"Architecture Portfolio

Eun Kyung Kim

Selected Works till 2024

About Me

email:

phone:

linkedin:

ek.gracekim@gmail.com

+61 412799896

www.linkedin.com/in/ekyung

Hello! My name is Eun Kyung but people call me Grace. I am a recent graduate of the Bachelor of Architectural Studies from the University of New South Wales (UNSW). My hobbies include baking, taking photos and staying active by regularly going to the gym.

February 2021 - January 2024

University of New South Wales [Sydney, Australia]

Bachelor of Architectural Studies with Distinction

- Dean's List 2022

September - December 2023

Yonsei University [Seoul, South Korea]

Fall Semester Exchange

- Awarded the New Colombo Plan Mobility Grant

2020

UNSW Global [Sydney, Australia]

Design & Architecture Stream

- Awarded with most outstanding achievement

2015-2019

CHIJ Secondary School (Toa Payoh) [Singapore]

- Tennis Recreational Team's Vice-Captain (2016)

- Class Representative (2015-2018)

| Languages

English

Korean

Chinese - Native - Native - Basic

| Software Skills

Revit

Rhinoceros 3d

SketchUp

InDesign

Illustrator

Photoshop

Word

Powerpoint

Excel

May 2022 - January 2023

Hot Black Architecture

Architectural Assistant

- Delivered accurate documentation packages, schedules and specifications under guidance of senior architect.

- Developed engaging thought starters.

- Responded appropriately in a timely manner to feedback and proactively managed issues under guidance of senior architect.

October 2022 - October 2023

UNSW Architecture Society

Treasurer

- Ensured and maintained all Club financial records are up to date and in good order.

- Kept Club informed of its financial position.

February - April 2022

BE Academic Support (BEAS)

Peer Mentor

- 20 hours of in-class assistance over a term.

- Enhanced learning experience of the students I assisted, built on skills including collaboration, demonstration, leadership and networking.

June - August 2022

UNSW Work Integrated Learning (WIL) with Powerhouse Museum

- Attended interactive workshops, debriefing and reflective activities to ensure progress and understanding of project.

- Collaborated in a team with feedback by academic and partner organisation staff.

2018

Lacoco Hair Salon [Singapore]

Receptionist

- Marketing assistant (editing social media posts)

- Administrative work

- Customer service

Albury-Wodonga, situated along the Murray River, serves as a regional hub straddling the border of New South Wales and Victoria. This design studio emphasises the role of architects' collaboration with communities, especially addressing the challenge of locating a contemporary design in flood-prone areas. Students are challenged to develop innovative architectural solutions that consider the brief, site, environment, and local community concerns, moving beyond mere functional problem-solving and composition.

My project’s purpose is to help with restoring the river bank while also strengthening the levee with the help of nature’s currents during floods. By having a suspended level of spaces above the flood level allows the visitors to embrace the re-occurring floods rather than running away from it. My project not only embraces the East and West relationship of the site but also extends out spaces and explores the North and South relationship of the site.

Sketches by Fiona

Addition from the list "Sustainable Plants for Albury's

Versatile and effective as a specimen plant, near ponds, under trees, as a border and in containers. Very hardy and tolerates drought and water logging.

It

in most

and conditions, but prefers moist areas.

Existing Activities/Population

Removal of Introduced Trees Addition of Native Trees

Climate" from AlburyCity

plant is a good structural plant. It will grow well in moist areas and poorly drained soils.

New Visitors

River Bottle Brush

(Callistemon sieberi)

River Bottle Brush

(Callistemon sieberi)

Materials

Steel made with added phosphorus, copper, chromium, and nickel-molybdenum. These alloys increase the resistance of corten steel to atmospheric corrosion by creating a protective patina on its surface. This protective layer regenerates continuously on the surface and acts as a barrier against moisture, oxygen, and pollution.

Polycarbonate due to its durability, sustainability, and the material providing levels of transparency allowing for natural light to enter while still providing privacy.

Walkway Grating is perforated, allowing natural light to pass through and not fully shade the area below.

Steel Posts, the main supports of the structure holding up the facilities above while also holding the river bank together. This support system gets even stronger with low flood currents which work together to also support the levee.

4mm POLYCARBONATE SHEET

40 x 30 x 2 TUBE IN GALVANISED STEEL

60mm GLASS

ALUMINIUM FRAMES

TOP PLATE

GYPSUM PANELS

CAVITY INSULATION

GYPSUM SHEATHING

METAL SHEET

CONTINUOUS INSULATION

AIR / WATER BARRIER

GYPSUM SHEATHING METAL TRACK TOP PLATE

GYPSUM PANELS

CAVITY INSULATION BOTTOM PLATE

STEEL FOUNDATION BOLTS

609x190mm I-BEAM

ADHESIVE

SCREED BED 20mm THICK

ACOUSTAMAT 700 5mm THICK

ADHESIVE

INSULATION

METAL TRACK

AIR / WATER BARRIER

CONTINUOUS INSULATION

METAL SHEET BOTTOM PLATE

SERVICE PIPE

OPEN WEB STEEL JOISTS 200mm TO 762mm DEEP

The course aims to design several dwellings to accommodate a mix of household types on a single suburban lot in a middle suburb of Sydney with reference to existing models for the processes of suburban densification. The studio draws on the knowledge and skills gained in the previous design studios to further develop students' skills in design generation, development and management at a moderate level of complexity. It promotes coordinated relationships between the medium of architecture, patterns of human activity and elements and patterns of the site.

The design prioritises maximising natural light and privacy for occupants while capitalising on positive views along Georgina Street and Hollis Park. Varied heights and excavation create diverse viewpoints, enhancing privacy and facilitating optional interaction with the public. Occupants can enjoy elevated privacy or engage with passersby near the boundary of the dwellings. All three residences benefit from appealing outlooks towards Georgina Street and/or Hollis Park due to the advantageous corner lot positioning. East-facing outdoor spaces and windows welcome morning sun, while north-facing areas ensure continual natural light throughout the day in the living and dining spaces.

Dwellings + Kiosk + External Communal Space Entry Points

Kiosk + External Communal Space

Dwelling One - Two Storeys

Dwelling Two - Wheelchair Accessible

Dwelling Three - One Storey with entrance at GF

Main entrance into project lot

Kiosk + External Communal Space

Dwelling One

Dwelling Two

Dwelling Three

8 .1 Outdoor living spaces facing the East towards Hollis Park has good potential outlook wise.

.2 The outdoor living space for the second dwelling still has a sense of privacy as it is elevated from the walkway up from Wilson Street.

9 Use of courtyards to not only create separation but also for ventilation into the spaces.

10 Use of planning and skylight to create a more welcoming entrance for Dwelling Three.

11 Perforated openings on the ground floor for Dwelling One to provide an increased level of privacy from other occupants walking along the path to enter their homes.

12 .1 Outdoor living space facing north, best orientation for warm winter sun into the living spaces through the balcony.

.2 Provides view up Georgina Street while having a greater level of privacy as it sits on the first floor - having a higher level of privacy from the public.

13 Elevated above ground floor by a metre to provide a level of privacy from Park Lane while allowing for a view out towards Georgina Street.

1 Main entrance gate set back from Park Lane to create a separation.

2 Ramp for wheelchair accessibility but also it wraps around the Kiosk, creating a journey down to the excavated level.

3 Kiosk at the same level as Park Lane with the entrance created on the existing pathway up from Park Lane.

4 Excavated Kiosk space creates a sense of separation from Hollis Park.

5 Wall seatings by the Kiosk, opportunity to enjoy the view towards Hollis Park. It's also a flexible open space to have a quick rest.

6 .1 This ramp by the walkway up from Park Lane provides wheelchair accessibility to the communal space.

.2 There are also steps behind the waste and recycling area for convenience and another way to access the space.

.3 By having the ramp accessible this way rather than by the entryways of the dwellings, it creates a journey for the occupants to come out of the project lot, walk along the path and into the space. It also increases the level of privacy for the dwellings.

7 .1 Excavated communal space enhances a feeling of enclosure and has a level of privacy from the public.

.2 Located on the East side, recieves good amount of sunlight during winter solstice and spring equinox.

.3 Acts as a buffer between the Dwellings and the Kiosk.

Point of Serenity Viewpoints

In this course, we deepened our understanding of construction material properties and their integration with architectural forms, particularly on exploring the role of the building façade as a multi-layered system which is able to simultaneously deliver thermal comfort and empower interaction between inside and outside of a building.

Two main aims of this course are to challenge the idea of building façade as just walls between inside and outside, and to expand and develop the understanding of material construction as a contributor to making good places for people to live.

After analysing case studies for assessment 1, assessment 2 was of my design strategies that explored opportunities for a building façade to respond to different scenarios in a project site. Finally, assessment 3 was to submit construction and detailed design drawings based on my design strategies, which is what I have presented in my portfolio. These drawings reflect on the arrays of solutions presented for design strategies assessment to finalise the detailed design of a building façade.

NOGAPINSULATION:

GYPROCK:

GYPROCK: 10MM GYPSUM PLASTERBOARD ARCHITRAVE

CENTOR: 405 FOLDING OUTWARD OPENING DOOR

PRANCE TIMBER FLOORING: 19MM THICK, 180MM WIDE TIMBER FLOOR BOARDS

QUIETWALK FLOOR UNDERLAYMENT

WATERPROOF MEMBRANE 160MM CONCRETE SLAB

SUSPENDED CEILING SYSTEM

2.5MM CONNECTOR CLIP

MOUNTING TRACK CENTRES

WATERPROOF MEMBRANE

PRANCE TIMBER FLOORING: 19MM THICK, 140MM WIDE LAMINATED TIMBER BOARDS

RIGID INSULATION SOFT INSULATION 10MM PLASTERBOARD CEILING

45 X 90MM DECKING JOISTS @ 430MM SPACING

BOTTOM RAIL SCREEN STILE 45 X 90MM BOTTOM PLATE SUMMER SUN 79°

WINTER SUN 33°

MEMBRANE

REINFORCED CONCRETE SLAB

DAMP-PROOF MEMBRANE 50MM SAND 50MM HARDCORE FILL EARTH

MESH

PRANCE TIMBER FLOORING: 19MM THICK, 180MM WIDE TIMBER FLOOR BOARDS

QUIETWALK FLOOR UNDERLAYMENT

WATERPROOF MEMBRANE 160MM CONCRETE SLAB

RIGID INSULATION

SUSPENDED CEILING SYSTEM

MOUNTING TRACK CENTRES 2.5MM CONNECTOR CLIP

10MM PLASTERBOARD CEILING

SOFT INSULATION

WATERPROOF MEMBRANE

PRANCE TIMBER FLOORING: 19MM THICK, 140MM WIDE LAMINATED TIMBER BOARDS

45 X 90MM DECKING JOISTS @ 430MM SPACING

GYPROCK: 10MM GYPSUM PLASTERBOARD

76 X 230 X 110MM DOUBLE BRICK WALL WITH 50MM CAVITY

10MMM THICK MORTAR

NOGAPINSULATION: 10MM FOILBOARD

50MM SAND

MEMBRANE

50MM HARDCORE FILL EARTH

WEEPHOLE FLASHING SKIRTING

300MM SLAB EDGE WALL TIE

TRENCH MESH

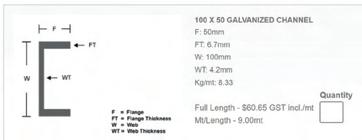

This course focused on enhancing technical knowledge of materials, construction, and structures through case studies and project applications, emphasising reinforced concrete, steel, and timber construction integrated with architectural design. It aimed to deepen understanding of how buildings are designed, documented, and constructed, with assignments directly relevant to building details and documentation, including exploring the assembly process through digital construction models. Additionally, the course aimed to familiarise students with building codes, standards, and regulations applicable to medium-scale buildings, fostering an understanding of structural design and construction procedures.

For my portfolio, only parts of my final assessment have been added instead of every plan and section. This is to show my understanding and completion of construction documentation.

150MM x 100MM DOUBLE L BEAMS (TOP & BOTTOM CHORDS) - HANDYSTEEL

L-PLATE ANGLED BRACKET - STRATCO

BOLTED FLANGE PLATE - STRATCO

2700MM X 1200MM X 21MM TONGUE AND GROOVE PLYWOOD SHEETING - PLYCO

200MM X 95MM TIMBER JOISTS - BLACKTOWN BUILDING SUPPLIES

2700MM X 1200MM X 21MM TONGUE AND GROOVE PLYWOOD SHEETING - PLYCO

L-PLATE ANGLED BRACKET - STRATCO

75MM x 50MM C CHANNEL (TRUSS WEB) - HANDYSTEEL

150MM x 100MM DOUBLE L BEAMS (TOP & BOTTOM CHORDS) - HANDYSTEEL

BOLTED T CONNECTION

SPEEDBRACE WITH SDB50 OR SDB60 - PRYDA WATERPROOFING MEMBRANE BOLTED T CONNECTION BOLTED T CONNECTION

H COLUMN - ORRCONSTEEL (200UC)

X

H COLUMN - ORRCONSTEEL (200UC) 200MM X 200MM H COLUMN - ORRCONSTEEL

BOLTED FLANGE PLATE - STRATCO

L-PLATE ANGLED BRACKET - STRATCO

(200UB) 198MM X 90MM I BEAM -

TIMBER JOIST BRIDGING 40MM X 40MM TIMBER JOISTS - BLACKTOWN BUILDING SUPPLIES

100MM SAND LAYER 200MM HARDCORE LAYER EARTH

BOLTED FLANGE PLATE - STRATCO

200MM X 95MM TIMBER JOISTS - BLACKTOWN BUILDING SUPPLIES

200MM X 45MM hySPAN H2-S 6.0m ROOF BATTENS - BLACKTOWN BUILDING SUPPLIES

L-PLATE ANGLED BRACKET - STRATCO

75MM X 50MM C CHANNEL (TRUSS WEB) - HANDYSTEEL

GUSSET PLATE

BOLTED T CONNECTION

(200UC) 200MM X 200MM H COLUMN - ORRCONSTEEL

(200UC) 200MM X 200MM H COLUMN - ORRCONSTEEL

BOLTED FLANGE PLATE - STRATCO

L-PLATE ANGLED BRACKET - STRATCO

(200UB) 198MM X 90MM I BEAM - ORRCONSTEEL

TIMBER JOIST BRIDGING

(200UC) 200MM X 200MM H COLUMN - ORRCONSTEEL

HIT-V-F-8.8 ANCHOR ROD - HILTI

300MM X 300MM BASE PLATE - EDCONSTEEL AND 300MM X 300MM GROUT PAD - SIKA

U-SHAPED BRACKET - STRATCO

100MM SAND LAYER 200MM HARDCORE LAYER EARTH

• PACIFIC MAPLE MARINE PLYWOOD ROOF BOARDS 2400MM X 1200MM X 25MM - PLYCO

• 200MM X 45MM hySPAN H2-S 6.0m ROOF BATTENS - BLACKTOWN BUILDING SUPPLIES

• 150MM X 100MM DOUBLE L BEAMS (TOP & BOTTOM CHORDS) - HANDYSTEEL

• 75MM X 50MM C CHANNEL (TRUSS WEB) - HANDYSTEEL

STRUCTURAL FRAME

• (200UB) 198MM X 90MM I BEAM - ORRCONSTEEL

• (200UC) 200MM X 200MM H COLUMN - ORRCONSTEEL

• CONCRETE BLOCKWORK WITH CONCRETE FILL AND STEEL REINFORCEMENT - NATIONAL MASONRY

CROSS-BRACING

• SPEEDBRACE WITH SDB50 OR SDB60 - PRYDA

CONNECTIONS

• L-PLATE ANGLED BRACKET - STRATCO

• U-SHAPED BRACKET - STRATCO

• BOLTED T-BLADE SUPPORT - VUETRADE

• NAILS - VUETRADE

• BOLTED FLANGE PLATE - STRATCO

• HIT-V-F-8.8 ANCHOR ROD - HILTI

• 300MM X 300MM BASE PLATE - EDCONSTEEL

• 300MM X 300MM GROUT PAD - SIKA

FLOORING

• 2700MM X 1200MM X 21MM TONGUE AND GROOVE PLYWOOD SHEETING - PLYCO

• 200MM X 95MM TIMBER JOISTS - BLACKTOWN BUILDING SUPPLIES

• 40MM X 40MM TIMBER JOISTS - BLACKTOWN BUILDING SUPPLIES

FOUNDATION

• 150MM CAST IN-SITU CONCRETE RAFT SLAB WITH RL818 MESH REINFORCEMENT - REOZONE

• 300MM THICK CONCRETE SLAB EDGE WITH R6 STEEL REINFORCEMENT BARS - REOZONE

This course investigates “Digital Making”, which encompasses blending learners' creative skills with technology. In this course, I will investigate advanced manufacturing technologies (CNC) for household object design. Through this course, I gained the conceptual understanding of sustainability, technical knowledge and critical thinking skills required to engage in digital making as a system that connects design to fabrication.

The purpose of this modular object is to work as a side table and a stool, with the intended user being me as I needed a bedside table.

Precedents

Plump Side Table by Ian Alistair

Concept Sketches

Both options use the design method of connecting and slotting the pieces together which was inspired by the precedents above.

Option 1 seemed more of just a stool and was too simple as a side table. Hence, I decided to further develop option 2 for my final design which consists of a slightly more complex installation but still easy enough to put together.

Nontalo Stool by NaifactoryLAB CochranInitial Design

I chose to design varying egg-shaped pieces to put together because I prefered an organic shaped design but did not want to work with circles.

My first proposal of my design as seen above had the left support piece on an angle which led to the opening cut of it to also be on an angle. Additionally, the slots on the underside of the top piece were also to be cut out on an angle.

Developed Design

However, after consultation and figuring out that the CNC machine does not cut on an angle, I had to develop my design so that all the pieces will stand upright, consist of openings and carve slots on just the horizontal and vertical plane.

Furthermore, a minor change to the design would be that I moved the right supporting piece inwards to reduce the amount it stuck out.

Fabrication set up of final product on fusion 360

• Frame for plastic press: 1100x1100x20mm

• Plastic Sheet then faced down to 18mm

• Volume: 593x432x500mm (complies to volume limits of 800x800x500mm)

• Total of 23kg of recycled plastic was used

Yonsei University and Friends

Yonsei University and Friends