www.enterprise-africa.net August 2023 Red Metal Mining Project Engineers / TerraClim / Optimi Group / Gaydons Motor Spares Exclusive interview with SGB-Smit Power Matla CEO, Sibulele Dlova New Transformer Factory Open and Thriving in Pretoria ALSO IN THIS ISSUE:

businessbanking@finbond.co.za 0860 000 471 www.finbondmutualbank.co.za CONTACT US FOR MORE INFORMATION LET FINBOND MUTUAL BANK GROW YOUR BUSINESS Finbond provides financing from R5 million to R25 million to small and medium-sized businesses. Do you meet the minimum requirements? Must be a registered Proprietary Company or Closed Corporation. Minimum annual turnover of R5 million. Trading for at least 3 years. Finbond Mutual Bank is an authorised financial services provider (FSP No 44907) & registered credit provider (NCR CP 6172). Finbond Mutual Bank is registered with & regulated by the South African Reserve Bank (Reg Nr 01102). Terms & Conditions Apply.

EDITOR Joe Forshaw

joe@enterprise-africa.net

SENIOR PROJECT MANAGER Sam Hendricks

sam@enterprise-africa.net

SENIOR PROJECT MANAGER James Davey

jamesd@enterprise-africa.net

PROJECT MANAGER Ekwa Bikaka

ekwa@enterprise-africa.net

PROJECT MANAGER Terry Hanley

terry@enterprise-africa.net

PROJECT MANAGER Eleanor Sarbutt-King

eleanor@enterprise-africa.net

PROJECT MANAGER Jamie Waters

jamie@enterprise-africa.net

LEAD DESIGNER Aaron Protheroe

aaron@enterprise-africa.net

FINANCE MANAGER Isabel Murphy

isabel@enterprise-africa.net

CONTRIBUTOR Manelesi Dumasi

CONTRIBUTOR Timothy Reeder

CONTRIBUTOR Benjamin Southwold

CONTRIBUTOR William Denstone

The engineering excellence in South Africa, often borne out of the mining industry, is unique and in high demand. The country’s knowledge and experience is fantastic – there’s few that have mines as deep, buildings as big, roads as long, and bridges as strong. Unfortunately, much continues to be lost to emigration but those that remain make a major difference in the country that needs it. With major opportunities in power, infrastructure, and industry, engineers are needed, and remain the backbone of building a prosperous future for South Africa.

At SGB-SMIT Power Matla – a leading manufacturer of transformers and associated electrical equipment – the next generation of electrical engineers is preparing to build on South Africa’s’ power grid, updating and improving, and reducing grid access congestion as (hopefully) new generating capacity comes online. German heritage combined with local excellence makes for a business that is able to grow and adapt to meet the demands of local conditions.

Red Metal Mining Project Engineers is also making a huge difference through the deployment of engineering expertise. Manufacturing and installing electrical transformers in the mines to keep tools working, this is a business that major mining houses simply could not operate without. In the quest for vital earth minerals for societal transformation, Red Metal Mining is helping miners to go deeper than ever before.

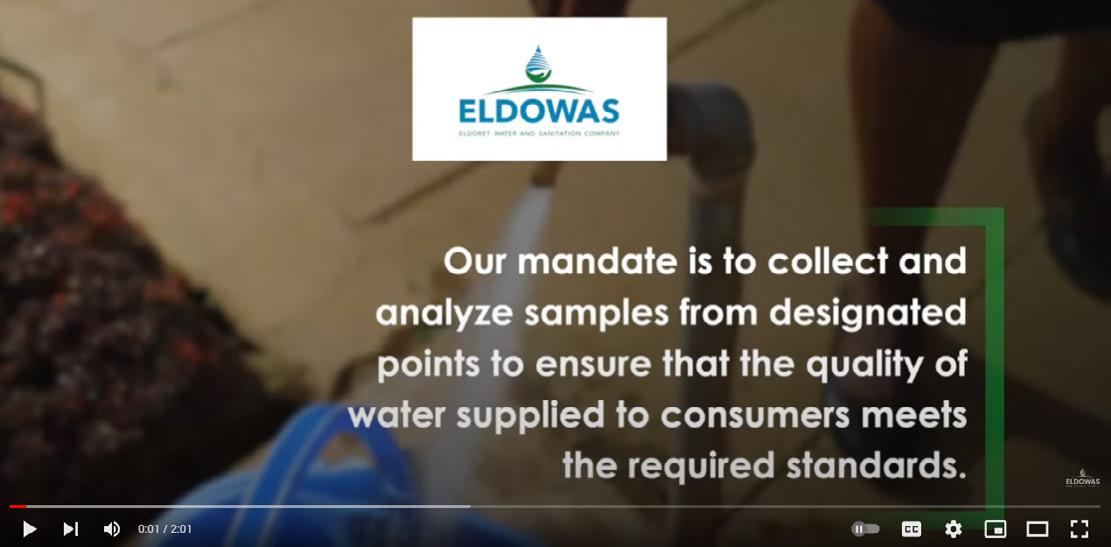

In Kenya, in Eldoret – the town famous for its well-engineered athletic champions – engineers work hard at the Water and Sanitation company, ELDOWAS. This leading water utility is aiming to be the best in the country, and operate to world-class standards, reducing waste, improving overall provision, and doing so in a cost-effective manner for consumers.

Columbit engineers are providing an after-sales service like no other, repairing and maintaining food and beverage equipment around the country, helping to keep providers on task and efficient. It’s a complicated job, with much learning involved, bringing skills from around the world.

Published by

Chris Bolderstone – General Manager

E. chris@cmb-multimedia.co.uk

Fuel Studios, Kiln House, Pottergate, Norwich NR2 1DX +44 (0) 1603 855 161 www.cmb-media.co.uk

CMB Media Group does not accept responsibility for omissions or errors. The points of view expressed in articles by attributing writers and/or in advertisements included in this magazine do not necessarily represent those of the publisher. Whilst every effort is made to ensure the accuracy of the information contained within this magazine, no legal responsibility will be accepted by the publishers for loss arising from use of information published. All rights reserved. No part of this publication may be reproduced or stored in a retrievable system or transmitted in any form or by any means without the prior written consent of the publisher.

© CMB Media Group Ltd 2022

Without the engineers who solve problems, the future will forever be more difficult. Without engineers, the pessimists will likely be proved right. Let’s do everything possible to keep engineering expertise in SA. Let us know ow your company is putting engineers to work to solve fundamental issues.

We’re online, as always, at LinkedIn.

EDITOR’S LETTER www.enterprise-africa.net / 3 Joe Forshaw EDITOR GET IN TOUCH +44 (0) 1603 855 161 joe@enterprise-africa.net www.enterprise-africa.net

GAYDONS

4 / www.enterprise-africa.net 6 12 18 26 32 38 44 CONTENTS ENTERPRISES UNIVERSITY OF PRETORIA: TRAINING SOLUTIONS Empowerment & Advancement Through Research & Education

POWER MATLA New Transformer Factory Open and Thriving in Pretoria

METAL MINING PROJECT ENGINEERS The Power Behind the Mine

SGB-SMIT

RED

MOTOR SPARES

in Driver Seat on Covid Recovery Journey

Becoming the African Centre of Excellence for Water & Sanitation OPTIMI Growing Optimi is Embracing Digital to Make Learning Accessible TERRACLIM SA Developed Climate Tool to Drive Agri Insight 18

Gaydons

ELDOWAS

52 60 66 72 78 82 88

SERIOPLAST SA Efficiency Tops Agenda for Global Manufacturer in Gauteng

PRIDE MILLING

Exponential Growth for Vital SA Grain Business

COLUMBIT Productivity and Efficiency – the Base of Good Business

MEDSCHEME Medscheme and AfroCentric to Expand African Exposure

CADCON

Proud History Opens Up Bright Future

FISHER DUGMORE FINANCIAL

Now is the Time to Start Your Financial Plan

GRAND REINSURANCE

First Choice Reinsurer Across Africa

60

www.enterprise-africa.net / 5

TRAINING SOLUTIONS

Empowerment & Advancement Through Research & Education

PRODUCTION: Sam Hendricks

ENTERPRISES UNIVERSITY OF PRETORIA: TRAINING SOLUTIONS

Shifting Knowledge to Insight is the promise by Enterprises University of Pretoria, a training and advisory solutions provider from a leading research university. A dynamic catalyst for innovation and growth, Enterprises UP provides comprehensive skills development solutions for individuals, private companies, and the public sector to help shape the workforce of the future.

Skills development stands as a vital pillar for propelling growth and triumph among African organisations. The convergence of disruptive forces has propelled us into the 5th Industrial Revolution (5IR), framed by the D-VUCAD environment. The 5IR encompasses not just the digital and technological facets of the 4th Industrial Revolution (4IR), but also integrates the essential human factor. D-VUCAD encapsulates the present landscape, characterized by Disruption, Volatility, Uncertainty, Ambiguity, and Diversity.

The only way businesses can maintain their competitive advantage in this rapidly changing information immersed world, is to out-think, out-learn, and out-create the competition. Skills development has become increasingly important for organisations and individuals across Africa. As economies evolve and industries become more competitive, it’s essential for employees to continually learn new skills and enhance their abilities.

Enterprises University of Pretoria has been at the forefront of training and skills development for over 20 years, leveraging experts from the University of Pretoria and private sector. Providing a range of scheduled short courses and customised corporate training to meet the growing demands of changing global business and professional environments.

Enterprises UP is committed to providing the best possible learning experience for its delegates. To achieve this, it continually re-evaluates and updates its instructional methods, ensuring that its courses are designed to maximise delegate success rates and prepare them for the future world of work.

Through this approach, Enterprises UP aims to foster critical thinking and problem-solving skills that can be applied in any dynamic and evolving environment, anywhere in the world.

www.enterprise-africa.net / 7

TRAINING SOLUTIONS

Enterprises UP’s Training Solutions is headed by Executive Manager Henry Karow , and he explains that the range of solutions on offer is deliberate and ensures a great product for almost every need in the market.

“We offer an extensive range of courses across 140 disciplines from the nine faculties of the University of Pretoria. Our training programmes are designed to future-proof both individuals and companies”

“Our bespoke solutions are co-developed in partnership with our clients, grounded in the current challenging market environment. We design and create experiences that activate learning and transform leaders at all levels so they can become accelerators of transformation in their organisations”

“We are easily accessible, we have an extensive range of courses with subject matter experts from the University of Pretoria producing our courses, we create tailored and bespoke solutions, and we are very targeted and innovative. We have a global footprint and we are seen as a thought leader in the market,” says Mr Karow.

In 2022, Enterprises UP successfully served around 13,500 delegates with course topics ranging from agriculture and food security to law and human rights. To achieve scale the business has invested in its distribution, catering for traditional in-house learning as well as digital and onsite courses.

“Our goal is to equip individuals with the tools they need to thrive in a rapidly changing world,” he says.

Henry Karow Executive Manager

8 / www.enterprise-africa.net

Investing in Skills Development

KEY REASONS TO INVEST IN SKILLS DEVELOPMENT WITH ENTERPRISES UP:

A single point of entry for all training, research and advisory services

Personalised services to achieve unique business and professional development goals. Innovative solutions for targeted training and critical business insight.

An extensive African and global footprint.

Draw from leading industry experts and South Africa’s finest thought leaders.

WHY SKILLS DEVELOPMENT IS CRUCIAL:

1. Improved productivity

A workforce can increase productivity by up to 30% through skills development.

2. Enhanced innovation and creativity

Equip employees to develop new ideas for challenges through skills development.

3. Increased employee retention

Employees are more likely to stay with an organisation that invests in their development.

TESTIMONIALS

“I had a great time attending this course, it was well structured, the facilitator was well-equipped and able to link theory to practice in terms of daily activities but also in terms of larger organisational aspects. The facilitator was able to take us through all relevant areas and went the extra mile to ensure we understand risk management.” – A recent Public Sector Risk Management course delegate.

“The programme is quite extensive and I use the subject matter on a daily basis. It helps me manage my team better.” – A recent Management Development Programme delegate.

“I would encourage everyone, irrespective of professional level to do this training in order to manage programmes better.” – A recent Project Quality, Risk and Time Management course delegate.

4. Competitive advantage

CPD courses for professionals equip employees with the ability to adapt to changing market demands.

5. Compliance with legislation

Skills development is a legal requirement in South Africa.

6. Addressing skills shortages

Investing in skills development can address South Africa’s skills shortage and improve the overall quality of the workforce.

01 02 03 04 www.enterprise-africa.net / 9

UPCOMING COURSES

Enterprises UP offerings include more than 500 career-focused training programmes and short courses that address the specific needs of various sectors and industries. These offerings are carefully designed to tackle the current and future needs of the ever-changing workplace. Whether you are looking to upskill, reskill, or embark on a new career path, Enterprises UP’s training solutions are designed to empower delegates with the necessary knowledge and competencies.

“Our courses are tailored to meet the diverse needs and preferences of our clients. We understand that flexibility is key, which is why we offer various learning formats including contact, online, virtual, and blended learning training interventions,” says Mr Karow, highlighting the fact that anyone can choose the method that best suits their schedule, learning style, and specific requirements.

PROGRAMME IN PROJECT MANAGEMENT

One of the core focus areas for Enterprises UP right now is Project Management. This niche but vital area is helping the business to unleash potential for businesses and individuals. One of the most in-demand courses available today, the Programme in Project Management (PPM) is highly regarded by employers and is delivered effectively by Enterprises UP. In March, the company celebrated its most recent batch of graduating delegates alongside the Graduate School of Technology Management (GSTM) at a ceremony in Pretoria. Currently, Enterprises UP offers a range of project management products for clients across different industry sectors.

“The Programme in Project Management (PPM) has been presented since 1997. With over 180 intakes and continuously updated content, the PPM has gained recognition and respect in the job market, benefiting thousands of professionals in both business and government sectors,” says Mr Karow.

The GSTM at the University of Pretoria is responsible for the academic content of the PPM. At the forefront of project management education in Africa, the GSTM brings together academic excellence and practical relevance. The PPM offers the flexibility of online learning, enabling delegates to study at their own pace and convenience, wherever and whenever it suits them.

The comprehensive PPM curriculum covers various key areas, including project management principles and practices, scheduling, project risk and quality management, procurement and contract management, financial principles, legal aspects, and project management in a business context. Delivered through a user-friendly online platform, each module offers engaging study materials fostering a structured learning experience.

Importantly, the PPM is acknowledged by ECSA, PMSA, SACPCMP, SACNASP and the PMI and this recognition boosts candidate success on course completion with candidates

able to apply for professional designation as a Project Manager (PM) conferred by Project Management South Africa (PMSA). PMSA is the South African Qualifications Authority (SAQA) recognised professional body representing the interests of project managers across sectors.

The exceptional coverage of Enterprises UP is what makes it unique. There are few, if any, that can boast the range, scope, and scale of Enterprises UP, and none that can support academic and theoretical principles with practical delivery. Covering 140 disciplines, with access to 7,500 faculty members and 760 different experts across different courses each year, the company runs 300–600 courses and welcomes around 750 intakes annually. International exposure is also an important separator for the company, active in 26 countries and attracting 5,000 delegates from outside of South Africa’s borders.

“We cover everything from how to safely blast a mine to how to perform surgery on a baby – that is what makes us different from the regular training providers in the market,” says Mr Karow.

Enterprises UP continues to deliver on its promise of Shifting Knowledge to Insight. Get in touch today to advance and develop your human assets and propel your business forward alongside a partner with unrivalled expertise.

10 / www.enterprise-africa.net

MORE THAN 45 NEW, UPCOMING COURSES

• Advanced Course in Employee Assistance Programmes

• Advanced Course in Hygienic Engineering and Design

• Advanced Course in Supervision and Management in the Social Sciences - Virtual

• Advanced Course in the Management of Performance and Discipline

• Aerial surveying (UAV) for 3-D surface modelling and detailed mapping

• Asset Management and GRAP Asset Accounting (Pretoria)

• Basic Course in Employee Assistance Programmes

• Basic Course on Supervision in the Social Sciences (Virtual)

• Business Process Management

• Business Writing

• Chamber of Mines Geotechnical Engineering Practitioner Theory [Paper 1 Preparation]

• Compliance Management - Online

• Contract Drafting

• Digital Marketing and Creative Writing

• Enhanced GROW Coaching

• Exam Preparation workshop for the Mine Managers Certificate of Competence: Legal Knowledge

• Executive Development Programme for the Public Sector

• Fraud Risk Management

• HIV and AIDS Counselling and Management - Virtual

• Human Resources, Communication and Scope Management in Projects

• Labour Dispute Resolution for Labour Relation Practitioners (Virtual) 02 October

• Mediation in Practice

• Modelling and Simulation of Wastewater Treatment Processes

• Museum Studies, Conservation and Preservation skills

• Online Course in E-Business and E-Commerce

• Online Course in National Credit Regulator (NCR) Debt Counselling

• Online Innovation in Industrialisation

• Online Masterclass: Equipping the Healthcare Professionals to Support Females Participating in Contact Sports

• Online Systems Thinking and Engineering

• Online Technology Management

• Outcomes-Based Monitoring and Evaluation

• Programme in the Detection and Investigation of Money Laundering and Terrorist Financing

• Project Estimating and Procurement

• Project Management Principles and Practices

• Project Management Principles and Practices with Microsoft Project

• Project Management Professional Exam Preparation (PMP®)

• Public Sector Risk Management

• Report Writing - Virtual

• Short Course in Design Solutions to accelerate SA’s progress in achieving the Sustainable Development Goals (SDG) targets within the built environment by 2030

• Short Course in Life Design Counselling

• Short Course in Musculoskeletal Ultrasound for Healthcare Professionals

• Strategic Environmental Management

• Supply Chain Management Fundamentals Board Game

• Transdisciplinary Research Communication Course

• Virtual Information Security Management

• Virtual Principles and Practices of Business Analysis

DISCOVER MORE www.enterprises.up.ac.za www.enterprise-africa.net / 11 See all new and upcoming courses at enterprises.up.ac.za/upcoming-courses CONTACT US +27 012 434 2500 info@enterprises.up.ac.za Mr Henry Karow is a dynamic and proactive business expert, driven by a genuine passion for crafting bespoke solutions to address distinctive challenges. Henry Karow Executive Manager: Training Solutions

SGB-SMIT POWER MATLA

New Transformer Factory Open and Thriving in Pretoria

PRODUCTION: Jamie Waters

New leadership and a state-of-the-art new facility is allowing power transformer manufacturing business SGB-Smit Power Matla to demonstrate its unique ability to produce size and quality. CEO Sibulele Dlova talks to Enterprise Africa about progress since joining the company last year.

12 / www.enterprise-africa.net

INDUSTRY FOCUS: MANUFACTURING

Sibulele Dlova, CEO

including a lack of upskilling and the need for infrastructure investment, and set about finding a solution. Extremely technical and complex, manufacturing even a small transformer is an engineering challenge that involves multiple processes. “I spoke to my Germany counterparts and requested them to make more effort in terms of skills transfer and sharing best practices in transformer manufacturing.”

COMPREHENSIVE COVERAGE

In Cape Town, smaller distribution transformers - pole mounted transformers, mini subs and very small transformers which have a voltage level of up to 33 kV - are manufactured for local and export markets including the US and UK. “It is very exciting that this year, we have broken through to international markets. We are still servicing our local clients and we are now expanding our footprint.

“In Pretoria, we make bigger sizes, 20 MVA or 40 MVA and we go all the way up to 500 MVA. We are the only transformer manufacturing company in the southern part of Africa that can make these bigger 3A or 3B transformers,” explains Dlova.

//Sibulele Dlova, CEO at SGB-Smit Power Matla, took the reins at the company in November 2022. At the time, the manufacturer of electrical transformers had lost some spark. The Covid-19 pandemic was still present, global logistics challenges were wreaking chaos across supply chain flows, and a devastating fire had wiped out the company’s factory capacity in Pretoria. When Dlova arrived, she quickly went about assessing and prioritising.

“My mandate is to turn the company around,” she smiles. “We have experienced challenges around finance, quality, and upskilling, and it is critical that I address those issues first.”

SGB-Smit Power Matla is the local arm of the wider SGB-Smit Group, based in Germany. A historic business in the

South African manufacturing industry combined with a highly successful local empowerment organisation active across multiple industries, the structure provides the ideal connection for positivity. In South Africa, the company has two facilities, one in Cape Town and one in Pretoria, as well as an insulation business, Calidus. For more than 100 years, SGB-Smit has been a leading name in the manufacture of transformers for international markets, and after opening its doors in South Africa in 1944 and going through much transformation to bring it to where it is today, the company has become a driving force in supporting energy security in the country.

Dlova, an energy and engineering expert, immediately found hurdles

But the Pretoria factory has been another key challenge for the CEO following the fire which broke out after a testing operation in 2021. While a successful evacuation ensured no one was hurt, equipment and infrastructure were damaged beyond repair. Thankfully, the decisions were taken to rebuild and Dlova is keen to see the facility reach its potential as soon as possible.

“Last year, we produced 36 units in total (partly because of fire and other issues). This year, in the first quarter, we have produced 19 units. Clearly, we are already on an upward trajectory

14 / www.enterprise-africa.net

// WE ARE FORMULATING A FORMIDABLE TEAM AND THAT IS EXCITING //

and that is because we have got the people together and fixed some of the errors we had in the processes. We are formulating a formidable team and that is exciting,” she says.

Eskom is still the key client, and the company relies on business from Eskom to grow the manufacturing sector in the country. Eskom, metros, and municipalities all use transformers, and SGB-Smit Power Matla is hoping to penetrate metros and municipalities more.

From Pretoria, the local market is targeted with Eskom as a key client. Botswana Power Company, and NamPower are important utilities, and South Africa’s metros are also buyers of larger transformers as southern African communities battle against an ongoing energy crisis.

“It’s exciting to announce that we have started building the first transformer in the new Large Power

Transformer (LPT), state-of-theart factory in May,” says Dlova. The opening of this factory also has other advantages including job creation and preservation of skills.

With this impressive new asset, alongside a proven track record which shows many units in

operation around the country, Dlova is able to focus on maximising the people power in the business.

PEOPLE POWER

Around 600 direct and indirect employees are supported by SGBSmit Power Matla and the company

SGB-SMIT POWER MATLA www.enterprise-africa.net / 15

INDUSTRY FOCUS: MANUFACTURING

are looking to employ more women and we are looking for more diversity and inclusion. As a female leader, my eye is on that so that we can continue to transform,” says Dlova.

is eager to nurture talent to assist in diversity and inclusions targets.

“Our staff is majority South African (98%) and we are aggressive about local upskilling. We take in students and women and train them, and we even train Eskom people. We

“We will be recruiting this year, without a doubt. Since we restarted the factory, we have had to add more people and upskilling is also a part of that,” she adds. “Because we are a global company, we have had counterparts from Germany come through once or twice a month to knowledge share and skills transfer. We are starting to understand more about how business is done in Europe compared to how business is done in South Africa. That has been very useful and quite the eye opener for a lot of our teams.”

This wide knowledge base is essential considering the range of products on offer from SGB-Smit Power Matla. The engineering house

produces small, medium, and large power transformers as well as shunt reactors. Three-phase and single-phase units can be manufactured, and autotransformers, arc-furnace, locomotive and traction transformers, miniature sub-stations, NERs, NECs, NECRTs, and oil transformers are also included in the range. The company’s laboratory is also state-of-the-art, providing testing capability and innovation around transformer materials. Dlova wants to see this skillset put to use more in South Africa and export markets.

“The last few years have been tough. We had the fire, and we had Covid which meant we had to lose a few employees. Getting back to the point where we were operating pre-Covid and pre-fire has been quite difficult as we have to upskill many people,” she says.

“Support of local manufacturing on the continent instead of us continuously

16 / www.enterprise-africa.net

// THERE IS A LOT MORE THAT WE CAN DO WHEN IT COMES TO CONTRIBUTION AROUND ENERGY SECURITY IN THE COUNTRY AND ACROSS SOUTHERN AFRICA //

importing is vital,” she adds “We have local talent and we have local manufacturing companies that can produce, but sometimes we experience lack of support from local partners. When you look at the economy in South Africa, it is clear that investing in manufacturing can improve our economic performance. My vision is for us to double the capacity we have in the factories, and we are more than capable of doing that, but we need support and protection from our government.”

INDUSTRY TRANSFORMATION

The manufacturing industry in South Africa has been on the decline in the last few years with many factories closing down due to financial challenges. SSPM has also experienced its fair share of financial challenges, but it is still standing and aims to grow stronger. SSPM is a Level 1 BBBEE company that supports a high-quality list of smaller local suppliers in the wider transformer manufacturing value chain in South Africa.

Right now, the majority of transformers that leave the factory are for Eskom and a few metros. For smaller transformers, SGB-Smit Power Matla has good market share in the Western Cape but hopes to penetrate further across the country. Longer-term, Dlova hopes the industry can get to a position where transformers are readily available for utilities to buy ‘off the shelf’ for smaller units and reduced lead times for larger units. All this while not compromising on the quality of the product.

“South Africa is currently experiencing an energy crisis which requires us to be able to support Eskom and municipalities by producing

E.I.S.

Established in 1979 EIS is privately owned and has been continuously active since its inception in the installation, commissioning and ventilation systems for all types of commercial and industrial applications

EIS aim to provide high quality engineering and service support as well as the design and manufacturing of equipment and therefore your preferred partner of choice in heating, ventilation and air conditioning (HVAC) systems in Southern Africa

www eis-hvac co za 0114772338

transformers. Transformers have a lead time, and so we need to be able to get to a point where lead times for transformers are reduced and we are upskilling more people to make transformers This will happen when we have good planning, transparency, and good communication between customers and suppliers. It’s sad to look at our capacity as a factory and say that we are not at 50%, yet, as a country, we are going through a crisis of this magnitude. There is a lot more that we can do when it comes to contribution around energy security in the country and across southern Africa.”

OPEN FOR BUSINESS

The Large Power Transformer (LPT) part of the factory is open for business. The company and others in this critical industry are vital in the future

energy security of the region. Dlova states that the company has made many improvements in the past few months and is looking forward to working with various partners by producing transformers in the new, fresh, state-of-the-art SGB-Smit Power Matla LPT factory in Pretoria.

“The factory is ready to service the Southern African market and the world, enabling security of supply through power evacuation in big transmission corridors,” she concludes, declaring the factories very much open for business.

www.enterprise-africa.net / 17

// WE WANT TO EXPORT TO EUROPE AS WE ARE ALREADY EXPORTING TO THE US AND UK //

Environmental Installation Services (PTY) ltd

SGB-Smit Power Matla Installation

SGBSMITPOWERMATLA.COM

RED METAL MINING PROJECT ENGINEERS

The Power Behind the Mine

PRODUCTION: Eleanor Sarbutt-King

Supplying specially made, high-quality, super strong transformers and electrical equipment for use deep in African mines, Red Metal Mining Project Engineers have seen it all. A long history in the mining industry combined with an innovative and problem-solving nature makes for a business that is the perfect partner for new mines, expansions, or extensions. CEO Lionel Wagner tells Enterprise Africa more about keeping mines electrified.

18 / www.enterprise-africa.net

INDUSTRY FOCUS: MINING

won’t fail. The engineers come to our facility and see the quality of our work, they inspect our processes. They meet our people and hear about our reputation. We get a lot of business this way, and we have a strong pipeline going forward.”

RMM is the sole agent for SGB in sub-Saharan Africa for cast resin dry-type transformers. SGB is the world’s leading manufacturer, based in Germany. Combined with RMM’s local expertise, the end result is a transformer that boasts superior quality and safety.

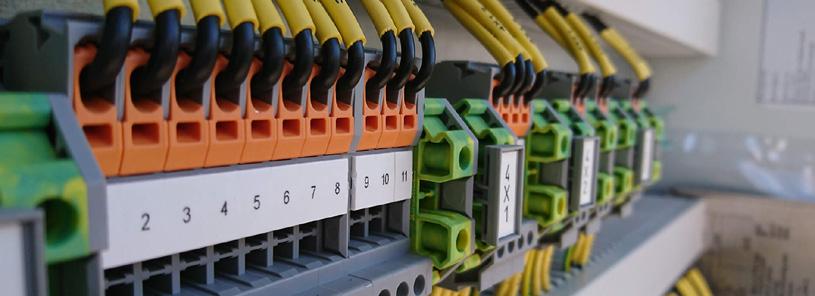

Transformers arrive at the company’s 3000 m2 site in Gauteng before being craned into the manufacturing space and being housed in the RMM custom-designed unit. From here, through a set of ISO certified processes, the company creates 1000kVA to 25 mVA cast resin dry-type transformers and underground cast resin mini substations, as well as oil immersed transformers.

The world’s mines use a monumental amount of electricity to unearth the valuable minerals that we need to live and work. Powering progress is difficult and costly. Typically in remote, rural locations, bringing reliable electricity supply to mines is an engineering challenge. And when the power arrives on site, working with it to remain safe and usable is a fresh hurdle for local teams to jump. In South Africa, where electricity supply is a major national problem, the mines are coming up with new solutions to keep the lights on.

Whatever the source – whether Eskom grid, solar installation, furnace generation, or any alternative – when the power is generated, it must then be transported underground and made usable. Doing so in a safe and sustainable way is a major problem. Usually coming in at 11,000 volts, the current is dropped to allow for safe working with machinery and tools.

Specialists head to the face in the mining shaft, often deep underground, and drill shotholes, where explosives blast away rock to be transported up and away for processing.

For this, specialist transformers are required. Robust, durable, temperature controlled, built to size, and above all, safe, these are essential high-performance assets that must be supplied by experts.

Edenvale-based Red Metal Mining Project Engineers (RMM) is an industry leader in the design, manufacture, maintenance, and support of transformers for the mining industry, allowing miners to work at optimal levels, without interruption resulting from electrical failure or voltage drops.

It’s highly technical, highly skilled work, and CEO Lionel Wagner tells Enterprise Africa that building a reputation for quality is the only way to be sustainable.

“The big mines want units that

“We handle consulting for companies that need to upgrade their mines. We have electrical engineers, mechanical engineers, and next year we will have the South African Bureau of Standards (SABS) quality mark,” says Wagner.

The success of the brand and its reputation for quality product and service has taken RMM beyond South Africa’s borders, opening an office in Zambia, to assist the country’s crucial copper industry, and also supporting projects in Angola, Zimbabwe, and Congo. Interest from India and Ethiopia and other parts of the world reinforces the idea that RMM is doing the right thing.

Wagner highlights the strength of the company with a 2016 disaster after which the product is still working as normal today.

“We supplied a transformer that got hit by lightning seven years ago. The housing crumbled and they sent it back to us for repair. We took off the housing and we cleaned it up. There was a small copper buzz bar that

20 / www.enterprise-africa.net

//

Lionel Wagner, CEO

blew the terminal off. We replaced it and it was back to 100% - after a full lightning strike. The client was very happy, and we have since sold them another 150 transformers.”

SOLE SUPPLIER

RMM was established in 2006, supplying oil transformers into Zambia. When the focus changed to cast resin dry-type transformers, with miners preferring to not have oil underground, the company was careful with innovation and became one of the only businesses to understand the unique needs of African mines.

“Everybody rushed to market and came back with these big products that couldn’t fit down the shaft,” says Wagner. “I flew to Germany and got the sole rights as the sub-Saharan Africa distributor for cast resin transformers. We came up with a design and cooling pack to cool the transformer

RED METAL MINING PROJECT ENGINEERS

that fits into the winder cage.”

An electrical and mechanical engineer, with decades of experience in the mining industry, Wagner is a seasoned entrepreneur who enjoys the practical work.

“I like to be there. I can’t sit still,” he says. “I did my apprenticeship as an armature winder and I started my first business aged 21, repairing electric motors. I then became a workshop manager and design engineer for another company. I learned about designing electric motors and mechanical engineering, and I learned about SolidWorks drawing and flow simulation. I have met many engineers who are purely theoretical and know nothing about doing the work on the ground.”

Growing the business has seen Wagner build a team from just a few engineers in a small office, becoming a multi-factory, multi-

national manufacturing company with 25 experts able to travel around the continent to keep mining moving deeper and further.

“We sell mini subs all over Africa and we just picked up a nice order in Congo. We recently sold 75 subs to a big, diversified miner and 100 to a big coal miner. Our target is to reach R250 million next year,” he says.

“We sell a lot of 630 kVA mini subs,” he adds. “There is always a demand for these products.” As miners move along a horizontal underground shaft, they must put a new mini sub every 800m to avoid voltage drops and keep drills and generators powered.

‘THEY NEED POWER’

In South Africa, RMM remains busy across all types of mine – coal, gold, iron, zinc etc. Every mine requires transformers and the company has become a preferred supplier for many

www.enterprise-africa.net / 21

INDUSTRY FOCUS: MINING

of the international mining houses with multiple sites in SA. In Zambia, copper mining continues to boom as demand for modern battery minerals grows quickly. Congo has some of the world’s largest cobalt reserves - a key mineral in the production of batteries for electrifying society.

“To mine, they need power, and for power, they must have transformers to take high voltage of 11,000 on overhead lines down to 6.6 and

eventually 5.3 volts,” explains Wagner.

“We manufacture PV transformers but once the transformer is there on the mine, it doesn’t matter about the energy source, the transformer is the same.”

Mines have been aggressive about ensuring their power supply and many are turning to renewable energy projects – solar or wind – to energise their sites when national grid supplies become unreliable. For RMM this does not impact workflow or quality. The

company is experienced in transformer connections for all types of supply and is excited that the mines continue to show ambition and innovation.

“The mines are taking things into their own hands. They are putting up their own power plants and they are not waiting for others to dictate the future. One of the big companies just put up a new power plant that cost R30 billion – they are not standing still, they know they need power, and they know they must spend money,” says Wagner.

This is why RMM has invested heavily in the oil transformer side of the business – to give clients across different regions and projects a choice. Today, engineers can pick cast resin or oil transformers, cast resin or oil substations, furnace oil

22 / www.enterprise-africa.net

// TO MINE, THEY NEED POWER, AND FOR POWER, THEY MUST HAVE TRANSFORMERS TO TAKE HIGH VOLTAGE OF 11,000 ON OVERHEAD LINES DOWN TO 6.6 AND EVENTUALLY 5.3 VOLTS //

transformers, oil purification, LV/ MV panels, containerised solutions, and much more, all from RMM.

“We have invested a lot of money into equipment for oil, and we put up a special test bed that we designed inhouse. We have had very good reviews and a number of clients that have come through saying this is the best test bed that they have ever seen,” says Wagner.

Typically, the company works closely with international engineering consultancy firms to ensure world-class rollout. From South Africa, RMM is currently preparing 28 transformers for a project in Zimbabwe, as well as a R20 million order for the second phase of a mine extension project in Zambia, and the first eight of a big contract in Congo.

“There was a company that

RED METAL MINING PROJECT ENGINEERS

supplied 40 transformers to a mine and all 40 failed,” explains Wagner. “The cooling system was made up of big fans pulling air from the surface and

allowing dust and dirt to blow onto the transformers. The mine engineers came to us to replace all of these transformers and we are busy with the first eight

www.enterprise-africa.net / 23

INDUSTRY FOCUS: MINING

right now with the balance to come next year. We use a closed loop system with a patented heat exchanger and an external fan. Our unit has received a lot of design work and is best-in-class.”

UNDENIABLE QUALITY

With mining activity ramping up in 2023, and innovation and reinvention at the heart of many expansion projects, ensuring there is no slowdown in Edenvale is vital for RMM. The factory is home to a sophisticated solar energy back up system, and a wind turbine to produce green power for the site, both connected to an industrial battery system.

Working in confidence that even with severe loadshedding RMM will not be forced to slowdown, the team

continues to build both internally and externally. Wagner encourages frequent upskilling activity and the result is an undeniable reputation for excellence.

“The design engineers are licensed with the engineering board and they take several courses. We pay for all of that and they are upskilled nicely. The private sector is proactive in making plans and that keeps people moving forward. We recently sent an electrician on a course to become an electrical engineer – we are upskilling, we are not waiting. We are building the skilled workforce of the future. SolidWorks runs its own private education system where you work online for certificates. We invested R500,000 in a programme called EPLAN to produce schematic drawings. This allows us to do 3D

modelling and comprehensive plans.

“There are a lot of others out there, but when it comes to cast resin and SGB transformers, we have developed a special technology,” Wagner details.

“People tried cast resin transformers, a dry model cooled by air. They cracked because of expansion and contraction of the wire. SGB came up with a special system for the wiring using epoxy resin. We have sold more than 600 of these transformers and never had a crack - this is the reason people buy from us. Our quality is undeniable; made in Germany. We import the core transformer and wrap it locally. Our products are designed to last at least 20 years in a mine.”

Conditions in deep African mines are harsh. Hot, hard, and dry,

24 / www.enterprise-africa.net

RED METAL MINING PROJECT ENGINEERS

Specialising in the manufacturing and supply of electrical equipment and turnkey solutions

Providing our clients with transformers, substations, control panels, motor control centres, containerised substations, and related products and services.

POWERING INDUSTRIES INCLUDING:

Data Centres & Commercial

Power Distribution

Marine & Offshore

• Industrial

• Oil & Gas

• Air & Rail

+27 (0)11 794 9498

sales@redmetal.co.za

• Mining

• Renewables

SUBSTATIONS

and with unique characteristics that those elsewhere in the world. Operating at the extremes – that advance as mines go deepermeans that standard transformers are simply not good enough.

“We overspec our units,” states Wagner. “European manufacturers tend to only understand +20 degrees at 1000m above sea level. We work, as standard, at 50 degrees, 1800m above sea level. With us, there are no heating problems. Our reputation is built around that and that is why we are a sole supplier of cast resin transformers to some of the biggest

mining companies in the world. There is a special housing which means you can hang the transformer upside down to send down the shaft before moving it across. It’s made out of heavy-duty steel and is very robust, weighing in at 4.5 tons.”

Considering RMM has one of the most reliable, most-recognised, and locally engineered products available, and that mining as we know it still requires electricity deep in the shaft, the company is buoyant about the future. Encouraged by the rampant demand for technology minerals across southern Africa, RMM is strongly positioned.

“We are in a niche market, supplying a top-class product to companies that are prepared to pay for it,” says Wagner.

“We don’t want to become one of the largest transformer manufacturers in the world. We want to put out a quality product on time, keeping our customers happy. Our reputation is superb – I had the call from Ethiopia because of a word-of-mouth recommendation - and we want to keep it that way.”

RMM Project Engineers make the toughest of mining that little easier, and with growing demand from around the continent, it looks likely that the factory in Edenvale will only get busier.

www.enterprise-africa.net / 25

CAST RESIN TRANSFORMERS

PANELS (LV/MV)

OIL TYPE TRANSFORMERS

WWW.REDMETAL.CO.ZA

// WE HAVE INVESTED A LOT OF MONEY INTO EQUIPMENT FOR OIL, AND WE PUT UP A SPECIAL TEST BED THAT WE DESIGNED IN-HOUSE //

GAYDONS MOTOR SPARES

Gaydons in Driver Seat on Covid Recovery Journey

PRODUCTION: James Davey

By providing unrivalled quality, service, and price, Gaydons Motor Spares is building on its reputation as the largest and most reliable independent automotive wholesaler in South Africa. MD Imthiaz Ahmed Bassa tells Enterprise Africa more about how the company is winning the race for market share in a tough industry.

26 / www.enterprise-africa.net

INDUSTRY FOCUS: AUTOMOTIVE

//In December 2022, Gaydons Motor Spares (GMS) – South Africa’s leading independent automotive wholesaler – was celebrating success after a positive experience at Automechanika and a move to a new office in Johannesburg.

“We are a key player in the motor industry,” MD Imthiaz

Ahmed Bassa said at the time.

Operating since 1986, the company has built a reputation from head office in Durban, across its branch in Johannesburg, with a national footprint in South Africa and helping brands move into the continent. GMS’ portfolio is a key strength, offering everything you could need for a car or light commercial vehicle.

This year at Automechanika, GMS was present once again, reiterating its commitment to the local industry,

and showcasing a brilliant range of house brands that has kept customers and end users moving through a challenging period. As a core sponsor at the event, the intention was for the 6000 attendees and 190 other exhibitors to go away recognising GMS as an industry leader and problem solver – a friend of South Africa’s aftermarket automotive industry.

“It’s one of the biggest automotive expos in the world and has become a prestigious international event,” says Bassa.

“We were a significant sponsor of the event and we sponsored bags that were given to every person who attended. Every person was handed a red bag adorned with the Gaydons logo. That was great exposure and we included various bits of info in the bags to bring attention to our house brands.”

This effort was recognised by the show organisers who issued an award for marketing excellence to GMS for the impressive stand.

“We have exhibited at a few events and this is the second time we have claimed an award,” says GMS’ Marketing Consultant, Rehman Kajee. “We set up our stand and we got the bronze award for marketing excellence based on how our stand looked, and we are proud of that because there are companies there that spend close to a million on their stands.”

A STRONG HOUSE

The stand was designed to showcase the company’s impressive portfolio of house brands which are leaders in their markets. These brands kept South African motors moving through the pandemic when spending patterns

28 / www.enterprise-africa.net

GMS at Automechanika 2022

for consumers and businesses were exhausted. GMS has always aimed to provide the best possible quality at the best price, and through its range of tried and tested house brands it has been able to do just that.

“We keep a large selection of brands both international and local, but we are keen on promoting our house brands which have become popular in the local market in South Africa,” says Bassa. “Some of our brands are a household name and they have been around for decades. Slik X Motor Oil (Unleash your engines potential) is one of the oldest brands we have – it is an engine oil and lubricant brand that has a wide range of products for petrol and diesel engine oils, brake fluids and antifreeze.”

Slik X has the closest viscosity to the world’s leading premium brand but for a fraction of the cost and is blended locally.

“Top Drive (Engineered to Perform) is home to a range of timing belts, drive belts, and multi v belts. It’s a

GAYDONS MOTOR SPARES

premium brand with excellent quality and value for money,” adds Bassa.

Bremskraft (Get Your Family There Safely!) is also a longstanding brand which is popular in the local market and is home to discs, drums, pads and shoes. It’s a high-quality, German-engineered brand that gives great mileage at a fantastic price.

“Spitzenza (Drive with Confidence!) is our brand of shock absorbers and struts for light duty vehicles and was launched with us alongside Bremskraft. It has excellent feedback from customers.”

HK Filters (Join the Billionaires Family) is a technology-based filter brand, with over a billion filters already on the road, HK Filters has been well-received in South Africa. “It is very reputable in the market and is in high demand because of its excellent quality with more than a billion filters sold worldwide. It’s an imported brand and is exclusive to us,” says Bassa.

“NR Gaskets (For Sealed in Quality and Performance) is a tried

and tested, extensive range of non-metallic, semi-metallic and metal gaskets and RTV sealers, also exclusive to us,” Bassa exclaimed, “and has cemented its place in the market as a trusted brand for excellent performance in extreme conditions.

“Newer in the house brand stable is Otomotive Parts (Built to MOVE You!), a rapidly growing range of quality electrical components like alternators and starters.” Bassa says that Its popularity is fast growing and consumers are delighted at its exceptional quality and price.

With the additions of Petromin (Performance from the Heart) – a leading Saudi Arabian motor oil brand – and CNC Clutches (Drive Green) – a leading Chinese manufacturer, GMS holds a portfolio of high quality, affordable parts and accessories that meet the needs of almost every client in the market. “Petromin is one of the best brands in the world in its class and CNC Clutches, manufactured to OEM specifications with 29

www.enterprise-africa.net / 29

INDUSTRY FOCUS: AUTOMOTIVE

less frequent. While challenging, Bassa says the company was wellpositioned to ride out the economic breakdown and continues to thrive.

“We pride ourselves on a vast range of various automotive parts. Suspension, drive train, engine, gear box, electrical, lighting, braking, fluids, accessories, mountings – we stock a large range,” he says.

economic environment of struggle.

years of excellence in engineering experience, is very popular and one we would like to grow further in the local market,” confirms Bassa.

Other international brands stocked by GMS include Ate, Engen, Schaeffler LUK, Pratley, Castrol, Shield, Spanjaard, Fuchs, 3M, and many more.

ECONOMIC BRAKES

By keeping an extensive range of products, backed by advice and service from industry veterans, GMS became a go-to during the slow Covid-19 period when cars were less used and servicing and repairs became

“We are technically the largest independent wholesaler for automotive parts in South Africa. There isn’t a retailer that can tell you they haven’t purchased from us at some point.”

Thankful for the ongoing support, based on deep relationships that come from meetings at the likes of Automechanika, the core focus of GMS on price, quality, and service help to set it apart from others. During a time when businesses were closed, new car sales down, car manufacturing at a standstill, and used car sales still lagging with weak supply of new vehicles, all points to an

“The mindset of the customer has changed,” admits Bassa. “In the past, people reported to offices and commuted into work on a daily basis. A lot are now working remotely and their vehicles are parked with no mileage. Intervals between repairs, servicing, and improvement have increased. If a car was being maintained every three or six months, and now it is happening every six or nine months, the impact on sales is obvious.”

He highlights the example of replacing plugs at a service. Previously, all plugs would be switched with new, but now only damaged or faulty plugs are being changed. Instead of replacing brake fluid yearly, people are just topping up. At the same time, competitors are slashing prices to make the most of the market – it’s a tough race to be in.

“Towards the end of the year, people are typically preparing for their holidays and a part of that is

30 / www.enterprise-africa.net

// THERE ARE NOT MANY WHOLESALERS IN SOUTH AFRICA, AND NONE THAT KEEP THE RANGE WE KEEP //

Our Drive – Your Success

servicing the vehicle so they can hit the road and not have to worry. But the economy has forced a squeeze on spending and people are not going on long road trip holidays and are staying in their own province. All of these factors impact sales and the way the industry performs,” says Bassa of the market conditions for all right now.

This is where the Gaydons brand outshines others. Range, exclusivity, price, and experience is exactly what customers require. “The fact that we have always supplied a quality product at an affordable price, backed by our reputation of more than 45 years, people trust us and we have managed to do well.

“There are not many wholesalers in South Africa, and none that keep the range we keep. We have always been able to provide the products

that are required, at the price required for all of our customers.”

www.continental-aftermarket.com

SERVICE, DELIVERY, AVAILABILITY

Going forward, expansion is on the agenda for GMS, but not physical growth into new spaces. The product range will likely expand, and the service portfolio will definitely increase.

“We also hope to increase our stable of house brands. We are launching Boost Additives (BOOST Your Car’s Performance!) soon and we have a few others on the cards. We are trying to look at more innovative ways to engage with our clients through technology. We want to be innovative in the digital space and we are working hard to understand more about social platforms and how they can open new avenues for availability and contactability with

external stakeholders,” Bassa adds. Furthering the brand will be important if GMS is to retain its position as the leading independent wholesaler. Creating fresh awareness around the house brand portfolio is key, and that is why GMS will continue to exhibit at major international events and accelerate marketing opportunities at every possible chance.

“Our pricing strategy means we have been able to exclusively offer our house brands at an affordable rate and that has helped us to capture market share. Pricing, quality, and excellent service sets us apart,” Bassa concludes, ensuring GMS remains a key player in the country’s automotive industry.

GAYDONS MOTOR SPARES www.enterprise-africa.net / 31

Best drive components for the Automotive Aftermarket GAYDONMOTORSPARES.COM

ELDOWAS

Becoming the African Centre of Excellence for Water & Sanitation

Progressing access to water in Uasin Gishu county and the town of Eldoret is the job of ELDOWAS – the water utility for the region that is showing the rest of the competition how to keep water flowing and how to ensure it will run for all in the future. MD Peter Kibet Arap Biwott tells Enterprise Africa about a three-pronged approach to long-term success and sustainability.

PRODUCTION: Eleanor Sarbutt-King

PRODUCTION: Eleanor Sarbutt-King

32 / www.enterprise-africa.net

INDUSTRY FOCUS: INFRASTRUCTURE

//According to global water and sanitation non-profit Water.org, 15 million people in Kenya lack access to safe water. Growing demand, increasing scarcity, and climate change are drivers of the imbalance. The problem is representative of the East African region as a whole where water security remains a problem. According to a recent UN report on water security in Africa, water feeds life and is a backbone of health, economic activity, ecosystems, governance, financing, and political stability. Security is just as much about management as it is about stock levels.

But, in every challenge flows opportunity and Kenya is a good example of how, through innovation and global cooperation, major structural problems can begin to be

addressed. Since 2005, Water.org has helped connect 6.5 million people to safe water infrastructure. The country has become increasingly savvy with its water resource management and, while much remains to be done, progress is underway.

In the Rift Valley, Eldoret is the capital of the Uasin Gishu county. The town is among Kenya’s top five in terms of population size. Water is a challenge here with the town at the centre of the region’s major grain and agricultural industry. Textiles and fertiliser industries also consume heavy water reserves, and management of the resource in the region is vital.

Responsible for the management and provision of water across Eldoret is ELDOWAS – the Eldoret Water and Sanitation Company. Managing

Director Peter Kibet Arap Biwott, an experienced executive across various sectors, explains that improvements are underway in Eldoret and new investments will further the good work that has been done to secure safe and reliable water supply to the town.

500,000 PEOPLE

“We are a utility of water and sanitation within a municipality of about 500,000 people,” he says of the company’s significance, highlighting ELDOWAS as among the top 10 of the around 100 water utility companies in Kenya. The country has a national development plan which aims for access to basic water and sanitation for all by 2030. With utility reforms that began in 2002 helping to attract some millions of dollars in funding,

34 / www.enterprise-africa.net

Peter Kibet Arap Biwott, MD

Kenya’s water resources reached around 500 cubic meters per person but the country remains challenged with water scarcity. More financing is required, and improved infrastructure and service delivery is essential.

Biwott is positioning ELDOWAS as the example to follow. Three key areas of focus will allow the business to achieve its vision of becoming the most customer-centric company in Kenya.

“Climate action, infrastructure investment, and customer service excellence will help us achieve our mandate,” he says.

Across the county, fresh initiatives are being put in place to protect and mitigate against changes in climate, where the temperatures and droughts have increased in recent years. “The long-lasting drought

in the Horn of Africa threatens a humanitarian catastrophe,” said WMO Secretary-General Prof Petteri Taalas, in a report on the past decade’s average heat increases.

Key in the challenge is increasing

conservation from both the private and public sector, and individuals. “We do participate in climate action because we have to control and restore our catchment areas so that we can have a sustainable supply of clean and potable

ELDOWAS www.enterprise-africa.net / 35

INDUSTRY FOCUS: INFRASTRUCTURE

area to help improve productivity.

“We are also promoting new methods in agriculture, especially in the area of livestock-keeping, and we are looking at carbon credit projects to help us move forward in a smart way.”

usage to ensure conservation.

“With the Eldoret-Iten Water Fund, we’re securing clean water for the City of Champions, preserving our natural heritage, and empowering communities,” says Biwott.

water to our residents,” says Biwott.

“Currently, we are working on the adoption of green energy with a view of reducing costs. We are also designing a programme called the Eldoret-Iten Water Fund (EIWF), which is funded by the international organisation to promote green energy, water conservation, forestation, and modern farming methods in the catchment

In 2019, the company adopted solar power at its Kesses Water Supply plant, and put plans in place to power HQ with green solar energy. The EIWF is a project that involved private and public sector organisations and promises the restoration and improvement of 120,000 hectares of land, the growth of a staggering one million trees, the construction of 2,000 water pans for household use and irrigation, and the installation of 10 water quality and quantity monitoring stations. Working alongside the Nature Conservancy, ELDOWAS will educate and support farmers, communities, and companies to change their approach to water

INFRASTRUCTURE INVESTMENT

As EIWF gains traction and money flows deeper into the region, infrastructure requirements will change and the company will be able to make the most of assets that are already in place, improving efficiency and service quality.

“We have a business plan,” states Biwott. “We are finalising development of a treatment works which is in construction. We are set to build another dam, and we are looking at the water catchment area and conservation projects. We are also looking at a reduction of water loss which we want to drastically decrease. These

36 / www.enterprise-africa.net

// CLIMATE ACTION, INFRASTRUCTURE INVESTMENT, AND CUSTOMER SERVICE EXCELLENCE WILL HELP US ACHIEVE OUR MANDATE //

are some of the priorities alongside enhancing customer service and experience, both internal and external. The dam project and treatment plant has been underway for two years and we hope to complete this year.”

Reducing loss is essential following a challenging period for all business as the Covid-19 pandemic made business uncertain and difficult, especially for utilities companies that stood at the forefront of the fallout.

“There was a lot of problems,” admits Biwott. “We lost business, but luckily we remained with 20% of our billing and payments. People felt that water was a free to use commodity because government policy was not to deny anybody water as it was essential in preventing the spread of Covid. But we have recovered with the support of government and the World Bank and we remain on the path to recovery.”

CUSTOMER CENTRICITY

Part of the recovery success has been thanks to ELDOWAS being active with marketing and communications and displaying its work to the community it serves. By generating interest in water and how it is managed, and then implementing world-class customer service standards, the company has been able to build a brand that is becoming recognised in Eldoret and further afield as an industry leader. Biwott wants to continue with this positivity and ensure every interaction with customers is seamless.

“I want us to be the most customer centric and customer focussed company, ensuring that we have sufficient water for the municipality by completing the water treatment plant and another dam. We are very keen on securing our catchment through conservation. I want a happy and motivated team that is productive, with enhanced governance to ensure that we reduce non-revenue water and operate with productive ethics. We want to be inline with global standards around human rights, environment, sustainably

livelihoods and business, and good corporate citizenship,” he explains.

“We are working to enhance our revenue collection through our customer service experience. Our revenue will grow as long as we can fix some of the challenges we face around non-revenue water and water tariffs.”

Around 265 permanent employees (300 including contractors) have helped to build the brand, and Biwott reminds that, internally, there is a focus on being the best.

“We believe we are the best because our water is the best in the country, and that is because of the catchment area we are in,” he says of the desire to maintain and conserve the valuable resource.

“For us, the priority is climate action,” he adds. “When we get this right, we won’t need to continue

building dams. We must have a continuous supply of water in the area and that is our main focus, while ensuring we don’t have water loss to the extent we have currently.”

In Eldoret, ELDOWAS is targeting 100% coverage for water and sanitation across the region by 2030, taking more and more people out of water poverty and addressing the backlog in Kenya. Managing supply as well as building strategic resources is the priority. Biwott has free-flowing ambitions, and progress is being made.

“My aim is to become a centre of excellence on the African continent in the provision of water and sanitation,” he concludes.

ELDOWAS www.enterprise-africa.net / 37

WWW.ELDOWAS.OR.KE

Growing Optimi is Embracing Digital to Make Learning Accessible

Optimi brings modern, efficient, and effective learning opportunities to all through innovative technology and supportive environments. CEO Stefan Botha tells Enterprise Africa that the company will continue to expand as its technology improves further and its reputation for quality learning is enhanced with each person it helps.

In 2020, as the world moved online, prioritizing the safety of digital interaction and embracing a new era of efficiency, the effects of Covid-19 on school attendance became evident, leading to significant teething pains and high hurdles of change. Across all industries, ensuring that both hardware and software were up to par presented a considerable challenge. However,

in certain spheres, there was little room for error, and in education the successful implementation of digital technology became critical. Thankfully, some in the industry were not only comfortable online, but ready and raring to go. Optimi, the Centurion headquartered education and learning business, had already positioned itself as an industry leader, providing to 200,000 learners every year,

PRODUCTION: Jamie Waters

PRODUCTION: Jamie Waters

38 / www.enterprise-africa.net

//

OPTIMI

INDUSTRY FOCUS: EDUCATION

Optimi believes that learners and facilitators require ongoing support during the learning journey and, as a result, the company developed the GuidED Learning™ technology – a model that provides clear guidance to learners and facilitators on what they should do next. “As an example,” says CEO Stefan Botha, “our homeschool offering empowers a parent to provide

high quality learning to their children without the need to be a trained teacher. Our approach is furthermore to offer a fully integrated solution to our clients, which includes content, assessments, and learner/facilitator engagement, this simplifies the learning and makes it more accessible.”

According to Botha, the company’s focus on technology has helped it to

thrive and helped learners to excel.

“We have a very strong technology focus,” he says, “and we have developed our own systems for learning and facilitation, product development, customer administration, warehousing and product distribution, and several others. Our learning platform includes industry-leading tools such as an innovative reader that allows teachers to add content to publisher textbooks, as well as online marking that allows us to have our homeschool assessments marked by teachers anywhere in the world.

“Digital transformation is an important trend in education,” he adds. “We’ve seen a shift to digital and online learning over the past few years, particularly during COVID when learners could not attend classes. Digitisation of education provides exciting opportunities to improve the effectiveness and efficiency of the learning journey.”

40 / www.enterprise-africa.net

CHANGING INDUSTRY

Digitisation in learning is not slowing down anytime soon. Learners are very different in the way they interact with information, and the increased choice of study methods that online tools offer is helping the open doors for more and more people. Whether it’s a child learning at home or a professional upskilling after work, digital tools are changing the industry for the better and breaking down barriers that have been problematic for South Africa in the past. In 2019, UNICEF found that ‘from birth to the final year of high school, children born into poverty face a range of challenges that their wealthy peers do not’. In 2020, an Amnesty International report highlighted a number of issues with ‘traditional schooling’ in the country. A 2021 UNESCO report stated that digital solutions can certainly make an impact.

“Developing a digital learning strategy is a key part of efforts to expand access to education, improve teaching quality

and make digital skills foundational. The strategy requires strong local ecosystems that bring together public, private and civil society partners to address key bottlenecks in digital transformation and upscaling in Africa’s education systems,” the paper said

In 2021, the University of Cape Town announced a large expansion of its scholarship offering for students enrolling in a fully digital school because of significant demand. Others in the industry have followed suit, realising the potential of Educational Technology (EdTech). There has been a lot of activity in recent years with large businesses acquiring digital training and education providers to bolster portfolios, and the sector is encouraged by the country’s major international organisations For Optimi, improving the accessibility of quality learning has been a core focus from day one. This is achieved by establishing a strong ecosystem, in an otherwise fragmented industry. The company

has grown through merger and acquisition and each of the business units have proven abilities in delivery of educational excellence.

“Optimi was established in 2019 through the merger of several South African education and training providers, including Impaq (previously Impak), Media Works, ITSI, CollegeSA, CAMI Education, Tuta-Me, IT Academy, and others,” details Botha. “As a result, Optimi boasts a comprehensive range of resources and skills to deliver world-class learning solutions to our customers. It is important to note that these companies that formed the building blocks of the Optimi Group have many years’ experience (our oldest company was founded in the 1980s) and an impressive track record in education.”

The portfolio is impressive – Impaq provides students with the ability to learn at home; ITSI has a hard copy and e-book library home to 440,000 resources; Optimi College offers more than 120 various qualifications and

OPTIMI www.enterprise-africa.net / 41

WITH

short courses; and Tuta-Me connects students with highly qualified tutors through the use of clever technology.

“Optimi provides accessible learning solutions for Home, Classroom, College, and Workplace,” confirms Botha. “We are a supplier of education products and services to institutions, facilitators, and learners. We integrate these products and services into easy-to-follow comprehensive learning offerings, based on our unique GuidED Learning™ model, and using our proprietary technology. Where we engage directly with learners, we typically make use of distance or online learning to deliver courses. Our aim is to build an education organisation that makes a significant contribution in SA and globally, serving learners along every step of their learning journey.”

OF

SOLVING PROBLEMS

Botha, a former civil engineer and management consultant, became CEO of Impak in 2012. He says that his passion is solving difficult problems and making a difference to people. Being part of Optimi allows him to accomplish this every day.

“I’m really proud of what we have built at Optimi, and I look forward to our journey ahead to further grow and improve.

“We started this journey in 2012, when well-known South African investor, PSG, acquired homeschooling business Impak (we subsequently re-branded it to Impaq). We set out to improve the Impaq offering, including the product quality, learning technology, and associated customer service and support elements. As a

PRODUCTS

result, Impak experienced top-line growth of approximately 30% per annum over the past 10 years, and is now the undisputed leader in the South African home and online schooling landscape, serving 30,000 learners from grades R to 12.”

This success can be attributed to the company’s ability to adapt. Embracing digital has allowed Optimi to provide quality learning, both in-person and at a distance. Learners are enabled to engage with their content in their preferred format, at their own pace, anywhere they prefer. Individuals and institutions can access learning with ease - this is what Optimi would love to encourage.

“Learning is an essential part of our evolution and happens all the time, whether we are aware of it or

INDUSTRY FOCUS:

42 / www.enterprise-africa.net

EDUCATION

//

AS

ANY INDUSTRY, THE PROVISION

EDUCATION

AND SERVICES IN SOUTH AFRICA IS MATURING AT A RAPID PACE DUE TO TRENDS IN TECHNOLOGY, CONNECTIVITY, AND DIGITISATION //

not. When we actively develop a love of learning and voluntarily pursue knowledge, whether for personal or professional reasons, we unlock unlimited benefits,” says Botha. “By developing a love of learning we are able to spur personal and professional growth, boost social connectedness, and improve our employability.”

FURTHER IMPROVEMENT

The future of education is hard to predict. Some argue that face-to-face interaction between student and teacher is irreplaceable, but others insist flexibility allows for true universal rollout. The most likely outcome will be a medium-term future that incorporates a blended method as the new normal.

Like in healthcare, finance and travel, technology will play an increasingly important role. To ensure that progress

Our solutions

Fully accredited & part-time qualifications

Community education & training

Skills development consulting & auditing

Skills programmes (e.g. learnerships)

Tutoring programmes

Accelerated learning programmes (e.g. short courses)

www.optimiworkplace.co.za

does not slow, Botha is busy building a robust platform for further growth.

“Following the conclusion of the mergers and acquisitions to establish the Optimi Group, our first focus was to integrate these businesses into a seamless collection of offerings, supported by capable teams. We continue to invest in our technology and our learning products, and we believe that this investment will distinguish us from our competitors in years to come,” he says.

Longer-term, Optimi will use its strengths to become an industry leader, supporting every step of the learning journey.

“As with any industry, the provision of education products and services in South Africa is maturing at a rapid pace due to trends in technology, connectivity, and digitisation. We want

to become a large, well-known, and trusted learning business, making a significant contribution in SA and globally. Given the fragmented nature of education, we also aim to enable institutions and 3rd-party educators to offer improved solutions to their customers. Our focus will be to further improve our integrated learning and blended delivery model with the use of technology,” Botha concludes.

By embracing technology and forcing the next steps in learning and education, Optimi is creating a new path for all who want to upskill, whatever their age, status or position.

OPTIMI www.enterprise-africa.net / 43

The best teams aren’t hired, they’re trained!

tailor-made

skills

development & training solutions

Optimi Workplace. for your business with Get for your business

WWW.OPTIMI.CO.ZA

SA Developed Climate Tool to Drive Agri Insight

Empowering long and short-term decision making at regional, farm and vineyard level, TerraClim is the latest agritech invention to come from the University of Stellenbosch. By utilising comprehensive research and data in a neatly packaged system, farmers can now understand better than ever how climate is impacting their land and potential. Founder Dr Tara Southey tells Enterprise Africa more about the development and promise for this exciting SA innovation.

PRODUCTION: Ekwa Bikaka

PRODUCTION: Ekwa Bikaka

44 / www.enterprise-africa.net TERRACLIM

Dr Tara Southey, Founder and Agricultural Methodologist

Dr Tara Southey, Founder and Agricultural Methodologist

INDUSTRY FOCUS: AGRITECH

By 2050, a further 17% of the world’s agricultural productivity could be lost as a result of climate change. In the past 40 years, a third of all arable land has been lost to erosion or pollution. Wildfires, tornadoes, floods, and drought are increasingly common, and they decimate soil and its growing potential. These phenomena are not new. The problem has been building since the 70s when the UN Scientific Conference raised concerns over human activity impacting the environment.

At the same time, the demand for food from a growing population is booming (some predict demand could rise by 90% by 2050). For farmers, the pressure is on. Land must be managed effectively, and crops must be cared for with precision. The time of the farmer’s sixth sense is over, and decision

making must be informed and based on viable data with provable results.

But in South Africa, the data and insight for the agricultural community is sparse. Technology has not been used to its full potential to aid in food production, reduce waste, and drive productivity.

TerraClim, a new company backed by the University of Stellenbosch, hopes to change this and is building out a system that can provide farmers with precise data about their land and climate in order to mitigate against impacts of climate change.

A world-leading wine industry, globally recognised maize, internationally in demand citrus, avocados, nuts, berries, and deciduous fruits, and a basket of vegetable exports that ship to markets in every corner of the planet make

for an agricultural industry worth more than $12 billion, 10% of GDP, supporting some 900,000 jobs.

EUREKA!