EXPERIENCE - Established in 1975, Powerscreen of Canada has been supplying portable screening, washing, stockpiling and crushing equipment to the aggregate and recycling industries for over 48 years.

PARTS - With over $4 million of parts inventory, highly trained service technicians and a full fleet of service vehicles, Powerscreen of Canada is committed to meeting your parts and maintenance needs to keep you producing.

SERVICE - We are ready to assist you in repairs, preventative maintenance and replacement of wear parts. On-site training is also available so that your operators get the most out of your machine, the maintenance process and troubleshooting techniques.

A STRONG LINE UP OF POWERSCREEN, CEDARAPIDS, TEREX WASHING & EVOQUIP.

LETTER

In the House of Commons, the NDP and Conservative parties are not known for seeing eye to eye.

However, a recent Private Members Bill from Chris Lewis, the Conservative MP for Essex, has earned the support of the NDP as well as the Bloc Quebecois and Green Party.

The bill, which is now making its way through the senate, would enable tradespeople to claim expenses for work that is located at least 120 km from their residence, including travel, accommodations and meals. Shockingly, the bill made it through parliamentary committee in 17 minutes without any amendments.

“If it is good enough for Members of Parliament to write off their travel expenses, their apartments and their meals, then it better darn

well be good enough for our skilled trades folks,” Lewis said.

Travel write-offs are not limited to MPs. Businesspeople have long been able to travel and write off the related expenses.

As well, the idea of including the trades in the write-off ability isn’t exactly new.

The NDP have previously tabled similar bills without gaining traction, while the 2022 budget included measures to allow tradespeople to claim up to $4,000 in expenses.

“This bill has no limit, so the more they work, the more money our skilled trades are putting back into our economy, and we are not handcuffing these same folks from going to work,” Lewis said.

Regardless of which political party came up with the

idea, the benefits of the tax write-off are numerous.

For the many tradespeople that travel across Canada to work, the tax benefit will make returning home for an occasional weekend more financially feasible. For jobsites in remote locations, lowering the cost of the lengthy commute will likely make the job more attractive to skilled labour.

The financial aspect aside, the amendment to the Income Tax Act is a sign of mutual respect. The tradesperson’s work that requires travel holds the same importance as any white-collar worker that’s on the road for their job.

And as Bloc Québécois MP Xavier Barsalou-Duval pointed out, the debate for the bill opened an unusual discussion for MPs.

“We address all sorts of

Bill Tremblay // Editor editor@equipmentjournal.com

theoretical questions in the House. We talk about families struggling to make ends meet, and it is important that we do. We also talk about the ultra-rich,” Barsalou-Duval said.

“However, we do not talk enough about tradespeople, the middle-class, the people who work so hard to build our country.”

CONTACT US

Editor Bill Tremblay editor@equipmentjournal.com

Publisher Mark Baker mark@equipmentjournal.com

PACE

Sales Manager Tara Rosen tara@equipmentjournal.com

National Account Manager Mona Fahmi mona@equipmentjournal.com

LOCAL: (905) 629-7500

TOLL-FREE: CDN/USA 1-800-667-8541

Creative Director/Creative Services Ryan Chuhaniuk ryan@equipmentjournal.com

Circulation Manager Lisa Bath lisa@equipmentjournal.com

EMAIL US: advertise@equipmentjournal.com

WEBSITE: www.equipmentjournal.com

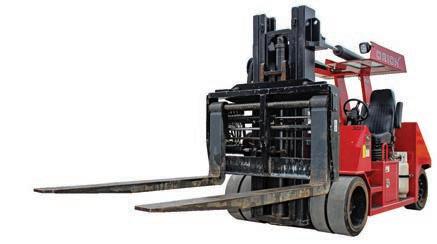

Doosan Bobcat has announced three additional product lines will be rebranded under the Bobcat trade dress.

Doosan Portable Power (DPP), a global manufacturer of air compressors, mobile generators and light towers; Doosan Industrial Air (DIA) rotary air compressor lines; and Doosan Industrial Vehicle (DIV), a supplier of material handling equipment, including forklifts, will rebrand under the Bobcat trade dress in North America and applicable markets worldwide.

“Bobcat is an iconic brand that changed the world with the invention of the compact equipment industry, and we are excited to unleash the brand in bold, new ways,” said Scott Park, Doosan Bobcat CEO and Vice Chairman.

“Doosan Portable Power, Doosan Indus-

trial Air and Doosan Industrial Vehicle have long legacies of developing high-quality products. Bringing these strong Doosan brands into the Bobcat portfolio allows us to further expand these business lines, while also growing our overall Doosan Bobcat business and providing even more solutions to help our customers accomplish more.”

The branding approach to the organization’s portable power, industrial air and industrial vehicle equipment offerings aims to strengthen overall brand equity, market recognition and consumer recall of all product offerings.

As well, the transition aims to create a cohesive customer experience and grow the organization’s footprint, making the brand accessible to more customers and in more places.

In the last five years, Bobcat has broadened its product portfolio significantly, launching more machines during this period than previously in its entire history.

The Bobcat brand has successfully expanded its offerings with new technologies and innovations and expanded product lines, such as grounds maintenance equipment, which includes compact tractors, small articulated loaders and zero-turn mowers.

“The Bobcat brand empowers ambitious and passionate groundbreakers to accomplish more. Across the globe, big challenges get smaller because of our equipment; from breaking down walls to building up communities, we’re proud to provide people what they need to be successful in

their endeavors,” said Laura Ness Owens, Doosan Bobcat Vice President of global brand and North American marketing.

“By expanding the Bobcat brand to the portable power, industrial air and industrial vehicle industries, Bobcat can help even more customers, in more ways than ever.”

With this refreshed identity, the new Bobcat-branded DPP, DIA and DIV product suites will, respectively, undergo design and aesthetic changes in alignment with current branding.

The Bobcat-branded material handling equipment, industrial air compressors and portable power products are expected to be available for customer purchase through Doosan Bobcat’s global dealer network at a later date.

The most powerful and most useful track jaw plant on the market! Engineered to be the highest capacity jaw crusher on the market, the Pioneer® Jaw Crusher will deliver up to 25 percent more tons per hour than comparable jaw crushers.

Intake Opening: 26” D x 50” W

Operating Weight: 104,000 lbs

Feeder: 50” x 18’ Vibratory

Engine: Cat Tier 4 - 300 hp AMACOCEI.COM

Holcim’s ECOPact low-carbon concrete has won the inaugural Next Level Awards Contractors’ Choice at ConExpo-Con/Agg and IFPE 2023.

ConExpo attendees were able to cast their vote for the Contractors’ Choice award during the trade show from March 14 to 16.

The Next Level Awards were announced in August, and the 10 finalists were selected by members of the Association of General Contractors in February.

The awards celebrate ConExpo exhibitors that push

boundaries and develop next-level products, technologies or services designed to advance the construction industry.

"We are proud to announce Holcim as the winner of the inaugural Next Level Awards – Contractors’ Choice,” said Dana Wuesthoff, ConExpo-Con/Agg. "Their commitment to excellence and innovation in the construction industry is truly impressive, and it is evident that they are highly regarded by the industry."

Holcim’s ECOPact concrete delivers a versatile solution to

the carbon challenge, offering up to 90 per cent lower carbon dioxide emissions compared with standard concrete mix designs.

"We are honoured to have ECOPact low-carbon concrete recognized as the Contractors’ Choice for the inaugural Next Level Awards Program," said Toufic Tabbara, Region Head for North America at Holcim.

“We are committed to changing the way we build a more sustainable future and helping our customers reduce the carbon footprint of their projects.”

Topcon Positioning Systems has acquired Digital Construction Works (DCW), a construction software and data integrations and services company.

DCW services and software integration platform will help customers navigate and maximize the use of construction data made available across multiple apps and software. Today’s construction business owners have more available data than ever before, but it is often a challenge to distill information from so many sources.

To make the most well-informed business decisions, Digital Construction Works provides contractors with an easy way to understand all of the data generated from multiple digital tools and software along every phase of a project.

Topcon announced the acquisition at ConExpo in Las Vegas.

“DCW enables the connection of the job site and the office,” said Jason Hallett, vice president and general manager of Digital Construction Works.

“Automation and the availability of integrated and aggregated data provide greater insights into project performance and status. Now, as part of Topcon, our integrations platform enhances the value of Topcon’s interoperability with third-party software typically used to execute machine-guided operations.”

The Digital Construction Works team continues to focus on integrations that connect a project’s planning and design phase with the construction and field completion phases.

The Contractors’ Choice finalists were judged on the following criteria:

· Addresses a common industry need in a unique and innovative way

· Benefits the industry across multiple applications

· Positively impacts safety, sustainability and workforce

ECOPact has equal or better properties than conventional concrete. As well, the concrete is available in a variety of strength classes and is compliant with in -

dustry standards. It can be easily handled, pumped and finished like conventional concrete.

ECOPact includes an innovative mix of supplementary cementitious materials and admixtures technology.

The concrete mix designs

may be used in a variety of structural components, including foundations, columns and beams, walls, driveways and walkways.

To save natural resources, ECOPact may also include construction and demolition waste.

We always deliver TOP QUALITY product on-time, every time for over 40 years.

Hyundai Construction Equipment has introduced the HL985A, its largest capacity A Series wheel loader model, which offers a standard 7 cubic metre bucket.

Introduced at ConExpo, the HL985A is designed for use in high-production jobs such as quarrying, aggregates and other mass-volume material handling applications.

“We refer to the HL985A as a ‘true twopass’ wheel loader because it can fill one of our HA30 articulated dump trucks with two bucket loads,” said Joe Turnage, Senior Product Manager for Hyundai Construction Equipment Americas.

“With the addition of the HL985A, the Hyundai wheel loader line includes models that fulfill the needs of every important wheel loader application. At the same time, like every A Series wheel loader model, the new Hyundai HL985A provides the combination of power, performance, fuel efficiency, and operator safety and comfort that successful contractors expect from Hyundai.”

The Hyundai HL985A wheel loader is powered by a 430-hp Cummins X12 Performance Series engine. The engine provides optimum power and torque, while maintaining fuel efficiency and meeting Tier 4 Final and Stage 5 emissions standards.

“Our customers tell us they appreciate that our A Series wheel loaders do not use exhaust gas recirculation because it is not necessary to do periodic shutdowns,” Turnage said.

Powered by a ZF 5-speed transmission, the loader is equipped with heavy-duty ZF axles with wet outboard brakes and coolers are standard equipment.

The HL985A bucket includes a three-piece

bolt-on cutting edge and an auto-level feature that helps prevent bucket spillage. Also, a heavy counterweight enhances the machine’s stability.

The Hyundai HL985A offers Smart Power Mode, which reduces fuel consumption by adjusting the engine speed in heavy-duty applications. This can save fuel while balancing traction and breakout forces to improve productivity.

As well, Hyundai’s Eco Gauge enables the operator to monitor fuel consumption in real time or to review historical data. Eco Gauge also displays engine torque, fuel efficiency, average and total fuel consumed. Hourly and daily fuel consumption is viewable through the menu.

The wheel loader is available with Hyundai’s All-Around View Monitoring (AAVM) system. Now enhanced with radar, the AAVM system includes four cameras, providing 360-degree views, and incorporates motion detection for enhanced operator and jobsite safety.

For high-volume, material-handling applications that require monitoring and reporting the weight of materials loaded or moved, Hyundai’s enhanced, proprietary onboard weighing system is accurate to within one per cent and includes a cumulative weighing function that facilitates the creation of production reports.

EH controls

The Electro-Hydraulic (EH) control system improves precision and ease of operation. The EH control lever simplifies attachment operation with integrated, third-spool proportional auxiliary control. The loader is

also equipped with a heated air-ride seat; cab heater and air conditioner; rearview camera; electronically adjustable, heated and foldable rearview mirrors; AM/FM radio with Bluetooth; and a 15 cm multi-function monitor and control panel.

Simplified maintenance

For operator convenience, consolidated service drains and the diesel exhaust fluid tank spout are located on the right side of the wheel loader. Furthermore, the hood opens and closes via an electronic control. Dual battery boxes and swing-out cooling package are easily accessible, while the incab HVAC system filter is within reach for removal and replacement.

Case Construction Equipment is reviving its “Construction King” backhoe loaders with the introduction of five new machines for the North American market.

The Case Utility Plus and the Case 580SV Construction King centre pivot models are immediately available. Case will introduce three additional models later this year, including 580SV Construction King side shift, and two 695SV models, including one with centre pivot and one with side shift.

“The Case backhoe was the original two-in-one machine, and 65 years later we’re experiencing workforce challenges and more diverse jobsite needs, all with a focus on efficiency, that is driving a true revolution for the backhoe market,” said George MacIntyre, Product Manager for Case Construction Equipment.

“Once the hero for the owner/operator, we’re providing even more backhoe loader options now that make these machines extremely at-

tractive for businesses who are having trouble finding skilled operators, and who could benefit from the lower owning and operating costs of having all that functionality in a single machine.”

The new Construction King models add to the existing lineup of N Series backhoes.

The all-new Utility Plus delivers full-sized backhoe performance in an efficient platform that’s easy to own and maintain. The new 74 hp machine features a large cab with sightlines to all work areas, a maintenance-free emissions system (no DPF and no DEF), and pilot or mechanical control options.

Mechanical controls are offered for the more experienced operators who like that traditional backhoe feel, while pilot controls are available for rental businesses and contractors with less-experienced operators.

“You could call this an entry-level machine, but it performs and delivers options like a full-sized backhoe,” MacIntyre said.

“We’ve built it so that you can focus on simplicity, ideal for rental applications and businesses where this isn’t a daily production tool, but also committed to options such as the Extendahoe and attachment performance via one-way auxiliary hydraulics on the dipper for businesses that want to use this machine for more. It’s built to be versatile and allow equipment owners to build up from a simple base model.”

The all-new Case 580SV Construction King brings a tool carrier-style front end back to the Case backhoe line in North America.

This backhoe is ideal for businesses who use the loader end of their backhoe as a primary material handler for loading and unloading pallets, moving pipe and other bundled material around the yard.

Adding a 4-in-1 bucket, a 6-in-1 bucket, or any of the countless attachments available for Case backhoes turns this into a multi-purpose jobsite solution. The new centre

pivot model is immediately available to the North American market, and Case will be rolling out a side-shift model later in 2023.

“At 97 horsepower, the Case 580SV Construction King is a simple yet robust addition to any backhoe fleet and, like the Utility Plus, can be optioned up into a more premium backhoe experience with features such as the Extendahoe and Auto-Ride Control,” MacIntyre said.

The side-shift model, available later in 2023, will deliver more jobsite flexibility and performance in confined spaces. The Case 580SV Construction King side shift will feature in-line vertical stabilizers for offset digging and working in applications where operators have to get right up against structures, or take up less space, such as in roadside utility work.

“The combination of inline stabilizers and a backhoe digging boom that can shift from side to side allows operators to get right up against buildings and structures and takes up even less space on roadside applications with stabilizers that operate within the footprint of the machine,” MacIntryre said.

New models coming soon

Later this year, Case will introduce the 695SV Construction King models, including a centre-pivot model and a side-shift model.

The 695SV Construction King is a larger, more powerful backhoe loader with four-wheel steer and equally sized tires.

The four-wheel steer and large tires make it an ideal machine for loading operations while offering the versatility to switch out loader and backhoe attachments. It also includes the parallel lift tool carrier style loader arms for more intense material handling operations.

“It’s perfect for municipalities and larger construction sites that need to effectively perform both loader and backhoe operations,” MacIntyre said.

“As these new models hit the market, Case will have one of the largest and most diverse backhoe offerings in the industry.”

Manitoba AgCon Equipment Springfield | 204-255-4772

C&C Rentals Brandon | 204-728-2699

Ontario Bobcat of Hamilton Ltd. Stoney Creek | 905-643-3177

New Brunswick

Paul Equipment and Sons

Balmoral | 506-826-3289

Fredericton | 506-449-3289

Northwest Territories

Ron’s Auto Service Ltd.

Yellowknife | 867-766-6025

Nova Scotia

East Coast International Trucks Inc.

Authorized Dealers

Alberta Brown’s Industrial Sales Cold Lake | 780-826-2399

Lloydminster | 780-875-2339

Rentco Equipment

Grande Prairie | 780-538-0791

British Columbia Rentco Equipment

Fort St. John | 250-785-1197

Westerra Equipment

Abbotsford | 604-850-7313

Kamloops | 250-314-3600

Nanaimo | 250-716-0443

Williams Machinery Prince George | 250-563-0181 Surrey | 604-930-3300

Terrace | 778-721-0398

C G Equipment

Guelph | 519-826-0550

Zurich | 519-236-4934

Eastrock Equipment Inc. Ottawa | 613-737-3963

Elvaan Equipment Solutions

Mississauga | 647-988-9931

G F Preston Sales & Service

Sundridge | 705-384-5368

Hartington Equipment

Hartington | 613-372-2744

ITEC 2000 Equipment

Rosslyn | 807-768-8584

ReadyQuip Sales & Service Ltd.

Timmins | 705-268-7600

Dartmouth | 902-478-3552

Quebec

Équipements Plannord

Beloeil | 450-464-8000

St-Augustin-de-Desmaures | 418-878-4007

Machinerie St. Pierre

Val-d’Or | 819-824-6931

Saskatchewan

Bobcat of Regina, Ltd.

Regina | 306-347-7600

Earthworks Equipment Corporation

Saskatoon | 306-931-7880

Yukon

MacPherson Rentals

Whitehorse | 867-633-4426

Patrick Doheny from Australia has won the title of World Champion in Caterpillar’s Global Operator Challenge.

Doheny took the crown out of nine finalists from around the world who competed in the final round of the Global Operator Challenge in the Cat Operator Stadium During ConExpo in Las Vegas.

“I am beyond thrilled to have earned the title of the best Caterpillar machine operator on the planet,” Doheny said. “Kudos to Caterpillar for hosting such an incredible event to highlight the importance of our profession. It is truly a dream come true to see your life’s passion be re -

warded in such an amazing way.”

As champion, Doherty wins a trip for two to a location where Caterpillar has one of its worldwide production facilities.

Matt Ferris from the United States placed second in the competition, followed by Łukasz Mokrzynski from Poland placing third.

“Caterpillar created this competition to celebrate machine operators who build our world, advocate and drive awareness for their trade, and highlight solutions that address jobsite challenges,” said Jason Hurdis, Caterpillar Global Operator Challenge Execution Lead and Global Market Professional. “All of the com-

petitors – and especially our nine finalists – showed tremendous skills and abilities operating the latest Cat construction machines and technologies, maneuvering through some difficult challenges and showing the world the invaluable role they play in infrastructure creation.”

5,500 contestants

The challenge kicked off in the spring of 2022 with more than 10,000 operators worldwide signing up to compete. After a pre-qualification phase, the first round featured 5,500 contestants competing in local events organized by 77 Cat dealers in 32 countries. The second round in the fall of 2022 consisted of four regional events held in the United States, Brazil, Spain, and Japan. These competitions included digging a trench, loading a precise amount of dirt, and hauling or maneuvering the machines through obstacles.

The finals kicked off with the “Fork ‘n Loader” challenge, where each operator used the Cat 950 wheel loader with Payload technology

to load and move material through specified locations on the course.

The “Backhoe Services” challenge had operators using both ends of the Cat 420 XE backhoe to open a small box and precisely place small objects inside. This challenge was designed by Canada’s Jaus Neigum, the 2020 inaugural Caterpillar Global Operator Challenge World Champion, and highlighted Caterpillar’s Customer Value Agreements and services offerings.

During the final “Trench Run” challenge, operators showed off their trenching skills using a Cat 315 excavator equipped with Grade technology.

Final scores were based on the operator’s skills, efficiency, and competence in executing a variety of tasks, with penalties imposed for errors. Awards were given to the overall event champion, the individual with the lowest time in each skills challenge, and the team with the lowest combined score. The operators completed the challenges using Cat construction machines

integrated with the latest machine-control and payload technologies, including Cat Payload, Grade and Command, Cat Grade Assist, rearview cameras, return to dig and return to carry.

Other Operator Challenge awards include:

· “Fork ‘n Loader” challenge winner – Patrick Doheny from Australia

· “Backhoe Services” challenge winner – John Schiedeck from the United States

· “Trench Run” challenge winner – Łukasz Mokrzynski from Poland

· Team champion Team Americas (Fernando Do Nascimento from Brazil and Matt Ferris and John Schiedeck, both from the United States)

1.866.488.0878

I can’t give enough credit to the SENNEBOGEN service team. They worked through all the ‘interesting’ challenges that came up along the way – there are no better guys out there. Being so new, there weren’t a lot of mechanics anywhere trained on this, but they and our dealer’s mechanics have been great about coming out and working alongside our mechanics.

Barge Terminal Manager, Huger, NC

Read more about how our “Beyond the Machine” aftersale commitment ensures life-long support for SENNEBOGEN customers with the nation’s largest network of factory-trained technicians.

Newfoundland and Labrador

Strongco

Mount Pearl, NL (709) 747-4026

www.strongco.com

Ontario

Strongco

Stittsville, ON (613) 836-6633

Sudbury, ON (705) 692-0552

www.strongco.com

Nova Scotia

Strongco

Dartmouth, NS (902) 468-5010

www.strongco.com

New Brunswick

Strongco

Moncton, NB (506) 857-8425

www.strongco.com

Quebec

Strongco

Baie-Comeau, QC

Chicoutimi, QC

St-Augustin, QC

Trois-Rivieres, QC

Val d’Or, QC

www.strongco.com

1-866-996-3091

1-800-323-1724

1-800-463-2662

1-855-840-0828

1-800-561-4192

Top Lift Enterprises, Inc.

St-Laurent, QC (514) 335-2953

Sherbrooke, QC (819) 612-5438

www.toplift.com

Thunder Bay, ON (807) 475-3052

www.strongco.com

Top Lift Enterprises, Inc.

Bolton, ON (905) 857-5200

Stoney Creek, ON (905) 662-4137

www.toplift.com

Manitoba

Westcon Equipment & Rentals Ltd.

Winnipeg, MB 1-800-453-2435 www.westconequip.ca

Saskatchewan Redhead Equipment

Estevan, SK (306) 634-4788

Lloydminster, SK (306) 825-3434

Melfort, SK (306) 752-2273

North Battleford, SK (306) 445-8128

Prince Albert, SK (306) 763-6454

Regina, SK (306) 721-2666

Saskatoon, SK (306) 934-3555

Swift Current, SK (306) 773-2951

www.redheadequipment.ca

Alberta Strongco Acheson, AB 1-877-948-3515

Calgary, AB 1-800-342-6523

Edmonton, AB (780) 464-1909

Fort McMurray, AB 1-855-799-4201

Grande Prairie, AB 1-888-513-9919

British Columbia

Great West Equipment Campbell River, BC (250) 286-0123

Cranbrook, BC (250) 426-6778

Fort St. John, BC (250) 785-4223

Kamloops, BC (250) 372-3996

Nanaimo, BC (250) 716-8804

Prince George, BC (250) 612-0255

Surrey, BC (604) 882-5051

Terrace, BC (250) 635-9033

Vernon, BC (250) 549-4232

Williams Lake, BC (250) 392-9599

www.gwequipment.com

Red Deer, AB

1-866-950-3473 www.strongco.com

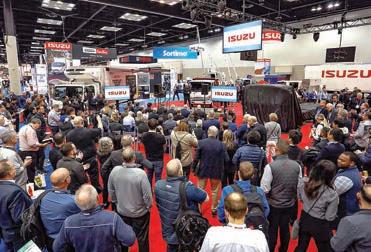

Following five days of showcasing the latest machines and products available to the construction, aggregate and fluid power industries,

ConExpo/Con/Agg and IFPE 2023 has ended, setting new records for the trade show.

The show returned to the Las Vegas Convention Center from March 14 to 18.

ConExpo 2023 surpassed expected attendance numbers, drawing more than 139,000 construction and fluid power professionals from 133 countries, representing a 6 per cent increase in attendance compared to 2020.

The number of attendees makes ConExpo the largest trade show in North America.

“The innovations in the construction industry unveiled this week will play a role in helping construction professionals drive meaningful and sustainable economic growth,” said Phil Kelliher, Caterpillar Senior Vice President and ConExpo-Con/Agg show chair.

“Live events in the construction industry are very important, because you can see, touch and experience the products. That value was reaffirmed this past week across the show floor.”

ConExpo by the numbers

This year, ConExpo covered more than 3 million net square feet of exhibits, a 10.5 per cent increase compared to the previous show. As well, more than 2,400 exhibitors from 36 countries, including 603 new companies, showcase their products at the trade show.

International visitors from 133 countries represented more than 24,000 of ConExpo’s total visitors, while more than 600 members of the media from 33 countries visited the trade show.

ConExpo’s 190 educational sessions recorded 91,000-plus badge scans throughout the seminars.

This year’s show emphasized how the construction industry is evolving to deliver sustainable technologies, products and practices. Show attendees were treated to sustainability in action, from electric, hybrid and hydrogen powered

construction equipment, to more recyclable materials and waste reduction opportunities.

One of the biggest sustainability efforts on the part of ConExpo directly is a partnership between the show and the Arbor Day Foundation. ConExpo-Con/ Agg and the Arbor Day Foundation will be planting more than 139,000 trees, one for every show registrant in a forest of greatest need.

Additionally, ConExpo-Con/Agg exhibitors, attendees and fans of the show can contribute to the Arbor Day Foundation’s funds, allowing them to further their goal of involving themselves in its mission of planting, nurturing and celebrating trees around the globe.

Held every three years, ConExpo is the must-attend event for construction industry professionals. The show features the latest equipment, products, services and technologies for the construction industry. The show is owned in partnership with NRMCA, NSSGA and AEM and managed by AEM.

ConExpo is held in conjunction with International Fluid Power Exposition (IFPE), which targets the fluid power, power transmission, motion control and construction and construction materials industries.

"The success of ConExpo-Con/Agg and IFPE 2023 is a testament to the resilience and strength of the construction and fluid power industries, which has continued to adapt and innovate despite the challenges of the past three years," said Marcia Klein, Treasurer of Casappa Corporation and Show Chair of IFPE.

"We're proud to have provided a platform for industry professionals from around the world to connect, learn and discover new solutions for improving their businesses and the world we build."

ConExpo-Con/Agg and IFPE returns to the Las Vegas Convention Center from March 3 to 7, 2026, in

At ConExpo, John Deere offered the first glimpse of its all-new future generation of excavators.

The new machines leverage advanced solutions developed for other product lines and production systems across the John Deere enterprise.

The first three future generation excavators include the 145 P-Tier, 360 P-Tier and the 210 P-Tier.

“This is the foundation for every future generation excavator that we will have,” said Aaron Klauer, John Deere’s global product manager for mid-and-large size excavators.

To create the new excavator foundation from the ground up, Deere built the machines in collaboration with its customers, who returned to assist with validating machine performance.

“There was feedback all the way to tell us this is the right way to go,” Klauer said.

The three new machines are designed to deliver industry leading performance, reliability and durability fea-

tures, including an exclusive full-size cab on the reduced tail swing 145 P-Tier machine.

In February 2022, John Deere announced it had acquired full ownership of three Deere-Hitachi joint venture factories. As well, the announcement officially ended the joint venture manufacturing and marketing agreements between the two companies.

“We took a giant leap forward in excavators about a year ago by taking complete design control of our entire excavator line,” Klauer said. With a new ability to leverage the entire suite of John Deere advanced technology solutions, the future generation excavators will provide enhancements in connectivity, safety, automation and grade management.

“By having that design control, we can leverage the entire power of the Deere enterprise and all of the technological capabilities and advancements we’re doing,” Klauer said. “We can

integrate that faster than we were able to before into our excavator lineup.”

Alongside the future generation models, Deere also introduced the new 85 P-Tier and 510 P-Tier current generation excavators. Both types of updates are examples of how John Deere can leverage technology from across the enterprise to extend advanced features and smart solutions to its full line of excavators.

“We are beyond excited about the future of our excavator lineup, including the new models available to our customers today and the machines being strategically designed and built for tomorrow,” Klauer said.

Compared to the 85 G-Tier model, the new 85 P-Tier boasts an 18 per cent engine horsepower increase and the addition of a turbo for high altitude performance.

Deere also improved upon hydraulic performance with

increased pump torque and improved dig forces.

The larger, redesigned cab is equipped with a 20-cm monitor and an integrated 270-degree camera system.

The 86 P-Tier is also equipped with an angle blade with float and continuous flow auxiliary hydraulics.

The 51-tonne 510 P-Tier replaces the current 470 P-Tier model. The excavator includes a variable undercarriage and the ability to handle buckets five yards and above.

By using a more efficient powertrain, including the integration of E-fans, the new 510 P-Tier provides up to 25 per cent lower maintenance costs, 15 per cent lower repair costs and 20 per cent lower fuel consumption.

“It has lower fuel consumption, better cost of maintenance and better reliability than we’ve ever been able to deliver before in this size class,” Klauer said.

The new Grove GMK6400-1 all-terrain crane, purchased by A.W. Leil Cranes and Equipment, has been in constant demand since it left its base in Dartmouth, Nova Scotia.

The crane arrived in December and is the first Grove GMK6400-1 to arrive in Canada. Due to fleet capacity constraints, A.W. Leil had been excluded from opportunities in its market, particularly in providing maintenance services to wind turbines it had erected in the early 2000s.

“Our largest crane was 400 tons, which usually left us just shy of being able to service larger wind towers, so we recognized there was a need to upsize,” said A.W. Leil President Ryan Long. “We were initially looking at 500 to 650-ton machines, but once we started doing careful comparisons, plotting out every tiny detail in a spreadsheet, the GMK6400-1 kept shining through.”

The 450-ton GMK6400-1 features self-rigging MegaWingLift and MAXbase variable-position outriggers that support a lifting performance usually only seen on seven or eight-axle cranes.

Shawmut Equipment of Canada provided hands-on operator and technician training to A.W. Leil’s team at handover, where the crane joined its fleet of Grove TMS truck cranes and National Crane boom trucks. The crane hasn’t stopped working since heading to its first wind farm on Prince Edward Island.

Working throughout the Maritimes, the GMK6400-1’s road-legal status is highly appreciated by A.W. Leil.

“Taxi work is crucial for us, so the icing on the cake is that we can just head straight out, trailing a boom dolly behind,” Long said. “Other machines in the region have to spend extra time and work sending extra permits, trucks and boom launching before every single mobilization. In the end, that’s added cost to the customer. The GMK6400-1’s easy roading really has been a major turning point for us.”

A.W. Leil’s Crane and Rigging Supervisor Ryan Bruce was also impressed by the speed and logical nature of the process and the easily accessible plug-in ports for the remote handset that eliminates trips to the operator’s cab.

“The best thing about it has to be the safety package,” Bruce said. “Manitowoc has outdone itself with the amount of fall protection and the easy erection of safety rails on everything from boom to jib.”

The GMK6400-1 has a 60-metre main boom and when fitted with its full complement of jib, it can achieve a maximum tip height of 136 metres. The all-terrain crane boasts a compact overall package, with a length of 17.5 metres and boom overhang of 1.8 metres. Grove’s MegaWingLift system increases lift capacities by up to 70 per cent on the main boom and up to 400 per cent on the luffing jib.

“We’re not a huge company,” Long said. “But our fantastic new crane helps us punch above our weight and hopefully tells the market that we’re ready to take on any challenge.”

When loading material is on your to-do list, Wacker Neuson is ready for action. Our powerful wheel loaders, excavators, skid steers and compact track loaders deliver both performance and comfort. And our newest utility track loader offers class-leading hinge-pin height and fast cycle times to help you load, move and place material precisely.

2010 NEW HOLLAND U80B

79 horsepower, 4WD, Deluxe cab w/Heater & Air Con., 4 forward x 4 reverse speed trans. w/ Power Shuttle, Ride Control, New Holland/FFC Hyd., QC on front loader, Aux. hyd. on front loader, Quick-attach bucket & AMI pallet forks, 3 point hitch, Dual tilt w/ holding valve, Additional rear counterweight $69,900

2007 NEW HOLLAND B95

95 hp, 4 cylinder diesel, cab w/heat and air conditioning, front & rear wiper, Extendahoe, 1.3 yard front bucket, 24” rear bucket, Pilot Controls, 4 speed power shuttle trans., loader aux. hyd., 1050 Hrs, pattern control changer $69,900

2005 NEW HOLLAND DC85 Dozer, 89 gross engine horsepower, 4 cylinder engine, LGP model, 28” grouser shoes, Drawbar, Mechanical suspension seat, Canopy, 124” wide PAT blade, New sprockets & track chains Installed, 3577 hours $69,900

2007

90 hp, 4 cylinder turbocharged diesel, Cab w/heat & A/C, pilot controls, 4 speed powershift trans., Extendahoe, 14x17.5 front tires, 19.5L24 Rear tires, 24” Rear bucket, front pin on bucket $54,900

2004

HL760-7 Wheel loader, 40785 lb. operating weight, Cummins QSB5.9-C engine with 205 horsepower, 4-speed Powershift transmission, Exterior mirrors, 23.5R25 radial tires, 3rd function Auxiliary hydraulics, 2272 hours showing, 4.25 yard bucket, New decals being installed $54,900

2004 HYUNDAI HL730-7 21384 lb. operating weight, Cummins B3.9C 4 cylinder engine, 125 gross engine hp, 4 forward x 3 reverse speed Full Automatic Powershift transmission, 17.5-25 tires, Front & rear fenders, 3rd function auxiliary boom hydraulics, ACS hydraulic coupler, ACS 2 yard material bucket with bolt-on cutting edge, 3647 hours $64,900

65 horsepower, 4 cylinder diesel, Cab with heat and air conditioning, radio, pattern control changer, Dozer blade, 1 and 2 way auxiliary hydraulics, hydraulic quick coupler, hydraulic thumb, excavating bucket, rubber tracks, ONLY 190 Hours $124,900

2012 HYUNDAI HL730TM-9 26370 lb. operating weight, Cummins 128 hp engine, 4-speed Powershift trans, Tool Carrier model w/ QA, 3rd function aux. hyd, 17.5-25 tires, Front & rear fenders, 2.2 yard material bucket w/ bolt-on cutting edge, Exterior mirrors, Beacon light, Backup camera, 2806 hours $102,900

Tool carrier model with hydraulic quick coupler, Cummins QSB6.7 engine with 138 horsepower, 26680 lb. operating weight, 4-speed Powershift transmission, Front & rear fenders, Exterior mirrors, 20.5R25 radial snow tires, 2.5 yard material bucket with bolt-on cutting edge, 3rd function auxiliary hydraulics, 7553 hours $79,900

2011 HYUNDAI R16-9 COMPACT EXCAVATOR Mitsubishi 17 hp engine, 3640 lb. operating weight, Variable undercarriage width, 9

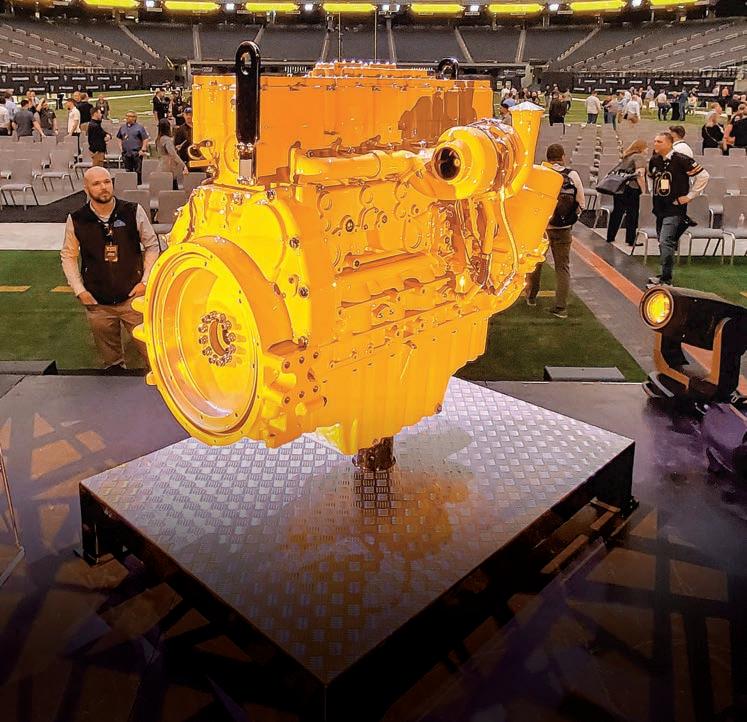

For Caterpillar, redesigning its 13-litre diesel engine is a once every three decades endeavor.

So, when Cat’s engineers set out to develop the new C13D engine, they were tasked with creating an engine that delivers best-inclass power density, torque and fuel efficiency for heavy duty off-highway applications.

The result is a new platform that can replace three existing engines in Cat’s portfolio. The C13D supplies comparable power and torque available from Cat’s current 13, 15 and single-turbo 18-litre engine platforms.

Caterpillar unveiled the new C13D at Allegiant Stadium, home to the NFL’s Las Vegas Raiders, during ConExpo in March.

“It gives us the ability to take this platform and use it in applications where our competition, and our own platforms, are using much bigger engines,” said Mark Stratton, Vice President of Large Engines at Cat Industrial Power Systems. “We only do this once every 30 years, so we’re going to do it right.”

The Cat C13D engine is targeted for a wide range of off-highway equipment, including rock crushers, screeners, grinders, trenchers, agriculture tractors, harvesters, woodchippers, material-handling equipment and large industrial pumps.

The inline, six-cylinder engine platform will offer eight power ratings from 456 to 690 hp with up to 3,200 Nm of peak torque. Engine mounted aftertreatment and cooling packs will also be available from the factory to reduce installation and validation costs.

The new engine platform offers up to a 20 per cent increase in power and up to 25 per cent more low-speed torque over the previous generation of Cat engines in its power class.

Engineers designed the Cat C13D engine with 45 per cent less leak joints to improve reliability and maintenance. As well, service intervals are extended up to 1,000 hours.

Depending on the application, the C13D also consumes between five and 25 per cent less fuel.

“For many of our customers, it really helps their bottom line,” Stratton said. “A significant portion of their operating budget is their fuel bill and if we can help them make that a little less painful, that’s something we can be proud of.”

The engine is designed to perform at altitudes of up to 3,657 metres, twice as high as legacy Cat engines, and in

temperatures as high as 60C or as low as -40C with aids.

“We know our customers are going to put these engines in some very harsh environments,” Stratton said.

“We’re pleased it can operate anywhere in the world.”

The combination of the all-new rear gear train, stiffer core architecture and common rail fuel system reduces noise by up to 3 dB when compared with the C13D’s predecessors.

“We spent a lot of time and effort making the engine quiet,” Stratton said. “We analyzed the harmonics over and over again of the block, the geartrain, the head and all components to reduce the vibrations that create noise.”

Renewable fuel options

The Cat C13D engine platform enables the use of 100 per cent Hydrotreated Vegetable Oil (HVO), B100 distilled biodiesel, and even up to B100 standard biodiesel. As well, its core architecture is designed to accommodate the future development of natural gas and hydrogen fuel capabilities.

The C13D will meet Tier 4 Final, Stage V, China Nonroad IV, Korea Stage V, and Japan 2014 emission standards.

By modularizing and eliminating components, its architecture is space-protected to accommodate configuration adjustments anticipated for future tiers of emission standards in the United States and Europe without relocating customer connection points.

The C13D is also the first engine that was designed and tested in a virtual environment.

Previously, developing a new engine would require building a physical prototype for testing, refining the prototype, then testing again.

“Before we ever made the first part or put it in our lab, we had extensive testing and validation in the virtual world,” Stratton said.

“We can literally run thousands of different piston ring simulations overnight with our simulation capability.”

The virtual design process also allowed Cat to optimize the engine for manufacturing.

“It’s not just the engine itself, we also fully simulated the assembly process to make sure when we get done with this engine, there’s not a bolt you can’t get to,” Stratton said.

“We believe we’ve really optimised this platform to perform for the future.”

Dedicated to diesel

Jaz Gill, Vice President of Sales, Marketing, Service and Parts at Caterpillar Industrial Power Systems, explained the company is investing heavily in new power technologies like, battery-electric, hybrid and alternative fuels such as HVO.

“While all of these new technologies bode well for the future, the tried and trusted internal combustion engine has been the pri -

mary workhorse of the vast majority of jobsites around the world,” Gill said.

“At Caterpillar, we’re dedicated to diesel. We see huge opportunities now and in the future for internal combustion engines.”

The C13D will be available for early OEM pilots in 2025 and scheduled for production in 2026.

With the introduction of the LR 1400 SX, Liebherr has extended its crawler crane range to include lifting capacities of up to 400 tonnes.

At ConExpo, Liebherr introduced the LR 1400 SX, its largest multipurpose crawler crane, as one of its new flagship machines for the North American market. At the trade show, the LR 1400 SX was fitted with a 41 metre main boom and a 44 metre luffing jib.

“The LR 1400 SX features a compact design which makes it easy to transport,” said Kai Friedrich, Managing Director of Liebherr USA.

“Like all Liebherr equipment, the crane features several assistance systems that support safe and easy operation on all jobsites.”

With the compact transport weight of 46 tonnes, the complete crane can be easily transported between jobsites. The machine’s platform and railings remain attached to the uppercarriage during transportation and only need to be folded down.

Due to the crane’s self-assembly system, the boom sections, carbody counterweight, crawlers and hoist winches can be easily assembled. The LR 1400 SX can even hydraulically lift, lower and secure the 150 tonne rear counterweight without assistance.

“The safe loading system and remote control enables this crane to be ready for operation within a work day, and does not require heavy tools or auxilliary cranes,” Friedrich said.

The four crawler drives make it easier to maneuver the LR 1400 SX on jobsites where space is tight. Thanks to the track width adjustment, access on narrow roads is also simplified.

Gradient Travel Aid im -

proves the crane’s ability to navigate slopes. The control system automatically calculates the centre of gravity and warns the operator before the crane leaves the safe area.

While travelling, the operator receives information about the permissible and actual gradient, and the crane's overall centre of gravity.

As well, the Ground Pressure Visualization feature calculates the real-time ground pressure of the crane and compares it with the specified safety limits of the relevant position.

During a lift, the operator can lower these plates to significantly increase the crane's ground contact area. This provides the ability to reduce ground pressure under the crane by more than half.

When erecting or lowering the boom, the Boom Up-and-Down Assistant system indicates the approach to the tipping border and automatically stops operation before the operator enters an unsafe zone. Furthermore, the operator no longer has to move the winches of the main boom and luffing jib separately. Controlled folding of the luffing jib begins at the press of a button. The speed of the laying down procedure is controlled with a single joystick.

Flexible operation

Radio remote control gives the crane operator flexibility and additional safety during operation. The crane can be operated from outside the cab to allow for a better overview of the construction site and avoid blind spots.

Depending on the application, a second person is no longer required to assist with hand signals during lifting operations.

10,000 HOUR Machine Structures

•

up to 12% cycle time improvements to get your work done quicker.

•

up to 12% better fuel consumption with NO DPF to ever worry about!

•

X4’s all new hydraulic system features electronically controlled pumps that take hydraulic efficiency to the next level.

•

Isuzu engine that utilizes a cooled EGR system with minimal maintenance in mind and with minimal DEF consumption.

•

Cab designed for shift-long comfort.

•

•

•

•

Link-Belt® Precision Grade®–powered by Trimble Earthworks—enables operators of all skill levels to increase their productivity by up to 50%

Equipped with

RemoteCARE® (GPS fleet management system). Free lifetime coverage to original owner.

WAVES (Wide-Angle Visual Enhancement System) option for a 230° visual.

X4’s have a beefed up undercarriage.

ALBERTA

Equipment Sales & Service Ltd.

Edmonton (780) 440-4010 essltd.com

BRITISH COLUMBIA

The Inland Group

Burnaby, BC 604-291-6431

Campbell River, BC 250-287-8878

Castlegar, BC 250-365-2807

Cranbrook, BC 250-426-6205

Fort St. John, BC 250-785-6105

Kamloops, BC 250-374-4406

Kelowna, BC 250-769-2933

Langley, BC 604-607-8555

Nanaimo, BC 250-758-5288

Penticton, BC 250-492-3939

Prince George, BC 250-562-8171

Quesnel, BC 250-992-7256

Terrace, BC 250-635-5122

Vernon, BC 250-545-4424

Williams Lake, BC 250-392-7101 inland-group.com

Paul Equipment

Balmoral (506) 826-3289 paulequipment.ca

Itec 2000

Rosslyn (888) 574-8530

Thunder Bay (888) 574-8530

Timmins (705) 267-0223 itec2000.com

McDowell B Equipment Ltd.

Sudbury (705) 566-8190

Barrie (416) 770-7706 bmcdowell.com

Stratton Equipment Sales & Service

Stratton (807) 483-7777 strattonequipment.com

Top Lift Enterprises Inc.

Stoney Creek (905) 662-4137 Bolton (905) 857-5200 toplift.com

QUEBEC

Équipement JYL Inc. Chicoutimi (418) 698-6656 equipementjyl.com

Micanic St-Aug-D-Desm (418) 878-2241 micanic.com

Paul Equipment (506) 826-3289 paulequipment.ca

Top Lift Enterprises Inc. St-Laurent (514) 335-2953

Sherbrooke (819) 612-5438 toplift.com

YUKON TERRITORY

The Inland Group Whitehorse, YT 867-668-2127 inland-group.com

Komatsu is planning to make a multimillion dollar investment to transform its facility in Sudbury, Ontario.

The investment is in support of the company’s strategic growth plan for its hard rock mining business. As well, the announcement will support Komatsu’s strategy of delivering customer satisfaction while supporting business growth through

successful supplier and manufacturing networks.

“Our commitment to hard rock mining will only continue to grow as we look to increase product, solution and service offerings for customers,” said Doug Eamer, Senior Vice President of hard rock mining for Komatsu.

Scheduled to begin in April 2023, the transformation of Komatsu’s hard rock operation includes the creation of a new product development, test and validation centre for the company’s underground drilling, LHD and truck products.

As well, the investment will increase production capacity for Komatsu’s underground drilling products, which includes streamlining the operations for improved safety, quality and lean manufacturing.

With the planned invest-

ment, Komatsu’s Sudbury facilities will become a centre of industry, technical and operational excellence for the company’s hard rock products. Komatsu will focus on the optimization of technical product core competencies including engineering, prototyping, testing and validation.

As well, operational efficiencies, capabilities and capacity will be improved through facility optimization and further leveraging the company and supplier networks.

“We are excited about the planned investment in Sudbury and the increased use of Komatsu’s network to support this evolution,” Eamer said. “Our teams remain focused on continuing to provide exceptional products and solutions for our customers.”

Ritchie Bros. Auctioneers has completed its acquisition of IAA Inc.

As previously announced in January, IAA shareholders will receive $12.80 per share in cash and 0.5252 common shares of Ritchie Bros. for each share of IAA common stock they own.

"The closing of the IAA acquisition represents the beginning of an exciting new chapter for Ritchie Bros. as we expect the combination of our businesses to drive long-term, profitable growth and significant, sustainable shareholder value creation," said Ann Fandozzi, Chief Executive Officer of Ritchie Bros.

"With IAA, we will accelerate our transformation into a premier digital marketplace and expand into an attractive, adjacent vertical, broadening our global footprint. Our combined yard footprint, marketplace infrastructure and comprehensive suite of innovative solutions will allow us to serve customers more effectively and efficiently than ever before."

IAA is a global digital marketplace connecting vehicle buyers and sellers. The company’s unique platform facilitates the marketing and sale of total-loss, damaged and lowvalue cars, trucks and motorcycles. Based in Westchester, Illinois, IAA has about 4,500 employees and more than 210 facilities throughout the United States, Canada and the United Kingdom.

"I would like to extend a heartfelt thank you to our colleagues at Ritchie Bros. for their unwavering focus on our customers and business success and welcome our new IAA teammates to the Ritchie Bros. family,” Fandozzi said. “With dedicated teams and detailed plans in place, we are excited to hit the ground running in integrating our businesses and pursue the significant opportunities that the combined Ritchie Bros. and IAA will create for employees, customers and shareholders."

As a result of the completion of the transaction, IAA's common stock ceased trading on the New York Stock Exchange under the ticker symbol "IAA" as of the close of trading on March 20.

ALBERTA

Liftboss JCB

Calgary: 403-301-0041

Edmonton: 780-474-9900 liftboss.ca

NEW BRUNSWICK

A.L.P.A. Equipment

Edmundston : 506-735-4144

Balmoral : 506-826-2717

Fredericton : 506-452-9818

Moncton, N.B. : 506-861-2572 alpaequipment.com

NOVA SCOTIA

A.L.P.A. Equipment

Truro : (902) 897-2717

alpaequipment.com

NEWFOUNDLAND

Harvey JCB

Corner Brook: 709-639-2960

St. Johns: 709-738-8911 harveyco.ca

ONTARIO

Advance JCB

Waterloo: 519-742-5878

Harriston: 519-510-5878 advanceequipment.net

D&W Group Inc.

Doughty & Williamson

Jarvis: 519-587-2273

Brant Tractor

Burford: 519-449-2500

Redtrac International

Vineland: 905-562-4136 dwgroup.ca

Delta JCB

Dunvegan: 613-527-1501

Renfrew: 613-432-4133

Winchester: 613-774-2273 deltapower.ca

Fulline JCB

Glencoe: 519-287-2840 fullinefarm.com

ONTARIO

Hub International Equipment Ltd.

Lindsay: 705-324-6136 Port Perry: 905-982-1500 hubinter.com

Jade Equipment

Oro-Medonte/Orillia: 705-325-2777 jadeequipment.com

John’s Equipment Sales & Service Frankford: 613-398-6522 johnsequipmentsales.com

Moore JCB Toronto, York & Peel Region: 416-747-1212 moorejcb.com

ONTARIO North Rock JCB North Bay, Sault Ste. Marie, and Sudbury: 705-897-7369 northrockrentals.com

ReadyQuip Sales & Service Ltd.

Timmins: 705-268-7600 readyquip.com

WPE Landscape Equipment - JCB

Hamilton/Halton: 905-628-3055 wpeequipment.ca

PEI

A.L.P.A. Equipment (506) 861-2572 alpaequipment.com

QUEBEC

A.L.P.A. Equipment

Bas-Saint-Laurent : (506) 735-4144

Gaspésie : (506) 826-2717 alpaequipment.com

Bossé Quebec Inc.

Desmaures: 418-878-2241 Saint-Augustin-debosse-frere.com

Moore JCB Montreal: 514-333-1212 moorejcb.com

SASKATCHEWAN & MANITOBA

Westcon JCB

Regina: 306-359-7273

Saskatoon: 306-934-3646

Winnipeg: 204-694-5364 westconjcb.com

Building in Canada has its own challenges. What you need for downtown is different from what you need out-of-town. It’s why our equipment is cold weather tested. It’s also why we offer compact sizes for flexibility, versatile attachments for multitasking, and comfort for long days on the job. Best of all, with a range of financing and extended warranty options, you can get started and keep working from dawn until deadline.

Yanmar Compact Equipment is now a comprehensive compact equipment provider following the introduction of its new line of compact track loaders.

Making their debut at ConExpo, the TL65RS, TL75VS, TL80VS and TL100VS compact track loaders are construction-grade machines ranging from 67 to 103.5 hp.

The new line of CTLs joins Yanmar’s compact equipment lineup that includes mini excavators, compact wheel loaders and tracked carriers.

“We’re a one-stop shop now for Yanmar customers. This really rounds out our compact equipment portfolio,” said Tate Johnson, President of Yanmar Compact Equipment North America.

The operator experience is a key focus of the machines with 360-degree visibility and a standard suspended seat for more comfort. A removable roof hatch escape offers an optimized safety feature for operators.

The four CTLs also include several optional efficiency-enhancing features to improve operator experience and productivity. These include a work tool positioner, return-to-position technology, self-levelling, ride control and auto two-speed capabilities.

The four CTLs are powered by Yanmar Tier 4 Final engines.

The loaders incorporate Yanmar’s optional SmartAssist telematics from the company’s mini excavator line. The telematics system features error detection and notification as well as real-time operational status updates and daily work reports. SmartAssist also includes integrated theft protection, allowing owners to set a range

ASV is expanding its compact track loader line with the new VT-100 and VT-100 Forestry Posi-Track CTLs.

Making its debut at ConExpo, the VT-100 compact track loader is a vertical lift machine designed for loading and grading applications in landscaping and construction. The VT-100 Forestry is suited for mulching, right-ofway clearance and site prep applications.

“They are the perfect option for those looking for a little more power than the RT-75 without having to go to the heavy hitter of all CTLs, the RT-135,” said Buck

Storlie, Product Manager for the ASV brand. “The lifting capabilities, pushing power and hydraulic flow of the new VT-100 and VT-100 Forestry is sure to impress.”

Both machines are equipped with a 103.5 hp Tier 4 Final Yanmar diesel engine and standard 151 litres per minute hydraulic flow. The loaders’ large line sizes, hydraulic coolers and direct-drive pumps transfer more flow and pressure directly to the attachment and reduces power loss. The VT100 features a 1,587 kg rated operating capacity and 4,665 kg tipping load while the VT-

100 Forestry includes a 1,678 kg rated operating capacity and a 4,470 kg tipping load.

The VT-100 and VT-100 Forestry feature ASV’s patented Posi-Track rubber track suspension.

The load-sensing system offers both improved efficiency and fuel savings. The system regulates the hydraulic pump, so it only produces what’s necessary to complete the work rather than using maximum flow all the time.

Both machines are available with optional remote-control capabilities. The remote is available as a factory or field-install option and al-

lows operators to control the loader from a distance with a harness-mounted control box.

from a specific location and trigger an alert if that range is exceeded. An 18-cm colour touchscreen display is standard on each of the new compact track loaders.

Production of the TL100VS will start this spring, while the other three machines will begin production in late 2023.

The new CTL line follows the announcement that Yanmar CE and ASV finalized its status as a single legal entity. The two brands have operated as Yanmar Compact Equipment North America (YCENA) since July 2020. The acquisition of ASV provided Yanmar with its first production capabilities in North America.

The alignment as one single entity will allow a wider range of compact equipment offerings long-term and a single route for dealers to do business with YCENA.

“We’re one consolidated team taking the best of legacy Yanmar and legacy ASV,” Johnston said. “It gives us a singular organization that is totally focused on compact equipment. It gives us an organization that eats, sleeps and breathes compact construction equipment.”

While the two equipment brands are a single legal entity, Yanmar CE and ASV will remain distinct under YCENA with each brand retaining its product lines and dealer networks.

The ASV brand will continue to develop loaders with its Posi-Track undercarriage and enhanced cooling capabilities aimed at high performance applications. As proof that “ASV isn’t going anywhere,” Johnson pointed to the new CTLs unveiled at ConExpo, the VT-100 and VT-100 Forestry.

“ASV will continue to live on as a loader specialist,” Johnson said.

The compact track loaders feature a maximum travel speed of up to 15 km per hour. A low 4.0 psi ground

pressure from both models allows smooth performance on sensitive or unstable surfaces.

Jackson Kuhn worked alongside his father in his sawmill as a young man and helped him with timber framing. “Working with my dad is what got me excited doing hands-on work,” exclaimed Jackson. From there, he worked for a top-notch landscaping company in Georgian Bay for five years. Being a machine operator is like second nature to Jackson. For three of those years, he ran his own crew. He learned a lot from this company and decided to run with what he had learned and started his own company, Georgian Rangers, after finishing school and playing professional hockey overseas for four years. His father Mark now works with him consulting and managing yet is not afraid to get his hands dirty.

Georgian Rangers specialize in large-sized landscaping, including stonework, site work, boulder walls, laying flagstone, and shoreline restoration in the Georgian Bay area. They also have an arborist and irrigation and lighting division with recent expansion considerations into full build construction division. “Since Covid, we have been working full throttle with no sign of slowing down. We are actually booked for the next two years,” exclaimed Jackson.

When asked why they use Bobcat® machines?

“First, it’s service. Like us, our philosophy is we have to offer our customer’s the best service

YOUR LOCAL AUTHORIZED BOBCAT DEALERS

BARRIE Bobcat of Barrie 705-726-2228 oakenequipment.ca

GREY BRUCE

Bobcat of Grey Bruce 519-372-9100 bobcatoftc.com

PARRY SOUND

Bobcat of Parry Sound Ltd. 705-342-1717

bobcatofparrysound.com

TORONTO WEST Bobcat of Toronto 416-679-4172 oakenequipment.com

BRANTFORD Bobcat of Brantford 519-752-7900 bobcatofbrantford.com

HAMILTON Bobcat of Hamilton 905-643-3177

bobcatofhamilton.com

PETERBOROUGH

Bobcat of Peterborough

705-748-9119

bobcatofpeterborough.com

THUNDER BAY Equipment World Inc. 807-623-9561 bobcat-tbay.com

possible and that includes communication. Oliver Kahl, sales specialist, for Bobcat of Parry Sound and I clicked right away. He has a sense of confidence and partnered with me on my mission. He gave me a Bobcat E35 compact excavator to demo and I called him and said I wanted to keep it. No one else offered to do that. He has always been reasonable and fair on price. I was young starting up my company, and he said, “let’s get you in these machines,” and he did. Secondly, Bobcat is the bee’s knees in equipment. Everyone I know that gets in a Bobcat machine and gets out of them says, “why would I want to operate anything else?” Even an operator that used to operate another brand for 30 years has now switched. You can’t find a smoother ride, and with all the attachments, you can’t beat it! Our customers like us to be very creative when designing their landscapes, so we need all types of different attachments. Sometimes in a day’s notice and I can rent that right away from Bobcat of Parry Sound when needed. It makes our customers feel valued and appreciated and that’s how you run a business.”

“90% of our work is in tight spots. We need machines that are compact enough but also powerful enough. I will always own a Bobcat E35 compact excavator for this reason alone. This machine has helped us earn the reputation that

CASSELMAN Bobcat of Ottawa Valley 613-764-2033 bobcatov.com

KITCHENER Bobcat of Tri-Cities Ltd. 1-866-214-3939 bobcatoftc.com

STRATFORD

Bobcat of Stratford 519-393-6040

bobcatofstratford.ca

SAULT STE. MARIE Bobcat of Sault Ste. Marie 705-949-7379 bobcat-ssm.com

CORNWALL Bobcat of Ottawa Valley 613-932-2034 bobcatov.com

LONDON Bobcat of London 519-455-4900 bobcatoflondon.ca

STRATTON Stratton Equipment 807-483-5505 strattonequipment.com

WINDSOR Bobcat of Windsor 519-737-0120 oakenequipment.ca

no one does tight flagstone like us. The Bobcat CT5550 compact tractor is very versatile. It can do anything. We used it to load stone off our trailer, and using the Bobcat angle blade to grade driveways is paramount. Last year we added a 72” Bobcat snowblower and it doubled our snow contracts. We are doing 5 km runs with it. We also love to have everything colour matched.”

“You can guarantee by the end of the year, I will be buying another Bobcat machine from Oliver Kahl, Bobcat of Parry Sound, so I wouldn’t hesitate to recommend them.”

COURTICE Bobcat of Durham East Ltd. 905-404-9990 bobcatofdurhameast.com

MUSKOKA

Bobcat of Muskoka 249-390-7000 oakenequipment.ca

SUDBURY McDowell B Equipment Ltd. 705-566-8190 bmcdowell.com

FRANKFORD John’s Equipment 613-398-6522 johnsequipmentsales.com

OTTAWA Bobcat of Ottawa Valley 613-831-5166

bobcatov.com

TORONTO EAST Bobcat of Toronto 416-679-4171 oakenequipment.ca

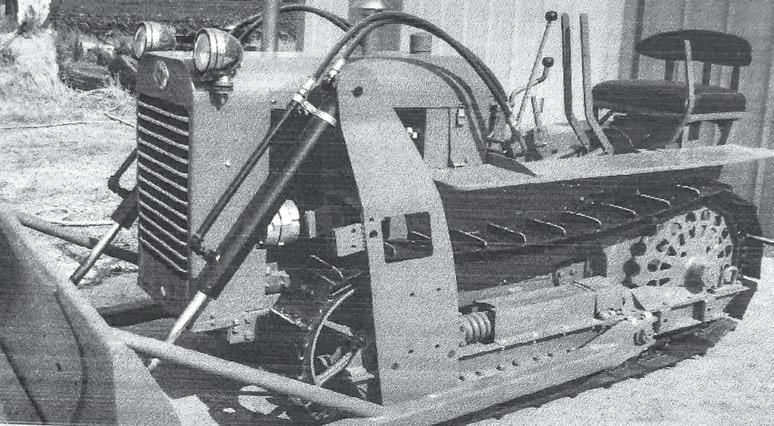

Pictured here is a USTrac Co. 'Airborne' compact dozer developed for use by the United States War Department during the Second World War. It was originally designed in 1937 as a trail tractor by Ted Flynn, a United States Forest Service engineer in Oregon, for clearing fire breaks in hard to access woodlands.

The American military saw the need for a compact lightweight dozer to compliment the LeTourneau Airborne scraper building forward airstrips in the Pacific. Clark Equipment Ltd. took on the manufacturing of hundreds of the CA-1 compact dozers.

Equipped with a hydraulic blade, and optional winches, the units were powered by a four-cylinder Waukesha gas engine, rated at a roaring 20 horsepower.

After the war, USTrac took over civilian production in 1950, eventually becoming American Tractor Co. (ATC) based in Indiana. Later in the 1950s ATC, with their successful small Terratrac crawler dozer, became part of J.I. Case Inc. line of construction equipment.

The machine shown here was restored to new condition by a well-known construction, aggregate producer and long time HCEA

Canada member, Mr. James Dick of Bolton, Ontario.

The Historical Construction Equipment Association (HCEA Canada) 2023 events Wheels & Tracks in Motion will be held on June 10 and 11, while the Last Blast event takes place on October 14. Both events are held at the Simcoe County Museum near Barrie, Ontario. To see more than 60 restored pieces of vintage construction equipment in action be sure to attend. HCEA Canada is a proud Heritage Partner of the Simcoe County Museum. Please visit our website hceacanada.org for updates.

Bobcat has stepped beyond the norms of the track loader industry with the unveiling of its new RogueX concept.

While the machine most closely resembles a track loader, the RogueX is in its own category.

The next-generation concept loader, unveiled during ConExpo 2023, explores the capabilities of electric power, autonomous operation and dual lift-arm geometry.

“Bobcat has a long history of innovation. We challenge what’s possible, break new ground and empower people to do more,” said Mike Ballweber, President of Doosan Bobcat North America. “Innovation is at the

heart of everything we do. It’s in our DNA.”

The Bobcat RogueX combines technologically advanced features to make it a one-of-a-kind conceptual machine.

Created as a research and development project, the machine was built as a proving ground to advance the Bobcat innovation roadmap, evaluate customer perceptions and test the limits of machine functionality.

“RogueX was concepted with consideration for the worksite of the future and how a customer’s needs may evolve, with a focus on ease of use, remote operations, autonomous functionality, sustainable operations and features that allow operators

to accomplish more with one machine,” said Joel Honeyman, Vice President of Global Innovation at Bobcat.

As jobsites evolve and operators turn to remote control operation, Bobcat took its concept further by fully eliminating the operator cab. Instead, RogueX explores the idea of operating where humans cannot go to tackle more work in more places than ever before from a remote position.

By designing the machine without a cab and using advanced kinematics, RogueX features unique functionality, and includes vertical-path as well as radial-path lift capabilities in one machine.

Toro has upgraded its eDingo with its HyperCell system, a battery technology developed to match the power of traditional combustion engine products, while delivering zero exhaust emissions and less noise.

The next generation eDingo 500 compact utility loader is ideal for indoor construction jobs that require heavy or continuous operation, fast completion times and reduced overall costs.

HyperCell was developed to meet customer demand and is optimized to deliver up to an eight-hour continuous runtime, allowing it to run for a full shift.

When it needs charging, the on-board charger plugs into a standard 120V wall outlet and fully charges the machine in up to eight hours. As well, the HyperCell Power System is built to run cooler than other systems,

meaning operators gain efficiencies, eliminate engine exhaust emissions, and can finish jobs with less hassle.

“Every improvement we’ve made to the next generation eDingo was driven by customer feedback,” says Sam Dando, Product Marketing Manager at Toro.

“For example, the HyperCell Power System is more powerful and reliable than ever. It allows for all-day run times and quick charging, which helps crews maximize productivity. Also, the new eDingo features a narrow width of 30 inches making it capable of fitting through even the tightest of doorways.”

The next gen eDingo still delivers an operating capacity of 234 kg and 24.6 litres per minute of hydraulic flow.

Plus, the new design has a hinge pin height of 205 cm, which allows for clearing into most standard dumpsters. The operating capacity

allows for the effective use of many attachments, including:

· Floor scraper

· Hydraulic breaker

· Buckets

· Adjustable forks

· Multi-Purpose tool

· Grapple

· Leveller

· Mixer bowl

As well, electric drive motors make the new eDingo

quiet, while still being able to complete zero-turn maneuvers in tight spaces and travel at a speed of up to 4.4 km per hour.

The next genreation eDingo also features a new onboard charger and cord compartment storage, patent-pending traction controls, a powerful 1200lumen work light for improved visibility and a comfort mat to fight operator fatigue.

An all-electric and autonomous concept, RogueX produces zero emissions and features a lithium-ion battery, electric drive system and no hydraulics.

“After our successful development of building an all-electric loader [the Bobcat T7X], we wanted to think bigger, broader and take a leap far into the future,” said Matt Sagaser, Director of Innovation Accelerated at Bobcat.

“Our dedicated innovation team took a bold approach and designed a machine that breaks all of the rules. RogueX sets a framework for what is possible, and our team is just getting started on what is next.”

At ConExpo, Develon offered a sneak peek of its new DTL35 compact track loader, the latest development in its lineup of compact construction equipment.

The 116-hp compact track loader is the company’s first entry into the CTL product category for the North American market. Thomas Lee, Director of Product Manage-

ment, at Develon explained the addition of compact track loaders is part of the company’s commitment to its dealers and customers to continue expanding its equipment offering. “Our lineup of construction equipment has grown considerably in the past five years,” Lee said.

“Last year, we introduced our own line of mini excavators and our company’s first dozer. These popular earthmoving machines help our dealers provide a more robust line of Develon heavy and compact construction equipment to our customers. And now we’re growing our compact construction equipment with the addition of compact track loaders for the North American market.”

The Develon DTL35 has an operating weight of 5,717 kg and a rated operating capacity of 1,662 kg.

The compact track loader will come standard with a torsion suspension system, providing a smooth ride for operators and durability for

use on construction jobsites. The torsion suspension system also provides additional stability with lifting and carrying loads.

Operators will be able to use a variety of attachments on the DTL35, one of the biggest selling points of the compact loader industry. Optional high-flow auxiliary hydraulics will be available for the DTL35 for enhanced performance with attachments like asphalt planers, forestry cutters and breakers that require additional hydraulic flow.

The machine’s cab is designed to provide operators with excellent visibility of the jobsite. A standard rearview camera gives operators a better view of the attachment and their surroundings. As well, an optional 360-degree all-around view monitoring (AVM) camera system will be available when the machine goes into production.

The Develon DTL35 is expected to arrive at North American dealerships in 2024.

With our products, technologies, and digital solutions, we are already shaping the construction sites of tomorrow.

Our Generation 8 machines work with our LiebherrPower-Efficiency, which optimises the interaction between the diesel engine, transmission, and working hydraulics for maximum efficiency, power, and enormous fuel savings.

At the highest efficiency, operating costs are reduced in a sustainable way, putting more money in your pocket.

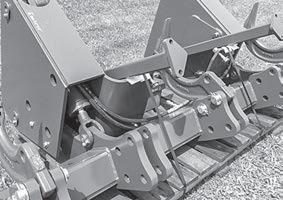

Before Brandt introduced its new line of heavy haul trailers, its engineers turned to its customers to ensure they created a product that’s tailored to the demands of the heavy haul industry.

The result is the Work Ready line of heavy haul trailers that feature a full range of open-deck models with mechanical, hydraulic or fixed goosenecks, multiple lengths, widths and capacities, as well as jeeps, boosters and other custom configurations.

“Four years ago, contractors and heavy haul truckers told us they needed more reliable trailers that would help them get the job done faster. We listened,” said Shaun Semple, CEO of the Brandt Group of Companies.

“With that valuable feedback, Brandt engineers created purpose-built trailers with unique innovations to increase productivity and make the workday easier for operators.”

At ConExpo, Brandt unveiled its C550 55-ton construction trailer and the H850 85-ton square-tail trailer.

The H850 has a narrow, low-profile gooseneck to load equipment further forward to balance the load, and the C550 delivers the largest deck well in the industry to haul a variety of equipment with ease.

“Few manufacturers would jump right into the ring and stick their neck out on an 85-ton multi-axle trailer, but with 100 years of manufacturing and engineering experience, we decided to go big or go home,” said Russell Solomon, Brandt’s Director of Sales for the United States.

Through a collaborative product design process, Brandt consulted extensively with customers to create heavy haul trailers that meet the needs, as well as solve common problems, of transporting heavy equipment.

“To be successful, we must deliver innovative solutions that quickly meet the needs of our customers,” Solomon said.

The initial consultation phase began with focus groups comprised of owners, operators and dealers from several target industries.

“We ask ‘what do you want? What do you need? What doesn’t work on your product now?’ Then we take those ideas work them through,” Solomon said. “There’s a lot of customers involved in this.”

Once feedback is received, a detailed design is created that aims to address the requests of the customer base. From there, Brandt builds a prototype and begins a validation process of the equipment.

“We’ll bring those customers back in again and ask what they like,” Solomon said. “A lot of the time, we will have to make some changes.”

A common concern from owners and operators was the need for more durable paint and more durable electrical harness.

“No matter who we talked to, those are the two things that came up,” said Brett Burke, Brandt’s Platform Team Lead for heavy haul trailers.

To remedy the issue, Brandt weather sealed the electrical connections, and reduced connectors when possible. To improve paint durability, Brandt is using a powder-coating process that starts with a zinc-based gel coat, followed by a baked-on topcoat.

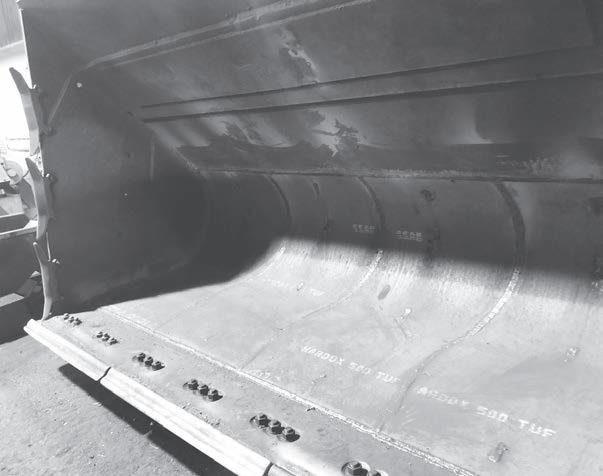

“Every component we paint is individually coated. It’s the most complete coverage you can get,” Burke said.