DISPATCH

As we move forward into 2025, I want to take a moment to express my gratitude for your continued trust and partnership. Each year presents new challenges and opportunities, and together, we are shaping a future that is stronger, smarter, and more sustainable.

This year, we gathered in San Antonio, Texas for our annual Ash Grove Conference with the theme of “Future Ready.” Through insightful discussions, we explored strategies to maximize our full potential in every aspect of our business – ensuring we are prepared for both the challenges and successes that lie ahead.

At the heart of our journey is our unwavering commitment to safety – both physical and emotional. We recognize that a workplace where employees feel valued, supported, and empowered is key to our collective success. By reinforcing our safety culture and prioritizing well-being, we are building a stronger foundation for the future.

Through it all, we remain guided by our purpose – “We stand together to reinvent the way our world is built.” We believe that prioritizing our people, leading with integrity, and holding ourselves to the highest standards of performance will continue to drive us forward. And as we look to the future, innovation remains at the core of our approach – embracing new ideas, technologies and ways of working to ensure we continue evolving and leading in our industry.

This commitment to progress is reflected in how we are enhancing sustainable materials and optimizing our operations for greater efficiency and environmental impact. We are also deepening our collaboration with customers, working together to develop solutions that not only meet today’s needs but also anticipate the demands of tomorrow.

As we look ahead, our focus remains clear: to grow, to innovate, and to create lasting value for our people, our partners, and our planet. Thank you for being a part of this journey. The best is yet to come.

Serge Schmidt Ash Grove President

It is our pleasure to welcome Luis to the Mississauga Cement plant. Luis is a recognized expert in cement plants who has extensive experience in all aspects of production management.

Luis comes to us from Lafarge Africa, where he was the General Manager at their Ewekoro I and II locations in Nigeria. Before that, he worked for FLS as the Operations and Maintenance Plant Manager in Cairo Governorate, Egypt. Previously to that, he was the Optimization Manager at the CRH Tunstead Plant and held numerous roles at CEMEX in both the United Kingdom and Mexico. He received his Bachelor of Science in Chemical Engineering from Instituto Tecnologico de Ciudad.

With 30 years of progressive experience, he has a strong track record of delivering successful results in every function, adding value and exceeding expectations through creative idea generation, collaborative problem solving, intuitive business judgment, and by focusing on continuous improvement and quality.

We look forward to collaborating with him to increase productivity and achieve sustained organizational performance.

At CRH, sustainability has been embedded in our business strategy for decades. Through the deep portfolio of products and services we provide, we are helping to deliver a more resilient and sustainable built environment.

Advancing our performance remains a constant focus. In 2024, we recycled 44.7 million tonnes of wastes and by-products, sourced internally and from other industries, into circular solutions for our customers, reinforcing our position as the leading recycler in North America. We progressed on our target to deliver a 30% reduction in absolute carbon emissions by 2030, keeping us on the path to achieving our ambition of becoming a net-zero business by 2050. We reduced our Scope 1 and Scope 2 CO2e emissions by 4% in 2024.

c.139bn liters of water recycled at our operations

44.7m tonnes of wastes and by-products recycled 4% reduction in Scope 1 and Scope 2 (Market) CO2e emissions

Our report, provide details of how our Framework for a Sustainable Future is centered on helping to solve three complex global challenges — water, circularity and decarbonization. By focusing on developing products, services and solutions for our customers that help to address each of these three global challenges, we are creating value for all and driving future growth for CRH.

Our approach is underpinned by our strong sustainability foundations — protecting the natural world, helping our people and communities to thrive and ensuring we operate as a responsible business. We have always had a culture of reinvention and continuous improvement. Individually our businesses help make homes, buildings and critical infrastructure that stand the test of time for generations to come.

We are innovating at every level to anticipate the changing needs of construction and respond to market demand.

Read our 2024 Sustainability Performance Report to discover how we hold ourselves accountable and make responsible business decisions in the best interests of our and our customers’ ongoing success.

We create value by uniquely integrating our materials, products and services to better serve our customers’ needs and advance our progress in water, circularity and decarbonization.

We continue to invest in our sustainability foundations: protecting the natural world, helping our people and communities to thrive and ensuring we operate as a responsible business.

Across the business, Ash Grove teams are engaging in a variety of projects to make the way we do business more sustainable. From generating efficient upgrades to dated equipment to imagining more environmentally conscious cement solutions for our customers, we are reimagining the way we do business to better serve our customers and better protect the environment.” Cement is considered to be the largest contributor to the concrete industry’s carbon footprint, accounting for ~85-90% of concrete emissions. In a situation like this, the need for Supplementary Cementitious Materials (SCM’s) has never been more crucial. As well, SCM’s play an important role in improving the strength, durability and life cycle of concrete structures. However, traditional supplies of SCM’s like coal fly ash, & blast furnace slag have been on a decline because of energy and steel industries slowly opting out of coal-based processes. The demand for cementitious products is going to keep increasing on the road to 2050, and it is of critical importance that the industry can meet this demand while lowering CO2 emissions and employing sustainable manufacturing practices. Such challenges necessitate the development and adoption of new locally sourced and produced SCMs to ensure the resilience and sustainability of the concrete industry.

Carbon Upcycling Technologies is a Canadian-based technology company enabling localized SCM production from

alternative feedstocks. Carbon Upcycling’s technology utilizes point-source CO2 from flue gas to enhance various material feedstocks into high performing SCMs to fill the void left behind by traditional materials. Depending on the material, a portion of the CO2 from flue gas can be permanently sequestered into the SCM, further reducing carbon emissions.

We are thrilled to announce that Carbon Upcycling has partnered with Ash Grove Cement to deploy its first industrial project at the Mississauga plant. Its technology will produce a high-performing cementitious material using byproducts from locally sourced industries and permanently sequester CO2 emissions produced from the cement kiln.

“We have chosen to further develop our existing partnership with Carbon Upcycling as its technology solution aligns directly with our circular, zero-waste sustainability values. The cement plant integration we are supporting means this technology will be deployed at commercial scale in one of the largest cement plants in Canada, demonstrating a cost-effective, circularity-based method of producing low-carbon cement.” says Eduardo Gomez Mendoza, Head of CRH Ventures.

Please reach out to your local Ash Grove Commercial and Technical Services team members to learn more about this exciting new project and product!

Carbon Upcycling offers a low-carbon, high-performance material solution.

CO2 emissions are permanently sequestered and used to replace a portion of cement in concrete, significantly reducing its emissions across a projects lifecycle*.

CLIMATE RESILIENCY

Enhanced materials provide greater resiliency to environmental factors like chloride and sulphate attacks, meaning concrete that’s not just stronger but lasts longer.

Carbon Upcycling sources local, underutilized materials to upcycle into lowcarbon cement alternatives – enabling a circular, zero-waste economy.

Carbon Upcycling provides the next generation of building materials for sustainable development.

* CO2 sequestration in applicable material chemistries

The Mississauga Cement plant is upgrading one of our main production mills to a new high efficiency separator. As we commission this new piece of equipment, samples are being collected and tested to evaluate both plastic and hardened concrete properties to ensure there will be no changes in quality and workability for our customers. In fact, we plan to see an improvement!

With this upgrade we can expect more efficiency in our mill system, allowing Ash Grove to continue to provide superior products to our customers. This new separator will produce a refined particle size distribution, increasing reactivity and contributing to reducing water demand. Secondly, the new upgrade will increase

Ash Grove’s GUL production, further ensuring that our customers cement demands are met, even during the busiest times of the year.

In combination with our other mills, Ash Grove will be able to continue to provide consistent high-quality products.

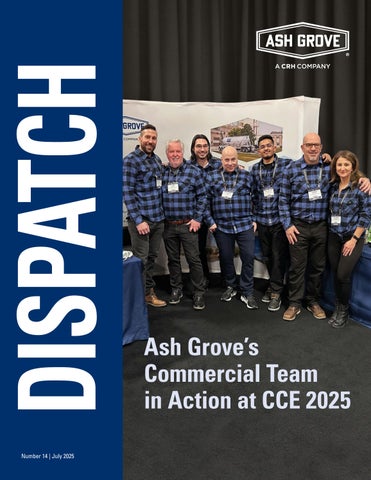

The first quarter of 2025 proved to be both busy and rewarding as Ash Grove Senior Market Managers John Hellyer and Gord Cawker travelled to several key industry events. Their journey not only showcased the latest innovations in concrete and precast technology but also highlighted the importance of building strong relationships and enjoying a bit of adventure along the way.

Las Vegas, Nevada

January 21–23

Kicking off the year with energy and enthusiasm, John and Gord headed to the 51st annual World of Concrete show in Las Vegas. This premier event attracted over 57,000 attendees and more than 1,500 exhibiting companies, all eager to explore innovative products, live demonstrations, and dynamic competitions. Amid the hustle and bustle of the show floor and the excitement of exploring the famous Las Vegas Strip, the SpecMix 500 competition stole the spotlight. In a thrilling contest featuring 27 of the world’s finest masons, Cole Stamper from Wheatley, KY, along with his brother Forest, impressed everyone by laying 612 bricks in one hour to secure both first place and the coveted SPEC MIX TOP CRAFTSMAN title. John and Gord embraced every moment— from networking over hearty meals with customers to experiencing the vibrant energy of the event.

Next, the duo journeyed to Indianapolis for The Precast Show, North America’s largest trade event dedicated to the precast industry. This event offered a comprehensive mix of educational sessions, plant tours, and networking opportunities designed to spark new ideas and business ventures. Although a slight dip in Canadian attendance was noted due to market concerns, John and Gord made the most of the experience by ensuring a well-organized schedule. They even managed a 12-hour drive from their home offices in Ontario (Stirling & Mulmur), taking in the charm of Indianapolis’ downtown and sampling its excellent culinary scene. And for those who know Gord’s penchant for memorable playlists, the road trip was as entertaining as it was productive (although John begs to differ).

In Toronto, the Canadian Concrete Expo provided a focused look at the latest trends in the concrete and aggregate industries. As Canada’s only national trade show of its kind, the event drew a diverse crowd—including concrete specialists and general contractors keen on innovative construction techniques. At the Ash Grove booth, team members from various groups collaborated closely to field questions and showcase their expertise, turning the experience into an excellent team-building opportunity. Even a bit of inclement weather couldn’t dampen the spirits of the attendees, highlighting the resilience and dedication of everyone involved.

Orlando, Florida

March 4–7

Wrapping up the quarter, John and Gord attended the CCPPA Annual General Meeting in Orlando. Held just before the winter break, the AGM offered a mix of professional development and leisure. One of the most memorable highlights was a guided tour of the Kennedy Space Center, led by former astronauts Bob Springer and Don Thomas. Their fascinating stories of courage and exploration resonated deeply with the group, sparking conversations that extended well beyond the confines of the event. A few rounds of golf and the chance to explore Orlando’s local attractions rounded out the trip, leaving the team energized and optimistic for the year ahead.

John and Gord’s travels through these significant association events were more than just a series of business trips—they were a testament to the value of blending industry engagement with genuine camaraderie. Their experiences in Las Vegas, Indianapolis, Toronto, and Orlando not only advanced our professional goals but also reinforced the importance of personal connections and team spirit. As we move forward into 2025, their journey serves as an inspiring reminder that hard work and a touch of adventure go hand in hand in driving success.

Hey Tech Team,

Sincerely,

Laz Esuzan

How can I keep up with the new CSA A23.1 changes? Only if a list of key changes existed…

The A23.1 standard sets requirements for materials and construction methods for cast-in-place and precast concrete, including residential concrete under Part 9 of the National Building Code of Canada. It is reviewed every five years and follows a consensus-based approach, involving representatives from various industry sectors and geographic regions.

Clause 4.1.1.1.4 advises specifiers to consider design strength at ages beyond 28 days to promote sustainable mix designs with lower GHG emissions and better thermal performance.

Section 4.3.5 clarifies:

• Minimum compressive strength must meet structural requirements or exposure class minimums.

• Water-to-cement ratio should align with strength needs without exceeding exposure class limits.

C-class concrete classification revised to focus on corrosion protection rather than structural reinforcement.

S-3 exposure class is mandatory for seawater exposure in C-class concrete.

A-class definitions modified to distinguish between structural and non-structural concrete without reinforcement references.

N-CF class clarified for concrete with minimal freeze-thaw exposure in air-dry conditions.

Additional clarifications in Table 2:

• Designers advised to avoid excessive water-to-cement ratio reductions that could affect constructability and sustainability.

Non-compliant

Clause 7.1.3 now mandates laboratories to identify noncompliant test specimens and notify stakeholders.

Non-compliant specimens may be tested for information but not used for rejection or statistical analysis.

Clear guidance added on proper handling of non-compliant specimens.

Clause 4.3.7.3 allows project owners to use Bulk Resistivity as an alternative to RCP if limits are defined in project qualification testing.

Applicable to C-1, C-XL, A-1, and A-XL exposure classes.

• Air entrainment is discouraged for troweled concrete but may be used in non-troweled concrete (excluding N-CF and R-3).

Definitions added for Recycled Concrete Material (RCM) and Returned Hardened Concrete (RHC), categorized into:

• Type 1 (single-source) & Type 2 (multiple-source)

Clause 4.2.3.4.1 allows up to 30% RHC or RCM in blends but not both, with restrictions based on exposure class.

Table 12 updated to include additional RCM and RHC requirements.

Annex O revised for recycled aggregate use in hydraulic cement concrete.

CSA A23.2-15A and CSA A23.2-27A updated for petrographic examination and alkali-reactivity risk assessment of aggregates. Environmental Product Declarations (EPDs)

Clause 6.3 of CSA A23.2-24C allows owners to request EPDs for mix designs.

Harmonization with CSA A3000

MH/MHL and LH/LHL cement types removed as hydration heat is now a general design concern.

MSL and HSL portland limestone cements added, allowing CSA A3004-C6 testing to ensuring sulphate resistance.

Sulphate expansion testing clarified: 6-month compliance suffices; otherwise, the 1-year test is required.

ASTM C-1157 cement types permitted upon owner approval. (excluding N-CF and R-3).

Recognition that ready-mixed and precast concrete have different criteria and cannot be compared to each other.

Mass Concrete

Temperature limits for mass concrete modified:

• 85°C max for 25% class F or CI fly ash

• 35% for class CH fly ash or slag

• 10% for metakaolin

Please refer to CSA’s official website for all changes that occurred with the latest CSA A23.1 standard update.

Back in March 2022, the Buffalo Bills ushered in a new era of construction to build their state-of-the-art stadium, which is set to open in 2026. The New Highmark Stadium promises to provide fans with enhanced experiences while solidifying the team’s presence in Orchard Park, New York.

The groundbreaking of the New Highmark Stadium took place on June 5, 2023, with construction making rapid progress. This new stadium is being constructed adjacent to the current Highmark Stadium, permitting a seamless transition once the construction is completed.

Designed by Populous, an architectural firm, the stadium is expected to house approximately 62,000 fans, which is slightly less than the former (71,600 seats), however, it comes with improved sightlines and more modern amenities, comfort and overall upgrades in technology. The open-air design, paired with curved sides will provide fans with protection from the elements, ensuring a more fun and cozy experience for all members of the audience.

The substantial completion of the New Highmark Stadium is scheduled for

Summer 2026. Once the meticulous testing and commissioning of the stadium has been completed, the New Highmark Stadium, will open for the 2026 NFL Season. This project is expected to surpass costs for $2.1 Billion, with the funding for this project coming from both private and public sources which includes $250 million from Erie County and $600 million from New York State. Once the stadium is built, the old Highmark Stadium is set to be demolished sometime in March 2027.

As the stadium gets built, there have been significant positive impacts to the local economy, with the construction portion of the project alone providing approximately 10,000 unionized jobs. Thanks to improved infrastructure and a boost to local business opportunities, the stadium promises to deliver long-term economic growth.

New Enterprise Stone & Lime Co., Inc., our valued ready-mix customer in the Great Lakes market has been called upon to pour the concrete that is to be used in the construction of this new home of the Buffalo Bills. New Enterprise has already supplied over 70,000 yd3 which contains Ash Grove GUL and Slag cement. Ash Grove is proud to support New Enterprise Stone & Lime Co. with high quality cement for this significant infrastructure project.

At Ash Grove, we are dedicated to fostering an inclusive work environment where diverse talent is recognized, developed, and valued. Our commitment to fairness, respect, and equality ensures that every individual has access to opportunities that support professional growth and success. By championing a culture of inclusion and belonging, we strive to contribute to a more equitable and supportive workplace for all.

One way we demonstrate this commitment is through our ongoing sponsorship of “Women on Site” (WOS), an organization dedicated to advancing women in construction and related industries. On January 11 of this year, WOS hosted a Winter Social, bringing together over 200 women to celebrate a significant milestone for the community. This elegant evening highlighted the achievements of women in construction, STEM, manufacturing, and other building sectors, providing a valuable opportunity for networking, reflection, and inspiration as we enter a promising new year for women in the workforce.

Ash Grove also proudly supports International Women’s Day (IWD), an annual global celebration recognizing the social, economic, cultural, and political contributions of women. As part of the CRH family, we marked this occasion by launching EVERGREEN, a Women’s Employee Resource Group (WERG) for our colleagues across our CRH business in North America. This initiative is designed to educate employees—both women and men—on effective ways to advocate for and promote gender equity in the workplace.

In honour of IWD and Women in Construction (WIC) Week, Ash Grove hosted watch parties and discussion panels across our business. These gatherings provided a platform for meaningful conversations, empowering speeches, and the celebration of the accomplishments of our female team members. The WIC panel, in particular, served as a testament to the incredible progress made by women within our organization and reinforced our commitment to their continued growth and development.

Ash Grove extends its gratitude to all those who support and advocate for women in construction and beyond. Together, we are building a stronger, more inclusive industry—one where every woman has the opportunity to thrive.

Ash Grove has always encouraged health and wellness among its employees; but with some employees frequently travelling and the support teams working long hours mostly at their desk, maintaining fitness routines can be challenging.

This past January, Richard Sluce, Sr. Director of Sales & Marketing, launched a Step Challenge to engage, educate, and motivate employees to take charge of their health.

Participants signed up to an online step dashboard that tracks individual progress on a live leaderboard, and it’s surprisingly addictive! Wearing a step count device has a powerful impact on everyone’s daily movement. We catch ourselves checking our devices dozens of times a day, and comparing progress with others online, feeling motivated to push further. The instant feedback drives us to outdo our previous counts and find creative ways to add more steps – whether it’s parking farther from the office, taking extra walks, or pacing during phone calls. Every step counts, and the challenge keeps us moving.

The camaraderie within our group unites us and the challenge is a mission for most. Each month there is a prize is awarded to a top stepper and a random top ten winner is announced to motivate those who don’t have as many step opportunities in their days.

So far, the benefits are overwhelmingly positive. The challenge is over a fourmonth period during which employees will have an opportunity to embrace exercise, form healthier habits, and improve their well-being. After all, a healthy employee is a productive one – step by step.