PRODUCTION: David Hill

Aberdeen-based J&S Subsea is quickly becoming an industry leader in design, manufacture, and engineering of underwater solutions for the energy sector. By helping assets last longer, or repurposing obsolete infrastructure, the company is also contributing to the circular economy. MD Phil Reid tells Energy Focus about a “phenomenal” four years.

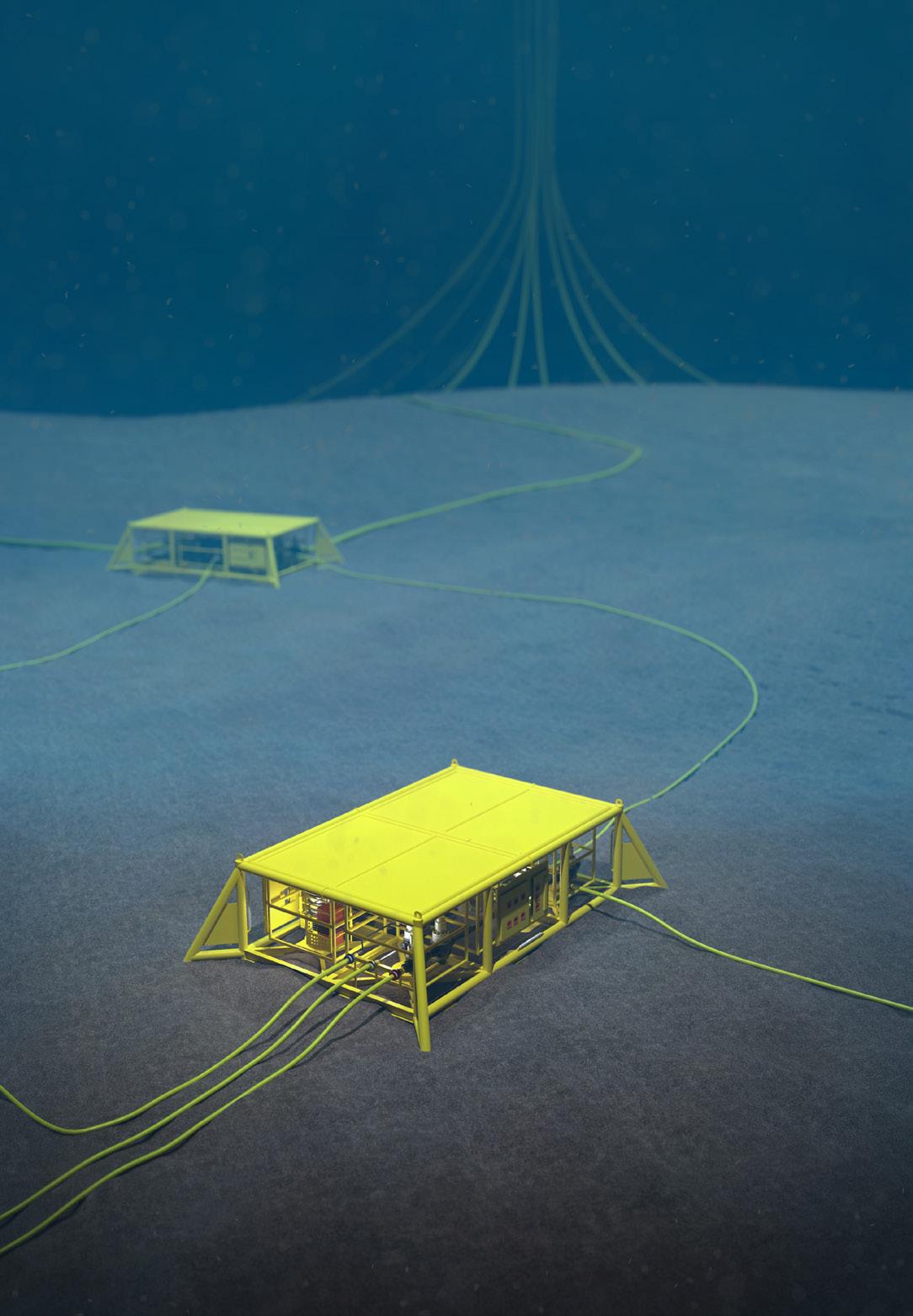

//The unseen, unheard, unnoticed activity that silently and invisibly powers energy production infrastructure from the seabed is increasingly becoming a talking point for project developers. The subsea sector plays a critical role in efficiency, sustainability, and

modernisation of the oil and gas industry, and is essential for the innovation of the renewables sector.

Recognised as a centre of excellence for subsea engineering, the UK’s northeast - with its vast network of locally manufactured and maintained undersea technology

– is brimming with opportunity. Production controls must be smaller, less intrusive, and more powerful. Mechanical and hydraulic systems must be sustainable and remotely serviceable. Electrical equipment must be, above all, safe and streamlined. Traditional

Phil Reid, Managing Director

energies need better, and new energies need pioneering.

J&S Subsea, the Aberdeen-based specialist in subsea engineering and field life extension, is riding the waves in the industry, and realising significant success on its journey into the industry’s elite portfolio of organisations.

Established in 2020 following a management buyout, the new company quickly set about its mission: providing proactive, responsive and

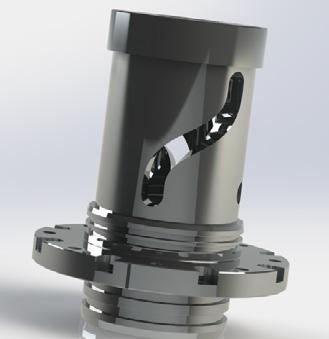

cost-effective solutions for design, engineering, operational support, and maintenance of subsea equipment across subsea energy sectors.

“The past few years have been phenomenal,” smiles MD Phil Reid. “Financial growth and company growth has been fantastic.”

Showing true ambition, the J&S team has established a business with extremely strong foundations. From day one, the goal was to provide

an alternative to Tier 1 industry suppliers. From human capital to financial security, the company is positioned to take on any scope of work, and this has been demonstrated by a swathe of recent successes.

In March 2024, J&S Subsea was lauded as Company of the Year (under 50 employees) at the Subsea Expo Awards. Environmental and Sustainability Adviser Kairvee Tyagi was also named as the winner of the Rising Star category. These awards came after the company was also a finalist at the Centre for Engineering, Education & Development (CeeD) Awards 2024 across three different categories as well as a finalist position at the Offshore Achievement Awards in the category of Exceptional SME/Founder. In 2023, J&S Subsea also claimed the Sustainability Award at the Decom Mission awards.

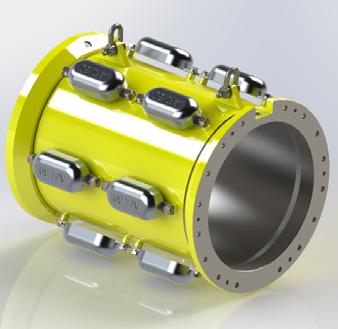

In the field, the company was recently in action in Canada on a prestigious project, undertaken in collaboration with an expert team

of partners. Supplying three subsea battery powered control systems, J&S Subsea helped the client to maintain integrity of the subsea electrical infrastructure when topside electrical power is unavailable. A complicated and pioneering project, the company was responsible for design, engineering, manufacture, marinisation and testing of subseadeployed systems. When the FPSO on the contract was down for scheduled maintenance – 350km offshore – a patented electrical passivation signal maintains the electrical integrity of the field and satellite extensions.

“Our supply chain is broad and we work with local and international partners. We want to work with other SMEs to answer industry problems that are not being fixed by big-name players.

The collaborative approach in Canada was something very special,” says Reid.

The result of four years of success is J&S Subsea doubling in size, outgrowing its former home in Kintore and moving into a specialist site in Dyce, allowing for growth in the team and achievement of the company’s £10 million turnover target.

“We are a credible option for our clients against Tier 1 competitors and we want to show that,” Reid says of the impressive new site. “We have dedicated engineering areas and dedicated workshops, we have overhead cranes, we have an R&D lab, and we did not have this in our old space. We have double the office space and double the yard space, and this all ties into our Legacy Locker offering and our journey to Net Zero that we like to shout about.”

Part of the genesis of J&S Subsea is a desire to be at the forefront of the push for Net Zero across the industry and the wider economy. Core in this idea is the company’s Legacy Locker. A catalogue of infrastructure assets, the Legacy Locker helps to push circularity and sustainability in the industry by focusing on reuse and recycling rather than new manufacturing. Over the years, the Legacy Locker has grown in size and importance, and today allows for faster reaction to client needs.

“Anything related to subsea controls, from new equipment to refurbished and repurposed, we have it all,” says Reid.

“The Legacy Locker is a fantastic initiative where we hold thousands of components, from small electrical

connectors to small couplings to full control systems or electrical distribution units, and we are repurposing and reusing that equipment. Kairvee Tyagi works out the carbon savings we get by reusing this material rather than manufacturing new and it is remarkable.

“Some equipment that was applied to a previous client project was a 2.3 tonne carbon saving versus manufacturing new. We also have a good grasp of the supply chain that is so broken at the moment. Some components are on a 66-week lead time but we have that equipment in the Legacy Locker today,” he adds.

After facing these problems first hand as the Subsea Controls and Umbilical Technical Authority for Spirit Energy (previously Centrica Energy)

for nearly a decade , Reid saw the opportunity to innovate and improve.

“I was working in a space where I had to deal directly with Tier 1 providers and I wasn’t getting good lead times, or sometimes not even a response on projects that needed it. I felt the pain, and that is why I want to address that problem.

“We can always deliver and we are very reactive, and our Legacy Locker feeds that reactiveness. We get production going, we reduce lead times, and we contribute to the circular economy,” he adds.

As the company sails its way closer to the top of the industry with each project, focus will be split between requirements in its core – oil and

MH Engineering (fife) Ltd is a privately owned business based in Glenrothes, Fife. It was established in 1995 by the current managing director, Mark Hoskisson. Since then, the company has remained family-owned and expanded, and now employs 10 personnel, including 8 engineers with many years of experience in machining services.

We pride ourselves on delivering machined precision components, general engineering, and bespoke parts for a multitude of industries.

Our CNC machining plant, which includes multi-axis CNC machining equipment, allows us to machine complex parts.

Our complete services include CNC milling, CNC turning, surface grinding, tool making, fabrication, and welding.

We can offer a ‘quick’ turnaround on urgent jobs/ breakdowns, and one-offs.

We offer our clients a one-stop shop for one-off precision machine prototypes through small to medium-volume production, and we know we can deliver a first-class machining service driven by quality, competitive price, and delivery.

We have extensive experience in machining various materials, including, all grades of Stainless Steel, Steels, super duplex, Nitronic, Inconel, Hastelloy, Monel k500, Phosphor Bronze, Aluminium, Plastic, Titanium, and Nickel Bronze.

gas in the UK North Sea – and international developments in the renewables industry. In July 2024, J&S Subsea was granted Fit for Offshore Renewable (F4OR) status by the Offshore Renewable Energy (ORE) Catapult following implementation of key management systems and competencies required for success in the sector.

Business Development Director Lucinda Craig said: “The immersive, 18-month process of participating in F4OR has empowered us to sharpen our focus on what we are working to achieve, and how. We are confident that our F4OR granted status will underpin those efforts to succeed in this important market.”

“We are looking for international growth,” details Reid, “but, like everyone

MH Engineering has been ISO-approved since 2009; and is approved to 9001:2015.

Quality checks are carried out in our fully equipped inspection department, which also houses a CMM coordinate measuring machine.

MH Engineering prides itself on building and maintaining close relationships with all its customers and suppliers, ensuring the continued growth of our business. Our professionalism, along with a continued interest in the advances in machining technology, ensures this.

MH Engineering liaise with other companies to provide additional services such as:

• Heat Treatment

• Fabrication

• Welding

• Plating

• Painting

• Wire & Spark Erosion

Specialising in high end precision components, providing bespoke parts for a multitude of industries, working in partnership with many industrial businesses

else, we are also looking to diversify into other sectors. The original J&S company had a renewables offering, including some world-firsts which are still in use on the European Marine Energy Centre (EMEC) in Orkney and Biscay Marine Energy Platform (BiMEP) in Spain. Investment was stopped in 2014, but the new J&S is picking up renewable projects again as we believe this is an area where we can really contribute. We have historic innovations that go back to 2009 and 2010 and we want to capitalise on the equipment that is out there already.”

Helping to drive further growth in the business, J&S Subsea gained investment from Foresight Group, a leading regional private equity and infrastructure investment manager. The investment is aimed at boosting J&S Subsea’s international growth aspirations and helping to build the

team. Already, two senior hires have been made and Foresight, which has invested more than £58 million in companies across Scotland, is keen to help J&S expand into new markets.

“Of course, we will be capitalising on the areas where we are strong, and take our business model from the North Sea into other regions where there are ageing assets that are no longer supported or obsolete. We extend the life of field by managing obsolescence with our Legacy Locker as well as our engineering expertise,” explains Reid.

Providing this expertise consistently, and proving its ability to extend life of equipment, therefore making production more sustainable, J&S Subsea is no longer a quiet alternative.

“My vision when we started through the management buyout was to challenge Tier 1 players, and

offer a reactive solution,” Reid states.

“We are not a massive corporate machine, but we recently won a £1 million contact in competitive tender against bigger players. We won that because we are more reactive, and that is exactly where we want to be. We want ageing assets jobs but we also want to be at the forefront of mind for new work.”

The company is loud and proud about its ability to deliver on the most complex projects, in the most difficult environments, alongside the most pioneering partners. From its home in Aberdeen, J&S is becoming a valuable industry player in an environmentally significant subsea sector.

J+S Subsea provides proactive, responsive and cost-effective solutions for design, engineering, operational support and maintenance of subsea equipment, primarily related to the Subsea Production Control market.

J+S Subsea can provide a range of solutions to fulfil all your Subsea Energy Controls needs. We can provide service and support whether you need to refurbish your existing equipment, deliver critical components or design, assemble and test a new system.

Our vision is to enhance subsea operations by delivering cutting-edge technology that is efficient, safe and environmentally sustainable. Our team of skilled engineers and technicians are dedicated to pushing the boundaries of Subsea Engineering. From concept design to installation, J+S Subsea delivers tailor-made solutions that meet the unique challenges of each individual project.

Dive into a new era of subsea excellence with us, where sustainability is more than a principle - it’s a commitment. We’re reshaping the subsea landscape by integrating sustainable practices and innovation. From efficient subsea equipment to responsible waste handling, our approach minimises our impact on the environment. Join our journey to redefine subsea operations with a focus on a greener future.

At the heart of the company’s commitment to achieving net zero, is the pioneering Legacy Locker initiative. This forwardthinking initiative embraces the principles of the circular economy, offering a portal for the reuse, refurbishment, and recycling of subsea equipment. Beyond unlocking capital tied up surplus equipment, the Legacy Locker users, enhance their environmental footprint by identifying opportunities to minimise waste and promote sustainability.