JUNE 17, 2024 ISSUE 8 FOCUS: DRILLING & FOUNDATIONS / LIFT & ACCESS RETURN UNDELIVERABLE ITEMS TO: EQUIPMENT JOURNAL, PO BOX 160 PORT MCNICOLL, ON L0K 1R0 PUBLICATIONS MAIL AGREEMENT: 40063867 www.essltd.com since 1946 DISCOUNTS ON ALL ESCO BUCKETS FOR ALL MAKES ! Jim Walsh jwalsh@essltd.com 416-358-3192 SEE OUR AD ON PAGE A6 Contact John or Mark at: 1-800-265-5747 www.marcelequipment.com Sales, Rentals & Rental Purchase Quality, Reconditioned Equipment Since 1976 KOMATSU WA500-8 (2021) • 4,925 total hours • 2,285 Idle hours • 8 CYD Bucket • 29.5R25 Michelin Tires • Steering Wheel • Rear Camera • Work Ready • Servicing / Repairs Complete PRICE: $CALL 2214 Line 9, Bradford, ON L3Z 2A5 19067 94th Avenue, Surrey, BC V4N 3S4 gearequip.com 416-644-3076 Hydro-Detection System & Gas Detection System DRY VAC RENTALS Equipped with: ONLINE HEAVY EQUIPMENT & TRANSPORTATION AUCTIONS 1-888-376-3155 • AllStarAuctions.ca 44 Line 9 South, Oro-Medonte, ON L0L 1T0 UPCOMING AUCTIONS: Consign Today! Consignment Commission Capped For Sellers 2015 Case 621F XR BARRIE - JULY 23-24th 2016 Kenworth T880 (1 of 2) 1.800.556.9452 amiattachments.com Scan QR code for all-inclusive, profit building deals that let you roll everything into one predictable payment. sales@deltapower.ca 1-888-880-6496 PUSHING THROUGH OBSTACLES. IT’S WHAT WE DO SINCE 1842. NO ONE WILL OUTWORK US. LUBECORE.COM 905-864-3110 NEXT GENERATION AUTOMATED LUBRICATION MADE IN CANADA Scan Me SERVICING ALL MAKES OF GREASERS. Ű Reduced Downtime. Ű Protect Your Investment. Ű Simple. Reliable. Ű Keeping Operators Safe. ACROSS NORTH AMERICA SO MUCH TO GREASE. SO LITTLE TIME. LIVE WEBCAST AUCTIONS NEXT EQUIPMENT AUCTION: June 22nd, 2024 @ 9AM CELEBRATING 21 YEARS SERVING THE INDUSTRY 866-229-2253 TO CONSIGN YOUR EQUIPMENT, CALL US sales@bmcdowell.com www.bmcdowell.com 705-566-8190 416-770-7706 BUY ME See our ad on page A8 EPIROC FlexiROC T15 ,self-propelled, 4-wheel dr drill rig7,870 lbs. Entire re-pinning op. takes only 180 secs. Long horizontal reach, drills 1”–2” diameter holes, stk# B20-105 NOW 1-855-625-0941 sales@creightonrock.com CRDCREIGHTON.COM DTH HAMMERS BITS PIPES SALESPARTS SERVICE 3 IN STOCK TOPLIFT.COM

A2 JUNE 17, 2024 EQUIPMENTJOURNAL.COM 800 Farewell Street, Oshawa Ontario, L1H 6N5, Canada psc@powerscreencanada.com powerscreencanada.com 1-877-797-7276 CONTACT POWERSCREEN OF CANADA ® CEDARAPIDS W AS H IN G SYST EMS WARRIOR 1800 - Designed for medium to large operators, a tough, heavy duty machine built for screening, 2 or 3 way splitting and stockpiling in quarrying, recycling, construction and demolition aggregates and top soil applications. 90’ x 36” HEAVY DUTY STACKER - Diesel power, hydraulic top fold, hydraulic axle jacks. POWERSCREEN | 1800 WARRIOR SCREEN & 90’ x 36” STACKER RECOVER, REPURPOSE, AND REUSE : The VacRecover is an innovative modular washing solution specifically designed for processing hydro excavated waste material that was typically a waste material. The washing process converts it into a saleable product, openign up a new revenue stream for many quarries. The Cobra 230R is a versatile and easy to use Small Impact Crusher that can operate in the most demanding of applications such as Reinforced Concrete, Recycled Asphalt, Construction and Demolition waste. Features include a 3.4yd3 hopper capacity, 34” crusher inlet, 8’ x 4’ single desk mesh screen, 281hp. Ideal for creating RipRap and recovering rocks up to 800mm (32”) that are mixed with clay and other sticky materials. The updated model has been redesigned to include new features that will improve transportation, access, and stockpile heights. MDS | M515 HEAVY DUTY TROMMEL CEDARAPIDS | LJ-TSV6203 3 DECK HORIZONTAL SCREEN EVOQUIP |COBRA 230R SMALL IMPACT CRUSHER

Volvo has updated multiple excavators to improve productivity, fuel efficiency and safety

ISSUE 8 June 17, 2024 A3 JUNE 17, 2024 EQUIPMENTJOURNAL.COM Convert an excavator into an HDD Indeco expands into Canada A10 A22 New Ammann plant tackles RAP A19 DRILLING & FOUNDATIONS FEATURED EQUIPMENT B11 LIFT & ACCESS FEATURED EQUIPMENT B3 A12 STORY ON

next

of

The

generation

Volvo CE excavators

In the last few weeks, Fleming College’s decision to cut its available programs has generated its fair share of anger, particularly in the heavy equipment sector.

Heavy Equipment Techniques and Generator Service Technician are two of 29 programs suspended by the college in April.

It’s almost comical that courses that teach in-demand trades are cancelled, while courses like Drawing and Painting, Artist Blacksmith and Ceramics will be offered next semester, but it’s reality. (It’s worth noting that Fleming is still a strong educator for the trades, with programs such as Resources Drilling Technician, Heavy Equipment Operator as well as various carpenter and electrician courses offered.)

The college says its decision is based on enrolment numbers, which were cut

due to a reduction in foreign students.

This year, about 140,000 foreign students will be permitted to attend post-secondary schools in Ontario, a 40 per cent decrease from last year. At Fleming College, about one third of its students are from outside of Canada.

Of the 29 suspended programs, Fleming explained some have low expected domestic enrolment, while others have zero projected domestic enrolment. Other programs are no longer financially sustainable with enrolment levels that do not cover the cost of delivery.

Canadian colleges and universities should be adjusting their program roster based on domestic demand. They are publicly funded institutions.

The domestic demand part is what should be angering.

Before graduating high

school, youth are being told to “follow their passion,” yet “passion’ is often only associated with the arts and sciences.

As any reader of Equipment Journal knows, passion can also apply to building someone’s first home or a community’s new hospital or providing and maintaining the tools needed to complete these projects. It’s also a more realistic career path.

In Ontario, one in five job openings are projected to be in the skilled trades by 2026, and the provincial government has made numerous announcements to provide funding for training.

However, funding can only help so much. High school educators — and parents — need to encourage youth to pursue careers that will play to their strengths, but also deliver a sustainable and fulfilling life.

After all, these decisions will dictate success or failure, and the aspirations of a teenager may not be viable for adult life, or collectively in the best interest of society. Freedom of choice is a cornerstone of our society, but that doesn’t mean students can’t be guided into studying for occupations that will translate into financial freedom, as well as build a stronger society.

A4 JUNE 17, 2024 EQUIPMENTJOURNAL.COM Published every third Monday at 6-5160 Explorer Dr., Mississauga, (Toronto). Subscription $44. per annum or $72. for 2 years including applicable tax., Payable in advance. Single copy $3.95. Authorized as Publications Mail Agreement No. 40063867, by the Post Office Dept. Ottawa and for payment in cash. Advertising is accepted on the condition that in the event of typographical error, that portion of the advertising space occupied by the error together with reasonable allowance for signature will not be charged for, but the balance of the advertisement will be paid for at the applicable rate. In the event of a typographical error advertising goods or services may not be sold. Advertising is merely an offer to sell and may be withdrawn at any time. We reserve the right to reject or refuse any or all advertising. Equipment Journal permission is required to reproduce original ad layout, artwork and photos. H.S.T. # 10403 7957 RT ADVERTISER INDEX JUNE 17/2024 LETTER FROM THE EDITOR EQUIPMENT JOURNAL IS AN AUDITED PUBLICATION CONTACT US Editor Bill Tremblay editor@equipmentjournal.com Publisher Mark Baker mark@equipmentjournal.com PACE PUBLISHING LIMITED EQUIPMENT JOURNAL 5160 Explorer Drive, #6 Mississauga, ON, L4W 4T7 Canada OFFICIAL SOCIAL MEDIA ACCOUNTS @EquipJournal @equipmentjournal @EquipmentJournal Equipment Journal LOCAL: (905) 629-7500 TOLL-FREE: CDN/USA 1-800-667-8541 EMAIL US: advertise@equipmentjournal.com WEBSITE: www.equipmentjournal.com Sales Manager Tara Baker tara@equipmentjournal.com National Account Manager Mona Fahmi mona@equipmentjournal.com Creative Director/Creative Services Ryan Chuhaniuk ryan@equipmentjournal.com Circulation Manager Lisa Bath lisa@equipmentjournal.com Alltrade Equipment B8 Amaco Construction Equipment Inc. A14 AMI Attachments A1 Ault A9 Bobcat A13 Brandt - Parts & Service A15 Brandt - Road & Mineral B19 Brandt Used B15 Brandt Used Truck & Trailers A5 Brandt Value Parts B6 Bull Powertrain A7 Carrière D'Aumond A10 Cooper Equipment Rentals A1 Creighton Rock Drill Limited A1,A20 Delta Power Equipment A1,B9 Develon B2 Elation-Tech Inc. B4 Equipment Sales & Ser vice Limited A1 Gear Equipment A1 High Reach Inc. A10 HLA Attachments B16 Hood Equipment A16 Hub Equipment B20 Hydrolexc A7 Hyundai Construction B7 Indeco Canada B14 Industrial Trailers A12 JCB A24 Jeffrey Machine, Inc. B12 JT Equipment A1 Komatsu A18 LBX Link-Belt Excavators A21 LGMG North America Inc. B5 Liebherr A11 Lubecore A1,A22 Lund Appraisal Svc. A22 Magnum Attachments A4 Marcel Equipment Limited A1,A6 McDowell B Equipment Ltd. A1,A8 Morgan's Diesel Truck Parts A22 Pine Ridge Lisco Edwards B4 Powerscreen of Canada A2 Robert Green Equipment A17 Shaw Bros. Limited A19 Strongco Equipment B17 Tarten Equipment Limited A20,B16 Top Lift Enterprises A1 Toromont Used Equipment B1 Tramac A14 Tri-City Equipment A19 UHI Machiner y A23 Word Rock Drills B10 AUCTIONS AllStar Auctions A1 Br yan's Auction..............................................................B13 North Toronto Auctions A1

Bill Tremblay // Editor editor@equipmentjournal.com Don’t blame Fleming College for reduction in trades programs magnumattachments.com For the profit end of your machinery MAXIMUM PRODUCTIVITY GRAPPLES processing buckets TILTROTATORS PULVERIZERS SHEARS HYDRAULIC BREAKERS COMPACTORS We’ve got attachments for all your needs: DEMOLITION RECYCLING SCRAP EARTHMOVING 1-877-640-2862

BOOST YOUR FLEET WITH A USED PETE.

Drive your operation to success with Brandt, Canada’s #1 Peterbilt dealer, backing used Peterbilts with unmatched

A5 JUNE 17, 2024 EQUIPMENTJOURNAL.COM

locations across Ontario

Get flexible financing

Find parts &

of any make or model

Canada’s #1 used equipment inventory. Brandt also buys used! More Locations More Flexible More Inventory

With 18

& Saskatchewan, Brandt is always just down the road, ready to help.

from experts who meet you on your terms & turf —even at your truck!

trucks

from

Scan Here

Explore Inventory

Dealership today!

support.

to

Or contact your local Brandt Peterbilt

A6 JUNE 17, 2024 EQUIPMENTJOURNAL.COM LONDON, ONTARIO, CANADA Contact John or Mark at: 1-800-265-5747 or 519-686-1123 Email: sales@marcelequipment.com VIEW our Complete Inventory at: www.marcelequipment.com REBUILT CAT 826H COMPACTORS - 0 HRS Components Rebuilt, Complete Machine Recondition, 3 year CAT Component Warranty 40 Compactors to choose from. $CALL Since 1976 SALES, RENTALS & RENTAL PURCHASE UNITS SOLD WITH WARRANTY WE ALSO RENT EQUIPMENT CONTACT MARK or JOHN 1-800-265-5747 or 519-686-1123 CAT 816K (2020) - 1,015 HRS CAT Warranty Remaining. Just like a New One, but for a lot Less! $CALL CAT 352FL (2018) – 4,195 HRS Reach Boom, 11’ Stick, Aux Hydraulics, Coupler, 30” Pads, Very Clean, CAT Inspected. $CALL CAT 938M (2018) - 6,680 HRS 3rd Valve, Diff Lock, Coupler, Choice of Bkt, Forks Available. $250,000 VOLVO A25G (2017) - 6,850 HRS 23.5R25 Tires, Rear-View Camera, Inspected, All Needed Servicing and Repairs Completed. $CALL CAT 980M (2019) – 7,740 HRS 3,125 Idle Hrs, CAT Scale, 7.75 CY Bkt, Bridgestone L4 Tires, Spade Bkt Available. $535,000 VOLVO A30G (2016) - 8,620 HRS 23.5R25 Tires, Tailgate, VOLVO Warranty til Sept 2025 / 10,000 Hrs $CALL CAT D6T LGP VP (2016) - 6,945 HRS 2,345 Idle Hrs, 31‘’ Pads, Drawbar, Ripper Available, Accugrade Ready, Work Ready. $350,000 (4) CAT D8T (2011-18) - 4,381-7,698 HRS SU or Angle Blades, Drawbar, Winch or Rippers, Very Clean Units. $CALL (3) CAT D8T LGP (2019/2020) 7,435 to 14,345 HRS 38” Pads, Choice of Blades, Drawbar, Winch or Rippers $CALL CAT 980M (2019) - 7,325 HRS 7.75 CY Bkt, Tire & Bucket options available All Needed Repairs & Servicing Completed. $540,000 $CALL KOMATSU WA470-8 (2016) – 7,380 HRS Coupler, 5.25 yd Bucket, Loadrite Scale, All Servicing / Repairs Completed. CAT 770 (2008) – 10,655 HRS 40 Ton, 33 CY, Dual Slope Bed, Very Straight Truck, All Servicing & Repairs Completed. New Tires. $CALL (2) KOMATSU HD325-7 (2010) - 11,000 HRS 40 Ton, 31 CY, Flat Floor, Very Straight, Clean Trucks, All needed Serving & Repairs will be Completed. $CALL CAT 772G's - 5 AVAILABLE (2016-2017) 7125 – 11,238 HRS Flat Floors, Liners, Auto Grease, Nice Straight Trucks. $CALL $CALL (2) VOLVO A30G (2018) - 6,000 HRS 23.5R25 Tires, 750/65R25 Tires Available, Tailgate, 2 Available. Very Clean. CAT 938M HI LIFT (2019) - 5,560 HRS 3rd Valve, Hi Lift Boom, Coupler, Choice of Bkt, NEW Michelin Tires. $300,000 CAT 988K XE HIGH LIFT (2020) – 6,650 HRS Bucket Options, Tire Options, Auto Grease, CAT Maintained, Very Nice. $CALL

Ausa acquired by Oshkosh Corporation

Oshkosh Corporation, the parent company of JLG and Hinowa, has entered into a definitive agreement to acquire Ausa.

Established in 1956, Ausa is a privately held company and manufacturer of wheeled dumpers, rough terrain forklifts and telehandlers for the construction, material handling, agriculture, landscape and specialty equipment industries. Upon closing, Ausa will become part of the Oshkosh Access segment.

“Ausa’s history of producing high-quality, purpose-built equipment aligns with our Innovate. Serve. Advance. strategy, allowing us to broaden our product offerings in both current and adjacent markets,” said John Pfeifer, Oshkosh Corporation’s President and Chief Executive Officer. “We look forward to welcoming the Ausa team into the Oshkosh family.”

Ausa products will enhance JLG telehandlers, as well as Hinowa tracked dumpers and forklifts to strengthen the Access segment’s portfolio of equipment.

Ausa and Oshkosh began working together through a partner agreement in 2020, with Ausa manufacturing the JLG-branded SkyTrak 3013 compact telehandler.

“We are excited to join forces with a proven partner like Ausa,” said Mahesh Narang, Executive Vice President of Oshkosh Corporation and president

of the Access segment.

“Combining our advanced technology capabilities and robust training, support and service infrastructures will allow us to better serve customers and enable targeted growth.”

Ausa was founded in 1956 in Barcelona, Spain. In 2023, the company reported sales of about EU$132 million. The company employs nearly 350 team members and its machines are sold through 600 dealers. Ausa operates in 90 countries and has subsidiaries in Madrid, France, the United Kingdom, Germany, the United States and China.

“We constantly pursue excellence in our products, services and business,” said Ramon Carbonell, Ausa’s Chief Executive Officer. “A

deeper relationship with Oshkosh will expand the reach of our products, which is an objective our companies share.”

The Ausa acquisition supports the Oshkosh accelerated growth strategy. The transaction, which is subject to customary closing conditions, is expected to close within 90 days.

Headquartered in Wisconsin, Oshkosh Corporation employs about 17,000 team members worldwide.

Its products can be found in more than 150 countries under the brands of JLG, Hinowa, Power Towers, Pierce, MaxiMetal, Oshkosh Defense, McNeilus, IMT, Jerr-Dan, Frontline Communications, Oshkosh Airport Products, Oshkosh AeroTech and Pratt Miller.

ARA predicts Canadian rental revenue to grow by 7.2 per cent

The updated forecast for Canadian equipment rental revenue predicts 7.2 per cent growth this year, reaching a total $5.79 billion, according to the American Rental Association (ARA).

In its updated forecast, the ARA indicates the Canadian and United States equipment rental industry’s growth projection has increased since last quarter.

“The 2024 ARA forecast through the lens of our exclusive rental revenue model, and survey results gathered from members, confirms the continuation of a growing rental industry,” states Tom Doyle, ARA Vice President program development.

Broken down by segment in Canada, general tool and construction and industrial equipment (CIE) are both expected to see growth.

Canadian general tool revenue this year is projected to

expand by 6.8 per cent, reaching $1.08 billion, up from last quarter’s projection of $954 million. Canadian CIE revenue is projected to reach $4.71 billion.

“Our experience mirrors what ARA is reporting.

Despite headwinds in the residential market, revenues are up, with western Canada stronger than eastern Canada,” said Darryl Cooper, President of Cooper Equipment Rentals.

The United States equipment rental industry’s growth projection has also increased since last quarter.

The most current projections indicate a 9.7 per cent increase in 2024 totalling $79.2 billion in construction and general tool rental revenue. This is an increase from last quarter’s projection of a 7.9 per cent increase totalling $77.3 billion.

“There has been no serious

bust, thus, there is no serious boom,” said Scott Hazelton, Managing Director at S&P Global. “The outlook remains steady and inflation is falling. The growth rates tail off in the future years, with growth of 3.8 per cent in 2025 and 3.1 per cent in 2026.”

General tool revenue in the United States is projected to increase 9.7 per cent this year to $16.6 billion and investment is expected to expand in 2024 and beyond. This year, investment in general tool is projected to increase 7.3 per cent with growth into 2025 at 7.9 per cent and into 2026 at 6.4 per cent.

“Our housing market is still being stubborn, so we see a 9.7 per cent growth in 2024, an 8.8 per cent increase in revenue growth in 2025,” Hazelton said. “Investment in general tool is higher than CIE, due to a faster replacement rate.”

A7 JUNE 17, 2024 EQUIPMENTJOURNAL.COM

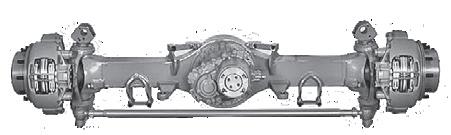

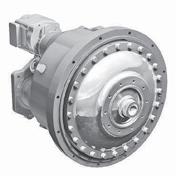

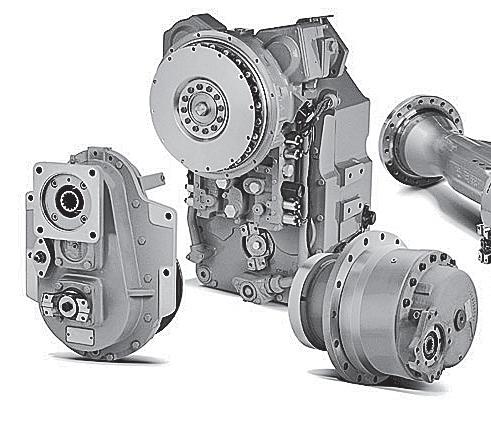

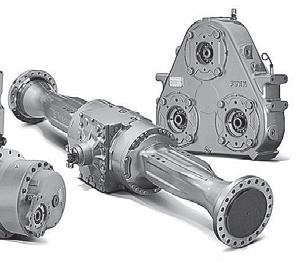

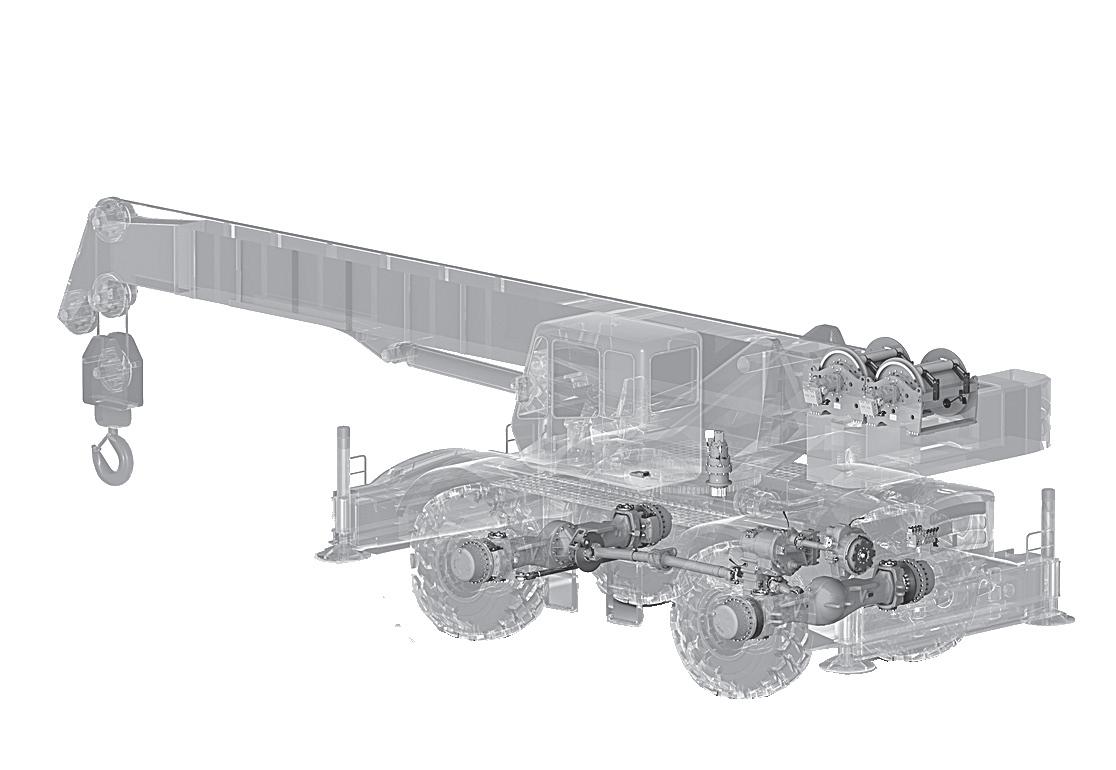

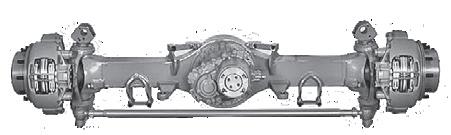

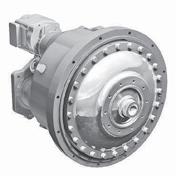

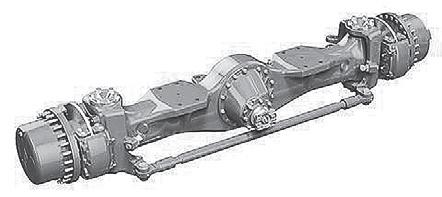

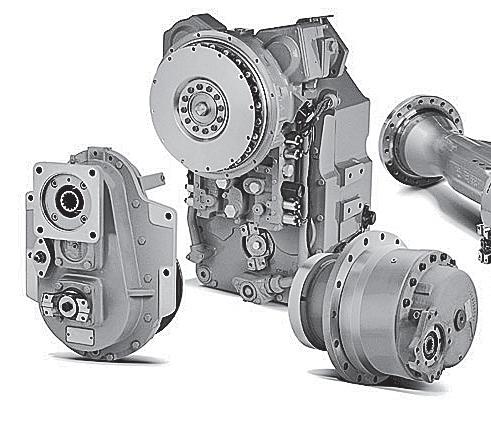

OEM parts and components for all your off-highway equipment Authorized to perform warranty work Factory trained technicians (705) 560-BULL (2855) 1510 Fairburn St. Sudbury, ON P3A 1N7 bullpowertrain.com We Manufacture OEM Driveshafts COME JOIN OUR TEAM! WE ARE CURRENTLY SEEKING EXPERIENCED COMPONENT REBUILDERS. WE ARE YOUR AUTHORIZED SERVICE CENTRE FOR 416-458-2334 HYDRAULIC HAMMER/BREAKER SPECIALIZING IN PARTS, SALES & SERVICE KENT MUSTANG OKADA RAMMER ROCK RAM STANLEY TRAMAC ALLIED ATLAS COPCO BTI CAT CP EPIROC ESCO INDECO NPK SINCE 1998 HYDROLEXC.COM HYDROL EXC EQUIPMENT SERVICES LTD.

Rubble Master releases new jaw crusher

Based on the RM Next philosophy, Rubble Master has introduced its latest jaw crusher: the RM J110X.

Designed from the ground up, the RM J110X is based on the RM Next philosophy and incorporates the manufacturer's new high efficiency drive concepts in addition to numerous new and innovative features.

The new mobile jaw crusher completes the Rubble Master product range, now offering full crusher and screen train solutions to cover all kinds of crushing requirements.

The 52,000 kg jaw crusher is made for processing hard and abrasive natural rock as well as heavy-duty recycling applications. The machine features an 1,100 mm by 700

mm inlet opening and is capable of processing up to 450 tonnes per hour depending on its application. As well, a 10 per cent deeper jaw box provides more crushing action.

“Apart from other brands that went into lighter designs, we went into more durable designs,” said Rubble Master Founder Gerald Hanisch.

Powered by a Cat C9.3B 280 kW engine, the RM J110X features the latest hydraulic degassing and return technology to extend the lifetime of the hydraulic oil.

The crusher is also available with a hydraulic or a hybrid drive for maximum fuel savings or to plug directly into the main power supply.

“We can see more and

more development in hybridization, particularly in mining where these machines will go,” Hanisch said.

The RM Next philosophy focuses on delivering simplicity of operation, a commitment to quality and the resulting high level of service, enhanced operator safety and optimized material throughput.

The RM J110X jaw crusher isn’t the last innovation Rubble Master will introduce.

Several product developments are in the pipeline and will both expand the portfolio of crushers and broaden the product offering of screens. As the demand for the RM screen line increases internationally, the RM Group follows a plan to enhance its screen produc-

tion together with a partner in Northern Ireland to ensure development and production of RM screens according to the market requirements. At the Austrian site, additional production lines are currently being built to increase production capacity for crushers.

In North America, Rubble Master’s parts warehouse was moved from Memphis to Ennis, Texas, to create the necessary capacity for further growth and to put the key staff under one roof. Also, construction of a completely new building began near the existing location. The new facility is expected to open in the third quarter of 2024. It will also include a training centre for sales and technical training.

Epiroc to acquire ACB+

Epiroc has agreed to acquire ACB+, a manufacturer of attachments and related couplers used in construction.

ACB+ is based in Saint Lager, France, and has several production facilities in the country. It manufactures attachments and quick couplers used on excavators for construction as well as scrap recycling and demolition.

Quick couplers are used with carriers, typically excavators, to enable safe and efficient change of attachments, such as buckets and hydraulic tools.

The company has 60 years of experience in manufacturing attachments, and more than 150,000 machines have been equipped with its original system.

“ACB+ is known for its competence and high-quality products and solutions. This acquisition will strengthen our offering of quick couplers and attachments, thereby providing customers a more complete portfolio of productivity-enhancing products and solutions,” said Helena Hedblom, Epiroc’s President and CEO. “We look forward to welcoming the strong team at ACB+ to Epiroc to grow together in the long term.”

The company is wellknown in France and has

B100-901

customers throughout Europe. It had revenues of about $47 million in the 12 months through to March 31, and has about 140 employees.

The acquisition is expected to be completed in the third quarter of 2024. The parties have agreed to not disclose the acquisition price as the transaction is not subject to a disclosure obligation pursuant to the EU Market Abuse Regulation.

The ACB+ purchase follows the completion of Epiroc’s acquisition of Stanley Infrastructure from Stanley Black & Decker Inc.

Stanley Infrastructure is headquartered in Milwaukie, Oregon. It designs, manufactures, and sells attachments, typically used on excavators, and handheld hydraulic and battery-powered tools for applications in infrastructure, construction, scrap recycling, demolition and railroad infrastructure.

Its brands include LaBounty, Paladin, Pengo and Dubuis.

Epiroc also recently completed the acquisition of Weco Proprietary Limited, a South African manufacturer of precision-engineered rock drilling parts and provider of related repairs and services. Weco is based near Johannesburg, South Africa.

A8 JUNE 17, 2024 EQUIPMENTJOURNAL.COM

416.770.7706 or 705.566.8190 sales@bmcdowell.com bmcdowell.com SALES • RENTALS • PARTS • SERVICE Hammers Compact Equipment Wheel Loaders Air Comp,ressors Trailers/Floats Compaction Carriers 2024 BOBCAT L95, 74 hp, Tier 4, nonDPF, 11,993 lbs O.W., power Bob-tach coupler, road & mirror kit, stk# B100-1027 2020 BOBCAT T64 & 2019 BOBCAT S550, 2 speed, SJC controls, aux. hyd., 68” bucket, stk# B100-1010/B100-887 GREAT CAREER OPPORTUNITY! Full-Time Sales Rep/Business Development Manager for Barrie Email resume to kevin_m@bmcdowell.com GROVE RT38, 15,000 lb lift capacity, 48’ tip height, 4 wheel dr & steer, 14.00x24 tires 30%, stk# B235-15 $12,500 2024 BOBCAT TL519, 74 hp, Tier 4 EPA, 9,898 lbs O.W., 233” lift height, Bob-tach coupler, U/G certified, road pkg, stk# B100-917 2024 BOBCAT L85, 68 hp, Tier 4, 11,164 lbs O.W., 2 speed hyd., turbocharged, 70.9” width (over tired), stk#

SANDVIK SECOMA MERCURY 1F/1B JUMBO DRILL, B26F boom, Hydratar 300 drill, stk# B20-602 BUY ME 2006 MANITOU MHT860L, 13000 lbs lift, 26’6” max height, OW 25,386 lbs, stk# B230-56 BUY ME 2016 BOBCAT V723, 100 hp, 7700 lbs max load, 23’ lift height, 4 wheel dr w/2spd, hyd. trans, stk# B100-780 CAT TL943, 9,000 lb lift cap., 43’ lift height, rebuilt boom & trans., 1300x24 tires, stk# B230-52 BUY ME (1 OF 3) CAT V300B FORKLIFT, mast 85” W, 30,000 lbs. max lift @ 24” center, stk# B230-31 BUY ME BUY ME BUY ME BUY/RENT BUY US BUY ME 2023 BOBCAT E35, Tier 4, 2022 US EPA label, manual Q/C, hyd. thumb, 4’4” stick, 12” rubber tracks, stk# B100-1022 BUY ME 2023 LINK-BELT 355 X4S, 205 hp, 78,709 lbs O.W., 21’10” max dig depth, 34’8” reach at ground level, zero tail swing, stk# B160-242 5 YEAR/5000 HOUR FULL MACHINE WARRANTY BUY ME 2024 LINK-BELT 220 X4S, 160 hp, 49,200 lbs O.W., 21’10” max dig depth, free swing, heavy duty boom, stk# B160-246 5 YEAR/5000 HOUR FULL MACHINE WARRANTY BUY ME CAT 725C, 730, 735B • VOLVO A25F, A30F, A35F READY TO HAUL! RENT US CAT DOZER DOZEN READY TO RENT! CAT D6T LGP, D6N, D6N LGP, D6N XL, D6R, D6K 2 LGP, D5K LP, D5K 2XL, D4K 2XL. RENT US

A9 JUNE 17, 2024 EQUIPMENTJOURNAL.COM

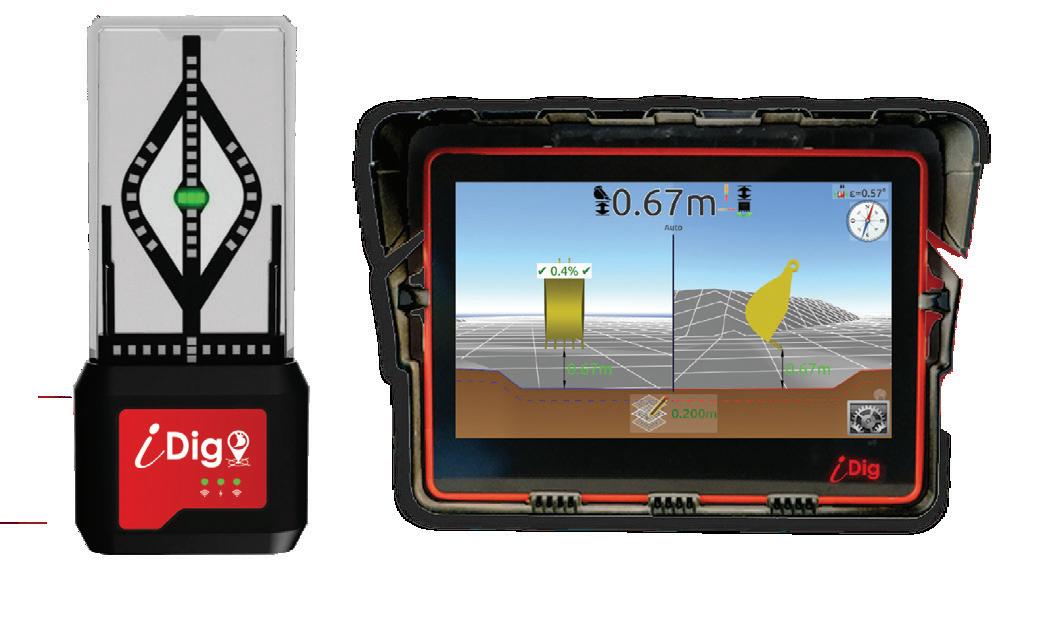

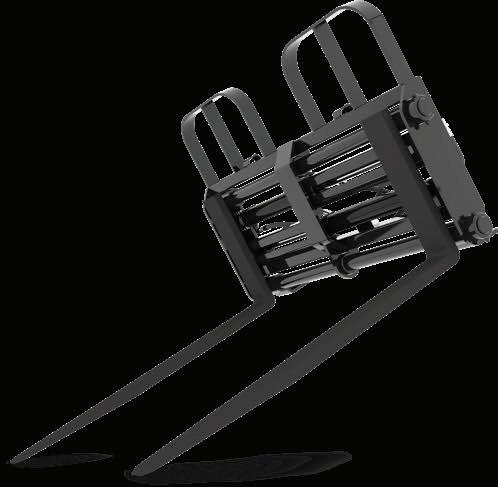

EasyDrill converts excavators into a directional drill

EasyDrill, an attachment that can transform an excavator into a horizontal directional drill (HDD) is now available in Canada.

Now manufactured in Germany, the attachment was developed in New Zealand about 15 years ago, and has gained popularity in the South Pacific, Asia and Europe. The Hamilton, Ontario-based Integrity Rail Products is now the first North American distributor for the EasyDrill. CG Equipment in Guelph, Ontario recently hosted the EasyDrill’s first Canadian demonstration.

“I'm pretty excited about the product overall because it has the potential to do what a directional drill can do, but for significantly less money,” said Peter Scholtens, President of Integrity Rail Products.

With the same capabil -

ities as a small self-propelled HDD, the EasyDrill can install fibre optic cable, gas, electric and water lines. The attachment requires 60 to 80 litre per minute of hydraulic flow from a single hydraulic line.

“It'll run on a 3.5 tonne excavator, but you get the best performance out of 5 tonne machines and higher,” Scholtens said. Thanks to its compact size, the EasyDrill can tackle surface or pit shots at 90-degree angles. The machine also features 360-degree rotation and delivers 3,628- kg thrust, 4,764 kg pullback force and 1,225-foot pounds of rotary torque.

“With a self-propelled unit, you always have to have setbacks so that you can get down at an angle to the depth that you need. With this unit,

you can dig a pit and do a pit shot and be down there without requiring a setback,’ Scholtens said.

The EasyDrill also has the potential to reduce transportation costs by eliminating the trailer space required for an HDD.

“Most guys will have a mini excavator on their jobsite anyway. And so, they need a truck and a trailer to move that, then they also need another truck and a trailer to move to self-propelled directional drilling equipment,” Scholtens said. “In this case, they can put it all on one float.”

The EasyDrill package includes a basket that carries 50 drill rods that are 97-cmlong, a 300-litre water tank and a 5-hp Honda engine to run the lubrication pump.

The system can be ex -

panded to run an additional 50 rods.

‘A lot of guys, once they've got some experience running

it and develop some confidence, will go ahead and buy a second set of rods,” Scholtens said. “But basically, you

get everything you need, except for tracking equipment, to start up your own drilling company.”

A10 JUNE 17, 2024 EQUIPMENTJOURNAL.COM CANADIAN DEALER FOR: F ROM 5,000 TO 160,000 LBS. BARE RENTAL RENTALSSALESSERVICE IC-20IC-35IC-40 Capacity 5,000 lbs 4 Tons 9,000 lbs Boom Height 22’33’ 6”33’ 6” IC-80IC-200IC-250 8 Tons15 Tons18 Tons 46’ 4”73’79’ 4” www.highreachinc.com Tel: (905) 844-4164 Broderson Carry Deck Cranes are extremely versatile, ideal for lifting material that require a compact, low-profile crane to maneuver in tight spaces and clear overhead obstacles. Multiple sizes and capacities, including optional equipment for customization, ensures your Broderson crane can fulfill all your lifting needs. BRODERSON

CARRY DECK CRANES ORIO N BETTER FORK LIFT TRUCKS 2021 KOMATSU PC700LC-11 WITH 1800 HRS CARRIÈRE D'AUMOND 3 Ch Petit Lac Taylor, Aumond, QC stevestosik@hotmail.com | sales@stosik.net 819-441-8749 PRICE ON REQUEST www.stosik.net

CARRY DECK CRANES

A11 JUNE 17, 2024 EQUIPMENTJOURNAL.COM 11670-2016_LBH_068_L550_L586-V_Z-K_2022-EN-Canada-263_525x387_35-v01-C21290248.indd 1 04.04.2024 14:33

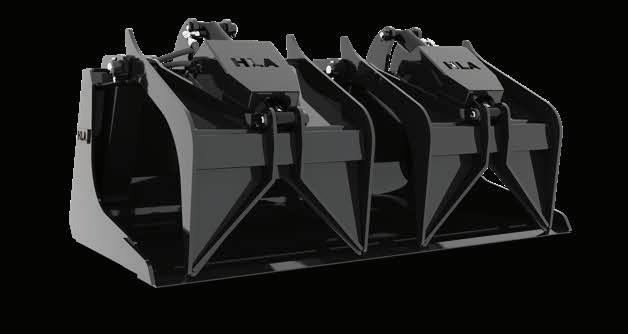

Volvo CE launches six revamped excavator models

Volvo Construction Equipment has completed its most significant update to its excavator range in two decades.

The new range of excavators deliver 15 per cent greater fuel efficiency, increased productivity, enhanced safety and numerous operator-friendly features.

The initial new model launch includes the ECR145 short swing, EC210, EC230, EC370, EC400 and EC500 crawler excavators. Volvo CE is expected to announce more new models in the coming months.

“This new excavator series is the realization of our commitment to our customers. Every design change, innovation and weld were made with our customers' needs top of mind,” said Scott Young, Head of Region North America for Volvo CE. “All together, these updates will substantially impact their productivity, uptime, employee satisfaction and ultimately, their success.”

Fuel efficiency

Volvo CE has equipped the new excavators with an optimized electro-hydraulic system, a smart cooling system and engine speed regulation for higher torque at a lower rpm. These new features provide as much as a 15 per cent improvement in fuel efficiency, when compared to the previous generation while outperforming the prior models.

The enhanced hydraulics improve machine control and deliver smooth and precise movement of the boom, bucket and other hydraulic components.

Volvo CE has expanded the number of

work modes to 10 settings, including two specific power modes and four specific modes for eco operation.

A new creep travel mode coupled with boom and arm shock reduction settings give operators precise command of loads and reduce spillage.

“Our customers are looking for ways to increase productivity and reduce expenses, and we deliver on that with these new excavators,” said Sejong Ko, Product Manager for large excavators at Volvo CE.

“Fuel in particular is a major expense, and the improved fuel efficiency will reduce costs with the added benefit of lowering the environmental impact.”

Volvo Smart View

The new excavator series also enhances safety. A safety-enhancing highlight is the Volvo Smart View with Obstacle Detection, which gives operators a 360-degree view of the machine’s surroundings. While cameras are increasingly being added to heavy equipment, Volvo Smart View with Obstacle Detection combines camera technology and a new radar detection system to distinguish between objects and humans for a heightened level of awareness.

As well, additional lights have been added to the cab, boom and arm to improve visibility on low-light jobsites.

New cab

Volvo has also enhanced the excavator cab, with features that address both ease of use and comfort.

An improved human-machine interface (HMI) helps deliver a productive workday. The automation of boom and bucket movement with the Volvo Active Control machine control system and an advanced electric control joystick help operators increase productivity.

The new excavators also include smaller upgrades that make a big impact on operator satisfaction, including:

· Updated seat design

· Improved ventilation

· New footrest support for working on slopes

· Keyless engine start

· Multiple operator preference settings

· Larger cab side mirror with heater

· In-cab wireless phone charger

· Built-in cooler/heater compartment for food or drinks

· Additional sunscreens and storage areas

· Additional safety railings and relocated footsteps

· New DEF sight gauges and splash guard

These models also include the latest generation Co-Pilot. The in-cab tablet’s larger, higher-resolution screen will display Dig Assist applications like on-board weighing, in-field design and more.

The new Volvo excavators offer a 50 per cent increase in hydraulic oil life with service intervals extended to 3,000 hours for regular hydraulic oil and 6,000 hours for long-life hydraulic oil.

A12 JUNE 17, 2024 EQUIPMENTJOURNAL.COM The Ultimate in Trailers® ... since 1905 Whether your hauling needs take you over or off-the-road, ROGERS trailers give you the reliability, versatility and efficiency you need to lower your costs and improve you profits LEASE AND FINANCE OPTIONS AVAILABLE TAG SERIES -63548 BLACKTOP SERIES -40693 ULTIMA SERIES -40692 FIXED GOOSENECK SERIES -63549 CENTURY SERIES -40691 SPECIALIZED SERIES -63553 Non ground bearing gooseneck. Four beam tapered design. Front fixed ramps 25’0” level deck. Boom well and bucket pocket Equipped for pin on 4th axle. 275 rubber/aluminum wheels/ABS brakes LED lights Load bearing trunnions between wheels. -72413 www.rogerstrailers.com Email: w.smith1@rogers.com Yard Location; 402 Mulock Dr. Newmarket, ON. L3Y 9B9 • NEW • USED • RENTALS 416-801-5292 "55 TONS IN STOCK NOW AND READY TO GO!" "55 TONS IN STOCK NOW AND READY TO GO!"

“What was most impressive was the stone it could lift...”

Jeff Ronhaar has been the head coach of Jeff’s Outdoor in Caledonia, Ont. for the past 30 years. His title tells you a lot about his personality. Jeff fondly remembers starting his business mowing lawns to earn money for beer, rent and some money to take a girl out on a date. Then it became a passion, so he went back to school and took horticultural classes. “When you are not focused on growth, you build better relationships. It’s either people or money.” He now has a team of 38 employees, and he values his team as much as his customers. Jeff has a lot of long-standing employees, like Paul Dumaresq, landscape consultant who has been with the company for 25 years. The office has a monthly social budget. One month they did bubble soccer and from that, got two resumes of people wanting to join the company. Jeff said he wanted to retire soon so that his people could grow. “How staff reports and reacts, shows how good a company is. If they are happy at work, that reflects on their work and the customers.” That seems to be working as all their work has been from repeat business and referrals. They are a design/build landscaping company that includes hardscape, softscape, outdoor kitchens, patios, basketball & volleyball courts, putting greens, lawncare maintenance, etc. They are primarily 95% residential and 5% commercial in the Golden Horseshoe areas. They enjoy the residential side more as it’s heightened job satisfaction as it’s more personal.

BARRIE

Bobcat of Barrie

705-726-2228 oakenequipment.ca

GREY BRUCE

Bobcat of Grey Bruce 519-372-9100

bobcatoftc.com

PARRY SOUND

Bobcat of Parry Sound Ltd.

705-342-1717

bobcatofparrysound.com

TORONTO WEST

Bobcat of Toronto

416-679-4172

oakenequipment.ca

BRANTFORD

Bobcat of Brantford 519-752-7900

bobcatofbrantford.com

HAMILTON Bobcat of Hamilton 905-643-3177

bobcatofhamilton.com

PETERBOROUGH

Bobcat of Peterborough 705-748-9119

bobcatofpeterborough.com

THUNDER BAY Equipment World Inc. 807-623-9561

bobcat-tbay.com

he

“I am an old-school

Loyal and happy kind of businessman so why change brands? My service level however did start to fall apart with the previous brand. Tom Morelli, sales specialist, from Bobcat of Hamilton, popped by and said, “Let me drop off a machine, the same size as you are currently using, try it out. All I am asking is for your opinion on how it compares to the one you currently have.” There was no pressure. It’s the best way to sell your business in my opinion. I and the other operators loved the comfort of the machine, great visibility, and ease of operation. What was most impressive was the stone it could lift, which was way more than my current machine so when Tom came back to pick the machine up, my reply to him was, I want the white one, leave it here, bring me the paperwork. The service and rapport are much better with Bobcat of Hamilton. Tom has since changed positions and now I work with Derek Brooker, sales specialist, and he has been just as terrific to work with. Mike Legere, our project manager, doesn’t cry wolf. If he needs something urgent, Andrew in rentals gets it for him right away. We have a great relationship with Bobcat of Hamilton and that’s so important. It has to work both ways. We just sold a Bobcat S100 compact skid-steer and Mike is already trying to figure out what Bobcat to buy with it. I give them a budget, and they can

CASSELMAN

Bobcat of Ottawa Valley 613-764-2033

bobcatov.com

KITCHENER

Bobcat of Tri-Cities Ltd. 1-866-214-3939

bobcatoftc.com

STRATFORD

Bobcat of Stratford 519-393-6040

bobcatofstratford.ca

SAULT STE. MARIE

Bobcat of Sault Ste. Marie 705-949-7379

bobcat-ssm.com

CORNWALL

Bobcat of Ottawa Valley 613-932-2034 bobcatov.com

LONDON

Bobcat of London 519-455-4900

bobcatoflondon.ca

STRATTON

Stratton Equipment 807-483-5505

strattonequipment.com

WINDSOR

Bobcat of Windsor 519-737-0120 oakenequipment.ca

spend it. We want to utilize our fleet to the fullest. I appreciate when Derek Brooker talks me out of buying a machine and tells me where it’s better to spend my money. You build trust with a client when you tell them you have $25k to spend and then are told you only need to spend $14k for what you need. Not only does that build trust but also lots of referrals. Not to mention more sales in the future.”

Jeff’s Outdoor now owns four Bobcat compact excavators, three compact track loaders, three compact skid-steers, an aerator, and a Bobcat stand-on zero-turn mower. They use them for grading, digging patios, and water features, excavating, material hauling and loading trucks, and clearing snow.

“Culture creates success in a company and the same goes with buying equipment. It’s been fun and easy with Derek Brooker and the rest of the team at Bobcat of Hamilton so I would highly recommend them in buying your next machine or rental.”

Thank you, Jeff.

FRANKFORD

John’s Equipment 613-398-6522

johnsequipmentsales.com

OTTAWA

Bobcat of Ottawa Valley 613-831-5166

bobcatov.com

TORONTO EAST

Bobcat of Toronto 416-679-4171 oakenequipment.ca

A13 JUNE 17, 2024 EQUIPMENTJOURNAL.COM

YOUR LOCAL AUTHORIZED BOBCAT DEALERS

When Jeff was asked why he chose Bobcat® machines,

answered,

Dutch.

(L to R) Jeff Ronhaar, head coach of Jeff’s Outdoor and Derek Brooker, sales specialist for Bobcat of Hamilton pose for a photo at Jeff’s Outdoor shop in Caledonia, Ontario.

COURTICE Bobcat of Durham East Ltd. 905-404-9990 bobcatofdurhameast.com SUDBURY McDowell B Equipment Ltd. 705-566-8190 bmcdowell.com MUSKOKA Bobcat of Muskoka 249-390-7000 oakenequipment.ca WYOMING Advantage Farm Equipment Ltd. 519-845-3346 advantage-equip.com

Manitou’s MRT rotating telehandlers are now available with a Woodcracker tree saw with grapple configuration.

The new telehandler configuration can significantly improve performance and productivity in tree and limb removal operations, particularly in urban areas and roadside land management applications.

The Woodcracker tree saw with grapple is compatible with Manitou’s MRT 2260, MRT 2660 and MRT 3060 Vision+. When matched with the MRT 3060 Vision+, operators can reach heights of about 30 metres and outreach to more than 25 metres. The maximum lifting capacity for the MRT with the tree saw attachment is 3,630 kg.

“The off-road capabilities, 360-degree rotation and the excellent reach of these rotating telehandlers makes this an extremely versatile solution for municipalities, public works departments and tree removal contractors regularly faced with challenging tree and limb removal jobs,” said Steve Kiskunas, Telescopic Handler Product Manager at Manitou.

Built from high-strength steel and capable of cutting tree branches and trunks up to 74 cm in diameter, the new Manitou tree saw rotates into position to cut, hold and deliver each limb.

It can also be matched with the Manitou rotating telehandler remote control to give the operator flexibility in how and where they perform the work.

“It delivers the ability to remove and place large and heavy tree limbs while maintaining excellent control of the load,” Kiskunas said. “This simplifies the work, helps keep the operator and other workers out of the fall zone, and gives the operator the ability to perform the work from the most advantageous vantage point when equipped with the remote control.”

Each Manitou MRT rotating telehandler equipped with the tree saw will include a spe-

cialized forestry package with a windshield guard, boom covers and guards, hydraulic and electrical system covers, and a second return-to-tank line. Manitou offers the attachment solution for new machine orders and for existing Manitou MRT Vision+ models: MRT 2260, MRT 2660 and MRT 3060.

While each Manitou rotating telehandler matched with the new tree saw with grapple is specialized, each machine retains compatibility with the full line of rotating telehandler attachments to deliver a versatile platform for businesses or public works departments.

“This new tree saw with grapple configuration delivers excellent heavy-duty performance for a specialized application while still delivering a broad range of capabilities as a three-inone machine — telescopic handler, jib and aerial work platform,” Kiskunas said. “This type of versatility can really be an asset in smart fleet building and management.”

The purposely matched solution of a rotating telehandler with a forestry package and a premium tree saw/grapple has an opportunity to evolve how tree removal, vegetation management, public works and other contractors approach safe limb and tree handling.

"Our customers are impressed with Manitou’s MRT 3060 for its performance versatility, precision, and unparallelled comfort," said Ben Siemen, Vice President of Sales for Shawmut Equipment. "This innovative piece of equipment is now designed to meet the demands of this harsh application — from the hydraulic hose and electrical component guarding at the boom tip, to the innovative remote control with designated controls for the grapple saw.”

A14 JUNE 17, 2024 EQUIPMENTJOURNAL.COM

• Astec FT2650 tracked mounted jaw crusher (2) • Astec FT4250CC tracked mounted closed circuit impactor (1) • Astec: 6x20 3 deck portable screening plant c/w overhead feed conveyor • SBM Remax500 track mounted closed circuit impactor • SBM Remax500 track mounted closed circuit impactor • Screencore Trident 124 track mounted scalping screen • Screencore 365R tracked radial stacker (3) • HKD GT400 trailer self powered dust suppression cannon with onboard generator (2) Call or Text (905) 670-3440 AMACOCEI.COM CRUSHING AND SCREENING PRODUCT LINEUP AVAILABLE FOR RENT, RPO & SALE Manitou equips its MRT Rotating Telehandler with Woodcracker tree saw Toronto Office: 2-78 Signet drive Toronto, ON M9L 1T2 Office: 416-748-1818 Cell: 416-580-6401 frank_genua@tramac.com SERVING THE CONSTRUCTION, DEMOLITION & MINING INDUSTRIES FOR OVER 58 YEARS Kingston Office: (613) 542-1500 28 Steve Fonyo Dr., Kingston, ON K7M 8N9 Montreal Office: (888) 663-8122 3421 Industriel Boulevard, Laval, Que. H7L 4S3 Quebec City Office: (418) 877-5557 1711 rte de L’aeroport #4, L’ancienne Lorette, Que. G2G 2P4 1966 - 2024 Cell: (613) 532-4823 Office: (613) 542-1500 shaun_brown@tramac.com CANADA Shaun Brown WWW.TRAMAC.COM

A15 JUNE 17, 2024 EQUIPMENTJOURNAL.COM brandt.ca 1-888-227-2638 SAVINGS DELIVERED. Get the best value Brandt has to offer on filters, batteries, undercarriage inspections, maintenance parts, and more, all delivered to your inbox every month. You deserve more uptime. The Brandt Values Flyer delivers it. View this month’s flyer at brandt.ca/ValuesFlyer

FAE debuts new road planer for 5–8 ton excavators

FAE is expanding its construction line for excavators with the RPL/HY road planer for 5-ton to 8-ton machines.

The new road planer is based on FAE’s cold planer technology. Using cold planer tech, the road's surface is scraped and cut by teeth arranged along a rapid spinning rotor. The RPL/HY has a specially designed layout to reduce vibration and increase performance.

The RPL/HY can mill up to 11.5 cm deep, and has a working width of 30 cm.

The head comes standard with several new tech and structural features. For ex-

ample, the RPL/HY allows the operator to manually adjust the working depth, and its wide-stroke self-levelling system allows them to maintain proper head alignment during operation. The product line includes special teeth designed for different road surfaces: R/44/A for asphalt and R/44/C for concrete.

The unique rotor design and tooth layout allows FAE road planers to penetrate easily, maintaining the desired depth and producing a finer product.

FAE augments the design with multiple water tank options to reduce wear and

prevent teeth from overheating.

The new RPL/HY joins the RPL/EX for 8-ton to 14 ton-excavators, to further expand FAE’s line of construction products.

With a range of more than 90 products and 400 models, FAE's range of heads includes forestry mulchers, cutters, stump cutters, stone crushers, soil stabilizers, road planers, wheel saws and multitasks. Its line of tracked carriers includes tracked carriers with cabs and remote-controlled tracked carriers.

FAE expands

In the last few years FAE has been expanding its construction attachment line, taking the industry know -

ledge and understanding gained through the success of its PTO units and transferring it over to the hydraulic line. This line includes such attachments as cold planers for skid steers, cold planers for excavators and a wheel saw for skid steers.

“The experience has been there for years, so we only needed to transfer that experience into the hydraulic version,” said FAE President Diego Scanzoni. “We saw the opportunities in the hydraulic construction attachment space thanks to the broad experience and success we have had with the PTO lines. The equipment is essentially proven and solid. Our next step is to work on building brand recognition on the hydraulic side of the market.”

Bateman Manufacturing unveils

orange peel grapple

Bateman Manufacturing recently launched its 210 series orange peel grapples, designed to change the way scrap and recycling facilities manage bulk materials.

The grapple made its debut at the ISRI 2024 conference in Las Vegas this spring.

"We were excited to introduce our new 210 series at ISRI 2024," said Jason McNeil, Division Director at Bateman Manufacturing.

"This product represents our commitment to innovation and providing our customers with tools that improve efficiency, safety and productivity in their operations."

The 210 series orange peel grapple is engineered to cater to the demanding needs of the scrap and recycling industry. Its unique design allows for efficient handling of various materials, including metal scrap, demolition debris and other bulk recyclables.

As well, an improved tine design, and thicker hardfacing on the tip, optimizes scrap penetration and material collection.

The grapple also features improved rotator guarding for greater impact protection as well as a larger pin diameter and improved bushing design with seals for longer life and optimized work time.

Newly designed double wall cylinders include return oil channel, which eliminates exposed hoses and risk of damage. Cylinder guards are now fully enclosed with zero chrome exposure.

Born in scrap metal recycling 30 years ago, Bateman has grown into a full-service grapple manufacturer. The company's product portfolio offers a solution to every grapple need, from small to large, scrap to forestry and everything in between.

Bateman Manufacturing designed the new grapple with a more robust body for durability and greater cylinder protection as well as a thicker frame design for better pin support and hose guarding.

A16 JUNE 17, 2024 EQUIPMENTJOURNAL.COM

RENTALS

SALES

Darren Hynnes: 807-252-6556 Trevor Hynnes: 807-629-3007 Steve Dobson: 705-816-4806 Jason Denis: 705-288-4685 9 Ferndale Drive N, Barrie, Ontario Pete Ferguson - Southern Ontario Sales Manager 705-734-4507

the 210 Series

EQUIPMENT CANADA

&

HOOD

888-9070

Cardico Drive, Gormley, ON L0H 1G0 robertgreenequipment@bellnet.ca

EXCELLENT LIFTING AND DIGGING PERFORMANCE IN NARROW SPACES

Drawbar Pulling Force (SAE J1309)

Excellent drawbar force lets you conquer rough terrain and slopes.

70,500 lbs {314 kN}

Lifting Capacity

27,540 lbs {12,490 kg} (Ground level over

KOBELCO CONSTRUCTION MACHINERY introduced the first short radius excavator at ConExpo in 1999, the Kobelco SK235SR. S.A. Sutcliffe Excavating from Bethany, Ontario purchased that unit at ConExpo. In 2023 Kobelco introduced the largest short radius excavator, the Kobelco SK380SRLC-7 with an operating weight of 84,700 lbs and an impressive swing radius of 17’7”.

ROBERT GREEN EQUIPMENT SALES has committed for a number of units to add to the over 600 Kobelco excavators in our service area.

ROBERT GREEN EQUIPMENT SALE would like to make an Introductory Offer to all their current clients and future clients:

ONE NEW KOBELCO SK380SRLC-7 with AMI COUPLER, choice of TWO BUCKETS - 30”, 36”, 42”, 48”, 54” or 60”. Add rotation plumbing for $10k.

Comes with FOUR YEAR WARRANTY — No travel time for warranty work.

KOBELCO FINANCING IS AVAILABLE AT .99% FOR 48 MONTHS & 1.99% FOR 60 MONTHS. TRADES WELCOME TO USE AS YOUR DOWNPAYMENT.

A17 JUNE 17, 2024 EQUIPMENTJOURNAL.COM ® robertgreenequipment.com Stephen Cargill at 647-554-5108 stephen@robertgreenequipment.com -7 SERIES

Hydraulic Excavator

RENTAL

350LC WITH COUPLER/BUCKETS & THUMB $10,000/MONTH

BEST SELLING PRICE: (905)

front @20’)

UNITS AVAILABLE 2 KOBELCO

$475,000

41

A18 JUNE 17, 2024 EQUIPMENTJOURNAL.COM © 2024 Komatsu Ltd. or one of its subsidiaries. All rights reserved. You need a partner that can meet your needs and embrace the future. One with new solutions for a changing world. Together, we can work toward a better future. komatsu.com/construction Innovative solutions. Positive transformation.

CE_PC900-11_EquipmentJournal_PrintAd_10.375x15.25_June24.indd 1 5/2/24 9:13 AM

PC900LC-11 large excavator

Ammann America has announced its latest counterflow drum mix plant, which is specifically designed for high production and high-capacity recycling technology.

Available in stationary, relocatable and portable configurations ranging from 300 tons per hour to 600 tons per hour, the Ammann ACC Alpine Drum Mix Plant covers all possible plant needs.

The Alpine series enables producers to maximize high total production as well as the amount of recycled asphalt (RAP) content without sacrificing mix quality by utilizing Ammann’s industry-leading controls and technologies. The plant is capable of creating a mix that includes up to 60 per cent RAP.

The counterflow drum mix plant’s control system is intuitive and allows tracking and analyzing plant operating data in real time to provide opportunities to gain further efficiencies over competitive equipment.

One of the benefits of the new plant is a single drum, multi-zone drying and mixing system with VFD, which increases performance and flexibility.

Other benefits of the counterflow drum mix plant include:

· Modular and scalable designed components

· Warm asphalt capability with the proven Amman Foam system

· Easy customization of plant arrangements

· Easy retrofit to existing facilities

· Extreme wear packages for extended operating life

Ammann’s HMA storage silos have capacities ranging up to 300 tons with extended mix storage options available. As well, silos are engineered with expansion in mind. The modular silo batcher arrangement is expandable and optimal for retrofitting and matching silo deck heights. Ammann’s aggregate feed systems include troughing feed belts to eliminate spills and large bin openings allow for greater capacity. Steep, sloped bin walls optimize material flow, while variable frequency drives promote simple, accurate calibration and production changes on the fly.

The reverse-air baghouse system is the newest version of a broad range of existing Ammann dust control products. The reduced length and increased width of the Alpine series baghouse allows for greater flexibility in accommodating all job

A19 JUNE 17, 2024 EQUIPMENTJOURNAL.COM WE ALSO CARRY: • Augers • Breakers • Brush Cutters • Buckets • Compactors • Demolition • Forest Mulcher • Grapples • Quick Couplers • Rippers • Compactors • Rubber Tracks • Thumbs • Screening Buckets BEST QUALITY ATTACHMENTS AT THE LOWEST POSSIBLE PRICE shawbros.ca info@shawbros.ca Gyru-Star compact screening systems are used primarily for screening soil, compost & aggregates. They bring an affordable, high quality and performance screening solution, with low or zero maintenance, to the compact attachment market. Barrie, Ontario 1-877-625-9677 QUALITY ATTACHMENTS

sites and portable requirements. TRI-CITYEQUIPMENT.COM WE BUY EQUIPMENT! ARTICULATED ROCK TRUCKS 25,30,40,45 TON AVAILABLE. FOR RENT 2012 CAT 349 - Q/C, choice of bucket, serviced and work ready. 13,199 hrs. $155,000 2022 HITACHI ZX245 - Excellent shape, hyd q/c, aux hyd, choice of bucket, 2270hrs $239,000 BUCKETS - BRAND NEW BUCKETS. - 13-50T. Rippers, Thumbs also available, made with AR400 Steel. FOR SALE 2007 VOLVO A30D, Tailgate, heated box, freshly serviced, ready to work. $109,000 HITACHI ZX245, aux hyd, Q/C, CAT 325 also available. FOR RENT CAT 980M, C/W auto greaser, spade nose rock bucket, scale. FOR RENT CAT 340 - Q/C, aux hyd, new units ready to go! FOR RENT CAT D3 - next gen, grade control, LGP or XL. All other sizes available FOR RENT CAT 349 - available with hyd hammer. Hitachi ZX490 also available. FOR RENT VOLVO A35D WATER TRUCK, 7000 Gallon tank with water cannon – available for seasonal rental – only one left! FOR RENT 2011 VOLVO A30F - Wide tires, tailgate, box heater, approx. 13,900hrs. $159,000 Tri-City Equipment is a 100% privately owned Canadian corporation YOUR HEAVY EQUIPMENT RENTAL HEADQUARTERS! 519-767-9628 1-800-646-2064 CALL OR TEXT RYAN ARMISHAW (519) 240-4672 DAVE ZAPPITELLI (226) 962-6106 Full Service Rebuild Shop, Aftermarket Parts & Repairs Available Ammann's latest counterflow drum mix plant is designed to tackle RAP

An efficient articulated hauler operator is able to deliver technical expertise, safety and situational awareness and combine those skills with effective communication and a commitment to productivity.

Scottish ADT manufacturer Rokbak explains how an operator can master the art of piloting an articulated hauler.

Be ready to move

Take control of the hauler

and your daily work before the engine is running by making sure you know the truck. It’s important to have a thorough understanding of the truck's controls, capabilities and limitations. This includes knowing how to operate it efficiently and safely in various conditions, such as on gradients, rough terrain or in adverse weather.

The inspection

At the start of the day, prestart checks are essential. A diligent operator conducts routine truck inspections to make sure the truck is ready for work.

Every day, the operator should check for pre-existing damage including leaks, loose parts and tire condition, as well as ensure lights and beacons are operational.

Rokbak trucks have ground

level test points and a fully tilting cab for quick, easy access when servicing.

A thorough equipment walkaround before starting a shift can make a big difference, and it doesn’t require a lot of time.

Know your limits

Before you start working, learn the elements of the jobsite, such as speed, ground bearing weight limits, travel direction, passing areas, width and height restrictions and no-go areas. Know your hauler’s capacity and ensure you are aware of your truck’s working limits regarding payload.

As well, keep an eye on how many buckets the loader is dumping in the truck to stay within the safe operating limits of the ADT and avoid accelerated component

wear through overloading. Rokbak provides an optional onboard payload system and exterior payload lights, which indicate to both the truck and loader operators whether the payload is on target. This information is recorded and transmitted via the Haul Track telematics system.

Safe operation

Follow all site operating procedures when driving the truck. Keep under speed and under control on gradients and check grade guides for safe and controlled descent speed. Correctly use differential locks — you’ll want to employ them when you’re operating in soft or slippery ground conditions to maintain traction and control. Also, be aware of what equipment is on your haul route and what sort of traffic you can expect to encounter.

Correct usage

The Rokbak RA30 and RA40 articulated haulers have fully enclosed multi-disc brakes on all six wheels plus a retarder. Understanding the correct use of the retarder can prolong the life of the service brakes and reduce maintenance intervals for lower total cost of ownership. If required, make use of the transmission lock in range or manual shift modes to maintain a steady ascent or descent on gradients.

Stay alert

A good ADT operator stays alert to their surroundings, including other workers, vehicles and obstacles on site. They anticipate potential hazards and adapt their driving accordingly to maintain safety. Inevitably there will be challenges, such as navigating tight spaces. An alert operator can quickly assess situations, make informed decisions and take appropriate action to resolve issues

while minimizing downtime. Never operate an articulated hauler if feeling fatigued or unwell.

Attention to detail

Operating an articulated hauler requires attention to detail to ensure proper loading, unloading and manoeuvring of materials. While an integrated payload system can account for the number of loads moved, manually recording progress keeps productivity proceeding on schedule. For improved fuel efficiency, minimize heavy acceleration and aim to reduce unnecessary idle time whenever feasible.

Don’t ignore fault codes

Critical information is delivered whenever system fault codes are triggered. If a Rokbak truck does develop a fault, the operator will receive a warning symbol on the dashboard. Faults should be reported when they occur as continued operation could exacerbate the issue.

Following the truck’s advice means increasing uptime by avoiding potential disruptions, and effective communication with site supervisors, co-workers and other equipment operators is crucial for coordinating tasks and ensuring smooth operations.

The closer At the end of a shift, follow the correct shutdown procedure. Allowing the truck to idle for a brief period at the end of a long workday enables the coolant to circulate through the engine. This helps to gradually lower the temperature, preventing potential damage from frequent hot shutdowns over time.

Adhering to the correct maintenance and start-up and shutdown procedures will help to keep operation costs low.

A20 JUNE 17, 2024 EQUIPMENTJOURNAL.COM

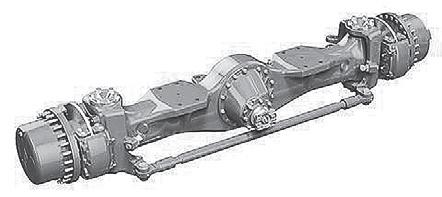

Sales • Rentals • Service ON Mississauga • Bracebridge • Sudbury • Timmins • North Bay • Ottawa QC Boisbriand • Lévis • Val-d'Or NL Mount Pearl NB Moncton NS Dartmouth Call: 1-855-625-0941•CRDCREIGHTON .COM SL 2 Vacuworx Vacuum Lifting System The ultimate attachment — lightweight & extremely versatile, for skid steers and excavators. AUTHORIZED DISTRIBUTOR POWER TRAIN SPECIALISTS TRANSMISSIONS - AXLES - STEERING PAR TS - EXCHANGE - REBUILDS TARTEN EQUIPMENT LIMITED 6199 Shawson Drive Mississauga, ON L5T 1E5 Phone: 905 670 1704 Fax: 905 670 4790 Toll Free: 1 888 670 1704WWW.TARTEN.COM COMMITTED TO SERVICE EXCELLENCE SINCE 1976 ALL MAKES ALL MODELS Here’s 9 tips to become a great ADT operator

GO THE DISTANCE... SAVE ON FUEL.

• Largest minimum swing radius exavator in Link-Belt lineup.

• Power of large machine at lower weight.

• 6-cylinder Isuzu Final Tier 4 engine with fuel efficiency and high productivity without need for DPF.

• 4 work modes, including the new Eco mode.

ALBERTA

Equipment Sales & Service Ltd.

Edmonton (780) 440-4010 essltd.com

BRITISH COLUMBIA

Inland Truck & Equipment

Campbell River, BC 250-287-8878

Castlegar, BC 250-365-2807

Cranbrook, BC 250-426-6205

Fort St. John, BC 250-785-6105

Kamloops, BC 250-374-4406

Langley, BC 604-607-8555

Nanaimo, BC 250-758-5288

Penticton, BC 250-492-3939

Prince George, BC 250-562-8171

Quesnel, BC 250-992-7256

Terrace, BC 250-635-5122

Vernon, BC 250-545-4424

Williams Lake, BC 250-392-7101 inland-group.com

NEW BRUNSWICK

Paul Equipment Balmoral (506) 826-3289 paulequipment.ca

ONTARIO Itec 2000

Rosslyn (888) 574-8530

Thunder Bay (888) 574-8530

Timmins (705) 267-0223 itec2000.com

McDowell B Equipment Ltd.

Sudbury (705) 566-8190

Barrie (416) 770-7706 bmcdowell.com

Stratton Equipment Sales & Service

5-YEAR/ 5,000 HOUR

Full Machine Warranty 5-YEAR/ 10,000 HOUR

Machine Structures Warranty

• New cab with more head and leg room making this the roomiest cab ever.

• Optional WAVES® camera system adds a third camera and gives the operator a full 270º view around the machine.

• RemoteCARE® GPS-enabled telematics system included with no subscription fee!

QUEBEC

Équipement JYL Inc. Chicoutimi (418) 698-6656 equipementjyl.com

Stratton (807) 483-7777 strattonequipment.com Micanic

Top Lift Enterprises Inc.

Stoney Creek (905) 662-4137

Bolton (905) 857-5200 toplift.com

St-Aug-D-Desm (418) 878-2241 micanic.com

Paul Equipment (506) 826-3289 paulequipment.ca

Top Lift Enterprises Inc.

St-Laurent (514) 335-2953

Sherbrooke (819) 612-5438 toplift.com

YUKON TERRITORY

Inland Truck & Equipment

Whitehorse, YT 867-668-2127 inland-group.com

A21 JUNE 17, 2024 EQUIPMENTJOURNAL.COM

355

Operating Weight: 78,709 lbs || Net HP: 205 hp || Max Dig Depth: 22’ 10” || Reach at Ground Level: 34’8” www.lbxco.com/X4S Your LINK-BELT Excavators Dealer has all the details!

Hamm electrifies its compact tandem rollers

Hamm is setting a milestone for the compaction industry with the creation of eight battery-electric tandem rollers.

The new machines complement the HD CompactLine series. Some models are equipped with oscillation drums, including the world's first E-combination rollers with oscillation.

The rollers are compact, emission-free and particularly quietly.

The battery-electric machines include the HD 10e (1 metre drum, 2.5 tonne operating weight) and the HD 12e (1.2 metre drum width, 2.7 tonne operating weight). Both rollers boast the same compaction power as their combustion engine counterparts, but produce zero local emissions. The e-rollers are operated in almost the same way as the other models in the HD CompactLine series.

A 48V Li-ion battery with 23.4

kWh capacity provides the energy for driving, steering and compaction. Charging from zero to 100 per cent takes about four hours on 220V. The roller is designed to operate in ambient temperatures of up to 45 C, while the battery supplies enough energy for an average working day.

The vibration or oscillation unit is electric driven only via specially designed, compact synchronous motors. As a result, the efficiency rating more than doubles and the energy demand is reduced. The electric drive motor and steering motor power a hydraulic system.

All e-components require zero maintenance and offer high torque.

The concept ensures the power is always available to deliver peak performance on demand. As well, a large portion of the braking energy is fed back into the system by means of regeneration.

The HammTronic control system

monitors and controls the components of the zero-emissions rollers.

Combined with the electronic driving levers, this makes the machine extremely easy to control with precision. Speed ramping is also implemented to ensure smooth accelerating and braking maneuvers.

Hamm has fine-tuned every aspect of the e-rollers to preserve resources.

For example, the models feature an automatic electric motor stop as standard. This deactivates all functions when the machine is idling, thereby reserving battery power. When Eco mode is selected, the control limits the working

Indeco opens new subsidiary in Canada

Indeco, an Italian manufacturer of hydraulic attachments, has announced it has opened a new subsidiary in Canada.

Indeco Canada recently moved into its temporary location in Riviere Beaudette, Quebec. In October, the company plans to move into

its permanent home in Vaudreuil-Dorion, Quebec.

“This important new development demonstrates our commitment to offering superior-quality products and services, maintaining a high standard of excellence and providing top-tier customer support,” the company said in a news release, adding the Canadian office marks “an important step in the process of strengthening our foothold and impact in the North American market.”

Indeco Canada stocks the complete line of Indeco prod-

speed. This also saves energy, as does the LED lighting, which is fitted as standard.

The innovative steering control also helps to conserve energy: In the parking position, it uses no energy at all. The steering motor does not switch on until the electric driving lever is actuated. Then, the machine steers with sensitive responsiveness and an adaptive energy supply with no additional effort.

Four of the e-models feature oscillation drums, two of which are combination rollers. This is where the already quiet oscillation meets with the quiet e-drive. The result is quiet compaction machines that

ucts, including rock breakers, grapples, shears, crushers, multi-processors, plate compactors, mulching heads and pedestal boom systems.

The new subsidiary is led by a team of qualified professionals with in-depth knowledge of the industry.

The team includes Chairman and General Manager Mike Pietroniro, a heavy equipment industry veteran with 40 years of experience; Pierre Cloutier, who has 25 years of experience in the industry, will lead the Canadian sales team; Denis Forget, who

produce no emissions and cause few vibrations in the surrounding area. They are ideal for compacting in noise-sensitive and vibration-sensitive areas, such as near hospitals or historical buildings.

All electrical components in the e-rollers are maintenance-free. The extensive electrification reduces the oil volume by more than 70 per cent. Across the entire system, there are few wear parts that require grease or that could suffer from abrasion.

The operating hours registered are also lower than on the diesel-engine models, as the operating hour meter is not activated until the driving lever is moved.

has been at Indeco North America for three years; Sales Manager Jason Pietroniro, with 20 years of experience in the sales and manufacturing of boom systems; and Andrew Caruana will be in charge of Parts and Services.

“This new chapter not

only strengthens our global network, it also represents a unique opportunity to consolidate the direct collaboration with our clients, listening to their needs and responding with targeted solutions,” the company said.

A22 JUNE 17, 2024 EQUIPMENTJOURNAL.COM

REDUCE DOWNTIME PROTECT YOUR INVESTMENT EXTEND COMPONENT LIFE KEEP OPERATORS SAFE BE UNSTOPPABLE GREASES WHILE YOU WORK NEXT GENERATION AUTOMATED LUBRICATION MADE IN CANADA LUBECORE.COM I 905-864-3110 We Sell Used Equipment & Trucks KINGSTON, ONTARIO VISIT morgan-diesel.com FOR OUR COMPLETE INVENTORY USED PARTS FOR HEAVY EQUIPMENT & TRUCKS 1-800-267-0633

416-801-6014 www.LundAppraisals.ca kenlundappraiser@gmail.com CPPAG Accredited - USPAP Compliant 2020/21

A23 JUNE 17, 2024 EQUIPMENTJOURNAL.COM ONTARIO 11488 Yonge St, Richmond Hill, ON L4S 1K8 1 800 580-7316 x1 QUEBEC 505 Boulevard Saint Jean Baptiste, Mercier, QC J6R 2A9 1 800 580-7316 x2 BRITISH COLUMBIA #103 1750 Coast Meridian Rd., Port Coquitlam, BC V3C 6R8 1 800 580-7316 x3 Kubota 13.8HP Engine, 15” digging bucket, Swing boom; Expandable track $15,200 2023 UHI UME12P Kubota 24.4HP Engine; full cabin with heating and A/C * Swing boom; high/low travel speed $50,400 2023 UHI-LONKING CDM6035 Yanmar 15.1HP diesel engine, Swing boom; high/ low travel speed; Expandable track $23,800 2023 UHI UME18 Yanmar 18HP Engine; full cabin with heating, Swing boom; high/low travel speed; Expandable track $31,700 2023 UHI-LONKING CDM6020 Yanmar 20HP engine, side joystick with cabin Swing boom; high/low travel speed $31,700 2023 UHI UME28 Kubota D1703 25HP Engine, Bondioli & Pavesi pump * Bucket+Fork included plus 2 yrs warranty $26,400 2024 UHI U25TK2 Yanmar 56.9HP Engine; full cabin with heating and, A/C * High/low travel speed $64,700 2023 UHI UME80 Cummins 74HP diesel engine, max speed 40km/h Articulated oscillating floating function $54,700 2023 UHI UWL825H GET IN TOUCH WITH US! SALES@UHIMACHINERY.CA WWW.UHIMACHINERY.CA SMALL MACHINES BIG SAVINGS ALL BRAND-NEW MACHINES $36,800 INTRODUCING LITHIUM-ION BATTERY FORKLIFT SERIES PARTNERSHIP WITH LONKING UHI LONKING ELECTRIC FORKLIFT LI-ION BATTERY WITH CAPACITY OF 3500-5500 LBS • 80V/205Ah Li-ion battery • 3 Stage Free Mast 4.5m, Side shift, Solid tires • 2 year machine warranty & 5 year Li-ion battery warranty • LG16 48V/346Ah Li-ion battery forklift • 3 Stage Free Mast 4.5m, side shift, solid tires • 2 year machine warranty and 5 year Li-ion battery warranty CPD25ESL 4-WHEEL LGB16BE3 3-WHEEL

Do more with BETTER results.

ALBERTA

You can meet expectations. Or you can crush them. The JCB Telehandler is the ultimate material handling machine. So, while everyone else is getting the job done, you can get it done better. Learn more at JCB.com

Liftboss JCB

Calgary: 403-301-0041 Edmonton: 780-474-9900 liftboss.ca

BRITISH COLUMBIA

Williams JCB

Surrey: 604-930-3316 williamsjcb.com

NEW BRUNSWICK

A.L.P.A. Equipment

Edmundston : 506-735-4144

Balmoral : 506-826-2717

Fredericton : 506-452-9818

Moncton, N.B. : 506-861-2572 alpaequipment.com

NOVA SCOTIA

A.L.P.A. Equipment

Truro : (902) 897-2717 alpaequipment.com

Harvey JCB

Corner Brook: 709-639-2960

St. Johns: 709-738-8911 harveyco.ca

ONTARIO

D&W Group Inc.

Doughty & Williamson Jarvis: 519-587-2273

Brant Tractor Burford: 519-449-2500

Redtrac International Vineland: 905-562-4136 dwgroup.ca

Delta JCB

Dunvegan: 613-527-1501

Renfrew: 613-432-4133 Winchester: 613-774-2273 deltapower.ca

ONTARIO

Fulline JCB

Glencoe: 519-287-2840 fullinefarm.com

Equipment Ontario Harriston: 519-510-5878 Lindsay: 705-324-6136 Port Perry: 905-982-1500 Waterloo: 519-742-5878 equipmentontario.com

Jade Equipment

Simcoe County and Districts of Parry Sound & Muskoka 705-325-2777 jadeequipment.com

John’s Equipment Sales Frankford: 613-398-6522 johnsequipmentsales.com

ONTARIO

Moore JCB Toronto, York & Peel Region: 416-747-1212 moorejcb.com

North Rock JCB North Bay, Sault Ste. Marie, and Sudbury: 705-897-7369 northrockrentals.com

ReadyQuip Sales & Service Ltd. Timmins: 705-268-7600 readyquip.com

WPE Landscape Equipment - JCB Hamilton/Halton: 905-628-3055 wpeequipment.ca

PEI

A.L.P.A. Equipment

(506) 861-2572 alpaequipment.com

QUEBEC

A.L.P.A. Equipment

Bas-Saint-Laurent : (506) 735-4144

Gaspésie : (506) 826-2717 alpaequipment.com

Bossé Quebec Inc.

Desmaures: 418-878-2241 Saint-Augustin-debosse-frere.com

Moore JCB

Montreal: 514-333-1212 moorejcb.com

SASKATCHEWAN & MANITOBA

Westcon JCB Regina: 306-359-7273

Saskatoon: 306-934-3646

Winnipeg: 204-694-5364 westconequip.ca

YOUR FAMILY OF LOCAL JCB DEALERS

NEWFOUNDLAND

• 416F, 420F, 422F, 430F New Cat

and pressure tested to Cat spec

• 950/980 Aftermarket front fenders $1250

• New Cat surplus bucket teeth, K series, Side Pin, cutting edges, corner bits, etc.

• New surplus parts arriving daily.

B1 JUNE 17, 2024 EQUIPMENTJOURNAL.COM HOT DEALS OF THE MONTH! toromontequip.com 2000 CAT CB634C ROLLER $24,400 7,865 HRS LONDON, ON 2012 NEW HOLLAND W80B LOADER $43,333 2,444 HRS LONDON, ON *US pricing subjected to actual exchange rates at time of sale. All units are subject to prior sale. TOROMONT EQUIP HUGE INVENTORY WEEKLY DEALS CAT CERTIFIED USED ALL IN ONE PLACE! › toromontequip.com › 1 833 953-7847 USED AND RESTORED PARTS Recent arrivals Buckets • D8T New Cat engine complete p/n 492 4952 $52,350 Out Right • 930/926 New Cat engine p/n 5485639 $42,000 Out right • 924F rebuilt transmission p/n 102 7502 $16,000 Exchange • 988H rebuilt torque with pump and housing $22000 Exchange • 988B rebuilt transmission p/n 3P9094 $14,500 Outright • IT18F rebuilt Transmission p/n 108 2075 $7500 Exchange • 330D reconditioned swing p/n 199 4539 $14,700 Exchange • D350E/400E rebuilt transmission p/n 123 0755 $47000 Exchange • 980G wheel end rebuilt p/n 160 5585 $16,500 Outright • 120G transmission Rebuilt p/n 8P5957 $14,650 Exchange • Hydraulic cylinders for wheel loaders, excavators all reconditioned

bucket p/n 337 7388 $2500 • 440, 450 New Cat front bucket p/n 521 6208 $4000 • 416F, 420F, 430F New Cat front bucket p/n 3377385 $2740 • New Cat 963 bucket with teeth p/n 468 1862 $13,700 • 950M/962M Used Cat bucket w/teeth p/n 362 6347 $7500 • 446/450 New Cat front bucket p/n 270 9163 $4200 • 950K/962K Used Bucket pin on $7500 • IT28G W/BOCE P/N 2240759 (2) $8400 • 953 Fusion converted from p/n 508 3230 $9750 CALL: 705-436-7770 or 1-800 771-9145 Andy EXT. 8747 Greg EXT. 8752 Joe EXT. 8748 16,103 HRS BATHURST, NB 2015 MAULDIN 1750-C PAVER $80,600 3,208 HRS POINTE-CLAIRE, QC 2008 KOBELCO SK350L EXCAVATOR $45,000 13,642 HRS WINNIPEG, MB 2015 CASE 590SN BACKHOE LOADER $57,800 9,705 HRS WINNIPEG, MB 2002 TANGUAY WL460 FORESTRY $39,000 9,755 HRS VAL-D’OR, QC 2011 DEERE 550JLT DOZER $62,500 7,374 HRS HAMILTON, ON 2015 DEERE 410L BACKHOE LOADER $76,500 3,796 HRS DARTMOUTH, NS 2017 JCB JS370LC EXCAVATOR $95,000 5,962 HRS CONCORD, ON 2013 CAT 420FIT BACKHOE LOADER $73,300 3,134 HRS ST. JOHN’S, NL 2012 HITACHI ZX250LC-5 EXCAVATOR $80,000 9,201 HRS ORILLIA, ON 2009 DEERE 410J BACKHOE LOADER $39,000 10,840 HRS WINNIPEG, MB 2010 DEERE 350DL EXCAVATOR $54,400 11,731 HRS QUEBEC CITY, QC 2003 CAT M322CMH WHEEL EXCAVATOR $58,900 42,621 HRS ORILLIA, ON 2013 KOMATSU D37EX-22 DOZER $70,000 5,483 HRS HAMILTON, ON 1998 CAT D3CIII DOZER 4,299 HRS CAMBRIDGE, ON $43,900 1 833 953-7847 FOR USED AND RESTORED PARTS

B2 JUNE 17, 2024 EQUIPMENTJOURNAL.COM

LIFT & ACCESS

BEYOND NET ZERO

A

Merlo Roto is helping Frontiers Design + Build reach their goal of Passive House construction

At the International Builders’ Show in 2019, Doug Taylor, President of the Frontiers Design + Build, attended a workshop on high performance construction.

By the end of the seminar, Taylor was captivated in the notion of building high efficiency homes.

After leaving the trade show, Taylor and his Guelph, Ontario-based company began the training process to become certified designers and builders of Passive House structures.

“I kind of fell in love with it, this made a lot of sense. It just kind of speaks to our approach as builders,” Taylor said.

Passive House construction requires the space heating and cooling energy demand to not exceed 15 kWh per square metre of net living space.

The total energy used for all domestic applications must not exceed 60 kWh per square metre and the home must be airtight to a maximum of 0.6 air changes per hour at 50 Pascals pressure.

The criteria are achieved through intelligent design and implementation of the five Passive House principles: thermal bridge free design, superior windows, ventilation with heat recovery, quality insulation and airtight construction.

“It's the most rigorous building standard in the world currently. So Passive House is well beyond Net-Zero or LEED or any mid-range programs that are out there. It's pretty intense,” Taylor said.

The Passive House concept was developed by an engineer based in Saskatchewan in the 1970s. After collaborating with colleagues in Germany, the building standard was created in the 1980s in Europe.

“It's essentially the culmination of like, 40 or 50 years of Canadian and German building science,” Taylor said.

Passive House buildings are planned, optimized and verified with the Passive House Planning Package (PHPP).