MAY 27, 2024 ISSUE 7 FOCUS: ROADBUILDING / LIGHT EQUIPMENT RETURN UNDELIVERABLE ITEMS TO: EQUIPMENT JOURNAL, PO BOX 160 PORT MCNICOLL, ON L0K 1R0 PUBLICATIONS MAIL AGREEMENT: 40063867 SEE OUR AD ON PAGE A6 Contact John or Mark at: 1-800-265-5747 www.marcelequipment.com Sales, Rentals & Rental Purchase Quality, Reconditioned Equipment Since 1976 VOLVO A30G (2016) • 8,620 hours • Volvo Power Train Warranty Til Sept 29, 2025 / 10,000 hrs • Very Clean Truck • 23.5R25 Tires • Optional Flotation Tires • Tailgate • Box Heater • All Repairs / Servicing Completed PRICE: $365,000 ONLINE HEAVY EQUIPMENT & TRANSPORTATION AUCTIONS 1-888-376-3155 • AllStarAuctions.ca 44 Line 9 South, Oro-Medonte, ON L0L 1T0 UPCOMING AUCTIONS: Consign Today! Consignment Commission Capped For Sellers 2003 CAT D4G LGP 2019 CAT 924K ANCASTER - JUNE 12th BARRIE - JULY 23-24th 1-877-640-2862 RHP COMPACTORS 3-30 ton carrier class 6200 lbs to an incredible 38,140 lbs of impulse force, at 2,000 cycles per minute. magnumattachments.com HYDRAULIC BREAKERS, SHEARS, GRAPPLES, COMPACTORS, TILTRATORS, PULVERIZERS AFTERMARKET PARTS EXPERTS! EQUIPMENT SALES & SERVICE LIMITED www.essltd.com 1-800-263-4597 UNDERCARRIAGE EXPERTS! AUTHORIZED DISTRIBUTOR • Engines • Transmissions • Pumps • Filters • Cabs • Rubber Tracks • Pins & Bushings • Electrical Parts • Bearings • Seats & More.... sales@deltapower.ca 1-833-981-4278 Operating Weight: 3755 lbs Rated Operating Capacity: 665 lbs Ground Pressure: 3.1 psi Engine Power: 24.7 hp The RT-25 Posi-Track® compact track loader is designed and created to feature the productivity and comfort that landscapers, homeowners and contractors needs. Purchase an ASV machine before May 31st, 2024, and receive cash back or 0% financing for up to 24 months. Contact us for full details. 2024 LINK-BELT 220 X4S, O.W. 49,220 lbs., free swing, heavy duty boom, stk# B160-247 sales@bmcdowell.com bmcdowell.com 705-566-8190 416-770-7706 See our ad on page A13 5 Yr/5000 hr. full machine warranty, 24/7 remote care - no subscription LIVE WEBCAST AUCTIONS NEXT EQUIPMENT AUCTION: June 22nd, 2024 @ 9AM CELEBRATING 21 YEARS SERVING THE INDUSTRY 866-229-2253 TO CONSIGN YOUR EQUIPMENT, CALL US SALES PARTS SERVICE INCOMING! TOPLIFT.COM LUBECORE.COM 905-864-3110 NEXT GENERATION AUTOMATED LUBRICATION MADE IN CANADA Scan Me SERVICING ALL MAKES OF GREASERS. Ű Reduced Downtime. Ű Protect Your Investment. Ű Simple. Reliable. Ű Keeping Operators Safe. ACROSS NORTH AMERICA SO MUCH TO GREASE. SO LITTLE TIME. ROAD KING 1-855-625-0941 sales@creightonrock.com CRDCREIGHTON.COM

POWERSCREEN WARRIOR 1800X

Designed for medium to large operators, a tough, heavy duty machine built for screening, 2 or 3 way splitting and stockpiling in quarrying, recycling, construction and demolition aggregates and top soil applications.

POWERSCREEN CHIEFTAIN 1700

Mid-sized track mobile screen aimed at end users requiring high volumes of finished products in applications including topsoil, crushed stone,recycling, iron ore,sand and gravel. 5’ x 16’ screen deck, 14’ wide feed hopper, hydraulic folding conveyors, hydraulic screen angle adjustment, fast set-up, double or tripple deck.

CEDARAPIDS CRC1150S

The highly mobile CRC1150S cone and screen plant combines a modern TC1150 300 HP

Cone crusher with the highly efficient TSV 6x20 3 deck screen. This 300 HP cone utilizes high efficiency roller bearings and boasts several notable advancements that enhance performance and functionality. Key features include automated cone controls and larger closed side settings and is rubber isolation mounted on a heavy-duty chassis frame.

POWERSCREEN PREMIERTRAK 450

High performance primary jaw crushing plant is designed for medium scale operators in quarrying, demolition, recycling and mining applications. The independent pre-screen option excels in applications with high fines contents by reducing wear rates, increasing throughputs and producing cleaner end products. Single toggle jaw, 44”x18” feed opening, CAT 308 hp or Scania 275 hp.

TEREX M 1700 WASHPLANT

A mid-sized mobile washing plant complete with on board hydraulically folding side conveyors for up to 5 way splitting of material in applications such as coal, crushed stone, recycled materials, iron ore, sand and gravel. The M 1700 Washplant can work independently or as part of an entire wash plant, making it one of the most flexible wash plants available.

A2 MAY 27, 2024 EQUIPMENTJOURNAL.COM 800 FAREWELL STREET, OSHAWA, ONTARIO, L1H 6N5, CANADA PSC@POWERSCREENCANADA.COM ||| POWERSCREENCANADA.COM SCREENING | STOCKPILING | WASHING | RECYCLING TOLL FREE: 1-877-797-7276 WE DO IT ALL. ® CEDARAPIDS W AS H IN G SYST E M S

Mining operations worldwide are improving efficiency with the use of teleremote equipment

ISSUE 7 May 27, 2024 A3 MAY 27, 2024 EQUIPMENTJOURNAL.COM Volvo rolls out updates for two CWLs New Construction King backhoes A7 A14 Kohler Energy acquired A8

EQUIPMENT FEATURED EQUIPMENT B11

FEATURED EQUIPMENT B3 A12 STORY ON

LIGHT

ROADBUILDING

More than just safety

Ontario creates an actual FAST track to success in the trades

After the first week of my college internship, I quickly realized I didn’t learn much in journalism school.

This isn’t a slant at my professors, but there’s learning in theory and learning in practice, and the actual job was far more in touch with reality than a classroom.

Ontario’s government has realized the importance of on-the-job training, at least for the skilled trades, and created the new Focused Apprenticeship Skills Training (FAST) stream for high school students.

FAST will allow students in Grades 11 and 12 to participate in more apprenticeship learning through additional co-operative education credits while completing high school. Graduates will receive a new seal on their high school diploma to signify their successful completion of the program and recognize

them for their dedication to learning in the skilled trades.

Ontario will also make it easier to find apprenticeship opportunities by launching a new online job-matching portal for potential apprentices, journeypersons and employers to network and share opportunities.

“We’re helping to tackle the labour shortage by allowing motivated, entrepreneurial students to get on a fasttrack to a career in the skilled trades,” said David Piccini, Minister of Labour, Immigration, Training and Skills Development.

“To get there, we’re opening pathways into the skilled trades today for the workers of tomorrow by making it easier for Ontarians to find apprenticeship opportunities.”

This program will help youth beyond providing a comfortable salary. The tu -

ition cost for trade school is significantly lower than college or university. Trade school graduates often enter the workforce with little to no student debt, which sets up youth for an easier transition into homeownership, raising a family and adulthood in general.

Career availability is also worth noting. The labour shortage in the trades serves as the catalyst for the FAST stream.

Looking back to my own post-secondary years, many of my friends majored in Philosophy or English Literature and walked away with sickening debt and next to zero career opportunities. In many cases, their education set them back in getting started on life, and sadly those dead-end areas of study were pushed upon them by guidance councillors that valued job titles over actual purpose

in the job market. Perhaps that is the most important societal change represented by the introduction of FAST. Governments and educators are realizing that while a successful community requires skilled doctors, scientists and lawyers, plumbers, electricians and equipment operators are of equal importance.

Circulation

lisa@equipmentjournal.com

A4 MAY 27, 2024 EQUIPMENTJOURNAL.COM Published every third Monday at 6-5160 Explorer Dr., Mississauga, (Toronto). Subscription $44. per annum or $72. for 2 years including applicable tax., Payable in advance. Single copy $3.95. Authorized as Publications Mail Agreement No. 40063867, by the Post Office Dept. Ottawa and for payment in cash. Advertising is accepted on the condition that in the event of typographical error, that portion of the advertising space occupied by the error together with reasonable allowance for signature will not be charged for, but the balance of the advertisement will be paid for at the applicable rate. In the event of a typographical error advertising goods or services may not be sold. Advertising is merely an offer to sell and may be withdrawn at any time. We reserve the right to reject or refuse any or all advertising. Equipment Journal permission is required to reproduce original ad layout, artwork and photos. H.S.T. # 10403 7957 RT Bill Tremblay // Editor editor@equipmentjournal.com LETTER FROM THE EDITOR EQUIPMENT JOURNAL IS AN AUDITED PUBLICATION CONTACT US Editor Bill Tremblay editor@equipmentjournal.com Publisher Mark Baker mark@equipmentjournal.com PACE PUBLISHING LIMITED EQUIPMENT JOURNAL 5160 Explorer Drive, #6 Mississauga, ON, L4W 4T7 Canada OFFICIAL SOCIAL MEDIA ACCOUNTS @EquipJournal @equipmentjournal @EquipmentJournal Equipment Journal LOCAL: (905) 629-7500 TOLL-FREE: CDN/USA 1-800-667-8541 EMAIL US: advertise@equipmentjournal.com WEBSITE: www.equipmentjournal.com Sales Manager

Account Manager

Creative Director/Creative Services

Tara Baker tara@equipmentjournal.com National

Mona Fahmi mona@equipmentjournal.com

Ryan Chuhaniuk ryan@equipmentjournal.com

Manager Lisa Bath

Alltrade Equipment B5,B9 Amaco Construction Equipment Inc. A17 AMI Attachments A1 Ammann B6 Bob Mark New Holland A19 Bobcat A21 Bull Powertrain A20 Converter Man Limited A7 Cooper Equipment Rentals A1,A15 Creighton Rock Drill Limited A1,A12 Delta Power Equipment A1 Develon B2 Elation-Tech Inc. A14 Equipment Sales & Service Limited A1 Flo Components B18 Gear Equipment A4 High Reach Inc. A8 HKX Inc. A8 HLA Attachments B6 Hood Equipment B16 Hub Equipment B20 Hydrolexc A14 Hyundai Construction A11 J & J Equipment Rentals A19 J.R. Construction A7 JCB A24 JT Equipment A1 LBX Link-Belt Excavators B12 Liebherr A9 Lubecore A1,B9 M-K Power Products B19 Magnum Attachments A1 Marcel Equipment Limited A1,A6 McDowell B Equipment Ltd. A1,A13 New Way Diesel A22 Pine Ridge Lisco Edwards A20 Powerscreen of Canada A2 Rokbak B15 Shaw Bros. Limited A10 Strongco Equipment A16 Tarten Equipment Limited A22,B14 Terapro B17 The Gear Centre B4 Top Lift Enterprises A1 Toromont Used Equipment B1 Tramac A17 Tri-City Equipment A10 UHI Machinery B7 Wacker Neuson A18 Wirtgen A23 XCMG A5 AUCTIONS AllStar Auctions A1 Corporate Assets Inc. B13 GIQ Auction B10 Maynard's Auction B14 Michener Allen Auctioneering Ltd. B8 North Toronto Auctions A1 Rideau Auctions Inc. B13 ADVERTISER INDEX MAY 27/2024 MCR SERIES EXCAVATORS 6MCR / 8MCR / 10MCR Operating Weight: 13,500 lbs / 16,755 lbs / 22,050 lbs Max Depth: 10’1” / 12’1” / 13’1” EQUIPPED WITH HYDRO-DETECTION SYSTEM & GAS DETECTION SYSTEM • No Water Required • Dump On Site • Material is Dry • Serving the GTA WE LEGALLY CARRY FULL LOADS! FOR ALL YOUR ROADBUILDING NEEDS 416-644-3076 gearequip.com 19067 94th AVENUE, SURREY, BC V4N 3S4 2214 LINE 9, BRADFORD, ON L3Z 2A5

A5 MAY 27, 2024 EQUIPMENTJOURNAL.COM Call us or visit our website to see our industry-leading machinery. Scan the code to find a XCMG dealer near you! info@xcmgca.com www.xcmgca.com 855-789-XCMG

A6 MAY 27, 2024 EQUIPMENTJOURNAL.COM LONDON, ONTARIO, CANADA Contact John or Mark at: 1-800-265-5747 or 519-686-1123 Email: sales@marcelequipment.com VIEW our Complete Inventory at: www.marcelequipment.com REBUILT CAT 826H COMPACTORS - 0 HRS Components Rebuilt, Complete Machine Recondition, 3 year CAT Component Warranty 40 Compactors to choose from. $CALL Since 1976 SALES, RENTALS & RENTAL PURCHASE UNITS SOLD WITH WARRANTY WE ALSO RENT EQUIPMENT CONTACT MARK or JOHN 1-800-265-5747 or 519-686-1123 CAT 816K (2020) - 795 HRS CAT Warranty Remaining. Just like a New One, but for a lot Less! $CALL CAT 770 (2008) – 10,655 HRS 40 Ton, 33 CY, Dual Slope Bed, Very Straight Truck, All Servicing & Repairs Completed. New Tires. $CALL CAT 352FL (2018) – 4,195 HRS Reach Boom, 11’ Stick, Aux Hydraulics, Coupler, 30” Pads, Very Clean, CAT Inspected. $CALL CAT 938M (2018) - 6,680 HRS 3rd Valve, Diff Lock, Coupler, Choice of Bkt, Forks Available. $250,000 VOLVO A25G (2017) - 6,850 HRS 23.5R25 Tires, Rear-View Camera, Inspected, All Needed Servicing and Repairs Completed. $CALL CAT 980M (2019) – 7,740 HRS 3,125 Idle Hrs, CAT Scale, 7.75 CY Bkt, Bridgestone L4 Tires, Spade Bkt Available. $535,000 CAT 336FL XE (2016) - 9,285 HRS You would think it has 5,000 hrs Very Clean, Tight & Well Equipped Check it out! $CALL CAT D6TXW VP (2014) - 4,945 HRS 1,020 Idle Hours, U/C Replaced 320 Hrs ago, CAT HDXL U/C, 28” Extreme Pads, Counterweight Drawbar, Ripper Available, Grade Control, All Servicing/Repairs Completed, FOR SALE OR RENT $399,000 (4) CAT D8T (2011-13) - 4,381-8,090 HRS Very Clean, Choice of SU or Angle Blade, Drawbar. Ripper/Winch Available. $CALL (7) CAT D8T LGP (2019/2020) 2,230 to 14,345 HRS SU Blades, 38” Pads, Draw-bar. $CALL (2) KOMATSU HD325-7 (2010) - 11,000 HRS 40 Ton, 31 CY, Flat Floor, Very Straight, Clean Trucks, All needed Serving & Repairs will be Completed. $CALL CAT 980M (2019) - 7,325 HRS 7.75 CY Bkt, Tire & Bucket options available All Needed Repairs & Servicing Completed. $540,000 $CALL KOMATSU WA470-8 (2016) – 7,380 HRS Coupler, 5.25 yd Bucket, Loadrite Scale, All Servicing / Repairs Completed. CAT 772G's - 5 AVAILABLE (2016-2017) 7125 – 11,238 HRS Flat Floors, Liners, Auto Grease, Nice Straight Trucks. $CALL $499,000 HITACHI ZX490 LCH-6 (2022) - 2,205 HRS Reach Boom, 12’10” Stick, Coupler, 76” Bkt, Aux Hyds, VG Undercarriage. CAT 938M HI LIFT (2019) - 5,560 HRS 3rd Valve, Hi Lift Boom, Coupler, Choice of Bkt, NEW Michelin Tires. $300,000 CAT 988K XE HIGH LIFT (2020) – 6,650 HRS Bucket Options, Tire Options, Auto Grease, CAT Maintained, Very Nice. $CALL

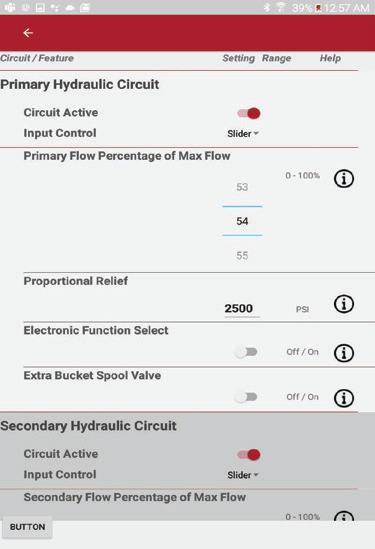

Volvo CE boosts functionality, operator experience on updated CWLs

and L35 compact wheel loaders to increased functionality and improve the operator experience.

With the latest L30 and L35 compact wheel loaders, customers looking for 1 to 1.2 cubic metre bucket capacity, or 2.4- to 2.6-ton fork payload, will experience faster work cycles in addition to improved manoeuvrability, tractive force and performance.

“These improvements set a new standard for compact loaders in this size class,” said Darren Ashton, Product Manager for Compact Equipment at Volvo CE. “For

customers who demand efficient handling in a small package, this is it.”

Improved visibility

In addition to the machine’s existing large range of sight, the updated compact wheel loaders provide greater visibility to the front and sides, thanks to a slimmer dashboard. As well, operators will benefit from more intuitive functions with a larger display that’s navigated via a jog wheel, and a more ergonomic multi-function joystick.

A new feature unique to this size class is an advanced boom kick-out and bucket leveller option. Equipped

with boundary limits, the loaders can automatically lift and tilt the bucket to pre-programmed positions. Not only does this help experienced operators ensure precise repetitive movement with less fatigue, but it also helps less experienced operators carry out speedier loading cycles.

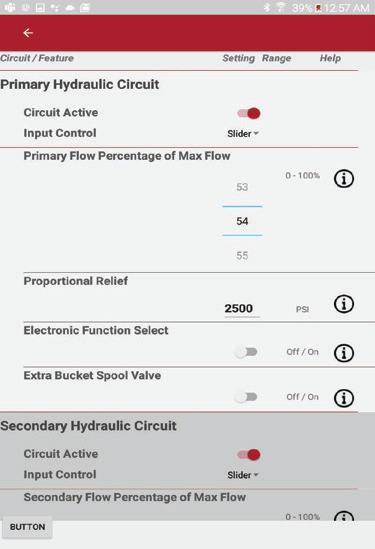

An electro-hydraulic main control valve enhances the flow sharing among the hydraulic functions. The optional adjustable boom and tilt function allows the operator to set the flow of these functions using the jog wheel and display. This enables customized flows for specialty buckets or attachments. Independent hydraulic pumps

provide simultaneous lifting and steering at speed.

Eight-pin harness

A big change for the new L30 and L35 is the addition of an eight-pin harness on the boom, which can be activated by a button on the joystick. This allows a wider range of attachments to be used without installing additional wiring, a convenience for both operators and service techs.

The models retain the Volvo cab’s adjustable steering column, seat and right armrest. The repositioned wheel chocks are now further away from the steps for ease of access.

The new-generation L30 and L35 come with additional sensors to monitor their engine and cooling performance. The standard reversible cooling fan is adjustable to handle dusty and high debris conditions. The operator is informed of deviations in machine behaviour, further improving reliability and reducing unplanned downtime.

Two popular features remain from the last series: ground-level access to service points — including fuel, oil, air and hydraulic filters, battery, radiator, oil dipstick and hydraulic oil level gauges — and long service intervals, which also support total cost of ownership.

The loaders offer the same performance, speed and versatility their previous versions provided. This is largely due to the exceptional rim pull and breakout/ lifting forces that customers might expect from larger machines. High traction comes from the combination of an articulating oscillating joint and 100 per cent differential locks on both axles, while the high breakout force is a result of the powerful linkage.

With CareTrack telematics, customers can see trends in the operation of their L30 or L35 to help plan maintenance, control costs and boost profitability.

A7 MAY 27, 2024 EQUIPMENTJOURNAL.COM YOUR FIRST STOP FOR PF-4410B Construction Equipment Sales & Rentals Ltd. (403) 253-8822 jrsalesandrentals.ca J.R. Construction, your trusted source to sell & rent equipment in AB since 1987 J.R. CONSTRUCTION EQUIPMENT SALES & RENTALS is thrilled to announce they are the new authorized Blaw-Knox dealer in Alberta! ARRIVING SOON: Designed with versatility in mind, the PF-4410B delivers unmatched fuel efficiency and powerful performance across a range of applications, as well as high reliability and low operating costs. Engine Power: 154 hp Basic Width: 8 ftMax Width: 18 ft TURNAROUND TIME REMANUFACTURED peter@converterman.com 246 Brockport Dr #21 Toronto, ON M9W 6W2 • All Construction Equipment • All Material Handling Equipment • All Mining Equipment

All Forestry Equipment

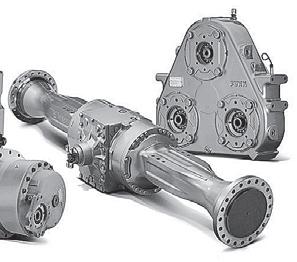

All Trucks & Vans ALL CANADIAN SINCE 1963 ALL MAKES JOHN DEERE • CAT • CLARK • FUNK • JCB • ZF • ALLISON 416-674-7000 | 800-265-8923 24 HR SUPER FAST Diesel Performance For Pickup Trucks TORQUE CONVERTERS Volvo Construction Equipment has updated its L30

•

•

Platinum Equity becomes majority owner of Kohler Energy

Kohler and Platinum Equity have closed a deal to establish Kohler Energy as an independent business.

Platinum Equity now becomes the majority owner

of the energy business, while Kohler remains an investment partner. Financial details of the deal were not disclosed.

“This strategic move allows

Kohler to focus and invest in our global kitchen and bath, wellness and hospitality businesses while also positioning the energy business to reach its full potential

under the ownership of Platinum Equity,” said David Kohler, Chair and CEO of Kohler Co.

“I want to thank the entire energy team, the perform -

ance of this business over the last three years has been remarkable. Exciting times are ahead, and energy will forever have a special place in our company’s heritage.”

Brian Melka is CEO of the energy business, elevating his leadership role after more than a decade working at Kohler and driving the group’s growth and success.

David Kohler serves on its board of directors.

“We are excited for this next phase of Kohler Energy with Platinum Equity as a partner. The demand for resilient energy is growing, and the world needs much more of what we do,” Melka said. “Kohler has been an excellent steward of our business for more than 100 years, and this decision positions Kohler Energy to better deliver on that demand. Platinum Equity firmly supports our growth path ahead and can help further accelerate our progress in the global energy resilience industry.”

Platinum Equity is a global investment firm with more than $48 billion of assets under management and is an experienced partner in the industrial products sector.

“Platinum is committed to strengthening Kohler Energy’s position as an in -

dustry leader and investing in development of a new generation of innovative energy resilience solutions,” said Platinum Equity Co-President Jacob Kotzubei. “We are excited about the prospects for the business, which has been at the forefront of energy resilience for more than a century.”

Kohler Energy provides solutions for home energy, industrial energy systems and powertrain technologies. Its portfolio of brands includes Power Systems, Home Energy, Kohler Uninterruptible Power, Clarke Energy, Heila Technologies as well as Curtis Instruments and Engines.

“The energy resilience business has an outstanding leadership team, dedicated employees and an opportunity to capitalize on the tailwinds driving demand for reliable power solutions for individuals, businesses, and communities around the world,” said Platinum Equity Managing Director Matthew Louie. “We are thrilled to work with Brian and the management team to continue investing in the company’s human capital, infrastructure, customer and vendor partnerships and growth.”

A8 MAY 27, 2024 EQUIPMENTJOURNAL.COM

P T T P A B SPT TPS LS LS A B SPT TPS A B TPS SPT A B TPS SPT 3 1 2 1 G 3 AB P 1 A PS A B TPS S PT P T P 2 2 A B SPT TPS P R LS LS P A B SP TPS A B S A B 3 1 2 2 1 3 G 2 1 G B AB 1 2 SPT TPS A B TPS SPT A B T PS SPT www.hkx.com | 1(800)493-5487 | sales@hkx.com FAST TOOL CHANGES! Proportional Pressure Control 3.0 HKX, Inc. is the leader in aftermarket hydraulic kit solutions for excavators sized from 5-150 metric tons. O ering hydraulic kits to t nearly any application on most excavators, we make auxiliary hydraulics easy. From basic hydraulic thumb kits to full tool carrier machine conversions, HKX kits provide support for a wide range of attachments & customer requirements. -Demolition | Breakers, Shears, Crushers, Thumbs -Forestry | Processor Heads, Hot Saws & Grapples -Scrap | Shears, Grapples, Magnet Genset -Utility | Augers, Rotary Tilt Buckets, Plate Compactors -Pipeline | Padding Buckets, Rock Grinders, Pipe Handlers -Custom Applications & Conversions ENGINEERED SOLUTIONS F OR E XCAVATORS www.hkx.com Order online 24/7! NEW WEBSTORE www.highreachinc.com Tel: (905) 844-4164 2.5 – 25 tons capacity 17,000 to 140,000 lbs capacity ORIO N BETTER FORK LIFT TRUCKS 24,000 to 160,000 lbs capacity “Keep your eyes on the stars, and your feet on the ground..” ~Theodore Roosevelt CANADIAN DEALER FOR: FROM 5,000 TO 140,000 LBS. BARE RENTAL RENTALSSALESSERVICE CARRY DECK CRANES

A9 MAY 27, 2024 EQUIPMENTJOURNAL.COM 11672-2037_LFR_139_R938_2021_11-EN-Canada-263_525x387_35-v04-C21290248.indd 1 15.05.2024 10:31

shawbros.ca

info@shawbros.ca

Topcon announces new manufacturing facility

Topcon Positioning Systems is building a new manufacturing facility in

Geisenheim, Germany, for the company’s Topcon Electronics operation.

Topcon broke ground on the new building in April. The groundbreaking ceremony coincided with the production milestone of 1 million products to come off the line at the company’s current Geisenheim facility, where in-cab displays are made for Topcon’s agriculture and construction solutions portfolios as well as for global OEM customers.

“The current operation is one of the company’s highest-rated manufacturing facilities, with ISO 14001 and ISO 45001, as well as an IATF automotive certification. The testing lab has become a standard for us worldwide,” said Mathias Kühn, Senior Vice President of Global Operations for Topcon.

“The dedicated manufacturing of operator consoles for heavy machinery is a world-class example of success based on a strong core competency. The new facility is designed to support enhanced manufacturing automation, which is key to accelerating production and growth.”

Owned by Topcon

Unlike the existing location, the new facility will be owned by Topcon, allowing for increased production capacities to triple the number of units produced annually. The new facility consolidates all operational buildings under one roof,

expanding the footprint to about 8,300 square metres, enhancing production efficiency and streamlining operations.

Sustainability focused

An integral aspect of the new building is its sustainability features.

Topcon prioritizes environmental responsibility, and the new facility is designed with sustainability practices, including solar panels, grey water drainage systems, electric vehicle charging points and nature-based solutions for ventilation and drainage.

“The environmentally sound architectural design marks our first building investment with sustainability in mind from the ground up,” said Ewout Korpershoek, Topcon’s Executive Vice President.

“We are thrilled to embark on this journey, further solidifying our presence in Germany and strengthening our commitment to delivering the most advanced, high-quality technology to meet the needs of our customers worldwide. The investment underscores our long-term vision for growth and success, reflecting the Topcon values of innovation, quality and sustainability.”

Topcon is a designer, manufacturer and distributor of precision measurement and workflow solutions for the global construction, geospatial and agriculture markets.

Epiroc completes Weco acquisition

Epiroc has completed the acquisition of Weco Proprietary Limited, a South African manufacturer of precision-engineered rock drilling parts and provider of related repairs and services.

Weco is based near Johannesburg, South Africa. The company has more than four decades of industry experience, about 80 employees and had revenues in the 2023 fiscal year of about $11.4 million.

Weco’s customers are mainly underground mining

companies in the Southern African region.

Last December, Epiroc announced it had agreed to acquire Weco.

“This acquisition will strengthen our manufacturing capabilities and expand our product portfolio of spare parts in the growing and important African region,” said Helena Hedblom, Epiroc’s President and CEO.

“We look forward to welcoming the strong team at Weco to the Epiroc Group.”

The purchase price of Weco was not disclosed.

A10 MAY 27, 2024 EQUIPMENTJOURNAL.COM WE ALSO CARRY:

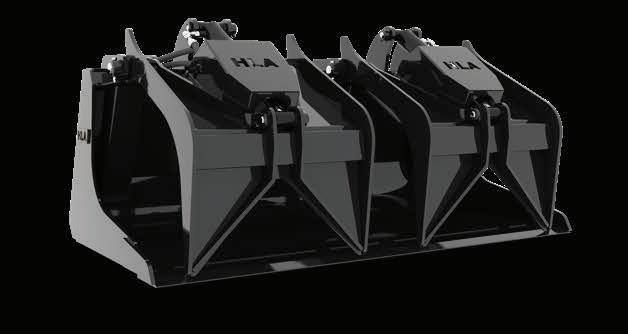

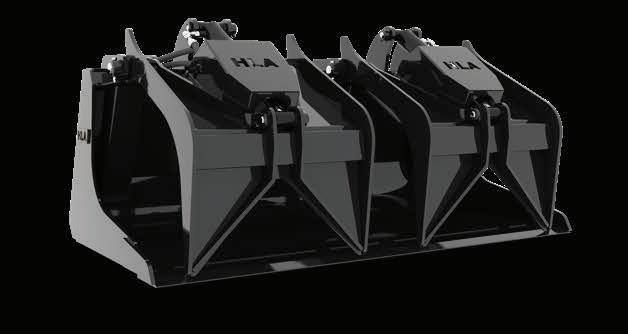

Augers • Breakers • Brush Cutters • Buckets • Compactors • Demolition

Forest Mulcher

Grapples • Quick Couplers • Rippers • Compactors

Rubber Tracks

Thumbs • Screening Buckets BEST QUALITY ATTACHMENTS AT THE LOWEST POSSIBLE PRICE

•

•

•

•

•

Gyru-Star compact screening systems are used primarily for screening soil, compost & aggregates. They bring an affordable, high quality and performance screening solution, with low or zero maintenance, to the compact attachment market. Barrie, Ontario 1-877-625-9677 QUALITY ATTACHMENTS

TRI-CITYEQUIPMENT.COM WE BUY EQUIPMENT! ARTICULATED ROCK TRUCKS 25,30,40,45 TON AVAILABLE. FOR RENT 2022 HITACHI ZX245 - Excellent shape, hyd q/c, aux hyd, choice of bucket, 2270hrs $239,000 BUCKETS - BRAND NEW BUCKETS. - 13-50T. Rippers, Thumbs also available, made with AR400 Steel. FOR SALE 2007 VOLVO A30D, Tailgate, heated box, freshly serviced, ready to work. $109,000 2011 VOLVO A30F - Wide tires, tailgate, box heater, approx. 13,900hrs. $159,000 HITACHI ZX245, aux hyd, Q/C, CAT 325 also available. FOR RENT CAT 980M, C/W auto greaser, spade nose rock bucket, scale. FOR RENT CAT 330 - aux hyd, Q/C, thumb, multiple buckets to choose from. FOR RENT CAT D3 - next gen, grade control, LGP or XL. All other sizes available FOR RENT CAT 349 - available with hyd hammer. Hitachi ZX490 also available. FOR RENT VOLVO A35D WATER TRUCK, 7000 Gallon tank with water cannon – available for seasonal rental – only one left! FOR RENT 2012 CAT 349 - Q/C, choice of bucket, serviced and work ready. 13,199 hrs. $155,000 Tri-City Equipment is a 100% privately owned Canadian corporation YOUR HEAVY EQUIPMENT RENTAL HEADQUARTERS! 519-767-9628 1-800-646-2064 CALL OR TEXT RYAN ARMISHAW (519) 240-4672 DAVE ZAPPITELLI (226) 962-6106 Full Service Rebuild Shop, Aftermarket Parts & Repairs Available

From left: Volkan Cakmak, Topcon Electronics; Geisenheim Mayor Christian Aßmann; Thilo Nagel, Senior Director OEM Sales; Mathias Kühn, Topcon Senior VP of Global Operations; Ewout Korpershoek, Topcon Executive Vice President.

THE DOER’S DREAM

Loved for the features. Trusted for the performance.

Do more without feeling like it in Hyundai’s new HX mini excavator series.

• Distinctive, award winning ‘Tiger Eye’ design

• Load-sensing hydraulic system (HX40A, HX48A Z)

• 5” color LCD monitor

• Auto safety lock for unintended operation

• Large, quiet, tilting cab delivers excellent service access

• Free Hi MATE telematics access for 5 years

• Bluetooth radio, now a standard option

Bob Mark New Holland bobmark.ca

42 Center St Sunderland, ON LOC 1H0 705-357-3121

1138 County Rd. 41 Napanee, ON K7R 3L2 613-354-9244

551 Grand Road Campbellford, ON KOL 1L0 705-653-3700

2197 Little Britain Rd Lindsay ON K9V 455 705-324-2221

Ontario, Canada Hyundai Dealers

Hood Equipment Canada Inc. hoodequipmentcompany.net 14 Haniak Road Thunder Bay Ontario P7KOC8 888-413-5454

1355 Riverside Drive Timmins, Ontario P4R1A6 705-288-4685

RTI Equipment Solutions, Inc. 2528 Bowman St. Innisfil, Ontario L9S 0H9 705-734-3350

No wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, or na.hd-hyundaice.com.

A11 MAY 27, 2024 EQUIPMENTJOURNAL.COM

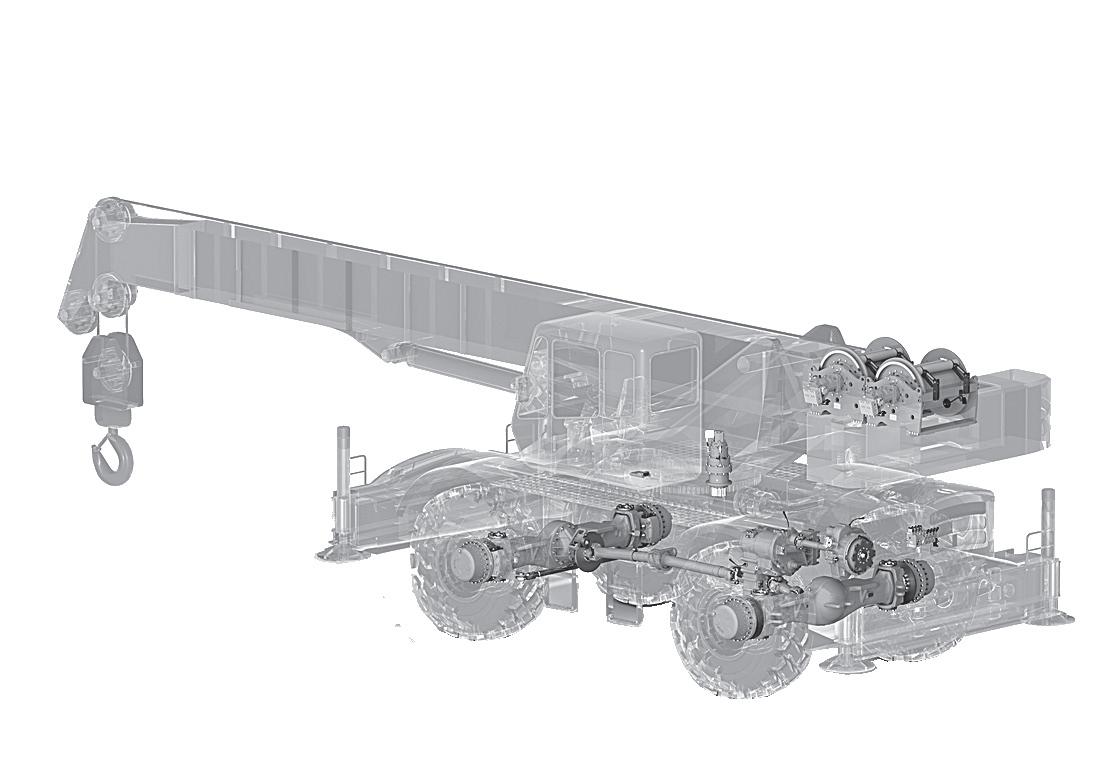

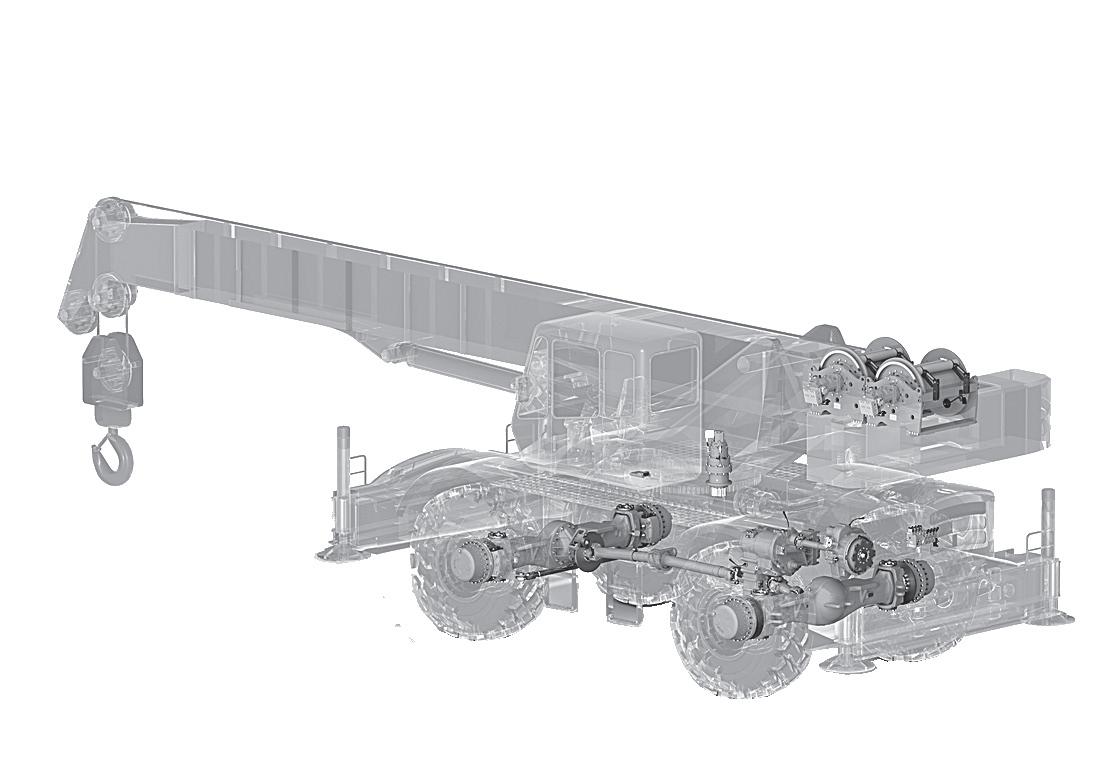

Teleremote operation is advancing beyond remote control

Since making its debut in the 1980s, teleremote operated equipment has become known for its ability to improve safety on a mine site.

However, the benefits of the ability to operate machinery via remote control go well beyond its ability to remove the operator from hazardous situations.

At the recent CIM Connect, Dillon McKinnon, Manager of Mining Equipment Technology at SMS Equipment, outlined how teleremote solutions deliver numerous benefits to mine operations above and below ground.

When strategically implemented, teleremote operations will improve safety onsite, as well as help customers tackle issues like resources, equipment utilization and decarbonization.

“It's about looking at it through a lens of a transformational approach. What are your pain points in the mining operation today? How can we look at layering in different solutions at the right level to mitigate those challenges?” McKinnon said.

Since the introduction of

basic remote-controlled machinery about four decades ago, teleremote operation has advanced significantly.

“It’s starting to layer in algorithms, artificial intelligence and decision making. It’s really offloading a lot of the monotonous control functions,” McKinnon explained. “So, an operator isn't having to fully control the machine. The machine can sort of run a lot of its functions on its own.”

Recruitment

With global mining operations facing a labour crunch, teleremote operation can tackle the issue on several fronts.

As teleremote allows the operator to control the machine from a distance, the use of offsite command centres can help attract a new workforce, as operators are not required to travel to remote locations or endure potentially rough working environments.

“Obviously, 12 hours a day on a machine can be extremely demanding and it can be uncomfortable. The environment can be very loud

and humid, all those factors go into it,” McKinnon said. “So now we can look at putting them in a much more comfortable operating environment.”

Teleremote technology also plays to the new generation of potential employees' existing skillsets.

“Some of the best operators that we see running teleremote equipment is the younger generation,” McKinnon said. “They grew up playing video games. They seemed to have a better ability to pick up the 2D spatial awareness and control equipment.”

Remote operation can also benefit training. For rookie operators, communication from the physical cab may be limited to radios. A remote command centre allows a trainer to supervise real-world operation.

“It helps close that gap between the simulation-based world and operating the machines,” McKinnon said. “Someone can stand next to them and kind of guide them and mentor them.”

Continued on Page A13

A12 MAY 27, 2024 EQUIPMENTJOURNAL.COM Sales • Rentals • Service Call: 1-855-625-0941•CRDCREIGHTON .COM ON Mississauga • Bracebridge • Sudbury • Timmins • North Bay • Ottawa QC Boisbriand • Lévis • Val-d'Or NL Mount Pearl NB Moncton NS Dartmouth SKID STEER SKID STEER PLC & PL Planers 18” 24” 30” 40” 60” Sweepster Sweeper 60” 72” 84” Stump Crusher 400 600 850 Pro ATTACHMENTS SALES& RENTALS SALES& RENTALS Planetary Drive RS RT RV Wheel Cutters T-TA RW ST Asphalt Float 59” 75” BC Beach Cleaner 200 Breakers D53 D68 D75

Utilization

The ability to automate mining equipment can reduce the requirement for employees to complete repetitive and physically demanding work. This may reduce the number of employees exposed to hazardous conditions, leading to fewer errors and injuries. By automating equipment, employees can take on a variety of tasks. McKinnon explained a frequent use case for teleremote operation is a mine requiring various machines that are not constantly utilized throughout the entire shift.

“They'll have a cleanup dozer at a shovel, and maybe you know another dozer at a dump. They have to staff both of those pieces of equipment conventionally, but they're not fully utilized 12 hours a day, they're kind of on standby when they're needed,” he said.

“From a remote operation standpoint, you only have one operator controlling both of those machines. You're only starting them up and using them when you need them.”

Decarbonization

The use of a single operator for multiple machines also carries environmental benefits. For example, the equipment is no longer required to idle.

“There's usually an operator in the machine, and they’re idling the machine to keep the cab climate controlled and other factors,” McKinnon explained.

Removing the operator from the cab can also reduce the mine footprint, by optimizing resource utilization, reducing waste and preventing ecosystem disruption.

“If there's not an operator in that piece of equipment, we can change the way we look at our slopes, how close you can get to the mine and how wide we have to build a road,” McKinnon said.

Automation may also improve compliance with environmental regulations, while using remote command centres eliminates emissions created in travelling to the mine.

5 key pillars

At CIM Connect, McKinnon outlined the five key pillars of teleremote solutions, which include digitization, interoperability, scalability, adaptability and information. When combined, addressing the five pillars can help mine operations thrive by implementing teleremote solutions.

For digitization, processes that were once manual are now transforming into digital workflows for efficient data collection, analysis and decision-making.

“What can we do with all this data that's now coming off the machine? A lot of it goes into semi-autonomous or autonomous func-

tions that we can use to start to automate,” McKinnon said.

Interoperability is ensuring data and communication can move seamlessly between different machines and other systems used on a mine site.

“Mines employ a whole plethora of technology these days. It's looking at how do we then start to integrate one machine into the broader ecosystem that a mine is operating under,” McKinnon said.

Scalability is enabling the system to adapt to different mining operations to accommodate future growth.

“As we add control systems to a machine, we can then start to take that from a single machine to a fleet of machines,” he said. “We can layer in the automated functions and start to have more autonomy.”

Adaptability refers to allowing custom-

ization and flexibility to cater to specific needs and operating environments within the industry.

The fifth pillar is information. Real-time data can optimize decision making, improve problem solving and enhance overall efficiency.

‘It's taking it from just having that information to what do we do with that information?” McKinnon said. “It's around developing those algorithms … to react to what's happening with the machine or the environment or the broader ecosystem.”

Growth

Alongside Komatsu equipment equipped with teleremote systems, SMS Equipment has partnered with RCT to provide their teleremote technology in Canada and Alaska.

“That opens the avenue well beyond Komatsu equipment. We have the ability to work with a customer and provide a solution across their fleet,” McKinnon said.

Teleremote equipment is growing in popularity at mining sites around the world with the systems primarily utilized in underground mining. However, surface mining operations are starting to account for more of the technology’s market share.

“We're seeing a lot of significant growth, ultimately driven by the need for improved safety. But again, it’s also addressing some of those labour shortages and sustainability goals,” McKinnon said.

While Australia is dominant in the use of teleremote machines, accounting for about 40 per cent of the market, Canada is also adopting the technology at an impressive pace.

“Canada is rapidly growing and currently has about 17 per cent of that global market share,” McKinnon said. “And that can be equipment above ground and underground — loaders, haul trucks, dozers, excavators. It’s really any type of equipment we can look at deploying the solution on.”

A13 MAY 27, 2024 EQUIPMENTJOURNAL.COM 416.770.7706 or 705.566.8190 sales@bmcdowell.com bmcdowell.com SALES • RENTALS • PARTS • SERVICE Hammers Compact Equipment Wheel Loaders Air Comp,ressors Trailers/Floats Compaction Carriers 2014 CAT 930K, 154 hp, ride control, Fusion coupler, third function, auto shift, stk# B110-197 2024 BOBCAT PL65 LIGHT TOWER, 119 hour runtime, 6kW, 12V, Tier 4 Kubota engine. 2021 CAT 908, 74 hp, O.W. 14617 lbs, aux. hyd, comes w/forks & buckets, stk #B110-232 CAT 725C, 730, 735B • VOLVO A25F, A30F, A35F - READY TO HAUL! CAT DOZER DOZEN READY TO RENT! CAT D6T LGP, D6N, D6N LGP, D6N XL, D6R, D6K 2 LGP, D5K LP, D5K 2XL, D4K 2XL. 2020 BOBCAT T64 & 2019 BOBCAT S550, 2 speed, SJC controls, aux. hyd., 68” bucket, stk# B100-1010/B100-887 MANY 2023 N&N TRAILERS TO CHOOSE FROM. CALL FOR CURRENT STOCK! OFFICE/SHOP/WAREHOUSE FOR LEASE IN BARRIE 14,000 SQ FT Shop/Warehouse + 1430 Sq Ft Office • 3x 16’x16’ Overhead Doors • 2x 8’ Garage Doors - 3x Man Doors • Overhead Crane Ready • Open Storage Allowed & Yard Space Available GREAT CAREER OPPORTUNITY! Full-Time Sales Rep/Business Development Manager for Barrie Email resume to kevin_m@bmcdowell.com 100 lbs gas 1000 lbs diesel SMOOTH OR PADFOOT - 56”, 66”OR 84” TONS OF MODELS TO CHOOSE FROM. 2022 LINK-BELT

lbs

max

ATLAS COPCO XAMS 850PSI COMPRESSOR, Cat engine 7 Acert III electronic, weight: wheel mounted wet: 7,497 lbs., 249 hp, 6 cyl., stk# B250-84

80 X3 Spin-Ace

, 54 hp,

18,900

O.W., 13’9”

dig depth, 13’9” reach at ground, dozer blade, stk# B160-248

2023 BOBCAT E35, Tier 4, 2022 US EPA label, manual Q/C, hyd. thumb, 4’4” stick, 18” digging bucket, 12” rubber tracks, stk# B100-1022

Continued

Page A12

from

Case debuts two new Construction King backhoes

Two additional models of Case CE’s Construction King backhoes are now available.

Leading up to ConExpo 2023, Case announced the return of the Construction King backhoe series. The loaders made a name for themselves as the original two-in-one tool-carrying machines.

Now, the Case 695SV sideshift and 695SV centre-pivot models join the Case Utility Plus and the Case 580SV Construction King centre pivot models in the series lineup.

STONEX STX-DIG 1D, 2D AND 3D EASY GRADE CONTROL (UPGRADABLE)

• Featuring geofence height and swing limitation. Ideal for municipal and provincial jobsite requirements and works safely around hydro and other utilities.

• With customizable limits (reach, height & depth), you have the flexibility to adapt the system to different job site requirements.

• Gain enhanced grade and limit control over the excavator movement.

• STX-DIG prevents accidental collisions, overreaching, and potential equipment damage.

• Safer environment for both operators and those working in close proximity to the excavator.

• STX-DIG benefits: Precise grading results, cost reductions, increased productivity, increased quality of work and safety, simplify construction site management and long-term financial benefits.

THE STONEX S980+ GNSS HIGH PERFORMANCE WITH IMU AND UHF

With its 1408 channels, provides excellent accuracy and has a 4G modem that operates with all world signals, a fast internet connection is guaranteed!

The IMU system supports tilt measurement with quick initialization, enabling the operator to obtain fast and accurate surveys.

“The new side-shift models take the legendary Case Construction King capabilities to new frontiers, putting them smack dab into confined spaces and up next to structures,” said George MacIntyre, Product Manager at Case for backhoe loaders.

“With a hydraulic side-shift boom and vertical outriggers, these machines can get more done in tight spaces. They also let operators dig rectangular trenches without having to reposition.”

Side-shift capabilities allow operators to move the boom left or right to work more efficiently parallel to walls or around obstacles.

The new machines carry over many popular features from the N Series, like Pro-

Control swing dampening, auto ride control and Eco modes for fuel savings, along with significant upgrades to manoeuvrability.

Designed to tackle bigger jobs, the powerful Case 695SV side-shift and centre-pivot models feature a tool carrier loader arm, allowing them to do double duty as a wheel loader, meaning one less machine to bring to the jobsite.

Both 695SV models are equipped with four-wheeldrive, four-wheel steer and four equal-sized tires and include a PowerShift transmission.

Both 695SV models feature a 5.97-metre digging depth, while the side-shift model weighs 10,090 kg and the centre-pivot model weight 9,040 kg. Both machines are powered by a 110 hp FPT engine.

The expanded Construction King backhoe offering is also compatible with numerous attachments, giving crews a big toolkit for improving productivity, speed and accuracy on highly varied jobs.

The new Construction King models add to Case’s existing lineup of N Series backhoes.

Frontline Machinery has announced it has acquired Lonetrack Equipment, a provider of specialized machinery for the aggregate, mining and road construction industries in British Columbia and the Yukon.

approach,” said Daryl Todd, President of Frontline Machinery.

Effective May 1, the combined entity will operate under the Frontline Machinery brand, leveraging shared resources, product options and expertise.

Frontline Machinery will retain Lonetrack Equipment employees, ensuring continuity in relationships, product knowledge and service.

• Ideal to be used as a base station!

• 5W radio

• 2-year warranty S980+ INCLUDES:

Lonetrack Equipment’s extensive range of heavy equipment includes crushers, screeners, conveyors and concrete construction equipment from brands including Astec, Sandvik, Vale, BTI and Gomaco. The company’s range complements Frontline Machinery’s existing portfolio, offering expanded capabilities and enhanced value for clients.

“This is not just about expanding our product offerings but also about bringing together two teams known for their industry expertise, dedication and most importantly, their customer-focused

“For over 30 years, Lonetrack Equipment has been built on our team members' hard work and the strong relationships we have forged,” said Hugh Porter of Lonetrack Equipment.

“The synergies and common philosophies of organizations are evident, and the advantages of Frontline Machinery’s operational strengths excite us about the future.”

A14 MAY 27, 2024 EQUIPMENTJOURNAL.COM 416-458-2334 HYDRAULIC HAMMER/BREAKER SPECIALIZING IN PARTS, SALES & SERVICE KENT MUSTANG OKADA RAMMER ROCK RAM STANLEY TRAMAC ALLIED ATLAS COPCO BTI CAT CP EPIROC ESCO INDECO NPK SINCE 1998 HYDROLEXC.COM HYDROL EXC EQUIPMENT SERVICES LTD.

Lonetrack

ELATION-TECH IS AN AUTHORIZED DISTRIBUTOR FOR 1D, 2D,3D MACHINE CONTROL & SURVEY EQUIPMENT Elation-Tech is proud to be an authorized distributor of Stonex, a world leading company in machine guidance and survey. 514-970-0114 INFO@ELATIONTECH.CA .ca

Frontline Machinery acquires

Equipment

A15 MAY 27, 2024 EQUIPMENTJOURNAL.COM FOR FULL INVENTORY VISIT: used.cooperequipment.ca EVAN TZARAS 416-720-6280 etzaras@cooperequipment.ca SALES CONTACTS MARK SHANNON 416-720-5570 mshannon@cooperequipment.ca 2013 GENIE GTH-5519 2,656 HOURS D568 $47,500 2015 SKYJACK SJ6832 RT 2,095 HOURS STK# F891 $28,000 2015 GENIE Z-45 2,170 HOURS STK# F120 $40,000 CAD 2017 BOBCAT S450 1,365 HOURS STK# 2212-031 $39,000 2013 MERLO P40.17 5,081 HOURS STK# F345 $69,750 2015 KUBOTA KX080-4 3,049 HOURS STK# S0802F-50 $75,000 2014 JOHN DEERE 323E 2,022 HOURS STK# S5505-14 $40,500 2014 SKYJACK SJIII 3220 118 HOURS. STK# D511 $8,000 2015 BOBCAT E55 3,615 HOURS STK# H348 $54,500 2015 MERLO P38.13 2,499 HOURS STK# F344 $71,750 2011 CORNIVER CT48P 48” PAD DRUM, 817 HOURS. STK# 2616-002 $29,500 2014 JLG M600JP 590 HOURS STK# 4417-008 $63,500 2016 BOBCAT T650 2,821 HOURS STK# 2238-014 $42,750 2014 JCB 512-56 4,755 HOURS STK# 4820-005 $99,000 2012 KOMATSU FG25T-16 1,042 HOURS STK# 4626-038 $21,000 2014 BOBCAT E85 1,365 HOURS STK# D414 $55,750 2020 TEUPEN TL54AJ 1,365 HOURS STK# M44-502 $115,000 2015 DYNAPAC CA 2500PD 5,189 HOURS STK# 2632-015 $79,000 2014 GENIE Z-80/60 2,539 HOURS STK# 4422-017 $84,750 $35,000 2016 BOBCAT T450 1,872 HOURS STK# 2232-011

A16 MAY 27, 2024 EQUIPMENTJOURNAL.COM ALBERTA ONTARIO QUEBEC ATLANTIC WWW.STRONGC O.C OM A FT ER S ALE S SUPPO RT PARTS INV ENTORY Ge nuine O EM part s & ma jor co mp o nen ts av ail a bl e n s to ck I n- Fi e ld s erv ic e | In - S ho p s e rvic e HUG E INV ENTORY U sed Eq u ipm ent | Ne w equipme nt FOR M OR E INFO J.J LY ON S CON TACT jjl y on s @strong c o. com (844) 288-4241 Co nn e ct wi th us VOLVO USED EQUIPMENT & COMPONENTS ASK US ABOUT FINANCING OPTIONS *Terms & Conditions apply Volvo Rebuilt Transmissions L220F transmission SN#6005-8485 L90E transmission SN#2005-8000 L110F transmission SN#3503-61501 Volvo Used Parts for: Articulated Haulers Wheel loaders Motor Grader 2020 VOLVO L90H 3,396 hrs 2011 VOLVO A40F Stk#2035102 17,271 hrs 2017 VOLVO ECR355EL 6,845 hrs 2018 VOLVO L60H Stk#2027304 862 hrs 2017 VOLVO EC480EL Stk#2035772 5,150 hrs 2020 VOLVO L70H Stk#2030529 3,396 hrs 2019 VOLVO L60H Stk#2027303 441 hrs L220F REBUILT TRANSMISSION 1 Year Strongco Parts Warranty A30D, A25D REBUILT TRANSMISSION 2017 VOLVO L30GS Stk#2033605 4,433 hrs 2020 VOLVO L90H 3,755 hrs 2018 VOLVO L60H 1,826 hrs Your one-stop dealer. From machinery to service, parts and certification. Your trusted partner for every project. 1 Year Strongco Parts Warranty 2020 VOLVO L90H 4,950 hrs 2020 VOLVO L90H Stk#2030536 5251 hrs $262,500 $233,500 $259,000 2009 VOLVO EC330L Stk#2034792 16,454 hrs Stk#2030533 Stk#2030535 $249,500 Stk#2027311 Stk#2035420 Stk#2030532 $172,500 $199,500

Enerpac has developed a cube jack lift for excavators

Enerpac has announced a new lifting system for excavator maintenance.

Based on Enerpac SCJ-Series Cube Jacks, it enables lifting and holding of the entire cab, boom and arm, which allows removal of the undercarriage.

During maintenance of the excavator’s swing drive and bearings, the undercarriage must be separated from the upper body cab and arm to give access to the swing motor and multiple sets of planetary gears. This typically requires at least two service engineers jacking up the body and holding it on stands, a time consuming and potentially hazardous practice.

According to Enerpac, the cube jack lifting system offers a safer, CE-certified, approach to removing the undercarriage. It includes two pairs of cube jacks providing coordinated hydraulic lifting of loads up to 25 tons per jack to a height of 2 metres.

“The excavator lifting system has been developed in collaboration with a leading excavator maintenance company looking for a safer CE-certified approach to removing the undercarriage,”

Enerpac said in a news release. “It automatically self-locks so that engineers can work safely under the raised cab without the need for secondary jack stands.”

Enerpac cube jack

Enerpac cube jack technology is used in many industrial lifting applications. The SC-Series Cube Jacks use a base lifting frame and self-aligning, lightweight steel cribbing blocks to provide high-capacity and stabilized lifting — offering a safer, controlled and more efficient alternative to climbing jacks with wooden cribbing. Lloyds witness tested to 125 per cent of maximum working load, the incremental cube jack lifting system is self-locking to support the load as each cribbing block is

Two cube jacks are positioned under a lifting beam at the rear of the excavator, while two cube jacks are located under the arm’s bucket lugs. Each pair of cube jacks is connected to a hydraulic pump to synchronously lift and lower the excavator body and arm.

Volvo Group to build new truck plant in Mexico

The Volvo Group is building a new heavy-duty truck manufacturing plant in Mexico to supplement the company’s production in the United States.

The plant will provide additional capacity to support the growth plans of both Volvo Trucks and Mack Trucks in the United States and Canadian markets, and support Mack truck sales in Mexico and Latin America.

The first trucks are expected to be produced in the new facility in 2026.

The Mack LVO plant in Pennsylvania and the Volvo NRV plant in Virginia will continue to be the company’s main North American heavy truck production sites. Volvo Group has invested more than $73 million over the last five years in LVO expansion and upgrades. As well, Volvo is currently investing an additional $80 million to prepare for future production.

manually added or removed, instead of being held by hydraulic pressure. Once the mechanical lock engages, the lift cylinder retracts, and another cribbing block can be added or removed.

•

•

The NRV plant is completing a six-year, $400 million dollar expansion to prepare for production of the new Volvo VNL model.

The new plant will be about 1.7 million square feet in size and will focus on production of heavy-duty conventional vehicles for the Volvo and Mack brands. It will be a complete conventional vehicle assembly facility including cab bodyin-white production and paint.

Adding production in Mexico will deliver logistical efficiencies for supporting sales to the southwestern/ western regions of the United States, Mexico and Latin America. It also provides a mature supply and production ecosystem that will complement the American system and increase the resilience and flexibility of Volvo’s North American industrial footprint.

A17 MAY 27, 2024 EQUIPMENTJOURNAL.COM

Toronto Office: 2-78 Signet drive Toronto, ON M9L 1T2 Office: 416-748-1818 Cell: 416-580-6401 frank_genua@tramac.com SERVING THE CONSTRUCTION, DEMOLITION & MINING INDUSTRIES FOR OVER 58 YEARS Kingston Office: (613) 542-1500 28 Steve Fonyo Dr., Kingston, ON K7M 8N9 Montreal Office: (888) 663-8122 3421 Industriel Boulevard, Laval, Que. H7L 4S3 Quebec City Office: (418) 877-5557 1711 rte de L’aeroport #4, L’ancienne Lorette, Que. G2G 2P4 1966 - 2024 Cell: (613) 532-4823 Office: (613) 542-1500 shaun_brown@tramac.com CANADA Shaun Brown WWW.TRAMAC.COM Visit us June 5-6th Booth #208, 210 & 212 Cornwall Civic Complex & Convention Centre • Astec FT2650 tracked mounted jaw crusher (2) • Astec FT4250CC tracked mounted closed circuit impactor (1) • Astec: 6x20 3 deck portable screening plant c/w overhead feed conveyor • SBM Remax500 track mounted closed circuit impactor

SBM Remax500 track mounted closed circuit impactor

Screencore Trident 124 track mounted scalping screen • Screencore 365R tracked radial stacker (3) • HKD GT400 trailer self powered dust suppression cannon with onboard generator (2) Call or Text (905) 670-3440 AMACOCEI.COM CRUSHING AND SCREENING PRODUCT LINEUP AVAILABLE FOR RENT, RPO & SALE

Keep your business on solid ground with the world’s original compaction brand. Wacker Neuson is the inventor of the rammer and dozens of

innovations, including reversible plates, articulated trench rollers and the newest batterypowered rammers and plates. Keeping with tradition, the newest generation of 4-stroke rammers are easy to handle and deliver excellent compaction results. Contact your local dealer today!

A.S.E. Equipment

8503 Wellington Road 18, Fergus, ON, N1M 2W5

Access Mining Services 1106 Webbwood Drive, Sudbury, ON, P3C 3B7

Advantage Farm Equipment 6915 Colonel Road, London, ON, N6L 1J1

Brownlee Equipment 332416 Hwy 11 N, Earlton ON, P0J 1E0

Coleman Equipment Inc. 3541 Trussler Rd New Dundee, ON, N0B 2E0

Construction Equipment Co. (Sault) Inc. 1245 Great Northern Rd, Sault Ste. Marie, ON, P6B 0B9

Eastrock Equipment Inc 100 Warehouse St., Vars, ON, K0A 3H0

Frontier Sales & Equipment 7213 Line 86, Wallenstein, ON, N0B 2S0

Hood Equipment Canada 14 Haniak Road, Rosslyn, ON, P7K 0C8

Hood Equipment Canada 1355 Riverside Drive, Timmins, ON, P4R 1A6

Hood Equipment Canada 9 Ferndale Drive N, Barrie, ON, L4N 9V4

Mark McCabe Tractor Sales Limited 708 Centreline Road, Lindsay, ON K9V 4R5

519-843-1161 www.aseequipment.ca

705-419-2602 www.acces-s.ca

519- 652-1552 www.advantage-equip.com

705-563-2212 www.bequip.ca

519-696-2213 www.coleman-equipment.com

705-942-8500 www.cec-ssm.com

613-443-0695 www.eastrock.com

519-669-8709 www.frontierequipsales.com

807-939-2641 www.hoodequipmentcompany.net

705-269-0830 www.hoodequipmentcompany.net

705-503-7732 www.hoodequipmentcompany.net

705-799-2868 www.mccaberepair.com

McGill Equipment 300 Midwest Rd, Scarborough, ON, M1P 3A9 416-751-4455 www.mcgillequipment.com

Oneida New Holland 634 Fourth Line, Caledonia, ON, N3W 2B3

Oneida New Holland 1410 Fourth Ave, St. Catharines, ON, L2S 0B8

Top Lift Enterprises 42 Pinelands Ave, Stoney Creek, ON, L8E 5X9

Top Lift Enterprises 12343 Highway 50, Bolton, ON, L7E 1M3

905-765-5011 www.oneidanewholland.com

905-688-5160 www.oneidanewholland.com

905-662-4137 www.toplift.com

905-857-5200 www.toplift.com

A18 MAY 27, 2024 EQUIPMENTJOURNAL.COM

Leading the

in

1-800-201-3346 • www.wackerneuson.com NEW 4-stroke models

other

industry

compaction

Equipment JournalCompaction 2024.indd 1 3/28/24 11:35 AM

Brandt Group of Companies expands its material handling network

The Brandt Group of Companies has announced an expansion to its material handling equipment dealer network.

The expansion is expected to generate about $500 million in revenue and up to 300 new jobs in the next three years.

Brandt acquired Cervus Equipment in 2021, which included material handling operations from Alberta to Manitoba. In March, Brandt announced it plans to expand its commitment to the material handling industry in Canada. The company will expand material handling

nationwide, creating a new and separate division that will deliver tailored solutions and aftersales support to customers from coast to coast.

As part of the expansion, Brandt plans to grow its network of material handling focused stores into new territories focused on delivering premium forklift brands backed by a dedicated rental fleet, parts network and dedicated service network focused on repair work and preventative maintenance.

“We believe that the material handling sector is primed for growth and

Werk-Brau debuts Steelwrist powered tiltrotators

Werk-Brau has introduced new tiltrotators, powered by Steelwrist, to provide 360-degrees of endless rotation with a 45-degree tilt angle.

The tiltrotators feature an SQ sandwich-style coupler and auto lubrication for precise control and flexibility which significantly enhances productivity.

Seamless integration and automatic lubrication ensure smooth operation, minimal downtime, maximum performance and reduced maintenance requirements.

An optional gripper with quantum technology

provides a secure grip on materials and improves operational efficiency. As well, compact steel cast components provide an optimal strength to weight ratio, while a low building height and low weight provide optimized digging geometry and fuel efficiency. Front pin hook or front pin lock safety solutions work with all types and sizes of excavators. Available for 2 to 33-ton excavators, WerkBrau Powered by Steelwrist Tiltrotators are ideal for use with general purpose and specialty buckets and attachments like rippers, grapples and pallet forks.

in need of a nationwide alternative to the existing patchwork of small dealer groups,” said Brandt CEO Shaun Semple.

“That is why we’re using the lessons we have learned from growing the agriculture, construction and forestry, and transportation pillars of our business to create a fourth pillar to serve the material handling industry.”

Canada depends on its material handling operations across the country, from ports and transportation hubs to warehouses and distribution centres.

Lift trucks and other ma-

terial handling equipment and related infrastructure are essential to support the flow of goods to Canadians and support the country’s ongoing national growth every single day.

Brandt recognizes an opportunity exists to provide tailored solutions and to build relationships with companies that operate lift trucks across the country. Brandt is uniquely suited

to leverage their customer-focused brand promise to ensure customers have access to the equipment, specialists, parts and service required to run thriving businesses.

A19 MAY 27, 2024 EQUIPMENTJOURNAL.COM

SUNDERLAND: 705-357-3121 LINDSAY: 705-324-2221 NAPANEE: 613-354-9244 CAMPBELLFORD: 705-653-3700 4 LOCATIONS TO SERVE YOU! 705-328-5145 (mobile) danderson@bobmark.ca 705-934-5025 (mobile) dskinner@bobmark.ca 613-922-1851(mobile) mlettner@bobmark.ca CONTACT DAVE CONTACT DOUG CONTACT MICHAEL 2017 HYUNDAI HX160LD Perkins 1204F engine with 137 hp, 44500 lb. operating weight, Dozer blade, 16’9” boom. $149,900 2000 HYUNDAI HL730-3 Cummins B3.9 engine w/ 105 hp, 16000 lb. operating weight, ACS hyd. coupler & 2 yd mat bucket,. $69,900 2021 WACKER NEUSON EZ26 6000 lb. operating weight, Yanmar 19.6 hp engine, Cab enclosure with heater, Dozer blade. $59,900 2023 HYUNDAI HL940A 29985 lb. operating weight, 156 gross hp, Cummins B6.7 Performance Series Engine. $219,900 2005 NEW HOLLAND DC85 89 gross engine hp, 4 cylinder engine, LGP model, 28” grouser shoes, Drawbar, Mech sus. seat $69,900 2020 NEW HOLLAND C332 74 engine hp, 9700 lb. op. weight, 3200 lb. lift cap. to full height, 2-Speed mech. hand/foot controls $54,900 2017 NEW HOLLAND B95B LONG REACH 97 gross engine hp, Deluxe cab w/ Heat & A/C, Four wheel drive, 4 Speed Power Shuttle trans $102,900 2016 HYUNDAI R60CR-9A 63 hp, 4 cylinder Yanmar diesel engine, cab w/ heat & A/C, 2150 hrs, radio, pattern control changer $72,900 2006 NEW HOLLAND E70SR 7 ton/16400 lb. operating weight, Isuzu 54 hp engine, Short Radius, 24 inch steel track pads,. $64,900 2017 NEW HOLLAND C227 74 hp, 3 cylinder diesel engine, Rops (open station), mechanical foot controls, hyd. quick attach. $39,900 2010 NEW HOLLAND U80B 79 hp, Four wheel drive, Deluxe cab w/ Heat & A/C, 4 forward x 4 reverse speed transmission $69,900 2018 NEW HOLLAND E60C MINI EXCAVATOR Cab with heat and A/C, Heated Suspension Seat. AMI Hydraulic Thumb, AMI Pin grab Coupler $89,900 www.bobmark.ca

CANADA’S NATIONAL HEAVY EQUIPMENT NEWSPAPER SINCE 1966 CONNECT WITH US! Visit us at: www.equipmentjournal.com

Liebherr crawler crane helps tackle Greenland’s largest-ever construction project

About 250 km north of the Arctic Circle, a Liebherr HS 8200 duty cycle crawler crane is part of the largest construction project in the history of Greenland.

Munck Civil Engineering is carrying out dredging work for two airport projects with the Liebherr crawler crane. The Arctic conditions and logistics are posing a challenge.

The new airports will make it possible for larger aircraft to fly directly from Europe or North America.

The jobsite is in the coastal towns of Ilulissat and Nuuk in the western part of Greenland, and to date, only propeller-driven planes could land in the area.

The new runway in Ilulissat is partly in the sea. A thick layer of clay sediment has to be removed from the seabed before it can be backfilled. Otherwise, settlement may occur over time.

"In one day shift, our extraction rate can be up to 1,000 cubic metres of excavated clay material," said construction manager Kevin van den Bos.

The 200-tonne duty cycle crawler crane is operating with a 35-metre long boom and a clamshell grab with a capacity of 3.5 cubic metres.

To achieve high productivity, the HS 8200 is equipped with Liebherr's Dredging Assistant, which

shows the operator the position and fill level of the grab, the number and duration of work cycles or the handling performance in real time. The system also makes it easier to calculate the amount of material needed to fill the area for the runway.

Munck Civil Engineering finds all the rock material used for the runway within the project boundaries.

"In total, we have to drill and blast around 5.5 million cubic metres of rock material. We then transport this to the construction section so that we can subsequently build a 2-kilometre long runway," van den Bos said.

After dredging, the duty cycle crawler crane is equipped with a stone grab to place stones along the new runway as part of the coastal protection program.

The average temperature in this region in summer is 8C. In winter, it can drop to -35C.

"It is very important for us to complete the dredging work before the ice spreads in the bay and makes our work impossible," van den Bos said.

The duty cycle crawler crane was supplied with the Liebherr cold package to ensure it is also operational in cold climatic conditions.

In addition to the icy conditions,

the logistics are challenging. The region is only supplied by a ship once a week and also brings parts and equipment for Munck Civil Engineering. A large store and the ability to repair everything itself is particularly important for the company in this remote region.

Munck Civil Engineering operates the HS 8200 six days a week in 10-hour shifts, and van den Bos is impressed with the performance of the duty cycle crawler crane.

"The machine runs really well and has exceeded our expectations. We will finish even earlier than anticipated. That is really positive," he said.

A20 MAY 27, 2024 EQUIPMENTJOURNAL.COM OEM parts and components for all your off-highway equipment Authorized to perform warranty work Factory trained technicians (705) 560-BULL (2855) 1510 Fairburn St. Sudbury, ON P3A 1N7 bullpowertrain.com We Manufacture OEM Driveshafts COME JOIN OUR TEAM! WE ARE CURRENTLY SEEKING EXPERIENCED COMPONENT REBUILDERS. WE ARE YOUR AUTHORIZED SERVICE CENTRE FOR LABOUNTY MSD2500R LEGEND W/DUAL MAX ™ PIERCING TIP =10% MORE FORCE pineridgeliscoedwards.ca HEAVY EQUIPMENT SALES, RENTALS AND REPAIRS SHEARS, HAMMERS, PULVERIZERS AND GRAPPLES PINERIDGE 1.866.488.0878 HSX Series 3,400 - 22,000 lbs VIBRATOR PLATE COMPACTORS

“...better diagnostics, better cab features, the clear poly side windows are much better for safety...”

C. Valley Group, a second-generation family business celebrating 42 years in business, has built and earned a reputation for excellence in service and professionalism. Their dedicated team prides itself on expertise, passion, and versatility, tackling projects ranging from small asphalt patches to complete roadway reconstructions while always mindful of their client budgets.

From its modest beginnings when Carmelo Calabro founded the company in 1982, C. Valley Group has evolved significantly. Today, C. Valley Group is comprised of four divisions - C. Valley Paving, C. Valley Asphalt, Done Rite, and Done Valley Services - the company offers a comprehensive range of services including asphalt paving, concrete works, pavement maintenance, grounds care and snow and ice management. Their clients include municipalities, property managers, building owners, school boards, new home subdivision builders and many more. The entire operation is complemented by their own asphalt manufacturing plant, and bulk salt and aggregate sales divisions.

When asked why they chose Bobcat® compact

BARRIE

Bobcat of Barrie

705-726-2228 oakenequipment.ca

GREY BRUCE

Bobcat of Grey Bruce 519-372-9100

bobcatoftc.com

PARRY SOUND

Bobcat of Parry Sound Ltd.

705-342-1717

bobcatofparrysound.com

TORONTO WEST

Bobcat of Toronto

416-679-4172

oakenequipment.ca

BRANTFORD

Bobcat of Brantford 519-752-7900

bobcatofbrantford.com

HAMILTON

Bobcat of Hamilton 905-643-3177

bobcatofhamilton.com

PETERBOROUGH

Bobcat of Peterborough 705-748-9119

bobcatofpeterborough.com

THUNDER BAY Equipment World Inc.

807-623-9561

bobcat-tbay.com

skid-steers, Emilio Caruso, general manager for C. Valley Group replied, “We looked at many options for skid-steers. Bobcat of Toronto was the only one who came with all the right answers to our questions and the equipment that we needed. They delivered. We decided on the Bobcat S76 and S86 models. One of the machines will be used on our asphalt removal crew (prepping and removing concrete) and one on our residential driveway paving crew (grading and paving).”

Aaron Beckett, equipment manager at C. Valley Group added that “we have owned many other brands in the past, but these newer models have way better diagnostics, better cab features, the clear poly side windows are much better for safety, a very comfy ride control seat and the Bluetooth option is more refined than others. I appreciate that the arm doesn’t obstruct visibility as much as other units we looked at.”

“A mutual friend referred us to Dalibor Cegar, sales specialist for Bobcat of Toronto (Oaken Equipment). Kai Sørensen, president of Oaken Equipment is also a mutual friend that we buy our specialty Boss Grip tires from. We

CASSELMAN

Bobcat of Ottawa Valley 613-764-2033

bobcatov.com

KITCHENER

Bobcat of Tri-Cities Ltd. 1-866-214-3939

bobcatoftc.com

STRATFORD

Bobcat of Stratford 519-393-6040

bobcatofstratford.ca

SAULT STE. MARIE

Bobcat of Sault Ste. Marie 705-949-7379

bobcat-ssm.com

CORNWALL

Bobcat of Ottawa Valley 613-932-2034 bobcatov.com

Bobcat of London 519-455-4900

bobcatoflondon.ca

STRATTON

Stratton Equipment

807-483-5505

strattonequipment.com WINDSOR Bobcat of Windsor 519-737-0120 oakenequipment.ca LONDON

make our machine purchase decisions between January and April. This time is crucial to us, and our decisions and delivery need to be within this time frame and our budget. Bobcat also has the best lease program out there! Brandon Kaschak, director of sales for Oaken Equipment, helped custom tailor the Power Lease to our needs.”

“Dalibor, Kai and Brandon are easy people to deal with and truly listened to our needs and met our demands. Bobcat of Toronto was also great at providing training and demoing the machines with us. The whole process was seamless for us and our shop. We wanted responsiveness and answers to all our questions - in other words, we got great service, and Dalibor delivered! We would 100% recommend him to purchase your next machine.” – Emilio Caruso, General Manager at C. Valley Group.

Thank you, Emilio and Aaron.

FRANKFORD

John’s Equipment 613-398-6522

johnsequipmentsales.com

OTTAWA

Bobcat of Ottawa Valley 613-831-5166

bobcatov.com

TORONTO EAST

Bobcat of Toronto 416-679-4171

oakenequipment.ca

A21 MAY 27, 2024 EQUIPMENTJOURNAL.COM

AUTHORIZED BOBCAT DEALERS

YOUR LOCAL

(L to R) Aaron Beckett, equipment manager at C. Valley Group, Dalibor Cegar, sales specialist, Bobcat of Toronto (Oaken Equipment), and Sigismondo Calabro, site supervisor, for C. Valley Group.

COURTICE Bobcat of Durham East Ltd. 905-404-9990 bobcatofdurhameast.com SUDBURY McDowell B Equipment Ltd. 705-566-8190 bmcdowell.com MUSKOKA Bobcat of Muskoka 249-390-7000 oakenequipment.ca WYOMING Advantage Farm Equipment Ltd. 519-845-3346 advantage-equip.com

Viably launches the Komptech Lacero high-speed horizontal grinder

The Komptech Lacero is the newest addition to the Viably product portfolio and was designed exclusively for the demands of the North American wood waste and organics recycling sector.

The Komptech Lacero fulfils the specialized needs of wood waste recyclers, mulch producers, logging, land clearing and organics recycling companies. It is precision-engineered and includes a 104-cm diameter downswing drum powered by a Caterpillar C18 diesel engine and PT Tech clutch, providing up to 812 hp.

The tracked machine also has an optional three-axle dolly system that allows for seamless on-road transport, making it flexible and functional.

AUTHORIZED

DISTRIBUTOR

CONSTRUCTION EQUIPMENT RENTAL

DOZERS - LOADERS - BACKHOES - ROLLERS CUSTOMER SER VICE TARTEN EQUIPMENT LIMITED

6199 Shawson Drive Mississauga, ON L5T 1E5 Phone: 905 670 1704 Fax: 905 670 4790

Toll Free: 1 888 670 1704WWW.TARTEN.COM

An integrated control system provides real-time diagnostics and a wireless remote control with a comprehensive machine status display for efficient use. The expansive feed hopper and innovative Smart Grind program control deliver continuous and efficient material feed.

“The Viably team takes pride in being at the vanguard of delivering innovation to North America waste recyclers, and the Komptech Lacero stands testament to our aspirations,” said Brandon Lapsys, President of Viably.

“Working with the Komptech factory engineers to craft this machine reflects our commitment to excellence and our insights into the real-world needs of our clients on this continent.

"The Lacero is not just a product; it’s a pivotal tool reshaping the waste processing landscape.”

The Lacero delivers throughput values of 400 cubic metres per hour in wood waste, while at the same time producing a homogeneous material quality.

The large feed area with active intake in the form of a steel link belt transports the material to the large intake opening of 760 mm by 1,520 mm.

The rotor design has 16 armoured wear plates and allows

use on both sides, doubling the service life. The Lacero 8010 is driven by a belt drive, which ensures maximum efficiency.

A two-part screen basket system allows the machine to be matched to the desired material quality. The screen basket carrier also has a safety system that is triggered on contact with a massive interfering material, thus protecting the machine from further damage.

Material discharge is provided by the powerful discharge system with a discharge height of almost five metres. Locomotion is ensured by a robust tracked undercarriage with a 50-cm width.

The machine is equipped with Komptech’s Connect condition monitoring system as standard. It can be expanded to include fully integrated volume throughput measurement to monitor machine performance data.

Last fall, Komptech Americas, the master distributor of Komptech industrial waste processing equipment in North America, announced it is rebranding as Viably.

The company will continue its longstanding partnership with Komptech GmbH while expanding its product portfolio with new brands and technologies.

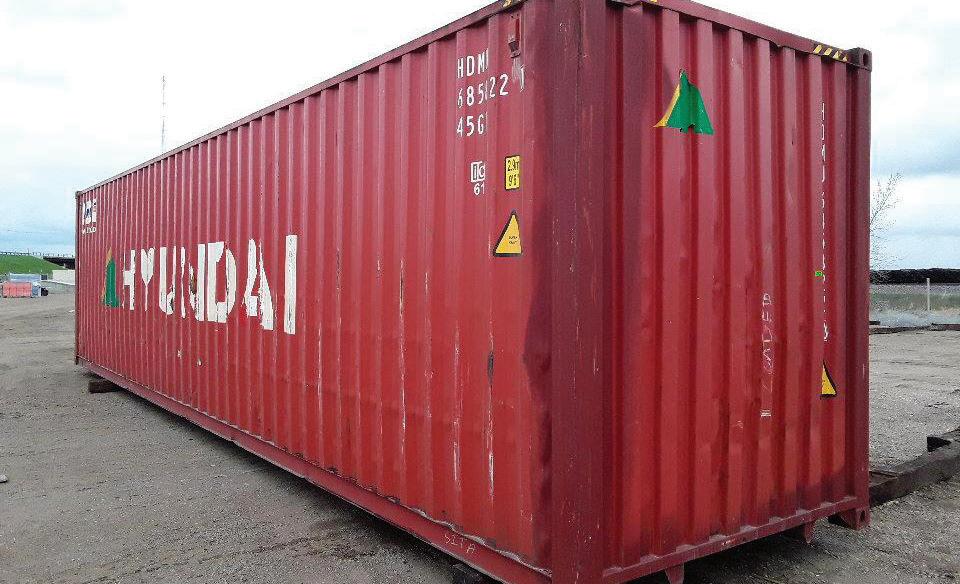

Brokk Opens Hamilton, Ontario distribution centre

Brokk is expanding its network of facilities into Canada with the opening of a new distribution centre in

Hamilton, Ontario.

The new 4,000-foot Canadian distribution facility will house the full line of

demolition machines with attachments as well as Aquajet Hydrodemolition robots and parts inventory for both brands.

KSD Series

The new centre will also offer Brokk and Aquajet hydrodemolition equipment demonstrations. Canadian customers now have access to an in-country distribution centre and no longer have to wait for equipment to go through customs from the United States.

The new location will be run by Jim Bennett, who joined Brokk in Canada as warehouse and logistics manager.

Bennett’s responsibilities include managing product and assisting customers and regional sales managers by providing parts support throughout Canada.

“Adding a distribution centre gets us closer to our Canadian customers and generally streamlines the ordering and shipping process,” said Brokk President Lars Lindgren.

“We’re all excited to see what Jim will make of the facility and how it will help our customers in the Toronto area and beyond. He has a wealth of warehouse management

experience and will closely monitor demand for Brokk and Aquajet products to ensure optimal stock.”

Bennett has more than 30 years of warehouse and logistics experience within the auto and construction sectors. He started working as a warehouse manager before working his way up to operations supervisor. His last two positions have been as a warehouse manager and warehouse supervisor before transitioning to his current role with Brokk.

“My whole career has been customer driven, and that’s what’s so exciting about this role,” Bennett said.

“My vision aligns with Brokk’s. The new facility will help meet our goal of providing Canadian customers with machines and parts from both Brokk and Aquajet.” Brokk’s North American Headquarters is located in Monroe, Washington, and serves as the administrative offices, parts warehouse, mechanical training facility and troubleshooting centre. Brokk also has an east coast service centre in

A22 MAY 27, 2024 EQUIPMENTJOURNAL.COM

Stanhope, New Jersey, and a Midwest service centre in St. Joseph, Missouri.

New Electronic fuel injection Saves time and increases productivity Durable components Simple, advanced, versatile Easy to integrate solutions Compatible with all kinds of machines Compliant with all emissions standards worldwide ATLANTIC CANADA1 877 663-9929 QUEBEC1 866 441-3401 Contact us or visit our website for more information newwaydiesel.com diesel-bec.com Details Ontario1 844 309-0086 High torque, compact design

A23 MAY 27, 2024 EQUIPMENTJOURNAL.COM A WIRTGEN GROUP COMPANY WIRTGEN AMERICA, Inc. · 6030 Dana Way · Antioch, TN 37013 · Tel: +1 615 501 0600 www.wirtgen-group.com Uncompromisingly good HD+ TA NDEM ROLLERS –THE PROFE SSION A L S FOR ROA D CONS TRUC TION CLOSE TO OUR CUSTOMERS. The extremely productive HD+ series tandem rollers bring high compaction performance and outstanding compaction quality to your construction site Throughout, they offer impressive ease of use along with perfect visibility

The JCB Teleskid is four machines in one and the world’s only skid steer with a telescopic boom. Imagine what that does for efficiency. Actually, don’t imagine it. Instead, give the Teleskid a try and see how much more you can accomplish. Visit JCB.com to learn more.

ALBERTA

Liftboss JCB

Calgary: 403-301-0041 Edmonton: 780-474-9900 liftboss.ca

BRITISH COLUMBIA

Williams JCB

Surrey: 604-930-3316 williamsjcb.com

NEW BRUNSWICK

A.L.P.A. Equipment

Edmundston : 506-735-4144

NEWFOUNDLAND

Harvey JCB Corner Brook: 709-639-2960

St. Johns: 709-738-8911 harveyco.ca

ONTARIO

D&W Group Inc.

Doughty & Williamson Jarvis: 519-587-2273

Brant Tractor Burford: 519-449-2500

Balmoral : 506-826-2717

Fredericton : 506-452-9818

Moncton, N.B. : 506-861-2572 alpaequipment.com

NOVA SCOTIA

A.L.P.A. Equipment

Truro : (902) 897-2717 alpaequipment.com

Redtrac International Vineland: 905-562-4136 dwgroup.ca

Delta JCB

Dunvegan: 613-527-1501 Renfrew: 613-432-4133 Winchester: 613-774-2273 deltapower.ca

ONTARIO

Fulline JCB Glencoe: 519-287-2840 fullinefarm.com

Equipment Ontario Harriston: 519-510-5878 Lindsay: 705-324-6136 Port Perry: 905-982-1500 Waterloo: 519-742-5878 equipmentontario.com

Jade Equipment

Simcoe County and Districts of Parry Sound & Muskoka 705-325-2777 jadeequipment.com

ONTARIO

Moore JCB Toronto, York & Peel Region: 416-747-1212 moorejcb.com

North Rock JCB North Bay, Sault Ste. Marie, and Sudbury: 705-897-7369 northrockrentals.com

ReadyQuip Sales & Service Ltd. Timmins: 705-268-7600 readyquip.com

WPE Landscape Equipment - JCB Hamilton/Halton: 905-628-3055 wpeequipment.ca

John’s Equipment Sales Frankford: 613-398-6522 johnsequipmentsales.com PEI

A.L.P.A. Equipment (506) 861-2572 alpaequipment.com

QUEBEC

A.L.P.A. Equipment

Bas-Saint-Laurent : (506) 735-4144

Gaspésie : (506) 826-2717 alpaequipment.com

Bossé Quebec Inc.

Desmaures: 418-878-2241 Saint-Augustin-debosse-frere.com

Moore JCB

Montreal: 514-333-1212 moorejcb.com

SASKATCHEWAN & MANITOBA

Westcon JCB

Regina: 306-359-7273

Saskatoon: 306-934-3646

Winnipeg: 204-694-5364 westconequip.ca

YOUR FAMILY OF LOCAL JCB DEALERS