Ehsan Ghaderi Architecture portfolio

Ehsan Ghaderi (515) 708 8878 eghaderi@iastate.edu Ames, IA, USA Architecture Design Technology Computation

Content

• Studio Projects

• Okra Culinary School

• Grow, a building as a vending machine

• Responsive Facade

• Pars Tower

• Digital Fabrication

• Bent Wood Panels

• Folded Steel Panels

• Eggcrate Surfaces

• Multi Dimensional Pavilion

• Lab Experience

• Architronics

• Hexadome Pavilion

• Pars IocAD Lab

Okra Culinary School

Design Studio - Iowa State University

Spring 2023

Instructor:

Ulrike Passe

Team:

Mahsa Taghavinejad

2

Culinary School as a Community Center

Okra Culinary School and Restaurant in Baton Rouge stands as a net-zero building designed to address the unique environmental challenges of Louisiana while celebrating its rich food culture. This architectural endeavor seamlessly blends form and function, contributing to the revitalization of the region and mitigating the urban issues plaguing Government Street, affected by the interstate highway.

Beyond its architectural experience, this project aspires to become a vibrant community center. By offering culinary education and training, the project actively addresses regional issues, creating opportunities for local residents and fostering a deeper connection to Louisiana’s rich culinary history.

Okra Culinary School and Restaurant transcends architectural boundaries, harmonizing with its environment, promoting sustainability, and serving as a symbol of community revitalization, reflecting the very essence of Louisiana’s vibrant culture and history.

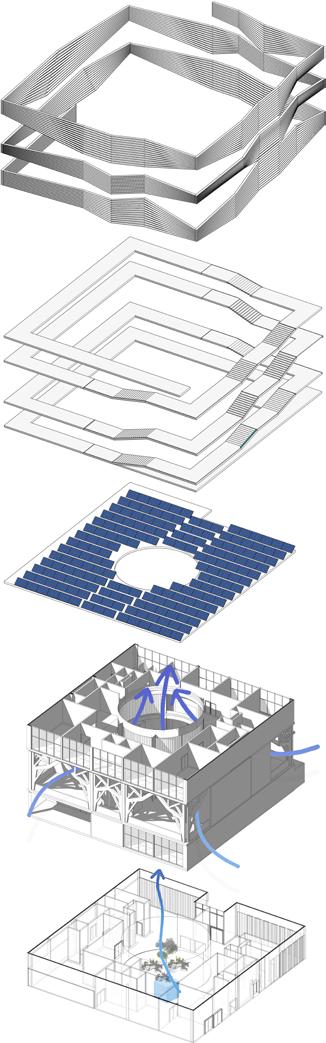

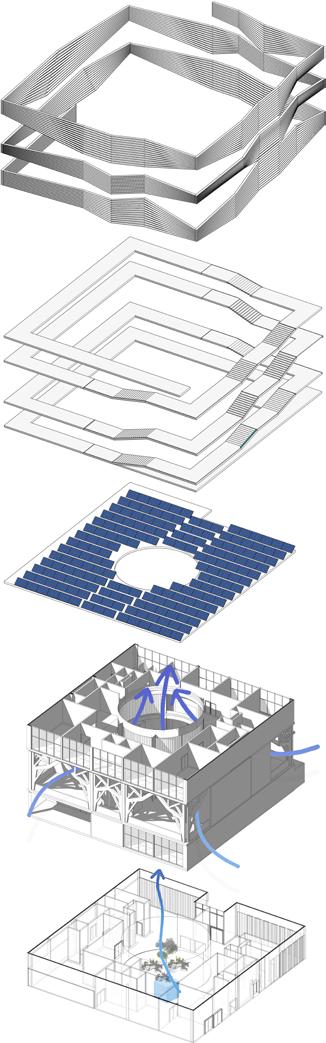

Baton Rouge’s climate is characterized by high humidity levels and hot temperatures for a significant portion of the year.

Our design approach sought to harmonize with these environmental factors, offering innovative solutions to combat the heat and humidity.

Culinary school needs considerable space due to having numerous rooms. Therefore, most of the site needs to be built.

A central courtyard is integrated into the design, allowing for increased airflow, and expanding daylight availability for all the spaces.

The third level is thoughtfully dedicated to a garden floor to grow Okra and other native food ingredients, and maximize the airflow in addition to the central courtyard.

A striking three-dimensional vertical circulation system that elegantly wraps around the building, not only enhancing its urban integration but also serving as a self-shading mechanism.

Shading elements incorporated into the design of the surrounding stairs form the primary facade feature, providing protection against sun exposure and reducing rain penetration.

4

1 2 3 4 5

5

6

1 2

Grow, a Building as a Vending Machine

Design Studio - Iowa State University

Spring 2022

Instructor:

Rob Whithead, AIA, LEED AP

Team: Ana Sofia Ramous, Kenna Winther, and Reid Snell

8

Building as a vending machine

Existing industrial agriculture supports food insecurity, creates and amplifies climate threats, and enforces inequality amongst groups of people. The issues are clear, yet they remain unaddressed.

Our goal is to nurture close relationships between people and where their food is grown with a human-centric standpoint. This will bring production directly to where the demand is. We intend to make this traditionally camouflaged process visible– inspiring civic, municipal pride through an exhibition of food production. The space will be curated for people to coexist with food systems. This becomes a new architectural identity.

The Center St. Park & Ride in Des Moines is selected as the site. Since many people use public transportation systems and parkings, it is an example of the potential of these locations for this new architectural phenomenon.

10

TRANSFER PRODUCE FROM CRATE TO BAG BAKE: RECIPES FROM MY KITCHEN BAKE: RECIPES FROM MY KITCHEN PARK N CENTER The day in the life of a frequent visitor starts through them using the Park n Ride as parking. n the case the person has children, they would drop their child at the Daycare facility before taking the bus or walking to work. During or on their way back from work they would order grocries through the app on their phone. DAYCARE DROF OFF TAKE BUS TO WORK ORDER GROCER ES N APP FRONT DESK P CK UP PERSONEL CONF RMS ORDER AND BR NGS T TO FRONT DESK DAYCARE P CK UP HEAD HOME FOR THE DAY After ordering, they go to the front desk at GROW where someone confirms their order and brings their purchase from the refrigerators over in a crate. The visitor has to transfer their produce from the crate to a reusable bag. Finally, the parent picks up their child from the Daycare and head home for the day. BON APPET i TE BAKE: RECIPES FROM MY KITCHEN BAKE: RECIPES FROM MY KITCHEN HAR v EST NG CLEAN NG PACKAG NG BACK OF HOUSE PROCESS SEED NG Although the crops take different periods of time to grow, all growth cycles start and end the same. The initial phases are seeding and germination cultivation, from there the crop eventually goes into vertical cultivation. After the produce grows for a while, it needs to change spaces in order for the plant to grow to its full potential. Lastly, the crop goes back into vertical cultivation until it is time to harvest. GERM NAT ON CULT iv AT ON MO v E PRODUCE v ERT CAL CULT iv AT ON TRANSPLANT NG FOR SPAC NG MO v E PRODUCE PRODUCE READY FOR P CK UP Most of this process is possible thanks to automated devices. These devices are responsible for regulating the growing conditions of the crops. Moreover, the automated devices are the ones responsible for changing crops from spacing and moving the crops accordingly through the vertical cultivation shelves. v ERT CAL CULT iv AT ON

11

Three different climate zones for growing diverse agricultural products using hydroponics automated systems, shape the growing section. Aquaponics are also considered to add to the nutrition diversity of the this section.

12

• The new construction as an add-on to the existing building.

• The growing section is located on the roof of the building to maximize daylight availability.

• Lighting of the growing section during the night makes it an iconic representation of the importance of food availability as an integrated part of the urban context.

13

Cultural-Commercial Building with Responsive facade

Design Studio - Pars Institute of Architecture and Art

Fall 2019

Instructors:

Dr. Katayoun Taghizadeh

Dr. Ali Andaji Garmaroudi

14

Commercial & Cultural Center

The project was situated in a high-rise residential area of Tehran, with the aim of addressing the urban needs of the densely populated neighborhood. The building consisted of various commercial and cultural components, including a one-story hypermarket, a two-story electronics store, and three stories of clothing stores for commercial purposes. For cultural purposes, the building featured a one-story gallery, a library, conference rooms, two stories of theater complexes, and two stories of cinema complexes. The food court, located on the sixth level, separated the commercial and cultural sections of the building.

Given the high population density and limited availability of land in the area, the design of the building was optimized to make the most efficient use of space. As a result, a variety of functions were incorporated into the building’s cubic design, maximizing land utilization, which is common approach in Tehran.

Conference Rooms Library Gallery Food Cour t

Commercial Section

16

Cultural Section

17

-7 to -2 Parking

2 Electronics

7 Galleries

3 Clothing Stores

8 Library

4 Clothing Stores

9 Confrence rooms

5 Clothing Stores

11 Theatres

13 Cinemas

6 Food Courts

-1 Hypermarket

1 Electronics

Facade Mechanism

As the sun intensifies, the panels automatically shade the facade, maximizing sun exposure for the photovoltaic panels.

18 1 2 3

19

Pars Tower

Design Studio - Pars Institute of Architecture and Art

Fall 2017

Instructors:

Prof. Mahmoud Golabchi

Dr. Matin Alaghmandan

Team:

Kian Jafari Pour

20

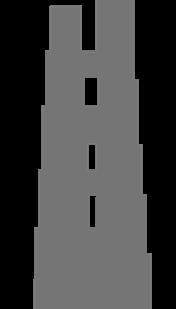

Intertwined Office Towers

Due to Tehran’s highly populated and congested nature, high rise buildings are a necessary addition to the city. This project is a 68-story office building with three distinct zones for small, mid-sized, and large corporate offices.

However, constructing a high rise building comes with significant challenges, namely in the structure and lateral forces. To combat this, the towers are intertwined and the building’s structural system is a combination of mega frame structure and concrete cores.

Form and Direction

Structure optimization

Additionally, the building’s mass is reduced as it increases in elevation, and its fully curved shape helps to decrease wind friction. The building also includes two refuge floors and four mechanical floors

22

23

Zone A: Small offices Zone B: Mid-size companies Zone C: Large corporations

Mega frame structure

Concrete Cores

Bent Wood Panels

Pars IoCAD - Experimental Fabrocation Workshop

Tutor & Organizer

January 2020

In Collaboration With:

Vahid Azizi and Abouzar Movahedi Qomei

Fabrication team:

Amir Khodapanahi, Maryam Anousha, Hamidreza Mirzaei,

Parisa Rasouli, Ghasem Tavakoli, Nima Alinejad, Hedie

Bakhtiari, Ali Khani, Ahmad Reza Bamesi

24

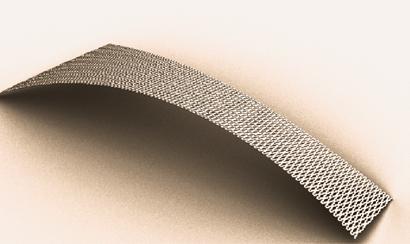

Bent Wood Panel

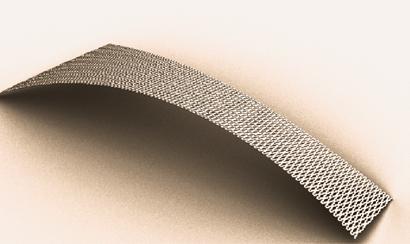

Nature serves as a paramount source of inspiration for all design disciplines. It abhors straight lines, offering instead a wealth of curves and flexibilities. Bending wood panels offers an excellent exploration of material properties. Wood is inherently rigid, but it can be made flexible using various methods. Among these bending techniques, such as steam bending and laminating, we have chosen kerfing patterns due to their computational nature and the role of geometry in the bending process.

The fabrication of bent wood panels served as an experimental study. The primary objective of this project was to investigate the bending capabilities of wooden pieces. Among various wood-bending methods, we chose Kerfing patterns due to their computational advantages. To achieve our goal, we designed a dedicated apparatus capable of measuring bending based on two factors: span and height.

26

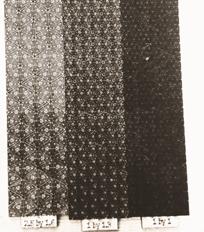

PATTERN

Bending Test

Various patterns with different scales were applied to identical wood pieces. An individual experiment was conducted for each pattern, and the results were meticulously recorded. Each piece of wood was inserted into the device and subjected to pressure until its endpoints met, or until it fractured into its components. The outcome yielded a chart revealing numerous intriguing findings.

This test yielded remarkable results. As the density of patterns increases, the wood’s flexibility also increases, although certain patterns, such as hexagons, can render the wood extremely fragile. When patterns expand in two directions with cut lines on both sides, they create a flexible, double-curved surface. Conversely, patterns that develop in only one direction with cut lines in one direction cause the wood to bend on one side only. Additionally, these methods can impart tension characteristics to the material, leading to a slight increase in the size of the wood pieces. We recorded these test results and compiled them into a chart to visualize the impact of pattern density on a piece of wood.

27

Natural Beauty through parametricism

This fabrication project aimed to transform the inherent rigidity of wood, traditionally utilized as a structural element to support building loads, into a flexible and resilient material capable of maintaining its structural integrity.

Parametric design tools offer remarkable capabilities for realizing intricate concepts such as this. Leveraging Grasshopper 3D, a series of experimental projects were conceived and executed to showcase the potential of kerfing patterns.

In the pursuit of designing a large-scale panel, numerous concepts were explored and materialized using cardboard as a medium for experimentation. Subsequently, the most captivating panel design was selected for realization on a grand scale.

28

Fabrication Day

1- The structural components. 2- 120 wooden pieces. 3- Assembly

The result was a panel composed of approximately 120 wooden pieces, each displaying impressive flexibility. The overall pattern gracefully converged toward its center.

This outstanding panel garnered recognition from the jury at the Patternitecture art and fabrication event, securing the 3rd place position in the open call category, held in Tehran, Iran.

29

Folded Steel Panels

Pars IoCAD - Experimental Fabrication Workshop

Tutor & Organizer

March 2018

In Collaboration With:

Vahid Azizi and Abouzar Movahedi Qomei

Farication team:

Hedie Bakhtiari, Khatere Hasanzadeh, Nazli Hosseini, Asra Khalesro, Amir Khodapanahi, Reyhane Khojasteh, Maryam Damanafshan, Dorsa Shapoori, Masome Shasti, Mohaddeseh Taheri, Parvane Farshchi

30

Folding, A Remarkable Experiment!

The primary objective of this project was to create a panel that effectively manages the influx of sunlight into the indoor space. To achieve this, we opted for Voronoi geometry, chosen for its intricate and distinctive geometrical characteristics.

Several key parameters play a vital role in determining the outcome, including the panel’s depth, height, and opening ratio.

We chose the folding method for its swiftness and structural stability. This approach eliminates the need for adhesive, binding materials, welding, or similar techniques. Moreover, it enhances the panel’s reusability and simplifies its transportation.

32

Design to Fabrication

Alternatives

Utilizing Grasshopper 3D, we generated multiple panels to meticulously analyze the ingress of natural light and assess their aesthetic qualities. Our primary objective was to achieve maximum transparency for these panels, while strategically regulating the amount of light entering. Specifically, we aimed to minimize light penetration at the bottom of the panel and maximize it at the top.

33

EggCrate Surfaces

Pars IoCAD - Experimental Fabrication Workshop

Tutor & Organizer

July 2017

In Collaboration with:

Vahid Azizi and Abouzar Movahedi Qomei

Fabrication team:

Hedie Bakhtiari-Reyhane Khojasteh-Dorsa Shapoori-Mohaddeseh Taheri-Parvane Farshchi- Shahab VafiAmir Sattari- Zahra zakaria- Sahar Asgari- Zahra Tarashiun- Amir arsalan Torani

34

EggCrate

Pars IoCAD’s initial activity into fabrication commenced with the EggCrate project—a two-day workshop dedicated to design and manufacturing.

1. Algorithm Development: The first step involved crafting an algorithm capable of generating contour lines in two distinct directions.

2. Subtraction and Integration: In the second step, these generated contours were strategically subtracted and then joined, creating a cohesive design.

3. Team-Based Form Design: Each team took charge of designing a unique form.

4. Algorithm Application: Next, the algorithm was applied to the designs, and the resulting forms were nested in preparation for laser cutting.

5. Fabrication: The final step encompassed the actual fabrication of the designs, bringing them to life.

36

Experimental Workshop

An exploration into Contours

Despite its seemingly straightforward appearance, this fabrication method boasts a multitude of remarkable attributes. The workshop process kicked off with an exploration of its historical roots and examination of relevant case studies, gradually unveiling the diverse range of its applications. From crafting furniture and small objects to undertaking colossal monumental constructions, the method’s advanced utilization in tackling intricately complex geometries became a focal point of study..

37

Multi Dimensional Pavilion

FABFEST 2018 Competition - Westminster University (UK)

3rd Place

June 2018

Supervisor:

Dr. Ali Andaji Garmaroudi

Designing In Collaboration With:

Vahid Azizi, Abouzar Movahedi Qomei, Farhad Barahimi, Amid Mortazavi, Jina Rashidzadeh, Nilofar Rafinia, Ramin Ghaemi Gargari

38

Modular Pavilion

FABFEST 2018, Westminster University, London

The entire pavilion derives from a single component, which seamlessly connects with others using a tongue-and-groove system—an architectural approach categorized as an aggregation system. In this method, 2D modules effortlessly assemble to give rise to a captivating 3D structure.

This pavilion draws its inspiration from the iconic Chahartagh, a prominent architectural motif in Iran, thus representing a revival of an ancient architectural form.

Regrettably, we were unable to personally attend the festival for the final assembly and presentation in London. Nevertheless, a dedicated group of volunteer students from Westminster University took up the task of constructing the pavilion on our behalf. This project’s realization wouldn’t have been possible without the generous support of Dr. David Scott, the festival’s organizer.

40

41

Architronic: Architecture + Electronic

Pars IoCAD - Training Courses

Tutor & Organizer

October 2019

In Collaboration With:

Ramin Ghaemi Gargari and Vahid Azizi

Participants:

Moein Maleki, Fatemeh Hoseini, Matin Barmaki, Ahmadreza Bamesi, Reyhane Khojasteh, Nima Alinejad,

Iman Sheikh Ansari, Dorsa Shapouri, Pasha Navadeh, Mahsa Elahivafa

42

Architronic

Architecture + Electronic

Architronic, a cutting-edge course provided by Pars IoCAD, comprised eight comprehensive sections dedicated to the profound domains of Arduino and Grasshopper3D. The principal aim of this course was to delve into the world of physical computing tools and their transformative influence on architecture and design. It entailed the exploration of sensors, motors, mechanisms, and more, all with the intent of comprehending and applying these technologies to create responsive, interactive, and intelligent architectural and design solutions.

Through the adept utilization of Arduino and scripting within both the Arduino platform and the Firefly plugin of Grasshopper3D, participants engaged in the hands-on construction of various objects, each designed to investigate and unlock the immense potentials inherent in these tools.

44

45

Panel

Lighting

Lighting

Projects Interactive

Responsive

Interactive

Pars.IoCAD laboratory

Pars Institute of Computation Aided Design

Research Group and Digital Fabrication Laboratory, Since 2017

www.parsiocad.ir

Role:

Co-founder, and Tutor

46

An Exciting Educational Hub!

Founded in 2017 and based in Tehran, Iran, this dynamic institution has partnered with Pars University to elevate students’ academic achievements. Their mission revolves around bridging the gap between theory and practice, offering students access to stateof-the-art design and fabrication methods, education, machinery, and seminars.

Key Areas of Focus:

Digital Fabrication: Exploring modern manufacturing techniques through research into new methods, materials, and machinery.

Educational Courses: Offering a wide range of enriching courses in emerging technologies, tools, and techniques within the AEC (Architecture, Engineering, and Construction) industry.

University Collaboration: Collaborating closely with Pars University to enhance academic offerings and opportunities.

Seminars and Knowledge-Sharing: Facilitating insightful knowledge-sharing events by inviting industry and academic leaders from around the world.

Community Services: Providing services by granting access to the fablab equipment for the community and students.

47

48 48