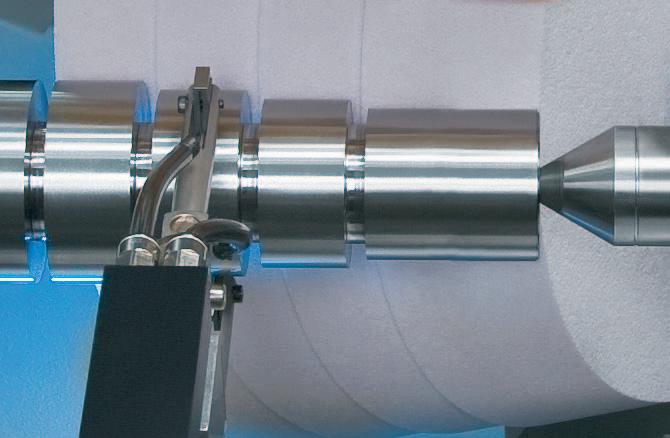

External cylindrical grinder

HG 2

When the EMAG Grinding Division introduced the HG 2 series to its horizontal grinding machine platform it took into account all the demands that are made on modern cylindrical grinders. In fact, with the HG 2 External Cylindrical Grinder EMAG presents a new, highly productive and flexible machine concept for the grinding of small, medium and large batches of shaft-type components.

HG 2

EXTERNAL CYLINDRICAL GRINDER

HG 2 – the efficient solution for low-cost component manufacture.

The HG 2 machines workpieces of up to 600 mm in length. The high static and dynamic rigidity of its thermostable cast iron machine base guarantees excellent manufacturing quality. The dimensions of the machining area offer easy access to the machine and accommodate extensive axis movements. Linear motion guideway systems allow for the smallest infeeds and excellent continuity of movement. These stick-slip-free and well dampened infeeds lead to exceptional contour integrity and outstanding surface finishes.

The HG 2 is equipped with precision ball screws, which - in combination with the absolute measuring systems in X- and Z-axis (linear glass scales) - make for high precision. The HG 2 is not subject to any vibrations from machine enclosure or automation equipment that could have a negative influence on the machining results. The optional equipment specification includes an integrated loader with recirculating pallet storage conveyor, a coolant purification plant and a grinding mist extractor

The HG 2 and its advantages:

• A high-powered wheel drive shortens machining times

• A contact and crash recognition and wheel balancing system monitors the grinding process

• An in-process gauging control checks O/Ds and the longitudinal position on shoulders

• Operator and setter menus simplify handling

• High-precision, sturdy linear roller guiderails in all axes guarantee the longevity of the machine

• Absolute measuring systems (linear glass scales) in all axes ensures the highest machining accuracy

• An NC tailstock with large stroke makes for easy resetting

• Short idle times lead to high productivity levels

• An operator-friendly workpiece error correction system automatically rectifies dimensional errors

• Large doors give optimal access, thus reducing the distance between operator and workpiece

HG 2