JULY 3, 2023 ISSUE 9 FOCUS: DEMOLITION & WASTE / ENGINES & COMPONENTS RETURN UNDELIVERABLE ITEMS TO: EQUIPMENT JOURNAL, PO BOX 160 PORT MCNICOLL, ON L0K 1R0 PUBLICATIONS MAIL AGREEMENT: 40063867 Hydro-Detection System & Gas Detection System WE LEGALLY CARRY FULL LOADS! DRY VAC RENTALS 416-644-3076 Equipped with: CONNECT WITH US www.essltd.com since 1946 DISCOUNTS ON ALL ESCO BUCKETS FOR ALL MAKES ! Jim Walsh jwalsh@essltd.com 416-358-3192 SEE OUR AD ON PAGE A6 Contact John or Mark at: 1-800-265-5747 www.marcelequipment.com Sales, Rentals & Rental Purchase Quality, Reconditioned Equipment Since 1976 CAT 988K (2014) • REBUILT COMPONENTS • 14,955 Frame Hrs • Rebuilt Engine • Rebuilt Torque • Resealed Transmission • Resealed Transfer Case • Rebuilt Pumps / Motors • All Pivot Points Tight • Replaced Worn Hoses • All Needed Repairs Completed • VERY Clean Unit $CALL for Price & Details PUBLIC AUCTIONS MARKETPLACE “Post It—Sell It—Buy It—Get It”on: NEXT AUCTION: July 29th @ 9am - Industrial Equipment ONLINE HEAVY EQUIPMENT & TRANSPORTATION AUCTIONS 1-888-376-3155 • AllStarAuctions.ca 44 Line 9 South, Oro-Medonte, ON L0L 1T0 UPCOMING AUCTIONS: 2005 Caterpillar 345CL Barrie, ON - July 19th & 20th, 2023 2020 & 2019 Kenworth T880 Consign Today! Consignment Commission Capped For Sellers (1 Of 4) CANADA 2055 PEGASUS ROAD NE, CALGARY, AB T2E 8C3 (587) 316-4558 EMAIL: canada@sunward.cc SUNWARDCA.COM DEALERS WANTED! Phone-alt (Call for details) sales@bmcdowell.com www.bmcdowell.com 705-566-8190 416-770-7706 BUY US 2023 LINK-BELT 350 X4, 300 X4, 245 X4, 210 X4, 160 X4, 145 X4, 5 Year Full Machine Warranty See our ad on page A16 TOPLIFT.COM SALESPARTS SERVICE https://bit.ly/deltapowerconstruction sales@deltapower.ca 1-833-981-4278 LOTS IN STOCK! 1-855-625-0941 sales@creightonrock.com CRDCREIGHTON.COM • K80 • K90 • K100 • K110 • K130 • K150 • K170 NOW AVAILABLE KSERIES TEETH LUBECORE.COM ACROSS NORTH AMERICA 905-864-3110 NEXT GENERATION AUTOMATED LUBRICATION MADE IN CANADA Ű Reduced Labour Cost. Ű Protect Your Investment. Ű Simple. Reliable. Ű DIY Installation Option. Ű Standard 400g Grease Tubes. Ű Easy to View Grease Levels. SMALL EQUIPMENT, BIG SAVINGS. LUBECORE’S NEW HP-400 GREASES COMPACT EQUIPMENT AUTOMATICALLY. POWER BOX RAKE 72” & 84” AVAILABLE FOR IMMEDIATE DELIVERY IN STOCK amiattachments.com

CEDARAPIDS

CRH1113R IMPACTOR/SCREEN PLANT

6’x16’ 2-deck screen, 450 hp T4F Scania Diesel, 150 kW generator, 48”x18’ vibrating grizzly feeder with 6’ stepped 2-deck grizzly. Great value for processing shot rock as well as concrete and asphalt recycle materials!

SOLUTIONS FOR EVERY PROJECT

POWERSCREEN

TRAKPACTOR 320SR IMPACT CRUSHER

Double deck 11’ x 5’ screen, bolt in cartridge grizzly, highly fuel efficient direct drive system.

Excellent reduction and high consistency of product shape in recycling, demolition and quarry applications.

EVOQUIP

COBRA 230 IMPACT CRUSHER

3.4yd3 hopper capacity, integrated pre-screen for fines removal, 34”x24” crusher inlet, hydraulic overload protection, 36” conveyor, diesel power. Great for Construction & Demolition, Asphalt Recycling, Quarrying or Contract Crushing.

POWERSCREEN

PREMIERTRAK 400 JAW CRUSHER

28” x 44” jaw, hyd. crusher adjust system for un-crushable materials, direct drive, diesel power.

Ideal for sand & gravel, blasted rock, river rock, C&D waste, overburden, foundry waste, processed ores, processed minerals.

A2 JULY 3, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL 800 Farewell Street, Oshawa Ontario, L1H 6N5, Canada

powerscreencanada.com

psc@powerscreencanada.com

psc@powerscreencanada.com CONTACT POWERSCREEN OF CANADA ® CEDARAPIDS W AS H IN G SYST EMS

Toll-Free: 1-877-797-7276 Email:

CEDARAPIDS CRC1150S PORTABLE CONE AND SCREEN PLANT

CEDARAPIDS CRS620H PORTABLE SCREEN PLANT

For the love of the game

ISSUE 9 July 3, 2023 A3 JULY 3, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL Addressing the technician shortage Cat’s new D10 dozer A16 A22 Mecalac’s MCL line arrives in Canada A19 A13 ENGINES & COMPONENTS FEATURED EQUIPMENT B9 DEMOLITION & WASTE FEATURED EQUIPMENT B3

Canada is keeping history alive with its fleet of vintage construction equipment

HCEA

Help preserve construction history with HCEA Canada

Some of my favourite events in the heavy equipment world are the demonstration weekends hosted by the Historical Construction Equipment Association (HCEA) Canada.

heavy equipment industry via articles, images and video, HCEA Canada is preserving the actual historical artifacts — the tools that were used to build Canada.

For example, the 1931 Caterpillar 30 Snow Special, operated by Paul Leavitt at the HCEA events, probably made front page news when it was originally purchased by a municipality to push snow. At the time, the crank-start, depression-era machine was the pinnacle of technology.

turing who share the same interest, on a different level.

The HCEA members are a testament to the industry itself. Many of the association’s members are retired technicians or operators who return to their former career to demonstrate their craft.

The wooden benches or steel circle stools included on vintage machinery are a far cry from the fighter jetlike cabs featured in today’s heavy equipment. Yet, you can tell they’re in their zone when they are in that cab.

Bill Tremblay // Editor editor@equipmentjournal.com

Aside from the impressive machines, part of the draw for me is the similarities between newspapers and historical associations.

And of course, the people make the event. At the recent Wheels & Tracks in Motion event, held June 10-11, more than 1,000 people attended

I imagine there are few professions that maintain this level of dedication post-retirement. I doubt there’s an association of accountants that meet to crunch numbers on a collection of vintage abacuses, simply for the love

While the events are an opportunity for HCEA to showcase their work, there’s

a lot of behind-the-scenes activity that leads up to the demos. More than 300 members work to restore the machines, find parts or catalogue antique owner’s manuals and sales materials. The group is always looking for new members who share an interest in preserving history, or simply working on a diesel engine. For more information, visit hceacanada.org, or check out the Last Blast event in October.

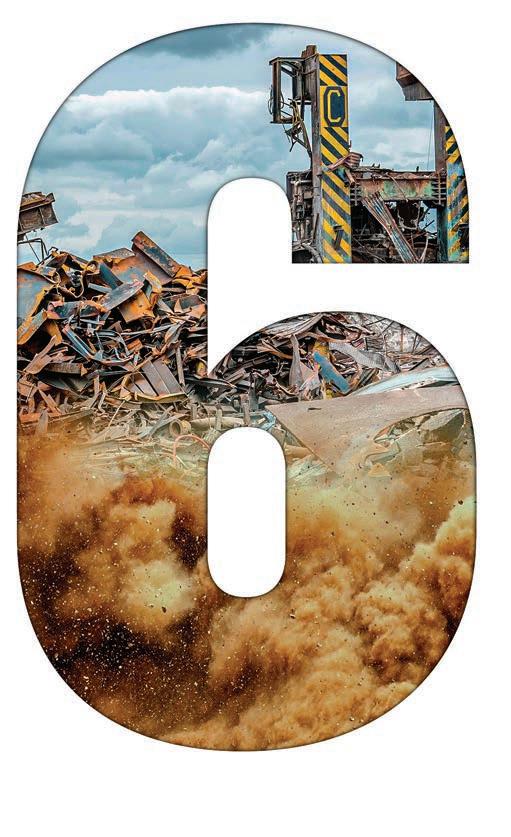

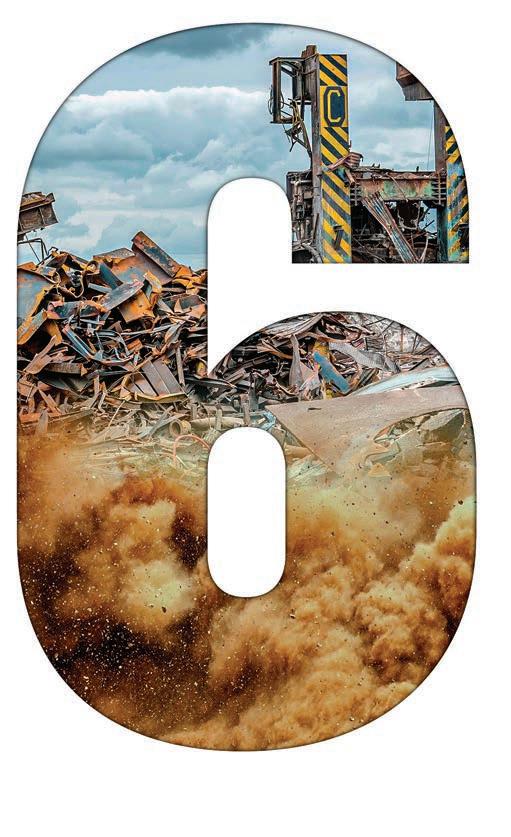

FOR ALL YOUR DEMOLITION NEEDS

Mona

mona@equipmentjournal.com

tara@equipmentjournal.com National Account Manager Advance Construction Equipment A7 Amaco Construction Equipment Inc. B4 AMI Attachments A1 Bobcat B2 Brandt Parts & Service B15 Bull Powertrain A19 Central Diesel Service B12 ConTrac Equipment A17,B5 Cooper Equipment Rentals A1 Creighton Rock Drill Limited A1,A11 D/S Manufacturing A7 Darvon Sales A5 Delta Power Equipment A1 Equipment Sales & Service Limited A1 Gear Equipment A1 HLA Attachments A20 High Reach Inc. A8 Hub Equipment B16 Hydrolexc Equipment Services Ltd. A14 Hyundai A9 Industrial Trailers A17 J.G. Stewart Construction A21 Jade Equipment B5 JBL Truck & Equipment Appraisal A21 JCB A24 JT Equipment A4 L & M Powertrain B8 LBX Link-Belt Excavators B6 Liebherr A18 Lubecore A1,A14 Lund Appraisal Svc. B7 Magnum Attachments B5 Marcel Equipment Limited A1,A6 McDowell B Equipment Ltd. A1,A16 MGM Attachments A8 Moore JCB A22 Morgan's Diesel Truck Parts B10 N. Johnson Equipment B4 Pine Ridge Lisco Edwards B7 Powerscreen of Canada A2 Shaw Bros. Limited A11 Strongco Corporation A15 Sunward Canada Equipment A1 Tarten Equipment Limited A19,B11 The Utility Expo B13 Top Lift Enterprises A1 Toromont CAT B1 Total Rentals A10 Tramac A12 Tri-City Equipment B11 Wirtgen A23 AUCTIONS AllStar Auctions A1 North Toronto Auction A1

(905) 629-7500

TOLL-FREE: CDN/USA 1-800-667-8541

A4 JULY 3, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL Published every third Monday at 6-5160 Explorer Dr., Mississauga, (Toronto). Subscription $44. per annum or $72. for 2 years including applicable tax., Payable in advance. Single copy $3.95. Authorized as Publications Mail Agreement No. 40063867, by the Post Office Dept. Ottawa and for payment in cash. Advertising is accepted on the condition that in the event of typographical error, that portion of the advertising space occupied by the error together with reasonable allowance for signature will not be charged for, but the balance of the advertisement will be paid for at the applicable rate. In the event of a typographical error advertising goods or services may not be sold. Advertising is merely an offer to sell and may be withdrawn at any time. We reserve the right to reject or refuse any or all advertising. Equipment Journal permission is required to reproduce original ad layout, artwork and photos. H.S.T. # 10403 7957 RT ADVERTISER INDEX JULY 3/2023 LETTER FROM THE EDITOR Bill Tremblay editor@equipmentjournal.com Publisher Mark Baker mark@equipmentjournal.com PACE PUBLISHING LIMITED EQUIPMENT JOURNAL 5160 Explorer Drive, #6 Mississauga, ON, L4W 4T7 Canada OFFICIAL SOCIAL MEDIA ACCOUNTS @EquipJournal @equipmentjournal @EquipmentJournal Equipment Journal LOCAL:

Fahmi

Circulation Manager Lisa Bath

EMAIL US: advertise@equipmentjournal.com WEBSITE: www.equipmentjournal.com EQUIPMENT JOURNAL IS AN AUDITED PUBLICATION

lisa@equipmentjournal.com

Twice a year, HCEA Canada opens their doors at the Simcoe County Museum to demo their collection of vintage machines. It’s an opportunity to see increasingly rare equipment in action, from a 1920s steam shovel to horse-drawn grading equipment.

John Deere debuts 3 P-tier compact wheel loaders

To address the needs of customers looking for compact solutions, John Deere is expanding its Performance Tier lineup with the new 244, 324 and 344 compact wheel loaders.

The new P-Tier compact wheel loaders carry over all L-Series features and will introduce new productivity-enhancing features, including standard ride control in base models and optional factory-installed features, including an auto-reversing fan option.

Additional optional features include attachment assist controls, which include integrated electrical, three-pin controls for attachments and combined creep control and throttle lock.

“As we continue to make the shift from past generation machines to our current generation of Performance Tiering mod -

els, we aim to keep the same features our customers know and trust on the L-Series models, with the added benefits of new productivity enhancements only available on the P-Tier machines,” said Luke Gribble, Solutions Marketing Manager for John Deere.

Ride control is now standard on all P-Tier compact wheel loaders. Ideal for customers moving materials over long distances, or on hard surfaces, ride control cushions boom movements during transport, acting like a shock absorber to help minimize material spillage.

Increasing operator comfort and productivity, this feature is applied with a flip of a switch in the cab and can be set to automatically engage and disengage at a predetermined speed.

As well, the P-Tier compact wheel load-

ers continue to feature industry-exclusive Articulation Plus, which enables rear-wheel steering to increase full-turn tipping load and improve maneuverability. This steering system combines 30 degrees of standard articulation with an additional 10 degrees of rear-wheel steering.

Articulation Plus also provides a significantly higher full-turn tipping load than machines without this feature, as the machine does not need to articulate as much to turn. This feature results in a significantly tighter turning radius than comparatively sized loaders without Articulation Plus.

Designed to provide increased ease of use for operators when utilizing attachments, the upgraded combined creep control and throttle lock found within the attachment assist controls package allows customers to run their machines with higher rpms and

lower ground speeds with overall fewer manual inputs. An enhanced pause and resume function means that reactivating the feature after a change in direction or switch to neutral is seamless as well.

An additional feature now offered on P-Tier compact wheel loaders is an optional auto-reversing fan, which is an easy-to-use solution for customers operating on sites with an abundance of debris or dust. This solution is also ideal for applications in agriculture, aggregate and site development.

To increase operator convenience, the fan can be turned on and off from the console in the cab.

The operator can also control the fan’s time intervals by holding down the switch, making for an automated convenience during operation, keeping the operator focused on the job at hand.

A5 JULY 3, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL Hours: 7300, hyd coupler, bucket. $CALL 2015 CAT 349FL Hours: 6300, equipped with hyd coupler. Work ready. $CALL 2017 CAT CAT 336FL Hours: 7400, clean unit. Work ready. $195,000 2013 CAT 336EL

Email us at: dsi@rogers.com 515 Welham Road, Barrie, ON L4N 8Z6 Hours: 6850, hyd quick coupler, aux hydraulics. $CALL 2018 CAT 320 Hours: 4500, hyd quick coupler, aux hydraulics, like new condition $225,000 2017 CAT 320 NEXT GEN Hours: 3300, quick coupler, aux hydraulics, AC, bucket. Like new condition. .$145,000 2015 CAT 311FL RR Hours: 1900, quick coupler, blade, aux hyd, hyd thumb. $97,000 2015 CAT 308EL Hours: 8100, hyd coupler, one bucket. $235,000 2014 CAT 962K Hours: 5000, comes complete with either complete original standard front end or complete long reach front end . $CALL 2013 CAT 349E COMING SOON! • CAT 992G • CAT 988H • CAT 950M • CAT 906 • CAT 336 NEXT GEN Please call for more details on any of the above equipment.

(647) 448-5361

A6 JULY 3, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL LONDON, ONTARIO, CANADA Contact John or Mark at: 1-800-265-5747 or 519-686-1123 Email: sales@marcelequipment.com VIEW our Complete Inventory at: www.marcelequipment.com REBUILT CAT 826H COMPACTORS - 0 HRS Components Rebuilt, Complete Machine Recondition, 3 year CAT Component Warranty 40 Compactors to choose from. $CALL Since 1976 SALES, RENTALS & RENTAL PURCHASE UNITS SOLD WITH WARRANTY WE ALSO RENT EQUIPMENT CONTACT MARK or JOHN 1-800-265-5747 or 519-686-1123 KOMATSU WA500-8 (2017) 8.25 CYD Bucket, 875/65R29 Michelin Tires Komatsu Scale, All Servicing/Repairs Completed. $CALL CAT D6T LGP (2019) - 7,645 HRS VPAT Blade, 31” Track Shoes, Drawbar, CAT Dealer Maintained since New. Ripper / Winch Available $CALL CAT 336FL XE (2016) - 9,285 HRS You would think it has 5,000 hrs Very Clean, Tight & Well Equipped Check it out! $CALL CAT 725C2 (2018) - 6,990 HRS 23.5R25 Tires, Rear Camera, All needed Servicing & Repairs to be Completed. $CALL RECONDITIONED / REBUILT CAT 816B/F/K LANDFILL COMPACTORS | Choice of 18 – Yes 18 Work Ready with Warranty $CALL (4) CAT 352FL (2018) – 3,900–4,470 HRS Reach Booms, 11’ Sticks, Aux Hydraulics, Couple, 30” Pads, Very Clean. CAT Inspected. $CALL CAT 980M (2014) – 8,910 HRS Aggregate Handler, 7.75 CYD Bucket, L3 Tires, Auto Grease, Rear Camera, All servicing & / Repairs Completed. $CALL CAT 988K XE (2019) – 6,200 HRS Spade & GP BKT Options, Serviced by CAT Dealer since New, Auto Grease, L-4 Tires, Very Clean. $CALL (4) CAT D8T (2011-13) - 4,381-8,090 HRS Very Clean, Choice of SU or Angle Blade, Drawbar. Ripper/Winch Available. $CALL CAT 730C2 (2019) – 3,160 HRS 23.5R25 Tires, Rear Camera, Tailgate Available. Just Arrived. $CALL CAT 745C (2015) – 7,340 HRS Inspected, Serviced, All Needed Repairs Completed, Rear Camera, Tailgate Available. $CALL CAT 980M (2016) – 7,885 HRS Aggregate Arrangement, 7.75 CYD Bucket, Auto Grease, Rear Camera, All servicing / Repairs Completed. $CALL (7) CAT D8T LGP (2019/2020) 2,230 to 14,345 HRS SU Blades, 38” Pads, Draw-bar. $CALL $CALL CAT 980M (2019) - 6,765 HRS Aggregate Handler Spec, GP Bucket, Payload System, Inspected, Serviced, All Repairs Completed. $CALL KOMATSU WA470-8 (2016) – 7,380 HRS Coupler, 5.25 yd Bucket, Loadrite Scale, All Servicing / Repairs Completed. VOLVO A25G (2017) - 6,850 HRS 23.5R25 Tires, Rear-View Camera, Inspected, All Needed Servicing and Repairs Completed. $CALL CAT 988K (2014) - 14,955 HRS 0 Hours on Engine, Transmission., Torque & Hydraulic Pumps & Motors Rebuild. Very Clean & Straight Loader. $CALL

KPMG: construction tech can help address Canadian labour shortage

A recent survey found that 90 per cent of construction firms are affected by ongoing labour shortages

According to new research by KPMG, digital technology could help address the backlog of Canadian housing and infrastructure projects as well as the ongoing labour shortage.

A KPMG survey of 275 Canadian construction companies found the skilled labour shortage is affecting nearly 90 per cent of the industry.

To address the shortage, digital technologies is a popular option to make the existing labour force more effective.

“Technology can help the construction industry address Canada’s housing and infrastructure challenges,” said Tom Rothfischer, Partner and National Industry Leader of Building, Construction and Real Estate for KPMG in Canada.

“Digital tools, if used smartly, save time and money, reduce waste and improve worker safety and productivity. In short, they help get projects done on time or ahead of schedule and on budget.”

Rothfischer explained many technologies employed in the manufacturing sector can be deployed by the construction industry to increase productivity and reduce costs. For example, 3D printing technologies in manufacturing have been adapted to the construction industry to lay concrete and build complex steel shapes. Robots can lay bricks and tie steel reinforcement bars. As well, drone-based surveying can help contractors quickly and accurately layout work, measure quantities and monitor progress. Building information modelling (BIM) allows project teams to collaborate more effectively to develop innovative solutions to optimize project cost and schedule. Digital twin technologies build on BIM to integrate real-time data from a built asset with its exact 3D virtual replica to test ‘what-if’ scenarios, including the impact of design changes, construction sequencing, weather disruptions and operational changes.

Slow to adopt Canada’s construction industry has slowly adopted new digital technologies. However, the pandemic, combined with the intensifying labour shortage, has proven to be the catalyst the industry needed to rethink how they go about their business.

“We’re seeing a definite recalibration taking place in the construction sector,” Rothfischer said.

“While many are still just at the beginning of their digital build, leaders see the power of technology to reshape the way they work and plan to invest heavily in the coming years. But having the technology is only half the battle. The real advantage will come to those firms who effectively integrate it into their operations – from the back office to the construction site.”

KPMG survey findings

· 73 per cent believe

Canada’s construction industry lags other countries in digital technology adoption

· 67 per cent say the impacts of the pandemic prompted investment in technology

· 86 per cent agreed that disruptive technologies can generate savings and efficiency

· 85 per cent believe disruptive technologies could make their companies more competitive

· About 80 per cent say their teams are excited and supportive of new technologies and approaches

· 46 per cent plan to spend more than 11 per cent of their corporate operating budget on tech and digital transformation

“Leading firms are already adopting technology to improve productivity and project management, safety on worksites, and decision-making,” said Mary Van Buren, President of the Canadian Construction Association (CCA).

“There is a cost however to investing in digitization that isn’t necessarily shared among all parties in the procurement process. Margins are slim in construction, especially for the small- and medium-sized contractors, making it increasingly difficult for them to adopt these types of innovations in their business operations. This is why CCA continues to work with federal departments in an effort to modernize procurement processes that encourage innovation by supporting shared risk.”

A double whammy

The KPMG survey found the Canadian construction industry is grappling with a double whammy of an unprecedented increase in

demand for housing and infrastructure projects, and a severe labour shortage.

To address this, almost all contractors are examining ways to alleviate current labour constraints to meet demands.

“The efficient allocation of trades is one of the industry’s most-pressing challenges and opportunities,” said Jordan Thomson, Senior Manager, Infrastructure Advisory, KPMG in Canada.

“Many companies are deploying or planning to deploy digital tools to better improve efficiency on site and do more with less.”

New roles required

Yet, as companies embrace technologies, the composition of the workforce will also need to undergo change to incorporate new roles, such as software engineers, BIM designers, data analysts and drone operators into the project team. For example, drones are increasingly used for planning and design, site analysis, topographic mapping, land surveys, real-time monitoring and on-site worker safety.

“With so many construction projects on the horizon, the only way companies will be able to compete, and finish the job on time and within budget is by digitizing and modernizing their operations and ensuring they fully harness the potential of

digital technologies,” Thomson said.

KPMG conducted the sur-

vey between November 23 and March 17 to gauge the progress the industry has

made in adopting new tech and transforming the way their organizations operate.

A7 JULY 3, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL

Harriston Location (519) 510-5878 advanceequipment.net

The use of drones, like this Wingtra mapping drone, are one of several methods to alleviate labour shortages in construction, according to KPMG.

2018 JCB HD110W HYDRADIG, 734 hours, Steelwrist, 2 buckets, like new! $POA.

2001

JCB 456HT, tool carrier design, hyd. coupler, 4 yd. bucket, auto greaser, completely rebuilt transmission & hyd. pump......................... $115,000.

KOBELCO SK210, 7400 hours, hyd. coupler, 2 buckets, new lower rollers, serviced................. $89,500.

JCB

550-170, 10,000 lb. capacity, 55’ lift height, approx. 4500 hours, fully serviced ..................... $72,500.

JCB

417 LOADER, hyd coupler, 2 yd bucket, aux hyd, fully serviced $POA.

TELESCOPIC SKID STEER, fully loaded with options $POA. Advance Construction Equipment Waterloo Location (519) 742-5878 Harriston Location (519) 510-5878 advanceequipment.net @advancejcb 607 Colby Drive, Waterloo, ON N2V 1A1 TEL (519) 742-5878 FAX (519) 742-0541 RR#3, 6297 City Road 109 S Harriston, ON N0G 1Z0 TEL (519) 510-5878 FAX (519) 510-4283 Here to Serve you Better! D/S Manufacturing 5087 Carman Road, Iroquois, ON. K0E 1K0 Phone: (613) 652-4025 dsmanufacturing.ca EQUIPMENT. SKILL. EXPERTISE. We Manufacture, Repair & Service Attachments & Hydraulics for Excavators, Loaders & Dozers EXCAVATOR & LOADER ATTACHMENTS

2020 JCB 3TS-8W

SWe have all your EARTHMOVING ATTACHMENTS SNOWPLOW BLADES LARGE GRAPPLES! We always deliver TOP QUALITY product on-time, every time for over 40 years. GET CUSTOM ATTACHMENTS IN JUST 5-6 WEEKS!

Komatsu’s new PC130LC-11 excavator boosts lifting capacity by 20 per cent

Komatsu has introduced its upgraded PC130LC-11 excavator, which is designed to provide a unique combination of lightweight power and agility in a small package.

Equipped with an 8 per cent longer undercarriage, the new PC130LC-11 increases lifting capacity by up to 20 per cent, compared to the PC130-8. The new design also increases stability and can help boost overall productivity of the conventional tail swing machine.

"The upgraded PC130LC-11 excavator can easily handle a wide variety of utility work or small construction jobs," said Andrew Earing, Director of Tracked Products for Komatsu. "It provides a versatile workhorse for you as your business expands and grows."

Engineered for efficiency, the updated PC130LC-11 uses up to 12 per cent less fuel than the previous model, thanks to new engine and hydraulic control technology. Fuel consumption on this excavator can also be reduced with the auto idle shutdown feature that can be set to automatically stop the engine after a preset amount of idle time. The Komatsu diesel oxidation catalyst

(KDOC) helps reduce particulate matter by using passive regeneration over 98 per cent of the time.

On the updated Komatsu PC130LC-11, high hydraulic pressures help optimize high arm and bucket digging forces. For long-term durability, steel castings in the boom foot, boom nose and arm tip help spread working loads away from high-stress areas.

The large one-piece hood, ground-level grease points, engine oil and fuel filters provide quick-and-easy service access for the upgraded excavator.

Komatsu PC130LC-11 specs

Horsepower: 97.2 hp at 2,050 rpm

Engine: Komatsu Tier 4 Final SAA4D95LE-7

Operating weight: 12,900 kg to 13,200 kg

Bucket capacity: 0.26 to 0.60 cubic metres

Max hydraulic flow: 242 litres per minute

Max travel speed: 5.5 km per hour

Swing speed: 11 rpm

A standard rearview monitoring system helps improve safety on the jobsite, while the

equipment management monitoring system (EMMS) continuously monitors machine operation and vital systems to identify machine issues and assist with troubleshooting.

The Komtrax telematics system is standard on Komatsu equipment with no subscription fees throughout the life of the machine. Using the latest wireless technology, Komtrax trans-

Bobcat completes $5.3 million renovation at its Wisconsin facility

Bobcat Company has completed a $5.3 million renovation at its Johnson Creek, Wisconsin, location. The Johnson Creek facility manufactures Bobcat mowers, turf and grounds maintenance equipment.

The investment in the facility modernized the office and employee spaces with an open-concept design, which includes multiple meeting and conference rooms, updated furniture and an enhanced employee break room.

“We continue to make investments in our facilities and operations, as part of our commitment to support our employees with a collaborative, inspiring workplace and to serve as a strong

community partner where we operate,” said Mike Ballweber, President of Doosan Bobcat North America.

The renovations are consistent with the interior design, finishes and furnishings of other Bobcat locations throughout North America.

Featuring open seating and no cubicles, the space is intended to encourage collaboration, drive innovation and support cross-functional teamwork. As an ode to its Wisconsin location, the facility’s meeting rooms are named for various local wildlife such as Badger, Whitetail Deer, Red Fox, Sandhill Crane and Bald Eagle.

As well, the renovation transformed the former

employee break room into a more versatile and welcoming café area.

“Seeing the many enhanced spaces throughout the facility and the new Bobcat signage has been exciting, and we are so appreciative of the support from our employees and construction partners during this process,” said Chris Knipfer, Vice President of Grounds Maintenance Equipment Business for Doosan Bobcat North America.

“Johnson Creek is an important part of our company’s operations, and we are thrilled to build on our success here in Wisconsin.”

Doosan Bobcat acquired the Johnson Creek facility and its product lineup in 2019 to

diversify its product portfolio, complement its existing business offerings and expand its footprint.

The location houses more than 375 employees working across sales, human resources, strategic sourcing, design and test engineering, and manufacturing operations for some of the company’s turf and grounds maintenance equipment products.

Bobcat has grown its product lineup significantly, launching more machines in the past five years than previously in its entire history. In addition to the mowers, turf and grounds maintenance equipment produced at the Johnson Creek facility, Bobcat offers an extensive line of compact equipment,

mits valuable information such as location, utilization and maintenance records to a PC or smartphone app.

Custom machine reports are provided for identifying machine efficiency and operating trends. Komtrax also provides advanced machine troubleshooting capabilities by continuously monitoring machine health.

including loaders, excavators, compact tractors, utility products, telehandlers, attachments, implements, parts and services.

Shultz + Associates

Architects supported the architecture plans, while ABC Construction served as the general contractor and Midwest Electric worked on

the electrical aspects of the facility.

In addition to its operations in Johnson Creek, Bobcat Company has an extensive presence throughout the United States, employing more than 5,000 people at offices, facilities and manufacturing operations across North America.

A8 JULY 3, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL

h

h

h

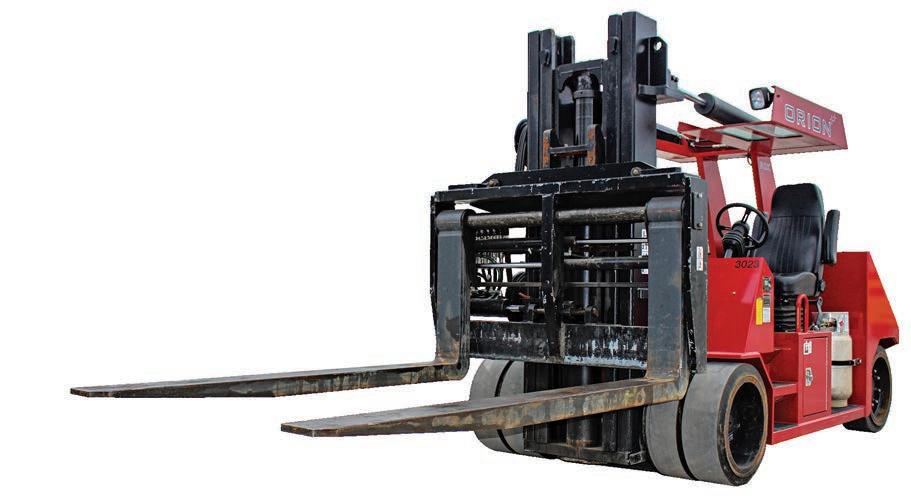

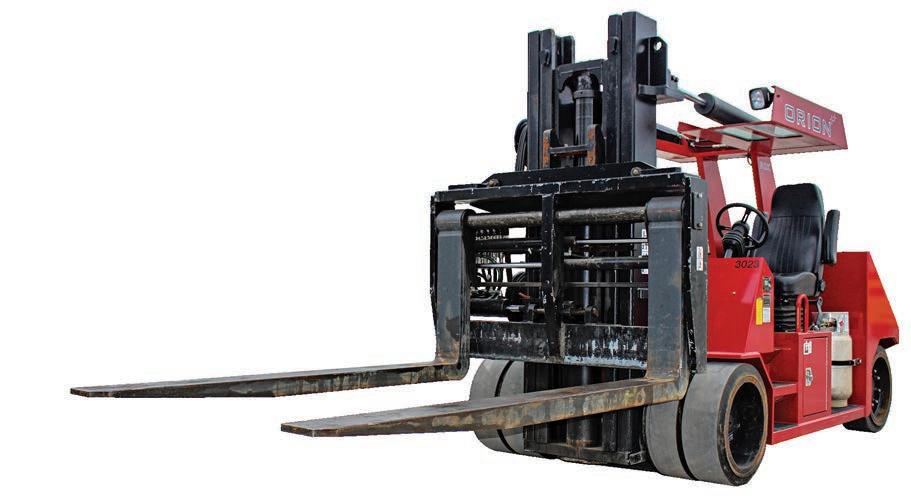

www.highreachinc.com Tel: (905) 844-4164 RENTALSSALESSERVICE FEATURING: REMOVE FORKS/INSTALL BOOM IN MINUTES. ORION’S QUICK-CHANGE RIGGER’S BOOM. Call 519-770-9844 for more information. mgmattachments.com

High Reach Inc. your authorized Broderson carry deck crane, Orion and Versa-Lift heavy fork lift truck dealer.

24,000

lbs to 160,000 lbs. in lifting capacity

h

Available with fullfunction radio remote control.

Smooth, accurate, hydrostatic drive. h Tier 4-Final Cummins

diesel.

Standard and Customized designs to suit the end application.

A9 JULY 3, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL THE DOER’S DREAM Offer expires 9/30/23 (or earlier at Hyundai discretion.) Contact your local Hyundai dealer for details. Special Finance Rates as low as 0% on Compact Excavators and other selected models. Loved for the features. Trusted for the performance. Do more without feeling like it in Hyundai’s new HX mini excavator series. • Distinctive, award winning ‘Tiger Eye’ design • Load-sensing hydraulic system (HX40A, HX48A Z) • 5” color LCD monitor • Auto safety lock for unintended operation • Large, quiet, tilting cab delivers excellent service access • Free Hi MATE telematics access for 5 years • Bluetooth radio, now a standard option hceamericas.com

Sure Grip Controls acquires IEC, opens new BC facility

Sure Grip Controls has opened a new facility in Victoria, British Columbia.

Located in University of Victoria Properties’ Vancouver Island Technology Park (VITP), Sure Grip’s new facility increases manufacturing space by more than 40 per cent, allowing the company to expand production lines to meet increasing customer demand.

It also provides the manufacturer of custom controls solutions for heavy equipment with additional space for development and testing of new products and technologies.

“We are excited about our new electronics facility in Victoria,” said Ken Baker, CEO of Bailey International, Sure Grip Controls’ parent company.

“This new location increases production capacity in one of our fastest growing product lines and represents Bailey’s strong commitment to our electronics business. This facility helps us strengthen our leader-

ship position in electronic controls and will enable additional new product offerings.”

The new location at VITP leverages the park’s technical and communications infrastructure to enable expanded testing and development capabilities.

With its Leadership in Energy and Environmental Design (LEED) Gold Certification, being in the VITP also helps Sure Grip Controls maintain its ISO 14001 certification and Vancouver Island Gold Rating for sustainable business practices.

“I am proud of the team that managed the development and launch of this facility and the dedication they showed to bring our second location online,” said Darren Lockyer, Vice President of Bailey International’s Electronics Business Unit.

“This new facility clearly demonstrates our commitment to helping our customers develop new products and increase their speed to market.”

Sure Grip acquires IEC

Sure Grip Controls has also acquired Rockford, Illinois-based Industrial Electronic Controls (IEC).

The acquisition of IEC will expand Sure Grip Control’s product portfolio and provide additional expertise in electronic throttles, displays and sensor manufacturing.

“Combining IEC’s high-quality products with Sure Grip Controls’ existing portfolio allows us to offer a very broad range of electronic controls products to the market,” Baker said.

“The addition of IEC’s products will help us fulfill our vision to provide mobile and industrial equipment manufacturers with a full range of products and expand our fingertip-to-tooltip offering.”

IEC’s electronic throttles, displays and sensors have a reputation for a rugged design and quality control. IEC has extensive design and engineering capabilities

combined with more than two decades of experience serving OEM customers.

“We look forward to providing more products, additional capabilities and continued excellent service to our customers,” Lockyer said.

Beyond complementary product portfolios, Sure Grip Controls and IEC are both dedicated to developing highly customized controls for heavy equipment applications in agriculture, construction, forestry, transportation and beyond.

“If there is one company in the mobile electronics control industry that matches our engineering capabilities and approach, it’s Sure Grip Controls,” said Joe Benjamin, Owner of Industrial Electronic Controls. “I am very excited that Sure Grip shares a very similar culture to IEC of unsurpassed service to their customers, which will make for a smooth and seamless transition for our much-valued customers.”

A10 JULY 3, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL Visit www.totalrentals.ca | Email info@totalrentals.ca Available with mulching head or tilt bucket 18'9" digging depth & 30' reach 35 km/hr travel speed Mulch 4-6" trees Process 6-8" trees

Epiroc launches new flagship construction drill rig

Epiroc is expanding its SmartROC family with the introduction of the T25 R surface flagship radio remote drill rig, built on a whole new platform.

The construction rig offers several valuable features such as an exceptional coverage area, excellent terrainability, application versatility and a smart Rig Control System (RCS), which future-proofs digital functions and helps to reduce the rig's climate impact through fuel savings.

“We are really excited to present this construction drill rig to the market, a rig that´s built on a completely new platform,” said Marcus Leü, Global Product Manager at Epiroc.

“SmartROC T25 R has the possibility to lead the way within its segment, with its

optimized coverage area, excellent terrainability, application versatility and the smart RCS control system. This rig can make a real difference for our customers’ productivity.”

The available boom options include a turning radius of either 45/45 or 90/90. This can be combined with a 5.5or a 6.1-metre boom system, giving the new SmartROC T25 R coverage areas of 28 square metres and 45 square metres respectively. These features are matched with a rotation unit that provides a 360-degree feed swing and a boom geometry that enables it to drill right next to the machine. This gives the SmartROC T25 R an excellent coverage area. The rig will have the highest efficiency in the segment thanks to its

engcon launches new and improved excavator coupler

To further enhance its customer experience, engcon is launching an improved version of the S60 excavator coupler for 12 to 19-ton excavators.

In addition to making the machine coupler stronger, retrofitting with EC-Oil blocks will be easier as the new machine hitch contains almost no hoses and minimizes the risk of leaks. EC-Oil block without hoses means a longer service life, as well as easier repairs and maintenance.

The end user will also notice that the new bolton EC-Oil block has an increased hydraulic flow.

“Thanks to our innovation-driven work with a focus on the end customer, our customers can rely on

coverage area and stability, according to Epiroc.

Terrainability features

A low centre of gravity, wide crawler spacing and a boom system with good maneuverability translates to excellent terrainability for the SmartROC T25. The well-balanced rig with enhanced stability delivers a safe work environment and improved productivity when the rig can tram more efficiently and therefore enable more drilling time.

In order to ensure that environmental impact is minimized, the rig utilizes a reduced amount of hydraulic oil. Furthermore, fuel consumption is optimized thanks to the smart RCS control system. This not only helps to reduce the environmental footprint, but also contributes to a better work environment for the operator. Each of these improvements is a vital step forward on the path towards sustainable construction.

The SmartROC T25 R offers valuable application versatil-

ity. The new 180-degree boom swing angle, which can be combined with a 360-degree feed swing angle device (hydraulic rollover), together with three different feed lengths, steel or rubber tracks and compact transport dimensions create numerous possibilities for new drilling applications

and new markets for the user.

“We have listened to our customers and developed a rig that will provide the operator with a wide range of valuable features,” Leü said.

“The SmartROC T25 R offers a service friendly design with easy access to important components. Fuel consumption

has been optimized, and the rig is extremely powerful in relation to size, which allows for use in demanding applications in confined spaces. This rig is designed to be the obvious choice for operators within this segment, a rig that will make their working day a lot easier.”

• Service

engcon to always deliver state-of-the-art technology. Our package should be the complete solution and the premium product that our customers want, now and in the future,” said Martin Engström, Product Manager at engcon.

Another advantage of the S60 coupler is increased stability around attachment points to the machine, which contributes to a better operating experience.

engcon also improve flexible hose routing between excavator and machine coupler and reinforced construction both laterally and in the digging direction.

EC-Oil block without hoses means a longer service life, as well as easier repairs and maintenance.

A11 JULY 3, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL

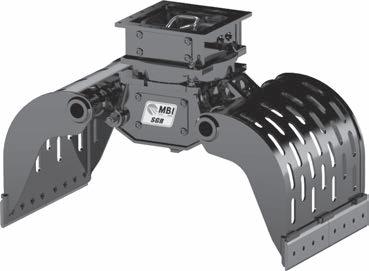

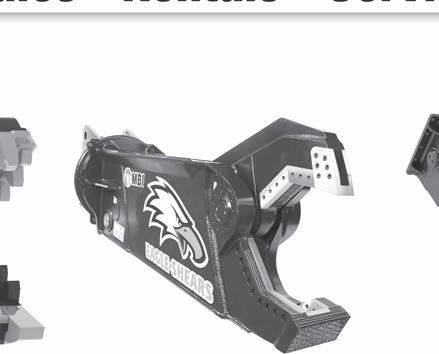

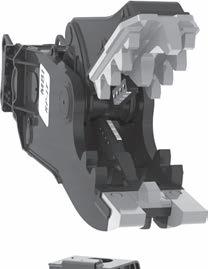

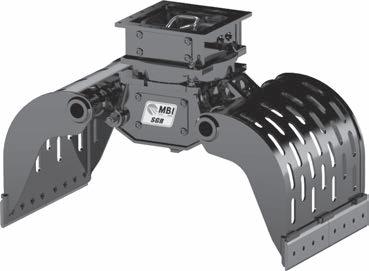

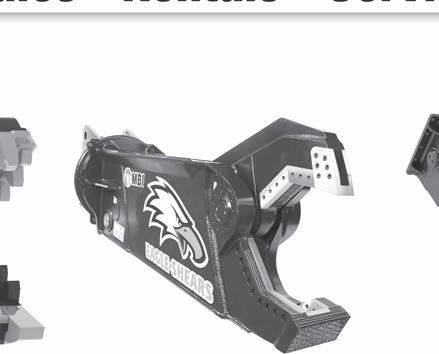

ON Mississauga • Bracebridge • Sudbury • Timmins • North Bay • Ottawa QC Boisbriand • Lévis • Val d’Or NB Moncton NS Dartmouth Call: 1-855-625-0941•CRDCREIGHTON .COM The perfect combination of tool strength, light weight and optimum wear resistance. DEMOLITION RP-IT Rotating Pulverizer SH Eagle Shear MCP-IT Fixed Pulverizer CC Combi Crusher SGR Grapple CR Crusher • Augers • Breakers • Brush Cutters • Buckets • Compactors • Demolition • Forest Mulcher • Grapples • Quick Couplers • Rippers • Compactors • Rubber Tracks • Thumbs • Screening Buckets BEST QUALITY ATTACHMENTS AT THE LOWEST POSSIBLE PRICE shawbros.ca info@shawbros.ca • Hydraulic Forestry Heads for Excavators 8-30 tons • Hydraulic Head for Compact Loaders • Hydraulic Brushcutter Head 2-8 tons • Agricultural Attachments Barrie, Ontario 1-877-625-9677 QUALITY ATTACHMENTS WE ALSO CARRY:

Sales • Rentals

The Mammoet SPMT transport goes electric

Mammoet is now offering a zero-emission option for its Self-Propelled Modular Transporter (SPMT transport), compatible with any trailer in its fleet.

The zero-emission option is possible through a conversion process for SPMT power pack units (PPUs), which replaces the diesel powertrain inside existing trailers with an electric alternative. Once retrofitted, each trailer combination has comparable power to existing industry standard units.

The PPU vastly reduces noise levels at project sites, resulting in a safer and more productive work environment.

Communication between staff is clearer, while longer operational windows are now possible at locations where sound restrictions are in place.

The system represents another step towards zero emissions on site, eliminating the carbon footprint of the SPMT transport.

This allows our customers to meet increasingly strict environmental legislation more easily, reducing the impact of transport phases on surrounding communities and infrastructure.

As well, retrofitting existing SPMT fleets cuts down on both waste and additional fabrication, compared to sourcing new zero emission equipment.

The electric option was partially financed by the DKTI, a Dutch government program to develop climate technologies and innovations in logistics.

Mammoet worked with a leading provider of zero-emissions powertrains for heavy industry to bring the electric power pack solution to market.

Developed by Mammoet in 1984 and with more than 40,000 axle lines in use globally, the SPMT Transport revolutionized heavy industry by maneuvering practically any load safely, efficiently and with precision.

Servus acquires Stride Capital

Servus Credit Union has acquired Stride Capital Corporation, a Calgary, Albertabased equipment financing and leasing provider.

Following the acquisition, Stride Capital becomes a wholly owned subsidiary and new division of Servus Credit Union.

The move represents Servus's next step in reimagining its credit union business in response to the changing Canadian financial landscape.

"We are excited that Servus and Stride are coming together to deliver ongoing exceptional leasing services to Stride's existing and new clients, and Servus's membership of over 380,000 Albertans," said Ian Burns, President and CEO of Servus. "Stride's leasing services will be available to Servus's commercial members, giving them greater access to credit and features to help them grow their own enterprises, while Stride's existing clients will benefit from more and larger leasing opportunities owing to Servus's financial strength."

Founded in 2016, Stride Capital provides leasing for new and used heavy equipment in British Columbia, Alberta, Saskatchewan, Manitoba, Ontario, Atlantic Canada and the Yukon.

Backed by Servus, Stride will increase its footprint in lease financing for businesses, helping them expand their equipment, machinery and operations in the agriculture, construction, energy, forestry, manufacturing, mining and transportation industries across Canada.

"Through this arrangement with Servus, we see tremendous opportunity for the expansion of our business in the provinces where we operate," said Randy Mannix, President of Stride. "We will be able to provide our customers with increased access to capital, while most of our management group and all 20 employees will become part of the new subsidiary."

Servus Credit Union was founded in 1938 in Alberta. Today, the credit union is one of Canada's Best Managed Companies and Canada's Best Banks and has more than 100 branches in 59 communities throughout the province.

Earlier this year, Servus announced an intent to amalgamate with connectFirst Credit Union, which, if approved, would create one of the leading credit unions in Canada. Stride's specialty leasing services would be available to all members of this new entity should the amalgamation proceed.

A12 JULY 3, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL

Ontario office: (613) 542-1500 28 Steve Fonyo Dr., Kingston, ON K7M 8N9 Montreal Office: (888) 663-8122 3421 Industriel Boulevard, Laval, Que. H7L 4S3 Quebec City Office: (418) 877-5557 1711 rte de L’aeroport #4, L’ancienne Lorette, Que. G2G 2P4 CANADA Shaun Brown Cell: (613) 532-4823 Office: (613) 542-1500 shaun_brown@tramac.com FOR EXCAVATION,DEMOLITION, MINING, CONSTRUCTION & QUARRIES. TRAMAC HAS AN ATTACHMENT FOR THAT. FEATURING A FULL LINE OF HYDRAULIC ROCK BREAKERS FOR CARRIERS RANGING FROM 1 TON TO 120 TON CLASS SERVING THE CONSTRUCTION, DEMOLITION & MINING INDUSTRIES FOR OVER 57 YEARS 1966 - 2023

Preserving the machines that built Canada

Paul Leavitt’s fascination with dozers began when he was five years old.

At the time, his father had hired a contractor to bring in a dozer and cable shovels to complete work on the family farm in Prince Edward County, Ontario. When Leavitt and his father went to pay for the work, the contractor had just taken delivery of a new Caterpillar D8.

“He said, ‘c’mon, you have to go for a ride.’ I was so little that my head didn’t catch the top of the tracks, but when my dad lifted me up, I was sold on things with tracks,” Leavitt said. “I bought my first one when I was 19 years old.”

Today, Leavitt has built an impressive collection of antique dozers, including several Caterpillar and International machines and the second last Model 10 ever built.

Considering his collection, joining the Historical Construction Equipment Association (HCEA) Canada was a natural fit.

“You get to coexist with all these other guys that like this stuff too. So that's what started me in HCEA,” Leavitt said, who joined the association in 2005. “So, it’s just the camaraderie. It’s everything. It's just fun.”

At HCEA’s Canada’s Wheels & Tracks in Motion event, held June 10-11 at the Simcoe County Museum, Leavitt brought his 1931 Caterpillar 30 Snow Special to operate during the demonstration.

“You’ve got to crank it to start it. You have to know a little bit about it. And when you're driving it, you're operating a part of history,” Leavitt said. “Old stuff is just neat. It's a hard thing for me to describe.”

HCEA Canada’s mandate

Leavitt is one of about 300 HCEA Canada members. The group’s mandate is to ensure current and future generations are aware of the antique construction equipment and personnel that built Canada from Confederation onward.

“We needed to do something to preserve the equipment, so the kids can find out how Canada was built,” said Frank Rooney, HCEA Canada President and author of Equipment Journal’s Looking Back section.

The group was formed with 15 members in 1996 in Hillsburgh, Ontario, before finding its permanent home on the grounds of the Simcoe County Museum near Barrie. In conjunction with the Simcoe County Museum,

HCEA Canada is the only national antique equipment association to host two annual demonstration events with working vintage equipment.

Through the museum partnership, HCEA volunteers provide the manpower to assist with ongoing maintenance and operation of the museum’s antique equipment, its own fleet and machines on loan to the association by its members. Combined, the group restores and manages about 60 machines in working (or near working) condition, as well as numerous static machines on display at the museum. HCEA Canada has also created a digitized database of more than 2,500 antique equipment manuals, sales literature and related items.

Stan Lougheed, owner of Osprey Equipment Repair in Singhampton, Ontario, is one of the technicians that helps restore the vintage machines. He’s also a founding member of HCEA Canada.

Lougheed explained many of the machines in the collection were donated by family run construction companies after they were bought out by larger firms.

“Maybe it was the first machine they ever had. So, it came here, and that's how this has just exploded into what we've got. And you know, we have some unique pieces,” Lougheed said.

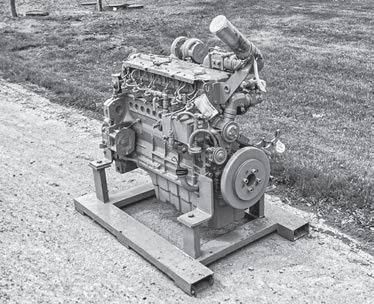

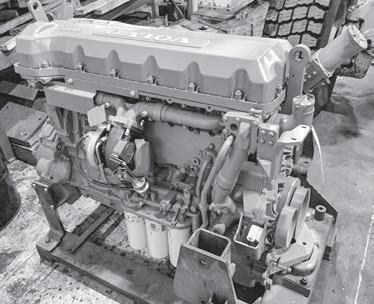

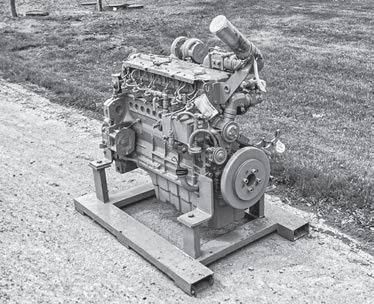

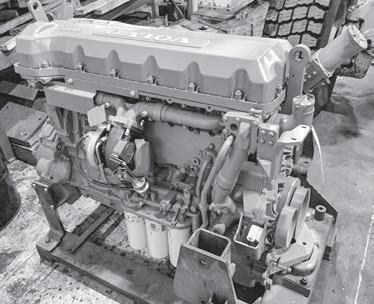

The current show piece for HCEA Canada is a recently restored 1940s Ingram three drum, 10-to-12-ton roller. Lougheed purchased a replacement engine for the machine in Sault Ste. Marie, Ontario to restore it alongside other association members.

“The engine was completely worn out. It used to be just a cloud of blue smoke coming out,” he said. “Now it runs really nice. There were some major changes to make to it. We had to tear it apart and put it back together again. But, you know, I enjoy that sort of thing. It’s a labour of love type of thing.”

At the recent Wheels & Tracks in Motion event, Lougheed was joined by his son Richard and his grandson Dallas.

“It’s become kind of a family affair type of thing. We’ve had a lot of fun out of it,” Lougheed said.

Like his grandfather, Dallas plans to pursue a career as a heavy equipment technician.

“The only way to learn for the future is to learn from the past,” Dallas said.

A13 JULY 3, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL

JLG has introduced the X660SJ, its first straight-jib (SJ) compact crawler boom lift.

With 20-metres of platform height, 227 kg of capacity for up to two workers, 11.9 metres of hori-

zontal reach and indoor/ outdoor versatility, the new SJ compact crawler boom lift is ideal for a wide range

of applications, including arboriculture, painting, general maintenance, electrical, HVAC and window washing.

“The X660SJ is designed with several unique features that are key to efficiently accessing work at height,” said Angela Patterson, JLG Boom Lift Product Management Lead.

“For example, the architecture of this new straight-boom compact crawler boom lift enables operators to reach full height more efficiently, while it’s crawler-mounted design and 40 per cent gradeability mean the X660SJ can climb slopes with ease compared to standard lifts.”

As well, the X660SJ compact crawler boom lift features an 89-cm width, 1.98 metre height and 3,299 kg weight.

“It’s … footprint allows

operators to go more places around the job site, such as through gates and standard doorways to work in yards and public buildings,” Patterson said.

Performance features

The X660SJ compact crawler boom lift is equipped with several features to enhance performance. For example, envelope tracking operation for work alongside buildings, walls and other infrastructure.

With a single control function, operators can boom up/down, while also telescoping out/in, so that the platform travels a path perpendicular to the ground.

As well, multiple position, one-touch self-levelling outriggers provide flexibility to work in tight areas and to maximize the working envelope.

The “Go Home" and "Back to Work" functions provide ease of returning to stowed or recorded work position. Software optimizes the path to the stowed or saved work position based on machine stability.

Power options

The X660SJ comes standard with a 14.5 hp Kubota diesel engine. A lithium-ion battery and AC drive system option is available, as is JLG’s new Bi-Energy option. This alternative equips the JLG compact crawler boom lift with two full-sized, independent power sources, combining an emissions-free lithium-ion battery pack with a dependable diesel engine. The Bi-Energy option enables operators to choose the best power source for the application — either the engine or the lithium-ion batteries.

“The Bi-Energy system is designed to maintain the high performance and efficiency our customers expect … while minimizing their

carbon footprint and decibel levels,” Patterson said.

“With this option, operators can choose the best power source for the application. This dual power source design means that JLG Bi-Energy models can be used in a wide variety of settings — from general greenfield construction projects to environmentally sensitive job sites.”

Common to all three power sources, all JLG compact crawler boom lifts available in North America, including the new X660SJ, come standard with fully synthetic biodegradable hydraulic fluid so it can be used with confidence in environmentally sensitive areas.

Easy loading

Additionally, like JLG’s other compact crawler boom lift models, forklift pockets for loading and unloading for transportation are standard.

Air, water and power lines to the platform, non-marking tracks for work on sensitive flooring, integrated front and rear LED lights for visibility and SkyGuard SkyLine enhanced control panel protection also come standard on the X660SJ crawler boom.

Component commonality

The new SJ compact crawler boom lift model also has similar components and serviceability features to JLG’s entire compact crawler boom lift product family, including the enclosed powertrack design, which protects machine components by reducing debris impact.

“With the X660SJ, productivity is a top priority,” Patterson said.

“This compact, low-weight straight-jib model will transform how facility and construction professionals get work done at height, indoors and outdoors.”

A14 JULY 3, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL

LUBECORE.COM ACROSS NORTH AMERICA 905-864-3110 NEXT GENERATION AUTOMATED LUBRICATION MADE IN CANADA Ű Reduced Labour Cost. Ű Protect Your Investment. Ű Simple. Reliable. Ű DIY Installation Option. Ű Standard 400g Grease Tubes. Ű Easy to View Grease Levels. SMALL EQUIPMENT, BIG SAVINGS. LUBECORE’S NEW HP-400 GREASES COMPACT EQUIPMENT AUTOMATICALLY. 416-458-2334 HYDRAULIC HAMMER/BREAKER SPECIALIZING IN PARTS, SALES & SERVICE KENT MUSTANG OKADA RAMMER ROCK RAM STANLEY TRAMAC ALLIED ATLAS COPCO BTI CAT CP EPIROC ESCO INDECO NPK SINCE 1998 HYDROLEXC.COM HYDROL EXC EQUIPMENT SERVICES LTD. JLG’s first straight-jib

compact crawler boom lift is now available

A15 JULY 3, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL ALBERTA ONTARIO QUEBEC ATLANTIC WWW.STRONGCO.C OM A FT ER S ALE S SUPPO RT PARTS INVENTORY Genuine O EM part s & ma jor comp o nen ts av ail a bl e n s to ck I n- Fi e ld s erv ic e | In - S ho p s e rvic e HUGE INVENTORY U sed Eq u ipm ent | Ne w equipme nt FOR M OR E INFO J.J LY ON S CON TACT jjl y on s @strong c o. com (844) 288-4241 Conn e ct wi th us VOLVO USED EQUIPMENT & COMPONENTS ASK US ABOUT FINANCING OPTIONS *Terms & Conditions apply Volvo Rebuilt Transmissions L220F transmission SN#6005-8485 L90E transmission SN#2005-8000 L110F transmission SN#3503-61501 Volvo Used Parts for: Articulated Haulers Wheel loaders Motor Grader 2,635 hrs $185,000 2015 VOLVO DD140 Stk#2032001 532 hrs Stk#2030405 6,934 hrs $167,500 2018 VOLVO L60H Stk#2027304 716 hrs 2018 VOLVO DD110C Stk#2011762 1,589 hrs $132,900 2020 VOLVO L70H Stk#2030529 3,133 hrs 2019 VOLVO L60H Stk#2027303 438 hrs L220F REBUILT TRANSMISSION 1 Year Strongco Parts Warranty A30D, A25D REBUILT TRANSMISSION 2018 VOLVO L60H Stk#2027313 1,198 hrs 2020 VOLVO L90H 3,753 hrs 2018 VOLVO L60H Stk#2027311 1,326 hrs $192,500 Your one-stop dealer. From machinery to service, parts and certification. Your trusted partner for every project. 1 Year Strongco Parts Warranty $228,000 $230,000 2020 VOLVO L90H Stk#2027121 869 hrs 2021 VOLVO EW60E Stk#2022013 17 hrs $282,000 $265,000 $282,000 $67,500 $237,500 2019 VOLVO L90H Stk#2030534 3,938 hrs $257,500 Stk#2030533

Four Ways to Address the Industry’s Technician Shortage

By Julie Davis, Senior Director of Workforce and Industry Initiatives at the Association of Equipment Manufacturers (AEM)

It’s no secret to anyone working in equipment manufacturing the ever-growing technician shortage is a problem poised to get worse before it gets better.

According to a 2020 AED Foundation industry research report, our industry may need to fill as many as 73,500 heavy equipment technician positions by 2025. In addition, the report stated equipment manufacturing possesses a job opening rate three times higher than the national average. Among survey respondents, 95 per cent agreed with the assertion there was a skills gap in the industry, while 89 per cent reported a shortage of workers within the walls of their respective companies.

Now, I don’t want to suggest the widespread technician shortage can be quickly

addressed, let alone easily solved. However, equipment manufacturers can embrace and adopt a number of short-term and long-term strategies to set themselves up for sustained success as it relates to workforce development.

1. Focus on retention

Many pieces of the technician workforce puzzle can only be lightly influenced. However, one area companies can focus efforts to drive positive change as it relates to retention is workplace culture.

Start by asking the following two questions: Are exit interviews being conducted?

Technicians leaving an organization within the first six months could indicate an onboarding problem, while technicians leaving between 2.5 and 3.5 years could indicate a lack of development opportunities. With exit interviews, it’s worthwhile to have both a manager and human resources represent-

ative conduct interviews separately, as each position is likely to elicit different responses from departing employee.

Are staying interviews being conducted?

Talking with staff in key positions about their individual experiences can shed light on missed opportunities or future red flags. Engaging in staying interviews can be particularly helpful in the first 12 months to understand what it’s like to be onboarded and how new employees experience the existing culture within the organization. Start by creating a culture check-in by surveying all employees. What changes can be made based off all the information learned? And remember, to those companies who aren’t currently acting on employee feedback being received, asking for additional input can (and likely will) negatively impact culture moving forward.

2. Fill the talent pipeline

There’s really no overstating the importance of finding ways to fill an organizational talent pipeline. And while it takes time to secure a return on investments of time, effort and resources to do so, it’s worth it to take proactive steps to ensure desired results.

Simply contacting the nearest local technical college once or twice a year isn’t going to be enough to attract and acquire talent. Regularly engage with educational institutions. As well, join review committees, get in front of students in classrooms or donate equipment. More than anything else, do what it takes to be top of mind when these schools begin looking to place their best students. It will pay dividends over time. In addition, it’s important to connect with

Continued on Page A17

A16 JULY 3, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL OEM PARTS & SERVICE Hammers Compact Equipment Wheel Loaders Air Compressors Trailers/Floats Compaction Carriers • 2 SHOPS & 14 BAYS • HIGHLY RECOMMENDED REPAIR SHOP WITH LONG TIME EMPLOYEES • KNOWLEDGEABLE, TRAINED, PARTS PROFESSIONALS WE ARE YOUR SOURCE FOR PARTS JUST ARRIVED FOR PARTS • CAT 350II 6X6 TRUCK • VOLVO A35D 6X6 TRUCK • CAT 988B LOADER • CAT 924H LOADER • CAT 769D ROCK TRUCK • BOBCAT S175 SKIDSTEER • BOBCAT 518 TELEHANDLER 416.770.7706 or 705.566.8190 www.bmcdowell.comsales@bmcdowell.com

&

EQUIPMENT SALES, RENTALS & REPAIRS SERVICE YOU CAN COUNT ON! • SANDVIK TH430,LH410 • CAT AD45 • COPCO ST7 AXLES,MT5020 • 2X JOHN DEERE 544 LOADERS COMPLETE $10,000 FOR BOTH OR BUY THE PARTS, 17.5R GOOD TIRES

GTA

SUDBURY HEAVY

high schools feeding into technical college programs. One effective way to do so is to introduce the high schools to a free, available high school technician curriculum offered through the Curriculum for Ag Science Education. It’s not just an ag technician curriculum, but rather a program that introduces the technician career to a wide audience and enhances industry perception to parents, teachers and students. As a bonus, there is a built-in industry connection opportunity though the collection of used parts and by offering several class visits.

Organizations must be willing to shed light on the significant industry demand for qualified workers and worthwhile career opportunities, because chances are they aren’t aware of the extent of the existing technician shortage.

Technician program partnerships, apprenticeships, job shadowing or any other work-and-learn program are the most effective way to connect with new workers. Ultimately, partnering with education is critical for retention, as technicians require ongoing training and development.

3. Diversity recruitment strategies

Want to really move the needle when it comes to acquiring talent? Try the following:

· Actively recruit women and people of colour.

· Change the way job postings are written and where they are being posted.

· Check language in job postings via a gender decoder website to determine if it’s overly masculine.

· Target locations and events where someone with the skills, interests and hobbies of workers the organization wants to replicate might be out and see if the openings can be posted.

4. Collaborate with others

As the technician shortage is one of our biggest issues, AEM’s Workforce Development Committee has created a technician taskforce.

We’ll share examples of survey questions, stay interview questions and other practices being used by industry members to help move the needle in this space.

AEM is also partnering with the AED Foundation. If you’re not aware of the AED Foundation’s work to accredit 100 colleges and recognize 150 high schools in heavy equipment technology programs, you can learn more about its Vision 2025 by visiting their website at aedfoundation.org.

When it comes to understanding the work being done to support the industry’s need in this space, there are many associations that are trying to collaborate rather than duplicate efforts.

Just as there’s no one thing that a company can do to help ease the technician shortage, there’s no one association that can solve the challenge on their own.

With much work to be done and a new technician taskforce being formed, more information will be generated on this topic. In the meantime, make sure to visit AEM’s Workforce Solutions Toolkit to access valuable resources.

A17 JULY 3, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL The Ultimate in Trailers® ... since 1905 Whether your hauling needs take you over or off-the-road, ROGERS trailers give you the reliability, versatility and efficiency you need to lower your costs and improve you profits LEASE AND FINANCE OPTIONS AVAILABLE TAG SERIES -63548 BLACKTOP SERIES -40693 ULTIMA SERIES -40692 FIXED GOOSENECK SERIES -63549 CENTURY SERIES -40691 SPECIALIZED SERIES -63553 Non

between

-72413 www.rogerstrailers.com Email: w.smith1@rogers.com Yard Location; 402 Mulock Dr. Newmarket, ON. L3Y 9B9 • NEW • USED • RENTALS 416-801-5292 PREMIUM QUALITY LOWBEDS AVAILABLE NOW! PREMIUM QUALITY LOWBEDS AVAILABLE NOW!

ground bearing gooseneck. Four beam tapered design. Front fixed ramps 25’0” level deck. Boom well and bucket pocket

Equipped for pin on 4th axle. 275 rubber/aluminum wheels/ABS brakes LED lights Load bearing trunnions

wheels.

PREMIUM

Darcy Wurban Territory Manager (780) 935-6766 DarcyW@contraceq.ca Calvin

Territory Manager (780) 222-1094 CalvinB@contraceq.ca Jeff Hayward Sales Manager (780) 916-5005 JeffH@contraceq.ca

Continued from Page A16

HEAVY EQUIPMENT RENTALS & SALES

Berube

2021 JOHN DEERE 872GP, 3800 Hours, 17.5x25 Michelin, Sno Plus, AWD, Ripper, Snow Wing, Front Blade, Espar ....... POR

2021 CAT D3 LGP-V, 34 Hours, 6-Way, Ripper, Full Guarding, Pos Air, Espar. POR

contraceq.ca 220 Diamond Ave., Spruce Grove,

T7X 4C7 •

• EXTENSIVE FLEET OF

600 UNITS Call or email today with all of your inquiries. We look forward to working with you!

2021 JOHN DEERE 300G LC, 2506 Hours, Q/A, 2 Buckets, Hyd.Thumb, Aux.Hyd., FOGS, Cat Walks, Pos. Air, Webasto.

POR

AB

SPECIALTY PIECES ALL THE WAY TO COMPLETE CUSTOM SPREADS

OVER

The new R 945 from the generation 8

With the largest bucket sizes available in the market, along with available factory installed options like cab guarding, stick re-enforcement, and air pre-cleaner, the Liebherr R945 is ideally suited to tough quarry applications. Furthermore, our engines achieve Tier IV Final certifications without the need for DPF or EGR, for the ultimate in durability and efficiency. www.liebherr.com Crawler

A18 JULY 3, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL Liebherr-Canada Ltd. • 1015 Sutton Drive • Burlington, Ontario L7L 5Z8 • Phone: +1 905 319 9222 info.lca@liebherr.com • www.facebook.com/LiebherrCanadaLtd • www.liebherr.ca Excavation in the blood

excavators R 945 2037-501_005 LFR_146_R945_G8_2021_EquipmentJournal_CAN_GB-01.indd 1 16.06.23 14:48

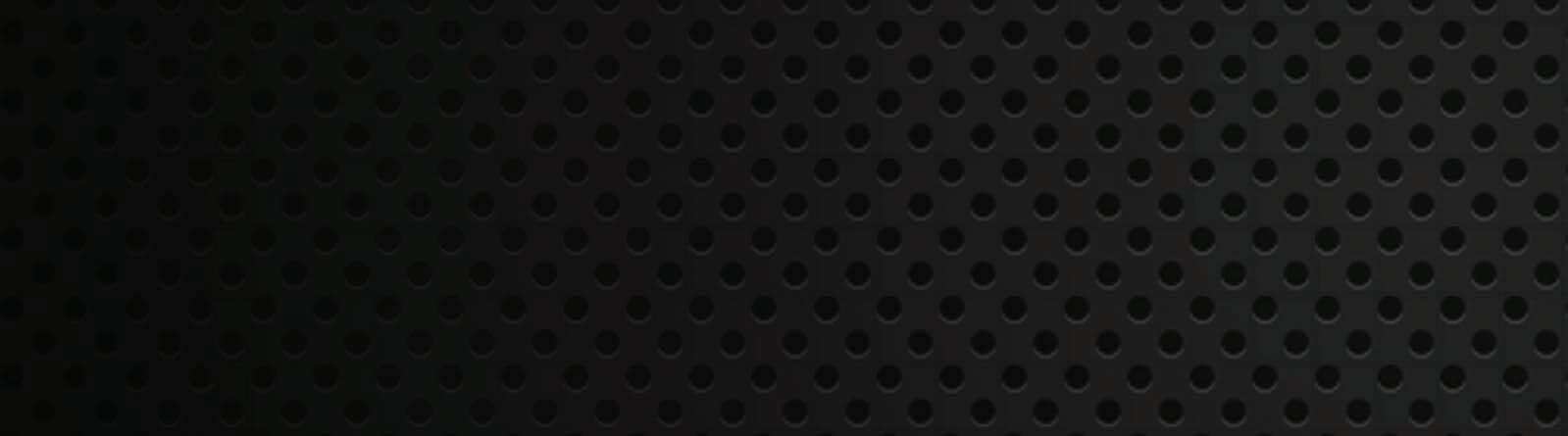

Mecalac’s compact loader line arrives in North America

Designed for space management, versatility and ergonomics, the Mecalac Compact Loader (MCL) line is now available in North America.

The MCL line is designed with a similar size as a skid steer, but with additional features and functionality. The new series of loaders includes the MCL2, MCL4, MCL4+, MCL6, MCL6+ and MCL8.

The smallest loader in the line, the MCL2 weighs 1,740 kg and is powered by a 25 hp engine that enables a maximum travel speed of 11 km per hour. The MCL8, the largest MCL loader, features a 2,850 kg operating weight and a 45 hp engine with a maximum travel speed of 30 km per hour.

“We came out with six machines. Why? Because the markets are very separate. It’s construction, it’s rental, it’s agriculture, its many markets, and each market takes care of different things,” said Patrick Brehmer, Head of Design and Product Management for Mecalac.

The MCL2 and MCL4 models deliver 30 litres per minute of hydraulic flow, while the MCL6 and MCL8 models provide 60 litres per minute of hydraulic flow.

Each compact loader has an option for auxiliary hydraulic lines on the boom and at the rear of the machine, as well as 12V electrical outlets, allowing the ability to use hydraulic attachments on either end of the machine.

All MCL machines feature 45-degree articulation that keeps the front wheels travelling in the same path as the rear wheels while driving. As well, a 10-degree oscillation allows a strong follow-up and maximum traction during travel.

“It's a very compact machine with a very high

articulation angle and taking the smallest footprint possible,” Brehmer said.

Comfort equals safety

Safety continues to be a key focus for Mecalac in the MCL series with easy accessibility for entering the cab or re-fuelling from a solid ground footing. Additionally, the machines offer enhanced side and top visibility over similar sized skid steers. In the cab, Mecalac has focused on operator comfort and ease of use to promote safe operation.

“Ergonomics is comfort, safety and efficiency. And it’s often linked: if something is comfortable, it will be safe and efficient,” Brehmer said.

M-Drive and speed control

The M-Drive and speed control features allow the loader to function as a tool carrier, providing control of rpm by hand throttle and speed via a foot pedal. This enables precise and controlled operation of a wide variety of hydraulic attachments.

The ability to define the speed range via the foot pedal provides supplemental benefits for several applications. For example, the operator can select a lower

speed to improve accuracy on precise applications, such as flail mowing, sweeping or when using log grapple attachments.

“So, you can manage independently completely the speed of your engine, the flow, hydraulic flow and driving speed. And you can set that this changes the way to work with hydraulic tools,” Brehmer said.

Both Speed Control and M-Drive are standard on the MCL6 and MCL8 models and are options for the MCL2 and MCL4 models.

Easy transportability

The MCL line’s ease of transportability appeals to contractors hauling multiple pieces of equipment as well as rental fleets handling pickup and delivery.

Each machine in the MCL series offers easy transportability between jobsites with transport weight ranging between 1,740 kg and 2,850 kg and a width range of 1 metre to 1.3 metres depending on tire selection.

Boom options

The MCL4+ and MCL6+ models come equipped with a short boom, which offers an improved tipping load, where the other four models

come with a long boom that maximizes tipping height. Long or short boom, the MCL series machines yield multi-functionality through compatibility with a wide range of attachments. For example, with its hydraulic and electric auxiliary lines, the MCL series is ideal for snow removal, as an operator can mount a snow blade on the front and a salt spreader on the rear of the machine.

Customization options for the MCL series allow customers to tailor the machine to their specific operation. A start-up code, entered on a keypad, offers the owner with tracking and monitoring capabilities by assigning a specific code for each operator. The code also minimizes the risk of theft. Each machine is available in three versions — canopy, canopy with foldable top or

a cab version — in combination with a wide selection of attachments, which drives versatility and customization capabilities for individual operations.

“The versatility is through the incredible hydraulics, electrical and drive functions with M Drive and speed control and the ergonomics because it's extremely safe, extremely stable and easy to enter,” Brehmer said.

A19 JULY 3, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL

OEM parts and components for all your off-highway equipment Authorized to perform warranty work Factory trained technicians (705) 560-BULL (2855) 1510 Fairburn St. Sudbury, ON P3A 1N7 bullpowertrain.com We Manufacture OEM Driveshafts COME JOIN OUR TEAM! WE ARE CURRENTLY SEEKING EXPERIENCED COMPONENT REBUILDERS. WE ARE YOUR AUTHORIZED SERVICE CENTRE FOR AUTHORIZED DISTRIBUTOR CONSTRUCTION EQUIPMENT RENTAL DOZERS - LOADERS - BACKHOES - ROLLERS CUSTOMER SER VICE TARTEN EQUIPMENT LIMITED 6199 Shawson Drive Mississauga, ON L5T 1E5 Phone: 905 670 1704 Fax: 905 670 4790 Toll Free: 1 888 670 1704WWW.TARTEN.COM COMMITTED TO SERVICE EXCELLENCE SINCE 1976

Boston Dynamics teaches Spot new tricks

Boston Dynamics has released new software and hardware for its autonomous Spot robot.

Spot 3.3 includes enhancements to inspection solutions, new features in Scout software, as well as new features to improve safety on busy jobsites.

With these updates, the robot can start working on a site in just a few hours and start to generate value in its first week of deployment.

Spot’s latest software

includes multiple, simultaneous inspection types built into the platform and an updated inspection configuration workflow to deliver a seamless user experience.

As well, Boston Dynamics has introduced a full endto-end thermal inspection workflow.

In addition to triggering Scout notifications when equipment exceeds pre-set ranges, the user can set up inspection actions to capture multiple regions of interest in a single photo. Post-inspection, users have access to more data.

Visual inspections like gauge reading are also more integrated in the new software release. With a gauge reading computer vision add-on provided by Levatas, Spot can inspect analog gauges across your site, monitor trends through Scout, and trigger alerts for abnormal readings.

With a Fluke SV600 payload for Spot, the user can trigger acoustic inspection actions directly from a tablet and evaluate inspection results remotely through Scout.

The SV600 can serve as an early warning system.

All these inspection workflows are made easy through Boston Dynamic’s remote inspection software Scout. Scout is Spot’s one-stop shop for mission editing, mission scheduling, real-time data reviews and data transfer to an asset management system.

Boston Dynamics enhancements

Boston Dynamics also enhanced the robot to include an audio and visual signalling system. Spot now includes an emergency stop button to increased safety.

The new audio-visual system is embedded into the robot and consists of safety

lights located around the robot’s body, a safety buzzer and a speaker. This new system provides enhanced safety and awareness for people working near the robot in industrial settings. To make sure people near Spot know what to expect, the system comes pre-configured with light patterns and tones to alert workers that Spot is performing actions in the area. These include:

· Standard operation:

When Spot is operating as intended during normal mission activities, it will project a green blinking pattern

· Inspection underway: When the robot is conducting inspections white lights will flash

· Caution recommended:

When people should pay extra attention and exercise caution around the robot, it will switch to an amber blinking pattern

· Stopped robot: When the robot’s emergency stop has been pressed, red lights will flash.

As well, Spot now includes a physical emergency stop button on the back of the robot, in addition to the existing quick stop options on the tablet and in Scout. When the button is pressed, the robot will quickly and safely sit down.

Boston Dynamics also added moving object detection, which can be turned on anytime a Spot EAP 2 payload is attached. Using this payload’s lidar, the robot can detect moving objects such as people or forklifts.

When the robot identifies a moving object in its path, it will signal, keep a safe distance and exercise increased caution as it continues on its mission.

A20 JULY 3, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL

CANADA’S NATIONAL HEAVY EQUIPMENT NEWSPAPER SINCE 1966 CONNECT WITH US! Visit us at: www.equipmentjournal.com

Hitachi introduces two Dash 7 wheel loaders

Hitachi Construction

Machinery Americas has added two new wheel loader models to its Dash 7 product line.

The 3.5 cubic-yard Hitachi ZW180-7 and ZW180PL-7 wheel loaders feature a 14,905 kg operating weight.

The ZW180-7 offers either standard or high-lift front arms that excel in most bucket applications.

Both loaders are powered by a 173 hp Cummins engine.

The ZW180PL-7 offers a parallel link arm configuration. It is ideal for use in fork and tool carrier applications by keeping attachments parallel with the ground as the loader arms move up or down. This ability delivers increased control while loading or unloading items. As well, the parallel link arm configuration expands operator visibility when using forks and other attachments.

“With the three front linkage options, these wheel loaders offer the versatility to handle any application, whether the loader is used to move pallets around the yard, load materials into trucks or manage stockpiles,” said Matt Koester, Wheel Loader Product Manager at Hitachi Construction Machinery Americas.

To improve upon productivity, Hitachi has equipped the loaders with Approach Speed Control and an Auto Power Up function. With ap-

proach Speed Control, the travel speed can be adjusted with fewer pedal operations during loading, which reduces operator fatigue and fuel consumption. Travel speed is controlled through the five-speed transmission during short loading operations. Limited-slip differentials also ensure traction in demanding applications. The Auto Power Up function increases hill climbing performance by identifying slopes and increasing power to prevent the engine speed from dropping.

Payload weighing system

The ZW180-7 wheel loader is equipped with a payload weighing system that uploads productivity information to the ConSite telematic system. Operators can check the weight of the load in the bucket from the in-cab monitor and log the material loaded. The system offers four modes:

· Tip-off to truck

· Tip-off to pile

· Auto-add

· Manual-add

These modes allow the payload weighing system to manage loads according to the application. As well, the unit is equipped with a warning function that reacts when the bucket is overloaded, improving safety during operation.

Hitachi improved the overall comfort of the ZW180-7

and ZW180PL-7 wheel loaders with larger and quieter cabs. The cab is enhanced with a seat-mounted armrest with ergonomic electric hydraulic controls, ergonomically located switches as well as an adjustable seat and mirrors.

A 20.3 cm anti-glare LCD monitor with Bluetooth radio allows hands-free phone capacity.

Designing cabs with panoramic visibility helps create a safe and comfortable working environment. The position and design of the cab pillars, the layout of the monitor and switch panel have been improved to ensure a wider field of view from the cab.

Hitachi also improved visibility with its Aerial Angle Peripheral Vision camera system. It provides a wide 270-degree bird’s-eye view of the machine’s immediate environment. Aerial Angle includes three cameras mounted on the rear of the machine. Operators can see both the left and right sides of the machine on the monitor inside the cab.

Obstacle detection

Hitachi’s latest safety innovation is an optional rear obstacle detection system with automatic speed reduction for the ZW-7 wheel loader product line.

“About 50 per cent of the time that wheel loader is going in reverse,” said Simon

Wilson, Vice President of Sales for Hitachi Construction Machinery Americas.

“We improved the styling around the back so that you can see, but there is also an optional tool now that has rear obstacle detection that will automatically slow the vehicle down, so it doesn't run into a person or into a wall.”

Design enhancements also help protect critical components of the wheel loader from the environment.

An inner element of the engine air filter protects the engine from dust ingress while cleaning the outer element. Even the air conditioner is protected with

a sealed internal filter that prevents intrusion of dust into the air conditioner unit.

Airborne debris can become an issue in many wheel loader operations, often leading to decreased cooling system performance. Hitachi

Construction Machinery

Americas addressed this with an intelligent automatic reversing hydraulically driven fan and wide-fin radiators to prevent clogging.

Daily maintenance has been simplified with easy access filters and improved access to components.

A21 JULY 3, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL

2012

Includes

6220 VGF