KiwaLtd.

BAF-18-042-S-A-UK

T:+44(0)1332383333

E:uk.bpenquiries@kiwa.com

W:www.kiwa.co.uk/bda

T:+44(0)2890428442

E:info@energystoreltd.com

W:www.energystoreltd.com

SCOPEOFAGRÉMENT

ThisAgrémentrelatestoenergystoreTLA®(hereinaftertheSystem),athermallyinsulating,non-structural,boundexpandedpolystyrene(BEPS)ballasting whichcontributestothethermalperformanceoffloors.TheSystemisforinternalandexternalapplicationtoground-supportedandsuspendedgroundfloorsin existingandnew,domesticandnon-domesticbuildingswithintheUKandIreland.TheSystemistypicallyusedasaninsulationlayerorvoidformerandis availableinthreegrades,TLA110,TLA150andTLA200.OthergradesareavailablebutfalloutsidethescopeofthisAgrément

SYSTEMDESCRIPTION

TheSystemconsistsofgrey,spherical,expandedpolystyrene(hereinafterEPS)beadsmanufacturedinaccordancewithBSEN13163andBSEN16809-1, factory-coatedwithaliquidadditive(EIA).ThecoatedEPSbeadsaremixedwithcementandwatertoformhomogeneousfreshmortarinaccordancewith BSEN16025-1.TheSystemcanbemixedon-siteortransportedtositepre-mixedintraditionalconcretemixingvehiclesTheSystemshallbeinstalledtoa minimumdepthof50mm;forspecialrequirementswheretheminimumdepthcannotbeachieved,consulttheAgrémentholder.

SUMMARYOFAGRÉMENT

Thisdocumentprovidesindependentinformationtospecifiers,buildingcontrolpersonnel,contractors,installersandotherconstructionindustryprofessionals consideringthesafetyandfitnessfortheintendeduseoftheSystemThisAgrémentcoversthefollowing: Conditionsofuse; ProductionControl,QualityManagementSystemandtheAnnualVerificationProcedure; Systemcomponentsandancillaryitems,pointsofattentionfortheSpecifierandexamplesofdetails; Installation; IndependentlyassessedSystemcharacteristicsandotherinformation; CompliancewithnationalBuildingRegulations,otherregulatoryrequirementsandThird-PartyAcceptance,asappropriate; Sources

MAJORPOINTSOFASSESSMENT

Moisturecontrol-afloorincorporatingtheSystemcancontributetolimitingtheriskofinterstitialandsurfacecondensation(seesection2.2.9).

Strength-subjecttodesignandspecification,afloorincorporatingtheSystemcanhaveadequatestrength(seesection2.2.10).

Fireperformance-afloorincorporatingtheSystemisclassifiedasEuropeanClassificationA2-s1,d0,inaccordancewithBSEN13501-1(seesection2.211).

Thermalperformance-theSystemimprovesthethermalperformanceoffloors(seesections2.2.12and2.5.4)

Durability-afloorincorporatingtheSystemshallhaveaservicelifedurabilityequivalenttothatofthebuildingintowhichitisincorporated(seesection2.2.13)

CEmarking-theAgrémentholderhasresponsibilityforCEmarkinginaccordancewithallrelevantharmonisedEuropeanProductStandards(seesection 2.2.14).

CONTENTS

Chapter1-Generalconsiderations

1.1-Conditionsofuse

1.2-ProductionControlandQualityManagementSystem

1.3-AnnualVerificationProcedure-continuoussurveillance

Chapter2-Technicalassessment

2.1-Systemcomponentsandancillaryitems

2.2-PointsofattentiontotheSpecifier

2.3-Examplesofdetails

2.4-Installation

2.5-IndependentlyassessedSystemcharacteristics

Chapter3-CDM,nationalBuildingRegulationsandThird-PartyAcceptance

3.1-TheConstruction(DesignandManagement)Regulations2015andTheConstruction(DesignandManagement)Regulations(NorthernIreland)2016

3.2-ThenationalBuildingRegulations

3.3-Third-PartyAcceptance

Chapter4-Sources

Chapter5-Amendmenthistory

Chapter6-Conditionsofuse

1.1-CONDITIONSOFUSE

1.1.1Designconsiderations Seesection2.2

1.12Application

TheassessmentoftheSystemrelatestoitsuseinaccordancewiththisAgrémentandtheAgrémentholdersrequirements.

1.1.3Assessment

KiwaLtd.hasassessedtheSystemincombinationwithrelevanttestreports,technicalliterature,theAgrémentholdersqualityplan,DoPsandsitevisitas appropriateTheNHBCStandardshavealsobeentakenintoconsideration.

1.1.4Installationsupervision

ThequalityofinstallationandworkmanshipmustbecontrolledbyacompetentpersonwhomustbeanemployeeofanApprovedInstaller.

TheSystemshallbeinstalledstrictlyinaccordancewiththeinstructionsoftheAgrémentholderandtherequirementsofthisAgrément.

1.1.5Geographicalscope

ThevalidityofthisdocumentislimitedtoEngland,Wales,Scotland,NorthernIrelandandIreland,withdueregardtoChapter3ofthisAgrément(CDM,national BuildingRegulationsandThird-PartyAcceptance)

1.1.6Validity

ThepurposeofthisBDAAgrément®istoprovideforwell-foundedconfidencetoapplytheSystemwithintheScopedescribedThevalidityofthisAgrémentis threeyearsaftertheissuedate,andaspublishedonwww.kiwa.co.uk/bda

1.2-PRODUCTIONCONTROLANDQUALITYMANAGEMENTSYSTEM

KiwaLtd.hasdeterminedthattheAgrémentholderfulfilsallobligationsinrelationtothisAgrément,inrespectoftheSystem

TheinitialauditdemonstratedthattheAgrémentholderhasasatisfactoryQualityManagementSystem(QMS)andiscommittedtocontinuouslyimprovingtheir qualityplanDocumentcontrolandrecord-keepingproceduresweredeemedsatisfactory.AdetailedProductionQualitySpecification(PQS)hasbeencompiled toensuretraceabilityandcomplianceunderthetermsofthisAgrément.

1.3-ANNUALVERIFICATIONPROCEDURE-CONTINUOUSSURVEILLANCE

TodemonstratethattheSystemconformswiththerequirementsofthetechnicalspecificationdescribedinthisAgrément,anAnnualVerificationProcedurehas beenagreedwiththeAgrémentholderinrespectofcontinuoussurveillanceandassessment,andauditingoftheAgrémentholdersQMS.

CHAPTER2-TECHNICALASSESSMENT

ThisAgrémentdoesnotconstituteadesignguidefortheSystemItisintendedasanassessmentofsafetyandfitnessforpurposeonly.

2.1-SYSTEMCOMPONENTS&ANCILLARYITEMS

2.1.1ComponentsincludedwithinthescopeofthisAgrément

ThefollowingcomponentsareintegraltotheuseoftheSystem:

Item Description EPSbead greybead,2to8mmdiameter,density12±2kg/m3 liquidadditive(EIA) proprietaryliquidforfactory-coatingEPSbeadstoensurehomogenousmixingwithcementandwater cement minimumgradePortland32.5CemIorCemII,inaccordancewithBSEN197-1 water potablewater,inaccordancewithBS8204-1

2.1.2AncillaryitemsfallingoutsidethescopeofthisAgrément

AncillaryitemsdetailedinthissectionmaybeusedinconjunctionwiththeSystembutfalloutsidethescopeofthisAgrément: latexadhesive.

2.2-POINTSOFATTENTIONTOTHESPECIFIER

2.21Designresponsibility

ASpecifiermayundertakeaproject-specificdesign,inwhichcaseitisrecommendedthattheSpecifierco-operatescloselywiththeAgrémentholder.The Specifierorinstallingcontractorisresponsibleforthefinalas-builtdesign.

2.2.2Appliedbuildingphysics(heat,air,moisture)

Acompetentspecialistshallcheckthephysicalbehaviourofaproject-specificdesignincorporatingtheSystemandifnecessarycanofferadviceinrespectof improvementstoachievethefinalspecification.TheSpecialistcanbeeitheraqualifiedemployeeoftheAgrémentholderorasuitablyqualifiedconsultant(in whichcaseitisrecommendedthattheconsultantSpecialistco-operatescloselywiththeAgrémentholder).

2.2.3Generaldesignconsiderations

TheSystemisforuseinfully-bonded,partially-bonded,unbondedandfloatingfloorapplicationsoncompactedhardcoreordryconcretebases(including ground-supportedandsuspendedgroundfloorapplications)

Therequirementforlimitingheatlossthroughfloors,includingtheeffectofthermalbridging,canbesatisfiedifthethermaltransmittance(hereinafterU-value) ofafloordoesnotexceedthetargetU-valuerequirementinthenationalBuildingRegulations.

NewconcretefloorsshallbedesignedandconstructedinaccordancewiththenationalBuildingregulations,BritishStandardsandCodesofPracticetoprevent moisturepenetration.

Aproject-specificdesignshalltakeintoaccountPAS2030andPAS2035asappropriate.

TheminimumapplieddepthoftheSystemshallbe50mm.Ifpipesorconduitsarepresentonthebase,aminimumdepthof50mmshallbemeasuredfromthe highestlevelofallpipes/conduits

Forground-supportedfloors,adampproofmembrane(hereinafterDPM)laidbetweentheSystemandthecompactedhardcoreissufficienttopreventground moisturepenetration.

ConcreteplacedpriortotheapplicationoftheSystemshallbefullycuredandstructurallysound.

TheSystemshallbecoveredbyascreedpriortotheinstallationoffloorfinishes.Thescreedshallbeawearingscreedifnosubsequentwearingsurfaceis requiredbytheproject-specificdesign

TheSystem: canbeusedinconjunctionwithunderfloorheatingandcoolingsystems; shallnotbeinstalledoverunprotectedelectricalcables,existingventsorventilationgaps.Considerreroutingorre-layinginconduitortrunking

Acousticmeasuresshallbeinstalledinafloor: beneathanypipesandconduits/trunkingpriortotheinstallationoftheSystem;or abovetheSystempriortoscreed

CareshallbetakenindesigndetailingofjointsatservicepipeopeningsandshouldbeinaccordancewithBS6093.

Existingstructuraljointsand/orexpansionjointsinaconcretebaseshallbemaintainedafterinstallationoftheSystem

Careshallbetakenintheoveralldesignandconstructionatjunctionswithexternalwallsandopeningstominimisethermalbridgesandairinfiltration.

Guidanceonlinearthermaltransmittance,heatflowsandsurfacetemperaturescanbefoundinthedocumentssupportingthenationalBuildingRegulationsand BSENISO10211,BREInformationPaperIP1/06,BREReport262andBREReport497

2.2.4Project-specificdesignconsiderations

Theproject-specificdesignshalltakeintoaccounttherequirementsofthenationalBuildingRegulations-seesection3.2

Theproject-specificdesignshallconsidertheservicelifedurabilityrequired-seesection2.2.13.

Nopre-installationsurveyisrequiredfortheinstallationoftheSystem-seesection2.4.3.

AninspectionshallbecarriedoutpriortotheinstallationoftheSystem.Typicalchecksshouldinclude: thesuitabilityandconditionofthebase; underfloorandroomspaceventilationrequirements.

U-valuecalculationsforacompletedfloorshouldbecarriedoutinaccordancewithBSENISO10211(takingintoconsiderationBSENISO6946, BSENISO13370andBREReport443),usingtheSystemsdeclaredthermalconductivity(D).Designanddeclaredthermalvaluescanbefoundin BSENISO10456.

ACondensationRiskAnalysiscanbecarriedoutbytheAgrémentholderinaccordancewithBS5250,ifrequired.

2.2.5Permittedapplications

OnlyapplicationsdesignedaccordingtothespecificationsgiveninthisAgrémentarepermitted.IneachcasetheSpecifierwillhavetoco-operatecloselywith theAgrémentholder.

2.2.6Installercompetencelevel

TheSystemshallbeinstalledstrictlyinaccordancewiththeinstructionsoftheAgrémentholderandtherequirementsofthisAgrément.

InstallationmustbebyemployeestrainedandapprovedbytheAgrémentholderandsubjecttoinspectionsbyKiwaLtd.underaKiwaInstallationAssessment& SurveillanceScheme.

2.2.7Delivery,storageandsitehandling

TheSystemisdeliveredtositeinsuitablepackaging,bearingtheSystemname,theAgrémentholdersnameandtheBDAAgrément®logoincorporatingthe numberofthisAgrément.

StoretheSysteminaccordancewiththeAgrémentholdersrequirements.Careshallbetakento: avoidexposuretodirectsunlightforextendedperiodsoftime; avoidexposuretohighorlowtemperaturesforextendedperiodsoftime; storeinawell-ventilatedcoveredareatoprotectfromrain,frostandhumidity; storeawayfrompossibleignitionsources.

2.28Maintenanceandrepair

Onceinstalled,theSystemdoesnotrequiremaintenanceprovidedthescreedismaintainedingoodconditionDamagedorpoorlyappliedareasoftheSystem shallberemovedandfreshmortarapplied.Minorcracksmayberepairedusingasuitablesmoothingcompound.Foradviceinrespectofrepair,consultthe Agrémentholder.

PerformancefactorsinrelationtotheMajorPointsofAssessment

2.29Moisturecontrol

TheSystemwill: beresistanttoatmosphericmoistureandwillresistthepassageofmoisturefromthegroundwhenusedwithaDPM; haveadequateperformanceinrespectofwatervapourtransmission,inaccordancewithBSEN12086.

CondensationriskanalysiscalculationsinaccordancewithBS5250arenotrequiredforfloorswithaground-bearingbase

2.210Strength

TheSystem: canhaveadequatestrengthtoresistnormalnon-structuralloadingsforinternalapplications; canbeinstalledeffectivelytocomplywithfloorusecategoriesA,BorC,inaccordancewithBSEN1991-1; wastestedforcompressivecreepinaccordancewithBSEN1606andthevaluesaredetailedinSection2.5.2.

2.211Fireperformance

AfloorincorporatingtheSystemisclassifiedasEuropeanClassificationA2-s1,d0,inaccordancewithBSEN13501-1.

2.2.12Thermalperformance

TheSystemwillimprovethermalperformancewhenincorporatedinanon-structuralfloor.

2.2.13Durability

TheSystemshallhaveaservicelifedurabilityequivalenttothatofthebuildingintowhichitisincorporated.Theexpectedlifespanofthebuildingitselfshouldbe atleast60-years.

TheSystemisnon-toxic,non-absorbent,rot-proof,stableovertimeanddoesnotsustainfungiormould.

TheSystem: willmaintainitsshape,size,structureandappearance; hassimilarmovementcharacteristicstoconcreteandtraditionalsand/cement-basedmixes

Toachievetheservicelifedurabilityindicated,thewearingsurfaceshallbemaintainedingoodcondition.

2.2.14CEmarking

ThereisnorelevantharmonisedEuropeanstandardfortheSystem.

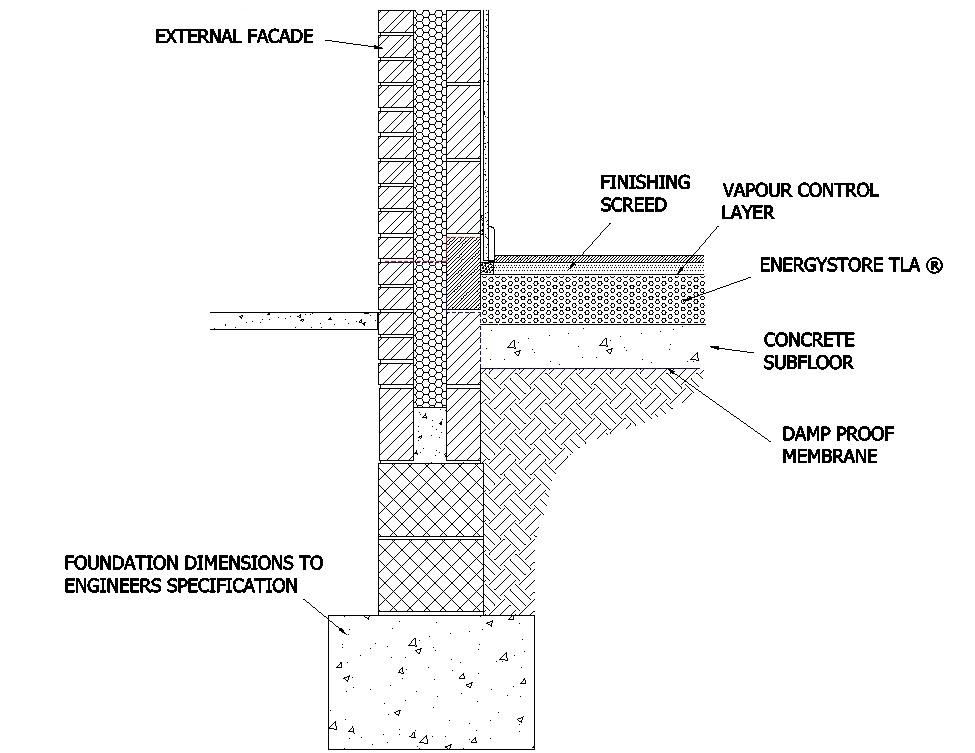

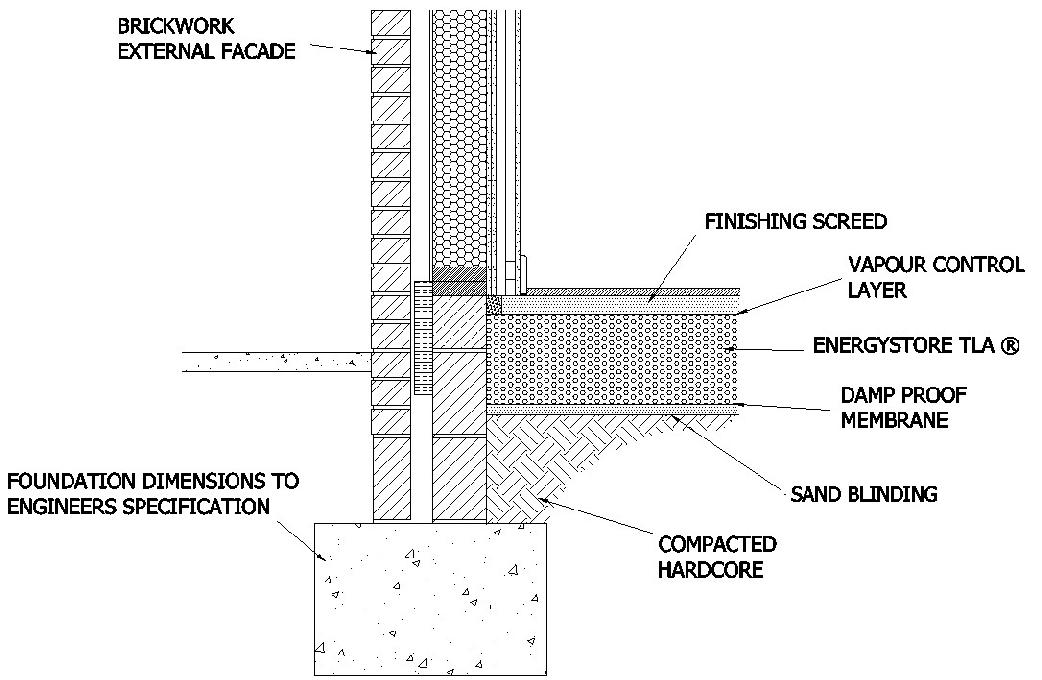

23-EXAMPLESOFTYPICALDETAILS

Diagram1-typicalfloormake-upwithaconcretesub-floor

-typicalfloormake-upwithoutasub-floor

2.4-INSTALLATION

TheSystemshallbeinstalledstrictlyinaccordancewiththeinstructions(hereinafterInstallationManual)oftheAgrémentholderandtherequirementsofthis Agrément.

2.4.1Installercompetencelevel Seesection2.2.6.

2.4.2Delivery,storageandsitehandling Seesection2.2.7.

2.4.3Project-specificinstallationconsiderations

Nopre-installationsurveyisrequiredfortheinstallationoftheSystem

InstallationshallbeinaccordancewithBS8000-0,BS8000-3,andBSEN16025-2

Freshmortarshallbeinstalled: atambienttemperaturesbetween5and35°C; withinthreehoursofmixing.

Expansionjointsarenotgenerallyrequired.Forfurtherguidance,contacttheAgrémentholder.

Whenrequired,dayjointsshouldbecastvertically.Priortorecommencingwork,dayjointsshallbetreatedwithlatexadhesive.

Ensuretheinstallationareaisadequatelyventilatedduring,andafterinstallationoftheSystem

Onceinstalled,avoidartificialheatingoftheareafor72hours.TheSystemwilldryattherateof10mmofthicknessperdayandmustbeprotectedfromfrost forsevendaysafterinstallation

Whenunprotected,theSystemshouldnotbesubjecttoanypedestriansitetrafficfor36to72hoursafterinstallation,subjecttoweatherconditionsandthe ambientairtemperature.Ifoverlaidwithtemporaryprotection,pedestriansitetrafficispermittedafter36hours.

Ifthefinishedfloorisinanareaofabuildingthatislikelytobecomewet,thewearingsurfaceshallincludewatertightseamsatalljunctions,detailsandedges

2.4.4Preparation

ThebaseoverwhichtheSystemistobeplacedshallbepreparedinadvanceofinstallation.Differentrequirementsapplyforfully-bonded,partially-bonded, unbondedandfloatingfloorapplications

Typically,thefollowingworksshallbeundertakenpriortotheinstallationoftheSystem: removalofdust,fragments,organicorotherextraneousmatter; removalofanylaitance; sealingwithsuitableprimer; removalandrepairofdamagedorfriablesectionstoensurethesurfaceisasregularaspossible; checksforanyevidenceofpondingonthebase; whererequired,installasuitableDPM.

2.4.5Outlineinstallationprocedure

ThedetailedinstallationsequencecanbefoundinfullintheAgrémentholdersInstallationManual.

Thekeysequenceforinstallationis: batchthefreshmortarpriortouse; installthefreshmortartothebaseviaahose-deliverysystem; spreadasrequired;levelandsmoothusingastraightedge; checktheinstallationiscorrectinrespectoffinishedlevel,surfaceregularityandthickness.

Afterinstallation,testingshallbeundertakenbytheInstallerinaccordancewiththerequirementsofBSEN16025-2,toensuretheSystemsuppliedon-site meetstherequiredspecification

2.4.6Finishing

Thefollowingfinishingisrequiredoncompletionoftheinstallation: ascreedshallbeinstalledinaccordancewithBS8204-7; ascreedcanbeinstalledassoonastheSystemissuitabletowalkon.ThiswillbeconditionalontheSystemthicknessanddryingconditions; avapourcontrollayer(VCL)mayberequiredbetweentheSystemandscreed; awearingsurfaceshallbeinstalledinaccordancewithBS8203; formoisture-sensitivewearingfinishessuchascarpetandlaminateflooring,theambientrelativehumidityshallbebelow75%beforetheapplicationof gypsum-compatibleprimers

2.5-INDEPENDENTLYASSESSEDSYSTEMCHARACTERISTICS

2.51Moisturecontrol

Watervapourpermeability(,indicativevalueonly)

2.52Strength

Compressivecreep

2.53Fireperformance

BSEN12086

BSEN1606

Reactiontofireclassification BSEN13501-1

2.54Thermalperformance

Test

Thermalconductivity(D) BSEN12667

2.5.5Other

Determinationofapparentdensity

CC(0.7/0.7/10)3.5

CC(0.7/0.7/10)6.5

CC(0.75/0.75/10)10 -

CC(0.5/0.5/10)3.5

CC(0.5/0.5/10)6.5

CC(0.5/0.5/10)10

3.1-THECONSTRUCTION(DESIGNANDMANAGEMENT)REGULATIONS2015ANDTHECONSTRUCTION(DESIGNAND MANAGEMENT)REGULATIONS(NORTHERNIRELAND)2016

InformationinthisAgrémentmayassisttheclient,PrincipalDesigner/CDMco-ordinator,designerandcontractorstoaddresstheirobligationsunderthese Regulations.

3.2-THENATIONALBUILDINGREGULATIONS

IntheopinionofKiwaLtd.,theSystem,ifinstalledandusedinaccordancewithChapter2ofthisAgrément,cansatisfyorcontributetosatisfyingtherelevant requirementsofthefollowingnationalBuildingRegulations

ThisAgrémentshallnotbeconstruedtoconfercomplianceofanyproject-specificdesignwiththenationalBuildingRegulations

3.2.1-ENGLAND

C2(c)Resistancetomoisture-floorsincorporatingtheSystemcancontributetoadequatelyprotectingabuildingfrominterstitialandsurfacecondensation L1(a)(i)Conservationoffuelandpower-floorsincorporatingtheSystemcancontributetolimitingheatgainsandlossesthroughabuildingenvelope Regulation7(1)Materialsandworkmanship-theSystemismanufacturedfromsuitablysafeanddurablematerialsfortheirapplication Regulation23(1)Requirementsrelatingtothermalelements-theSystemcancontributetoabuildingenvelopecomplyingwiththeRequirementsofL1(a)(i) Regulation26CO2emissionratesfornewbuildings-theSystemcancontributetoabuildingtonotexceeditsCO2emissionrate Regulation26AFabricenergyefficiencyrates-theSystemcancontributetosatisfyingthisRequirement

3.2.2-WALES

THEBUILDINGREGULATIONS2010ANDSUBSEQUENTAMENDMENTS

C2(c)Resistancetomoisture-floorsincorporatingtheSystemcancontributetoadequatelyprotectingabuildingfrominterstitialandsurfacecondensation L1(a)(i)Conservationoffuelandpower-floorsincorporatingtheSystemcancontributetolimitingheatgainsandlossesthroughabuildingenvelope Regulation7(1)Materialsandworkmanship-theSystemismanufacturedfromsuitablysafeanddurablematerialsfortheirapplication Regulation23(1)Requirementsrelatingtothermalelements-theSystemcancontributetoabuildingenvelopecomplyingwiththerequirementsofL1(a)(i) Regulation26CO2emissionratesfornewbuildings-theSystemcancontributetoabuildingtonotexceeditsCO2emissionrate Regulation26APrimaryenergyconsumptionratesfornewbuildings-theSystemcancontributetosatisfyingthisRegulation Regulation26BFabricperformancevaluesfornewdwellings-theSystemcancontributetosatisfyingthisRequirement

3.2.3-SCOTLAND THEBUILDING(SCOTLAND)REGULATIONS2004ANDSUBSEQUENTAMENDMENTS

3.2.3.1Regulation8(1)Durability,workmanshipandfitnessofmaterials

TheSystemismanufacturedfromacceptablematerialsandisadequatelyresistanttodeteriorationandwearundernormalserviceconditions,provided itisinstalledinaccordancewiththerequirementsofthisAgrément

3.2.3.2Regulation9Buildingstandards-Construction

3.15Condensation-floorsincorporatingtheSystemcancontributetoprotectingabuildingfrommoisturecausedbysurfaceorinterstitialcondensation

6.1(b)Carbondioxideemissions-floorsincorporatingtheSystemcancontributetolimitingCO2emissionsfromabuilding

6.2Buildinginsulationenvelope-floorsincorporatingtheSystemcancontributetothethermalperformanceofabuilding

7.1(a)(b)Statementofsustainability-theSystemcancontributetosatisfyingtherelevantRequirementsofRegulation9,Sections1to6,andtherefore willcontributetoaconstructionmeetingabronzelevelofsustainabilityasdefinedinthisStandard;inaddition,theSystemcancontributetoa constructionmeetingahigherlevelofsustainabilityasdefinedinthisStandard

3.2.3.3Regulation12Buildingstandards-Conversions

AllcommentsgivenunderRegulation9alsoapplytothisRegulation,withreferencetoSchedule6ofTheBuilding(Scotland)Regulations2004and subsequentamendments,clause0.12oftheTechnicalHandbook(Domestic)andclause0.12oftheTechnicalHandbook(Non-Domestic)

3.2.4-NORTHERNIRELAND

THEBUILDINGREGULATIONS(NORTHERNIRELAND)2012ANDSUBSEQUENTAMENDMENTS

23(1)Fitnessofmaterialsandworkmanship-theSystemismanufacturedfromsuitablematerialsfortheirapplication 29Condensation-floorsincorporatingtheSystemcancontributetoprotectingabuildingfrommoistureintheformofinterstitialcondensation 39(a)(i)Conservationmeasures-floorsincorporatingtheSystemcancontributetolimitingheatgainsandlossesthroughabuildingenvelope 40(2)Targetcarbondioxideemissionrate-theSystemwillcontributetoabuildingnotexceedingitstargetCO2emissionrate 43Renovationofthermalelements-floorsincorporatingtheSystemcancontributetorenovationworktoensureafloorcomplieswithrequirement39(a)(i)

3.2.5-IRELAND BUILDINGREGULATIONS1997ANDSUBSEQUENTAMENDMENTS

InordertodemonstratecompliancewithIrishBuildingRegulations,thisBDAAgrément®certifiesthattheSystemcomplieswiththerequirementsofa recogniseddocumentandindicatesitissuitableforitsintendedpurposeanduse

C4Resistancetoweatherandgroundmoisture-floorsincorporatingtheSystemcancontributetoprotectingabuildingfrommoistureintheformof interstitialcondensation

D1Materialsandworkmanship-theSystemismanufacturedfromsuitablysafeanddurablematerialsfortheirapplication

L1ConservationofFuelandEnergy-floorsincorporatingtheSystemcancontributetolimitingheatgainsandlossesthroughabuildingenvelope,andcan contributetolimitingCO2emissionsfromabuilding

33-THIRD-PARTYACCEPTANCE

NHBC-IntheopinionofKiwaLtd.,theSystem,ifinstalledingroundfloorsincorporatingaconcretelayer,usedandmaintainedinaccordancewiththis Agrément,cansatisfyorcontributetosatisfyingtherelevantrequirementsinrelationtoNHBCStandards,Chapter5.1Substructureandground-bearingfloors andChapter5.2Suspendedgroundfloors.

CHAPTER4-SOURCES

BSENISO6946:2017Buildingcomponentsandbuildingelements.Thermalresistanceandthermaltransmittance.Calculationmethods

BSENISO10211:2017Thermalbridgesinbuildingconstruction.Heatflowsandsurfacetemperatures.Detailedcalculations

BSENISO10456:2007Buildingmaterialsandproducts.Hygrothermalproperties.Tabulateddesignvaluesandproceduresfordeterminingdeclaredand designthermalvalues

BSENISO13370:2017Thermalperformanceofbuildings.Heattransferviatheground.Calculationmethods

BSEN826:2013Thermalinsulatingproductsforbuildingapplications.Determinationofcompressionbehaviour

BSEN197-1:2011Cement.Composition,specificationsandconformitycriteriaforcommoncements

BSEN1602:2013Thermalinsulatingproductsforbuildingapplications.Determinationoftheapparentdensity

BSEN1606:2013Thermalinsulatingproductsforbuildingapplications.Determinationofcompressivecreep

BSEN12086:2013Thermalinsulatingproductsforbuildingapplications.Determinationofwatervapourtransmissionproperties

BSEN12667:2001Thermalperformanceofbuildingmaterialsandproducts.Determinationofthermalresistancebymeansofguardedhotplateandheat flowmetermethods.Productsofhighandmediumthermalresistance

BSEN13163:2012+A2:2016Thermalinsulationproductsforbuildings.Factorymadeexpandedpolystyrene(EPS)products.Specification

BSEN13501-1:2018Fireclassificationofconstructionproductsandbuildingelements.Classificationusingdatafromreactiontofiretests

BSEN16025-1:2013Thermaland/orsoundinsulatingproductsinbuildingconstruction.BoundEPSballastings.RequirementsforfactorypremixedEPS dryplaster

BSEN16025-2:2013Thermaland/orsoundinsulatingproductsinbuildingconstruction.BoundEPSballastings.ProcessingofthefactorypremixedEPS dryplaster

BSEN16809-1:2019Thermalinsulationproductsofbuildings.In-situformedproductsfromloose-fillexpandedpolystyrene(EPS)beadsandbonded expandedpolystyrenebeads.Specificationforthebondedandloose-fillproductsbeforeinstallation

BS5250:2011+A1:2016Codeofpracticeforcontrolofcondensationinbuildings

BS6093:2006+A1:2013Designofjointsandjointinginbuildingconstruction.Guide

BS8000-0:2014Workmanshiponconstructionsites.Introductionandgeneralprinciples

BS8000-3:2020Workmanshiponconstructionsites.Masonry.Codeofpractice

BS8203:2017Codeofpracticeforinstallationofresilientfloorcoverings

BS8204-1:2003+A1:2009Screeds,basesandinsitufloorings.Concretebasesandcementitiouslevellingscreedstoreceivefloorings.Codeofpractice

BS8204-7:2003Screeds,basesandinsitufloorings.Pumpableself-smoothingscreeds.Codeofpractice AccreditedConstructionDetailsforScotland

BREInformationPaper1/06:2006Assessingtheeffectsofthermalbridgingatjunctionsandaroundopenings

BREReport262:2002Thermalinsulation:avoidingrisks

BREReport443:2006ConventionsforU-valuecalculations

BREReport497:2016Conventionsforcalculatinglinearthermaltransmittanceandtemperaturefactors GovernmentAccreditedConstructionDetailsforPartL-EnglandandWales NHBCStandards2023

PAS2030:2019Specificationfortheinstallationofenergyefficientmeasuresinexistingdwellingsandinsulationinresidentialparkhomes

PAS2035:2019Retrofittingdwellingsforimprovedenergyefficiency-Specificationandguidance

Remark:apartfromthesesources,technicalinformationandconfidentialreportshavebeenassessed;anyrelevantdocumentsareinthepossessionof KiwaLtdandkeptintheTechnicalAssessmentFileofthisAgrémentTheInstallationManualfortheSystemmaybesubjecttochange,andtheAgrément holdershouldbecontactedforclarificationofrevisions

CHAPTER5-AMENDMENTHISTORY

CHAPTER6-CONDITIONSOFUSE

ThisAgrémentmayonlybereproducedanddistributedinitsentirety.

WhereaNationalAnnexexistsinrespectofaBSEN(orother)standard,itsuseisdeemedmandatorywherevertheoriginalstandardisreferenced. KiwaLtd.hasuseddueskill,careandattentioninthepreparationofthisBDAAgrément®

Whilstallduediligencehasbeenused,noliabilityorwarrantyisextendedbyKiwaLtd. ForfulltermsandconditionsrefertoKiwaLtd.