carbon media of their choosing.

Pre-filled for immediate installation

Carbon ready for on-site filling

Oil Adsorption Capacity (liters)

Size Dimension GPM m3/h

2 7 Ø x 32" 2 0.45

Maximum Operating Temperature 200 °F / 93 °C

Change out when Activated Carbon media reaches saturation or when effluent quality is compromised

Applications

Typical applications suited to OWS filter bags include:

• Industrial Parts Manufacturing

• Chemical Process

• Industrial Process Water

• Metal Casting

Product Codes Example: OWS-PO-5-AC2SH-P

The SampsonTM high efficiency filter bags have been designed for demanding applications that require critical particle size retention and dirt holding capacity. Constructed from chemically resistant polypropylene microfibre for a wide range of process applications, SampsonTM filter bags can achieve particle retention efficiencies of up to 99.9%† Configured from gradient density layers, SampsonTM filter bags provide all the benefits and convenience of a filter bag system at lower operating costs than other high efficiency technologies.

All SampsonTM high efficiency filter bags are manufactured from chemically resistant polypropylene microfibre media. Multiple layers of polypropylene microfibre media are combined to create a high-loft filter with excellent dirt holding characteristics. The layers are arranged for graded density filtration with the inner layers serving as a pre-filter to remove coarse particles, while the denser outer layers progressively remove finer particles for a polishing effect.

Thermally bonded components coupled with staggered seam construction combine to achieve improved particle retention efficiencies of up to 99.9%.

† Efficiency data verified by independent testing laboratory

Codes Example: POMF 1 HE2P

Applications

Typical applications suited to SampsonTM filter bags include:

• Automotive

• Food, Beverage and Petrochemical

• Paint, Coatings, Ink and Adhesives

• Oil and Gas

Polyprolylene

S Zinc Plated Steel Ring SS Stainless Steel

* All above part numbers include handles and plastic rings (other models and sizes available upon reques)

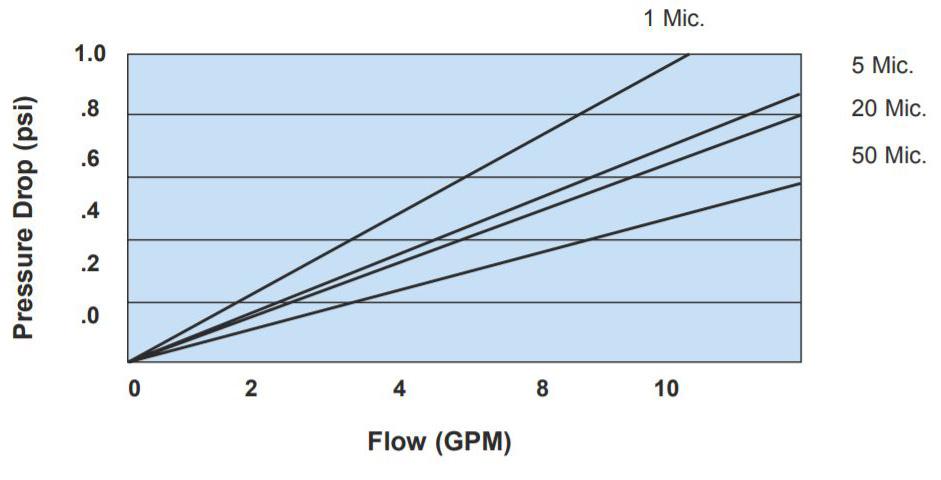

To Use Chart

• Select micron rated bag at the top of the chart.

• Follow the corresponding vertical row down until it intersects the selected viscosity in centipose.

• The left number in the square indicates the flow rate for a size #1 filter bag at 1 PSI pressure drop and the right number represents the flow rate for a size #2 (both figures are in US GPM).

Notes

• A For greater than 1 PSI ΔP simply multiply the resultant GPM times PSI desired to obtain flow - or - divide desired flow by the resultant flow to obtain ΔP

• B For #3 size filter bag multiply size 1 flow rate by 0.28

• C For #4 size filter bag multiply size 1 flow rate by 0.44

• D For bags with covers reduce results by 25%

To calculate the required amount of size #2 filter bags you must know the micron size, the viscosity and the desired flow rate of the bag. Use the following formula:

Example: If you want to use a 10 micron, size 2, Polyester felt filter bag @ 150 GPM, 200 CPS with 3 lbs ΔP:

Desired flow (150)

Flow rate from chart (33.84) ÷ Target clean delta P (3.0) = 1.47 bags (Round up to eliminate decimal points = 2 bags)

PE, PO:

Polyester, Polypropylene Felts

NMO, PEM:

Nylon Monofilament & Polyester Multifilament Woven Mesh

* Dirt load and temperature may vary the results Filter Bag Flow Rate @ Desired Viscosity with 1 PSI Delta P for Size 1/Size2 Filter Bags

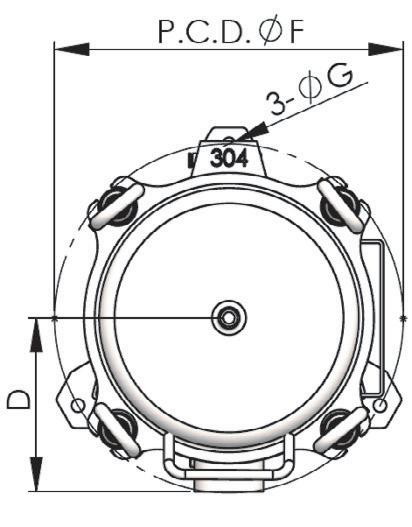

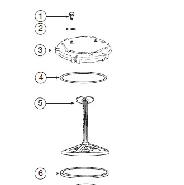

ERE INC manufactures the SampsonTM Stainless Steel Cartridge Housings. Great for sediment filtration in high pressure applications up to 150 PSI. Constructed of high quality stainless steel.

ERE INC also manufactures cartridges which are sold separately

Features Applications

• Lighweight and easy installation.

• Wall-hanging installation makes for space-saving.

• O-ring design improves sealing and prevents loosening

• Clamp type clousure for fast installation and easy filter cartridge change-outs without any tools.

• Acid washed

• Electropolished

• Operating Temperature 750C

• Chemicals

• Petrochemical

• Beverage

• Food

• Electroplating

• High temperature manufacturing processes

* Also available in 222 or 226 connection. As well as in 316 stainless steel

• RO Pre-filtration process

• Water filtration

• Pharmaceutical

• Sewage treament

• Electronic

• Etc...

1. What are you filtering?

2. How large are the particles?

3. What is your desired flow rate?

4. What are the conditions (flow, pressure, temperature) of the process?

5. What is the quality of filtration required?

6. Will you require treatment of the liquid?

Sampson™'s Cartridge Filters Housings are high precision filtration systems. Their unique body design made of uPVC makes them ideal for corrosive environments and processes.

Industries where it can be used are: electronics, sewage treatment, beverage, foods, pure water treatment, home water purification, etc.

Features

• All the parts of this filter series are made of uPVC

• uPVC material has a good corrosion resistance

• Light weight design and very easy to install

• The inlet and outlet are in line

• The distribution system is from bottom to top (see flow diagram)

• Cartridges are easy to install, push down and close, preventing inside leaking

• The lid and the body are connected using flanges to ensure the housing can withstand higher pressure

• Compatible with all cartridges 2 ½″ to 2 ⅞″ (all micron sizes and materials)

• Max. operating temperature is 45°C,

• Size of pressure gauge holes on cover is ¼″

The SampsonTM brand of filters have been around since 1979. ERE INC. continues to manufacture High Quality Filtration products. Made of high purity 100% polypropylene. These Sampson™ cartridges are made for industrial applications where an inner core is required. Can withstand high pressures and will not implode. Available in different lengths and micron sizes.

Features

• Depth filtration

• 100 % high purity polypropylene

• Rigid polypropylene core

• No adhesives

• Thermally bonded

• Withstands pH levels from 1-13

• High dirt capacity hold

• Manufactured in a clean room

• Low cost

• High particle retention efficiency

• Durable

• DOE (double open ended)

Applications

• Cooling water

• Power generation

• Chemicals

• Oil & gas

• General industrial

• Food & beverage

• High pressure applications

• Etc...

Normal operating temperature

Max. operating temperature

Normal

Reverse

* Special orders are available on bulk quantity

<50ºC (122º F)

(176º F)

Depth filters are commonly seen as wound string, spun, or “melt-blown” cartridges that trap particles of larger size on the surface, and smaller particles under the surface down to the center core. They work best when a variety of particle sizes are being filtered. Depth filters remove more sediment and hold more sediment in general, without losing pressure, than a surface filter cartridge.

ERE INC manufactures a vast variety of cartridges include the String Wound Cartridges. Many different models to choose from. Available in different materials and sizes depending on your application.

Features

• Precision winding patterns ensure filtration ratings that are ac-curate and result in high retention efficiency.

• In-house state-of–the-art production machinery ensures repeat-able and consistent high quality products.

• Various fiber and core materials are available to suit a broad range of applications.

• Suitable for both liquid and gas filtration.

• Cost effective and proven versus melt blown, spun-bond and resin bonded cartridges.

• Available in standard 2-1/2" diameter and others.

• Many different cartridge sealing options and end configurations are available.

Applications

• Oils

• Air / Gas

• Petrochemicals

• Photo Solutions

• Process Water

• Food & Beverage

• Solvents

• Pre-filtration

• Paint / Inks

• Water & Wastewater

• Chemicals

• Etc...

B = 2.00" (51 mm)

D = 2.75" (70 mm)

= Polyester

= 29-1/2" (749 mm)

= 30" (762 mm)

* The example shown above is a bleached cotton cartridge, 0.5 micron filtration, 1-½" OD, 9¾" long with a core. No Options selected.

Exceptional value with depth filtration is required

Features

• Excellent chemical resistance

• Food grade ingredients

• No leachables

• High dirt holding capacity

• Wide range of lengths and micron ratings

Specifications

Material

Maximum temperature

Maximum pressure

Recommended change out

Maximum flow rate

Cartridge packaging

Types

Micron ratings

Pressure Drop

Applications

• Potable water

• Beverages

• Pre-filtration for reverse osmosis equipment

• Fine chemicals

• Electronics

• Plating solutions and more!

Melt blown polypropylene

140˚ F / 60˚ C

40 PSI

30 PSI

2-8 GPM (based on micron rating)

Individually shrink wrapped for purity

Standard, Full-Flow

1, 5, 20 and 50

*Other micron sizes are available on bulk orders

SampsonTM’s Single and Double Barrel filters housings are the filtration systems of the future.

The Single and Double-Barrel filter line is the new way to do hydrocarbon removal for in-situ applications because of their light weight and ease of manipulation compared to the standard carbon drum. Use the MAGNUM media cartridges to meet the requirements of your application.

Their unique light body design and ease of maintenance makes them ideal for on site applications or closed space environments and processes.

Features Applications

• All the parts of this filter series are made of uPVC

• uPVC material has a good corrosion resistance

• Lightweight design and very easy to install

• The inlet and outlet are in line

• Cartridges are easy to install and replace

• The lid and the body are connected using flanges to ensure the housing can withstand higher pressure

• Can be installed vertically or horizontally

• Can be installed in series or parallel

• Oil/Water Separation

• Industrial Waste Water

• Food Waste Water

• Fuel Depots

• Compressor Condensate

• Garages

• Equipment Wash Down

• Carwash

• Remediation Sites

• Etc…

• Compatible with ERE’s MAGNUM UltraSorber™, UltraSorber Plus™ and SuperSorber™ media cartridges

• Max. operating temperature is 45°C

• Size of pressure gauge holes on cover is ¼"

Part Number Model Description

ER-89-000-001-04

ER-89-000-001-05

ER-89-000-001-06

MAGNUM UltraSorber™ Cartridge Canisters

MAGNUM UltraSorber™ Plus

MAGNUM SuperSorber™ Cartridge Canisters

Accessories also available!

Contains: UltraSorber™ Media for Low to High Molecular Weight Contaminants and Color Removal 30

Contains: UltraSorber Plus™ Media for Dissolved MOG Removal and Low to High Molecular Weight Contaminants Removal 50 lbs

Contains: SuperSorber™ Media for Total Petroleum Hydrocarbons (TPH), Oil and Grease and Soluble Hydrocarbons Removal

Part Number Description

OBS-GO-0-030PP 0-30 PSI Pressure Gauge ¼" Connection

OBS-GO-0-060PP 0-60 PSI Pressure Gauge ¼" Connection

OBS-GO-0-100PP 0-100 PSI Pressure Gauge ¼" Connection

WA-FV-4M1-1/4 Automatic Air Vent ¼" Connection

42 lbs

ER-89-000-002-OR O-ring for Lid on the Single or Double Barrel Housings

ER-89-000-002-OR O-ring for In/Outlet on the Single or Double Barrel Housings

ER-89-000-002-RD 3" to 2" Reducer for In/Outlet

5. Put the cover and align spring in the

4. Put the spring plug in the top of second cartridge

3. Put the second cartridge in the vessel and align with special spacer

2. Put the special spacer in the top of first cartridge

1. Put the first cartridge in the vessel and align whith bottom middle orifice

Water flow diagram Mechanical drawing Cartridge installation

Is Your Filtration Application? 1. What are you filtering? 2. How large are the particles? 3. What is your desired flow rate? 4. What are the conditions (flow, pressure, temperature) of the process? 5. What is the quality of filtration required?

6. Will you require treatment of the liquid?

DESCRIBE THE APPLICATION:

DESCRIPTION OF THE PRODUCT TO BE FILTERED:

Water ( ) Acid ( ) Base ( ) Solvent ( ) Other ( )

Viscosity ( ) cps (centipoise)

DESCRIPTION OF THE CONTAMINANT:

Type :

Concentration :

DESIRED MICRONS

Required Flow Rate ( gallons / minute) ( litres / minute) ( cubic meter / minute)

FEED PRESSURE ( ) psi ( ) bar ( ) kPa

LIQUID TEMPERATURE ( ) °F ( ) °C

STANDARDS ( ) FDA ( ) NSF ( ) OTHER

FILTRATION GOALS:

SYSTEM TYPE Filters Bag Cartridges Backwash ( ) ( ) ( )

FILTRATION UNIT

Plastic ( ) Steel ( ) Stainless Steel 304 ( ) Stainless Steel 316 ( )

Male NPT fittings ( ) Female NPT fittings ( ) Flange ( ) Sanitary ( )

Electropolishing ( ) Mechanical polishing ( )

FILTRATION MEDIA

Bag Filter: PO ( ) PE ( ) PEM ( ) NMO ( )

Pleated Cartridge: Cellulose ( ) Cellulose-Acetate ( ) Polypropylene( )

Other Cartridge Types: Spun/Melt-Blown ( ) String Wound ( )

Others: