Process Control Modeling Design And Simulation 1st Edition Bequette Solutions Manual Full Download: http://testbanktip.com/download/process-control-modeling-design-and-simulation-1st-edition-bequette-solutions-manual/ Download all pages and all chapters at: TestBankTip.com

Table of Contents

Solutions for Chapters 1-14

Solutions for Module 5.4 and Module 5.5

Solution for Module 16, Discrete PI Example

Chapter1Solutions

1.1

i Drivingacar

Pleaseseeeitherjogging,cycling,stirredtank heater,orhouseholdthermostatforarepresentativeanswer.

ii Twosamplefavoriteactivities: Jogging

(a) Objectives:

• Jogintensely(heartrateat180bpm) for30min.

• Smoothchangesinjoggingintensity andspeed.

(b) InputVariables:

• JoggingRate–Manipulatedinput

• Shockingsurprises(dogs,cars,etc.)–Disturbance

(c) OutputVariables:

• BloodOxygenlevel–unmeasured

• Heartbeat–measured

• Breathingrate–unmeasured

(d) Constraints:

• Hard:MaxHeartRate(toavoidheart attack → death)

• Hard:Bloodoxygenminimumand maximum

• Soft:Timespentjogging

(e) Operatingcharacteristics:Continuousduringperiod,SemiBatchwhenviewedover largertimeperiods.

(f) Safety,environmental,economicfactors: Potentialforinjury,overexertion

(g) Control:Feedback/Feedforwardsystem. Oxygenlevel,heartbeat,fatigueallpartof determiningactionafterthefact.Path, weatherarepartoffeedforwardsystem

Cycling

(a) Objectives:

• Ensurestability(don’tcrash)

• Enjoyride

• Preventmechanicalfailure

(b) InputVariables–Manipulated:

• BodyPosition

• Steering

• BrakingForce

• GearSelection

InputVariables–Disturbances:

• Weather

• PathConditions

• Otherpeople,animals

(c) OutputVariables–Measured:

• Speed

• Direction

• CaloricOutput(viaelectronicmonitor)

OutputVariables–Unmeasured:

• Levelofenjoyment

• Mechanicalintegrityofpersonandbicycle

• Aesthetics(smoothnessofride)

(d) Constraints–Hard:

• Turningradius

• Mechanicallimitsofbikeandperson

• Maximumfatiguelimitofperson

Constraints–Soft:

• Steeringdynamicsthatleadtoinstabilitybeforemechanicalfailure(i.e.you crash,thebikedoesn’tbreak)

• Terrainandweathercanlimitenjoymentlevel.

(e) Operation:Continuous:Steering,weight distribution,terrainselectionwithinapath, pedalforceSemibatch:Gearselection, brakingforceBatch:Tirepressure,bikeselection,pathselection

(f) Safety,environment,economics:Safety: StabilityandmechanicallimitspreventinjurytoriderandothersEnvironment:Trail erosion,noiseEconomics:Healthcosts, maintenancecosts

(g) ControlStructure:Feedback:Levelsofexertion,bikeperformancearemonitoredand rideisadjustedafterthefactFeedForward: Pathisseenaheadandrideisadjustedaccordingly.

iii Astirredtankheater

(a) Objectives

• MaintainOperatingTemperature

• Maintainflowrateatdesiredlevel

(b) InputVariables: 1-1

• Manipulated:Addedheattosystem

• Disturbance:Upstreamflowrateand conditions

(c) OutputVariables–Measured:Tankfluid temperature,Outflow

(d) Constraints:

• Hard:Maxinflowandoutflowasper pipesizeandvalvelimitations

• Soft:Fluidtemperatureforoperating objective

(e) Operatingconditions:Continuousfluid flowadjustment,continuousheatingadjustment

(f) Safety,Environmental,Economicconsiderations:Safety:Tankoverflow,failurecould causeinjuryEconomics:Heatingcosts,spill costs,processqualitycostsEnvironmental: Energyconsumption,contaminationdueto spillsofhotwater

(g) ControlSystem:Feedback:Temperatureis monitored,heatingrateisadjustedFeedforward:Upstreamflowvelocityisusedto predictfuturetankstateandinputisadjustedaccordingly.

iv. Beerfermentation

Pleaseseeeitherjogging,cycling,stirredtank heater,orhouseholdthermostatforarepresentativeanswer.

v. Anactivatedsludgeprocess

Pleaseseeeitherjogging,cycling,stirredtank heater,orhouseholdthermostatforarepresentativeanswer.

vi. Ahouseholdthermostat

(a) Objectives:

• Maintaincomfortabletemperature

• Minimizeenergyconsumption

(b) InputVariables:

• Manipulated:Temperaturesetting

• Disturbance:Outsidetemperature,energytransmissionbetweenhouseand environment

(c) OutputVariables:

• Measured:Thermostatreading

• Unmeasured:Comfortlevel

(d) Constraints:

• Hard:Maxheatingorcoolingdutyof system

• Soft:Maxorminimumtemperaturefor comfort

(e) Operatingconditions:Continuousheating adjustment,continuoustemperaturereading.

(f) Safety,Environmental,Economicconsiderations:Safety:heatermaybeanelectricalorburninghazardEconomics:Heating costsEnvironmental:Energyconsumption.

(g) ControlSystem:Feedback;temperatureis monitored,heatingrateisadjustedafter thefact.

vii Airtrafficcontrol

Pleaseseeeitherjogging,cycling,stirredtank heater,orhouseholdthermostatforarepresentativeanswer.

1.2

a. FluidizedCatalyticCrackingUnit

i. Summaryofpaper:

Afluidizedcatalyticcrackingunit(FCCU)is oneofthetypicalandcomplexprocessesin petroleumrefining.Itsprincipalcomponentsare areactorandagenerator.Thereactorexecutes catalyticcrackingtoproducelighterpetro-oil products.Theregeneratorrechargesthecatalystandfeedsitbacktothereactor.Inthis paper,theauthorstesttheircontrolschemeson aFCCUmodel.Themodelisanonlinearmultiinput/multi-output(MIMO)whichcouplestime varyingandstochasticprocesses.Considerable computationisneededtousemodelpredictiveprocesscontrolalgorithms(MPC).StandardPIDcontrolgivesinferiorperformance.A simplifiedMPCalgorithmisabletoreducethe numberofparametersandcomputationalload whilestillperformingbetterthanaPIDcontrol method.

ii FamiliarTerms:Constraint,nonlinearity,controlperformance,MPC,unmeasureddisturbancerejection,modeling,simulation.

b. ReactiveIonEtching PleaseseeFCCUforarepresentativeanswer.

c. RotaryLimeKiln PleaseseeFCCUforarepresentativeanswer.

d. ContinuousDrugInfusion PleaseseeFCCUforarepresentativeanswer.

1-2

e. AnaerobicDigester PleaseseeFCCUforarepresentativeanswer.

f. Distillation PleaseseeFCCUforarepresentativeanswer.

g. PolymerizationReactor PleaseseeFCCUforarepresentativeanswer.

h. pH PleaseseeFCCUforarepresentativeanswer.

i. BeerProduction PleaseseeFCCUforarepresentativeanswer.

j. PaperMachineHeadbox PleaseseeFCCUforarepresentativeanswer.

k. BatchChemicalReactor PleaseseeFCCUforarepresentativeanswer.

1.3

a. Vortex–sheddingflowmeters

Theprincipalofvortexsheddingcanbeseeninthe curlingmotionofaflagwavinginthebreeze,orthe eddiescreatedbyafastmovingstream.Theflag outlinestheshapeofairvorticesastheflowpastthe pole.VanKarmanproducedaformuladescribingthe phenomenain1911.Inthelate1960’sthefirstvortex sheddingmetersappearedonthemarket.Turbulent flowcausesvortexformationinafluid.Thefrequency ofvortexdetachmentisdirectlyproportionaltofluid velocityinmoderatetohighflowregions.Atlow velocity,algorithmsexisttoaccountfornonlinearity. Vortexfrequencyisaninput,fluidvelocityisanoutput.

b. Orifice–plateflowmeters

Pleaseseevortex–sheddingflowmetersforarepresentativeanswer.

c. Massflowmeters

Pleaseseevortex–sheddingflowmetersforarepresentativeanswer.

d. Thermocouplebasedtemperaturemeasurements

Pleaseseevortex–sheddingflowmetersforarepresentativeanswer.

e. Differentialpressuremeasurements

Pleaseseevortex–sheddingflowmetersforarepresentativeanswer.

f. Controlvalves

Pleaseseevortex–sheddingflowmetersforarepre-

sentativeanswer.

g. pH Pleaseseevortex–sheddingflowmetersforarepresentativeanswer.

1.4

NosolutionsarerequiredtoworkthroughModule1

1.5

a.

Themainobjectiveistomaintaintheprocessfluid outlettemperatureatadesiredsetpointof300C.

b.

Themeasuredoutputistheprocessfluidoutlettemperature.

c. Themanipulatedinputisthefuelgasflowrate,specificallythevalvepositionofthefuelgascontrolvalve.

d.

Possibledisturbancesinclude:processfluidflowrate, processfluidinlettemperature,fuelgasquality,and fuelgasupstreampressure.

e. Thisisacontinuousprocess.

f. Thisisafeedbackcontroller.

g.

Thecontrolvalveshouldbe fail-closed.Increasing airpressuretothevalvewillthenincreasethevalve positionandleadtoanincreaseinflowrate.Lossof airtothevalvewillcauseittoclose.Thegainofthe valveispositive,becauseanincreaseinthesignalto thevalveresultsinanincreaseinflow.

h.

Itisimportantfromasafetyperspectivetohavea fail-closedvalve.ifthevalvefailedopen,theremight notbeenoughcombustionair,causingalossofthe flame-thiscouldcausethefurnacefireboxtofillwith fuelgas,whichcouldthenre-igniteundercertainconditions.Althoughthecombustionairisnotshown,it shouldbesuppliedwithasmallstoichiometricexcess. Ifthereistoomuchexcesscombustionair,energyis wastedinheatingupairthatisnotcombusted.If thereistoolittleexcessair,combustionwillnotbe complete,causingfuelgastobewastedandpollutiontotheatmosphere.Theprocessfluidisflowing 1-3

toanotherunit.Iftheprocessfluidisnotatthe desiredsetpointtemperature,theperformanceofthe unit(reactor,etc)maynotbeasgoodasdesired,and thereforenotasprofitable.

i.

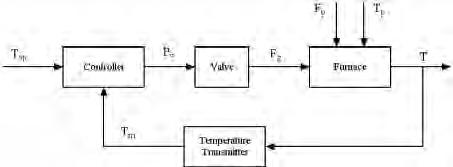

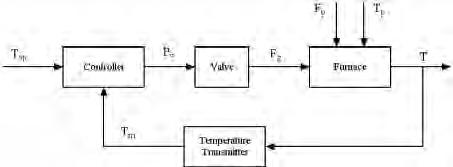

Thecontrolblockdiagramfortheprocessfurnaceis shownbelowinFigure1.Wherethethesignalsas

1.8

Weknowfromtheproblemstatementthattheinlet (Fin)andoutlet(Fout)flowratescanberepresented withthefollowingequations:

Fin =50+10sin(0.1t)

Fout =50

Thechangeinvolumeasafunctionoftimeis dV dt = Fin Fout

substitutingwhatweknow:

dV

dt =50+10sin(0.1t) 50

Figure1-1:Controlblockdiagramofprocessfurnace

follows:

• Tsp:Temperaturesetpoint

• pv :Valvetoppressure

• Fg :Fuelgasflowrate

• Fp:Processfluidflowrate

• Tp:Processfluidinlettemperature

• T:Temperatureofprocessfluidoutlet

• Tm:Measuredtemperature

1.6

Theproblemstatementtellsusthatthegasolineis worth$500,000aday.A2%increaseinvalueis:

$500, 000 day x 0.02= $10, 000 day

Wearealsogiventhattherevampwillcost $2,000,000.Wecannowcalculatethetimerequired topaybackthecontrolsysteminvestment.

$2, 000, 000 $10,000 days =200days

Therefore,weknowitwilltake200daystopayoff theinvestment.

1.7 2yrs · 4 4million$/yr · 0 2%=$176, 000

Simplifying dV dt =10sin(0 1t)

Rearrangingtheequation

dV =10sin(0 1t)dt

Takingtheintegralofbothsides

dV = 10sin(0 1t)dt

Usingbasiccalculustosolve

V V0 = 10 0 1 cos(0 1t)|t t=0

Weknowtheinitialtankvolumeis500liters

V 500= 100cos(0 1t) 100cos(0)

V 500= 100cos(0 1t)+100

V (t)=600 100cos(0 1t)

Theequationabovetellsushowthevolumeofthe tankwillvarywithtime.ThiscanalsobeseenvisuallyinFigure2below.

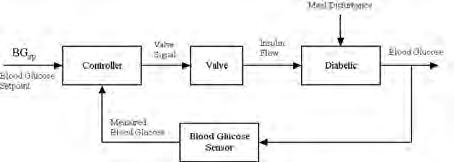

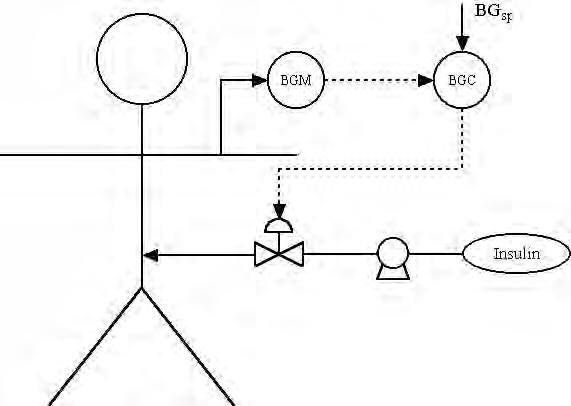

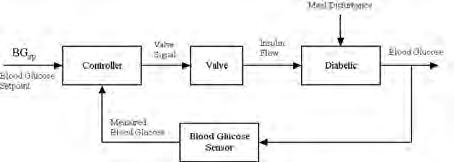

1.9 a.

Theobjectiveistomaintainadesiredbloodglucose concentrationbyinsulininjection.Insulinisthemanipulatedinputandbloodglucoseisthemeasured output.Asperformedbyinjection,theinputisreallydiscreteandnotcontinuous.Also,glucoseis notcontinuouslymeasured,sothemeasuredoutput isdiscrete.Disturbancesincludemealconsumption andexercise.Feedforwardactionisusedwhenadiabeticadministersaninjectiontocompensatefora

1-4

Figure1-2:Liquidvolumeasafunctionoftime

meal.Feedbackactionoccurswhenadiabeticadministersmoreorlessinsulinbasedonabloodglucose measurement.Itisimportantnottoadministertoo muchinsulin,becausethiscouldleadtotoolowofa bloodglucoselevel,resultinginhypoglycemia.

b.

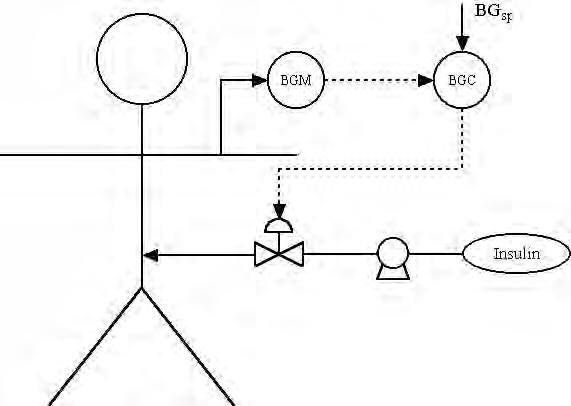

Aprocessandinstrumentationdiagramofanautomatedclosed-loopsystemisshowninFigure3below. Forsimplicity,thisisshownasapumpandvalve

Figure1-4:controlblockdiagramofclosed-loopinsulininfusion

gainispositive.A fail-closed valveshouldbespecified.Ifthevalvefailed-open,thecoldstreamoutlet temperaturecouldbecometoohigh.

b.

Anincreaseinthehotby-passflowleadstoadecrease inthecoldstreamoutlettemperature,sothegainis negative.A fail-open valveshouldbespecified.

c.

Anincreaseinthecoldby-passflowrateleadstoa decreaseintheoutlettemperature,sothegainisnegative.A fail-open valveshouldbespecified,sothat theoutlettemperatureisnottoohighortheairpressureislost.

d. Strategy(c),coldby-pass,willhavethefastestdynamicbehaviorbecausetheeffectofchangingthebypassflowwillbealmostinstantaneous.Theother strategieshaveadynamiclagthroughtheheatexchanger.

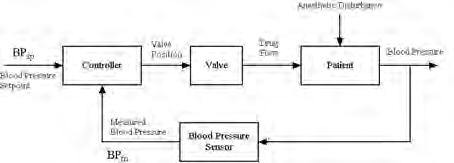

1.11

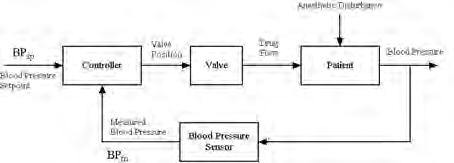

Theanesthesiologistattemptstomaintainadesired setpointforbloodpressure.Thisisdonebymanipulatingthedrugflowrate.Amajordisturbanceisthe effectofananestheticonbloodpressure.

Thecontrolblockdiagramfortheautomatedsystem isshowbelowinFigure5,where,forsimplicity,the drugisshownbeingchangedbyavalve.

Figure1-3:P&IDofclosed-loopinsulininfusion

arrangement.Inpractice,thepumpspeedwould bevaried.Theassociatedcontrolblockdiagramis showninFigure4below.

1.10

a.

Anincreaseinthehotstreamflowrateleadstoanincreaseinthecoldstreamoutlettemperature,sothe

0 50 100 150 500 550 600 650 700 time V(t) Liquidvolumeasafunctionoftime

Figure1-5:Controlblockdiagramofdrugdelivery

1-5

Chapter2Solutions

2.1

Themodelingequationis dP dt = RT V qi RT V β P Ph

Atsteadystate

dt = RT V qi RT V β P Ph =0

V β Ps Phs = RT V qis

s = Phs + q 2 is β 2

Thuswecanconcludethatitisaself–regulatingsystem,asforachangeininputitwillattainanew steady–state.

Thesketchofthesteady–stateinput–outputcurve shouldlooklikefigure2-1.

theinletandoutletflowratesarethesame.Thus Fi V (Ti T )+ Q =0 100 500 (20 40)+ Q =0 Q =4◦ C/min

b.Forthispartweneedtointegrate dT dt = 100 500 (22 T )+4

fromaninitialstateof T =40◦ C.TheEuler formulais

xk +1 = xk +∆txk

xk = f (xk )

where f ( )istherighthandsideofthedifferentialequation,and x isthestate,inthiscase T Using∆t =0 5,andforatotalof2minutes,we have

2.2

a.Atsteady–state,thevolumewillnotchange,as

Figure2-2showsthecurveofthesolutionfound using matlab’s ode45,withthecirclesmarking thepointsoftheEulersolution.

dP

RT

P

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 0 5 10 15 20 25 30 qis P s Steady−state input−output curve

Figure2-1:Plotfor2.1

Themodelequationsare dV dt = Fi F dT dt = F

V

T

T )+ Q

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2 40 40.1 40.2 40.3 40.4 40.5 40.6 40.7 40.8 Time − min Outlet Temperature − C Euler integration vs. ode45 ode45 Euler

i

(

i

Figure2-2:Plotfor2.2

x0 =40 x1 =40+0.5 1 5 (22 40)+4 =40.2 x2 =40 2+0 5 1 5 (22 40 2)+4 =40 38 x3 =40 38+0 5 1 5 (22 40 38)+4 =40 542 x4 =40 542+0 5 1 5 (22 40 542)+4 =40 6878

2-1

2.3

Sincethemodelequationshaveonlytwostates, Vl and P ,wehavetoassumethefollowingareconstant: densityoftheliquid(ρ),temperature(T ),theideal gasconstant(R)andthemolecularweightofthegas (MW ).

Startingwiththebalanceoftheliquidmassinthe system,wehave

dMl dt = dVl ρ dt = Ff ρ Fρ

dVl dt = Ff F

Forthebalanceofthemassofgas

dnMW dt = qi MWi qMW

dn

dt = qi q

Fromtheidealgaslaw PVg = nRT ,wherethevolumeofgasis Vg = V Vl Then,

d(PVg )

dt = nRT dt

P d(V Vl ) dt +(V Vl ) dP dt = RT dn dt

andusingthepreviouslyderivedexpressionsfor dn dt and Vl dt

P d(V Vl ) dt +(V Vl ) dP dt = RT dn dt

P dVl dt +(V Vl ) dP dt = RT (qi q ) dP dt = P V Vl (Ff F )+ RT V Vl (qi q )

Thusourmodelequationsare

dVl dt = Ff F

2.4

solvingatsteady–state,weget

CP 1s = CAis Fs kV +1

Weneedtomeetayearlyproduction,soourfinal constraintis

Fs CP 1s S =100x106 lb/yr

Where S =62lb/lbmol 504000min/yrisourconversionfactor,assuming350daysofoperationinayear. Then,

Fs CAis Fs kV +1 S =100x106 lb/yr

solvingfortheflowrate,weget Fs =7.9256ft3 /min.

Nowweneedtoconsiderthesecondreactorinseries,whichwillalsochangetheflowrateneededto meetproductionlevels.Theequationsforthesecond reactorare dC

Solvingatsteady–state,weget

Again,weneedtomeetproductionlevels,so

Solvingfortheflowrate,weget Fs =6 5799ft3 /min. Thuswehaveasavingsof16 98%usingthetworeactorsinseriesoverasingleone.

dP

dt = P V Vl (Ff F )+ RT V Vl (qi q )

Sincewehavealargervolumethantheexample,we havetocalculatetheflowrateforasinglereactoras well.Ourvolumeis V =106.9444ft3 .Theequations forthefirsttankare

2.5

Theresultinggraphshouldbethesameasfigure2-5, exceptthatthetimerangefrom-1to0willnotappear.

P 1 dt = F V CP 1 + kCA1

dCA1 dt = F V (CAi CA1 ) kCA1 dC

dt = F V

CA1 CA2 ) kCA2 dCP 1 dt = F V (CP 1 CP 2 )+ kCA2

A2

(

CP 2s = kV Fs kV Fs +2 CAis kV Fs +1 2

Fs CP 2s S =100

kV kV Fs +2 CAis kV Fs +1 2 S =100x106 lb/yr

x106 lb/yr

d(VCa ) dt = Fin CA

kVC

dV dt = Fin 2-2

2.6

in

A

Weneedequationswhosestatesare V and CA ,then

d(VCa ) dt = Fin CAin kVCA

V dCa dt + CA d(V ) dt = Fin CAin kVCA

V dCa dt = CA d(V ) dt + Fin CAin kVCA

V dCa dt = CA Fin + Fin CAin kVCA

dCa dt = Fin V (CAin CA ) kCA

ourtwoequationsare dV dt = Fin dCa dt = Fin V (CAin CA ) kCA

2.7

a.Themodelingequationsare dCw 1 dt = F V1 (Cwi Cw 1 ) kC 2 w 1 dCw 2 dt = F V2 (Cw 1 Cw 2 ) kC 2 w 2

b.Atsteady–statewecansolvethefollowingequations

Rearrangingthefirstequation,wehavethe quadratic

=0

thepositiverootgivesus Cw 1s =0 33333mol/liter

Rearrangingthesecondequation,wehavethe quadratic kC 2 w 2s + Fs V2 Cw 2s Fs V2 Cw 1s =0

thepositiverootgivesus Cw 2s =0 0900521mol/liter

c.Tolinearize,wehavethefunctions

f1 = dCw 1 dt = F V1 (Cwi Cw 1 ) kC 2 w 1

f2 = dCw 2 dt = F V2 (Cw 1 Cw 2 ) kC 2 w 2

d.Evaluatingthesecoefficientsatoursteady–state, wehave

e.Since y = x,itisstraightforwardtoshowthat

= 10 01 D = 00 00

f.Using matlab,theeigenvaluesare 0.320156 and 1.25.

F

1

C

1

2

1

Fs V2

C

1s C

2s

2

2s =0

s V

(

wis Cw

s ) kC

w

s =0

(

w

w

) kC

w

kC 2 w 1s + Fs V1 Cw 1s Fs V1 Cwis

a11 = δf1 δx1 ss = δ δCw 1 F V1 (Cwi Cw 1 ) kC 2 w 1 ss = Fs V1 2kCw 1s a12 = δf1 δx2 ss = δ δCw 2 F V1 (Cwi Cw 1 ) kC 2 w 1 ss =0 a21 = δf2 δx1 ss = δ δCw 1 F V2 (Cw 1 Cw 2 ) kC 2 w 2 ss = Fs V2 a22 = δf2 δx2 ss = δ δCw 2 F V2 (Cw 1 Cw 2 ) kC 2 w 2 ss = Fs V2 2kCw 2s b11 = δf1 δu1 ss = δ δF F V1 (Cwi Cw 1 ) kC 2 w 1 ss = 1 V1 (Cwis Cw 1s ) b12 = δf1 δu2 ss = δ δCwi F V1 (Cwi Cw 1 ) kC 2 w 1 ss = Fs V1 b21 = δf2 δu1 ss = δ δF F V2 (Cw 1 Cw 2 ) kC 2 w 2 ss = 1 V2 (Cw 1s Cw 2s ) b22 = δf2 δu2 ss = δ δCwi F V2 (Cw 1 Cw 2 ) kC 2 w 2 ss =0

andusingthestateandinputvariablesasdefined,wehave

A = 1.25hr 1 0 0.05hr 1 0.320156hr 1 B = 0 0016667mol/l2 0 25hr 1 0.000121641mol/l2 0

C

2-3

analytically,wehave

g.Figure2-3showstheplotforthelinearandnonlinearresponses;asitcanbeseen,theextraction

UA =183 9Btu/(◦ F min)

Fjs =1 5ft3 /min

b.Applyingtheequationsfortheelementsofthe linearizationmatrices

a11 a12 a21 a22 = 0 40 3 1.2 1.8

B = 0 7.50.10 20000.6

C = 10 01

D = 0000 0000

c heater.m fileshouldbeliketheexampleinthe book(p.73)

d.Using delJ=0,run ode45 tosolvetheequationsdefinedin heater.m,thenplotthetwo statesvs.time.Theresultshouldbeconstant valuesthatmatchthesteadystatesforalltime.

h.Iftheorderofthereactionvesselsisreversed, thesteady–stateequationswehavetosolveare

e.Togetthedesiredplotsforthetwostepresponses,them–fileshowninpages74-75can beused,startingwiththedefinitionofthestate spacelinearmodel.Sincethemodelislinear, theoutputofthestepresponsecommandcanbe scaledaccordinglyforstepsofdifferentsizesby justmultiplyingby delFj.Figures4(a)and4(b) showtheresponsesforasmall(0.2%changein Fj )andalarge(10%changein Fj )steps,respectively.

f.Sinceweknow UA forthesmallvessel,andwe areassumingthat U remainsconstant,wecan findthevalueof UA foralargervolumeas

UAsmall · Alarge Asmall = UAlarge

2.8

a.Solvethefollowingtwosimultaneousequations usingtheparametersandsteady–statevalues provided:

Modelingthevesselasacylinder,thevolumeis V = π 2 D 3 ,andtheareais A =2.25πD 2 .Wecan thencalculatetheareaofthesmallvesselasa functionofitsvolume,forwhichweget

2 3

Asmall =2.25π 20 π

Similarly,wehavetheareaofthelargervesselin termsofitsvolume

Alarge =2 25π

det (λI A)=0 det λ +1.250 0.05 λ +0.320156 =0 (λ +1.25)(λ +0.320156)=0

λ1 = 1 25and λ2 = 0

thustheeigenvaluesare

320156

requirementsarestillmet. 0 2 4 6 8 10 12 14 16 18 0.33 0.335 0.34 0.345 0.35 0.355 time (hrs) C w1 mol/l Response to a 10 l/min step change from steady state 0 2 4 6 8 10 12 14 16 18 0.09 0.092 0.094 0.096 time (hrs) C w2 mol/l nonlinear linear nonlinear linear

Figure2-3:Plotfor2.7g

Fs V2 (Cwis Cw 1s ) kC 2 w 1s =0 Fs V1 (Cw 1s Cw 2s ) kC 2 w 2s =0 solvingthenweget Cw 1s = 1 6 mol/land Cw 2s = 0

mentsarenolongermet.

10301mol/l.Thus,theextractionrequire-

Fs V (Tis Ts )+ UA Vρcp (Tjs Ts )=0 Fjs Vj (Tjins Tjs ) UA Vj ρj cpj (Tj s Ts )=0

then

2V π 2 3 2-4

Applyingthis,wefindthat

Wecanalreadyseethatthesteady–statejacket temperaturehasgoneup,sowewanttoknow howlargewecanmakethevesselbeforethe jackettemperatureapproachestheinletjacket temperature.Wecansolvethefollowingequation,using Fs V =0 1min 1 ,aswewanttomaintaintheresidencetime.Wealsousetheexpressionintermsofthevolumethatwefoundin part f

then V =270ft3

h.Applyingtheequationsfortheelementsofthe linearizationmatricesusingthesteadystatefor thelargervessel,wehave

Theeigenvaluesforthesystemwiththelarge vesselareat λ1 = 0.1957and λ2 = 2.0197. Whileforthesystemwiththesmallervessel, theyare λ1 = 0.1780and λ2 = 2.0220.They areveryclosetoeachother,thusthespeedof theresponsewillbesimilarforbothvessels.

i.Figure2-5showstheresponsetoastepof 0 1ft3 /min.Comparingthistofigure4(a),we canseethatbothlinearmodelresponsesare practicallythesameasthenonlinearmodelresponse.Thechangeintemperaturesisalsominor,asthechangeinjacketflowrateissmall (0.2%ofthesteadystatevalueinbothcases).

j.Figure2-6showstheresponsetoastepof10%of thesteadystatejacketflowrate.Comparingthis tofigure4(b),wecanseethatbothlinearmodel

0 5 10 15 20 25 30 125 125.02 125.04 125.06 125.08 nonlinear vs. linear, small step, V=10 ft3 time (min) temp − F 0 5 10 15 20 25 30 150 150.02 150.04 150.06 150.08 150.1 time (min) jacket temp − F nonlinear linear nonlinear linear (a) 0 5 10 15 20 25 30 125 125.5 126 126.5 127 127.5 nonlinear vs. linear, large step, V=10 ft3 time (min) temp − ° F 0 5 10 15 20 25 30 150 150.5 151 151.5 152 152.5 153 153.5 time (min) jacket temp − ° F nonlinear linear nonlinear linear (b)

Andtheratiooftheareasis Alarge Asmall = V 10 2 3

Figure2-4:Plotfor2.8e(a)smallstepof0.2%(b) largestepof10%

UAlarge =853.588Btu/(◦ F min) g.Solvethefollowingtwosimultaneousequations usingthevalueof UA calculatedforthelarge vessel Fs V (Tis Ts )+ UA Vρcp (Tj s Ts )=0 Fjs (Tjins Tjs ) UA ρj cpj (Tj s Ts )=0

T

◦ F F

=35

478ft3

then

js =178 86

js

.

/min

Fs V (Tis Ts )+ UA Vρcp (Tj s Ts )=0 0 1(Tis Ts )+ UAsmall V 10 2 3 Vρcp (Tj s Ts )=0

A = 0 23920 1392 0 5570 1 9761 B = 0 0 750 10 0 8456001 4191

= 10 01

= 0000 0000

C

D

2-5

responsesareclosetothenonlinearmodelresponse,butthereisanoffsetinthesteadystate. Thechangeintemperaturesisalsomoremarked, andlargerinthecaseofthesmallerreactor,as wouldbeexpectedduetothesmallervolume.

0 5 10 15 20 25 30 125 125.005 125.01 125.015 125.02 125.025 125.03 125.035 nonlinear vs. linear, small step, V=100 ft3 time (min) temp − F 0 5 10 15 20 25 30 178.86 178.87 178.88 178.89 178.9 178.91 178.92 178.93 time (min) jacket temp − F nonlinear linear nonlinear linear

Figure2-5:Plotfor2.8i

0 5 10 15 20 25 30 125 125.5 126 nonlinear vs. linear, large step, V=100 ft3 time (min) temp − F 0 5 10 15 20 25 30 178.5 179 179.5 180 180.5 181 time (min) jacket temp − F nonlinear linear nonlinear linear

2-6

Figure2-6:Plotfor2.8j

Chapter4Solutions

4.1

Themaximumrate-of-changemeanstakingaderivative.Theoutputis:

y (t)= kp ∆u{1 exp( t θ τp )}

Thederivativewithrespecttotimeis:

dy dt = kp ∆u τp exp( t θ τp )

Duetothenegativesign,thelargestthatexp {− t θ τp } canbeis1.Anexponentialwillgiveavalueof1when theargumentis0.Thatmeansthefollowingistrue:

t θ τp =0

Solvingfor θ gives t = θ

Tofindthemaximumslope,plug t = θ intotheslope equation:

dy dt = kp ∆u τp exp( θ θ τp )

Whichsimplifiesdowntoamaximumslopeof:

dy dt = kp ∆u τp

4.2

Theoutputresponse y (t)forafirstorderplusdead time(FOPDT)modeltoastepchangeis:

y (t)= kp ∆u{1 exp( t θ τp )}

Recognizingthat∆y = kp ∆u gives:

y (t)=∆y {1 exp( t θ τp )}

Substituting t1 = τp 3 + θ intotheoutputequation:

y (t)=∆y {1 exp(

Cancellingouttermsgives:

Whichsimplifiesdownto:

y (t1 )=0.238∆y

Substituting t2 = τp + θ intotheoutputequation:

y (t)=∆y {1 exp( τp + θ θ τp )}

Cancellingouttermsgives:

y (t)=∆y {1 exp( 1)}

Whichsimplifiesdownto:

y (t1 )=0 632∆y

Usetheequationsfor t1 and t2 tosolvefor θ and τp

Solvingfor θ inthe

Pluggingthatintothe t1 equation:

Solvingfor τp yields:

4.3

Thefirsttechniquetoestimatetheparametersina firstorderplusdeadtime(FOPDT)modelisthe 63.2%method.Findthegainusingtheformula:

τp 3 + θ θ τp )}

y (t)=∆y {1 exp( 1 3 )}

Thetimedelaycanbe“eyeballed”bylookingat whentheoutputbeginstochangesignificantly,and whentheinputchangewasapplied.Forthisprocess:

θ =5min 1min=4min

Thetimeconstantisestimatedusingthe63.2% method.First,calculatewhat63.2%oftheoutput changeis:

t1 = τp 3 + θ t2 = τp +

θ

= t2 τp

t2 equationgives: θ

t1 = τp 3 + t2 τp

τp = 3 2 (t2 t1 )

kp = ∆y ∆u

p = 68 50 ◦ C 28 25psig =6 ◦ C psig

k

632∆y =0.632(68 50)=11.376 ◦ C

0.

4-1

Process Control Modeling

Design And Simulation 1st Edition Bequette Solutions Manual Full Download: http://testbanktip.com/download/process-control-modeling-design-and-simulation-1st-edition-bequette-solutions-manual/

Lookingattheoutputresponse,thetimefortheresponsetoreach11.376 ◦ Cis15minutes.Thetime constantcanthenbecalculatedusingtheformula giveninthechapter.

t63 2% = τ + θ

τ = t63 2% θ =15 4=11min

TheFOPDTcanthenbeexpressedas:

gp (s)= 6e 4s 10s +1

Thesecondtechniquetoestimatetheparametersin afirstorderplusdeadtime(FOPDT)modelisthe MaximumSlopemethod.Findthegainusingthe

Thetimedelaycanbe“eyeballed”bylookingat whentheoutputbeginstochangesignificantly,and whentheinputchangewasapplied.Forthisprocess:

θ =5min 1min=4min

Thetimeconstantcanbeestimatedbyfirstdeterminingwhat63.2%and28.3%oftheoutputis.

0.632∆y =(0.632)(18)=11.376

0.283∆y =(0.283)(18)=5.094

Lookingattheresponse,therespectivetimestoreach thoseoutputvaluesare t63 2 =15and t28 3 =8. Thetimeconstantcanthenbecalculatedusingthe formula:

τp =1.5(t63 2 t28 3 )

τp =1.5(15 8)=10.5min

TheFOPDTcanthenbeexpressedas:

kp = 68 50 ◦ C 28 25psig =6 ◦ C psig

Thetimedelaycanbe“eyeballed”bylookingat whentheoutputbeginstochangesignificantly,and whentheinputchangewasapplied.Forthisprocess:

θ =5min 1min=4min

Thetimeconstantcanbeestimatedusingthemaximumslopeoftheoutputresponse.Lookingatthe response,wecanseethatthemaximumslopecanbe

gp (s)= 6e 4s 10 5s +1

Notethatallthreemethodsgivesimilar,butnotidenticalFOPDTmodels.

4.4

Anintegratorplusdeadtimemodelhastheform:

gp (s)= kp e θs s

Thetimeconstantcannowbecalculatedusing:

Wethereforeneedtoestimateagainandatimedelay. Thetimedelayisestimatedbylookingatwhenthe outputbeginstochangesignificantly,andsubtracting thetimewhentheinputchangewasmade.Forthis process:

θ =3min 1min=2min

Togetthegain,weneedtofindboththeslopeof theoutputandthechangeininput.Lookingatthe figure,weseethat:

∆u =9 5 10 0lps= 0 5lps

TheFOPDTcanthenbeexpressedas:

slope = 0 3 1m 10 3min = 0 1 m min

Wecanthencalculatethegainusingtheformula:

Thesecondtechniquetoestimatetheparametersin afirstorderplusdeadtime(FOPDT)modelisthe TwoPointmethod.Findthegainusingtheformula:

kp = slope ∆u

kp = 0.1 m min 0.5lps =0 2 m min lps

Theintegratorplusdeadtimemodelisthus:

formula: kp = ∆y ∆u

slope = 58 50 15 5 =0 8 ◦ C min

calculatedusing:

τp = ∆y slope τp = 6 ◦ C 0 8 ◦ C min =7

.5min

gp (s)= 6e 4s 7.5s +1

kp = ∆y ∆u kp = 68 50 ◦ C 28 25psig =6 ◦ C psig

gp (s)= 0.2e 2s s 4-2 Download all pages and all chapters at: TestBankTip.com