NGM

BUILDING ARCHITECTURE THESIS

Politecnico di Milano

School of civil architecture AA 2020/2022

Master’s thesis in Building Architecture Professors

Prof.ssa Francesca Battisti Prof. Giovanni Dotelli Prof.Romano francesco Prof.Grigor Angjeliu Prof.Massimiliano Nastri Author Eden Nimni

Author : Eden Nimni, Eden.nimni@mail.polimi.it

DI MILANO

MIND ,MILAN

NGM MILAN E.N 2

POLITECNICO

NEW GATE

MILAN CITY & MIND DISTRICT

MILAN-MIND CONNECTIVITY

URBAN FABRICS

AN INNOVATION ECOSYSTEM

MIND- PRINCIPALS

MASTER PLAN’S GUIDELINES

LINEAR PARK

MIND WEST GATE

PARCO VERDE BLUE

HILL

THE EAST GATE

STRATEGIC MASTER PLAN

MUSEUM/RESEARCH CENTER

FUNCTION & CIRCULATION

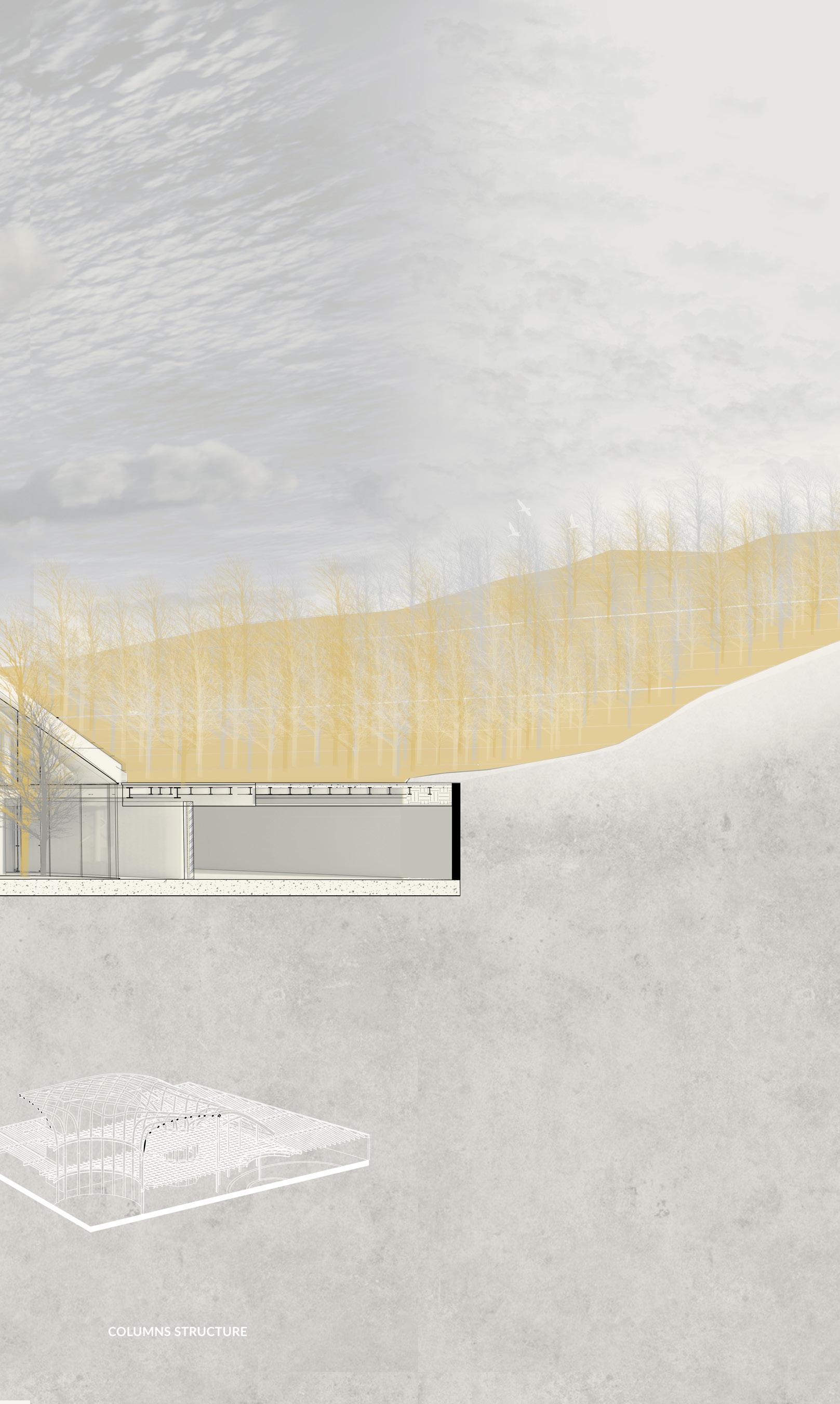

PLANS AND SECTION

SLAB DESIGN

ROOF

NGM MILAN 3 INDEX ABSTRACT 6-8 ANALYSIS 10-25

CONTEXT 26-27

THE

STRATEGY 28-35

NGM

THE PROJECT 36-47

FLOOR

SUSTAINABLE MATERIALS 48-63

GREEN

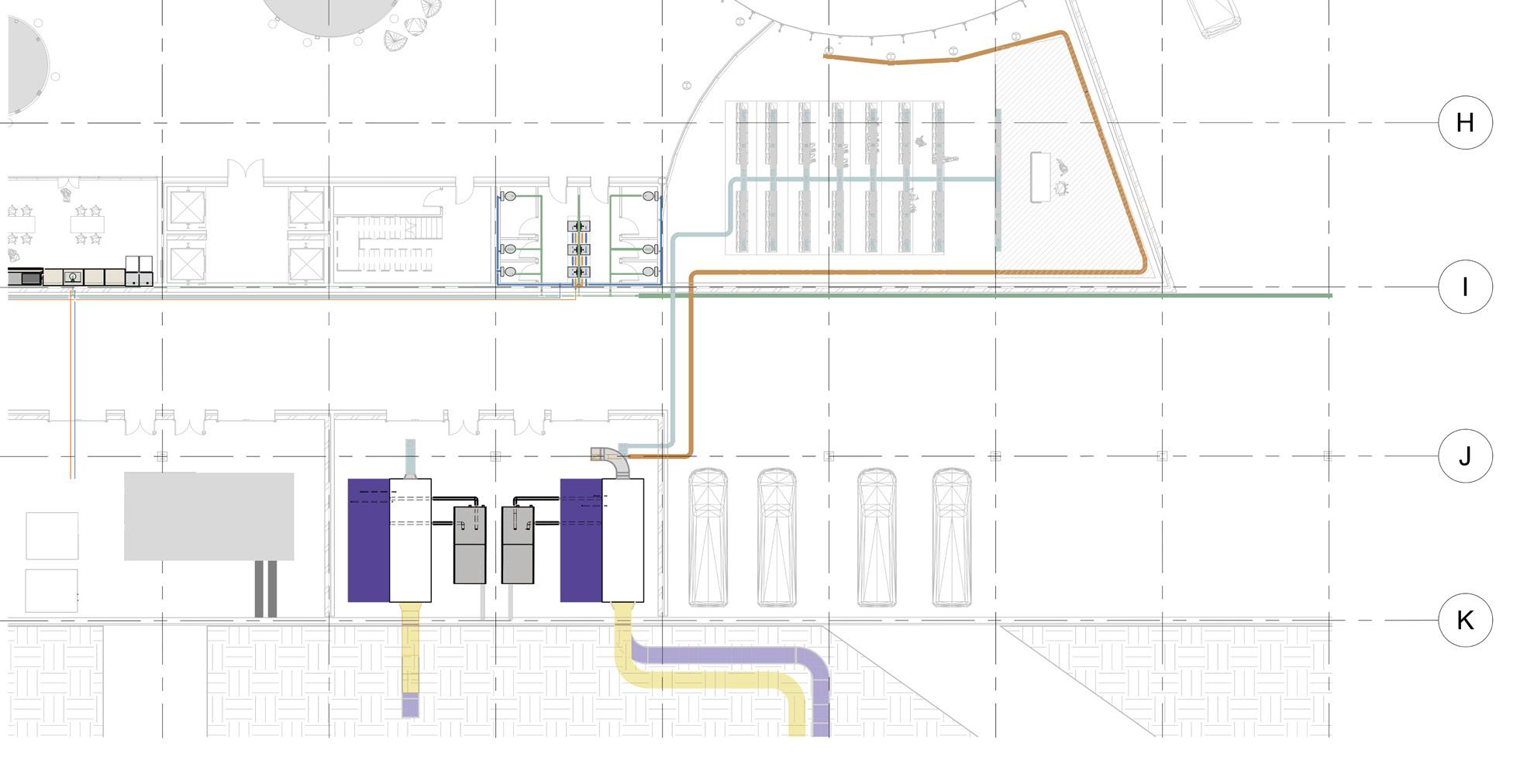

FACADE DESIGN COLUMNS CLADDING STRUCTURAL DESIGN 64-103 STRUCTURAL LOAD CALCULATIONS SLAB DESIGN CONTINUOUS BEAM DESIGN COLUMN DESIGN CASE STUDY STRUCTURAL DRAWINGS SERVICE DESIGN 104-133 OPAQUE AND ROOF STRATIGRAPHY TRANSPARENT U VALUE SUMMER HEAT LOAD WINTER HEAT LOAD COLD WATER SUPPLY HOT WATER SUPPLY DRAINAGE SYSTEM

BIBLIOGRAPHY 133-135

ABSTRACT

Who look to the future” ( 2022 MIND).

MIND DISTRICT

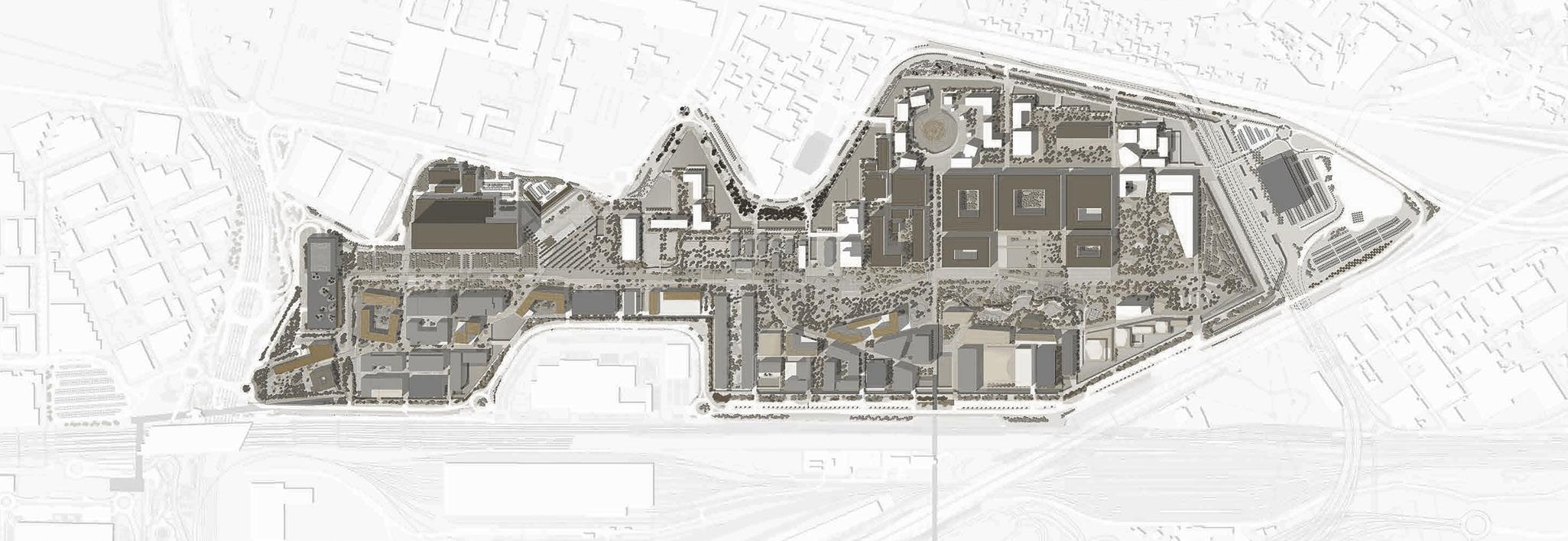

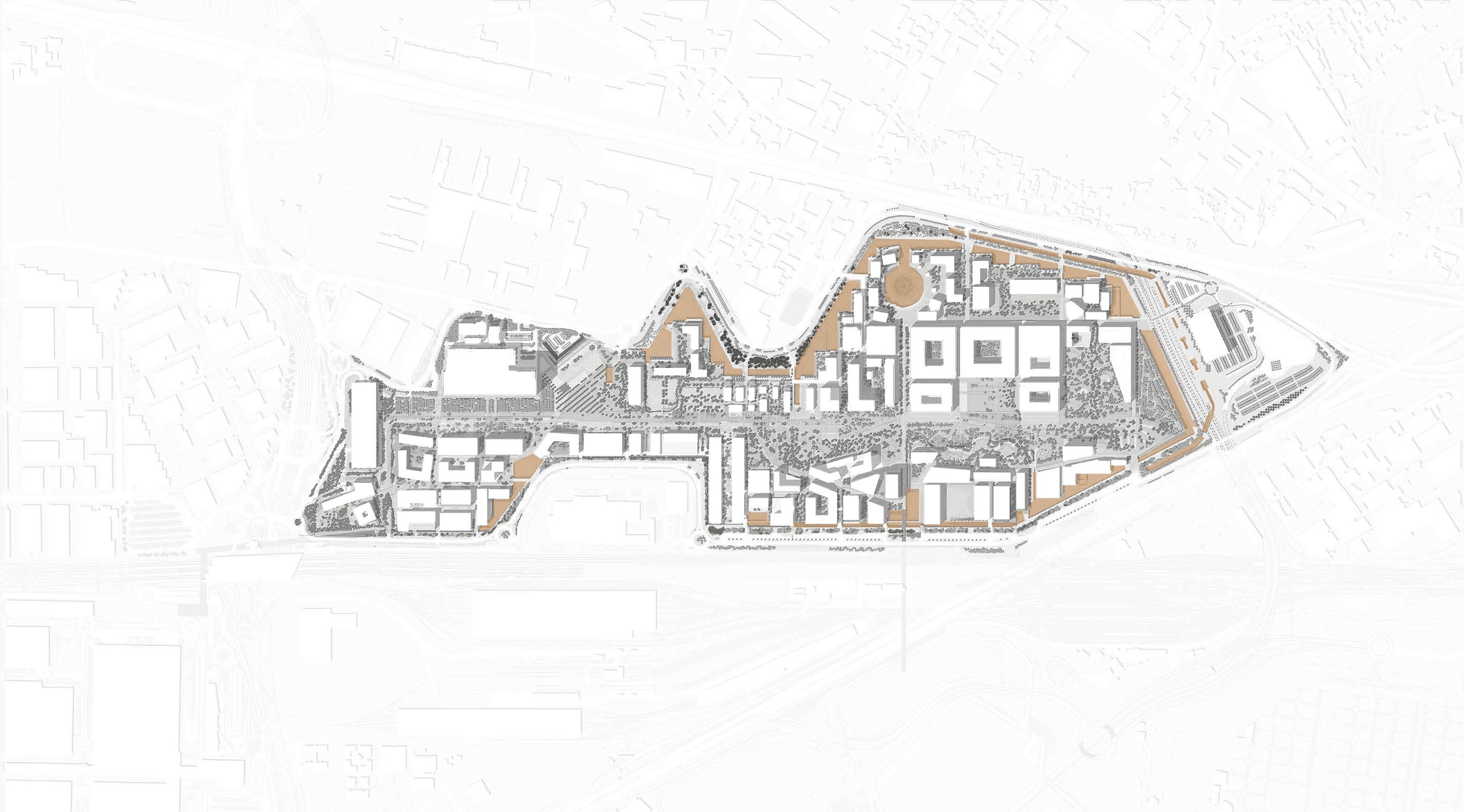

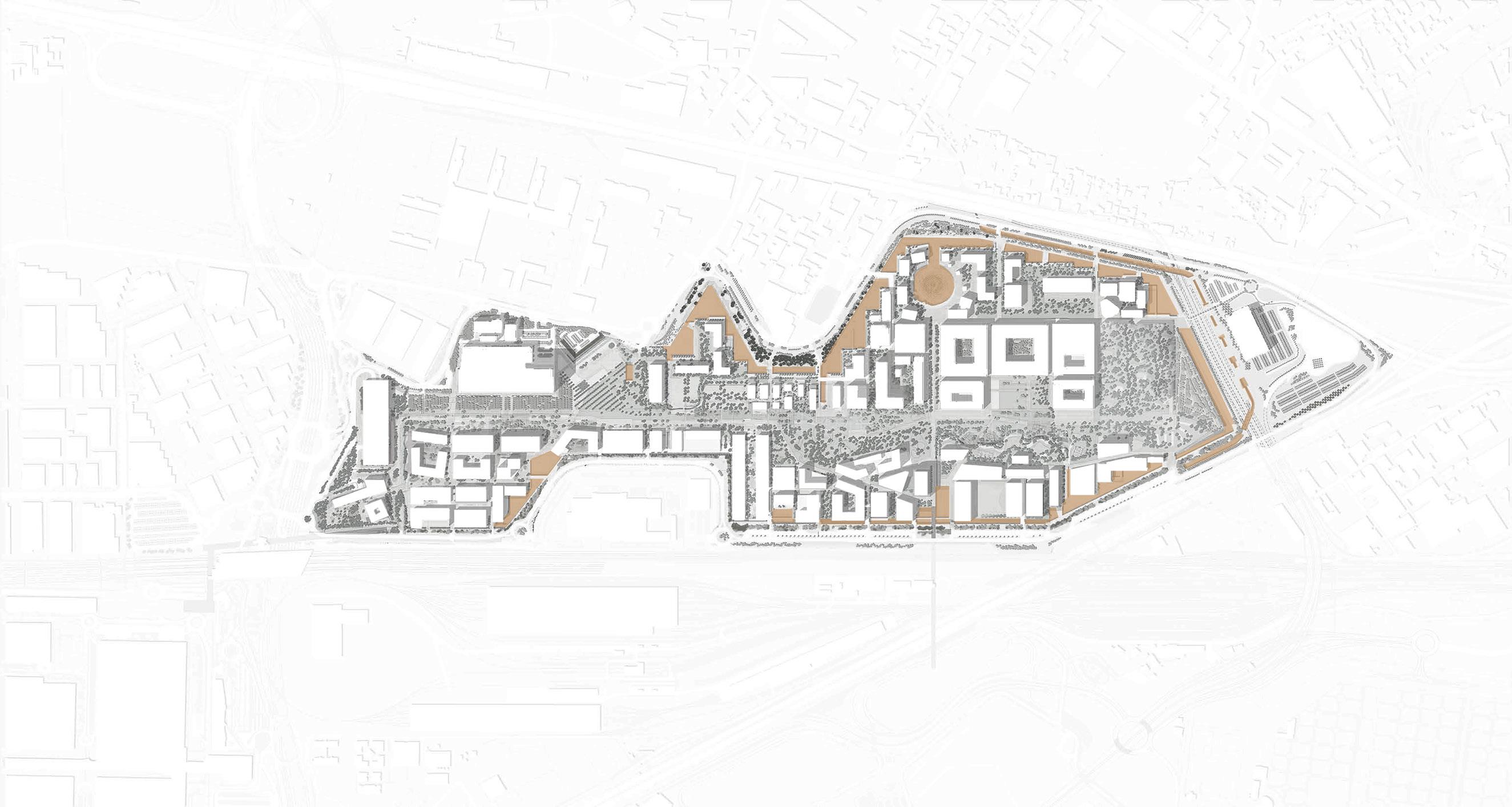

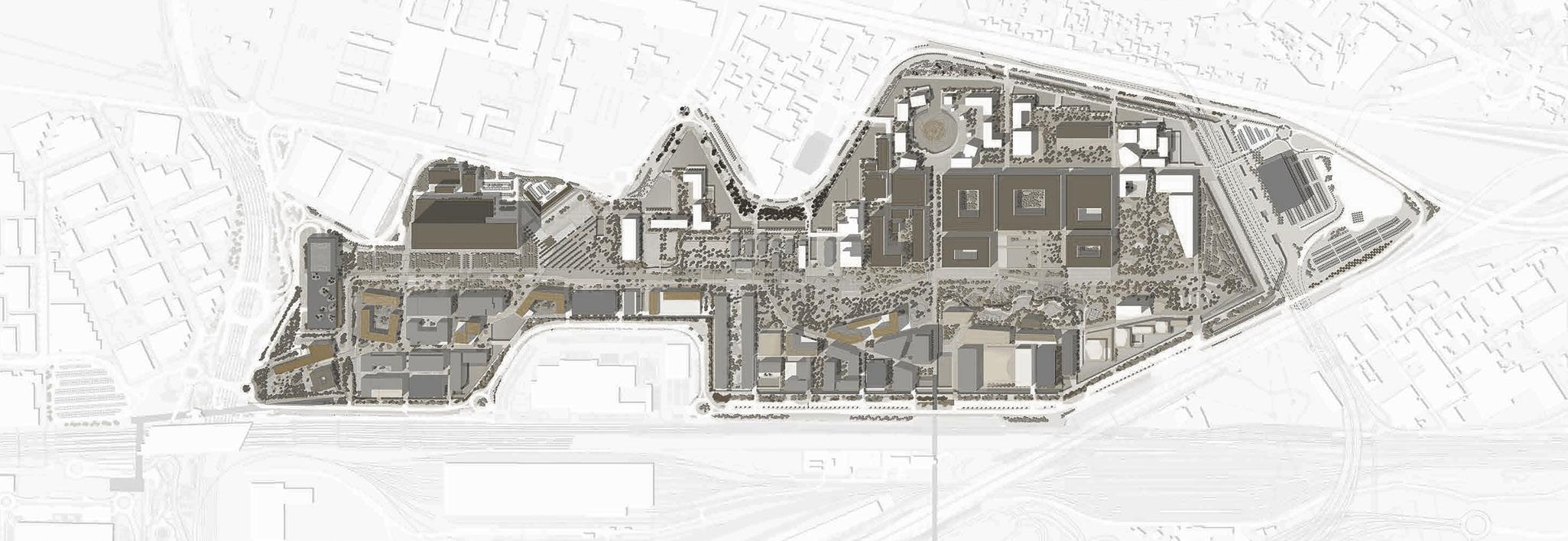

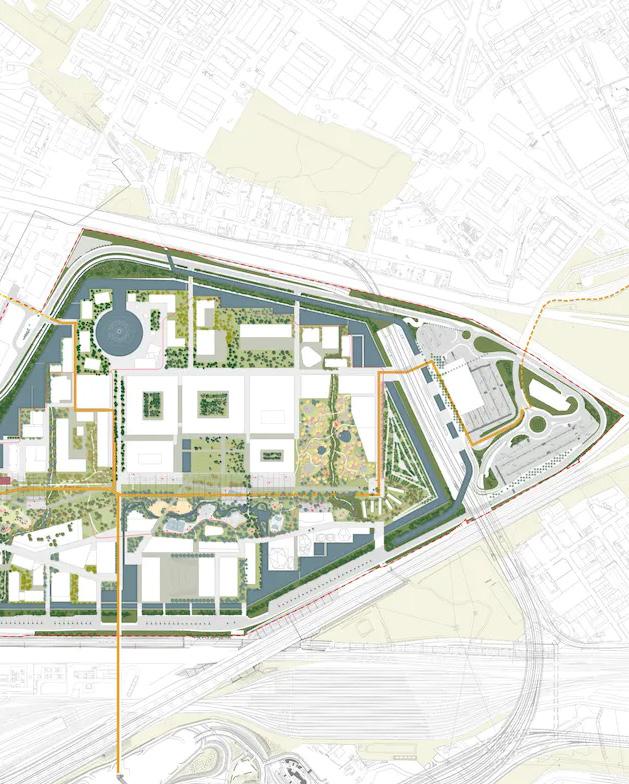

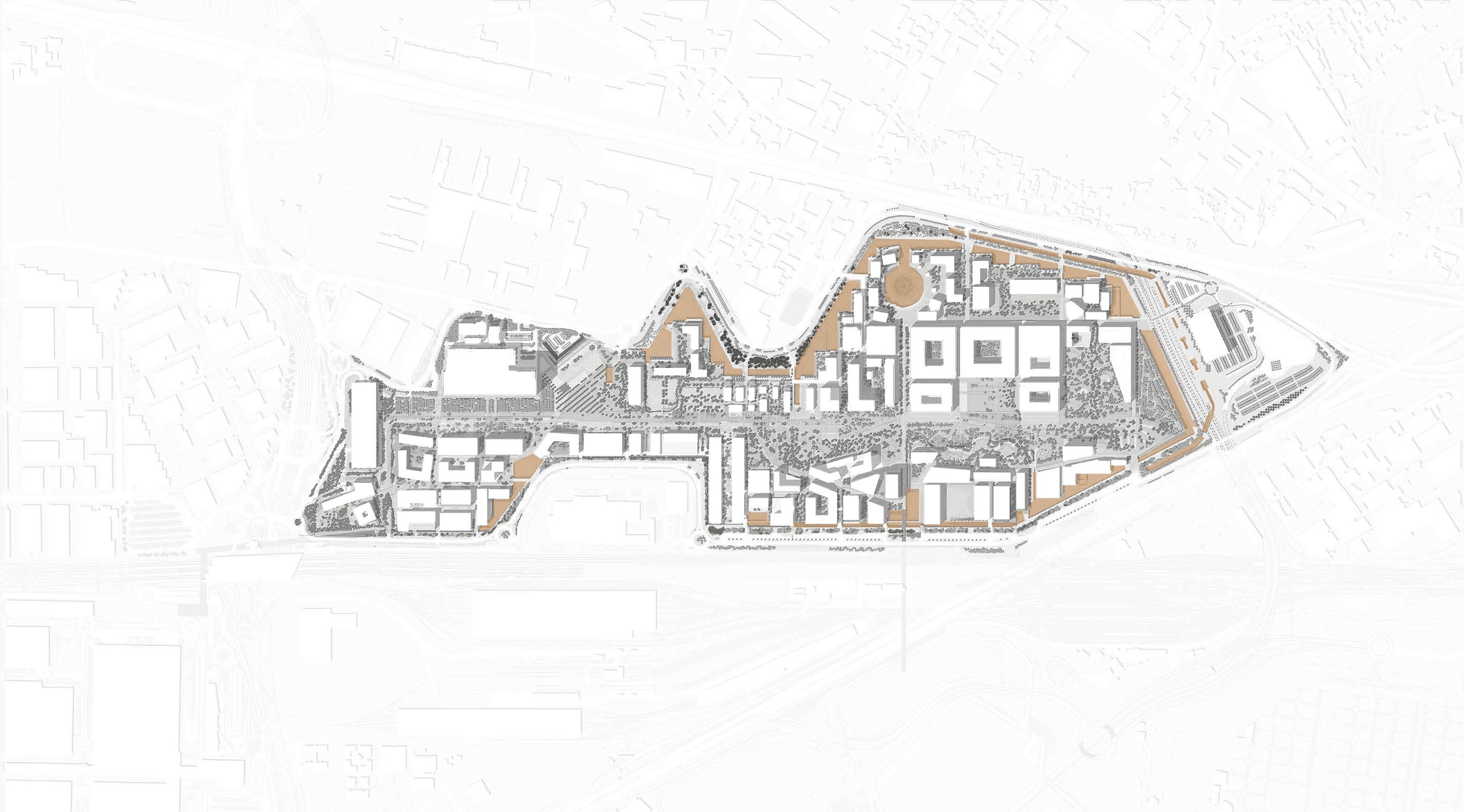

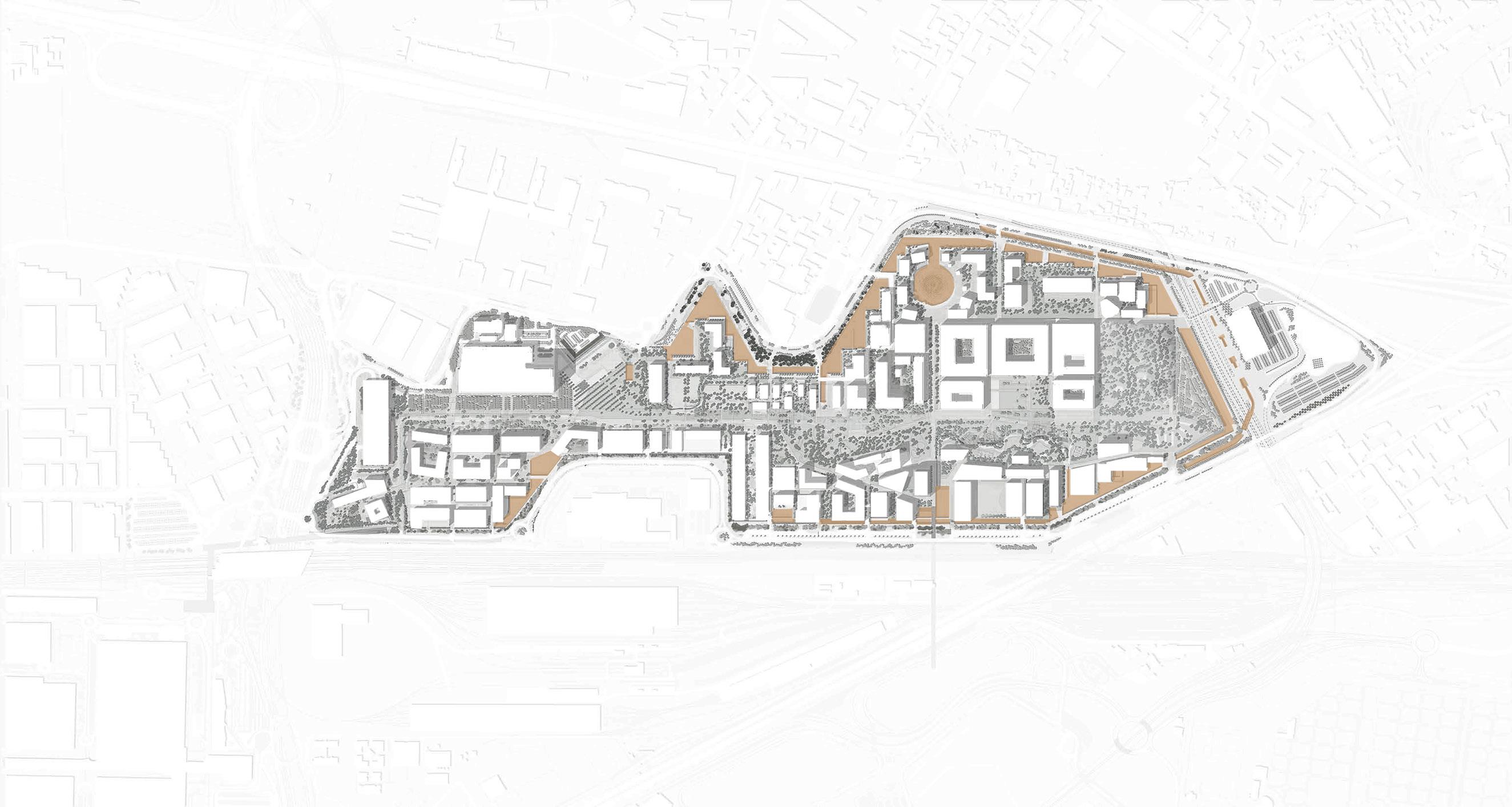

Originally developed to host Expo Milan 2015, the former World Exposition’s site is nowadays undergoing an overall urban renewal aimed at the rise of the future Innovation District. Unique in Europe for model and size, Mind’s design is based on sustainability, wellness inspired spaces, integration with nature.

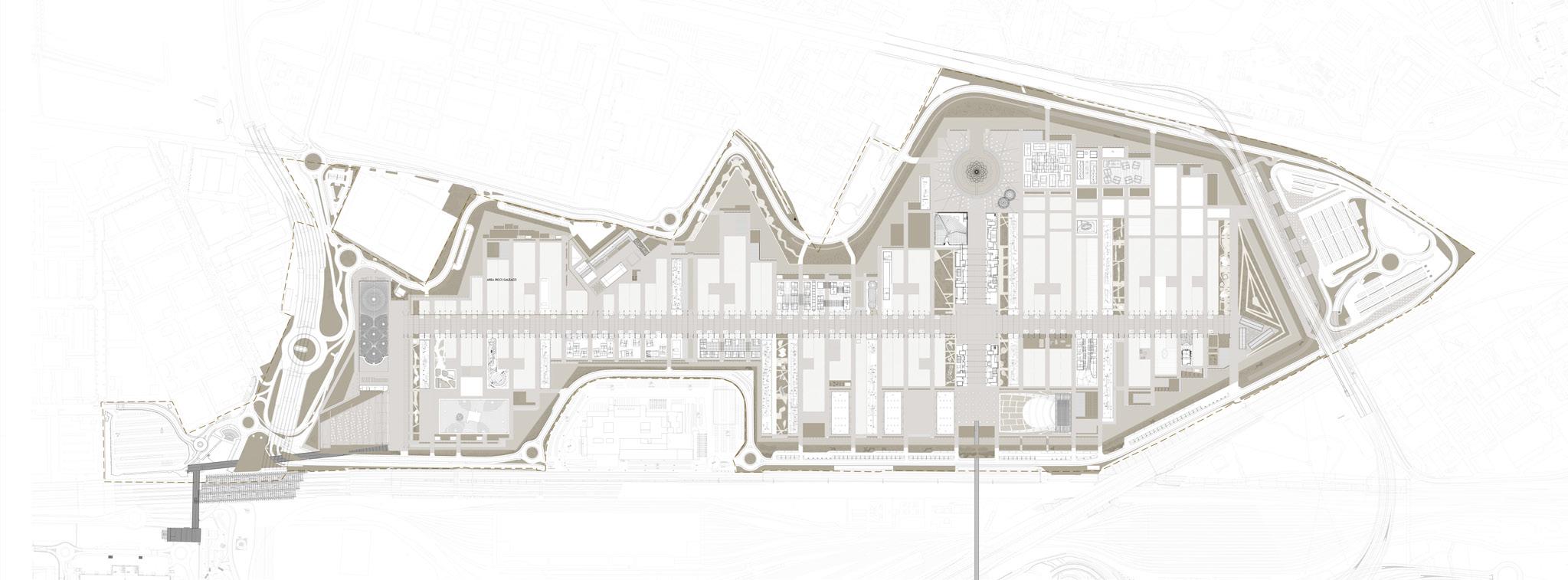

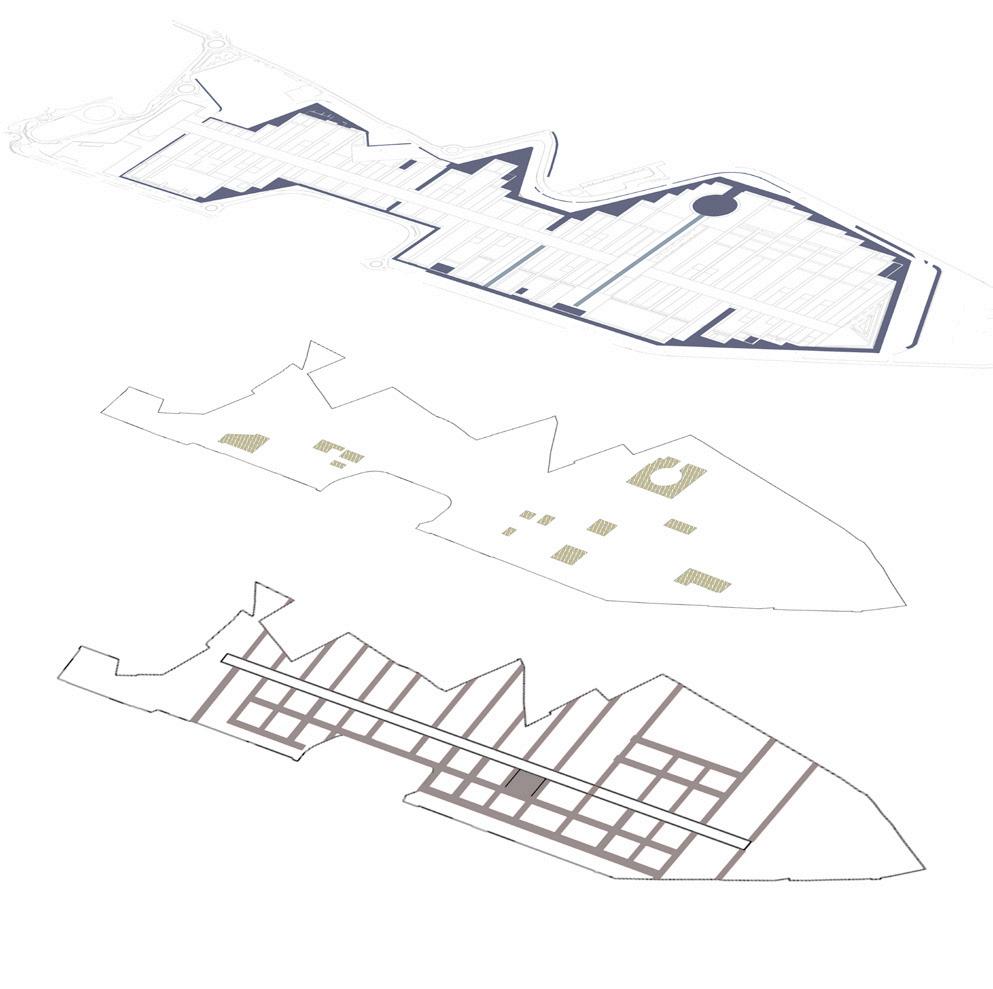

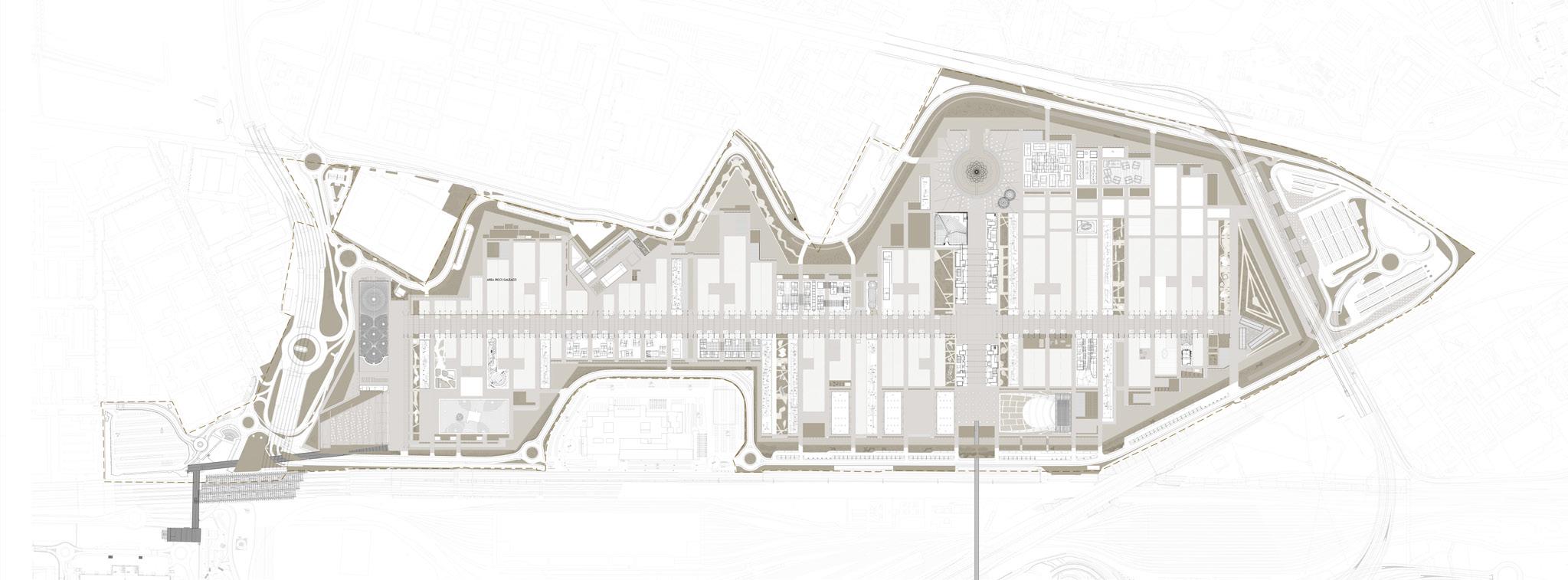

The one million square meter area will host the headquarters of some public interest excellences, in addition to research, training, and business activities, services and commerce, residential compounds, open spaces and large parks, agglutinated along the main longitudinal axis from west to east, the Decumanus.

The infrastructural framework of the 2015 Expo Exhibition (the so-called Piastra, or Plate) offers a suitable frame for the development of MIND: an “infrastructure” to be re-used with the aim of containing the resources for the site “adaptation”.

THE EAST GATE

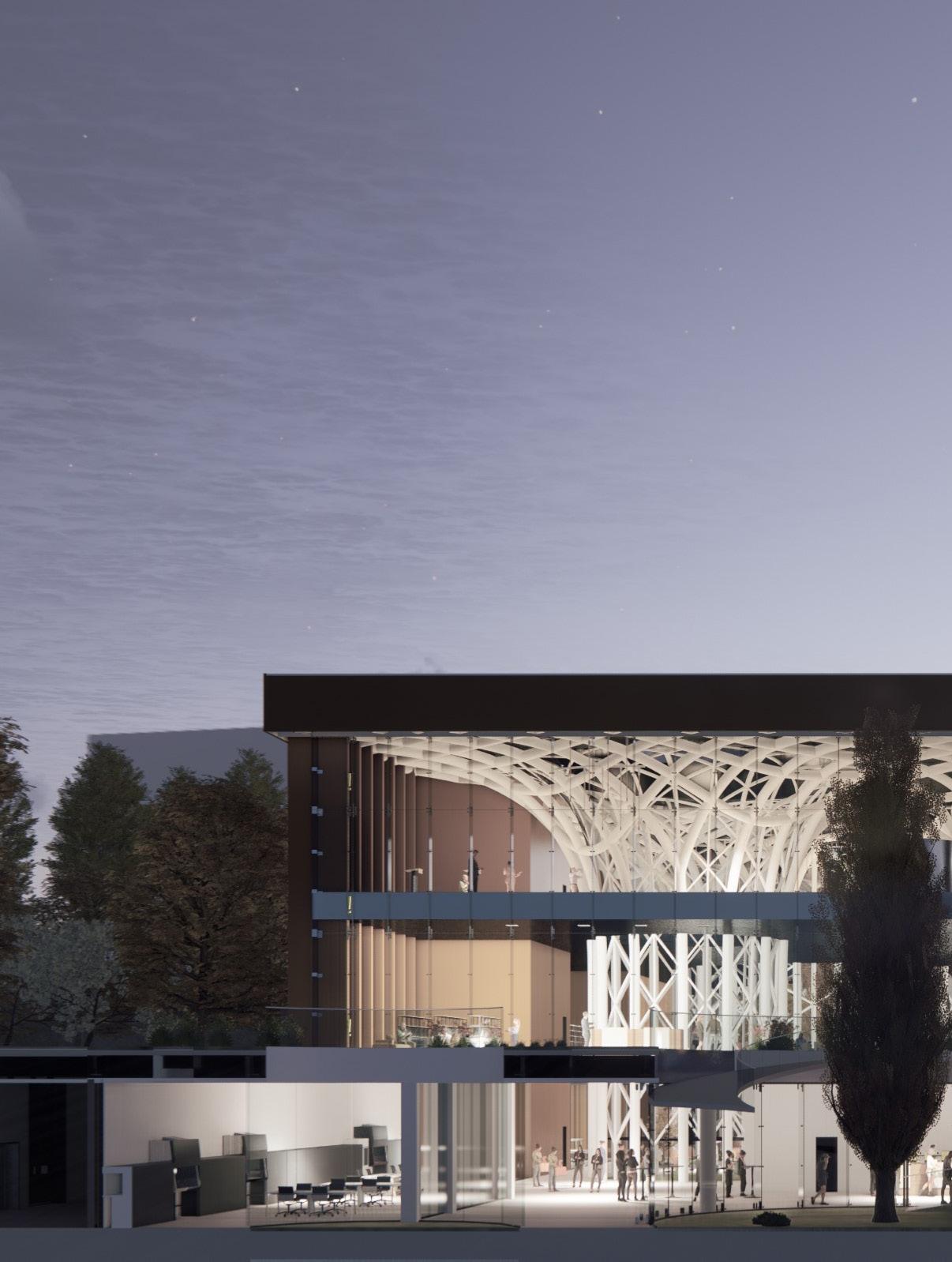

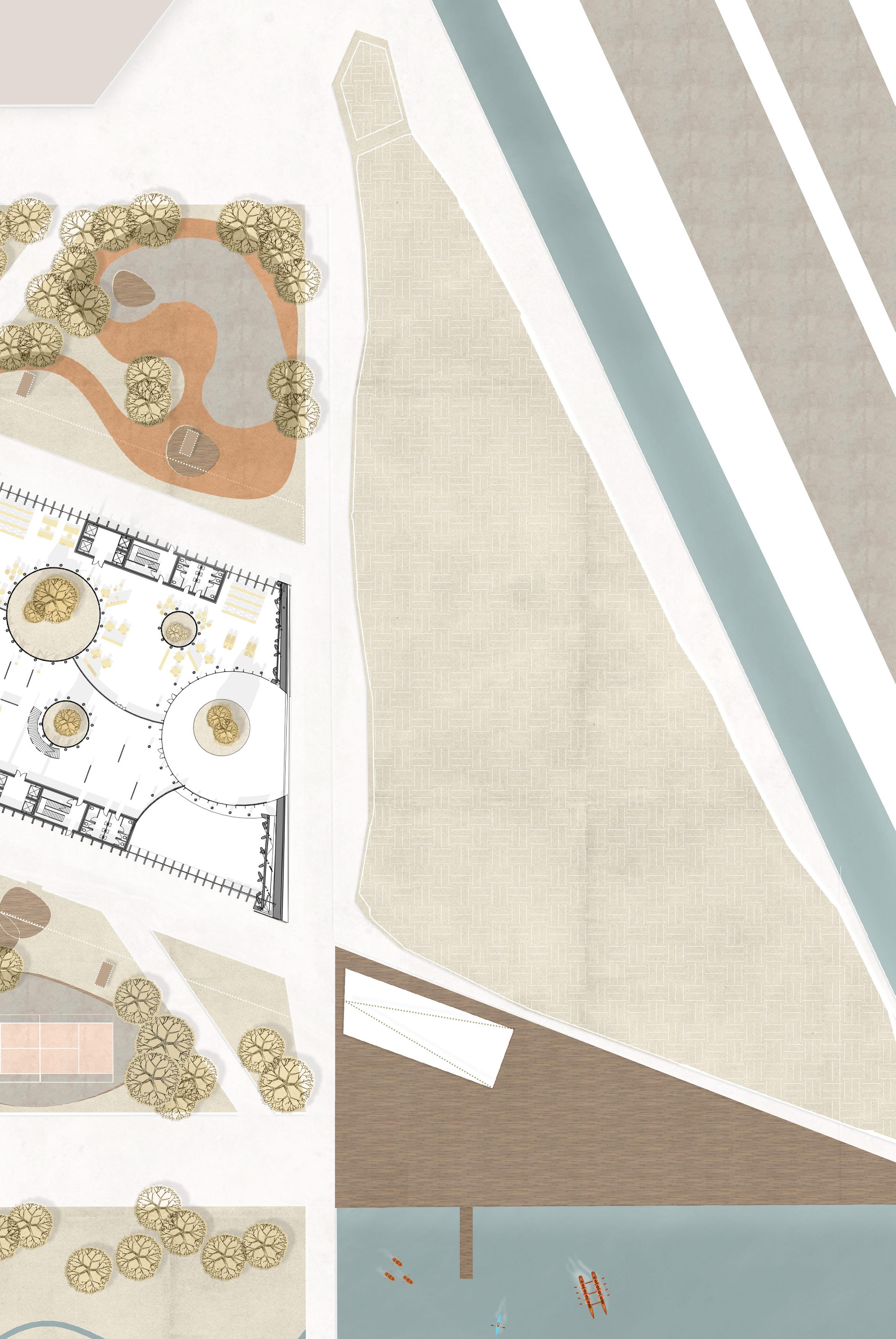

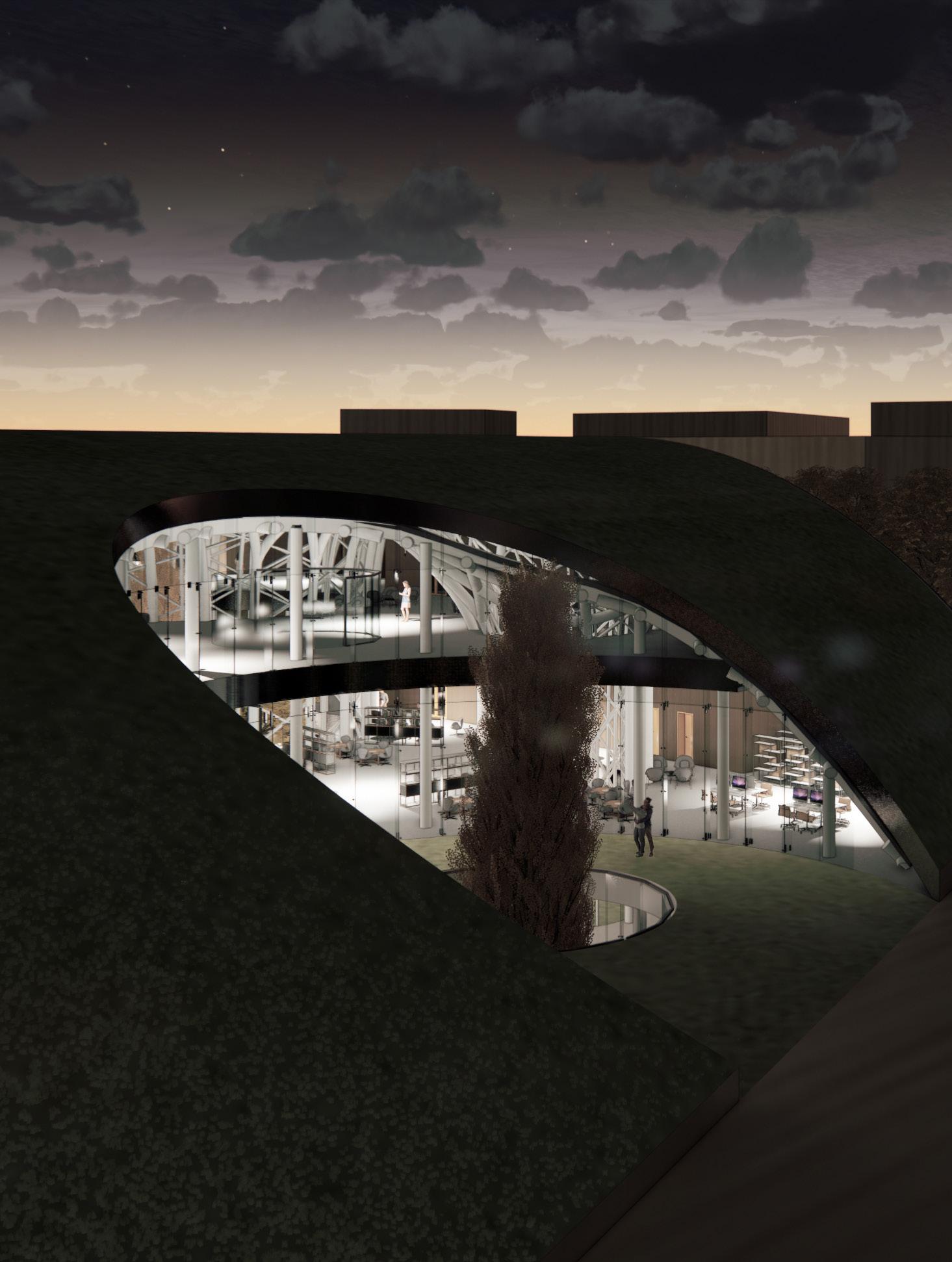

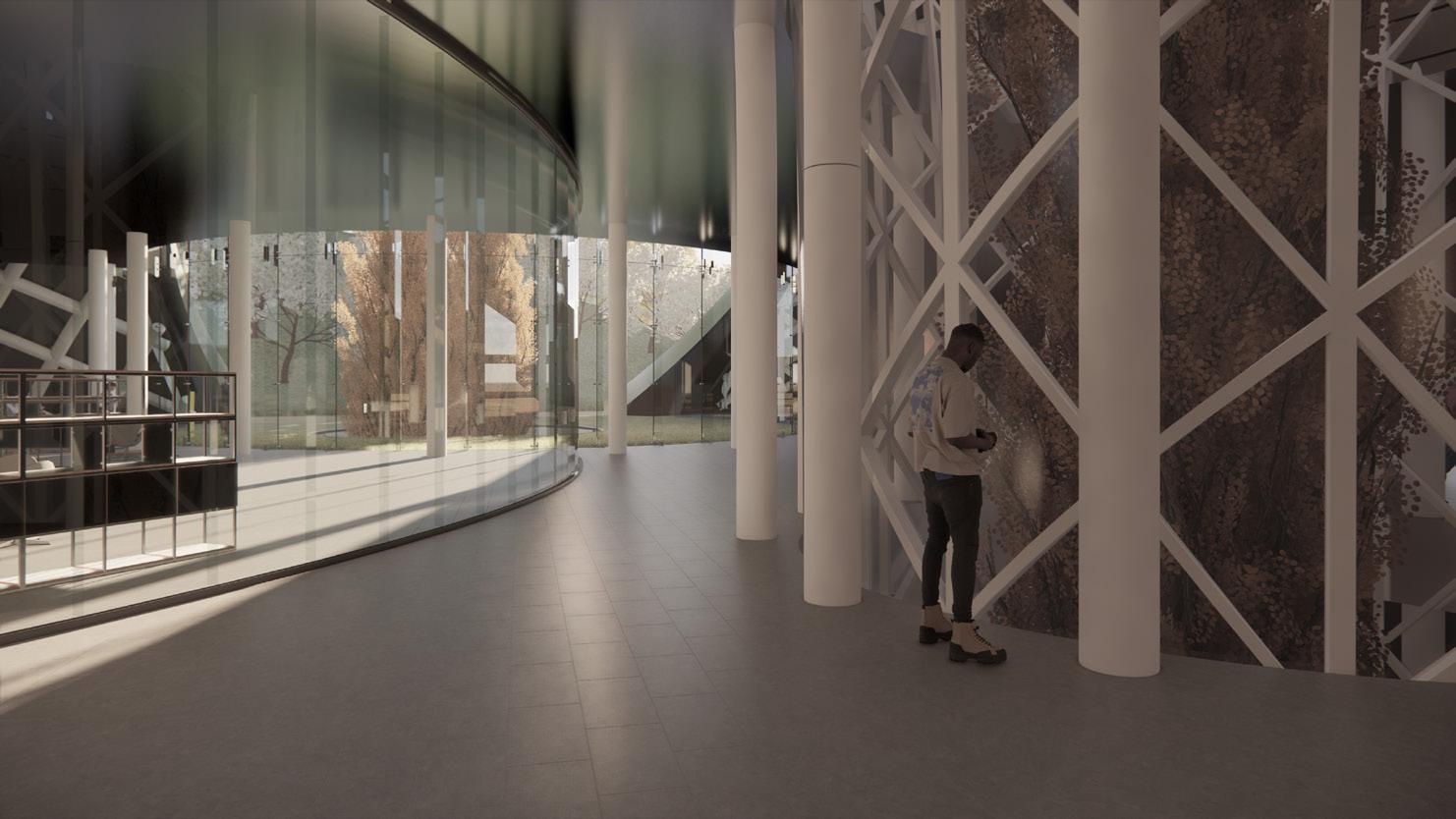

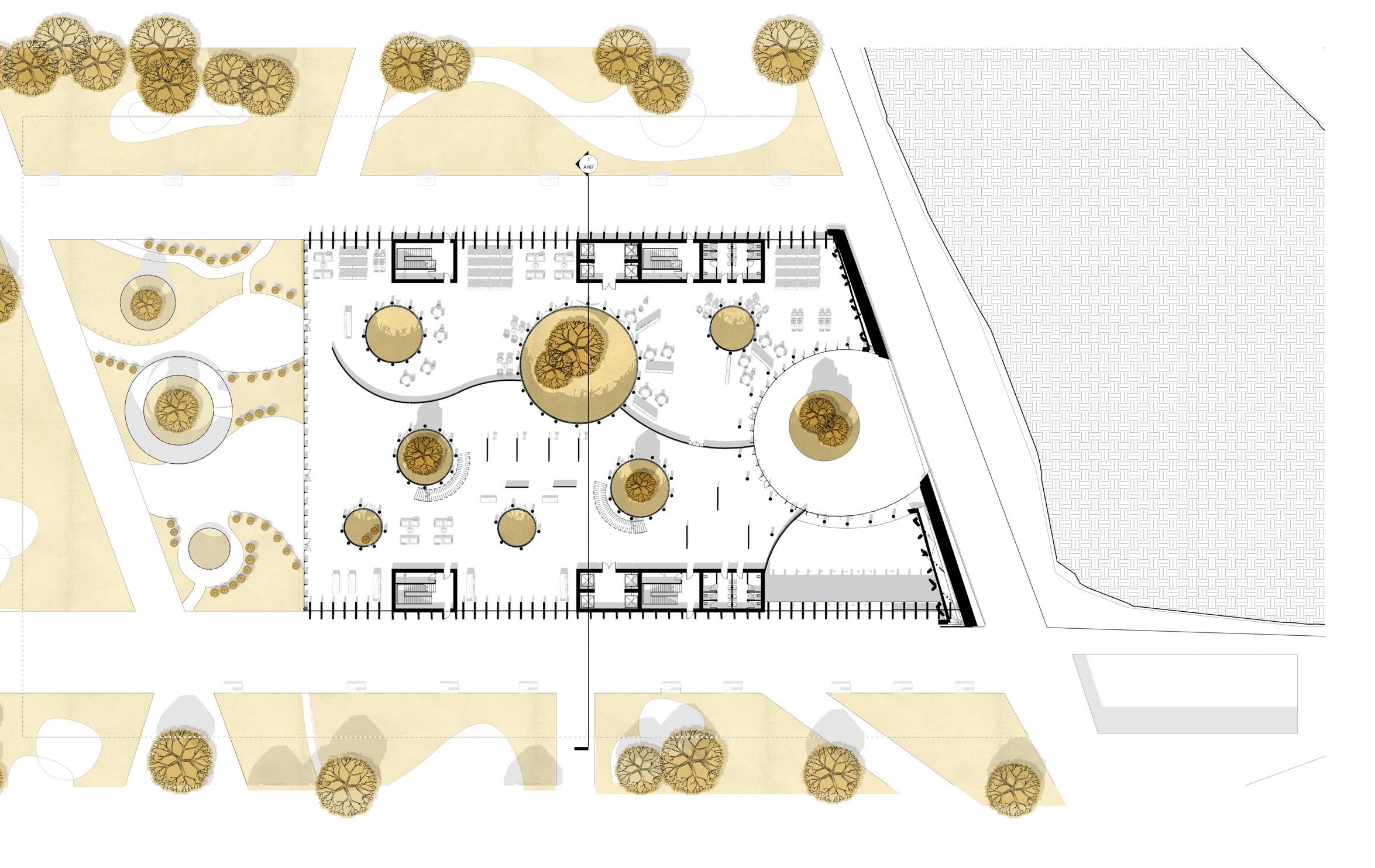

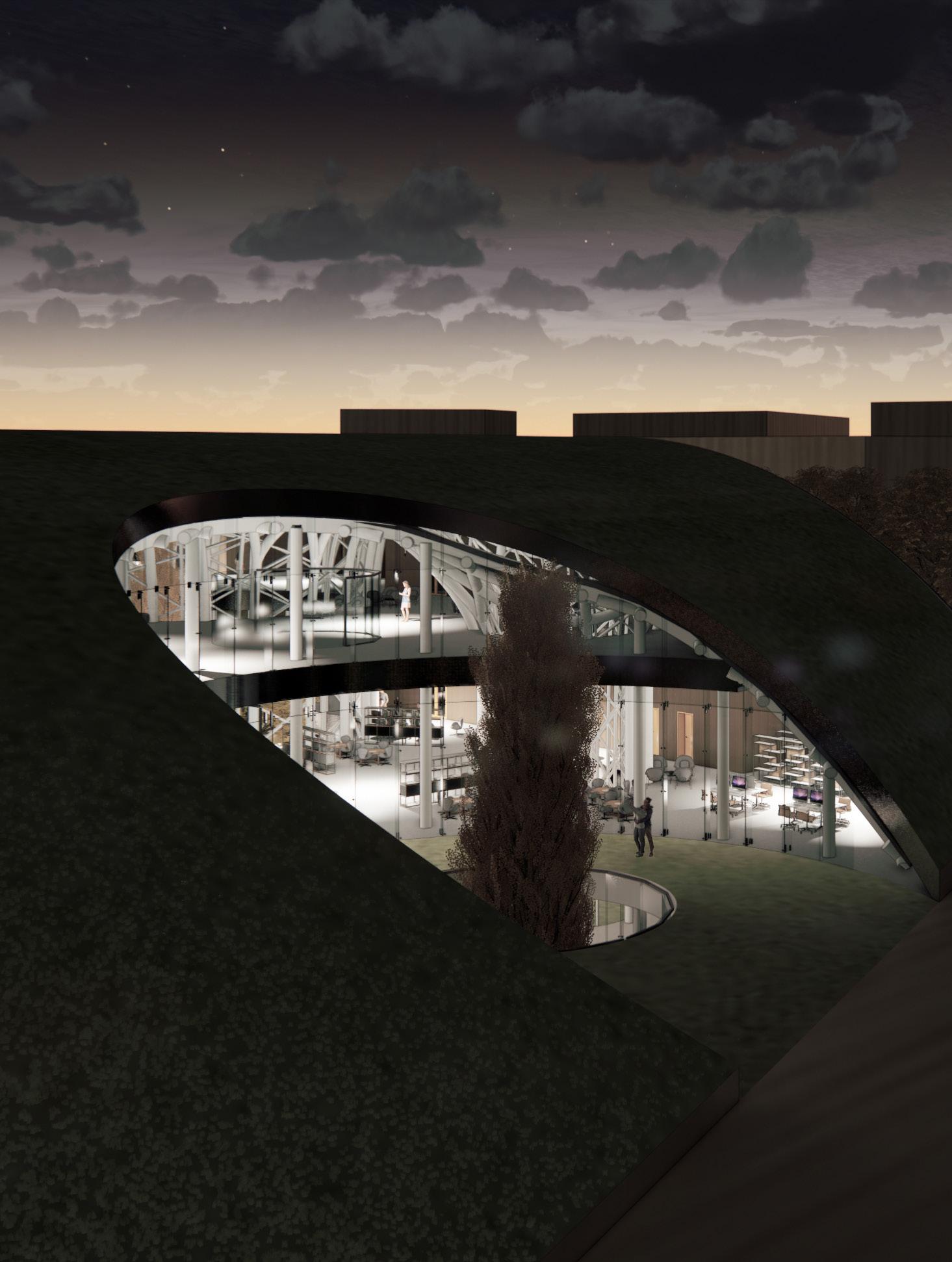

Within this frame, the East Gate sub-district exposes three main assets and zones: Science, Knowledge, and the Innovation Park. The area of intervention chosen for the thesis’s theoretical and project research is the northeastern entrance, the future Innovation Park, connecting MIND “inner” urban district with the water ring around it towards the highway and the main parking zone behind them. Identifying the potential of this site, the thesis project reinforces the current main axis and the east entrance through a further “public anchor”: the museum and research centre for new sustainable technologies in construction and design.

The green paths are redesigned to be better integrated with the adjacent urban anchors: the Statale University’s scientific campus to the west, the artificial green hill - serving as an acoustic barrier towards the highways - and east gate to the opposite side. The main path intersects the park from Mind’s main axis to the east, defining the project’s footprint. To create a relationship between the new intervention

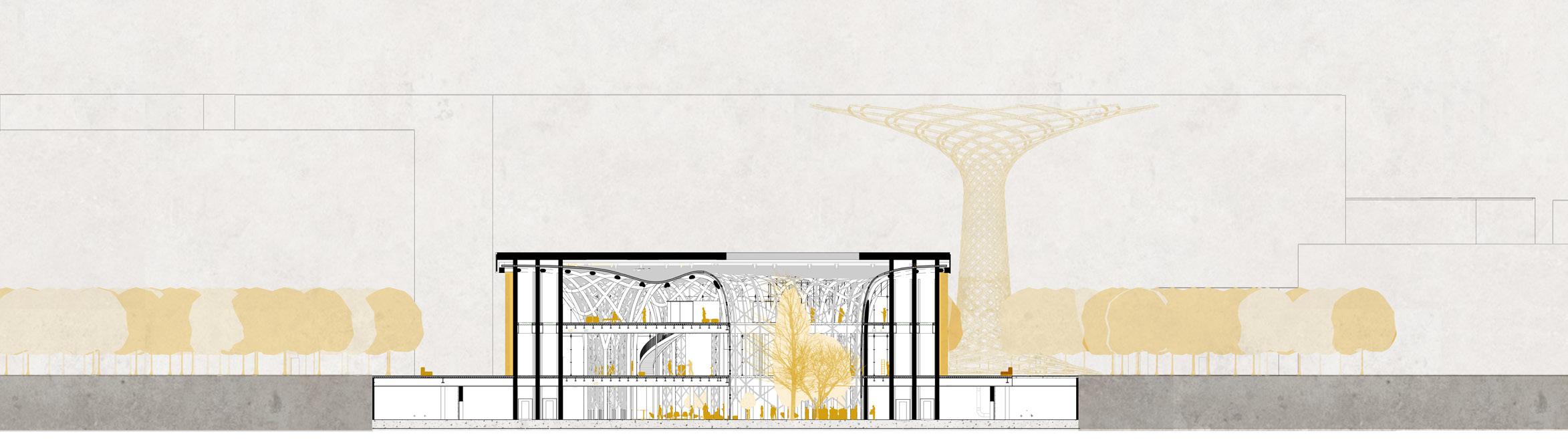

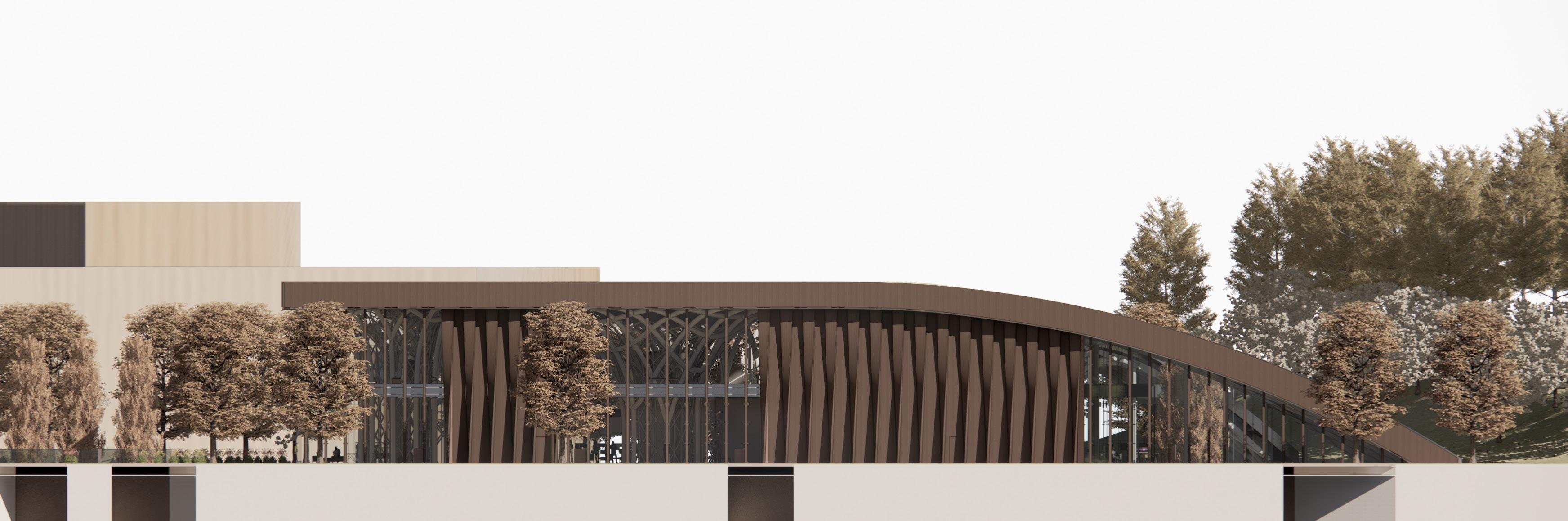

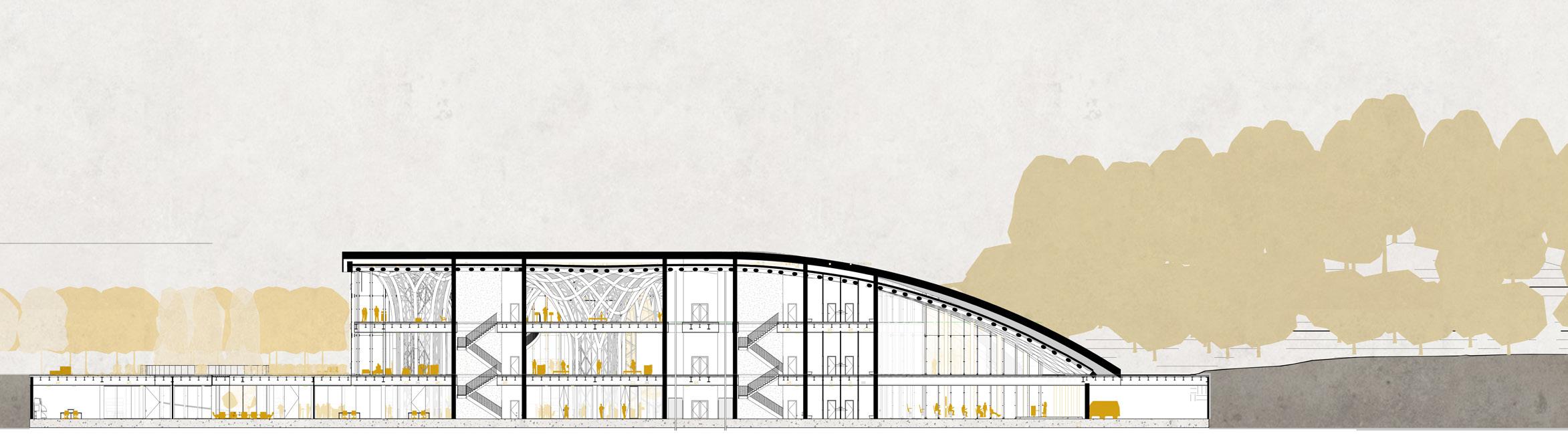

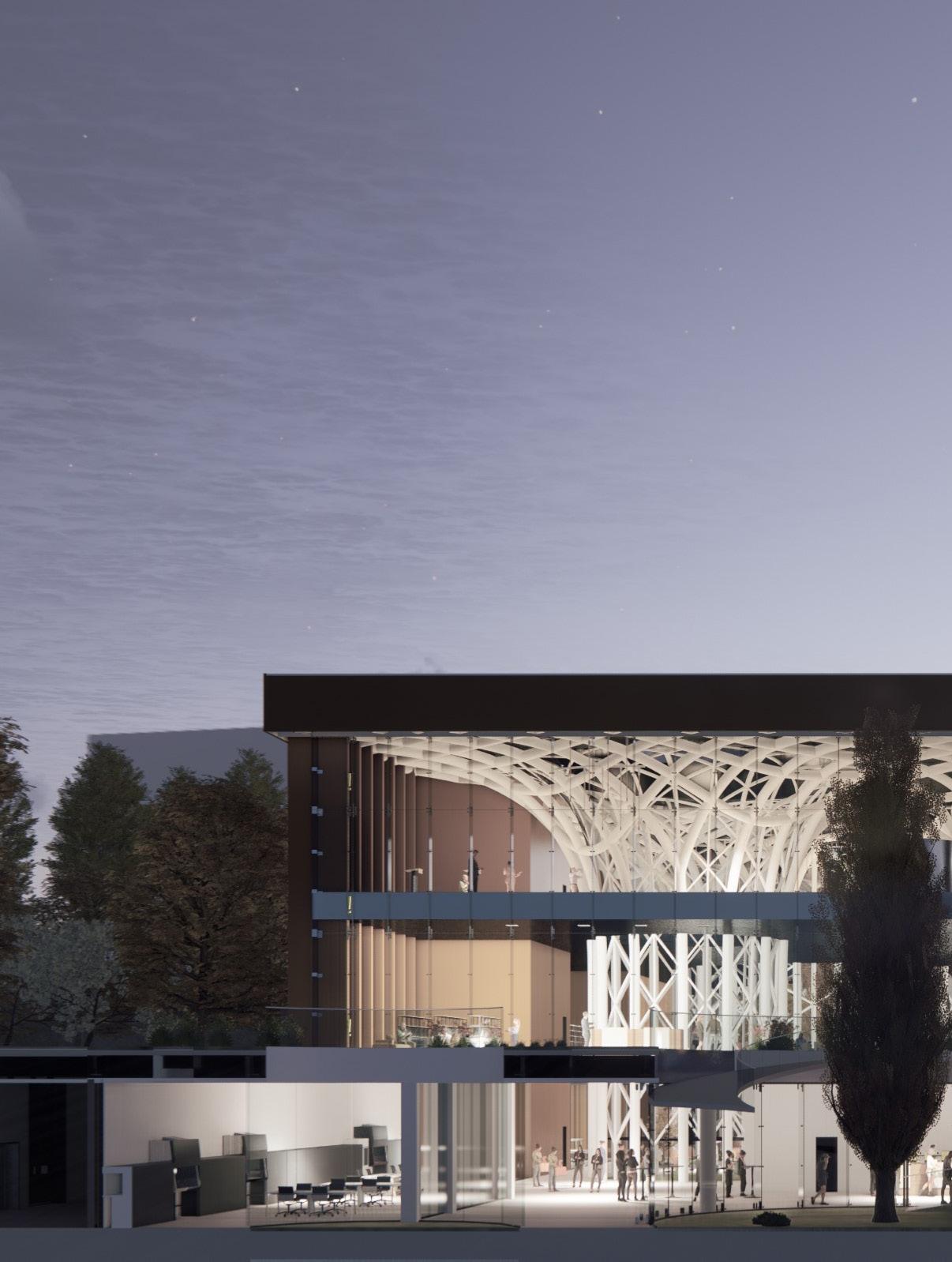

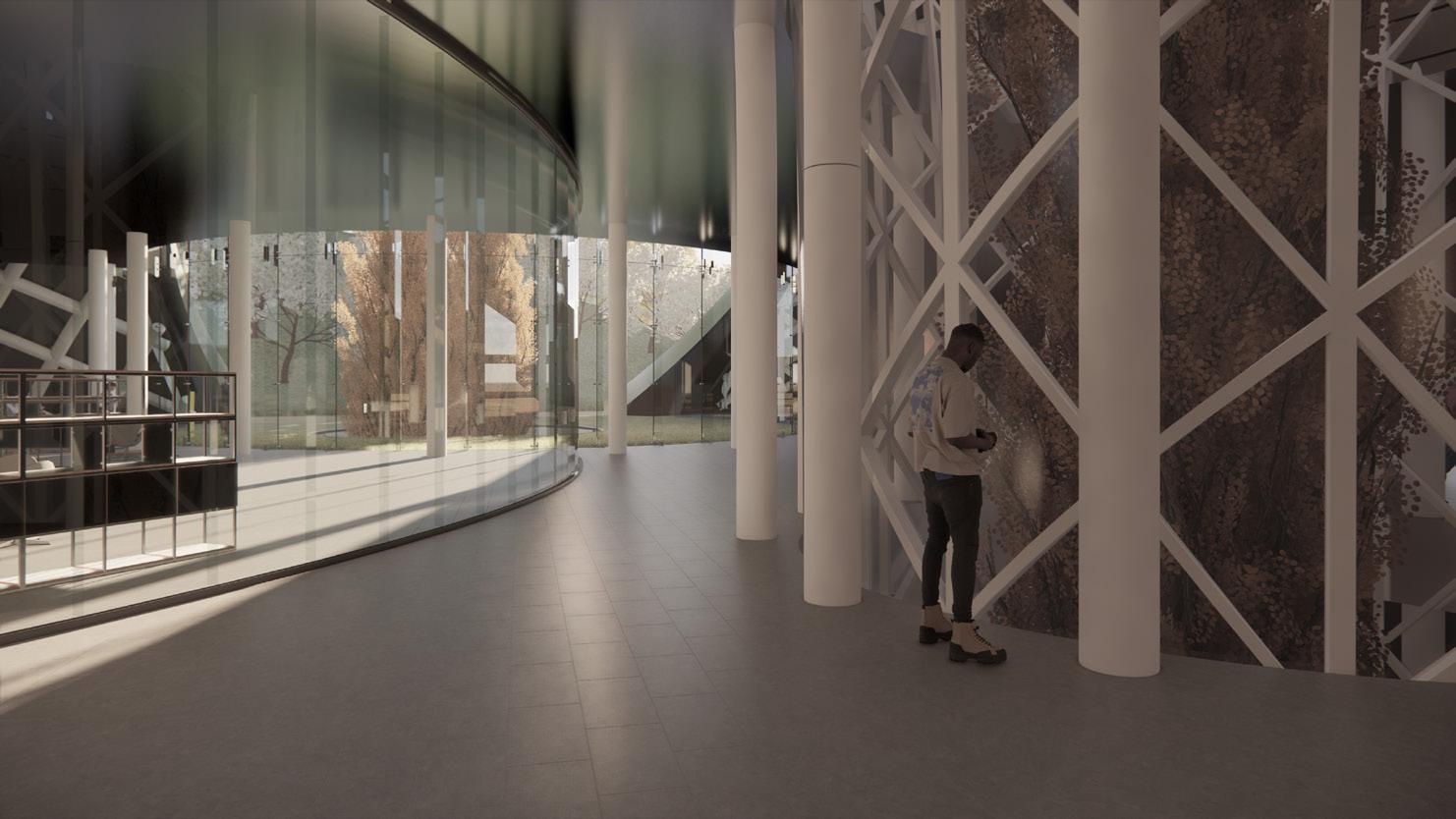

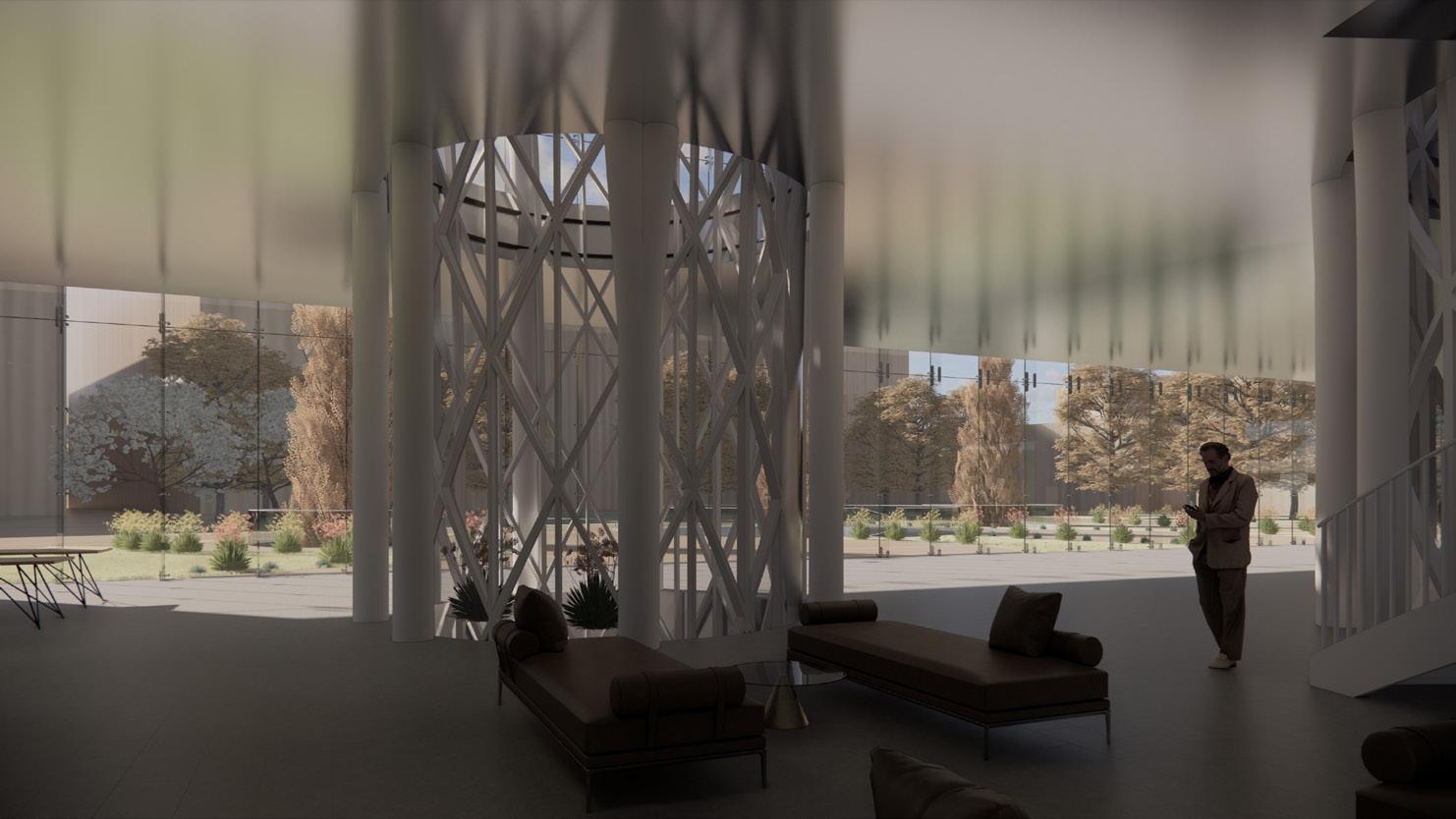

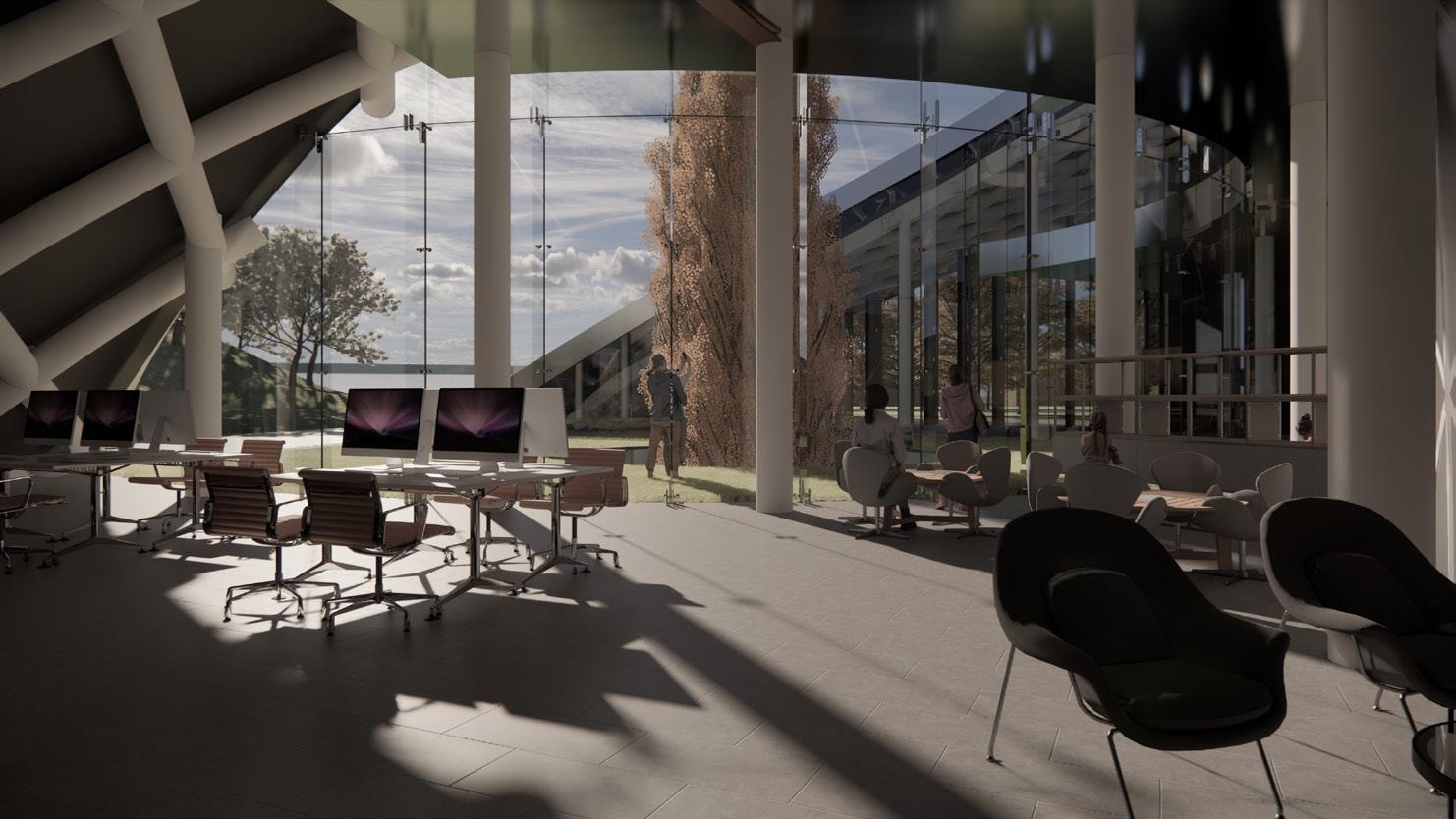

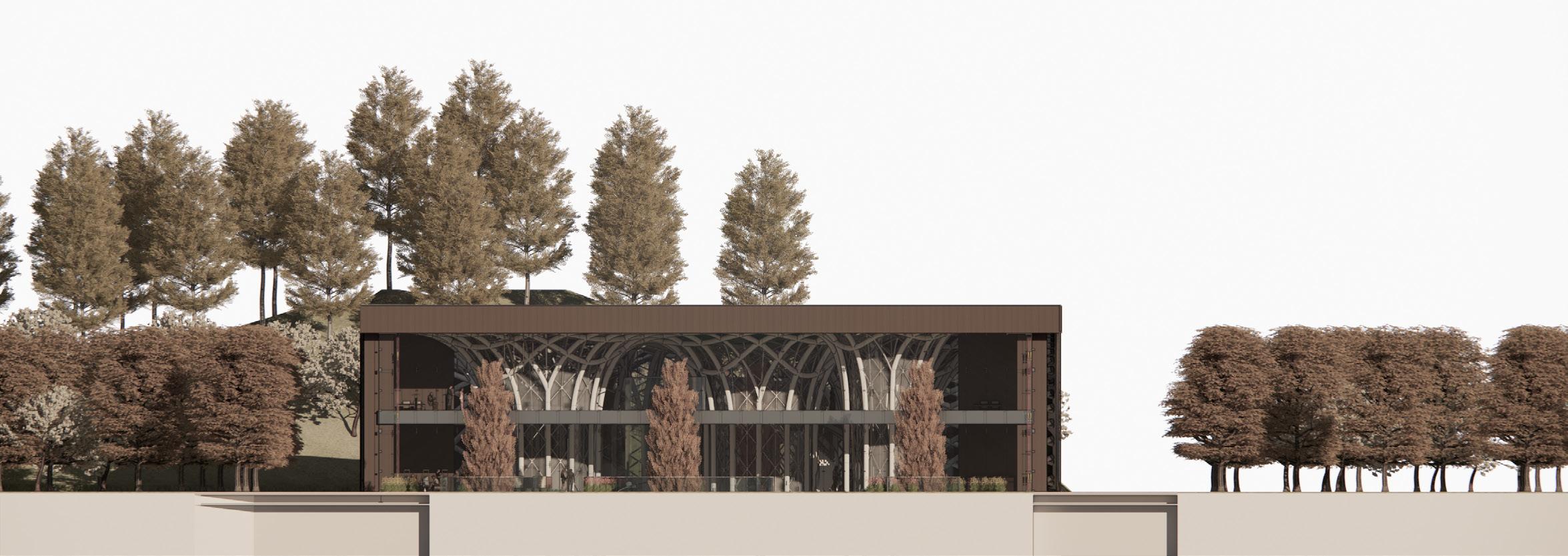

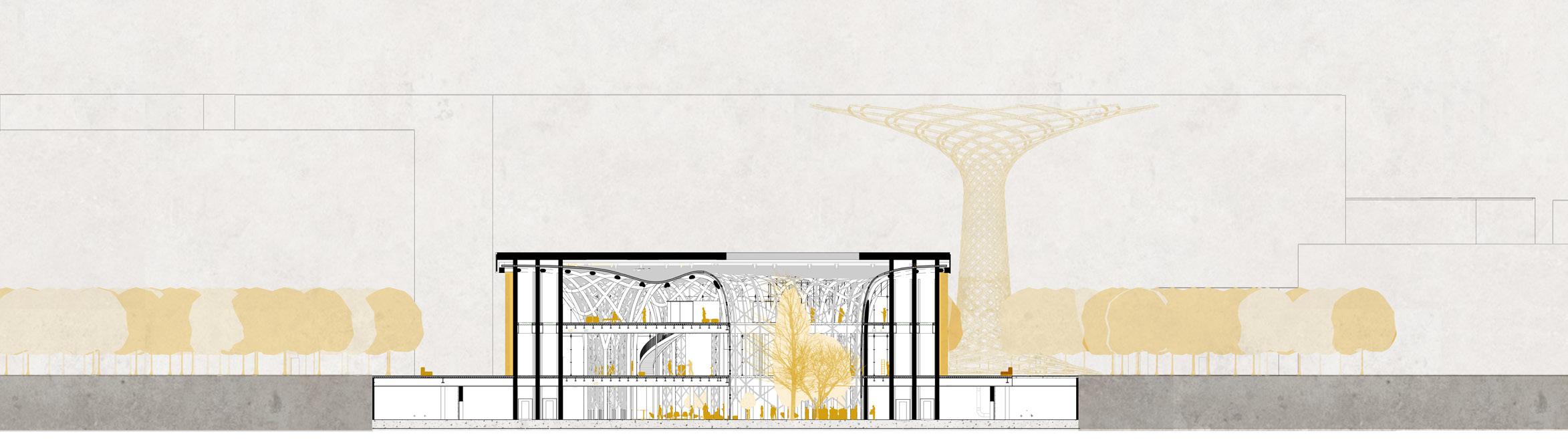

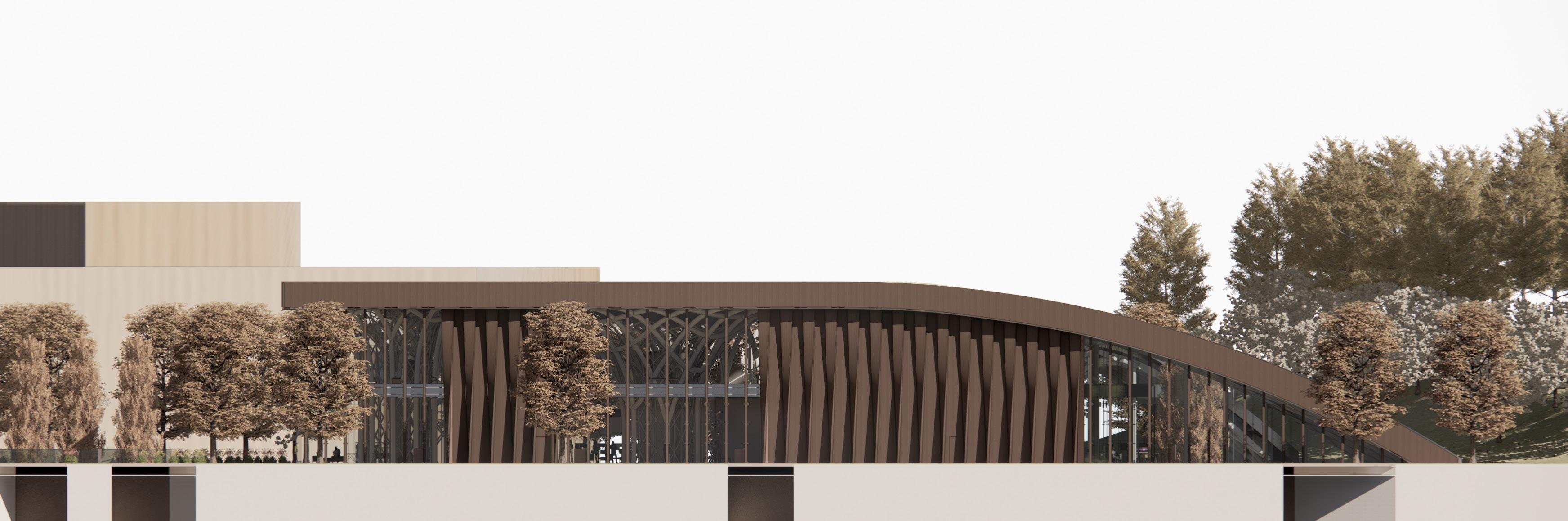

and the hill it is facing, the east façade is designed as a glazed elliptic opening, revealing the view of the hill from the east. The Opposite view, from the hill itself, Reveals instead a set of tree-like columns, supporting a curved green roof, ideal continuation of the park.

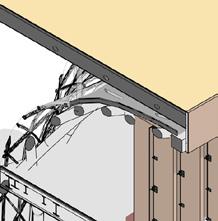

THE COLUMNS

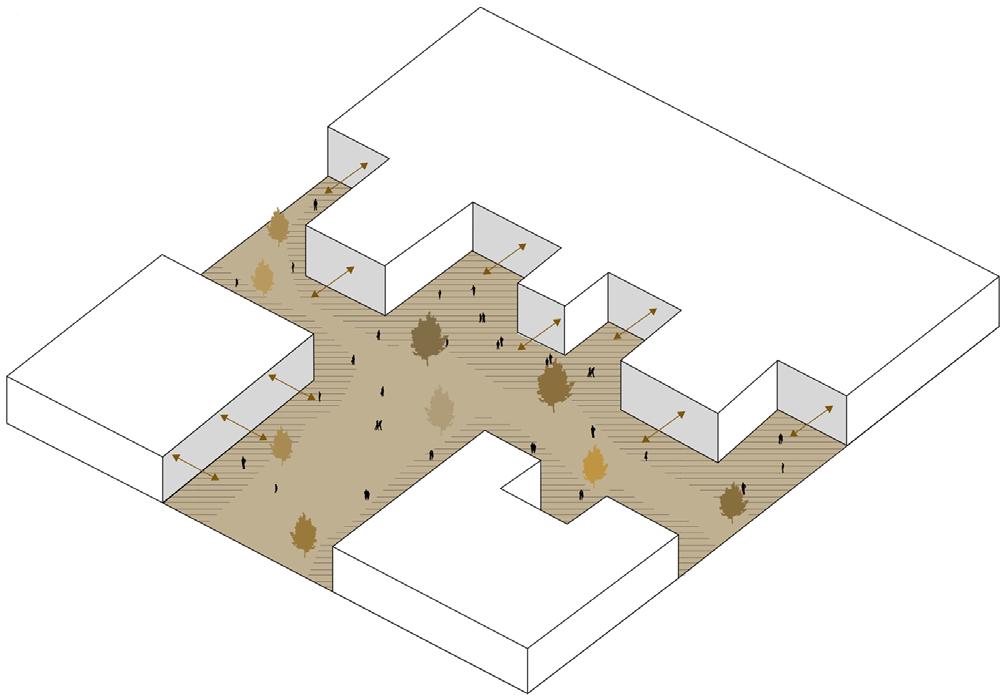

The “Forest” of massive parametric design columns dictate the circulation within the building while providing sources of light and ventilation as they are used as inner courtyards, accessible from the building’s underground floor, where the research activities are concentrated. In front of the main façade of the museum, directly from the park, the main path introduces into this “inhabited terrain”, the innovation and research environment, through the main ramp which penetrates in a stenographic way into the hypophyseal level.

KEY WORDS: Innovation park,New gate,Parametric design.

NGM MILAN E.N 6

“MIND Milan Innovation district opens its doors to the ideas of those

NGM MILAN 7

MIND DISTRICT

Originariamente sviluppato per ospitare Expo Milano 2015, l’ex sede dell’Esposizione Universale è oggi oggetto di un complessivo rinnovamento urbanistico volto alla nascita del futuro Innovation District. Unica in Europa per modello e dimensioni, il design di Mind si basa su sostenibilità, spazi ispirati al benessere, integrazione con la natura.

L’area di un milione di metri quadrati ospiterà le sedi di alcune eccellenze di interesse pubblico, oltre ad attività di ricerca, formazione e impresa, servizi e commercio, complessi residenziali, spazi aperti e grandi parchi, agglutinati lungo l’asse longitudinale principale da ovest a est, il Decumano.

Il quadro infrastrutturale dell’Expo 2015 (la cosiddetta Piastra) offre una cornice adeguata allo sviluppo di MIND: una “infrastruttura” da riutilizzare con l’obiettivo di contenere le risorse per l’”adattamento” del sito.

ABSTRACT

LA PORTA EST

All’interno di questo quadro, il sottodistretto di East Gate espone tre risorse e zone principali: Scienza, Conoscenza e Parco dell’Innovazione. L’area di intervento prescelta per la ricerca teorica e progettuale della tesi è l’ingresso nord-est, il futuro Parco dell’Innovazione, che collega il distretto urbano “interno” di MIND con l’anello d’acqua circostante verso l’autostrada e il parcheggio principale retrostante. Identificando le potenzialità di questo sito, il progetto di tesi rafforza l’attuale asse principale e l’ingresso est attraverso un’ulteriore “ancora pubblica”: il museo e centro di ricerca per le nuove tecnologie sostenibili nell’edilizia e nel design.

I percorsi verdi sono ridisegnati per integrarsi meglio con gli ancoraggi urbani adiacenti: il campus scientifico dell’Università Statale a ovest, la collina verde artificiale - che funge da barriera acustica verso le autostrade - e la porta est sul lato opposto. Il percorso principale interseca il parco dall’asse principale di Mind a est, definendo l’impronta del progetto. Per creare un rapporto tra il nuovo intervento e la collina

su cui si affaccia, la facciata est è progettata come un’apertura ellittica vetrata, che rivela la vista della collina da est. La veduta Opposta, dalla collina stessa, rivela invece un insieme di colonne alberate, che sorreggono un tetto verde curvo, ideale prosecuzione del parco.

LE COLONNE

La “Foresta” delle colonne massicce di progettazione parametrica detta la circolazione all’interno dell’edificio fornendo al contempo fonti di luce e ventilazione in quanto sono utilizzate come corti interne, accessibili dal piano interrato dell’edificio, dove si concentrano le attività di ricerca.

Davanti alla facciata principale del museo, direttamente dal parco, il percorso principale introduce in questo “terreno abitato”, l’ambiente dell’innovazione e della ricerca, attraverso la rampa principale che penetra in modo scenografico nel livello ipogeo.

PAROLE CHIAVE: Parco dell’innovazione, Nuovo cancello, Progettazione parametrica

NGM MILAN E.N 8

“MIND Milan Innovation district apre le porte alle idee di chi Chi guarda al futuro” ( 2022 MIND).

ITALIAN

NGM MILAN 9

ANALYSIS

MILAN CITY & MIND DISTRICT

Milan-mind connectivity

Urban fabrics

An innovation ecosystem

MINDPRINCIPALS

Master plan’s guidelines

Linear park

Mind west gate

NGM MILAN E.N 10

NGM MILAN 11

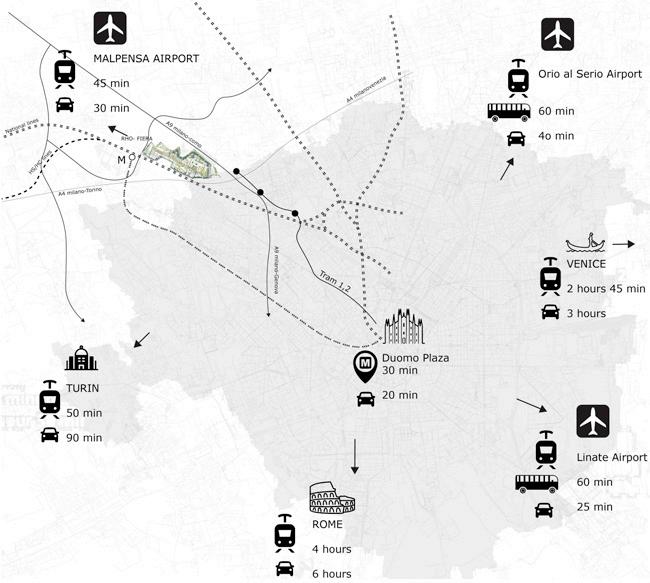

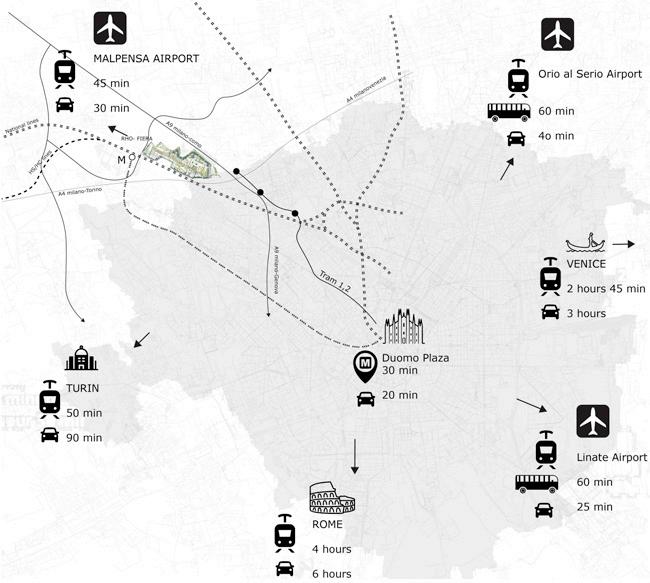

The new urban development of MIMD will include one of the most significant global innovation hubs, a testing ground for emerging contemporary living forms. The exceptional level of accessibility that distinguishes the Ex Expo 2015 site within the regional and metropolitan context is directly related to Milan’s strategic position as a node of European importance in the complex framework of national, European, and international connections.

MILAN-MIND CONNECTIVITY

In addition to being the hub of an airport system that comprises the airports of Malpensa, Linate, and Bergamo Orio al Serio, Milan is the major node of the highspeed system of Northern Italy, an infrastructure hinge within a macroregion that enjoys a vital position with respect to the transEuropean transport network.In terms of the regional framework, the metropolitan area of Milan is very attractive to nearly the entire region of Lombardy (as well as the neighboring provinces of Novara and Piacenza). Currently, it accounts for nearly one-third and draws about three-fifths of the region’s total

production values of mobility, or 16.4 million trips per day. The area undergoing urban regeneration thus forms a pivot between Milan’s urban fabric and the significant north-western territorial quadrant that grows along the Sempione axis. This area is characterized by the presence of significant transportation infrastructure, including roads and railways, whose upgrading represents the most significant infrastructural legacy of Expo 2015, infrastructural investments to be enhanced as a tangible component of the legacy.

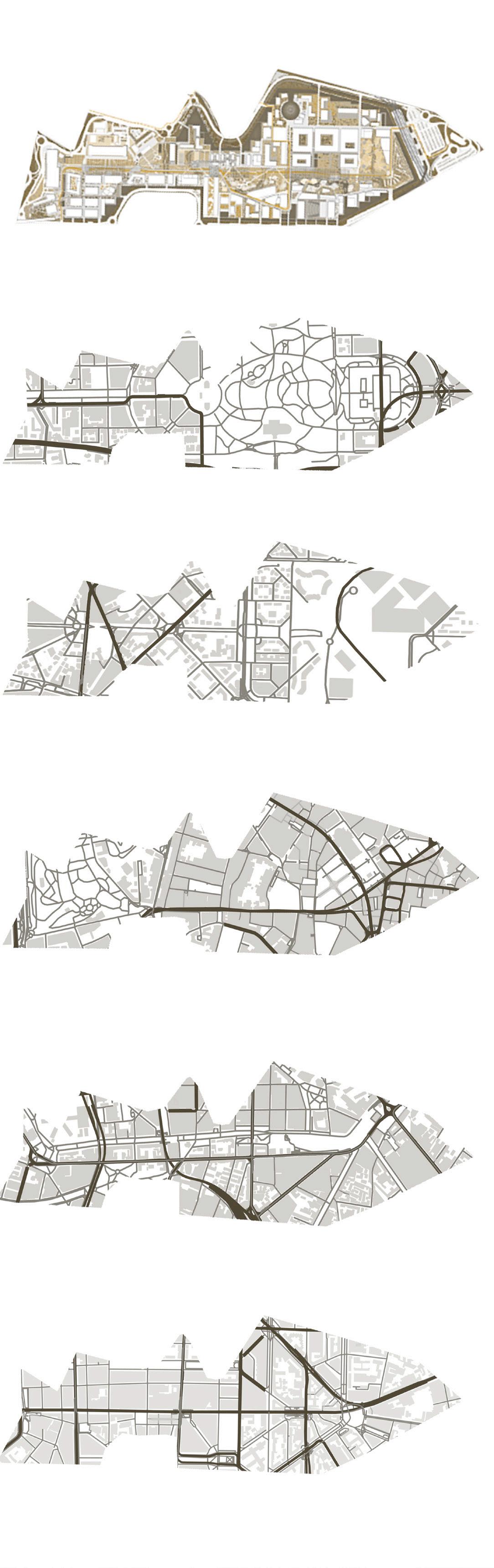

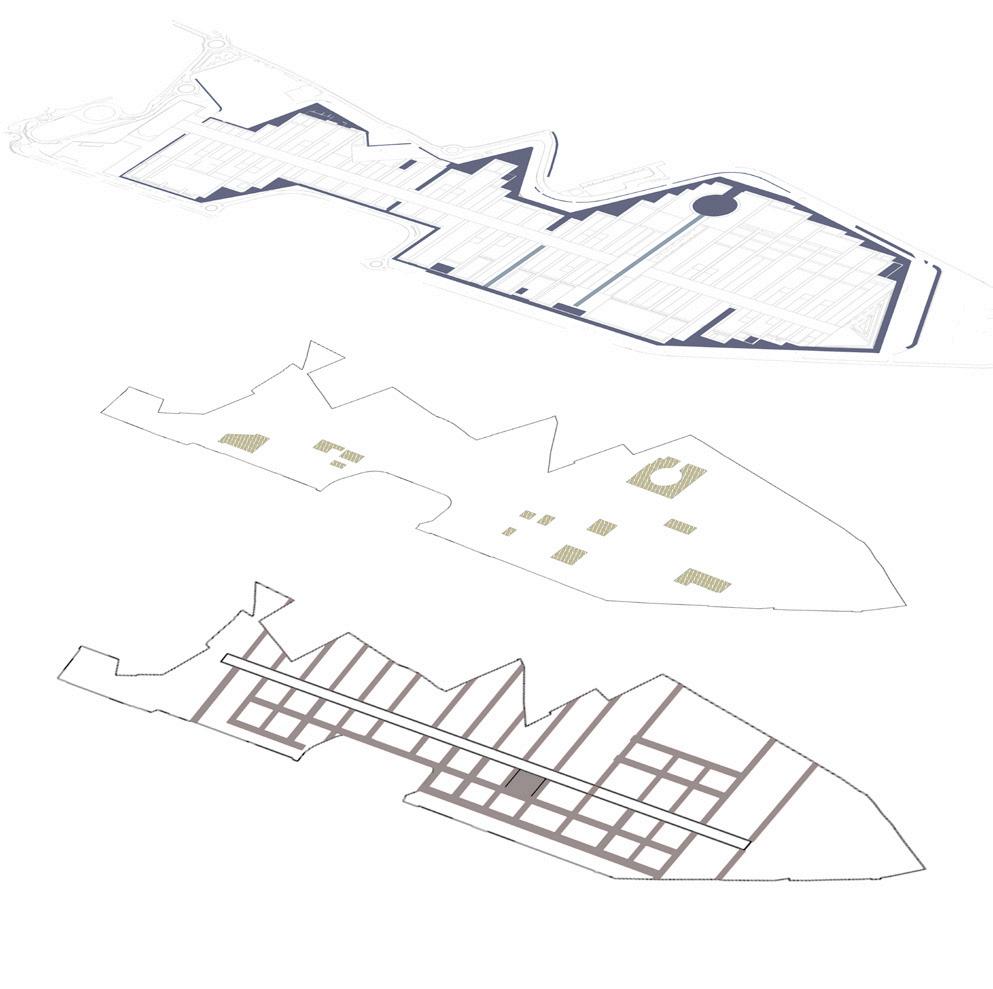

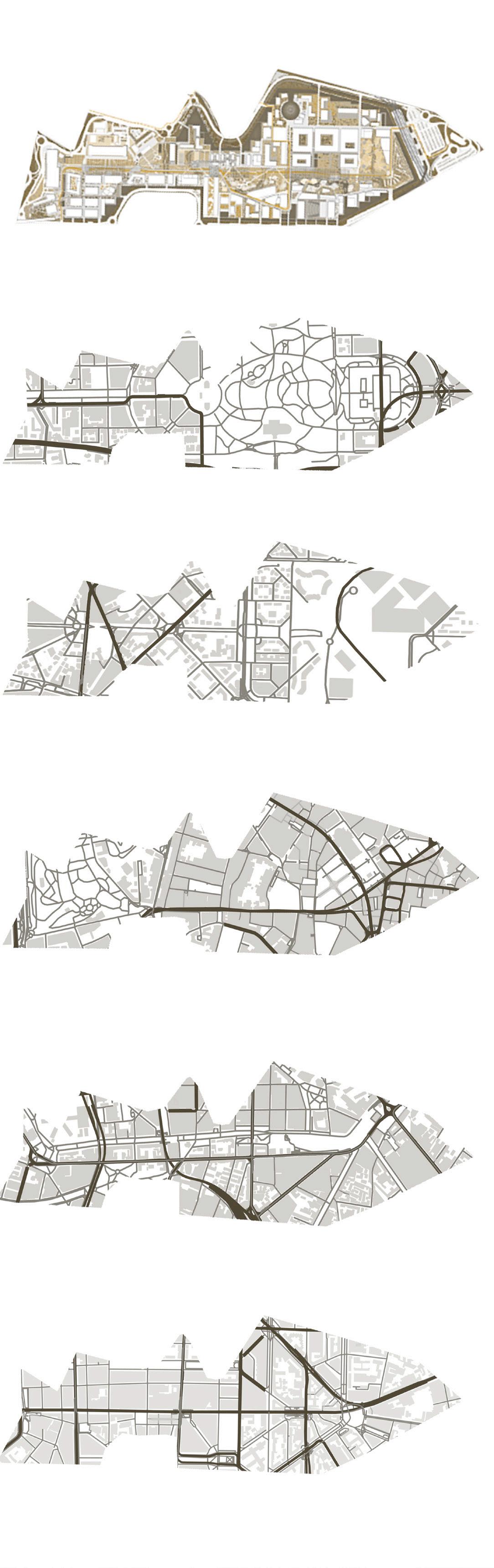

URBAN FABRICS

The Arco della pace/parco sempione zone, Navigilo canals, Corso Buenos aires, the center of Milan’s historical district and City-life zones can all be used to identify the city’s urban fabric. The overlap of both city fabrics allows for a comparison of past and contemporary urban evolution. The comprehension of MIND’s masterplan project’s growth, logic, and proportions is shown by overlaying the MIND district’s island-like design shape with the described urban fabrics of Milan.

NGM MILAN E.N 12

URBAN FABRICS,MILAN

VS OPEN SPACES

CANALS RING

OPEN SPACES

MASTER PLAN LAYERS

MIND MASTER PLAN

SEMPIONE

LIFE

(HISTORIC CENTER)

CANALS

NGM MILAN 13

R-EXPO

ROADS AND CONNECTIONS PUBLIC

WATER

BUILD

PARCO

CITY

DUOMO

NAVIGILO

CORSO BUENOS AIRES

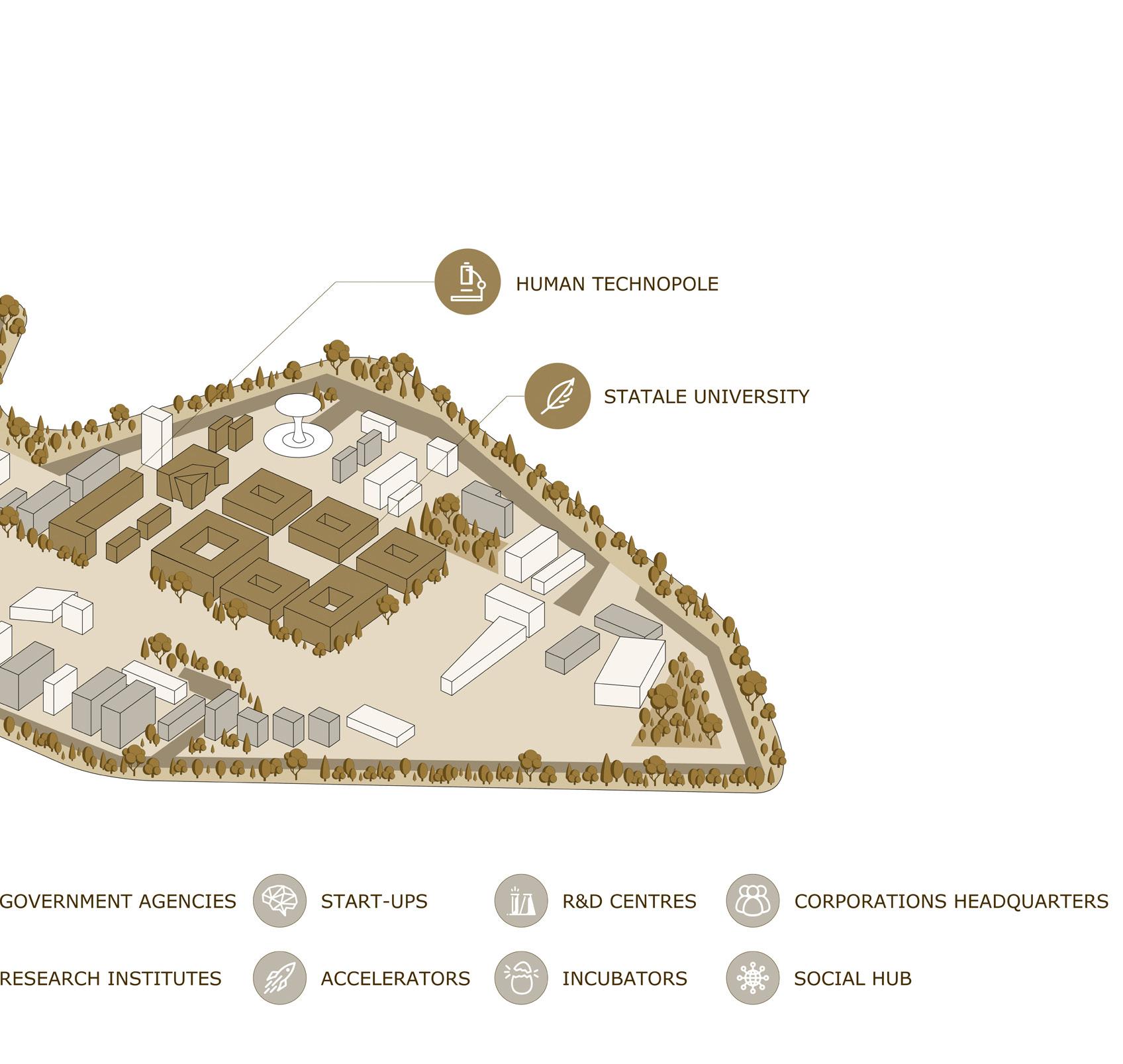

AN INNOVATION ECOSYSTEM

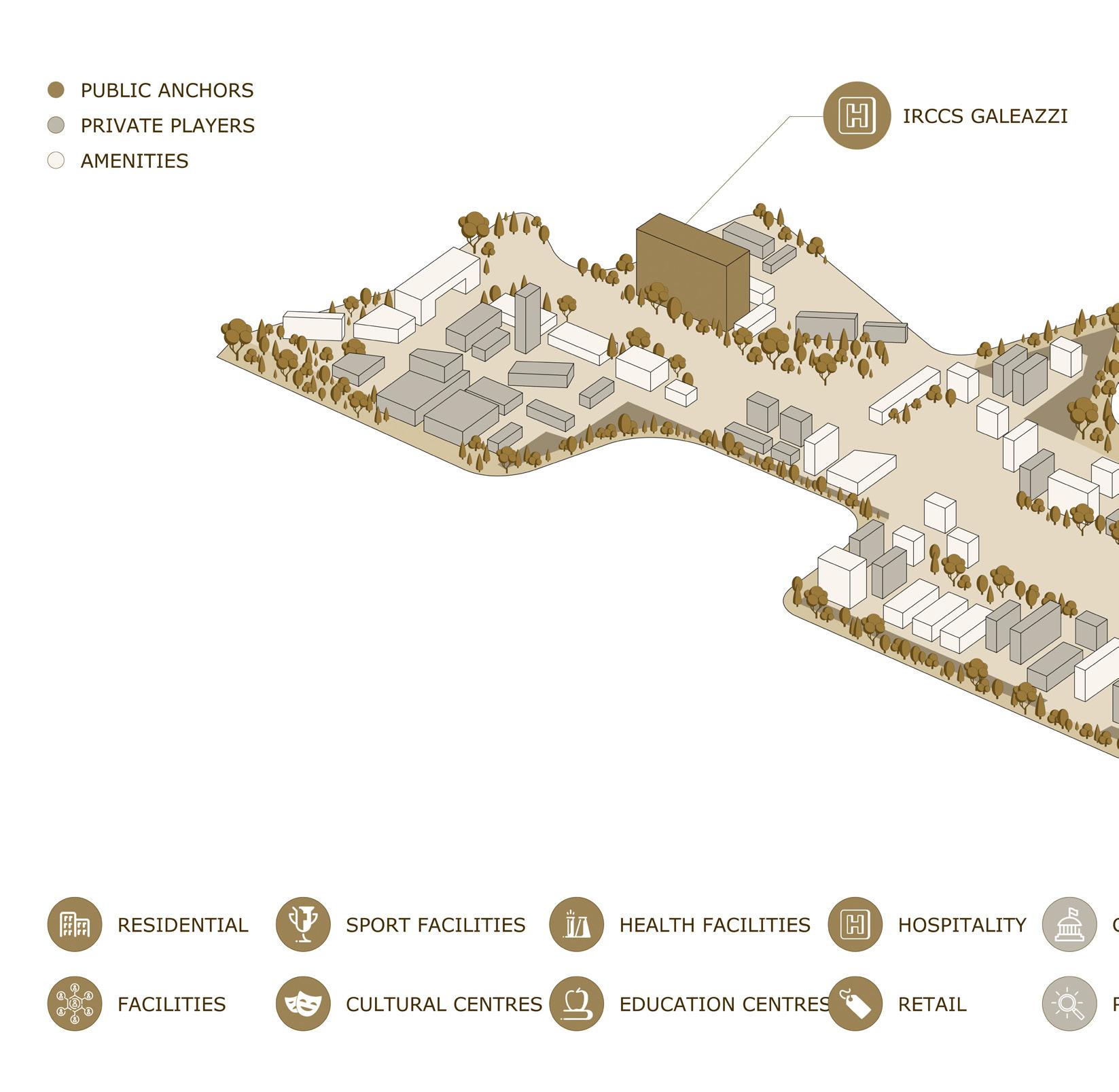

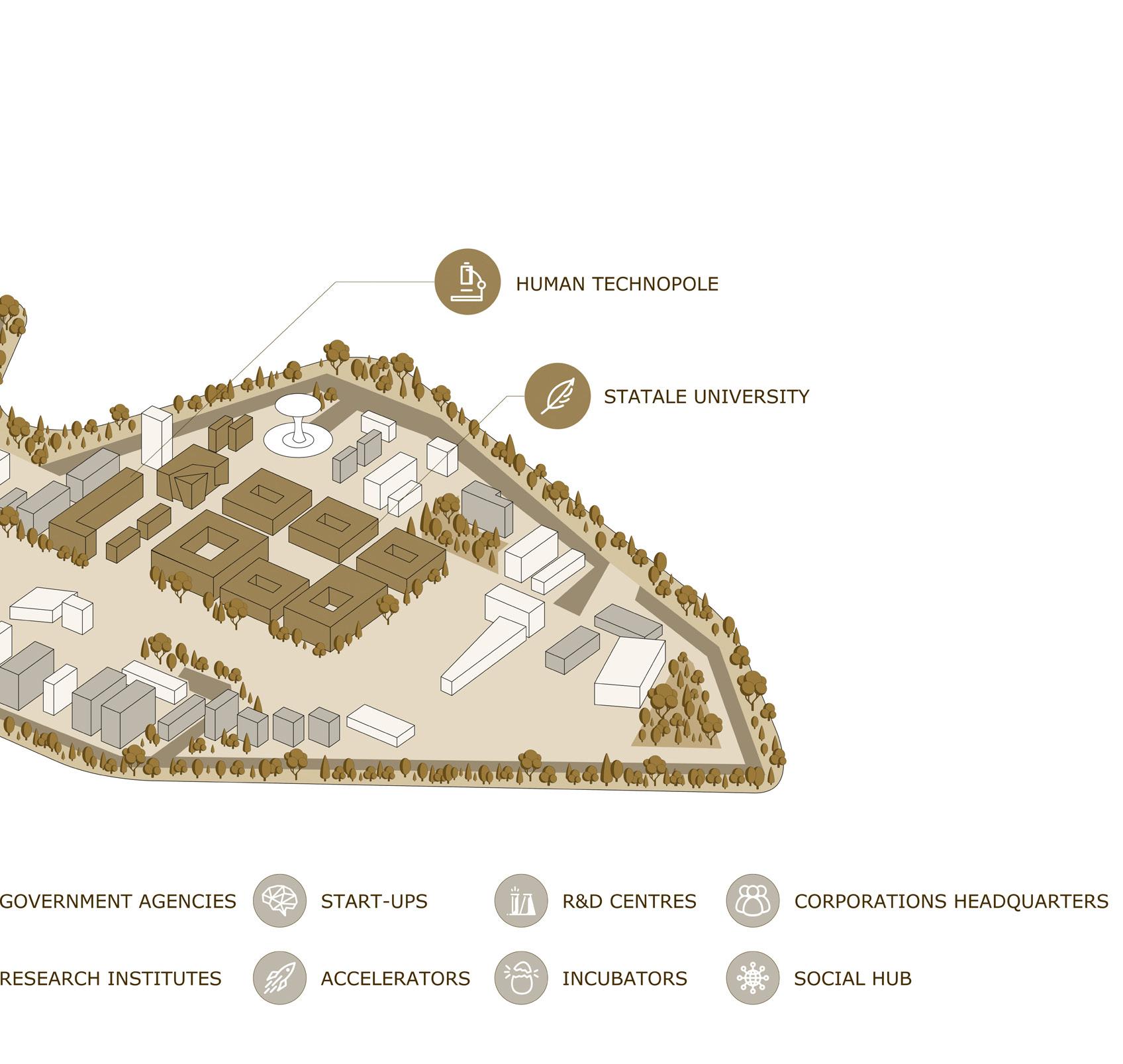

The Post Expo urban transformation project includes creating a sustainable ecosystem as one of its primary goals. This ecosystem will be capable of fostering the emergence of a new community and serving as an example of a new urban catalyst, one that is distinguished by a significant functional and social mix ,connected not only to Milan’s center but also to the nearby epicenters. Thus,MIND project will be developed to welcome international excellence and a Science and Technology Park distinguished by the capacity to connect technical know-how and humanistic knowledge within the original framework of Milan’s “polytechnic culture”.

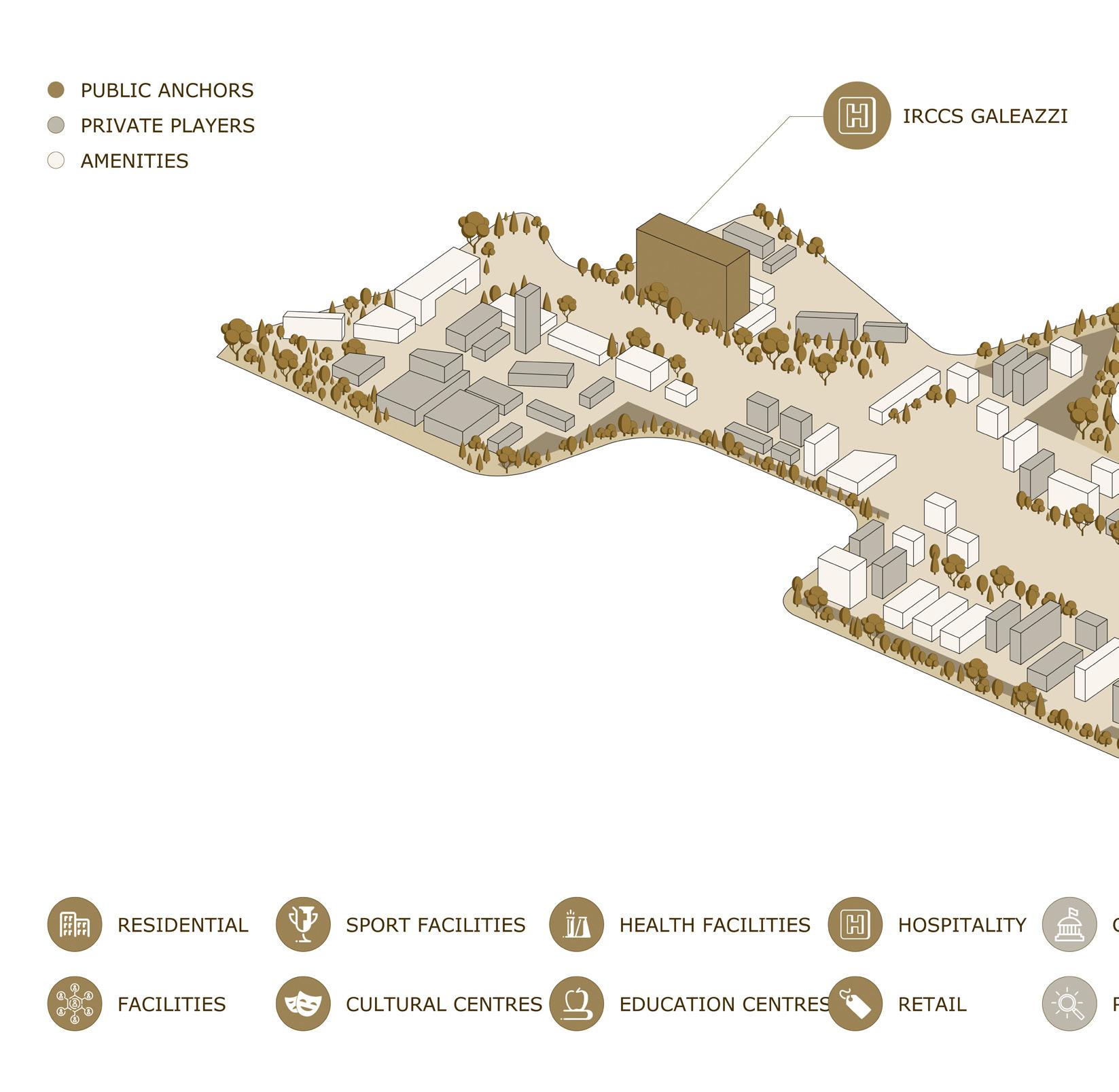

MIND’s functional mix ensures that a variety of users participate in activities in the area during the course of the day. The Human Technopole, Hospital Galeazzi, Fondazione Triulza and Unimi scientific departments campus are the 4 public institutions that are fostering the advancement of MIND and will spark an influx of new businesses and projects.

NGM MILAN E.N

THE HUMAN TECHNOPOLE

A 35,000 sqm of a national and international hub incorporating research and hospital functions. The hub sets its goals to tackle cancer and neurogenerative, developing personalized medicine. It contains buildings ,and 7 research centers with a focus on agri-food and advanced technologies. the structure consist of two functional and flexible volumes, which will develop around a Common Ground, the focal point from which the entire construction is generated, a central space that will be the heart of the building both for its location and for the its function.

Starting from the ground, the common space will unfold within the ten floors, creating an interconnected unicum that reaches up to the roof, creating new spaces for aggregation and relaxation.

The first to ninth floors will be dedicated to laboratories and administrative offices, while the top floor will host refreshment areas, classrooms for training activities, representative meeting rooms, executive offices and terraces with direct access to the accessible green roof.

STATALE UNIVERSITY

A 150.000 sqm of a modern scientific education and research campus aiming for the most advanced international standards for teaching, research and interaction with the privet industry. Containing 5 buildings, of which 4 are scientific faculties. The buildings pay homage to the Ca ‘Granda, the fifteenthcentury brick building designed by the Renaissance architect Filarete, which now houses the headquarters of the University; the facades were designed with an innovative construction technique, with each brick positioned individually by a robotic arm and treated as a pixel within a large bas-relief: the result will be a three-dimensional tapestry with textual and visual content.

GALEAZZI RESEARCH HOSPITAL(IRCSS)

A 150000 sqm research hospital ,gathering the orthographic field of IRSCC and the cardio-thoracovascular field of the Sant Agostino clinic institution. With 16 floors of height, It has been designed following the future hospital concept, paying attention to environmental sustainability, renewable energy and minimizing waste and consumption, but also noise and pollutant emissions. Great attention has also been paid to comfort, humanization of interior spaces and natural lighting.

Within this context, the task in hand for this thesis was to study the existing masterplan in search of a strategic area for an intervention in a form of a research/scientific complex, or a cultural center. a project that will express the values of Mind and will integrate with the overall masterplan.

NGM MILAN 15

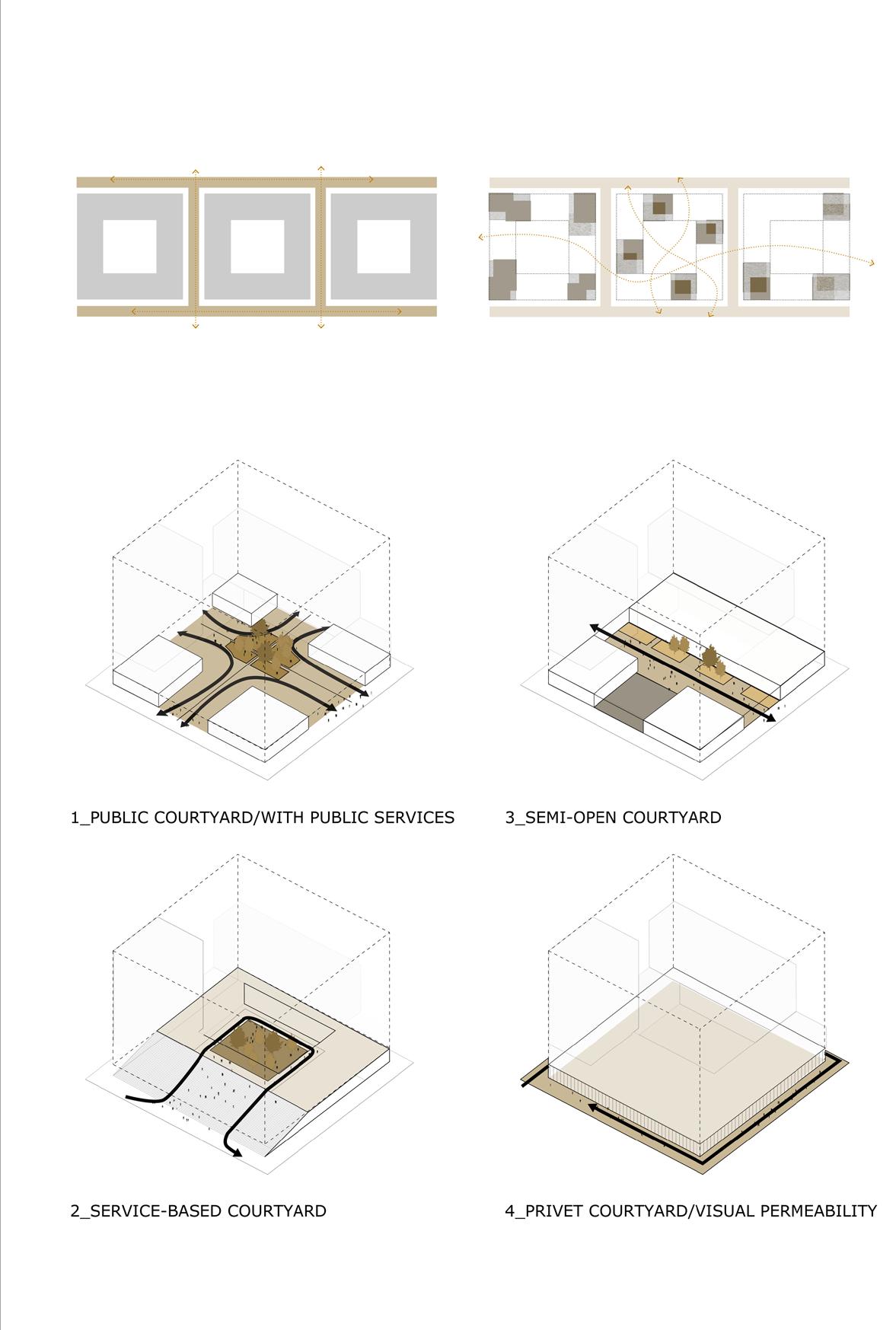

NGM MILAN E.N 16 ANALYSIS MIND- PRINCIPALS PRIMARY INTERIORS CROSSINGS SECONDARY INTERIORS CROSSINGS URBAN OPEN SPACES NEW WATER CHANNELS THE PODIUM INNER COURTYARDS HIGH ELEMENT ALIGNMENTS MARGINS COMMERCE, COMMUNITY & SERVICES 10 PRINC. 1 2 3 4 5 6 7 8 9 10

COMMON GROUND

NGM MILAN 17 FOOTPRINT ALIGNMENTS MARGINES

NGM MILAN E.N 18 8080 16 1616 Piazza delle Ar Piazza del Benessere Piazza delle Culture Piazza Italia Piazza dell’InnovazionePiazza del MercatoContadino Piazza d’acqua 01 02 03 04 05 06 07 08 09 10

Any open area within the Lot, arranging the building’s various components in accordance with their respective ties.

Any notable elements with a maximum height of 300 meters that could be located, either from the ground or from the Podium.

Building alignment in relation to open spaces.

Relevant view of the buildings towards the open spaces.

Possible large construction,designated to preserve urban links through various sorts of alignment.

A service and pedestrian link between the interior spaces of the site and the perimeter through the feasible implementation areas.

Potential crossing infrastructure between Areas.

Any accessible public open areas that are relevant to the urban design.

Potential canal system implementations at the site.

Localization of accessible facilities that enable and implement the usage of public spaces.

NGM MILAN 19

PRIM. INTERIORS CROSSINGS SEC. INTERIORS CROSSINGS URBAN OPEN SPACES01 02 03 NEW WATER CHANNELS04 THE PODIUM05 INNER COURTYARDS HIGH ELEMENT ALIGNMENTS06 07 08 MARGINS09 COMM. COMMU. § SERVICES10

01_PRIMARY INTERIORS CROSSINGS

Principals:

◊

crossings - primary / secondary- for greater accessibility.

◊

Guarantee the connection between the external road network (loop) with the main interior spaces (ex: Decumano)

◊ Continue the existing path lines within the site forallow, where possible, a physical and visual continuity between thecontext and the new

◊ Allow the crossing of the Areas without having totravel too long, avoiding the sense of barrierurban

◊ Ensure privileged / visual perspectives of landmarks

◊ Ensure the creation of large systems of collective space

02_SECONDARY INTERIORS CROSSINGS

Principals:

◊

Reproportion the Expo plan’s grid transversally in order to adapt it to new purposes.

◊ Allow the crossing of areas on secondary roads to provide more options and diversified journey times.

◊ Connect two or more main crossings.

◊ Encourage the growth of activities and the presence of pedestrians for a stronger sense of security.

03_URBAN OPEN SPACES

Principals:

◊ Create relevant public spaces as part of the urban design

◊ Relate public space with

Characterize the areas with aspects that make them distinctive and readily distinguishable (a central element that focuses attention might invite visitors to explore the space).

◊ Maintain the vibrancy of the entire fabric by offering varied activities at different times of day and ensuring at least one busy front of the buildings overlooking the open space.

04_NEW WATER CHANNELS

Principals:

◊ Contribute to the characterization and usability of urban spaces.

◊ Reduce the site’s heat island effect by integrating a rainwater collection, storage, treatment, and reuse system.

05_THE PODIUM

Principals:

◊

Define the alignments and morphology of open space

◊ Host functions with a more direct relationship to urban spaces

◊ Connect the high elements to each other and promote interactions and relationship.

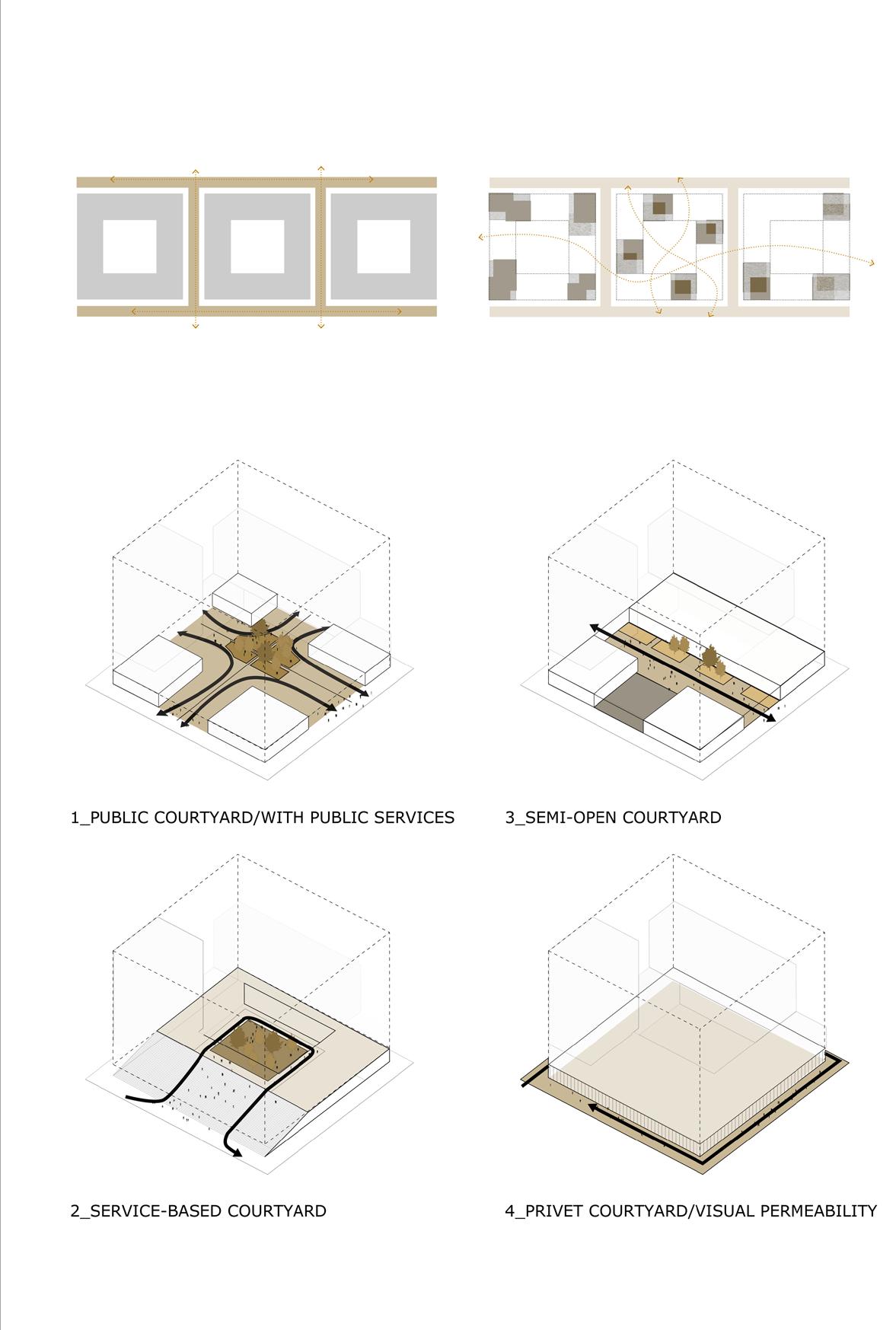

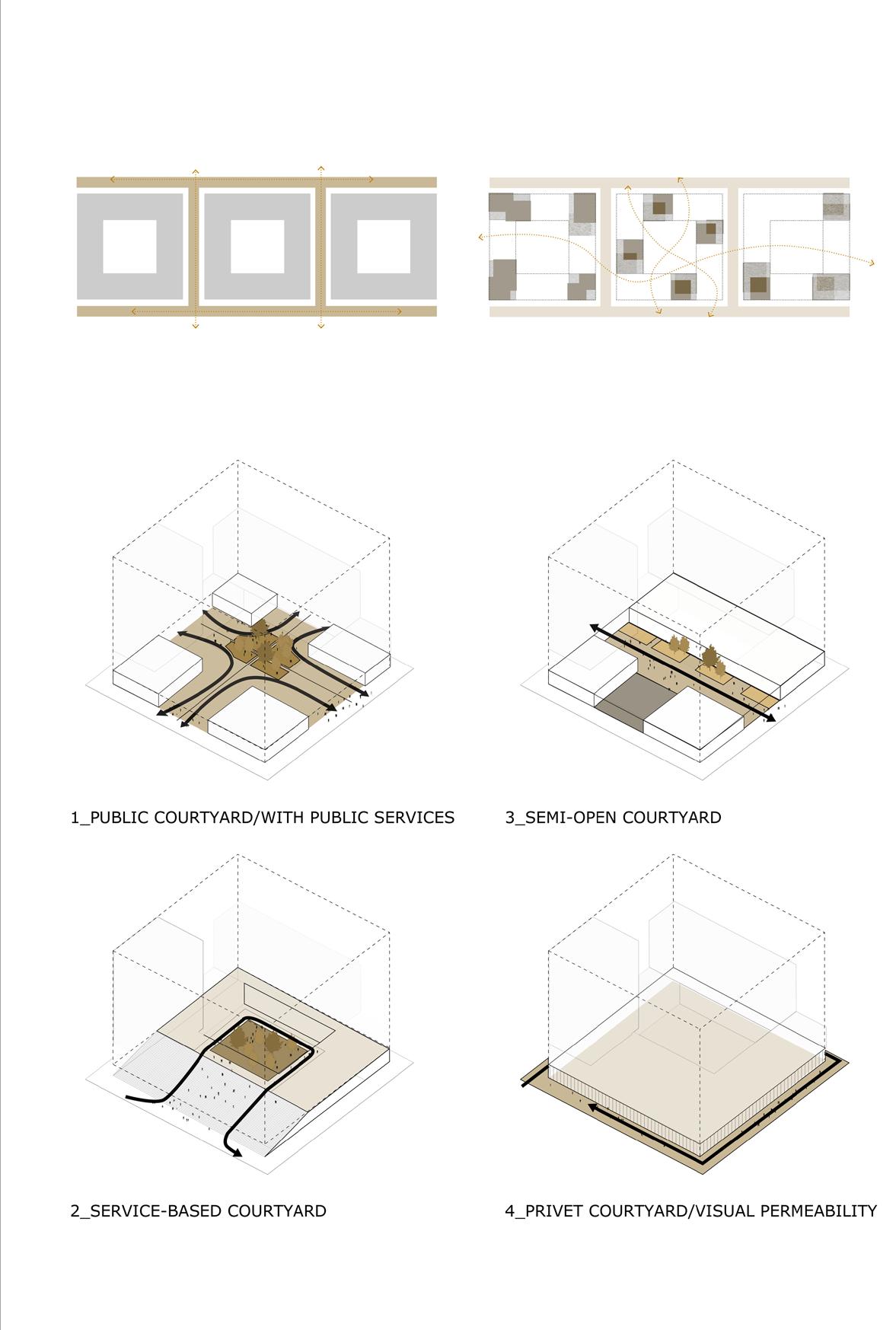

06_INNER COURTYARDS

Principals:

◊ Ensure sufficient permeability: courts might be entirely public, partially open, elevated with

NGM MILAN E.N 20

◊ services and private courts, however with guaranteed visual permeability.

• Maintain the continuity of public spaces within the building while giving it a more private sense.

• Establish ties with the foot of the buildings that will house the program’s ‚active lobbies,’ or the most public and communal operations, in order to provide informal surveillance and a greater sense of safety.

07_HIGH ELEMENT

Principals:

◊ • Ensure the best perspective and the most effective form factor in connection to the various functional programs.

• Maintaining the environmental quality of courtyards and open places (sun exposure, ventilation, etc.)

• Establish a good relationship with nearby open areas, which may be regulated through the Podium.

• Help to build a network of visual references and focus points that perceptually shape the urban environment.

08_ALIGNMENTS

Principals:

◊ Define specific correlations with respect to the Elements that characterize the site.

• Create recognized metropolitan sceneries using a variety of elements.

◊ Create recognized metropolitan sceneries using a variety of elements.

09_MARGINS

Principals:

◊

• Provide appropriate openings to ensure a good view of the public environment.

• Contribute to the definition of the urban landscape by introducing a distinct rhythm in the façade and its architectural components.

• Promote public space activation by direct interaction with pedestrians in the area in front of it.

10_COMMERCE, COMMUNITY, § SERVICES

Principals:

◊

• Commercial activity must be positioned where there is the possibility of informal surveillance as a result of nearby activities.

• It has to be visible from a distance.

• Situated near the busiest crossings

• Adequate circulation must be possible around the structures.

• Extend the structure into the surrounding public area to encourage parking and a welcoming environment.

NGM MILAN 21

LINEAR PARK ON THE DECUMAN

An important public intersection, a pillar of social aggregation highlighted by the presence of nature.

Principals:

◊

Verify the link between the site’s various polarities.

◊ Using landmarks and focal lines, establish visual links with the rest of the site and the surroundings.

◊ Physically or visually connect the site’s urban green spaces to encourage the illusion of a massive urban green system of high quality.

◊ Reduce the corridor impression by generating spaces with filters, dilations, and compressions, maintaining continuity and new linkages between the sections involved.

◊ Host public activities and common areas to foster the formation of a cohesive community.

◊ Ensure physical and visual continuity of the different paths,

◊ promoting the coexistence of soft mobility vehicles (pedestrian,

◊ cycle path, driverless).

NGM MILAN E.N 22

NGM MILAN

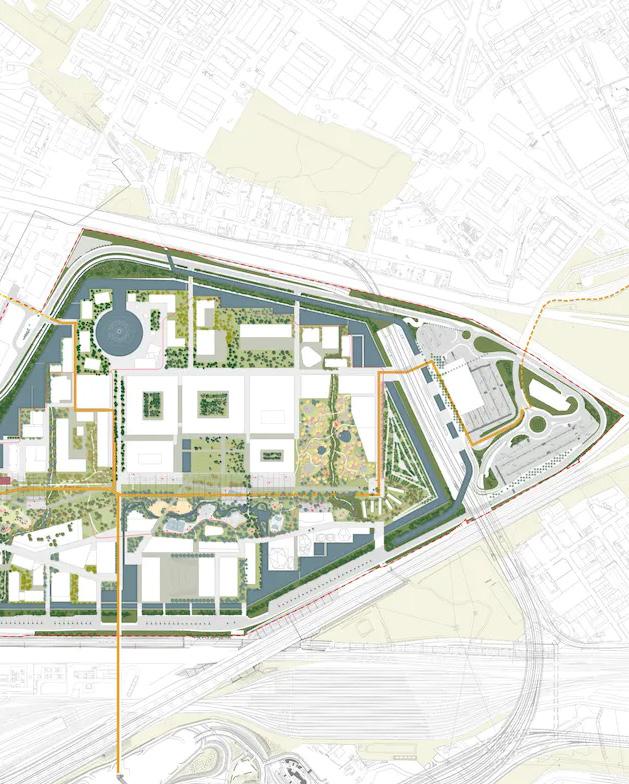

A site analysis exposed 3 main divisions of the master plan as:science, knowledge, and the innovation park.

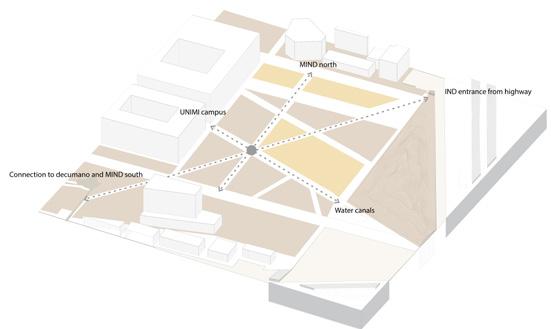

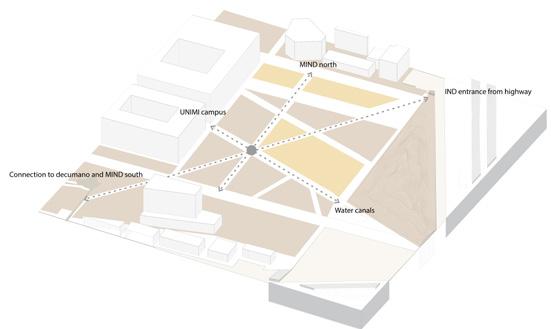

The chosen area of intervention of this thesis’s theme was the east-north entrance, which is currently the innovation park. The east gate connects Mind district with the water ring around it towards the highway and the main parking zone of the district’s north part.

Acting as an important reference to this choice is the West Gate, The west gate is a mixed-use development within MIND district that marks the western entrance. It includes a variety of green spaces that aren’t only decorational but are an important aspect of the conceptp; Boundaries between indoor and outdoor settings are blurred. The project is mainly about developing a neighborhood based on a new model of social relationships in which people can live and work; Offices, residential, services: a space based on the mix of functions. The goal of West Gate is to create a modern, mixed-use neighborhood. Innovative smart structures and environmentally friendly architecture are housed

there for an urban regeneration best practice example.

MIND WEST GATE

NGM MILAN E.N 24

NGM MILAN 25

CONTEXT

PARCO VERDE BLUE

The green-blue belt, relegated to a rich separation during Expo2015 consisting of the perimeter green, reacquires an urban character in MIND, delineating new areas for socializing and being, but attentive to that ecological environmental renovation essential for a contemporary scientific theme park.

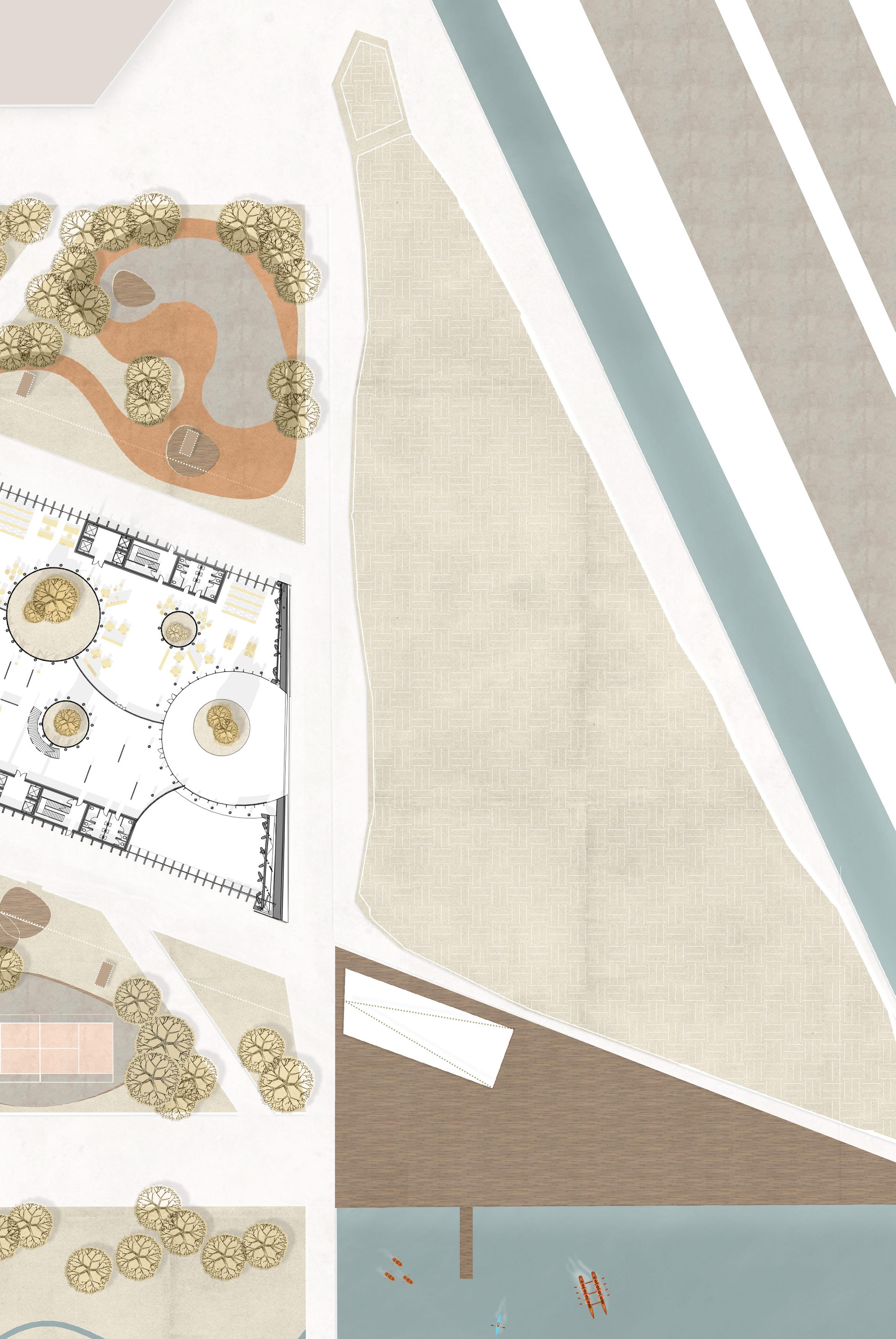

The fitted connecting park makes its way through the green belt: a 1 km walk that runs on the north side from Cascina Triulza to the planned skate park beneath the viaduct, enhanced by the presence of the Expo2015 Children Park. The water channel is an essential component of the green-blue system, fed by the Villoresi canal and connecting to the north with the Groane Park and the cycle system of the long Canale Villoresi.

Water is an important component of the Site: The canal expands inside MIND in a ring along the circumference with various dimensions and identities

(canals, basins, docks, and lakes), with a total length of about 4.4 kilometers and a total area of the liquid mirror of roughly 83,000 square meters. They are strongly linked to the created wetlands for Expo2015 at the canal to enable the purification of rainwater from the Site’s superficial run-off.

To ensure conformity with the qualitative characteristics of the receiving water bodies, MIND project has allowed for the re-functionalization of them, keeping the largest number and integrating them with naturebased solutions.

THE HILL

„La collina mediterranea”

The Mediterranean Hill, with a base area of 8723 square meters, is located at the site’s eastern end. It is one of the fundamental landscape monuments developed for Expo2015, rising at the ends of the Decumano and representing one of MIND’s cardinal points of reference.

NGM MILAN E.N

NGM MILAN 27

STRATEGY

STRATEGIC MASTER PLAN

STRATEGIC MASTER PLAN

THE EAST GATE VS THE WEST GATE NGM MUSEUM/ RESEARCH CENTER LANDSCAPE & AMENITIES

NGM MILAN E.N 28

THE WEST GATE

Human Technopole

Campus Scienze UNIMI

As previously explained, the MIND masterplan sets various anchor points to reach the overarching goal of an inventive, futuristic area that will bring a new way of life to Milan. These projects shape the urban environment and impact future development in the district, providing a distinctive backdrop for MIND. The major elements of each of these initiatives, as well as their roles within the masterplan, are outlined below.

Ircss galeazzi-sant’ambrogio

With a multi-specialist vocation, the hospital’s development thrives to promote innovation and growth by providing ample space for university teaching and scientific research: in 2006, the Galeazzi Orthopedic Institute received the prestigious I.R.C.C.S. from the Ministry of Health for research in the field of musculoskeletal diseases. It contributes significantly to MIND’s goals as a Science&Technology center.

Human Technopole’s overarching goal is to develop innovative strategies to promote human health through a multidisciplinary and integrated approach to the study of human biology. it is a key anchore to MIND as it goes hand in hand with the distrcit’s principals of innovation and knowledge.

Campus unimi

Creating an expansion of campus unimi, one of Milan’s main universities, in the MIND district is an important strategic move to attract young tenants and a step forward in developing a new international hot spot

Parco verde blue

The green-blue belt from the east that continues in the shape of an artificial hill serves several purposes, including noise reduction from the busy E64 highway, providing a panoramic view of the entire district, and

contributing to the district’s sustainable eco-system, which is one of its main distinguishing features.

The west gate

Offices, residential, services: a space based on the mix of functions, with the purpouse of a common ground principal and innovative urban sapces.

29

IRCSS GaleazziSant’Ambrogio

The Hospital for Health of the future

Fondazione Triulza

The Third Sector hub for social innovation.

MIND Village

A global mini-district for innovation.

The Italian institute for research on Life Sciences for innova tion

The future home of the scientific faculties of

Statale

University

PARCO VERDE BLUE

The

system of gardens and canals around MIND

Commertial work space,built-to-rent,light industri al,hotel & placemaking retail

THE WEST GATE

Commertial work space,built-to-rent,light industri al,hotel & placemaking retail

THE WEST GATE VS THE EAST GATE

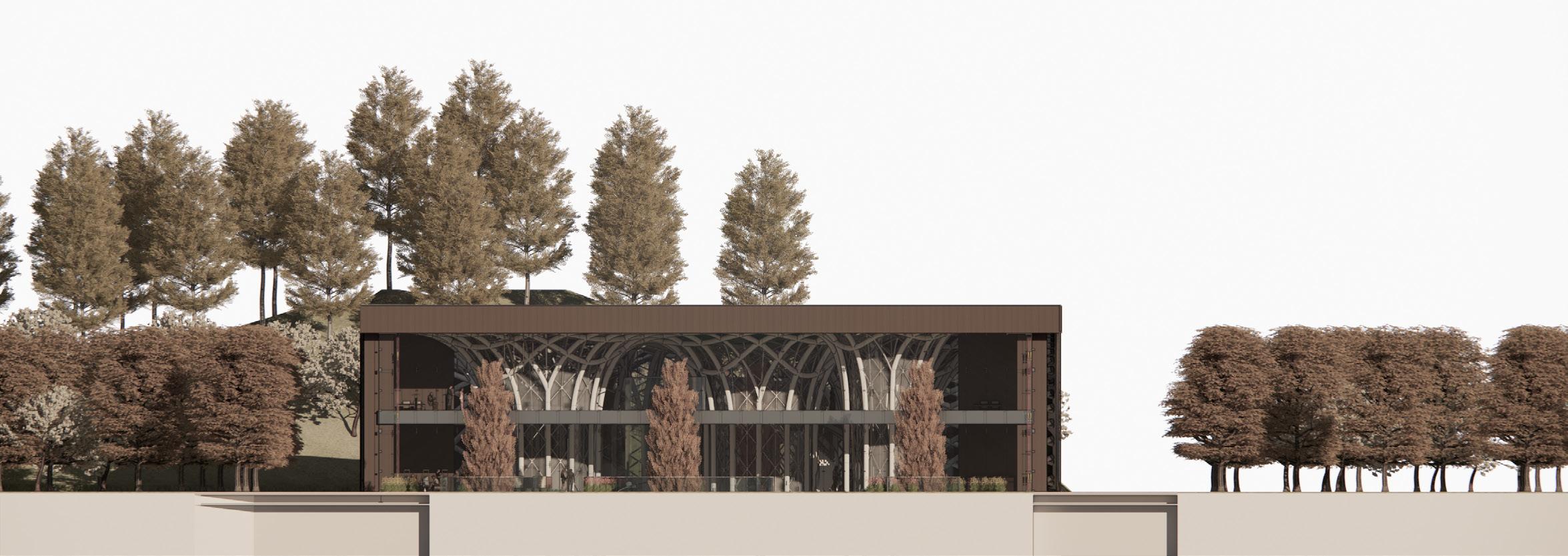

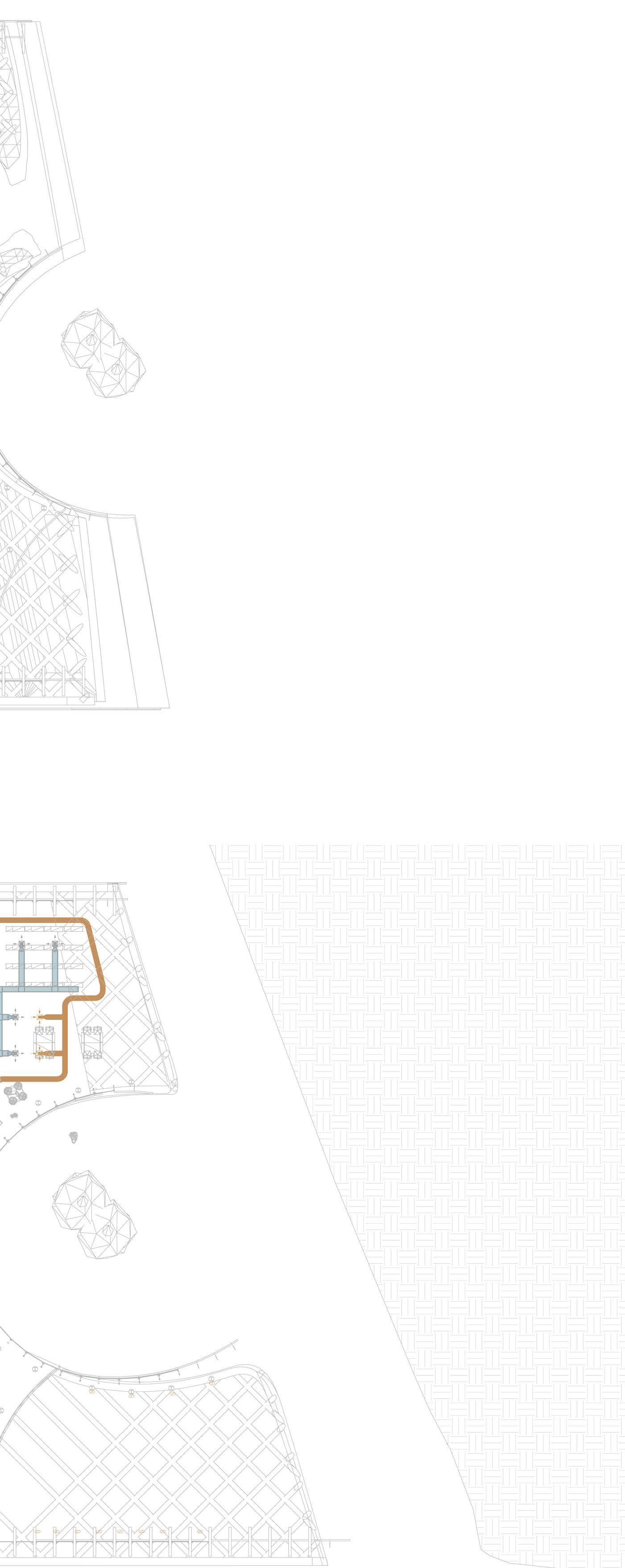

The East gate is a parallel development, defining the entrance to mind from that direction, using the west gate as a point of reference. A legacy from the R-expo concept, „parco verde blue,” is being expanded as part of the urban strategy for the new east entrance, along with a cultural and educational facility that will blend in with the park surrounding it.

The west gate serves as a landmark inside the district, maintaining the masterplan guidelines and presenting a new way of living. Studying the various uses and developments of the west gate was critical for constructing the concept of the East gate. Referencing the role of a gate inside the district, the initial thought was to continue the landscape integrated within the build area, while connecting to the existing park area and maintaining the high ratio of green to the development suggested in the previous mester

plan. as mentionaed before ,The east gate, like the west, will mark the entrance from it’s direction, but instead of offering high density build spaces, it will serve as an extension of the current Parco verde blue, offering various ‚common ground’ amenities to incomers. The NGM project, a museum/research facility, will serve as an ancor point within the east gate, integrated within the park, and an attraction point.

E.N 30

THE EAST GATE chosen project area -Integrated research and cultural center amid the network of parks and waterways surrounding MIND

THE EAST GATE STRATEGIC PLAN

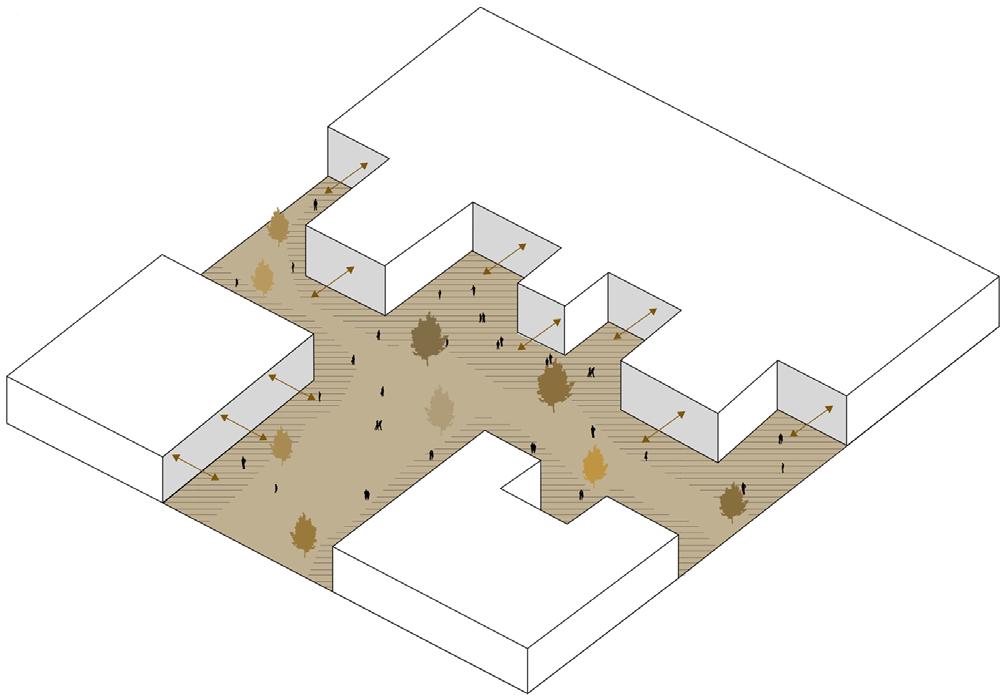

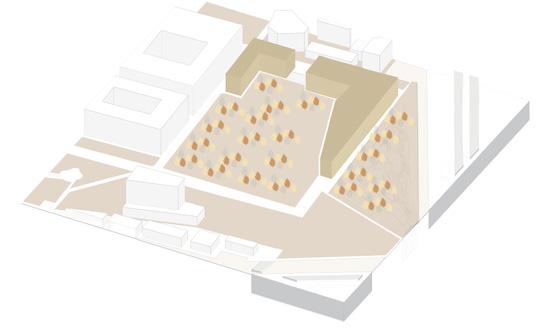

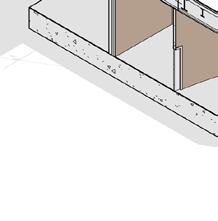

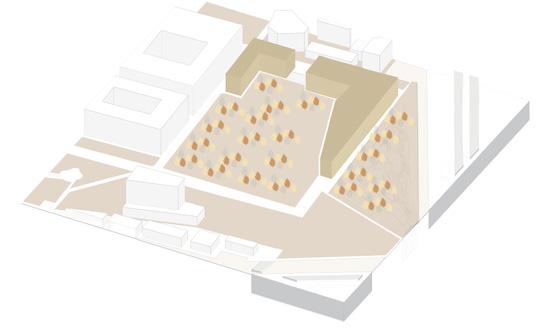

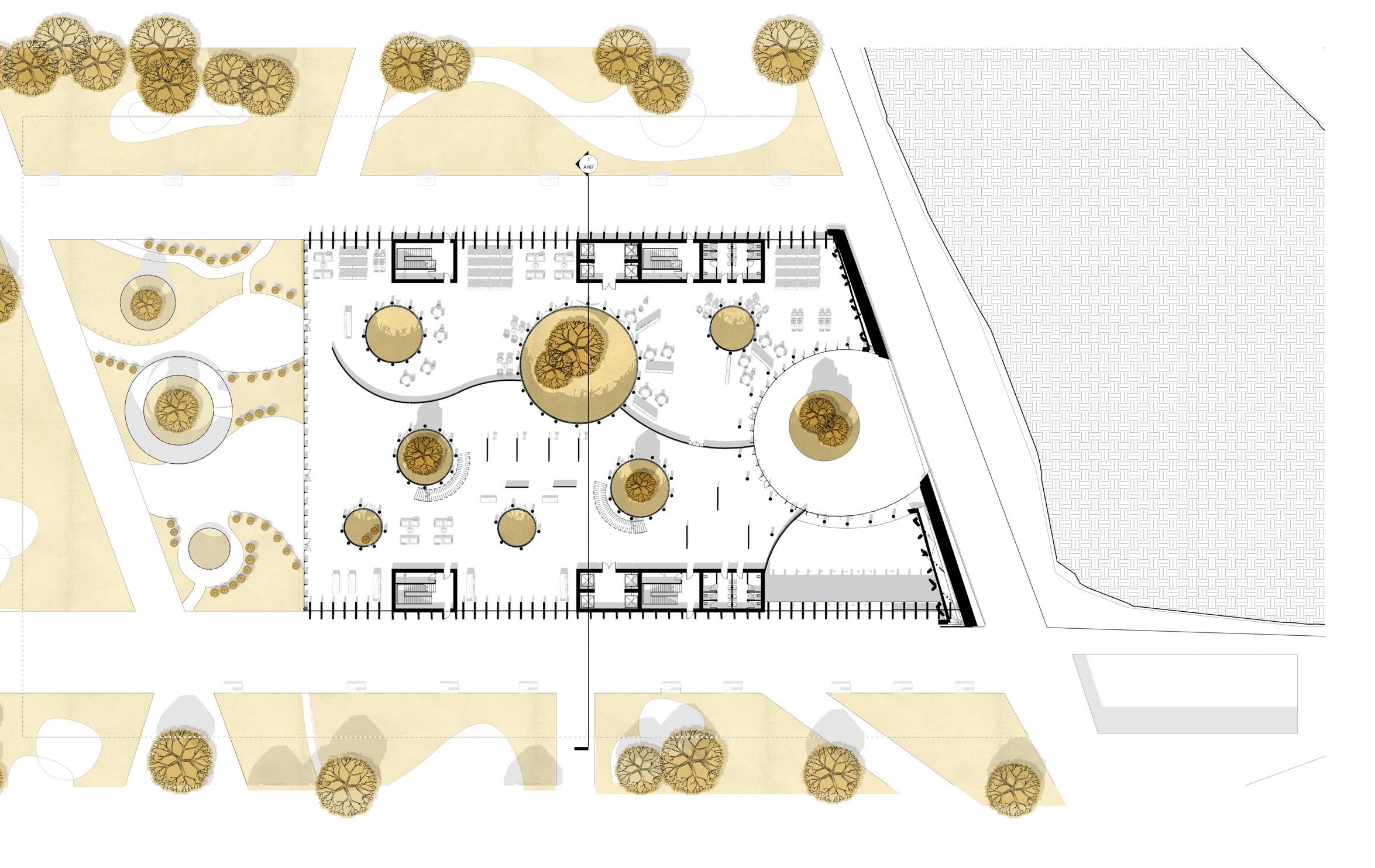

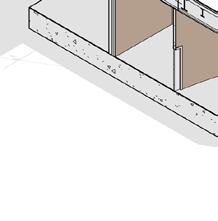

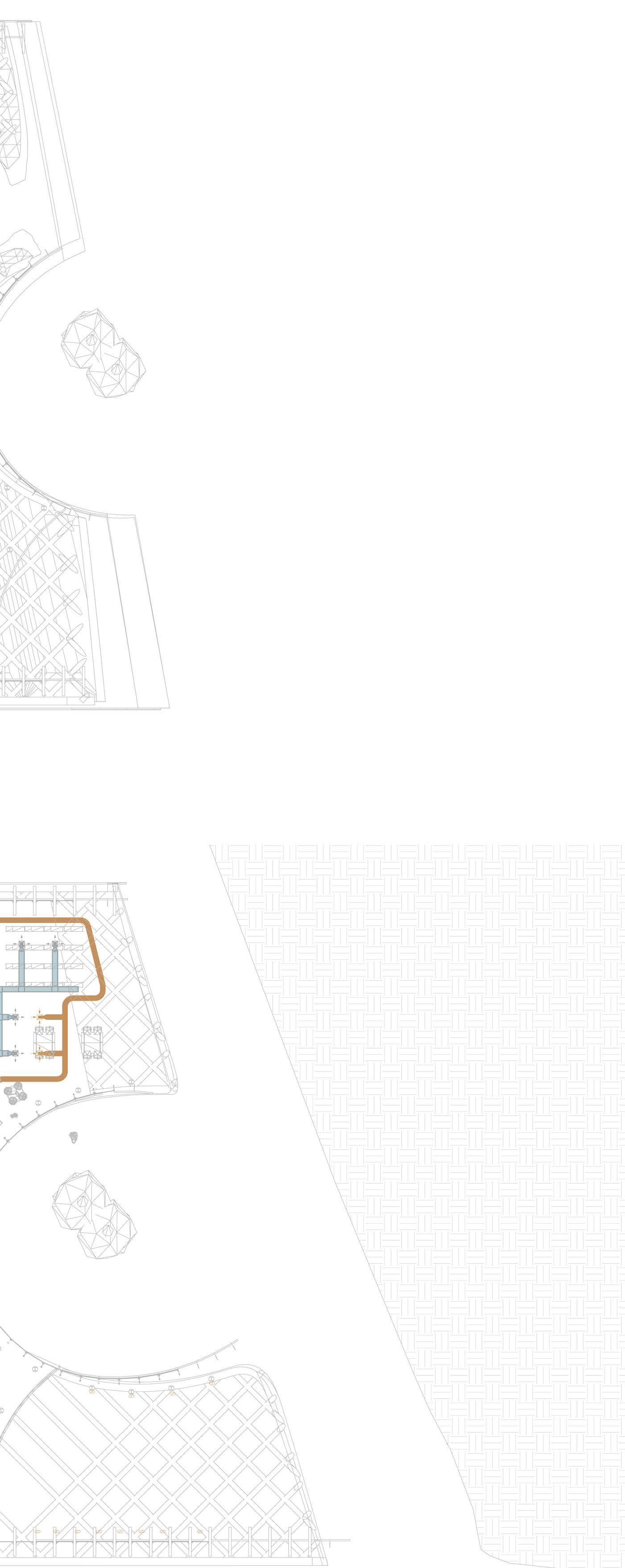

The strategic plan makes reference to two previously stated key landscape components: the green blue park and the Mediterranean hill; the new east gate is next to the east entrance, with the Mediterranean hill bordering it from the district boundary direction. It is, in essence, an extension of the park and green fabric that wraps around the hill, forming a green rectangle between the hill and the UNIMI buildings.

The new park will incorporate additional green public areas and will then be divided into specific alignments with the hill in the east and the Milan University in the west, defining the footprint of the NGM building. It was possible to incorporate the east facade with the slope in front of it by orienting the building’s east front to face the hill and developing inner courtyards on the ground level.

31

center (green roof) Laboratory Building

THE EAST GATE Incorporating a museum/research center that is oriented toward the east entrance and extending Parco Verde Blue.

Parco verde blue

STRATEGY

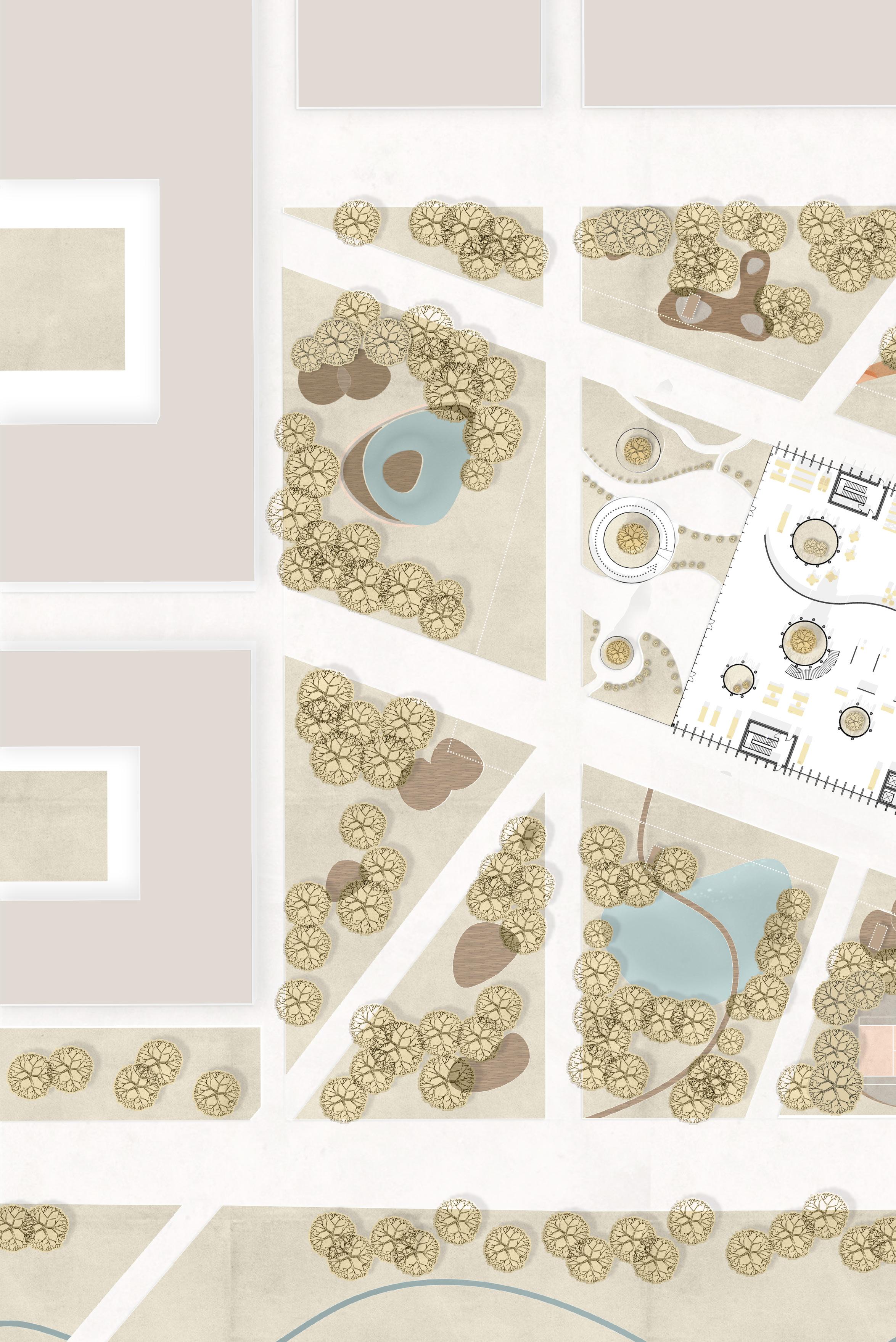

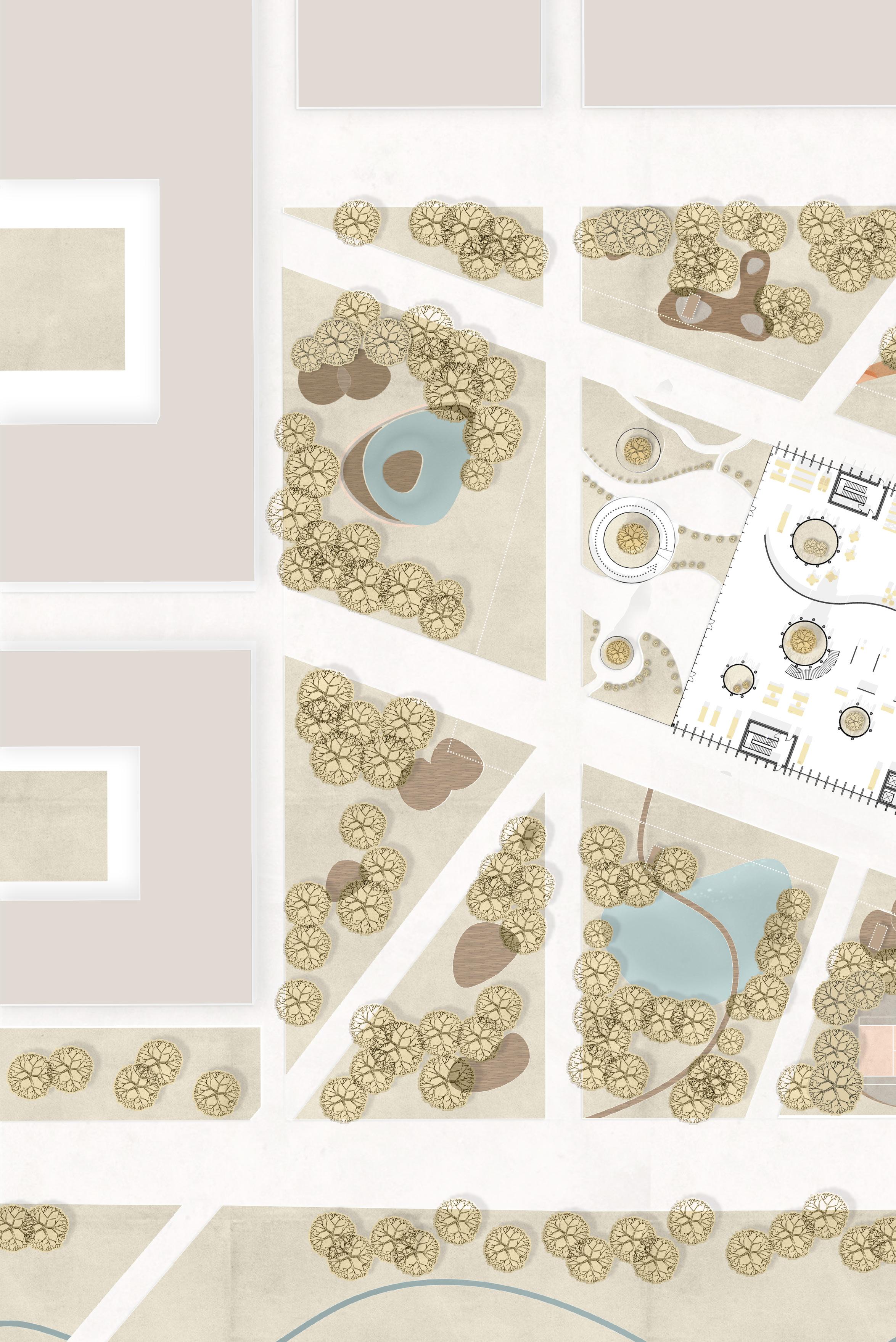

LANDSCAPE DESIGN

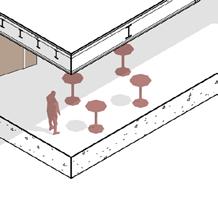

The landscape design of the December 2021 concept inspired the internal organization of the green patches around the structure. The project focuses on the design of innovative urban spaces in the form of various integrated utilities within the ‘raddure’ ,clearings ,that are spread throughout the green sections, imitating the organic organization of a forest.

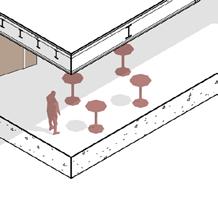

The various utilities are positioned within the clearings as part of the forest-like landscape concept. Each clearing investigates a distinct urban space with various purposes, utilizing Mind’s concept of common ground.

WATER PIAZZAS

A water piazza, placed in front of the NGM building, acts as an outdoor attraction with seating areas and a water fountain. It is intended to draw visitors to the open spaces surrounding the

building by emphasizing pedestrian movement and human interactions.

RELAXATION AREAS

Relaxation areas are distributed among the clearings, containing wooden decks for people to rest on and enjoy the greenery around them

ACTIVE URBAN REALMS

Active urban realms are areas dedicated for sporting activity. The role of these areas is to combine open-to-all sport activities within urban green spaces, encouraging people to use the green spaces actively.

NGM MILAN E.N 32

LANDSCAPE & AMENITIES

& AMENITIES

NEW

GATE MILAN MUSEUM/ RESEARCH CENTER IVRELATIONSHIP TO THE AREXPO LADSCAPE FORMATION II ESCAVATION OF THE INTERCOURTYARDS IIIFOOT-PRINT ALIGNEMENTI

CURRENT MASTERPLAN PROPOSAL (MIND MASTERPLAN)

LANDSCAPE

STRATEGY- ACCESS & CIRCULATION

FUNCTIONS

NGM MILAN E.N

WATER PIAZZA

URBAN LAKE TENNIS

RELAXATION AREAS

RELAXATION AREAS

RELAXATION AREAS

SMART TOTEM SMART TOTEM

NGM MILAN 35 SKATING RANGE

TENNIS COURT

WATER SPORT

SMART TOTEM

SMART TOTEM

SMART TOTEM

SMART TOTEM

NGM MILAN E.N 36

NGM MILAN 37

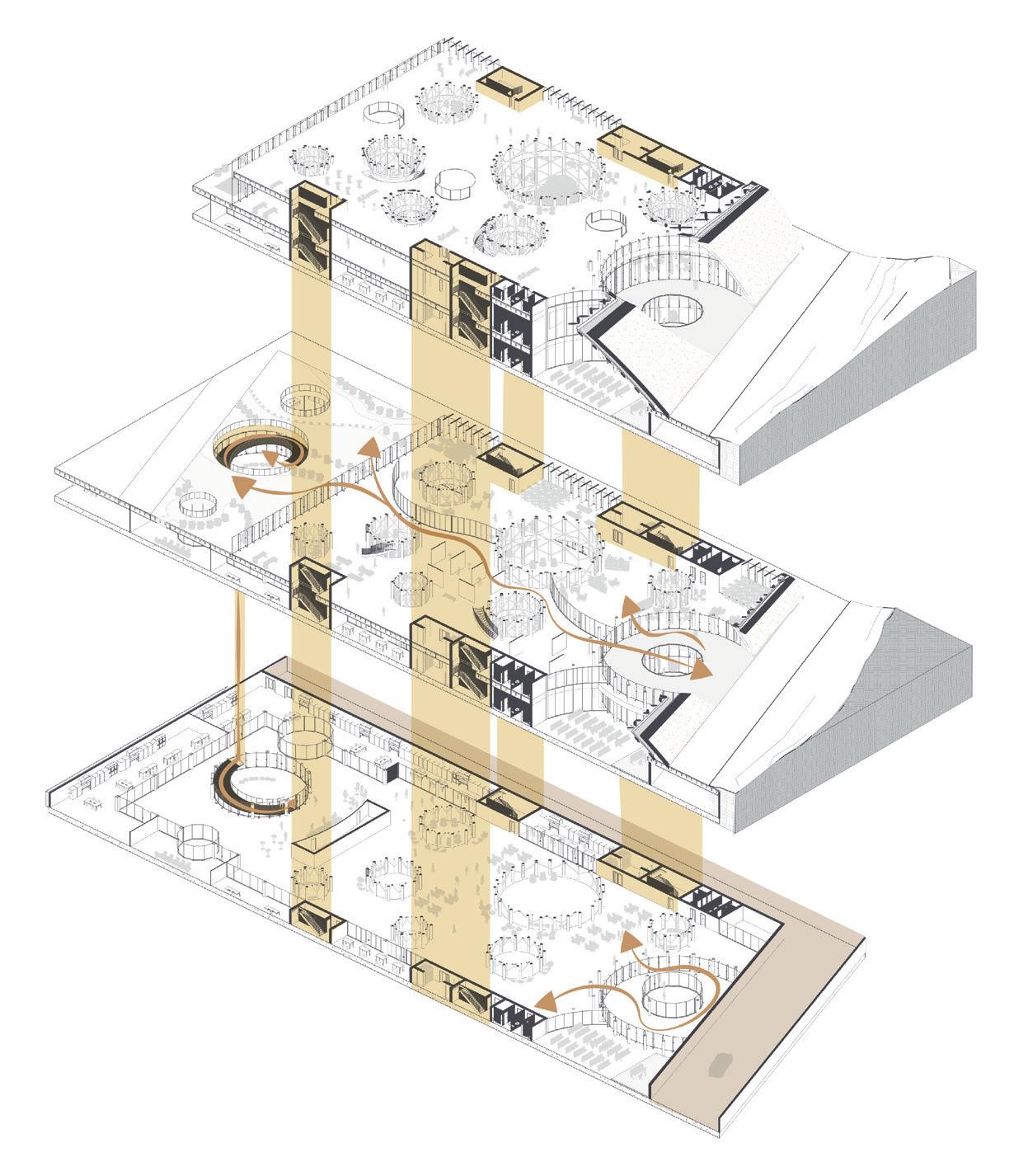

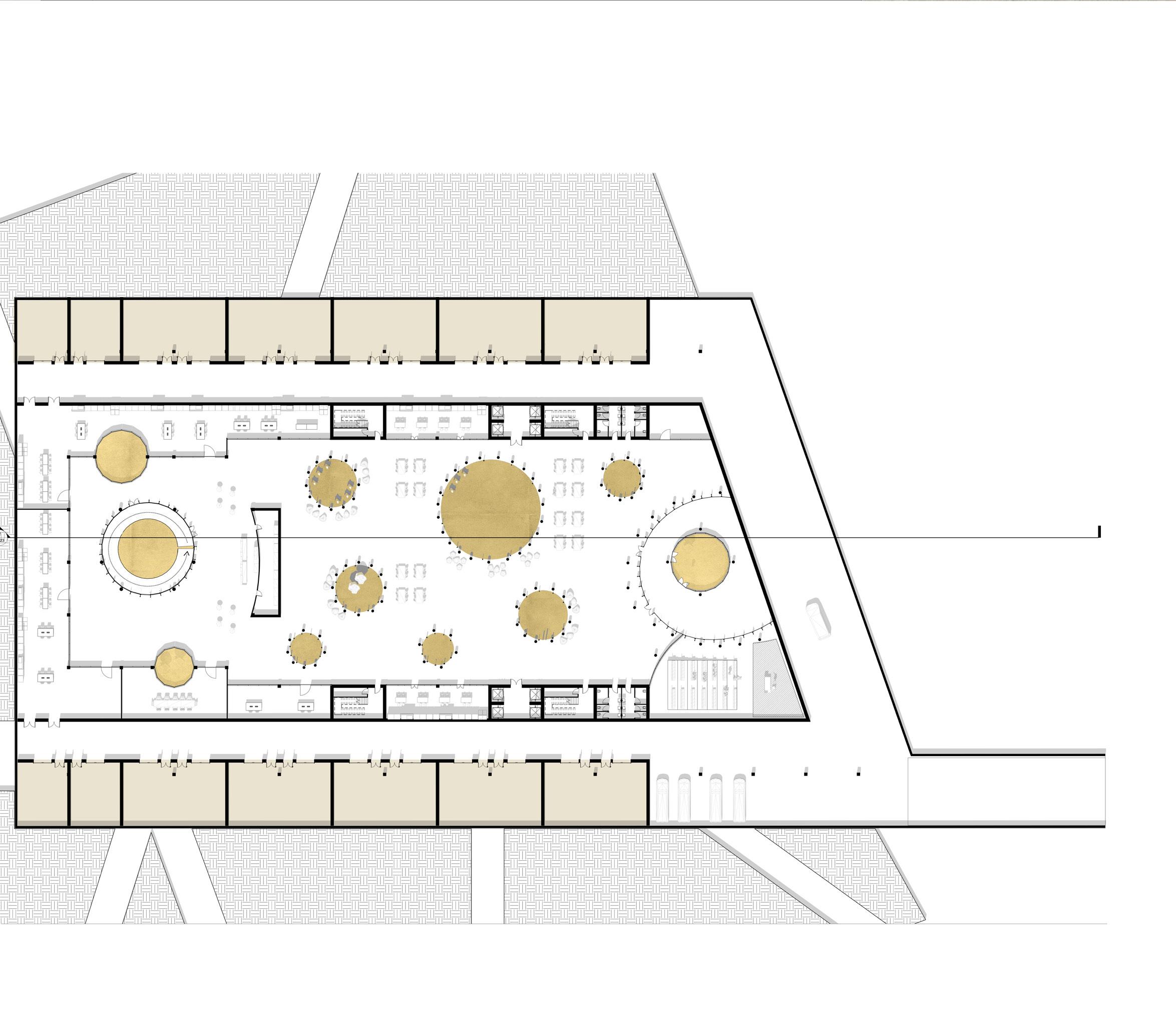

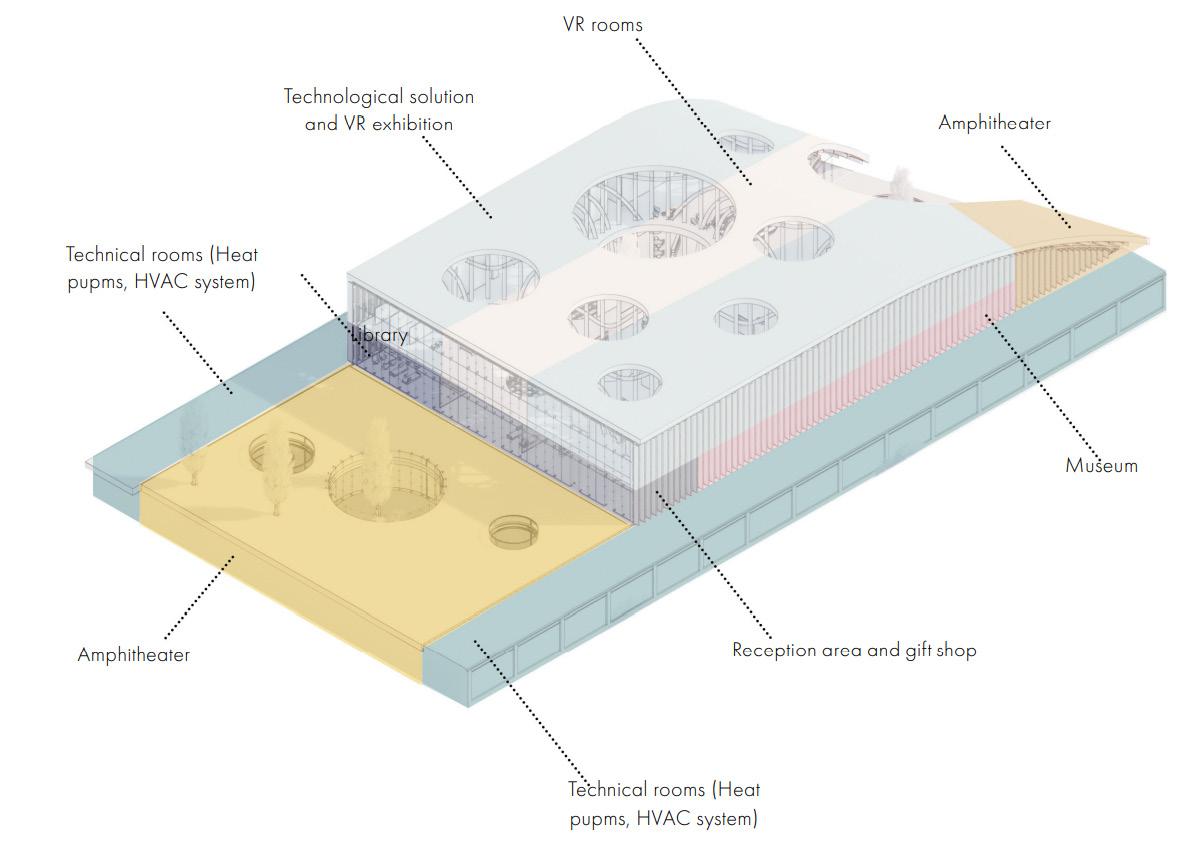

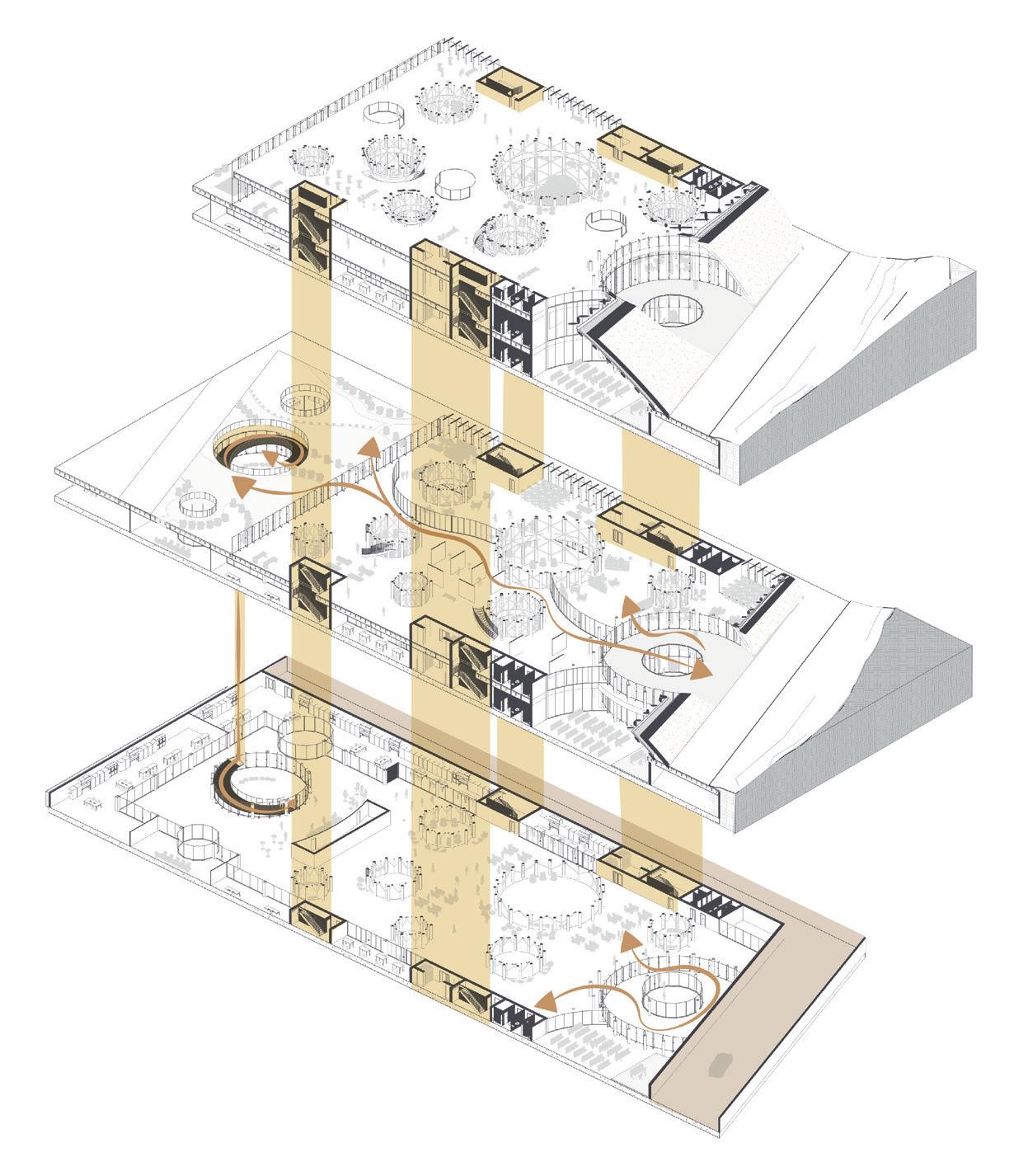

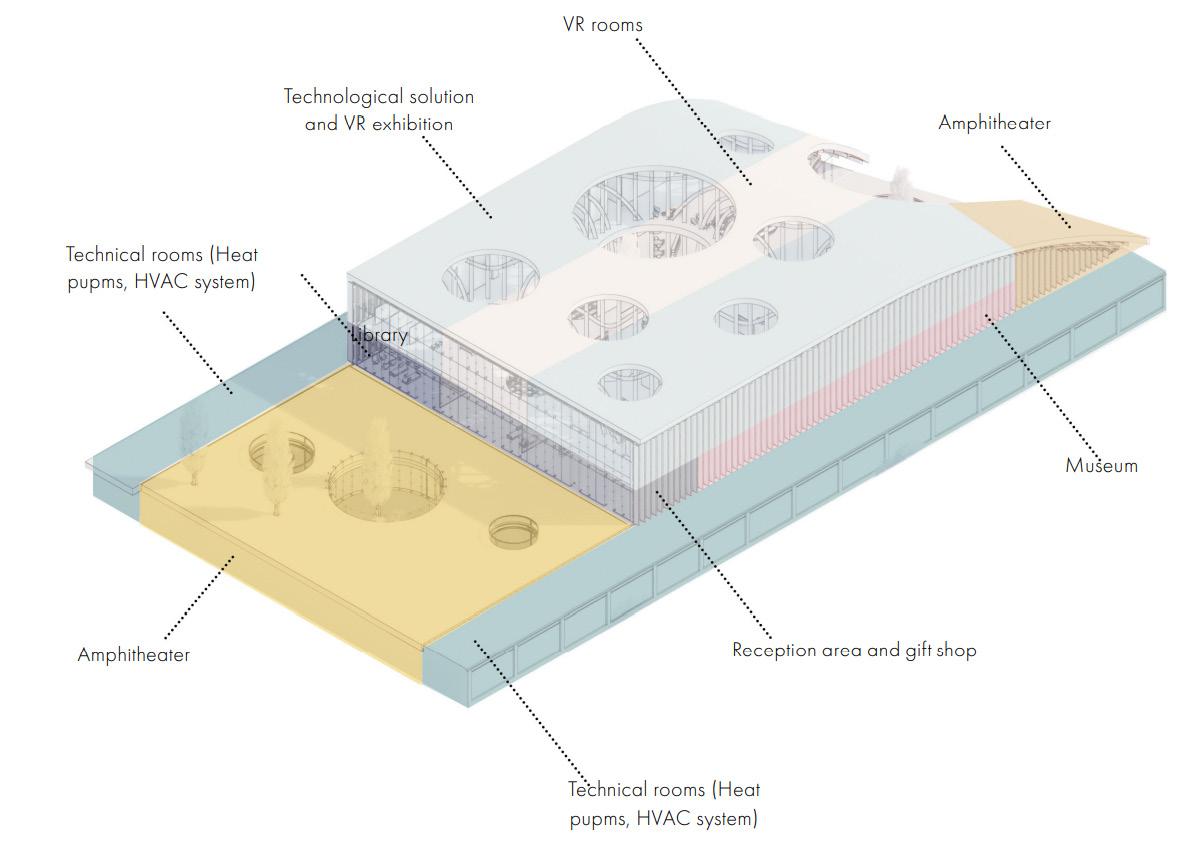

THE PROJECT ABOUT FUNCTION & CIRCULATION FLOOR PLANS & SECTION

NGM MILAN E.N 38

ABOUT

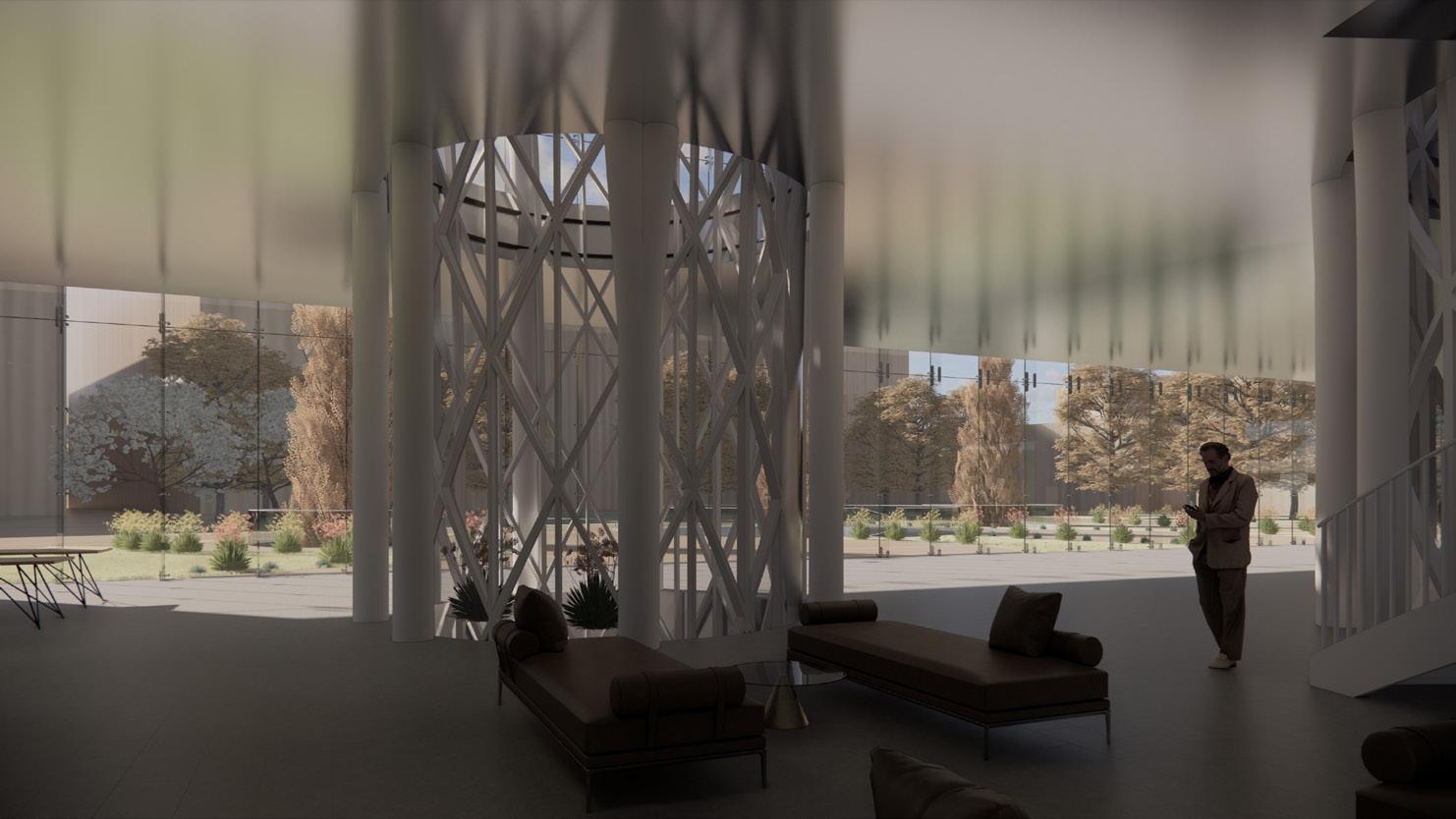

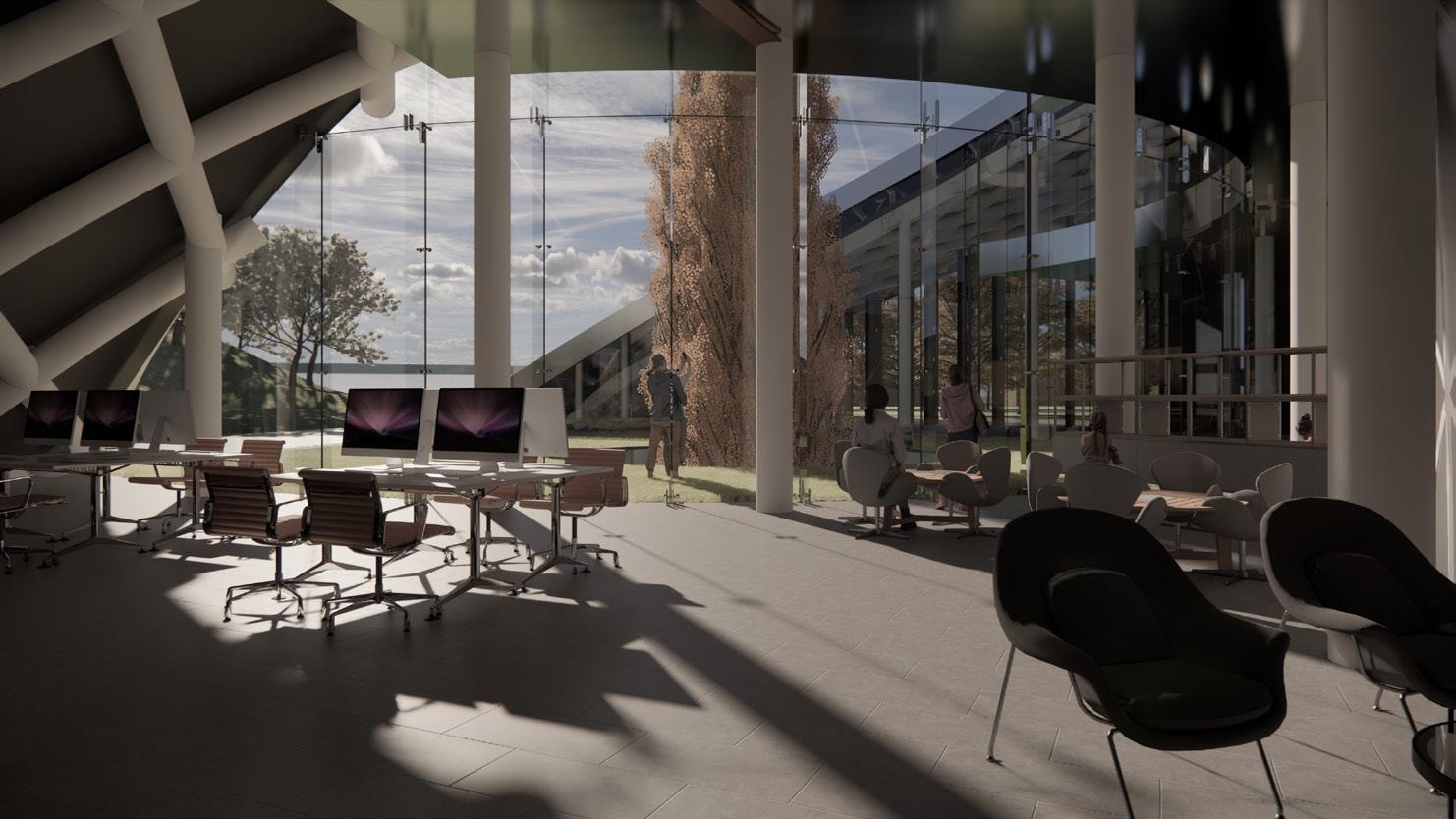

NGM is a mixed-programmed cultural development of 13,804 m2 with the primary purpose of exhibiting the most advanced architectural approach and research, with a focus on a made in Italy identity. Following MIND’s principles of science, knowledge, and innovation, the cultural centre offers research, an appealing focal point for visitors, and a sustainable solution by integrating its structure within the existing green fabric, expanding it, and generating new green urban areas.

The project, which was inspired by MIND’s common ground concept, features public urban spaces close to its two entrances from west to east. The building is oriented in a strategic location to connect the educational center to the park beside it, creating an urban quality that goes hand in hand with MIND’s concept of introducing a new way of walking within the city and a whole new perception of how green spaces are integrated within the public space.

THE PROJECT

FORM

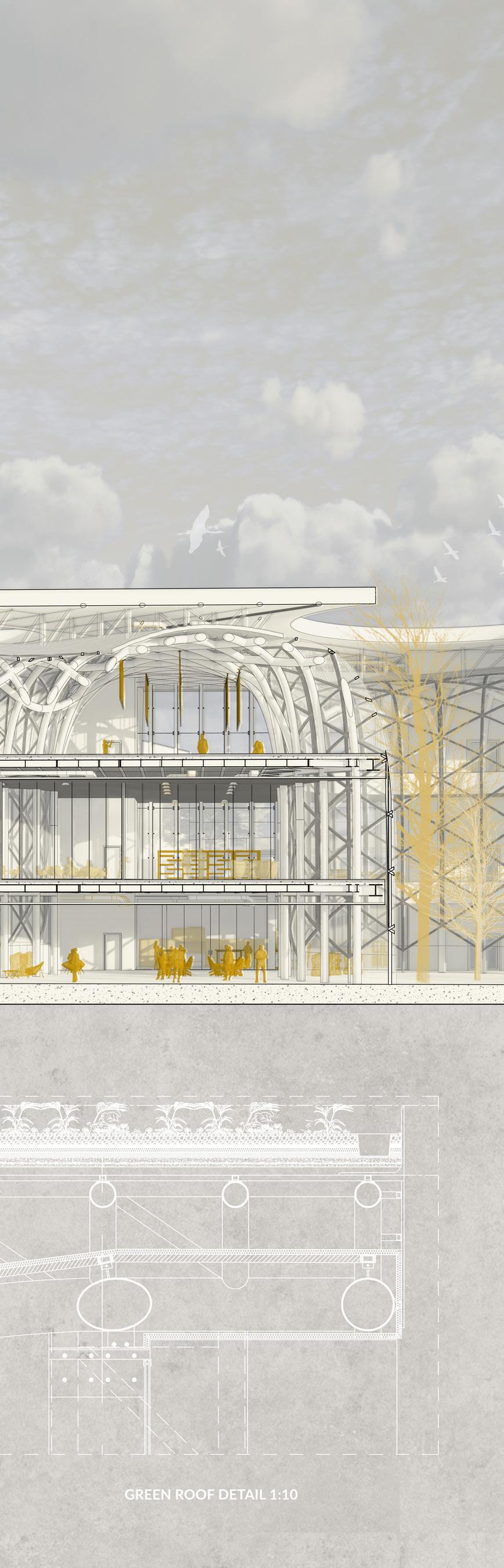

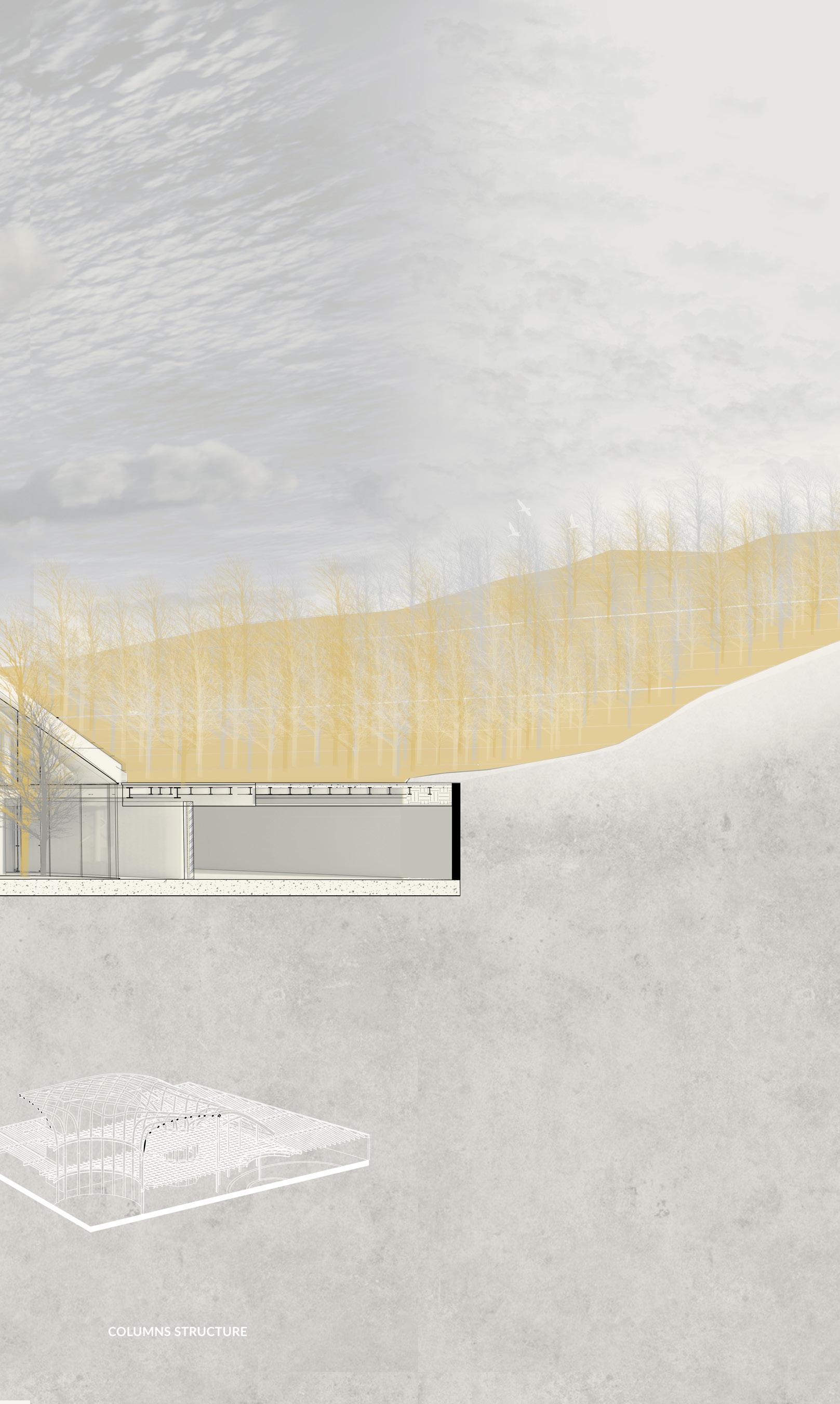

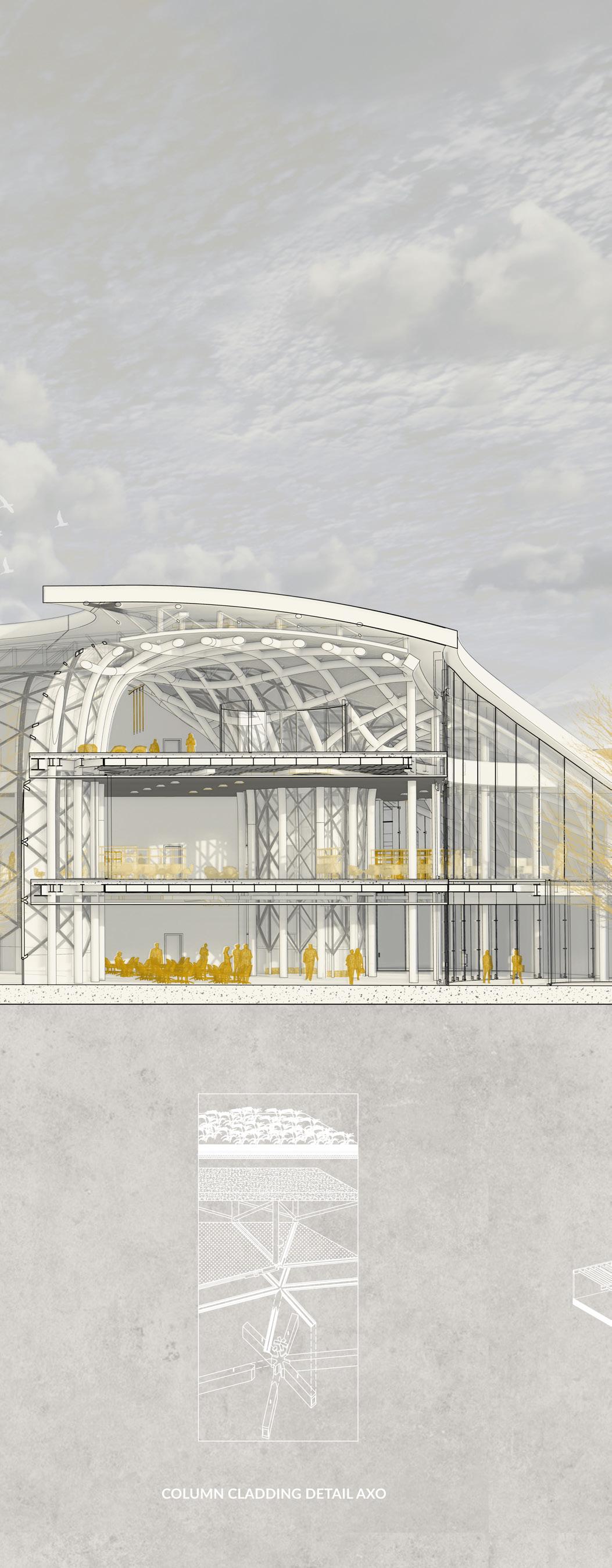

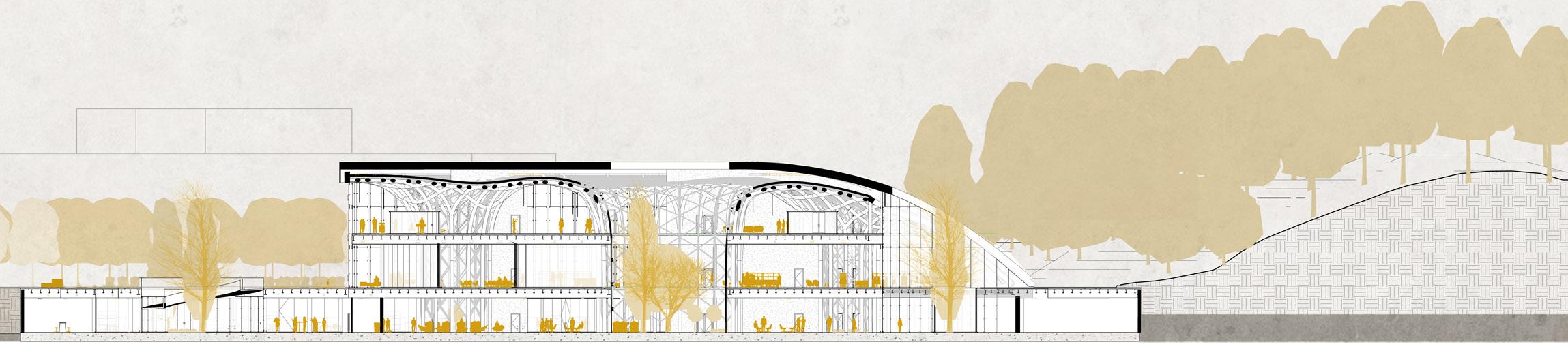

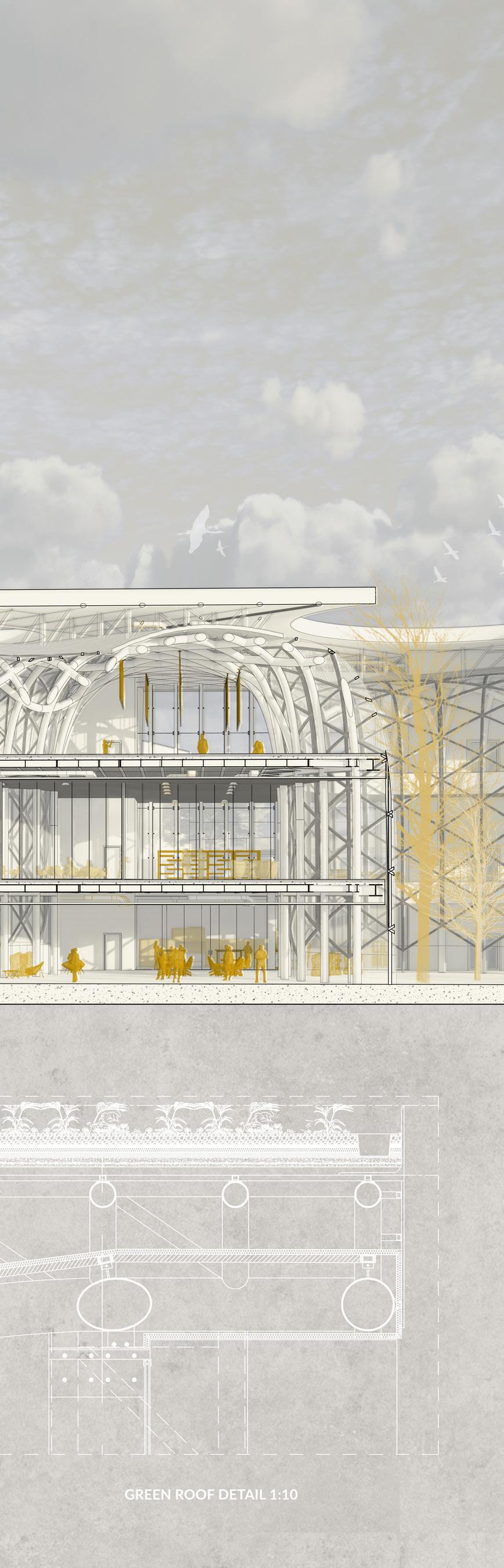

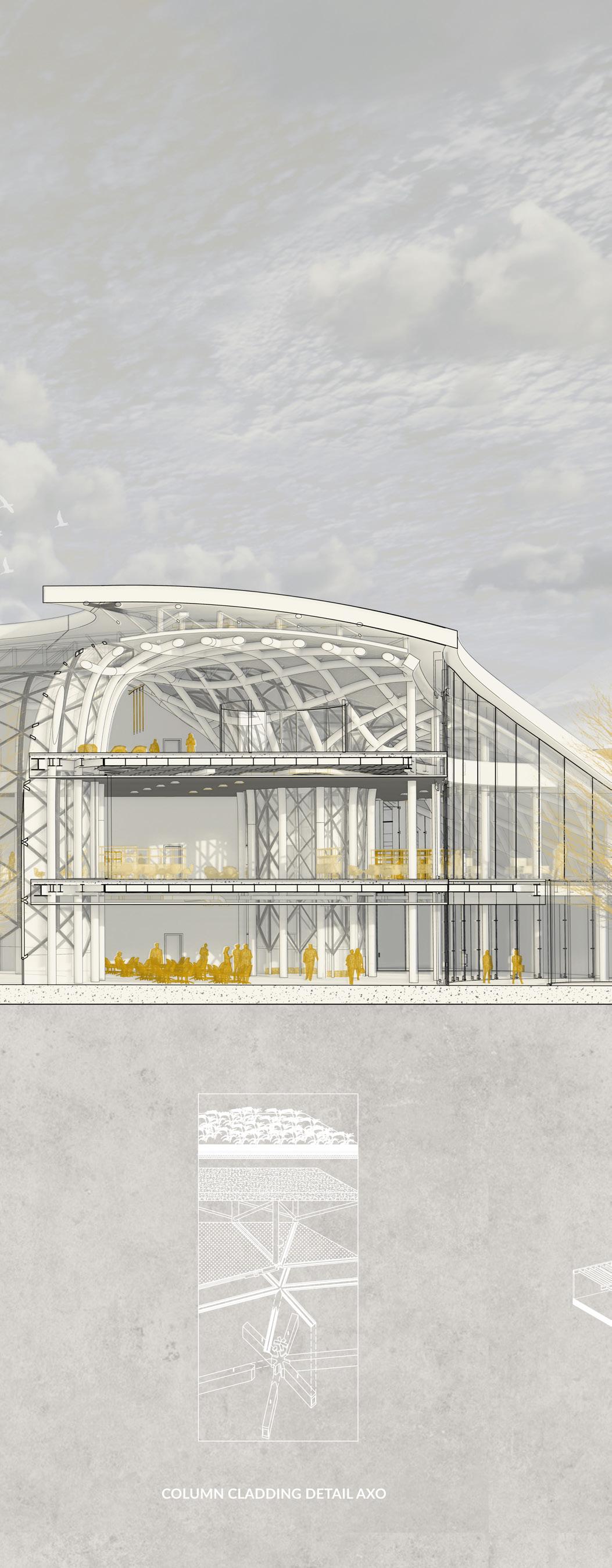

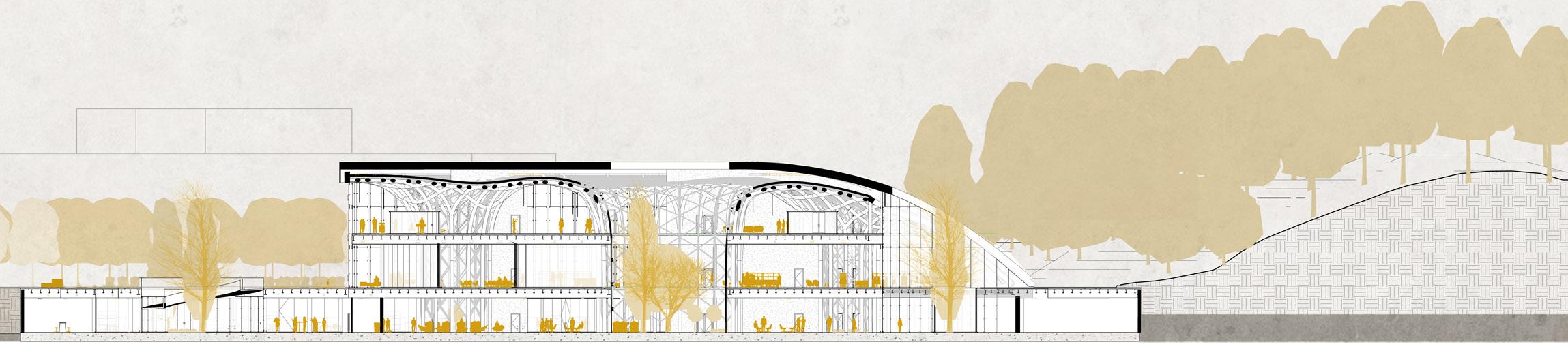

The structure is composed of four parts: a sequence of weaving structural tree-like columns, floor plates, an integrated facade that serves as the structure’s „skin,” and a green roof. It is designed as part of a green fabric, with columns that reflect the natural appearance of the flora around it.

The east façade, as previously stated, faces the Mediterranean hill; the structural glass façade on that side offers transparency between indoor and outdoor, bringing nature into the building and letting those standing on top of the hill to see the steel construction inside.

Another essential criterion was the concept of the inner courtyards which are created within the columns. Because of their scale, the columns can function as inner courtyards within the building, delivering light and ventilation to the interior. The various column widths and their asymmetrical distribution around the structure creat a distinctive shading effect and inspirational spaces around the floor plans, setting the tone of the circulation and atmosphere within the building.

CONCEPT

The concept of a building blended into the green fabric is largely inspired by MIND’s sustainability , energy and resource maximizing principles. In addition to the high environmental standard set for materials used in the project, the use of local materials predicts reduced carbon emissions.

As previously stated, the tree-like columns and skylight openings on top of them are the major elements that set the tone in the structure. They direct the building’s rhythm and the design of interior spaces. Their existence disrupts the normal floor plan nature and necessitates creative solutions in the planning of the building’s vital operations.

The diagrams below show the flow within the interior spaces with a non-traditional rhythm set by the columns.

NGM MILAN E.N 40

ABOUT Land Area Floor Area 3,948 m² 2,844 m²

THE PROJECT

&

Research center Circulation

Exhibition/library Circulation Services and maneuver

Entrances and

NGM MILAN 41

exits Vertical Circulation

FUNCTION

CIRCULATION

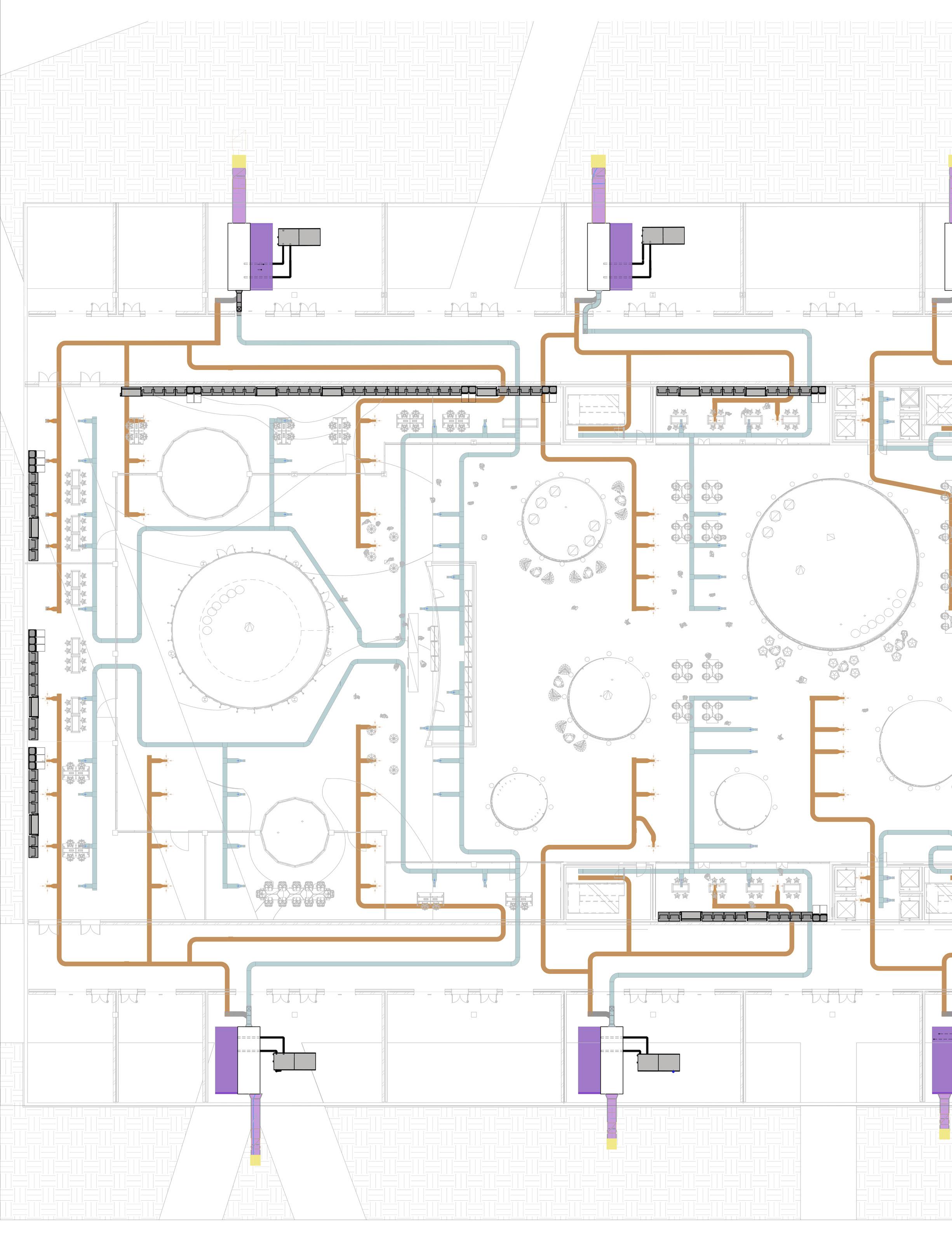

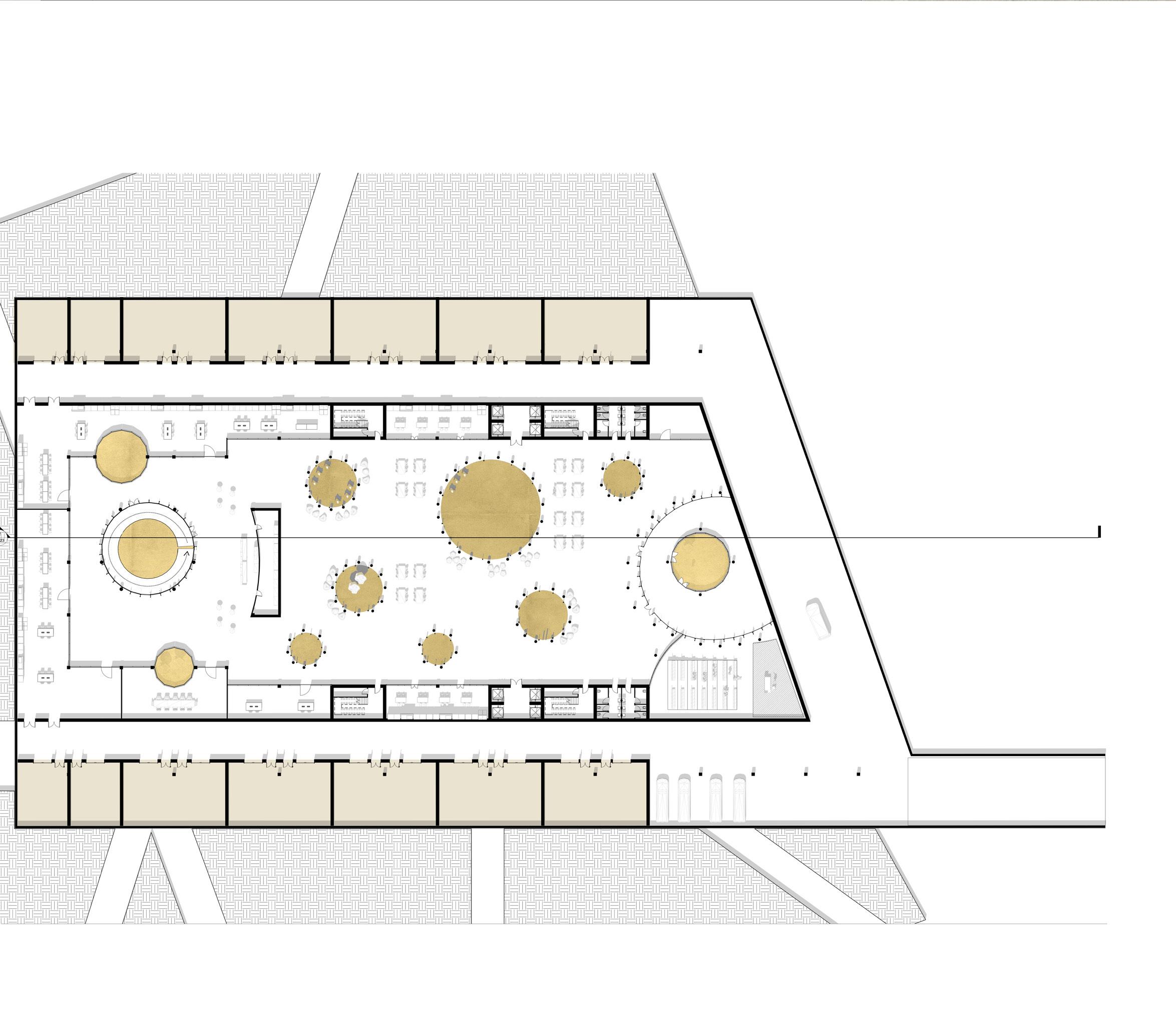

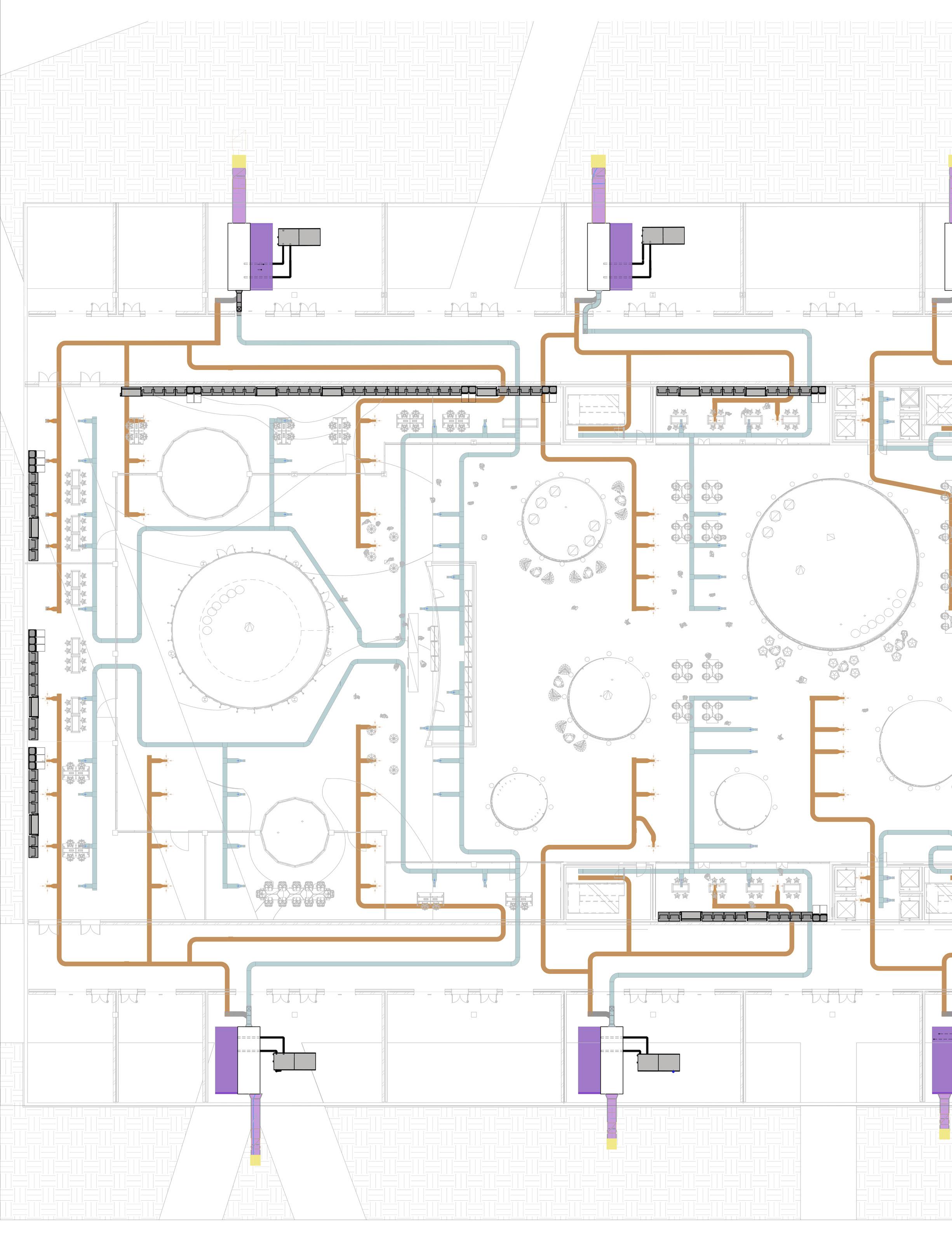

NGM MILAN E.N 42 THE PROJECT FLOOR PLANS AND SECTION Laboratory

view

Open work spaces

Perspective from the courtyards

NGM MILAN 43 SECTION A-A’ 1:1000 Tecnical rooms and services UNDERGROUND PLAN 1:1000

NGM MILAN E.N 44

Hill side view

Main entrance view

Library hill view

NGM MILAN 45 SECTION A-A’ 1:1000 GROUND PLAN 1:1000

NGM MILAN E.N 46

Exhibition view

Emergency exit

Exhibition floor

NGM MILAN 47 SECTION C-C’ 1:1000 FIRST FLOOR PLAN 1:1000 VR rooms

SUSTAINABLE MATERIALS

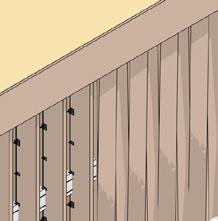

FACADE DESIGN

NGM MILAN E.N 48

ABOUT

SLAB

DESIGN

GREEN

ROOF COLUMNS CLADDING

NGM MILAN 49

ABOUT

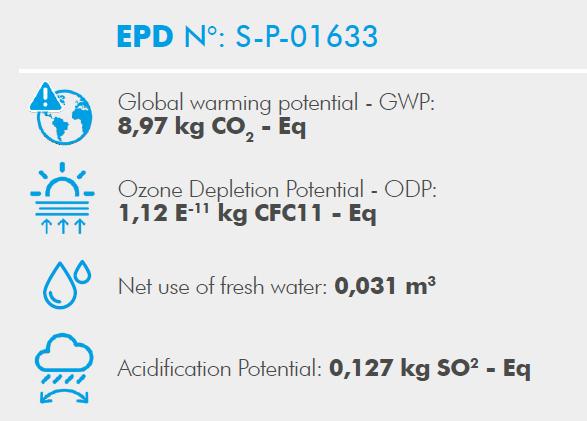

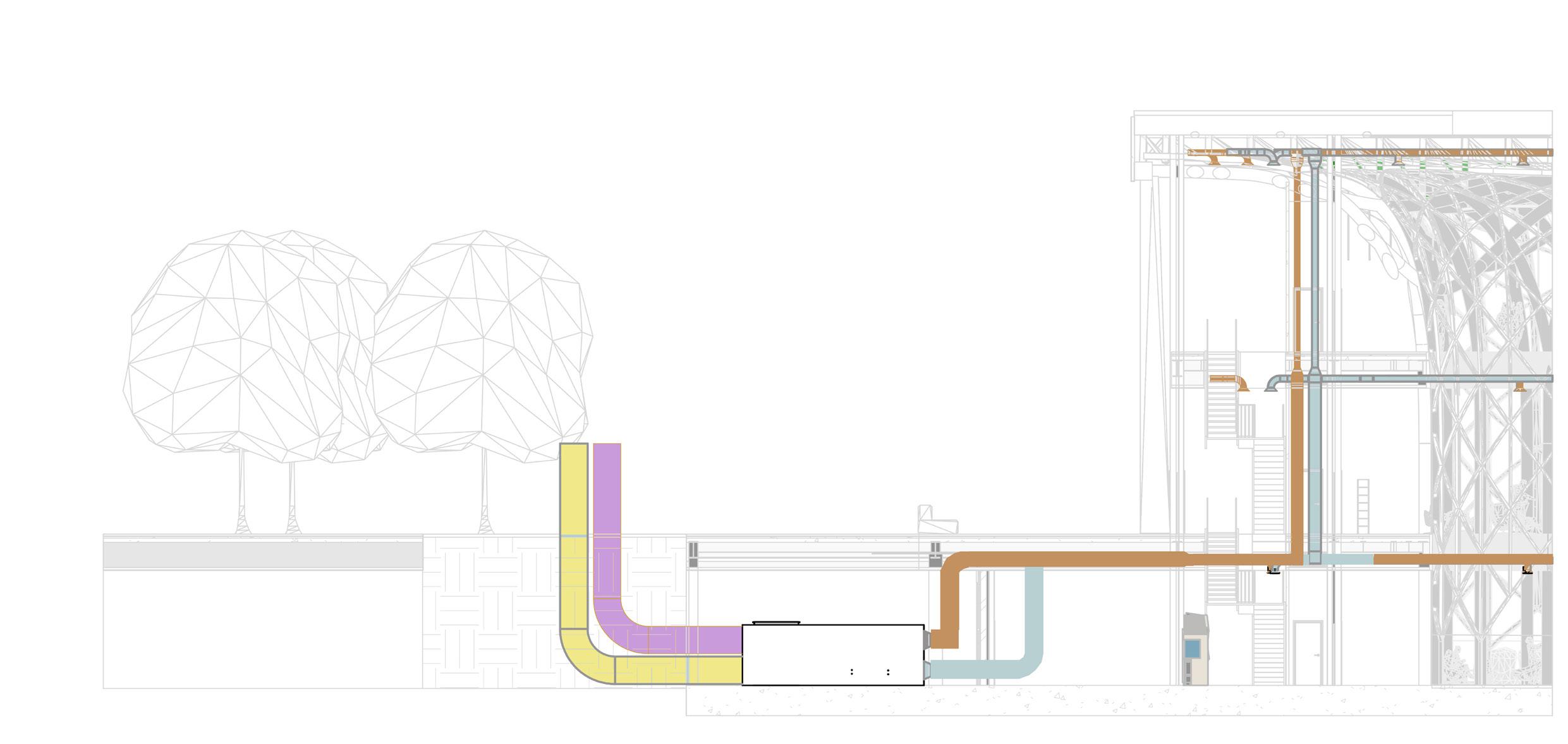

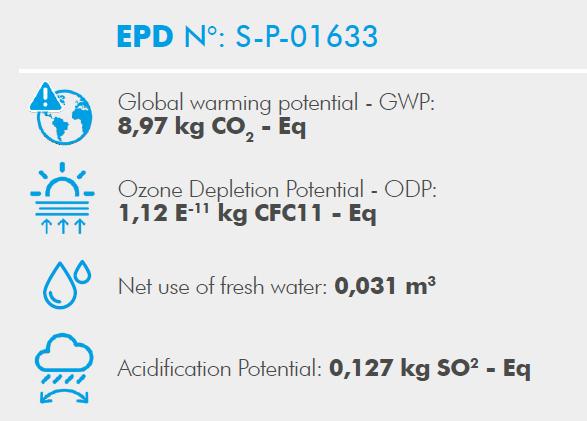

One of MIND’s primary features, as previously stated, is sustainability. From its origins in the R-Expo display, the site’s goal has been to self-generate the energy that it consumes and to focus most of the design effort on consuming less energy and emitting less carbon. As a result, all developments in the district must meet a curtain sustainability level imposed by the overall concept.

In accordance with MIND’s sustainability criteria, all materials for the project were selected primarily from Milanese/Lombard enterprises, with consideration given to Co2 friendly modes of transportation to the site. In addition, each selected company lobbied for environmentally friendly products, which are outlined in this chapter

The design process in terms of materials is a delicate balancing act of architectural choices, longterm viability, and compatibility with the

project and its surroundings.

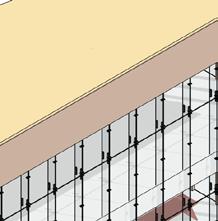

One of the primary issues in constructing the building’s envelope was solar gain, which will ultimately determine the energy consumption to keep the building at a comfortable temperature. Given the architectural notion of transparency, it was necessary to balance both design anchores. The solution consists of three façade types that are arranged in accordance with the light analysis. It enables the evaluation of the building’s facades that are most exposed to solar radiation, allowing the design to be properly changed.

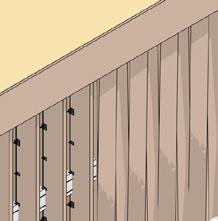

The three types are: a completely glazed double-glass façade (structural glass), glazes with shading louvers, and timber opaque panels that allow controlling the rhythm of the façade and offering a sense of the internal arrangement.

Aside from the façade, another aspect of the building that contributes to energy

consumption is the material used for the roof. In this example, the solution presented was in line with both energy usage and concept, in the shape of a green roof (non-walkable to decrease structural loads) that provides a nice connection between the building and the park and contributes to the eco system.

NGM MILAN E.N 50

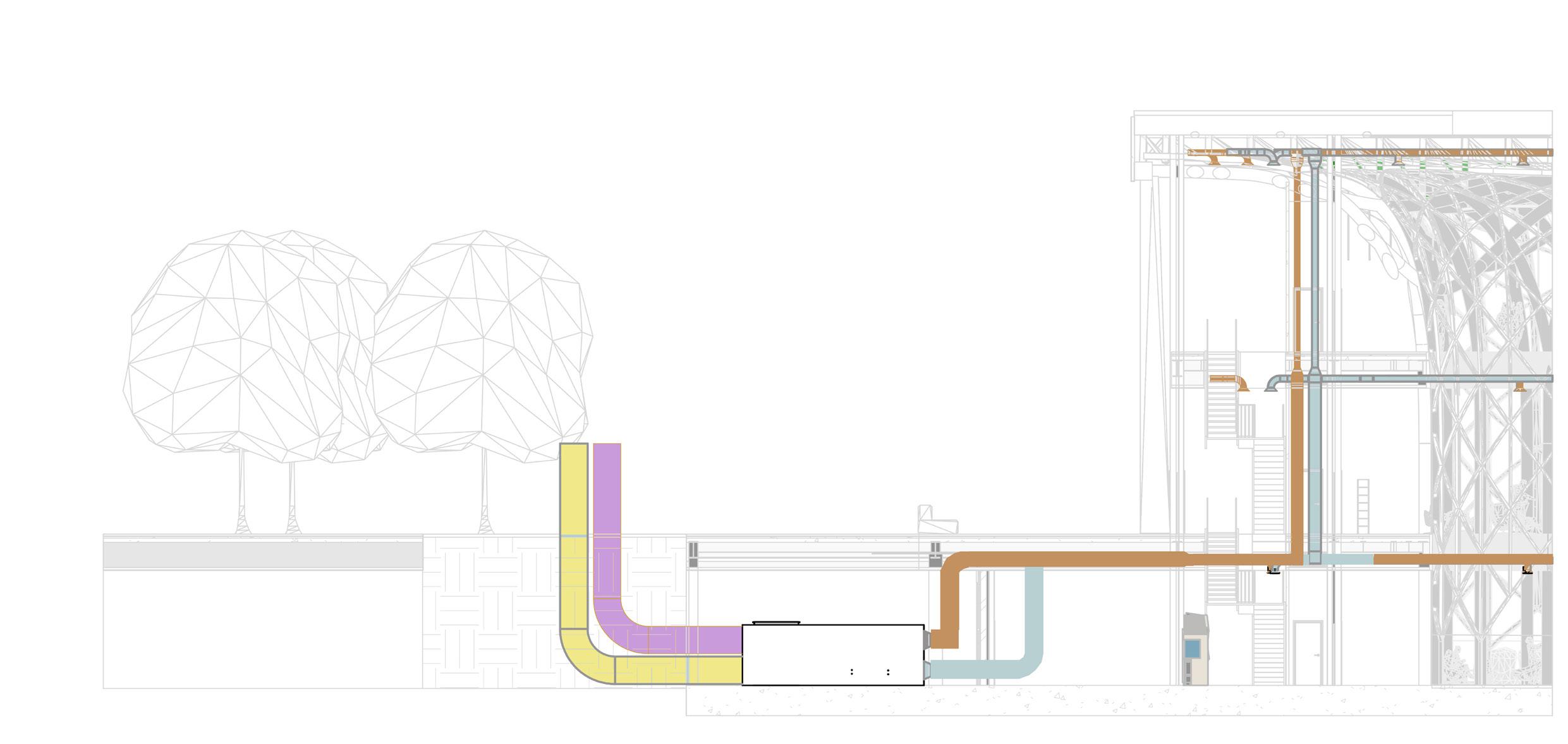

NGM MILAN 51 C Raft Foundation -7000 Excavation -7300 Roof Level L2 0 3 2 1 0 Raft Foundation -7000 Excavation -7300 Underground Level -5000 Groundfloor Level 0 1st Level +6000 Roof Level +13800 L3 0 W1 S1 S2 S2 S4 S2 S2 S4 W5 S1 T1 T2 HEB 550 IPE 500 IPE 500 IPE 330 A20 9 A19 9 A18 9 HEB 550 WEST FACADE- MAIN ENTRANCE Detail 1:100

NGM MILAN E.N 52 3 2 1 0 I Raft Foundation -7000 Excavation -7300 Underground Level 5000 Groundfloor Level 0 Leve1st +6000 Roof Level +13800 W2 S1 S3 Curt.W1 S2 S2 S4 Louv1 HEB 550 IPE 500 IPE 500 IPE 330 T2 T1 A14 7 A13 7 A12 7 FACADE STRAIGHT LOUVERS Detail 1:100

NGM MILAN 53 C 3 2 1 0 Raft Foundation -7000 Excavation -7300 Underground Level 5000 Groundfloor Level 0 Leve1s +6000 Roof Level +13800 W2 S1 S3 S2 S2 S4 W3 Louv2 IPE 330 IPE 500 IPE 500 T2 T1 A17 8 A3 4 A16 8 A15 8 FACADE TWISTED LOUVERS Detail 1:100

The

Pilkington Structural Glass System

Benefits : Load sharing

Specially developed fittings com bined with the much higher modulus of thestructural interlayer (compared with tra ditional inter layers) allows the System to share applied loads be tween both glass components of the laminate, giving a significant increase in load bearing capacity while at the same time reducing the thickness required.

Low deflection fully utilises the increased stiff ness of the interlayer (in some cases 100 times that of PVB) to reduce deflections under wind,

CS Wood grain powder coat

**Warm Walnut #011.

Construction Specialties:

CS Wood Grain Powder Coat

Finish is durable, with superior scratch and fade resistance. It offers the realistic look of wood without destruction of trees or the costly, time consuming main tenance required with real wood. In addition it will not deteriorate due to weather. It is an earth friendly product that can stand up to all types of weather condi

**This finish is suitable for all CS Grilles and Sun Con

NGM MILAN 54

Structural glass system

Pilkington Planar™ Support Structures

Glass Fin (Mullion) Systems

use of Pilkington Planar in combination with a glass fin system creates the ultimate in transparency. Glass fins are used to transfer wind loading to the structure. Pilkington Architectural have led the way in the development and testing of this design technology. Structures of this type can be either supported at the base (ground based) or suspended (hung) from above depending upon the height of the façade. The weight of both the panels and the fins is carried by the connection at the head or base of each fin. Stonehenge Visitor Centre – Wiltshire. Images Courtesy of Vitrine Systems Ltd. Glass Fin (Mullion) Systems processes permit. Final color selection should be from actual finished color chips. The super durable textured finish comes

Douglas

Fir #003 Lyptus #004 Warm Knotty Pine #005 Black Cherry #009 Light Walnut #010 Warm Walnut #011

Barnwood

#016 American Oak #017 Pacific Coast Fir #018 Scrubbed Walnut #020 Oxidized Bronze #021 SOLUTIONS COLOR CARD

HP is tested on steel structures according EN 13381-

on concrete/profiled sheet steel composite member accord

13381-5,

of them in

NGM MILAN 55 Fixed twisted louvers Construction Specialties, Italy Features ◊ Design flexibility ◊ Promotes lower energy use ◊ Increases safety and security Benefits ◊ Blades can be in sequential or irregular order to express ◊ your design aesthetic ◊ Lessens glare and solar heat gain yet allows filtered light in Applications ◊ Decorative facades ◊ Parking facilities Aluminum composite panel COMPOSITES Finish- Wood grain powder coat, European Walnut 832-3A Rock Mineral Wool panels Knauf Insulation benefits: ◊ Indoor Air Quality thanks to ECOSE Technology® ◊ Non-combustible (Euroclass A1) ◊ Excellent thermal insulation (λD 0.034 W / mK) ◊ Black glass veil coating Environmental impact indicators: **Perlifoc

4 and

ing EN

all

accredited laboratories. ©2020 Construction Specialties, Inc. |c-sgroup.com PS.TWSS.1120 design enthusiasts looking response to the architectural we have created a twisted achieved by mounting blades on innovative approach by creating a Material Properties Standards Units Linear Thermal Expansion EN 1999 1 1 2,4 mm / m at 100 C temperature difference Tensile Strength of Aluminum EN 485 2 Rm >130 (N/mm^2) Core Mineral filled polymer Surface Lacquering Gloss (initial value) Pencil Hardness EN 13523 2 EN 13523 4 Acoustical Properties Sound Absorption Factor Sound (as) Transmission Rw ISO 354 ASTM E90 0.05 OITC: 24 Thermal Properties Thermal Resistance Temperature Resistance ASTM C518 0.009 [m K/W] 50 to +80 Fire classification acc. to EN 13501 1 Class B s1,d0 Twisted louvers, Construction Specialties

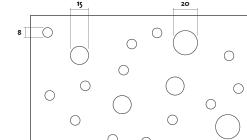

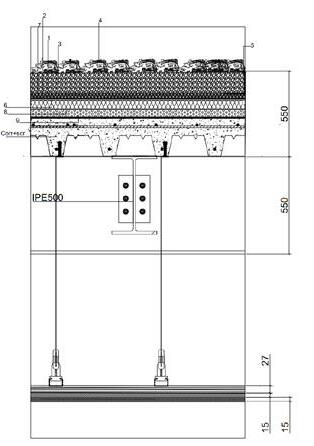

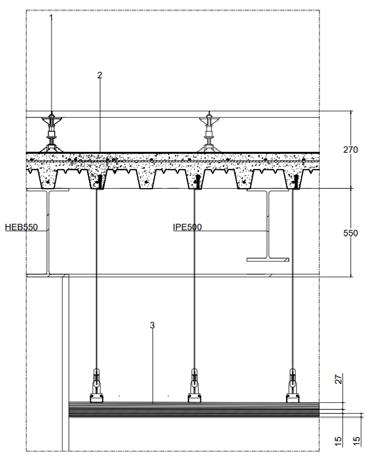

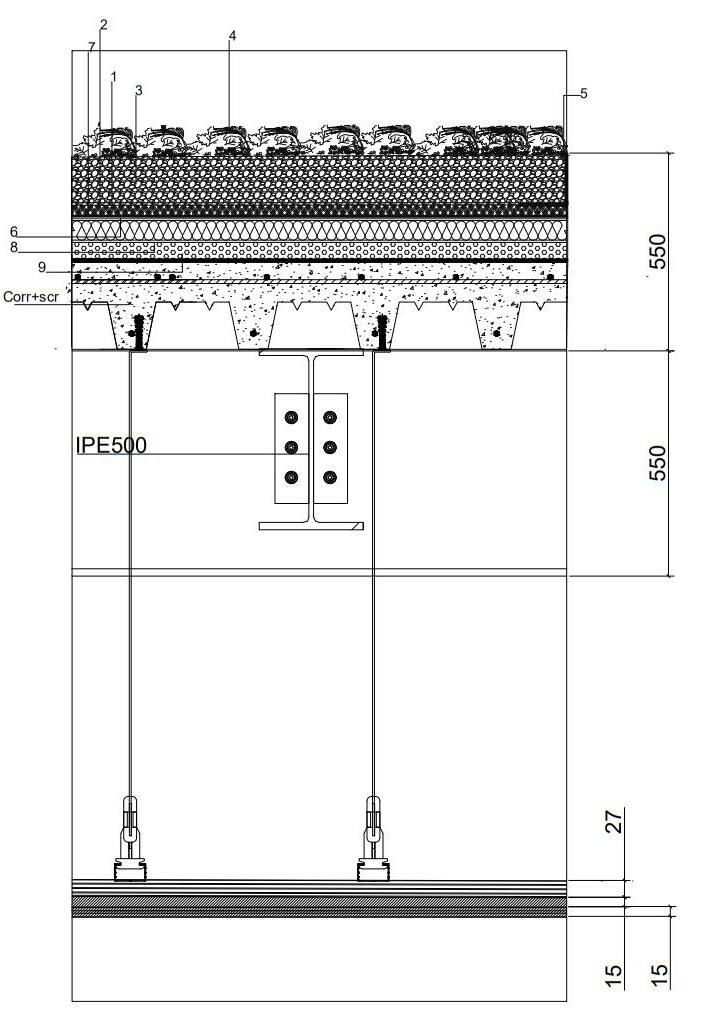

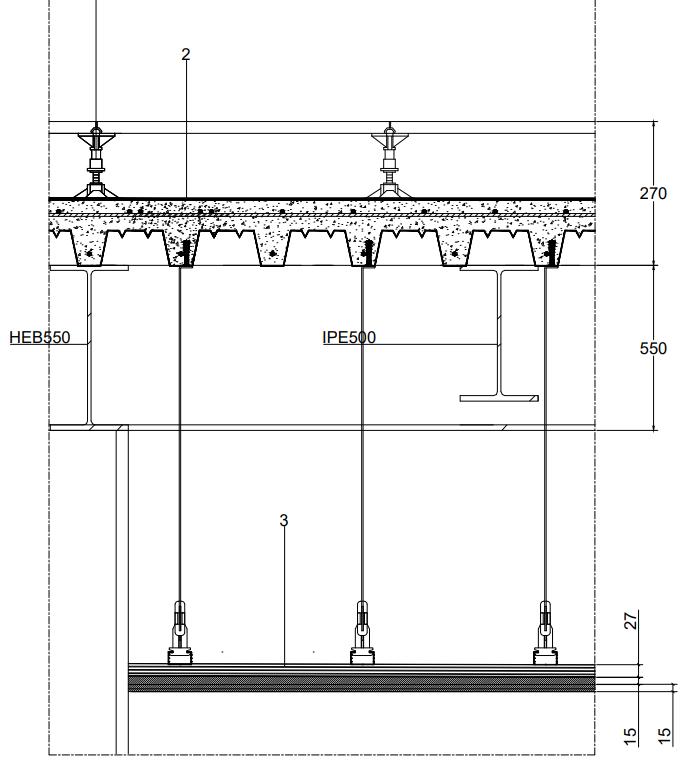

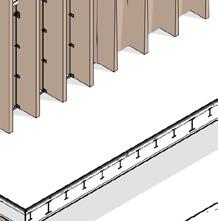

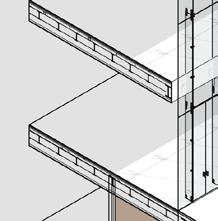

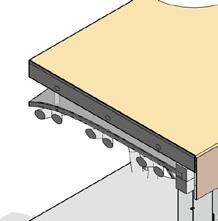

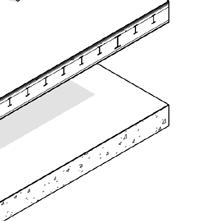

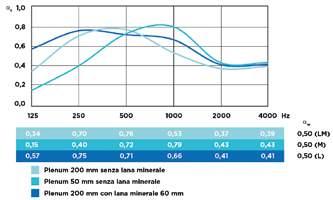

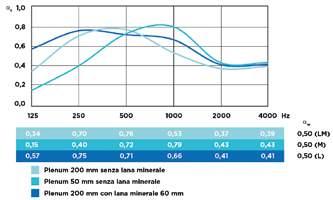

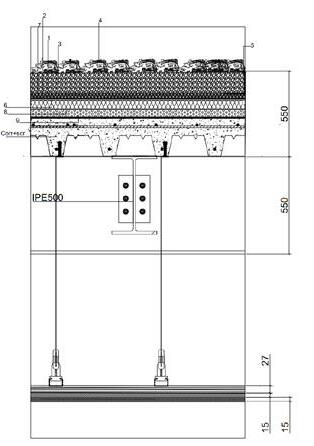

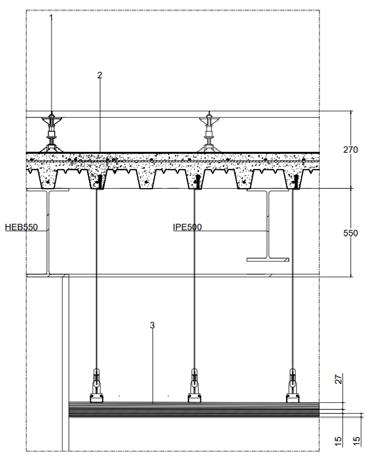

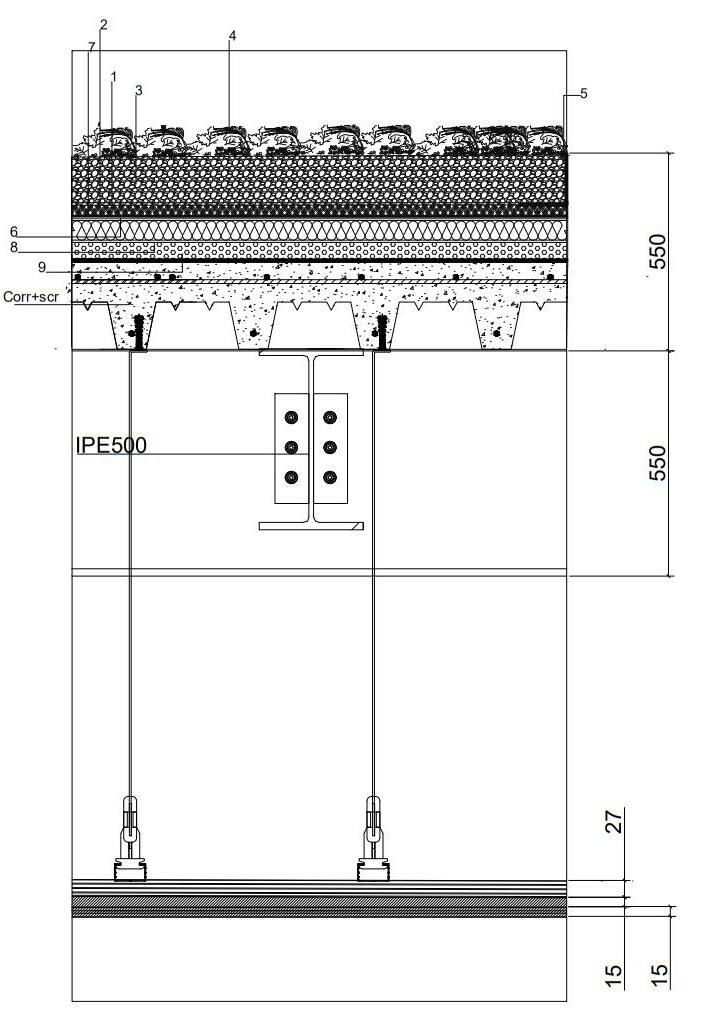

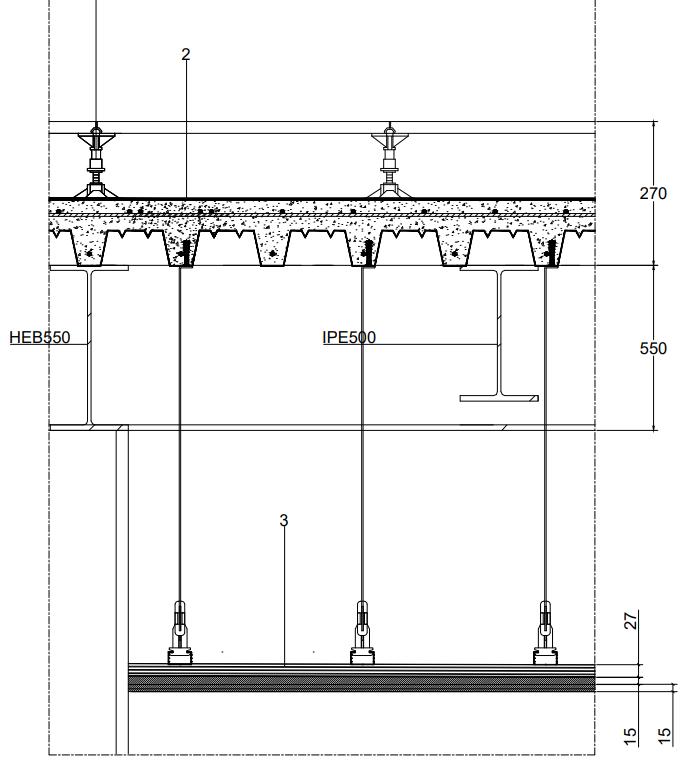

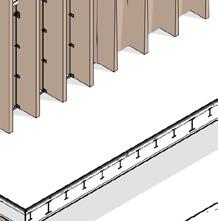

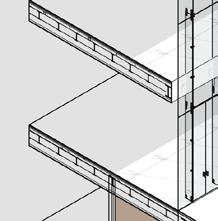

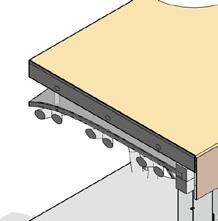

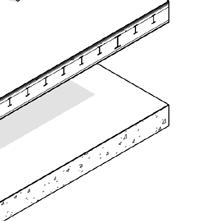

SLAB LAYERS

1 Corrugated sheet with concrete screed -cls- SANRDINI METALLI, thickness 140 mm.

2 Raised floor 4.0 by NESITE, A completely customizable raised floor finished with a pigmented heterogeneous resin,which, after drying, forms an anti-scratch and shock-resistant film, which makes it suitable for mediu traffic. Grey whale color. Thikness 250 mm. 100% Recyclable

3 Countertop by GYPROC -Rig itone® Activ’Air®8-15-20 Super v- metallic structure Gyprofile with organic chromium-free, eco logical, anticorrosive, dielectric, antifingerprint coating, com posed of C 27/48 metal profiles in 0,6 mm Z100 galvanized steel sheet. Thikness 57 mm.

NGM MILAN E.N 56 1 2 27 15 15 IPE500 550 270 HEB550 3

SLAB DETAIL 1-50

Rigitone

colours

FLOOR

finishes.

color range is available in 2 versions, PLAIN (homogeneous effect) and CONCRETE.

formaldehyde-free panel (class EN 717-1) with a low volatile content varnish.

the production process are used only 100% separately recyclable components.

to obtain the LEED certification.

SHEET

Environmental Product Declaration

the International EPD® System. The EPD

■

■

been developed

General

Instructions

accordance with ISO 14025,

Activ'Air

Dimensioni

Prodotto

TOP

Qualità dell’aria

prodotto contiene l’esclusivo sistema Activ’Air®, che permette di assorbire e ridurre fino al

della formaldeide

nell’aria dell’ambiente

classificato

l’air intérieur», riguardante

NGM MILAN 57 ◊ versatility of

and

◊ the

◊

◊ in

◊ contributes

MILK CONCRETE WHITE 9003 GREY WHALE NESITE COLLECTION SILVER GREY 7044 AGATE GREY 7038 STONE GREY 7030 COURROGATED

4.0

COUNTER

◊ Rigitone® Activ’Air® 8-15-20 Super -Perforat ed coated gypsum board with 4 straight edges ◊ Irregular round drilling, with offset holes ◊ Acoustic fabric applied on the back Rigitone ® Activ'Air ® 8-15-20 Super LASTREIl prodotto deve essere decorato in opera, dopo la finitura (riempimento) dei giunti. Tipo bordo 4 bordi diritti Bordo (dimensioni in mm) Rotonda irregolare sfalsata (mm) 1200x1960 12,5 9,3

®

8-15-20 Super ■ Lastra di gesso rivestito forata con 4 bordi diritti ■ Foratura rotonda irregolare, con fori sfalsati ■ Tessuto acustico applicato sul retro ■ Installazione su struttura Gyprofile, per una perfetta planarità del controsoffitto Assorbimento acustico Ambiente, sanità, riciclo ■ I prodotti Rigitone® possiedono la Dichiarazione Ambientale di Prodotto (EPD, vedi pag. 8), verificata da un ente terzo indipendente. ■ I prodotti sono caratterizzati da basso impatto ambientale, come previsto dall’approccio Gypsum Forever. ■ Sono prodotti naturali, costituiti in massima 1960 12,5 Dimensioni in mm Superficie forata: 10% Has an

in

has

in

the

Programme

MATERIAL STRATIGRAPHY Rigitone ® Activ'Air ® 8-15-20 Super LASTRE Reazione al fuoco Euroclasse A2-s1,d0 secondo norma EN 13501-1. Finitura Il prodotto deve essere decorato in opera, dopo la finitura (riempimento) dei giunti. Installazione Per le modalità di installazione delle lastre Rigitone® Activ’Air® vedere le pagine da 254 a 257. Tipo bordo 4 bordi diritti Bordo (dimensioni in mm) Tipo di foratura Rotonda irregolare sfalsata Dimensioni (mm) 1200x1960 Spessore (mm) 12,5 Peso (kg/m2) 9,3 Rigitone® Activ'Air® 8-15-20 Super ■ Lastra di gesso rivestito forata con 4 bordi diritti ■ Foratura rotonda irregolare, con fori sfalsati ■ Tessuto acustico applicato sul retro ■ Installazione su struttura Gyprofile, per una perfetta planarità del controsoffitto Assorbimento acustico Ambiente, sanità, riciclo ■ I prodotti Rigitone® possiedono la Dichiarazione Ambientale di

(EPD, vedi pag. 8), verificata da un ente terzo indipendente. ■ I prodotti sono caratterizzati da basso impatto ambientale, come previsto dall’approccio Gypsum Forever.

Sono prodotti naturali, costituiti in massima parte da materiali riciclati, che non spolverano e sono privi di fibre o sostanze pericolose per la salute. 1960 12,5

interna Il

70%

presente

interno.

Il prodotto è

A+ secondo la norma francese «Émissions dans

l’emissione di COV.

in mm Superficie forata: 10%

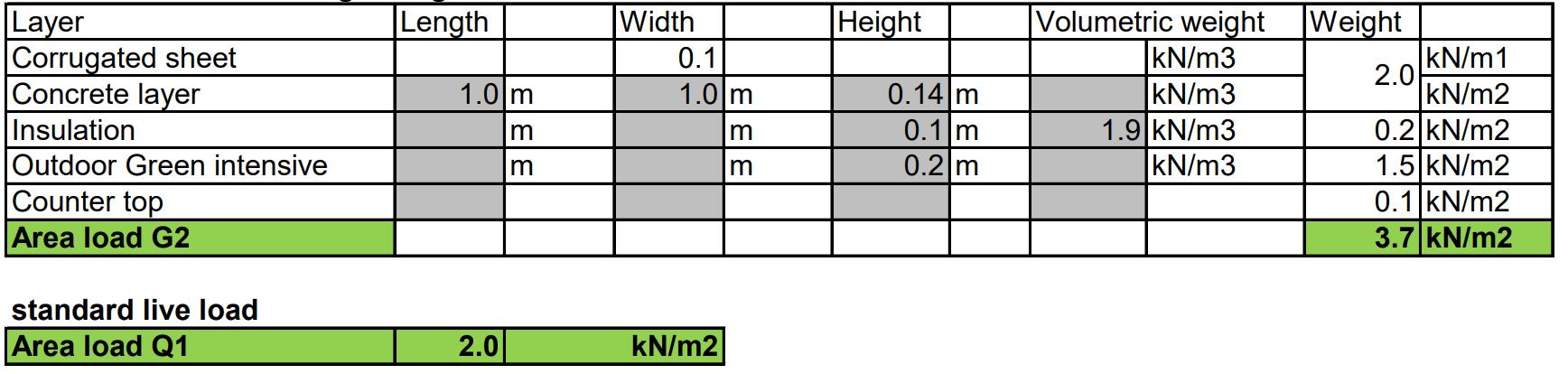

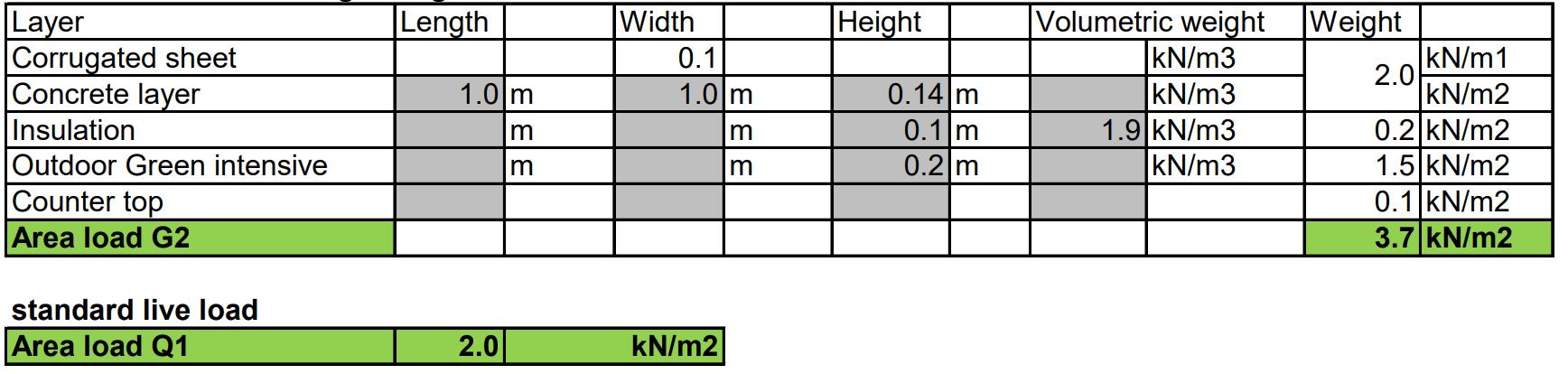

SLAB LAYERS

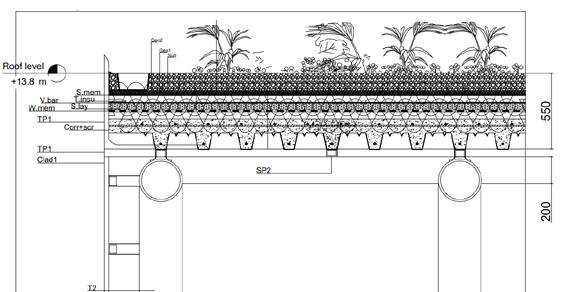

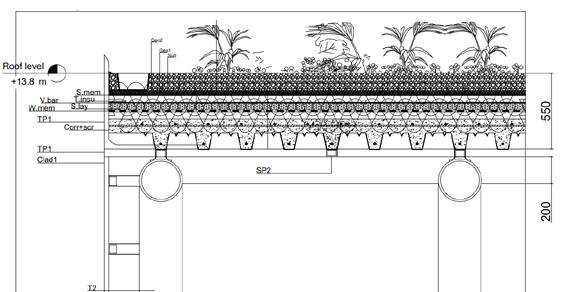

GREEN ROOF SYSTEM (FERTIL)

1 Needle-punched and heat-set non-woven geotextile (GTX-N)

FERTILROOF Stratum 500 to protect the element sealing and protec from the action of the roots. Thickness 3.0 mm. Weight 500 g / m2.

2 Draining geocomposite, con sisting of geomat coupled with non-woven geotextile, 20 mm thick.

3 Cultivation substrate LightTer Extensive type, with prevalent mineral composition, complying with the requirements of the UNI11235: 2015 standard.

4 Vegetation in Sedum spp.Se dum acre(herbaceous essences).

5 Perforated L-shaped shingle metal profile in Aluminum, 1.5

mm thick, for separation from the bands of ballasting and pe rimeter drainage, with dual direc tion of installation (h 8,0 - 10,0 cm).Musola Metalli S.p.a.

6 Single-layer synthetic mem brane made of homogeneous PVC-P obtained by coextrusion. (1,50 mm).SOPREMA ITALIA

7 Thermo insulating element: Self-extinguishing sintered ex panded polystyrene. 30 mm thick. COPERNIT S.p.A.

8 Vapor barrier layer in water proof class W1 (resistance to a water column pressure of 20 cm for a duration of 2 hours) in accordance with the provisions of UNI EN 13984 and UNI EN 13859-1, with guaranteed even after the UV / IR aging tests required by UNI EN 1296

NGM MILAN E.N 58

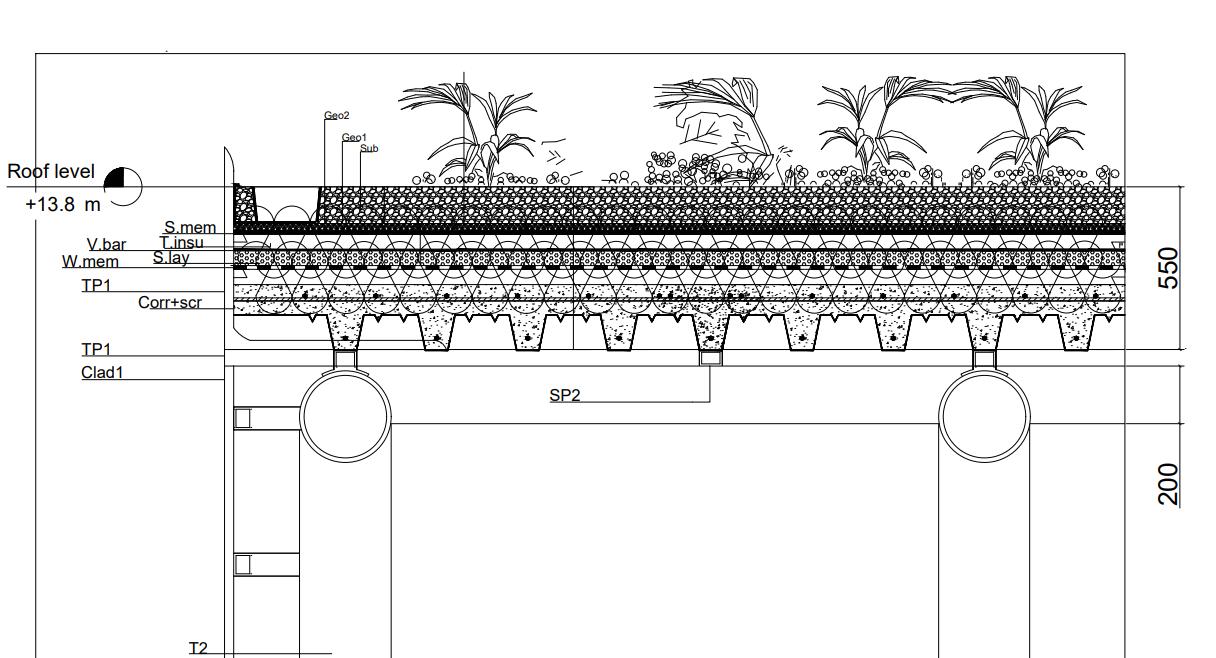

1 3 5 6 7 Corr+scr 550 IPE500550 27 15 15 4 2 8 9 SLAB DETAIL 1-50 220Scr Connecting Oticplacode Pav TP1 Clad1 T1 550 200 400 Geo1 Sub Geo2 S.mem T.insuV.bar S.lay Corr+scr W.mem T2 TP1 SP2 300 200 1 2 3 4 5 6 A B C D E F G First floor +6.00 Roof level Ground floor +13.7 Roof level +13.8 m First floor +6.00 m A12 10GREEN ROOF DETAIL 1-50

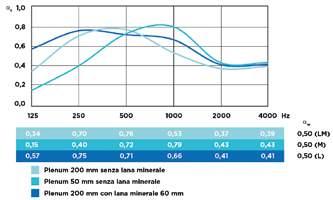

EXTENSIVE SYSTEMS

Extensive systems are roofs built mainly with an ecological func tion in mind, to improve living comfort, and are rarely usable spaces. Nowadays, they often host a solar, thermal or electro voltaic system which improves efficiency.

Extensive systems are built with prostrate or creeping plants, suit able for growing in thin layers of substrate.

The load on the building is re duced and suitable for almost all building types.Maintenance is reduced and irrigation is optional (to be evaluated in particular cli mate zones).

NGM MILAN 59 TYPE OF GREENING Semi intensive with turf. Intensive with perennials, trees and shrubs. STRUCTURAL STRENGTH OF THE BUILDING 250 350 kg m2 RUNOFF COEFFICIENT 0,3 0,5 NOTES High ecological interest with abundance of species. Possible fruition

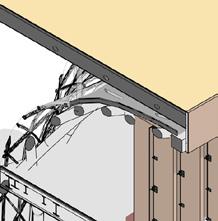

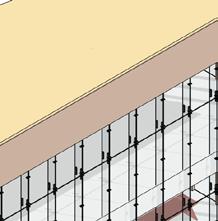

Raft Foundation -7000 Excavation -7300 Underground Level -5000 oorGroundf Level 0 Level1st +6000 Roof Level +13800 3 2 1 0 T1 S1 S5 S2 S2 T1 IPE 500 HEB 550 T2 S4 Cod. Technical Elem.M aterial Dim. TP1 Tubular profile 100x100 mmsteel Gla.p double glazed glass Af1 T=50 mm aluminum Glass panel Aluminum frame 1 T=120 mm SF2 steel T=20 mmSteel frame 2 SF1 steel T=160 mmSteel frame 1 T2 steelTube 2, secondary structure R=20 cm C.Alu ACPComposite Aluminum Panel T=50 mm NGM MILAN 61 COLUMN CLADDING DETAIL 1:100

DEATIL SECTION Detail 1:20 3 1 20 16 95 120 500 335 86 8016 44 32 140 229 Sub Geo1 Geo2 TP1 S.mem T.Insu V.bar Corr+scr W.mem S.lay Sp2 Sp1 Pav1 RF Corr+scr 250 168 1100 T2 200 800 200 650 300 550 IPE 500 IPE 500 HEB 550 T1 T1 C.Alu Gla.p Af1 NGM MILAN E.N 62

Cod. Technical Elem.M aterial Dim.s TP1 Tubular profile 100x100 mmsteel Gla.p double glazed glass Af1 T=50 mm aluminum Glass panel Aluminum frame 1 T=120 mm SF2 steel T=20 mmSteel frame 2 SF1 steel T=160 mmSteel frame 1 T2 steelTube 2, secondary structure R=20 cm C.Alu ACPComposite Aluminum Panel T=50 mm COLUMN CLADDING DETAIL 120 160SF1 SF2 T2 C.Alu Corr+scr NGM MILAN 63

STRUCTURAL DESIGN

LOAD

design Continuous beam design Column design

NGM MILAN E.N 64

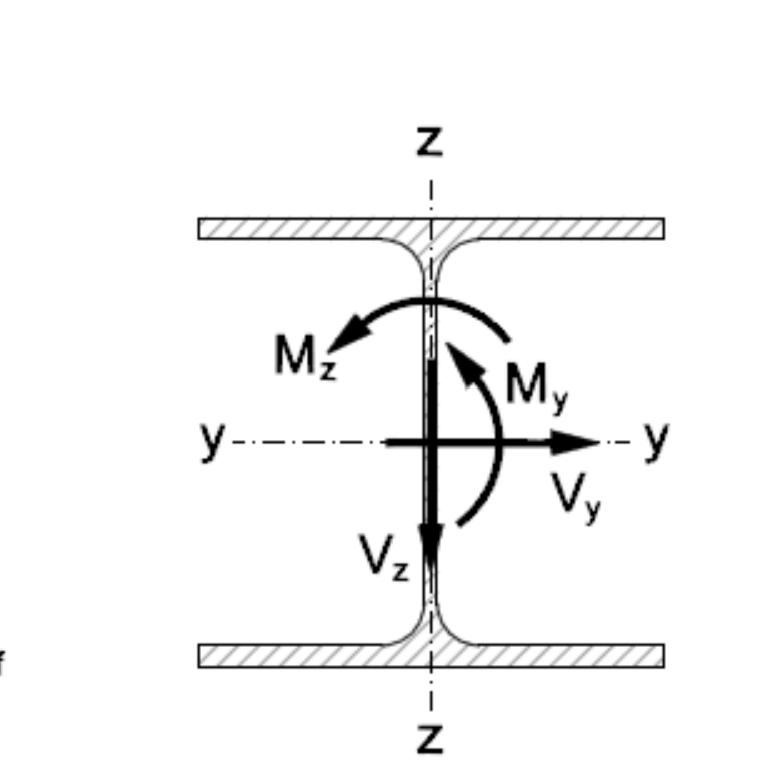

INTRODUCTION STRUCTURAL DRAWINGS STRUCTURAL

CALCULATIONS Slab

SPECIAL STRUCTURAL SYSTEM CASE STUDY

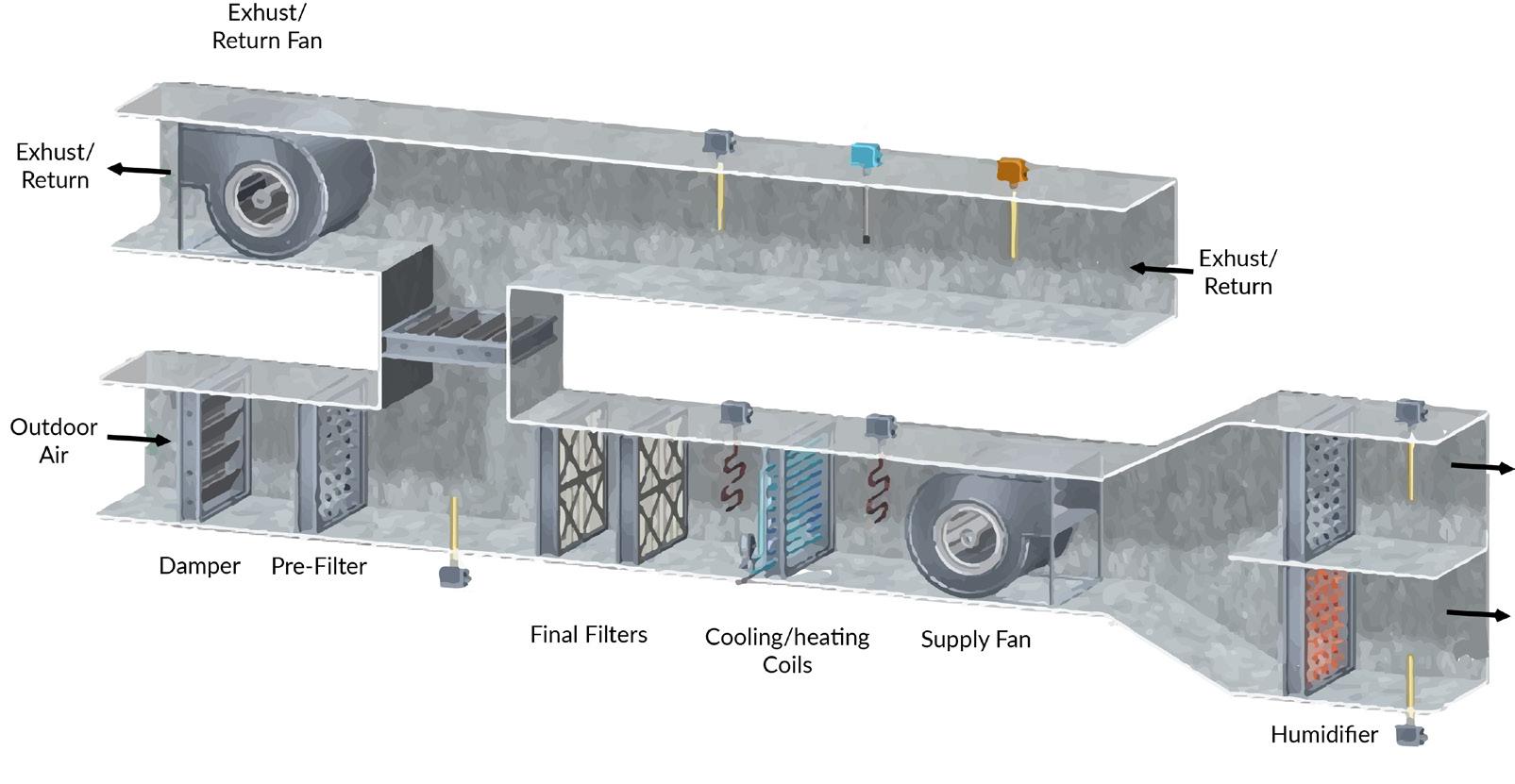

INTRODUCTION

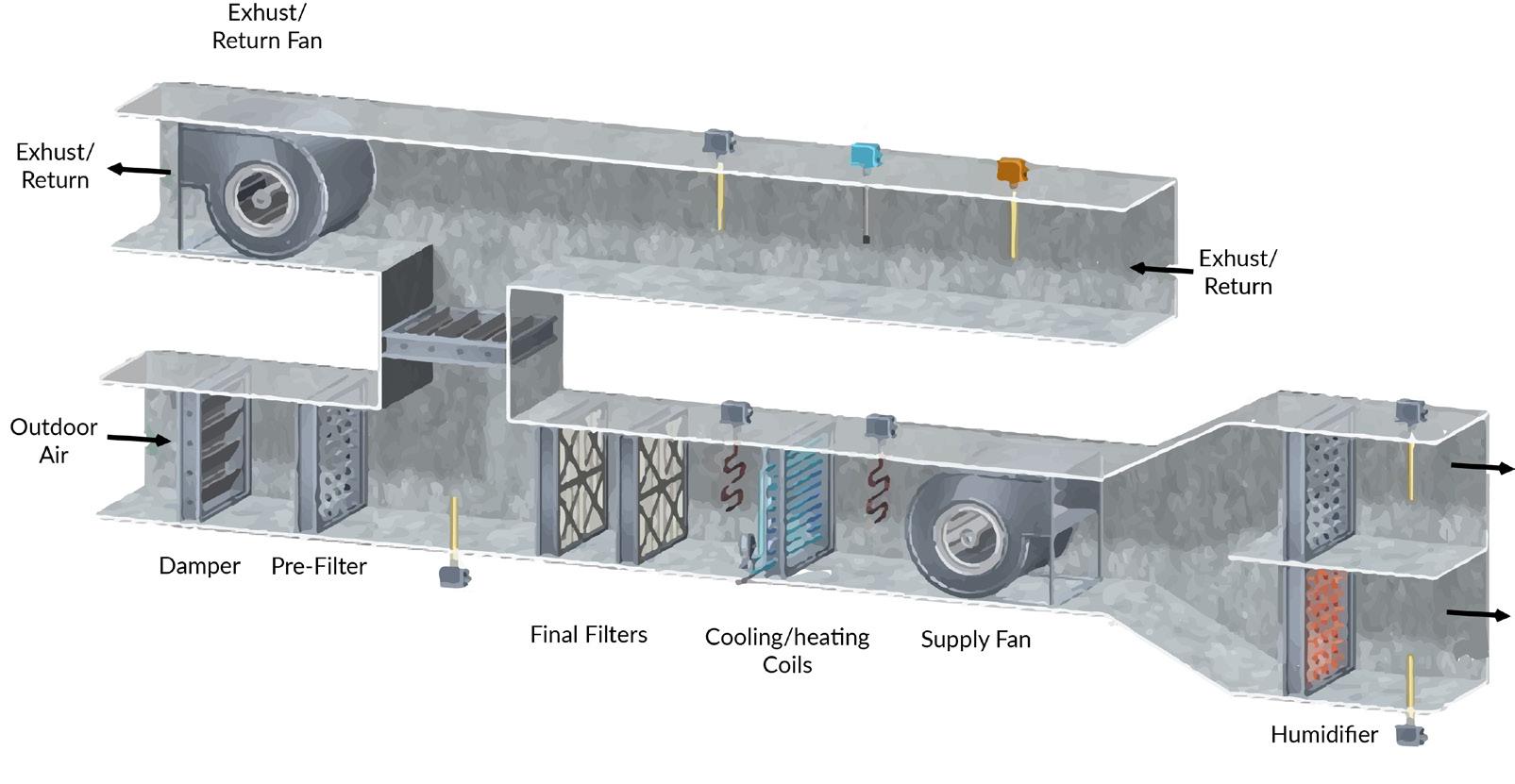

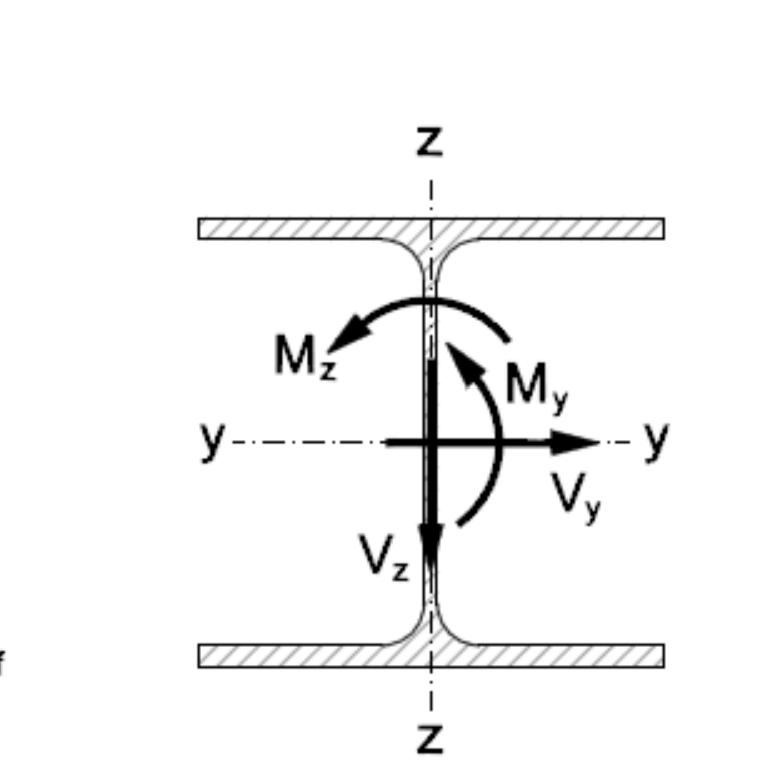

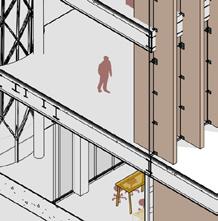

The project’s concepts Is demon strating how the architectural and structural systems integrate, reaching the final result of spaces which are not only visually intri guing but also using new tech nologies to enhance structural performances. Throughout the process of the design, The struc tural development and the archi tecture go hand in hand, chan ging and developing according to both structural and architectural needs.

New Gate Milano is a mixed -program which combines Lib rary, Museum, Exhibitions, and Laboratories. It is designed for in specific area in MIND innovation district in city of Milano in Italy.

The building is approximately 13,804 m² ,Which in three levels of facility provides a wide range of services such as experience are as including VR technology, Free movement museum, a book-len ding library, laboratories(open to public), an Amphitheater, indoor and outdoor gardens, and coffee shops.

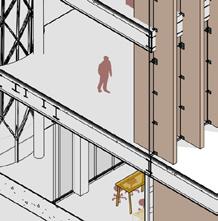

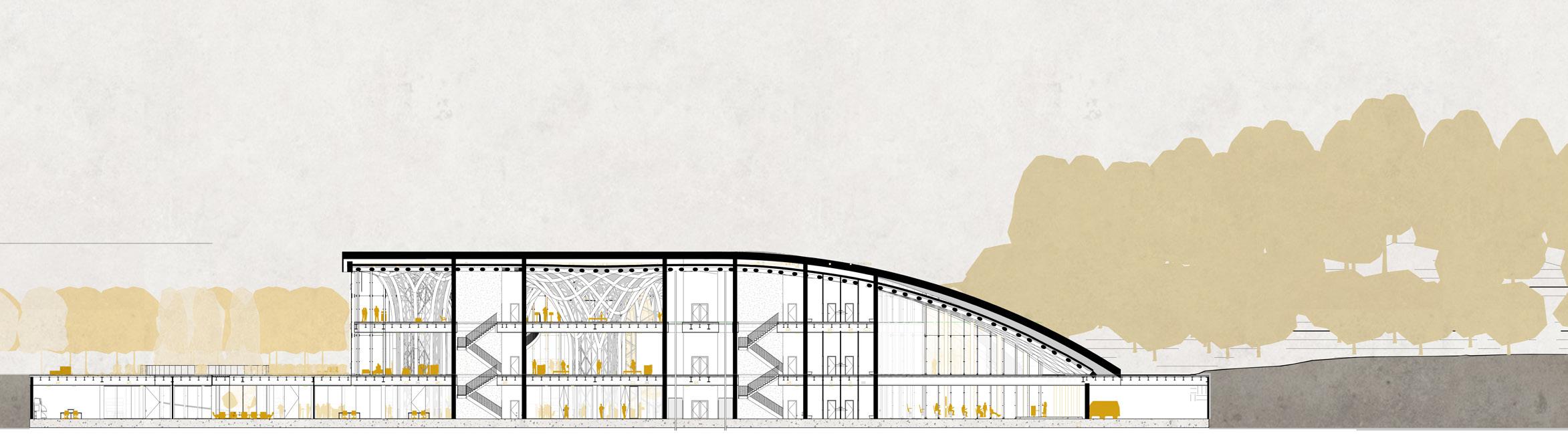

All 3 platform (one of which is underground) are supported by big scale columns systems which have 3 functions: structural sup port, ventilation, and light pe netration into the building. The challenge we faced throughout the structural design was to allow the main structural support to be the anchor points, creating as much free space as we could on the upper floors were the exhi bition and library are located.

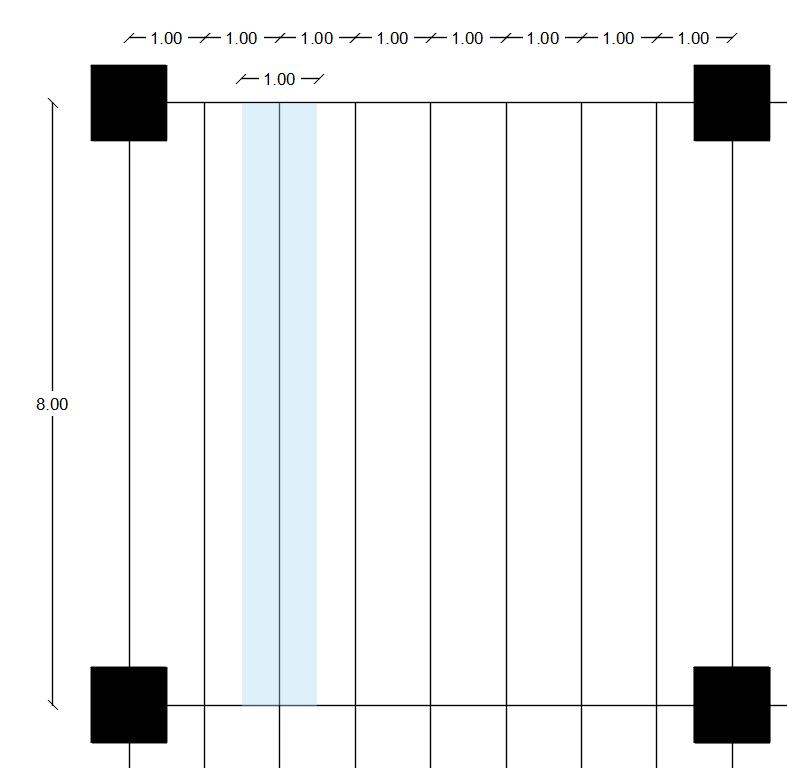

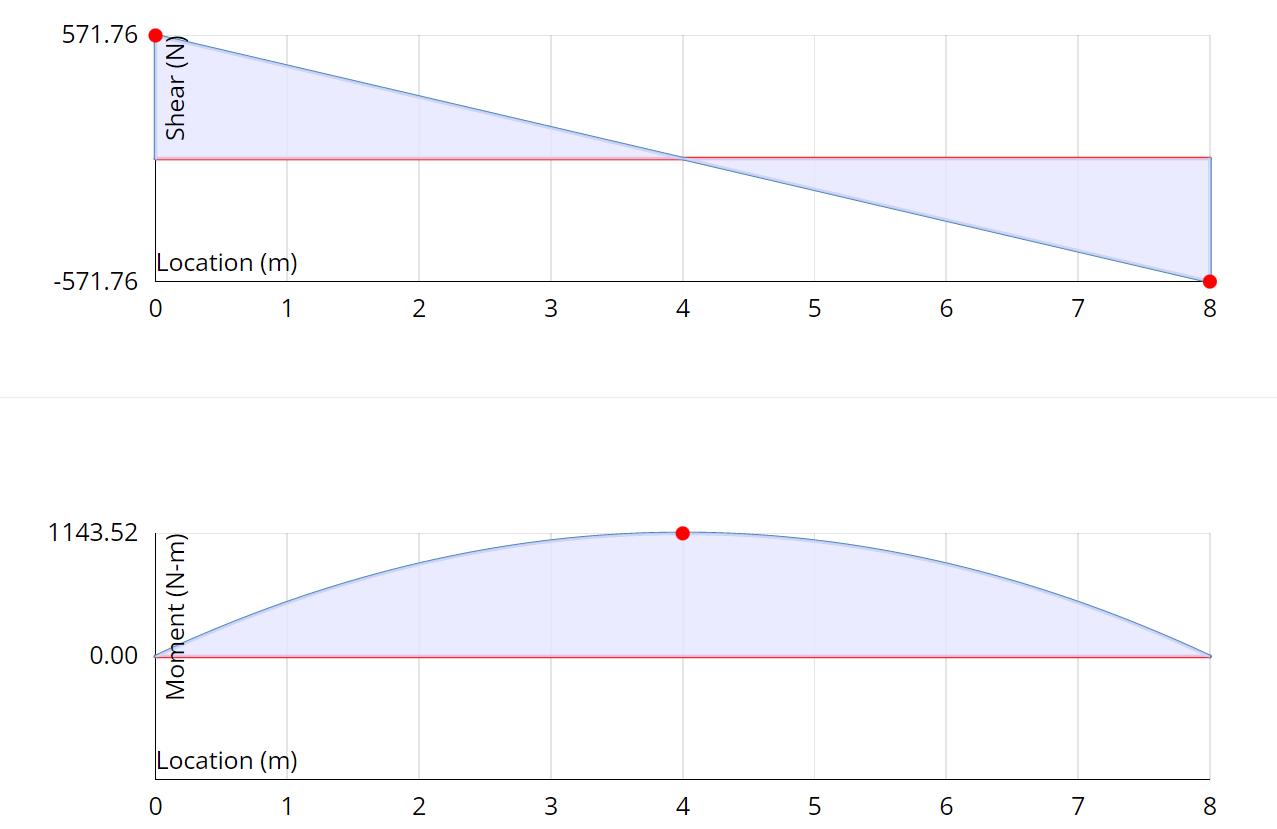

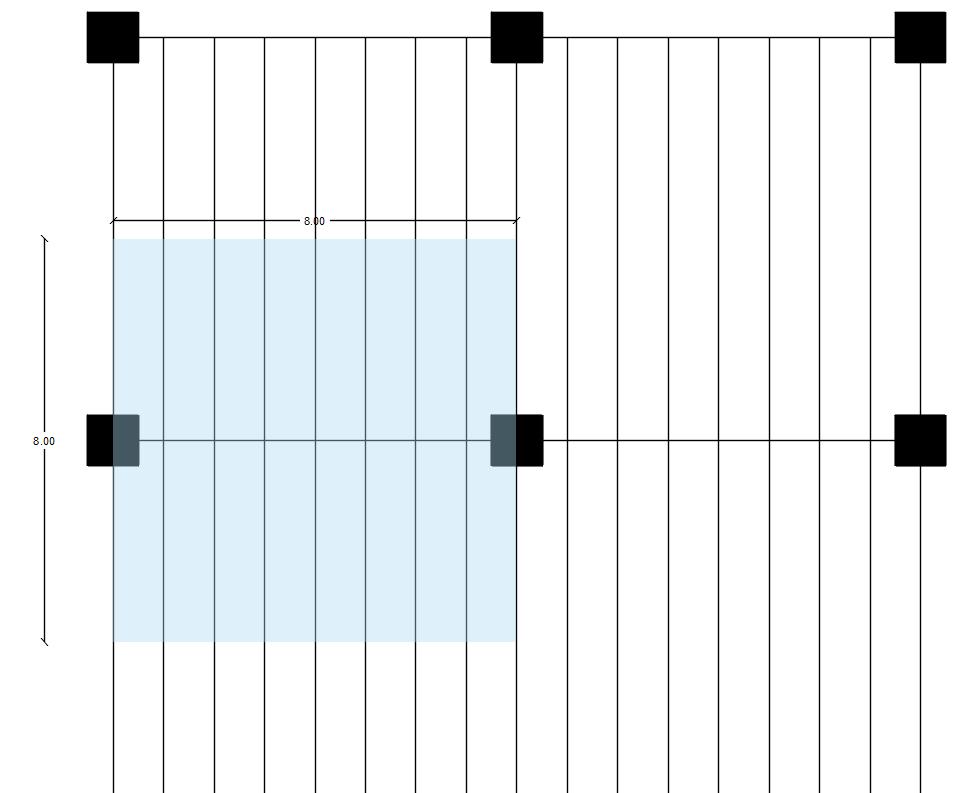

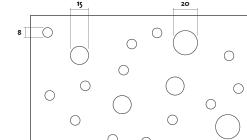

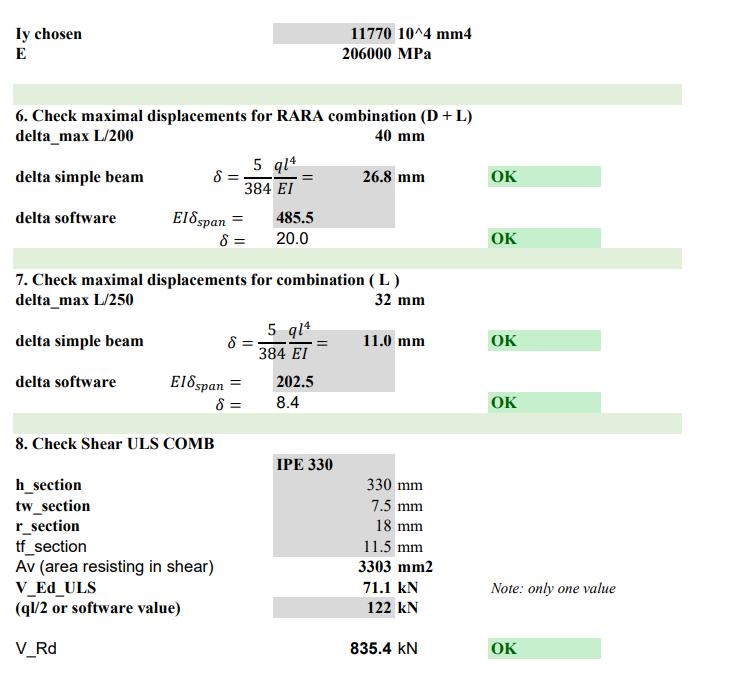

TYPICAL DIMENSIONS

The boundary of the building is a trapezoid with lengths of 104/48m and with approxima tely 3686 sqm foot print.

Each level floor area is as follows: 1- Underground: 7256 m² 2- Ground level: 3642 m² 3- First floor: 2906 m²

The building has three types of structural systems integrated with each other. The main one is The truss/tree columns (anchor points) integrated with the roof’s

structure. The second is the combination of a honey comb slab structure and regular beams structure of the slabs. the third one is more of a regular struc tural system which is located underground and in the external laboratories part.

All of these different structural systems are divided by grids of 8 meter. The height of each flo or considering the slab thickness is 6m(the ground floor’s height is 5m) . Thus the total height of the building is 12m above ground.

HOW DOES THE STRUCTURE WORK?

The truss/tree column bear the load of all slabs and roof by using a system of arches. Thus, in some parts of the structure the arched shape of the single elements gi ves a hand to the load bearing system. Almost all the back part of the building is self supported thanks to the arched shaped of the structure in this area.

NGM MILAN 65

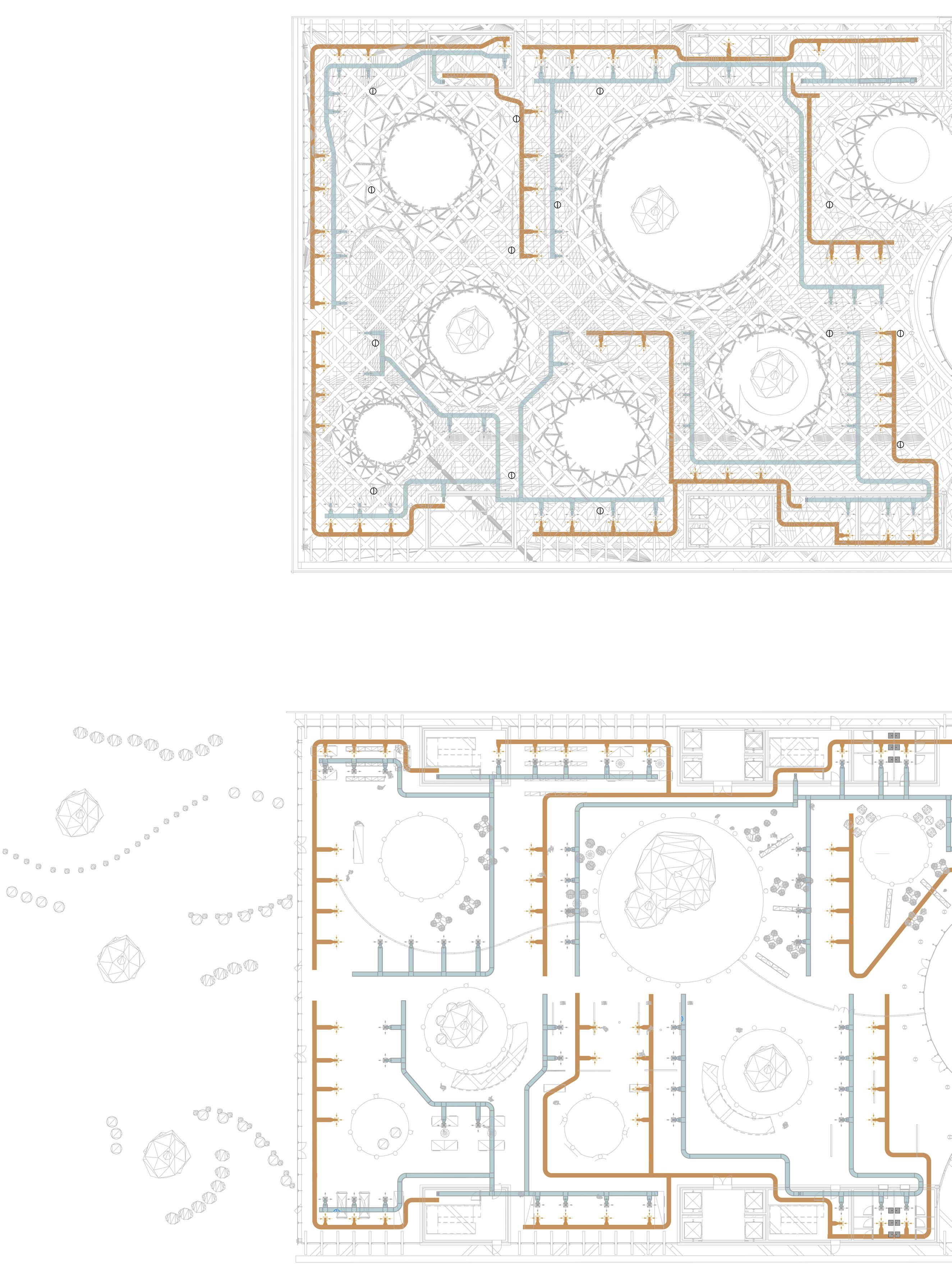

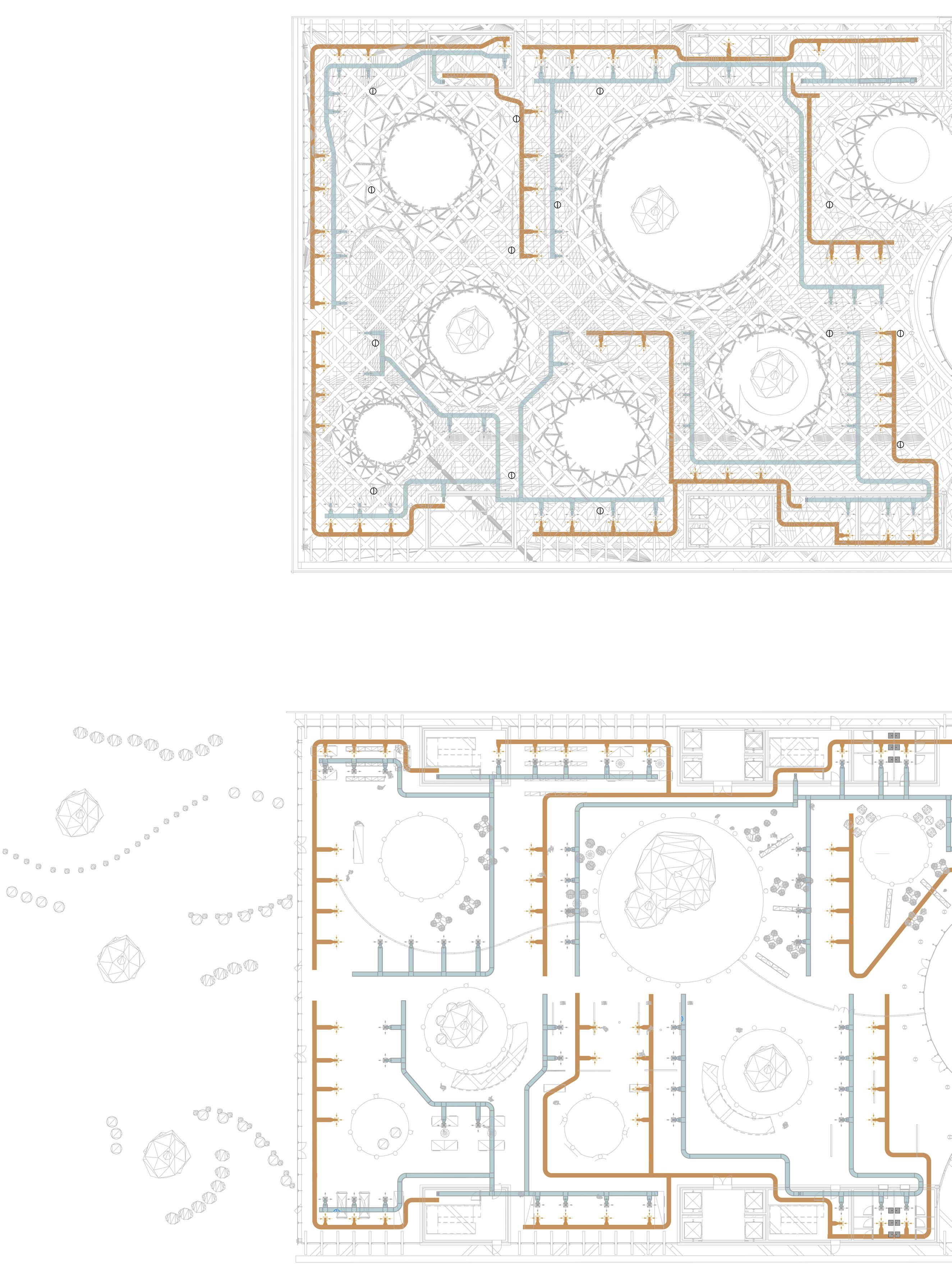

NGM MILAN E.N 66 STRUCTURAL DRAWINGS Steel pipes 400 mm R Framing system IPE500 Shear walls 400 mm Underground steal columns HEA500/300

Snd

B C D E F G H I J 21 3 4 5 6 7 8 9 10 Pav2 Scr2 Pop Sct V.Cl Cod. Technical Pavement Screed Extruded panel Isocal screed systems Ventilated cavity Finishing foundation Fsl Waterproofing membrane W.mem Snd Sand Hc Hard WallW1 Insu Insulation 0 202 100 1000 390 160 160 85 20 165 200 200 200 200 200 200 30050 50 W2 W2 200 200 200 200 300 50 50 200 0 400 0 Raft Foundation -7000 Underground Level -5000 Raft Foundation -7000 Underground Level -5000 200 200 200 200 200 200 200 90 200 200 200 200 200 90 90 90 1000 50 50 Pav2 Scr2 Pop Sct Fsl V.Cl Rft.F Rft.F W2 Rft.F Raft Hc Snd W.mem A3 4 A4 4 A5 4 Pav2 Scr2 Pop Sct V.Cl Cod. Technical Elem.M aterial Elem Cod. Dimensions Pavement Screed Extruded polysterene panel Isocal formworks screed with transit for systems cavity with Iglu’® Plus Finishing slab Ceramic Concrete Polysterene Concrete Reinforced Concrete C25 W=12 cm W=6 cm W=10 cm W=8 cm W=27 cm W=5 cmFsl membrane W= negligibleW.mem

Sand layer Sand W=10 cm Hc Hard core layer Concrete W=20 cm Wall 1, retaining wall W= 40 cm, H=5 m W1 W=10 cmInsu Reinforced Concrete C25 H=1 mC25Reinforced Concrete NGM MILAN 67 UNDERGROUND COLUMNS FOUNDATION 1:50

21 3 4 5 6 7 8 9 10 A B C D E F G H I J 21 3 4 5 6 7 8 9 10 20 Raft Foundation -7000 Excavation -7300 Underground Level -5000 Raft Foundation -7000 Excavation -7300 Underground Level -5000 A6 5 A7 5 A8 5 A9 5 20 2 0 0 200 100 1000 90 90 200 200 1604 160 85 20 110 45 1560 800 T1 Sct 200 100 1000 90 90 200 200 390 160 160 85 20 Pav2 Scr2 Pop Sct V.Cl Cod. Pav2 Scr2 V.Cl Snd Hc Sct V.Cl Snd Hc Pop Pop Pav2 Scr2 C1 C1 Pl.C T1 Pl.T 800 W.memW.mem Fsl W.mem Snd Hc Sub Geo1 T.insu Geo2 V.bar S.lay Sub Geo1 Geo2 T.insu S.lay Pl.T T1 Pl.C C1 1100 1100 110 110 2 1100 110 Pl.T Pl.C 715 715 Fsl Fsl165 230 250 230 390 165 230 250 230 Rft.F Rft.FRft.F PARAMITRIC COLUMNS FOUNDATION1:50 NGM MILAN E.N 68

21 3 4 5 6 7 8 9 10 A B C D E F G H I J 21 3 4 5 6 7 8 9 10 Raft Foundation -7000 Excavation -7300 Underground Level -5000 A11 5 0 200 100 1000 390 160 160 85 20 Pav2 Scr2 Pop W.mem Hc Snd K K 1 Sct Fsl V.Cl W1 Insu Dr 200 200 200 200 200 200 200 200 270 45 W.mem 165 A10 5 200400 W1 200 300 50 50 200 200 135 50 50 400 440 Pav2 Scr2 Pop Sct V.Cl Cod. Technical Pavement Screed Extruded panel Isocal screed systems Ventilated cavity Finishing foundation Fsl Waterproofing membrane W.mem Snd Sand Hc Hard WallW1 Insu Dr Insulation Municipality Rft.F Raft PERIMETER COLUMNS FOUNDATION1:50 Snd Sand layer Sand W=10 cm Hc Hard core layer Concrete W=20 cm Substrate H=6 cmSub Draining geocomposite H=2 cmGeo1 H=3 mmGeo2 H=10 cmT.insu Draining geocomposite Slope layer H=10 cmS.lay Slope layer according to UNI 8627 Pl.T Column plate Steel R=60 cm T1 Tube 1 Steel D=40 cm, r=20 cm Pl.C Column plate Steel W=20 cm, H=20 cm C1 Column 1 Steel HEA 500 H=1 mReinforced Concrete C25 Cod. Technical Elem. Material Elem Cod. Dimensions NGM MILAN 69

B C D E F G H I J K L M N 21 3 4 5 6 7 8 9 10 O 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 A B C D E F G H I J K W1 C1 C1 C1 C1 C1 C1 C1 C1 C1 W2 W1 W1 C1 C1 C1 C1 C1 C1 C1 C1 C1 C1 W1 C1 C1 C1 C1 C1 C1 C1 C1 C1 C1 C1 C1 C1C1 C1 C1 C1 C1 C1 C1 C1 C1 C2 C2 C2 C2C2 C2 T1 T1 T1T1 C2 C2 W1 8000 8000 8000 8000 8000 8000 8000 8000 8000 8000 112000 152000 8000 8000 8000 8000 8000 8000 8000 8000 8000 8000 80000 3530 1640 2500 2670 2750 2500 5170 4980 3020 4000 4000 4000 4000 3400 2920 3400 2920 4000 4000 2820 2930 2830 35301640 2500 2670 2750 2500 5170 4980 3020 R6720 R3850 R3850 W1 W2 W1 L8 3 L6 3 L6 3 C1 C2 C3 T1 W1 W2 IPE 500 IPE 330 HEB 550 Cod. column 1 column 2 column 3 tube 1 wall 1, retaining wall wall 2, concrete core secondary beam secondary beam primary beam Technical Element steel steel Concrete Material C25 C25 IPE 500 IPE 330 HEB 550 Element Code HEA 500 HEA 500 HEA 300 d = 40 cm, r = Dimensions Concrete steel steel steel steel steel w = 40 cm, r = w = 40 cm, r = H = 55 cm, W H = 50 cm, W H = 33 cm, W Foundation plan 1:1000 NGM MILAN E.N 70

11 12 13 14 15 16 17 18 19 20 B C D E F G H I J K L M N O Prof. Massimiliano Nastri Architectural Design Studio for Complex Constructions 2 (A.Y. 2021-2022) Students: Eden Nimni, Marianne Esses, Bita Rostamiyar Technical Drawings: Foundation localization drawing L1 Group: 11 Date: 22.06.2022 1Page: 11 12 13 14 15 16 17 18 19 20 11 12 13 14 15 16 17 18 19 20 A B C D E F G H I J K C1 C1 C1 C1 C1 W1 W2 W1 C1 C1 C1 C1 C1 C1 C1 W1 C2 C2 C2 C2 C2 C2 C2 C2 C2 C2 C2 C2 C2 C2 C2 C2 C2 T1 T1 T1 C2 8000 8000 8000 8000 8000 8000 8000 8000 8000 8000 152000 10730 2500 2750 4980 3020 29302500 2750 4980 3020 R5870 W2 W1 2830 2080 C2 C2 C2 1606 1501 A4 1 L8 3 L6 L6 20 cm Dimensions = 5 m = 17 m = 21 cm = 20 cm = 16 cm C1 C2 C3 T1 W1 W2 IPE 500 IPE 330 HEB 550 Cod. column 1 column 2 column 3 tube 1 wall 1, retaining wall wall 2, concrete core secondary beam secondary beam primary beam Technical Element steel steel Concrete Material C25 C25 IPE 500 IPE 330 HEB 550 Element Code HEA 500 HEA 500 HEA 300 d = 40 cm, r = 20 cm Dimensions Concrete steel steel steel steel steel w = 40 cm, r = 5 m w = 40 cm, r = 17 m H = 55 cm, W = 21 cm H = 50 cm, W = 20 cm H = 33 cm, W = 16 cm NGM MILAN 71

GROUND FLOOR STRUCTURE 1:1000 SECTIONL8/3 1:1000 NGM MILAN E.N 72 K L M N 21 3 4 5 6 7 8 9 10 O 5 6 7 8 9 104321 3 1 2 3 0 8000 8000 8000 8000 8000 8000 8000 8000 8000 8000 136000 T1 W2 W2 W1 T1 W2W2 21 3 4 5 6 7 8 9 10 A B C D E F G H I J K L 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 A B C D E F G H I J K W1 C1 C1 C1 C1 C1 C1 C1 C1 C1 W2 W1 W2W1 C2 C1 C1 C1 C1 C1 C1 C1 C1 C1 W1 C2 C2 C2 C1 C1 C1 C1 C1 C1 C1 C1 C1 C1C1 C1 C2 C2 C2 C2 C1 C1 C1 C2 C2 C2 C2C2 C2 T1 T1 C2 C2 W1 8000 8000 8000 8000 8000 8000 8000 8000 8000 8000 112000 152000 8000 80000 W1 W2 W2W1 8000 8000 8000 8000 8000 8000 8000 8000 8000 C1 C1 T1 T1 T1 L8 3 L6 3 L6 3 IPE 330 HEB 550 HEB 550 HEB 550 HEB 550 HEB 550 HEB 550 HEB 550 HEB 550 HEB 550 HEB 550 IPE 330 IPE 330 IPE 330 HEB 550 HEB 550 HEB 550 IPE 330 IPE 330 IPE 330 HEB 550 HEB 550 HEB 550 IPE 330 IPE 330 IPE 330 IPE 330 IPE 330 IPE 330 IPE 330 IPE 330 IPE 330 HEB 550 HEB 550 IPE 330 IPE 330 HEB 550 HEB 550 IPE 330 IPE 330 HEB 550 HEB 550 IPE 330 IPE 330 HEB 550 HEB 550 IPE 330 IPE 330 HEB 550 HEB 550 IPE 330 IPE 330 HEB 550 HEB 550 IPE 330 IPE 330 HEB 550 HEB 550 IPE 330 IPE 330 HEB 550 HEB 550 IPE 330 IPE 330 IPE 330 HEB 550 HEB 550 IPE 330 IPE 330 HEB 550 HEB 550 IPE 330 IPE 330 HEB 550 HEB 550 IPE 330 IPE 330 HEB 550 HEB 550 IPE 330 IPE 330 HEB 550 HEB 550 IPE 330 IPE 330 HEB 550 HEB 550 IPE 330 HEB 550 HEB 550 HEB 550 HEB 550 HEB 550 HEB 550 HEB 550 HEB 550 HEB 550 HEB 550 IPE 330 HEB 550IPE 330 HEB 550 IPE 330 HEB 550 IPE 330 IPE 330 HEB 550 HEB 550 HEB 550 HEB 550 HEB 550 HEB 550 HEB 550 HEB 550 HEB 550HEB 550 HEB 550 HEB 550 IPE 330 HEB 550 IPE 330 HEB 550 IPE 330 HEB 550 IPE 330 HEB 550 IPE 330 HEB 550 IPE 330 HEB 550 IPE 330 HEB 550 IPE 330 HEB 550 IPE 330 HEB 550 IPE 330 HEB 550 IPE 330 HEB 550HEB 550 HEB 550 HEB 550 HEB 550HEB 550 HEB 550 HEB 550 IPE 500 HEB 550 IPE 500 IPE 500 HEB 550 IPE 500 IPE 500 HEB 550 IPE 500 IPE 500 HEB 550 IPE 500 IPE 500 IPE 500 Cod. Technical Element Material Element Code Dimensions HEB 550 HEB 550 HEB 550 HEB 550 HEB 550

NGM MILAN 73 Prof. Massimiliano Nastri Architectural Design Studio for Complex Constructions 2 (A.Y. 2021-2022) Students: Eden Nimni, Marianne Esses, Bita Rostamiyar 11 12 13 14 15 16 17 18 19 20 K L M N O Technical Drawings: Structural Sections L6 and L8 scale 1:200 1st Level Structural Plan L5 scale 1:200 Structural Louver Detail A1-2 scale 1:20 Group: 11 Date: 22.06.2022 3Page: 11 12 13 14 15 16 17 18 Raft Foundation -7000 Excavation -7300 Underground Level -5000 Groundfloor Level 0 1st Level +6000 Roof Level +13800 L8 3 8000 8000 8000 8000 8000 8000 8000 W2 W2 W1 W1 T1 W2 11 12 13 14 15 16 17 18 19 20 A B C D E F G H I J K L 11 12 13 14 15 16 17 18 19 20 11 12 13 14 15 16 17 18 19 20 A B C D E F G H I J K C1 C1 C1 C1 C1 W1 W1 C1 C1 C1 C1 C1 C1 C1 W1 C2 C2 C2 C2 C2 C2 C2 C2 C2 C2 C2 C2 C2 C2 C2 C2 C2 C2 8000 8000 8000 8000 8000 8000 8000 8000 8000 10730 W1 C2 C2 C2 T1 T1 L5 2 L8 3 HEB 550 HEB 550 IPE 330 IPE 330 HEB 550 HEB 550 IPE 330 IPE 330 HEB 550 HEB 550 IPE 330 IPE 330 HEB 550 HEB 550 IPE 330 IPE 330 HEB 550 HEB 550 IPE 330 IPE 330 IPE 330 HEB 550 HEB 550 IPE 330 IPE 330 HEB 550 HEB 550 IPE 330 IPE 330 HEB 550 HEB 550 IPE 330 IPE 330 HEB 550 HEB 550 IPE 330 IPE 330 HEB 550 HEB 550 IPE 330 IPE 330 HEB 550 HEB 550 IPE 330 IPE 330 HEB 550 HEB 550 IPE 330 HEB 550 HEB 550 HEB 550 HEB 550 HEB 550 HEB 550 HEB550 HEB 550 HEB 550 HEB 550 HEB 550 HEB 550 HEB 550 HEB 550 IPE 330 HEB 550 IPE 330 HEB 550 IPE 330 IPE 330 IPE 330 IPE 330 IPE 330 IPE 330 IPE 330 IPE 330 IPE 330 IPE 330 HEB 550 HEB 550 HEB 550 HEB 550 IPE 500 HEB 550 IPE 500 HEB 550 IPE 500

FIRST FLOOR PLAN 1:1000 SECTIONL6/3 1:1000 NGM MILAN E.N 74 5 6 7 8 9 10 11 12 13 14 5 6 7 8 9 10 11 12 13 14 5 6 7 8 9 10 11 12 13 14 C D E F G H I C D E F G H I A B C D E F G H I J K 1 2 3 0 5 6 7 8 9 10 11 12 13 1443 15 16 8000 8000 8000 8000 8000 8000 8000 8000 8000 Raft Foundation -7000 Excavation -7300 Underground Level -5000 Groundfloor Level 0 1st Level +6000 Roof Level +13800 L8 3 L6 3 L6 3 L8 3 L7 3 rectangular composite wood grain 8000 8000 8000 8000 8000 8000 48000 72000 8000 8000 8000 8000 8000 8000 8000 8000 8000 8000 80000 8000 8000 8000 8000 8000 8000 8000 8000 8000 8000 8000 8000 8000 8000 136000 C1 C2 C2 C2 C2 C2 C2 T1 T1 C2 C2 C2 T1 T1 T1 T1 T1 HEB 550 HEB 550HEB 550 HEB 550 HEB 550 HEB 550 HEB 550HEB 550 HEB 550 HEB 550 HEB 550 IPE 500 HEB 550 IPE 500 IPE 500 HEB 550 IPE 500 IPE 500 HEB 550 IPE 500 HEB 550 IPE 500 IPE 500 HEB 550 IPE 500 IPE 500 HEB 550 IPE 500 IPE 500 IPE 500 HEB 550 HEB 550 HEB 550 HEB 550 HEB 550 W2 W2 W2 W2 W2W2 W2 W2 T1 T1 T1 C1 C2 C3 T1 W1 W2 IPE 500 IPE 330 HEB 550 Cod. 6 7 8 9 10 11 12 13 14 15 5 6 7 8 9 10 11 12 13 14 5 6 7 8 9 10 11 12 13 14 C D E F G H I C D E F G H I A B C D E F G H I J K 1 2 3 0 5 6 7 8 9 10 11 12 13 144 15 16 17 8000 8000 8000 8000 8000 8000 8000 8000 8000 Raft Foundation -7000 Excavation -7300 Underground Level -5000 Groundfloor Level 0 1st Level +6000 Roof Level +13800 L8 3 L6 3 L6 3 L8 3 L7 3 L6 3 8000 8000 8000 8000 8000 8000 48000 72000 8000 8000 8000 8000 8000 8000 8000 8000 8000 8000 80000 8000 8000 8000 8000 8000 8000 8000 8000 8000 8000 8000 8000 8000 8000 136000 C1 C2 C2 C2 C2 C2 C2 T1 T1 C2 C2 C2 T1 T1 T1 T1 T1 HEB 550 HEB 550HEB 550 HEB 550 HEB 550 HEB 550 HEB 550HEB 550 HEB 550 HEB 550 HEB 550 IPE 500 HEB 550 IPE 500 IPE 500 HEB 550 IPE 500 IPE 500 HEB 550 IPE 500 HEB 550 IPE 500 IPE 500 HEB 550 IPE 500 IPE 500 HEB 550 IPE 500 IPE 500 IPE 500 HEB 550 HEB 550 HEB 550 HEB 550 HEB 550 W2 W2 W2 W2 W2W2 W2 W2 T1 T1 T1 W2 W2 W2 W2W2W2W2 C1 C2 C3 T1 W1 W2 IPE 500 IPE 330 HEB 550 Cod. column column column tube 1 wall 1, wall 2, secondary secondary primary Technical

Straight louvers serving as columns to provide extra support

EXPLODED AXO. STRUCTURAL SUP 21 3 4 5 6 7 8 9 10 11 A B C D E F G H I J K L 5 6 7 8 9 10 11 5 6 7 8 9 10 11 C D E F G H I A B C D E F G 1 2 3 0 5 6 7 8 9 10 114321 8000 8000 8000 8000 8000 8000 L8 3 L6 3 L6 3 3 A2 3 A1 3 1164 10 x 1164 mm 290 1500 160 120x200x10 rectangular steel tubes 120x200x10 rectangular steel tubes Aluminum composite panel with a wood grain pattern finish 8000 1600000 8000 8000 8000 8000 48000 72000 8000 8000 8000 8000 8000 8000 8000 80000 8000 8000 8000 8000 8000 8000 8000 8000 8000 8000 136000 C1 T1 T1 T1 T1 T1 T1 HEB 550 HEB 550HEB 550 HEB 550 HEB 550 HEB 550HEB 550 HEB 550 HEB 550 IPE 500 HEB 550 IPE 500 IPE 500 HEB 550 IPE 500 IPE 500 HEB 550 IPE 500 IPE 500 HEB 550 IPE 500 IPE 500 IPE 500 HEB 550 HEB 550 HEB 550 HEB 550 HEB 550 W2 W2 W2 W2 W2W2 T1 T1 T1 W2 W2 W2W2W2W2 T2 T1 IPE 500 HEB 550 IPE 330 HEB 550 HEB 550 HEB 550HEB 550 W1 C1 T2 T1 IPE 500 LOUVERS AS STRUCTURAL ELEMENTS NGM MILAN 75

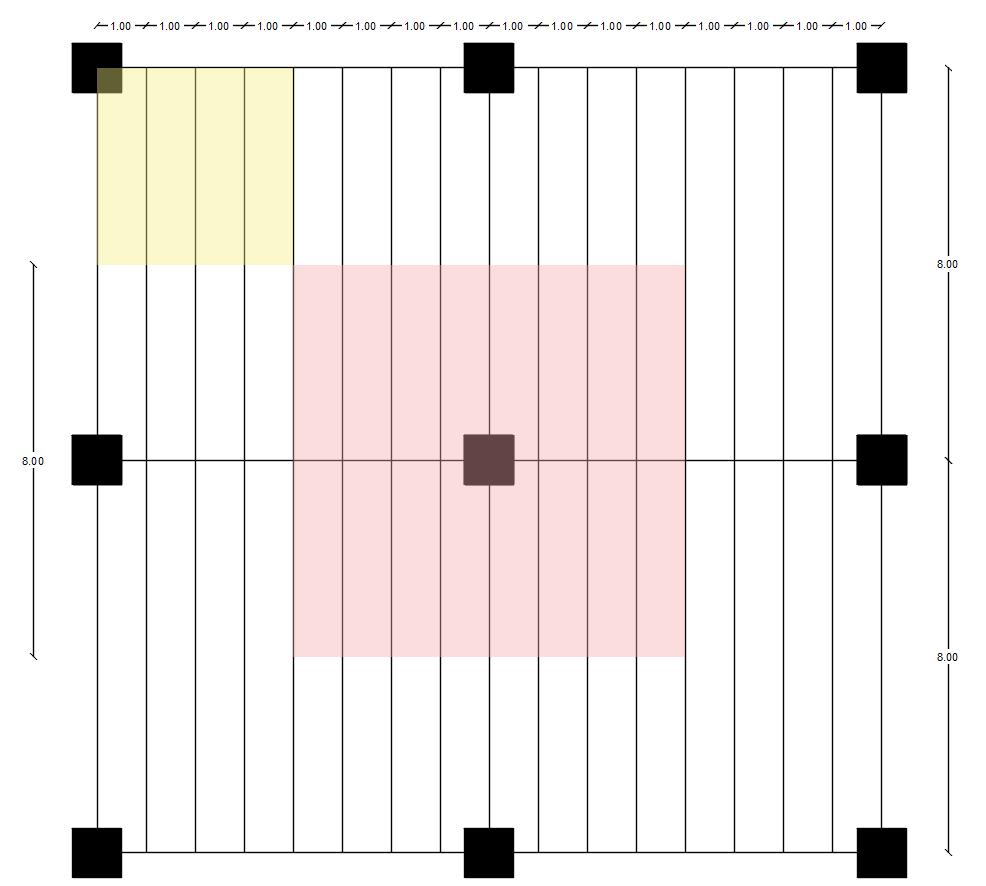

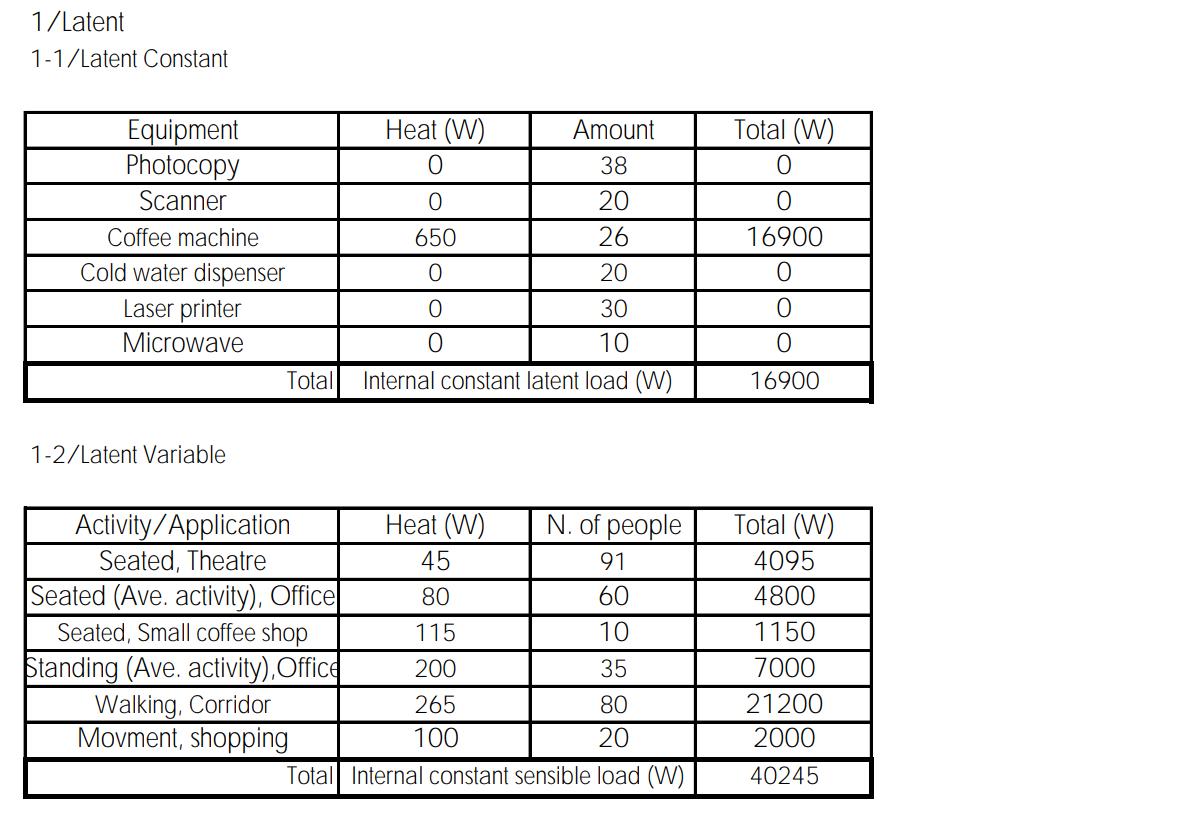

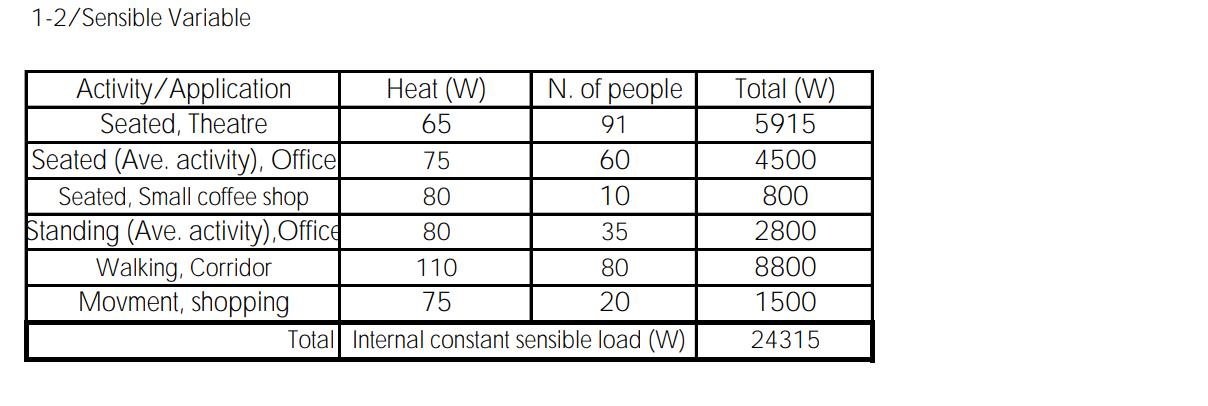

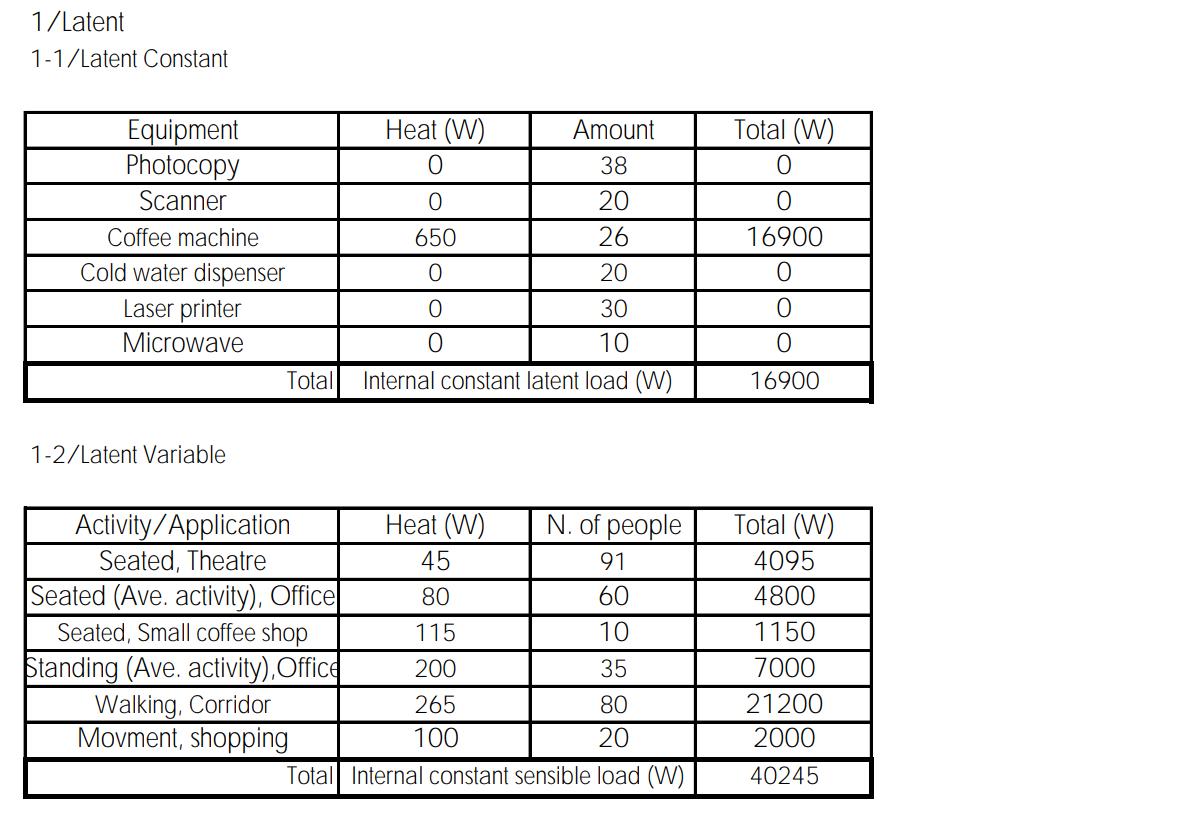

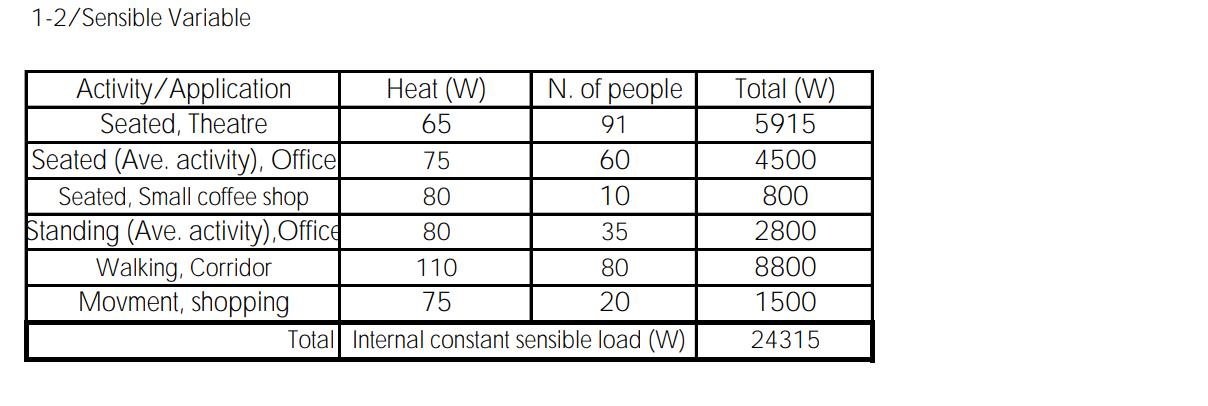

LOAD CALCULATIONS

SLAB DESIGN

NGM MILAN E.N 76

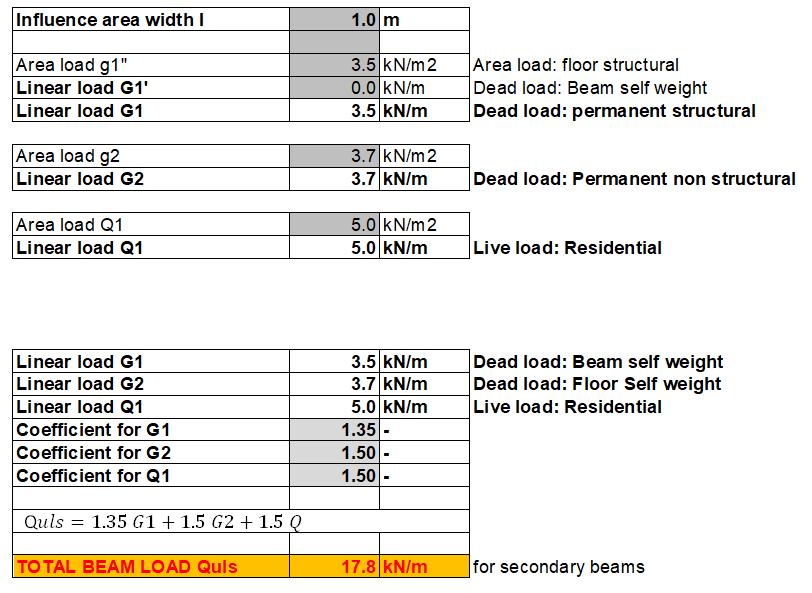

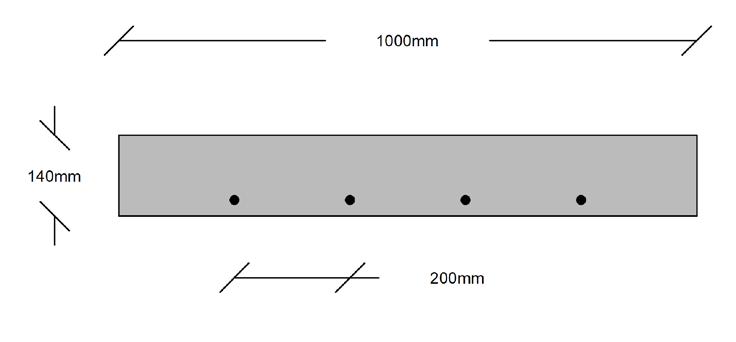

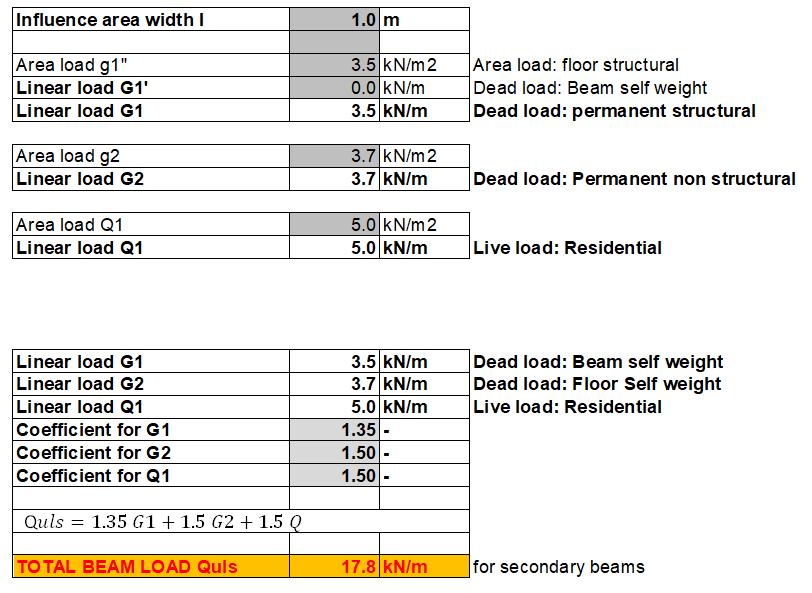

SLAB DESIGN

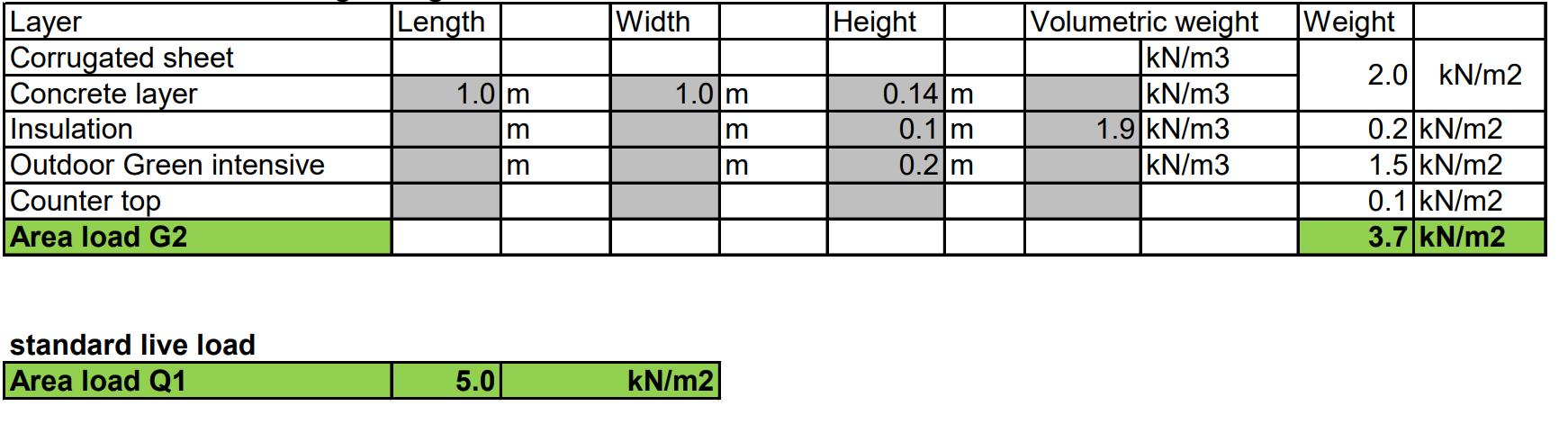

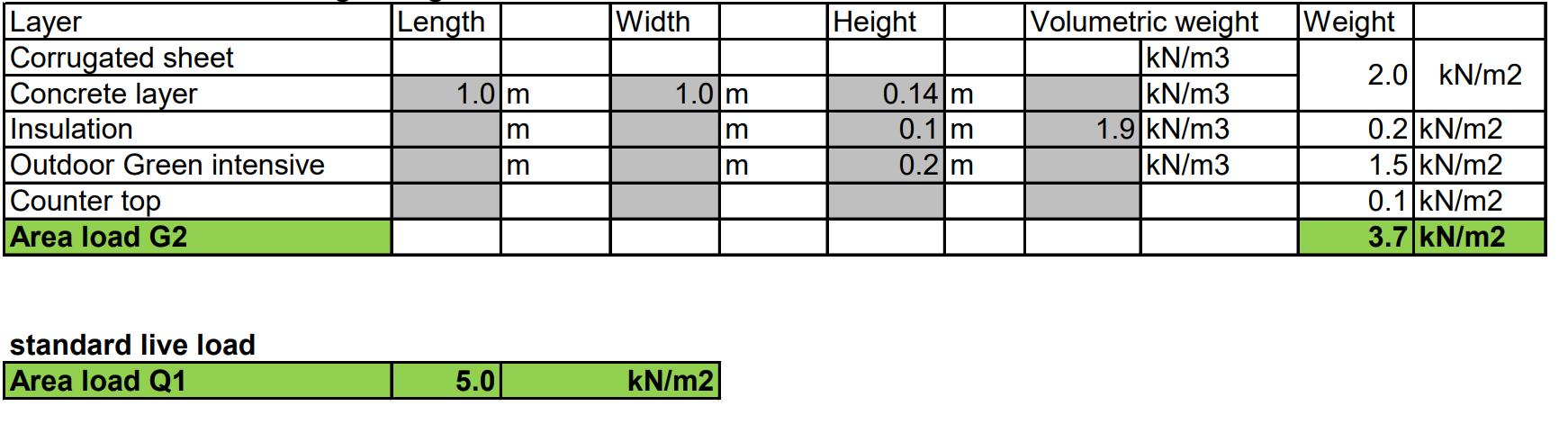

LOADS

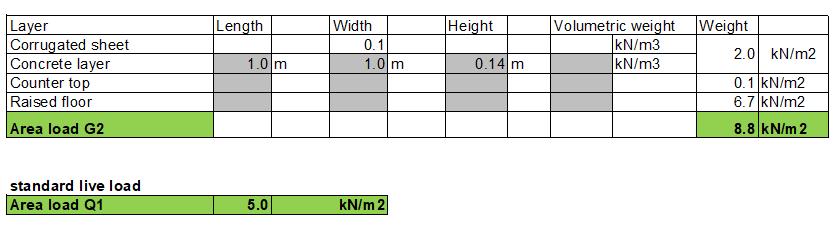

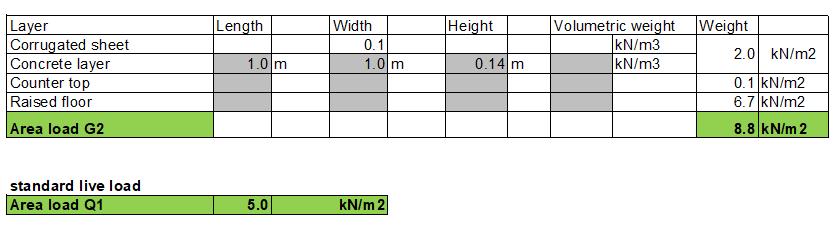

Using the rule of thumb:

Slab thickness = span/20 >> 100 / 20 = 5 cm,

As rule of thumb shows 5cm which is not acceptable, the slab thickness can be 14cm.

Total load under ultimate limite state:

With having the amount of permanent structural deat load G1, permanent structural deat load G2 and live load Q, we obtain:

Quls =1.35 G1+1.5 G2 +1.5 Q =1.35 (3.5)+1.5 (3.7) +1.5 (5) =17.8 kN/m

>>Largest bending moment: Muls = (Quls * l^2)/8 =(17.8*1)/8 =2.22 kNm

NGM MILAN 77

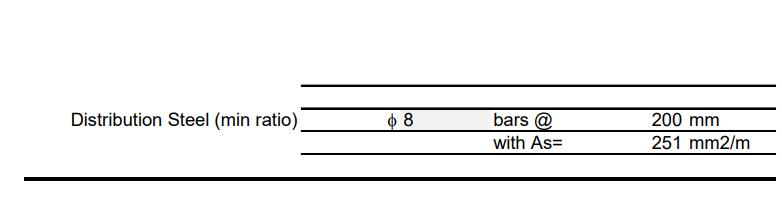

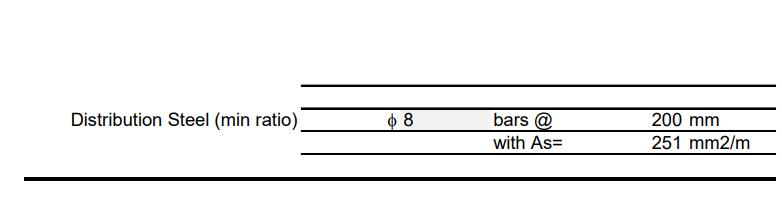

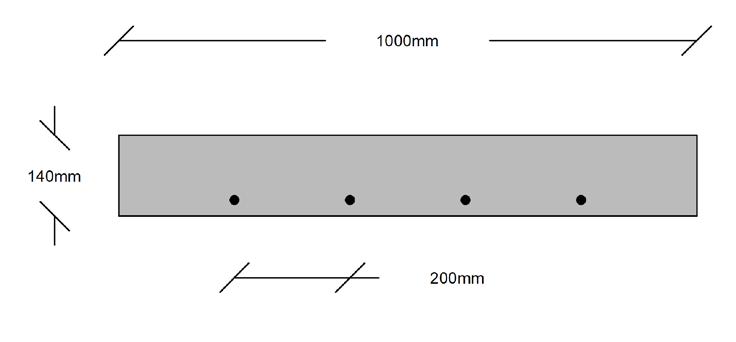

NGM MILAN E.N 78 REINFORCED CONCRETE SLAB DESIGN Module: Structures Prof. Grigor Angjeliu Academic Year 2020-2021 1. M_ED External Bending Moment Calculation M_ED_ULS 2.22 kNm 2220000 Nmm (ql^2/8 or software value) 2. Choose steel class Steel class S… 460 fyk 460 MPa γs 1.15 fyd 400 MPa 3. Choose concrete class Concrete class C… 25 fck 25 MPa γc 1.5 fcd 17 MPa 4. Beam parameters b 1000 mm usually 1/2 - 2/3 h h 140 mm usually 1/8 - 1/12 span c(cover) 25 mm bar diameter 8 mm d 111 mm effective depth 5. Section calculations 0.007 110 mm 50 mm2 Check minimum and maximum reinforcement 0.13% 4% 144.3 mm2 4440 mm2 6. Convert reinf. area into bars Bar diameter 8 mm suggestions: slab - fi 8 - fi12 mm Bar area 50.2 mm2 concrete beam fi 14mm or more Provide bars 5 per meter Provided area 251 mm2 OK bars @ 200 mm ro = A s /bd 0.23% OK 7. Check Beam Dimension 1 row Minimum width "b" 170 OK 8. Summary One way slab thickness 140 mm Tension Steel f 8 bars @ 200 mm with As= 251 mm2/m In the grey cells the numbers can be hard typed. In other cells there are already formulas. ���� = ���� ��������2 ������������ = < 0 167 ���� = ���� 0 5 + 0 25 ���� 1 134 = �������� = ���� 0 87 ������������ ���� = ����min ≤ ���� ≤ ����max , Then we put the amount of Muls = 2.22 kN/m and information about the slab such as thickness and etc to understand the if K value is oh and also the total section area of the bars.

SLAB DESIGN

NGM MILAN 79 Laboratory

part roof

LOADS

NGM MILAN E.N 80 FLOORS SLAB

ROOF

NGM MILAN 81

LOAD CALCULATIONS

CONTINUOUS BEAM DESIGN

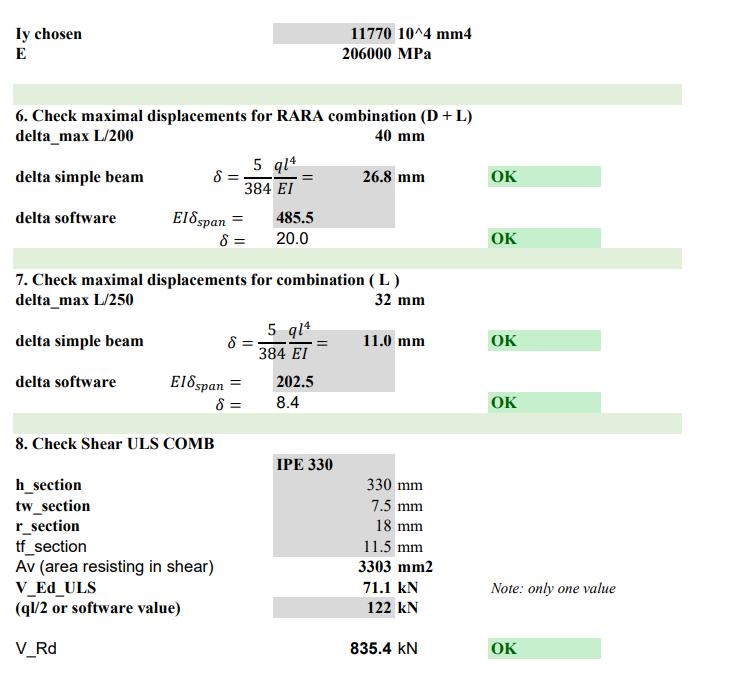

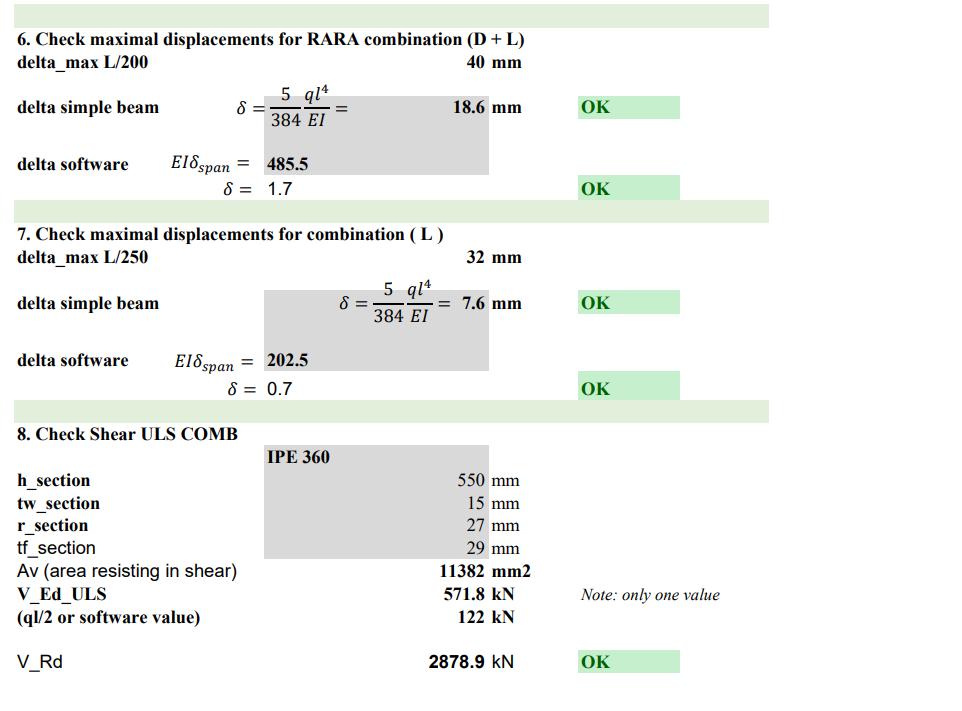

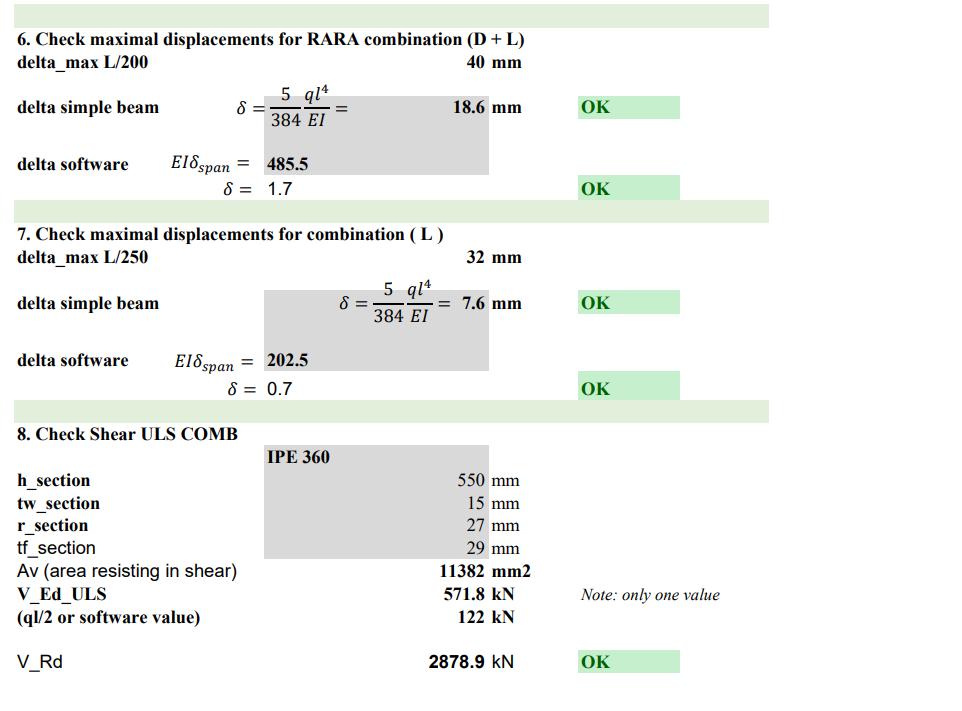

NGM MILAN E.N 82

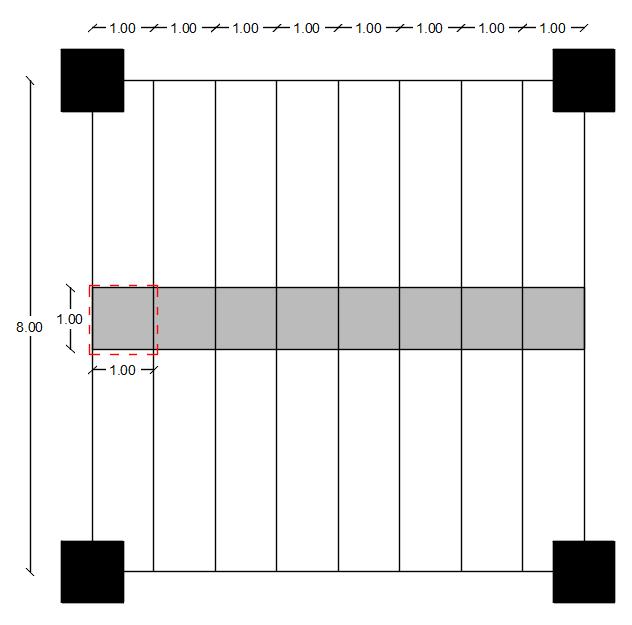

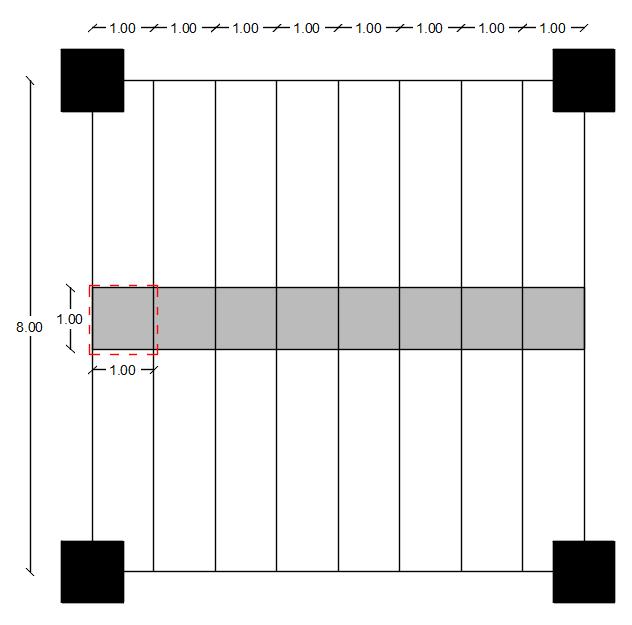

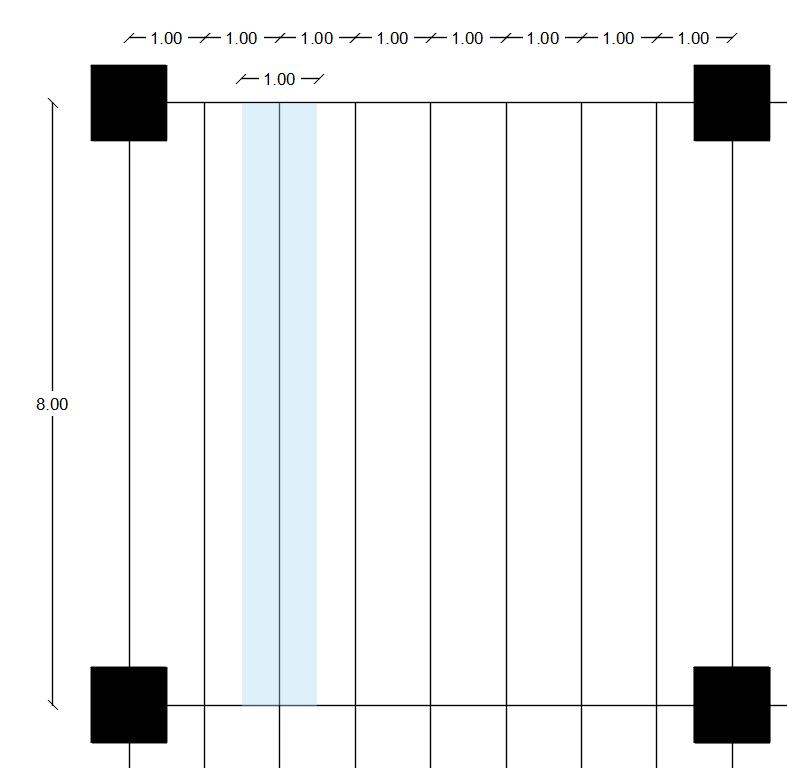

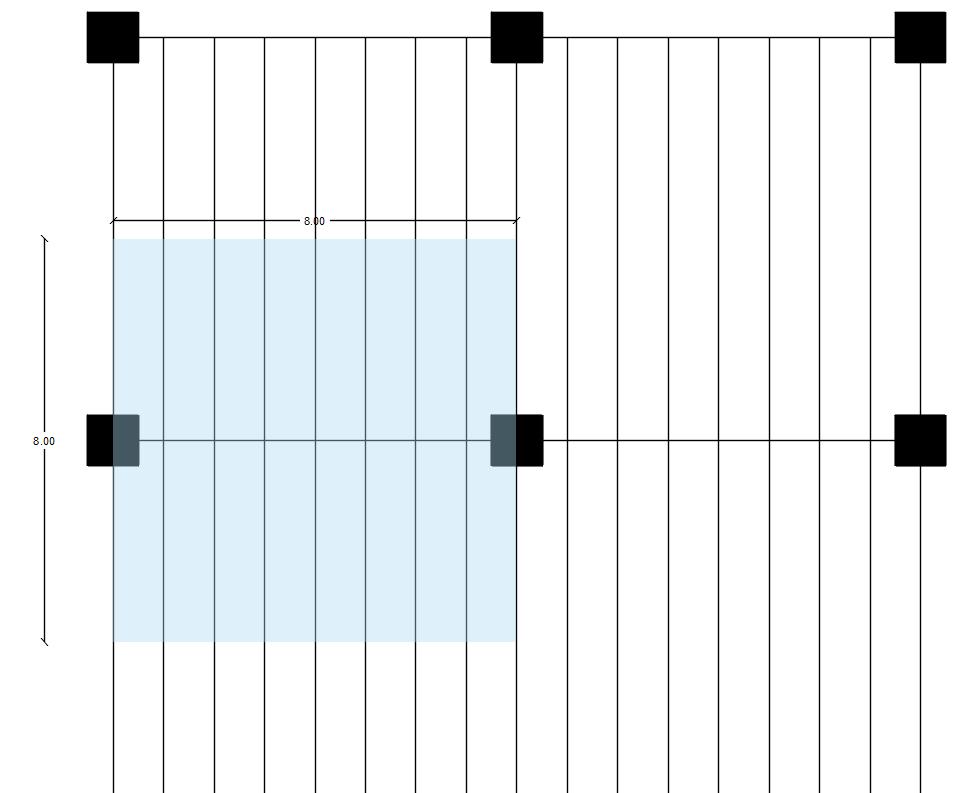

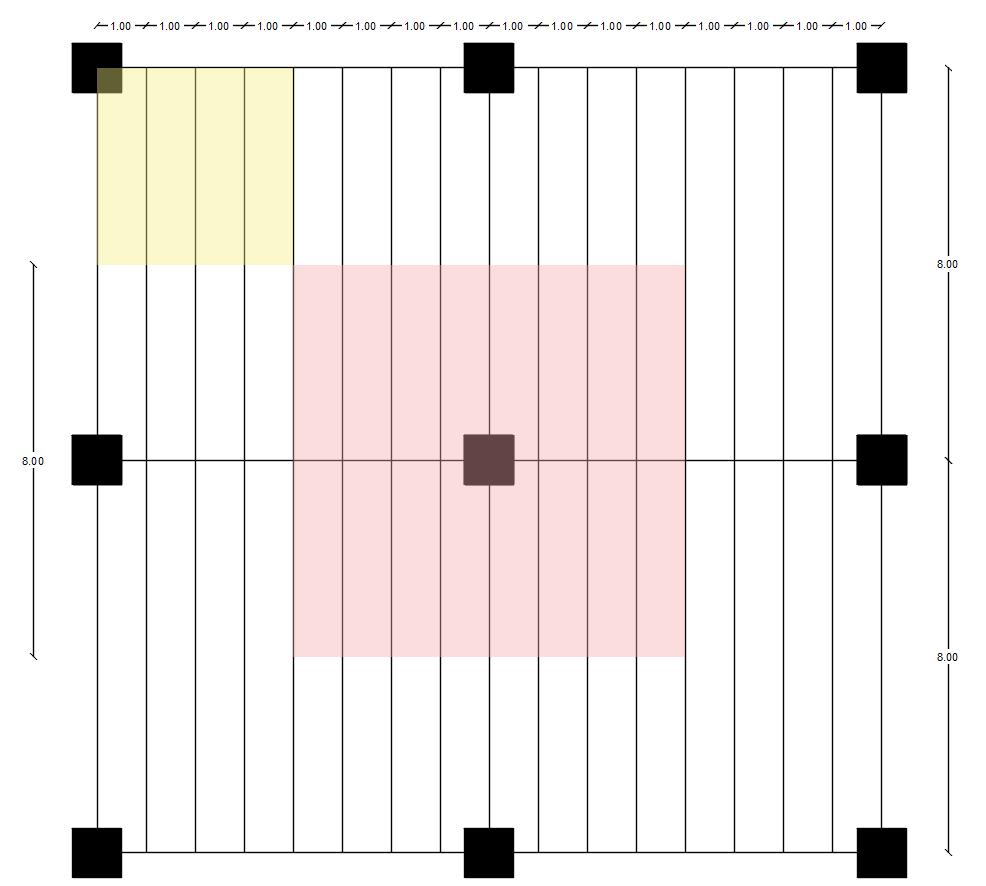

Influence area = 1m

Beam length = 8m

Calculations for the course Architectural Design Studio for Complex Constructions

Module: Structures

Prof. Grigor Angjeliu

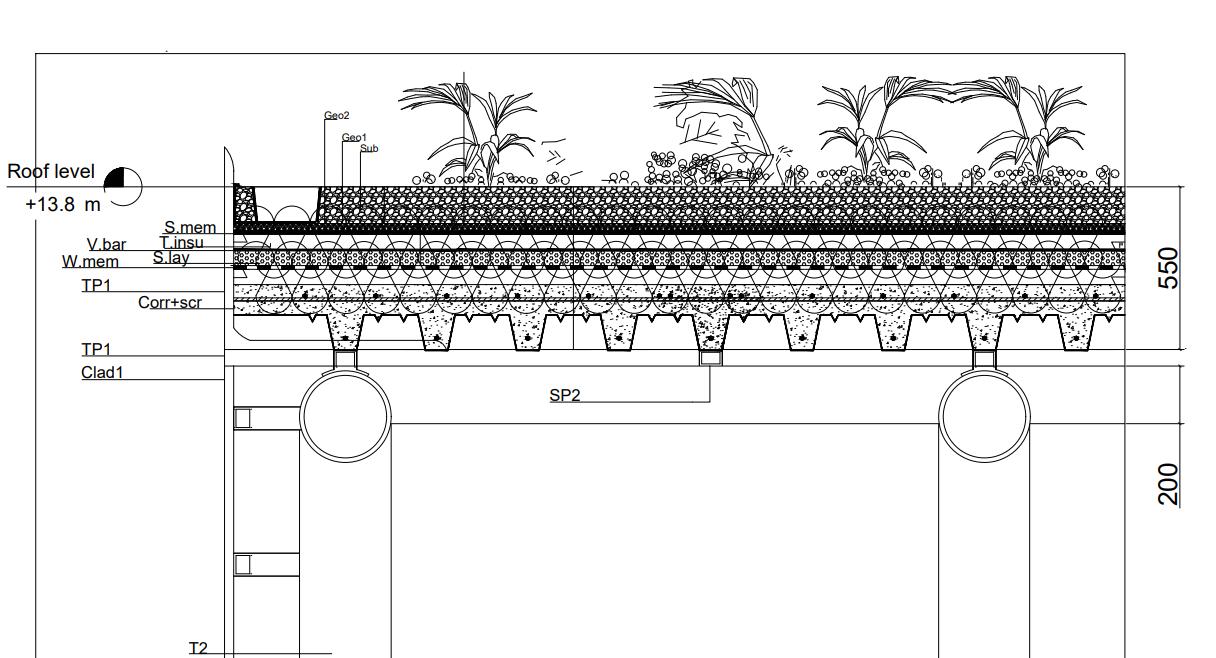

Permanent structural deat load G1 = 3.5 kN/m2 permanent structural deat load G2 = 3.7kN/m2 Live load Q = 5 kN/m2

Academic Year 2021-2022

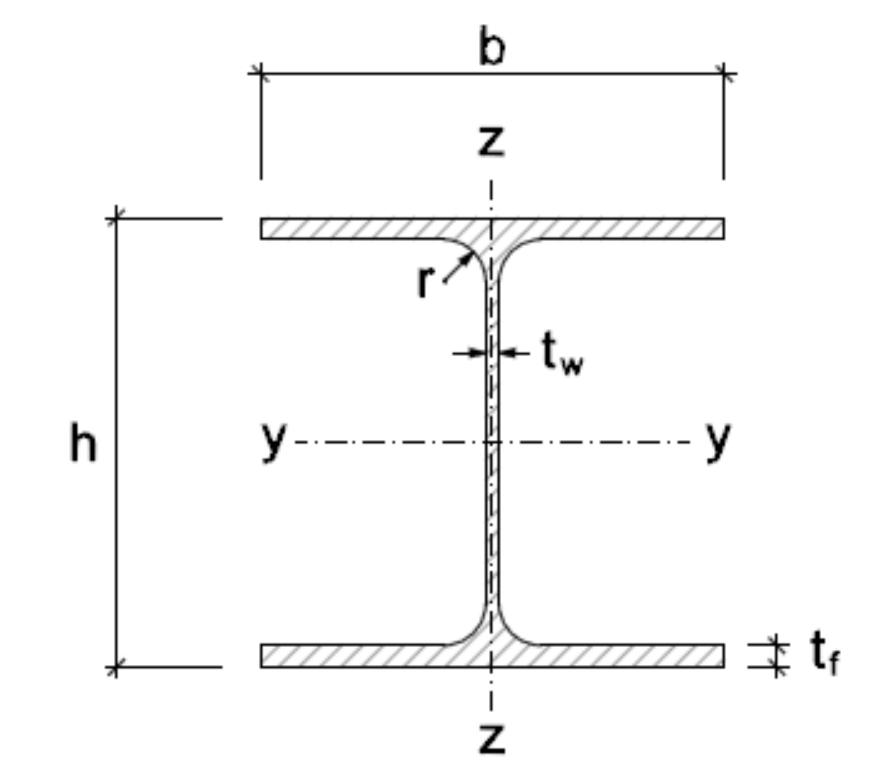

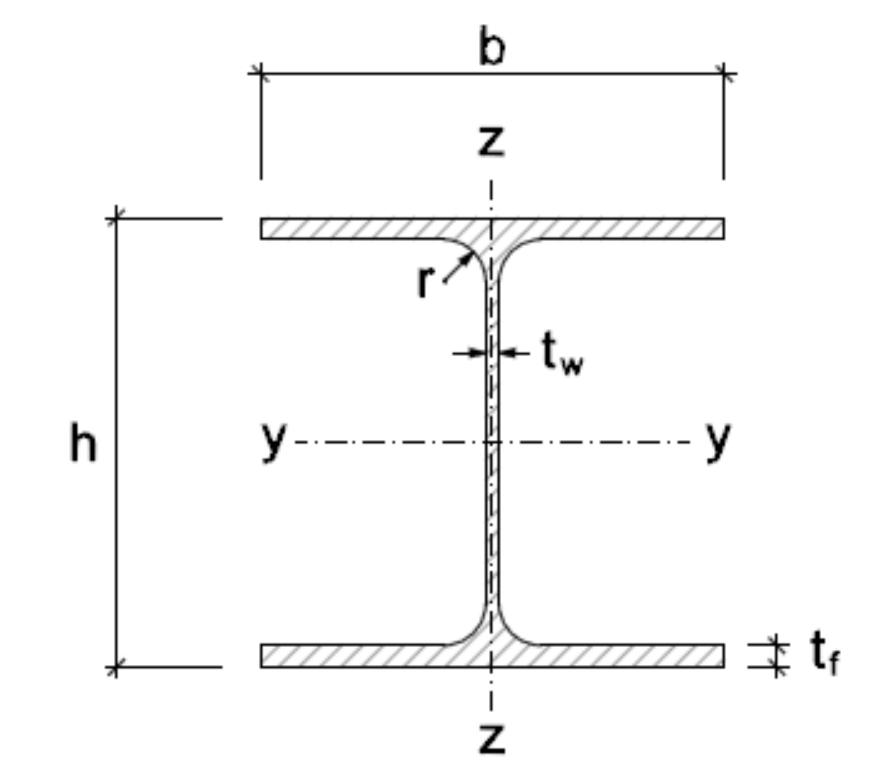

We insert the values in the excel sheet and multiply each by the influence area which is 1m. From the re we got M ed-uls. Then after finding the W ply we went to Eurocode 3, Table of design properties for flanged steel profiles and chose the section that has less Wply that what we calculated.

Secondary beam calculation

1. Load information

In the grey cells the numbers can be hard typed. In other cells there are already formulas.

Beam Lenght L 8 m 8000 mm

Influence area width I 1 m

Linear load g1' 0 kN/m Dead load: Beam self weight - Structural

Area load G1'' 3.5 kN/m2 Dead load: Floor Self weight - Structural Linear load g1'' 3.5 kN/m

Area load G2 3.7 kN/m2 Linear load g2 3.7 kN/m Dead load: Floor Self weight - Non Structural

Area load Q1 5 kN/m2 Linear load q1 5.0 kN/m Live load: Residential

2. M_ED External Bending Moment Calculation

Load_ULS COMB 17.78 kN/m Load_RARA COMB 12.20 kN/m Load_LIVE COMB 5 kN/m

1.35 ����1 + 1.5 ����2 + 1.5 ����

M_ED_ULS 142.20 kNm 142200000 Nmm (ql^2/8 or software value)

3. Choose steel class Steel class S… 460 fyk 460 MPa

1.05 fyd

MPa

4. Calculate Wpl Wpl 324587 mm3 325 10^3 mm3

5. Choose the cross section such as it has a Wpl greater than the one calculated Beam chosen IPE 330 Wpl chosen 713.1 10^3 mm3 OK

γs

438

2

NGM MILAN 83 SECONDARY STEEL BEAM

Area

NGM MILAN E.N 84

of influence

PRIMARY STEEL BEAM

Influence area = 8m

Beam length = 8m

Permanent structural deat load G1 = 3.5 kN/m2

Calculations for the course Architectural Design Studio

permanent structural deat load G2 = 3.7kN/m2

Module: Structures Prof. Grigor Angjeliu

Live load Q = 5 kN/m2

Academic Year 2021-2022

Beam self weight - Structural| IPE 360 = 0.55 kN/m

In the grey cells the numbers can be hard typed. In other cells there are already formulas.

The same prcess happened here. The difference is that the dead load is summing up dead load of secondary beam and dead load of floor and mulitiplide by 1.35(safety factor).

Primary beam calculation

1. Load information

Beam Lenght L 8 m 8000 mm

Influence area width I 8 m

Linear load g1' 0.55 kN/m Dead load: Beam self weight - Structural| IPE 360

Area load G1'' 3.5 kN/m2 Dead load: Floor Self weight - Structural Linear load g1'' 28 kN/m

Area load G2 3.7 kN/m2 Linear load g2 29.6 kN/m Dead load: Floor Self weight - Non Structural

Area load Q1 5 kN/m2 Linear load q1 40.0 kN/m Live load: Residential

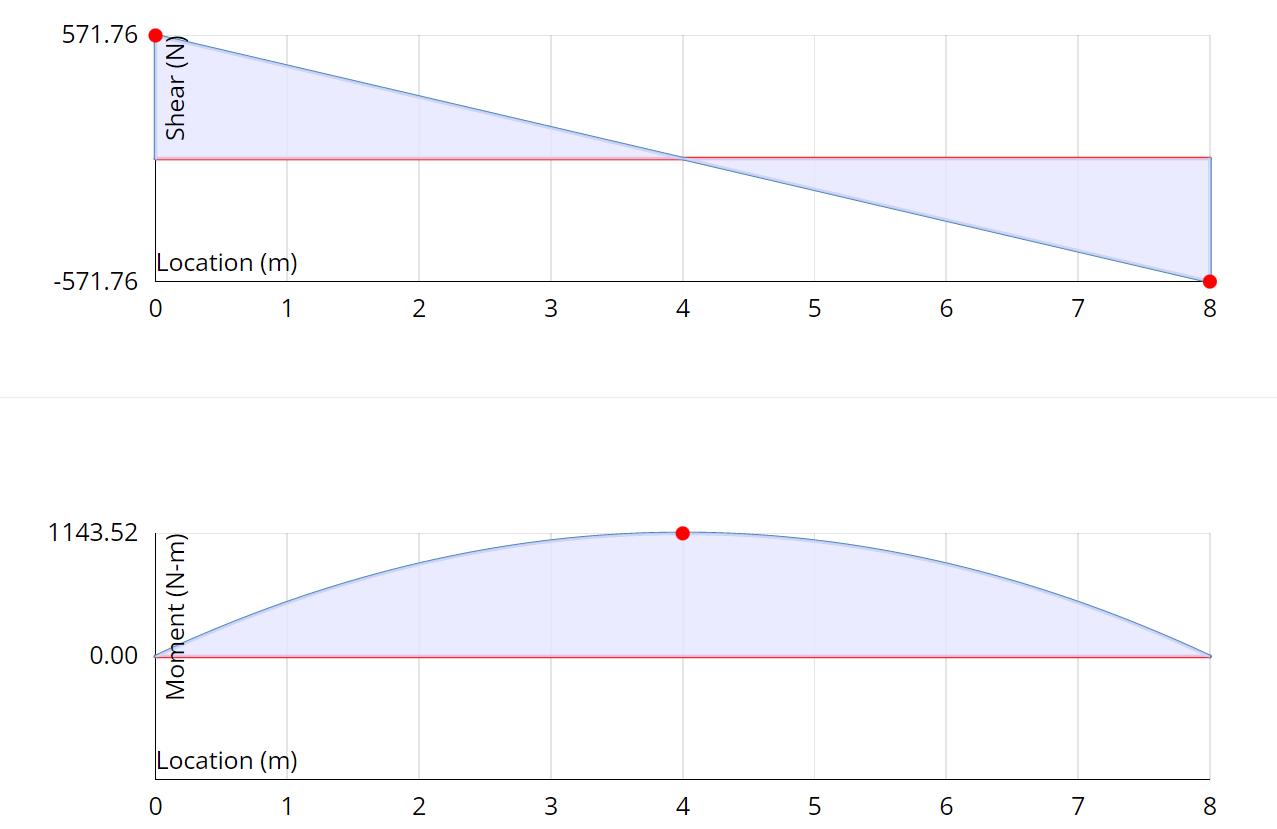

2. M_ED External Bending Moment Calculation

Load_ULS COMB 142.94 kN/m Load_RARA COMB 98.15 kN/m Load_LIVE COMB 40 kN/m

1.35 ����1 + 1.5 ����2 + 1.5 ����

M_ED_ULS 1143.54 kNm 1143540000 Nmm (ql^2/8 or software value)

3. Choose steel class Steel class S…

fyk

fyd

4. Calculate Wpl

Wpl

MPa

MPa

mm3 2610 10^3 mm3

5. Choose the cross section such as it has a Wpl greater than the one calculated Beam chosen HEB 550 Wpl chosen

10^3 mm3 OK Iy chosen 136700 10^4 mm4 E 206000 MPa

NGM MILAN 85

460

460

γs 1.05

438

2610254

5591

Area of influence

NGM MILAN E.N 86

NGM MILAN 87

LOAD CALCULATIONS

COLUMN DESIGN

◊ TYPES OF LOADS ON COLUMN:

◊

◊

Self weight of the column x Number of floors

Self weight of beams per run ning meter

◊

◊

Load of walls per running me ter

Total Load of slab (Dead load + Live load + Self weight)

◊

The columns are also sub jected to bending moments which have to be considered in the final design

NGM MILAN E.N 88

The underground level hosts 2 types of columns: central columns(column 2) and corner columns(columns 2).

Calculations for the course Architectural Design Studio for Complex Constructions 2

Module: Structures Prof. Grigor Angjeliu Academic Year 2020-2021

Area of influence -

In the grey cells the numbers can be hard typed. In other cells there are already formulas.

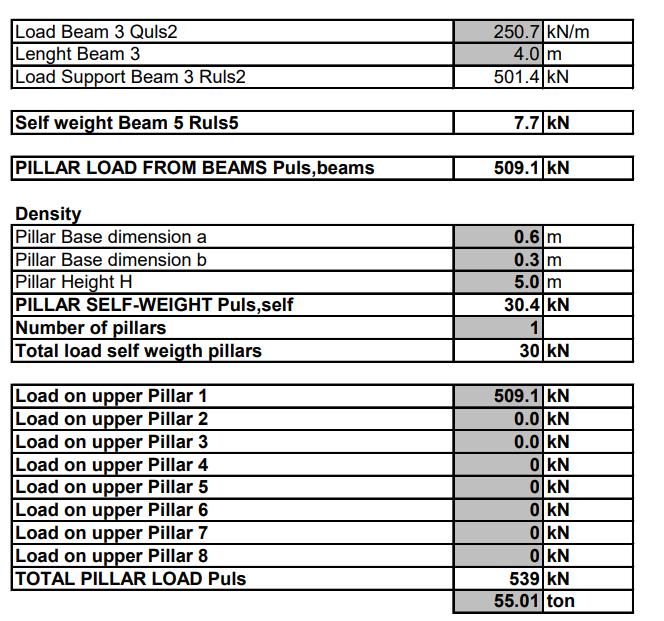

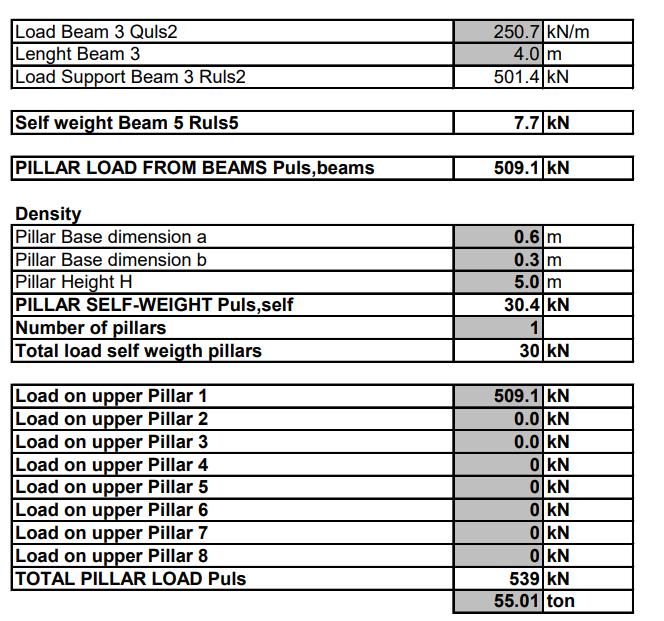

Part 3: Pillar Total Load Calculation

Pillar total load: Central column:

Central column

Load Beam 1 Quls1 258.9 kN/m

Lenght Beam 1 8.0 m Load Support Beam 1 Ruls1 1035.8 kN green force -> Lenght Beam 12 Load Beam 2 Quls2 250.7 kN/m Lenght Beam 1 8.0 m Load Support Beam 2 Ruls2 1002.8 kN red force ->

Self weight Beam 3&4 Ruls3&4 15.4 kN normal direction

PILLAR LOAD FROM BEAMS Puls,beams 2054.0 kN green+red forces -> 206.0 ton

Density

Pillar Base dimension a

m HEB 600 Pillar Base dimension b 0.3 m Pillar Height H 5.0 m

PILLAR SELF-WEIGHT Puls,self 30.4 kN Number of pillars 1 Total load self weigth pillars 30 kN

Load on upper Pillar 1 2054.0 kN 2054.0

Load on upper Pillar 2

Load on upper Pillar 3

Load on upper Pillar 4

Load on upper Pillar 5

Load on upper Pillar 6

Load on upper Pillar 7

Load on upper Pillar 8

kN 2054.0

kN 2054.0

2054.0

2054.0

2054.0

2054.0

2054.0

TOTAL PILLAR LOAD Puls 2084 kN 212.5

COLUMNS CALCULATION NGM MILAN 89

cloumn 1 column 2

0.6

0.0

0.0

0 kN

0 kN

0 kN

0 kN

0 kN

ton

NGM MILAN E.N 90 Module: Structures Prof. Grigor Angjeliu Academic Year 2020-2021 Middle column| 8*8 1. Obtain N_ED Axial force N_ED 539 kN 539000 N pre-selected profile HEA 500 As 197.5 cm2 i_min 72.4 mm As 19750 mm2 2. Choose steel class Steel class S… 355 3. Calculate fyd from the steel class fyk 355 MPa γs 1.15 fyd 309 MPa 4. Calculate λ l= 8 m koef= 1 lo= 8000 mm λ= 110.5 < 150 OK 5. Calculate 76.4 1.45 6. Calcualte cross section area A 0.8 N_Rd 4877 kN 7. Check that capacity NRd > demand NEd N_Ed 539 kN check OK N_RD 4877 kN ratio 11% Calculations for the course Architectural Design Studio for Complex Constructions 2 In the grey cells the numbers can be hard typed. In other cells there are already formulas. ���� ����1 = ���� ���� = ������������ = ���� ���� ������������ Load check: Central column: Pillar total load: Corner column:

NGM MILAN 91 Load check: Corner column:

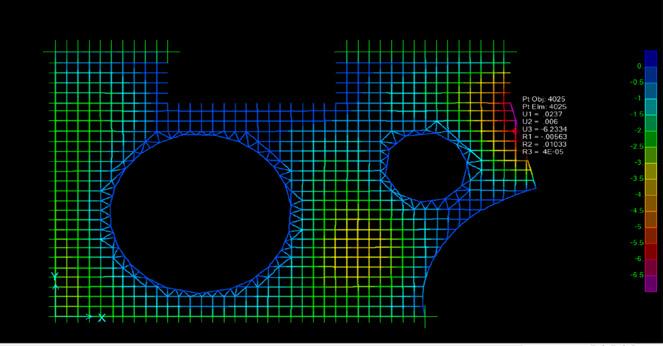

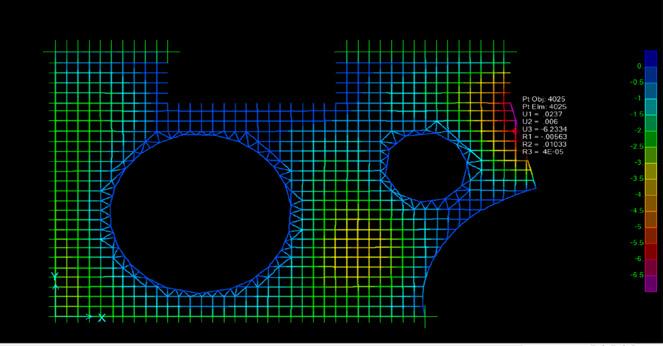

SPECIAL STRUCTURAL SYSTEM

NGM MILAN E.N 92

COMPLEX GEOMETRY

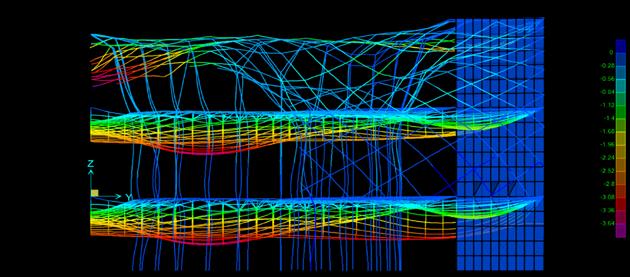

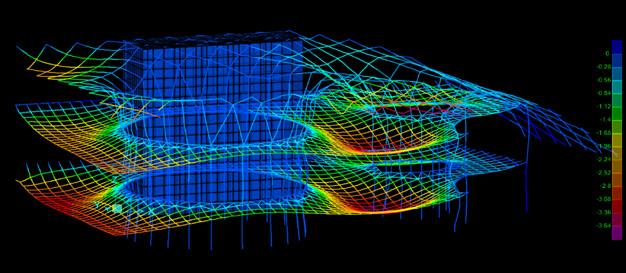

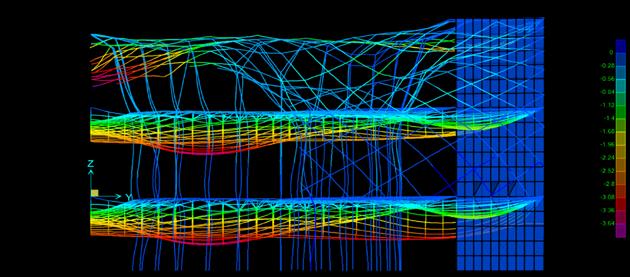

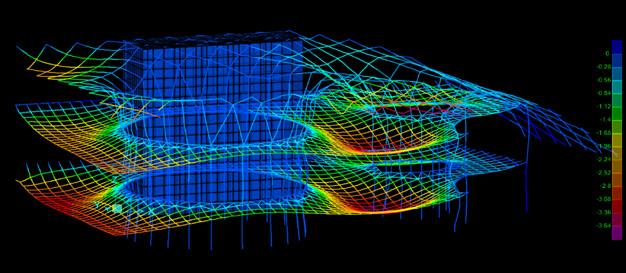

SAP2000 software was used to analyse and define structural elements sections. As mentioned in project description, The strustural system of the main building is consist of system of arches. The designing and analysing process of the structure is consist of different levels and layers. We started from the very initial phase to the most complicate and completed model.

The modelling process started from a combination of Rhino, grasshopper and Revit and ended in SAP2000 for the structural analysis.

The first phase was to determine how the intended geometry responded to the loads it was required to carry. Following that, we began the modelling processes in Rhino , grasshoper and later in SAP. With each stride forward, we encountered new problems and strove to overcome them one at a time. As previously stated, the geometry of our construction is curved, which is expressed

as points in the Rhino system. However, when performing the structural analysis in SAP, curved expressions defined by points will generate numerous constraints. To avoid the aforementioned issue, the model was divided into portions in rhino utilizing grasshopper and a manual technique throughout this process.

In the first step of the analysis, a single unit of Tree/Truss columns was investigated. The honeycomb structure of the slab, which was developed in Revit, was then added to the junction points in the following stage.

Given that the structure is a combination of arches in the shape of columns and an inclined piece of the roof, a segment that contained those components was required. To that goal, a fifth of the building’s structure with columns and arches was chosen for inspection.

NGM MILAN 93

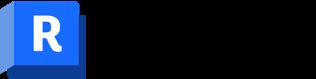

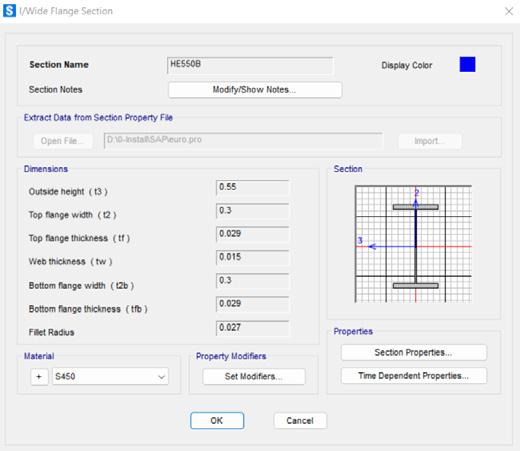

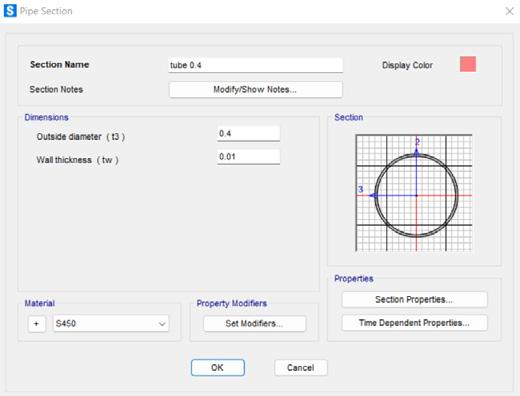

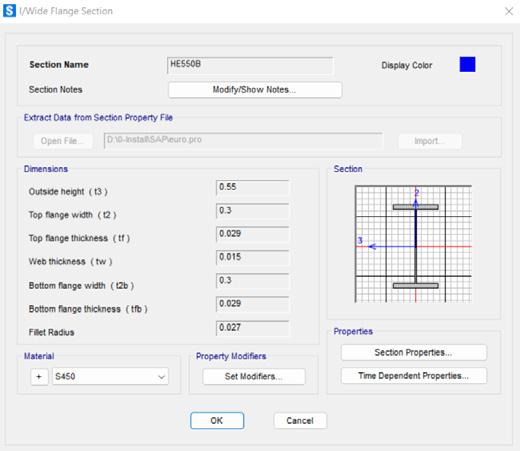

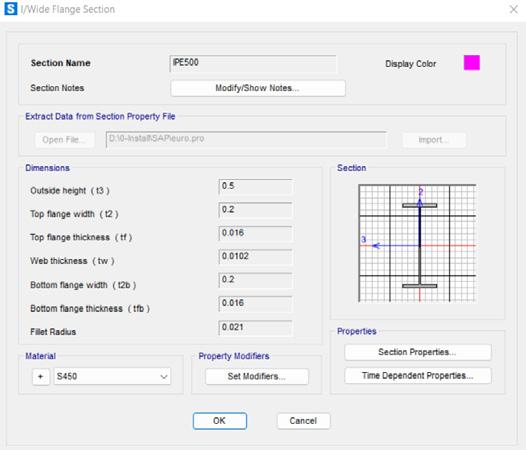

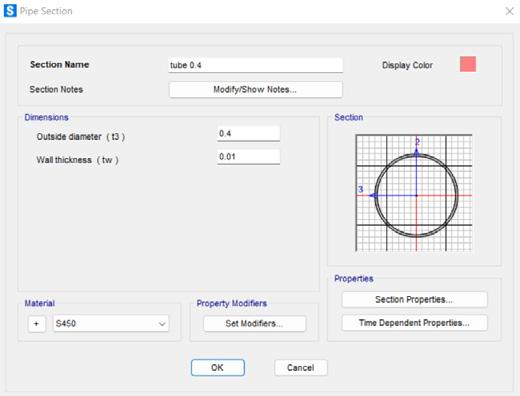

1.Defining the steel section size:

Throughout the traditional calculation IPE330 section size was obtained. After performing the analysis it was discovered that IPE330 section cannot withstand the loads.

* From Define> Section properties> Frame: sections, the following sections were defined:

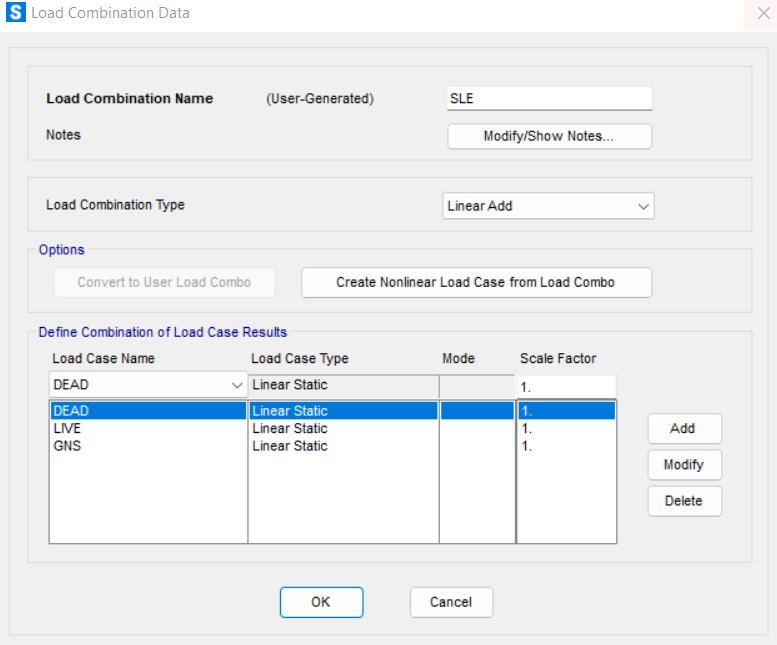

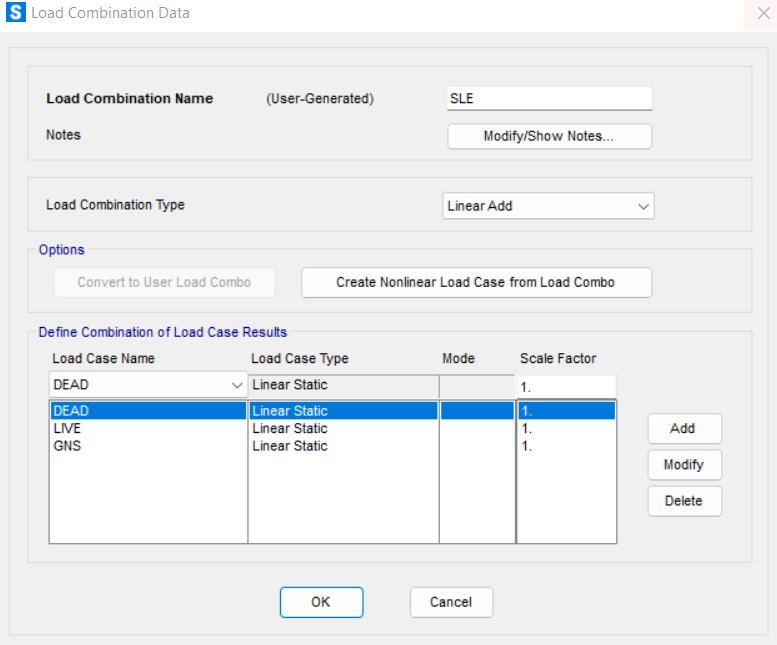

2. Defining load combinations

*From Define> Load combination:

Two load combinations named ULS and SLS.

A. For ULS load combination the load factors are:

Dead load fac. = 1.35

GNS fac. (Gravity non-structural load, G₂) = 1.5

Live load fac = 1.5 (Q₁)

Live load fac (Q₁) = 2.0 kN/m >>>>> 2.0 kN/m² x 4.0 m = 8.0 kN/m

*From Assign> Frame loads> Distributed, we have: Slab load (Distributed load in the pattern of 1by 1):

GNS fac. (Gravity non-structural load, G₂) = 8.8 kN/m²

Area load = 1 m² (each square patern in 1 by 1) >>>>> 8.8 kN/m² x 1.0 m = 8.8 kN/m

Live load fac (Q₁) = 5.0 kN/m² >>>>> 5.0 kN/m² x 1.0 m = 5.0 kN/m

1- IPE 500 : As the section used for the Honey combed structure of slab structure.

B. For SLS load combination the load factors are:

Dead load fac = 1

GNS fac. (Gravity non-structural load, G₂) = 1

Live load fac = 1(Q₁)

3. Applying the loads

2- Tubular section with 40cm diameter: As the section used for the main Tree/Truss column.

*From Assign> Joint Loads> Forces:

Roof load (Nodal laod at intersection of lines in 45 degree):

***For the simplicity of HTE model, the part of the secondary structure was omited from the analysed model.

GNS fac. (Gravity non-structural load, G₂) = 3.7kN/m²

3- HEB550: As the section for the ring beams (Intersection part of column and slab).

Area load = 4 m² (each square patern in 2 by 2) >>>>> 3.7 kN/m² x 4.0 m = 14.18 kN/m

NGM MILAN E.N 94 DESIGNING PROCESS: SAP2000

The model was extended in the final version, accounting for almost a quarter of the entire structure. The perimeter supports, some extra columns, and eventually the building core were added to help the roof and slab remain stationary. Yet, The slab of the first floor had a large displacement, approximately 6.5cm, which was greater than the allowable displacement.

Final analysis displacement results>>allowed displacement.

As presented in the images above, The slab of the second storey is clearly displaced for 6.2cm in this plan and elevation view.

The maximum displacement is L/250, Which equals L = 6.1m. So, 6.1/250 = 0.024m = 2.4cm 6.2 > 2.4

Not allowed displacement

In this situation, there were two options: support it with additional columns, which was not ideal because it intruded on the architectural spaces of the ground floor. The second and chosen option was to attach this slab to the sloped section of the roof.

>>In the plan and elevations above, it is clear that the slab of the second floor is displaced for 3.6cm .

The maximum displacement is L/250 where L = 13m

So, 13/250 = 0.052m = 5.2cm 3.6 < 5.2>>allowed displacement.

NGM MILAN E.N 96 SAP2000 FINAL RESULTS

The results of this last analysis is presented in the following images>>>>>>>>>

6.1m 13m

NGM MILAN 97

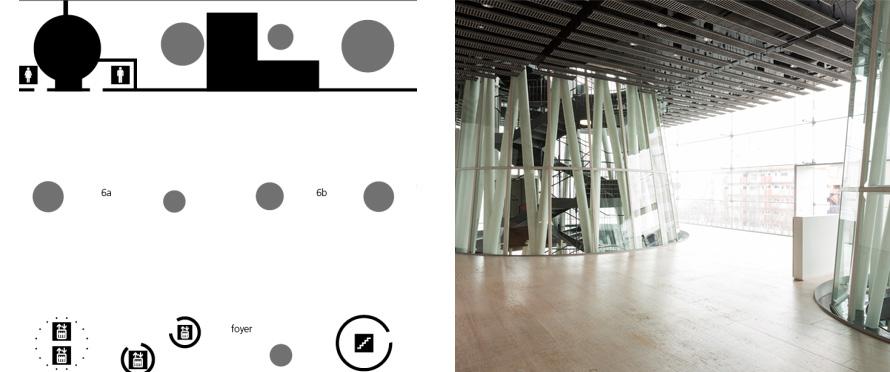

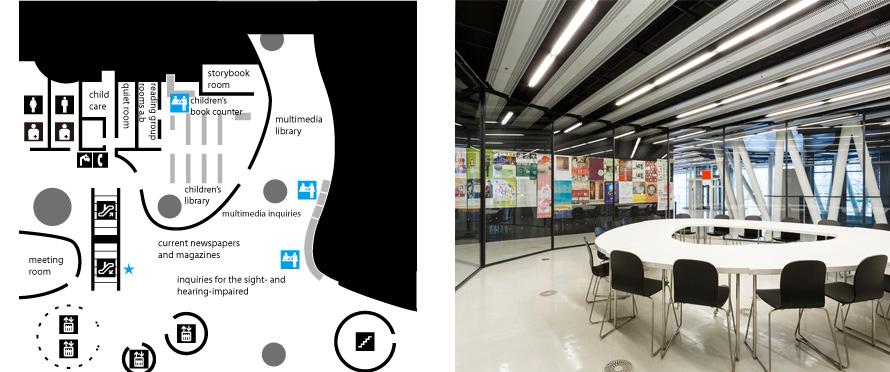

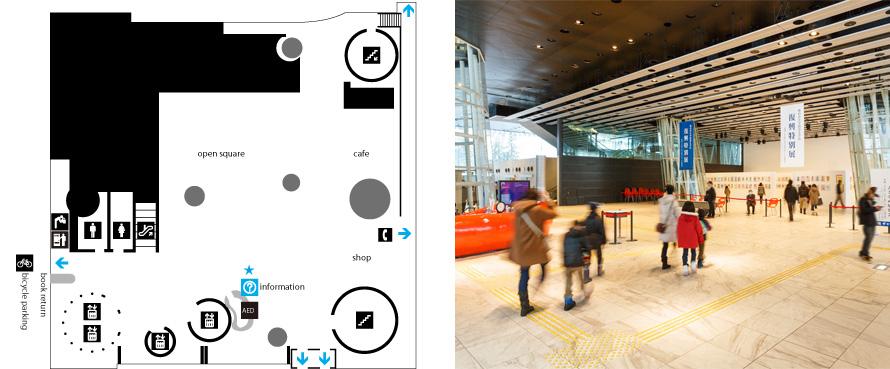

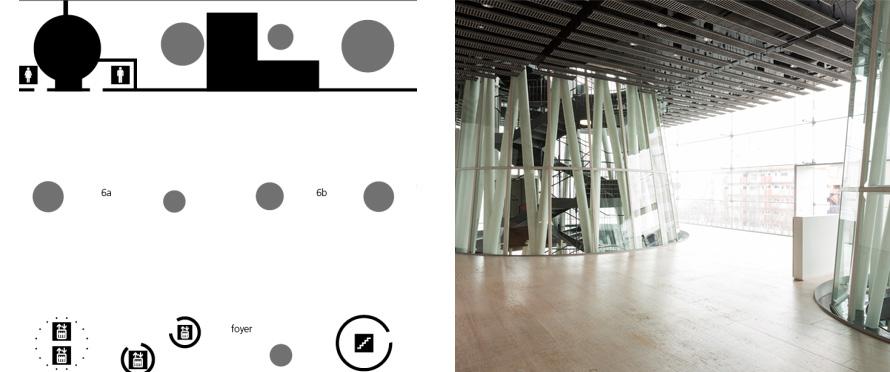

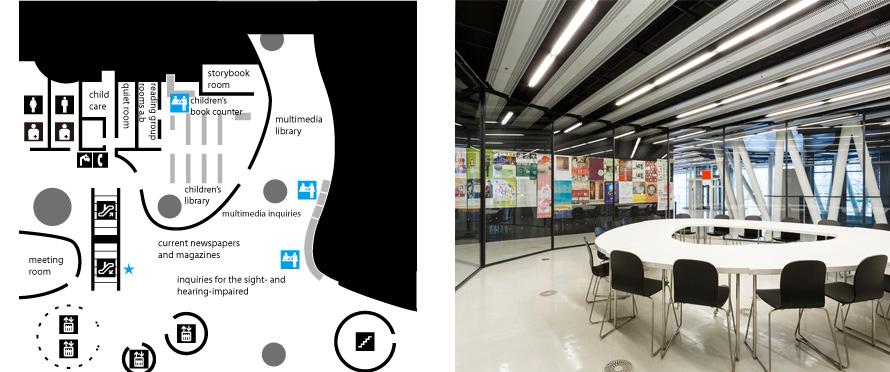

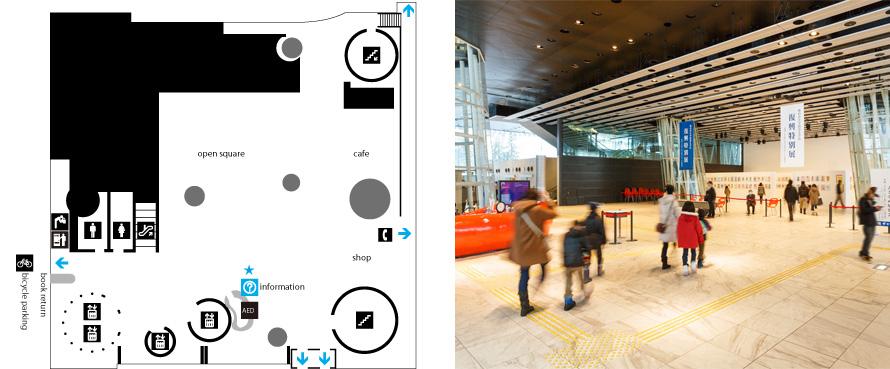

CASE STUDY

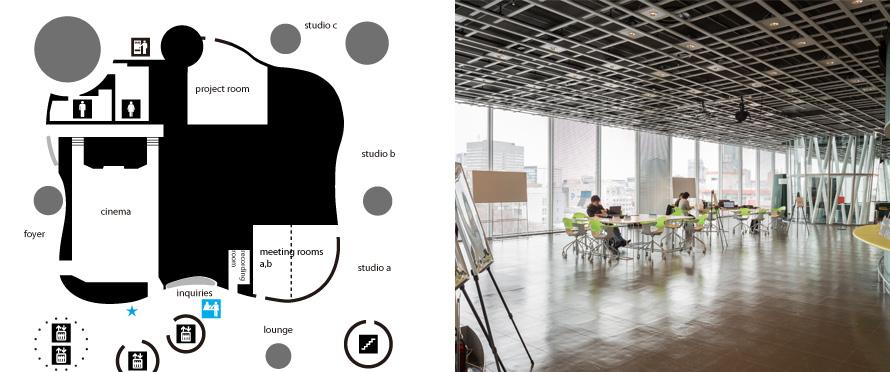

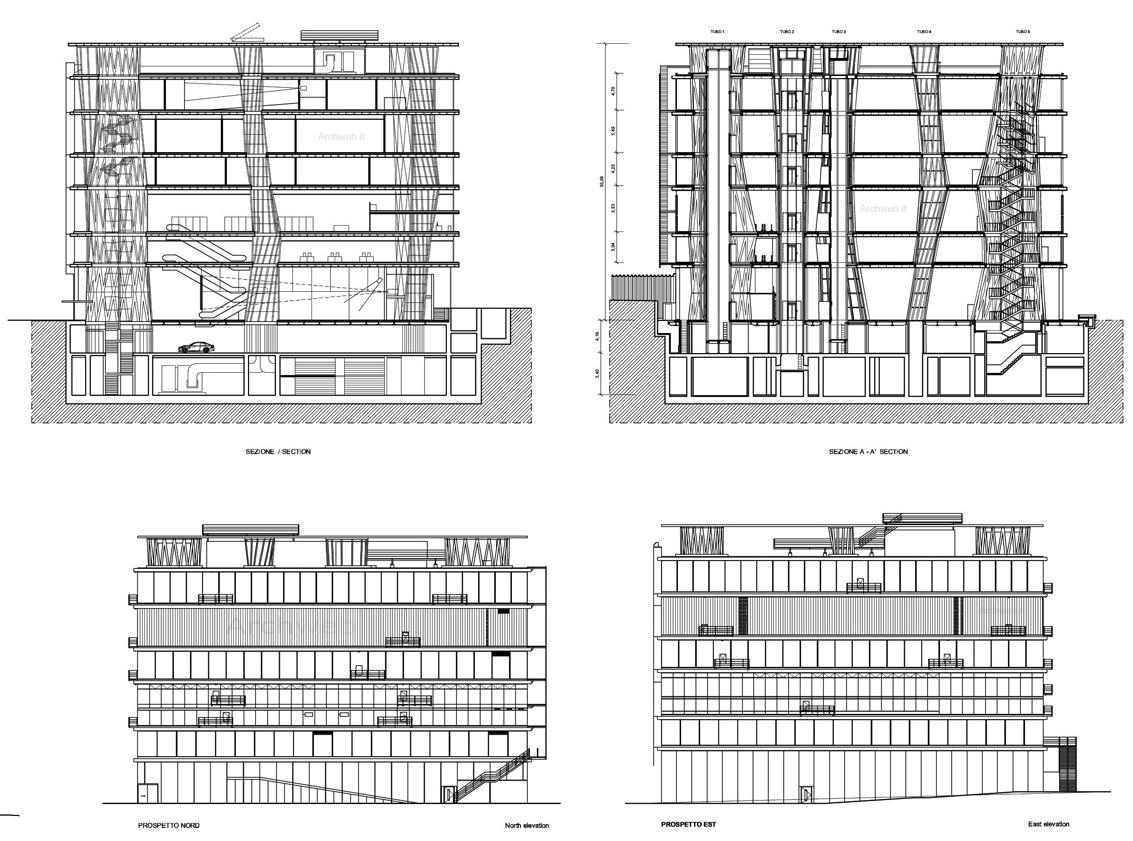

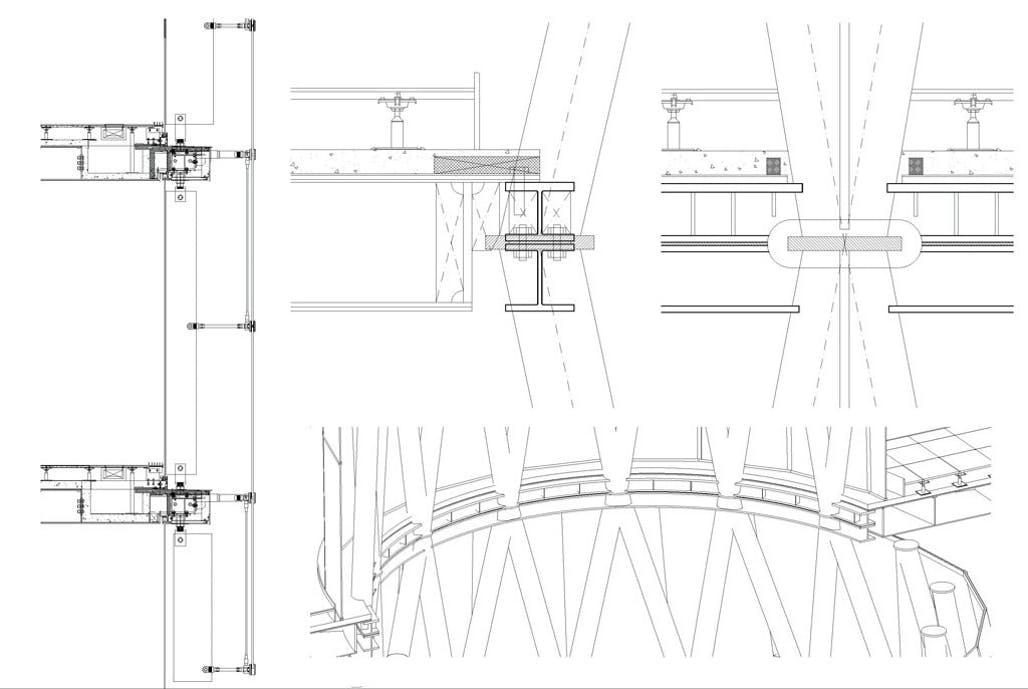

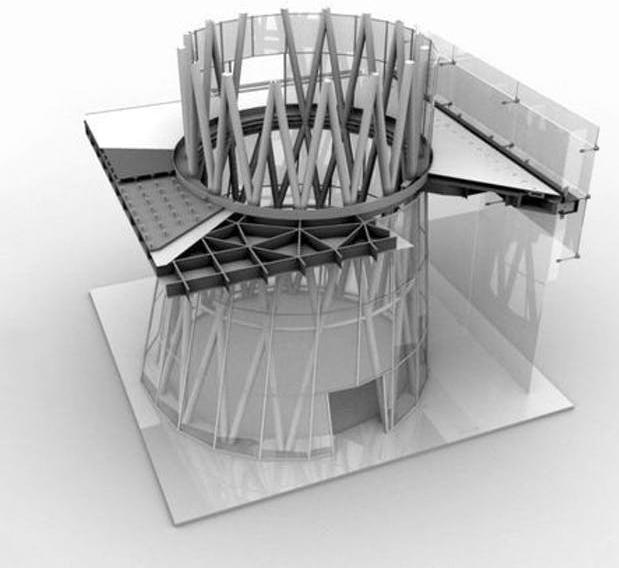

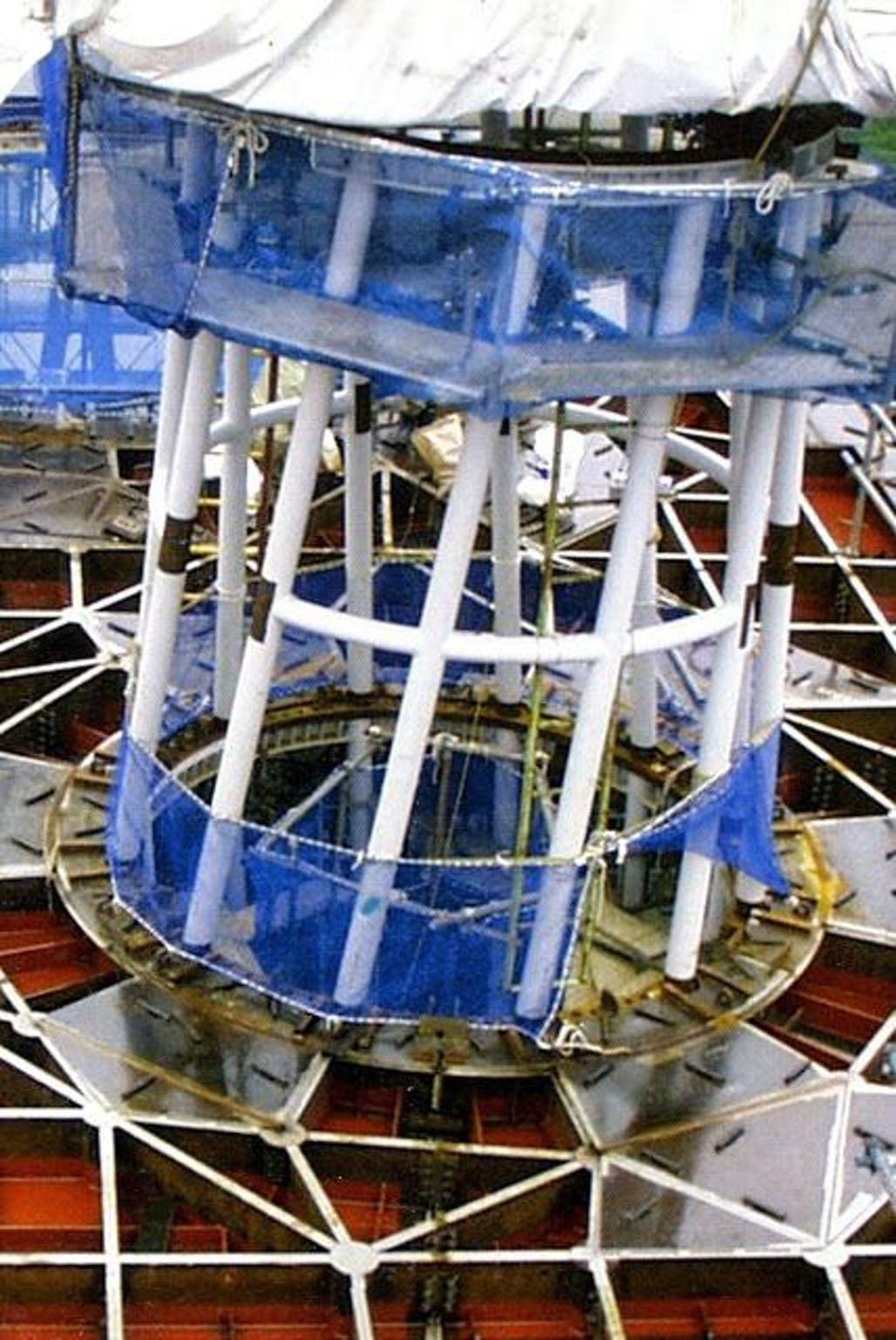

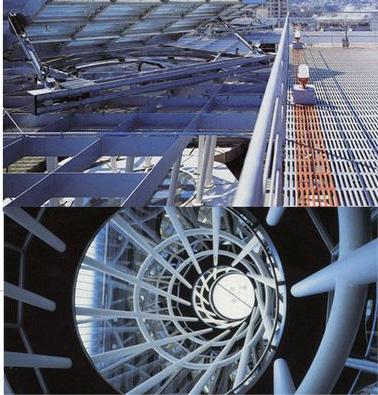

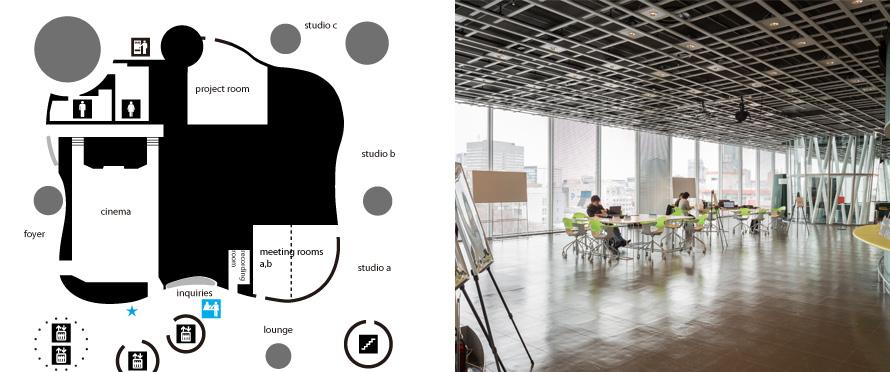

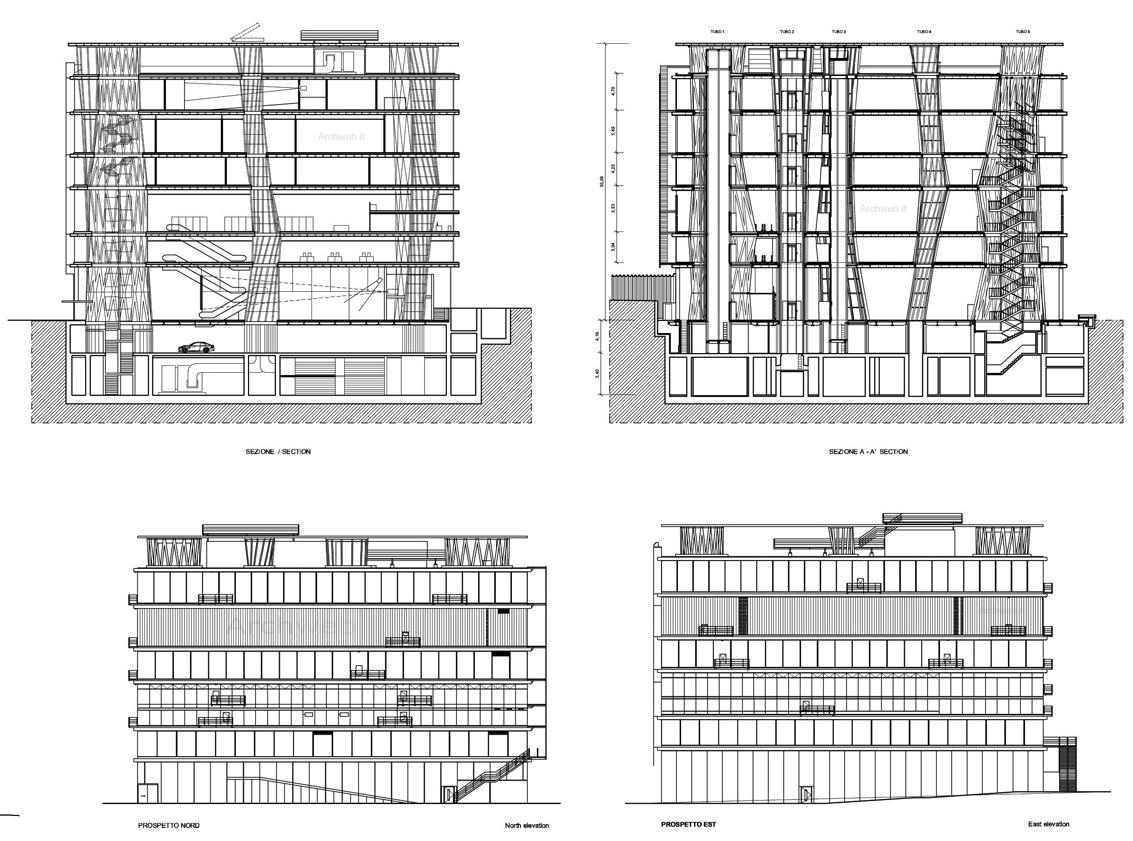

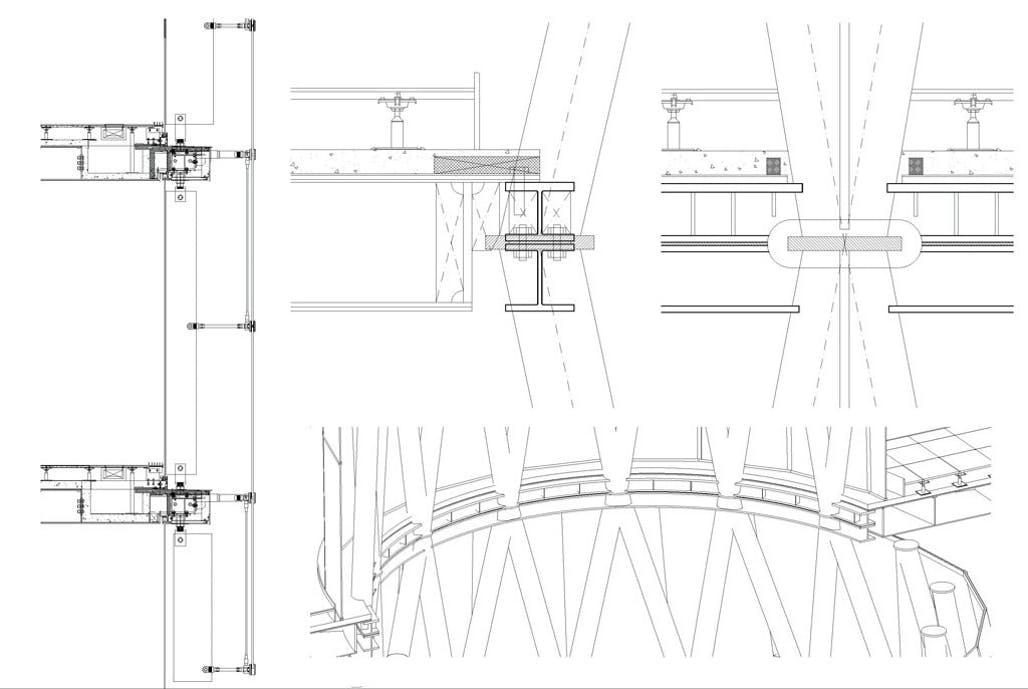

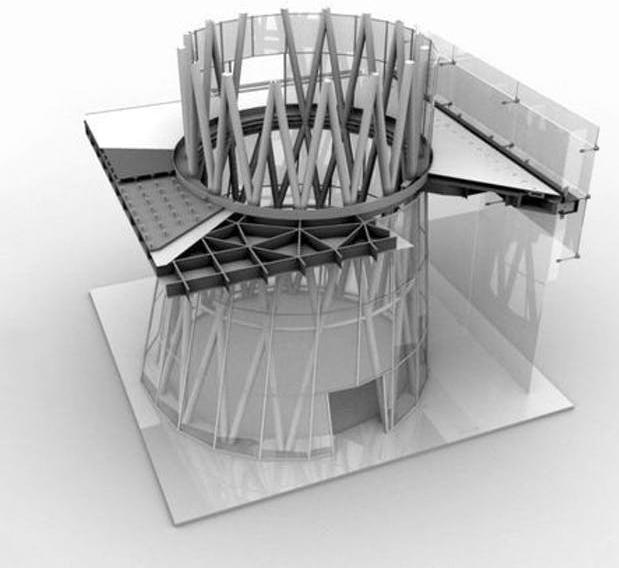

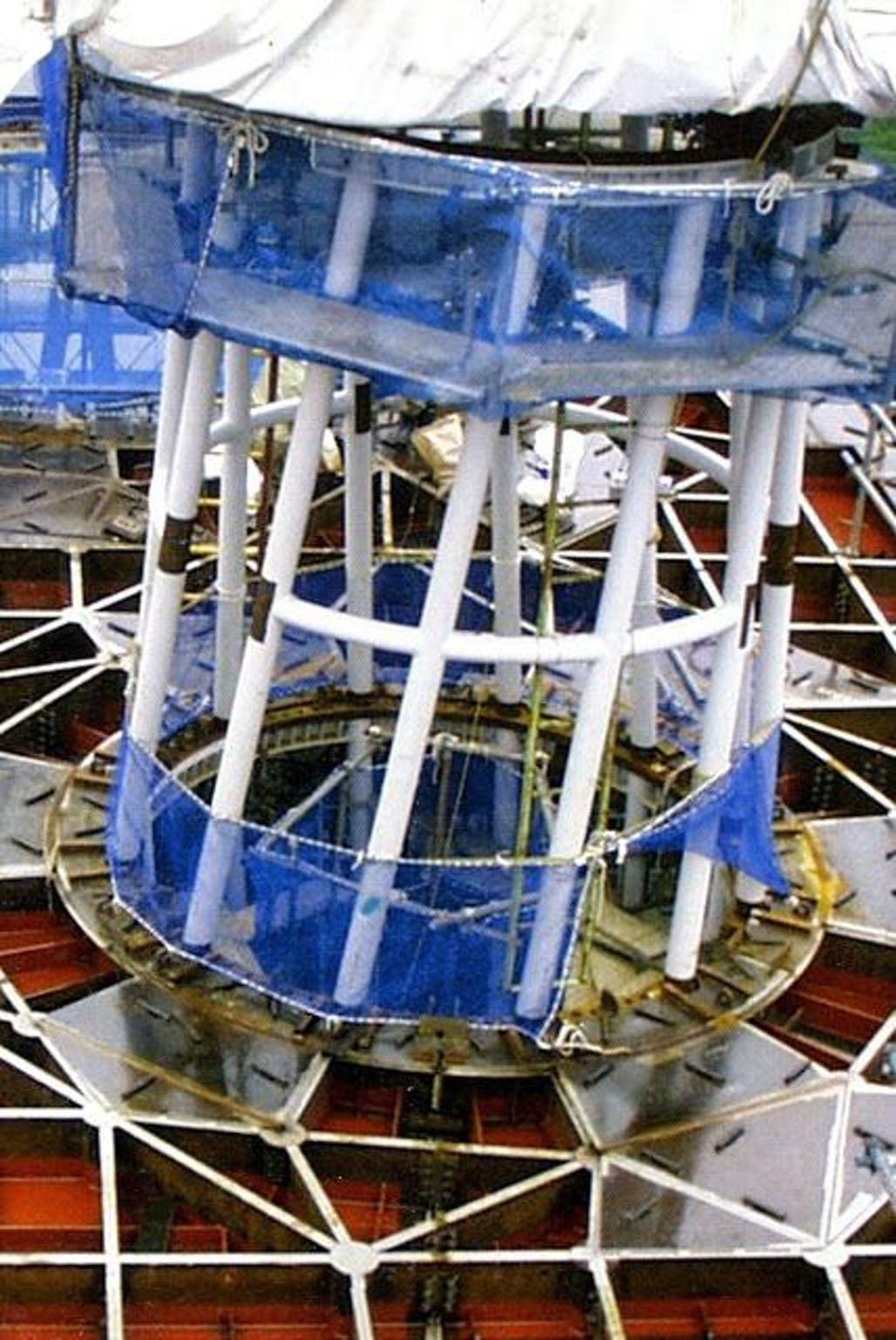

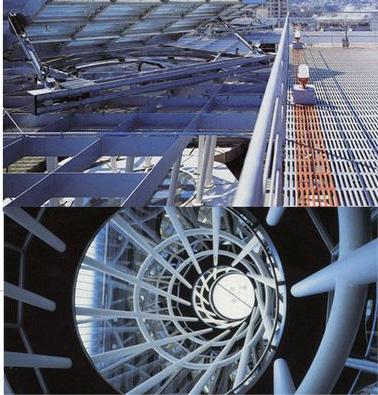

SENDAI MEDIA-THEQUE, SENDAI, JAPAN

Architect Designed in Built in Land Area Floor Area Toyo Ito 1995-1997 1998-2001 3,948 m² 2,844 m²

ABOUT