NAME : ELKARNEEB ALLAA NAGEEB ABDALLA MOHAMED. STUDENT ID : 0351182.

MODULE : BUILDING SCIENCE AND SERVICES. E-PORTFOLIO.

NAME : ELKARNEEB ALLAA NAGEEB ABDALLA MOHAMED. STUDENT ID : 0351182.

MODULE : BUILDING SCIENCE AND SERVICES. E-PORTFOLIO.

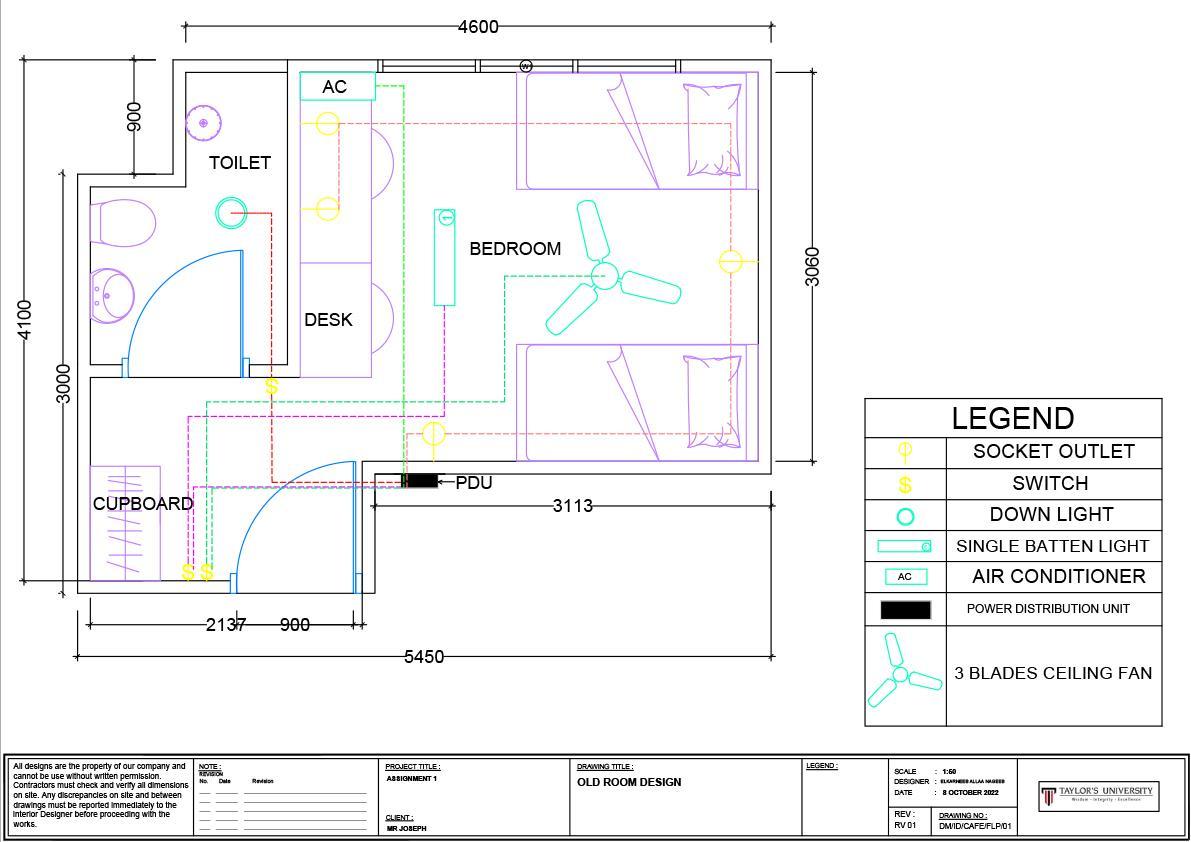

1) The position of the air conditioner does not make the air flow to were the beds are; resulting for the room to be so hot and the air conditioner does not cool the room.

SOULATION:

For this I added a new unit on the same wall that the air conditioner is on. This way the air will be flowing through the room and it will make the room cooler.

2) The A/C produces a high sound; making me wake up sometimes and make it hard to sleep. It is also not energy efficient because it cools the room way too slow

SOULATION:

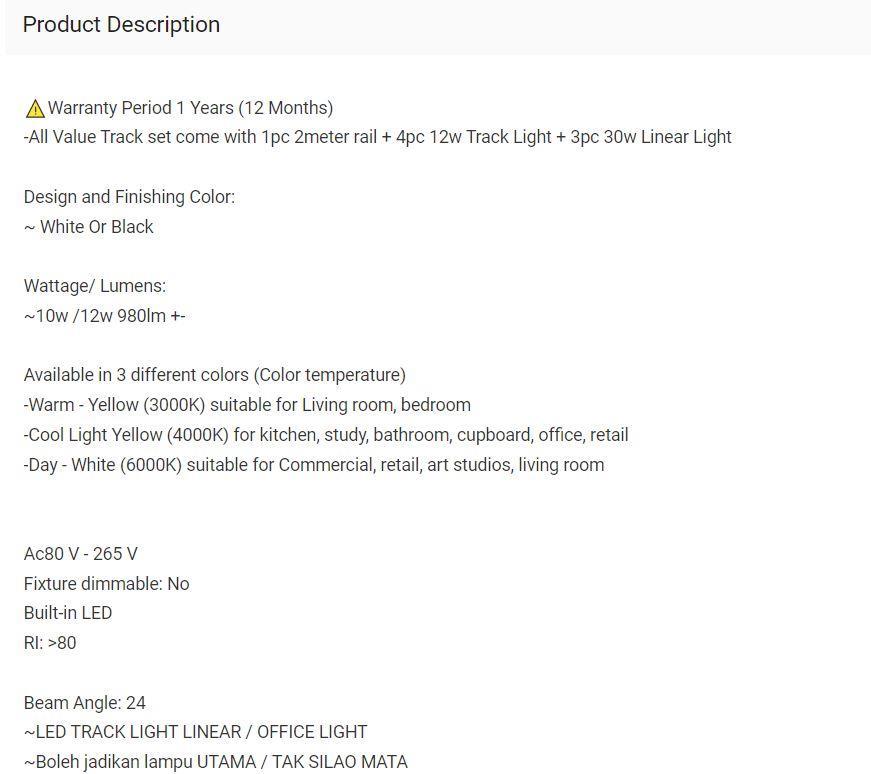

For this I changed the A/C from York YWM10L-AMLDB A/C model to Panasonic CS-U10VKH-1 A/C model as it asserts silent operation and it has an inverter compressor which will vary the power based on the load.

Wattage= 2930W

Energy= PowerXTime. = 2930WX6HRS = 2.93KWX6HRS = 17.58KW/H.

In month (assuming the month has 30 days) = 17.58X30 = 527.4KW/H.

Wattage= (225-920) W

Energy= PowerXTime. = 920Wx6HRS = 0.92KWX6HRS = 5.52KW/H.

In month (assuming the month has 30 days) = 5.52X30 = 165.6KW/H.

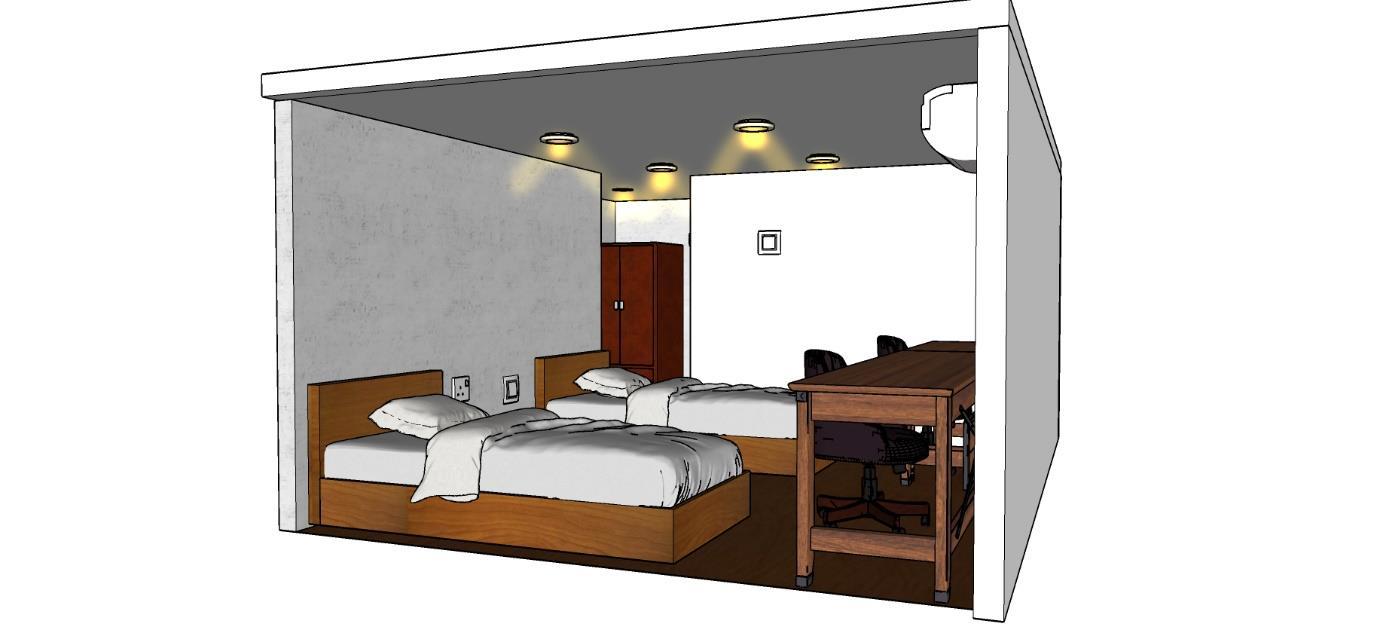

3) The room has a light glare. The brightness is pretty high on the right side of the study desk where the window is and the left side has a small amount of light; making me feel uncomfortable studying in the room.

SOULATION:

For this I added a ceiling lights where there is low brightness

4) The A/C has no switch which maybe dangerous if electric trip happens.

SOULATION:

For this I have added a switch to control the A/C so it is safer

5) The fan blades (3 blades) is not suitable for the room size.

SOULATION:

For this I replaced the 3 blades fan with 4 blades fan as it makes the room cooler than the 3 blades fan.

6) The batten light has exposed weirs which is very dangerous

For this I replaced the batten light with recessed lights were all the wires will be inside the ceiling which will be safer.

A-1

A-2

B-1

C-1

Downlight 190MM(D)X11MM(H)round downcilinglightincoolwhite color.

nos 2 25.9 51.8

Recessedlight5inchultra-thin ledinwhitecolor. nos 4 45.9 183.6

4bladesceiling56inchinblack color. nos 1 390 390

LotLG2.119,LG2.120&LG2A.01,LowerGround

Two SunwayPyramid,PetalingJaya,3,JalanPJS 11/15,SunwayCity,47500SubangJaya, Selangor

LotLG2.119,LG2.120&LG2A.01,LowerGround

Two SunwayPyramid,PetalingJaya,3,JalanPJS 11/15,SunwayCity,47500SubangJaya, Selangor

Tingkat3,Commercedotcom,15,JlnTandang, Seksyen51,46050PetalingJaya,Selangor

Lot10,Jalan13/2,Sekysen13,46200Petaling Jaya,Selangor TOTAL 4623.4

Panasonic 1.0HPPremium InverterR32AirConditionerCSU10VKH-1. nos 2 1,999 3,998

NAME : ELKARNEEB ALLAA NAGEEB ABDALLA MOHAMED.

STUDENT ID : 0351182.

PROGRAM : BA ( HONS ) INTERIOR ARCHITECTURE.

MODULE : BUILDING SCIENCE AND SERVICES.

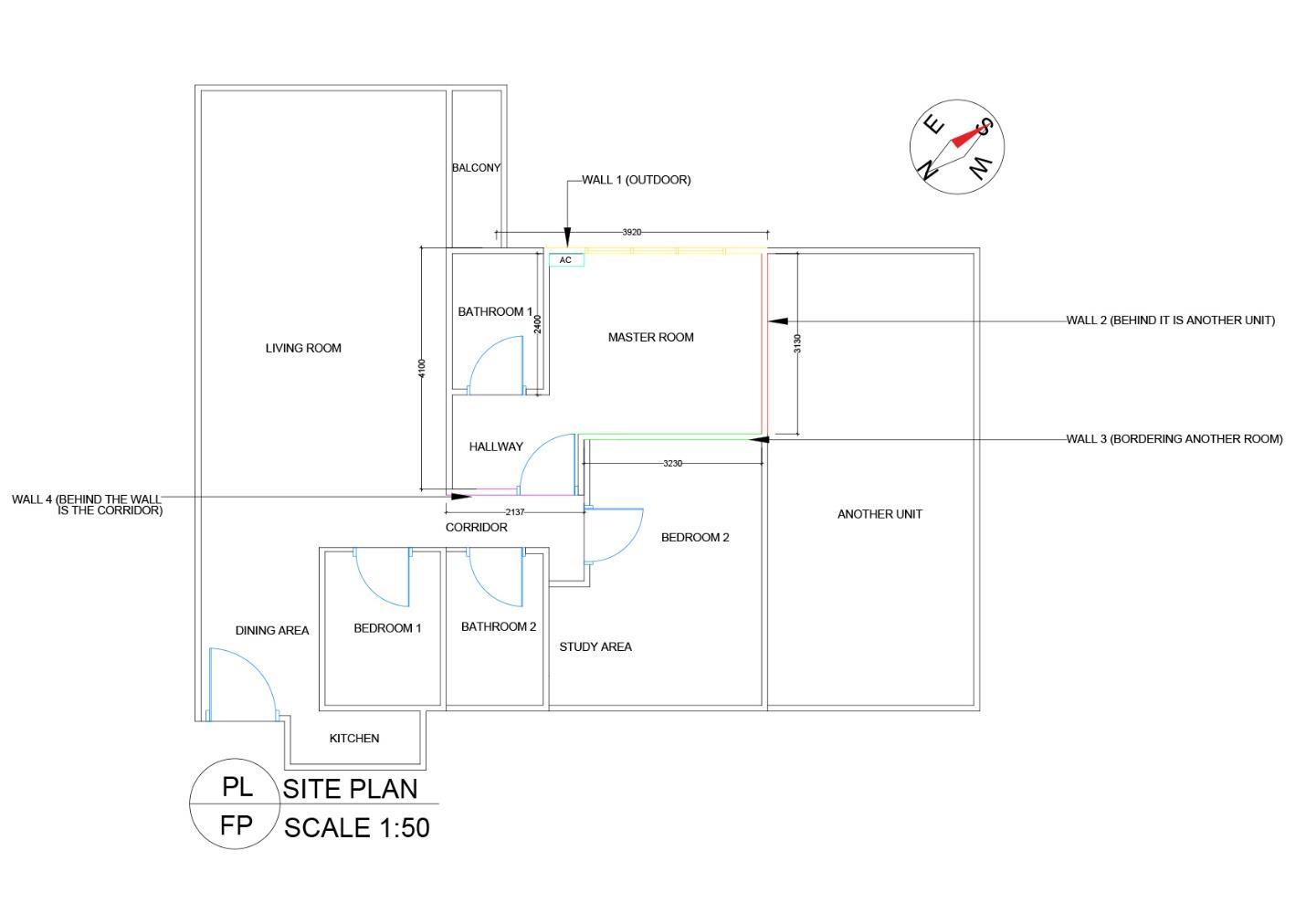

Window, door, walls area:

Height (ft) Width (ft) Area (ft²)

Window 6.2532ft 5.9055ft 36.9282ft² Door 6.8897ft 2.9527ft 20.3432ft²

Wall 1 8.8582ft 12.8608ft 76.9952ft² Wall 2 8.8582ft 7.8740ft 69.7494ft² Wall 3 8.8582ft 10.5971ft 93.8712ft² Wall 4 8.8582ft 7.0111ft 62.1057ft²

Internal and External temperature: 7AM 12PM 5PM Internal temperature (℉) 68℉ 68℉ 68℉

External temperature (℉) 75.20℉ 84.20℉ 80.60℉

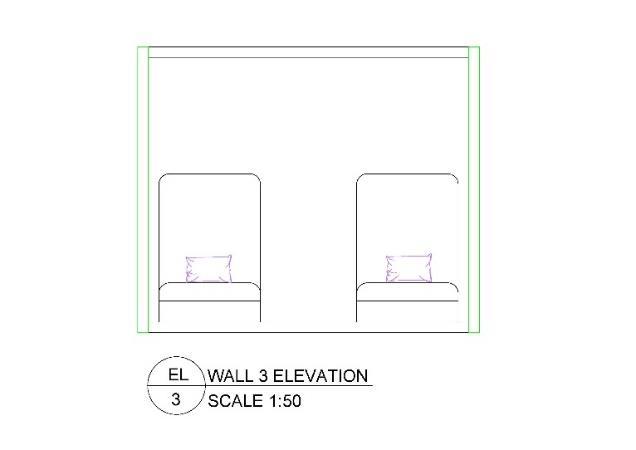

Tables of R values:

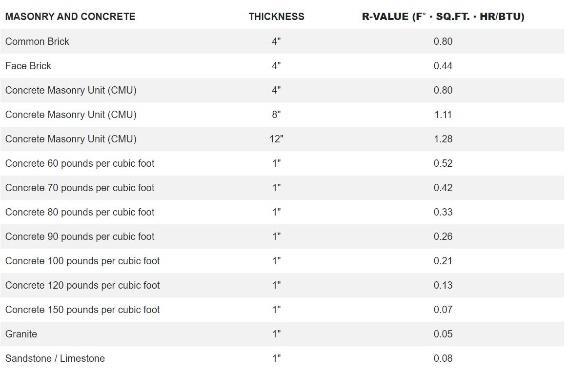

- Area of wall without the window = A wall – A window = ( 12.8608 x 8.8582 ) – ( 5.9055 x 6.2532 ) = 76.9952ft².

- Wall Thickness = 5.78in (0.48ft).

- R of wall = Material x Thickness = Concrete Masonry Unit x Thickness = 0.80 x 5.78 = 4.624 / 4 = 1.156.

7AM 12PM 5PM

T for wall

Exterior – Interior = 75.20℉ - 68℉ =7.2℉.

Q for wall = A x T / R 76.9952ft² x 7.2℉/ 1.156 = 479.5548Btu/hr.

Exterior – Interior = 84.20℉ - 68℉ =16.2℉. Exterior – Interior = 80.60℉ - 68℉ =12.6℉.

76.9952ft² x 16.2℉/ 1.156 = 1078.9984Btu/hr.

- Area of window = (5.9055 x 6.2532) = 36.9282ft².

- R of window = Material x Thickness = ( 0.5 / 0.25 ) x 0.91 = 2 0.91 = 1.82

T for window

Q for window = A x T / R

76.9952ft² x 12.6℉/ 1.156 = 839.2210Btu/hr.

7AM 12PM 5PM

Exterior – Interior = 75.20℉ - 68℉ =7.2℉.

36.9282ft² x 7.2℉/ 1.82 = 146.0895Btu/hr.

Exterior – Interior = 84.20℉ - 68℉ =16.2℉.

36.9282ft² x 16.2℉/ 1.82 = 328.7015Btu/hr.

Exterior – Interior = 80.60℉ - 68℉ =12.6℉.

36.9282ft² x 12.6℉/ 1.82 = 255.6567Btu/hr.

Q wall + Q window:

7AM 12PM 5PM

Q wall + Q window 479.5548Btu/hr + 146.0895Btu/hr = 625.6443Btu/hr.

1078.9984Btu/hr + 328.7015Btu/hr = 1407.6999Btu/hr.

839.2210Btu/hr + 255.6567Btu/hr = 1094.8777Btu/hr.

Picture of the wall

Elevation drawing

- Wall area = W X H = 7.8740ft x 8.8582ft = 69.7494ft². - R = 0.80 x 5.78 = 4.624 / 4 = 1.156.

7AM 12PM 5PM

T for wall Exterior – Interior = 75.20℉ - 68℉ =7.2℉. Exterior – Interior = 84.20℉ - 68℉ =16.2℉. Exterior – Interior = 80.60℉ - 68℉ =12.6℉.

Q for wall = A x T / R 69.7494ft² x 7.2℉/ 1.156 = 434.4253Btu/hr.

69.7494ft² x 16.2℉/ 1.156 = 977.4569Btu/hr.

769.7494ft² x 12.6℉/ 1.156 = 760.2443Btu/hr.

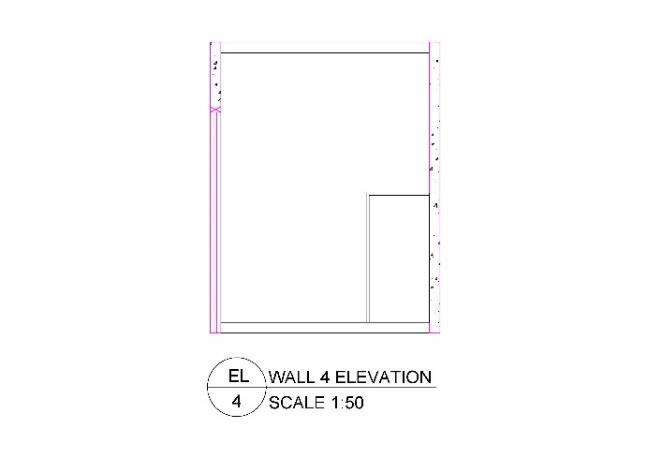

- Wall area = 10.5971 x 8.8582 = 93.8712ft².

- R = 0.80 x 5.78 = 4.624 / 4 = 1.156.

7AM 12PM 5PM

T for wall Exterior – Interior = 75.20℉ - 68℉ =7.2℉ Exterior – Interior = 84.20℉ - 68℉ =16.2℉

Q for wall = A x T / R 93.8712ft² x 7.2℉/ 1.156 = 584.6649Btu/hr.

93.8712ft² x 16.2℉/ 1.156 = 1315.4960Btu/hr.

Exterior – Interior = 80.60℉ - 68℉ =12.6℉

93.8712ft² x 12.6℉/ 1.156 = 1023.1635Btu/hr.

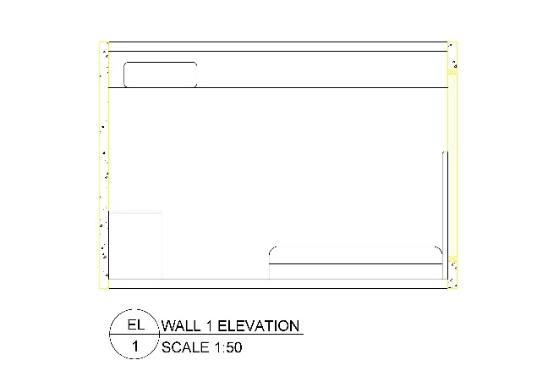

- Wall area = ( 7.0111 x 8.8582 ) – ( 6.8897 X 2.9527 ) = 41.7625ft².

- R wall = 0.80 x 5.78 = 4.624 / 4 = 1.156.

7AM 12PM 5PM

T for wall Exterior – Interior = 75.20℉ - 68℉ =7.2℉

Q for wall = A x T / R 41.7625ft² x 7.2℉/ 1.156 = 260.1124Btu/hr.

- Door area = 6.8897 X 2.9527 = 20.3432ft².

Exterior – Interior = 84.20℉ - 68℉ =16.2℉

41.7625ft² x 16.2℉/ 1.156 = 585.2530Btu/hr.

- R door = Material x Thickness = hardwood x 1.75 = 0.91 x 1.75 = 1.5925.

Exterior – Interior = 80.60℉ - 68℉ =12.6℉

41.7625ft² x 12.6℉/ 1.156 = 455.1967Btu/hr.

7AM 12PM 5PM

T for door Exterior – Interior = 75.20℉ - 68℉ =7.2℉.

Q for door = A x T / R 20.3432ft² x 7.2℉/ 1.5925 = 91.9755Btu/hr

Exterior – Interior = 84.20℉ - 68℉ =16.2℉. Exterior – Interior = 80.60℉ - 68℉ =12.6℉.

20.3432ft² x 16.2℉/ 1.5925 = 206.9449Btu/hr

Q wall + Q door:

20.3432ft² x 12.6℉/ 1.5925 = 160.9571Btu/hr

7AM 12PM 5PM

Q wall + Q door 260.1124Btu/hr + 91.9755Btu/hr = 352.0879Btu/hr.

585.2530Btu/hr + 206.9449Btu/hr = 792.1979Btu/hr.

455.1967Btu/hr + 160.9571Btu = 616.1538Btu/hr.

The highest wall that gains heat is wall 1 with a rate of heat transfer = 1407.6999Btu/hr at 12PM because wall 1 is facing the south east where the sun is at the most heat at 12PM and because that the wall has a big window with the dimension of 5.9055ft W and 6.2532ft H and the windows that face the South produce the most solar heat gain and natural lighting.

Problem statement: the bathroom is located at the master bedroom and the window of the bathroom faces the south east (the bathroom’s window is at the same direction of wall 1) which the wall has the most heat gained especially at 12PM. The bathroom usually is hot and it gets more hotter in the afternoon and evening the sun rays become so direct and strong making me sweat and feel uncomfortable

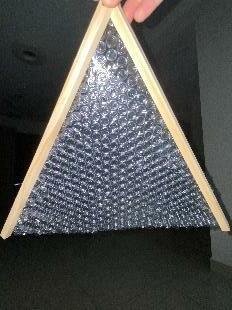

Design idea: my idea is to make a detachable product that reduces the heat transferred to the bathroom. The product can be hanged over the window to reduce the strong and direct sunlight coming from the window and at the same time it can be used as light source and shower products hanger.

1) Make a hole in the wood pieces to attach them together.

2) With a screw and a screwdriver make the hole by twisting the screw multiple times. (I do not have a screw gun so I used this alternative).

3) After the hole is made use a wing nut screw to attach the 2 wood pieces together.

4) Cut the bubble wrap on a triangle shape.

5) With a stapler gun/super glue, glue the bubble wrap into the wood.

6) Repeat the steps for the second triangle.

7) With rubber band tie the triangle heights with the base.

8) Screw the two bases together.

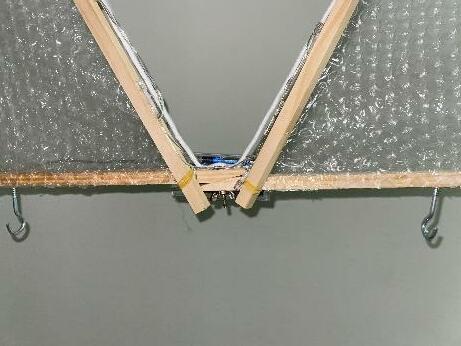

9) Using a hot glue gun, glue the LED lights to the wood.

10) Use a string and glue it to the wood so it works as a hanger for the product.

11) Twist the hook screws into the triangle’s base to be used later as a hanger for shower area.

Plywood is used in the main structure of the product as wood has a low thermal conductivity (act as a high heat insulator); resulting to slow the heat transfer. Another reason to use wood it because of its lightweight; making the product easy to carry and remove.

Bubble wrap is a good heat insulator because air is a good heat insulator and since the air pockets has air trapped inside the plastic sheet it makes the bubble sheet a good heat isolator. The bigger the bubbles the less heat will be transferred. Plastic is also a good heat insulator. Another reason to use bubble wrap is because its cheap, easy to place and waterproof.

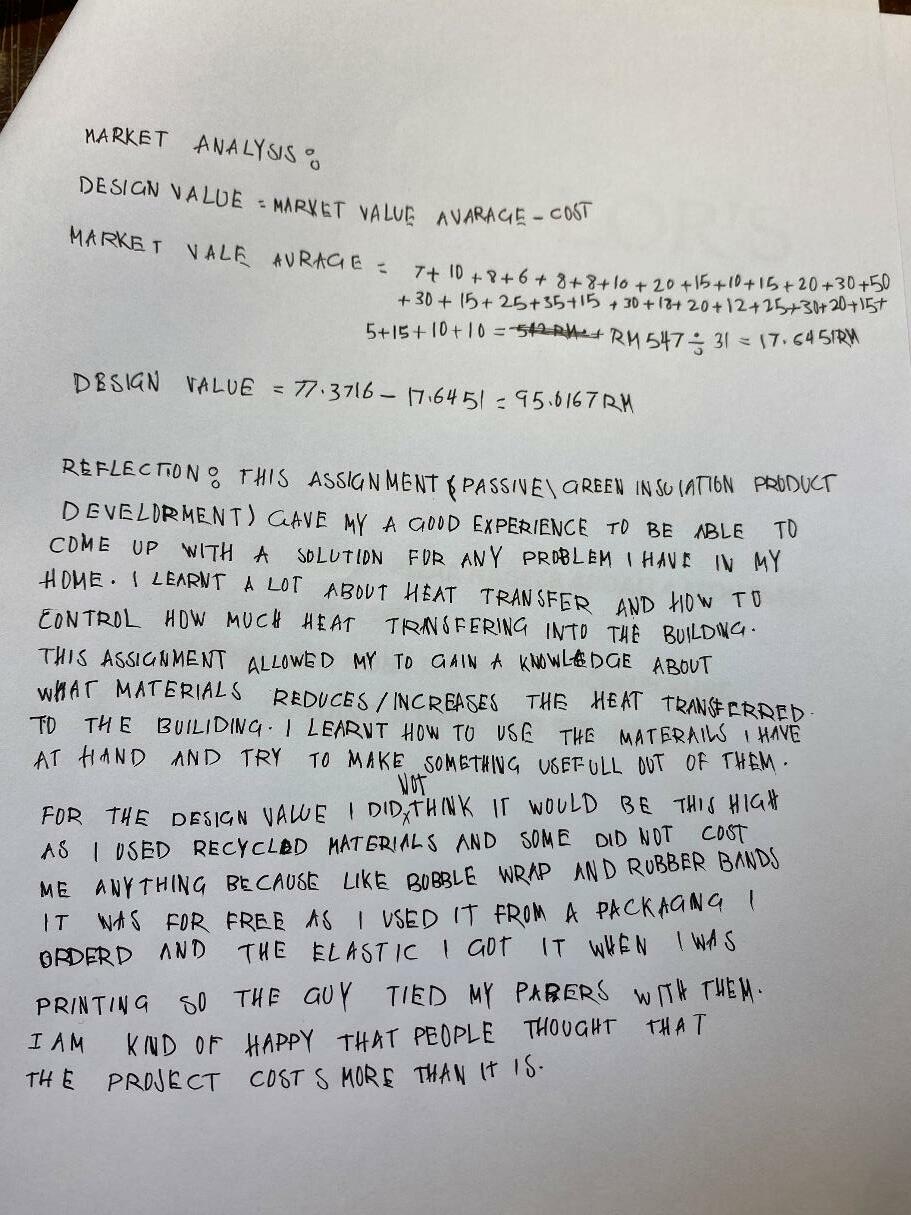

Plywood (6 sticks 11.811inch/30cm). 17.40RM. LED lights. 4.30RM. AA battery 4pcs (only 2 pcs used). 2.10/4 =0.0525x2=1.05RM. Hook 12pcs (only 1pc used). 3.50/12=0.2916RM. Cutter knife. 4.20RM Super glue. 1.20RM. Screws. 1.00RM. Screwdriver. 13.11RM. Hot glue gun. 4.90RM. Left handed Scissors. 15.90RM. Double face tape. 3.00RM. Wood glue. 8.90RM. Nails. 1.70RM. Hook screws 10pcs (only 2 pcs used). 2.10/10=0.21x2=0.42RM. Rubber bands. 0.00RM. Stapler gun. (bought it from a friend). 0.00RM. String. (I took it from one of my shoes). 0.00RM. Bubble wrap (I ordered tuna from Lazada and it came in a huge bubble wrap). 0.00RM. TOTAL 77.3716RM.

**Some of the materials receipts I cannot find as I bought them long time ago so I googled the materials pricing.

NAME : ELKARNEEB ALLAA NAGEEB ABDALLA MOHAMED.

STUDENT ID : 0351182.

MODULE : BUILDING SCIENCE AND SERVICES. FINAL PROJECT.

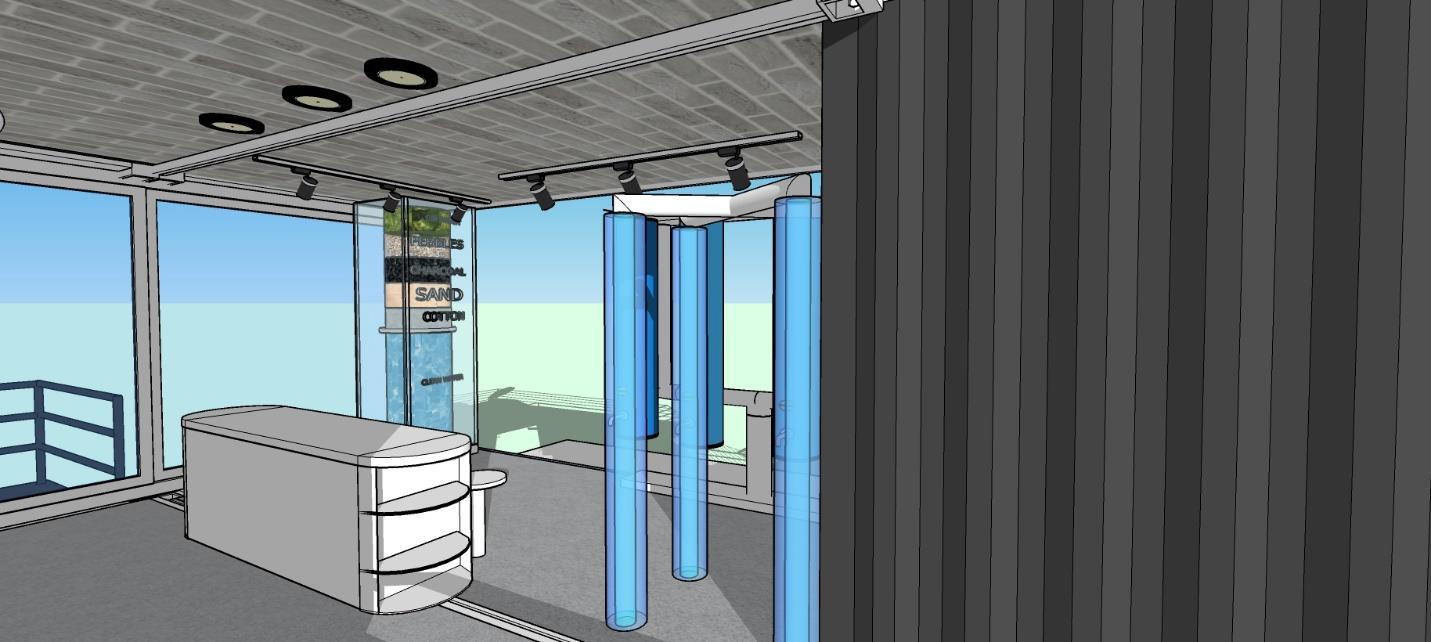

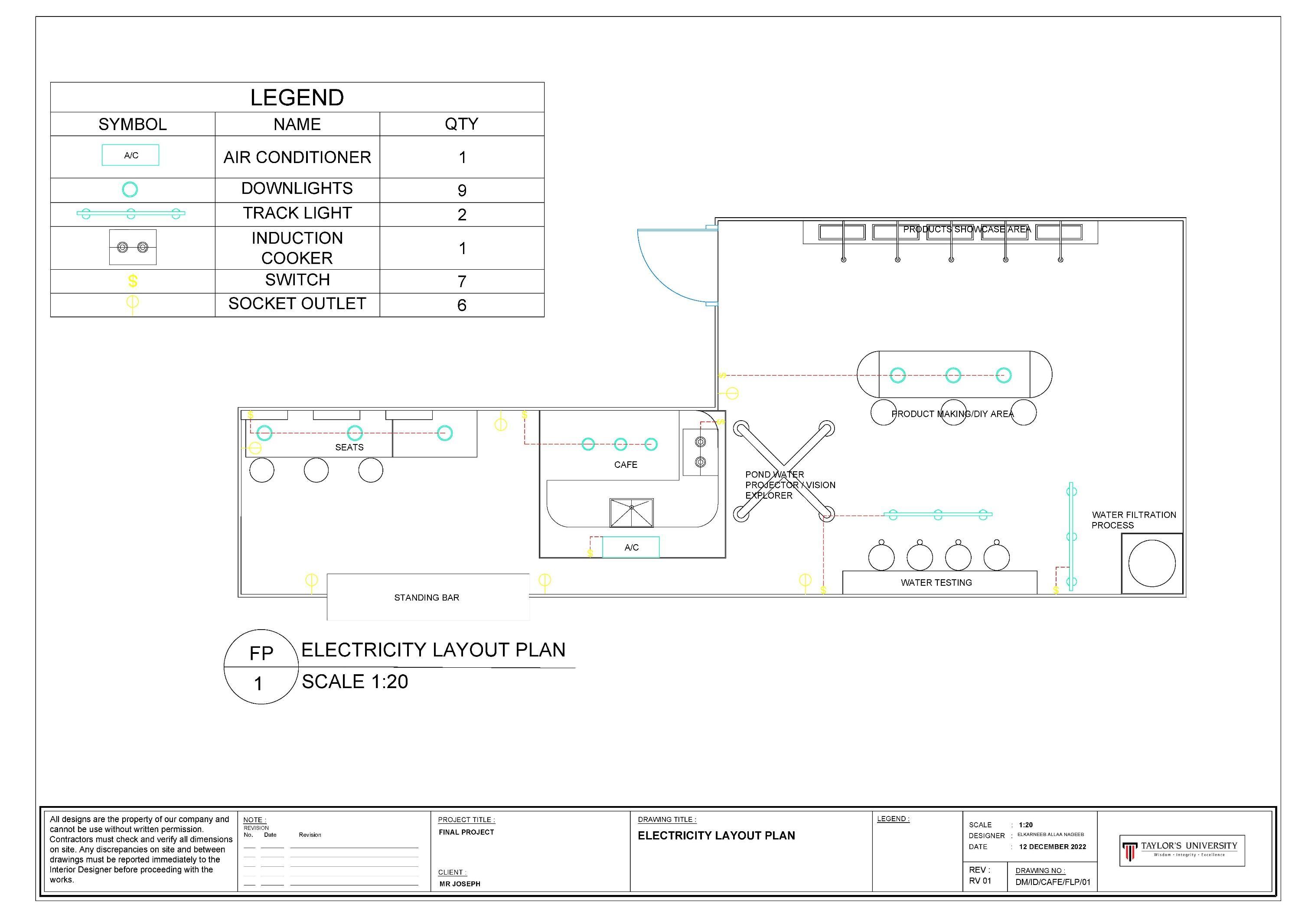

The site I have chosen is the first-floor plan from my IADII final project. The site focuses on the SDG 6 which is Clean Water and Sanitation. My project idea is providing a space where women can have an access to clean water as well as educating them on the process of water filtration and how they can make their own their own sanitary products. My main container has downlight and track lights Apart from that, my place also has a small café space that has a sink, gas stove, downlights, and A/C unit.

In this perspective the downlights are place on top of the café’s table and seats and it is also lighting up the canvas so visitors can read about the prosses of water filtration while drinking.

*The closed area is the café area

Down lights are place on top of the table (workshop area) so women can see clearly while working and doing their own products. The track lights are focusing on the water filtration process and tasting explorer so women can have a nice experience exploring.

Café area has an A/C unit so it makes the space cool for the worker, wall display lighting is provided to light up the place as it is a closed area.

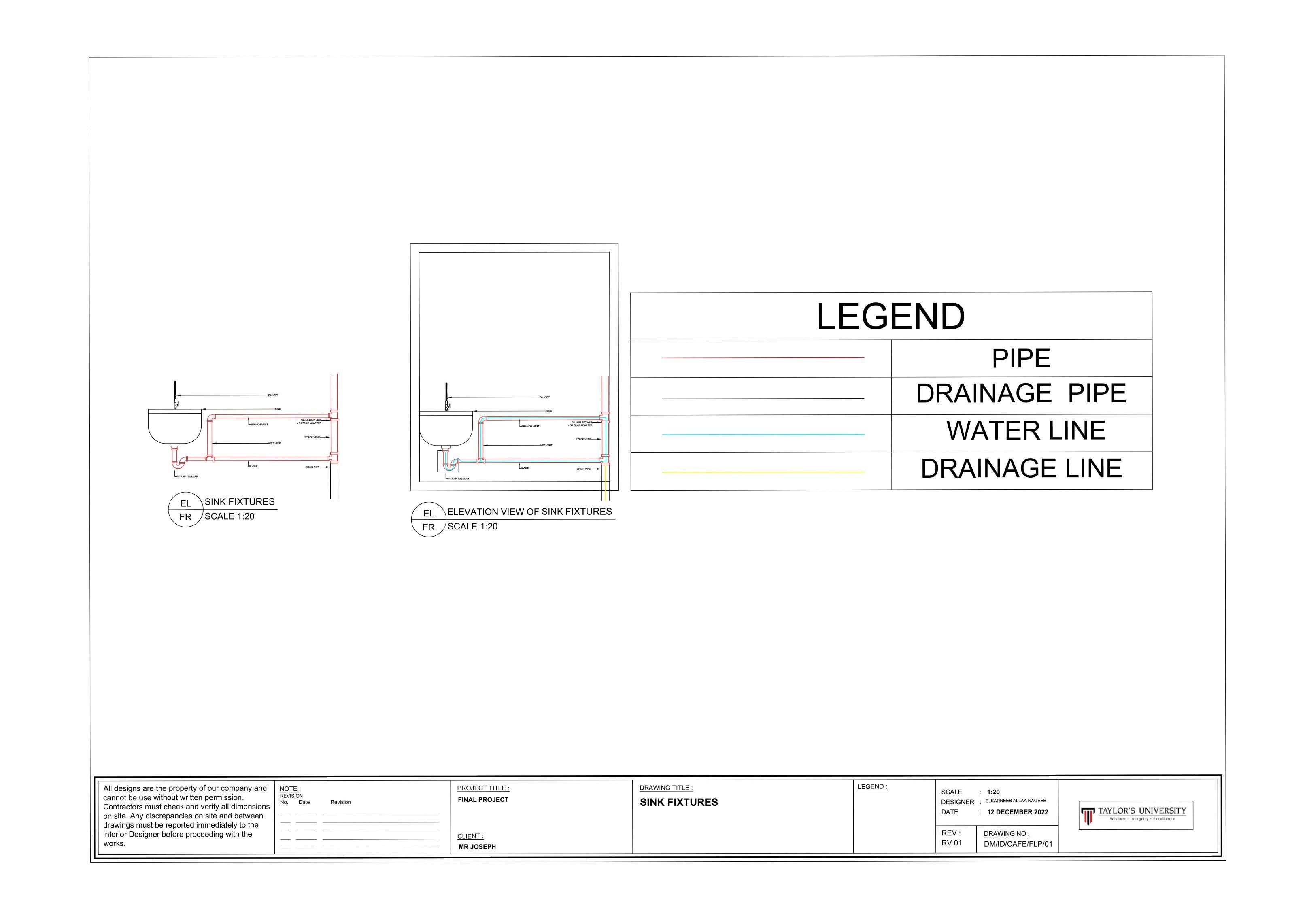

Below the sink in the café area there is a septic tank that acts like a drainage where water get collected in and it can be thrown away later.

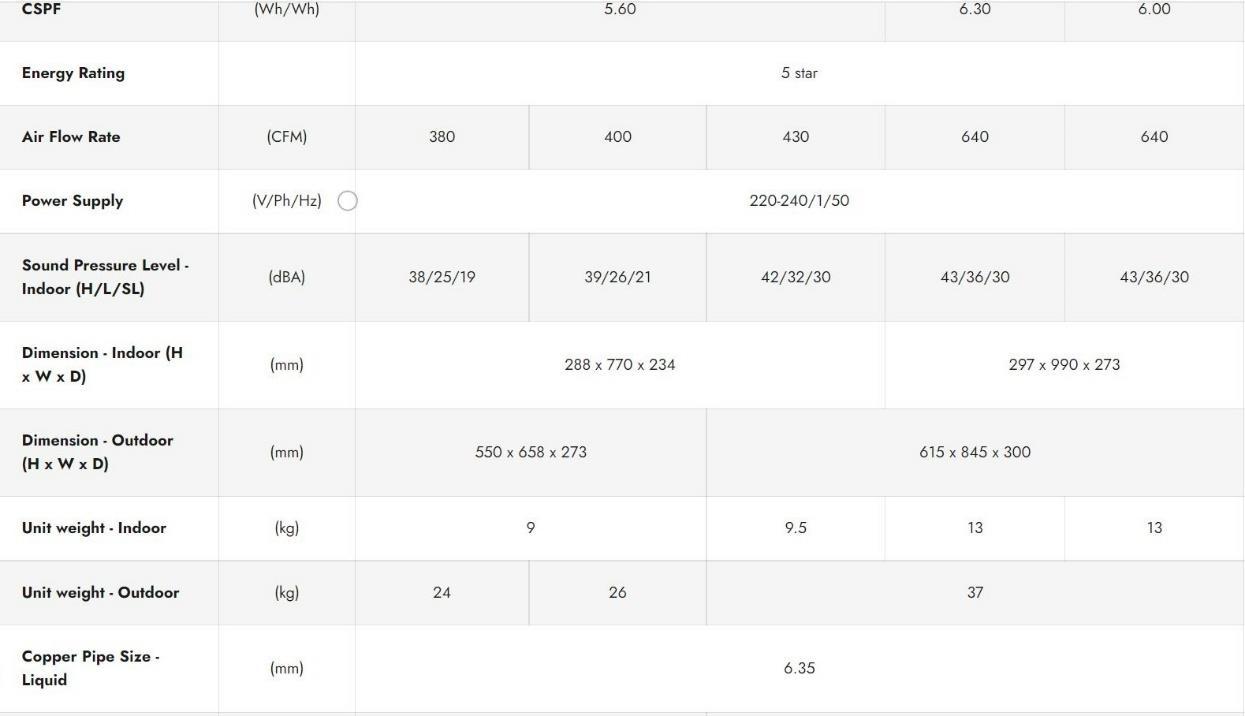

Task 1(b): Designing and Justification of Building Services Selection & Location.

Specifications (from actual product catalogues):

Lightings:

1) LED Downlights:

Are used in the café seating area and the workshop area For the café area the most common and suitable colour temperature of lighting for dining place is warm white colour with colour slightly whiter than 2,700 to 3000 Kelvin as this makes the place more comfortable, welcoming and cosy to the visitors. Also, if the light is too bright it will make the food and drinks look faded in colour so that is the reason, I decided to choose warm colour in the café dining area. For the workshop area, the light colour temperature I chose is bright white between 3500 to 5500 Kelvin as is will increase workers enthusiasm throughout the day, anything higher than 5500K will be too much blue and anything lower that 3500K will make the workers s less productive I used LED lights not fluorescent lamps or incandescent light bulbs because LED lights has a 18% lower electricity consumption compared to fluorescent lamps and 85% less electricity consumption compared to incandescent light bulbs so it saves energy.

I used 6000K light temperature where is the water filtration process and tasting exploring activity as it is best to highlight them.

Specifications:

Vac:

Air Conditioner:

The reason why I used air conditioner unit in the café area is because the worker in the café will feel hot while preparing the food and drinks for the visitors. The air conditioner will make the air fresh and reduce humidity.

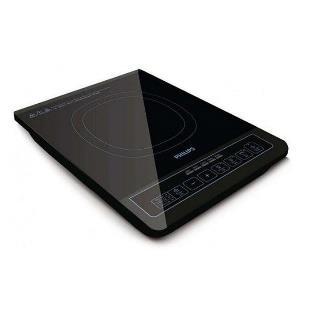

Induction Cooker:

I choose to use induction cooker as it is easy to clean and it has high heat efficiency.

Specifications:

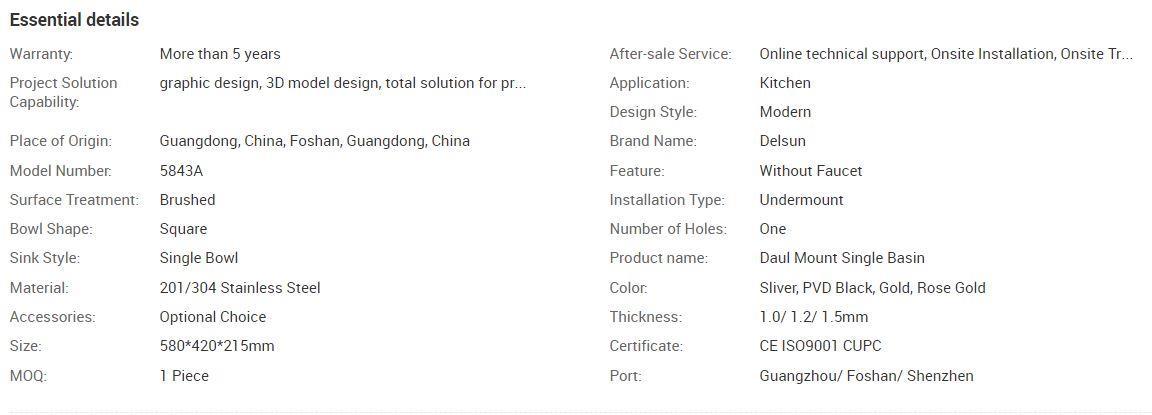

Sink:

I decided to use stainless steel sink as it is cost friendly and cheaper than other materials such as cast iron and granite and because it is durable. Other reason why I chose stainless steel as a material for the sink is because stainless steel is staining and heat-resistant and do not peel.

Specifications: Faucet:

I decided to use a pull-out faucet because of it is flexible design and because you can control it so it does not cause much splashing.

Specifications:

B1.1: Building Services design justification:

A/C sizing calculation for the café:

Room Area= L x W= 1.5m x 2.3m= 3.45m².

Btu/hr= A X 700= 3.45 x 700= 2415Btu/hr.

Estimate occupant in the café room is 2.

2 x 500= 1000Btu/hr.

Estimate heat from electrical equipment (3 lighting and induction cooker).

All lights wattage= 3 x 18W= 54Btu/hr.

Induction cooker= 2100W.

Total W= 1000W + 2100W= 3100W

Total Btu/hr= 3100W x 3.5= 10850Btu/hr.

We should divide the total heat by 9800 to get the A/C size.

10850/9800= 1.1HP.

For big container:

Area= L x W= 39.3700ft x 7.8740ft= 309.9993ft².

Lux= Lumen x Number of lights / Room Area.

Lux of track lights (2 track lights each is 3pcs) = 6000K x 6 / 309.9993 ft²= 116.1292lm/ft².

For small container:

Area= L x W= 19.6850ft x 7.8740ft= 154.9996ft².

Lux of downlights= 4000K x 3 / 154.9996ft²= 77.4195lm/ft².

For café area:

Area= L x W= 5.0360ft x 7.7263ft= 38.9096ft².

Lux= 3000K x 3 / 38.9096ft²= 231.3053lm//ft².

B1.2: Qualitative and quantitative justification (energy use, safety) to be included:

Air conditioner:

Energy= power rating x hours.

Energy= 1200W x 8

1Kw = 1000W

1.2Kw = 1200W

Energy= 1.2Kw x 8= 9.6kw/hr.

Per month (30days) = 9.6 x 30= 288kw/hr.

Café lighting:

Energy= power rating x hours.

Energy= 15W x 8

1Kw = 1000W

0.015Kw = 15W

Energy= 0.015Kw x 8= 0.12kw/hr.

Per month (30days) = 0.12Kw x 30= 3.6kw/hr.

Café dining area lighting:

Energy= power rating x hours.

Energy= 18W x 8

1Kw = 1000W

0.018Kw = 18W

Energy= 0.018Kw x 8= 0.144kw/hr.

Per month (30days) = 0.144Kw x 30= 4.32kw/hr.

Workshop area lighting:

Energy= power rating x hours.

Energy= 18W x 8

1Kw = 1000W

0.018Kw = 18W

Energy= 0.018Kw x 8= 0.144kw/hr.

Per month (30days) = 0.144Kw x 30= 4.32kw/hr.

Track lights (2units each 3pcs):

Energy= power rating x hours.

Energy= 10x (2)W x 8

1Kw = 1000W

0.02Kw = 20W

Energy= 0.02Kw x 8=0.16kw/hr.

Per month (30days) = 0.16Kw x 30= 4.8kw/hr.

Induction cooker:

Energy= power rating x hours.

Energy= 2100W x 8

1Kw = 1000W

2.1Kw = 1500W

Energy= 2.1Kw x 8= 16.8kw/hr.

Per month (30days) = 16.8Kw x 30= 504kw/hr.

Alaa Nageeb

Alaa Nageeb