JULY 24, 2023 ISSUE 10 FOCUS: AGGREGATE/QUARRIES & TECHNOLOGY RETURN UNDELIVERABLE ITEMS TO: EQUIPMENT JOURNAL, PO BOX 160 PORT MCNICOLL, ON L0K 1R0 PUBLICATIONS MAIL AGREEMENT: 40063867 AFTERMARKET PARTS EXPERTS! EQUIPMENT SALES & SERVICE LIMITED www.essltd.com 1-800-263-4597 UNDERCARRIAGE EXPERTS! AUTHORIZED DISTRIBUTOR • Engines • Transmissions • Pumps • Filters • Cabs • Rubber Tracks • Pins & Bushings • Electrical Parts • Bearings • Seats & More.... ONLINE HEAVY EQUIPMENT & TRANSPORTATION AUCTIONS 1-888-376-3155 • AllStarAuctions.ca 44 Line 9 South, Oro-Medonte, ON L0L 1T0 UPCOMING AUCTIONS: Barrie, ON - September, 2023 Visit our website for updates Want Top Dollar For Your Equipment? Consign Today! The preferred choice for remarketing your excess inventory for Heavy Equipment, Transportation, Recreation and Powersports Products. TOPLIFT.COM SALESPARTS SERVICE COMING SOON! POWER BOX RAKE 72” & 84” AVAILABLE FOR IMMEDIATE DELIVERY IN STOCK amiattachments.com CANADA 2055 PEGASUS ROAD NE, CALGARY, AB T2E 8C3 (587) 316-4558 EMAIL: canada@sunward.cc SUNWARDCA.COM DEALERS WANTED! Phone-alt (Call for details) https://bit.ly/deltapowerconstruction sales@deltapower.ca 1-833-981-4278 LOTS IN STOCK! sales@bmcdowell.com www.bmcdowell.com 705-566-8190 416-770-7706 RENT ME See our ad on page A5 2020 LINK-BELT 300 X3 Weldco Beales 60’ Long Reach 207 net hp Isuzu diesel Tier IV eng., stk# R160-1020 SEE OUR AD ON PAGE A6 Contact John or Mark at: 1-800-265-5747 www.marcelequipment.com Sales, Rentals & Rental Purchase Quality, Reconditioned Equipment Since 1976 KOMATSU HD325-7 (2010) • 2 Available • 10,535 & 11,495 Hours • 40 Ton / 31 CY Capacity • Flat Floors – Steel Liners • Heated Bodies • Stockpile Application Use • Good, Straight Condition • Will be Inspected & Serviced • Needed Repairs to be Completed. $CALL for Price & Details LUBECORE.COM ACROSS NORTH AMERICA 905-864-3110 NEXT GENERATION AUTOMATED LUBRICATION MADE IN CANADA Ű Reduced Labour Cost. Ű Protect Your Investment. Ű Simple. Reliable. Ű DIY Installation Option. Ű Standard 400g Grease Tubes. Ű Easy to View Grease Levels. SMALL EQUIPMENT, BIG SAVINGS. LUBECORE’S NEW HP-400 GREASES COMPACT EQUIPMENT AUTOMATICALLY. 1-877-640-2862 RHP COMPACTORS 3-30 ton carrier class 6200 lbs to an incredible 38,140 lbs of impulse force, at 2,000 cycles per minute. magnumattachments.com HYDRAULIC BREAKERS, SHEARS, GRAPPLES, COMPACTORS, TILTRATORS, PULVERIZERS Thank you SAM RABITO CONSTRUCTION LTD. for your recent purchase of Magnum’s RHP60V PUBLIC AUCTIONS MARKETPLACE “Post It—Sell It—Buy It—Get It”on: NEXT AUCTION: July 29th @ 9am - Industrial Equipment 1-855-625-0941 sales@creightonrock.com CRDCREIGHTON.COM EXPANDER PINS The strength of your machine is defined by its pivots

POWERSCREEN CHIEFTAIN 1700

A mid-sized track mobile screen aimed at end users requiring high volumes of finished products in applications including topsoil, coal, crushed stone, recycling, iron ore, sand and gravel. 5’ x 16’ screen deck, 14’ wide feed hopper, hydraulic folding conveyors, hydraulic screen angle adjustment, fast set-up, double or tripple deck.

CEDARAPIDS CRJ3255

Combines the popular JW55 jaw crusher with the high stroke 52”x20’ vibrating grizzly feeder making this plant a high production portable crushing machine. This quarry duty JW55 crusher, with its large 32”x55” opening, long jaws, and aggressive stroke, is in a class by itself in a portable crushing plant.

MDS M515

Heavy Duty Trommel ideal for creating RipRap and recovering rocks up to 800mm (32”) that are mixed with clay and other sticky materials. The updated model has been redesigned to include new features that will improve transportation, access, and stockpile heights.

CEDARAPIDS CANICA CRV2000 PORTABLE VSI

Features the Canica 2000 Vertical Shaft Impactor. Highly mobile all electric plant with the latest CCM automation system. Available in single or dual drive. Designed to handle a wide range of different applications and is ideal for manufacturing sand. Also available as a static crushing chamber or on the MV2000 modular platform.

A2 JULY 24, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL 800 FAREWELL STREET, OSHAWA, ONTARIO, L1H 6N5, CANADA PSC@POWERSCREENCANADA.COM ||| POWERSCREENCANADA.COM SCREENING | STOCKPILING | WASHING | RECYCLING TOLL FREE: 1-877-797-7276 WE DO IT ALL. THE ULTIMATE IN... CRUSHING AND SCREENING

® CEDARAPIDS W AS H IN G SYST EMS

Confidence in Canadian construction

A majority of Canadian construction firms are optimistic about market conditions, according to a survey by Procore

ISSUE 10 July 24, 2023 A3 JULY 24, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL A22 Caterpillar’s

A8

A19

A10 TECHNOLOGY FEATURED EQUIPMENT B9 AGGREGATE & QUARRIES FEATURED EQUIPMENT B3

new 995 wheel loader

Cooper acquires two rental companies

Link-Belt’s

5th gen lattice crawler crane

Canada needs a long-term trade infrastructure plan

In 2009, Canada ranked 10th in the world in terms of trade infrastructure.

While it’s embarrassing for a G7 nation to fall out of grasp of a Top 10 ranking on infrastructure, it’s also a great opportunity for construction. And Canadians agree. A recent Ipsos survey found that more than 90 per cent of Canadians believe trade is important to the economy, while merely nine per cent believe Canada’s trade infrastructure is in good shape.

Roughly nine out of 10 Canadians also believe it is important to remain competitive with other major economies.

Although Canadians believe in the importance of international trade, the Ipsos

poll found the proportion of Canada’s economic activity that relies on doing business with other countries is largely underestimated. Those surveyed guessed that about 50 per cent of our GDP relies on international trade.

“According to World Bank Data, two-thirds of Canada’s income is derived from trade. We’re three times more dependent on trade than the United States,” said Canadian Construction Association (CCA) President Mary Van Buren. “We need the revenues that trade returns to government to fund the vital social services and the infrastructure we need, such as for hospitals and schools.”

Despite the importance of trade, Canada is the only major economy without a long-term trade infrastructure plan.

At the recent meeting

of the Council of the Federation, six of Canada’s premiers welcomed the call for the creation of a Canada Trade Infrastructure Plan (CTIP) at the request of several business organizations, including the CCA, the Civil Infrastructure Council Corp. and the Western Canada Roadbuilders and Heavy Construction Association.

The group asked the Council of the Federation to support and lead a campaign to persuade the federal government to include funding for the CTIP in the 2024-25 budget.

The concept includes governments working with the private sector and national stakeholder associations to set out the building blocks of the plan.

“We are championing to build a better Canada from that long-term infrastructure planning,” Van Buren said.

Bill Tremblay // Editor editor@equipmentjournal.com

The case for a trade infrastructure plan is a no-brainer. When it comes to construction though, most of the public conversation is focused on housing, which obviously has its own urgent problems to overcome.

However, the need for adequate railways, highways and ports only grows with each new home that is built.

FOR ALL YOUR DEMOLITION NEEDS

Fahmi

mona@equipmentjournal.com

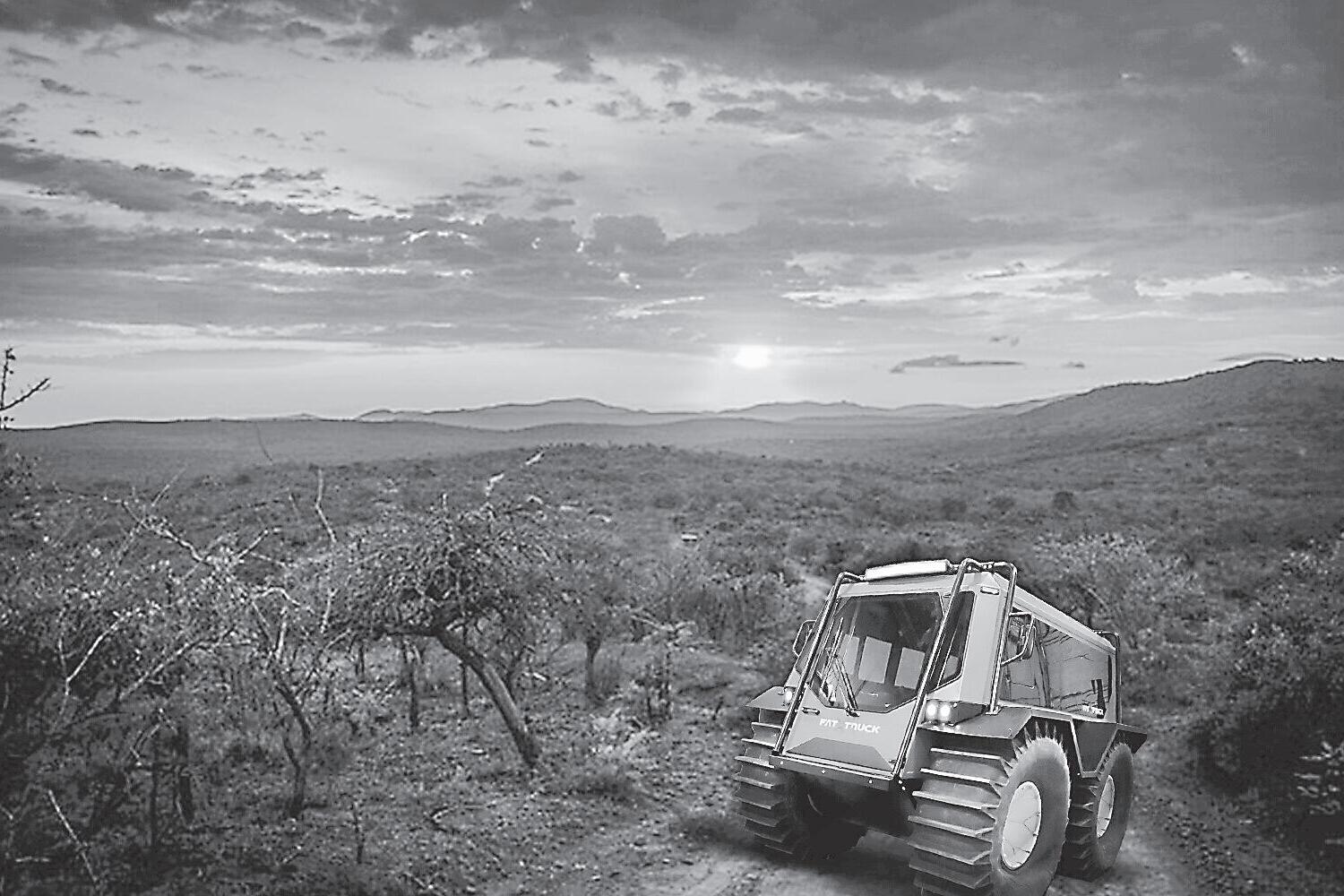

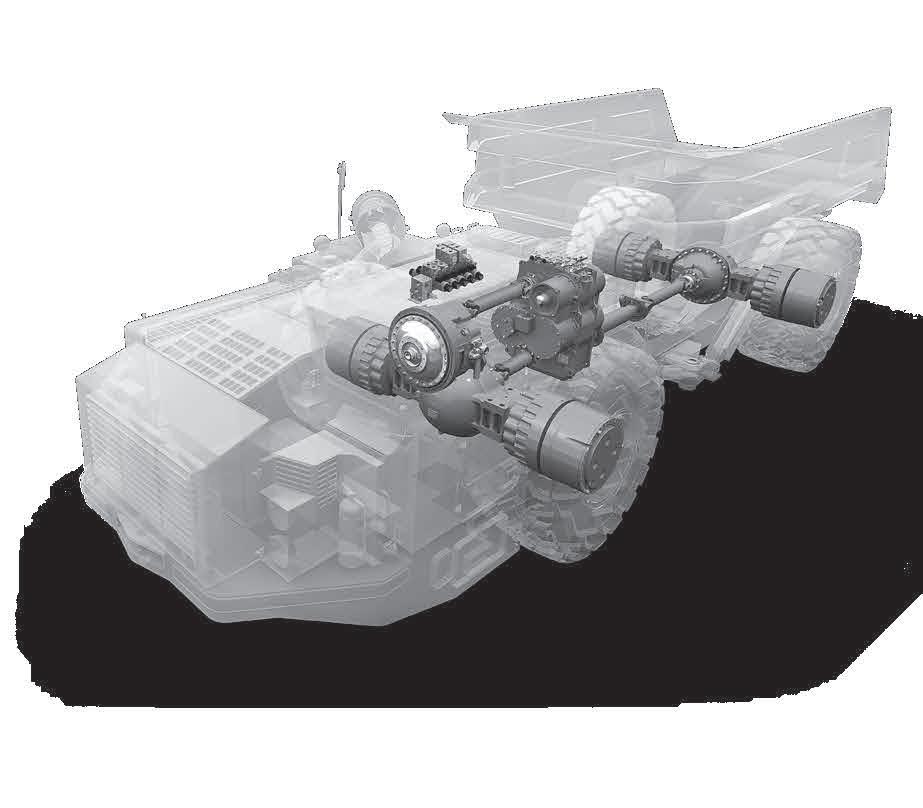

tara@equipmentjournal.com National Account Manager Mona Amaco Construction Equipment Inc. A16 AmCast B6 AMI Attachments A1 Bobcat A12 Bob Mark New Holland A21 Brandt Mining B15 Brandt Used Equipment A11 Brandt Value Parts A19 Bull Powertrain B5 ConTrac Equipment A14,B10 Cooper Equipment Rentals A1 Creighton Rock Drill Limited A1,A22 Crushco B2 Delta Power Equipment A1 Develon A18 Equipment Sales & Service Limited A1 Equipement Lourd S.L. Inc. A14 HLA Attachments B4 High Reach Inc. A10 Hood Equipment A8 Hub Equipment B16 Hydrolexc Equipment Services Ltd. B7 Hyundai B11 Jade Equipment A20 JBL Truck & Equipment Appraisal A20 JCB A24 JT Equipment A4 L & M Powertrain A15 Latec Machine Control A7 LBX Link-Belt Excavators A17 LSW Wearparts A16 Lubecore A1,A22 Magnum Attachments A1 Marcel Equipment Limited A1,A6 McDowell B Equipment Ltd. A1,A5 OBW Equipment B7 Onocon B10 Pine Ridge Lisco Edwards A14 Powerscreen of Canada A2 Protech Diamond A19 Rokbak B13 Sennebogen A9 Shaw Bros. Limited A13 Strongco Equipment B8 Sunward Canada Equipment A1 Tarten Equipment Limited A8,B12 Top Lift Enterprises A1 Toromont CAT B1 Total Fat Truck B5 Tramac B12 Tri-City Equipment A13 Wirtgen A23 Word Rock Drills A7 AUCTIONS AllStar Auctions A1 Murphy Auctions B14 North Toronto Auctions A1

(905) 629-7500

TOLL-FREE: CDN/USA 1-800-667-8541

A4 JULY 24, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL Published every third Monday at 6-5160 Explorer Dr., Mississauga, (Toronto). Subscription $44. per annum or $72. for 2 years including applicable tax., Payable in advance. Single copy $3.95. Authorized as Publications Mail Agreement No. 40063867, by the Post Office Dept. Ottawa and for payment in cash. Advertising is accepted on the condition that in the event of typographical error, that portion of the advertising space occupied by the error together with reasonable allowance for signature will not be charged for, but the balance of the advertisement will be paid for at the applicable rate. In the event of a typographical error advertising goods or services may not be sold. Advertising is merely an offer to sell and may be withdrawn at any time. We reserve the right to reject or refuse any or all advertising. Equipment Journal permission is required to reproduce original ad layout, artwork and photos. H.S.T. # 10403 7957 RT ADVERTISER INDEX JULY 24/2023 LETTER FROM THE EDITOR

Tremblay editor@equipmentjournal.com Publisher Mark Baker mark@equipmentjournal.com PACE PUBLISHING LIMITED EQUIPMENT JOURNAL 5160 Explorer Drive, #6 Mississauga, ON, L4W 4T7 Canada OFFICIAL SOCIAL MEDIA ACCOUNTS @EquipJournal @equipmentjournal @EquipmentJournal Equipment Journal LOCAL:

Bill

Circulation Manager Lisa Bath

EMAIL US: advertise@equipmentjournal.com WEBSITE: www.equipmentjournal.com EQUIPMENT JOURNAL IS AN AUDITED PUBLICATION

lisa@equipmentjournal.com

A decade later, we have slipped to 32nd place, behind the former Soviet republic of Azerbaijan.

BUY/RENT

2023 LINK-BELT 350 X4, 13”3 arm or choice of arm, HD Linkage, multi-function hyd., 84,400 lb OW, No DPF, stk# B160-233

2018

BUY/RENT

Liebherr’s

R

9300 mining excavator is now available

Liebherr’s 250-tonne R 9300, the second Generation 8 excavator in the company’s mining portfolio, is now available.

The R 9300 replaces the R 9250 in Liebherr’s mining excavator lineup and is equipped with the latest Liebherr Mining technology. This tech provides the machine with improved on-site performance as well as compatibility with Liebherr’s Assistance Systems and future product enhancements, such as automation, zero emission technologies and digital services.

As part of the validation phase for the R 9300, Liebherr Mining partnered with its customer Karunia in Indonesia to establish the capabilities of the excavator on site. The machine is being used to load overburden into 100- and 130-tonne trucks at Karunia’s Tabang mine. Since September 2022, the R 9300 has averaged 486 operational hours per month and 94 per cent availability –surpassing Karunia’s KPIs for the machine.

To further demonstrate the capabilities of the R 9300, a production study of the pre-series excavator at Tabang mine was conducted in March 2023. During the study, the R 9300 achieved a 26-second average cycle time, helping the excavator reach 1,371 bank cubic metres (BCM) per hour equalling 3,017 tonnes per hour. The R 9300 also attained a fuel efficiency ratio of 9.22 BCM per litre of fuel burned.

Improved fuel efficiency

The latest machine uses 15 per cent less fuel and improves fuel efficiency by 25 per cent compared to the R 9250.

Liebherr Power Efficiency (LPE), a proprietary engine and hydraulics management system, helps to decrease the amount of fuel a machine consumes while maintaining optimal productivity and performance.

The R 9300’s engine is available in FCO and EPA Tier 4 and Stage V compliant versions (with SCR after-treatment technology) to

adhere to international emissions standards. As well, an electric-drive version of the R 9300 is in development and will be available soon.

R 9300 design

To increase productivity and efficiency, a range of design improvements have been implemented in the R 9300.

The mining excavator has an updated attachment design that is lighter and stronger than the R 9250. The new attachment is paired with high-performance components such as a new stick and boom design and aluminum covers all installed as standard. This lean design has enabled an increase in bucket size in both the backhoe and face shovel configurations. The standard bucket sizes of 16.5 cubic metres in backhoe configuration and 16 cubic metres in face shovel configuration (at 1.8 tonne per cubic metre with the heavy-duty wear package) makes the excavator an effective pass match for trucks with 100-, 130- and 180-tonne payloads.

The R 9300 has also been designed for simplified maintenance and a longer service life. This excavator shares parts commonality with Liebherr’s current machines to help minimize maintenance costs and streamline on-site inventory. The lifespan of the R 9300 has been increased by 33 per cent above the R 9250 from 45,000 to 60,000 hours. Extending the service life of the R 9300 helps the machine to better align with the service life of major excavator components.

The R9300’s new cab includes enhanced ergonomics, larger touch screens, a new control panel design and optimized visibility to help promote operator wellbeing while increasing safety.

The R 9300 enters serial production in 2024, with the backhoe configuration available in the first quarter and the face shovel configuration from the second quarter of the year.

RENT ME

ride control, OW: 66,337 lbs, joystick control, heat & A/C, stk# R110-1006

RENT ME

2013 CAT 972H,CAT C13 Acert diesel eng. 311 hp -Tier 3, heat & A/C, backup camera, forks & jib avail., stk# B110-176

BUY/RENT

BUY ME

RENT ME

A5 JULY 24, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL BMCDOWELL.COM FOR FULL LIST OF ATTACHMENTS Hammers Compact Equipment Wheel Loaders Air Compressors Trailers/Floats Compaction OEM PARTS & SERVICE 416.770.7706 or 705.566.8190 www.bmcdowell.com / sales@bmcdowell.com SERVING GTA & SUDBURY SINCE 1968 2012 TO 2018 AMMANN ASC110 & ASC130, 84” smooth and padfoot, Cummins, 25,289 & 27,820 lbs. RENT US 2014 CAT 735B, Cat C15 Acert diesel eng. 452 hp, 6 wheel drive, 36 ton payload, 25.8 cu.yd. heaped body capacity, stk# B145-143 RENT ME HUGE INVENTORY OF BUCKETS AVAIL. (MAKES/MODELS) VARIETY OF SNOW BLADES & PUSHERS AVAILABLE AMI HYDRAULIC THUMB CAT 330 A/B/C HYD THUMB SANDVICK RAMMER S26, 416/426 B&C, 1000’lb, fit any backhoe, #ACK17-003 2020 BD750-4, 7500’lb hyd hammer fits Link-Belt 350, #ACK17-0026 2018 CAT 980M, Cat C13 Tier IV diesel eng. 386 hp,

LINK-BELT 80 SPIN ACE, Isuzu eng. 54 hp, OW: 18,900 lbs., 17’7” boom, 6’11” arm, A/C, Esco pin grabber, stk# R160-1011

2019 BOBCAT S550, 2 speed, heat, aux. hyd., hydraulic coupler, complete with 68” bucket, stk# B100-887

2013 BOBCAT 324, pattern changer, swing boom, 49”stick, aux. hyd., USA EPA label, blade, manual Q/C, 9” rubber track, stk# B100-836

2014 CAT 416F, extendahoe, 4x4, Cat C4.4 Acert diesel eng. 88 hp, ride con- trol, rear outriggers, stk# B110-187

2017 CAT D3K2, Cat C4.4 Acert diesel eng 92 hp, Tier IV F, hyd. trans., A/C & heat, 18” pads, radio AM/FM/CD, stk# R130-1001

RENT ME

BOBCAT CONCRETE MIXER CAT R1600G TRANSMISSIONS

A6 JULY 24, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL LONDON, ONTARIO, CANADA Contact John or Mark at: 1-800-265-5747 or 519-686-1123 Email: sales@marcelequipment.com VIEW our Complete Inventory at: www.marcelequipment.com REBUILT CAT 826H COMPACTORS - 0 HRS Components Rebuilt, Complete Machine Recondition, 3 year CAT Component Warranty 40 Compactors to choose from. $CALL Since 1976 SALES, RENTALS & RENTAL PURCHASE UNITS SOLD WITH WARRANTY WE ALSO RENT EQUIPMENT CONTACT MARK or JOHN 1-800-265-5747 or 519-686-1123 KOMATSU WA500-8 (2017) 8.25 CYD Bucket, 875/65R29 Michelin Tires Komatsu Scale, All Servicing/Repairs Completed. $CALL CAT D6TXW VP (2014) - 4,945 HRS 1,020 Idle Hours, U/C Replaced 320 Hrs ago, CAT HDXL U/C, 28” Extreme Pads, Counterweight Drawbar, Ripper Available, Grade Control, All Servicing/Repairs Completed, FOR SALE OR RENT $399,000 CAT 336FL XE (2016) - 9,285 HRS You would think it has 5,000 hrs Very Clean, Tight & Well Equipped Check it out! $CALL CAT 725C2 (2018) - 6,990 HRS 23.5R25 Tires, Rear Camera, All needed Servicing & Repairs to be Completed. $CALL RECONDITIONED / REBUILT CAT 816B/F/K LANDFILL COMPACTORS | Choice of 18 – Yes 18 Work Ready with Warranty $CALL (4) CAT 352FL (2018) – 3,900–4,470 HRS Reach Booms, 11’ Sticks, Aux Hydraulics, Couple, 30” Pads, Very Clean. CAT Inspected. $CALL CAT 980M (2014) – 8,910 HRS Aggregate Handler, 7.75 CYD Bucket, L3 Tires, Auto Grease, Rear Camera, All servicing & / Repairs Completed. $CALL CAT 988K XE (2019) – 6,200 HRS Spade & GP BKT Options, Serviced by CAT Dealer since New, Auto Grease, L-4 Tires, Very Clean. $CALL (4) CAT D8T (2011-13) - 4,381-8,090 HRS Very Clean, Choice of SU or Angle Blade, Drawbar. Ripper/Winch Available. $CALL CAT 730C2 (2019) – 3,160 HRS 23.5R25 Tires, Rear Camera, Tailgate Available. Just Arrived. $CALL CAT 745C (2015) – 7,340 HRS Inspected, Serviced, All Needed Repairs Completed, Rear Camera, Tailgate Available. $CALL CAT 980M (2016) – 7,885 HRS Aggregate Arrangement, 7.75 CYD Bucket, Auto Grease, Rear Camera, All servicing / Repairs Completed. $CALL (7) CAT D8T LGP (2019/2020) 2,230 to 14,345 HRS SU Blades, 38” Pads, Draw-bar. $CALL $CALL CAT 980M (2019) - 6,765 HRS Aggregate Handler Spec, GP Bucket, Payload System, Inspected, Serviced, All Repairs Completed. $CALL KOMATSU WA470-8 (2016) – 7,380 HRS Coupler, 5.25 yd Bucket, Loadrite Scale, All Servicing / Repairs Completed. VOLVO A25G (2017) - 6,850 HRS 23.5R25 Tires, Rear-View Camera, Inspected, All Needed Servicing and Repairs Completed. $CALL CAT 988K (2014) - 14,955 HRS 0 Hours on Engine, Transmission., Torque & Hydraulic Pumps & Motors Rebuild. Very Clean & Straight Loader. $CALL

Amaco Construction Equipment acquired by Chadwick BaRoss

Chadwick BaRoss (Ontario) Limited (CBRO) has acquired Amaco Construction Equipment Inc.

CBRO is a Canadian based heavy equipment leasing and sales company.

The company has more than 90 years of experience in the heavy equipment industry in the Northeast United States, covering Maine, New Hampshire, Vermont, Massachusetts, Rhode Island and Connecticut.

“Amaco has been a respected brand in the Ontario and GTA market for over 40 years. We look forward to continuing to

build upon our local industry knowledge and experience while leveraging the expertise and knowledge of the CBRO team to further grow our mutual business,” Amaco General Manager Jeff MacDonald said in a statement on the company’s website.

The acquisition is effective as of June 30. Amaco will continue operations at its site, and MacDonald and his experienced staff of 16 will remain with CBRO after the deal has closed.

"We are pleased that Jeff, Jaime and the team will be remaining," said CBRO CEO Yedidia Koschitzky. "We look forward to

the opportunity to continue working to leverage Amaco's 40 years of experience in Ontario."

Based in Mississauga, Ontario, Amaco was founded in 1983 by James MacDonald and two silent partners as a Gradall dealer. James MacDonald (Jeff MacDonald’s father) had been in the equipment industry since the Second World War and sold the first Gradall machine in Ontario in the 1950s.

Today, Amaco provides a wide range of new and used heavy equipment leasing, renting, parts, service and sales options to serve the equipment needs of Ontario.

The company serves numerous markets, including municipal public works, road -

building, aggregate, concrete and asphalt recycling, steel mill furnace maintenance and underground mine scaling.

The company name comes from its founders: Ambler, MacDonald, and Courtney.

“We are committed to continuing to earn your business and build upon the excellent relationships that we already have with the added benefit of new product lines to better serve your needs,” MacDonald said.

“As with all such business arrangements, some steps may be ahead as we transition to new systems, procedures, and internal support networks. We expect these changes to be seamless for our customers and vendors.”

A7 JULY 24, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL WORDROCKDRILLS.COM 1.336.584.6700 IN-STOCK PARTS VERSATILITY DRILLING MACHINE When You Need Them CZM Drilling Canada ECA - Eastern Canada VAN-ED Equipment ECA - Western Canada Jean Paul Aube Kevin Sharp Al Ellerington Rick Thompson (514) 444-5687 (905) 640-9800 (416) 948-0148 (604) 290-7036 OUR FAMILY OF LOCAL DISTRIBUTORS Visit Us At Booth #E513

MACHINE CONTROL LT-800 FEATURES INCLUDES: LMC produces after-market cables and harnesses, for machine control and heavy machinery. We also design and manufacture electronic grading solutions specializing in laser and inclinometer machine control systems. ACCURATE – STABLE – RELIABLE latecmc.com 519-235-4585 orders@latecmc.com • Fully automatic self-leveling • Height of instrument alert (HI alert) • Long 500 feet operating radius • Machine control compatible • 20 arc second accuracy • 635nm visible red beam

Amaco Construction Equipment's headquarters in Mississauga, Ontario.

Cooper Equipment Rentals acquires Warner and Scotty’s rentals

The

Cooper Equipment Rentals has acquired Warner Rentals and Scotty’s Rentals and Landscaping.

With headquarters in British Columbia and Alberta, the new acquisitions expand Cooper’s branch and specialty footprint in western Canada.

“Our entire team is excited about these two ac-

quisitions. They reaffirm our on-going commitment to building a truly Canadian, coast-to-coast equipment rental company,” said Justin Wharton, Cooper’s western Canada Director of Operations.

Warner Rentals

Warner Rentals was founded in 1975 by owner Ralph Warner and currently has five locations in Kamloops, Princeton, Revelstoke, Salmon Arm and Scotch Creek, British Columbia.

“Adding Warner Rentals and Scotty’s to the Cooper network helps us deliver the Cooper Difference — unsurpassed customer care, the best solutions and deep expertise — at a whole new level in western Canada,” said Cooper CEO Doug Dougherty.

The acquisition of Warner Rentals sees Cooper expand the company’s footprint in the central British Columbia interior and intensify their service coverage in a rapidly growing and important western Canadian market.

“We knew of Cooper’s well-established presence in the market and already have a great working relationship with their team in British Columbia, enhancing our ability to serve customers better across western Canada,” Warner said.

“Warner Rentals brings a highly experienced and respected team to the Cooper family, sharing the same deep passion for customers and community,” added Rob Potter, Cooper's Regional Manager for BC.

Scotty's Rentals and Landscaping

services, as well as fencing for residential construction.

Founded in 2007, the company has built a reputation for providing excellent service and support.

“We are excited to join the Cooper family. The company being Canadian was a key factor in this decision, and Cooper’s size allows us to continue to service our customers with a variety of equipment solutions,” said Peter Jensen, owner of Scotty’s. “Our team is looking forward to continuing to deliver the exceptional service we have built our business on, while being part of a larger company that is also committed to servicing local communities with a customer-first approach.”

The addition of Scotty’s bolsters Cooper’s climate control division, while also adding a new product line in fencing.

"These acquisitions not only exemplify our unwavering commitment to expanding our presence in western Canada but also reinforce our dedication to providing top-tier rental solutions to all major markets across Canada,” said Brian Spilak, Chief Operating Officer of Cooper. “By integrating the strengths of Warner Rentals and Scotty’s with our own, we are poised to continue to deliver an unmatched level of service and support to customers across many new markets.”

Wacker Neuson has dominated the compaction industry for over 160 years. As the inventor of the rammer and reversible plate, Wacker Neuson understands the compaction needs of contractors. From confined area trench compaction to the newest soil compactors designed for large area compaction, Wacker Neuson has all it takes to keep your job on solid ground.

Ontario’s Compaction Headquarters

Headquartered in Rock View County, Alberta, Scotty’s Rentals and Landscaping specializes in climate control equipment, including heaters, generators, and tarping

Established in 1972, Cooper Equipment Rentals Limited is a Canadian-owned and operated construction equipment rental company. With 68 locations in six provinces, Cooper provides service and support, along with all equipment needs, including general tools, earthmoving, heavy equipment, aerial, climate control, trench safety and pump and power.

A8 JULY 24, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL

Thunder Bay Jeff Marshall: 1-807-628-6300 Trevor Hynnes: 1-807-629-3007 Timmins Southern Ontario Darren Hynnes: 1-807-252-6556 Jason Denis: 1-705-288-4685 CONTACT US

AUTHORIZED DISTRIBUTOR POWER TRAIN SPECIALISTS TRANSMISSIONS - AXLES - STEERING PAR TS - EXCHANGE - REBUILDS TARTEN EQUIPMENT LIMITED 6199 Shawson Drive Mississauga, ON L5T 1E5 Phone: 905 670 1704 Fax: 905 670 4790 Toll Free: 1 888 670 1704WWW.TARTEN.COM COMMITTED TO SERVICE EXCELLENCE SINCE 1976 ALL MAKES ALL MODELS

latest acquisitions strengthen Cooper's branch and specialty footprint in western Canada

CONTACT A SENNEBOGEN DEALER IN YOUR AREA

Newfoundland and Labrador

Strongco Mount Pearl, NL (709) 747-4026

www.strongco.com

Nova Scotia

Strongco

Dartmouth, NS (902) 468-5010

www.strongco.com

New Brunswick

Strongco

Moncton, NB (506) 857-8425

www.strongco.com

Quebec

Strongco

Baie-Comeau, QC

Chicoutimi, QC

St-Augustin, QC

Trois-Rivieres, QC

Val d’Or, QC

www.strongco.com

Ontario

Strongco

Stittsville, ON (613) 836-6633

Sudbury, ON (705) 692-0552

Thunder Bay, ON (807) 475-3052

www.strongco.com

Top Lift Enterprises, Inc.

Saskatchewan

Redhead Equipment

Estevan, SK (306) 634-4788

Lloydminster, SK (306) 825-3434

Melfort, SK (306) 752-2273

North Battleford, SK (306) 445-8128

Prince Albert, SK (306) 763-6454

Regina, SK (306) 721-2666

Saskatoon, SK (306) 934-3555

Swift Current, SK (306) 773-2951

www.redheadequipment.ca

785-4223 Kamloops, BC (250) 372-3996

Nanaimo, BC (250) 716-8804

Prince George, BC (250) 612-0255

Surrey, BC (604) 882-5051

Terrace, BC (250) 635-9033

Vernon, BC (250) 549-4232

1-866-996-3091

1-800-323-1724

1-800-463-2662

1-855-840-0828

1-800-561-4192

Top Lift Enterprises, Inc.

St-Laurent, QC (514) 335-2953

Sherbrooke, QC (819) 612-5438

www.toplift.com

Bolton, ON (905) 857-5200

Stoney Creek, ON (905) 662-4137

www.toplift.com

Manitoba

Westcon Equipment & Rentals Ltd.

Winnipeg, MB 1-800-453-2435

www.westconequip.ca

Alberta Strongco

Acheson, AB 1-877-948-3515

Calgary, AB 1-800-342-6523

Edmonton, AB (780) 464-1909

Fort McMurray, AB 1-855-799-4201

Grande Prairie, AB 1-888-513-9919

Red Deer, AB 1-866-950-3473

www.strongco.com

Williams Lake, BC (250) 392-9599

www.gwequipment.com

A9 JULY 24, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL BEYOND THE MACHINE sennebogen-na.com/beyond-the-machine Learn more about our commitment to our customers SENNEBOGEN is committed to leading the industry in aftersale support throughout the life of its equipment. We’re thinking “beyond the machine” to deliver dependable uptime and lower Total Cost of Ownership (TCO) for every customer. Parts • Service • Training • Application Specialists • Flexible Financing • Attachments +1-704-347-4910 sennebogen-na.com It’s difficult to find heavy equipment mechanics. If we don’t have the people we need on our own payroll, we can end up waiting a long time for machine service. Scrap Metals Recycler, Burnaby BC Read more about how our “Beyond the Machine” aftersale commitment ensures qualified service for SENNEBOGEN machines with factory training provided free to customers at our dedicated training center in Stanley, NC. Our own team of factory trained technicians makes a huge difference SENNEBOGEN Training Facility • Stanley, North Carolina Prince Edward Island Strongco Prince Edward Island (902) 468-5010 www.strongco.com British Columbia Great West Equipment Campbell River, BC (250) 286-0123 Cranbrook, BC (250) 426-6778 Fort St. John, BC (250)

22-SEN-0294.3 CO-OP EJ Demo-Training 10.375x15.25 4C.indd 1 2022-11-10 9:25 AM

According to a new survey by Procore Technologies, nine out of 10 construction firms in Canada express confidence in industry conditions in the next 12 months.

To compile its industry benchmark report How We Build Now: Technology and industry trends shaping Canadian construction in 2023, Procore partnered with Censuswide to survey 502 construction industry stakeholders in Canada, including owners, general contractors and subcontractors.

The report examines the general sentiment of the industry, the digital maturity and adoption of construction technologies, as well as the challenges and opportunities that businesses face.

“We are encouraged to see the Canadian construction industry’s leaders express

optimism as they look to consolidate and build on post-pandemic progress,” said Nolan Frazier, Procore’s Regional Sales Director for Canada.

While 90 per cent of respondents express confidence, 44 per cent are “very confident” about industry conditions over the next 12 months. As well, about 71 per cent of construction firms expect an increase in the number or value of projects over the same time frame.

Residential construction

The survey also found 43 per cent of companies that work in the residential sector expect to build more housing units in 2023 compared to 2022. In Ontario, 60 per cent of companies surveyed expect to build and deliver more housing this year.

However, more than half of respondents from British Columbia (51 per cent) and Alberta (55 per cent) who work in the residential sector expect to build and deliver fewer housing units in 2023.

Key concerns

Labour shortages and supply chain issues remain as key concerns for Canada’s construction sector. The report found that nearly one-third of construction companies have been unable to take on new projects in the past three to six months due to a lack of available labour. As well, 32 per cent fear their most experienced staff will retire in the next few years. Despite labour challenges, respondents are optimistic about the future. About eight in 10 companies are confident they will have

enough people to meet their organizational needs and the necessary skills to meet demand over the next 12 months.

Across Canada, supply chain issues are impacting respondents to a varying extent. In Québec, respondents reported the highest impact, with 41 per cent reporting significant delays due to supply chain issues, compared to 35 per cent of respondents from Ontario and just a quarter of respondents in B.C.

Digital transformation

Construction firms in Canada understand that a digital transformation is required to overcome the labour shortage with 22 per cent of construction businesses consider themselves a digital-first business and 51 per cent are “well on the way”

to adopting digital formats and workflows.

Construction decision makers recognize that technology is about to improve resource efficiency through less rework. The survey shows that about 27 per cent of the total time spent on a project is spent on rework or rectifying issues. The report also highlights:

· Almost half of all projects go over budget and over schedule

· More than 30 per cent of respondents identify the need for new technology to improve operational efficiency and cost controls

· Paper remains a common medium for Canadian construction decision makers. About a quarter of respondents still use paper-based records or non-digital processes as part of their workflow

The drive for data

According to the report, the industry realizes the value of data. However, the full value of data is not yet leveraged to its potential. The report explains 41 per cent of respondents feel they would make better decisions if they had better access to real-time and historic information on project performance. As well, respondents believe they could save up to 12 per cent of their total spending on projects if they captured, integrated and standardized data more efficiently.

Respondents report spending 17 per cent of their time on a typical project searching for data or information, and one in five say much of their data exists in spreadsheets or on paper and they do not leverage data to drive business outcomes.

Half of the respondents say they have a foundation in place to begin learning from their data but don’t necessarily have a dedicated data team in place.

“In particular, this survey shows half of the respondents see a need to embrace greater collaboration in projects among stakeholders; half of them are also well on their way in their digital transformation journey,” Frazier said. “Some also recognize the opportunity to leverage the massive amounts of data generated through the use of technology to make more data-driven decisions across every phase of the construction life cycle. Ultimately, smarter construction empowers construction businesses to have better control of their projects and deliver higher quality builds.”

The future of construction tech

Respondents rate construction management platforms, clean technologies involving green, sustainable or innovative materials, and next generation BIM as the top technologies that will drive change in the next three years.

More than 50 per cent of companies surveyed are currently using or plan to adopt a construction management platform within the next year.

The industry is also moving towards clean technologies, with 62 per cent of respondents either moving towards or currently using clean tech.

Overall, the industry is keen to adopt more environmentally conscious and sustainable building practices. About half of the respondents have started to focus on strategies like prefabrication and improved material selection to reduce the carbon footprint of their projects. Four in 10 are either currently tracking or plan to start tracking (within the next 12 months) carbon emissions on their construction

A10 JULY 24, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL

projects. High Reach Inc. your authorized Broderson

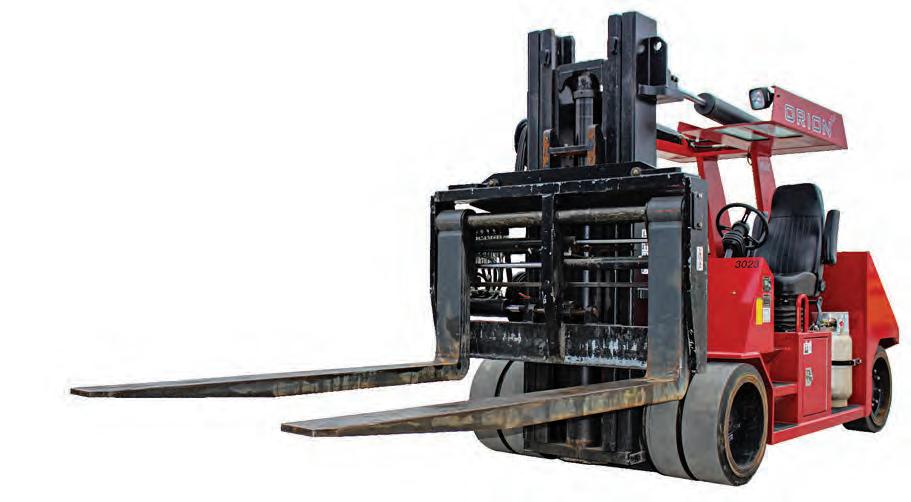

Orion

h 24,000 lbs to 160,000

in

h

h Smooth,

h

h

www.highreachinc.com Tel: (905) 844-4164 RENTALSSALESSERVICE FEATURING: REMOVE FORKS/INSTALL BOOM IN MINUTES. ORION’S QUICK-CHANGE RIGGER’S BOOM.

carry deck crane,

and Versa-Lift heavy fork lift truck dealer.

lbs.

lifting capacity

Available with fullfunction radio remote control.

accurate, hydrostatic drive.

Tier 4-Final Cummins diesel.

Standard and Customized designs to suit the end application.

Despite labour challenges, construction companies remain optimistic

A11 JULY 24, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL CUSTOMIZED, FLEXIBLE OPTIONS FIND OUT MORE 1-855-711-4545 FINANCING 1-888-227-2638 2011 JOHN DEERE 320D Unit #: 0U204384 $41,100 2015 JOHN DEERE 2154D Unit #: 0U210857 $210,000 2017 KLEEMAN MR130ZI Unit #: 0U780029 $750,000 2010 JOHN DEERE 953K Unit #: 1U187530 $109,500 JOHN DEERE RQ712029 $665,000 2016 JOHN DEERE 853M Unit #: 0U287800 $230,000 JOHN DEERE 410L $97,900 2019 JOHN DEERE 210G LC Unit #: 0U521047 $182,000 JOHN DEERE 870GP 2021 JOHN DEERE 850L Unit #: 0U409897 $595,000 848L 2023 JOHN DEERE 50G Unit #: 0U297767 $119,900 2008 CATERPILLAR 140M Unit #: 1U000547 $120,000 2023 JOHN DEERE 244L Unit #: 0U071060 $224,800 2018 JOHN DEERE 624K Unit #: RQ001187 $320,000 2019 JOHN DEERE 317G Unit #: 1U349325 $75,900 Canada’s #1 used equipment inventory | brandtused.ca 2016 JOHN DEERE 35G Unit #: 0U277042 $66,000 2012 JOHN DEERE 2154G Unit #: 0U210251 $59,000 2018 JOHN DEERE 244K Unit #: RQ049040 $115,000 2022 JOHN DEERE 324G Unit #: 0U413946 $91,000 2017 JOHN DEERE 317G Unit #: 0U315447 $75,500 2016 JOHN DEERE 953M Unit #: 0U297009 $217,000 2019 JOHN DEERE 1050K Unit #: 0U348885 $710,000 2014 JOHN DEERE 470G LC Unit #: 0U470302 $215,000 CATERPILLAR 430F2 IT KOMATSU 845 35G RO292242 859MH 35G $77,000 909K $159,900 330G $72,000 CHAMPION 750A $53,700 848L-II KLEEMANN MR130ZI Unit #: 0U780029 2154G KUBOTA R630C $118,800 CATERPILLAR 289D 325G 0U403683 DYNAPAC CC424HF 650K $167,900 1050K 200D LINKBELT LX350X3 CUSTOMIZED, FLEXIBLE OPTIONS FIND OUT MORE 1-855-711-4545 FINANCING used machines, one click away at brandtused.ca Your go-to choice for quality refurbished, used and aftermarket industrial equipment parts. brandt.ca/valueparts 2008 DEERE 310SJ Unit #: 0U164539 $55,900 2018 JOHN DEERE 17G Unit #: 0U227879 $33,400 2013 JOHN DEERE 953K Unit #: 0U233120 $184,900 2015 JOHN DEERE 772G Unit #: 0U667199 $335,000 2018 JOHN DEERE 544K Unit #: 0U687826 $165,000 2013 KOMATSU D65EX-17 Unit #: 0U001289 $155,000 2014 JOHN DEERE 903KH Unit #: 0U259733 $111,000 2016 JOHN DEERE 772G Unit #: 0U673522 $359,000 2018 JOHN DEERE 544K Unit #: 1U691707 $219,100 2016 JOHN DEERE 35G Unit #: 0U277310 $50,850 2013 BOBCAT T770 Unit #: 0U011945 $46,900 2007 HITACHI ZX350LC Unit #: 0U052255 $89,000 2018 JOHN DEERE 324K Unit #: 0U047382 $124,000 2019 JOHN DEERE 324G Unit #: 0U345845 $62,500 2017 CATERPILLAR 730 Unit #: 0U400509 $439,000 2015 KOMATSU PC290LC1 Unit #: 0U027252 $128,000 2015 JOHN DEERE 204K Unit #: 0U038979 $79,900 2016 JOHN DEERE 314G Unit #: 1U297290 $42,900 2014 JOHN DEERE 333E Unit #: 1U264976 $55,000 2010 JOHN DEERE 310SJ Unit #: 0U190497 $50,000 580SM 260E RQ682829 CATERPILLAR 430F2 IT $115,200 CATERPILLAR 289D 35G RO296107 $108,000 HAMM GRW18020 324L $135,800 1050K 2154D JOHN DEERE LC 903K $110,600 PONSSE ERGO $98,000 650K RQ326696 JOHN DEERE 320D 545D 872GP 772G 848L $177,900

Noah Romeo always had a dream of owning his own business since he was young. After gaining some great experience hustling with another company and having a great mentor, he felt it was time to fulfill his childhood dream and open his own company. Just over one year ago, Romeo Demolition & Excavation Inc. was born offering a wide range of services including interior and exterior demolition for residential, industrial, commercial and heritage, commercial (development sites and condos) and residential excavating, environmental remediation/spill clean-ups, grading and site preparation, site services, concrete crushing, trucking and haulage. They service customers in southwestern Ontario, GTA and Muskoka areas as well.

When asked why Bobcat® machines Noah responded with, “when I was looking for compact equipment, I did my research and prices were all pretty comparable, but I didn’t find any of them to have the bells and whistles Bobcat machines had. I really like the look of the white machines and I am familiar with the Bobcat machines as well. They are great machines. I also like dealing with Rob Bolger, sales specialist for Bobcat of TriCities. I had just walked into the dealership and met with Rob, and we hit off right away. We have a great relationship. In fact, I was looking to purchase the Bobcat T66 compact track loader and it wasn’t immediately available, so Rob talked me into purchasing the Bobcat T76 compact track loader instead, and it ended up being a way better option for my business. The Bobcat financing was a great option for me as the rates were under 3%. Rob has given me great advice and I will continue to work with him.”

Romeo said the applications he will use the Bobcat T76 compact track loader and the Bobcat E50 compact excavator which are both fully loaded, will be for his residential projects, demolition, excavating, loading dump trucks, grading, and taking material to and from sites, as he can get them anywhere. He also has bigger machines but will be using the Bobcat machines on most sites. They also have a Bobcat grapple

YOUR LOCAL AUTHORIZED BOBCAT DEALERS

BARRIE Bobcat of Barrie 705-726-2228 oakenequipment.ca

GREY BRUCE Bobcat of Grey Bruce 519-372-9100 bobcatoftc.com

PARRY SOUND

Bobcat of Parry Sound Ltd.

705-342-1717

bobcatofparrysound.com

TORONTO WEST Bobcat of Toronto 416-679-4172 oakenequipment.com

BRANTFORD Bobcat of Brantford 519-752-7900 bobcatofbrantford.com

HAMILTON Bobcat of Hamilton 905-643-3177 bobcatofhamilton.com

PETERBOROUGH

Bobcat of Peterborough

705-748-9119

bobcatofpeterborough.com

THUNDER BAY Equipment World Inc. 807-623-9561 bobcat-tbay.com

CASSELMAN Bobcat of Ottawa Valley 613-764-2033 bobcatov.com

KITCHENER Bobcat of Tri-Cities Ltd. 1-866-214-3939 bobcatoftc.com

STRATFORD Bobcat of Stratford 519-393-6040 bobcatofstratford.ca

SAULT STE. MARIE Bobcat of Sault Ste. Marie 705-949-7379 bobcat-ssm.com

CORNWALL Bobcat of Ottawa Valley 613-932-2034 bobcatov.com

LONDON Bobcat of London 519-455-4900 bobcatoflondon.ca

STRATTON Stratton Equipment 807-483-5505 strattonequipment.com

WINDSOR Bobcat of Windsor 519-737-0120 oakenequipment.ca

“I wouldn’t hesitate to recommend Rob Bolger, Bobcat of TriCities and Bobcat machines for your next compact machine purchase,” exclaimed Noah.

Romeo has accomplished so much in just over a year. He is very excited that his company is currently starting up a recycling plant as well. With them continuing to expand and grow, I am sure so will their fleet. It will be interesting to see where Noah and his company are five years from now at this rate.

Thanks Noah.

COURTICE Bobcat of Durham East Ltd. 905-404-9990 bobcatofdurhameast.com

MUSKOKA Bobcat of Muskoka 249-390-7000 oakenequipment.ca

SUDBURY McDowell B Equipment Ltd. 705-566-8190 bmcdowell.com

FRANKFORD John’s Equipment 613-398-6522 johnsequipmentsales.com

OTTAWA Bobcat of Ottawa Valley 613-831-5166 bobcatov.com

TORONTO EAST Bobcat of Toronto 416-679-4171 oakenequipment.ca

A12 JULY 24, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL

attachment, forks and bucket for the Bobcat T76 compact track loader.

(L to R) Rob Bolger, sales specialist for Bobcat of TriCities and Noah Romeo, owner of Romeo Demolition & Excavation Inc. outside a huge job about to start in Puslinch, Ontario.

With a focus on digitalization, Bauer is confident its new BE 600-C desanding plant will set new standards in its field.

The successor to the BE 500, the new desanding plant can process up to 120 tonnes of solids per hour.

The two-stage plant with double cyclone design is installed within a container frame, and includes a reservoir tank, solids discharge, hose guide, all-round access platform and upstream coarse screen. It delivers 174 kW of power and a throughput capacity of 600 cubic metres per hour.

The BE 600-C is comprised of two standard Type BE 300-C desanding plants. However, the optimized separation is new. After being fully treated in a first step, the slurry is pumped through the second tank inside — rather than outside — the plant toward the desilter unit.

Another feature is the comparatively low space requirement, as pumps and desilters are located within the container frame and not outside, as would be the case for standard double cyclone plants. This allows the BE 600-C to achieve a base area of just 6.1 x 5.9 metres.

With all components installed within the container frame, it is possible to transport the desanding plant, assemble and commission on site, quickly and easily.

What makes it unique is the BE 600-C can be divided back into two individual BE 300-C units as needed, and the upstream coarse screen can feed a single unit.

“This makes our plant as flexible as our customers’ projects,” said Tim Eberwein, Sales Manager at Bauer Mat Slurry Handling Systems. New tech

The BE 600-C also includes numerous new tech features. For example, each of the two individual plants features a 30-cm touchscreen display. The complete plant can also be operated from a single screen in master-slave mode. The operator can see

at a glance which parts of the equipment, like the conveyor belt, flow meter or accessories, are running and which are not. Other information such as pressures, operating hours or power consumption is also displayed. An EWON router establishes a connection with the Internet, which allows all data to be called up via remote access, along with error messages.

“In this way, our service specialists can connect to the equipment quickly and easily and perform a remote diagnosis, if necessary,” said Yilmaz Ipeksoy, Technical Manager at Bauer. “This saves lots of time as well as costs, since our customers don't have to wait for service technicians to arrive on site.”

Anywhere bentonite or cement slurry needs to be mixed, this MAT equipment can be used.

“Whether for mixing, pumping, stockpiling or separating, our products are a key element of the complete cycle,” said Kurt Ostermeier, Head of Product Management Mixing and Separation Technology at Bauer Maschinen.

More than 30 years of expertise in mixing and separation technology contribute to the process when equipment or components are newly developed or enhanced at Bauer Mat Slurry Handling Systems, but new trends such as digitalization and automation are also in focus.

“Digitalization as well as automation are ongoing processes that will continue to play a major role in the future. Our goal is to fully and permanently integrate our equipment into the cycle of a digital site.”

A13 JULY 24, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL

2019 HITACHI ZX245 - coupler, aux hyd, choice of buckets, approx 2,700 hrs. $217,000 Tri-City Equipment is a 100% privately owned Canadian corporation YOUR HEAVY EQUIPMENT RENTAL HEADQUARTERS! 519-767-9628 1-800-646-2064 TRI-CITYEQUIPMENT.COM WE BUY EQUIPMENT! CALL OR TEXT RYAN ARMISHAW (519) 240-4672 DAVE ZAPPITELLI (226) 962-6106 Full Service Rebuild Shop, Aftermarket Parts & Repairs Available CAT 930/950 LOADERS, aux hydraulics, bucket & forks, multiple units available. FOR RENT 25, 30, 40, 45 TON TRUCKS - available with tailgates + floatation tires. FOR RENT 2016 JOHN DEERE 844II - Only 4,300 hrs! Clean unit with loadrite scale, auto grease, matching Michelin 875’s (approx. 65%). $339,000 2019 HITACHI ZX135 - aux. hyd, clip on rubber pads, choice of bucket, Approx 3750 hrs. NEW PRICE $127,000 HITACHI ZX245 - aux hyd, choice of bkt. Cat325 also available. FOR RENT BRAND NEW BUCKETS - All sizes. FOR SALE CAT 972 - Scale, auto greaser. CAT 980 also available. FOR RENT KUBOTA U55 – 3, 5, 8 Ton units available - Multiple attachments. FOR RENT CAT D8 – Available w/winch or ripper. FOR RENT 60 FOOT LONG REACH – choice of buckets, 250 & 300 sizes available. FOR RENT CAT 336 – Next Gen - grade control, q/c, choice of buckets - Hitachi ZX350 also available for rent. FOR RENT Bauer’s new desanding plant processes up to 120 tonnes per hour • Augers • Breakers • Brush Cutters • Buckets • Compactors • Demolition • Forest Mulcher • Grapples • Quick Couplers • Rippers • Rubber Tracks • Screening Buckets • Thumbs • Tree Shears BEST QUALITY ATTACHMENTS AT THE LOWEST POSSIBLE PRICE shawbros.ca info@shawbros.ca • For clearing field edges, plots and roadside • Installation work• • Thinning • For removing problematic trees and branches • For rescue and clearing work Barrie, Ontario 1-877-625-9677 QUALITY ATTACHMENTS WE ALSO CARRY: PROFITABILITY AND EASE OF WORKING WITH THE KX TREE SHEER ENERGY WOOD GRAPPLE ARE GREAT FOR:

With the new BE 600-C, Bauer Mat Slurry Handling Systems has taken a major step towards that goal.

To maximize its opportunities in the growing compact equipment segment, Volvo Construction Equipment has launched a new compact business unit.

According to Volvo CE, an increase in population and urbanization has expanded the construction sector worldwide, with particularly strong demand for compact equipment. The compact segment now represents 50 per cent of the total market, compared to 35 per cent a decade ago,

with the growth trend likely to continue.

The new global business unit is the latest step forward in Volvo CE’s ambition to lead the transformation of the industry and provide dedicated productivity-boosting solutions built to fit customers’ evolving needs.

Thomas Bitter, Volvo CE’s Head of Technology, will take on the role as Head of the Compact Business Unit, starting in September.

“Our pioneering work

in electrification and digitalization has positioned us as an innovator in compact equipment. And now because of compact equipment’s ever-growing influence on the market, we are focusing our attention on our compact machine portfolio to provide customers with productive and sustainable products and services,” Bitter said.

“The people who join us in this journey will not only develop specialized skills in this important area but be

playing an integral role in our wider purpose of building the world we want to live in.”

An independent entity within Volvo

The Compact Business Unit will operate as an independent entity within Volvo CE, focused on maximizing the opportunities in the growing market for compact equipment. Initially, it will be responsible for compact excavators up to 9 tons and compact wheel

loaders up to the L50 model. The business unit will have responsibility for the entire value chain, including development, assembly, purchasing and the go-to-market strategy (together with the existing distribution network) for the compact equipment offering.

As well, the new business unit will take advantage of the shift to electrification in the compact equipment segment to secure a fully electric line up of machines

across the whole compact range.

In 2019, Volvo CE made an industry-first move and shifted its entire branded compact range to electric and stopped development of new diesel variants. Since then, it has launched five electric compact models: the ECR25 Electric, ECR18 Electric and EC18 Electric excavators and the L20 Electric and L25 Electric wheel loaders. The EC55 Electric excavator has also been introduced to China.

A14 JULY 24, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL

PREMIUM HEAVY EQUIPMENT RENTALS & SALES Darcy Wurban Territory Manager (780) 935-6766 DarcyW@contraceq.ca Calvin Berube Territory Manager (780) 222-1094 CalvinB@contraceq.ca Jeff Hayward Sales Manager (780) 916-5005 JeffH@contraceq.ca

Hours,

POR

2021 JOHN DEERE 300G LC, 2506 Hours, Q/A, 2 Buckets, Hyd.Thumb, Aux.Hyd., FOGS, Cat Walks, Pos. Air, Webasto. POR contraceq.ca 220 Diamond Ave., Spruce Grove, AB T7X 4C7 • SPECIALTY PIECES ALL THE WAY TO COMPLETE CUSTOM SPREADS • EXTENSIVE FLEET OF OVER 600 UNITS Call or email today with all of your inquiries. We look forward to working with you! SERGE LEGAULT 514-239-3146 12slequipment@videotron.ca 1 Rue

slheavyequipment.com 2011 VERMEER BC1000XL WOOD CHIPPER, 1760 hours, CAT diesel engine. $31,000 2015 BANDIT 255XP WOOD CHIPPER, 1530 hours, CAT diesel engine. $46,000 2015

WOOD CHIPPER, only 22 hours, Kubota diesel engine. $36,000 Volvo CE establishes new compact business unit The

50 per cent of the total

CE. DEMOLITION UPX UNIVERSAL PROCESSOR Ranging from 6,300-45,000 lbs. pineridgeliscoedwards.ca 1.866.488.0878 SHEARS, HAMMERS, PULVERIZERS AND GRAPPLES RENTALS/SALES/REPAIRS Specializing in DEMOLITION Equipment PINERIDGE 1.866.488.0878

2021 JOHN DEERE 872GP, 3800

17.5x25 Michelin, Sno Plus, AWD, Ripper, Snow Wing, Front Blade, Espar .......

2021 CAT D3 LGP-V, 34 Hours, 6-Way, Ripper, Full Guarding, Pos Air, Espar. POR

Du Carabinier, Blainville, QC J7C 5B8

ALTEC DMR12

compact equipment segment now represents

market, according to Volvo

A15 JULY 24, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL LMPOWERTRAINPARTS.COM Celebrating 64 Years of Service Worldwide L&M POWERTRAIN PARTS LIMITED 201 Snidercroft Road, Concord, Ontario, Canada L4K 2J9 Telephone: 905-669-2292 Fax: 905-669-6319 Toll-Free in North America: 1-800-387-3765 Email: parts@landmparts.com

Systems We’re celebrating our 64th Anniversary thanks to the confidence our customers have shown around the world in over 100 countries. Supplying Transmission, Torque Converter, Differential, and Planetary Axle parts from all the top OEM’s. L&M Powertrain; the worlds heavy equipment parts & component supplier that always has your part in stock! See Us at Booth #12849 YOUR PARTS ARE IN STOCK AT L&M

Off-Highway

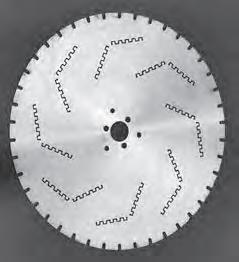

The most powerful and most useful track jaw plant on the market! Engineered to be the highest capacity jaw crusher on the market, the Pioneer® Jaw Crusher will deliver up to 25 percent more tons per hour than comparable jaw crushers.

Opening: 26” D x 50” W

Weight: 104,000 lbs

50” x 18’ Vibratory

Cat Tier 4 - 300 hp

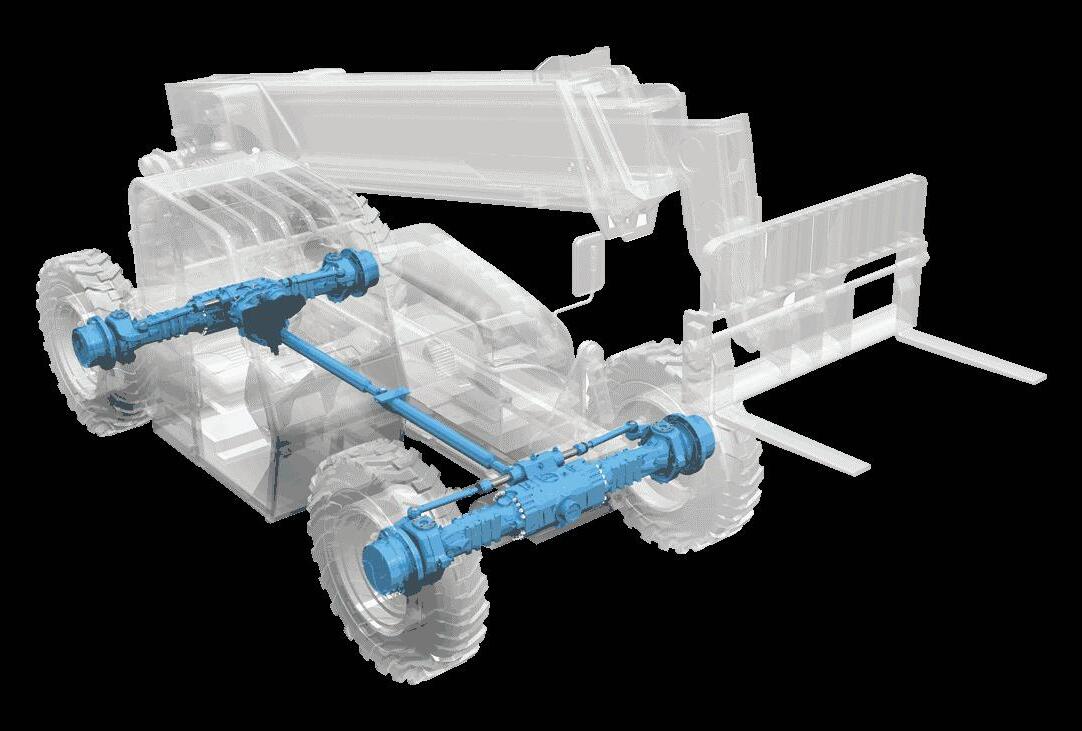

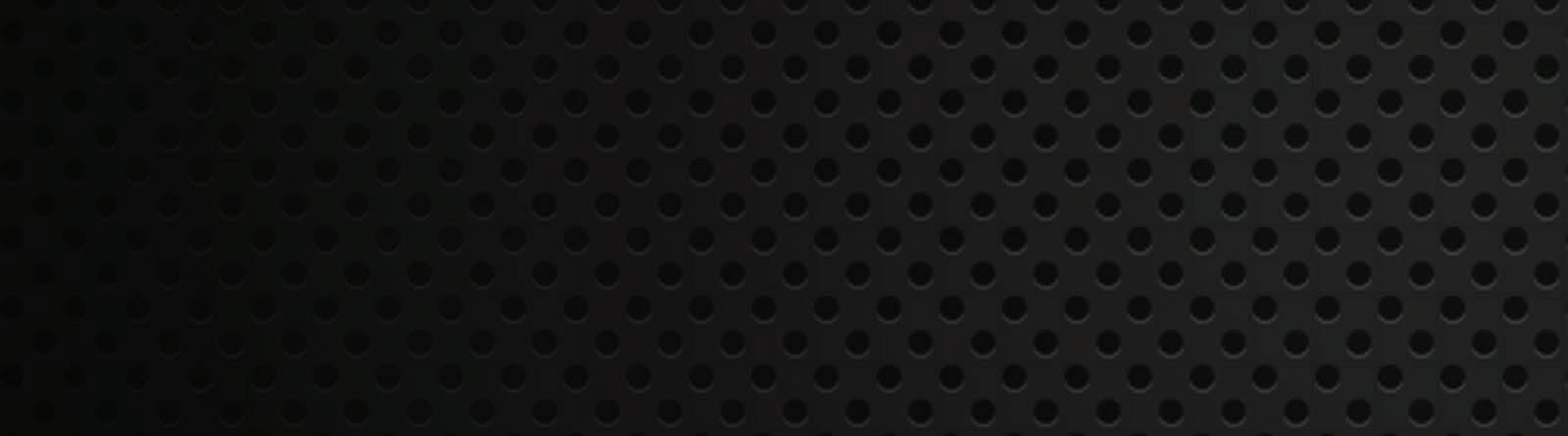

JLG is redesigning its SkyTrak telehandler line

JLG Industries is redesigning its SkyTrak telehandler line to include the most requested features with zero sacrifice.

The resign starts with the all-new 6034 and 6042 models. Featuring a redesigned build, reworked functionality, reimagined technology and refocused serviceability, these 2,721-kg maximum lift capacity telehandlers are ideal for pick-and-place applications, such as handling, loading and unloading bulk materials on demanding residential, commercial, urban and suburban job sites.

“Understanding the demands and challenges crews face on work sites day after day, we redesigned the all-new 6034 and 6042 models with features and capabilities directly inspired by the needs of those who need them most,” said John Boehme, Senior Product Manager for Telehandlers at JLG, “These updated models deliver our customers’ most requested features, with zero sacrifice.”

The 6034 telehandler replaces the previous 6036 model, while the 6042 telehandler has been updated with new features inspired by the way customers work. For example, the telehandlers feature a lower operating weight — 6,577-kg on the 6034 and 8,663-kg

on the 6042 — allowing for more efficient transport. These machines’ lightweight design with an optimized frame structure allows three 6034 models or two 6042 models to be hauled on a single flatbed trailer. In fact, the 6034 model is lightweight enough that it can be transported with a standard pickup truck and trailer.

The 6034 model offers a lift height of 10.3-metres and a 7-metre forward reach. The 6042 model provides a 12.8-metre lift height and 8.8-metre forward reach. Both the 6034 and 6042 offer three steering modes — two-wheel, four-wheel and four-wheel crab — which operators can select as needed for better maneuverability.

Additionally, both telehandlers have a 2.4 metre width and smaller tires, giving them best-inclass maneuverability, while still maintaining their 38-cm ground clearance.

An enclosed cab is available with optional air conditioning for both machines.

Reworked functionality

The 6034 and 6042 are equipped with a 74 hp, 2.9 litre Deutz diesel engine that doesn't require diesel exhaust fluid. The hydrostatic transmissions provide greater control and ease of operation. They also have inching functionality, which allows operators to run the boom at high speeds without shifting the transmission into neutral,which translates to faster delivery of materials at height.

The single joystick is electric rather than hydraulic for greater multifunction capability. The auxiliary hydraulic function and attachment tilt are included on the joystick for enhanced productivity.

To switch attachments, both models feature a common coupler for use with all JLG and SkyTrak attachments, allowing the 6034 and 6042 telehandlers to adapt based on what's needed on the job site. As well, the auxiliary hydraulic connections on these telehandlers are now on the side of the boom head so operators can change attachments more efficiently. The 6034 and 6042 models feature a standard boom-mounted lifting lug that can be used to properly

handle a suspended load and an integrated tow hitch on the rear counterweight for added jobsite versatility.

Telehandler tech

The design of the 6034 and 6042 telehandlers emphasizes convenience and productivity. The new machines feature an advanced control system that allows for more options like load stability indication (LSI), seatbelt engagement and operator presence (SEOP), along with improved diagnostics. The new cab design features a larger LCD display for a more data-rich interface and larger, single-page load charts for added convenience.

Several optional systems are designed to improve productivity and operator confidence. The optional multi-reverse camera system lets operators backup with confidence by displaying multiple views from behind the machine to the left, right and rear. This system can be used during the day and night, and it features four components: left and right-side backup cameras, a rear backup camera and a tri-view monitor.

The optional reverse sensing system alerts operators to rear obstructions with an audible alarm. This feature helps crews be more aware of their surroundings, especially on busy job sites. And finally, the optional white noise backup alarm emits a directional alarm signal on the machine as it travels in reverse. This type of alarm helps cut down on jobsite noise while enhancing worker safety outside the machine.

Service enhancements

The new SkyTrak models include a 30 per cent reduction on hydraulic hoses and connections, resulting in fewer potential leak points. The top-mounted telescopic cylinder provides easier access for service, and the rear access door on the frame has been replaced with a bolt-on panel for added durability.

Enhancements to the boom on both SkyTrak models include faster boom function speed, an 8 per cent improvement over previous models, and an updated single compensation and lift cylinder design for fewer components to maintain, streamlining maintenance.

A16 JULY 24, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL

lswwearparts.com Fredericton, NB 506-458-5613 Truro, NS 902-895-4913 A WINNING COMBINATION ESC O Snow Plow Blades Ultralok® Tooth System MaxDRP™ Replacement Teeth ESC O Crusher Jaw and Cones LSW Wear Parts and ESCO® are the Leading Choice for Contractors and Aggregate Producers www.esco.weir Copyright ©2023 ESCO Group LLC, The Weir Group PLC. All rights reserved

Operating

Feeder:

Engine:

AMACOCEI.COM IN STOCK! 2023 ASTEC (KPI) FT2650 TRACK MOUNTED JAW CRUSHER Call or Text (905) 670-3440 AMACOCEI.COM

Intake

GO THE DISTANCE... SAVE ON FUEL.

5-YEAR/ 5,000 HOUR Full Machine Warranty

5-YEAR/ 10,000 HOUR Machine Structures Warranty

• Largest minimum swing radius exavator in Link-Belt lineup.

• Power of large machine at lower weight.

• 6-cylinder Isuzu Final Tier 4 engine with fuel efficiency and high productivity without need for DPF.

• 4 work modes, including the new Eco mode.

• New cab with more head and leg room making this the roomiest cab ever.

• Optional WAVES® camera system adds a third camera and gives the operator a full 270º view around the machine.

• RemoteCARE® GPS-enabled telematics system included with no subscription fee!

Your LINK-BELT Excavators Dealer has all the details!

ALBERTA

Equipment Sales & Service Ltd.

Edmonton (780) 440-4010 essltd.com

BRITISH COLUMBIA

The Inland Group

Burnaby, BC 604-291-6431

Campbell River, BC 250-287-8878

Castlegar, BC 250-365-2807

Cranbrook, BC 250-426-6205

Fort St. John, BC 250-785-6105

Kamloops, BC 250-374-4406

Kelowna, BC 250-769-2933

Langley, BC 604-607-8555

Nanaimo, BC 250-758-5288

Penticton, BC 250-492-3939

Prince George, BC 250-562-8171

Quesnel, BC 250-992-7256

Terrace, BC 250-635-5122

Vernon, BC 250-545-4424

Williams Lake, BC 250-392-7101 inland-group.com

NEW BRUNSWICK

Paul Equipment

Balmoral (506) 826-3289 paulequipment.ca

ONTARIO

Itec 2000

Rosslyn (888) 574-8530

Thunder Bay (888) 574-8530

Timmins (705) 267-0223 itec2000.com

McDowell B Equipment Ltd. Sudbury (705) 566-8190

Barrie (416) 770-7706 bmcdowell.com

Stratton Equipment Sales & Service

Stratton (807) 483-7777 strattonequipment.com

Top Lift Enterprises Inc.

Stoney Creek (905) 662-4137 Bolton (905) 857-5200 toplift.com

QUEBEC

Équipement JYL Inc.

Chicoutimi (418) 698-6656 equipementjyl.com

Micanic St-Aug-D-Desm (418) 878-2241 micanic.com

Paul Equipment (506) 826-3289 paulequipment.ca

Top Lift Enterprises Inc. St-Laurent (514) 335-2953

Sherbrooke (819) 612-5438 toplift.com

YUKON TERRITORY

The Inland Group Whitehorse, YT 867-668-2127 inland-group.com

www.lbxco.com/warranty

A17 JULY 24, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL

Operating Weight: 78,709 lbs || Net HP: 205 hp || Max Dig Depth: 22’ 10” || Reach at Ground Level: 34’8” 355

For your local DEVELON dealer, innovation takes many forms. Whether it’s our expanding lineup of equipment, exclusive technologies that improve productivity or ongoing services that help your business grow — DEVELON is developing onwards.

Authorized Dealers

Alberta Brown’s Industrial Sales Cold Lake | 780-826-2399

Lloydminster | 780-875-2339

Rentco Equipment

Grande Prairie | 780-538-0791

British Columbia Rentco Equipment Fort St. John | 250-785-1197

Westerra Equipment Abbotsford | 604-850-7313

Kamloops | 250-314-3600

Nanaimo | 250-716-0443

Williams Machinery Prince George | 250-563-0181 Surrey | 604-930-3300

Terrace | 778-721-0398

Manitoba

AgCon Equipment Springfield | 204-255-4772

C&C Rentals Brandon | 204-728-2699

Ontario Bobcat of Hamilton Ltd. Stoney Creek | 905-643-3177

C G Equipment Guelph | 519-826-0550 Zurich | 519-236-4934

Eastrock Equipment Inc. Ottawa | 613-737-3963

Elvaan Equipment Solutions Mississauga | 647-988-9931

G F Preston Sales & Service

Sundridge | 705-384-5368

Hartington Equipment

Hartington | 613-372-2744

ITEC 2000 Equipment

Rosslyn | 807-768-8584

ReadyQuip Sales & Service Ltd.

Timmins | 705-268-7600

New Brunswick

Paul Equipment and Sons

Balmoral | 506-826-3289

Fredericton | 506-449-3289

Northwest Territories

Ron’s Auto Service Ltd.

Yellowknife | 867-766-6025

Nova Scotia

East Coast International Trucks Inc.

Dartmouth | 902-478-3552

Quebec

Équipements Plannord

Beloeil | 450-464-8000

St-Augustin-de-Desmaures | 418-878-4007

Machinerie St. Pierre

Val-d’Or | 819-824-6931

Saskatchewan

Bobcat of Regina, Ltd.

Regina | 306-347-7600

Earthworks Equipment Corporation

Saskatoon | 306-931-7880

Yukon

MacPherson Rentals

Whitehorse | 867-633-4426

A18 JULY 24, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL ©2023 HD Hyundai Infracore. All rights reserved. DEVELON is a brand of HD Hyundai Infracore; HD Hyundai Infracore is an affiliate of HD Hyundai. Your success drives our innovation. Scan the code to find a DEVELON dealer near you.

Link-Belt debuts 5th generation 218 lattice crawler crane

Link-Belt Cranes has announced the release of its 5th generation 218|V lattice crawler crane.

The 218|V (five) represents the fifth generation crane since the original HYLAB introduction more than 35 years ago.

“Larger cranes often get more publicity for making eye-catching big lifts, but the daily, versatile workhorse in the industry is this size of machine,” said Brian Elkins, LinkBelt Cranes’ Product Manager for Crawler Cranes.

The 99.79 tonne crawler crane is powered by a Cummins QSB 6.7 Stage 5 engine that delivers 281 hp to a Kawasaki pump and motor package for fast, responsive, fingertip control providing simultaneous operation wherever it is needed.

As well, the 218|V can be run on hydrotreated vegetable oil (HVO) which is also fully mixable with regular diesel fuel.

The Eco Winch system provides

improved fuel economy, resulting in lower operating cost, less engine rpm under load, fewer emissions and all the line pull required with 26 mm rope.

When activated by the operator, Eco Hoist provides maximum line speed with lighter loads, all with the engine under 1,000 rpm. Also, the operator-selectable “auto-engine shutdown” is standard, allowing the engine to shut down automatically after extended periods of inactivity, so long as critical operating criteria are met.

Other new features include:

· New access ladders and steps to the upper work platform

· Main load transports under 45,359 kg

· 48.7 metres of boom on three 15.2 metre trailers

· Standard power pack lug mounting brackets

· Extended hydraulic oil service interval of 4,000 hours

The 218|V comes with the same bulletproof undercarriage components and two-speed travel as the previous 218 HSL. However, the undercarriage is now equipped with quick deploy swing-out axle extenders. New front and rear car body counterweights feature a hook and pin design that fit neatly between side frames allowing access to side frames for extend and retract. The front car body counterweight has an attached toolbox for additional storage.

More visibility

The lattice crawler crane is equipped with a new 30 cm touchscreen LMI operating system that offers better visibility with improved sightlines. As well, ergonomic foot pedals are closer to the cab floor offering unobstructed views of ground level.

The new display features an operator interface with new

counterweight sensing for live readout of stacked counterweight, live goundbearing, swing angle indicator, list and trim indicator, engine rpm monitoring and improved diagnostics.

The crane operator is assisted by on-board high-resolution winchview, back-up and non-cab side swing-view cameras with night vision to enhance jobsite visibility from within the cab.

A new optional lighting package also adds LED light on the cabside upper, below the upper and on the front cab for jobsite settings that require additional early morning or evening cover.

Counterweight

The lattice crawler crane self-assembles with 30,844 kg of upper counterweight and 13,698 kg of lower car body counterweight. The counterweight removal system is common to Link-Belt’s tele -

crawler lineup and comes with a remote control for single person operation.

An additional 5,443 kg of counterweight provide a 5 per cent average capacity gain over the previous 218 HSL.

As well, the lattice crawler crane features a new quick reeve boom head with button style termination for easy setup for block and ball removal from a 26 mm rope. Lattice boom extensions on the 218|V are common to 218 HSL. Maximum main boom length is 70 metres and maximum fixed-jib length is 22.8 metres. The maximum boom-and-jib combination gives the 218|V a maximum tip height of 85 metres.

The main boom for the new 218|V will come with new pendant storage brackets for secure pendant storage when transporting any section of main boom, with optional boom floodlights.

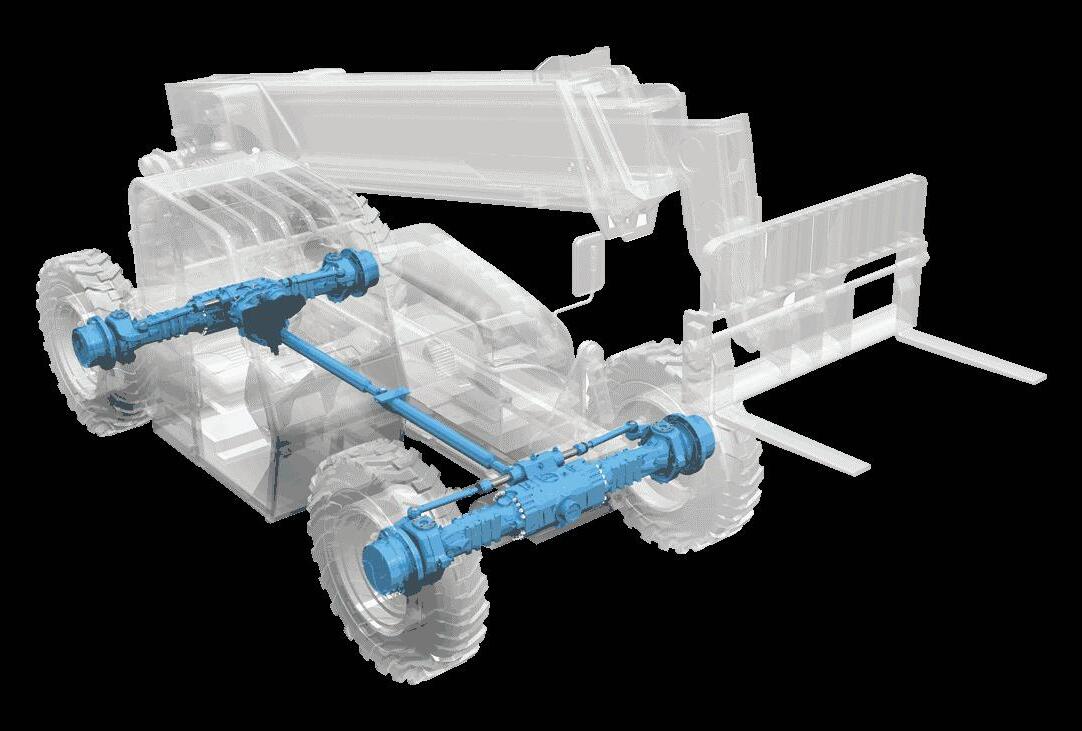

A19 JULY 24, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL E-mail: usedparts@brandt.ca Inventory: brandt.ca/ValueParts 1-877-685-4886 Aftermarket: Final drives, swing bearings, H-links, & more... Refurbished: Rotary manifolds, hydraulic cylinders, final drives, & more Used: Cab assemblies, bucket pins, hydraulic cylinder parts, & more... Current stock for excavators Parts available for all models & generations! CUSTOM DIAMOND SEGMENTS FOR COMPLEX AGGREGATES Silent Zzzz Core 40” & 48” Low vibration & super quiet blade. Diamond matrix custom designed for your stone & machine. Long life & fast cutting QUARRY BLADES #105, 1626-115 Ave NE Calgary, Alberta T3K 2E4 main: 403-230-8826 sales & delivery text/call: 587-433-8702 (Robbie) 1600 109 Street, Grand Prairie, Texas 75050 main: 1-972-602-0080 Technical Consultant Mario protechdiamond.ca/quarry RETIP, TENSION & REPAIR mario.barrera@protechdiamondusa.com / 1 (972)835-8048 protechdiamond.ca @protechdiamond

Case begins launch of new D Series mini excavators

Case has introduced the first mini excavator in its new D Series line.

The diesel-powered, true zero tailswing 4.2 tonne CX42D is the first model in the new series. Complementing the existing C Series mini excavators, the CX42D gives Case a broad reach into core weight classes that are in high demand.

“The CX42D exists in a critical industry weight class between four and five metric tons that we did not previously have machines,” said Brad Mace, Product Manager for Case Construction Equipment.

“This ensures that we have a total fleet of solutions to deliver to contractors and business owners and allows us to bring the next level of premium mini excavator performance to the market.”

The CX42D includes a

standard two-way blade with float to improve backfilling and grading operations, while an optional six-way blade improves upon those capabilities. While the zero tailswing design provides excellent access to tight locations, additional counterweights can be added for further balance and confidence.

The standard two-speed travel with automatic shift down improves performance when tracking/carrying up hill. Standard multifunction (one-way/two-way) hydraulics and a standard second, two-way auxiliary circuit enhance performance. As well, an optional third auxiliary circuit is available.

Each machine comes standard with a thumb bracket and can be ordered from the factory with an optional thumb.

Additional options include a mulcher package and a direct drain for equipment requiring drainage to the tank without back pressure. Two different coupler options are available from the factory for meeting operator attachment and bucket preferences, including a hydraulic quick coupler, mechanical quick coupler and a standard pinon-bucket.

“Mini excavators are continuously underrated as attachment platforms, and the new CASE D Series models are built to prove they can deliver excellent multipurpose capabilities,” Mace said. “And we give them the ability to set up and save parameters for nine different attachments, and customize the flow based on tool type for optimal performance and operator experience.”

The mini excavator cab is designed to deliver an automotive-style experience. The machine features excellent control adjustability, and clear visibility down to working areas with large glass and an intelligent structural design of the machine.

A large, 18-cm LCD monitor with a navigation wheel mounted near the joystick

gives operators access to critical machine information and controls without having to reach to the screen. As well, the screen allows operators to select working modes (Power, Standard or Economy), and customize hydraulic proportional controls and auxiliary hydraulics for optimal performance.

Additional CASE D Series mini excavators will be introduced in 2024.

Metso to acquire Häggblom

To expand its loading and hauling offering, Metso has signed an agreement to acquire Häggblom Oy, a privately owned Finnish engineering and manufacturing company.

Häggblom's key offering includes mining truck bodies and buckets as well as wear parts, truck body and bucket refurbishments and related field services.

Metso and Häggblom have partnered for several years in the manufacturing of truck bodies.

“Loading and hauling is a growing business, and our goal is to further develop our capability to serve our customers,” said Heikki Metsälä,

President of Metso’s consumables business area.

“Häggblom's product range, manufacturing know-how and engineering capabilities, as well as service expertise, are a good addition to Metso's wear parts portfolio. Häggblom’s employees will bring valuable skills to Metso, and we look forward to building on the great partnership we have developed over the years.”

Through the acquisition, Metso aims to leverage Häggblom's engineering and manufacturing expertise in collaboration with existing partners on a regional and global basis.

The acquisition effectively

broadens Metso’s offering in bodies and buckets by providing complete end-to-end loading and hauling solutions and strengthening the company’s position in the aftermarket.

“This is the beginning of an exciting new chapter for our company. We have successfully cooperated with Metso for many years, and we are now excited to become part of an international company,” said Jukka Karhula, CEO of Häggblom.

“We are confident that our expertise and products will align well with Metso's loading and hauling offering. This acquisition will benefit our customers and employees who are our most important assets.”

The acquisition is estimated to be finalized in August 2023. The parties have agreed not to disclose the transaction value, which has no material impact on Metso’s financials.

Häggblom Oy’s ownership is divided between Finnish private equity investors and the management.

The company has about 100 employees, with manufacturing, service, and logistics facilities in Finland and Sweden.

Häggblom’s sales in 2022 were about EUR$25 million.

A20 JULY 24, 2023 EQUIPMENTJOURNAL.COM @EQUIPJOURNAL

www.jadeequipment.com ● info@jadeequipment.com Proud Member Canada’s Grader People Edmonton, Alberta Toll Free: 1-800-663-0715 • Orillia, Ontario Toll Free: 1-866-404-5233 10807-209 St, Edmonton, AB T5S 1Z7 Tel: 780-452-7021 • Fax: 780-453-1477 47 Forest Plain Road, Oro-Medonte, ON L3V 0R4 Tel: 705-325-2777 • Fax: 705-325-9777 We are your source for Wille, the World Leader in Agile Urban Machines. nowOrder forthe winterseason! Small and efficient partner for all seasons - robust and agile. Unrivalled in its weight category, with the most powerful operating hydraulic system on the market. 275 375 665 865 465 Trusted player in the renovation of street and park areas, 365 days a year. The king of multi-purpose machines - an agile, versatile and powerful workhorse. Most popular environmental management machine in its weight category. Multi-function Bucket Leaf Collector Collection Sweeper Mowers Rear Blade Rotary Brush Snow Blower & Rear Spreader Pressure Washer Wille Four Season Versatility TRUCKS, MACHINERY AND EQUIPMENT APPRAISALS USPAP Compliant and CPPAG Certified On-Site Orderly Liquidation Services Jeff Lillycrop, CPPA 905-977-8402 www.jblservices.ca jblappraisalservices@gmail.com

CANADA’S NATIONAL HEAVY EQUIPMENT NEWSPAPER SINCE 1966 CONNECT WITH US! Visit us at: www.equipmentjournal.com

WE ARE PROUD TO ANNOUNCE WE ARE OFFICIALLY A BEARCLAW DUMP TRAILER DEALER!

2010 NEW HOLLAND U80B

79 hp, 4WD, Deluxe cab w/Heat/Air Con., 4 forward x 4 reverse speed trans. w/Power Shuttle, Ride Control, NH/FFC Hyd., QC on front loader, Aux. hyd., QA bucket & AMI pallet forks, 3 point hitch, Dual tilt w/ holding valve, Additional rear counterweight $69,900

2007 NEW HOLLAND B95 95 hp, 4 cylinder diesel, cab w/heat and air conditioning, front & rear wiper, Extendahoe, 1.3 yard front bucket, 24” rear bucket, Pilot Controls, 4 speed power shuttle trans., loader aux. hyd., 1050 Hrs, pattern control changer $69,900

2005 NEW HOLLAND DC85 Dozer, 89 gross engine horsepower, 4 cylinder engine, LGP model, 28” grouser shoes, Drawbar, Mechanical suspension seat, Canopy, 124” wide PAT blade, New sprockets & track chains Installed, 3577 hours $69,900

2007 JCB 3CX BACKHOE

90 hp, 4 cylinder turbocharged diesel, Cab w/heat & A/C, pilot controls, 4 speed powershift trans., Extendahoe, 14x17.5 front tires, 19.5L24 Rear tires, 24” Rear bucket, front pin on bucket $54,900

2007 HYUNDAI R140LC-7 Cummins B3.9C engine with 115 gross horsepower, 31000 lb. operating weight, 24 inch track pads, 15’1” boom length, 9’10” stick length, Auxiliary hydraulics, Helac powertilt with coupler, Hydraulic thumb, Digging & Ditching bucket, 4207 hours $99,900

2004 HYUNDAI HL730-7 21384 lb. operating weight, Cummins B3.9C 4 cylinder engine, 125 gross engine hp, 4 forward x 3 reverse speed Full Auto. Powershift trans., 17.5-25 tires, Front/rear fenders, 3rd function aux. boom hyd., ACS hyd. coupler, ACS 2 yd mat. bucket with bolt-on cutting edge, 3647 hours $64,900

2011 NEW HOLLAND L230 90 horsepower, 8800 lb. operating weight, 3000 lb. lift capacity to full height, Mechanical foot controls, 2 speed transmission, Auxiliary boom hydraulics with standard flow (24.2 gpm), 1417.5 tires, Mechanical quick-attach $29,900

2013 HYUNDAI R180LCD-9A 43760 lb. operating weight, Perkins 4 cylinder engine with 137 gross hp, Dozer blade, 28” track pads, 16’9” boom length, 8’6” arm length, Aux boom & arm hyd. with 1 or 2 pump flow, Air ride suspension seat, 7” color LCD screen, (3) Power Modes & (2) Work Modes, 4670 hours $119,900

2009 HYUNDAI HL740TM-7A

Tool carrier model w/hyd. QC, Cummins QSB6.7 engine w/ 138 hp, 26680 lb. operating weight, 4-speed Powershift trans., Front/rear fenders, Ext. mirrors, 20.5R25 radial snow tires, 2.5 yd mat. bucket w/ bolt-on cutting edge, 3rd function auxiliary hydraulics, 7553 hours $79,900

2011 HYUNDAI R16-9 COMPACT EXCAVATOR