5.5.4

FUEL AND ENGINE CONTROL - SERVICE PROCEDURE

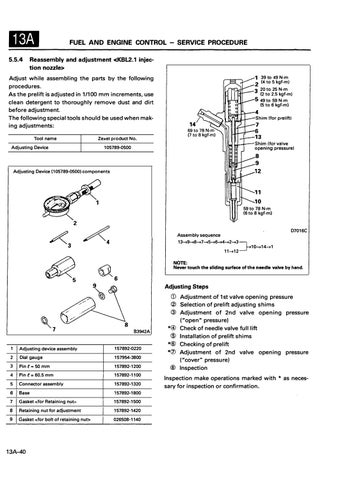

Reassembly and adjustment <KBL2.1 injection nozzle>

Adjust while assembling the parts by the following procedures. As the prelift is adjusted in 1/100 mm increments, use clean detergent to thoroughly remove dust and dirt before adjustment. The following special tools should be used when mak ing adjustments: Tool name Adjusting Device

1 39 to 49 N-m {4 to 5 kgf-m} 2 20to 25 N-m 3 {2 to 2.5 kgf-m} 5 49to 59 N-m {5 to 6 kgf-m}

4

Shim (for prelift)

14

Zexel product No .

7 6 13

u....-+--Shim (for valve opening pressure}

105789-0500

8 9 Adjusting Device (105789-0500) components

11 10

59to 78 N-m {6to 8 kgf-m}

D 7016C

Assembly sequence 13➔9➔8➔7➔5➔6-+4➔2➔3, 11➔12

____r 1O➔ 14➔1

NOTE: Never touch the sliding surface of the needle valve by hand.

Adjusting Steps

83942A 1

Adjusting device assembly

157892-0220

2

Dial gauge

157954-3800

3

Pint= 50 mm

157892-1200

4

Pin e = 60.5 mm

157892-1100

5

Connector assembly

157892-1320

6

Base

157892-1800

7

Gasket <for Retaining nut>

157892-1500

8

Retaining nut for adjustment

157892-1420

9

Gasket <for bolt of retaining nut>

026508-1140

13A-40

CD Adjustment of 1st valve opening pressure ® Selection of prelift adjusting shims @ Adjustment of 2nd valve opening pressure ("open" pressure) *@ Check of needle valve full lift @ Installation of prelift shims *@ Checking of prelift *(/) Adjustment of 2nd valve opening pressure ("cover" pressure) @ Inspection Inspection make operations marked with sary for inspection or confirmation.

* as neces