HiPo is an event that, under different circumstances, might easily have resulted in injuries or fatalities.

Medical Treatment Injuries

First Aid Injuries

Near Miss, Unsafe acts, Unsafe conditions and property damage

Report minor or significant incident

Identify and analyze the cause

• Near miss and observation that c ould lead to different outcome

• Compromise on LSR

• Events with high consequence

26- March-2024 – 02:50 AM – CCD Dubai Metro (DNE)

02- March -2024 – 09:15pm – Miral Experience (AUH)

14- March -2024 – 9:00am Miral Experiences (AUH)

Importance of LOTO devices

Apply LOTO right

24- March-2024 – 09:04pm DC-P6 site (KSA)

Hot work

05- March-2024 – 12:00am – MIRAL Experiences - (AUH)

30- March -2024 – 10:25pm UQUEPC site (KSA)

31- March-2024 – 02:00pm UQU-EPC site (KSA)

14-March-2024 – 10:30am NU-EPC site (KSA)

19-March-2024 – 3:00 PM - ADAC –MTC (AUH)

30- March-2024 – 10:30pm UQU-EPC site (KSA)

Mobile elevated working platform

Safe scaffold

Complacency affects us

Permit to work

08- March -2024 – 3:30pm-DA

DXB,(UAE)

08- March -2024 – 3:30pm-DA DXB,(UAE)

Safe start of task

Standard operating procedure

26- March-2024 – 02:50 AM – CCD Dubai Metro (DNE)

02- March -2024 – 09:15pm – Miral Experience (AUH)

Importance of LOTO devices

Apply LOTO right 14- March -2024 – 9:00am Miral Experiences (AUH)

26-March-2024–02:50AM–CCDDubaiMetro (DNE)

Hazardous Occurrence / Violation to Lockout Tag out Procedure

No minor / Major injuries

On 26-03-2024, team had the schedule for overhaulingactivity of Fan coil unitin CCD Metro Station. After the booking-in process at 00:00 Hrs, PIC (Person In Charge)conducted a dynamicrisk assessment and toolbox talk with the team Subsequently,the PIC and the workgroup commenced the activity. However, during a site visit by theclient inspector, it was observed thatthe LOTO procedurewas not adequately implemented and did not meetthe project requirements Thisissue was then escalated tothe Project Manager,Lead Engineer, and HSE department.

Human

• Person in-charge (PIC) to ensure proper isolation of Equipment’s by implementing Safe Lockout Tag out Procedure prior to commencing of activity

• Tools and equipment required for the tasks, should be arranged prior to work.

Organizational

• Ensure Sufficient LOTO devices (Padlock , breaker lockouts & LOTO Tag) provided to the team

• Adequate level of work supervision must be ensured by Management throughout the work completion.

• Hazardous energy risks and controls refresher trainings shall be given to all staff.

Technical

• Activity should be started only after confirming all energy isolation.

• Ensure no residual current existing prior to start the activity.

PIC Isolated the Fan Coil Unit by turning off the isolator switch and covered with masking tape without following LOTO Picture refers to panel board contains Multiple Fan Coil Units isolated in substandard and Unsafe Methods

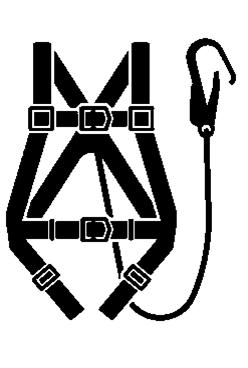

A LOTO device (a physical device) in conjunction with an individual pad lock and LOTO tag is required as part of the energy isolation procedure.

Individual lock

LOTO device

LOTO Tag

This ensures the state of energy is sustained even in absence of a person near the isolation point.

Key Points to remember

Choose LOTO device based on the isolation point

Enova LOTO tag to be completely filled

Group LOTO to be applied for group tasks

Usage of LOTO devices must be recorded

02-March-2024–09:15pm–Miral

Potential risk of personnel becoming trapped within the operational rides area, resultingin a major incident

Three Technicians from the high accessteam were involved for a high accesscleaning task using MEWP at the rideslocation where the MEWP was positioned outside the ride's fence Therewere 2 rides in the location of which two team members had applied the Rides LOTO for the EEL Racer Ride OCC, while other one operative had applied the LOTO for the JellyPlunge Ride OCC.

Shortly after commencing work, two members of the client's rides team arrived and requested the LOTO key for the JellyPlunge Ride for maintenance purposes. The Technician who had applied the LOTO for the JellyfishPlunge Ridehandedover the key tothe rides Team Member, who subsequently removed the LOTO and the lock was returned tothe Technician. The works team was instructed not to maneuver the MEWP without further instruction

The rides team then tested the ride by operating the same Meanwhile, two works team members were already on the MEWP platform who continued the vacuuming of the Hanging Scenic Art without maneuvering the MEWP. This is when a part of the Hanging Scenic Art loosened and fell. The same rides team member from the Jelly Plunge Area arrived, instructed to barricade the fallenmaterial, and advised against cleaning the Hanging Scenic Art until further instructions were given

In course of the client investigation of the fallen part of the Hanging Scenic Art, the investigation teamrevealed that while the ride was beingoperated by the rides team, there was no LOTO applied at the OCC, and the High AccessTeam was cleaning the scenic art using the MEWP at a high level This situation raised concerns as the team was working near the operational ride without applying LOTO

NOTE: Howeverthere was an error by the operative that applied the LOTO at the Jelly Plunge rides OCC by logging the date in the LOTO register as 03rd March 2024 in the LOTO register instead of 02nd March 2024

• Donot give the LOTO keys under your responsibility to anyone else.

• Notify immediately to your supervisor on any Unforeseen/ Unplanned Simultaneous Operations (SIMPOS) at the work site by otherparties

• Ensure that the entries and recordings in official registers areclearandaccurate

• Any simultaneous operations (SIMPOS) by the client at the work location that are unforeseen andunplanned should be referred tothe ENOVA OperationsManager for an assessment of the task's continuity.

• Assess risks involved or generated before proceedingany task that has compromisedon a predefined safety controls

Hanging Scenic Art that was cleaned MEWP Positioned location with Handing Scenic Art outside the ride fence Jellyfish Plunge Ride inside the ride fence EEL Racer Ride Track beside the MEWP Position14-March-2024–9:00amMIRAL

Potential risk of personnel becoming trapped within the operational rides area, resulting in a major incident or complaint from the Client Team leading to Business breakdown for the ride operations

On 14th March 2024 before 09:00am, the Enova Mid-Management Team accessed Level 3- Back ofHouse (BOH) at Sea World Abu Dhabi in response to a complaint regarding open firedampers Theyusedtheguestexit lane within the MicroOcean - EEL Racer Ridessection, a routepreviously usedto reach the location.

Unlike the previousoccasions, there was no ride operator at the OCC (Operations Control Center)to grant entry permission. Since it was outside park operational hoursand no LOTO (Lockout/Tagout) requirement was communicated bythe Ride Operator(s) during previous entries, and considering theexit queue gate was open, access point is behind the OCC cabinand does not impactride operations, the ENOVA team failed to identifythe requirement toseek authorizationfrom therides management via phones to proceeded throughthe door behind the OCC cabin for their task This ledthe Client toidentify,throughtheSecurityFootage, and escalate it as“UnauthorizedEntry Into Critical Ride’s Area”

However,there is an alternative exitroute from Level 3 that does not disrupt theRides Area.

• Ensure avoidance of human errors stemming from complacency from experience atwork & work location.

• Escalate tothe client on theobstacles hindering safe access to critical areas that require frequentattention & entry for ENOVA Team.

• Refresher on Client Procedural Training on LOTO Requirement for accessing the Ride Areas for all ENOVA & Contractor Colleagues

• Technical

• Prepare and share a survey report withthe client torequest improved, safer access to critical areas

Fire Damper Door that were to be attended Access route to the L3BOH through the Ride Area Open gate identified

Right understanding of LOTO process and application is necessary to stop incidents from occurring

Know the LOTO Procedure

Trained on HRMS – Control of Hazardous Energy

Only authorized person to apply LOTO

Identify the risk involved in the Simultaneous Operations (where LOTO is applicable)

Maintain LOTO Register at site

Apply group LOTO for multiple stakeholder involvement

LOTO Register

Write the correct details

Monitor the register

"Before

starting a task, I always perform a dynamic risk assessment and I stop if it's unsafe".

24- March-2024 – 09:04pm DC-P6 site (KSA) Hot work

24-March-2024–09:04pmDC-P6site(KSA)

Using grinder without full PPE and without fire blanket.

Cable drum without plugs.

Grinder without guard.

Sub-contractor working without availing permit to work and also using unsafe power tools.

Sub-contractor has been assigned for car parking extension and fabrication of security cabin at DC P6 Project. They have been using Hand grinder and welding machine to perform these tasks. However, on 23rd of March 2024 around 09:04pm, Enova site supervisor has noted that contractor team went to actual location at site without informing the Enova team and moreover, the contractor team has involved in an unsafe act by starting the work activities without availing permit to work and also using unsafe power tools (Grinder without guard, Welding machine without inspection, Cable drum without switches). The contractor team has completely ignored the hot work safety requirements such as fire blanket, fire extinguisher and mandatory PPE. This unsafe act could have caused fire at site resulting serious injuries along with property damage.

Human

• Ensure to have competent workmen and with full PPE to perform hot work activity.

Organizational

• Strict implementation of administrative controls and disciplinary actions to control contractors at site.

• Strict implementation of PERMIT TO WORK and continuously monitoring the contractor.

Technical

• Make sure that all power tools and their components are safe prior to work as per respective permit to work checklist.

and

Always refer to the High-Risk Management Standard on Hot Works and abide by the Life saving rule of Hot Work

05- March-2024 – 12:00am – MIRAL

Experiences - (AUH)

30- March -2024 – 10:25pm UQUEPC site (KSA)

31- March-2024 – 02:00pm UQU-EPC site (KSA)

14-March-2024 – 10:30am NU-EPC site (KSA)

19-March-2024 – 3:00 PM - ADAC –MTC (AUH)

30- March-2024 – 10:30pm UQU-EPC site (KSA)

Mobile elevated working platform

Safe scaffold

Complacency affects us

Permit to work

PPE Non-Compliance on Boom Lift Platform

05-March-2024–12:00am–MIRALExperiences-(AUH)

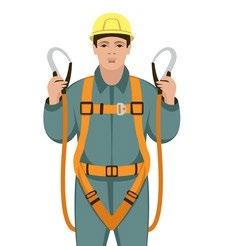

Potential risk of Personnel Fall from Height while working from the MEWP Platform resulting in a major incident

At 12:00 am on 05/03/2024 during the night shiftoperation, it was observed that, a Subcontracted employee to Fire Safety Systems Refurbishment Contractor,was using the Boom-Lift Platform without complying with the required PPE standards. This includes the absence of a Full Body Harness,Hi-Viz Jacket,and Safety Hard Hats.

Due to this being a repeated violation by the contractor despite previous re-induction & specific training for the team, the Permit To Work for this operation was revoked, and a work stop noticewas issued for this specific activity.

The subcontract team was instructed to be replaced with immediate effect from theactivity and recommendation for strict compliance to CloseHSEMonitoring directlyfrom the Fire Safety Systems Refurbishment Contractor team till the end of the project.

Human

• NIL

Organizational

• Replace subcontractors who have violated the terms or rules.

• Close Monitoring and Supervision for the replaced staff operations directly by Fire Safety Systems Refurbishment Contractor.

Technical

• NIL

Working at height is one of the high-risk activities in our organization. All safety measures must be adhered to while working at height.

Key points to check when contractors perform task using MEWP’s

Equipment inspected and certified safe

Operator to be certified Wear appropriate PPE

Task to be performed by Enova Employees Site and

30-March-2024–10:25pmUQU-EPCsite(KSA)

Scaffoldingdoes nothaveproper safeplatformand isnotinspected bycompetent scaffolder.

Scaffoldwithout wheels,without safework-platform andmoreover, electricalcablesof thepowertoolsare incontactwith metalpartsof scaffolding.

SubContractorteamhasBroughtinscaffoldsthatareunsafeandnot complyingwithsafetyrequirements.

Concernedperson/Company.

SubContractor Company

SubContractorcompanyhasbeenworkingwithENOVAatUQUEPCsitefor BMSworkatprojectandasapartoftheiractivitytheyarerequiredtoperform workusingscaffolding,On30-03-2024at10:25pm,wehaveobservedthatthe contractorteamhasbroughtinascaffoldingwithfollowingunsafefeatures.

• Scaffoldingdoesnothaveproperworkingplatform.

• Nofallpreventionarrangementlikeguard-railssystems.

• Propersupportsarenotinstalled.Nosafeaccess/egressladder.

• Wireisusedtotiescaffoldingcomponentsthatmakesitunstable

• Thewheelsofthismobilescaffoldingarealsonotinstalled.

• Ignoredtheinspectiontagsystem.

• Damagepowercabletouchingwithmetal.

Keypoint:Despitebeinginformedearlieraboutscaffoldingsafety requirementsonvariousoccasions,thecontractorhaserectscaffoldingin unsafecondition

Human

•Ensuretohave3rdpartycertifiedscaffolder.

•Ensuretohavecompetentworkmentoperformworkatheightusingscaffold

Organizational

•PriortoissuingPTWtocontractormakesuretheycomplywithallsafety requirement.

• Technical

•Makesurethatthescaffoldinghasallsafetyfeaturestobeeligibletoget allowedintositeforintendedwork

31-March-2024–02:00pmUQU-EPCsite(KSA)

NoFall prevention arrangement guard-rails system

UnsafeScaffold:

• Withoutsafe wheels/Baseplate,

• Theworking platformhas gaps

•

• Nosupportbars forscaffolding. Improperguard railsandtoeboard.

Sub-contractorteamhasBroughtinscaffoldsthatareunsafeand notcomplyingwithsafetyrequirements.

Concernedperson/Company.

Sub-contractorCompany.

Sub-contractorcompanyhasbeenworkingwithENOVAatUQUEPC siteforlightingreplacementprojectandasapartoftheiractivitythey arerequiredtoperformworkusingscaffolding,On31-03-2024at 02:00pm,wehaveobservedthatthecontractorteamhasbroughtina scaffoldingwithfollowingunsafefeatures.

• Scaffoldingdoesnothaveproperworkingplatform.

• Nofallpreventionarrangementlikeguard-railssystems.

• Supportsarenotinstalled.

• NoSafewheels(Sinceitisamobilescaffolding).

• IgnoredtheInspectiontaggingsystem. Wehavestoppedthecontractorfromproceeding.

Keypoint:Despitebeinginformedearlieraboutscaffoldingsafety requirementsonvariousoccasions,thecontractorhasbrought-in thisunsafescaffoldingstructure.

Human

• Ensuretohave3rdpartycertifiedscaffolder.

• Ensuretohavecompetentworkmentoperformworkatheightusing scaffoldings

Organizational

• PriortoissuingPTWtocontractormakesuretheycomplywithallsafety requirements

Technical

• Makesurethatthescaffoldinghasallsafetyfeaturestobeeligibletoget allowedintositeforintendedwork

Mobile aluminum scaffolds are vastly used by Enovians and our contractors for various activities as access equipment.

Key Points to consider

Standard equipment

Perform pre-use check using the checklist

14-March-2024–10:30amNU-EPCsite(KSA)

UnfoldedanAtypeladderupto180degreesangletomakeitas astraightoneandthenusingitunsafely

Concernedperson/Company. Contractor Company.

Contractorhasbeenassignedforreplacementoflightingand motionsensortaskatNUProjectandtheyhavebeenusingladderto performthesetasks.However,on14thofMarch2024around 10:30am,EnovasiteEngineerhasnotedthatcontractorteamwere involvedinanunsafeactinwhichtheyhaveunfoldedanAtype laddertomakeit180degreesstraightoneandmoreovertheladder wasstationedonstaircasemakingitmorepronetoaccident,a contractortechnicianstoodonlaststepoftheladderinanunsafe posturetoperformtheassignedtask.Thisunsafeactcouldhave causedfallfromheightresultingseriousinjuriesalongwith propertydamage.

Note:Hereakeypointisthat,contractorteamhasignoredthesafe workpracticesthatwerecommunicatedthroughtoolboxtalkthat wasconductedon10-Mar-2024pertainingtoladdersafety.

HumanandOrganizational

• Ensurecontinuoussupervisionoversub-contractorworkerstostop themfrombypassingsafetyrulesatsiteandcanceltheworkpermit incaseofmisconduct.

Technical

• Makesurethatsubcontractorusessuitablesafemeanstoperformwork atheightalongwithusageofsafetyharness.

Unsafeactbyusing anAtypeladderby contractorUnsafeActivity-WorkatHeight

19-March-2024–3:00PM-ADAC– MTC(AUH)

Potential Risk of Falling from Height

Unsafe activity Work at a height

Sub-contractortechnician was observeddoing an unsafe activity while working at a height approximately 4 meters in pump room,where he used cable trays asanaccess to reach the valve and then stood the pipeline for the purposeofclosing the water line valve.

No safe work-at-heightprecautions were put into place. There was neither safe working at-height platform utilized, nor any fall arrest system were used.

This act hadthe potential riskof fall from heightand could lead to severe injuries in case of afall

Human

• Refresher TBT is to be conducted of safe working at Height, Working Platforms, and PPEs.

• Ensuring proper instructions and supervision during work activity.

Organizational

• Communication with all the teams about reporting difficulties faced at the site.

• Warning Signs to be put in place on subjected area on not to access the valves till safe platform is available.

Technical

• Provision a safe working platform

Complacency can be the most dangerous mindset that may results in an injury or accident

Complacency is extremely dangerous in the workplace.

Creates numbness to hazard

Leads to shortcuts at work place

You need to focus physically and mentally on your work, no matter how many times you have done the same job in the past

30-March-2024–10:30pmUQU-EPCsite(KSA)

Hot work activity: Welding machine without inspection hot work activity: without fire blanket

Cable drum without safe plug

Sub-contractor company was found working without availing permit to work and also using unsafe power tools.

Sub-contractor has been assigned for BMS activity at UQU Project. They have been using Hand grinder and welding machine to perform these tasks. However, on 30th of March 2024 around 10:30pm, Enova site HSE officer has noted that contractor team went to site to preform their job and while doing so, the contractor team was involved in an unsafe act by starting the work activities without availing permit to work and also using unsafe power tools (Cable drum without safe plug, Welding machine without inspection) The contractor team has completely ignored the hot work safety requirements such as fire blanket, fire extinguisher and mandatory PPE. (safety shoes, hand gloves and hard hats) This unsafe act could have caused fire at site resulting serious consequences.

Key point: In spite of being informed earlier about scaffolding safety requirements on various occasions, the contractor has brought-in this unsafe scaffolding structure.

Human

• Ensure to have competent workman and with full PPE to preform hot work activity.

Organizational

• Strict implementation of administrative controls and disciplinary actions to control contractor at site

• strict Implementation of PERMIT TO WORK and continuously monitoring contractor.

Technical

• Make sure that all power tools and their components are safe prior to work as per respective permit to work checklists.

A Permit To Work (PTW) is a documented management system that includes

• specific processes to request,

• record,

• review, and

• authorize tasks to becarried out by designated employees

If a work is authorized by a PTW

All hazards of the task are identified and mitigated

Person responsible for the task is identified

Competent staff performing the task

Adequate PPE with the working team

Safe and Sufficient tools and equipment's

All stakeholders notified of the activity

08- March -2024 – 3:30pm-DA

DXB,(UAE)

08- March -2024 – 3:30pm-DA

DXB,(UAE)

Safe start of task

Standard operating procedure

InadequatePPEandAbsenceofPATTest

08-March-2024–3:30PM-DADXB(UAE)

Hazardous Occurrence

No minor/Major injuries

Chemical Used For PPM

On 08/03/2024 atapproximately 3:30 Pm, During the Veolia Senior Management site visit at T1( Dubai Airport) Enova staff were found engaged in AHU PPM task. They were using a compressor to pressure wash the unit While performing the task,staff were notwearing task specific Personal Protective Equipment (Chemical gloves & EarPlug) & the compressor was not PAT tested.

Human

• Ensure the task specific PPEs to be worn.

• Ensure to inspect the equipment prior to start the task.

Organizational

• TBT on TT28 PPEs Dos & Don'ts, TT43 Hand and Power Tools to be communicated to the team.

• Ensure all equipment are PAT tested with stickers available.

• Technical

• NA

Most common human failure occur because of lack of knowledge on safe practice and poor perception of risk involved in the activity.

08-March-2024–3:30pm-DADXB,(UAE)

Covered Motor

Hazardous Occurrence

No minor/Major injuries

On 08/03/2024 at approximately 3:30 Pm, During the leadership walk at T1( Dubai Airport)noticed Enova staff were engaged in AHU PPM task. While inspection observed thatAHU motorwas covered with plastic whichcould have burnt due to excessive heat & temperature.

Human

• Be aware of the proper work methods and equipment protection at work sites.

• Refer the updated SOP and the Risk assessments before commencing works.

Organizational

• Conduct TBT on topic, TT34 hazard identification & Risk Assessment.

• Update the SOP to include the right steps for the task.

Technical

• Explore the option to have fire resistant coverings for the motor unit.

• Task specific PPM checklist to be developed and staff trained on implementation .

Standardizationof maintenanceregime

Reduceconsumablesand st Improvedworkplace safety

Proactive monitoringof theactivity

LegalandRegulatory compliance

RevisetheSOP ifrequired Communicatechanges toall

Timely reporting of all incidents and near miss leads to reduction of incidents and reoccurrence of incidents.

Strengthen safety culture

Incidents are recorded

Staffs are empowered to report incidents

Trends and opportunity of improvement is identified

Reduction in incidents

Operational and organizational gaps are corrected

Incident reporting timeline