LIFE CYCLE ASSESSMENT REPORT | SUPERBEAD

S U P E R B E A D L I F E C Y C L E A S S E S S M E N T

energystore produces the cavity wall insulation product ‘energystore superbead®’, an expanded polystyrene (EPS) bead used across the UK Sustainable Homes was commissioned to undertake a life cycle assessment quantifying the carbon emissions associated with superbead's manufacture and distribution The first of its kind in the UK, this cavity wall insulation life cycle assessment (LCA) shows energystore's commitment to transparency, responsibility and high environmental performance It sets a precedent for the building and retrofit industry, which has high embodied carbon emissions that must be recognised and reduced to enhance the sustainability of the sector

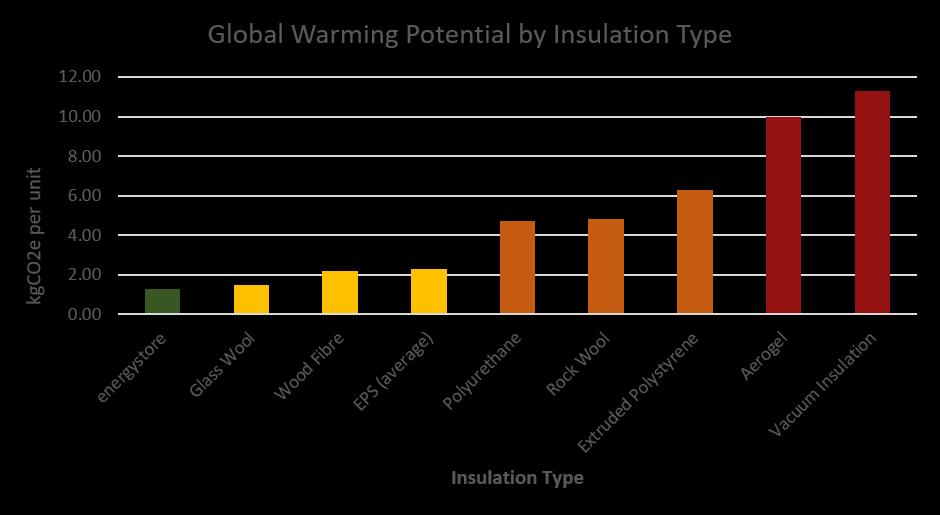

This LCA revealed that each cubic meter block of superbead emits 41kg of carbon dioxide and other greenhouse gases (CO2e) per 12kg cubic meter block produced Compared to other insulation studies, superbead had the lowest embodied emissions per functional unit

M E T H O D O L O G Y

To undertake this LCA, Sustainable Homes collected data from energystore on volumes of expanded polystyrene (EPS) processed, energy used in factories and transportation distances of both the raw material and the manufactured product Publically available data was used to estimate emissions from raw material processing Due to a lack of data availability, extraction and disposal stages were excluded The image below shows the areas of focus in the study To compare superbead's performance with other cavity wall insulation products, Sustainable Homes undertook a literature review of insulation product LCAs in Europe

Included in Life Cycle Assessment

Data from

R A W M A T E R I A L P R O C E S S I N G

Data on emissions from raw material processing was sourced from the PlasticsEurope EPS Ecoprofile The primary energy inputs for average European factories were used to estimate the total global warming potential (GWP) of raw material processing

Expandable polystyrene is typically made using a suspension polymerisation process Droplets of styrene polymerise (combine into longer chains) when heated in a reactor At the same time the expansion agent pentane is added This produces the expandable polystyrene bead

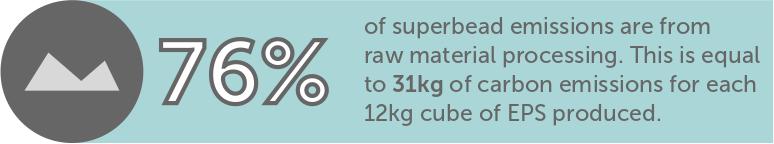

Emissions from raw material processing were calculated at 31kg CO2e per 12kg of expandable polystyrene produced This is by far the largest source of emissions from any stage in the manufacturing and distribution process It accounts for over 3/4 of embodied emissions

R A W M A T E R I A L T R A N S P O R T A T I O N

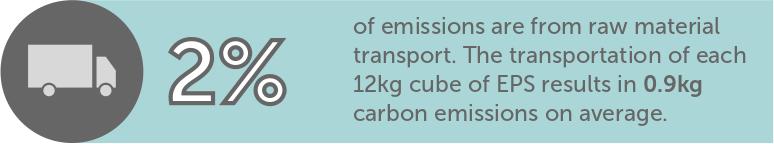

Each of energystore’s four factories obtained their raw material from a site on mainland Europe The distances from the source to each of the energystore factories were noted, along with the assumed number of deliveries per year.

Based on the annual tonnage of processed material, the number of deliveries of raw materials was calculated to be 20 tonnes per trip, and 16 5 tonnes in the case of Wrea Green Information was provided on travel method and distances, as follows:

Calculations were based on a single journey, rather than a round trip, based on the assumption that other loads could be taken on the return journey

Total annual emissions for transportation of the raw material were calculated as being 154 tonnes CO2e in total This equates to an average of 0 85kg CO2e per cube

Energystoreltd_superbead_lifecycleassessment_2018_v1

M A N U F A C T U R I N G

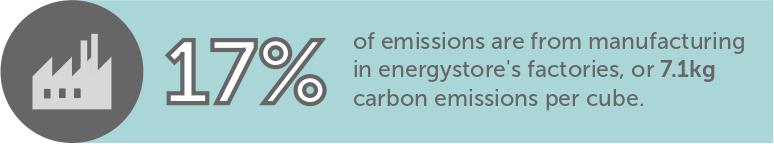

During the manufacturing stage, energystore's raw material (comprising plastic pellets) is steam-heated to 80°C to trigger expansion, via the expansion agent pentane which is contained within the pellets The process lowers the density of the beads to approximately 3% of their original value

Of energystore’s four factories, three used oil as the primary fuel and one used gas All four used electricity The carbon emissions associated with this energy use were calculated per factory using DEFRA 2017 conversion factors and extrapolated over the course of a year On average this energy consumption across the factories equated to an average of 5 3kg CO2e per 12kg cube produced

In addition to the emissions from factory energy use, carbon dioxide output is increased by the presence of pentane in the chemical process CO2 emissions are raised by 152 5g per kg of EPS produced, or 1 8kg per cube Water usage was also assessed, but the contribution to carbon emissions was minimal

I N S T A L L A T I O N

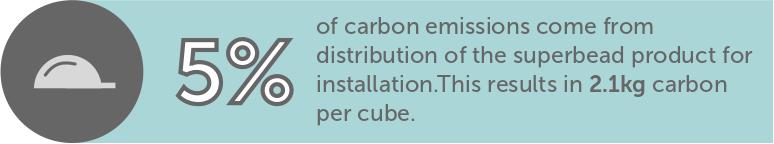

Distribution from each of energystore’s factories was either via an in-house transport team, or collected by customers

To calculate carbon emissions from these deliveries, energystore provided a list of deliveries made over a period of six months, including both energystore deliveries and customer collections Every delivery is considered to be a return trip Due to the product being very lightweight (12kg/m³), DEFRA conversion factors relating to unladen vehicles were used

energystore's factories are dispersed across the UK and this helps to reduce delivery distances As a result, emissions from EPS transportation are fairly low compared to other stages of the process. On average, carbon emissions from distribution of insulation cubes were 2.1kg CO2 per cube transported

T O T A L C

A R B O N F O O T P R I N T

The absolute emissions reported for raw material production, transportation, manufacture and installation of energystore's superbead® were 7,399 tonnes of CO2e. This resulted in the production of approximately 181,600 cubes over the course of the year

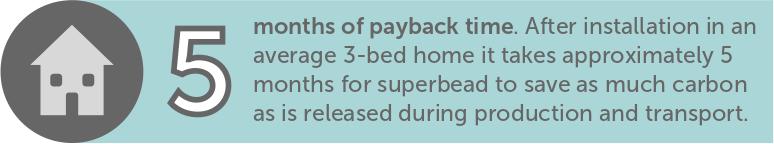

It is estimated that once installed in the home, 6 cubes of energystore’s superbead® cavity wall insulation will save 26 23 tonnes of carbon emissions from being emitted by the average house over the course of their expected 42-year lifespan This is based on Ofgem and BRE's Deemed Scores Matrix figures

The insulation will therefore save 0 62 tonnes (625kg) of CO2 per year 6 cubes of superbead insulation result in 246 7kg of CO2e emissions, so the payback time is therefore estimated to be approximately five months (excluding disposal).

Sustainable Homes undertook a literature review of LCAs for cavity wall insulation materials across Europe, to benchmark energystore EPS’s embodied carbon with other insulation types It must be noted that the methodologies and scope of these LCAs will vary between each other and with this energystore LCA However, this assessment provides an approximate comparison of the embodied emissions of different insulation products energystore's superbead® displayed the lowest Global Warming Potential per equivalent unit of insulation, as shown in the graph below