Combines the high production MVP380X cone and the LJ-TSV6203 screen. Unique in the industry with its High Lift Screen (HLS) and integrated flow buffering features. Operators can take advantage of the cone’s and screen’s capabilities without needing to throttle back the feed for surges.

Combines the popular JW55 jaw crusher with the high stroke 52”x20’ vibrating grizzly feeder making this plant a high production portable crushing machine. This quarry duty JW55 crusher, with its large 32”x55” opening, long jaws, and aggressive stroke, is in a class by itself in a portable crushing plant.

Able to operate in both heavy duty scalping and precision screening applications and will manage the most difficult of materials. 3’6” x 4’ - 2 deck screen, variable screen angle, configurable layout/ability to convert to 2-way split, wide range of screen media, quick set-up time, reversible side conveyors, 55kW/74hp @2300rpm CAT engine.

Mid-sized track mobile screen aimed at end users requiring high volumes of finished products in applications including topsoil, crushed stone,recycling, iron ore, sand and gravel. 5’ x 16’ screen deck, 14’ wide feed hopper, hydraulic folding conveyors, hydraulic screen angle adjustment, fast set-up, double or tripple deck.

Ideal for creating RipRap and recovering rocks up to 800mm (32”) that are mixed with clay and other sticky materials. The updated model has been redesigned to include new features that will improve transportation, access, and stockpile heights.

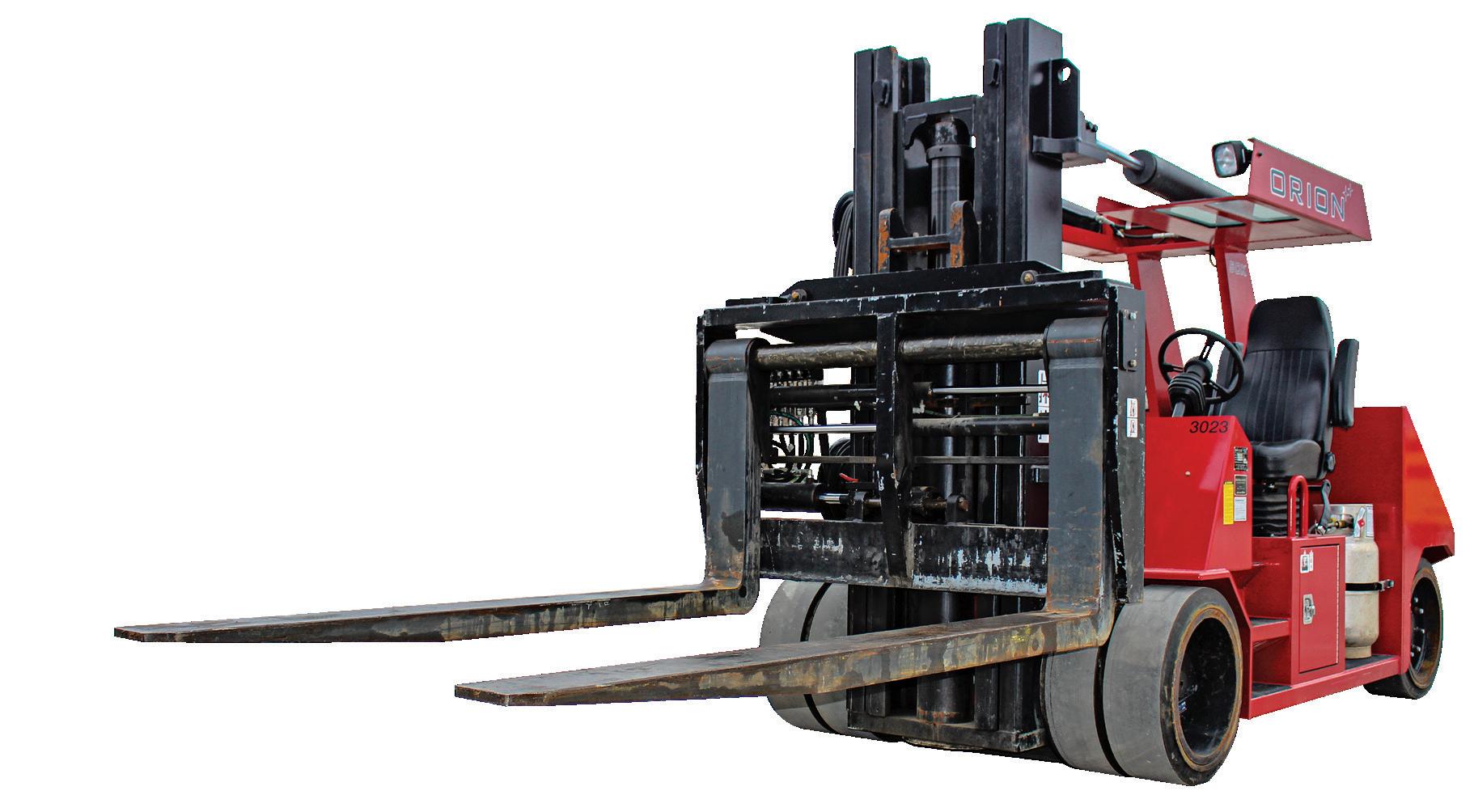

Terapro equips a mechanical backhoe

I was recently reminded that 2024 is the 20th anniversary since my byline was first published.

A college classmate sent me one of the first articles we collaborated on for the front page of a small community newspaper. While it was fun looking back, this opportunity to reminisce was humbling. Back then, we were hot shots in our own minds. But hot shots we were not.

The front-page placement was likely pity from a veteran editor. Apart from the energy possessed by someone in their 20s, by all accounts we sucked. Together, we prob -

ably spent a week writing that story. Today, I’d be hardpressed to justify spending more than a couple hours putting the article together.

Tasks I struggled with in my first year on the job are now just muscle memory.

Looking back to 2018, I wrote an article titled Canada faces a construction labour crunch . The story outlined a presentation on the construction labour crisis from Bob Collins, Senior Economist for BuildForce Canada.

Collins explained that by 2027, more than one fifth of the construction labour force will retire from the jobsite.

“This is a reality. There is no changing this,” Collins said. “And they’re taking their skills with them.”

The housing construction sector heeded Collins’ warning. According to the Canada Mortgage and Housing Corporation (CMHC), the nation employed about 650,000 construction workers in the homebuilding sector, the highest number of employees ever recorded in the industry. Despite labour growing 136 per cent, new housing starts only increased by 63 per cent.

“Construction activity didn’t keep pace with the growth in dedicated resources,” CMHC noted.

A recent article in the Financial Post pointed out that productivity has fallen.

Canada built more homes in 1987 than in 2023.

Obviously, many factors are at play. For example, the

CMHC points to the need to cut red tape at the municipal level to increase the number of housing starts.

Lost experience also needs to be factored into the equation. The people that knew how to build 246,000 homes in 1987 are likely now retired, taking their know-how with them off the jobsite. And no matter how motivated the new generation is to succeed, without guidance and time to develop skills, a task that should take two hours will require a week.

John Deere has launched the 744 X-Tier and 824 X-Tier wheel loaders, its latest production class loaders equipped with the Electric Variable Transmission (EVT) E-Drive system.

Engineered with the demanding conditions of the jobsite in mind, the tech-packed loaders are ideal for customers looking for fuel efficiency, enhanced productivity and operator comfort.

“In a market where efficiency and sustainability go hand in hand, we are proud to lead the way with our E-Drive 744 and 824 X-Tier loaders as we continue to deliver new, innovative solutions for our customers,” said Katie Voelliger, Product Marketing Manager at John Deere. “These production class loaders are not just about saving our customers downtime

and costs associated with ownership, but they also embody our commitment to offering premium features, hybrid solutions and advanced technologies on machines of all sizes, including our large wheel loaders.”

The new 744 and 824 X-Tier loaders feature the John Deere Electric Variable Transmission (EVT) E-Drive system.

X-Tier E-Drive

Deere equipped both loaders with a JD9 diesel engine as the primary power source.

However, the torque converter and traditional transmission have been replaced by the EVT system, offering more efficiency. As well, the E-Drive component provides instant power, while simplifying operation.

The hybrid design not only equals significant reductions in annual fuel costs, but also enhances productivity features to deliver up to a 7 per cent total cost of ownership lifecycle advantage over conventional drive systems.

In the cab, operators can expect a quiet environment thanks to the constant engine speed. As well, operators can expect enhanced comfort, thanks to features such as premium seats and a Bluetooth AM/FM radio. Also, if customers are hauling material over longer distances, like those seen in aggregates and roadbuilding applications, the addition of the tire pressure monitoring system can help increase tire life and lower fuel consumption by ensuring tires maintain proper inflation throughout the day.

To improve awareness and safety, both models provide increased visibility and situational awareness. With the Advanced Vision System and Advanced Object Detection, operators can enjoy an improved range of view on both sides of the loader and better visibility beyond conventional mirrors.

Also, dynamic reversal projected path lines assist with visualizing the anticipated reversal path to ensure a better line of site. The LED lights on the 744 and 824 X-Tier also help amplify vision in toughto-see settings.

In terms of controllability, the 744 and 824 X-Tier loaders deliver easier operation. Now equipped with John Deere exclusive Pile Slip Assist, operators can experience proactive differential lock ahead of pile engagement, which reduces

tire slip, improves bucket fill and lowers cycle time.

The EVT also reduces complexity by allowing for a more instantaneous response with fewer operator inputs and the use of one pedal for operation.

Both loaders offer two fuel efficient operational modes including Standard Mode and Performance Mode.

The default Standard Mode delivers up to 25 per cent reduced fuel consumption while keeping sustainability a priority and ensuring productivity.

Performance Mode makes productivity the top priority with 5 per cent increased performance and 15 per cent reduced fuel consumption.

HD Hyundai Construction Equipment North America has added the HX355A LCR,

a 35.5-ton compact-radius excavator, to its lineup of full-sized crawler excavators.

With an operating weight between 35,600 and 36,200 kg, the HX355A LCR fits between the Hyundai HX350A and HX380A conventional-swing excavators. However, the compact-radius allows the excavator to perform jobs within confined areas typically reserved for smaller machines.

“When contractors and other equipment users need an excavator that delivers serious power with a relatively compact footprint, the Hyundai HX355A will serve them well,” said Joe Hodges, Product Manager at HD Hyundai CE North America.

“In the case of this compact-radius model, the cab remains inside the tracks during front or rear operations and extends a minimal 4 inches outside the tracks during side operations.”

The 258 hp HX355A LCR is typically equipped with a 1.34 cubic metre bucket and features 47.5 cm of ground clearance.

A 3.6-metre dozer blade is also an option from Hyundai. Adding a dozer blade to a 35-ton excavator boosts versatility that is particularly useful, in construction and landscaping projects where digging and levelling are required.

“With a dozer blade, operators can push and move materials more efficiently, which is especially beneficial for tasks like backfilling trenches, levelling terrain or pushing debris,” Hodges said.

The HX355A LCR has four selectable power modes and one-touch power boost for better control over machine power and efficiency. The HX355A also comes with an integrated smart power control (SPC) system. This system uses sensors and software to monitor the excavator’s workload in real time. Based on this data, it automatically adjusts engine power and hydraulic flow to match the required digging force. This ensures the excavator operates efficiently without unnecessary fuel consumption or strain on the engine.

“SPC helps keep the excavator running longer,” Hodges said, “It keeps the machine operating within optimal power ranges, which reduces wear and tear associated with overloading or inefficient operation. This extends the life of critical components, including the engine, hydraulic system and attachments.”

Hodges described the Hyundai HX355A LCR as a full-featured machine. “Hyundai is known for delivering value by outfitting our excavators with more standard features,” he said. The features on the excavator include five years of Hyundai’s proprietary Hi MATE telematics system, heated air-suspension seat, a 20-cm automotive-style interactive display monitor and remote ignition.

“Making these types of features standard equipment helps keep operators safer, more comfortable and more productive,,” Hodges said.

BOBCAT SPECIAL OFFER:

Select a new compact loader and get as low as 0% for 48 months or rebates up to $13,500 CAD in lieu of financing until 09/30/2024. See your local dealer below for more details and conditions.

16 years old,

started his journey in the landscaping industry working part-time summers. He saw an ad on Kijiji, and he was persistent until he got the job. For this company, all they had was one truck and a helper (Eduard). He learned a lot from that job. Including, that he wanted bigger things for both him and his customers. He has learned what to do and not do over the years. In 2006 Avanti Landscaping was established and it’s still going strong. “At Avanti, we are all about serving our customers.” The Avanti team of skilled and certified tradesmen take great pride and passion in their landscape construction design builds of beautiful outdoor spaces. From woodwork (decks, fences, patios, and gazebos) to pools/water features, stonework (walkway/driveway/patios), complete landscape and garden designs, lighting, sodding, grading, irrigation, concrete, demolition, underpinning, foundation waterproofing/repair, excavation and more all over the GTA! They lay out everything for their customers. No hidden surprises. “I am not going to say running a

BARRIE

Bobcat of Barrie

705-726-2228 oakenequipment.ca

GREY BRUCE

Bobcat of Grey Bruce 519-372-9100 bobcatoftc.com

PARRY SOUND

Bobcat of Parry Sound Ltd.

705-342-1717 bobcatofparrysound.com

TORONTO WEST

Bobcat of Toronto 416-679-4172 oakenequipment.ca

BRANTFORD

Bobcat of Brantford 519-752-7900 bobcatofbrantford.com

HAMILTON

Bobcat of Hamilton 905-643-3177 bobcatofhamilton.com

PETERBOROUGH

business is always easy, but I have been one to take risks and so far, it has worked out for me. I have learned without risks, there is no reward.”

“When I first started my business, I had a pickup truck and a Bobcat® MT52 mini track loader. Now, I have 15 Bobcat machines, 12 trucks and 15 other machines.” When asked why he chose Bobcat machines, Eduard replied, “My first experience was with another brand track loader, which had very little maneuverability. The next machine was a Bobcat mini track loader, and it was an older machine but worked so much better. I really like the Bobcat MT mini track loaders. No other brand makes a walk-behind machine as well as Bobcat does. Cheaper doesn’t mean better. Bobcat machines are easy to operate, plug and play, like running an Xbox. Very user friendly.” Avanti uses the Bobcat machines for grading, trenching, levelling, hauling material, excavation, and loading trucks. “I also love the versatility of all the Bobcat attachments. We own breakers, augers, buckets, and forks, but can rent any from Bobcat of Toronto anytime. No other brand offers as many attachments as Bobcat does.”

“Gino Cervo, my sales specialist from Bobcat of Toronto, gets things done for me. I am very happy to work with Gino. I was referred to Gino by a friend and have never been the same since then (he chuckled). Gino even sends me Bobcat videos to watch during breakfast. He also has my insurance set up on my new machine, so I am all set and ready to work. The mechanic from Bobcat of Toronto helps us too. He will teach us the little things, so we don’t have to pay to bring them in all the time for service and they have

a huge availability of parts. Between Gino Cervo and the Bobcat of Toronto dealership as a whole, they have a great support system in place. That’s what you get with a good brand. Bobcat was also willing to work with flexible financing options that suit my needs. Pay when I earn and skip the winter months. I find many people buy older equipment when first starting their business but then it breaks down all the time and they end up losing way more in the long run, whereas they could be buying brand new and end up costing them less at Bobcat. For example, it costs you say $4000 a month for a labourer vs $1200 a month for a brandnew machine.”

“I wouldn’t hesitate to recommend Gino Cervo and Bobcat of Toronto (Oaken Equipment) for your next purchase or lease of equipment and attachments.”

Thank you, Eduard.

CASSELMAN

Bobcat of Ottawa Valley 613-764-2033 bobcatov.com

KITCHENER

Bobcat of Tri-Cities Ltd. 1-866-214-3939 bobcatoftc.com

STRATFORD

Bobcat of London 519-455-4900 bobcatoflondon.ca

Bobcat of Ottawa Valley 613-932-2034 bobcatov.com STRATTON

Bobcat of Peterborough 705-748-9119 bobcatofpeterborough.com COURTICE

THUNDER BAY

Equipment World Inc. 807-623-9561 bobcat-tbay.com

Bobcat of Stratford 519-393-6040 bobcatofstratford.ca

SAULT STE. MARIE

Bobcat of Sault Ste. Marie 705-949-7379 bobcat-ssm.com

Stratton Equipment 807-483-5505 strattonequipment.com

WINDSOR

Bobcat of Windsor 519-737-0120 oakenequipment.ca

Bobcat of Durham East Ltd. 905-404-9990 bobcatofdurhameast.com

SUDBURY

McDowell B Equipment Ltd. 705-566-8190 bmcdowell.com MUSKOKA

Bobcat of Muskoka 249-390-7000 oakenequipment.ca WYOMING

Advantage Farm Equipment Ltd. 519-845-3346 advantage-equip.com

FRANKFORD

John’s Equipment

613-398-6522

johnsequipmentsales.com

OTTAWA

Bobcat of Ottawa Valley 613-831-5166 bobcatov.com

TORONTO EAST

Bobcat of Toronto 416-679-4171

oakenequipment.ca

Terex Corporation has signed a definitive agreement to acquire Environmental Solutions Group (ESG) from Dover Corporation in a $2 billion all-cash transaction.

ESG is comprised of several brands in the solid waste industry, including Heil, Marathon, Curotto-Can and Bayne Thinline, as well as digital solutions offerings 3rd Eye and Soft-Pak.

ESG's array of turnkey products and services across equipment, digital and

aftermarket offerings are complementary to Terex's businesses, and will allow Terex to expand its customer base and provide customers with a broader suite of environmental equipment solutions. ESG has a track record of consistent growth, delivering an about 7 per cent compound annual growth rate over the last 10 years.

for all our stakeholders."

As a market leader in waste and recycling, ESG holds the top position in refuse collection vehicles and waste compaction equipment in North America, enabling Terex to create three market-leading business segments in the fast-growing waste and recycling end-market.

Terex's North American industry exposure will increase to 65 per cent, expanding its global market opportunity to $40 billion.

"This acquisition announcement of ESG marks an incredibly exciting milestone in our multi-year transformation and aligns with our goal of strengthening our portfolio and leveraging our operating system to drive sustainable, accelerated long-term growth," said Terex President and CEO, Simon Meester. "ESG will add a non-cyclical, financially accretive, and market-leading business to Terex's portfolio with tangible synergies in the fast-growing waste and recycling end market. In addition, ESG is led by a world-class management team and has a strong track record of operational excellence. We look forward to welcoming the ESG team to Terex and driving long-term, sustainable value

Terex will create the new Environmental Solutions segment that includes ESG as well as Terex's existing Utilities business. The segment combines Terex's position in utility equipment with ESG's portfolio of brands.

The segment will service the waste, recycling and utility end markets that are expected to benefit from growth themes including electrification, circularity and energy transition.

The transaction is expected to close in the second half of 2024, subject to required regulatory approvals and closing conditions.

The initiative marks a significant expansion in Zeal Motor’s commitment to mobility solutions across various industries including energy infrastructure, mining exploration, search & rescue and military operations.

The establishment of the Fat Truck Defense division is driven by two main objectives:

· Enhancing mobility capabilities in Arctic conditions with models specifically configured for cargo logistics, personnel transport and search & rescue operations

· Advancing the exclusive partnership with leading defense supplier Rheinmetall Canada

The collaboration integrates Rheinmetall’s autonomous vehicle technology into the Mission Master family of uncrewed ground systems (UGSs), based on the Fat Truck platform.

“Our team is dedicated to supporting the defense market with innovative mo-

bility solutions. Our new factory is equipped to meet growing demands, and we are committed to providing responsive support for our products and users in the field,” said Maxim O’Shaughnessy, President of Zeal Motor.

“The creation of a dedicated defense division aligns with our strategic plan to further develop innovative off-road vehicle solutions and expand production capacity.”

The Fat Truck was previously tested in the Arctic, where it performed at temperatures as low as -46 C.

The truck is capable of travelling at 40 km per hour on Arctic land and 5 km per hour on water, as well as climb steep icy hills and vertical walls. As well, the Fat Truck meets rigorous safety standards and adds remarkable new capabilities to operational readiness.

Zeal Motor continues to invest in its research and development centre and has inaugurated a new manufacturing plant to ensure it can meet the fast-growing demand for its pioneering off-road products.

Medium-size, top class: the L 526, L 538 and L 546 wheel loaders score top marks across all performance parameters. With the new, optimised Z-bar linkage, Liebherr has opened unlimited application possibilities aligned to even better productivity. Generation 8 is bigger, tougher and more powerful than its predecessors – but with consistently low fuel consumption.

www.liebherr.ca

Wheel loaders L 526, L 538 and L 546

Komatsu is importing a new portfolio of demolition excavators to the North American market.

For more than two decades, the Komatsu PC490HRD-11, PC290LC-11, PC360LC-11 and PC490LC-11 demolition excavators have been successfully operating in the European market.

Now, the machines are available to the North American demolition industry.

“Komatsu understands that the demolition industry is a fast growing and evolving segment that demands

new product innovation,” said Bruce Boebel, Director of Products and Services at Komatsu.

“We are excited to be able to now provide this family of demolition excavator solutions in support of the industry, offering the ability to quickly customize for different working environments and provide versatility and efficiency at the job site.”

The PC490HRD-11 demolition excavator features the K100 boom change system, which enables operators to start working within minutes of arriving at a job site. The boom change system also minimizes the time required

of 55,200 kg to 75,830 kg and a 5,000-kg maximum attachment weight.

The Komatsu PC290LC-11, PC360LC-11 and the PC490LC-11 straight boom excavators boost reach, providing 22 per cent to 26 per cent more reach than standard excavators with customization that allows users to program up to 15 different tools.

The operating weight of the three straight boom machines ranges from 30,445 kg to 48,760 kg and engine power of 196 hp to 359 hp.

The machines are built to tackle tough demolition jobs with robust protection elements like heavy-duty revolving frame and under guards, bucket cylinder guard, boom light protection guards and reinforced attachment linkage.

Komatsu’s additional product line of Lehnhoff quick couplers and Montabert demolition attachments can be paired with the demolition excavators to further increase the versatility of these machines.

CZM Foundation Equipment recently produced its 500th machine in the United States, marking a significant milestone for the company.

Established in 1976, CZM engineers and manufactures drilling machinery. The production of the 500th machine highlights the company's growth and its dedication to meeting the needs of the construction industry.

"We are excited to celebrate the production of our 500th machine in the USA," said Giuliano Clo, CEO of CZM Foundation Equipment.

"This milestone reflects the hard work and dedication of our entire team, as well as the trust and support of our valued customers and partners. We are committed to continuing our tradition of excellence and innovation as we look forward to the next 500 machines."

CZM’s roster of foundation equipment includes

machines engineered for drilled shafts on a long or short mast configuration, cylinder crowd and cable crowd, long reach, CFA, micropiles, pile driving and machines for specialty foundations.

The company is the only Cat OEM manufacturer in North America.

CZM manufactures its machines in Savannah, Georgia, at its 7,500 square metre factory. The company’s headquarters is also located on the 16-acre site in Georgia. As well, CZM operates factories in Italy and Brazil. Its presence across North America includes service centres strategically located to provide aftersales support in Texas, California and Kentucky. The network allows CZM to offer comprehensive solutions, including rental services, corrective and preventative maintenance and a vast inventory of parts.

Get new-machine productivity at a used price! Brandt backs all used equipment with unmatched parts & service support.

With the largest used inventory in Canada, chances are Brandt has exactly what you’re looking for.

installation may be the first of its

While pilot controls have become the norm for backhoes, there are operators that prefer the mechanical style, four-stick operation for the machines.

Last year, Stittsville, Ontario-based Terapro sold a Case 580 Super N backhoe with mechanical controls — a machine that required a special order from the manufacturer due to its now unconventional controls.

“Some guys like the mechanical backhoes because they get a lot more feedback. You can feel the pressure from the system through the mechanical levers. So, once they get good at them, those guys stick with that,” explained Jake Sparling, a Technician with Terapro.

While the customer that purchased the 580 Super N backhoe opted for the classic mechanical controls, they

also wanted to equip the machine with a Rototilt R3 tiltrotator.

The contractor will use the machine for commercial and industrial foundation work. Adding the tiltrotator will allow the operator to reduce the number of times the backhoe is repositioned while digging.

“The customer has been wanting it for a while, and I think he was getting shut down a lot by people,” Sparling said.

Working with Rototilt, Terapro decided to attempt to fit the machine with the tiltrotator. However, with no known mechanical backhoes operating with an R3, there was no reference point for installation.

“It's a full mechanical backhoe too. So, that was the big challenge with it — trying to figure it out,” Sparling said.

“We put a little bit of effort into figuring it out and seeing if it was even possible.”

With mechanical backhoes, the operator is unable to control the auxiliary hydraulics with the Rototilt, which is how the tiltrotator is usually set up.

To overcome this, Sparling used large diverter valves to redirect the hydraulic flow from the front auxiliary line.

“On these machines the front auxiliary is still electric over hydraulic. So, the front loader valve goes to the diverter valve, and then we diverted it to the back end,” Sparling explained. “Then it’s all keyed into the plumbing of the existing rear auxiliary.”

Sparling was then able to plug the Rototilt controls and required electrical components into the existing front auxiliary hydraulic controls.

The Rototilt carrier also required modifications to

make sure it fit the Case quick coupler. To complete the modification, Terapro cut off pin bossed and fabricated a custom floating pin.

“We had to react quickly and modify it. We did a little bit of cutting and we had some custom parts machined to make sure it fit properly,” Sparling said.

To control the tiltrotator, Sparling recruited a friend in engineering to design mounts to attach the rollers to the four sticks.

“He 3D printed brackets to mount the rollers onto the rear controls for the fourstick,” Sparling said.

Installing the R3 on the backhoe took about five days, compared to the typical three-day install time for a machine with pilot controls.

“Most people said it wasn't going be possible,” Sparling said.

Hitachi Construction Machinery Americas unveils a dedicated super long front excavator for the North American market.

The ZX210LC-7H Super Long Front (SLF) excavator provides 15.35 metres of reach at ground level and an 11.94-metre dig depth with fewer trade-offs due to its dedicated design.

As well, Hitachi engineered a proprietary hydraulic circuit for smooth and safe operation. It includes an upgraded swing motor for improved reach and control as well as Hitachi genuine bucket attachments that pair with the new ZAXIS-7 Super Long Front excavators.

“As Hitachi Construction Machinery Americas continues to grow into the North American market, so does the expansion of our excavator product offerings,” said Patrick Baker, Excavator Product Manager for Hitachi Construction Machinery Americas.

“The ZX210LC-7H SLF, with added reach, productivity and performance, will allow customers to grow their businesses into new applications with another tool in their toolboxes.”

As part of the ZAXIS-7 series, the 24,900-kg SLF ex-

cavator meets the needs of customers in North America who dredge riverbeds, dig canals or perform projects that require extended reach.

The ZX210LC-7H SLF is the first of multiple longreach excavators Hitachi will introduce to the market. The ZAXIS-7 SLF series offers unique features and functionalities that help customers reach further.

The ZAXIS-7 SLF is equipped with a new operator station featuring a larger, more comfortable space with less vibration and noise.

The heavier counterweight, proprietary hydraulic circuit and enhanced swing motor provide confidence while operating the super long arm.

An updated hydraulic control valve provides an immediate response, even when operating at or near maximum extension. Operators can select from two work modes — economy and power — to tailor operations for jobsite conditions.

An aerial angle camera gives operators a 270-degree bird’s-eye view where they can choose from multiple image options to see the machine’s immediate environment on a 20-cm antiglare LCD monitor. The monitor also controls the

Metso has announced it has signed an agreement to acquire Jindex, a privately owned Australian company specializing in valves and process flow control.

The acquisition will allow Metso to combine its experience in slurry handling, hydrocyclones and minerals processing equipment with Jindex’s valve offering to strengthen its capacity to provide more comprehensive slurry handling solutions for the mining industry.

“This is a great development and an exciting next step. The Jindex product offering and our technical expertise in valves are an excellent addition to Metso’s Pumps business and will enable Metso to provide more extensive flow control solutions to the mining industry,” said Stephen Fowler, Managing Director of Jindex Pty Ltd.

“We look forward to contributing our unique knowledge and experience as part of the Metso team.” Established in 1995, Jindex is based in Sydney, Australia and has 25 employees. The company serves the mining and minerals processing sec-

Bluetooth radio, which allows operators to listen to music and make hands-free calls while in the pressurized, quiet cab featured on all ZAXIS-7 excavators.

Hitachi's excavators also include ConSite Oil. Two sensors detect if oil quality has deteriorated and transmit data to Hitachi's Global e-Service. This helps drive uptime by catching oil degradation before damage to critical systems occurs, which reduces maintenance and downtime.

tor with about 50 per cent of sales in Australia.

“This acquisition is yet another important step in the development of Metso’s pumps business line offering to bring us closer to being our customers’ lifecycle partner of choice. Flow and isolation control play a vital role in ensuring smooth slurry handling to maximize the productivity and efficiency of minerals processing plants,” said Tiago Oliveira, Head of Pumps business line at Metso.

“In the past, we have collaborated with Jindex on many customer projects and are now glad to welcome the Jindex experts to the Metso team. Jindex has extensive expertise and strong capabilities in valve technology and control equipment, as well as in many types of slurry valve projects.”

Metso’s Pumps business line offers complete solutions for slurry handling and hydrocyclones.

The equipment offering includes slurry pumps, pipes, hoses, valves and hydrocyclones.

The acquisition is expected to close this month.

PERFORMANCE, PRECISION AND SUSTAINABILITY. The MOBIREX MR 130i PRO mobile impact crusher excels with outstanding performance in a di ve rse range of applications. With its double-deck post screening unit, the plant ensures top product quality with up to two graded end-products, while ach iev ing impressive throughput rates of up to 6 00 t/h in natural stone and recycling. The all-electric E-DRIVE is not only efficient, it can also be operated with zero local emissions. Operation is intuitive thanks to SPECTIVE components. The MOBIREX MR 130i PRO – the sustainable p ow er house.

www.kleemann.info

Enerpac has created its new PPH-Series hydraulic pin puller, which provides an efficient and safe method for removal of joint pins during the maintenance of heavy equipment.

The PPH40 and PPH66 pin puller kits use hydraulic power to remove joint pins on excavators used in the construction industry.

“Safety on the job site is paramount, which is why these kits offer a safer alternative than old-school,

traditional methods involving sparks, heat, hammering and loose parts,” said Ejnar Christensen, National Accounts Manager for Enerpac.

“We wanted to provide a safe and efficient way for a single operator to extract pins from construction vehicles that eliminated damage to parts, but also provided a lightweight and portable tool that was practical to move about on-site.”

With a pulling capacity of 40 tons to 66 tons, the

PPH-Series pin puller provides safe and efficient removal of joint pins up to 30-cm long. It uses a powerful, Enerpac hydraulic cylinder to extract pins with precision and minimal damage, allowing a single operator to remove a multitude of joint pin sizes easily.

Safe pin pulling

Supplied in a portable, wheeled carry case, the PPH-Series pin pullers are designed to handle a di -

verse range of pin-pulling tasks.

Each set includes three stacking and locking patented C-Sleeves, with the option of adding an extra two for longer pins up to 50-cm long. The C-shape design creates a fitment around the flag of heavy machinery pins, providing a precise and safe pin removal.

Improving operator safety, each kit contains a shackle for lifting via a crane

or lifting system. The column sections have multiple hoist points, designed to give the user more control over the balance of the tool while it is suspended. The kit also contains a quick nut for fast attachment to threaded rods, with alternative thread sizes available to purchase separately.

The PPH-Series kits are engineered to streamline even on the most demanding pin pulling projects. The split Quick Nut makes

it easier and faster to manipulate damaged threads. The one-handed closure is quick to assemble around a rod and avoids running the nut over damaged threads. Each PPH-series kit includes three column sections that lock together. Multiple column sections can be stacked together depending on the length of the joint pin.

Up to a maximum of five column sections can be locked together.

MacLean and Sandvik have completed the first phase of a collaboration to provide mining companies with more options for expanding automation in the underground environment. The two mining equipment manufacturers are working together to improve automation zone interoperability of production and support fleets. The partner ship includes the Sandvik AutoMine Interoperable ACS system at the MacLean Research & Training Facility and the demonstration of a surface-controlled MacLean BT5 boom truck activating multiple AutoMine automation zones with light curtain safety gates.

With AutoMine, a mixed fleet of underground loaders, trucks, drills and auxiliary equipment can now be managed with one seamless safety system.

Third-party equipment designs must conform to the functional safety requirements specified for AutoMine operations and non-Sandvik equipment can be retrofitted with an AutoMine ACS Onboard Box to provide the needed interface between ACS and the machine’s safety circuit.

“While we are confident that customers will achieve

optimal performance with Sandvik equipment, we understand the importance of maximizing automation's potential across all equipment, regardless of manufacturer,” said Robert McEwan, Product Line Manager, Automation, Sandvik Mining and Rock Solutions.

“This technology enables mixed-fleet customers to benefit from enhanced safety and improved productivity with the support of AutoMine."

With the first testing phase now complete, the first step in the companies’ interoperability collaboration have been successfully achieved: automation communications, infrastructure installation and the testing of a non-Sandvik mining machine activating the safety gate system.

“If we want to advance the mine of the future where an increasing amount and complexity of automation is available as an option for mining customers around the globe, we need to work differently,” said Patrice Corneau, MacLean Director of Advanced Vehicles and Technology. “Realizing that broader, longer-term goal will require collaboration between original equipment manufacturers in the indus-

CM Labs is expanding its earthmoving simulations to include walkaround inspection for earthmoving training packs.

CM Labs’ virtual walkaround inspection is an additional exercise included with CM Labs’ most used simulated earthmoving equipment training packs.

It addresses the need for training operators on safety protocols and daily pre-use inspections. The exercise includes hints and detailed information at each inspection checkpoint during the evaluation. Walkaround Inspection is included on the backhoe, dozer, tracked excavator and wheel loader training packs.

“Operators-in-training need more than just a checklist — they need instruction and support on how best to identify equipment maintenance issues before they risk becoming safety and productivity concerns,” said Davis Sieu, Product Manager for CM Labs Earthmoving Training.

“CM Labs scoring and randomized evaluation means

try, who historically have perceived each other primarily as competitors as opposed to mining technology development co-practitioners. This collaboration between MacLean and Sandvik embodies that new way of thinking about the mine of the future and how mining equipment manufacturers can help successfully deliver it to mining companies.”

trainees can continue to refine skills while companies can benchmark safety progress. Our walkaround inspection extends training capabilities with unparallelled learning opportunities for safer operations.”

As with all exercises, scores from walkaround inspection are managed in the CM Labs training management Intellia Instructor, providing insight and a deeper understanding of operator skills than exercise scores alone. Via a tablet, instructors can monitor both classroom and individual student progress.

Intellia Instructor allows students to complete lessons at their own pace, while trainers can support those who need it most. Transitioning walkaround inspections between each simulated machine is quick and seamless, allowing organizations to minimize downtime and maximize learning.

Virtual Walkaround Inspection is an ideal tool to use when training to identify equipment failures that are unsafe and impractical to replicate on real equipment.

Working in tight conditions, a Liebherr 81 K.1 fast-erecting crane proved its capabilities in Vancouver Island’s second largest city.

The 81 K.1 fast-erecting, supplied by crane provider Bigfoot Crane Company, helped an apartment take shape in Nanaimo, British Columbia.

Construction of the Departure Bay apartment building presented Bigfoot Crane and the contractor Westurban Developments Ltd. with several challenges, mainly due to the complex nature of the structure and the site conditions.

The crane’s successful operation required meticulous planning, followed by precise implementation.

“It's easy to get a crane onto site when there isn't a building yet. But additional challenges arise once the building is erected because of its structure. When we're planning a project, we al -

ways start by looking at how to remove the crane at the end,” said Cale Anderson, Chief Operating Officer at Bigfoot Crane.

The site’s access road was used for assembling the fast-erecting crane. However, disassembly proved to be a tougher challenge.

“The completed building was in the way as far as normal dismantling was concerned,” Anderson said.

“This meant the fast-erecting crane had to be lifted over the newly constructed building. A large Liebherr mobile crane was used to safely set the 81 K.1 down on the other side of the building.”

Accomplishing the lift required flexibility, technical expertise and being able to think outside the box.

“As well as the challenges on site requiring the right equipment, we also needed a team willing to find creative and innovative solutions,” Anderson said.

Liebherr technology performs

The Liebherr crane’s work on the construction site in British Columbia demonstrates the efficiency and versatility of modern crane technology.

Anderson said he is impressed by the Liebherr crane's features and sees great potential for fast-erecting cranes in North America.

The hoist rope's two-fall operation and the Load Plus feature have particularly caught his attention. Both functions ensure fast lifting speeds and allow heavy loads.

“Our customers especially appreciate the crane's speed and performance that these features make possible,” Anderson said.

On the jobsite, the fast-erecting crane played an integral role in various construction tasks, including trailer unloading, concrete work and the installation of rooftop equipment. While working in British Columbia, the 81 K.1 proved itself as the ideal lifting partner when used with several other cranes on site. Its maximum hook height of 38.9 metres combined with 2.4 metre tower sections meant it could maintain the necessary safety distance between other cranes and buildings in its vicinity, and to slew above or below other cranes, depending on the circumstances.

The 81 K.1 can lift a maximum 6,000 kg. It can reach a maximum radius of 48 metres and has a jib head lifting capacity of 1,350 kg.

The Bigfoot crane fleet

Bigfoot Crane has 36 cranes in its fleet, six of them are from Liebherr. Tailored Liebherr solutions make all the difference for the crane hire company.

“The flexibility and adaptability of Liebherr cranes are key elements in our success. Liebherr understands what we need and works closely with us to ensure we always get the best equipment and service. The versatility of Liebherr cranes allows us

to efficiently handle a broad range of projects,” Anderson said. “Liebherr offers innovation, quality and exceptional service, all of which are a perfect match for our requirements.”

Based in Abbotsford, Bigfoot Crane Company is a full-service provider for the sale, rental and maintenance of tower cranes and fast-erecting cranes. The company also offers training for crane operators and construction site workers and is active in the areas of anti-collision systems, underhook attachments and construction hoists. Established in 2014, Bigfoot Crane provides services in Western Canada and North America.

Since the DTL35 first appeared at ConExpo as a prototype machine, Develon has refined the design, incorporating input from its dealers and contractors.

Now, the company’s first compact track loader is available at Develon dealerships across North America.

Equipped with one of the most powerful engines in its class, at 115.3 hp, the DTL35 helps operators gain traction and manoeuvrability on construction sites and in tight spaces.

“The new DTL35 is the first compact track loader from Develon in North America and has several features and technologies for excellent

performance, visibility and high-end comfort,” said Dylan Freeman, Product Manager for Compact Track Loaders at Develon.

“We’re excited to continue to expand our compact equipment line, giving our customers more machines to help with their work demands.”

The DTL35 compact track loader is equipped with the D34 engine, which is also used in the Develon DD100 dozer. The engine helps minimize downtime, reduce maintenance costs and ensures consistent performance in demanding work conditions.

The machine is available with two rubber track patterns, and both include a wide and narrow version. A wide multi-bar track comes standard, while a block pattern is optional. The wide multi-bar tracks offer increased contact with surfaces for better traction. This design increases stability and reduces vibration and the risk of slippage.

The optional block pattern is designed for durability on challenging terrain, such as rock, gravel or uneven ground. It also minimizes ground disturbance, making these tracks an ideal option for landscaping and turf management.

The vertical lift arm configuration allows the DTL35 compact track loader to extend its reach forward, making it easier to deposit materials into high-sided trucks or bins.

To help maintain stability, a self-levelling feature automatically adjusts the attachment to remain level as the arms are raised or lowered.

As well, the bucket shake feature helps release material stuck to the attachment and facilitates efficient dumping without the need to stop and manually clean the machine.

Ride control reduces shocks and vibrations, which enhances bucket stability and minimizes spillage when the compact track loader navigates rough terrain while carrying full loads.

Auto return to dig automatically returns the arms to the lowered position, saving operators time while delivering a more consistent digging depth.

The standard 2-speed travel feature allows the compact track loader to operate at the

right speed for the job. The higher speed (up to 14.8 km per hour) is ideal for travelling longer distances or quickly moving between job sites, while the lower speed (up to 9.8 km per hour) aids in stabilizing the machine during more precise and controlled movements in challenging conditions.

The reversible fan protects against dust and debris, keeping the compact track loader’s engine cleaner and cooler to help extend the life of the machine.

The rearview camera provides an additional view, allowing operators to easily see behind the machine.

The DTL35 compact track loader has a 90-cm-wide spacious interior, a large polycarbonate swing-out door, electric over hydraulic controls and a roof panel with an unobstructed view of what’s overhead.

The seat is adjustable, heated and equipped with air-suspension to ensure a comfortable working environment.

As well, air-filled cushions adjust to the operator’s

weight and movement, providing a smooth and comfortable ride, especially over uneven terrain. The air-suspension system helps absorb shocks and vibrations, reducing the impact of bumps and rough terrain.

The DTL35’s torsion suspension system also helps absorb shocks and vibrations over rough or uneven terrain. This results in a smoother ride throughout the day compared to traditional fixed-frame machines.

The DTL35 compact track loader is also equipped with a hydraulic quick coupler that allows fast and toolfree attachment changes, significantly reducing the time required for manual attachments.

An optional around view monitor (AVM) camera system with ultrasonic proximity sensors displays a 270-degree view of the machine’s surroundings for greater confidence when operating the loader in tight work areas or busy job sites. The ultrasonic proximity sensors further enhance safety by alerting operators to nearby objects as they back up the machine.

The JCB Teleskid is four machines in one and the world’s only skid steer with a telescopic boom. Imagine what that does for efficiency. Actually, don’t imagine it. Instead, give the Teleskid a try and see how much more you can accomplish. Visit JCB.com to learn more.

ALBERTA

Liftboss JCB

Calgary: 403-301-0041 Edmonton: 780-474-9900 liftboss.ca

BRITISH COLUMBIA

Williams JCB

Surrey: 604-930-3316 williamsjcb.com

NEW BRUNSWICK

A.L.P.A. Equipment

Edmundston : 506-735-4144

Balmoral : 506-826-2717

Fredericton : 506-452-9818 Moncton, N.B. : 506-861-2572 alpaequipment.com

NOVA SCOTIA

A.L.P.A. Equipment

Truro : (902) 897-2717 alpaequipment.com

NEWFOUNDLAND

Harvey JCB

Corner Brook: 709-639-2960

St. Johns: 709-738-8911 harveyco.ca

ONTARIO

D&W Group Inc.

Doughty & Williamson Jarvis: 519-587-2273

Brant Tractor Burford: 519-449-2500

Redtrac International Vineland: 905-562-4136 dwgroup.ca

Delta JCB

Dunvegan: 613-527-1501

Renfrew: 613-432-4133 Winchester: 613-774-2273 deltapower.ca

ONTARIO

Fulline JCB

Glencoe: 519-287-2840 fullinefarm.com

Equipment Ontario Harriston: 519-510-5878

Lindsay: 705-324-6136 Port Perry: 905-982-1500 Waterloo: 519-742-5878 equipmentontario.com

John’s Equipment Sales Frankford: 613-398-6522 johnsequipmentsales.com

Moore JCB Toronto, York & Peel Region: 416-747-1212 moorejcb.com

ONTARIO

North Rock JCB North Bay, Sault Ste. Marie, and Sudbury: 705-897-7369 northrockrentals.com

ReadyQuip Sales & Service Ltd. Timmins: 705-268-7600 readyquip.com

WPE Landscape Equipment - JCB Hamilton/Halton: 905-628-3055 wpeequipment.ca

PEI

A.L.P.A. Equipment (506) 861-2572 alpaequipment.com

QUEBEC

A.L.P.A. Equipment

Bas-Saint-Laurent : (506) 735-4144

Gaspésie : (506) 826-2717 alpaequipment.com

Bossé Quebec Inc.

Desmaures: 418-878-2241 Saint-Augustin-debosse-frere.com

Moore JCB

Montreal: 514-333-1212 moorejcb.com

SASKATCHEWAN & MANITOBA

Westcon JCB

Regina: 306-359-7273

Saskatoon: 306-934-3646

Winnipeg: 204-694-5364 westconequip.ca

The new filter press is designed to meet the needs of the waste recycling, quarrying

CDE has unveiled its new ProPress high-performance filter press, adding to its lineup of water management and recycling systems.

Developed to meet the evolving needs of the construction, demolition, waste recycling, quarrying and mining sectors, the ProPress integrates the latest technological advancements to deliver operational efficiency and maximum water recovery.

The new ProPress made its debut during Hillhead 2024 in Buxton, U.K.

The filter press features patent-pending technology, and benefits from a flexible design and variable throughput that can be scaled to fit the processing volume of any operation.

“Tackling the most challenging of materials is our expertize. We’ve poured over 30 years of engineering excellence into the development of the ProPress,” said Darren Eastwood, CDE’s Business Development Director.

“We’ve listened to and worked alongside our customers around the globe to design a solution that is adaptable to their needs, be they in the waste recycling or natural minerals processing sectors.”

Unlike traditional filter presses, the system is dual feed, meaning sludge is fed from both sides of the ProPress for improved efficiency and faster cycle times.

Optimized sludge feed pressure also allows for faster dewatering to increase overall throughput. This is further supported by an overhead beam design that ensures reliability by reducing stress on the unit and improving its durability.

The ProPress features plates that are 25 per cent larger, measuring 2.5 metres by 2 metres. Greater chamber volume and overall fewer plates serve to provide maximum capacity on a smaller footprint and improve mechanical cycle times.

Plate shake tech

Safe and efficient maintenance is made possible by integrated plate-shaking technology, which addresses filter cake build-up within chambers to help reduce the need for manual intervention.

As well, an access walkway provides unobstructed access to carry out maintenance safely and efficiently.

CDE also included flush mounted drip trays that lock in place to reduce material entrapment and provide a secure maintenance platform for operators.

The smart design is supported by an innovative, multifunctional robot, which serves as the main workhorse for the ProPress, controlling plate opening, plate shaking, cloth washing, plate winch and the maintenance platform.

The CDE ProPress is available in a range of different sizes to suit all markets and applications. Available worldwide, the ProPress is also largely pre-assembled to expedite commissioning, allowing operators to get up and running quickly to help achieve fast return on investment.

ProPress process

As materials are washed and graded, the water used accumulates silt and other residues to form a sludge. A challenging material to pro-

cess, that sludge is pumped under high pressure into the CDE ProPress, which consists of a sequence of plates, the composition of which forms a series of chambers.

As sludge is pumped under high pressure through the press, solid materials build within the chambers to form a filter cake which is dewatered to maximize water recycling and recover a by-product with multiple applications.

“Those needs were clear: sustainable water management was key to minimize freshwater dependency and maximize water recycling, all while improving processing capacity, reducing operating costs and minimizing maintenance downtime,” Eastwood said.

“The ProPress is our response to all of this and more and it is already delivering for

our customers. By the end of the year, the ProPress will be found on eight plants across three regions, processing around 1,000 tonnes per hour of material.”

With the CDE ProPress, owners and operators can recycle up to 95 per cent of process water for immediate reuse in their wash plant while simultaneously recovering a filter cake product that can be used for pipe bedding and landfill capping. This eliminates the need for settling ponds, which typically require extensive maintenance, consume labour resources and incur significant costs.

Once the ProPress is commissioned, every customer is introduced to the CDE CustomCare team which provides aftersales support to help achieve maximum performance from their equipment.

“Our most significant product launch in recent years, the ProPress really encapsulates CDE’s purpose: to create our best world, a ton at a time. It represents a constant push for improvement to make our equipment, our customers’ operations and the sectors we operate in more efficient and less wasteful,” Eastwood said.

“We’re very pleased to finally bring this latest innovation to the wider market to help maximize the availability of our natural resources and reduce the industry’s waste burden.”

At Hillhead, CDE also presented its AggMax 252SR scrubbing and classification system, which combines pre-screening, scrubbing, organics removal, sizing,

stockpiling, fines recovery and filtrates removal on a compact chassis.

Also on display was the latest generation of FreeFlow, the fully mobile washing solution for aggregate and sand classification. Designed and built onto the bed of a semi-trailer for optimal mobility, the plant helps achieve maximum in-situ material recovery and boasts integrated water storage and recycling.

“We see the world through our customers’ eyes, and we engineer practical, scalable and proven solutions that address real-world problems, from the big picture issues concerning global sand shortages and the industry’s waste burden, to the everyday needs of our customers,” said David Kinloch, Director of Business Development, UK & Ireland for CDE.

Terex

Tesab

Tesab

Tesab

Tesab

Tesab

By Garry Moore, Rokbak Customer Support Manager

Rokbak articulated haulers are equipped with the Haul Track telematics system as standard. It’s a productivity-enhancing, connected tec hnology that enables more efficient — and more sustainable — operations.

Telematics takes data from the truck’s onboard diagnostics system and combines it with GPS and wireless communication to monitor truck performance. Fleet managers can access Haul Track via any Internet-connected device, and its user interface makes navigating the system easy.

Here’s five of the biggest advantages of using the connected technology:

Haul Track helps machine owners achieve the lowest possible total cost of ownership (TCO). It does this by monitoring fuel consumption and machine use and identifying potential issues that could cause downtime.

Real-time tracking gives customers more visibility and control, even if they’re managing multiple trucks across several sites. As well as providing location data, Haul Track enables productivity tracking, operational cost monitoring and performance management. There’s a wealth of information that helps owners ensure trucks are used to their full potential, keeping TCO as low as possible.

Information from Haul Track can be easily harnessed to develop a maintenance program, reducing the chances of downtime or disruption. Telematics improves efficiency by encouraging proactive maintenance and continually monitoring health parameters such as engine temperature and oil pressure.

Users receive maintenance alerts and fleet activity reports to help prevent breakdowns and identify issues early. Each maintenance alert includes a list of specific items that require service or inspection.

Having multiple machines monitored by Haul Track allows for coordinated

maintenance scheduling, minimizing downtime further and leaving more time to focus on optimizing operations.

Beat bad habits

Harsh braking, rapid acceleration or excessive idling are not uncommon in articulated hauler operation, whether through misuse, poor planning or a lack of training. Yet issues such as these can have an impact on truck performance and long-term efficiency.

Using telematics to observe, when these issues occur allows owners to introduce corrective measures, such as retraining for operators or an alternative working route for the truck.

Ultimately this will help extend the hauler’s service life, protect uptime and reduce TCO.

Seamlessly integrate

Haul Track has the capacity to cover fleets with hundreds of machines working across multiple sites. It is also designed per the Association of Equipment Management Professionals (AEMP) Telematics Standard 2.0 application programming interface. That means owners with mixed-brand fleets (not only Rokbak trucks) can monitor data from their entire fleet via Haul Track.

To make working with Haul Track even easier, data is presented in a standard format so it can be easily integrated

into a customer’s working platform.

Location control

Without telematics, there’s a lot of uncertainty of where machines are and what they’re doing. With Haul Track, customers not only get pinpoint accuracy, which can offer huge help to service technicians trying to locate a machine on site, but a history of working routes.

There’s also the ability to set geofencing, which involves creating a virtual boundary around the truck and defining where it can travel.

The GPS tracks each truck and sends an alert if it breaches its defined operational area.

The Liebherr plant in Bischofshofen, Austria recently demonstrated two new developments from Liebherr: the world's first large wheel loader with a hydrogen engine and the opening of the first hydrogen filling station in the region.

Both innovations were demonstrated at a trade event, where the hydrogen wheel loader was demonstrated for the first time in practical use.

At the same time as this world premiere, the first hydrogen filling station in

the state of Salzburg was inaugurated, representing an important milestone in the use of hydrogen as a sustainable energy source.

"To make progress in hydrogen research, we need to have access to hydrogen. We built this filling station to further advance our goals for decarbonizing construction machinery," said Dr. Herbert Pfab, Chief Technical Officer of Liebherr Bischofshofen.

Prototype L 566 H

The L 566 H from Liebherr is the world's first prototype

large wheel loader with a hydrogen engine.

Following extensive studies, the new technology was identified as the optimal solution for operating large vehicles that are difficult to electrify without carbon dioxide emissions.

For smaller vehicles up to about 15 tons, battery-electric solutions are often suitable. However, the situation is different with larger machines with an operating weight of up to 40 tons and high energy requirements.

Hydrogen reciprocating

piston engines prove to be ideal in this case.

These hydrogen engines are manufactured at the engine plant of Liebherr's Components product segment in Bulle, Switzerland. They enable not only zero emissions of greenhouse gases and almost no nitrogen oxides but are also highly efficient. Another advantage is the interfaces are comparable to those of a diesel engine, both thermally and mechanically. This represents a significant step forward in the development of sustainable

large-scale machinery.

Another highlight of the event was a MAN truck, also powered by a hydrogen engine. This shows that hydrogen technology is not only feasible in wheel loaders but is already used in construction site trucks.

First hydrogen filling station

As part of the development of the hydrogen wheel loader, Liebherr Bischofshofen opened its own hydrogen filling station — the first of its kind in the state of Salzburg, Austria.

An important strategic partner in this project is Maximator Hydrogen, which is not only the manufacturer of the newly opened filling station, but also a research partner of Liebherr. Together, they are working on mobile filling facilities so machinery can be refuelled directly at the construction sites. This is important for remote construction sites and machines that are not very mobile. MPREIS is also a partner for the filling station by ensuring the supply of green hydrogen.

The team at Superior Industries’ Arizona manufacturing facility recently celebrated the first piece of finished equipment to exit the newly expanded operation.

The expanded facility now includes a third equipment production line, focusing on non-telescoping portable conveyors.

"This means we can reserve the existing lines of production to be more product specific," said Superior Industries President Jason Adams.

"Most notably, it's really going to take stress off TeleStacker

conveyor production in Arizona and allow us to produce more of these high demand telescoping stackers."

Along with the new line for non-telescoping portable conveyors, the Arizona facility also replicated a new idler manufacturing setup launched in Minnesota earlier this year. This investment in machinery, robotics and automation significantly increases conveyor idler throughput company wide.

"The headline says more manufacturing space out west, but this is going to

have a positive effect on all of our operations and improve lead times across the board," Adams said.

Superior Industries, headquartered in Morris, Minnesota, is a privately-owned American manufacturing company. Its product line includes crushing, screening, washing and conveying systems.

Alongside its four production facilities in the United States, Superior has international manufacturing locations in Canada, Brazil and Asia.

To mark its 70th anniversary and 40th year as an articulated dump truck (ADT) manufacturer, Bell Equipment demonstrated the cap abilities of its autonomous B40E ADT.

The demo was held at Hillhead 2024 as part of the trade show’s live quarry demonstrations.

The truck is the same machine that Bell UK customer Chepstow Plant International (CPI) have been using since March 2024, when it was

launched as the first autonomous ADT in the United Kingdom.

“We were excited to be able to demonstrate our autonomous ADT at Hillhead and also have a static display so visitors could see exactly how the hardware is incorporated into the machine,” said Bell Equipment Product Manager Brad Castle.

Supplied by technology platform specialists xtonomy, the autonomous hardware includes radar sensors, high-precision GPS, multi-channel communication systems and on-board processing hardware to create a drive-by-wire B40E solution.

“We’re pleased by how our autonomous ADTs have enhanced operational efficiencies on the sites where they are working by being able to operate for longer periods, deliver really accurate tipping results and improve productivity,’ Castle said.

He added autonomous trucks can extend component life, reducing wear and tear and improve fuel efficiency from enhanced operational efficiencies.

“CPI’s autonomous B40E takes environmental benefits a step further by using HVO fuel instead of diesel, making the machine almost carbon neutral, which is a significant achievement in the current quarrying and mining industry,” Castle said.

“Autonomous ADTs also improve site safety, as borne out by our two Bell B30E

6x6 test trucks, which have achieved over 1,000 hours of safe autonomous operation in a quarry in the Austrian Alps, without any incidents.” When choosing to operate a Bell ADT autonomously, customers have a choice of third-party suppliers and the level of autonomy they want to achieve.

At Hillhead, Bell Equipment’s niche 4x4 range was also represented by the B45E 4x4, which is ideally suited to quarrying and smaller mining operations.

“Our 4x4 range of ADTs have full articulation and oscillation steering so all four driving wheels are kept on the ground to utilize the traction that’s available. This makes them more capable off-road than conventional rigid trucks. The double axle also results in tighter turning circle for greater manoeuvrability and prevents tire scuffing, reducing road maintenance costs,” Castle said.

"Like the other models in the 4x4 range, the B45E 4x4 has the same payload as the 6x6 model and features full suspension for improved ride comfort. It also has the option of a narrower bin for sites with width restrictions.”

Other machines on display at Hillhead 2024 included the EU-marked Bell B30E 27,000litre water tanker, designed for dust-suppression duties on mines and construction sites, and the Bell tracked carrier, a robust solution for short-haul applications in soft underfoot conditions.

At Hillhead 2024, the UK-based Agg-Pro showcased the largest mobile crusher ever seen at the show.

The Jonsson L130 is one of five jaw crushers manufactured by Jonsson at their headquarters in Sweden.

Developed to crush Scandinavian granite, the L130 can achieve up to 800 tonnes per hour and performs exceptionally, even in demanding applications.

The 120-tonne machine

features a 13-litre Stage 5 Volvo engine and a 400 kVA Volvo generator. The dual-power design of the L130 significantly reduces operational costs.

The crusher is extremely fuel efficient and when it is plugged in, the machine runs at a cost of about 45 cents per tonne for 1.48kWh per tonne.

The 10 cubic metre capacity hopper of the L130 can be increased to 18 cubic metres with optional extensions, and features 100 mm rubber

liners with Hardox liners on the hopper edges. Jonsson products are customizable and the L130 can be equipped with an independent vibrating pre-screen if required.

To eliminate bridging, the L130 features a remote-controlled rock hammer that can be operated from the cab of an excavator or on the machine itself. There is also a viewing tower with a camera looking into the jaw, allowing monitoring whenever required, as well as a load sensor.

In the heart of the machine is a Metso Nordberg C130 jaw crusher, measuring 1.3 metres wide by 1 metre deep that is optimized for aggressive crushing to allow for coarse feed material.

Jonsson machines are also equipped with the Jonsson Monitoring System (JMS) — a web-based monitoring tool that helps optimize the production and administration of crushing operations. This integrated telematics system allows live remote monitoring

of the machine’s production and component running statistics, including bearing temperatures, belt conveyor tonnage, warnings and signals and closed-side settings.

An 18-cm monitor can be fitted in the excavator cab for easily accessible read outs from Jonsson machines, as well as the ability to change parameters.

Agg-Pro was selected by a major quarry company in England to supply a replacement for one of its primary

crushes. The company selected the Jonsson L130.

The quarry produces 1.7 million tonnes of limestone aggregates annually for use in asphalt, concrete and construction. The quarry currently produces 750 tonnes per hour while consuming 20.2 litres of fuel per hour.

Jonsson has provided mobile crushing solutions since the company was founded in the 1950s. The manufacturer was acquired by Metso in 2018.

With the new Lokotrack EC range, Metso brings a new diesel-electric power line to the aggregates market.

All the process functions of the range are electric, reducing the use of hydraulic oil required in the crushing operations. All Lokotrack EC range units can be powered with external electricity.

During its Lokolaunch event in Finland, Metso introduced the first two products of the new EC range.

The Lokotrack LT400J is a 68-ton mobile jaw crusher designed for the primary crushing of hard rock and recycled aggregates. The Lokotrack LT350C is a 50-ton mobile cone

crusher for secondary and tertiary crushing.

“When external electricity is available, the new electric power transmission provides high capacity with minimized operational cost and CO2 emissions,” said Jarmo Vuorenpää, Director of the new Lokotrack offering at Metso.

“When not available, the onboard diesel gensets allow maximum independent operation time. Also, auxiliary units, such as mobile screens and stackers, can be powered from the same gensets, which will further reduce the needed power to run the complete plant.”

To reach high capacity, the LT350C is equipped with the new Nordberg HP350e cone crusher, while the LT400J counts on the proven Nordberg C120 jaw crusher. Both units can be seamlessly combined with each other as well as with the Lokotrack mobile screens to produce high quality aggregates.

The Lokotrack EC range has been developed using new, modular architecture, which reduces the number of components and provides scalable solutions that can be adapted for different applications and capacities.

“The new way to do product development enables a faster and more

agile way to meet the changing customer needs,” said Renaud Lapointe, Senior Vice President of Metso Products business line in the Aggregates business area.

“Furthermore, it enables more efficient support for the machines with less parts needed and easier upgrades of new features.”

All the components of the new EC range are designed and tested to perform in demanding conditions to achieve maximum uptime.

As well, safety and usability have been given special attention. The design of the LT400J and LT350C fulfills the latest safety standard while being

easier to use than previous machines. With new digital tools, the units can be operated safely from the excavator and be quickly set from transport to operation.

Lokotrack units are ideal for processing both natural aggregates and recycled materials. Lokotrack EC is a new diesel-electric range that complements the existing offering. Lokotrack EC range contributes significantly to Metso’s Planet Positive offering with lower carbon dioxide emissions when operated with electric power. It also helps reduce carbon footprint due to the reduced need for hydraulic oil.

At Hillhead, Quarry Manufacturing and Supplies (QMS) unveiled the new QMBack and C3 Complete Crusher Control System, which are both designed to improve crusher efficiency and productivity.

The QMBack is the latest version of QMS’ own brand of crusher backing. QMBack is made of a 100 per cent solid epoxy resin backing compound that has been formulated to provide high, compressive strength support for wear parts in all kinds of quarry and mining machinery, such as crushers, grinders and other heavy-duty equipment.

QMBack combines high impact resistance, superior compressive strength,

non-flammability, high stability and low shrinkage all in one system.

The latest version has been developed to prolong the life of machinery while protecting against impact and shock vibration. It extends equipment life, enhances productivity and delivers more labour savings. It is easily applied by machinery operating personnel with minimal training and has a proven track record to enhance performance in all types of crushers and climatic conditions.

C3 system

In addition to QMBack, QMS also featured an advanced solution for its leading range of B-Series cone crushers.

This is the integrated Complete Crusher Control (C3), a PLC system designed and developed that simply controls all aspects of the crusher operation.

With the C3, operating the crusher is straight forward as the automatic start up routine incorporates cavity calibration to compensate for liner wear, with automatic adjustments made to the crusher setting to give consistent and reliable product shape. Pressure and power in relation to load are automatically adjusted with all influencing conditions being taken into consideration.

Furthermore, C3 automatically monitors all health functions and provides the operator with

information via a touchscreen interface.

The remote touchscreen gives full process control, and displays continual real-time monitoring of all parameters, and logs all events and alarms. Energy costs can be calculated as C3 records kilowatt hours used. The touchscreen also stores pdf versions of all operator manuals, spare parts list and electrical layouts. C3 also includes the main and auxiliary starters, eliminating the need for any third-party electrical equipment.

As C3 is an integrated part of the crusher system, it also eliminates nearly all local electrical installation work. The only requirement is for power to be connected.

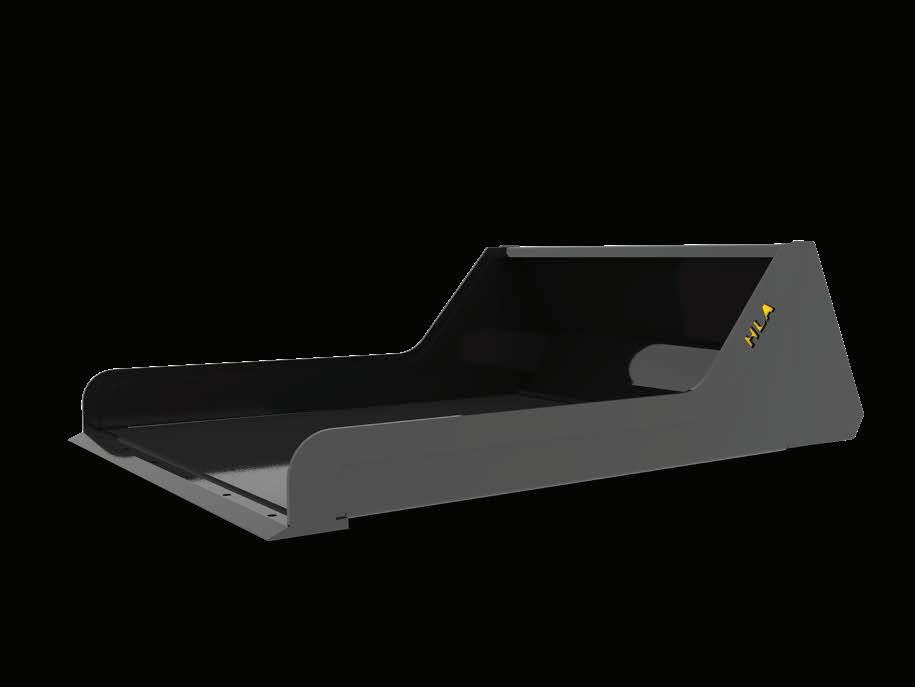

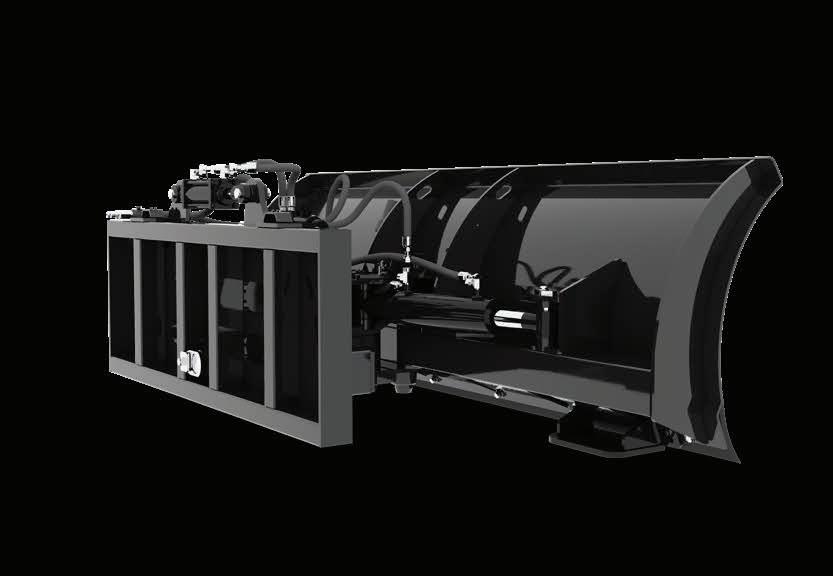

To ensure a steady income year-round, many Canadian landscapers turn to snow and ice management once the ground freezes.

As operating costs increase, the practice is becoming more and more popular for landscape contractors. Jonathan Gardner, Product Manager for Construction Equipment and Attachments at Kubota Canada, explained snow removal also serves to retain skilled employees.

“If they don't keep their equipment going and paying their operators, they risk losing them for the next year,” Gardner said.

Preparing to work in snow and ice management does require owners and operators to plan for the unknown.

“In landscaping, you can kind of plan your jobs. Rain does get in the way, but it’s not as big. With snow removal, you never can predict when it's going to snow,” Gardner said. “If it doesn't snow, like some years, you don't even go out. But if it does come and it's coming heavy, you're working 24/7 until that snow is gone.”

Leading up to winter, owners must ensure machines used for landscaping are able to transition to snow and ice removal. As safety

is a factor in snow removal, quickly completing the job is imperative.

“It’s very important that your equipment is in good working order. It’s not just removing snow, it’s safety. If you're cleaning parking lots, it’s because people want to shop there. And if there's snow, they can slip and fall,” Gardner said.

The transition

When to start winterizing depends on where in Canada the machine will operate. In Ontario, for example, landscapers may be able to work as late as November, while Western Canada may be plowing their first snowfall in October.

“So really, the transition is when the ground starts to freeze and you cannot do any more landscaping,” Gardner said.

Winterizing equipment starts with checking all fluids and changing the engine oil. As well, summer diesel should be swapped out for winter fuel.

“If you're using the wrong diesel fuel, it could gel up and then you're down,” Gardner said.

He also encourages an overall inspection, including the in-cab heating system, to avoid issues when snow does

begin to fall.

“Really check to make sure everything's in working order. Downtime is money,” he said.

Before snow starts to fall, machines should be equipped with the proper attachments for the winter maintenance tasks assigned. Wing blades, V blades or snow blowers are all popular attachments for the right task.

For parking lots with uneven ground, a snow pusher with a trip head blade is a popular option.

“When you get pushing snow and get moving pretty quickly, you can accidentally hit a sewer cover or a curb. The operator feels those, so those trips systems usually help soften the blow,” Gardner said.

Typically, skid steers are the compact machine of choice for snow removal. However, the use of compact track loaders has been gaining popularity. While skid steers are able to move quickly and provide more grip, CTLs are more productive and operate with lower ground pressure during warmer months for landscape projects.

“It's getting too expensive for contractors to have two types of machines. So, they'll

use their track machines for the winter for snow removal. So, they are becoming more popular,” Gardner said. “The benefits of having a track machine in the summer outweighs a wheeled machine.”

To winterize CTLs, the tracks should be greased, and bar tracks should be considered for maximum traction on snow and ice.

“When they put a bar track on, they find they're getting the grip level that they need to actually do the snow removal,” he said.

Once a contractor begins to fulfill their snow removal contracts, machine maintenance is crucial.

“Winter is harsh on the equipment and salt is a killer for everything,” Gardner said. Equipment should be inspected and cleared of snow and ice to avoid damage. For example, Gardner explained ice can accumulate on hydraulic cylinders and potentially damage the system.

On tracked machines, ice can build up in the undercarriage, which can damage the tracks or the carrier.

“You want to keep it just as clean as you would during the summer because summer has a different effect,”

Gardner said. Keeping attachments clear of ice is also important to ensure optimal performance.

“If there's snow buildup or ice buildup on the cutting edge, you're not going to get a clear path,” Gardner said.

For the new contractor looking to expand their business into the winter months, Gardner said there

isn’t much of a learning curve between landscaping and snow removal. The skills required to properly operate a bucket for grading transfer to operating a snow pusher or wing blade.