EXCLUSIVE INTERVIEW: PRECISION IN MOTION

MIDSTREAM & PIPELINE SECTORS: BIG FOCUS

AUTOMATION: DO’S AND DONT’S

A DEEP DIVE INTO THE CURRENT FPSO MARKET

Spring

2024 Helping Lead the Energy Transition

Emery Hill Media Ltd. © 2024

INNOVATION

www.oilandgasinnovation.co.uk

CEO Matthew Patten

Managing Editor

Simon Milliere

Publishing Director

Edward Findlay

edward@oilandgasinnovation.co.uk

Commercial Director & Advertising Enquiries

Nicholas Parker nparker@oilandgasinnovation.co.uk

Technical Director and Website

Nathan Bedmann web@oilandgasinnovation.co.uk

Office Assistants

Janet Elseberg admin@oilandgasinnovation.co.uk

Contributing Journalist

Emma Patten

Business Development Executives

Mylene Daugan

mylene@oilandgasinnovation.co.uk

Augusto Trinidad Jr

augusto@oginnovation.co.uk

Tim Martens

tim@oginnovation.co.uk

Janna Garcia

jannagarcia@oginnovation.co.uk

Anjel Miller

anjel@oginnovation.co.uk

Emery Hill Media

Dalton House

60 Windsor Avenue

London

SW19 2RR

Tel: +44 330 043 49

Follow Us

A NOTE FROM THE EDITOR

Navigating the Waves: A Deep Dive into the Current FPSO Market

The Floating Production Storage and Offloading (FPSO) market has been a cornerstone of the offshore oil and gas industry for decades, offering a flexible and cost-effective solution for the production and processing of hydrocarbons in remote and deepwater environments. As we sail into 2024, the FPSO market continues to evolve in response to shifting global energy dynamics, technological advancements, and environmental considerations.

The FPSO market is experiencing a period of transition and adaptation. Several factors are influencing its current trajectory. The volatility in oil prices over the past years has significantly impacted investment decisions in the oil and gas sector, including FPSO projects. While lower oil prices can delay investment in new projects, they also drive efforts to optimize existing assets, thus increasing demand for FPSO services.

The global push towards renewable energy sources and decarbonization initiatives has spurred discussions about the future of fossil fuels. However, oil and gas remain integral to the energy mix for the foreseeable future, particularly in meeting the rising demand from emerging economies. FPSOs, with their versatility and mobility, continue to play a vital role in offshore oil and gas production, offering operators the flexibility to adapt to changing market dynamics.

Technological Innovation: Advancements in technology have led to the development of more efficient and environmentally friendly FPSO designs. From enhanced processing capabilities to the integration of digital solutions for predictive maintenance and remote monitoring, these innovations are enhancing the reliability, safety, and productivity of FPSO operations.

Stricter environmental regulations and growing societal pressure to reduce carbon emissions are driving the adoption of cleaner technologies within the oil and gas industry. FPSO operators are increasingly investing in solutions to minimize their environmental footprint, such as incorporating renewable energy sources, implementing emissions-reducing technologies, and adopting stringent waste management practices.

Despite the challenges posed by market volatility and the energy transition, the FPSO market remains resilient, with several key trends shaping its future. As the energy landscape evolves, FPSO operators are exploring opportunities to integrate renewable energy sources, such as wind and solar, into their operations. Hybrid FPSO systems that combine conventional oil and gas production with renewable energy generation are emerging as a viable solution to reduce carbon emissions and enhance operational efficiency.

The adoption of digital technologies, including artificial intelligence, IoT sensors, and predictive analytics, is transforming FPSO operations. These technologies enable real-time monitoring of equipment performance, predictive maintenance scheduling, and optimization of production processes, leading to improved asset reliability and operational efficiency.

With many FPSOs reaching the end of their operational life, decommissioning activities are on the rise. However, operators are also exploring options to extend the life of existing assets through refurbishment, upgrades, and repurposing initiatives. This trend is driven by the desire to maximize the value of existing investments and minimize environmental impact.

The FPSO market is at a pivotal juncture, characterized by both challenges and opportunities. While the industry grapples with the uncertainties of oil price volatility and the energy transition, technological innovation, environmental stewardship, and market diversification are driving its evolution.

As FPSO operators navigate these uncharted waters, agility, innovation, and collaboration will be key to unlocking value, mitigating risks, and ensuring sustainable growth in the years to come. By embracing change and leveraging the latest advancements in technology and best practices, the FPSO industry is wellpositioned to chart a course towards a more efficient, resilient, and environmentally responsible future.

2

HILL MEDIA © 2024

Spring 2024 EMERY

COVER STORIES & SPECIALS

Interview: Precision in Motion

In the dynamic landscape of the oil and gas sector, innovation and precision are paramount. Enter ANT AG, a global leader renowned for its cutting-edge technology and manufacturing prowess in mobile waterjet cutting systems.

WORLD INDUSTRY NEWS

EXPLORATION & PRODUCTION

Continuous Production Logging From Tracers.

Tracking fluid connections using tracer is a well-known technique across multiple science disciplines, including oceanography, hydrology, meteorology as well as in petroleum science. In most applications unique tracers are introduced at specific locations as a neat liquid or as a small pre-mixed batch of liquid containing the tracer substance. Once introduced, the tracer provides direct proof of mass transport from one location to another.

Innovative Pumping Solutions

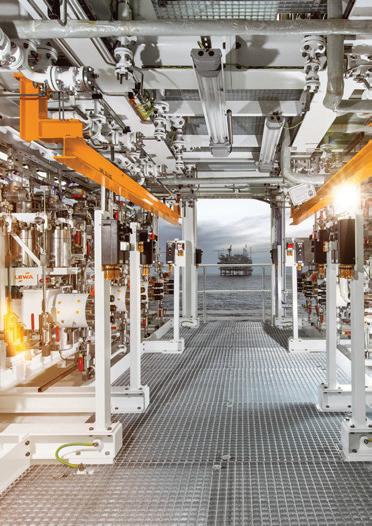

The Buzzard oil field, located about 100 kilometers northeast of Aberdeen, has been a central hub in the European oil and gas industry since its discovery in 2001. The field plays a pivotal role in the energy supply chain, contributing to the vast oil and gas network that sustains the region’s economic vitality. Despite its importance, the Buzzard field presented a unique challenge because of the presence of mercaptan in its crude oil, leading to a groundbreaking solution from SEEPEX that has transformed operations.

Keeping Oil and Gas Customers in Stock

Based in Newcastle, UK on the banks of the River Tyne, a family-run business with an abundance of knowledge and experience to share with the oil and gas industry.

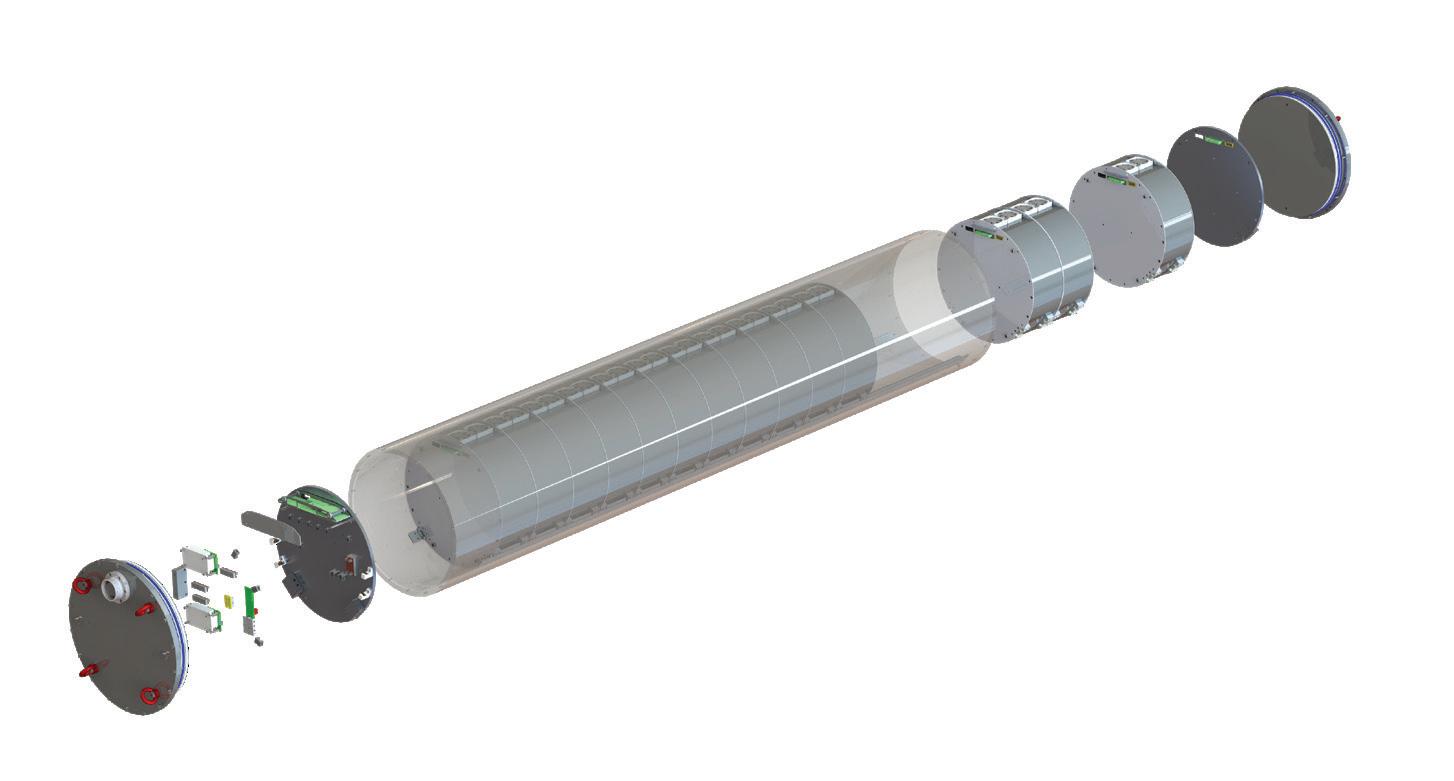

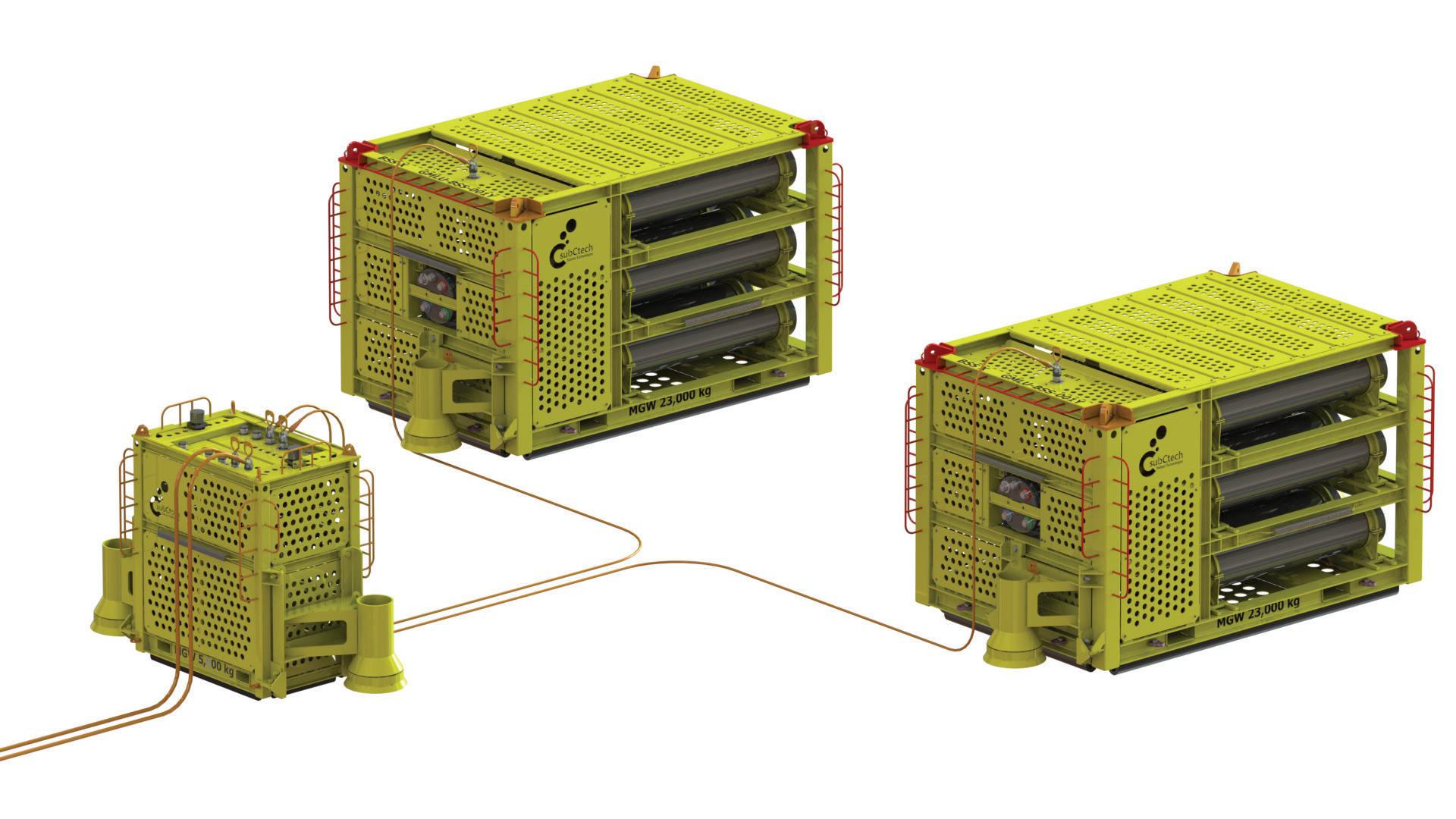

Powering Up Subsea Operations

22 24 26 28

4

CONTENTS 8 22 8

Europe North America Africa Asia Pacific MENA 10 32 64 58 72 28

MIDSTREAM & PIPELINES

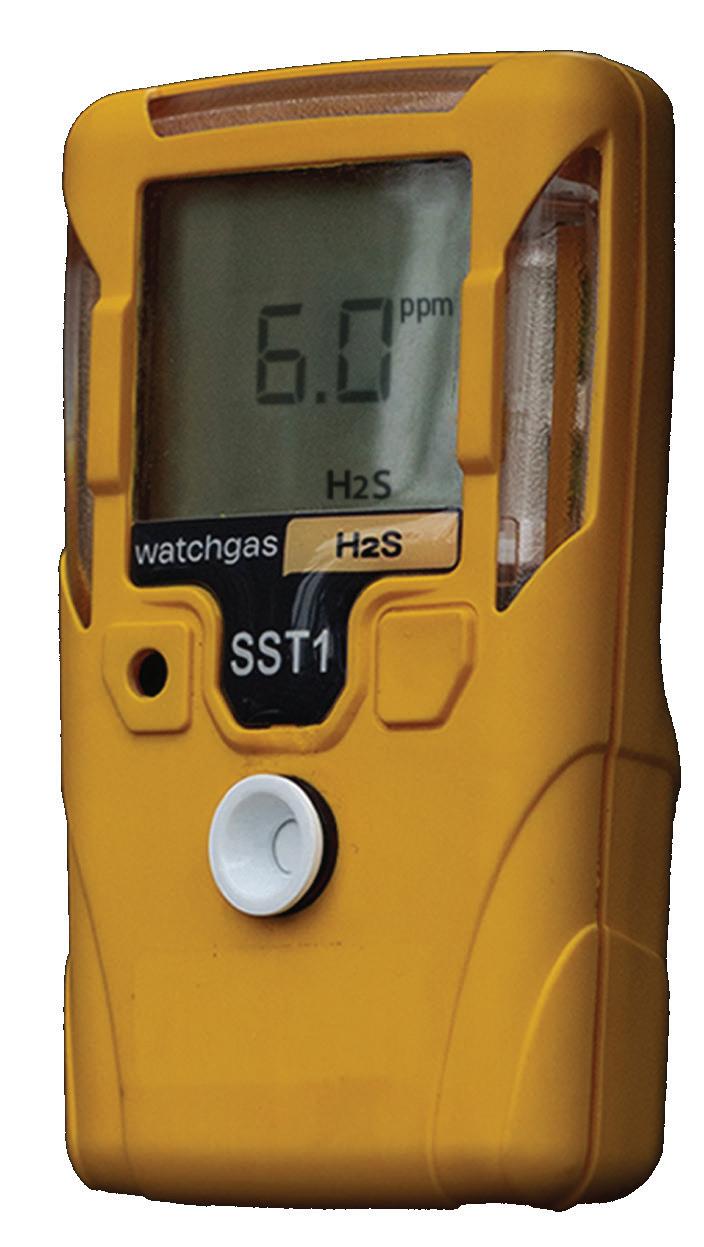

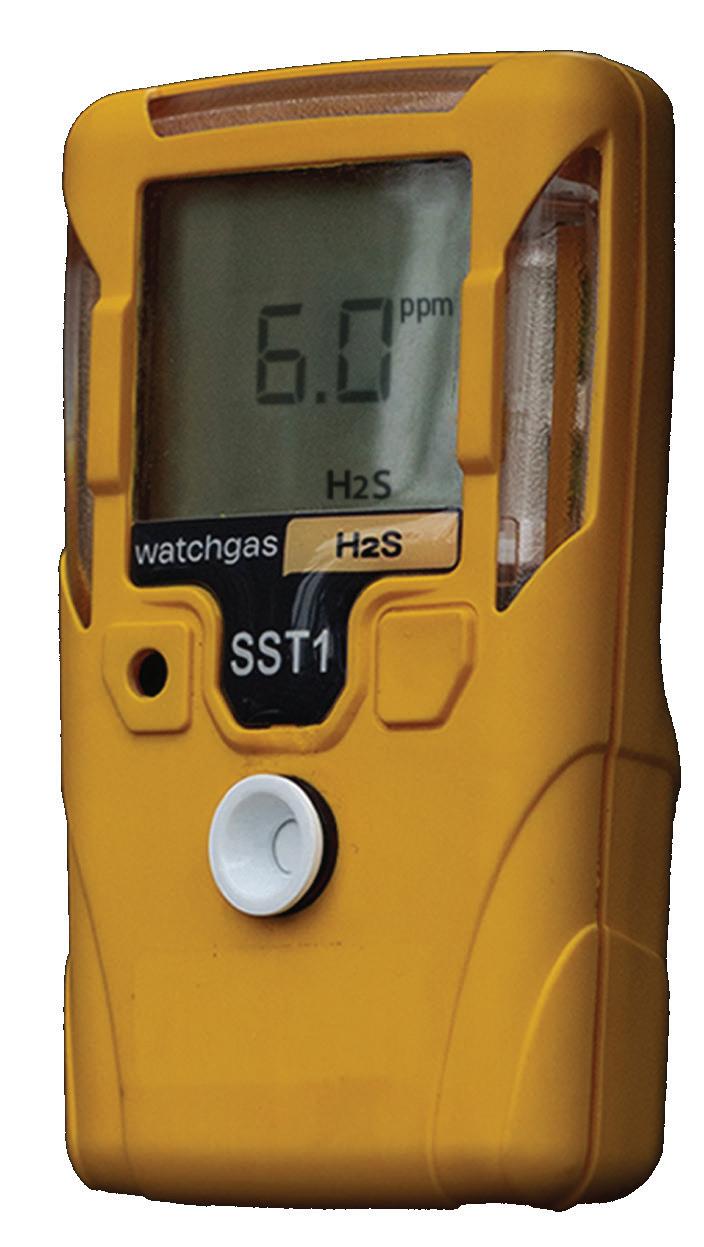

Enhancing Safety and Efficiency

Gas detection systems during shutdowns and the tracking and maintenance of your fleet.

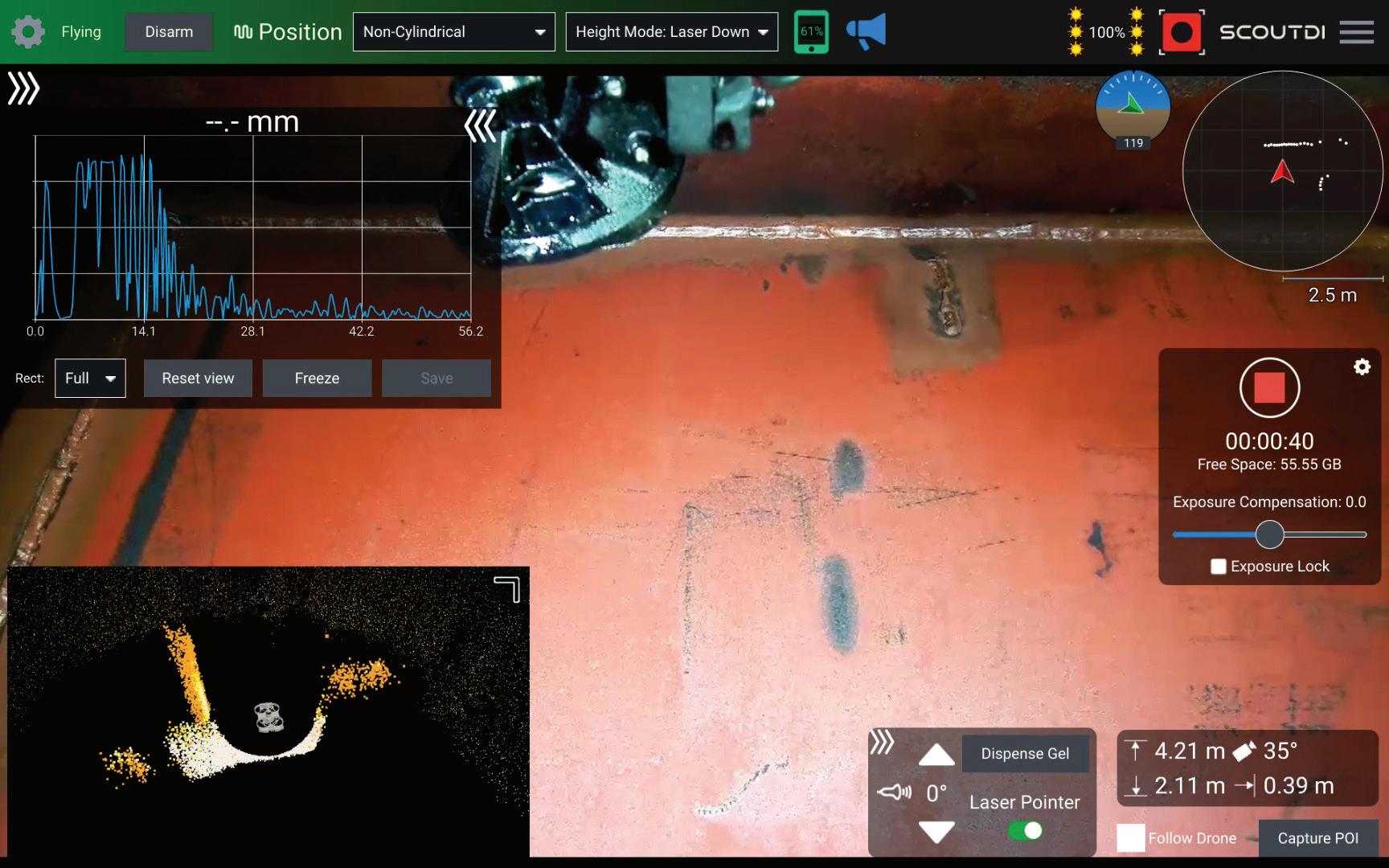

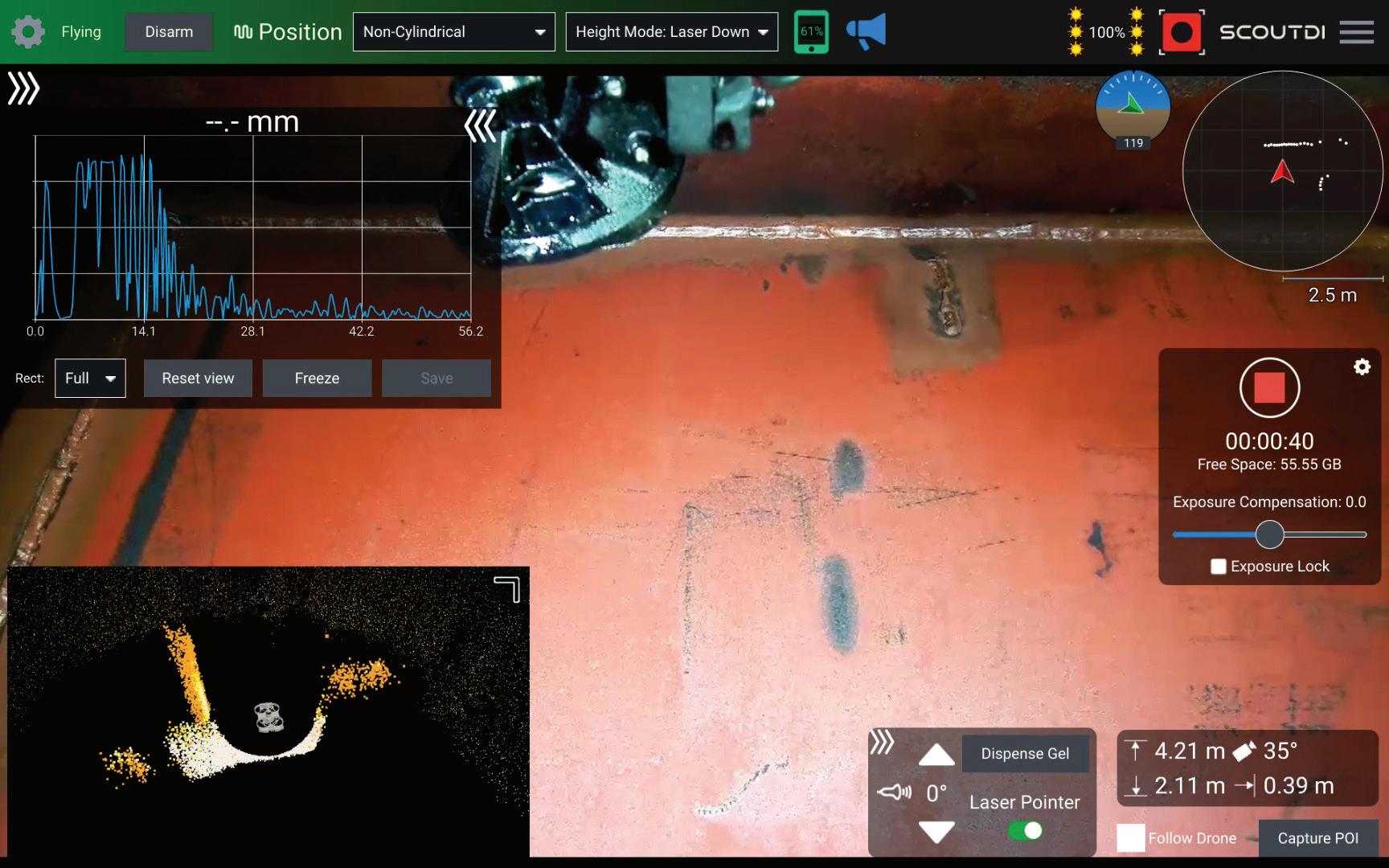

Tank Inspection on FPSO, Gets Surveyor Approval On-The-Spot

TDBR has performed visual inspection on a large FPSO offshore of Brazil, using the Scout 137 Drone System from ScoutDI. This being a large unit, the tethered solution of the ScoutDI drone becomes indispensable with its unlimited flight-time.

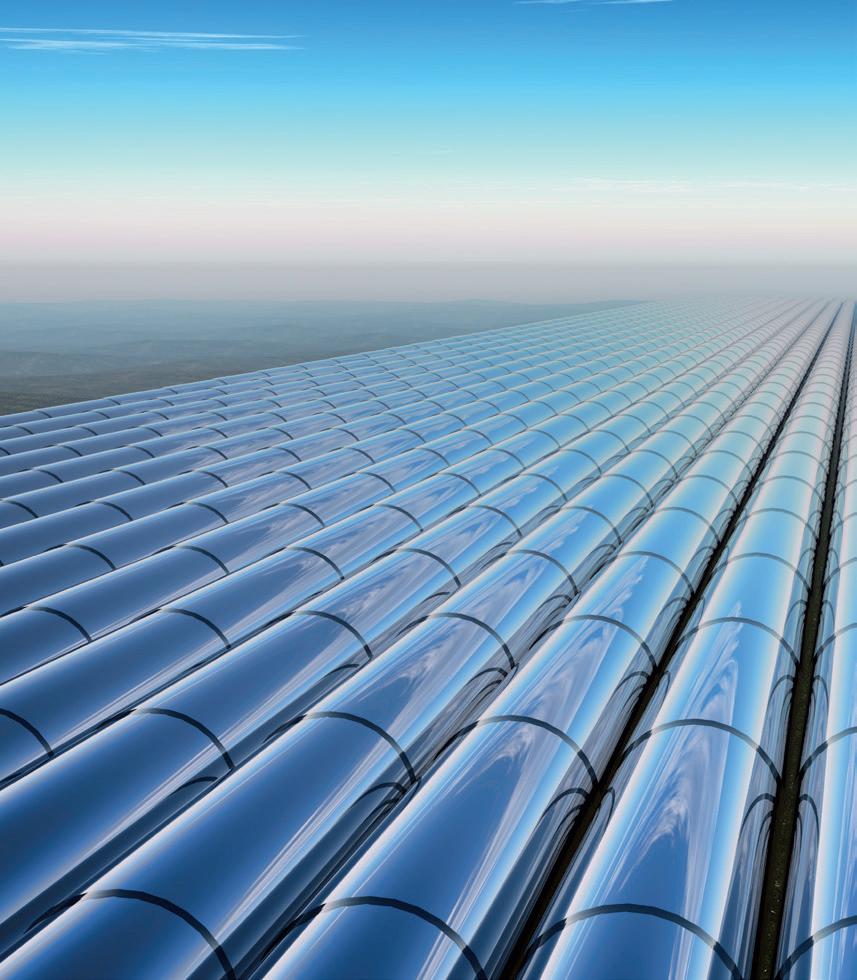

Pathfinder® Foam Caliper Pig, The Next Generation.

The Pathfinder foam caliper pig is unique in the smart pigging arena. With more than 300 successful projects completed and over 10,000 km of pipeline surveyed since initial development in 2016, it has fast become an established geometry inspection technology supporting a range of pipeline pigging applications from construction through to decommissioning.

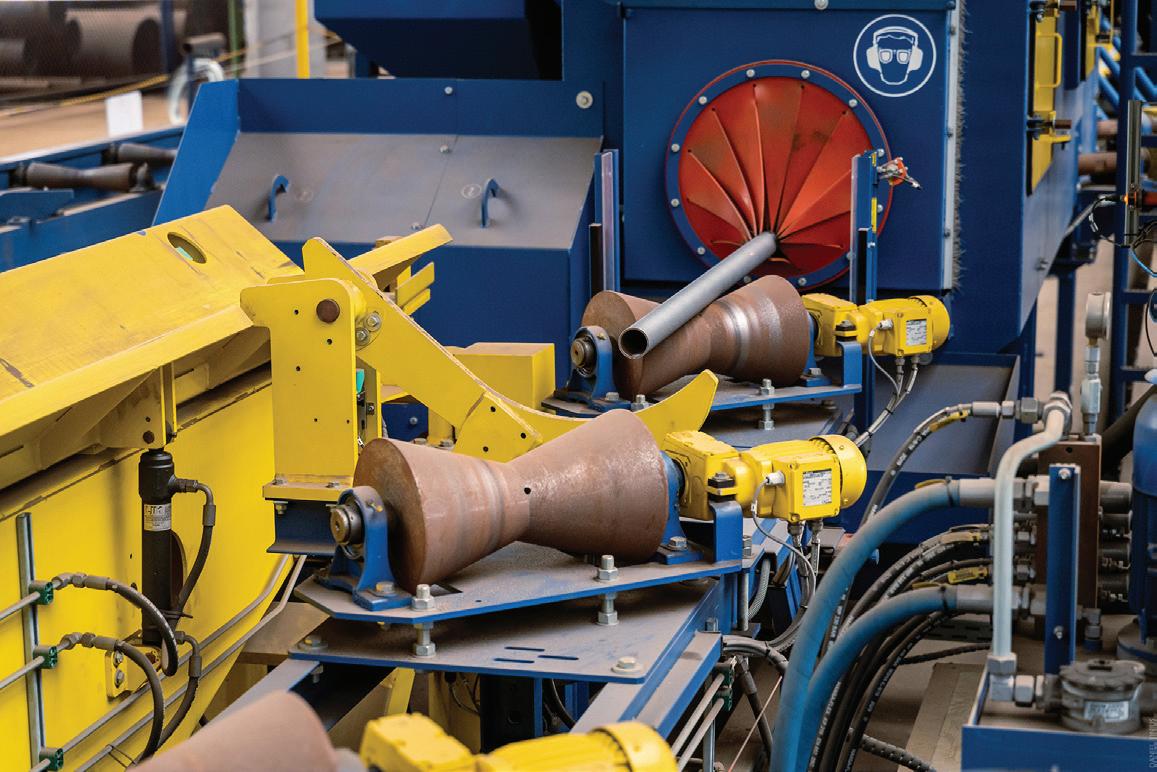

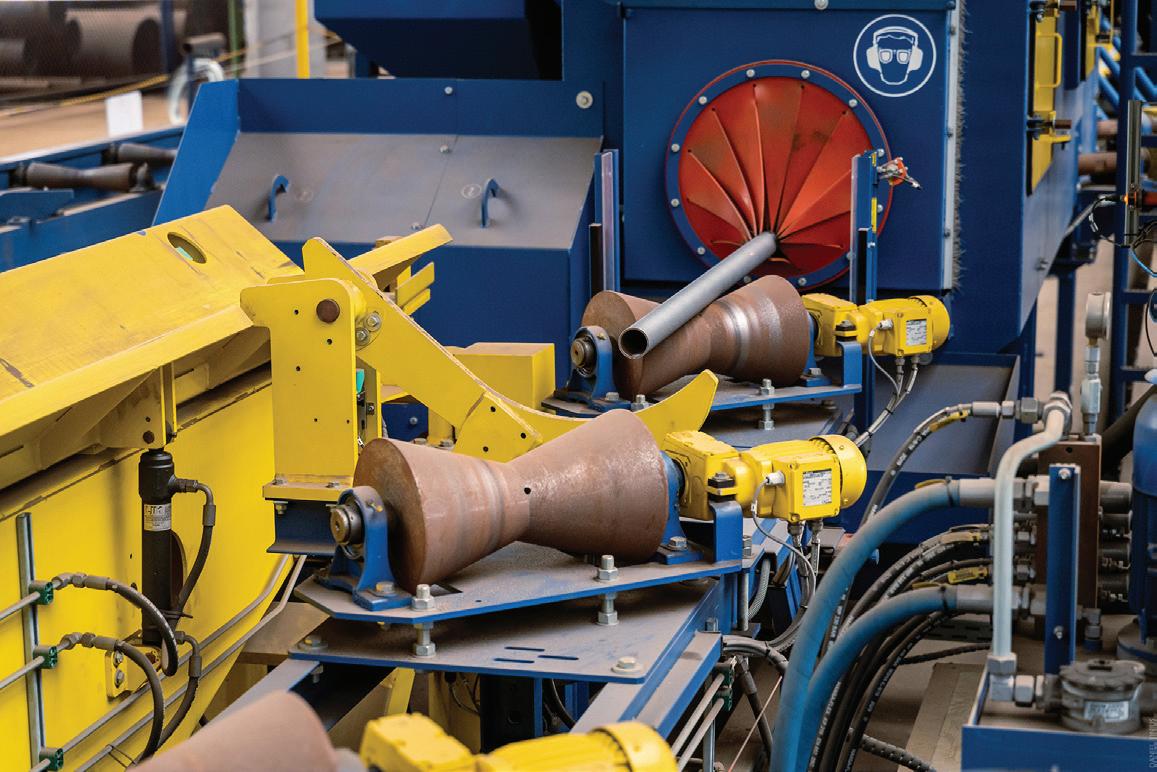

Automation Done Right – Do’s and Don’ts

One of the key components of any oil and gas project are pipes. Whether it is a refinery, a tanker, an offshore rig, or simply a crosscountry pipe-line, it is impossible to complete without extensive piping systems.

PROCESSING

Online TOC Analysis in Return Condensate and Boiler Feed Water

TOC analysers as money makers in refineries Crude oil refinement is a very energy intensive process. Steam and hot water are of a big concern for processing. HYDROGEN

6

CONTENTS

HEALTH, SAFETY & ENVIRONMENT EVENTS CALENDAR 56 50 38 36 36 40 56 50 42 56 80

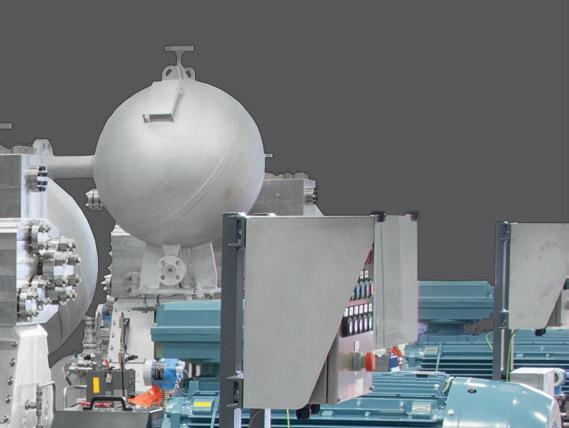

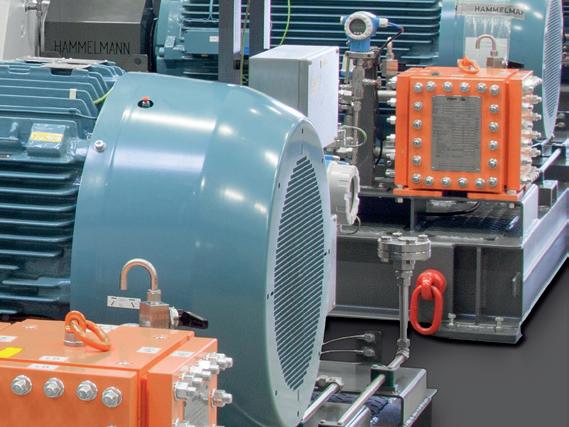

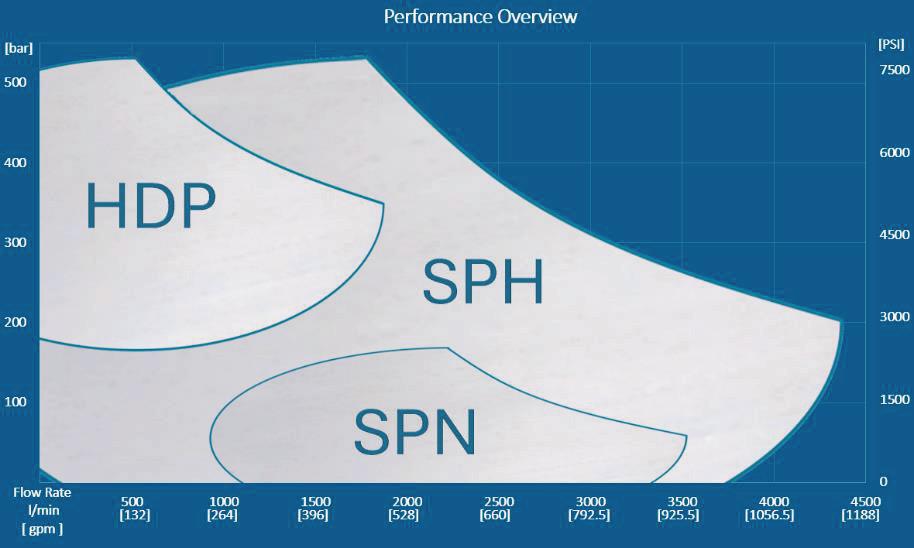

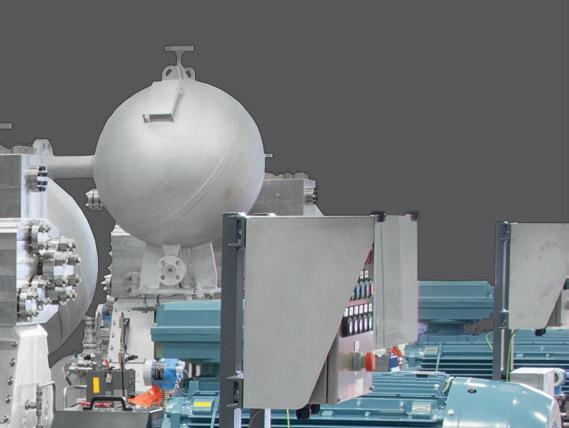

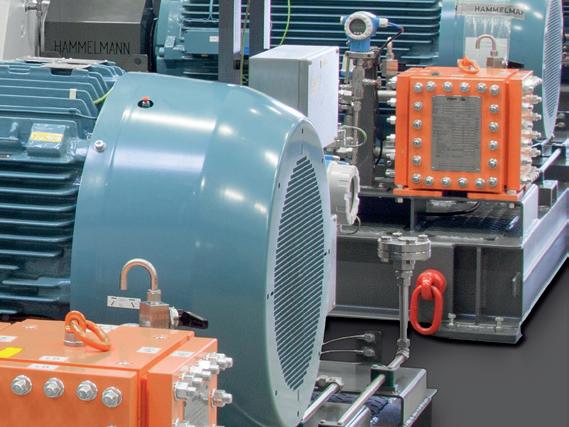

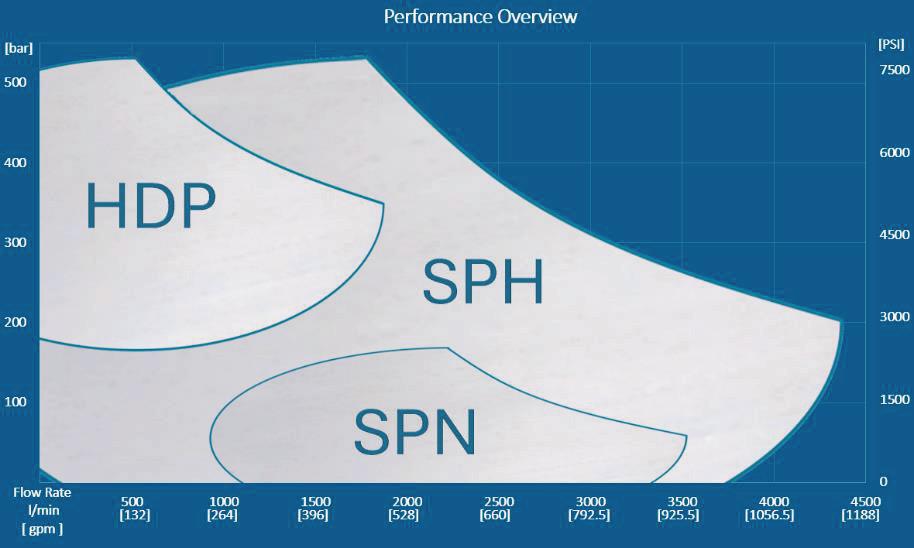

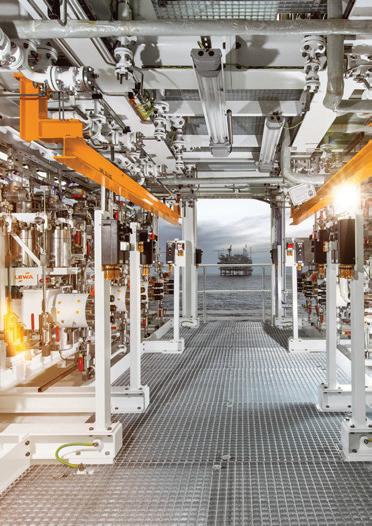

HAMPRO® HIGH-PRESSURE PROCESS TECHNOLOGY

The high-pressure pumps of the HAMPRO® series are used in the Oil and Gas Industries to pump a very wide range of fluids, meet the stringent requirements of the relevant safety and reliability regulations and are characterized by a robust design and careful use of resources.

Our experienced team of experts will be happy to help configure the perfect solution for your individual application.

RECIPROCATING PUMPS

TO API 674

- Glycol pumps

- Leak test pumps

- Methanol pumps

- Produced water injection pumps

- Sea water injection pumps

Pressure: 50 – 4000 bar

Flow rate: 0,1 – 256 m³/h

Hammelmann GmbH

Carl-Zeiss-Straße 6-8

(0) 25 22 / 76 - 0 pp@hammelmann.de

D-59302 Oelde www.hammelmann-process.com

TAILOR-MADE AND

INTEGRATED

FULLY

Precision in Motion: Exploring ANT AG’s Innovations

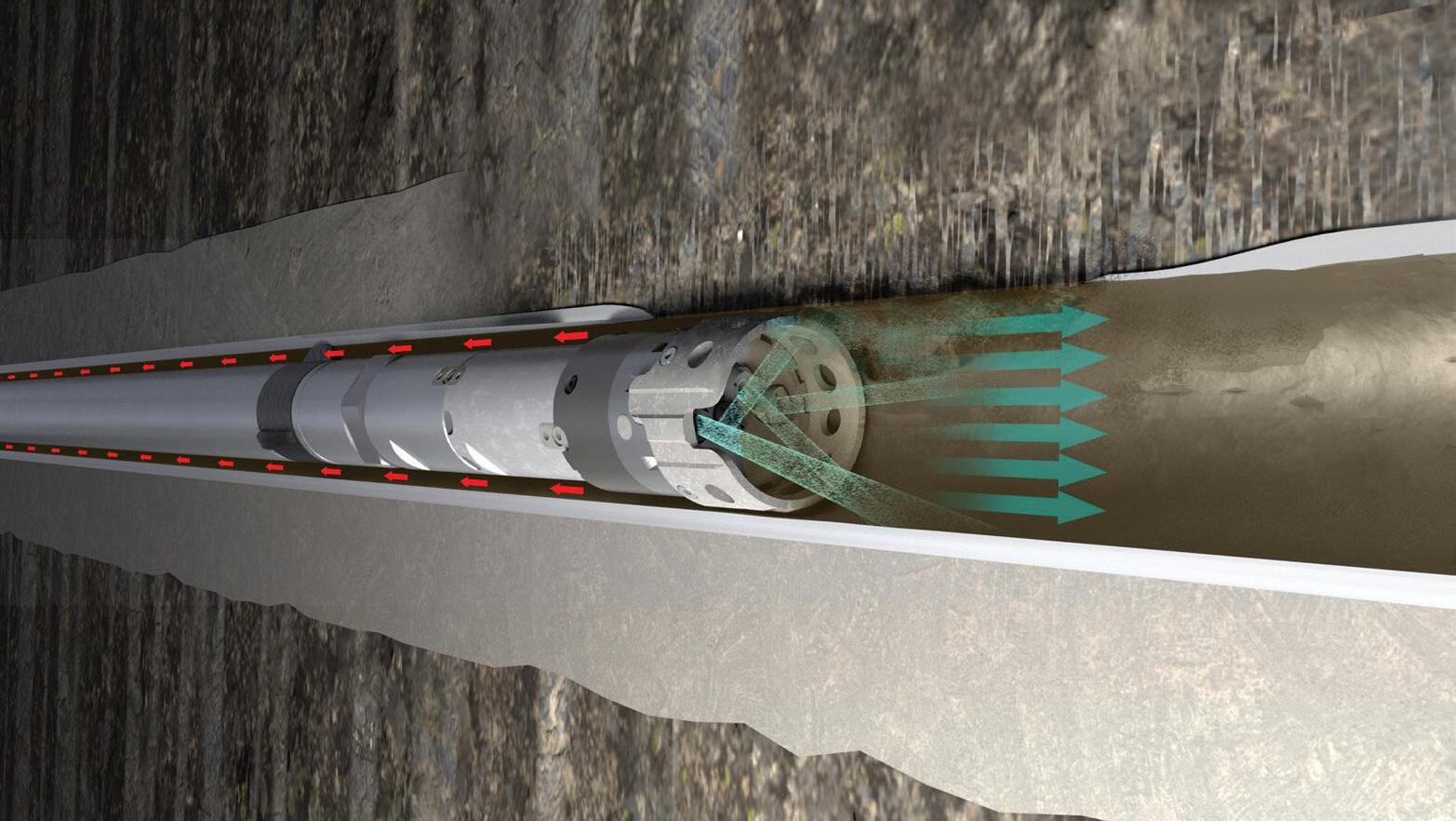

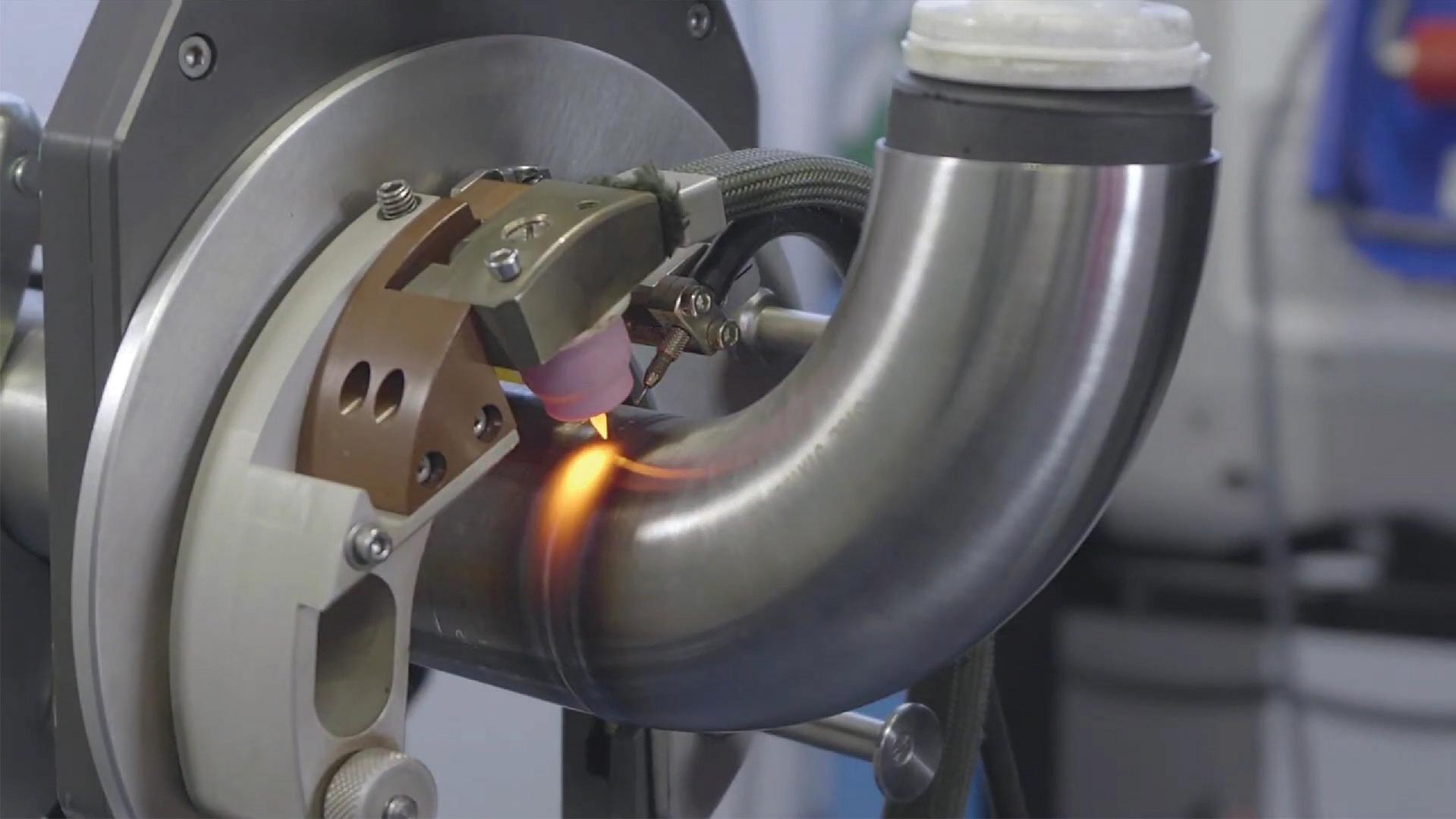

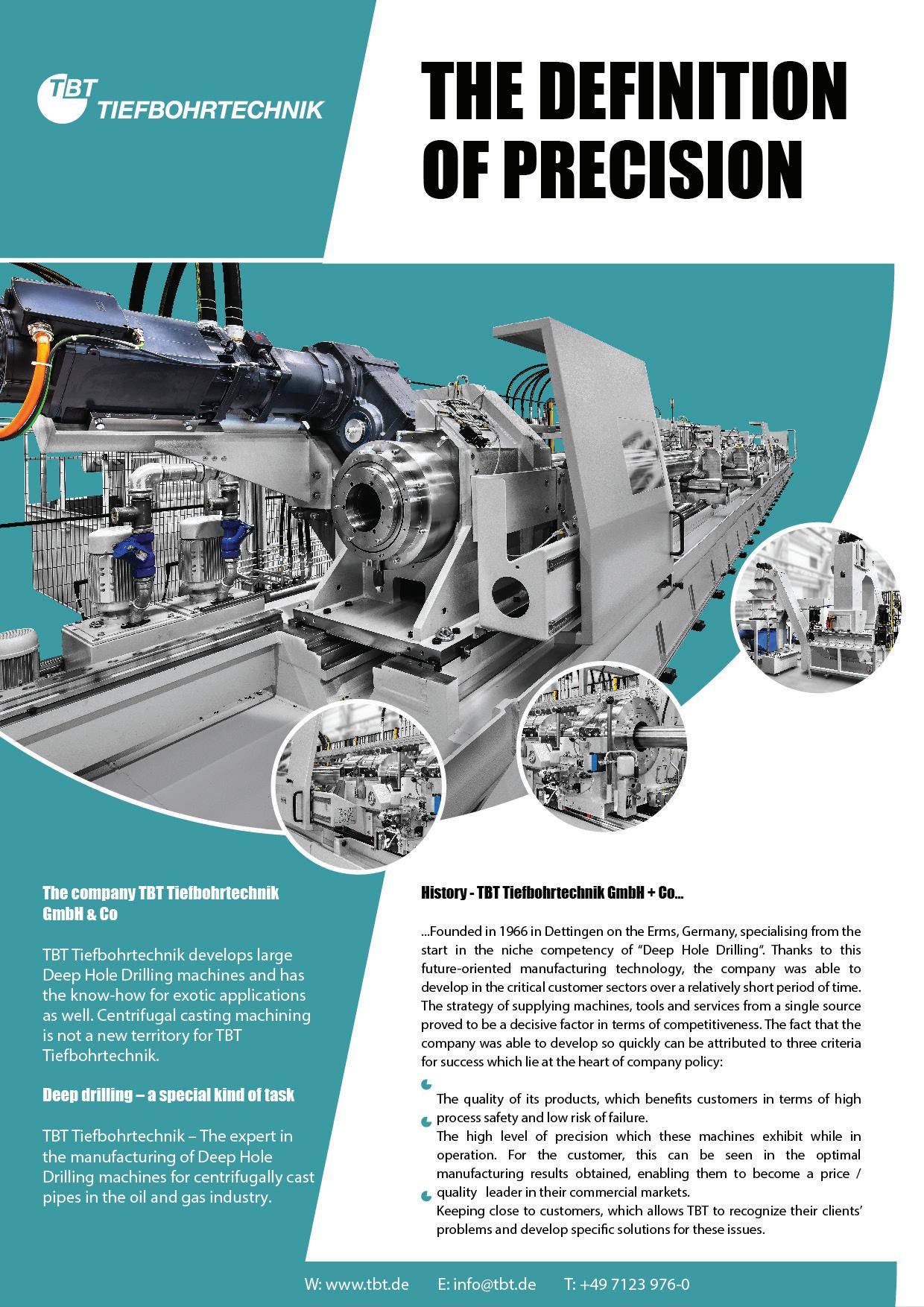

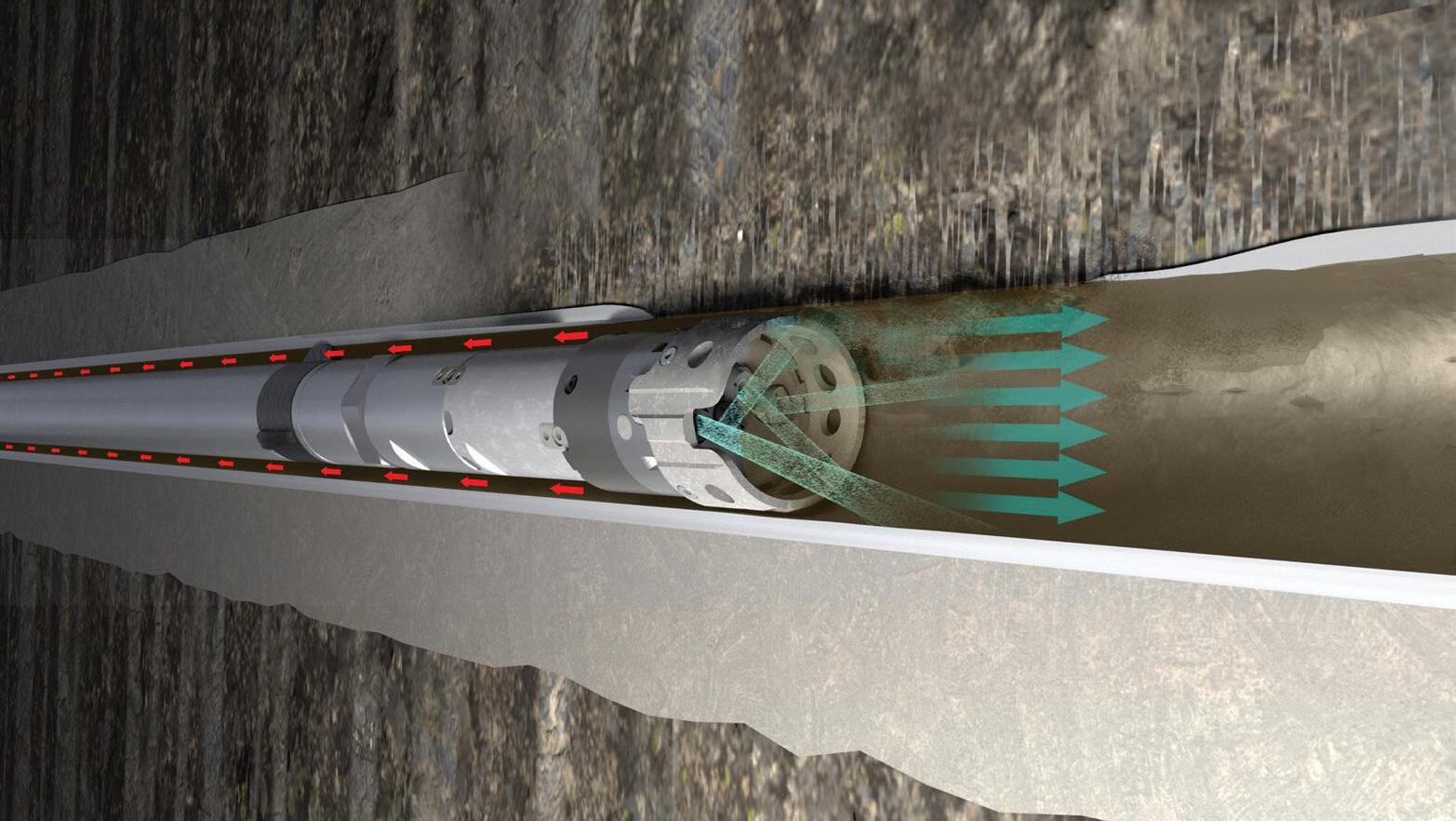

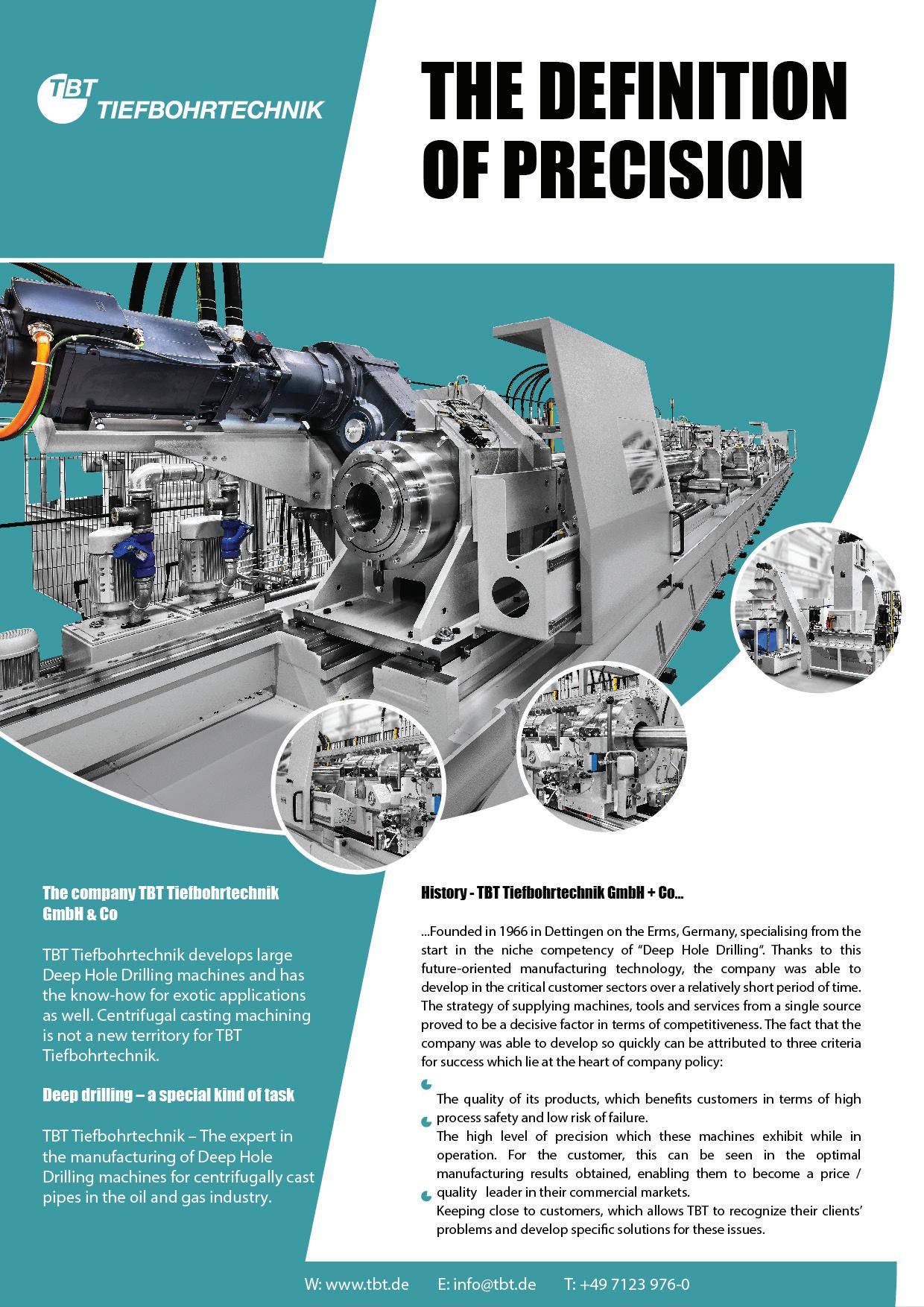

In the dynamic landscape of the oil and gas sector, innovation and precision are paramount. Enter ANT AG, a global leader renowned for its cutting-edge technology and manufacturing prowess in mobile waterjet cutting systems. With over two decades of expertise, ANT AG has carved its niche by offering tailored solutions that merge safety, efficiency, and environmental consciousness. In this exclusive interview with OGI, we delve into ANT AG’s credentials, particularly its subsidiary, ANT UK, which has recently emerged to bolster customer service in the region. From pioneering Water Abrasive Suspension (WAS) cutting systems to its pivotal role in offshore decommissioning projects, ANT AG unveils its commitment to excellence, innovation, and safety in every facet of its operations.

OGI: Could you start by explaining ANT UK’s credentials and experience in terms of your products and services for the oil and gas sector? Could you tell our readers the breadth of your experience, how long the company has been active, and its reach?

ANT AG: ANT, a global leader in technology and manufacturing of mobile waterjet cutting systems, boasts 25 years of experience. We have collaborated with over 100 clients worldwide and actively engage in research and development, holding more than 100 patents globally. In the oil and gas sector, we offer tailored solutions, provide training, and assist clients with their projects. Our subsidiary, ANT UK, was recently established to enhance customer service.

ANT specializes in advanced abrasive cutting and eroding technology, offering integrated solutions for challenging tasks in a safe, efficient, and environmentallyfriendly manner. These solutions are particularly crucial for offshore structures in both the oil and gas and wind power industries. With over two decades of experience, we have partnered with global oil and gas companies and major industry service providers, successfully supporting various projects worldwide.

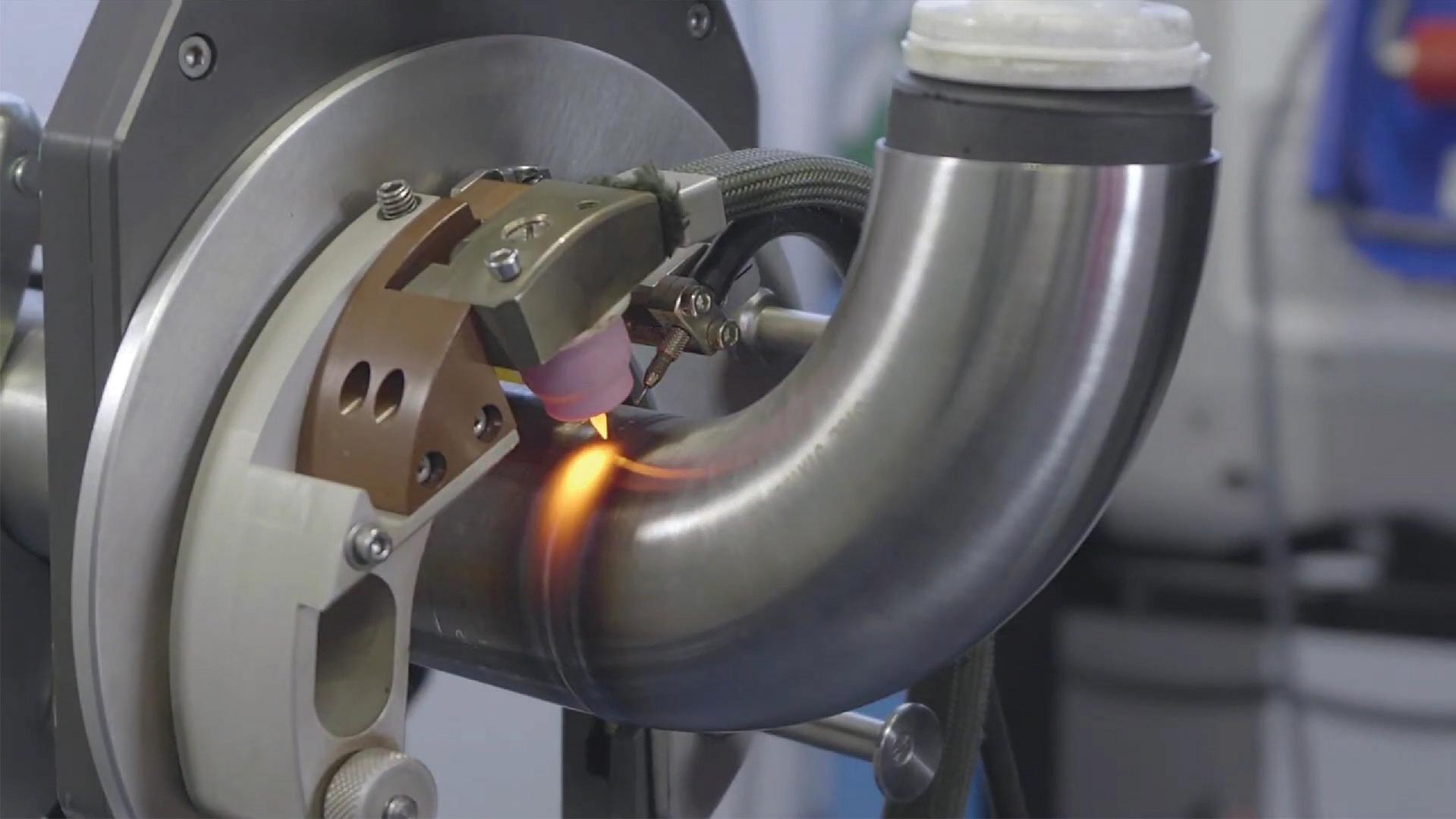

OGI: Could you explain to our readers the advantages of your Water Abrasive Suspension (WAS) cutting systems?

ANT AG: In WAS (Water Abrasive Suspension) systems, abrasive particles are directly suspended in water, resulting in a significantly more stable, precise, and powerful ANT suspension jet compared

to conventional waterjets. Moreover, ANT WAS systems operate without air inside the jet, eliminating the need for high pressure and conserving resources. This technology is versatile, capable of cutting a wide range of materials. The process is contactless, generates no heat, and prevents deformation.

This specialized waterjet cutting technique can be applied both in the air and underwater, as well as in potentially explosive and sensitive environments. Depending on the application, WAS enables safe and remote cutting of materials up to 1,000 mm thick from distances of up to 1,000 m, and up to 250 m underwater.

OGI: What are ANT UK goals in the UK?

ANT AG: Our primary goal at ANT UK is to prioritize customer proximity and service excellence. This is why we took the initiative to establish our presence here. With the rugged North Sea right on our doorstep, we are uniquely positioned to support and facilitate numerous

8

COVER STORY

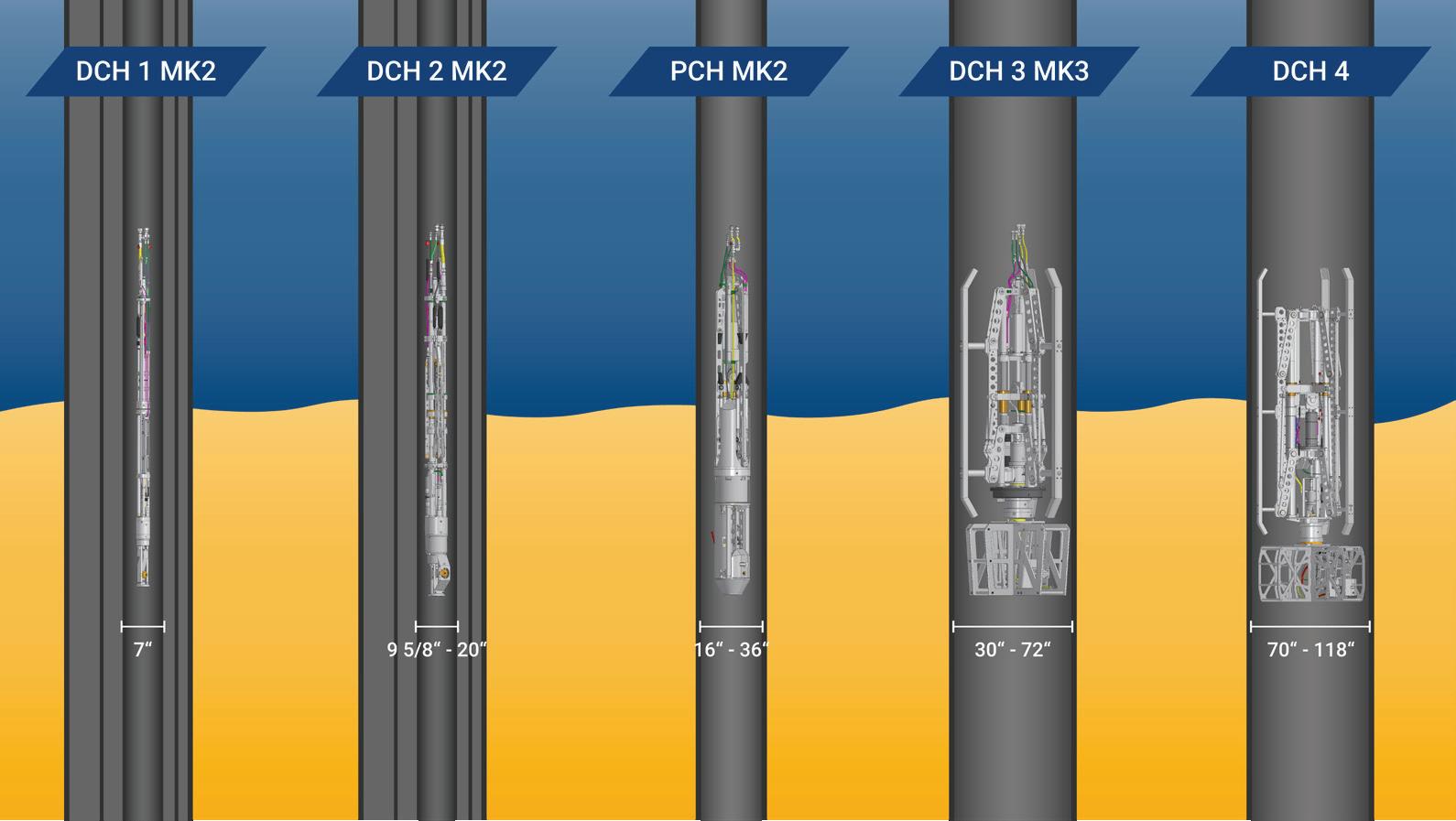

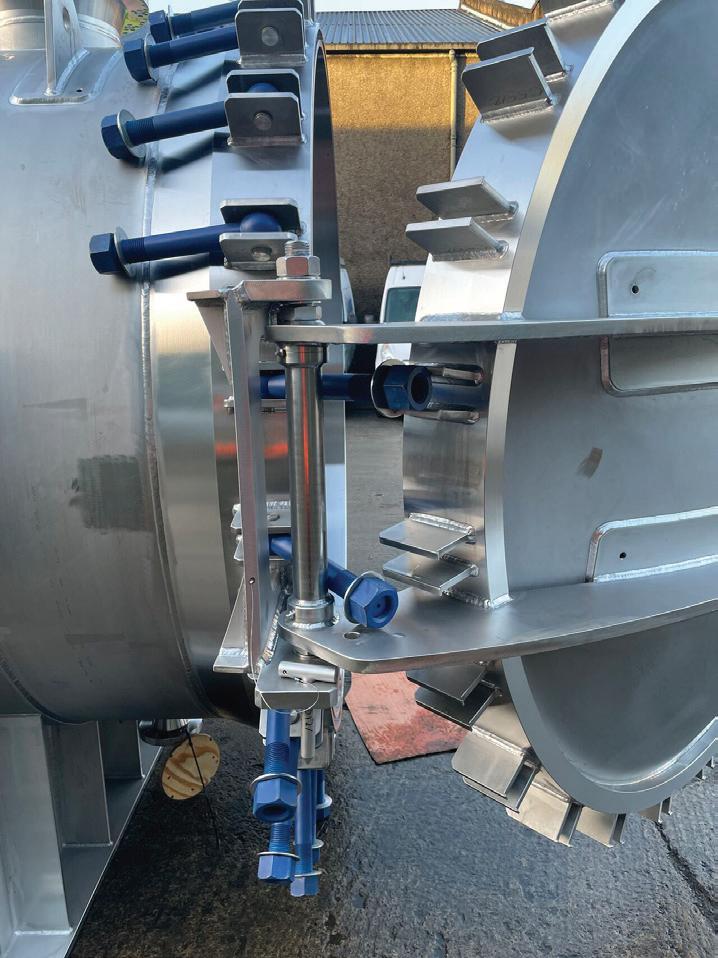

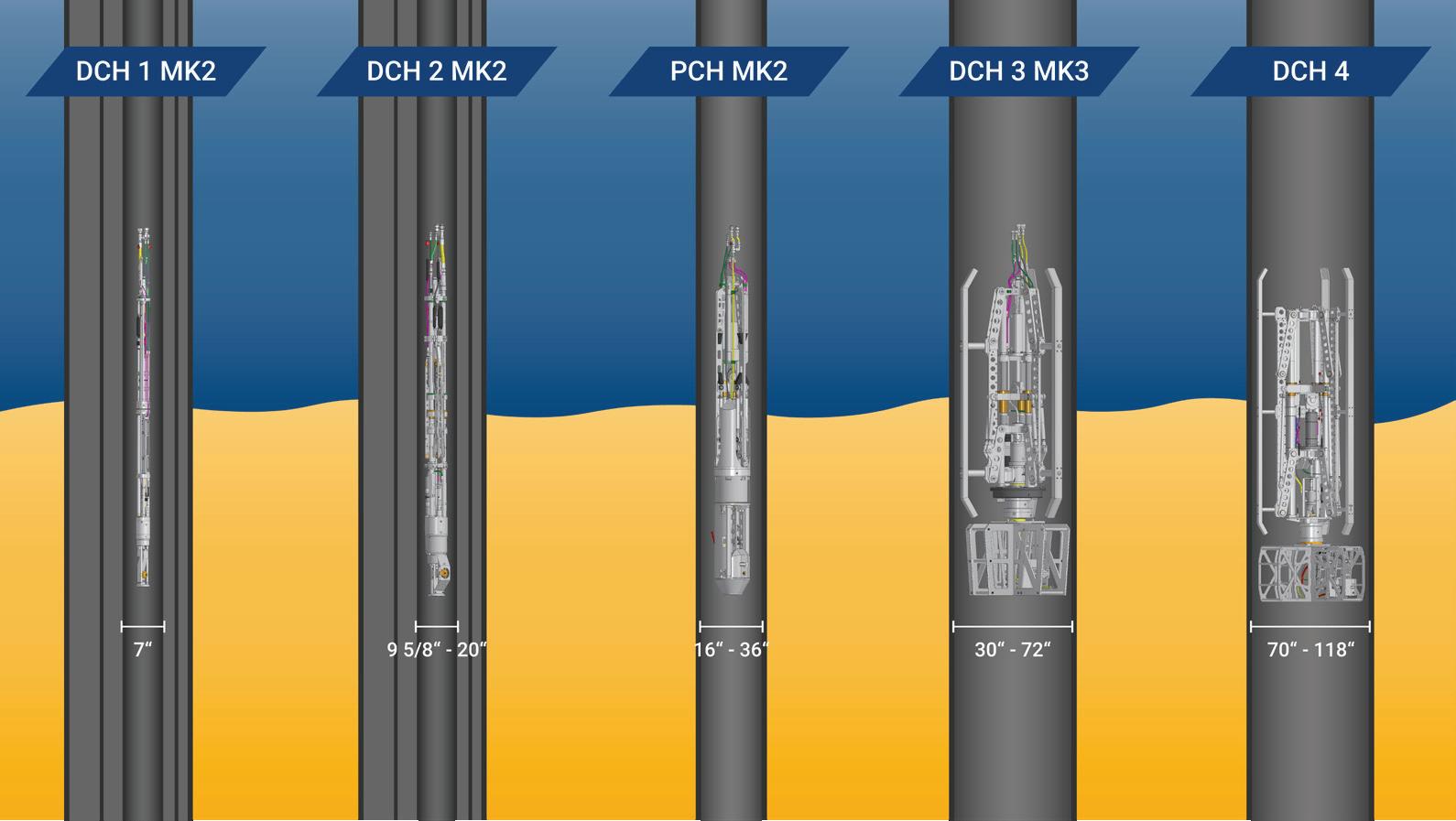

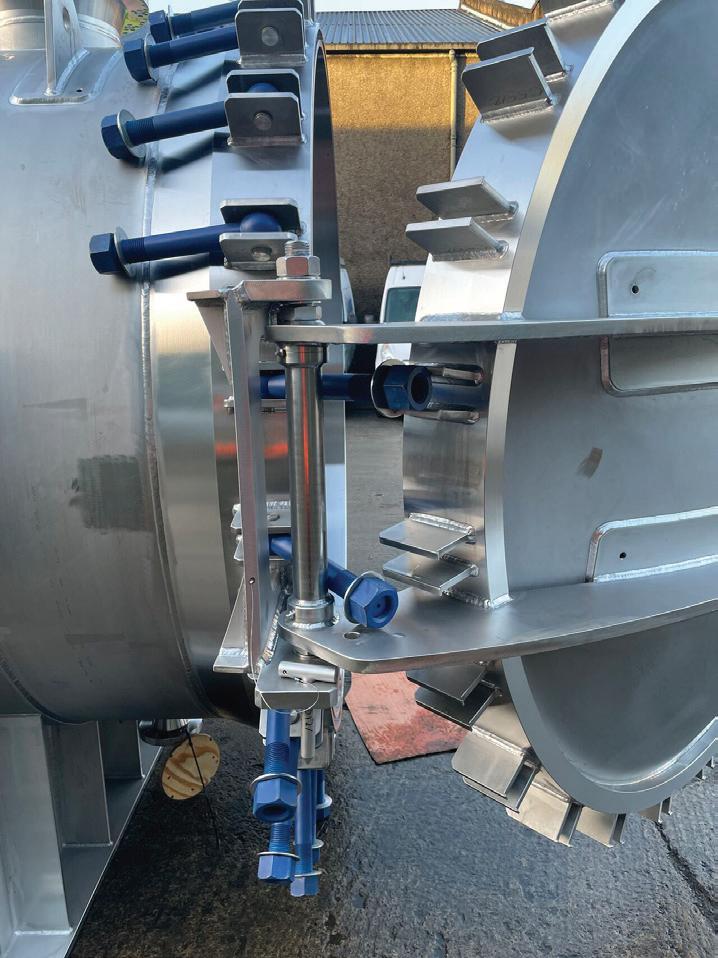

External pile cutting with chain manipulation system.

Internal pile cutting up to 118’’ with DCH 4.

Liam Toovey, ANT Applied New Technologies AG

decommissioning projects in the region. Our commitment is to offer local expertise and dedicated service to our clients, ensuring that we are readily available to meet their needs and challenges in the UK market, especially given that many local service providers are our clients as well.

OGI: Can you talk about the work that ANT does in relation to decommissioning?

ANT AG: In the context of decommissioning, our products and integrated solutions are tailored to address challenging tasks safely, efficiently, and in an environmentallyfriendly manner. These solutions are particularly effective for sustainable repairs, demanding production enhancements, efficient decommissioning, and Plug & Abandonment operations.

the optimal cuts, tools to be used, and estimated cutting durations. This planning tool enhances project efficiency and reliability.

Our technology allows for the cutting of multistring conductors, piles, and structures up to 5 meters below the mudline using our unique cutting technology and equipment.

ANT’s expertise extends to cutting concentric multistring dual bore wells in a single pass without the worry of concentricity . They also offer manipulation systems designed for external cutting of piles and other offshore structures, which can complement an offshore cutting spread for internal cutting or be integrated into a customized WAS cutting system tailored to address a wide range of cutting challenges both offshore and onshore.

Certainly, when it comes to decommissioning, ANT offers a range of innovative solutions and services. Our cutting-edge technology includes remote-operable systems equipped with signals that provide real-time visualization of the cutting process. This feature allows operators to monitor and assess the progress of their cuts in real-time, ensuring precision and efficiency.

In addition to this, we provide our clients with the unique ANT Cutting Calculator. This invaluable tool enables our clients to plan their projects with precision, helping them determine

We understand the unique challenges faced by our customers, and we are dedicated to helping them find the best solutions for their business operations. Our solutions are suitable for ATEX zones, easy to set up, and have a small footprint.

We take pride in offering comprehensive support, including commissioning, system testing, onsite support withand thorough training to ensure our clients are well-prepared to utilize their waterjet cutting systems safely and effectively. Safety is paramount in everything we do.

Furthermore, our own service team is on hand to provide maintenance services, ensuring minimal downtime and reliable troubleshooting, including through augmented reality tools.

At ANT, we embrace challenging projects and have a dedicated research and development team with extensive experience, technological expertise, and a commitment to innovation. We also collaborate with universities and research institutes to drive innovation and continuously improve our solutions.

For P&A and challenging wells, we have

developed our own product called wellANT. This tool doesn’t cut but rather erodes, for instance, removing stuck plugs effortlessly with our two-phase jet.

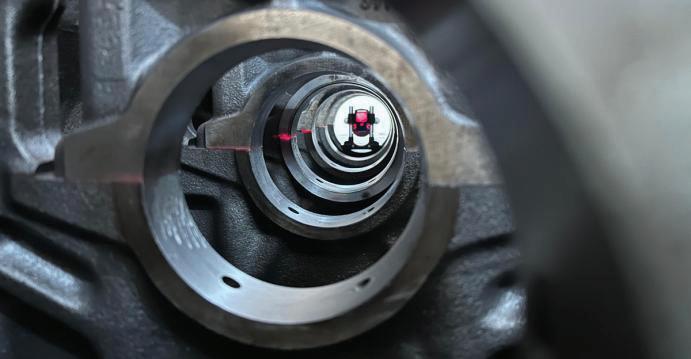

OGI: What is the DCH 4 and it’s applications?

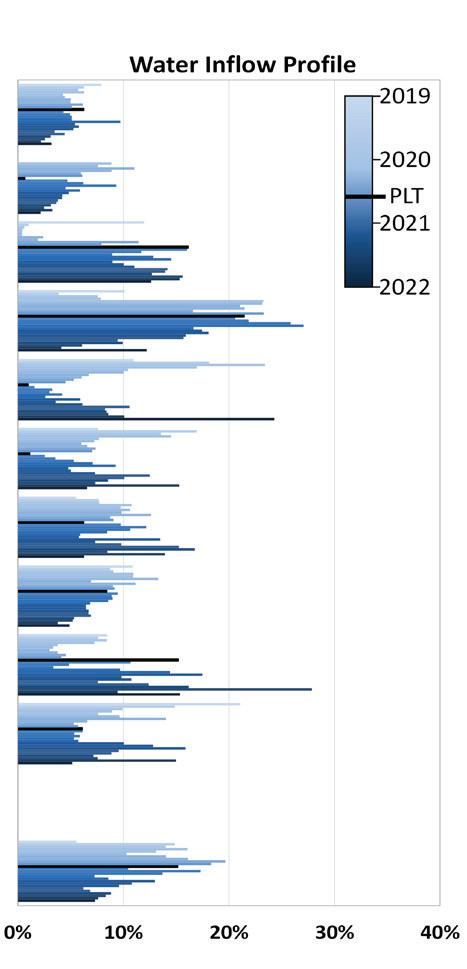

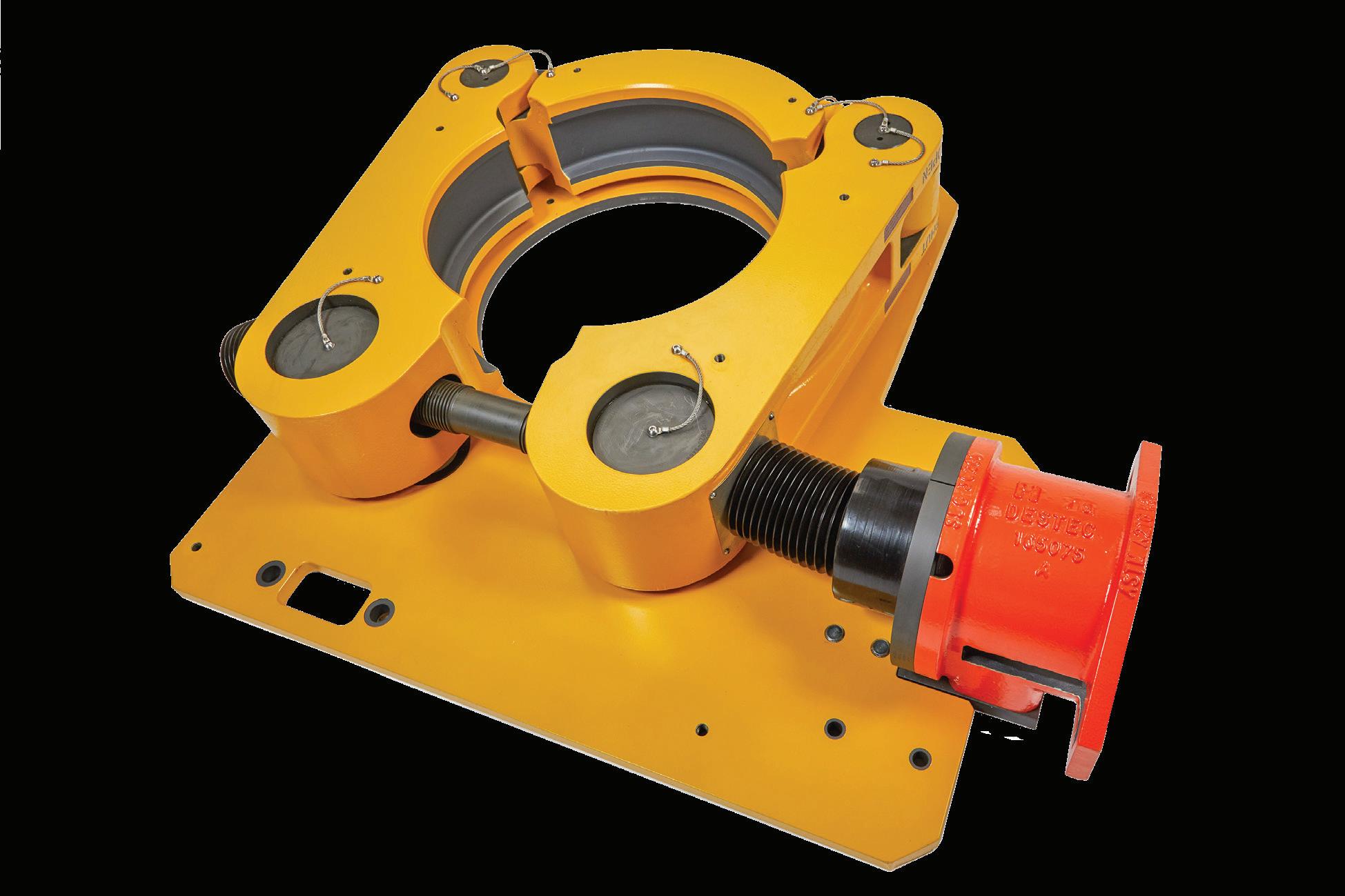

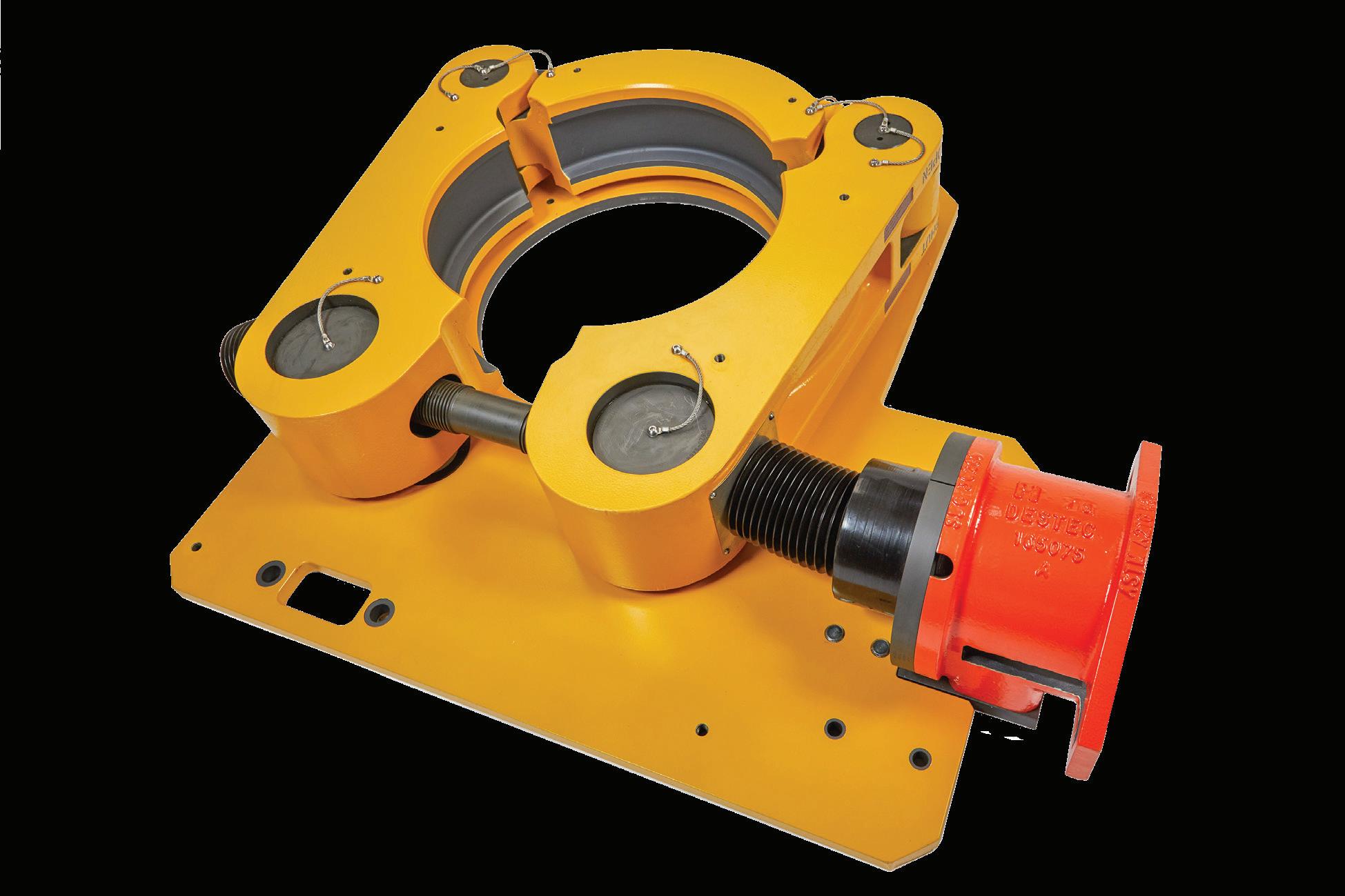

ANT AG: The DCH 4, or Downhole Cutting Head 4, is a specialized manipulation tool designed by our company in response to global market demands for offshore decommissioning projects. It stands out for its continuous clamping mechanism and stepless extendable cutting head, enabling it to cut a wide range of pipe diameters efficiently.

The DCH 4 Manipulation Tool is versatile and suitable for various offshore decommissioning applications, such as efficiently and accurately cutting piles with diameters ranging from 70” to 90” and from 90” to 118”.

OGI: What type of products do you have that suitable for ATEX zones?

ANT AG: All of our decom waterjet systems are ATEX zone certified, including our comprehensive range of products designed for operations in potentially explosive atmospheres. This includes all Downhole Cutting Heads/Manipulation Tools (e.g., DCH 1-4, PCH for internal cutting, Chain manipulator for external cutting), our Packer, capable of cutting in waters up to 250 meters deep, as well as our Pump, Lifting Unit, Control Container, and Systems. Furthermore, our central component, the Abrasive Mixing Unit (AMU), is fully approved for ATEX Zone II 3G IIB T3 environments, ensuring that our entire product range is suitable for use in such zones while maintaining the highest safety standards.

OGI: Thank you for your time. •

If you would like to know more about how ANT Applied New Technologies AG can help your company and its operations, please contact them:

ANT Applied New Technologies AG

T.: +44 7904 244738

E: decom@ant-ag.com

W: https://www.ant-ag.com

9

Plug Removal & Rigless Sidetracking with wellANT.

KROHNE Reaches Important Milestone in Ethernet-APL technology

In December 2023, KROHNE made Ethernet-APL demo devices available to selected customers. This step marks an important milestone in the company’s own Ethernet APL development project for various sensor types.

Ethernet-APL technology is a revolution in the process industry: for the first time, a high data rate (10 Mbit/s) is combined with intrinsic safety for the field level. In addition, the technology enables a two-wire operation including power supply. KROHNE was a founding member of the Ethernet-APL consortium in 2018 and has thus actively promoted the technical design of the standard.

Customer interest in Ethernet-APL has been growing steadily for several years, particularly in the chemical industry, but also beyond. “With Ethernet-APL, we are fully digitalizing the field level,” explains Dr Christoph Spiegel, Head of Strategic Product Management in the Electronics Division at KROHNE. “Our demonstrators already have most of the functions that are possible with this technology. They provide the implementation of PROFINET according to the PA (Process Automation) profile 4.0 with generic or alternatively manufacturer-specific GSD file. There is also an FDI package for use with all modern asset management systems and an integrated web server with a convenient user interface for simple commissioning and diagnostics.”

“We hope that we can obtain early feedback and test results via the demonstrators, including interoperability test results with various host systems,” continues Spiegel. “We want to strengthen our customers’ trust in KROHNE as a reliable partner that brings the latest technology into practice at an early stage. Ethernet-APL is still a very young technology, which is why we are working particularly closely with users here. Looking at the progress of the project, I am confident that KROHNE will be able to present the first Ethernet-APL devices by the end of the fourth quarter of 2024.”•

Global LNG Demand to Grow Beyond 2040, Driven by Industrial Demand in China and Economic Development in South Asia and SouthEast Asia

London

– Global demand for liquefied natural gas (LNG) is estimated to rise by more than 50% by 2040, as industrial coal-to-gas switching gathers pace in China and South Asian and South-east Asian countries use more LNG to support their economic growth, according to Shell’s LNG Outlook 2024.

Global trade in LNG reached 404 million tonnes in 2023, up from 397 million tonnes in 2022, with tight supplies of LNG constraining growth while maintaining prices and price volatility above historic averages. Demand for natural gas has already peaked in some regions but continues to rise globally, with LNG demand expected to reach around 625-685 million tonnes a year in 2040, according to the latest industry estimates.

“China is likely to dominate LNG demand growth this decade as its industry seeks to cut carbon emissions by switching from coal to gas,” said Steve Hill, Executive Vice President for Shell Energy. “With China’s coal-based steel sector accounting for more emissions than the total emissions of the UK, Germany and Turkey combined, gas has an essential role to play in tackling one of the world’s biggest sources of carbon emissions and local air pollution.”

Over the following decade, declining domestic gas production in parts of South Asia and South-east Asia could drive a surge in demand for LNG as these economies increasingly need fuel for gas-fired power plants or industry. However, countries in South Asia and South-east Asia would need significant investments in gas import infrastructure.

The Shell LNG Outlook 2024 shows that gas complements wind and solar power in countries with high levels of renewables in their power generation mix, providing short-term flexibility and long-term security of supply.

European energy security

LNG continued to play a vital role in European energy security in 2023, following a slump in Russian pipeline exports to Europe in 2022, with new regasification facilities helping to improve security of energy supplies. European LNG imports remained at similar levels to 2022, despite an overall decline in European gas demand in 2023.

Relatively mild winter temperatures in countries that rely on gas for heating, combined with high gas storage levels, stronger nuclear power generation and a modest economic recovery in China, all helped balance the global gas market in 2023.

This helped bring down and stabilise gas prices in the key importing regions of Europe and East Asia compared to the record highs and unprecedented volatility seen from late 2021 through 2022. However, gas prices and volatility remained significantly higher in 2023 than in the 2017-2020 period. •

10

NEWS - EUROPE

SMART PIPE-SHOP AUTOMATION

Eni, Fincantieri and RINA Establish Partnership for Maritime Transport Decarbonization

Rome, Eni, a global energy company, Fincantieri, one of the world’s largest shipbuilding groups, the only one active in all high-tech marine industry sectors, and RINA, a multinational inspection, certification, and engineering consultancy, have signed an agreement to develop joint initiatives for the energy transition. The partnership formalises the commitment to develop joint projects, in line with the partners’ strategies, to decarbonise the maritime sector in the medium to long term with the goal of Net Zero by 2050. Additionally, the establishment of a permanent global observatory regarding future technological, regulatory, and market developments will be evaluated.

The three companies will conduct a comprehensive analysis and evaluation of the most sustainable alternatives to support the maritime decarbonisation pathway. This will also be based on the development of complementary solutions to fuels already available for other hard-to-abate sectors. The partnership’s areas of interest also include an analysis of the reference energy infrastructure and the development of new logistic structures, including the investments that the sector requires.

Giuseppe Ricci, Chief Operating Officer for Energy Evolution at Eni, commented: “The collaboration with Fincantieri and RINA, two major Italian players, is a further step in our journey towards the transition and decarbonisation of maritime transport. To meet the objectives of the UN 2030 Agenda, it is important not only to manage what is immediate but also to act with a medium to long-term perspective, developing partnerships to create more sustainable solutions and products. The ability to network among the partners, with their wealth of skills and technological capabilities, can make a significant contribution to finding more effective solutions for decarbonising maritime transport and meeting the needs of shipowners and logistics operators, always leveraging a holistic approach”.

Pierroberto Folgiero, CEO and Managing Director of Fincantieri, said: “We are highly committed to supporting our clients in addressing the industrial challenges of the maritime energy transition, and this initiative is aimed at initially creating a hub of study to harness Italy’s extraordinary expertise in new technologies, novel fuels, and their profound industrial implications for the ship system. We are very pleased to join forces with Eni and RINA in an alliance to materialize existing solutions and to pave the way for the future with a proactive ecosystem approach. Indeed, new technologies must be industrialized on board ships, just as new fuels must be produced and distributed at the dock. Only with a concept of “operationalizing innovation”

can we lead our industry and project our shipbuilding leadership into the future”.

Carlo Luzzatto, CEO and General Manager of RINA, said: “We strongly believe in the value of collaboration and the opportunities it brings, particularly when it involves players of international calibre such as Eni and Fincantieri. Together, we have the opportunity to share knowledge and experience and to contribute to more sustainable solutions that support the shipping supply chain. RINA brings to the partnership its engineering and technological skills, developed across various sectors, to support shipping in its journey towards reducing its carbon footprint, without excluding any energy options”.

The understanding may be the subject of subsequent binding agreements that the parties will define in compliance with the applicable legislation, including that relating to transactions between related parties. •

Siemens @ Hannover Messe 2024

Cedrik

Neike, Member of the Managing Board of Siemens AG and CEO of Siemens Digital Industries, will share the solutions Siemens is developing for a sustainable, resilient and intelligent industry.

In order to become more sustainable along the entire value chain, industrial enterprises need to drive their digital transformation forward. Artificial intelligence, sustainability and competitiveness are focus of the motto “Accelerate Transformation”. Find out what it means for industrial companies to quickly become a sustainable and resilient Digital Enterprise. At this year’s Hannover Messe, Siemens will use showcases from the automotive, chemical, food and semiconductor industries to demonstrate how we connect the real and digital worlds to design, manufacture and recycle products. •

OPTIBAR FC 1000: new flow Computer Complements the KROHNE DP Portfolio

WithOPTIBAR FC 1000, KROHNE introduces a compact, high performance flow computer for volumetric flow calculation and heat quantity measurement of liquids and gases, including saturated steam and superheated steam. The device complements the extensive portfolio for differential pressure flow applications that KROHNE has been steadily expanding since 2010.

Its compliance with IAPWS-97 for water and steam calculations with condensate detection, makes this flow computer particularly useful for differential pressure (DP) flow measurement of saturated and super-heated steam. In addition, a variety of other calculation methods are available for the correction calculation of gases and liquids. For highly accurate measurements, the KROHNE flow computer provides correction of linearity errors of DP flow elements in real-time and in accordance with ISO 5167 requirements. •

12 NEWS - EUROPE

Repsol Begins Large-Scale Production of Renewable Fuels in Cartagena, the First Plant of its Kind in the Iberian Peninsula

• Repsol is the only company in Spain and Portugal with a plant fully dedicated to the production of renewable fuels on an industrial scale.

• The new plant has the capacity to annually produce 250,000 tons of renewable fuels from waste, such as used cooking oil. The fuel can be used in airplanes, ships, buses, trucks, or cars.

• Renewable fuels are an already available alternative that can be used in existing vehicles and infrastructures to help speed up the decarbonization of transport.

• The renewable fuels manufactured in Cartagena will avoid the emission of 900,000 tons of CO2 per year.

Repsol marks a milestone in the decarbonization of transport in the Iberian Peninsula with the start of large-scale production of renewable fuels at its industrial complex in Cartagena (Spain). This plant is the first on the Iberian Peninsula dedicated exclusively to the production of 100% renewable fuels. The company has invested €250 million in the construction of the unit, which has a production capacity of 250,000 tons per year. It can produce renewable diesel and Sustainable Aviation Fuel (SAF), which can be used in any means of transport: cars, trucks, buses, ships, or airplanes, and with existing refueling infrastructure.

The renewable fuels are produced from organic waste, such as used cooking oil or agri-food waste, thereby giving a second life to these types of residues. They are a quick and cost-efficient solution for the decarbonization of all transport sectors.

The production of 100% renewable fuels at the plant in Cartagena will avoid the emission of 900,000 tons of CO2 a year, since they reduce net emissions by 90% compared to the mineral fuel that they replace due to the lower carbon intensity of the former.

Repsol’s executive managing director of Industrial Transformation and Circular Economy, Juan Abascal, highlighted the milestone that the start of industrial-scale production of 100% renewable fuels represents for the company: “With this first plant on the Iberian Peninsula we are taking another step forward in our transformation towards decarbonization, with a cutting-edge technological project”.

The new plant will process 300,000 tons of organic waste a year - used cooking oil, among others - prioritizing residues of national and European origin. Repsol is certified under the ISCC-EU Voluntary Sustainability Scheme and the Spanish National Sustainability Verification System, ensuring traceability and the production of sustainable biofuels in accordance with Renewable Energy Directive (RED) standards.ENGIE obtained approval from the National Electricity Coordinator (CEN) to start commercial operation of BESS Coya, the largest battery energy storage system in Latin America to date. •

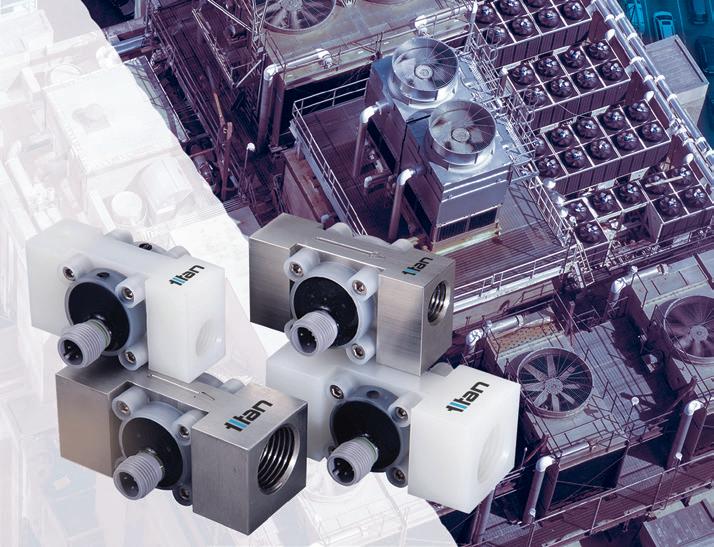

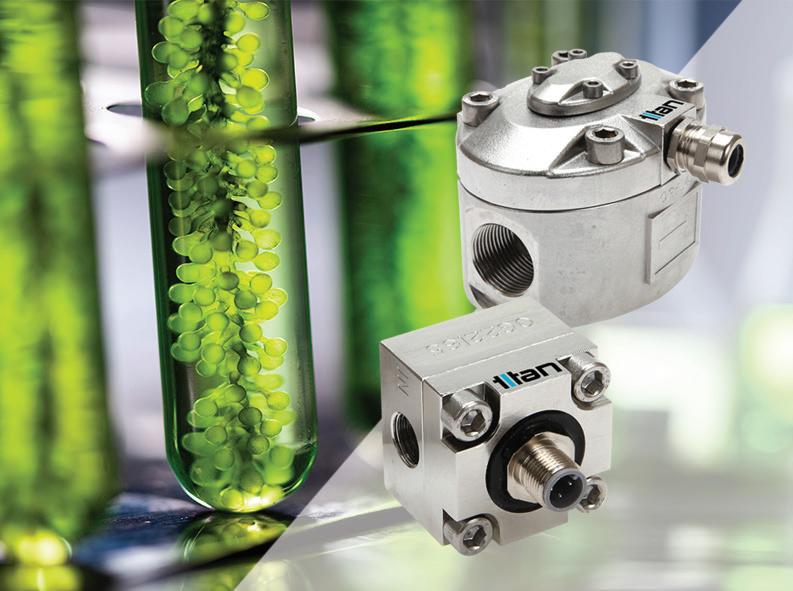

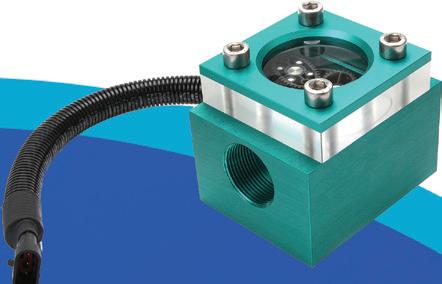

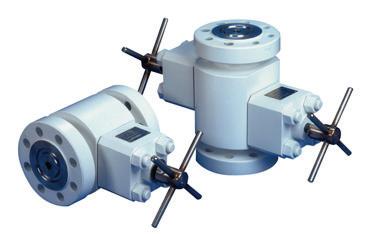

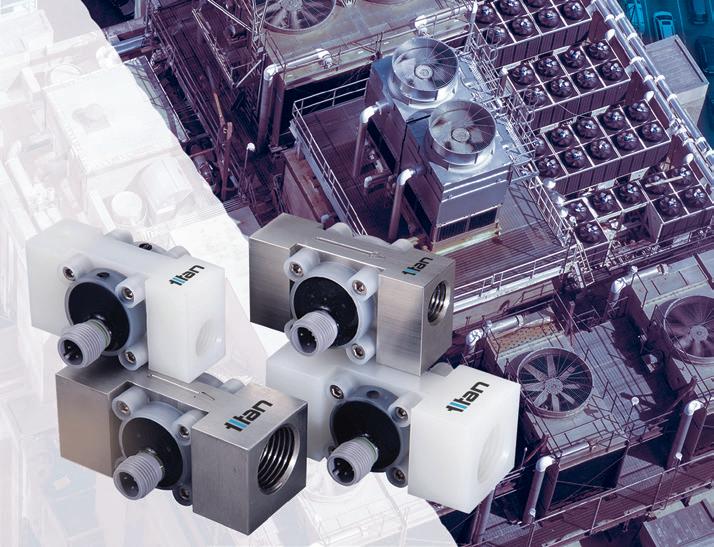

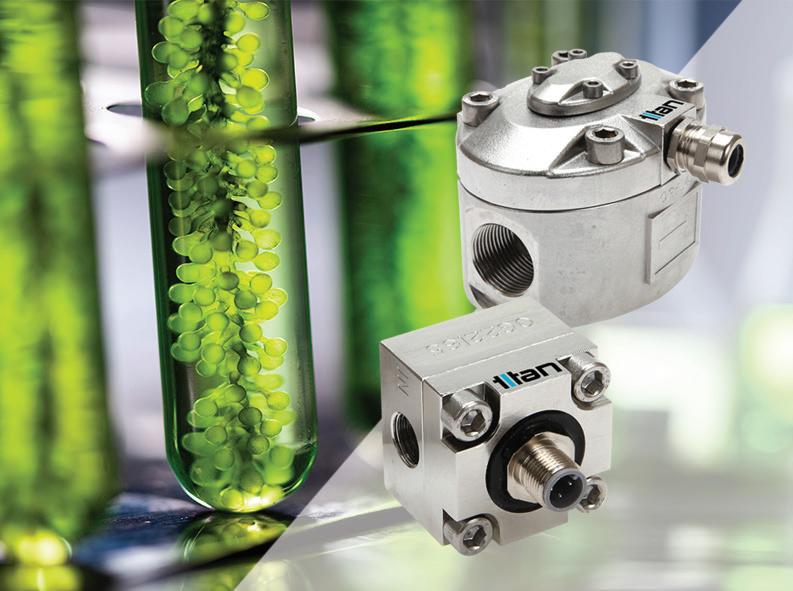

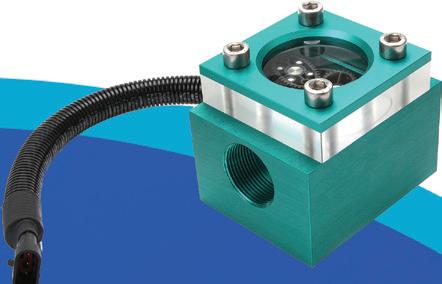

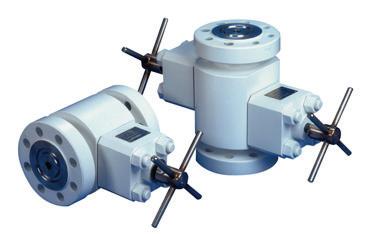

Innovative Liquid Flow Measurement Solutions

Titan is a leading design and manufacturer of innovative end user and OEM high-performance flow meters, used within a wide range of environments and applications.

• Compact, robust, reliable

• Excellent accuracy and repeatability

• Measure low to high flow ranges

• High chemical resistance

• OEM bespoke design capability

13

Ultrasonic

Turbine Flowmeters Oval Gear Flowmeters Instrumentation

Flowmeters

REQUEST A QUOTE TODAY +44 (0)1935 812790 sales@flowmeters.co.uk www.flowmeters.co.uk

Repsol and Bunge Create a Partnership in Spain to

Boost Supply of Renewable Fuels

• Through this strategic agreement, Repsol increases its access to the feedstock needed to reach its goal of producing up to 1.7 million tons of renewable fuels by 2027.

• The collaboration is another step forward in Bunge’s long-term strategy to create alternative paths towards the decarbonization of agricultural and oil supply chains.

Repsol and Bunge have agreed to partner in the development of new opportunities to help meet the growing demand for lower carbon intensity feedstocks for the production of renewable fuels. This alliance, the first of its kind in Europe, will help to accelerate the ramp-up of production of these fuels mandated by the European Union.

Through this strategic agreement, the multi-energy company Repsol acquires 40% of three industrial facilities that are part of Bunge Iberica, one of Bunge’s subsidiaries in the Iberian Peninsula, for a total amount of $300 million plus up to $40 million in contingent payments. The transaction is subject to customary closing conditions, including regulatory approvals.

Under this agreement, Bunge will continue to operate its three plants dedicated to the production of oils and biofuels in Bilbao, Barcelona, and Cartagena, near Repsol’s industrial complexes located in the same regions. Bunge will also continue to be a key producer of protein meals, vegetable oils and distributor of agricultural commodities in Spain.

Through the partnership, Repsol increases its access to a wide portfolio of low-carbon intensity feedstocks to produce renewable fuels, an immediate way to accelerate the reduction of emissions from transport, including cars, trucks, airplanes, and shipping.

Repsol’s current production capacity of 1.1 million tons of renewable fuels per year saves the CO2 emissions equivalent of more than 1.7 million electric vehicles. The company expects to increase its output by up to 55%, reaching 1.7 million tons in 2027. It is accelerating the rollout of renewable fuels at its service station network – the biggest in Spain – by adding pumps which supply with 100% renewable fuel. Currently, the company has more than 120 service stations with 100% renewable fuels, with the objective of reaching 600 by the end of the year and 1,900 by 2027.

Repsol is starting up its 250,000 tons-a-year advanced biofuels plant in Cartagena, Spain, the first of its kind in the Iberian Peninsula. The company is retrofitting another unit at its industrial complex in Puertollano, Spain, with a capacity to produce 200,000 tons of renewable fuel per year.

Under the partnership, the companies plan to explore other areas of cooperation and project development designed to increase the potential availability of non-food lipidic feedstocks for the renewable fuels market.

“With this agreement, Repsol has secured its leadership in renewable fuels in the Iberian Peninsula. It is clear proof of the

steadfast progress we are making in our ambitious roadmap to provide society with solutions to reduce the net emissions of CO2 from transport as quickly and efficiently as possible,” said Juan Abascal, Executive Managing Director for Industrial Transformation and Circular Economy at Repsol.

“This is an exciting step for Bunge in Spain and supports our commitment to create alternative paths towards the decarbonization of agricultural and oil supply chains in our industry. Together, thanks to our companies’ in-depth expertise in the agri-food sector and global connectivity for renewable feedstocks, we aim to unlock wider opportunities in the renewable energy space,” said Julio Garros, Co-President, Agribusiness at Bunge. •

Easy-Laser at APM in Singapore

Wewill be participating in the Asia Pacific Maritime (APM) exhibition, a leading maritime event in Singapore, scheduled for March 13–15, 2024.

At the exhibition, we will showcase our precision alignment tools designed to ensure the efficient operation and minimal wear of any type of rotating machinery onboard ships. Our alignment equipment is crucial for the installation and maintenance of propulsion systems, engines, and many other critical ship components.

By optimizing alignment, you can reduce energy consumption and extend the lifespan of components, which leads to fewer replacements. This, in turn, helps minimize the environmental impact associated with excessive fuel consumption and part failure.

We invite you to visit us at stand E-M01 to discuss your onboard alignment challenges! •

14

NEWS - EUROPE

North America’s Leading Event For Carbon Capture, Utilization & Storage www.ccus-expo.com FREE TO ATTEND REGISTER NOW Carbon Capture Technology Conference & Expo is dedicated to discussing the increasing role that Carbon Capture, Utilization & Storage (CCUS) will play in transition to a net-zero carbon economy. Leading experts from around the world will discuss the latest advances in new technology for carbon capture, storage and transport, as well as unique ways of utilizing CO2 to produce netzero fuels and for other manufacturing processes. 2023 WINNER Multi-Award Winning Show June 26-27 2024 NRG Center, Houston, Texas, USA 400+ EXHIBITORS 130,000Sq ft EXHIBITION SPACE 200+ SPEAKERS 8,000+ ATTENDEES 5 CONFERENCE TRACKS

Eni Welcomes UK Government’s Development Consent Order for HyNet CO₂ Pipeline

Eni welcomes the decision by the Secretary of State for the UK Government’s Department for Energy Security and Net Zero (DESNZ) to grant a Development Consent Order (DCO) for the HyNet North West CO2 pipeline. The DCO will allow the construction, operation, and maintenance of infrastructure to transport captured CO2 as part of the HyNet CCS cluster, where Eni is the transportation and storage operator.

The DCO is the first Anglo-Welsh cross border application for a Nationally Significant Infrastructure Project (NSIP) to be granted a DCO by DESNZ. It marks the completion of an 18-month determination process following Eni’s submission of the DCO application in October 2022. The DCO brings the HyNet CCS cluster closer to the execution phase, with FID expected by September 2024.

The UK Government’s decision to grant a DCO to the HyNet CO2 pipeline is an important milestone to allow for the world’s first asset-based regulated CCS business. A DCO is the consent required to authorise the development of any Nationally Significant Infrastructure Project (NSIP). The HyNet CO2 pipeline will transport carbon dioxide from capture plants across the North West of England and North Wales through new and repurposed infrastructure to safe and permanent storage in Eni’s depleted natural gas reservoirs, located under the seabed in Liverpool Bay.

Claudio Descalzi Eni CEO commented: “We see the UK as an attractive destination for Eni’s investments, particularly in the area of decarbonisation. We welcome the UK Government’s ambition to promote and develop the kind of groundbreaking projects we need to address climate change, especially within hard-to-abate sectors. Carbon Capture will play a critical role in meeting this challenge by safely eliminating emissions from industries that currently do not have equally efficient and effective solutions. This decision marks a significant step towards establishing a significant new industry for the country and consolidates the Eni’s leading position providing a service to decarbonise both its own and third parties’ industrial activities at a competitive cost and with a fast time to market. This position was further reinforced following our acquisition of Neptune Energy, which gives Eni access to three additional CO2 storage licences for a total gross storage capacity of about 1GT in the UK.”

Eni has established a leading position in the UK as HyNet’s CO2 transportation and storage operator. The Company also leads the Bacton Thames Net Zero project, which is looking to decarbonise the South East of England and Thames region. Eni has extensive experience in developing natural gas fields, operated over many decades, and will apply its know-how and skills to repurpose some of its existing assets into CO2 storage hubs, allowing the decarbonisation of its own, as well as third-parties’, industrial activities at a competitive cost.

Eni’s transportation and storage system at HyNet will have a capacity of 4.5 million tonnes of CO2 per year in the first phase, with the potential to increase to up to 10 million tonnes of CO2 per year after 2030 making HyNet a major contributor to the UK’s target of decarbonisation and CO2 storage. It will transform

one of the country’s most energy intensive industrial regions into one of the world’s first low-carbon industrial clusters. The project will help preserve local jobs by supporting the decarbonisation of hard-to-abate industries, as well as attracting investment and creating new jobs. •

Introducing Bore Alignment for Generation XT

Measure the straightness of bore center lines, bearing journals, and other cylindrical objects with the new EasyLaser® XT Bore alignment solutions.

The new bore alignment offer includes extension kits for the XT770 alignment system, a separate system for those who only perform bore alignment, and measurement software.

New XT app functionality

The Bore center program measures 3–50 points at each position (Multipoint) for highest accuracy. If required, you can set tolerances to align towards, which speeds up the work. The result can be displayed as raw data or best-fit calculated. Individual points can be re-measured at any time. Documentation with measurement data and photos is, as usual, provided with the XT Alignment app.*

More

power to XT770

With shaft alignment, flatness measurement and bore alignment combined into one package, you can now seamlessly handle all critical tasks for marine propulsion drive lines (motor, gearbox, propeller shaft, support bearings, stern tube) and rotating machinery installations, such as compressors. This ensures a versatile and cost-effective alignment solution.

These are the new XT bore alignment products:

• XT Bore bracket kit. This is an add-on kit for XT770, including a laser transmitter and brackets. The XT70-M measuring unit of your XT770 system is used as a detector. For bore diameters 130–500 mm [5.12–19.68”].

• XT Bore upgrade kit. Comes with the new wireless detector XT9 and brackets. Its compact size makes it possible to measure even smaller bores with diameters between 80–500 mm [3.15–19.68”].

• XT950 Bore alignment system. This is a complete system for those who only perform bore alignment. It includes all necessary brackets, detector XT9, and laser transmitter. Learn more

16 NEWS - EUROPE

Osbit’s Innovative Cable Test Rig Showcased at Flagship Launch

Cable installation equipment specialist Osbit showcased its ‘first-of-a-kind’ cable fatigue test rig at the high profile launch of Offshore Renewable Energy Catapult’s flagship National Floating Wind Innovation Centre today (Monday 18th March).

Humza Yousaf MSP, First Minister of Scotland joined 150 VIPs, dignitaries and offshore wind industry experts at the launch of the Offshore Renewable Energy (ORE) Catapult’s new Floating Wind Innovation Centre.

Osbit delivered and installed its cable test rig as part of a multi-million-pound project for ORE Catapult for its new floating offshore wind facility, which is set to accelerate the commercialisation of floating offshore wind projects.

The facility - a collaborative programme between the internationally recognised ORE Catapult, along with industry and academic partners – will fast-track floating offshore wind by providing world class testing facilities for R&D and certification of new technology.

The centre will not only accelerate the build-out of floating farms, but create opportunities for the UK supply chain, and drive innovations in manufacturing, installation, and Operations & Maintenance (O&M).

Osbit’s 60-tonne cable fatigue test rig is at the heart of the centre’s development, enabling ORE Catapult to offer globally leading cable testing capability to its customers, and maximising power cable reliability.

Responding to recently updated CIGRE TB862 industry requirements, Osbit has created a highly innovative design to carry out dynamic fatigue testing of subsea cables and bend stiffeners connected to offshore floating wind structures.

Osbit’s unique design provides a vast range of test capability and configurability allowing for adjustability for cable diameters and lengths, tensions and bend radii. The system is highly optimised for tension stability and simplified drive mechanisms for long machine life and efficient running.

The cable test rig was assembled and tested at Osbit’s Port of Blyth facility in Northumberland, England, prior to transportation and installation into the new centre in Aberdeen, Scotland this month.

The system is the second test rig Osbit has provided to ORE Catapult. The company previously delivered a state-of-the-art cable test rig to verify the performance and reliability of floating and tidal cables, for ORE Catapult’s Blyth facility, in 2018.

Osbit’s project with ORE Catapult is the latest in a string of contract deliveries for the company. These include twin wind turbine tower lifting tools to GE Vernova for use on the world’s largest offshore wind farm, Dogger Bank, and an upending hinge to offshore contractor Boskalis, to support key US and Scottish offshore wind projects. •

Building a Gas Plant in Voss

LABEntreprenør AS, a company within the AF Gruppen, has been selected as the contractor by BIR AS (Bergensområdets Interkommunale Renovasjonsselskap) for the construction and infrastructure of a new biogas plant in Voss. The contract is a turnkey project with an estimated value of approximately NOK 120 million (excluding VAT).

The facility, which will convert organic waste into biogas, will be located at Bjørkemoen in Voss. It comprises several buildings, technical infrastructure, and external tanks to accommodate the process plant, which will be delivered as a separate contract.

- We are very satisfied at being chosen as the contractor for this forward-looking project by BIR. The project adheres to various environmental requirements, including BREEAM certification, a fossil-free construction site, and specific material usage criteria. These challenges will contribute to the development of our organization, says Gard Kvalheim, CEO of LAB Entreprenør.

Construction work is scheduled to commence in early June 2024, with completion expected by December 2025.

The final contract is subject to approval by the BIR board. •

18 NEWS

Yinson Announces Private Placement of up to 120 Million Ordinary Shares to Support Energy Transition Businesses

Yinson has completed an accelerated book-building exercise, placing out 120,000,000 new ordinary shares, representing approximately 4.1% of the total number of issued shares (excluding treasury shares) of the Company, to a selected group of institutional investors. Putting this into perspective, Yinson raised RM283.2 million in proceeds from this energy transition placement exercise.

Kumpulan Wang Persaraan (Diperbadankan) [KWAP]

subscribed 50 million shares as the anchor investor supporting the transition placement. As a signatory to the UN Principles for Responsible Investment (UN PRI), KWAP’s commitment towards responsible investment practices underscores this mobilisation of capital.

The proceeds will primarily be used to expand Yinson’s renewables and green technology businesses. This move is expected to contribute positively to the Group’s earnings potential moving forward while further strengthening the Group’s equity and capital base. AmInvestment Bank has been appointed as the Adviser and Placement Agent for this exercise.

Commenting on the private placement, Yinson Group Chief Executive Officer Lim Chern Yuan said, “Prospects for our renewables and green technologies businesses have never been stronger, given the world’s critical need to strengthen global clean energy infrastructure to facilitate a just and equitable energy transition. Proceeds from this placement will enable us to accelerate our strategic plans for Yinson Renewables and Yinson GreenTech to capitalise on market opportunities, which we are confident will contribute to stronger, sustained returns over the long-term. We thank KWAP, as well as other valued institutional investors, for placing your trust in us.”

Hazman Hilmi Sallahuddin, Chief Investment Officer at KWAP commented, “We are proud to support Yinson’s energy transition endeavours as an anchor investor in this placement. •

Specialist Training for the Storage Tank Industry

Live online, classroom, blended, e-learning or in-house

• Gain or renew your 5-year Certificates of Competence*

• Courses based on EEMUA 159

• English, Dutch, German and French language options

• Select from courses throughout year, including:

TankAssessor courses*

20-23 May 2024 – in English

–classroom – London, UK

27-30 May 2024 – in English

–live online – Riyadh time

3-6 June 2024 – in Dutch

–classroom – Rotterdam, NL

10-13 June 2024 – in French

–classroom – Paris, FR

4-7 November 2024 – in German

–live online

Storage Tanks e-learning

On-demand – in English or Dutch

TankInspector courses*

16-18 September 2024 – in English

–live online – Houston time

23-25 September 2024 – in Dutch

–classroom – Rotterdam, NL

28-30 October 2024 – in English

–classroom – London, UK

TankBasics courses

16 September - 25 October 2024

–in English – blended learning (live online, e-learning, and more)

In-house courses

By arrangement for your choice of: time, language, location, or live online

Also... EEMUA Seminar – Engineering the Energy Transition 6 June 2024 – London, UK

More choices, information and registration at www.eemua.org and events@eemua.org

Above ground flat bottomed storage tanks A guide to inspection, maintenance and repair Publication 159 Edition5

Precision Flow Measurement Supports an EnergyEfficient Future

Precision liquid flow measurement supports innovation and diversification in the oil, gas and energy industries. The pressure towards sustainability is pushing the oil, gas and energy sectors to evolve innovative and diverse solutions in a move to create an energy efficient future.

Major transformations within the oil and gas industry in the form of adopting sustainable practices, developing new revenue streams and pushing the boundaries of technology, are being trialled and delivering success. Expanding into new areas such as renewable energy, advanced chemicals and biofuels, is driving innovation and diversification.

Titan Enterprises provides optimised and custom designed liquid flow measurement solutions for oil, petrochemical and green energy applications for OEM customers. These have included bespoke oval gear flow meters for marine fuel flow measurement, monitoring the volume of grease lubricating wind turbine bearing mechanisms, high pressure intrinsically safe units for offshore oil drilling additive injection, and for biodiesel plants converting bio waste into sustainable biofuels.

Monitoring

Grease Lubrication Flow in Wind Turbines

One of the fundamental requirements for ensuring reliable and efficient wind turbine operation is to keep the heavily loaded main bearings fully lubricated in all operating conditions. Fully IP65 / NEMA 4 compliant, Titan’s compact oval gear flowmeters are optimised for measuring the flow of viscous liquids. Designed to operate at pressures of up to 700 bar and temperatures up to 150°C, and with a standard flow range of 0.01 to 4.0 litres/min on 30Cstk oil, the OG1 or OG2 models can routinely achieve outstanding accuracy (0.75%) and repeatability (0.1%).

Optimum Flow Meter Accuracy Critical to Biofuel Production Titan’s Oval Gear (OG) flow meters are an intrinsic component within Green Fuels’ biodiesel plants converting bio waste into sustainable biofuels. Green Fuels’ award-winning research and pioneering process plants have powered buildings with sustainable fuel from used cooking oil, with ongoing development to convert fish oil and sewage sludge into biofuel. Simple, accurate and chemically resistant, Titan’s OG flow meters, with

the addition of the Namur switch, have proved the ideal solution for precise chemical dosing for Green Fuels’ biofuel plants within a potentially hazardous environment.

Adaptive Flow Measurement Designs for Petrochemical Applications

Titan Enterprises offer special options and adaptive designs of its Oval Gear (OG) flow sensors to meet specific high-pressure requirements, aid chemical compatibility, and ensure safe operation in potentially explosive atmospheres. Titan’s Oval Gear range include ATEX compliant IP65/NEMA 4 protection models, and devices that offer intrinsically safe options for processes that operate within harsh environmental conditions, such as explosive or corrosive atmospheres, where flowmeters are required to withstand tough environments whilst maintaining accurate and reliable measurement.

The pivotal role of oval gear flow meters lies in controlling precise liquid dosage for efficient and economical process operations. Within the petrochemical sector, a chemical injection system employs accurate low-flow measuring sensors to inject a precision dosage of chemicals required, including antifoaming scale inhibitors and methanol, into oil wells. Accurate chemical dosing is essential for the optimal functioning of the well system, promoting efficiency and heightened productivity without excessive costs. OG flowmeters are critical in preventing overdosing that can lead to unnecessary expenses, or underdosing that may trigger premature maintenance and suboptimal well performance.

For measuring high viscosity liquids like thick oils, bitumen and tar, precision-engineered flow meters are necessary. Titan’s standard OG flowmeters are designed to provide highly accurate flow measurement up to 1000 cSt. For viscosities above 1000 cSt, Titan provides High Viscosity OG options specially designed with profiled gears to facilitate additional flow of the liquid and prevent hydraulic lock.

Visit Titan Enterprises’ website for further information on flow measurement or to discuss specific OEM applications, please contact Titan Enterprises on +44 (0)1935 812790 or email: sales@flowmeters.co.uk. •

20

NEWS - EUROPE

Bridging Energy Access Gap Vital for Nigeria’s Economic Growth, Says NNPC Chief

The Nigerian National Petroleum Company Limited (NNPC Ltd) has emphasized the critical importance of bridging the energy access gap to the creation of economic prosperity of the country.

The Group Chief Executive Officer of NNPC Ltd, Mr. Mele Kyari, made this submission in a keynote address on industry operations with the theme, “Stability in the Energy Sector: Integrated Strategies for Infrastructure, Transportation and Security,” at the 2024 edition of Society of Petroleum Engineers Oloibiri Lecture Series and Energy Forum (SPE OLEF) held in Abuja, on Thursday.

To bridge the energy access gap in Nigeria, Kyari said NNPC Ltd was working on developing the right infrastructure to deliver oil and gas to drive prosperity for Nigerians.

“We are committed to developing gas infrastructure across the country,” Kyari stated, stressing that the company’s commitment was not just a statutory requirement of the Petroleum Industry Act, but a pledge to ensure energy security beyond fuel supply.

“We are dedicated to investing in critical infrastructure to enhance economic prosperity by supplying gas to the domestic market, targeting at least 8 billion cubic meters,” Kyari added.

He listed some of the infrastructural projects being undertaken by the NNPC Ltd to help bridge the energy access gap in Nigeria to include the Obiafu/Obrikom/Oben (OB3) and AjaokutaKaduna-Kano (AKK) pipelines, adding that they are designed to enhance the nation’s gas supply network.

On the global front, Kyari said NNPC Ltd was working on expanding gas supply to the international market primarily through the NLNG Train 7 project while efforts were also being made to kick off Train 8 as well as the various floating LNG initiatives.

Kyari called for support in leveraging Nigeria’s abundant gas resources for economic prosperity, emphasizing the need to bridge access gaps in electricity and clean cooking fuel.

He assured stakeholders and investors of the support of President Bola Ahmed Tinubu, whom he said is committed to the gas revolution. •

Immediate benefits for efficient, safe primary containment

From day one, Learners on the EEMUA MIPC® training build a unique workbook of mechanical integrity know how tailored to each Learner, site and company

EEMUA's MIPC course helps practitioner-level engineers to be where they are needed – on-site and on top of the latest industry developments and good practice in primary containment of hazardous substances, including for pressure systems.

Flexible, in-depth training for engineers on-site / on-call, EEMUA’s Mechanical Integrity Practitioner Certificate courses combine: live online classes; 1-1 sessions with expert Tutors; on-demand e-learning; and more – all enhanced by Mentor support and guidance throughout.

Covers: Inspection and Test Techniques; Asset Condition; Equipment Design Elements; Legislative Environment; Reporting; Risk and ALARP; Audit; User Responsibilities and Competencies; Postponement; Feedback; WSE; and more.

Adapts to engineering needs of each individual Learner, their company, and their site/s – via a 2-hour Induction...

Next MIPC course: Induction to fit work diaries from September 2024. Learning starts October 2024. Registration open now.

For details please contact EEMUA online-learning@eemua.org +44 (0)20 7488 0801

MIPC® shortlisted for the Best E-learning/ Online Education Initiative memcom membership excellence awards 2020 and 2022

www.eemua.org

Continuous Production Logging From Tracers.

Tracking fluid connections using tracer is a well-known technique across multiple science disciplines, including oceanography, hydrology, meteorology as well as in petroleum science. In most applications unique tracers are introduced at specific locations as a neat liquid or as a small pre-mixed batch of liquid containing the tracer substance. Once introduced, the tracer provides direct proof of mass transport from one location to another.

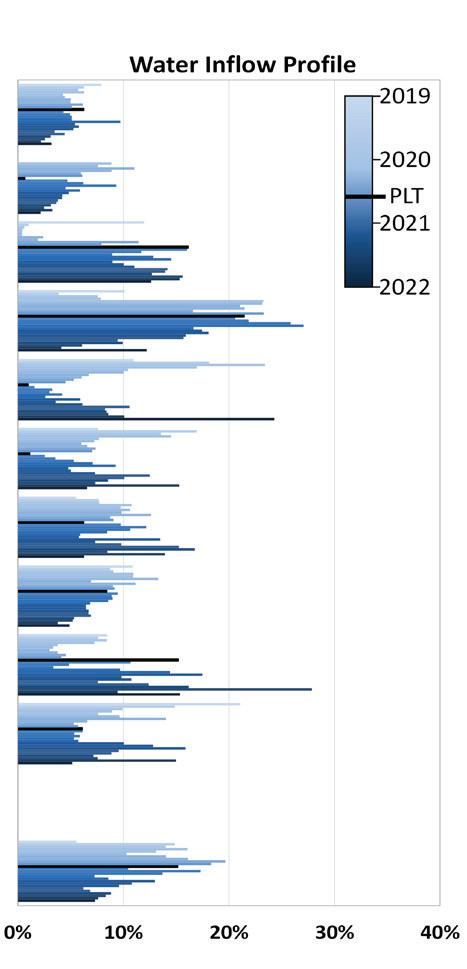

Whenthe amount introduced is known, sampling the produced tracer mass over time also provide information about the amount of flow in a system. This general tracer methodology was taken a significant step further in oil and gas applications by the invention of polymer tracer systems. In these systems the polymer acts as a deployment method and a source of tracer material over a time span of several years. In practice, specially designed polymer and tracer mixes are custom made and fitted into zonal completions, providing identification of flow from more than 50 different zones. Specific polymer tracer systems for oil, water and gas have been devised and have been deployed in more than 800 wells world-wide.

In addition to directly proving mass transport, tracers also provide flow rate information. Generally, this can be achieved either by comparing a continuously added tracer concentration to a sampled concentration or by measuring the time elapsed from injection to arrival of the tracer. For tracers deployed using polymer tracer systems, the latter method was introduced by (Nyhavn, 20101) and has since been used in numerous applications to quantify zonal inflow contribution in production wells. Briefly, whenever a quantification of inflow rates is desired, the well is shut for a short period of time, to allow accumulation of mass of individual tracer at the installation points. Upon

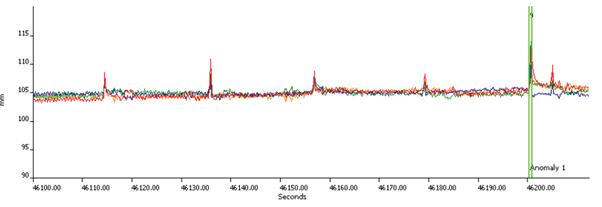

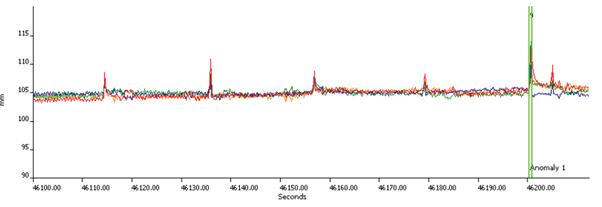

restart, the transient tracer signals are then characterized either by their decline or by the time of arrival of the signals.

When time of arrival of two tracer signals are compared and used together with information on volumes in the well-bore this gives a direct measurement of flow rate along the well-bore. On a fundamental level this methodology bears resemblance to the application of spinners used by a production logging tool (PLT) to estimate flow rate along the well-bore and hence provide a chemical PLT. Spinnerbased and chemical PLTs have ben compared

in a range of applications (Prosvirnov at al., 20162; Solovyev et al ., 20193; Zoshchenko at al ., 20184; Kolupaev et al. 20185; Shtun at al. 20176; Eviany 20237) and some interesting observations can be made from these studies. One obvious difference between chemical and spinner based PLTs is that the latter requires introduction of a tool into the well bore. The tracer systems are pre-installed, and no tool is required, hence any risk of a tool getting stuck is avoided. For this reason, a chemical PLT are often a preferred solution in the longest horizontal wells (Aljan et al 20238). In addition, during a chemical PLT sampling campaign, the flow is unrestricted whereas the presence of a tool in the well does introduce some restriction, that may impact the flow (Eviany 20237). Even if chemical PLTs have proven their usefulness, the requirement for a temporary shut-in and restart may pose challenges and has an economical impact, in the form of deferred production during the shut-in period. It has therefore been important to overcome these challenges and work towards providing measurement while production (MWP) from the tracer systems. Recently Resman reported significant breakthrough in MWP using tracers in the Eldfisk field in the greater Ekofisk area (Urdal et al. 20239). In the patented application, tracer pre-installed in the completions are displaced

22

EXPLORATION & PRODUCTION

in a controlled manner into the formations and provide continuous rate quantification for an extended period. One the appealing benefits of the MWP methodology is that no shut-in of the production is required. In every production sample the inflow contribution of oil and of water is available simply by interpreting the concentration data in that sample. Continued sampling of fluid from that well provides what can best be described as a PLT in every bottle. Continuous sampling over time thus provides a continuous stream of PLT data. This gives the opportunity to investigate the evolvement of production of hydrocarbon and water in all zones where tracer is installed.

As for all chemical PLTs, the MWP methodology also avoids any tools in the well. Additionally, as there is no need for a shut-in, the well is without crossflow or any other transient behaviour during or immediately after restart. This implies that the MWP using tracer systems provide information as the well is producing “naturally” without any observer effect. Changes occurring over time – such as influx of water can therefore allocated to single zones and remediated. In the greater Ekofisk Area example (Urdal et al. 20238) more than 20 production wells have been installed with Resman’s production tracer technology. Application of the MWP methodology is therefore possible across a number of wells, providing continuous zonal inflow rate contributions across all these wells for every sample. In total this provide a close to four dimensional PLT (4D-PLT) study for a field.

If you would like to know more about the topics discussed in this article, or learn more about their solutions, please contact RESMAN at: RESMAN AS https://www.resmanenergy.com contact@resmanenergy.com +47 91 67 13 33

1. Nyhavn, F. 2010. Extracting Well Inflow Rate Profiles from Transient Tracer Production Curves (in Norwegian). Norwegian Patent No. NO 342,835.

2. Prosvirnov, M. N., Kovalevich, A., Oftedal, G. et al. 2016. Dynamic Reservoir Characterization and Production Optimization by Integrating Intelligent Inflow Tracers and Pressure Transient Analysis in a Long Horizontal Well for the Ekofisk Field, Norwegian Continental Shelf. SPE Bergen One Day Seminar, Bergen, Norway, 20 April. SPE-180061.

3. Solovyev T., Soltanov D., Galimzyanov A., Naydenskiy K., Nukhaev M., Mukhametshin I.: “Successful Application of the Intelligent Inflow Tracers for Monitoring of Horizontal Wells on North Komsomolskoe Field”. SPE196831. SPE Russian Petroleum Technology

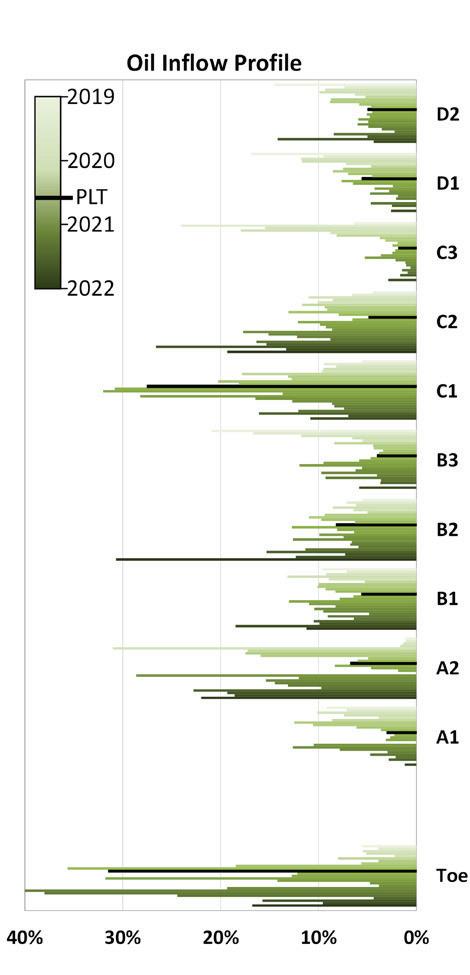

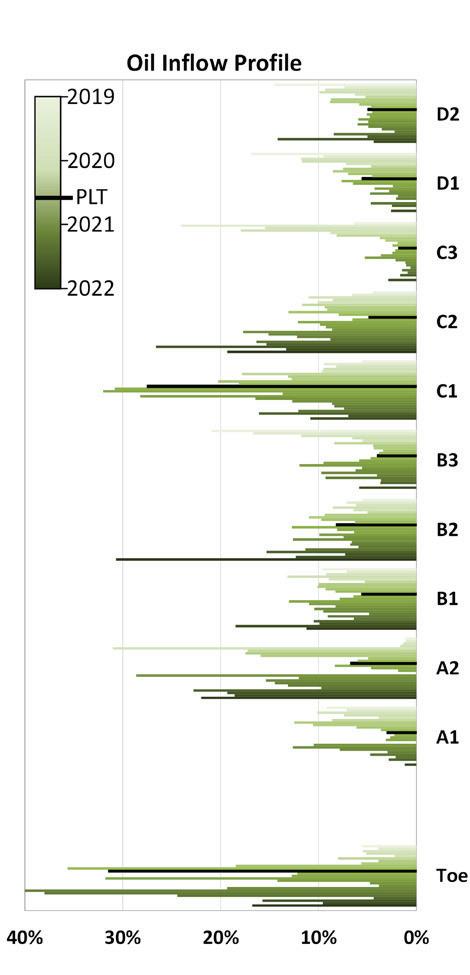

Figure 1. Figure adapted from Udal et al.8 displaying inflow tracer profiles for oil and water found using the MWP chemical PLT described in the text. A chemical PLT result is obtained in every sample bottle and gives an overview of the well performance over time. In the figure every line in the histogram correspond to one sample bottle taken over a period from 2019 to 2022. The letters in the figure corresponds to individual zonal oil and water tracer systems.

Conference, October 22–24, 2019

4. Zoshchenko O., Yury Trushin Y., Anton Aleshchenko A., Ilkam Mukhametshin I., Artem Galimzyanov A., Marat Nukhaev M.: “Novel Well Monitoring Technology Implementation for Multi-Zonal Well in Carbonate Kharyaga Oil Field”. SPE191556. SPE Russian Petroleum Technology Conference, October 15–17, 2018

5. Kolupaev D., Uchuev R., Bikkulov M., Matevosov M., Sheremeev A., Mukhametshin, Galimzyanov A., Nukhaev M.: ‘Selection of Optimum Monitoring Technique for Wells with Multistage Hydraulic Fracturing on Priobskoe Oilfiel’. SPE-191564. SPE Russian Petroleum Technology Conference, October 15–17, 2018

6. S. Y. Shtun, A. A. Senkov, O. I. Abramenko, V. V. Matsashik, I. R. Mukhametshin, A. V. Prusakov, M. T. Nukhaev: “The Comparison of Inflow Profiling Technologies for ERD Wells Including PLT, Fiber Optics DTS, Stationary Chemical Tracers: A Case Study from the Caspian offshore Yuri Korchagin Field in Russia”. SPE-188985. Annual Caspian Technical Conference and Exhibition, November 1–3, 2017

7. Eviany A., Mario C.C., Hakim A.L., Nugrahanto A., Pramana H., Murtani A.S., Rashed R., Koumouris S., Huseby O.: “A New Technology Approach Using Permanent Chemical Tracer for Water Source Identification in Ujung Pangkah Field”. SPE215343. SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, October 10–12, 2023.

8. Alyan M, Parihar S, Al-Haji L, Leung E, Elder C, Othman A, Al-Tamimi A, Al-Harbi M, Al-Kiyoumi A, Wills J: “Novel Application of Inflow Tracers in Record Well for Assessing 1-MD Reservoir”. SPE-211403, ADIPEC, Abu Dhabi, UAE, October 2022.

9. Urdal J., Habib M.A., Mikalsen T., Chowdhury S., Cleveland K.O., Huseby O., Bergo C., Pride S.: “Application of Inflow Tracers to Complement Production Logs in a Carbonate Field”. SPE-214804-MS. SPE Annual Technical Conference and Exhibition, October 16–18, 2022

23

Innovative Pumping Solution by SEEPEX Revolutionizes Operations at Buzzard Oil Field

The Buzzard oil field, located about 100 kilometers northeast of Aberdeen, has been a central hub in the European oil and gas industry since its discovery in 2001. The field plays a pivotal role in the energy supply chain, contributing to the vast oil and gas network that sustains the region’s economic vitality. Despite its importance, the Buzzard field presented a unique challenge because of the presence of mercaptan in its crude oil, leading to a groundbreaking solution from SEEPEX that has transformed operations.

The Forties Main Oil Line, responsible for transporting 150,000 barrels of crude oil daily from the Buzzard oil field to the refinery of a global oil and energy company on the east coast of Scotland, has been a crucial artery in the European oil and gas infrastructure. However, the mercaptan content in the Buzzard field’s crude oil posed a major challenge for pipelines and discharge systems, particularly during maintenance. Mercaptan, also known as thiol, is not only a chemical compound but also a toxic substance with a distinctive and penetrating smell.

The project at Buzzard identified two critical challenges. Firstly, the maintenance of the main oil line required draining the crude oil, which contained up to 15% entrained gas. This created extreme process conditions with a low net positive suction head available (NPSHa) of 0.5m, making many conventional pump technologies unsuitable as they risked cavitation damage.

Above: SEEPEX range E pumps are semisubmersible progressive cavity pumps that empty barrels, pits, basins and containers. They are a cost-effective alternative to conventional pumping systems, especially in applications with critical suction heads or limited installation space.

NPSHa is a critical element defined by factors such as vapor pressure, density, system inlet pressure, geodetic level and loss level. Finding a pump with a low NPSHr (required) figure became imperative for overcoming this challenge. The second challenge required pumping a water-hydrocarbon solution from a 6m deep open drain tank, containing various hydrocarbons and water, to an oil/ water separation unit. The choice of pump was crucial to ensure that the pumping action would not emulsify the oil and affect the separation process.

SEEPEX, a leading provider of progressive cavity pumps and pump systems, approached these challenges with an innovative singlepump solution. The solution involved a vertically mounted BE pump installed in a can, designed to overcome the low NPSHa. SEEPEX’s engineers fitted two suction connections to the can, one linking to the main oil line and the other to the open drain tank. Individual isolation valves equipped both suction pipes, offering operational flexibility to either drain the main oil line or pump out the open drain tank.

One of the key advantages of the chosen progressive cavity pump was its low shear capabilities, preventing oil emulsification and ensuring the efficiency of the oil-water separation process. This feature proved crucial in handling shear-sensitive products with high gas fractions, characteristic of the Buzzard field’s crude oil. The pump, certified ATEX CE EX II 2G IIB T3 X, featured a 53B mechanical seal system to ensure product containment and prevent environmental leakage, considering the hazardous nature of the pumped hydrocarbon mixture.

Beyond the specific success at Buzzard, the SEEPEX BE CAN design pump is indicative of broader trends in the European oil and gas market, especially in the UK. The industry, with its rich history and technological advancements, constantly seeks innovative solutions to overcome challenges and optimize efficiency. SEEPEX’s ability to address unique challenges with a tailored, efficient, and long-lasting solution reflects the commitment to excellence in engineering, setting a benchmark for future endeavors.

The European oil and gas market, particularly in the UK, has witnessed dynamic shifts over the years. Focusing on sustainability, environmental consciousness and energy transition compels companies in this sector to adapt and innovate. The SEEPEX solution aligns with these industry trends, not only providing operational efficiency but also contributing to the overall sustainability goals. In the broader context of the European oil and gas industry, reducing investment costs and minimizing unplanned maintenance are paramount objectives. SEEPEX’s single-pump solution, handling two applications seamlessly, has resulted in reduced investment costs, highlighting the potential for substantial cost savings. This success story offers a valuable lesson for industry players seeking sustainable, efficient and cost-effective solutions.

In conclusion, the SEEPEX pumping solution at the Buzzard oil field stands as a testament to the innovative spirit driving advancements in the European oil and gas market. As the industry navigates the complexities of the modern energy landscape, solutions that address specific challenges while contributing to broader sustainability goals become increasingly vital. SEEPEX’s achievement at Buzzard exemplifies the capacity of engineering innovation to redefine operational standards and drive long-term success in the dynamic and evolving oil and gas sector. • If you would like to know more about how SEEPEX can help your company and its operations, please contact them at:

SEEPEX GmbH

W: https://www.seepex.com

T: +49 2041 9960

E: info@seepex.com

24

EXPLORATION & PRODUCTION

TO EXACTING STANDARDS API 676 PUMP

The progressive cavity pump to fulfill your exacting requirements in Oil & Gas applications.

The BNA pump from SEEPEX ensures compliance with API 676 and API 682 while reducing costs in petrochemical applications.

YOUR BENEFITS

API 676 and API 682 compliant

Extremely robust design

High containment pressure and corrosion resistance

Simple integration into piping systems

Non-welded casing means reduced documentation and fewer inspections

Shorter lead time

High operational safety

Act now to experience the benefi ts of this API pump for yourself.

SEEPEX GmbH T +49 2041 996-0 www.seepex.com

Masfix, Keeping the Oil and Gas Customers in Stock of Their Fasteners and Consumables Through Sustainable Solutions and Experience in the Industry.

Based in Newcastle, UK on the banks of the River Tyne, a family-run business with an abundance of knowledge and experience to share with the oil and gas industry.

The Masfix roots were planted by Ron Slater and George Mordue in 1982, initially a duo with just one delivery vehicle, providing fixings and fasteners to local companies within a 15-mile radius. Today we are still very much a family business with sons, Mark Slater and Ian Mordue ensuring the continuation of their father’s legacy.

Now into our 42nd year of business, we have moved with the times and increased our offer to the North East manufacturing industry. With goals to become the largest independent fastenings distributor in the North East of England, offering over 40,000 individual SKUs we put our success down to the evolution of our product offering, diversifying to include tools, engineering consumables, hardware and PPE. All the necessities our oil and gas customers need.

Richard Ward, Sales Director stated: “We’re extremely passionate about the North East and want to support organisations throughout the region, although we’ve grown into a good size business, we’re still a small, family business at heart. We pride ourselves on the service we deliver to our customers. We introduced a new Kanban just-in-time stock management system to ensure our customers always have stock availability, without having to lift a finger.”

“Even our on-site vending machines are cloud-based, allowing for seamless stock control where our customers don’t have to do anything, and we handle it all for them.”

Richard continued: “95 percent of what we deliver is in our own vehicles and can be delivered next day. We’re always listening to customer demands and can adapt to suit their requirements, exactly like we did during the pandemic by going online.

We see our customers as partners. Our years of experience, vast product range and streamlined processes allow us to offer a service that is dedicated and satisfactory every time.”

Richard said: “Being based in the North East of England and having one of the biggest stock ranges of fixings & fastenings and engineering consumable products, allows us to be a one stop supply partner to the North East industry key players.

We supply to a wide range of small and large customers in the process sector, including robotics, gas and petrochemical, renewables,

automotive and everything in between.”

The benefits of a stock management solution are:

• Save money, by avoiding costly stock outs and downtime situations, reduce panic buying and one-off purchasing. Consolidate your supply chain and reduce admin procedures.

• Save time, eradicate lead times as stock can be managed to never run short. Strategically have your solution in the optimal location to reduce the time it takes to access parts. Minimises time taken on stock takes.

• Stock visibility, you can track low stock levels and identify the re-order points for each product, in turn avoiding the occurrence of stock-outs. Helps identify obsolescence and reduce the amount of stock required.

• Utilise data, Use the data provided to strategically plan your stock around future projects or fluctuations throughout the year. Get to understand

26

EXPLORATION & PRODUCTION

which department uses what and to what levels creating better business intelligence.

• Create Space, transform a disorganised work space into as streamlined operation through tailormade storage solutions. The space created can be utilised in more productive way.

Our Solutions are perfect for the oil and gas industry. Vending machines can be placed onsite to manage all consumable items from PPE to engineering tools. This allows 24/7 access, control operator access and is proven to reduce consumption. Our customers like the option of branding their vending machine which gives it a feel for the business it is placed within. The Kanban solution is very popular where we

supply all necessary racking, storage bins and labels. Both options are maintained by our fulfillment team where they do regular thorough checks to reduce the risks of errors occurring in stock numbers. Smart Store setups with RFID solutions are also something we can offer.

Our team will meet up and perform a site visit to assess the best solution for your business. Working with this information and date we will provide you with our recommended levels based on usage. We then get to work on setting up your solution. For our Kanban’s this includes unique bar-codes and bespoke labeling identifying the contents of the bin. For our Vending Machines this includes creating user access and permissions

along with product groups. Soon after we will arrange to install the solution on site with minimum fuss. You can then relax knowing your stock is being managed. We can provide reports and data on everything from usage down to the individual, cost savings and future trends.

With sustainability at the forefront of many businesses’ strategy plans, these solutions play an integral part in helping you reach these goals by reducing deliveries, packaging and waste.

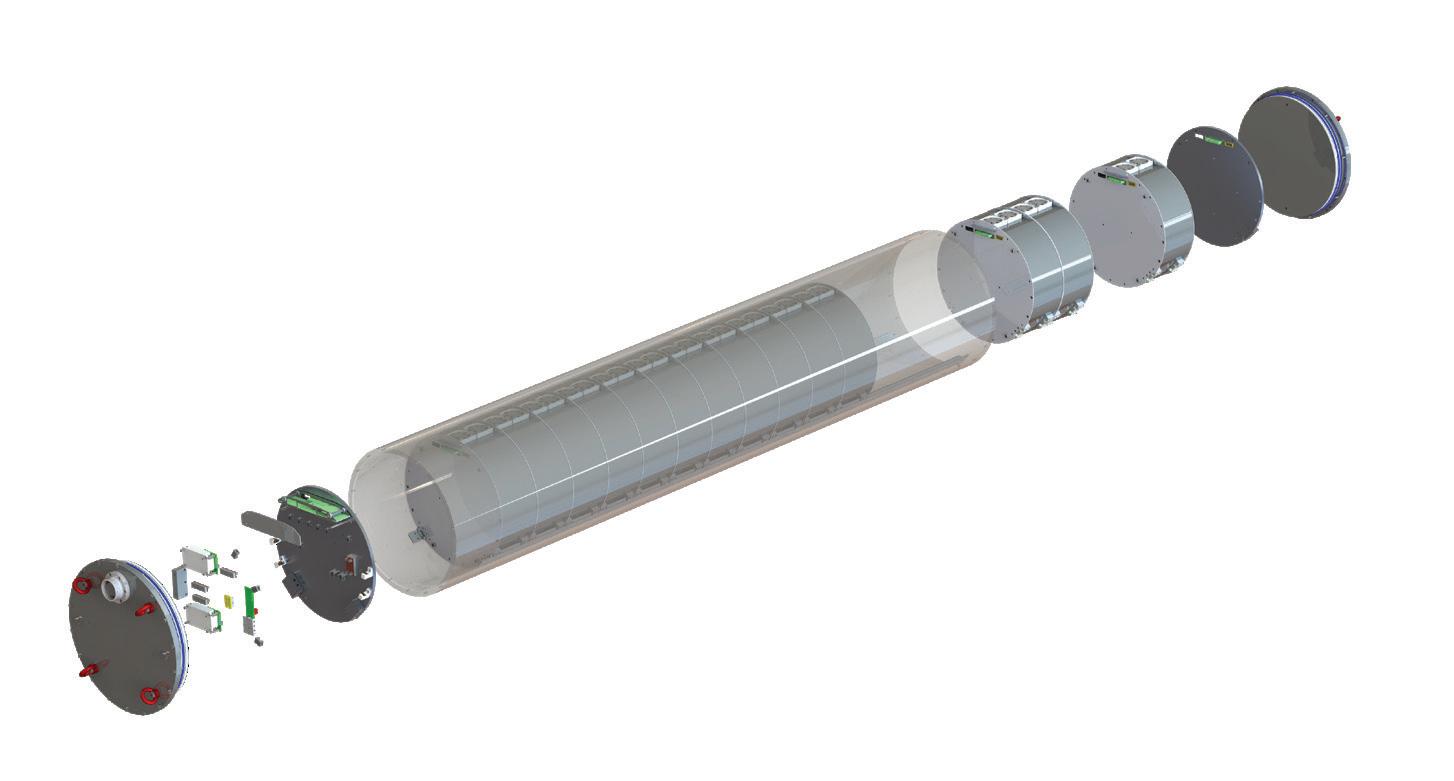

With this in mind, we offer sustainable alternatives to your PPE and work-wear. We have partnered with brands like Globus, Rockfall, Uneek and Portwest to be able to offer our customers the best with no reduction in quality.