In the age of technological innovation, modern production facilities are indispensable. However, purchasing new machines is often costly and time-consuming. With Retrofit, EMAG offers an intelligent alternative: the comprehensive modernization of your existing machines. We extend the service life of your systems, increase their efficiency and reduce energy consumption - all at a fraction of the cost of a new machine. Retrofit is an investment in your future: sustainable, economical and a perfect fit.

Retrofi t refers to the modernization or conversion of existing machines in order to increase their performance and adapt them to modern requirements. EMAG offers a wide range of retrofi t services, from mechanical overhauls to digitalization with IoT technologies. Our solutions guarantee as-new quality - at up to 25 % lower capital investments compared to a new purchase.

Advantages at a glance:

+ Cost savings: up to 25 % cheaper than a new machine

+ Sustainability: resource- and energy-efficient processes

+ Flexibility: tailor-made solutions for individual requirements

+ Short downtimes: fast implementation thanks to exchange modules

With over 25 years of retrofi t expertise, EMAG makes your machines fi t for the future. The original manufacturer knowhow ensures that used EMAG machines or production lines deliver top performance after the retrofi t.

EMAG is your partner for all retrofit needs - from small adjustments to complete overhauls.

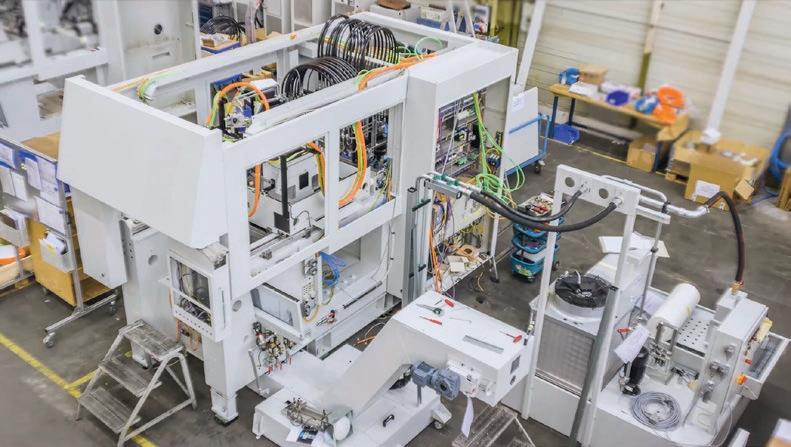

Mechanical and electrical modernization

EMAG performs precision overhauls, whether at our facilities or at your own. Customized solutions and an upgrade to the latest control generation increase productivity.

EMAG overhauls turning, grinding and milling machines as well as machines from Scherer, Karstens and Weiss.

With seven retrofi t plants on three continents, EMAG modernizes machines according to the latest standards and in close proximity to the customer. The exchange between the plants guarantees uniform quality standards worldwide.

» Replacement, repair and overhaul of machines from the EMAG Group

» Testing and replacing mechanical, hydraulic and electrical components

» Use of new, repaired / overhauled components

» Modification & conversion of existing systems

» Changing the machine configuration

» Adjustments to the machine layout

» Technology adaptation and expansion

» Consideration of legal guidelines such as CE

+ Cost savings:

After extensive modernization, the price of a retrofi t machine is about 15 to 25 % below that of a comparable new machine - and that with same performance.

+ Increasing energy efficiency:

Energy savings of up to 30% can be achieved by replacing obsolete components.

+ Sustainability:

The reconditioning and reuse of machines significantly reduces the consumption of resources and protects the environment.

» Design and development of tool and machining concepts

» Set-up of a new / additional workpiece on existing machines

» Quality inspections

» Production support

+ Fast availability:

Retrofi t solutions off er significantly shorter delivery times than new machines, which can be a competitive advantage during global supply bottlenecks.

+ State-of-the-art technology:

Integrating IoT systems and new automation solutions make retrofi t machines ready for the future as well as provide optimal production monitoring and increased effi ciency.

» Upgrade to the latest controller generation

» Increasing performance and efficiency

» Standardized operating concepts across all machines

» New production of assemblies such as spindles & turrets

» Our assembly department works for the entire EMAG Group as well as for our customers worldwide

» Repair and refurbishment of defective individual parts

» Reduction of downtimes due to exchange modules

1. Inventory

Analysis of the existing machine and its components

3. Dismantling

Disassembly of the machine, cleaning and testing of all assemblies 1 2

2. Planning

Development of a customized retrofit concept based on the customer‘s requirements

» Purchase and sale of used machines on the global market

» Modernized solutions are available for many production tasks

5. Modernization

Integration of new technologies, e.g. new machining technology, IoT solutions, automation, energy-saving systems

7. Testing

Comprehensive testing and commissioning including logging of results 3 4 5 6 7 8

4. Renewal

Replacement or overhaul of wearing parts and critical components, e.g. spindles, control systems or hydraulics

6. Reconstruction

Mechanical and electrical rebuilding of the machine

8. Delivery

Return and installation at the customer‘s premises or on-site use

Sustainability plays a central role in the EMAG retrofit concept. With targeted measures such as the optimization of hydraulic systems, energy-efficient motors and state-ofthe-art control technology, we drastically reduce the energy consumption of your machines. Savings of up to 30 % can be achieved, which means that the investment in a retrofit often pays for itself after a short time.

Example:

By retrofi tting a frequency converter, the energy consumption of a machine tool was reduced from 104,000 kWh to 86,000 kWh per year - a saving of 6.7 tons of CO₂.

Further advantages:

+ Extension of service life through reuse of base bodies

+ Reduction of the ecological footprint

+ Sustainable production without compromising on performance

With IoT Retrofi t, we make your machines fi t for the future of digital production. Our EDNA IoT ecosystem enables you to analyze machine data in real time, monitor productivity and proactively plan maintenance work.

Highlights:

» EDNA Health Check: monitoring the condition of the machine

» EDNA Visualize: Display of overall equipment effectiveness (OEE)

» Data-based decisions: Optimization of production processes

Advantages:

+ Reduced downtime

+ Transparent production processes

+ Future-proof through Industry 4.0 technologies

The spindle is the heart of many machines. EMAG off ers a comprehensive spindle retrofi t program, ranging from basic overhaul to complete replacement. We only use new parts or reconditioned components in original quality. With our modular approach, you can choose between diff erent options: from simple bearing replacement to complete overhaul.

Services at a glance:

» Basic Repair: Replacement of bearings and sealing systems

» Full Repair: Complete overhaul including motor and guide replacement

» Initial commissioning: Logged test according to EMAG standards

Your advantages:

+ Maximum precision and stability

+ Rapid availability of replacement spindles

+ Process reliability through comprehensive tests

Grinding machines play a key role in precision machining. But even high-quality machines reach their technical limits over the years. This is where EMAG Retrofi t comes in. Through comprehensive modernization measures, we make older grinding machines fi t again for the challenges of modern production requirements. Mechanical overhauls, the latest CNC technology and energy-effi cient components ensure that your machine is in no way inferior to new models in terms of precision and performance.

Technological upgrades:

+ General mechanical overhaul: Guideways and critical components are overhauled with precision.

+ CNC upgrade: Integration of modern control technology for maximum user-friendliness and fl exibility.

+ Drive technology: Replacement of outdated drives with energy-efficient servomotors.

+ Process optimization: Adaptation to specific production requirements such as out-of-round or taper grinding

Our comprehensive retrofit warehouse offers you immediately available used machines that can be individually modernized. Each machine is cleaned and overhauled in advance and equipped with the latest technologies.

Advantages:

+ Large selection of machine models

+ Original spare parts in high quality

+ Fast delivery and short project lead times

Give your machines a second life and benefit from the advantages of our retrofit solutions.

Contact our team of experts for a non-binding advisory service. Together we will develop the perfect solution for your production requirements.

EMAG Maschinenfabrik GmbH

Stuttgarter Strasse 115 73054 Eislingen

Phone: +49 (0) 7162 / 17 -0

E-Mail: info.retrofi t@emag.com