MAY 6, 2024 ISSUE 6 FOCUS: ATTACHMENTS / FORESTRY RETURN UNDELIVERABLE ITEMS TO: EQUIPMENT JOURNAL, PO BOX 160 PORT MCNICOLL, ON L0K 1R0 PUBLICATIONS MAIL AGREEMENT: 40063867 JTEQUIPCORP.COM CALGARY, AB 888-214-5038 YOUR WACKER NEUSON DEALER 2214 Line 9, Bradford, ON L3Z 2A5 19067 94th Avenue, Surrey, BC V4N 3S4 gearequip.com 416-644-3076 Hydro-Detection System & Gas Detection System DRY VAC RENTALS Equipped with: SALESPARTS SERVICE TOPLIFT.COM 1.800.556.9452 amiattachments.com sales@deltapower.ca 1-833-981-4278 Operating Weight: 3755 lbs Rated Operating Capacity: 665 lbs Ground Pressure: 3.1 psi Engine Power: 24.7 hp The RT-25 Posi-Track® compact track loader is designed and created to feature the productivity and comfort that landscapers, homeowners and contractors needs. SEE OUR AD ON PAGE A6 Contact John or Mark at: 1-800-265-5747 www.marcelequipment.com Sales, Rentals & Rental Purchase Quality, Reconditioned Equipment Since 1976 CAT 352FL (2018) For RENT / SALE • 4,350 hours • Reach Boom • 11’ Stick • Aux Hydraulics • Pin Grabber Coupler • Variable Gauge U/C • Choice of Buckets • Very Straight Machine • Price: $525,000 • Call for Rental Rates LIVE WEBCAST AUCTIONS NEXT EQUIPMENT AUCTION: May 25th, 2024 @ 9AM CELEBRATING 21 YEARS SERVING THE INDUSTRY 866-229-2253 TO CONSIGN YOUR EQUIPMENT, CALL US 2024 LINK-BELT 3240 PROCESSOR, 20’2” boom, 11’arm, 36’5”reach, Waratah H424 processing head, stk #R160-3240 sales@bmcdowell.com www.bmcdowell.com 705-566-8190 416-770-7706 BUY ME See our ad on page A13 ARRIVING SOON! REDUCE DOWNTIME PROTECT YOUR INVESTMENT EXTEND COMPONENT LIFE KEEP OPERATORS SAFE BE UNSTOPPABLE GREASES WHILE YOU WORK NEXT GENERATION AUTOMATED LUBRICATION MADE IN CANADA LUBECORE.COM I 905-864-3110 Sales & Rentals 1-855-625-0941 sales@creightonrock.com STUMP CRUSHER FEATURES �Crushes a stump in 20 seconds �Changable blades and screw �14 to 20 ton excavators �Model 400 & 600 range from Mini SSL to 20 ton excavator 850 Pro CRDCREIGHTON.COM www.essltd.com since 1946 DISCOUNTS ON ALL ESCO BUCKETS FOR ALL MAKES ! Jim Walsh jwalsh@essltd.com 416-358-3192 ONLINE HEAVY EQUIPMENT & TRANSPORTATION AUCTIONS 1-888-376-3155 • AllStarAuctions.ca 44 Line 9 South, Oro-Medonte, ON L0L 1T0 UPCOMING AUCTIONS: 2018 Kubota SSV75 2015 Peterbilt 567 ANCASTER - MAY 30TH & BARRIE - MAY 14 & 15TH

POWERSCREEN TRAKPACTOR 550

The Powerscreen® Trakpactor 550 horizontal shaft impactor is designed for processing soft to medium-hard primary & secondary materials such as natural rock & construction derived materials like asphalt, recycling & demolition waste.

MDS M515 HEAVY DUTY TROMMEL

Ideal for creating RipRap and recovering rocks up to 800mm (32”) that are mixed with clay and other sticky materials. The updated model has been redesigned to include new features that will improve transportation, access, and stockpile heights.

CEDARAPIDS CANICA CRV2000 PORTABLE VSI

Features the Canica 2000 Vertical Shaft Impactor, available in a number of chamber configurations. Highly mobile all electric plant with the latest CCM automation system. Available in single or dual drive. Designed to handle a wide range of different applications and is well suited for manufacturing sand. Also available as a static crushing chamber or on the MV2000 modular platform.

RECOVER, REPURPOSE, AND REUSE

The VacRecover is an innovative modular washing solution specifically designed for processing hydro excavated waste material that was typically a waste material. The washing process converts it into a saleable product, openign up a new revenue stream for many quarries.

CEDARAPIDS CRS620H SCREEN PLANT

Features the popular 6’ x 20’ TSV6203 screen, along with a flex shaft screen drive and rollaway blending chutes, make this a leader in the screen plant market. The wide conveyor belts handle peak load conditions easily. The plant is designed to get the most out of the screen so there is plenty of capacity to make the crushers the bottleneck in the circuit, not the screen.

A2 MAY 6, 2024 EQUIPMENTJOURNAL.COM 800 Farewell Street, Oshawa Ontario, L1H 6N5, Canada psc@powerscreencanada.com powerscreencanada.com Toll-Free: 1-877-797-7276 Email: psc@powerscreencanada.com CONTACT POWERSCREEN OF CANADA

FOR A PRODUCTIVE SPRING

ISSUE 6 May 6, 2024 A3 MAY 6, 2024 EQUIPMENTJOURNAL.COM Manitou's new compact loader line Volvo CE’s three-pass rehandler A7 A13 Caterpillar’s updated asphalt compactors A8 North America’s

FORESTRY FEATURED EQUIPMENT B9 ATTACHMENTS FEATURED EQUIPMENT B3 The former home of the Maclean Publishing Company is being transformed into a 55-story condo development A18 STORY

largest heritage retrofit

ON

An excavator is obviously quite different than a dishwasher. This is an obvious statement, but it needs to be said.

Thanks to right to repair legislation, construction equipment is at risk of being grouped in with other products like appliances, electronics and automobiles.

As you will read on Page A12 of this issue, right to repair legislation is gaining a lot of attention at various levels of government throughout North America.

Quebec is the first province to pass right to repair legislation. In October, the Act to protect consumers from planned obsolescence and to promote the durability, repairability and maintenance of goods came into force. However, the act does not include new laws for heavy equipment.

At the federal level, the

Liberal government has launched a study to see if a similar national law is required.

“The challenge, of course, is when they apply that lens of appliances and dishwashers to your businesses, which you know, are fundamentally different,” Huw Williams, President of Impact Public Affairs, told a recent meeting of the Canadian AED.

Days after Williams delivered his AED speech, the Ontario NDP tabled a bill that lumps together electronics, appliances, wheelchairs, automobiles and heavy farming equipment.

The bill would require the manufacturer to provide manuals, parts, tools and software at a reasonable cost to the product owner. The bill also notes the net profit percentage of the charged fee does not exceed a reasonable estimate of the net

profit percentage that the manufacturer earns for diagnostic, maintenance or repair services. Although heavy farm machinery is not directly related to our readers, this four-page bill does show an inability to distinguish between product categories.

Sure, it’s reasonable for the end user to be able to fix their own machine, but there is a fine line between freedom to repair and intellectual property.

What all of these products do share in common is the years of research and development required in their development. For each category, the threshold for intellectual property is vastly different, not to mention the wear and tear experienced by a tractor is far more extreme than a wheelchair.

To help politicians understand, Williams encourages dealers and manufacturers to

Bill Tremblay // Editor editor@equipmentjournal.com

Bill Tremblay // Editor editor@equipmentjournal.com

invite federal and provincial decision makers to their facilities this summer to better understand the equipment. Hopefully, other industries are engaging in similar meetings. If the public is demanding right to repair laws, it’s important to ensure the nuisances of each product type are reflected, and that legislation includes clear specifics for excavators as well as dishwashers.

A4 MAY 6, 2024 EQUIPMENTJOURNAL.COM Published every third Monday at 6-5160 Explorer Dr., Mississauga, (Toronto). Subscription $44. per annum or $72. for 2 years including applicable tax., Payable in advance. Single copy $3.95. Authorized as Publications Mail Agreement No. 40063867, by the Post Office Dept. Ottawa and for payment in cash. Advertising is accepted on the condition that in the event of typographical error, that portion of the advertising space occupied by the error together with reasonable allowance for signature will not be charged for, but the balance of the advertisement will be paid for at the applicable rate. In the event of a typographical error advertising goods or services may not be sold. Advertising is merely an offer to sell and may be withdrawn at any time. We reserve the right to reject or refuse any or all advertising. Equipment Journal permission is required to reproduce original ad layout, artwork and photos. H.S.T. # 10403 7957 RT ADVERTISER INDEX MAY 6/2024 LETTER FROM THE EDITOR EQUIPMENT JOURNAL IS AN AUDITED PUBLICATION CONTACT US Editor Bill Tremblay editor@equipmentjournal.com Publisher Mark Baker mark@equipmentjournal.com PACE PUBLISHING LIMITED EQUIPMENT JOURNAL 5160 Explorer Drive, #6 Mississauga, ON, L4W 4T7 Canada OFFICIAL SOCIAL MEDIA ACCOUNTS @EquipJournal @equipmentjournal @EquipmentJournal Equipment Journal LOCAL: (905) 629-7500 TOLL-FREE: CDN/USA 1-800-667-8541 EMAIL US: advertise@equipmentjournal.com WEBSITE: www.equipmentjournal.com Sales Manager Tara Baker tara@equipmentjournal.com National Account Manager Mona Fahmi mona@equipmentjournal.com Creative Director/Creative Services Ryan Chuhaniuk ryan@equipmentjournal.com Circulation Manager Lisa Bath lisa@equipmentjournal.com Alltrade Equipment B14 Amaco Construction Equipment Inc. A7 AMI Attachments A1 Bobcat A16 Brandt Road & Mineral A19 Brandt Used Equipment A9 Brandt Used Truck & Trailer B13 Bull Powertrain A17 Converter Man Limited...................................................B11 Cooper Equipment Rentals A1 Creighton Rock Drill Limited A1,A10 Delta Power Equipment A1,B7 Demo International B10 Don Cordingley Gradall A18 Elation-Tech Inc. A15 Equipment Sales & Service Limited A1 Flo Components A18 Gear Equipment A1 High Reach Inc. A8 HLA Attachments A7 Hub Equipment B16 Hydrolexc A12 Hyundai Construction A11 JCB A20 JT Equipment A1 LBX Link-Belt Excavators B2 LSW Wear Parts B7 Lubecore A1,B12 Lund Appraisal Svc. B5 Magnum Attachments A4 Marcel Equipment Limited A1,A6 McDowell B Equipment Ltd. A1,A13 Morgan's Diesel Truck Parts B12 Olofsfors/Hultdins B5 Pine Ridge Lisco Edwards B4 Powerscreen of Canada A2 Sennebogen B8 Shaw Bros. Limited A15 Strongco Equipment A5 Tarten Equipment Limited A17,B4 Tigercat A12 Top Lift Enterprises A1 Toromont Used Equipment B1 Tramac B6 Tri-City Equipment A14 UHI Machinery B15 Word Rock Drills B11 AUCTIONS AllStar Auctions A1 North Toronto Auction.......................................................A1

Heavy equipment deserves to play in a league of its own magnumattachments.com For the profit end of your machinery MAXIMUM PRODUCTIVITY GRAPPLES processing buckets TILTROTATORS PULVERIZERS SHEARS HYDRAULIC BREAKERS COMPACTORS We’ve got attachments for all your needs: DEMOLITION RECYCLING SCRAP EARTHMOVING 1-877-640-2862

A5 MAY 6, 2024 EQUIPMENTJOURNAL.COM ALBERTA ONTARIO QUEBEC ATLANTIC WWW.STRONGCO.C OM A FT ER S ALE S SUPPO RT PARTS INVENTORY Genuine O EM part s & ma jor comp o nen ts av ail a bl e n s to ck I n- Fi e ld s erv ic e | In - S ho p s e rvic e HUGE INVENTORY U sed Eq u ipm ent | Ne w equipme nt FOR M OR E INFO J.J LY ON S CON TACT jjl y on s @strong c o. com (844) 288-4241 Conn e ct wi th us VOLVO USED EQUIPMENT & COMPONENTS ASK US ABOUT FINANCING OPTIONS *Terms & Conditions apply Volvo Rebuilt Transmissions L220F transmission SN#6005-8485 L90E transmission SN#2005-8000 L110F transmission SN#3503-61501 Volvo Used Parts for: Articulated Haulers Wheel loaders Motor Grader 2020 VOLVO L90H 3,379 hrs 2011 VOLVO A40F Stk#2035102 17,271 hrs 6,934 hrs 2018 VOLVO L60H Stk#2027304 862 hrs 2017 VOLVO EC60E Stk#2034177 3,514 hrs 2020 VOLVO L70H Stk#2030529 3,394 hrs 2019 VOLVO L60H Stk#2027303 441 hrs L220F REBUILT TRANSMISSION 1 Year Strongco Parts Warranty A30D, A25D REBUILT TRANSMISSION 2017 VOLVO L30GS Stk#2033605 4,433 hrs 2020 VOLVO L90H 3,755 hrs 2018 VOLVO L60H 1,826 hrs Your one-stop dealer. From machinery to service, parts and certification. Your trusted partner for every project. 1 Year Strongco Parts Warranty 2020 VOLVO L90H 4,950 hrs 2020 VOLVO L90H Stk#2030536 5251 hrs $278,500 $233,500 $259,000 2009 VOLVO EC330L Stk#2034792 16,454 hrs Stk#2030533 Stk#2030535 $267,500 Stk#2027311 Stk#2030405 Stk#2030532 $172,500 $213,500

A6 MAY 6, 2024 EQUIPMENTJOURNAL.COM LONDON, ONTARIO, CANADA Contact John or Mark at: 1-800-265-5747 or 519-686-1123 Email: sales@marcelequipment.com VIEW our Complete Inventory at: www.marcelequipment.com REBUILT CAT 826H COMPACTORS - 0 HRS Components Rebuilt, Complete Machine Recondition, 3 year CAT Component Warranty 40 Compactors to choose from. $CALL Since 1976 SALES, RENTALS & RENTAL PURCHASE UNITS SOLD WITH WARRANTY WE ALSO RENT EQUIPMENT CONTACT MARK or JOHN 1-800-265-5747 or 519-686-1123 CAT 816K (2020) - 795 HRS CAT Warranty Remaining. Just like a New One, but for a lot Less! $CALL CAT 770 (2008) – 10,655 HRS 40 Ton, 33 CY, Dual Slope Bed, Very Straight Truck, All Servicing & Repairs Completed. New Tires. $CALL CAT 352FL (2018) – 4,195 HRS Reach Boom, 11’ Stick, Aux Hydraulics, Coupler, 30” Pads, Very Clean, CAT Inspected. $CALL CAT 938M (2018) - 6,680 HRS 3rd Valve, Diff Lock, Coupler, Choice of Bkt, Forks Available. $250,000 VOLVO A25G (2017) - 6,850 HRS 23.5R25 Tires, Rear-View Camera, Inspected, All Needed Servicing and Repairs Completed. $CALL CAT 980M (2019) – 7,740 HRS 3,125 Idle Hrs, CAT Scale, 7.75 CY Bkt, Bridgestone L4 Tires, Spade Bkt Available. $535,000 CAT 336FL XE (2016) - 9,285 HRS You would think it has 5,000 hrs Very Clean, Tight & Well Equipped Check it out! $CALL CAT D6TXW VP (2014) - 4,945 HRS 1,020 Idle Hours, U/C Replaced 320 Hrs ago, CAT HDXL U/C, 28” Extreme Pads, Counterweight Drawbar, Ripper Available, Grade Control, All Servicing/Repairs Completed, FOR SALE OR RENT $399,000 (4) CAT D8T (2011-13) - 4,381-8,090 HRS Very Clean, Choice of SU or Angle Blade, Drawbar. Ripper/Winch Available. $CALL (7) CAT D8T LGP (2019/2020) 2,230 to 14,345 HRS SU Blades, 38” Pads, Draw-bar. $CALL (2) KOMATSU HD325-7 (2010) - 11,000 HRS 40 Ton, 31 CY, Flat Floor, Very Straight, Clean Trucks, All needed Serving & Repairs will be Completed. $CALL CAT 980M (2019) - 7,325 HRS 7.75 CY Bkt, Tire & Bucket options available All Needed Repairs & Servicing Completed. $540,000 $CALL KOMATSU WA470-8 (2016) – 7,380 HRS Coupler, 5.25 yd Bucket, Loadrite Scale, All Servicing / Repairs Completed. CAT 772G's - 5 AVAILABLE (2016-2017) 7125 – 11,238 HRS Flat Floors, Liners, Auto Grease, Nice Straight Trucks. $CALL $499,000 HITACHI ZX490 LCH-6 (2022) - 2,205 HRS Reach Boom, 12’10” Stick, Coupler, 76” Bkt, Aux Hyds, VG Undercarriage. CAT 938M HI LIFT (2019) - 5,560 HRS 3rd Valve, Hi Lift Boom, Coupler, Choice of Bkt, NEW Michelin Tires. $300,000 CAT 988K XE HIGH LIFT (2020) – 6,650 HRS Bucket Options, Tire Options, Auto Grease, CAT Maintained, Very Nice. $CALL

Manitou unveils its new generation of mid-range CTLs and skid steers

The new generation of Manitou’s mid-range skid steers and compact track loaders are now rolling off the manufacturing line in Madison, South Dakota.

The lineup reflects a range of sizes and options that provide contractors with a tool for material handling, attachment use and multi-purpose work around the jobsite.

The new machines include the 2100 V, 2300 V and the 2750 V skid steers and the 2100 VT, 2300 VT and 2750 VT compact track loaders.

All models are vertical lift and feature a new lift arm design to improve visibility.

The operator experience has also been improved with an update on Manitou’s patented folding door, and the cab improves visibility with a new window and roof design. Breakout forces and tank capacities are increased for greater productivity and longer operating times.

The new models also include IdealTrax. This patented track-tensioning system tensions the track to the proper tension when the machine is started and relieves the tension when the machine is turned off, which prolongs the track’s life and makes cleaning out the tracks easier.

Instead of greasing to achieve proper tension every 50 hours or so, Manitou uses a hydraulic system to keep constant tension on the tracks. As this happens automatically, it takes significantly less time to achieve

proper tension. It also increases track life by up to 15 per cent by always ensuring proper tension and guarding against over tensioning.

Over-tensioned tracks wear from the inside out and rob horsepower from the machine as it takes more effort to turn the track, which also causes poor fuel efficiency. Fleet managers will also see improved idler and bogie bearing life.

Each new CTL also features the exclusive Manitou IdealAccess door. Contractors are increasingly moving away from the traditional swing-out doors for a variety of reasons, including visibility, easier access to the cab, and less likelihood of damage to the door. This bi-folding door gives the operator more headroom, and allows operation with the door opened or closed.

Vertical-lift arm design

The all-new vertical-lift arm design is one of the most distinct features of the skid steers and CTLs. The sloped-arm design improves visibility and reduces the amount of material that gathers on the arms, and allows for all hydraulic lines to be routed in or under the arms for greater protection.

Manitou has transitioned exclusively to a vertical lift arm design with these models, which provides more reach at dump height to dump closer to the centre of the truck being loaded, while also improving rear visibility

thanks to the elimination of rear towers.

Breakout forces have been improved by an average of 12 per cent compared to the previous Manitou models, and the manufacturer has increased fuel tank size by 14 per cent to allow for extended run times without refuelling and the associated downtime.

Additional standout features include keyless start, LED lighting and a patented Pilot joystick system that moves with the seat to ensure a common operator experience is standard.

Both standard and highflow auxiliary hydraulics have been enhanced to make attachment use more productive, and Manitou offers a full and expansive lineup of Manitou Group attachments to make these machines even more versatile.

Operator experience

The operator experience has been seriously upgraded with a larger, one-piece cab that gives the operator 23 per cent more space than previous models.

As well, a larger, more ergonomic foot area reduces operator fatigue while enabling precise control of the standard foot throttle and lift-arm cushioning and an optimized undercarriage provides a smooth, more comfortable ride.

Each machine also features high auxiliary power to meet all attachment requirements commonly

found with skid steers and CTLs.

The new loaders include the full Manitou EasyMan-

ager fleet management telematics platform.

This allows business owners and fleet managers

to stay better connected to the health, performance and efficiency of each Manitou machine.

SPRING

2023 and 2024 (2) ton Falcon Asphalt Patching Trailers available for rent and purchase.

Call today for more information about our fleet.

A7 MAY 6, 2024 EQUIPMENTJOURNAL.COM

IS HERE AND IT’S POTHOLE

SEASON. FALCON Road Maintenance Equipment Call or Text (905) 670-3440 AMACOCEI.COM

REPAIR

Cat adds new features to its mid-sized asphalt compactors

Caterpillar has updated its CB7, CB8 and CB10 midsized asphalt compactors with new features, including edge-management options, operator cab, optional split drums and a new mapping display.

Asphalt compaction can make or break a project and meeting the required density and smoothness specifications can be essential to maximizing profitability. Proper management of unconfined edges can help optimize density and lead to better road quality. The vertical edge created by the

cut-off wheel helps provide a stable vertical face for joint matching on the next paving pass. The bevel edge options provide sloped profiles for smoother transitions on and off the paved surface. Three versions are available to help contractors meet job site requirements.

Mapping display

The new mapping display provides an enhanced on-screen visual for easier recognition and touchscreen capability for simplified setup. Cat Compact helps operators visualize the cover-

Hyundai showcases specially outfitted equipment at ISRI

HD Hyundai Construction Equipment showcased its latest advancements for the recycling industry at ISRI (Institute of Scrap Recycling Industries).

Held in mid-April in Las Vegas, ISRI is the largest event in the scrap and recycling industry. At the show, Hyundai CE showcased its updated HW250AMH material handler, the HX235AL CRD excavator with SAS Auto Dismantler and an HL960AHDXT wheel loader.

“We’ve seen increasing in-

terest in specially outfitted machines like the Hyundai material handler, heavy-duty wheel loader and excavator with auto dismantler that we are featuring in our exhibit this year,” said Mike Ross, Senior Vice President at HD Hyundai Construction Equipment North America. “These machines are designed to handle the rigours of scrap and recycling.”

The recently updated Hyundai HW250AMH wheeled material handler now features Hyundai EPFC (electronic

positive flow control), which allows greater control of hydraulic flow to suit operator preferences, specific applications and attachments. Some of the adjustments include:

· The ability to set up to 10 single-flow and two-way settings

· Load sensitivity, adjustable between swing and boom and boom and arm speed priority

· Preferred timing before auto engine shutdown to idle

Operators can set the preferences and other controls through the 20-cm touchscreen monitor in the cab.

The material handler is also equipped with guarding to protect the machine and operator, and a telescoping cab to provide exceptional visibility when loading and unloading trucks and containers in scrap and waste yards. In addition to handling scrap and recycling work, the Hyundai material handler is suitable for other on/off-road applications, including for-

age area while recording pass-count and temperature data. The system utilizes infrared temperature sensors and GPS mapping to keep the operator informed of current mat temperatures, machine position, pass-count and pass coverage. This intuitive system enhances nighttime performance, while also capturing data for future process analysis and quality control documentation. When combined with drum edge and drum surface lighting, Cat Compact helps extend the workday and increase daily production.

Making turns

Making tight turns on hot asphalt can result in mat tearing that can lead to quality issues. The dual split-drum option on the front drum can help eliminate tears when manoeuvring around obstacles or when compacting tight turns by reducing the speed of the inner drum half.

The split drum option can be a great solution for parking lots, driveway approaches and other applications that require frequent turning.

Vision Link

VisionLink is a cloudbased software application that provides data to a desktop or mobile device, taking the guesswork out of fleet management with key insights to maximize performance – regardless of fleet size or equipment manufacturer. The system provides maintenance needs, machine hours, location, fuel usage, idle time, diagnostic codes and other machine data to your mobile device, desktop or through an API to other software applications. The three mid-sized asphalt compactors also include an AM/FM Bluetooth radio, heated seat and spacious legroom, unobstructed sight lines and climate control functions.

estry and marine terminals.

Key specs include an operating weight of 27,900 kg when outfitted with a standard SNS grapple and a net power of 170 hp with a Cummins B6.7 diesel engine.

Powered by a Cummins B6.7 Tier 4 Final and Stage V-compliant diesel engine, the HX235AL CRD incorporates HX A-series features like improved visibility and handling, EPFC hydraulic system, automatic engine shutdown, auto safety lock and eco gauge lifting mode to help improve productivity. The ISRI model was outfitted with an SAS automobile dismantler attachment.

The Hyundai HL960AHDXT wheel loader on display was equipped with front and rear cab guard and rear grille guard and other light guarding that will help protect operators moving sharp, heavy and abrasive materials. The heavy-duty wheel loader comes standard with a Cummins B6.7 Tier 4 Final and Stage V-compliant diesel engine, heated and air-ride seat, a hood that tilts back for easy access by the flip of a switch, filters serviceable from the platform, heavy-duty ZF axles with outboard wet breaks and a rear hood design that provides better visibility to the rear of the machine.

A8 MAY 6, 2024 EQUIPMENTJOURNAL.COM

CANADIAN DEALER FOR: F ROM 5,000 TO 160,000 LBS. BARE RENTAL RENTALSSALESSERVICE IC-20IC-35IC-40 Capacity 5,000 lbs 4 Tons 9,000 lbs Boom Height 22’33’ 6”33’ 6” IC-80IC-200IC-250 8 Tons15 Tons18 Tons 46’ 4”73’79’ 4” www.highreachinc.com Tel: (905) 844-4164

ideal for lifting material that require a compact, low-profile

to maneuver in tight spaces and clear overhead

Multiple sizes and capacities, including optional equipment for

your

can fulfill all

BRODERSON CARRY DECK CRANES CARRY DECK CRANES ORIO N BETTER FORK LIFT TRUCKS

Broderson Carry Deck Cranes are extremely versatile,

crane

obstacles.

customization, ensures

Broderson crane

your lifting needs.

A9 MAY 6, 2024 EQUIPMENTJOURNAL.COM 1-888-227-2638 Financing Customized, flexible options. Find out more: 1-855-711-4545 Canada’s #1 Used Equipment Inventory brandtused.ca 2011 JOHN DEERE 753J Unit #: :0U197741 $171,000 2014 JOHN DEERE 903K Unit #: 0U261869 $166,300 2021 JOHN DEERE 903M Unit #: 0U396476 $395,000 2015 JOHN DEERE 948L Unit #: 1U670682 $163,000 2019 JOHN DEERE 903M Unit #: 1U343698 $475,000 2019 JOHN DEERE 903M Unit #: 0U343763 $395,000 2021 JOHN DEERE 953M Unit #: 0U402059 $499,000 2017 JOHN DEERE 1210E Unit #: 0U001913 $245,000 2019 JOHN DEERE 959M Unit #: 0U343680 $499,500 2018 JOHN DEERE 959M Unit #: 0U333143 $400,000 2010 JOHN DEERE 903KH Unit #: 1U189321 $65,000 2014 JOHN DEERE 2454D Unit #: 1U240189 $215,500 2018 JOHN DEERE 953MH Unit #: 0U333360 $259,000 2012 JOHN DEERE 2154D Unit #: 2U210520 $55,000 2016 JOHN DEERE 2454D Unit #: 0U240315 $240,000 2018 JOHN DEERE 959M Unit #: 1U332708 $429,900 2011 JOHN DEERE 748H Unit #: 0U636164 $87,000 2016 JOHN DEERE 848L Unit #: RS675070 $145,000 2017 JOHN DEERE 948L Unit #: 0U680390 $176,900 2017 JOHN DEERE 3756G Unit #: 0U376011 $279,000

New features introduced for Develon Fleet Management telematics

The new My Develon digital platform is an expansion of the company’s existing Develon Fleet Management telematics offering.

The new platform makes navigating the system easier for customers and dealers when managing Develon construction equipment.

“Dealers and customers can access and manage the Develon construction equipment maintenance and operation data using the My Develon app or on a web browser,” said Develon Telematics Manager Stojan Arezina. “Our customers can

remotely check the status of their equipment and communicate with their machines by sending certain messages.”

Some of the new features now available on the platform are the ability to download service tools and receive personalized quotes for parts for Develon machines.

“We provide a menu for customers to request a quote for Develon genuine parts from their local dealer,” Arezina said. “It will be a very useful resource for customers. They can select the parts they want to receive a quote on and send it to their dealer.

Additionally, customers can subscribe to our exclusive digital services.”

Telematics usage

More dealers and customers are utilizing telematics data, based on data tracked by Develon.

Arezina explained that during ConExpo 2023, the company successfully showcased the telematics service and how it can benefit customers.

Although some customers can be intimidated by the amount of data, Arezina said Develon and its deal -

ers are working to develop training programs that help educate customers on how to navigate the system. That starts with dealers using brief, streamlined training materials, which Arezina said have been effective with sales specialists.

“When a customer purchases a new machine, our dealership sales specialists provide some basic training about telematics with the customer,” he said. “When the customer leaves with the new machine, the customer has a telematics profile. The customer can log in and start

tracking the new machine immediately.”

One of the most popular features of telematics services today, according to Arezina, is the ability to receive codes from machines. Dealers and customers can subscribe to receive notifications when a Develon machine requires service. This allows dealers to proactively engage with customers and their machines, which optimizes uptime protection.

“Our telematics offering helps keep our customers’ machines working the way they were intended,” Arezina

said. “Dealers and customers can better remotely monitor machines to ensure they are in good health and can schedule routine maintenance to ensure it’s done when it’s needed.” The My Develon app is available for download from popular app service providers. Current users of the Develon Fleet Management system should replace the current app by downloading the new My Develon app. They can log in with their same credentials. The system is also available on a web browser at na.develon-ce.com/en/innovation/ my-develon.

Sommers partners with film industry to test hydrogen power generator

Sommers Generator Systems is piloting a project to supply the film and television industry with emissions-free hydrogen power equipment.

The HGDWS 165 ST generator looks and performs like a conventional diesel generator. However, it delivers a quiet, mobile, zero-emission and serviceable system.

H2OnSet, a company that provides film production sets with hydrogen from local producers, approached Sommers

to create a generator solution.

H2OnSet integrates hydrogen production, distribution and use into a turnkey service. They asked Sommers if they would be interested in building a hydrogen powered generator initially for use on TV and film sets. At that time, there was interest, but no marketable product.

The challenge for hydrogen fuel cells included cost of equipment, the need for peripheral devices and the

unknown performance of operating the equipment. McGregor thought they could overcome those.

“We said, ‘Sure, we can do this’,” explained Sommers President Chris McGregor

The Sommers engineering team, led by Frank Noda, designed a generator using fuel cells, although there was interest, the cost was a factor. It was about 10 times the price of a comparable diesel system. As chance would have it, Sommers was introduced to an engine and hydrogen drive solution manufacturer based in Europe. This led to the opportunity to simplify the process, reduce costs and test efficiencies.

The result was a 60 Hz 120/208V 165 kW hydrogen generator classified as zero emissions with a smaller footprint.

“Earlier hydrogen generators were bulky, unconventional looking,” McGregor said. “What we’re building today looks almost identical to what our other generators look like but with almost zero emissions.”

Sommers will work closely with the engine manufacturer to provide feedback and operational data for future builds for a wide cross sec-

tion of industries looking for opportunities to reduce their carbon footprint.

Both aspects appealed to the film industry that want a trailer-mounted unit with easy distribution for fuel and low noise, while significantly reducing any environmental harm. This included SAG-AFTRA members who want the opportunity to work in environmentally friendly sites.

“They are on a quest to produce movies without carbon impact,” McGregor said.

According to McGregor, this is just the beginning.

“These units can be used and parallelled to produce as much clean energy required for any application whether it be standby or prime power.”

Although production of the hydrogen generator will begin this spring, McGregor has already started fielding inquiries from several industries and applications from across the continent.

McGregor said the generator will have a big environmental impact on communities.

“The future needs new ways of power generation,” he said. “Hydrogen has been around for years. Today, it is as safe as any other. We are building these systems.”

A10 MAY 6, 2024 EQUIPMENTJOURNAL.COM

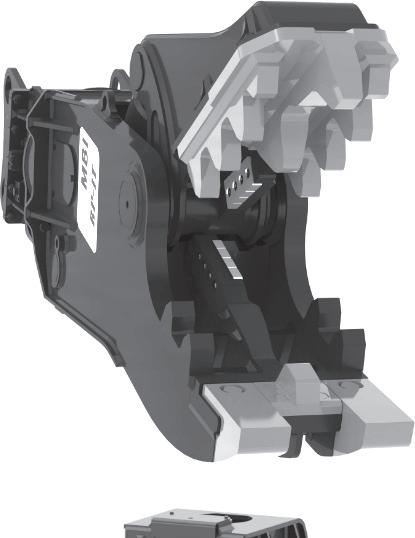

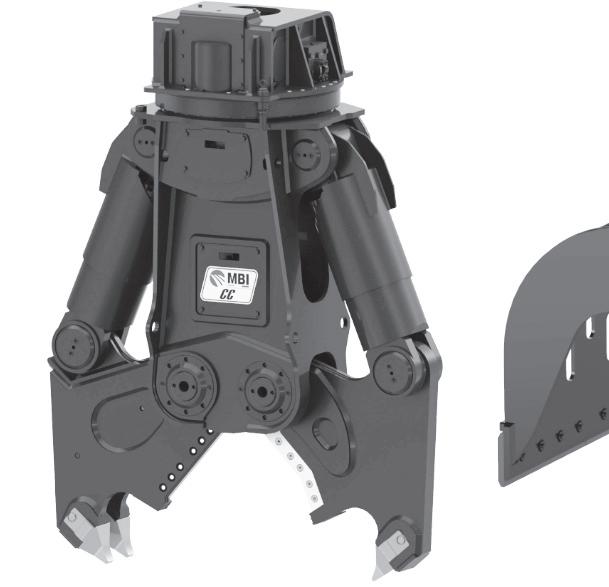

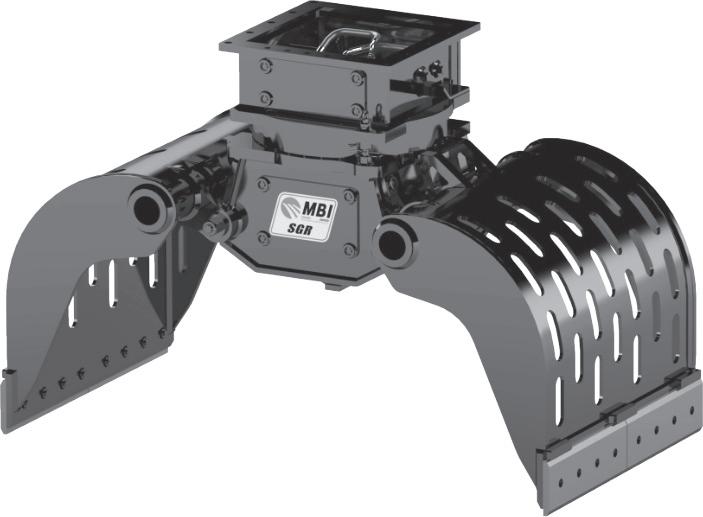

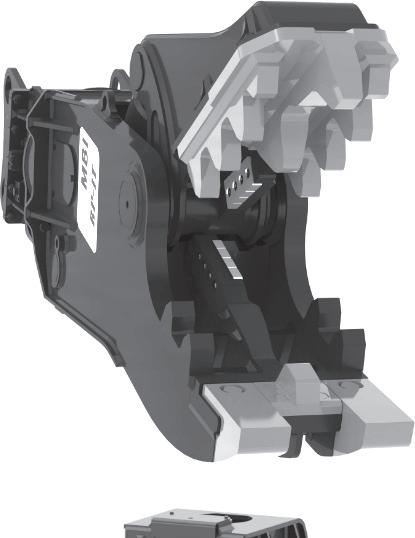

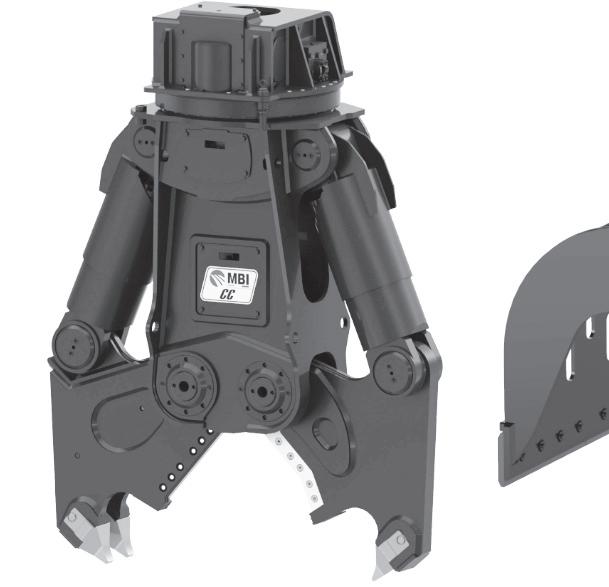

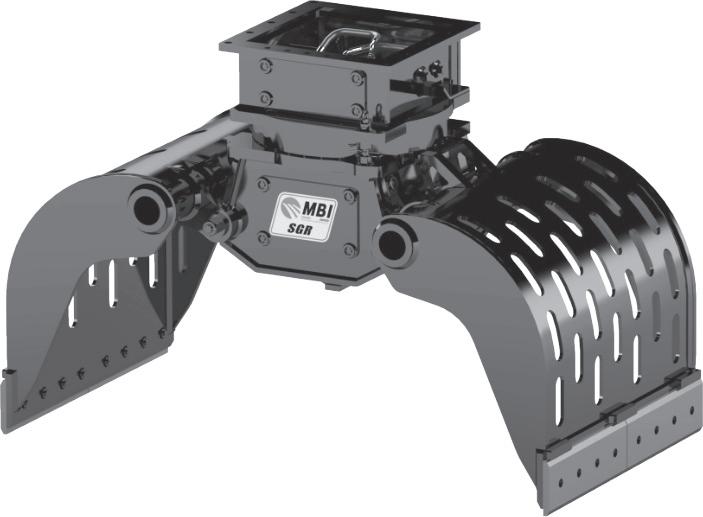

Sales • Rentals • Service ON Mississauga • Bracebridge • Sudbury • Timmins • North Bay • Ottawa QC Boisbriand • Lévis • Val-d'Or NL Mount Pearl NB Moncton NS Dartmouth Call: 1-855-625-0941•CRDCREIGHTON .COM Large inventory of Demolition and Recycling Attachments ATTACHMENTS RP-IT Rotating Pulverizer SH Eagle Shear III MCP-IT Fixed Pulverizer CC Combi Crusher SGR Grapple CR Crusher SALES& RENTALS

THE DOER’S DREAM

Loved for the features. Trusted for the performance.

Do more without feeling like it in Hyundai’s new HX mini excavator series.

• Distinctive, award winning ‘Tiger Eye’ design

• Load-sensing hydraulic system (HX40A, HX48A Z)

• 5” color LCD monitor

• Auto safety lock for unintended operation

• Large, quiet, tilting cab delivers excellent service access

• Free Hi MATE telematics access for 5 years

• Bluetooth radio, now a standard option

Bob Mark New Holland bobmark.ca

42 Center St Sunderland, ON LOC 1H0 705-357-3121

1138 County Rd. 41 Napanee, ON K7R 3L2 613-354-9244

551 Grand Road Campbellford, ON KOL 1L0 705-653-3700

2197 Little Britain Rd Lindsay ON K9V 455 705-324-2221

Hood Equipment Canada Inc. hoodequipmentcompany.net

14 Haniak Road Thunder Bay Ontario P7KOC8 888-413-5454

1355 Riverside Drive Timmins, Ontario P4R1A6 705-288-4685

RTI Equipment Solutions, Inc. 2528 Bowman St. Innisfil, Ontario L9S 0H9 705-734-3350

Dealers

Ontario, Canada Hyundai

No wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, or na.hd-hyundaice.com.

A11 MAY 6, 2024 EQUIPMENTJOURNAL.COM

This summer, equipment manufacturers and dealers should open their doors to provincial and federal policymakers to help showcase why heavy equipment is in a league of its own, according to Huw Williams, President of Impact Public Affairs.

Williams provided an update on the right to repair

debate in Canada during the recent AED breakfast held during the National Heavy Equipment Show. The right to repair debate has received ample attention at both the provincial and federal levels. While federal legislation hasn’t been tabled, Williams noted the government is studying the right to repair, and KPMG

has been hired to research the issue.

“At the moment, I feel very good about our position. But I can tell you that our objective is to make sure that policymakers on all sides of the of the political spectrum understand that right to repair in your sector is not a good idea,” Williams said. However, one of the chal-

lenges faced in the right to repair debate is consumers outside of heavy equipment and its related industries. Across North America, politicians are responding to demands from the public to be able to repair a wide variety of products, from mobile phones to automobiles.

“Consumers are mad as hell that their dishwashers or their fridge or stove breaks down after 18 months or two years, and they can't get it fixed,” he said.

Impact Public Affairs is working to ensure politicians understand that an excavator is not in the same realm as an oven.

“The challenge, of course, is when they apply that lens of appliances and dishwashers to your businesses, which you know, are fundamentally different,” Williams said.

To emphasize the difference between heavy equipment and consumer goods, Williams urged AED members to work with the association to invite elected officials out to see their machines. He explained the Ontario AED has created a summer program for MPs and MPPs to visit manufacturers and dealers to see their business in action.

“When we get Members of Parliament, regardless of what party they are, out to see your businesses, to see dealers and facilities across the country, it gives them a different perspective on right to repair,” Williams said.

“That gives all of you an advantage to be involved in the right to repair debates locally with your Member of Parliament, and to share how different your work is.”

To date, Quebec is the only province to pass right to repair legislation. In October, an Act to protect consumers from planned obsolescence and to promote the durability, repairability and maintenance of goods came into force.

However, the act doesn’t include new laws for heavy equipment.

“It's not part of the mix that they want to focus on,” Williams said.

While right to repair legislation for heavy equipment isn’t looming, Williams advises it’s worth paying attention. He explained such laws could lead to sharing of copyright and programming information as well as the ability to dictate parts at cost.

“It's a slippery slope towards big, big challenges,” Williams said.

A12 MAY 6, 2024 EQUIPMENTJOURNAL.COM

The Tigercat 6900 is a heavy duty upswing horizontal grinder designed for high throughput mulch production and material reduction. The 6900 is designed and built for extreme duty, long life and high uptime. www.tigercat.com Scan to learn more THROUGHPUT HIGH 416-458-2334 HYDRAULIC HAMMER/BREAKER SPECIALIZING IN PARTS, SALES & SERVICE KENT MUSTANG OKADA RAMMER ROCK RAM STANLEY TRAMAC ALLIED ATLAS COPCO BTI CAT CP EPIROC ESCO INDECO NPK SINCE 1998 HYDROLEXC.COM HYDROL EXC EQUIPMENT SERVICES LTD. AED members urged to engage MPs on right to repair debate Impact Public Affairs

Huw Williams

President

Volvo Construction Equipment has adapted its triedand-true L180H wheel loader to tackle three-pass rehandling.

Volvo took its L180H, swapped in larger 875/65 R29 tires and a long boom, added a rehandling counterweight, and created a new truck-loading variation called the L180 3-Pass Rehandler. The machine is designed for rehandling applications, with a higher tipping load, better fuel efficiency and longer reach to fill a truck in three passes.

“We’ve had this concept in mind for several years, driven from conversations with our quarry and aggregate customers,” said Eric Yeomans, Product Manager, Wheel Loaders at Volvo CE.

“The new L180 3-Pass Rehandler will take operators to the next level of loading efficiency. It’s exciting to introduce this game-changer to the market and see the response.”

The larger tires provide lateral traction and flotation, durability and resistance to cuts and impacts, a stable and comfortable ride and good fuel economy.

The long boom brings an additional 675-foot pounds in breakout force and an additional 60 cm of dump clearance.

The longer reach also allows the operator to maintain distance from the truck while still dumping material into the centre of it.

“The worst thing you can have is the load sitting toward one side of the truck, because when you drive around a

corner you run the risk of the material spilling out,” Yeomans said.

The machine’s configuration also decreases the risk of wheel spin and protects the tires as operators are able to stay farther from the pile where the ground is less stable and away from rocks that can damage the tires.

“These tires are what we typically spec for our larger L220 and L260 wheel loaders, so the added traction and rimpull are really noticeable in the L180 size,” Yeomans said.

The rehandling counterweight allows for a bucket that is about 0.19 cubic metres larger than the standard L180H bucket. Customers can choose between four different buckets to find the right fit based on material density, including 4.8 cubic metres, 5.2 cubic metres, 5.5 cubic metres and 5.8 cubic metres.

“The goal is to make three full bucket passes to maximize productivity and fuel efficiency,” Yeomans said. “No more wasting time on two full buckets and a partial bucket with a larger machine, or several passes with a smaller one.”

Improved cycle times

Cycle times are also improved by the higher reach because the operator doesn’t have to roll the bucket back to move away from the truck, especially when dumping the last bucket.

Ultimately, every second shaved off a cycle saves fuel and time, which can add up quickly. Having a slightly

smaller class of machine can save owners on purchase and transport costs, and the opti-

mizations can help operators improve their skills.

The L180 3-Pass Rehand-

A13 MAY 6, 2024 EQUIPMENTJOURNAL.COM

ler supports a variety of Volvo services, including Load Assist with On-Board Weighing, Connected Map and ActiveCare Direct advanced telematics. 416.770.7706 or 705.566.8190 sales@bmcdowell.com WELDCO BEALES BUCKETS, 48”, 1.32 C/Y to fit Link-Belt/Case 210 excavator, ACK10-0473. 54”, 3 C/Y to fit LinkBelt/Case 350 excavator, ACK10-0474 CRAIG MFG 12’ HYDRAULIC ANGLE SNOW BLADE, 2 way hyd., trip edge, Fusion coupler, fits CAT 924-926, stk# ACK11-0052 AMI ATTACHMENTS 80X3 48” HYD. TILT BUCKET, fits LBX 80, Case CX80, 12.150CFT capacity, 850 lbs weight, stk# ACK10-0448 2020 BDI BD500-4 & BD750-4, 5000/ 7500’lb hyd hammer fits LinkBelt 210/350, #ACK17-0028/26 SANDVICK RAMMER S26, 416/426 B&C, 1000’lb, fit any backhoe, #ACK17-003 AMI HYDRAULIC THUMB BOBCAT CONCRETE MIXER CAT 330 A/B/C HYD THUMB CAT R1600G TRANSMISSIONS 2021 CAT 950H, 962H FUSION QUICK COUPLER, CAT Part #310-939, stk# ACK23-0102 CAT FUSION FORKS, fits CAT wheel loaders 924, 930, 938, stk# ACK120089 CAT D6N MULTI-SHANK RIPPER, NEW, UNUSED, stk# ACK26-0002 CAT THUMB, fits CAT 316F excavator, Four tines, stk# ACK28-0057 & CAT D6T WINCH, Allied W6G, 60,0000 lb, stk #ACK15-0007 ASPHALT CUTTER TO FIT CAT 330 EXCAVATOR 101” ST8B STANDARD BUCKET, stk# AD10-1083 NEW ATLAS COPCO T40 & T45 TRACK FRAME UNDERCARRIAGES, part #’s 3196368500/3226370400/3222345559 16’ HLA 5500 SNOW PUSHER BLADE, drive-in style, stk# ACK11-0023 CAT 950M BUCKET, 4.5 cu.yd., 114”, CAT coupler, stk #ACK10-0325 BRAND NEW CATERPILLAR UNDERCARRIAGES IN STOCK LOADS OF NEW & USED ATTACHMENTS FOR SALE bmcdowell.com Hammers Compact Equipment Wheel Loaders Air Comp,ressors Trailers/Floats Compaction Carriers GREAT CAREER OPPORTUNITY! Full-Time Sales Rep/Business Development Manager for Barrie Email resume to kevin_m@bmcdowell.com Volvo CE modifies its L180H for three-pass rehandling CANADA’S NATIONAL HEAVY EQUIPMENT NEWSPAPER SINCE 1966 CONNECT WITH US! Visit us at: www.equipmentjournal.com

By Rod Stromberg, General Manager, Climate, and Justin Warton, Director of Operations, Canada West - Cooper Equipment Rentals

By Rod Stromberg, General Manager, Climate, and Justin Warton, Director of Operations, Canada West - Cooper Equipment Rentals

Propane isn’t new, but its use in construction is on the rise.

As the industry transitions to cleaner, lower-cost fuel sources, propane is proving

itself as a great alternative.

It has the benefits of gas and diesel and then some. Propane can heat your jobsite, fuel your equipment and power your generators –all while lowering emissions and saving money.

one in only a few minutes by someone who's been trained to handle propane.

These operational benefits make it a great energy source for a wide variety of construction projects – from small or temporary jobsites without electricity or limited gas fuel sources to sites that have indoor operational needs. And when it comes to powering equipment, we're seeing more rental customers look to propane to help operators reduce downtime, lower maintenance costs and improve safety, while matching the performance of other fuels.

You may already be using propane on your site. Maybe you’re a bit unsure of how to integrate more of it into your fuel mix.

Since propane is a heavily regulated industry and each province has its own set of rules, safety codes and permits, finding a reputable fuel provider is a great first step to setting you up on the path to success.

A range of applications

In general, emissions regulations are getting stricter, particularly indoors and in residential areas. Propane is naturally odourless and non-toxic, and its product combustion is much lower than diesel or gas-powered engines, it’s safer for both workers and the environment.

Propane-powered scissor lifts, forklifts and telescoping booms are as reliable as diesel and gas powered equipment, but come with the added benefit of lower fuel costs. The fuel savings goes far beyond the day-to-day fuel costs as propane-powered equipment is also typically less expensive to rent and has lower maintenance costs over its lifetime.

Propane can be more efficient, too. According to the Canadian Propane Association, one tank of propane can typically power a forklift for an eight-hour shift.

When it’s time to refuel, the empty propane cylinder can be exchanged for a full

We are also seeing big investment into propane powered generators to heat trailers, power ground thaw equipment and to heat jobsites.

Propane generators are quieter, cleaner and more cost-effective than diesel generators.

With propane, fuel savings can be substantial depending on how long your generator is in operation. Propane is also much easier and less expensive to compress, ship and store, and most reliable propane providers can schedule delivery according to your needs, which is particularly handy for projects located outside of major energy infrastructure. Many of our customers are starting to realize it is a logical economic choice for their power needs.

At Cooper, we rent a fleet of propane generators throughout Alberta and into British Columbia and we also provide fuel delivery services at select locations across the country. We’re seeing more customers asking for full-service solutions like these from their rental partner. Accessing both equipment and fuel from the same provider just makes sense.

This not only saves time and costs, but brings peace of mind knowing your propane solutions are coming from a partner you trust.

Safe storage

The construction industry is better at recognizing and reinforcing the practices and procedures needed to keep everyone safe, but there is always room for improvement. Don’t forget to extend your safety practices to the fuels you’re storing and using on site.

Regardless of the fuel source, ensure workers are trained and know when to engage their propane provider so they can safely handle the equipment. Propane is gas under pressure, so training and safe handling are crucial. Is everyone on your site familiar with propane safety procedures and how to identify a propane leak?

A14 MAY 6, 2024 EQUIPMENTJOURNAL.COM

TRI-CITYEQUIPMENT.COM WE BUY EQUIPMENT! HITACHI ZX490 - Q/C, choice of bucket. CAT 349 also available. FOR RENT ARTICULATED ROCK TRUCKS 25,30,40,45 TON AVAILABLE. FOR RENT KUBOTA 5T, zero tail, blade, thumb, multiple attachments available. 3T and 8T also available. FOR RENT 2019 HITACHI ZX135 - Aux, hyd., Q/C, choice of buckets, 4,100 hrs. $127,000 2022 HITACHI ZX245 - Excellent shape, hyd q/c, aux hyd, choice of bucket, 2270hrs $239,000 2014 CAT 336E - Q/C, aux hyd, choice of bucket. Work ready, 13,600hrs. $104,000 BUCKETS - BRAND NEW BUCKETS. - 13-50T. Rippers, Thumbs also available. FOR SALE 2007 VOLVO A30D, Tailgate, heated box, freshly serviced, ready to work. $109,000 CAT 980M, C/W auto greaser, spade nose rock bucket, scale. FOR RENT CAT D3 - next gen, grade control, LGP or XL. All other sizes available FOR RENT VOLVO A35D WATER TRUCK, 7000 Gallon tank with water cannon – available for seasonal rental – only one left! FOR RENT 2011 VOLVO A30F - Wide tires, tailgate, box heater, approx. 13,900hrs. $159,000 Tri-City Equipment is a 100% privately owned Canadian corporation YOUR HEAVY EQUIPMENT RENTAL HEADQUARTERS! 519-767-9628 1-800-646-2064 CALL OR TEXT RYAN ARMISHAW (519) 240-4672 DAVE ZAPPITELLI (226) 962-6106 Full Service Rebuild Shop, Aftermarket Parts & Repairs Available Looking for a cleaner energy source? Propane is a solid option More contractors are considering propane to power equipment on the jobsite Continued on Page A15

Continued from Page A14

Do they know to keep propane containers away from ignition sources, combustible materials, air intakes and building structures? They should. Propane suppliers have dedicated procedures in place to support customers and can ensure crews are trained to work with this energy source.

Every propane supplier is governed by the Canadian gas code. Liquid propane is tied into a vapourizer and must be handled by a qualified gasfitter. Your propane provider should know all these requirements and be up to date on any changes in industry regulations.

I’d like to say we’ve never encountered an unqualified customer who tried to hook propane up themselves, only to realize they’ve done it backwards … but I can’t.

One of our biggest challenges with propane is around training and ensuring the people who are carrying, maintaining and installing the fuel are properly trained and qualified.

Some companies are starting to supply gasfitters, provide safety training for workers and can apply for the necessary permits on your behalf. In Ontario, anyone handling propane must

have propane and/or natural gas awareness training and a current record of training certificate. The Canadian Propane Association also provides industry training through its Propane Training Institute (PTI). PTI courses are recognized across Canada and have been designed to provide instruction on the safe handling of propane and propane-powered equipment.

There are a lot of factors at play when it comes to choosing the right fuel source: the size of your project, its location, the materials you’ll be using, the number of workers on site and how long the project will take.

Propane can fit any project and it’s a proven and reliable option for construction equipment, heating and generators. If you’re still not sure if propane is the right solution, you don’t have to make these decisions on your own.

When you work with a rental provider who can not only provide you with the equipment and fuel you need, but help you understand the budget and scope of your job site – you’ll be on your way to a much more efficient and cost-effective operation.

A15 MAY 6, 2024 EQUIPMENTJOURNAL.COM ELATION-TECH IS YOUR NATIONWIDE AUTHORIZED DISTRIBUTOR FOR 2D,3D MACHINE CONTROL & SURVEY EQUIPMENT 514-970-0114 INFO@ELATIONTECH.CA THE NEW IDIG CONNECT 3D has all the advantages of TOUCH 2D. No certification required. Create small projects with just your GNSS antenna installed on your excavator. It is removable, allows you to survey points with a rod and renders in full 3D. SPECIAL! GET AN EXTRA 30% OFF (UNTIL JUNE 30TH) on your machine coupler and 2 buckets when you purchase a complete tiltrotator setup. Contact Elation-Tech for details. 3D MACHINE CONTROL FOR DOZER GRADING. The 3D solution makes landscape grading independent and accurate with guidance from our GNSS system and high-accuracy sensors, giving you high-quality grading! LEVEL BEST leads the industry in precision grading automation within 0.1” of spec to save on material costs. .ca KBX-R HYDRAULIC FORESTRY MULCHING HEAD SHAW HIGH-PERFORMANCE FORESTRY MOWER FOR SKID STEER LOADERS WITH FIXED HAMMERS FOR COMPACT LOADERS Visit us at NHES April 11-12 Booth #1006 877-625-9677 •Augers •Breakers •Brush Cutters •Buckets •Compactors •Demolition •Forest Mulcher •Grapples •Quick Couplers •Rippers •Rubber Tracks •Screening Buckets •Thumbs •Tree Shears WE ALSO CARRY: BEST QUALITY ATTACHMENTS AT THE LOWEST POSSIBLE PRICE shawbros.ca info@shawbros.ca

“ EVERYONE CALLS SKID-STEERS BOBCATS BECAUSE THAT IS THE REPUTATION THEY HAVE BUILT BECAUSE THEY ARE MADE WELL .”

Taylor Kirkwood and Cody Clancy share over 25 years of combined industry experience as they started working with their company part-time in 2023. By 2024, they incorporated RockSolid Excavation Inc. and are operating full-time, specializing in the design and installation of septic systems, excavation, sewer and watermains, lot clearing/grading, armour stone, retaining walls, driveways, etc. within a two-hour radius from the Peterborough area. They are a testament to how hard work, planning, budgeting, and investing in themselves with intense branding/marketing, all within the first year, can make their business grow faster. With their branding, everyone knows who they are. “The main reason we wrapped our equipment with our logos and branded ourselves the way we did was because we wanted our branding and image to reflect the way we do business. We do quality work, and we are transparent with our clients from start to finish. We show up and look professional and leave our clients with professional work done,” stated Cody.

When asked why they chose Bobcat®, Taylor replied, “Everyone calls skid-steers Bobcats because that is the reputation they have built

YOUR LOCAL AUTHORIZED BOBCAT DEALERS

BARRIE

Bobcat of Barrie 705-726-2228

oakenequipment.ca

GREY BRUCE

Bobcat of Grey Bruce 519-372-9100

bobcatoftc.com

PARRY SOUND

Bobcat of Parry Sound Ltd. 705-342-1717

bobcatofparrysound.com

TORONTO WEST

Bobcat of Toronto 416-679-4172

oakenequipment.ca

BRANTFORD

Bobcat of Brantford 519-752-7900

bobcatofbrantford.com

HAMILTON

Bobcat of Hamilton 905-643-3177

bobcatofhamilton.com

PETERBOROUGH

Bobcat of Peterborough 705-748-9119

bobcatofpeterborough.com

THUNDER BAY

Equipment World Inc.

807-623-9561

bobcat-tbay.com

because they are made well.” Still, they did their due diligence and shopped around to see what else was out there in comparison. “Others brushed us off because we were not a big company or just gave us numbers and didn’t follow up. Kyle Chessman, sales specialist for Bobcat of Peterborough, took the time to go over everything and followed up with us, yet wasn’t a pushy salesperson either. Kyle helped us pick the Bobcat T66 compact track loader as it’s big enough and powerful enough for what we need yet can still squeeze into tighter spaces we need to. It actually lifts more than it says it does. It can lift 3600 lb rocks. Also, it’s one size before being in the DEF category too.”

Cody has always run Bobcat machines. “I love how reactive they are, the sensitivity of the controls makes things happen right then and there whereas in other machines there is a delay. The Bluetooth system works fantastic. We get calls all day long and this allows us to keep working without having to gear down the machine to take the calls. I like the backup cameras for extra safety and heated seats. The R-series is worth paying for and the warranty is really good. Kyle also showed us how a Power

CASSELMAN

Bobcat of Ottawa Valley 613-764-2033

bobcatov.com

KITCHENER

Bobcat of Tri-Cities Ltd. 1-866-214-3939

bobcatoftc.com

STRATFORD

Bobcat of Stratford 519-393-6040

bobcatofstratford.ca

SAULT STE. MARIE

Bobcat of Sault Ste. Marie 705-949-7379

bobcat-ssm.com

CORNWALL

Bobcat of Ottawa Valley 613-932-2034

bobcatov.com

LONDON

Bobcat of London 519-455-4900

bobcatoflondon.ca

STRATTON Stratton Equipment 807-483-5505

strattonequipment.com

WINDSOR

Bobcat of Windsor 519-737-0120

oakenequipment.ca

Lease would be more beneficial for us and keep our expenses as low as possible which is important too.” They use the Bobcat T66 compact track loader for material handling (whipping around the site), grading, backfilling, and loading trucks.

“We had also got a set of Bobcat forks. Bobcat of Peterborough gave us a great package deal. Kyle Chessman was no pressure right from the start and has stood behind his service. Too many broken promises with others. Kyle has the same values as we do so we wouldn’t hesitate to recommend him and Bobcat of Peterborough to buy your next machine. In fact, marketing has been such a huge success for our business bringing in a lot of great customers we are expanding and will be looking to purchase a 5-ton excavator from Kyle Chessman soon!”

Thank you, Taylor and Cody.

COURTICE

Bobcat of Durham East Ltd.

905-404-9990

bobcatofdurhameast.com

MUSKOKA

Bobcat of Muskoka 249-390-7000

oakenequipment.ca

SUDBURY

McDowell B Equipment Ltd.

705-566-8190

bmcdowell.com

WYOMING

Advantage Farm Equipment Ltd.

519-845-3346

advantage-equip.com

FRANKFORD

John’s Equipment 613-398-6522

johnsequipmentsales.com

OTTAWA

Bobcat of Ottawa Valley 613-831-5166

bobcatov.com

TORONTO EAST

Bobcat of Toronto 416-679-4171

oakenequipment.ca

A16 MAY 6, 2024 EQUIPMENTJOURNAL.COM

(L to R) Cody Clancy, co-owner of RockSolid Excavation Inc., Kyle Chessman, sales specliast for Bobcat of Peterborough and Taylor Kirkwood, co-owner of Rock Solid Excavation pose for a picture just outside a current jobsite where they are filling in a customer’s pool, installing new fence, redoing a new driveway and front walkway in Peterborough.

Hitachi begins taking orders for the ZW310-7 wheel loader

Hitachi Construction Machinery Americas has announced the ZW310-7 wheel loader is now available to order from select dealers.

The 24.5 tonne loader is part of the new ZW-7 series, which Hitachi first announced at ConExpo 2023. The machine is powered by a 312 hp engine and features a bucket capacity of 4.2 to 4.7 cubic metres.

The ZW310-7 includes features designed to boost operator comfort translating to boosted operator productivity. The machine will be offered as a base model and a premium model.

“Operator comfort was a key design priority with our new wheel loaders series.

A lot of work went into the cab to make it more comfortable to operate. The new pressurized, quieter cab has easier-to-reach seat-mounted controls, reducing operator fatigue,” said Matt Koester, Wheel Loader Product Manager at Hitachi Construction Machinery Americas. Both the base model and the premium model include a standard fully adjustable, heated air ride seat with a seat-mounted armrest and ergonomic electric over hydraulic controls. The armrest and controls adjust forward or reverse to comfortably accommodate operators of varying sizes. Both models have Approach Speed Control,

which gives the operator control of the top speed selected during loading. A payload checker allows the operator to weigh and log material moved, while a power up feature anticipates power requirements.

The premium model will include the Aerial Angle peripheral vision camera system providing a wide 270-degree bird’s-eye view of the machine’s immediate environment.

The new wheel loader’s updated features also include improved traction with a limited-slip differential, a four-speed powershift transmission and lockup torque converter.

An intelligent automatic reversing hydraulically driven fan and wide-fin radiators are included as standard to prevent clogging. Easy-access filters and improved access to components simplify daily maintenance.

The ZW310-7 will have ConSite Air to remotely monitor the operational status and alert owners and operators to upcoming maintenance needs, allowing for both remote diagnosis and software updates. The servicing dealer can quickly troubleshoot issues that may arise with the ConSite response team to rapidly resolve issues to keep projects on schedule.

Vanair’s new Underdeck delivers six forms of power in one system

Vanair’s new Underdeck All-in-One saves space above deck and delivers six forms of power in one centralized, compact, chassis-mounted system.

The new power system was revealed at Work Truck Week 2024 in Indianapolis, Indiana.

The PTO Shaft-Driven Underdeck All-in-One Power System has been designed to seamlessly integrate beneath the vehicle chassis, opening cargo space while enhancing overall efficiency.

"Our Underdeck Allin-One Power System streamlines six independent machines into a single unit with one footprint," said Ralph Kokot, Chief Executive Officer of Vanair.

"With the new Underdeck All-in-One Power System, we deliver the same comprehensive power, including welding capabilities, without encroaching on any vehicle bed space."

The six forms of power include a 125 to 185 cam rotary screw air compressor; a 10-kW generator; a 330A welder; 12V to 48V battery boosting and charging capabilities; and up to 114 litres per minute at 2,000 psi of hydraulic-driven power.

The power system represents a weight savings of more than 1,800 kg. As well, the new design uses Vanair’s new Sansgear belt drive, for the hydraulic system, which is quieter and provides more torque than traditional gearbox designs.

With the PTO Shaft-Driven Underdeck Power System, jobsite personnel will be equipped with the tools

needed for welding, powering essential equipment and jump-starting other vehicles.

"Vanair continues to be at the forefront of innovation with our PTO Shaft-Driven Underdeck Power System," said John Dunn, Strategic Manager of Underdeck and Utility at Vanair. "This system not only offers unmatched power and functionality but also ensures minimal downtime, which is crucial for professionals who rely on dependable equipment to get the job done."

The power system also features the XERO rapid blow down tank design, which allows for immediate compressor disengagement and reengagement with zero blow-down time. This unique tank design eliminates the need to wait for the system to blow down completely, preventing oil carryover issues and significantly increasing operational efficiency. Moreover, the XERO Tank permits up to a 15 per cent angle of operation from sideto-side or front-to-back.

For reliability and security, Vanair equips all its PTO Shaft-Driven Underdeck Power Systems with the Fail Safe dual sensory redundancy system as a standard feature. This system guarantees an uninterrupted power supply by seamlessly switching to the backup unit in the event of a thermistor or transducer sensor failure. Furthermore, the optional ThermalGuard weather protection kit preheats the compressor oil and regulators using the vehicle's warm engine coolant. This feature prevents oil starvation and freeze-ups during frigid conditions, further enhancing the overall system's performance and reliability.

"We take great pride in offering unmatched cost savings and performance with our UltraLife Air/Oil Separator Element," Dunn said. "This innovative element sets new industry standards with its extended lifespan of 6,000 hours, delivering up to six times more separator life compared to other units on the market."

A17 MAY 6, 2024 EQUIPMENTJOURNAL.COM

OEM parts and components for all your off-highway equipment Authorized to perform warranty work Factory trained technicians (705) 560-BULL (2855) 1510 Fairburn St. Sudbury, ON P3A 1N7 bullpowertrain.com COME JOIN OUR TEAM! WE ARE CURRENTLY SEEKING EXPERIENCED COMPONENT REBUILDERS. WE ARE YOUR AUTHORIZED SERVICE CENTRE FOR AUTHORIZED DISTRIBUTOR CONSTRUCTION EQUIPMENT RENTAL DOZERS - LOADERS - BACKHOES - ROLLERS CUSTOMER SER VICE TARTEN EQUIPMENT LIMITED 6199 Shawson Drive Mississauga, ON L5T 1E5 Phone: 905 670 1704 Fax: 905 670 4790 Toll Free: 1 888 670 1704WWW.TARTEN.COM COMMITTED TO SERVICE EXCELLENCE SINCE 1976

The United Bldg isn’t a typical condo development for downtown Toronto.

Rather than starting from below ground up, the 55story condo development is preserving the 10-storey heritage facade that pays tribute to this building’s past as the former home of the Maclean Publishing Company. Eventually becoming Maclean-Hunter, the publishing company became Canada’s largest publisher of trade journals and national publications. Its titles include Maclean’s Magazine, Chatelaine and the Financial Post

By preserving elements

from the 1928 building and the 1961 expansion, the Davpart development has earned a place in the historical conservation sector, making The United Bldg North America’s largest heritage retrofit.

Usually, a heritage building would be dismantled and removed from the site allowing demolition to continue. However, for the United Bldg, Toronto Heritage Preservation insisted the façade stayed in place while excavation is completed.

Recently, Avenue Building Corporation deployed two Raimondi LR273 luffing jib

cranes for the construction of The United Bldg.

“Avenue Building Corporation is adding another significant project milestone to our site portfolio by renting these two Raimondi LR273 luffing jib cranes to EllisDon, contractor of the project and international leader in construction services,” said Jim Patullo, President of Avenue Building Corporation.

Installed between December 2023 and January 2024, the two 18 tonne-luffers are currently onsite at a height of 60 metres and 54 metres with jib lengths of 45 metres and 50 metres respectively,

and a tip load of 4.5 tonnes.

Equipped with an 86 kW hoisting gear, the LR273s lift at a maximum speed of 204 metres per minute and have a drum capacity of 980 metres.

“With the project preserving the 10-storey existing facade, along with its structural steel retention systems, 75 per cent of the jobsite space was already occupied. We carefully evaluated both of the crane positionings to ensure maximum site safety and efficiency,” Patullo said. He added the small out-ofservice radius of 16 metres and 17 metres, and the ease of installation of the LR273 due to the model’s weight optimization, were key features considered during the site planning phase.

The wide swing angles of the LR273 allow for greater site coverage, coupled with the superior machine performances in terms of lifting capacity, also played a significant role in the deployment of this specific luffing model.

“Witnessing the participation of our models on such a prestigious jobsite highlights the reliability and high performance of our luffing range, reaffirming Raimondi’s commitment to delivering excellence in every product we manufacture,” said Luigi Maggioni, Raimondi Group CEO.

“Raimondi technology not only enhances productivity, but it also ensures precision in even the most challenging environments.”

Scheduled to be onsite for several years with varying timelines, the cranes will be internally climbed to reach final heights of 65 metres and 195 metres.

“The versatility of the Raimondi LR273 makes it one of the bestselling cranes for jobsites of this nature in the region,” Patullo said.

Located along University Avenue, the high-rise mixed-use development will include modern residential units and commercial spaces.

When complete, The United Bldg will include 224,245 square feet of commercial office space, 39,320 square feet of retail space and 759 residences starting on the 10th floor.

A18 MAY 6, 2024 EQUIPMENTJOURNAL.COM

FOR SALE Call Don for more info: (416) 460-5576 GRADALLS FOR SALE 2001 XL4100 SERIES I - 2,536 Hrs, 59 Cummins, 30,951 miles, 330 HP Cummins. 1996 XL4100 SERIES I - Railroad gear, 4,358 Hrs, 5.9 Cummins (rear) 27,380 miles, 8.3 Cummins (front). 2008 XL4100 SERIES III - 7,000 Hrs, Mercedes motor, new tires & brakes, paint, safety. 2008 XL3300 SERIES III - 3,249 Hrs, Mercedes motor, railroad gear. 1999 XL4100 SERIES I - 3,978 Hrs, 5.9 Cummins (rear), 6,157 miles, 8.3 Cummins (front). SERIOUS OFFERS ONLY PLEASE CALL - DON’T TEXT Call Don: (416) 460−5576 WE ALSO DO GRADALL REPAIRS All machines come with safety and ownership, and can be plated as requested by law. PARTS AVAILABLE FOR ALL GRADALLS XL5200 SERIES IXL4100 SERIES IXL4100 SERIES III IN STOCK (YOU DON’T HAVE TO WAIT 6 WEEKS) Mississauga: 1.800.668.5458 Winnipeg: 204.832.3040 sales@flocomponents.com VEHICLE FIRE SUPPRESSION SYSTEMS For Fire Suppression Solutions, GO WITH THE FLO! Protect your equipment Protect your operator Protect your resources & facilities Keep your operations running Keep insurance costs down Avoid bad press Avoid fines INSTALLED BY FLO COMPONENTS √ √ √ √ √ √ √ Raimondi luffing cranes help create landmark development in TO

Maximum Efficiency

Most Reliable

Unmatched Support

A19 MAY 6, 2024 EQUIPMENTJOURNAL.COM

Crushers deliver optimal draw and flow rates, and screening plants free up crushers’ capacity.

With high fuel efficiency, crushers have extended engine life and reduced wear and repair costs.

by Brandt, with the best-trained, most committed 24/7/365 after-sales support in the business. Kleemann makes the most reliable machines out there—period. And your local Brandt dealership has them in stock right now. IN STOCK, READY TO ROCK. brandt.ca/mineral-technology 1-888-227-2638

Backed

Just because space is limited, doesn’t mean your PERFORMANCE has to be.

The JCB mini excavator makes navigating confined areas so easy and efficient, you’ll forget what it felt like to be limited on space. Experience the kind of maneuverability only JCB can deliver. Experience better. Learn more at JCB.com

YOUR FAMILY OF LOCAL JCB DEALERS

ALBERTA

Liftboss JCB

Calgary: 403-301-0041

Edmonton: 780-474-9900 liftboss.ca

BRITISH COLUMBIA

Williams JCB

Surrey: 604-930-3316 williamsjcb.com

NEW BRUNSWICK

A.L.P.A. Equipment

Edmundston : 506-735-4144

Balmoral : 506-826-2717

Fredericton : 506-452-9818

Moncton, N.B. : 506-861-2572 alpaequipment.com

NOVA SCOTIA

A.L.P.A. Equipment

Truro : (902) 897-2717 alpaequipment.com

NEWFOUNDLAND

Harvey JCB

Corner Brook: 709-639-2960

St. Johns: 709-738-8911 harveyco.ca

ONTARIO

Advance JCB

Waterloo: 519-742-5878

Harriston: 519-510-5878 advanceequipment.net

D&W Group Inc.

Doughty & Williamson

Jarvis: 519-587-2273

Brant Tractor

Burford: 519-449-2500

Redtrac International

Vineland: 905-562-4136

dwgroup.ca

ONTARIO

Delta JCB

Dunvegan: 613-527-1501

Renfrew: 613-432-4133 Winchester: 613-774-2273 deltapower.ca

Fulline JCB

Glencoe: 519-287-2840 fullinefarm.com

Equipment Ontario Lindsay: 705-324-6136 Port Perry: 905-982-1500 equipmentontario.com

Jade Equipment

Simcoe County and Districts of Parry Sound & Muskoka 705-325-2777 jadeequipment.com

John’s Equipment Sales

Frankford: 613-398-6522 johnsequipmentsales.com

ONTARIO

Moore JCB

Toronto, York & Peel Region: 416-747-1212 moorejcb.com

North Rock JCB

North Bay, Sault Ste. Marie, and Sudbury: 705-897-7369 northrockrentals.com

ReadyQuip Sales & Service Ltd.

Timmins: 705-268-7600 readyquip.com

WPE Landscape Equipment - JCB

Hamilton/Halton: 905-628-3055 wpeequipment.ca

PEI

A.L.P.A. Equipment (506) 861-2572 alpaequipment.com

QUEBEC A.L.P.A. Equipment Bas-Saint-Laurent : (506) 735-4144

Gaspésie : (506) 826-2717 alpaequipment.com

Bossé Quebec Inc.

Desmaures: 418-878-2241 Saint-Augustin-debosse-frere.com

Moore JCB

Montreal: 514-333-1212 moorejcb.com

SASKATCHEWAN & MANITOBA

Westcon JCB

Regina: 306-359-7273

Saskatoon: 306-934-3646

Winnipeg: 204-694-5364 westconequip.ca

A20 MAY 6, 2024 EQUIPMENTJOURNAL.COM

B1 MAY 6, 2024 EQUIPMENTJOURNAL.COM HOT DEALS OF THE MONTH! toromontequip.com 2012 CAT 308ECRSB EXCAVATOR $57,800 7,734 HRS WINDSOR, ON 2012 NEW HOLLAND W80B LOADER $43,333 2,444 HRS LONDON, ON *US pricing subjected to actual exchange rates at time of sale. All units are subject to prior sale. TOROMONT EQUIP HUGE INVENTORY WEEKLY DEALS CAT CERTIFIED USED ALL IN ONE PLACE! › toromontequip.com › 1 833 953-7847 USED AND RESTORED PARTS Recent arrivals Transmissions (rebuilt & tested) Final Drives & Differentials • 330B Rebuilt Swing drive p/n 114 1441 $6,950 exchange • 938, 950, 962 GP buckets, new take off’s $6,200 and up • New CAT 420 pin on front bkt, c/w bolt on edge $950 ea • Numerous Fusion couplers, IT couplers all new take off’s $1,800 ea • 446D Side Dump new Cat unused 1.25 cu/yd $16,500 • 430E 30’’ rear bucket, new CAT $1,800 • Numerous Hydraulic cylinders rebuilt, Excavator and loader. • Numerous new Cat surplus cutting edges and bucket teeth. • Rebuilt 950G trans, 114 8945 $18,300 exchange • Rebuilt IT28G trans p/n 2013318 $13,500 exchange • Rebuilt 928G trans p/n 177 0017 $14,500 exchange • IT18F transmission (1082075) $10,500 exchange • 988B Transmission p/n 3P9094 $25,850 outright • 924 transmission rebuilt. p/n 1807503 $11,200 exchange • 980C rebuilt, p/n 6Y3197 h/d arrange. $22,700 exchange • New arrivals for tear down, 966H, 324D, 980G, 930H. • 740 Final Drive, reconditioned, p/n 3710565 $22,500 • 324D Rebuilt final drives, new bearings/seals $10,500 • 365B Rebuilt final drive, P/N 136 2956 (2) $18,500 ea • 345 Final drive 227 604 $24,000 • 319/320/321/323 p/n 3530611 $8,900 final drive open & insp CALL: 705 436-7770 or 1 800 771-9145 Andy EXT. 8747 Greg EXT. 8752 Joe EXT. 8748 16,103 HRS BATHURST, NB 2015 MAULDIN 1750-C PAVER $83,900 3,208 HRS POINTE-CLAIRE, QC 2008 KOBELCO SK350L EXCAVATOR $50,000 13,642 HRS WINNIPEG, MB 2015 CASE 590SN BACKHOE LOADER $57,800 9,705 HRS WINNIPEG, MB 2011 CAT 321DLCR EXCAVATOR $79,000 9,381 HRS CONCORD, ON 2015 CAT 420F2ST BACKHOE LOADER $79,000 7,749 HRS CHARLOTTETOWN, PE 2015 CAT D6K2LGP DOZER $165,600 8,516 HRS POINTE-CLAIRE, QC 2019 CASE 590SN BACKHOE LOADER $94,440 2,696 HRS WINNIPEG, MB 2013 CAT 420FIT BACKHOE LOADER $73,300 3,134 HRS ST. JOHN’S, NL 2013 CAT 420FIT BACKHOE LOADER $72,200 7,042 HRS SUDBURY, ON 2009 DEERE 410J BACKHOE LOADER $39,000 10,840 HRS WINNIPEG, MB 2010 DEERE 350DL EXCAVATOR $54,400 11,731 HRS QUEBEC CITY, QC 2003 CAT M322CMH WHEEL EXCAVATOR $58,900 42,621 HRS ORILLIA, ON 2001 CAT CB634C ROLLER $18,500 9,175 HRS OTTAWA, ON 1998 CAT D3CIII DOZER 4,299 HRS CAMBRIDGE, ON $43,900

DELIVERS PERFORMANCE IN HARSH AND RUGGED JOBSITES

Operating Weight: 39,500 lbs || Net HP: 120 hp || Max Dig Depth: 19’11” || Reach at Ground Level: 29’2”

• With new features on all models, such as custom flow balance, customizable joystick function buttons, new work modes and Trimble-Ready components, the new X4S delivers improved efficiency and up to 5 per cent improved cycle times.

• Yanmar - Tier 4, diesel engine. Superior fuel efficiencyup to 19% better fuel consumption over it’s predecessor.

• Cab is 9% bigger than previous generation, designed for shift-long comfort including new air ride seat, and front sun visor.

• Heavy duty arm option available and additional heavy duty counterweight.

• Equipped with RemoteCARE® (GPS fleet management system) with a new dualband modem with improved range and real-time capabilities -providing 24/7 remote monitoring with zero subcription charges or fees!

• 270° WAVES (Wide-Angle Visual Enhancement System) 3-Camera System, ideal for safety.

• Other extras are LED lights all around and 10” monitor.

Your LINK-BELT Excavators Dealer has all the details!

ALBERTA

Equipment Sales & Service Ltd.

Edmonton (780) 440-4010 essltd.com

BRITISH COLUMBIA

The Inland Group

Burnaby, BC 604-291-6431

Campbell River, BC 250-287-8878

Castlegar, BC 250-365-2807

Cranbrook, BC 250-426-6205

Fort St. John, BC 250-785-6105

Kamloops, BC 250-374-4406

Kelowna, BC 250-769-2933

Langley, BC 604-607-8555

Nanaimo, BC 250-758-5288

Penticton, BC 250-492-3939

Prince George, BC 250-562-8171

Quesnel, BC 250-992-7256

Terrace, BC 250-635-5122

Vernon, BC 250-545-4424

Williams Lake, BC 250-392-7101 inland-group.com

NEW BRUNSWICK

Paul Equipment

Balmoral (506) 826-3289 paulequipment.ca

ONTARIO

Itec 2000

Rosslyn (888) 574-8530

Thunder Bay (888) 574-8530

Timmins (705) 267-0223 itec2000.com

McDowell B Equipment Ltd.

Sudbury (705) 566-8190

Barrie (416) 770-7706 bmcdowell.com

Stratton Equipment Sales & Service

Stratton (807) 483-7777 strattonequipment.com

Top Lift Enterprises Inc.

Stoney Creek (905) 662-4137

Bolton (905) 857-5200 toplift.com

QUEBEC

Équipement JYL Inc.

Chicoutimi (418) 698-6656 equipementjyl.com

Micanic

St-Aug-D-Desm (418) 878-2241 micanic.com

Paul Equipment (506) 826-3289 paulequipment.ca

Top Lift Enterprises Inc.

St-Laurent (514) 335-2953

Sherbrooke (819) 612-5438 toplift.com

YUKON TERRITORY

The Inland Group

Whitehorse, YT 867-668-2127 inland-group.com

B2 MAY 6, 2024 EQUIPMENTJOURNAL.COM

5-YEAR/ 5,000 HOUR Full Machine Warranty 5-YEAR/ 10,000

Machine Structures Warranty

HOUR

170

www.lbxco.com/X4S

ATTACHMENTS

The most innovative product launch in its history

Steelwrist has introduced its third generation tiltrotators, new rotor couplers and a wide range of new work tools.

The company introduced its latest product developments during a media event at Steelwrist in Deutschland. As part of the event, Steelwrist also inaugurated its new facility in Germany.

The centerpiece of the new product launch includes the first model of the third generation Steelwrist tiltrotators, the XTR20, which demonstrates several innovative hardware and software features.

The XTR20 is complemented with the first generation XR rotor couplers as well as with the second-generation XT tilt couplers.

“The XTR20 represents a leap forward in performance and reliability and with features like LockSense, OptiLube, more tilt and rotation torque and easy upgradeability, we show our continued commitment to improving excavator efficiency,” said Stefan Stockhaus, Steelwrist CEO. “I am extremely proud of what our team has accomplished and I look forward to seeing the new Steelwrist XTR20 tiltrotator improving job sites around the world.”