LETTER FROM

Politicians love to talk.

I know this isn’t a ground-breaking revelation. However, nowadays it appears talk, which is maybe more accurately described as virtue signalling, supersedes any actual plan to tackle an issue. I frequently read quotes about politicians engaging in “meaningful conversations” or “sharing of stories.” It all seems to be wording designed to avoid the promise of measurable results, in favour of simply alluding to agreement and cooperation.

Unfortunately, these meaningful conversations seem to stop where they’re required. For example, the never-ending trade dispute between Canada and the United States on softwood lumber.

The lumber dispute has been ongoing for longer than I’ve been alive. The

American lumber lobby has successfully argued Canadian products receive unfair subsidies leading to the tariff.

An agreement met in 2006 that provided stability and predictability for industry on both sides of the border, expired in 2015. Now, after eight years without an agreement, the United States Department of Commerce has announced a combined duty rate for Canadian forestry products of 7.99 per cent, which is slightly less than the previous 8.59 per cent duty rate established after the last administrative review.

Following the duty rate announcement in July, the Independent Wood Processors Association of British Columbia asked the provincial and federal government to resume talks and have their duty fees returned.

“It’s time for the provincial

and federal government to get re-engaged on solving this dispute,” the association said in an open letter to government.

In anticipation of US President Joe Biden’s visit to Canada in March, the chief executive officers of Canada’s top lumber companies urged the Canadian government to place the softwood lumber discussion on the agenda.

It doesn’t sound as though lumber made the cut.

“They failed to raise it with the importance it deserved when President Biden visited Ottawa earlier this year,” said Kyle Seeback, Conservative Shadow Minister for International Trade. “Our efforts to demand action on this file have been met with silence and failure from this Liberal Government."

Canada’s forestry industry

Bill Tremblay // Editor editor@equipmentjournal.com

generates about $35 billion annually, and accounts for about 7.3 per cent of our exports. As well, the industry directly employs more than 205,000 people. Forestry is undoubtedly an important element of our economy.

So, if talk is cheap, surely, Canada can afford to engage our neighbour in actual "meaningful conversation" on fair trade of our natural resources.

CONTACT

Sales Manager Tara Baker tara@equipmentjournal.com

National Account Manager Mona Fahmi mona@equipmentjournal.com

TOLL-FREE: CDN/USA 1-800-667-8541

Creative Director/Creative Services Ryan Chuhaniuk ryan@equipmentjournal.com

Circulation Manager Lisa Bath lisa@equipmentjournal.com

EMAIL US: advertise@equipmentjournal.com

WEBSITE: www.equipmentjournal.com

Hitachi Construction Machinery Americas has introduced the new ZW220-7 wheel loader, which is equipped with several new productivity enhancing technologies.

The 4-cubic-yard wheel loader is an efficient loading tool available in both standard and high-lift arm configurations.

The new loader features an 18,613 kg operating weight and is powered by a 210 hp Cummins engine. Power is transferred to the ground through a five-speed transmission and limited slip differentials for effective job site traction.

“The next-generation ZW-7 wheel loaders feature upgraded technology for advanced productivity, enhanced operator comfort, improved serviceability and new safety features with a rear collision detection system,” said Matt Koester, Product Manager for wheel loaders at Hitachi Construction Machinery Americas.

Productivity boost

To improve productivity, the new loader is equipped with approach speed control, an auto power up function and a new payload weighing system.

The auto power up feature increases hill climbing performance. It identifies slopes and adds power to prevent engine speed from dropping when travelling uphill.

Approach speed control sets the desired speed the wheel loader will achieve as it approaches a loading point. The operator holds down the accelerator while lifting the load and the machine maintains a slower speed as it approaches the loading point. The operator taps the brake to bring the machine to a complete stop when it reaches the dump area. With approach speed control, the travel speed can be adjusted with fewer pedal operations during loading. This reduces operator fatigue as well as fuel consumption.

Hitachi’s payload weighing system uploads information reporting productivity to the ConSite telematic system. Operators can check the weight of the load in the bucket from the cab monitor and log the material loaded.

The system offers four modes: tip-off to truck, tipoff to pile, auto-add and manual-add. These modes allow the payload weighing system to manage loads according to their application. In addition, the unit is equipped with a warning function that reacts when the bucket is overloaded, improving safety during operation.

The latest safety innovation from Hitachi is an optional rear obstacle detection system on the ZW220-7 wheel loader. It offers rear object detection alerts to improve safety and help reduce potential damage on the job site.

The ZW220-7 also features emergency steering. The emergency electric pump delivers the necessary oil pressure for power steering even in the case of an emergency. This always allows normal steering, even if the engine fails.

Hitachi improved the overall comfort of the ZW220-7 with a larger and quieter cab. As well, the cab is equipped with a seat-mounted armrest with low effort electric hydraulic controls, ergonomically located switches as well as adjustable seat and mirrors. A 20-cm anti-glare LCD monitor with Bluetooth radio allows hands-free phone capability.

Cabs with panoramic visibility helps create a safe and comfortable working environment. The position and design of the cab pillars, the layout of the monitor and switch panel have been improved to ensure a wider field of view for the operator.

For more visibility, Hitachi’ equipped the loader with its Aerial Angle peripheral vision camera system. It provides a wide 270-degree bird’s-eye view of the machine’s immediate environment. Aerial Angle provides three cameras mounted on the rear of the machine. Operators can see both the left and right sides of the machine on the monitor inside the cab, providing visibility to the sides and rear of the machine.

Design enhancements help protect critical components from the environment. An inner element of the engine air filter protects the engine from dust ingress while cleaning the outer element. Even the air conditioner is protected with a sealed internal filter that prevents intrusion of dust into the air conditioner unit.

Airborne debris can become an issue in many wheel loader operations, often leading to decreased cooling system performance. Hitachi addressed this with an intelligent automatic reversing hydraulically driven fan and wide-fin radiators which prevent clogging.

Daily maintenance has been simplified with easy-access filters and improved access to components.

ConSite, Hitachi’s telematics system, remotely monitors operational status and alerts owners and operators to upcoming maintenance needs. As well, ConSite Air is a new optional add-on that allows the wheel loader to be diagnosed remotely, as well as deliver remote updates of the software. No matter where a machine is located, the servicing dealer can remotely diagnose issues that may arise, leading to increased uptime. A ConSite response team is on standby to rapidly resolve issues as they emerge.

416.770.7706 or 705.566.8190 sales@bmcdowell.com bmcdowell.com

2018 LINK-BELT 240 X2, 19’2 boom, 11’6” arm, Isuzu diesel eng. 177 hp, A/C, 48” 1.61 cu.yd. bkt, stk# R160-1002

McDowell Tilt N’ Load Service

ROLLBACK TRUCK, 12,000 lbs winch, rate max. vehicle cap. 15875 kg GVWR

2020

Robots’ (ACR) TyBOT is now available with a railfree deployment method, which expands the rebar tying robot’s opportunities in construction.

In response to feedback from the field, ACR has developed a new deployment method for TyBOT, called edge form bogies. The new method provides a significant enhancement that simplifies and speeds up on-site deployment.

The unique design eliminates the need for screed rails, a prerequisite previously required for TyBOT deployment. With TyBOT freed from the screed rail, the solution becomes available to more contractors.

"At Advanced Construction Robotics, we believe that true innovation in infrastructure comes from listening to those working with our solutions in the field,” said Stephen Muck, ACR’s Founder and Executive Chairman.

“Their feedback is invaluable, influencing our product road maps and driving us to develop problem-solving solutions that revolutionize construction. Together, we are shaping the future of infrastructure."

TyBOT previously relied on installed screed rail or a

porta-rail system that simulates screed rail for successful deployment. The requirement could sometimes be a limiting factor in locations where the screed rail was not readily available. The new bogies ride directly on the timber framing, called edge forms, that is erected on job sites to support concrete pouring.

TyBOT's edge form bogies are adjustable, compatible with 2x4 to 2x8 edge form caps and can handle any ex isting obstructions such as double-headed nails. With edge forms always available and in place, TyBOT can work on a wider range of projects, providing con tractors with the flexibility and efficiency they need. This new deployment meth od eliminates the need for pre-installation of screed rail, allowing contractors to maximize their resources and accelerate project timelines.

"By redesigning how TyBOT deploys on construction sites, we've created an opportunity for contractors to conduct deck operations more rapidly and efficiently than ever be fore," said ACR President and CEO, Danielle Proctor.

"We are excited to release edge form bogies because it provides our clients a more flexible and accessible solu tion, increasing TyBOT's

Trackunit has enhanced its Manager platform with a new CO2 reporting solution.

Emissions data reporting is currently based on estimated numbers. Trackunit’s Emissions Reporting app will, for the first time, introduce live-tracking of emissions data signalling an end to estimates and help construction companies become more sustainable.

“Essentially, we’re taking the guesswork out of emissions reporting,” said Trackunit CEO Soeren Brogaard. “It’s a game changer because it’s a level of accuracy and sophistication that is new to the construction market.”

Trackunit CEO Soeren Brogaard said the new CO2 reporting solution would use data to not only measure but also help to change operational behaviour.

viability for a wider range of projects."

TyBOT self-ties bulk horizontal rebar intersections. The robot is able to achieve a tie rate of more than 1,100 ties per hour.

“For the first time ever, customers will experience a fleet-wide estimate of emissions,” Brogaard said. “Unlike previous reports that worked only for machines that reported emissions-related data, our solution generates an estimate for every customer and jobsite.”

Brogaard highlighted the average idle time for machines in construction is 36 per cent while 15 per cent of construction companies have lost business in the last year due to non-compliance with environmental standards. He added the construction industry accounts for roughly 19 per cent of all greenhouse emissions.

Trackunit is an IoT services provider that connects construction through one platform to create a data ecosystem for the off-highway sector.

Liebherr

expands machine control availability to Gen 8 crawler excavators

Liebherr is extending its range of Leica Geosystems machine control options for its Generation 8 crawler excavators.

The R 922, R 924, R 926, R 928, R 930, R 934, R 938 and R 945 models are now available with 2D "3D-ready" and 3D semi-automatic machine control systems. The 2D "3D-ready" passive machine control system is also offered for these models.

The equipment variants are available from Liebherr ex works. All machine control components from Leica Geosystems are installed during the production process and the customer receives a pre-calibrated machine. This avoids the downtime required due to aftermarket installation.

Depending on the situation and requirements, Liebherr offers the right machine control system for every application. With a passive system, machine operators must follow the indications on the display in the cab and operate the machine themselves to complete the job.

The semi-automatic machine control system provides active support with a semi-automated removal mode. The machine operator must only control the machine's stick movements and speed via the joystick. The system automatically adjusts the correct movement of all the equipment to create the target profile.

Productivity can be significantly increased by using a semi-automatic machine control system. Work can also be carried out much more precisely over a longer period, reducing time-consuming and cost-intensive reworking.

Generation 8 excavators with a passive machine control system can be retrofitted with a semi-automatic system via a corresponding software package at the customer's request if they are equipped with a Master 5 Premium.

Machine control options

2D or 3D machine control systems from Leica Geosystems provide the machine operator with information about the height and inclination of the machine as well as the corresponding position via the display in the operator's cab.

While a 2D machine control system is designed for working from flat and sloping surfaces, a 3D machine control system uses reference models and GNSS to guide the machine operator.

shortened and the need for control measurements on the construction site is reduced.

Through 3D GNSS positioning in conjunction with 3D model data, all information on excavation, removal and the machine's position on the construction site is visible in real time.

With the 2D "3D-ready" variant, work can be done immediately in 2D, either passively or semi-automatically depending on the purchased option.

The 2D control system can be upgraded to a full 3D machine control system at any time.

Machine control systems are increasing in importance across a variety of construction projects. They offer significant added value to operators, companies and the environment and enable the operators to use their machines even more productively and precisely.

The consistent use of sensors and software provides the operator with real-time information, which in turn optimizes work processes in terms of time and cost thanks to the ability to automate functions. Waiting times for surveyors are

in the direct vicinity of the machine. The operator's workload is also reduced, Ontario office: (613) 542-1500 28 Steve Fonyo Dr., Kingston, ON K7M 8N9

FEATURING A FULL LINE OF HYDRAULIC ROCK BREAKERS FOR CARRIERS RANGING FROM 1 TON TO 120 TON CLASS

FOR EXCAVATION,DEMOLITION, MINING, CONSTRUCTION & QUARRIES. TRAMAC HAS AN ATTACHMENT FOR THAT.

which prevents driver fatigue and the associated susceptibility to errors. Montreal Office: (888) 663-8122 3421 Industriel Boulevard, Laval, Que. H7L 4S3

CANADA Shaun Brown Cell: (613) 532-4823 Office: (613) 542-1500 shaun_brown@tramac.com

Quebec City Office: (418) 877-5557 1711 rte de L’aeroport #4, L’ancienne Lorette, Que. G2G 2P4

SERVING THE CONSTRUCTION, DEMOLITION & MINING INDUSTRIES FOR OVER 57 YEARS 1966 - 2023 AUTHORIZED DISTRIBUTOR CONSTRUCTION EQUIPMENT RENTAL DOZERS - LOADERS - BACKHOES - ROLLERS CUSTOMER SER VICE TARTEN EQUIPMENT LIMITED 6199 Shawson Drive Mississauga, ON L5T 1E5 Phone: 905 670 1704 Fax: 905 670 4790 Toll Free: 1 888 670 1704WWW.TARTEN.COM COMMITTED TO SERVICE EXCELLENCE SINCE 1976

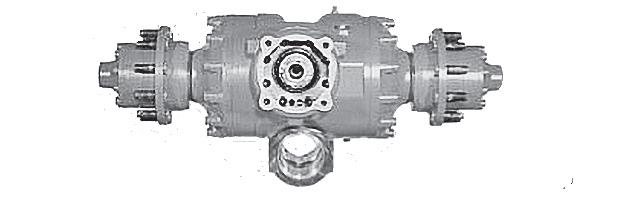

ECA Canada has acquired the Calgary, Alberta-based Ridgeline Equipment.

The acquisition serves to strengthen ECA Canada's position in western Canada, expanding its aftermarket service and parts offerings for the foundation, construction, oil and gas and drilling sectors.

Ridgeline, founded in 2016, specializes in delivering field service solutions, with expertise in engines, transmissions, torque converters, final drives and hydraulic cylinders.

The acquisition provides ECA Canada access to Ridgeline's extensive experience, equipment fleet and wide-reaching network.

"We are delighted to welcome Ridgeline Equipment into the ECA family," said Roy Kern, President and CEO of ECA.

"Their exceptional expertise in aftermarket heavy equipment service and parts perfectly complements our existing capabilities. Together, we will be able to provide our customers with an even broader range of solutions, ensuring their equipment operates at peak performance levels."

ECA offers sales, rentals, service, parts and training from 11 facilities through -

out the eastern United States and all Canadian provinces. The company has supplied foundation construction equipment for more than a century.

ECA (Equipment Corporation of America) entered Canada by acquiring Special Construction Machines of Toronto in 1999. The company deepened its commitment to the Canadian market in 2012 by building a new facility stocked with its full line of equipment to house 16 employees and more than $4 million in parts.

By leveraging Ridgeline's market presence and the company’s skilled workforce, ECA Canada is poised to expand its footprint in the foundation drilling and piling market.

ECA is the exclusive distributor for Bauer drilling rigs, Klemm anchor and micropile drilling rigs, RTG piling rigs, and Bauer MAT slurry handling systems. The company also distribute HPSI vibratory pile hammers, Word International Drill attachments, Pileco diesel hammers, Dawson Construction Products, Allu Ground Improvement Equipment, Pile Master air hammers, Digga auger drives and Olin concrete pumps. In April, ECA Canada announced its plans to open a 24,000 square foot facility in Calgary by the end of the year to support its growing presence in the region. ECA is also working to establish a new site in Maple Ridge, British Columbia.

OUR 7-POINT PLAN FOR MAKING YOUR JOB EASIER.

1 SWIFT, SMOOTH, SMART NEW MACHINES. We’re inventing and rolling out more than 30 new machines this year. Like the rest of our line, they help you make more money because they work in the real world.

2 HIP-POCKET SUPPORT.

CASE has 66 dealers, 325 locations and 6000 team members, and we’ve nearly doubled the size of our field support team. We’re as close as the phone in your pocket, ready to deliver the can-do-now response you need to win.

3 FINANCING THAT LIGHTENS YOUR LOAD.

From payment schedules with seasonal cash-flow cycles to revolving lines of credit for parts, service, attachments and rentals, our focus on construction customers means flexible solutions you won’t get from a traditional banker.

4 OPERATOR-FIRST FOCUS.

We build machines that keep operators comfortable, productive, proud and working hard. Because recruiting and retaining great operators is the bedrock of your success.

5 JOB-CRUSHING ATTACHMENTS & SOLID PARTS.

Our attachments catalog is 200 pages long. Our parts are engineered, tested and proven for durable, reliable performance. So you get both the right tools and the best parts to keep your equipment running strong.

6 REAL WORLD KNOW-HOW. Technology is the future, but the key to making it work on the jobsite is old-fashioned knowhow. We share the knowledge you need to make it make money for you.

7 HUSTLE.

We’re 180 years into this, but we’re building with the energy of a start-up. We’re hungrier than ever to roll up our sleeves and help your business succeed.

To learn more, see your dealer or visit CaseCE.com.

High digging force, short tail swing radius and its enormous flexibility – the Liebherr A 918 Compact Wheeled Excavator is the ideal partner on any construction site.

Combined with the largest modern driver’s cab, this machine provides the best possible environment to optimize operators’ health, focus and productivity, allowing for more efficient work.

www.liebherr.ca

Wheeled Excavator A 918 Compact

PP**

While Vermeer started as a small machine shop to meet the needs of local farmers in Pella, Iowa, the company has grown into a manufacturer with a dealer network of more than 600 locations worldwide.

This year, Vermeer Manufacturing celebrates its 75th anniversary. Built on Founder Gary Vermeer’s legacy of finding a better way, Vermeer Corporation has focused on impacting people and the world for the better. Today, Vermeer operates eight facilities in six continents, including its headquarters in Pella, and offers service and support in more than 60 countries.

Vermeer President and CEO Jason Andringa, the grandson of Gary Vermeer, explained the next 75 years will continue to aim for the same purpose.

2022

L 506 C

PREMIER

Used 2019 Liebherr PR 736 XL Dozer, equipped with A/C in cab, rear auxiliary hydraulics for winch, U-frame with 6-way adjustable straight blade 3638x1350mm 4.67m3, 610mm pads, Tier 4f.

**WARRANTY : 24M/2000HRS PREMIER PP**

Used 2022 Liebherr L 506 C Loader, equipped with A/C in cab, front auxiliary hydraulics, Z-bar hydraulic coupler, GP bucket , 4-fenders, Tier 4f.

“With the guiding principle of treating other people how you’d want to be treated yourself, we’ve created a culture over the last 75 years of making a real impact on the way work gets done that continues to drive our company forward,” Andringa said.

“Ultimately, it’s a commitment that is part of every interaction we have among ourselves, suppliers, dealers, customers and the com-

munities we live and work in.”

Today, Vermeer has expanded from its modest beginnings to an organization of more than 4,000 team members worldwide, recently having been recognized by Forbes Magazine as one of America's Best Midsize Employers.

From Gary Vermeer's first invention of the wagon hoist followed more equipment innovations from the company. With the invention of the hydraulic horizontal directional drill, large round baler and stump cutter, Vermeer has shown its commitment to creating equipment that addresses the challenges its customers face.

Looking ahead to the future, new innovations Vermeer plans to bring to market will include expanding digital product offerings, developing next-generation machines and introducing new equipment.

“We are committed to carrying on the legacy of innovation and continuous improvement to make a lasting impact around the world,” Andringa said. “We understand the important work our customers and equipment are doing, and we support them, wherever they are. Together, we are equipped to do more.”

Topcon Positioning Systems has unveiled Aptix, a new inte gration-platform-as-a-service (iPaaS) desig ned to optimize management of heavy civil construction projects.

Used 2015 Liebherr R 946 LC Excavator, equipped with A/C cab, auxiliary hydraulics, wedge hydraulic coupler, excavation bucket, automatic greaser, mono boom 6.45m, stick 4.10m, lock valves boom and stick cylinders, reversible fan, track pads 750mm triple grouser, new batteries.

2019

**WARRANTY : POWERTRAIN/ HYDRAULIC PP 2000HRS/24M**

Used 2019 Liebherr R 970 S-HD

Excavator, equipped with A/C cab, excavation bucket 2450mm 5.50m3, automatic greaser, one piece boom 7.00m, stick 2.60m, lock valves boom and stick cylinder, rear and side camera, reversible fan, metal track pads 900mm, heavy 14.5t Counterweight, Tier 4f.

Used 2020 Liebherr R914 Compact Excavator, equipped with A/C cab, high pressure auxiliary hydraulics and medium pressure, tilting hydraulic coupler, excavation bucket, automatic greaser, monoboom 4.60m, stick 2.05m, lock valves boom and stick cylinders, rear and side camera, reversible fan, dozer blade 2640mm, steel track pads 600mm, tier 4f.

The Aptix platform integrates Topcon solutions with multiple third-party applications to automate and coordinate data connections between the office and the job site.

“Aptix integrates Topcon’s heavy civil construction solutions with third-party solutions to share data, automate workflows, and facilitate built actuals reporting. Being open and ready to integrate with the rest of the world is what moving the construction industry forward is all about,” said Murray Lodge, Topcon’s Executive Vice President and General Manager.

**WARRANTY

24M/2000HRS PWRT/ HYD PP**

Used 2015 Liebherr LH 22 M Material

Handler, equipped with A/C, cab riser, auxiliary hydraulics high pressure and medium pressure lines, pressureless return line, automatic greaser, angled mono boom 5.00m, stick 2.65m, lock valves boom and stick cylinders, rear and sidecamera, reversible fan, 4 outriggers, twin Liebherr 10.00-20 tires, Tier 4i.

visibility for carbon footprint and sustainability initiatives.

Aptix can automate the distribution of machine control files, constructible models, project schedules and reports on actuals.

As well, it shows, in near real-time, the machine locations with the ability to aggregate as-built data from mixed fleet telematics. It provides real-time reports on people, materials, machines and carbon dioxide emissions, creating greater

“By automating previously manual processes, Aptix eliminates time-consuming and error-prone data entry, allowing construction professionals to focus on more strategic tasks,” said Jason Hallett, Vice President and General Manager of Topcon Integration Services. “Project managers can make better, more informed decisions by having real-time visibility into project progress and potential roadblocks. We are confident that Aptix will optimize how construction projects are managed.”

A key feature of Aptix is the ability to automate the distribution of constructible models and scheduled task changes. Frequent changes make it difficult to keep management teams, operators and other stakeholders updated with current infor-

mation. Aptix addresses this challenge by integrating with industry-standard applications, including Autodesk Construction Cloud and Microsoft OneDrive.

Through the integrations, Aptix actively monitors file updates within Autodesk Build, Autodesk Docs, BIM 360 and Microsoft OneDrive. When a constructible model or schedule change occurs, it automatically distributes these updates to all key stakeholders, ensuring operators have access to up-to-date models and scheduled tasks and that project managers have up-to-date reports.

“Without up-to-date, accessible and actionable information, construction teams will always struggle to communicate and collaborate,” said James Cook, Director of Partner Integrations at Autodesk Construction Solutions.

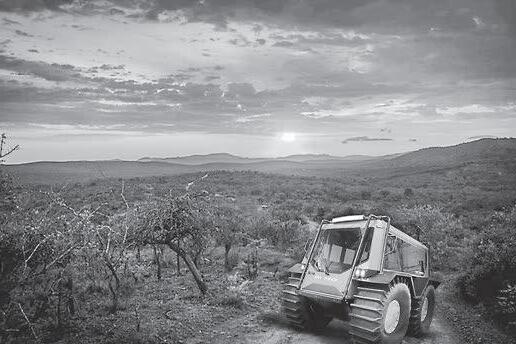

Originally created for excavation on slopes, the versatility of the Menzi Muck line of spider excavators has allowed the machines to expand their scope on construction projects.

At the Redwater, Alberta-based Evolution Mechanical, customers have selected spider excavators for various applications, from forestry to drilling to rail construction.

“Everybody says ‘it’s so specialized,’ which is right. But it’s specialized in a lot of areas,” said Josh Caouette, President of Evolution Mechanical. “It's a pretty diverse package when you look at it.”

Originally designed to work on the steep grades of the Alps, Swiss manufacturer Menzi Muck introduced their first spider, also known as a walking excavator, in 1966. The machines move on four wheels connected to the undercarriage by legs. The legs allow the adjustment of track width and the height of the excavator. This ability to ‘walk’ allows the machine to travel over rough terrain or steep slopes.

“The units are able to self-load and unload very quickly off the trailer,” Caouette said. “And it’s able to travel fairly easily, unlike a tracked excavator that travels quite slowly. It’s not a big deal for it to walk a kilometre or two.”

In Canada, Evolution Mechanical is the exclusive dealer for Menzi Muck. Founded in 2013 as a family-owned and operated business, Evolution Mechanical has grown from a single service truck to employing 50 people and opening a second location in Vernon, British Columbia.

Caouette was introduced to the spider excavator line after seeing the machine on YouTube and became a dealer for the Menzi Muck eight years ago.

"This partnership with Menzi Muck is not just about expanding our reach. It's about joining forces with a company that shares our commitment to innovation and excellence Caouette said. “Together, we're not just changing the landscape of excavators; we're shaping the future of the Canadian equipment industry."

Menzi Muck M545x

The M545x is the largest machine in the lineup, and the machine has become the most popular Menzi Muck spider excavator sold by Evolution Mechanical. Introduced at bauma in 2019, the M545x weighs 13,500 kg and features a travel speed of 15 km per hour and a maximum lifting capacity of 9,800 kg.

“Everybody who's bought one has bought more or is planning to. The feedback has been great,” Caouette said. The machine is equipped with claws and rams that extend beyond the tires, providing an unobstructed view of the job without impeding travel. Its versatility is further enhanced by the machine's ability to steer in any configuration, making it ideal for work in challenging conditions.

The Anticipating Power Management (APM) controller ensures fast and harmonious interplay between the 154

hp Deutz 4-cylinder turbodiesel engine and hydraulics.

As well, a separate powerline delivers 220 litres per minute of hydraulic flow for attachments.

“The powerline allows you to run bigger attachments. It's basically a tool carrier really,” Caouette said. “We put Wimmer rock drills on them and the unit can be turned into a self-contained drilling unit. We can even mount the compressor directly to the unit.”

The Menzi Powerboom allows the M545x to achieve the lifting force of 9,800 kg. The boom cylinder is positioned horizontally in the centre section of the excavator, which also eliminates collisions at the boom cylinder.

P-Vation

The new P-Vation stabilizers provides automatic and symmetric stabilization of the spider excavator. Strategically arranged pivot points on the chassis ensures horizontal and vertical parallel adjustment of all wheels.

The M545x features 4-wheel, crab and front or rear axle steering. A maximum width wheel adjustment of more than 6 metres boosts stability and allows closer proximity to slopes.

As well, the maximum 2.2 metres of ground clearance enables deployment in water or work on embankments.

“I can’t quite hop our 10-foot chain-link fence, but just about. I tried,” Caouette said. “I've climbed on a sea can with one once."

CDE’s largest construction and demolition waste plant in Canada is now operational.

CDE designed and engineered the washing solution for Calgary Aggregate Recycling (CAR), an Alberta-based concrete, asphalt and aggregate recycling firm.

The plant, capable of producing 250 tons per hour, is now operational at CAR’s recycling facility in southeast Calgary.

“We have been very busy hosting tours since opening and have received tremendous feedback from the community on how we can help them achieve their business and environmental goals,” said Travis Powell, President at Calgary Aggregate Recycling.

The CDE plant aims to disrupt “out-ofdate practices” in the construction industry. The set-up will reduce Calgary Aggregate Recycling’s financial cost of construction, as well as the social and environmental costs.

“We set out to establish economical and viable solutions to position Alberta as a leader in sustainable and responsible construction,” Powell said. “We started this process by applying for a grant with Emissions Reduction Alberta (ERA). It believed in the impact of our proposal and gave us the start we needed to get to where we are today.”

Enabled by CDE washing technology, the company now has the capacity to process an additional 600,000 tons of waste material to produce more than 1.25 million tons of construction sand and aggregate products annually across the wider company operations.

“This plant is the largest we have ever commissioned in Canada, and also our first partnership with CAR, which demonstrates real confidence in our washing technology and recycling process,” said Adrian Convery, CDE’s Business Development Manager for Canada.

“It’s a partnership that is pioneering better ways of managing resources in Canada, driving forward the agenda for change, and

building a strong case for the adoption of recycled materials in the construction industry by highlighting the immense potential of C&D waste streams.”

In addition to the significant volume of material the plant is diverting from landfill, the circular approach to resource management is also helping to reduce carbon emissions.

The plant is expected to help reduce carbon emissions in Alberta by about 22,567 tons annually.

“As well as landfill diversion, our solutions help to realize sustainability aims by reducing, or completely eliminating, the requirement to truck in sand and aggregate resources from other jurisdictions – an approach that generally comes at a significant environmental cost,” Convery said.

CDE’s experience in developing waste recycling solutions in North America made the company an ideal partner for CAR when it set out to commission the system.

CDE hosted virtual meetings and utilized 3D modelling to showcase many of its international waste recycling plants, from Scotland to New York. Confident CDE was the partner of choice, CAR commissioned its first-ever wash plant consisting of a R4500 primary feeding and scalping screen with the M4500 modular sand washing plant and AggMax 253R scrubbing and classification system, which combines pre-screening, scrubbing, organics removal, sizing, stockpiling, fines recovery and filtrates removal on a compact chassis.

The solution also features CDE’s EvoWash, a modular sand washing system that screens and separates smaller sand and gravel fractions through an integrated high-frequency dewatering screen and hydrocyclone technology to control silt cut points and eliminate the loss of fines, as well as its Counter Flow Classification Unit

(CFCU) technology, which offers a variable separation point to provide greater control over sand classification.

Underscoring the solution is CDE’s AquaCycle thickener water management system, which offers efficient recycling of up to 90 per cent of process water. With its filter press sludge dewatering system that presses sludge discharged from the thickener to recover even more water, recovery reaches up to 95 per cent.

Processing up to 250 tonnes per hour of raw feed material, the CDE solution is transforming C&D waste into seven construction products, helping CAR to generate additional revenue while simultaneously diverting significant tonnages of material from the landfill.

Among the outputs are 0-1 mm fine and 0-4 mm coarse sands as well as 4-10 mm undersize, 10-20 mm midsize, 20-40 mm, 40-100 mm and 100 mm oversize aggregates.

The products are frequently tested to ensure compliance with municipal standards and specifications.

As well, the products are being marketed to the wider construction industry in Alberta and are supporting a range of public works and infrastructure projects.

Before working with CDE, CAR did not have an outlet for contaminated soils, and trucks were required to take a 350 km round trip to dispose of contaminated soils at a landfill. Now, the trucks have increased load frequencies per day, with less servicing required resulting in a reduction in carbon emissions. As well, CAR is producing in spec material for the wider construction sector.

While electric drives score well with regards to emissions, in some situations a fuel-saving diesel drive is the better solution.

Kleemann uses three different drive concepts that offer the ideal solution depending on the task at hand, including E-DRIVE, D-DRIVE and H-DRIVE.

The decision on the most efficient solution depends on many factors. For example, whether there is a power supply option available on site, whether the machines are used in an urban environment or which local environmental regulations apply.

E-DRIVE

E-DRIVE offers two options: diesel fuel or all-electric. All-electric operation is environmentally friendly as there are no carbon dioxide emissions on site. A precondition for this is an ample and available power supply, which is often available in quarries or in larger recycling yards.

If a sufficient power supply is not available, a diesel-electric work option is available. For example, if the complete plant in the quarry is to be moved along the rock face, power is then supplied from a long cable, which is often too complex, or even no longer possible. In this case, power comes from the fuel-efficient diesel engine. The crusher and all conveyor belts are then driven electrically by a generator. Depending on the local situation, the E-DRIVE concept offers high flexibility.

D-DRIVE

The diesel-direct D-DRIVE provides power directly from the engine to the crusher. In the last few years, it was possible to reduce consumption through the load-dependent fan drive of the new EVO2 Generation. The diesel-direct drive has the edge in lowering

fuel consumption significantly. Thanks to a compact size and well thought-out transport options, the machines can be positioned in any place on the jobsite. If continuous use of the all-electric drive is not possible, D-DRIVE is the better option and the more sustainable choice whenever flexibility is required. This is the case with demolition and processing work in urban areas, but also in road construction where the machines have to be moved along as construction progresses.

H-DRIVE

Screening plants from Kleemann use a diesel-hydraulic drive. Hydraulic pumps operate all machine parts such as the screen, belts and drive system. The power requirements of the screens are considerably lower than a crusher, which reduces fuel consumption during operation. The optional Start-Stop system can reduce consumption even more. With the Dual Power configuration, Kleemann screening plants have an option for an all-electric power supply. If a connection is available, the plant operates on site free of emissions. For example, in ecologically sensitive areas with strict stipulations.

Many factors play a role in the area of sustainability. Energy required for production, transport, storage, sales and disposal are all incorporated in the ecological footprint of the production process.

As far as emissions during operation are concerned, an all-electric plant is without doubt the best choice. In other cases, you must weigh whether supply via an external power source involving high equipment and material costs is more constructive at the end of the day than technology with lower fuel consumption.

Ecology can also mean placing your trust in low material usage and high durability.

416-458-2334

Eagle Crusher is expanding its UltraMax line with a new portable impactor.

The new UltraMax 1600XOC portable impactor is designed for larger-size aggregate operations and quarries. It features Eagle Crusher’s UltraMax 69X Impactor with a 175 cm x 130 cm feed opening to allow larger material into the impactor to increase throughput. The 1600X-OC produces up to 1,000 tons per hour. This means producers can prep less and crush more to

reduce costs and increase profits. The plant’s massive, solid-steel, three-bar, sculptured rotor, weighs in excess of 13 tons and crushes even the largest feed material in a single pass.

The 1600X-OC features a large hopper/feeder to accommodate large aggregate or recycle operations and can be configured as either a flat or sloped feeder. The impactor also includes a grizzly bypass chute and optional cross-belt conveyor with hydraulic controlled flop gate allowing for either removal of the material that passes through the grizzly deck for stockpiling or blending back with the crushed material.

The plant’s discharge conveyor features a vibrating pan to ensure material flows smoothly out of the crusher and onto the belt to be transported stockpiling or to a stockpile or onto the new 8×20 screen. The conveyor can optionally be equipped

with a magnet for removal of steel contaminants in recycle operations.

Eagle Crusher’s new 8x20 screen with integrated feed conveyor and blending gates is designed for producers that require multi-product screening and can produce up to four products simultaneously, three with absolute sizing, or return the oversized product for further reduction. The integrated 153-cm feed conveyor remains on for transport and eliminates the need for a separate conveyor, while each screen deck features four blending gates to allow for a wide range of custom product mixes to meet specific product needs.

The 8×20 triple-shaft screen also features service platforms on both sides that remain on for transport.

The six-leg hydraulic lift and levelling system enable quick and easy set up and tear down for complete runon capabilities.

When loading material is on your to-do list, Wacker Neuson is ready for action. Our powerful wheel loaders, excavators, skid steers and compact track loaders deliver both performance and comfort. And our newest utility track loader offers class-leading hinge-pin height and fast cycle times to help you load, move and place material precisely.

Montabert USA has expanded its distribution and rebuild facility to allow in-hous e repair and remanufacturing for its North American operations.

Prior to the Nashville facility expansion, rebuilds and repairs of Montabert breakers were handled by a partner facility in Tennessee. Relocating the work to the Montabert Distribution and Rebuild Facility provides several benefits to enhance the company’s factory-certified rebuild program.

“We now have the capability of lowering breakers up to 15,000 lbs. into a pit for safe extraction of power cells and to perform inspections and maintenance,” said Amanda Carpenter, Sales Office, Warehouse and Distribution Manager for Montabert USA.”

“We have also added a factory-trained breaker technician who is dedicated to working on Montabert equipment. The in-house rebuild centre offers more visibility into scheduling, al-

lowing accuracy of quoting and timely completion of customer rebuilds.”

Montabert began the expansion plan last year working within the existing 4,650 square metre distribution centre. New capabilities for the facility now include a 10-ton crane, the pit with lift table and a hydraulic power unit for breaker testing prior to shipping.

While these new capabilities are now offered onsite, the expanded facility officially opens on Sept. 28.

“With the addition of a rebuild and repair centre strategically located within our existing U.S. distribution facility in South Central Illinois, we are now taking our already industry-leading product support capabilities to the next level,” said General Manager Aaron Scarfia.

“This expansion will enable us to more efficiently support our customers with preventative maintenance of their Montabert products, protecting their investments into the future.”

In 1982 Robert Green Equipment set up shop as an equipment broker and became a registered company Robert Green Equipment Sales Ltd. in 1985. In 1988 Robert sold the first Yutani excavator in Toronto (Kobelco distributed by Mitsubishi) and in 1991 Robert became the official Kobelco dealer for the Toronto and surrounding area. Robert G. Green Equipment Sales Ltd. is the only single dealer in the Kobelco organization that sells only Kobelco excavators and attachments.

Since 1991 there are over 600 Kobelco excavators serviced in the trade area. Kobelco introduced the first short radius at Con-Expo in 1999, the Kobelco 235SR. Robert sold the first unit in North America to S.A Sutcliffe Excavating in Bethany, Ontario.

(905) 888-9070

41 Cardico Drive, Gormley, ON L0H 1G0 robertgreenequipment@bellnet.ca

Valentine Underground Services Ltd., a highly respected sewer and watermain contractor, has been proudly serving Southern Ontario for over 35 years. Valentine Underground specializes in commercial, industrial, and institutional storm sewer, sanitary and watermain installation and repair, municipal connections, road work improvements, trenching and supply, and install interior drains, which many contractors don’t do.

When Robert Beiforte, co-owner, was asked why they decided to purchase the new Kobelco SK380SKLC-7, his reply was “we have a big project coming up in Burlington that requires to bulk out a large area for a storm trap system (82 pieces) to manage stormwater under a parking lot. We currently have three Kobelco’s but wanted a bigger one so that we could bulk out faster and with the zero tail swing this was also key as the

This year Kobelco has introduced the largest short radius excavator, the Kobelco SK380SRLC-7 with an operating weight of 84,700 lbs. and a swing radius of about 17’7”.

Robert Green sold the first Kobelco SK380SRLC-7 in Canada to a long-time customer Valentine Underground Services. Stephen Cargill sold the second one after his customer Troy Smith of TAS Excavating & Rentals from Ethel, ON, saw Valentine’s machine ready for the road.

Kobelco Construction Machinery is shipping 54 new Kobelco SK380SRLC-7 to North America this fall with 8 coming to Robert Green Equipment Sales Ltd. Come and see the future.

excavator has a decreased chance of damaging property when working close to buildings and other obstructions. We find Kobelco machines the most fuel-efficient excavators on the market and have very little downtime. The most reliable manufacturing excavator out there. Our operators love how smooth the machines are and their comfort is important. Also, the quick change bucket is a breeze. We can change attachments in less than a minute. With our company continuing to grow, it now doesn’t limit us as a company what we can do now that we have a bigger Kobelco excavator to get any job done.”

Our service has been second to none with Robert Green Equipment Sales Ltd. We have been working with Robert Green since the beginning. He really makes a difference when buying a machine and always takes really good care of us.

To provide more eco-friendly building materials to the construction industry in eastern Canada, Lafarge is changing the way it produces cement at its plant in Bath, Ontario.

Since its creation in 1973, the Lafarge Bath Cement Plant has held significant importance in Canada. With more than 100 skilled workers, the plant currently produces more than 1.1 million tons of cement per year.

The Lafarge plant is responsible for supplying cement to several major infrastructure projects that contribute to the growth and development of several local cities.

Rather than continuing to produce general use cement (GU), the plant is being retrofitted to create OneCem, a product that generates less carbon dioxide.

While production of OneCem generates less CO2, its use also reduces the carbon footprint of construction projects. Typically cement represents only 11 per cent of a concrete mix, but it may account for 80 per cent of all energy to produce concrete.

The conversion to OneCem is part of Lafarge's plan to reduce its carbon footprint that will save more than 140,000 tons of carbon dioxide per year

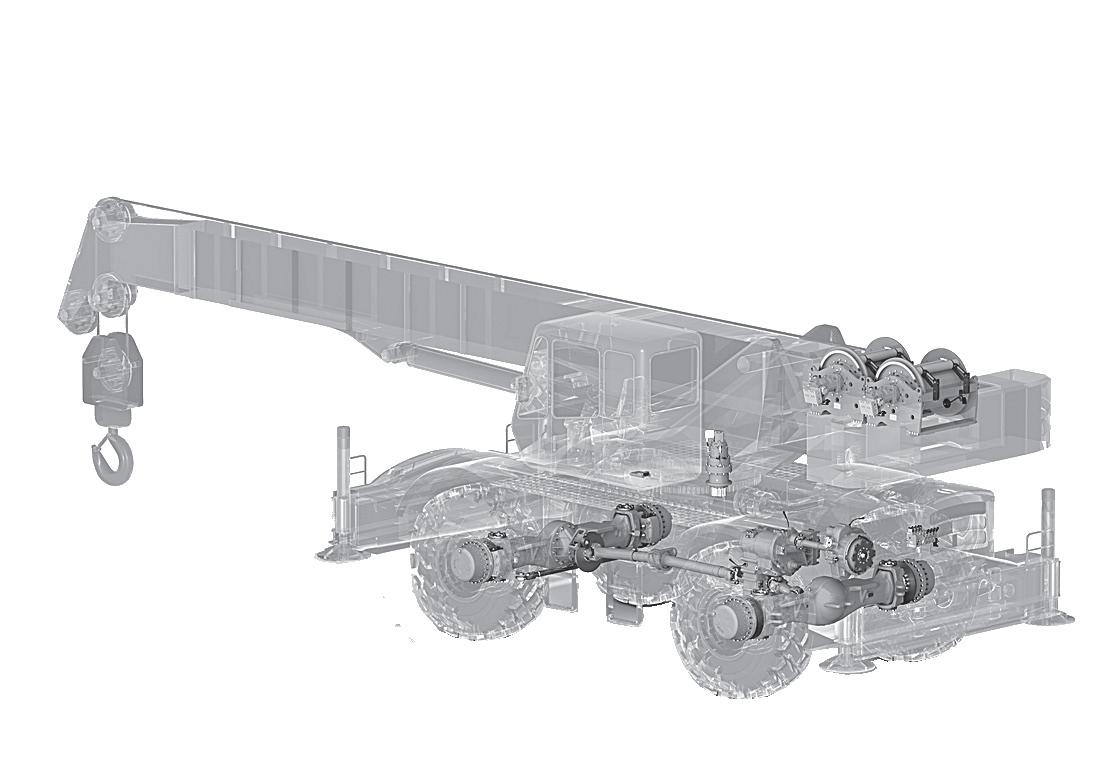

As part of the cement plant retrofit, the kiln dryer required replacement. Sarens was responsible for the removal of the old kiln dryer and the installation of the new unit.

The kiln is the part in charge of drying cement during the manufacturing process, so it plays a key role in cement production going forward.

To meet the project's objectives, Sarens had a one-week deadline to remove the old kiln and transport, lift and install the new one. To meet the deadlines, Sarens had a week before the start of the lift to ensure the conditions were suitable and to assemble the crane that would later carry out the lifting of the furnace, saving valuable time to meet the proposed objectives.

For the required lifts, Sarens utilized some of its most experienced operators to ensure the safe and efficient execution of the project.

Operating Weight: 17,660 lbs - 20,376 lbs

Dig Depth: 18’1” /Max Reach: 25’8”

Max Engine Power: 109 hp

TORONTO 370 OAKDALE RD., TORONTO, ON M3N 1W5 1-800-561-3212 / (416)-747-1212

WEST Nick D’Onofrio - 416-417-1539 ndonofrio@moorejcb.com

EAST Alex Patten - 647-206-6663 awpatten@moorejcb.com

JCB 50Z-1

Operating Weight: 10,583 lbs

Gross Engine Power: 48.3 hp

Bucket Tearout: 8,542 lbf

MONTREAL 4955 CHEMIN ST FRANÇOIS, ST. LAURENT, QC H4S 1P3 1-800-363-4958

SERVICE

A Liebherr LR1600 crawler crane was also required, a model with a maximum 660-ton lifting capacity. The crane was configured with 48 metres of main boom and 36 metres of derrick mast, weighing a total of 231,935 kg.

Counterweight requirements for the lift included 65 tons of counterweight in the carbody, 150 tons in the superstructure and an additional 250 tons in the superlift tray, adding up to a total weight of 696,803 kg.

"The features of the LR1600 added to the smooth execution of lifting the 664-ton furnace that the LR was commissioned to lift,” said Luke Goodfellow, Sarens Area Manager.

“With skilled and professional personnel paired with the powerful LR1600 crawler crane, Sarens was able to exceed expectations for this project.”

Sarens provides crane rental, heavy lift and engineered transportation services. The company maintains one of the world's largest inventories of cranes, transporters and special rigging equipment.

With more than 100 entities in 65 countries, Sarens employs more than 4,500 people worldwide.

The new HT 160 SLD 3 Hooklift from Palfinger is designed to deliver higher performance, easy installation and user-friendliness.

The new hooklift, created for the North American market, is part of Palfinger’s Vision & Strategy 2030, which aims to remain constantly challenged to find better solutions for its customers.

“Our focus is always on

developing an exemplary product portfolio specialized for our regional customers to address their challenges effectively,” said Ismael Daneluz, Palfinger’s Vice President of Sales & Service for North and Latin America.

“We are proud to offer the HT 160 SLD 3 Hooklift to meet industry demands. We are confident that this new model will boost productivity and overall satisfaction for our customers.”

The HT 160 SLD 3 Hooklift delivers a 10 per cent reduction in dead weight while maintaining a consistent lifting and tipping capacity of 7,250 kg at a 90-cm hook height and 8,165 kg at a 1.4 metre hook height. This enhancement helps to boost operational efficiency.

Coupled with a subframe design that includes a raised front cross member, the HT 160 SLD 3 Hooklift fits a

wide range of trucks. It also has a Standard Advanced Mounting (SAM) system that enables quick and easy installation, minimizing downtime during set-up.

The hooklift is designed to be user friendly. For maximum flexibility, it includes an adjustable hook height, measuring 90 and 140 cm, for maximum flexibility.

“In response to customer feedback, we have redesigned the hook shape to enable easier connection to the container bar. Furthermore, the introduction of greaseless bushings reduces maintenance time and costs for the customer,” said James Hanson, Palfinger’s North America Director of Sales.

The HT 160 SLD 3 Hooklift is finished with the Palfinger Origin Protection (POP) painting and surface treatment for protection, which significantly increases the unit’s lifetime value for customers.

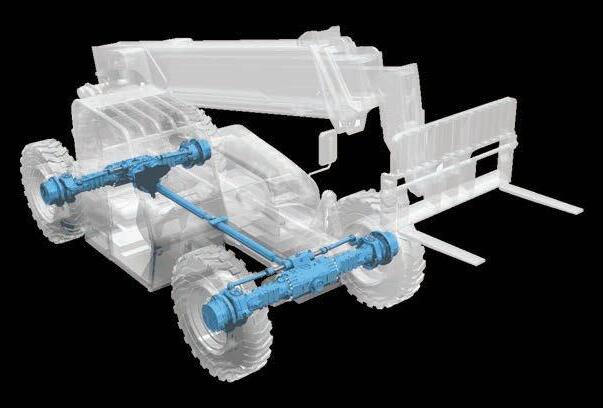

Manitou Group has won a 2023 Sustainable Industry Award in the “decarbonization” category. The award recognizes the innovation and sustainability of the group’s hydrogen program.

The France-based Sustainable Industry Awards recognize innovative projects that combine profitability and sustainability in industry. Among the 70 entries submitted for this year’s event, the jury selected Manitou Group’s hydrogen-focused approach, and in particular the development of two prototype telehandlers running on green hydrogen.

In December, Manitou introduced the world’s first prototype telehandler powered by a fuel cell that will soon be tested on a worksite.

Manitou based its first prototype on an existing model from its range of construction machines, capable of lifting loads up to 18 metres. This machine will be tested and sent out to construction sites by the end of 2023.

“We’ve now reached the second stage of our project: testing the machine in real-life conditions,” said Julien Waechter, Manitou Group’s Vice President of Research & Development.

“In a few months’ time, it will be joined by a second prototype of a rotating telehandler with even greater lifting capacity. More than anything, this prize rewards the innovation at the heart of Manitou Group’s DNA, and our determination to accelerate our energy transition.”

Manitou Group is eager to promote and accelerate the development of the French hydrogen industry, having joined forces with local green hydrogen producers. As a result of the technologies implemented in its products and the use of green hydrogen, Manitou estimates the carbon emissions linked to the entire life cycle of a telehandler will be 25 per cent of a telehandler equipped with a combustion engine machine.

Manitou Group has set a target of reducing greenhouse gas emissions by 34 per cent per hour of use of its machines by 2030. Its low-carbon trajectory was validated by the SBTi in 2022. The company is aiming to see its electric and hydrogen ranges side by side depending on each user’s applications, with a target of 43 per cent low-emissions products marketed in 2030.

ALBERTA

Liftboss JCB

Calgary: 403-301-0041

Edmonton: 780-474-9900 liftboss.ca

BRITISH COLUMBIA

Williams JCB

Surrey: 604-930-3316 williamsjcb.com

NEW BRUNSWICK

A.L.P.A. Equipment

Edmundston : 506-735-4144

Balmoral : 506-826-2717

Fredericton : 506-452-9818

Moncton, N.B. : 506-861-2572 alpaequipment.com

NOVA SCOTIA

A.L.P.A. Equipment

Truro : (902) 897-2717 alpaequipment.com

NEWFOUNDLAND

Harvey JCB Corner Brook: 709-639-2960 St. Johns: 709-738-8911 harveyco.ca

ONTARIO

Advance JCB

Waterloo: 519-742-5878

Harriston: 519-510-5878 advanceequipment.net

D&W Group Inc.

Doughty & Williamson

Jarvis: 519-587-2273

Brant Tractor

Burford: 519-449-2500

Redtrac International

Vineland: 905-562-4136 dwgroup.ca

ONTARIO

Delta JCB

Dunvegan: 613-527-1501

Renfrew: 613-432-4133 Winchester: 613-774-2273 deltapower.ca

Fulline JCB

Glencoe: 519-287-2840 fullinefarm.com

Hub International Equipment Ltd. Lindsay: 705-324-6136 Port Perry: 905-982-1500 hubinter.com

Jade Equipment

Simcoe County and Districts of Parry Sound & Muskoka 705-325-2777 jadeequipment.com

John’s Equipment Sales Frankford: 613-398-6522 johnsequipmentsales.com

ONTARIO

Moore JCB

Toronto, York & Peel

Region: 416-747-1212 moorejcb.com

North Rock JCB

North Bay, Sault Ste. Marie, and Sudbury: 705-897-7369 northrockrentals.com

ReadyQuip Sales & Service Ltd.

Timmins: 705-268-7600 readyquip.com

WPE Landscape Equipment - JCB

Hamilton/Halton: 905-628-3055 wpeequipment.ca

PEI

A.L.P.A. Equipment (506) 861-2572 alpaequipment.com

QUEBEC A.L.P.A. Equipment

Bas-Saint-Laurent : (506) 735-4144

Gaspésie : (506) 826-2717 alpaequipment.com

Bossé Quebec Inc.

Desmaures: 418-878-2241 Saint-Augustin-debosse-frere.com

Moore JCB

Montreal: 514-333-1212 moorejcb.com

SASKATCHEWAN & MANITOBA

Westcon JCB

Regina: 306-359-7273

Saskatoon: 306-934-3646

Winnipeg: 204-694-5364 westconjcb.com

James Roes has been in concrete construction for 32 years and decided he wanted to open a rental business specializing in concrete equipment rentals as he saw a need for it in the industry. In 2015 he established Festival City Rentals Inc., a family-owned business in Stratford, Ontario. James’ son Adrian started in 2019 and has been the manager for the past two years. They have found that their customers like to support local family businesses and appreciate that they go above and beyond and don’t treat them as a number. They provide the best service they can to ensure they return with that extra personal touch. Service is their keyword. Festival City carries everything from Bobcat machines to specialized equipment such as ride-on power trowels, concrete supplies, sealers and concrete stamps, shovels, rakes, and anything else that contractors need. They are a fullline concrete supply rental shop. Festival City offers small engine repair and Wacker Neuson service as well. They sell brand-name products like Husqvarna, Stihl, Wacker Neuson, Honda engines, Leika and Topcon lasers. They serve contractors and homeowners in Perth, Huron, Oxford, and Waterloo counties and reach as far as Toronto with their specialty concrete equipment offering.

YOUR LOCAL AUTHORIZED BOBCAT DEALERS

BARRIE Bobcat of Barrie 705-726-2228 oakenequipment.ca

GREY BRUCE Bobcat of Grey Bruce 519-372-9100 bobcatoftc.com

PARRY SOUND

Bobcat of Parry Sound Ltd.

705-342-1717

bobcatofparrysound.com

TORONTO WEST Bobcat of Toronto 416-679-4172 oakenequipment.com

The first year Festival City Rentals opened its doors, they purchased three pieces of Bobcat® equipment to start. “When buying equipment, dealer relationship is #1. I have been dealing with Stratford Farm Equipment (Bobcat of Stratford) from the very beginning. They are the oldest Bobcat dealer in Ontario, 50 years this year. I have been running Bobcat machines for 25 years. Even 15 years ago Bobcat had a full line of attachments manufactured to the highest standard, not Mickey Mouse like some other manufacturers. Today they have a much greater selection. Availability to a wide attachment offering is big for our renters”, stated James. Adrian added, “we now own a Bobcat T450 compact track loader, an MT85 mini track loader, 3x MT100 mini track loaders, 2x E20 compact excavators, 1x E35 compact excavator, a wide variety of Bobcat attachments, and the most recent addition is an RP49.20D reversible plate compactor.”

James stated, “I enjoy operating Bobcat machines because they are user-friendly, have smooth controls, and are well-balanced while offering ease of maintenance and great dependability.” Adrian adds, “both contractors and homeowners call in looking specifically to rent Bobcat machines. They are a well-known good brand of machines, and we don’t receive

calls from renters regarding any issues when they rent them and that speaks volumes. We have received a lot of positive feedback specifically on the Bobcat MT100’s, on how amazed people are with their capability despite their small physical size. In Stratford, there are a lot of small spaces and tight areas between homes, and this is where the MT100 and E20 excavator with its retractable undercarriage really shines. Renters pay a premium for equipment, so we get them the best. With warranties for up to five years, we have extra peace of mind.”

“It has been awesome working with Steve Brown, sales specialist for Bobcat of Stratford. Deciding on a brand of equipment for us is based 50% on the dealership and 50% on the equipment. From the beginning, we have been with Bobcat of Stratford and will continue to purchase from them. We gladly recommend Steve and Bobcat of Stratford to anyone looking to purchase their next piece of compact equipment. Just like us, they are a family-owned business” stated James and Adrian.

Thanks James and Adrian

BRANTFORD Bobcat of Brantford 519-752-7900 bobcatofbrantford.com

HAMILTON Bobcat of Hamilton 905-643-3177 bobcatofhamilton.com

PETERBOROUGH

Bobcat of Peterborough

705-748-9119

bobcatofpeterborough.com

THUNDER BAY Equipment World Inc. 807-623-9561 bobcat-tbay.com

CASSELMAN Bobcat of Ottawa Valley 613-764-2033 bobcatov.com

KITCHENER Bobcat of Tri-Cities Ltd. 1-866-214-3939 bobcatoftc.com

STRATFORD Bobcat of Stratford 519-393-6040 bobcatofstratford.ca

SAULT STE. MARIE Bobcat of Sault Ste. Marie 705-949-7379 bobcat-ssm.com

CORNWALL Bobcat of Ottawa Valley 613-932-2034 bobcatov.com

LONDON Bobcat of London 519-455-4900 bobcatoflondon.ca

STRATTON Stratton Equipment 807-483-5505 strattonequipment.com

WINDSOR Bobcat of Windsor 519-737-0120 oakenequipment.ca

COURTICE Bobcat of Durham East Ltd. 905-404-9990 bobcatofdurhameast.com

MUSKOKA Bobcat of Muskoka 249-390-7000 oakenequipment.ca

SUDBURY McDowell B Equipment Ltd. 705-566-8190 bmcdowell.com

FRANKFORD John’s Equipment 613-398-6522 johnsequipmentsales.com

OTTAWA Bobcat of Ottawa Valley 613-831-5166 bobcatov.com

TORONTO EAST Bobcat of Toronto 416-679-4171 oakenequipment.ca

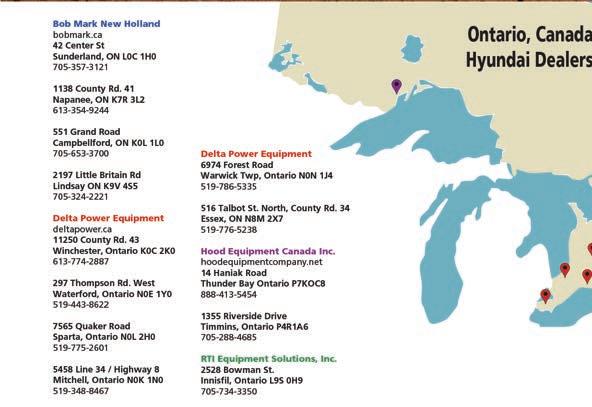

Hyundai Construction Equipment

Americas has re-entered the compact loader market with the introduction of the HS120V skid steer loader and HT100V compact track loader.

The large-frame size class loaders are powered by a 148-cubic-inch Hyundai 4HTI4 four-cycle, turbocharged, electronic-controlled diesel engine. The new 70 hp Hyundai engine meets Tier 4 Final emissions standards.

“With the addition of the HS skid steer and HT compact track loader, Hyundai’s compact equipment lineup will serve even more customers in construction, landscaping, agriculture and material handling,” said Adam Ford, Product Manager for Hyundai Construction Equipment Americas. “Combined with Hyundai compact excavators, these Hyundai machines provide a broad range of capabilities to contractors and other equipment users whose work requires powerful, dependable and affordable compact equipment.”

The HS and HT Series machines are engineered to meet demands for performance, durability and operator comfort, while satisfying strict environmental requirements.

The Hyundai HS120V skid steer loader has a rated operating capacity of 1,220 kg, an operating weight of 3,847 kg, a 2.4 metre dump height and a heaped bucket capacity of 0.44 cubic metres. The Hyundai HT100V compact track loader also has a rated operating capacity of 1,220 kg, and its heaped bucket capacity of 0.44 cubic metres. The CTL features an operating weight of 4,425 kg, a dump height of 2.4 metres and a 40 cm track width.

Both loaders feature a vertical lift

path of the boom that allows the bucket to be raised straight up with minimal forward extension or bucket drift. This provides good stability, optimum reach and less spillage. A vertical lift path is beneficial when using forks or other attachments that are more productive when level. At the same time, the bucket and boom geometry remain productive for digging applications.

The Hyundai HS and HT models also feature an auto self-levelling system that keeps the bucket or forks level without the need to manually adjust the angle on the way up during lifting. This feature can be engaged with the flip of a switch. Auto-self-levelling while raising the bucket helps ensure fast cycle times and better load retention.

Key features

Built on the same platform, the new Hyundai HS and HT models provide a combination of features that translates into high productivity and on-the-job performance.

Standard features include:

· A multi-function joystick that enables operators to control all machine functions with their hands

· A vertical lift path that allows the boom to raise the bucket straight up to full height for better stability, less spillage and greater lift height

· Two-speed travel enabling quick movement around the jobsite

Both machines are equipped with standard control and comfort features, including excellent visibility from the operator’s seat, air-conditioning, a spacious cab, a sliding door that allows the operator to work

with the door opened or closed and LED working lights to illuminate the jobsite in low-light conditions. As well, the optional ride control reduces operator fatigue and material spillage when operating over rough surfaces.

“Operators will enjoy Ride Control, which comes standard on HS120V skid steer,” Ford said, noting Ride Control will be available for the HT100V CTL this fall. “Owners will also appreciate the extra load retention and productivity they get from Ride Control.”

The Hyundai HS and HT Series models all feature a hydraulic quick coupler enabling the operator to change attachments quickly and safely from the cab, boosting uptime and productivity.

Standard safety features include

a rearview camera for enhanced operator awareness of jobsite hazards; an “escort system” that keeps the LED lights illuminated for 30 seconds after machine shutdown to give the operator a safe view of the jobsite when exiting the cab; emergency escape through the front door; and an emergency boomdown feature that enables manual descent of the boom in the unlikely event of electrical system failure. The optional high-flow hydraulic system provides extra capacity to run attachments that need an additional hydraulic boost, significantly expanding the machines’ versatility.

To quickly access the back of the loaders, Hyundai designed the machines to include an easy-to-

open wide rear door. The radiator module also swings out to provide full access to the engine compartment, hydraulic filter and other key components.

The cabin tilts up without having to lift the loader arms, which allows for easy access and maintenance while avoiding some of the common safety issues associated with tilt cabs.

Hyundai’s exclusive Hi MATE telematics system is available on both the new HS and HT models. With Hi MATE, users can remotely evaluate machine performance, access diagnostic information and verify machine location.

Its geo-fencing capability protects equipment from theft or unauthorized use outside custom-defined boundaries.

HD Hyundai Construction Equipment has created a new team dedicated to its compact equipment line in North America.

The formation of the new team follows Hyundai’s introduction of skid steers and compact track loaders, along with recent updates across its compact excavator lineup. Hyundai has hired Jeff Pate as

Vice President of Compact Equipment Sales, reporting to Mike Ross, Senior Vice President of HD Hyundai CE North America.

Reporting directly to Pate are four new team members with responsibilities for sales and dealer development in distinct regions covering the United States and Canada.

Dale McLemore, an industry veteran with 35 years of experience in compact equipment, is joining the company as Senior Dealer Development and National Accounts Manager for compact equipment covering the southeastern region.

Brian Slavinski brings 12 years of experience to his role as District Manager for the Northeastern

United States and Eastern Canada, including extensive knowledge of the equipment industry from both the retail and manufacturing side.

Darren Wallace, District Manager for the Central region of the United States and Canada, also brings a wealth of knowledge to the team, with 20 years of industry experience in sales and dealer development.

And finally, Mike Dahs joins the team as District Manager for the Western region of the United States and Canada.

Dahs has spent the last two years on the OEM side of the business, following nine years of retail experience working for a successful multi-line construction equipment dealer.

New Holland Construction is expanding its 300 Series compact track loader lineup with the introduction of the C330 vertical lift CTL.

The new addition to the New Holland Construction lineup features a medium frame with the ability to manoeuvrer in tight spaces. The C330 CTL, with a 172-cm working width and 67 hp engine, is equipped with New Holland Construction’s Super Boom lift, with low shoulder positioning and small towers to enhance operator visibility and worker safety on the jobsite.

“The C330 vertical lift compact track loader creates the perfect mix of job versatility and maneuverability on any residential construction and landscape jobsite,” said Ryan Anderson, Product Marketing Manager for New Holland Construction North America.

“We can’t wait to get this machine out into the field to showcase how our power

management technology, and enhanced visibility to get the job done, efficiently performs.”

The C330 is nimble enough to navigate through tight residential spaces, like backyard gates and between houses or buildings.

Equipped with electro-hydraulic (E-H) controls, the compact track loader allows operators to switch between ISO and H-Pattern. This delivers control over drive function and attachments, making it an ideal machine for residential contractors or operators who work on a variety of jobs with one machine.

The New Holland CTL also feature EZ E-H control to allow the operator to customize speed and sensitivity settings.

The power management function enables control of rpm speed to deliver power to the drives while the loader valve is under load. This management feature allows the

CTL operator to move heavy loads without interruption.

Super Boom vertical lift

Outfitted with the New Holland Construction’s Super Boom vertical lift, the C330 compact track loader offers more height and reach to load materials into high-sided trucks. The vertical length super boom design also provides more visibility from the cab. Operators have an unobstructed view of attachments and a large visibility panel in the cab roof for a clear view of overhead attachments. Visibility is also enhanced thanks to low shoulders, narrow cab pillars and optional seat suspension.

Utilizing the same cabs as New Holland’s other 300 series compact track loaders, the C330 will have the same ergonomic features, including soft button joysticks and

more room between the operator’s knees. It also comes equipped with a 20-cm colour display that shows all working parameters with key machine information like engine performance, rpm, fuel level, battery life and hydraulic oil temperature.

“We designed the C330 vertical lift compact track loader to provide ultimate operator ease with the intent to reduce fatigue and keep the machine’s weight low with truck and trailer weight limitations in mind,” Anderson said. “This can be useful for landscape and residential contractors who may have trailer and truck weight restrictions, but also farmers looking for a machine to move hay bales and other necessities on livestock and crop operations.”

The C330 vertical lift compact track loader is expected to commercially launch in late 2023.

WE www.bobmark.ca

ARE PROUD TO ANNOUNCE WE ARE OFFICIALLY A BEARCLAW DUMP TRAILER DEALER!

2010 NEW HOLLAND U80B

79 hp, 4WD, Deluxe cab w/Heat/Air Con., 4 forward x 4 reverse speed trans. w/Power Shuttle, Ride Control, NH/FFC Hyd., QC on front loader, Aux. hyd., QA bucket & AMI pallet forks, 3 point hitch, Dual tilt w/ holding valve, Additional rear counterweight $69,900

2007 NEW HOLLAND B95 95 hp, 4 cylinder diesel, cab w/heat and air conditioning, front & rear wiper, Extendahoe, 1.3 yard front bucket, 24” rear bucket, Pilot Controls, 4 speed power shuttle trans., loader aux. hyd., 1050 Hrs, pattern control changer $69,900

tonne capacity, Patented High Clearance Up & Over Tailgate, HARDOX tapered body, Single multi-stage lift, Spring hitch, Heavy Duty Hydraulic jack, Fenders, Mud flaps, Road light kit, 2 wheel hydraulic brakes, 560/60R22.5 high flotation tires, Minimum 100-150 hp tractor required, Swiveling ball hitch $73,800 BUI L T A ROUND Y OU email: dbuttar@bobmark.ca

2005 NEW HOLLAND DC85

Dozer, 89 gross engine horsepower, 4 cylinder engine, LGP model, 28” grouser shoes, Drawbar, Mechanical suspension seat, Canopy, 124” wide PAT blade, New sprockets & track chains Installed, 3577 hours $69,900

2007 JCB 3CX BACKHOE

90 hp, 4 cylinder turbocharged diesel, Cab w/heat & A/C, pilot controls, 4 speed powershift trans., Extendahoe, 14x17.5 front tires, 19.5L24 Rear tires, 24” Rear bucket, front pin on bucket $54,900

2007 HYUNDAI R140LC-7 Cummins B3.9C engine with 115 gross horsepower, 31000 lb. operating weight, 24 inch track pads, 15’1” boom length, 9’10” stick length, Auxiliary hydraulics, Helac powertilt with coupler, Hydraulic thumb, Digging & Ditching bucket, 4207 hours $99,900

2004 HYUNDAI HL730-7 21384 lb. operating weight, Cummins B3.9C 4 cylinder engine, 125 gross engine hp, 4 forward x 3 reverse speed Full Auto. Powershift trans., 17.5-25 tires, Front/rear fenders, 3rd function aux. boom hyd., ACS hyd. coupler, ACS 2 yd mat. bucket with bolt-on cutting edge, 3647 hours $64,900

2011 NEW HOLLAND L230 90 horsepower, 8800 lb. operating weight, 3000 lb. lift capacity to full height, Mechanical foot controls, 2 speed transmission, Auxiliary boom hydraulics with standard flow (24.2 gpm), 1417.5 tires, Mechanical quick-attach $29,900

2013 HYUNDAI R180LCD-9A 43760 lb. operating weight, Perkins 4 cylinder engine with 137 gross hp, Dozer blade, 28” track pads, 16’9” boom length, 8’6” arm length, Aux boom & arm hyd. with 1 or 2 pump flow, Air ride suspension seat, 7” color LCD screen, (3) Power Modes & (2) Work Modes, 4670 hours $119,900

2009 HYUNDAI HL740TM-7A

Tool carrier model w/hyd. QC, Cummins QSB6.7 engine w/ 138 hp, 26680 lb. operating weight, 4-speed Powershift trans., Front/rear fenders, Ext. mirrors, 20.5R25 radial snow tires, 2.5 yd mat. bucket w/ bolt-on cutting edge, 3rd function auxiliary hydraulics, 7553 hours $79,900

2011 HYUNDAI R16-9 COMPACT EXCAVATOR

Mitsubishi 17 hp engine, 3640 lb. operating weight, Variable undercarriage width, 9 inch rubber tracks, Mechanical pin grab quick coupler, 18 inch bucket, Auxiliary boom hydraulics, Canopy, Dozer blade with folding wings $19,900

Develon has introduced a new 4-tonne -7 Series mini excavator designed to deliver fast cycle times and a powerful digging force.

The conventional tail swing DX42-7 mini excavator is powered by a 47-hp engine, and designed for navigating tight, congested jobsites and urban areas.

“Weighing in at 4 tonnes, the DX42-7 delivers the power, maneuverability and versatility our customers have come to expect from

Develon mini excavators,” said Thomas Lee, Director of Product Management at Develon. “Whether it’s utility work, landscaping, construction or site prep, the DX42-7 boasts an impressive lifting capacity, enabling effortless movement of pipes, boulders and various materials. With its powerful digging forces, customers can accomplish more tasks in less time.”

Mini excavator specs

· Horsepower: 47 hp at 2200 rpm

· Operating weight: 4,480 kg

· Maximum digging depth: 3.5 metres

· Max digging reach (ground): 5.6 metres

· Max loading height: 3.8 metres

· Max travel speed: 5 km/h

Thumb-ready arm

The DX42-7 comes equipped with a standard thumb-ready arm. Durable thumb mounts are seamlessly integrated into the excavator arm, eliminating the need for any welding when adding a thumb attachment.

As well, with quick-coupler

hydraulic piping installed at the end of the arm, the DX427 eliminates the need for additional accessories when installing a compatible quick coupler to the machine. This design enhancement reduces the time needed to switch attachments.

Customers can choose between ISO or BHL control patterns, allowing them to select the pattern that best suits their preference and ensures ease of use during operation.

An optional four-way swing blade is also available, enabling optimal blade positioning and reducing the need for frequent machine repositioning, as well as facilitating efficient backfilling.

The DX42-7 effectively addresses various challenges

encountered on jobsites, particularly concerning visibility and safety. Safety features on the mini excavator include:

· A framed full-glass door to improve visibility

· An optional rearview camera

· High-illumination LED lamps

· A standard travel alarm that is activated when the machine is moving in reverse

· An optional rotating beacon for high-traffic areas or low-light situations

Mini excavator comfort

The mini excavator is available in two cab options: open canopy and enclosed cab configuration.

The enclosed cab model comes with standard heating and air conditioning and hands-free Bluetooth audio. The air conditioning system improves airflow through multiple vents, enhancing operator comfort even during long, hot days.

The controls, buttons and general operations on the DX42-7 make it easy to operate with confidence. A simple thumb switch located on the right joystick controls auxiliary hydraulic functions, making fine adjustments effortless and improving efficiency and comfort throughout the workday.

The boom swing is also controlled by a thumb switch on the right joystick, eliminating the need for foot pedals and further simplifying operation.

The Develon Fleet Management system comes standard on the DX42-7. The system gives owners and dealers access to vital equipment data, such as machine location, health and productivity. Through a user-friendly app and website, customers can conveniently monitor and analyze this information, helping them make informed decisions.