FEATURED EQUIPMENT

EARTHMOVING & EXCAVATION

FEATURED EQUIPMENT

DEMOLITION & WASTE

FEATURED EQUIPMENT

EARTHMOVING & EXCAVATION

FEATURED EQUIPMENT

DEMOLITION & WASTE

In my hometown of Mississauga, tent encampments — which were once unimaginable — have become a reality.

Growing up in the city in the 80s, tents were generally only seen being packed into car trunks for camping trips. The idea that a tent is now housing in suburbia is as sad as it is unfathomable.

And this new issue isn’t contained to Mississauga. It’s widespread throughout North America. Regardless of where you may fall on the political spectrum, I think we can agree this is not a problem that should exist in Canada.

When I drive by the encampment closest to my house, at the right angle, I can see the solution to the housing crisis. Dozens of tower cranes, near and far, serve as a backdrop to the hopefully temporary shelters.

Fortunately, Toronto continues to lead the North American crane index, which is released twice a year by construction consultant Rider Levett Bucknall (RLB).

However, data indicates the GTA is facing a slowdown in construction activity.

The crane count in Toronto decreased by 19 cranes from the third quarter of 2023 to a current total of 221 cranes. (Los Angeles placed in a distant second place with 50 tower cranes.)

“It is worth noting that the first quarter of 2024 has set a record by marking the lowest number of cranes in Toronto since 2022, signalling a slowdown in overall construction activity,” the RLB report explained.

Toronto is seeing construction reach completion on multiple commercial building projects. The commercial sector saw the most signifi-

cant drop, with a reduction of 10 cranes, while the hospitality sector recorded a five-crane decease.

Fortunately, the residential sector continues to grow, with residential and mixeduse projects continuing to dominate the crane count, accounting for more than 80 per cent of cranes in the city.

Looking west, Calgary was one of only three to record an increase in cranes.

This quarter, one new crane was erected in Calgary for a total count of 20. Most of the cranes are being used on residential projects.

Calgary’s housing starts hit record highs in 2023, with the municipality receiving 21,317 applications for building permits, contributing $5.96 billion in residential and non-residential construction value to Calgary’s economy.

Construction is clearly the answer, and it’s booming in Canada. Unfortunately, the housing issue is reaching toxic levels of politicism. All three levels of government are too busy pointing fingers rather than working together. Canada is a first world nation, and I’ll still argue the greatest nation. If we want to hold that designation, we need to make sure more Canadian cities rank on the crane index.

C G Equipment

Guelph | 519-826-0550

Zurich | 519-236-4934

Eastrock Equipment Inc.

Ottawa | 613-737-3963

Elvaan Equipment Solutions

Mississauga | 647-988-9931

Orillia | 705-325-2777

G F Preston Sales & Service

Sundridge | 705-384-5368

Hartington Equipment Hartington | 613-372-2744

ITEC 2000 Equipment

Rosslyn | 807-768-8584

ReadyQuip Sales & Service Ltd.

Timmins | 705-268-7600

New Brunswick

Paul Equipment and Sons

Balmoral | 506-826-3289

Fredericton | 506-449-3289

Yellowknife | 867-766-6025

Nova Scotia

East Coast International Trucks Inc.

Dartmouth | 902-478-3552

Quebec

Équipements Plannord Beloeil | 450-464-8000

St-Augustin-de-Desmaures | 418-878-4007

Machinerie St. Pierre Val-d’Or | 819-824-6931

Saskatchewan

Bobcat of Regina, Ltd.

Regina | 306-347-7600

Earthworks Equipment Corporation

Saskatoon | 306-931-7880

Yukon

MacPherson Rentals

Whitehorse | 867-633-4426

ment.

The strategic move aims to provide Strongco customers with enhanced options to manage their cash flow effectively, while ensuring minimal delays and downtime to complete their projects on time and within budget.

"Our commitment at Strongco has always been to support our customers in achieving their project goals efficiently and cost-effectively," said Stephen George, Vice President, Rental Equipment at Strongco.

"With the introduction of our dedicated rental fleet featuring the latest Volvo equipment, we are furthering that commitment by offering more options to manage cash flow and minimize project delays."

The new rental fleet includes a comprehensive inventory of Volvo heavy equipment, including medium to large size crawler excavators (EC140E to EC500FL5 models), articulated haulers (A30G and A40G), and the SD115 soil compaction roller. The range

of equipment ensures customers have access to rent a variety of tools to meet their specific needs, whether it's excavation, material transport or compaction.

"We understand the importance of keeping projects on track and within budget," said Oliver Nachevski, President and Chief Executive Officer at Strongco.

"That's why we've curated our rental fleet to feature the latest Volvo equipment, ensuring that our customers have access to dependable machinery that can withstand the rigours of the job site."

One of the key advantages of Strongco's rental fleet is its availability, ensuring that customers can access the equipment they need when they need it most. Rental eliminates the need for large capital investments in purchasing equipment outright, allowing businesses to allocate their resources more strategically.

Strongco, a Nors company, is one of Volvo CE’s largest construction equipment dealers in North America. The company has about 500 employees based at 25 locations across Canada.

The vast majority of Ontario residents support building new roads, including plans for Highway 413, the Bradford Bypass and the Ring of Fire.

The Residential and Civil Construction Alliance of Ontario (RCCAO) and the Ontario Road Builders Association (ORBA) recently

commissioned a poll to gauge public support for critical road infrastructure in the province. The poll was created fol -

lowing the statement from the federal Minister of Environment and Climate Change, Steven Guilbeault, that government should

“stop investing in new road infrastructure.”

The results revealed that 66 per cent of respondents disagree with Guilbeault’s statement. The same number of respondents support Highway 413, the Bradford Bypass and believe the government should build or expand more roads and highways.

For the Ring of Fire, 80 per cent of respondents were in favour of its development.

“Ontarians have made it clear that they want all levels of government to invest in new and existing road infrastructure to alleviate congestion and open up more economic opportunities,” said Nadia Todorova, Executive Director of RCCAO. “It is time for the federal government to accept the will of the people and support transformational infrastructure. Projects like Highway 413 and the Bradford Bypass, and their supporting transit pairings, will better enable the movement of people and goods throughout one of North America’s fastest growing regions.”

Highway 413 and the Bradford Bypass are key components of the Great-

er Golden Horseshoe’s Transportation Plan. The plan includes record investments in both road and transit infrastructure to support the country’s most populous and growing region, including support for housing and other required critical infrastructure.

“Canadians depend on roads and highways to get to work, drive their children to hockey practice and ensure their loved ones receive adequate health care.

Today’s results show everyday people understand the critical need for these generational transportation infrastructure projects,” said Walid Abou-Hamde, CEO of ORBA.

“The road building industry also employs more than 56,000 men and women in Ontario, that is tens of thousands of good paying jobs supporting workers and their families across the province.”

The study was conducted from Feb 28 to March 1, among a sample of 1,959 respondents who are residents of Ontario and are members of Maru Blue’s online panel. The full findings of the research are available at rccao.com.

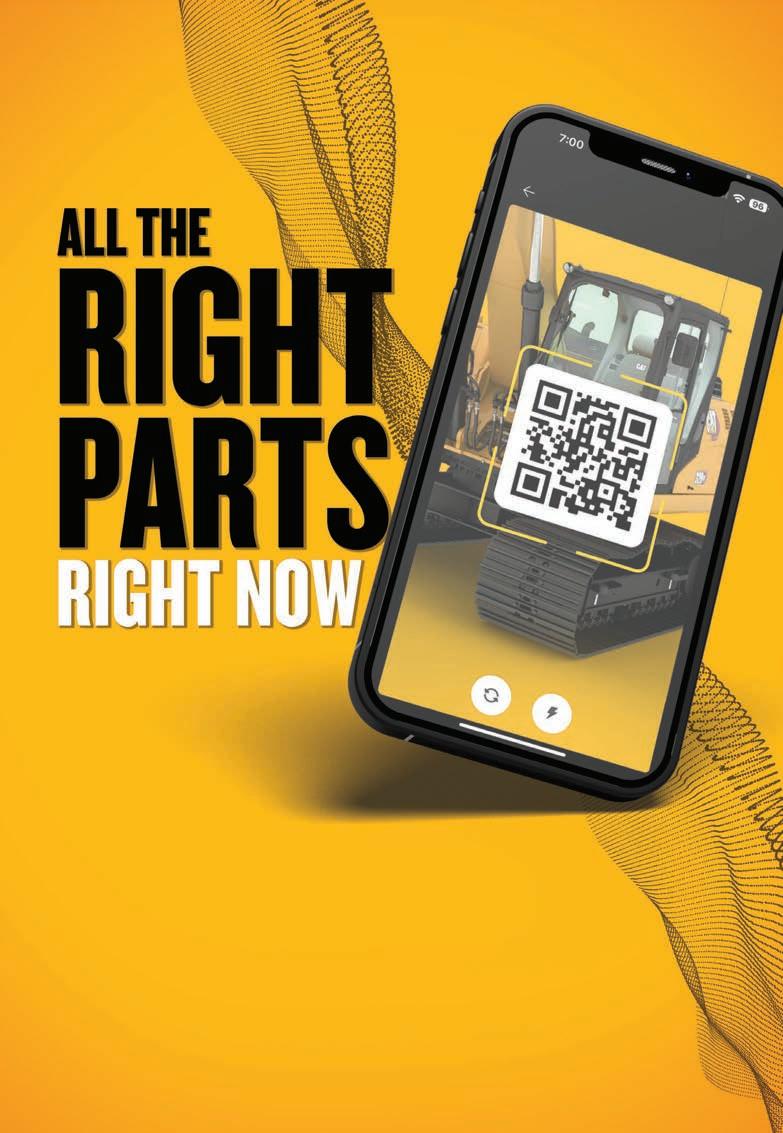

Order parts and get support when you need it — anytime, anywhere. The all-new Cat® Central app offers features that put a whole lot of power in your hands. Find local pricing and in-stock availability for parts, get support and maintenance info whenever you need it and scan the QR code on your asset to immediately access its information.

We’ve put it all in one place. That’s Cat Central.

Skyjack’s new micro scissor range represents a new option in the low-level access arena.

The new SJ3213 micro and SJ3219 micro were unveiled at The ARA Show in New Orleans in February.

The “mighty micro” line aims to combine reliability with low cost of ownership and product support.

“We're really excited about these new machines. We think they're going to be a

significant new presence in the low-level access arena,” said Corey Connolly, Senior Product Manager at Skyjack.

“They’re ideal for easy accessibility in tight spaces, as well as featuring enhanced duty cycle through the use of AC electric drive motors.”

The new lifts feature fully proportional E-Drive and lift controls for more efficiency, controllability and improved torque.

“Our focus is always on

improving productivity and cost of ownership, and E-Drive allows our newest micro scissors to give you more for less,” Connolly said.

The new micros have been designed to fit most passenger style elevators and work in environments where space is at a premium, while still providing a substantial work area.

The micro scissor lifts feature 4-metre or 5.8-metre platform heights as well as a 227-kg capacity. A 50-cm roll out extension increases the work area and provides up and over capability.

“This is an exciting launch for Skyjack,” said Skyjack President Charlie Patterson. “Our team understands the importance of maximum uptime and we pride ourselves on providing machine features that combine durability, quality and serviceability.”

ECO mark

Rental companies and contractors are facing increasing demands for sustainability information. As a solution, Skyjack has introduced its ECO mark to support customers by providing products that deliver benefits in environmental

performance and long-term sustainability.

“SkyJack's ECO mark supports our customers by providing products that deliver environmental benefits, performance and long-term sustainability,” Connolly said. “So, that's one of the things you'll notice on these machines, as well as providing some additional information that our customers are interested in.”

Skyjack’s E-Drive scissors deliver a 16 per cent operational carbon saving compared to the previous model, as well as up to a 20 per cent improvement in duty cycle over an equivalent hydraulic drive machine.

The micro lifts are approved for use with bio-degradable hydraulic oil and generate zero emissions. The machines are also 90 per cent recyclable by weight.

Skyjack’s ECOtray is also an option, which contains possible fluid leaks from the machines.

Designed for the North American market, the SJ3213 micro and the SJ3219 micro will replace the previous SJ3013 model in North America. The SJ3014 will remain available in Europe.

To strengthen the focus on its tools and attachments business, Epiroc is creating two separate divisions as well as appointing a new division president.

Epiroc’s tools and attachments division has expanded significantly in recent years and becomes significantly larger with the completion of the acquisition of Stanley Infrastructure.

To maintain focus on each business line, Epiroc will split tools and attachments into two new divisions: the Rock Drilling Tools division and the Mining & Infrastructure Attachments division.

“With past growth and now the ongoing acquisition of Stanley Infrastructure – our largest acquisition ever –our tools and attachments business is expanding significantly,” said Helena Hedblom, Epiroc’s President and CEO. “By dividing up the business into two dedicated divisions, we are optimizing the focus for all the business lines and supporting sustainable, profitable growth.”

Martin Hjerpe, currently Senior Vice President M&A, Strategy and Supply Chain, will become President of the Tools division. Goran Popovski, currently President of the Tools & Attachments division, will become President

of the Attachments division. The two divisions will cover the following areas:

Tools division

· Tophammer and Handheld

· DTH, Rotary and Raiseboring

· Ground Support

· Supply Chain

Attachments division

· Ground Engaging Tools (CR)

· Hydraulic Attachment

Tools

· Stanley Infrastructure

After Martin Hjerpe assumes his new role as division president, the position as Senior Vice President M&A, Strategy and Supply Chain will be dissolved. The

M&A and Strategy function will report to the Chief Financial Officer.

Supply Chain will become part of the Tools division.

Epiroc announced on December 15, 2023, it had agreed to acquire Stanley Infrastructure from Stanley Black & Decker, which includes the LaBounty, Paladin, Pengo and Dubuis brands. It designs, manufactures and sells attachments, typically used on excavators, and handheld hydraulic and battery-powered tools for applications in infrastructure, construction, scrap recycling, demolition and railroad infrastructure.

The acquisition is expected to be completed around the end of the first quarter 2024.

✔ Low financing rate

✔ Industry-leading fuel features

✔ Extended service intervals

✔ THE reliability Cat is known for Find the excavator you need for the job.

Bobcat Company’s product portfolio now includes forklifts, industrial air compressors, turf renovation equipment and portable power products following the

rebrand of several Doosan equipment lines.

Last year, Bobcat announced Doosan Industrial Vehicle, Doosan Portable Power, Doosan Industrial

Air and Ryan turf renovation products would change to the Bobcat brand as part of the organization’s global brand strategy.

All product lines have now

officially rebranded under Bobcat in North America with transitions on these product lines also happening globally in applicable markets.

“Through our unwavering

commitment to innovation and excellence, we have significantly broadened our product portfolio to not only meet the needs of our loyal customers but also to inspire and empower new customers to conquer their toughest job site challenges,” said Scott Park, CEO and vice chairman of Doosan Bobcat Inc. “With an expanded range of solutions, we're empowering even more customers to accomplish more.”

The products are now available at select Bobcat dealerships throughout North America.

Customers can now purchase the Bobcat branded products at select Bobcat dealerships throughout North America, including:

· Forklifts: Internal combustion cushion and pneumatic tire forklifts, electric counterbalance

forklifts, narrow aisle forklifts, pallet trucks, stacker forklifts and warehouse vehicles.

· Industrial air: Industrial air compressors ranging from 30- to 200-hp, with both fixed and variable speed offerings.

· Turf renovation: Aerators, sod cutters, dethatchers, overseeders, and other specialty products that serve landscaping and grounds care professionals across a variety of industries including golf, sports turf, landscaping and rental.

· Portable power: Air compressors ranging from 185 to 1,600 cfm, mobile generators ranging from 25 to 570 kVA and light towers with runtime up to 105 hours.

The latest innovation from MEC combines the abilities of a telescopic boom and an articulated boom in a single machine.

The DualReach 85-J Boom allows users to turn a switch, while the machine is stowed, and select between telescopic mode for maximum outreach and articulated mode for up-and-over tasks.

The patent pending design offers the flexibility to adapt to different jobs with-

out the need for two different machines, which enhances productivity, especially in dynamic environments.

The two-in-one machine functionality is a gamechanger for projects with different work-at-height needs, where traditionally, both a telescopic boom and an articulated boom may have to be sent to a jobsite.

“For the longest time, there’s been two distinct segments of boom lift machines,

articulated and telescopic,” said Gary Crook, Vice President of Engineering at MEC.

“Now, as construction unfolds, there’s no longer a need to swap out a machine with a lot of expense related to the transportation.”

The 85-J DualReach offers a working height of 28 metres.

In telescopic mode, it's maximum outreach measures 21.3 metres. When in articulated mode, the 85-J of-

fers a maximum up-and-over height of 6.4 metres, allowing easy access to challenging environments.

A key feature of the 85-J is its articulation and capacity. The boom features an articulated jib capable of up to 135 degrees of movement. This feature, along with a 272-kg unrestricted or 410-kg restricted platform capacity at maximum outreach in both telescopic and articulated modes, provides flexibility and efficiency across various operational settings.

The DualReach 85-J Boom prioritizes mobility and stability in its design, featuring a self-levelling platform and optional automatic frame levelling of up to 7 degrees on slopes for assured stability.

Its steering options, including standard twowheel, four-wheel and crab steering, ensure optimal manoeuvrability and stability on the job.

MEC is a manufacturer of mobile elevating work platforms (MEWPs) in Kerman, California. Founded more than 45 years ago, MEC's portfolio ranges from all-electric and direct electric drive slab scissors and vertical masts to rough terrain scissors and booms with patented and award-winning design features.

deal with specification changes on individual dump trucks and deliver quality products and services that cater to customers’ needs.

Construction Truck Manufacturing’s predecessor, Euclid-Hitachi Heavy Equipment Ltd., was acquired by Hitachi Construction Machinery in 1988. It stopped production of dump trucks in 2018 to focus on producing service parts for delivered dump trucks and remanufacturing parts for ultra-large hydraulic excavators and dump trucks.

At the start of full-scale production of dump trucks in fiscal year 2026, staff is expected to double the current size as part of Hitachi's efforts to strengthen the production system.

Earlier this year, Hitachi Construction Machinery Americas also opened its new sustainable, state-ofthe-art headquarters facility in Newnan, Georgia.

“Building The Future 2025,” the Hitachi Construction Machinery Group’s mediumterm management plan that started in fiscal year 2023, includes “expanding business in the Americas” among the four core strategies.

In line with this purpose, Hitachi Construction Machinery aims to achieve a revenue of over 300 billion JPY in fiscal year 2025 from independent business expansion in the Americas alone.

Cooper Equipment Rentals has purchased 100 per cent of the shares of Red Deer, Alberta-based Action Equipment Rentals. Action was formed in 1991 by Reginald Bloomfield and his father Ray Bloomfield in Sundre, Alberta, to serve the central Alberta market.

The company opened a second location in Red Deer about a year later.

“Action’s prime location and facility in Red Deer intensifies our coverage in the important Alberta market and their strong presence in Alberta enhances our ability to serve customers better in Western Canada,” said Lee Briscoe, Regional Manager, Cooper Equipment Rentals.

NORTHERN ONTARIO

Jeff Marshall: 1-807-628-6300

Trevor Hynnes: 1-807-629-3007

SOUTHERN ONTARIO

Darren Hynnes: 1-807-252-6556

Jason Dennis: 1-705-288-4685

In 2015, Action consolidated operations in Red Deer, and under the leadership of General Manager, Gabriel Castella-Chin, embarked on a plan to renew the rental fleet and grow their market share.

“Joining a Canadian-owned company with an excellent reputation was important in our decision to join the Cooper family,” Castella-Chin said.

“We are looking forward to continuing to serve central Alberta with the benefits and resources that allow us to expand our presence and continually improve our already excellent service.”

The company rents a variety of equipment, from handheld garden tools to mini excavators to telehandlers.

“I was once told that if you build it, they will come. That was our charge for Action Rentals from the start, and this is the next natural step going forward. Cooper will take what we built and continue to build so they will come. And if we treat them

right, they will stay,” said Founder Reginald Bloomfield.

Action joins the Cooper family as the Red Deer branch and will continue to be led by Gabriel Castella-Chin, supported by the team of Action employees.

“Action has built a fine business with a reputation for quality and integrity in the construction equipment industry, and we are proud to welcome them into the Cooper family as we continue to grow our company across Canada,” said Doug Dougherty, CEO of Cooper Equipment Rentals.

Established in 1972, Cooper Equipment Rentals is a full-service construction equipment rental company, servicing contractors across Canada.

With more than 75 branches in six provinces, Cooper specializes in the rental of compact, aerial, heavy construction, pump and power, and trench safety equipment, while providing a wide range of supplies, along with service and support.

A record number of asphalt and aggregates professionals gathered in Nashville for the largest World of Asphalt and AGG1 Aggregates Academy & Expo in the show’s history. Held March 25 to 27, the trade show set new records in both attendance and square footage.

According to organizers, more than 15,800 industry professionals attended the event to see the latest products from more than 440 exhibitors and to attend 120 educational sessions.

This year’s show represents 38 per cent increase in attendance, shattering the previous record of 11,400 set in 2022.

“The success of this year’s event is thanks to the dedication and collaboration of all our teams and partners,” said World of Asphalt Show Director Brittany Schmidtke. World of Asphalt and Agg1 attendees travelled from across North America, some travelling from as far as Africa, England and Argentina.

The exhibit floor encom-

passed more than 207,000 square feet of the Music City Center; a 14,000 foot-increase compared to 2022’s event in the same space.

Education at World of Asphalt’s People, Plants & Paving Conference and the AGG1 Academy totalled more than 120 sessions. Some of the most popular sessions included Best Practices for Milling & Profiling, Best Practices for Residential & Commercial Paving, and Relational Leadership.

"The AGG1 Academy & Expo is a unique environment that facilitates the connection of exhibitors and attendees to experience the latest innovations, technology and education," said NSSGA President and CEO Michael Johnson. "The show also hosted a record number of press events with 12 companies introducing new products or partnerships.

World of Asphalt and AGG1 returns in 2025 when the show travels to St. Louis, Missouri on March 25 to 27.

Central Diesel Service, singularly focused on our Deutz Customers.

“The only source of knowledge is experience.” Albert

Since 1983 Central Diesel Service has specialized in DEUTZ. In fact, we’re proud to say “Nobody knows Deutz products better,” and we can prove it! CENTRAL DIESEL SERVICE Solid Service Since 1983 Email: deutz@on.aibn.com (905) 564-9444 Fax: (905) 564-9313

Truck World is returning to the International Centre in Mississauga, Ontario to showcase the latest products and vehicles from more than 500 companies.

Held April 18 to 20, Truck World features the latest advancements, technology and alternative fuel options, along with trends shaping the future of the trucking and transportation sectors.

New for 2024, Truck World’s GreenTECH Pavilion encourages attendees to learn, discover and network with companies dedicated to alternative fuel equipment, as well as sustainable products and technologies.

Built out of the popularity of Truck World’s past Greener Route showcases, the GreenTECH Pavilion will showcase the latest in green products, advanced technologies and sustainable solutions across 100,000 square feet of dedicated space.

“As a one-stop-shop, Truck World offers an expansive show floor full of the latest in trucking innovation, as well as the chance for industry professionals to connect and learn more about emerging trends and best practices,” said Joe Glionna, President of Truck World and Newcom Media.

“In addition to featuring new and exclusive products, we’re thrilled to be opening our new GreenTECH pavilion, dedicated to educating and showcasing everything related to sustainable transport and alternative fuel options.”

Another new feature for Truck World 2024 is a special, early-access workshop from 8 a.m. to 12 p.m. on April 18, with the North American Council for Freight Efficiency (NACFE). Attendees can learn more about the scaling of electric trucks across the industry.

South Asian Day will be held on Friday, April 19, in celebration of the South Asian community and its importance to the Canadian trucking industry.

The Ride & Drive show feature will also return this year, allowing showgoers the opportunity to experience commercial vehicles with the latest fuel technologies, including hydrogen, battery and electric during the first two days of the show (Ride & Drive participation requires an AZ License). As well, the New Product Showcase returns, offering the opportunity to explore some of the latest trucks.

Okada’s OS Series Scrap Shear is versatile for cutting ferrous and non-ferrous scrap, concrete, pipe, solid round I-beams, and plate materials.

Perfect for the 13-20,000 lb. class carrier, which provides flexibility for hard-to-get demolition areas.

• Your all-in-one sealcoating trailer!

SPHD 3.0

ton and 4 ton units available.

Low profile design + dumping capabilities, joined with oil jacketed heating system, make this the most advanced patching trailer in the world!

• Green friendly exhaust = Green back in your pocket!

• Your all-in-one sealcoating trailer!

• 850 gall steel tank w/7 gauge heads, 10 gauge sidewalls and reinforced tank ends.

• With so many options & extra deck space, this sealcoating trailer is ready to work!

• 700 gall steel tank w/7 gauge heads, 10 gauge sidewalls and reinforced tank ends.

• Comes complete w/hyd agitation system and spray system, so all you have to do is add sealer and to to work!

• 7 Wheel design creates greater compaction than conventional 9 wheel machines in its weight class because weight is dispersed between fewer tires.

• Easily towed on a trailer behind a 1/2 ton pick up when tanks are empty.

• Excellent maneuverability on small job sites.

• With its innovative dual selective steering option, this cutting-edge striper excels at tackling challenging tasks such as intersections, long straight lines, and wide curves that traditional stripers struggle with.

• The PROSTRIPE 400 DC is the perfect choice for roundabouts, local city jobs, DOTs and intersections, ensuring professional results every time.

• This entry-level line marking unit can be adapted to any vehicle, including a retractable arm bracket and foldable chassis, automatic spray guns, pressurized bead tank, marking controller & HD camera kit.

• Equipped with 1 or 2 HYDREX pumps, TCS technology and a fully automatic control & monitor system - contractors can level up their business & profit.

• Accurate material delivery and line precision for striping application such as parking lots, crossways, ports, athletic fields, city road maintenance and local striping jobs.

“I’d get these huge safety vests, which just didn't fit me properly,” Hutt said.

“The arms were super baggy, and then I would catch the back of my vest on door handles or rebar or whatever I was walking by.”

With the majority of clothes for jobsites designed specifically for men, Hutt was unable to find the right size, as well as clothing that eliminated the safety hazard created by loose fitting clothing.

“You can go into super small men's work wear, but it's still not going to fit you the way that it should,” Hutt said.

“So, I really wanted to create something that kind of fit our bodies better. Safety is a huge thing. I’m making sure that we have the right clothes for the job.”

Following CSA guidelines for safety requirements, Hutt began to design the clothing line in 2022.

Alongside the Ruud brand, Hutt is also founder of Women in Steel Toes, an advocacy group that highlights the challenges women may face on jobsites, and inspire a younger generation of people to enter the construction industry.

To tailor the clothing designs to what women require, Hutt was able to call upon members of Women in Steel Toes to provide input. The final product aims to address safety, comfort as well as confidence.

“I think there's a lot to be said about wearing something that fits and that you feel good wearing. That can help you overall with your job and your career as well,” she said.

Ruud Gear officially launched in March. The work wear company’s first products include a high-visibility shirt, branded T-shirt as well as a baseball hat and silk hair elastics. Hutt plans to roll out UV

protective clothing and fall and winter jackets in the near future.

“I don't know if we'll venture into boots, but we’re looking at everything else,” Hutt said.

“Then we're looking to kind of make a compatible men’s line, as well. So we can offer a one stop shop.”

Ruud (pronounced rude) was named after Hutt’s frustration with how women are expected to act on jobsites.

“I was tired of this idea that I was supposed to be nice on site. The idea that I was supposed to, you know, be gentle and lady like and all that stuff, when really, I'm just going there to do a job,” she said.

The construction industry will have its first opportunity to see the Ruud line at the National Heavy Equipment Show held April 11-12 in Mississauga, Ontario.

“It’s our first big introduction, which is kind of cool,” Hutt said.

Although Hybrid Power Solutions’ product line offers contractors an opportunity to reduce their carbon footprint, the financial savings are the selling point.

Established in 2015 in Etobicoke, Ontario, Hybrid Power Solutions engineers and builds a range of power options, from 3,000 watts to 150 kW, that replace diesel generators.

The company builds batteries as well as solar/diesel power generators that can reduce fuel cost by about 75 per cent.

“We're not saying ‘here's a green product.’ That's not how we sell. We just say, ‘here's a way more cost-effective product’,” said

Francois Byrne founder and Chief Executive Officer of

Hybrid Power Solutions. “You're going to be saving a huge amount of money on fuel, maintenance, wear and tear and rental.”

Hybrid Power Solutions was created to meet the needs of the mining industry and has since expanded to transit, military and now construction.

“We’ve been battle-hardened over time, and now we have a streamlined product line That can go from small contractors to full site power,” Byrne said.

How it works

To replace an on-site diesel generator, a hybrid system includes solar panels, batteries to store energy and a diesel generator, which acts as a safeguard in case energy demands ex-

ceeds electricity created by the solar panels.

“The diesel engine that we're using is direct DC diesel charging. So, you have very high efficiency between the two,” Byrne said.

“It’s also a much smaller diesel generator that we're using, because we're using the batteries as an intermediate.”

A site trailer, for example, may require two to three kilowatts of electricity while running a 25-kW diesel generator, which operates 24 hours a day, seven days a week.

To meet the required power demand, Hybrid Power Solutions would install a system that generates electricity at double what is required.

“In a day, we're charging

and we're running off the battery. So, we're always making sure that you have power. The charge speed isn't as important as properly sizing your solar to your actual needs,” Byrne explained.

A hybrid system does require more space than a traditional generator to accommodate solar panels. However, Byrne explained the panels are usually placed in areas that are not utilized on site.

“They can be placed on top of a container. Usually, it’s dead space that we’re using,” he said.

Hybrid benefits

While an all-electric power source would eliminate the need for a diesel generator, the benefit of

using a hybrid energy source is security.

“Having a backup, just in case, is so important because these guys are running 24/seven, 365 days a year,” Byrne said.

“You can't show up to work and your crane kit doesn't move because you don't have power to it, right? That's just not happening.”

Understanding the system, how it works and the right renewable energy set up is another barrier to electric or hybrid adoption.

To ease the transition from solely diesel, Hybrid Power Solutions systems are designed to replicate a traditional generator.

“It plugs in just like you would with diesel. We're going to give you that exact same plug and that exact

same feeling. We'll take care of the rest,” Byrne said. "And I think that's what we really need until people get familiar with these systems, and it becomes just the same as anything else.”

Expansion Hybrid Power Solutions is currently constructing its second manufacturing facility on 2.5 acres in Parry Sound, Ontario. The 560 square metre facility will boost production of the company’s residential lithium-ion batteries and larger-scale portable power solutions, including the recently unveiled Batt Pack Spark.

The land is currently undergoing clearing, with plans to break ground this spring.

In Lancaster County, South Carolina, March 21 will now be known as Continental Tires of The Americas Day.

Brian Carnes, Vice Chair of Lancaster County council made the proclamation during the official grand opening of Continental Tire the Americas’ new headquarters in Fort Mill, South Carolina.

The modern 90,000 square foot building, which sits on 33 acres in northern Lancaster County, has capacity for 350 employees and is designed and built for future expansion potential.

“It feels like Christmas and my birthday all on the same day,” said Jochen Etzel, CEO of Continental Tire the Americas. “Since we moved to South Carolina, we have received unwavering support from Lancaster County and the State of

South Carolina. In fact, this consistent support for Continental is the reason why we have expanded our footprint.”

Since moving to South Carolina in 2009, Continental has invested more than US$800 million in its facilities throughout the state employing more than 2,000 people. Alongside numerous businesses, the new HQ2 will be home to Continental’s earthmoving tire business, which was relaunched in 2016.

“The new HQ in Fort Mill solidifies our commitment to the earthmover and construction businesses,” said Matt Futrelle, Head of Global Business Field Earthmoving. “People are a top priority for our strategy and this location gives us an outstanding talent base to pull from as well as room to grow.

Many of our Specialty Tire Americas management and operations team are excited to operate from the new headquarters.”

To build the new three-storey headquarters, Continental invited its employees to provide input on every aspect of the facility, from the selection of the architect to colour and furniture selection.

The result is a building that blends into its natural forest surrounding. The design allows natural light to flood the interior year-round. Collaborative spaces of various sizes are located on all three levels, as well as offering numerous quiet areas for focused work.

“Our new facility is so much more than a typical office with desks and meeting rooms,” Etzel said.

“In the past, the office was a place you had to come to. Our objective for this building was to create a workplace destination that you want to come to.”

Sustainable vision

The sustainability features incorporated into the building will allow Continental Tire the Americas to apply for Leadership in Energy and Environmental Design (LEED) Gold Certification.

The open office layout incorporates natural materials installed by local artisans. The building utilizes LED lighting for cost savings and contains recycled content carpet tiles and low VOC paint.

The parking area is optimized for a decreased heat signature and includes 10 EV charging stations.

“One of the things that I'm really

proud of is our sustainability future,” said Tim Rogers, former CFO of Continental Tires of the Americas .

A total of 840 solar panels are located on the roof and in the parking area, which are able to generate up to 25 per cent of the building’s energy consumption. Rainwater harvesting will be utilized for landscape irrigation.

“We do have huge opportunity to move towards net zero energy use for the entire building,” Rogers said. During construction, more than 135,000 works hours were invested with zero accidents. Preparing the site also required the removal of 12 million pounds of rock.

“I want to personally recognize the countless hours by all of the trades who made this vision a reality,” Etzel said.

The new Manitou MTA 519 compact telehandler features a quick attach system that makes the machine compatible with any standard-flow skid steer or compact track loader attachment.

The quick attach feature is a benefit for rental businesses who can rent out the telehandler with a range of attachments, as well as a convenience for fleet managers who may already own a significant number of attachments that can now be used on another asset.

“Attachment compat -

ibility increases utilization, both for rental businesses and contractors,” said Steve Kiskunas, Product Manager for telescopic handlers at Manitou. “This increases profitability. The ability to run standard-flow attachments with this machine, in addition to its more standard fork and bucket operations, makes it a productive addition to any fleet.”

The new MTA 519 is extremely compact at 1.8 metres wide and 1.9 metres tall, with

an excellent tight turning radius of 1.8 metres. This makes it small enough to fit through garage doors and down ramps into the lower levels of structures.

Although compact, it retains excellent operating capacities, including a maximum load capacity of 2,500 kg; a 5.8 metre maximum working height; and outreach of up to 3.4 metres for loading and unloading materials on the second floor of a structure. It also features five different tire options and a ground clearance of 33 cm

for working on varied terrain.

“There is continued growing demand for compact telehandlers in the market today,” Kiskunas said. “We’ve made this MTA 519 even stronger than previous Manitou compact telehandlers and are delivering even greater versatility to the North American market.”

Manitou has further built the compact telehandler for use with a wide variety of ground-engaging attachments, from snow pushers to brooms, through the specialized design of its ground-engaging boom.

The outer shell of the boom is designed with steel of equal thickness on all sides for optimal strength, and the extension and retraction of the boom is entirely hydraulically driven for extreme and performance.

The boom is also situated lower within the framework

of the machine to optimize visibility from the right side of the cab.

“In addition to the traditional lifting and placing strengths, these booms are also designed to better handle the side-to-side forces you experience in ground-engaging applications, really giving you a purpose-built operator’s experience,” Kiskunas said. “Operators can run this telehandler in all functions with confidence that it will perform as desired.”

Lower TCO

The new MTA 519 features a 74-hp engine that is also placed low within the framework of the machine, along with all critical power and drivetrain components. This allows for a low, sloping hood for better visibility, as well as easy access to all critical daily service and preventive maintenance serving points.

“We know that the easier service is, the more likely it is that it will be done regularly and done properly,” Kiskunas said. “A big part of our mission at Manitou to lower total cost of ownership is to help extend machine life cycles and increase uptime through extremely simple service. The MTA 519 delivers on that.”

The compact telehandler also features a two-speed hydrostatic Dana transmission, along with Dana axles — limited slip in the front, and open axles in the back.

One area of focus for Manitou in introducing this machine is ensuring parts availability ahead of the launch for fast response times to parts orders.

“We have pre-stocked our warehouse in support of this new model, ensuring that dealers and fleet managers alike have fast and easy access to parts, further ensuring uptime and a lower total cost of ownership,” Kiskunas said.

EasyManager

To further reduce the total cost of ownership is the standard Manitou EasyManager fleet management platform (telematics). These systems allow business owners and fleet managers to stay better connected to the health, performance and efficiency of each machine.

“We make it extremely easy to access, understand and act on all of the great data coming off of the machine,” Kiskunas said.

While the MTA 519 is a compact telehandler, it features a full-sized operator’s compartment. The cab is 78-cm wide, and the entryway is 1.8 metres tall. This makes it easy to get in and out of the machine, and comfortable to operate throughout the day.

It also features a new joystick that is ergonomically situated and operates in the same pattern and functions as all other North American telehandlers.

Not only is JCB the world’s biggest backhoe manufacturer, but we also sell as many backhoes around the globe as all other manufacturers combined. It’s not that big makes us better. Rather, we’re big because we’re better. Buy better at JCB.com.

ALBERTA Liftboss JCB

Calgary: 403-301-0041

Edmonton: 780-474-9900 liftboss.ca

BRITISH COLUMBIA

Williams JCB

Surrey: 604-930-3316 williamsjcb.com

NEW BRUNSWICK

A.L.P.A. Equipment

Edmundston : 506-735-4144

Balmoral : 506-826-2717

Fredericton : 506-452-9818

Moncton, N.B. : 506-861-2572 alpaequipment.com

NOVA SCOTIA

A.L.P.A. Equipment

Truro : (902) 897-2717 alpaequipment.com

Harvey JCB

Corner Brook: 709-639-2960

St. Johns: 709-738-8911

harveyco.ca

ONTARIO

Advance JCB

Waterloo: 519-742-5878

Harriston: 519-510-5878

advanceequipment.net

D&W Group Inc.

Doughty & Williamson

Jarvis: 519-587-2273

Brant Tractor

Burford: 519-449-2500

Redtrac International

Vineland: 905-562-4136

dwgroup.ca

ONTARIO

Delta JCB

Dunvegan: 613-527-1501

Renfrew: 613-432-4133

Winchester: 613-774-2273 deltapower.ca

Fulline JCB

Glencoe: 519-287-2840 fullinefarm.com

Equipment Ontario

Lindsay: 705-324-6136

Port Perry: 905-982-1500 equipmentontario.com

Jade Equipment

Simcoe County and Districts of Parry Sound & Muskoka 705-325-2777 jadeequipment.com

John’s Equipment Sales

Frankford: 613-398-6522

johnsequipmentsales.com

ONTARIO

Moore JCB

Toronto, York & Peel

Region: 416-747-1212 moorejcb.com

North Rock JCB

North Bay, Sault Ste. Marie, and Sudbury: 705-897-7369 northrockrentals.com

ReadyQuip Sales & Service Ltd.

Timmins: 705-268-7600 readyquip.com

WPE Landscape Equipment

- JCB

Hamilton/Halton: 905-628-3055

wpeequipment.ca

PEI A.L.P.A. Equipment (506) 861-2572 alpaequipment.com

QUEBEC

A.L.P.A. Equipment

Bas-Saint-Laurent : (506) 735-4144

Gaspésie : (506) 826-2717 alpaequipment.com

Bossé Quebec Inc.

Desmaures: 418-878-2241 Saint-Augustin-debosse-frere.com

Moore JCB

Montreal: 514-333-1212 moorejcb.com

SASKATCHEWAN & MANITOBA

Westcon JCB

Regina: 306-359-7273

Saskatoon: 306-934-3646

Winnipeg: 204-694-5364 westconequip.ca

Caterpillar rounds out its track loader lineup with the debut of the 973

Caterpillar’s new 973 is the largest track loader in the industry, but maintains agility and ease of operation.

The new machine, the third in the cat track loader lineup, delivers more productivity while consuming less fuel to deliver greater profit.

The 275 hp crawler loader has an operating weight of 29,892 kg and replaces the 973K worldwide. It joins the160-hp 953 and the 202-hp 963 in the Cat track loader line.

The 973 is powered by a Cat C9.3B engine. Fuel consumption is reduced by up to 10 per cent with Auto Mode, which adapts the engine speed to the load. Eco Mode will use an even lower speed for further reduction in fuel consumption in lighter duty applications. Power Mode will always maintain a high engine speed for readily available power.

Control options

The 973 features joystick or V-lever and pedal steering for transmission controls and either joystick or two-lever implement controls.

The joystick option provides familiar con-

trols for operators experienced with compact loaders. With either control scheme, operators can set implement response to fine, normal or coarse to match operator preference or application.

Repetitive lift, lower, rack, dump and float functions can be preset to make jobs like truck loading easier. Smoother implement and steering response and improved steering performance provide more controllability.

An optional Performance Series bucket boosts productivity up to 20 per cent. An optional Fusion Quick Coupler enables fast attachment changes. A variety of buckets, forks and other tools can be shared among track loaders, wheel loaders and other Fusion compatible machines.

Buckets come from the factory with Advansys bucket tips/adapter/locking system. Advansys tips are built to maximize productivity and deliver the lowest bucket lifecycle cost. Hammerless retention system means safe, fast removal and installation without special tools.

Purpose-built low ground pressure (LGP), waste handling/demolition and ship hold

arrangements are factory equipped with specialized undercarriage, guarding and other features designed to take on tough tasks.

The 973 Steel Mill package includes a specialized cab, insulated steel fuel tank, high temperature undercarriage and insulation throughout the machine, making it suitable for handling slag.

The updated cab features a suspension seat as well as adjustable armrests and controls.

A 25-cm touchscreen in-cab display is easy to use and features a standard high definition rearview camera. Slope Indicate helps make operation easier by showing machine mainfall and cross slope right on the display.

Cat Payload technology delivers precise bucket load information with on-the-go weighing, which helps prevent over or underloading. More accurate loading reduces cycle times to help save time, labour and fuel costs.

Cat Equipment Management telematics technology helps take the complexity out of

managing jobsites by gathering data generated by equipment, materials or people and delivering it in customizable formats.

Product Link collects data automatically and accurately from equipment assets – any type and any brand – which can be viewed online through web and mobile applications.

Access information anytime, anywhere with VisionLink. A Cat dealer can help configure a customized subscription, available with cellular or satellite reporting or both. The Cat App helps manage assets — at any time — right from a smartphone.

Remote Troubleshoot saves time and money by allowing Cat dealers to perform diagnostic testing remotely. Remote Flash updates on-board software without a technician being present, at a convenient time, potentially reducing update time by as much as 50 per cent.

Application Profile and Operator ID help save time by saving preferred machine settings.

For machine security, a passcode provides an optional additional level of security by requiring an operator to enter an ID before the machine will start.

Iowa’s Kait Burds is the winner of Caterpillar’s first Women in Construction celebration.

Burds successfully demonstrated her advanced machine operator skills by manoeuvring difficult work site challenges in record time with extreme precision during the competition held in mid-March.

“I feel really good. The competition was pretty stiff. It’s good affirmation of the hard work I put into my career,” Burds said. “I hope this event gives women in construction more exposure and gives them the confidence to go out and do things that scare them.”

Burds was one of 18 women from Cat dealers throughout the Americas who gathered at Caterpillar’s Edward J. Rapp Customer &

Training Center to compete in the operator skills tests, learn about the latest industry trends and network with peers.

The operators’ skills were tested in three challenges, including:

· Small wheel loader: Move material through the course to achieve 7 to 7.5 tons; then change to forks and use them to move a pallet.

· Compact track loader: Navigate an obstacle course using multiple machine functions.

· Small hydraulic excavator: Load a truck to achieve a 10-ton payload.

Along with the tests, the competitors par-

ticipated in a panel discussion where they shared best practices, discussed managing a successful career in a male-dominated industry and talked about the importance of recruiting more female operators and technicians into the workforce.

“The event is a celebration of female machine operators who build our world, advocate and drive awareness for their trade, and highlight solutions that address jobsite needs,” said Chrissy Metz, Caterpillar Marketing Manager.

“Each competitor demonstrates advanced abilities operating the latest Cat construction machines and technologies, showing the world the invaluable role women play in the construction industry.”

Liebherr has developed the MyAssistant for Earthmoving, a new app that provides support for operators on the jobsite.

The mobile app is available for wheeled excavators, material handling machines and wheel loaders of generation 6.0 and higher as well as crawler excavators, graders and crawler loaders, pipelayers and articulated trucks of generation 8.0 and higher.

The new mobile app can be downloaded from the Apple

App Store and the Google Play Store.

After successful authentication via the MyLiebherr portal, the full range of features is available to the user.

Once logged in, MyLiebherr makes all Liebherr earthmoving and material handling machines in the company's fleet available to the user via a drop-down menu. The machines can then be selected via the model designation and serial number.

identify unknown symbols on operating panels, keyboards and switches as well as on the control panel in the cab. The user can simply scan the symbol using the camera on their smartphone. Following a successful match in the symbol database, the user is shown the suggested solutions that fit the context as well as corresponding links to the Liebherr operator's manual.

In addition, the entire Liebherr operator's manual is available to the user digitally via the app. Furthermore, any required spare parts can be selected in the menu tile of the same name and placed in the shopping cart. Depending on the user's authorization level in MyLiebherr, a corresponding order can then be triggered.

The "Scan Operating Symbol" function can be used to

This quick analysis of the symbol in question not only saves the machine operator time, the app also increases clarity and safety during daily operations on the construction site. Machine operators whose companies have a large fleet of machines that undergoes frequent changes, as well as newcomers to the profession and inexperienced machine operators, will find this feature especially useful.

John Deere has entered a strategic partnership with Leica Geosystems, part of Hexagon, to accelerate the digital transformation of heavy construction equipment.

The partnership between Deere and Leica will leverage the strengths of both companies to bring new technologies and services to construction professionals worldwide.

“The availability of SmartGrade with Leica solution allows John Deere and our dealers to participate and support various jobsites while meeting the technology needs of our customers,” said Mark Colvin, Senior Product Manager for Grade Management at John Deere.

“Working with Leica Geosystems is a tremendous opportunity, as their advanced technology solutions, paired with the power and performance of the John Deere construction equipment lineup, makes for a highly productive, efficient and seamless jobsite for our customers.”

"We are thrilled to be working with John Deere, a company that shares a similar culture and commitment to innovation, quality, and customer satisfaction," said Troy Dahlin, Vice President of Heavy Construction for the United States and Canada at Leica Geosystems.

"Together, we will bring new levels of accuracy, productivity and accelerate the implementation of safe and sustainable workflows to the construction industry, helping our customers succeed in today's competitive marketplace and enhancing their resilience for tomorrow."

Leica Geosystems software and services will be available for purchase on select John Deere construction equipment models starting this year.

By combining the manufacturing expertise of John Deere with Leica Geosystems' knowledge of positioning and sensor technology, the two organizations will work to develop and deliver solutions that improve productivity, reduce material costs and the number of passes required, which can help improve safety by minimizing traffic on construction sites.

• up to 5% cycle time improvements to get your work done quicker.

• 17% increase in engine HP and 19% improved fuel economy

• X4S all new features such as Custom Flow Balance allowing the operator to prioritize hydraulic functions based on application, customizable joystick function buttons, 4 new work modes, Trimble-Ready components, all to increase efficiency and productivity.

• Additional options such as HD arms, WAVES +, reversible

engine fans, and Precision Grade on select models add to the perks of owning and operating a Link-Belt excavator.

• WAVES (Wide-Angle Visual Enhancement System) with 270° birds-eye view standard, therefore improving site.

• The spacious cab offers unprecedented ergonomics and comfort. A high-back seat with air, tilt, and heat features is standard. Adjustable pivoting armrests, headrests, seat height, and lumbar support provide operators comfort on long workdays.

BRITISH COLUMBIA Équipement JYL Inc. Chicoutimi (418) 698-6656 equipementjyl.com

Castlegar, BC 250-365-2807

Cranbrook, BC 250-426-6205

Fort St. John, BC 250-785-6105

Kamloops, BC 250-374-4406

Langley, BC 604-607-8555

Nanaimo, BC 250-758-5288

Penticton, BC 250-492-3939

Prince George, BC 250-562-8171

Quesnel, BC 250-992-7256

Terrace, BC 250-635-5122

Vernon, BC 250-545-4424

Williams Lake, BC 250-392-7101 inland-group.com

YUKON TERRITORY

er Marketing Manager for Develon.

As well, a fine swing function and a cast push link with lifting eye delivers a 5 tonne lifting capacity to help operators complete the job faster.

“The benefit of 2D grading is being able to control your grading capabilities. Also with this particular machine, we have a standard weighing system. So, it’s easier to be able to find out if you are moving material fast enough,” said Jacob Sherman, Product and Deal-

“With fine swing, if you have something dangling or attached to a chain while you’re moving the boom and arm, when you stop you can absorb some of that energy, so you don't get a drastic pendulum effect,” Sherman said.

The hydraulic system delivers a maximum flow rate of 211 litres per minute for each of the two main pumps. The conventional tail swing excavator also features

a 6.6-metre digging depth and a 36,376-foot-pound maximum digging force with power boost. An optional dozer blade and standard counterweight design provide strength and stability. Operators can also activate the tiltrotator mode for enhanced precision when using a tiltrotator accessory.

Added comfort features include improved, automotive-style heating and cooling with an optional heated and cooled seat, easy-touse joystick controls, a rear view camera, Smart Touch screen and

optional 360-degree around view monitor (AVM) camera system.

“It’s very similar to what you'd expect in an automobile, same type of settings in this particular machine,” Sherman said. “And, of course, there is a lot of glass space for visual safety.”

Efficiency & serviceability

The 163 hp Tier 4 Final Develon engine does not require a Diesel particulate filter. Several fuel efficiency features are standard, including Smart Power Control (SPC), D-EcoPower system and the Electronic Power Optimizing System (EPOS).

Fuel filters and the cooling system are all at ground level and easily accessible. For added protection, components are shielded by vandalism-proof latches.

The Develon Fleet Management telematics system comes standard on all -7 Series crawler excavators, making it easy for customers to remotely monitor and maintain their machines.

Develon Fleet Management is an equipment diagnostic tool that monitors the health, location and productivity of Develon construction equipment from a user-friendly mobile app and website.

The Caterpillar DW 15 scraper was introduced in 1954 to supplant the DW 10 model made from 1941 onward. Powered by a Caterpillar diesel of about 112 Kw, the unit was initially rated as 11-12 cubic yard heaped capacity. By the end of its run in 1960, it had been updated in both horsepower and capacity.

Earthmoving contractors of the era were quick to augment their tractor & scraper fleets with the more productive wheeled scrapers. In operation since the 1930s, the Leaside, Ontario-based McNamara got its start in highway construction in Ontario continuing through to the early 1960s. Ever expanding, McNamara took on several construction projects in the United States as well as the building of major airports and dams throughout Canada. However, by mid-1960 it had ceased operations. Nonetheless, it had been an important player and innovator in several facets of the industry.

During this same period, Caterpillar had introduced the DW 20 and the DW 21 scraper models that became common on earthmoving jobs.

The Historical Construction Equipment Association 2024 events include Wheels & Tracks, held June 8-9, and the ‘Last Blast’ event on October 19.

Both events are held at the Simcoe County Museum, near Barrie, Ontario. To see more than 60 pieces of vintage construction equipment in action be sure to attend.

HCEA Canada is a proud Heritage Partner of the Simcoe County Museum. For more information, visit hceacanada.org.

To boost performance and comfort, Hitachi Construction Machinery Americas has added several enhancements to its ZAXIS-5N compact excavators ranging from 1.7 to 6 tonnes.

These compact excavators excel in applications where operating space is limited. A short tail swing radius or ultra-short tail swing radius with swing boom makes it easier to work around buildings, walls, guard rails and other structures.

“The ZAXIS-5N excavators,

which include the ZX17U5N, ZX26U-5N, ZW30U-5N, ZX35U-5N, ZX50U-5N and ZX60USB-5N, continually evolve to stay ahead of customer expectations,” said Kei Matsumoto, Product Manager of Compact Excavators at Hitachi Construction Machinery Americas.

“Our focus is to provide customers with a machine that delivers efficiency, reliability and safety.”

ZAXIS-5N compact excavators are commonly used as tool carriers with a wide range of attachments, increasing job-site versatility. Several features enhance attachment compatibility, including an auxiliary flow rate changer. On the ZX30U-5N to ZX35U-5N, the operator can match the flow rate of the auxiliary hydraulic circuit to the requirements of the attachment with either a low or high setting.

Hitachi has also upgraded the ZAXIS-5N excavators with LED work lights that provide enhanced visibility in low-light conditions, improving operator comfort and safety.

Ergonomic hydraulic pilot valve control levers reduce fatigue and provide smooth control.

Hydraulic pilot controls for attachments, boom, swing, travel and blade maximize controllability and ensure smooth operation. Swing boom and foldable travel pedals are positioned for easy operation while allowing plenty of foot room.

Maintenance simplified

The ZX50U-5N to ZX60USB-5N excavators now feature a multistage flow rate changer that allows the operator to select five different hydraulic flow settings for increased productivity and efficiency.

As well, ready-to-use hydraulic quick coupler piping and second auxiliary hydraulic piping are preinstalled on premium versions of the ZX30U-5N to ZX60USB-5N. The second auxiliary hydraulic piping is beneficial for popular tilting and rotating attachments, making the excavators more versatile.

The other ZAXIS-5N excavators in the range come with mounting points built in for hydraulic quick coupler piping. This eliminates welding of brackets for quick coupler lines and simplifies piping installation.

An auxiliary function lever (AFL) includes an analog switch, trigger switch and horn for running attachments, such as a breaker or a tool with swing.

A standard wedge lock quick coupler makes attachment hookup a snap and a factory-installed bracket for a thumb cylinder simplifies installation.

A standard dozer blade enables the ZAXIS-5N excavators to grade while providing extra stability. A blade float option on the ZX30U-5N to ZX60USB-5N uses the blade’s weight to help perform easier and faster grading operations. The optional factory-installed angle blade version of the ZX35U-5N to ZX60USB-5N allows for enhanced grading and backfilling ability without the need for a second machine.

The ZAXIS-5N excavators provide simplified access for maintenance with a hinged door for access to the side-by-side oil cooler and radiator core and the engine cover slides vertically with less rear projection.

Routine checks, such as engine oil level, are quickly accomplished from ground level. Daily maintenance points are grouped behind easy-access covers, while spin-on filters provide quick, easy access for filter maintenance.

The top of the track frames on all the models ranging from the ZX30U-5N to ZX60USB-5N have been sloped for easy mud removal. To reduce the cost of repair, the traditional curved glass used in the cab has been exchanged with more easily obtainable flat glass.

Installed on top of the battery, a battery disconnect prevents battery discharge during long-term storage.

Maintenance is simplified since there is no need to disengage terminals and cables from the battery.

The excavators are powered by fuel-efficient Yanmar diesel engines ranging from 14.7 to 53.8 hp, and are paired with proprietary hydraulic systems for optimum performance.

“Our hydraulic system is especially great for efficient fuel consumption, and it delivers the speed and power the operator wants,” Matsumoto said.

The compact excavators, from ZX30U-5N to ZX60USB5N, incorporate power/ economy work modes. The power mode provides higher engine speeds for most general digging work, while the economy mode reduces engine speed for lighter digging jobs.

An auto-idling system is available on these models to reduce fuel consumption, emissions and noise.

A tiltrotator can transform your excavator into a flexible do-it-all tool carrier and allow you to take on more tasks while improving your safety, productivity and end-result.

rototilt.com

Rototilt® tiltrotators

• R1 | 1.5–3.5 tonnes

• R2 | 3–6.5 tonnes

• R3 | 6–12 tonnes

• R4 | 10–16 tonnes

• R5 | 14–19 tonnes

• R6 | 15–24 tonnes

• R8 | 23–32 tonnes

• RC9 | 32–43 tonnes

The United States Marine Corps. have awarded JCB with a contract to supply 206 3TS-8T Teleskid telescopic compact track loaders.

JCB secured the bid for the Marine Corp’s Multi-Terrain Loader (MTL) Replacement program.

The initial delivery order is for USD$19 million, and JCB projects first delivery to the Marine Corps prior to the end of the year. The total contract is worth USD$29 million.

"We are thrilled to win this contract from the Marine Corps. for the JCB Teleskid, the world's only skid steer and compact track loader with a telescopic boom,” said Richard Fox-Marrs, President and CEO of JCB North America.

“This machine is designed, engineered and manufactured by our talented team in Savannah, Georgia, who also produce the commercial Teleskid that we sell globally. The military and commercial versions of the JCB Teleskid are almost identical.”

The Teleskid features a telescoping boom with a hinge pin height of 4 metres, more than 60 cm higher than most conventional skid steers.

The loader has a rated operating capacity of up to 1,680 kg and a travel speed of 12.5 km per hour.

"This is a great achievement for JCB and a testament to the dedication and skill of our team,” said Viengkeo Johnson, Senior Manager –Government & Defense for JCB North America.

“A special thanks to the entire JCB team for their hard work, commitment and perseverance. Together, we will be delivering a worldclass product that will make a difference to those who help protect our nation."

The Teleskid offers sidedoor entry, which increases visibility and enhances safety by providing a quick and obstacle-free exit rather than forcing the operator to enter and exit over the front of the machine and attachment.

“It’s fantastic that the Marines have made the switch and chosen the unique benefits of the JCB telescopic compact track loader over conventional skid steer designs, and that they have the confidence to deploy this machine on missions throughout the world,” FoxMarrs said.

“We are honoured to again have the opportunity to support the U.S. military with JCB equipment, and we look forward to furthering our long-standing relationship."

The contract also includes a selection of attachments, allowing the Marine Corp. to complete a variety of mission requirements with the Teleskid.

"We are immensely proud to provide yet another product to the U.S. military, which has been a valued customer for over three decades,” said Chris Giorgianni, Vice President of Product for JCB North America.

“This contract demonstrates the quality and versatility of our machines, which are designed to meet the most demanding and challenging environments, whether it’s supporting the military mission or allowing our commercial customer to just get the job done. We are honoured to support the Marine Corps. and all branches of the U.S. military in their vital work of protecting and serving our country and its allies."

JCB is also celebrating 70 years of manufacturing its backhoe loader with the unveiling of platinum editions of the 3CX and 4CX models.

Company founder Joseph Cyril Bamford CBE invented the backhoe concept, and the first JCB model was manufactured in 1953 after he combined a lightweight backhoe with a Major Loadall tractor loader. It created the first machine that combined a front shovel and rear excavator arm.

While it took 20 years for JCB to build 50,000 backhoes, more than 900,000 have now been made. A total of 70 70th birthday 3CX PRO and 4 CX PRO machines will be manufactured.

Purchasing a new articulated hauler is a significant decision. Choosing the right truck can lead to increased productivity, more uptime and a safer working environment.

As Rokbak explains, articulated dump trucks (ADTs) play a crucial role in various applications from commercial construction projects to quarries, mines and infrastructure developments.

The best ADTs offer efficient transportation of heavy loads across challenging terrain and easy manoeuvrability on tight, tricky sites. Before investing in an articulated dump

truck, it's essential to consider several factors to ensure the machine aligns with your specific needs and operational requirements. With its trucks designed and built for tough jobs and rough sites, Scottish articulated hauler manufacturer Rokbak outlines five key considerations:

One of the primary factors to consider is the truck’s hauling capacity. You need to assess typical load capacity and weight to ensure the equipment can handle the demands of the specific application. Rok-

bak offers two hauler models, the RA40 is the largest with a gross power of 444 hp, a maximum torque of 2,225 Nm and a 38-ton payload. It is a popular choice for major infrastructure projects, with its effective power to weight ratio enabling the fast movement of heavy-duty materials. Rokbak also offers the smaller 28-ton RA30, with a gross power of 370 hp and a maximum torque of 1,880 Nm.

Consideration of the type and size of material being handled allows the truck's load-carrying body to be specified correctly to ensure optimum payload, load retention and longevity. Body options such as side extensions for lighter materials, tailgates for free-flowing material retention and additional liner plates for highly abrasive or large blasted rocks are all popular choices. Matching the hauler to existing equipment ensures onsite efficiencies and safety.

Site conditions

Articulated haulers are designed to navigate challenging terrain, but the extent of their capabilities can vary.

It’s important to evaluate the application and climate the truck will be used in, as well as consider the materials that will be transported and the topography of the site, including slope gradients, ground conditions and potential obstacles. Choosing a hauler that can handle the specific conditions of the site is crucial for optimal efficiency and safety.

Operating costs

Operating costs, including fuel consumption and maintenance, are significant considerations for any heavy equipment investment. Efficiency in the use of power is as important as having a high-performance truck.

A lean-burning, high-performing engine and responsive transmission shift control are good for low fuel consumption and environmental impact, as well as increased uptime and extended service intervals. An

adaptable, perfectly balanced drivetrain provides performance and productivity in all hauling conditions, while meeting worldwide emission standards with low cost of operation.

High-level, user-friendly retardation systems, as found in Rokbak trucks, facilitate control of the machine and allow the operator to manage the safety and speed of the hauler to increase efficiency and reducing wear-and-tear with shorter cycle times on the haul route.

As well, machine owners should also look for strong after-sales support and assess the availability of spare parts and maintenance services. A well-supported machine will lead to increased uptime and lower operating costs throughout the equipment’s lifecycle.

The well-being of operators is paramount in any heavy equipment operation. Features such as ergonomic design, operator visibility and the quality of the in-cab environment provide a comfortable and safe workspace that not only enhances productivity, but also contributes to employee satisfaction and retention. A planetary gear transmission also increases operator comfort. Haulers equipped with safety features such as stability systems with traction control, body tip inhibits and advanced braking mechanisms help to ensure a secure working environment.

Modern articulated haulers often come equipped with advanced technology and telematics solutions. These features can provide insight into machine performance, fuel efficiency and maintenance needs – helping machine owners to manage their operating costs. For example, the RA30 and RA40 are linked to the Rokbak telematics system, providing customers with complete visibility and control of the hauler, enabling you to monitor and manage fleets effectively.

“ THE BOBCAT T770 COMPACT TRACK LOADER IS LIKE A TANK, IT DOESN’T SINK AND MANEUVERS WELL.”

This spring, Burlington Paving Co. Ltd. is celebrating its 50th anniversary that Guido “Curly” Cupido and his sons, Dan and Ray started. Richard Cupido and his wife, Kate, are proud to be the third generation to carry on Curly’s legacy through the same high standards, hard work and passion both he and his sons had. BPC has many long-time employees, like Steve Filkin, who has worked with them for 42 years. That tells you a lot about their company culture. BPC specializes in installation, removing, replacing and repairing courts, and running tracks in the Golden Horseshoe area, but has even built tennis courts in Halifax and installed tracks for the Pan Am games. They have been hired by many high-profile clients over the years but treat every client just the same. Other services they provide are commercial, municipal, residential, parking lot, and golf course paving projects.

When Richard was asked why Bobcat®, his reply was “The owner. John Quast, owner of Bobcat of Hamilton, came to us in the late 80’s and we were impressed by him. He had us try a Bobcat machine, and it was everything we wanted. We have stayed loyal to both Bobcat and Bobcat of Hamilton ever since. Last summer, I started working with Derek Brooker, as a sales specialist at Bobcat of Hamilton. He pursued my request and did a presentation for us (my wife handles the finances) which led us to just buy four new

Bobcat machines, 3x T770 compact track loaders and 1x S770 skid-steer loader. That will make it our 12th Bobcat machine. Derek has been great to work with. Bobcat of Hamilton carries a large inventory of parts, so we never worry about that. If we ever have a machine that needs servicing, they come to fix it or they will give us a rental. If we are in a different town and we need a Bobcat machine or an attachment, I make one phone call, and they have a machine or attachment for us from whatever Bobcat dealer is nearby. They just take care of it for us.”

When John Buist, operator lead hand grading crew, was asked what he liked about operating Bobcat machines, his reply “I first started on foot control. It’s straightforward. The Bobcat T770 compact track loader is like a tank, it doesn’t sink and maneuvers well. Having all the different attachments is great. It’s like a mini dozer. Grading is extremely important in what we do. It has to be exact when we do courts. Power is there as well. I prefer Bobcat.”

BRANTFORD Bobcat of Brantford 519-752-7900

bobcatofbrantford.com

HAMILTON Bobcat of Hamilton 905-643-3177

bobcatofhamilton.com

PARRY

PETERBOROUGH

Bobcat of Peterborough 705-748-9119

bobcatofpeterborough.com

THUNDER BAY Equipment World Inc. 807-623-9561

bobcat-tbay.com

CASSELMAN

KITCHENER

Bobcat of Tri-Cities Ltd. 1-866-214-3939

bobcatoftc.com

STRATFORD

Bobcat of Stratford 519-393-6040

bobcatofstratford.ca

SAULT STE. MARIE

Bobcat of Sault Ste. Marie 705-949-7379

bobcat-ssm.com

WINDSOR

Steve Filkin, asphalt foreman, uses the Bobcat S770 skid-steer loader. He added, “I like the speed of it, it’s fast! We do a lot of golf courses and I need to get around big areas fast. I like the foot control. Keeps us alert. It’s easy to maintain. Oil and hoses are right there. Great for loading trucks with broken asphalt and feeding a paver. The Bobcat S770 skid-steer (wheels) is easy to turn on asphalt. I also like the backup cameras.”

Evan Flicks, grading foreman, when asked what he liked about Bobcat machines, “The hand control (SJC – selectable joystick control) is a step up for them. I learned how to operate machines using hand controls. I use the Bobcat T770 compact track loader. I am in it for a full day, and I push and rip a lot with it. It’s a comfortable and powerful ride. The higher arms make it easier to load dump trucks.”

When Richard was asked if he would recommend Derek Brooker and Bobcat of Hamilton, his answer was, “I would highly recommend them!!!”

Thank you, Richard.

COURTICE

Bobcat of Durham East Ltd.

905-404-9990

bobcatofdurhameast.com

MUSKOKA

Bobcat of Muskoka

249-390-7000

oakenequipment.ca

SUDBURY

McDowell B Equipment Ltd.

705-566-8190

bmcdowell.com

WYOMING

Advantage Farm Equipment Ltd.

519-845-3346

advantage-equip.com

Prince Edward Island Strongco Prince Edward Island (902) 468-5010

www.strongco.com

Nova Scotia Strongco Dartmouth, NS (902) 468-5010

www.strongco.com

New Brunswick Strongco Moncton, NB (506) 857-8425

www.strongco.com

Manitoba

Westcon Equipment & Rentals Ltd.

Winnipeg, MB 1-800-453-2435

www.westconequip.ca

Saskatchewan

Redhead Equipment

Estevan, SK (306) 634-4788