ELIZAVETA VERETILNAYA

Architect & Researcher

I am a multidisciplinary architect with close to 2 years’ experience developing design solutions for small and medium architectural practices for public spaces, cultural, office buildings, and urban scale projects. My research endeavours are focused on emergent technologies of Computation and Digital Manufacturing combined with scientific advancements from the fields of Material Science and Robotics for the development of design methodologies and construction techniques for circular built environments.

Barcelona, Spain

elizaveta.veretilnaya@gmail.com

+34 619 23 39 42

experience

nov 2021feb 2022

Institute for Advanced Architecture of Catalonia (IAAC) | Barcelona

Multimedia Art Installation ‘Aigua Invisible’ for LLUM BCN 2022 Light Art Festival Project Coordinator

Handled project planning, production and budget; oversaw project development from the stage of design to fabrication, assembly and disassembly; provided support to animation and sound design team; created visual material for project social media account

aug 2019sept 2020

A&L Architects | Moscow

Architectural Assistant

Worked on stages of concept, design development and construction;

Generated technical documentation for office and commercial buildings (in Revit); Created visual identity for exhibitions, 3D visualizations for competition projects

june 2018oct 2018

Moscow Committee for Architecture & Urban Planning | Moscow

Architectural Intern

Worked on model making, technical drawings, schematic design, presentation drafting and document writing for urban development and infrastructural projects

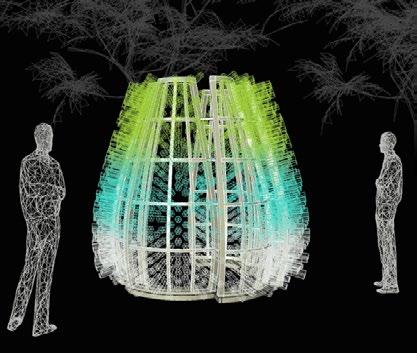

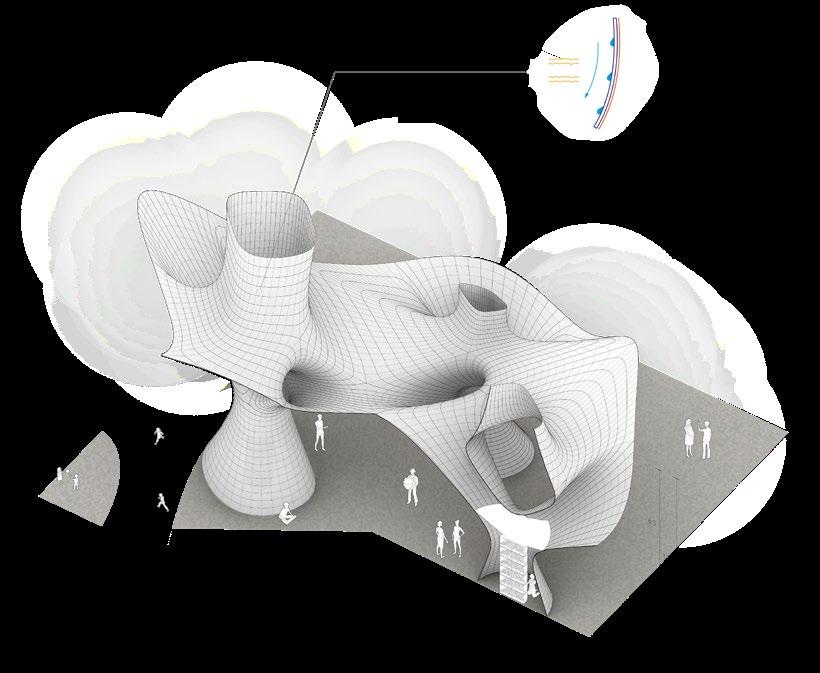

AIR WELL: FROM DROP TO FRUIT

Introductory studio G2: Architecture of Algorithms Team project | IAAC | 2020

Contribution to the project: design development, model making, parametric modelling, graphics design

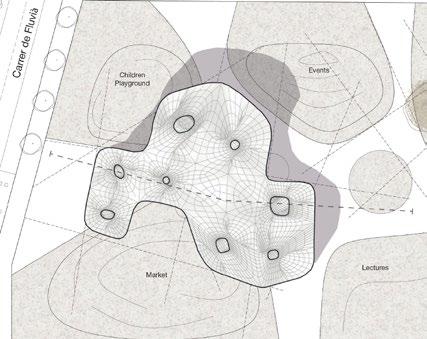

This project foresees the design of an innovative public spaces in a former industrial neighbourhood of Barcelona - Poblenou. The focus of the project is one portion of Poblenou which is characterized by low to middle class residential buildings, art clusters, and newly introduced green spaces. The

Studio Advisors: Rodrigo Aguirre, Ivan Marchuk

design proposal involves an experimental public space where people can socialize, attend a variety of workshops, and most notably, grow and consume their own food. The concept re-imagines the form of an industrial chimney into a passive water collecting machine that hosts a hydroponic vertical farming system.

History

The site is located in Provencal de Poblenou at Carrer Pere IV, a historical axis of Barcelona, which is part of the former industrial district of Poblenou. In the XIX century Pere IV was serving as a vital connection of the industries to the town of Mataró. After the industrial activity subsided, many factories became empty. In 2000 the city made a special plan for the area which is called 22@district. It foresees the conversion of the industrial area to an innovative hub with three main goals: conservation of the industrial heritage, development of infrastructures, and sustainable strategies.

Wind and solar radiation analysis

The environmental analysis reveals constant solar radiation throughout the day. The site experiences constant winds, coming from the south

Form finding

Modules catalogue

Reversing industrial chimney

New spaces for local community

The design concept reverses the classic shape of an industrial chimney that was originally conditioned to constantly emit CO2 and substitute its harmful function with a sustainable one. By exercising the main principles of a dew water collection system, the chimney’s funnel-like shape is designed to direct the collected water to an underground tank that stores it for vertical farming. Any excess water can be guided to the existing sustainable drainage system which is already functioning within the neighbourhood.

Vertical farming unit

Vertical farming requires 70-90% less water compared to traditional farming techniques. It allows for more efficient use of the limited urban surface area that is available for farming. The team designed a controlled environment unit for growing vegetables, herbs and fruits. It incorporates a suspended growth bed above the hydroponic solution that carries the necessary nutrients. These units can be stacked and form a tower with a common system of pipes in the centre.

water collecting surface funnel

farming area vertical farming units pipe system

LEDs glass

plant growing bed

cover hydroponic soluiton

hot air condensation

insulation layer

Passive water collection system

Dew collection is an under-explored alternative source of fresh water. The most important factors contributing to the water collection performance of a passive system are: relative humidity, wind, a funnel-shaped surface constructed with a material of high emissivity,

inclination and exposure area. For water collection projects in Spain were extensively studied. While they are using different water collecting technologies and are situated in rural areas, they provided insight into the water collecting process in the local climate.

Water runoff simulation

Solar radiation analysis

Crop turn over time and water needs

With total area of 170,9 m2 for farming several types of crops were distributed along the chimney’s surface. By examining the turnover time of selected crops, as well as their average water consumption, the crops are

categorized based on their efficiency. Crops with a combination of low water needs and fast turnover time (3 weeks in case of lettuce) are prioritized and given a bigger share of the available farming area.

Fabrication statistics

Material: 16 polypropylene sheets, 1050 x 750 x 0.5 mm

Number of strips: type A: 108 + type B: 120 = 228

Number of holes: 1600

Connectors: 1600 nylon nuts and bolts

Cutting time: 10 hrs

Assembly time: 12 hrs

Final model dimensions: 1028 x 1028 x 563 mm

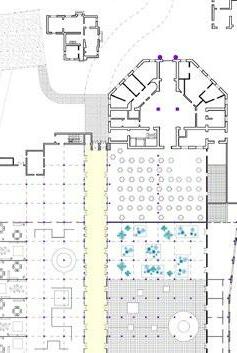

YAC KIDS FACTORY

Architectural competition | Honourable mention | 2019

Contribution to the project: concept development, 3D modelling, CAD drawing, and graphics design

Can fairies live in the majestic remains of an industrial architecture? The former pottery of Laveno Mombello, Italy, is a 27,000 m2 titan that fell asleep on the banks of Lake Maggiore. It is a building with an intriguing layout and a pattern, where huge open spaces co-exist with hyperbolically stretched out, narrow halls and corridors. This project presents an idea of an abandoned utilitarian

Project team: Elizaveta Veretilnaya, Sofia Pozdeeva, Ekaterina Pozina

building that has been redefined and revitalized into the hub for education, socialization and entertainment, creating a central public centre for all little citizens of Laveno Mombello. By doing so, it opens a majestic architectural complex to childhood, and transforms it into one of the most impressive industrial architectures of Europe into the ‘largest kindergarten in the world’.

Inside and outside: House street

Breathing life into an old factory

The design treats the old factory like city inside the city with its own main street of little house-like modules. The House street is the principal artery of the factory that courses along the central axis of the building, accumulating all programmed activities around it, bringing people of all ages together to have fun and enjoy all kinds of experience, from art classes and workshops, to theatre studio, to sports and multi-level playground that is connected to a large open public courtyard.

2nd level playground

1st level playground art gallery

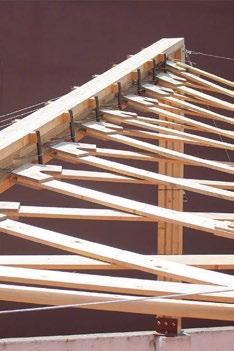

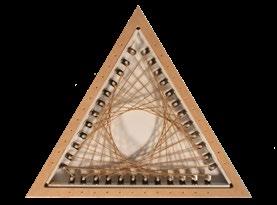

TIMBER IN TENSION

Temporary installation Team project IAAC | 2021

Contribution to the project: project management, team coordination and scheduling, physical prototyping and digital fabrication assistance

This experimental roof structure bridges the gap between digital and physical worlds of computation by tackling technical questions of structural design for timber, joinery, fabrication, logistics, assembly and teamwork. By being committed to the goal of ‘doing a lot with little’, the project explores structural timber design through computational

Tutors: Manja van de Worp and Raimund Krenmueller Collaborator: Shyam Francesco Zonca

analysis, physical prototyping and digital fabrication. It investigates how digital design and simulation together with hands-on experimentation can help create innovative and enjoyable public space. A space that transforms a university rooftop into an environment that promotes social interaction, and provides a small escape from the intensity of student life.

Context investigation

Timber, most prevalently, is used in structures that take pure compression (eg. column), or a combination of compression and tension loads (eg. beam or truss) in its system. However, it is rarely used for elements that are in pure tension, which is exactly how timber is applied in this roof structure. The structure is based on an anticlastic surface where the principal stress lines

are positioned along its UV diagonals. Having this in mind, multiple proposals that follow a network of catenary and anticatenary curves were generated and run through structural and environmental simulations. The final proposal incorporates design measures that would allow the structure to stay stable, while being able to act against the self-weight forces and a strong wind uplift.

Layout setup

Timber grid development

Grid statistics

grid

TIT

number:

grid

Environmental factors: moderate northbound wind extensive solar radiation (south)

grid

Detailing and joinery

Construction challenges

The process of construction faced many challenges ranging from design and fabrication to logistics, coordination and assembly. One of them was to support the structure with the existing structural conditions of the roof. For that, two portal frames were mounted directly on the roof’s parapet,

redirecting the load from the columns onto the walls of the existing building. Furthermore, a detailed construction sequence and specific props were devised to pre-assemble the grid with the curved form already in place before the commence of lifting and mounting process.

TAILORED LANDSCAPE

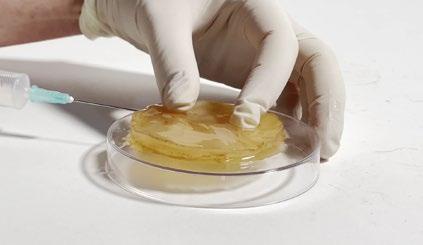

Exploration of Design Potential of Microbial cellulose in Biofabricated Architecture Master Thesis | Circular Biomaterials Research Cluster IAAC | 2022

Thesis Advisors: Marcos Cruz (UCL) Ricardo Mayor (IAAC)

Tailored Landscape investigates architectural applications for the consolidated material research of microbial cellulose (SCOBY) developed and implemented by multidisciplinary designers in building skin solutions by examining biofabrication techniques practised in the fields of sustainable fashion and textile. The research aims

to develop a comprehensive design methodology through hybrid fabrication strategies using microbial cellulose as a primary shaping material for skin structures comprised of inflated interconnected components with robotically pre-woven tensioned threads that act as fabric reinforcement, flexible connectors, and physical boundary for inflation.

Material experiments

Inflation and biocompatibility with natural fibers

The research methodology operates between four objectives: material comprehension, development of hybrid fabrication strategies, design proposal for macroscale material-informed structure, and development of a physical prototype as proof of concept. The first phase sets up a series of experiments investigating the growth

of microbial cellulose in accordance with culture medium type, sugar content and growth accelerators. The result is assessed by the criteria of film growth speed, thickness, and texture. Additional experiments are performed to test the film’s compatibility with natural fibers (jute, hemp) as a way to introduce integrated reinforcement network.

SCOBY

timeline

7 days (initial fermentation)

14 days (5 mm thickness)

21 days (10 mm thickness)

days (infllated)

(green

(hemp fibers)

Hybrid fabrication workflow

Adapting the formwork for scoby growth

Second phase of the thesis is dedicated to the development of a computational workflow for robotic weaving and testing out digital fabrication methods that could adapted to the conditions of SCOBY growth. Multiple prototypes were produced to establish optimal

parameters for robotic weaving, such as end effector configuration, tool path strategies, maximum weaving resolution, etc. Growth cell variations were and tested against robot pulling force during weaving in combination with different thread types and thicknesses.

adapted container setup mature scoby as growth accelerator

final result: biofabricated reinforced cell

Proof of concept

Physical prototype

This 1:5 scale prototype is inspired by 3d textiles - fabrics or meshes with integrated components (wooden panels, 3d printed patterns, metal scales, etc.) that enable the fabric’s seamless transition

from planar surface to volumetric geometries. The 26 cells are reinforced and interconnected by threads, allowing flexibility in its joinery, thus giving a lot of freedom for the designer.

1200

Fabrication statistics

Cell count: 26

Nail count: 758

Thread length: 30m (jute and hemp, 2mm)

Volume of starter liquid: 13.6 litres

Liquid used for cultivation : 14.8 litres

Total liquid used: 28.4 litres

[NON]CARBON COPIES

Towards bi-material casting of functionally graded structural elements Team project | IAAC | 2021

Contribution to the project: design development, graphics design, digital fabrication expertise, robotic fabrication

Non-carbon copies is a project that focuses on the development of a multi-material concrete casting technique within functionally graded design that provides sustainable and material efficient production method for the construction industry. Biochar was selected and studied as partial substitute to concrete, thus facilitating material savings and

Studio Advisors: Areti Markopoulou, David Andres Leon, Raimund Krenmueller

substantially lowering the amount of embedded carbon in concrete structures. Based on the results of structural optimization of building elements a multi-material casting system operating in conjunction with robotic technologies was developed so concrete can be cast where it is structurally required, while biochar-based mix was used to fill the rest of the formwork.

Material testing

In order to understand the principal material behaviour and properties of the composite, a setup of different material recipes for casting prototypes is created. In each recipe, different combination of materials and water ratio are tried. After the prototypes were cast, they were evaluated by its weight, helping to draw several conclusions about the composites:

1. The sample with the highest ratio of biochar is the lightest composite.

2. Incorporation of biochar did not accelerate or delay the cement hydration.

3. Increased percentage of biochar = higher demand in water content.

4. Increased fibre length = stronger binding behaviour

Example of material testing composites: set of biochar, OPC (ordinary portland cement) and fine sand

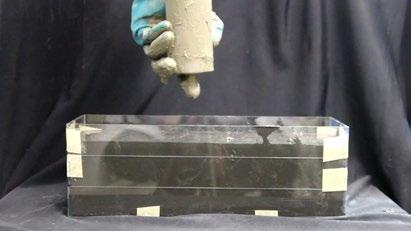

Fabrication techniques exploration Manual casting

For the stage of manual casting a set of fabrication techniques was developed, executed and evaluated within a holistic approach. The proposed fabrication strategies were distributed in two categories: physical boundary (techniques that require the use of guiding separators for clear

material deposion) and seamless casting that investigates binding behavior between two material mixes. In the end of manual casting stage the decision was made to combine the concepts of voxel grid technique with free bi-material pouring and adapt it for future robotic autonomous system.

Automated robotic casting

Based on the results of

casting stage

technique helped achieve the highest accuracy of material pouring. To overcome the technique’s limits, the project integrated a custom robotic fabrication workflow that facilitated better control over multi-layered bi-material deposition.

From the results of material exploration stage, two suitable mixture compositions were created and adapted for the robot. Crucial aspects for fabrication, such as material deposition timing,

path, end effector configuration

reinforcement options were investigated and realized in parallel.

End effector design

Prototype development

Geometry optimization

Throughout the investigation the goal was to produce a physical prototype based on the structural and material optimization of scaled down beam sample. Based on the input parameters for computational protocol, such as target density, cell size, load and support

cases, a target optimization result is acquired, clearly demonstrating the distribution of two materials for casting process that still uses conventional formwork, but allocates both cement and biochar-based mixes exclusively where it is structurally required.

Optimization ResultOptimization setup

Target geometry

Model setup

Target Density: 0.26

Smoothing: 0.30

Cell Size: 0.1667

Load: 500N/m²

Expected result

Showcase

Computational workflow

Prefabricated material optimized structural elements

Presented diagrams showcase the developed computational workflow that rethinks the case of a traditional beam-column concrete structural system by breaking it down into individual elements (columns, beams and slabs). A number of specific load and support conditions is set to perform structural analysis and material optimization, introducing

Building structural system

Optimization result

biochar-concrete mix to each element, thus reducing the amount of cement that would be used for manufacturing. The data derived from both operations shows qualitative reduction of mass and embodied carbon in each element, thus solidifying the potential of proposed process for customization and prefabrication.

Optimization setup

Main Beam 1 Load: Ground Floor: 3860 kN

First Floor: 3774 kN

Second Floor: 3650 kN Element Volume: 0.81m³

Pure Cement Mass: 2259.9 kg

Main Beam 2 Load: Ground Floor: 3860 kN First Floor: 3774 kN Second Floor: 3650 kN Element Volume: 1.01m³

Pure Cement Mass: 2999.7 kg

Main Beam 3 Load: Ground Floor: 600 kN First Floor: 597 kN Second Floor: 595 kN Element Volume: 0.27m³

Pure Cement Mass: 801.9 kg

Column Load: Ground Floor: 19806 kN First Floor: 13153 kN Second Floor: 6729 kN Element Volume: 1.44m³

Pure Cement Mass: 4276.8 kg

Slab Load: Ground Floor: 4804 kN

First Floor: 4780 kN

Second Floor: 4763 kN Element Volume: 7.56m³

Pure Cement Mass: 22453.9 kg

Ground floor

Mass: 1967.0 kg Biochar Ratio: 40.0% Cement Ratio: 60.0% Embodied Carbon: -277.5 kg

First floor

Mass: 18860.5 kg Biochar Ratio: 16.0% Cement Ratio: 84.0% Embodied Carbon: -120.0 kg

Mass: 1740.5 kg Biochar Ratio: 28.0% Cement Ratio: 72.0% Embodied Carbon: -170.1 kg

Second floor

Mass: 1710.3 kg Biochar Ratio: 51.0% Cement Ratio: 49.0% Embodied Carbon: -382.5 kg

Mass: 10777.4 kg Biochar Ratio: 52.0% Cement Ratio: 48.0% Embodied Carbon: -390.0 kg

Mass: 1582.9 kg Biochar Ratio: 29.1% Cement Ratio: 70.9% Embodied Carbon: -176.8 kg

Mass: 1438.6 kg Biochar Ratio: 62.0% Cement Ratio: 38.0% Embodied Carbon: -465.0 kg

Mass: 7858.5 kg Biochar Ratio: 65.0% Cement Ratio: 35.0% Embodied Carbon: -487.5 kg

Mass: 1326.8 kg Biochar Ratio: 41.9% Cement Ratio: 58.1% Embodied Carbon: -254.5 kg

AIGUA INVISIBLE

Barcelona LLUM Festival | Multimedia Light installation Team project | IAAC | 2022

Contribution to the project: concept design, project management, animation and sound design, digital fabrication assistance

Water is the essence of life. It leaves its marks all around us, some of which are difficult to see. This work shares knowledge about the notion of ‘water footprint’ - water, that is invisible to consumers, but utilized for production of most objects and materials we use every day, from goods to energy, to manufactured products, but mostly that is hidden in our food. The installation operates within the

Tutors: Pablo Ros and Cristian Rizzuti Collaborator: Shyam Francesco Zonca

concept of data visualization showing ‘water footprint’ of the most common food products consumed every day in Europe with three colours: blue - for fresh and ground water, green - for water in soil after rain, and grey - for polluted water. The data is represented through a series of dynamic animation sequences accompanied with sound with an aim of providing an interactive experience that is both educational and entertaining.