Cabinet & Furniture Components Specification Guide

© 2022–2025 EcoDomo®. All rights reserved.

INTRODUCTION

Dear Designer and Industry Partner,

Specification Guide

Thank you for taking the time to review our Recycled Leather Veneer Resource Guide. EcoDomo® offers made-to-measure cabinetry components finished with our elegant and high-performing Recycled Leather Veneer (RLV™), constructed in a manner that is similar to the process used to produce laminates.

This guide will support your designs and ideas while also providing practical information on the sizes, colors, and configurations available for each component. The guide is the result of well over a decade of collaboration with industry leaders, designers, and OEM programs across the country.

We look forward to benefiting from your expertise and experience as we increase our options for leather finishes to enable designers to offer new materials and new aesthetics to their clients. We can guarantee leather is a classic, and it’s a trend which is here to stay.

The guide is meant as a resource for designers, cabinet makers, and furniture manufacturers. Aluminum, acrylic, or leather doors are all just…doors! In general, the method you specify aluminum or acrylic doors is the same way you specify our leather doors.

The guide is divided into seven distinct categories, which follow the structure of cabinetry/cabinetry design applications, plus an eighth section with examples and information about how to order:

1. Company & Product Overview

2. Product Specifications

3. Doors & Drawer Fronts (framed doors, appliance panel doors)

4. Complimentary Items (shelving, fillers, panels)

5. Countertops

6. Interior Components

7. Custom Requests (nonstandard materials, colors, configurations)

8. Examples & Ordering Information

The Resource Guide is available in a PDF format that’s easy to search and navigate.

We hope you will find ideas and answers on everything from the size of a column to how to specify Shaker doors or alternate materials. EcoDomo’s cabinetry division offers ready-made solutions, just like other manufacturers of cabinet components. We look forward to working with you on projects soon and sharing your realizations in future editions of our guide!

Component Program

ABOUT ECODOMO®

SECTION 1: Company and Product Overview

EcoDomo® LLC develops, designs, and manufactures truly sustainable architectural leather luxury pieces for use as cabinetry / furniture components, countertops, shelving, panels, and so much more. Our primary goal is to enhance your designs by adding an element of elegance and timeless beauty.

EcoDomo® was founded in 2005 in response to increasing demand for high-end ecological and renewable products. The first collection of EcoDomo® on the market consisted of recycled leather floor tiles. Our capabilities have since expanded, and we are now experts in applying leather surfacing to a variety of substrates. Our standard materials include both recycled and hide leathers; each has its own unique characteristics and advantages

Today’s luxury market demands diversity, performance, elegance, and ease of maintenance. The following pages outline the specifications of each leather type, and our website gallery will give you a hint at the ways you can incorporate EcoDomo® leathers into your unique designs for the most discerning clients.

Located in Gaithersburg, Maryland, nestled between the vibrant cities of Baltimore and Washington, D.C., our facility serves as a hub of creativity and craftsmanship. At our factory, we proudly employ a diverse array of artisans hailing from various fields, including woodworking, manufacturing, printing, upholstery, and even the equestrian sector. By harnessing the collective expertise of our skilled team, we are adept at seamlessly blending different skills to craft truly unique leatherfinished components.

We ship across the nation, crated when needed, to ensure a damagefree arrival. To inquire further, please contact our office by phone or email. We look forward to a partnership with you!

EcoDomo® LLC

630 East Diamond Avenue, Suite M Gaithersburg, MD 20877

Phone: 301-424-7717

Email: info@ecodomo.com

Visit www.EcoDomo.com

SECTION 1: Company and Product Overview

COMPONENT PROGRAM LEATHER OVERVIEW

Our most popular material, Recycled Leather Veneer (RLV™), is the basis for our Component Program RLV™ is ideal for a wide array of architectural components and applications due to the diversity of colors and textures as well as its durability for daily use.

Below is an outline of the typical architectural component applications:

Component Description Application

Doors and Drawer Fronts

Specialty Front for Appliances

Insert Panels

Vertical Panels

Horizontal Surfaces

Component Accessories

Cabinets, closets, furniture

Slab, five pieces; with or without center panels

Door and drawer front center panels

(provided for field installation, similar to decorative glass )

Drawer liners

(typically used in closet and / or jewelry drawers)

Typically for interior back of closet, display cabinets, backs of islands, ends of cabinets

Counters

Shelves

(typically for closets, bookcase / display)

Floating shelves

Fillers

Flat moldings Island legs

Component Program

SECTION 1: Company and Product Overview

SECTION 1: Company and Product Overview

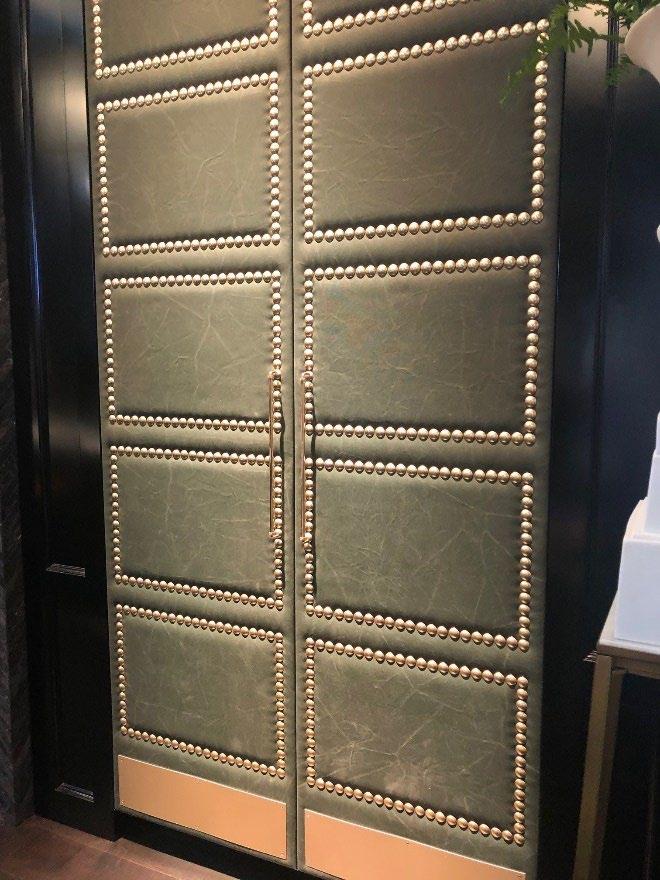

CUSTOM OPTIONS AND EMBELLISHMENTS OVERVIEW

Beyond our standard Recycled Leather Veneer Component Program, we also offer specialty materials and combinations that can be found in SECTION 7: Custom Requests and on the EcoDomo® website. Examples include:

Component Program

SECTION 1: Company and Product Overview

(LEFT

BLANK INTENTIONALLY)

Component Program

SECTION 2: Product Specifications

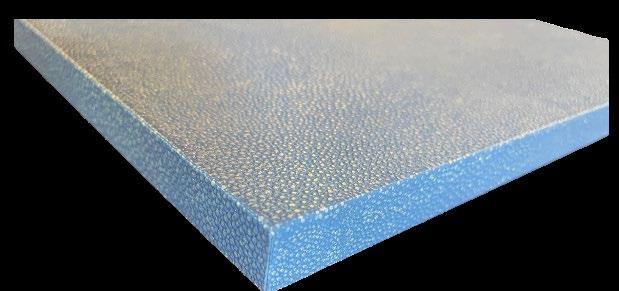

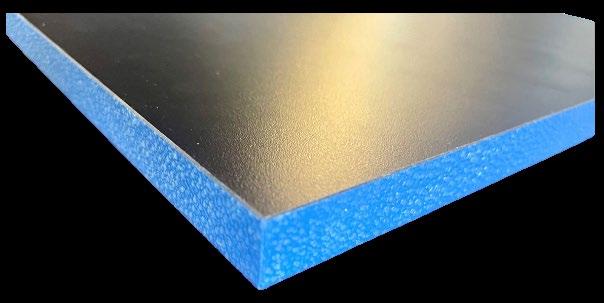

RECYCLE LEATHER VENEER (RLV™) TECHNICAL SPECIFICATIONS

Recycle Leather Veneer (RLV™) Definition

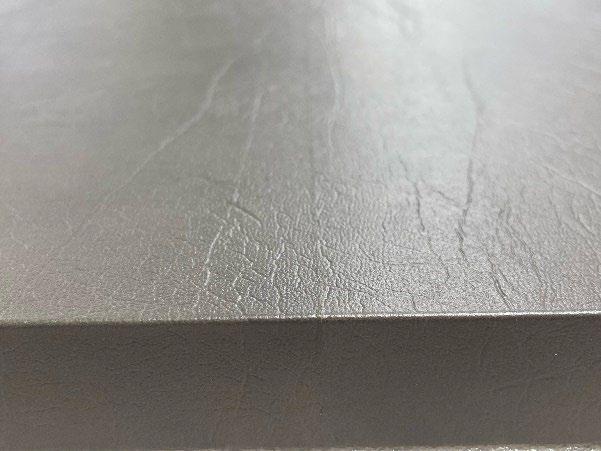

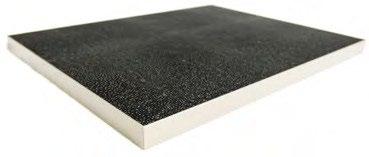

EcoDomo® RLV™ repurposes pre-consumer leather remnants from the automotive and shoe industries. These remnants are pulverized and compressed together with water and a small amount of latex. Below is a visual comparison of the process of making RLV™ versus a laminate. After the sheet is made, patterns are embedded and it is finished with natural pigments in our tannery, just like natural leather. A proprietary highperformance resin topcoat provides RLV™ with exceptional durability, cleanability, and elegance.

Substrates

EcoDomo® uses a high-density, cabinet-grade HDF (high-density fiberboard) for most of its components. High-density fiberboard provides stability, excellent adhesion, and a perfect surface for lamination. We also use commercial-grade particle board for countertops and plywood for vanities and other potential wet areas.

The processes for creating RLV™ is similar to that of creating laminate, but the finished products are quite different. RLV™ is made from leather fibers recovered from automobiles and leather tanneries. These fibers are pulverized and mixed with small amounts of tree bark and natural latex. A final layer of resin renders the product highly impervious to wear and tear. Our finishing process allows us to control the color and texture for repeated use throughout a design to maintain overall visual consistency.

RLV™ is real leather, with a few added elements that allow for placement in high-use areas such as kitchens and bathrooms, resulting in a luxurious and elegant surface.

Recycled Leather Veneer

Laminate

Compressed Leather Fibers and Resin

Compressed Paper and Resin

SECTION 2: Product Specifications

Specification Guide

RECYCLED LEATHER VENEER (RLV™) MATERIAL SPECIFICATIONS

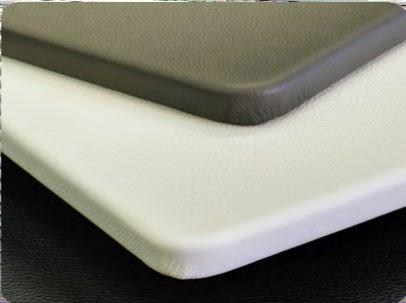

Recycled Leather Veneer (RLV™) Thickness

Our Component Program utilizes RLV™ in 1/32” thickness (0.8mm)

In comparison, note that the typical thickness of wood veneers is 0.6mm. High Pressure Laminate (HPL) varies from 0.7mm to 1.2mm. Melamine is only 20 microns or 0.02mm thick.

Recycled Leather Veneer (RLV™) Sheet Size / Component Size

Our standard RLV™ sheets are stocked in a 4’ x 8’ size.

Each component within this guide includes size parameters widely based on the standard sheet sizes of RLV™. Size limitations are specific to each component.

Extended sheet sizes (4’ x 10’ and 4’ x 12’) are available through a Custom Request. These larger sheets help you to avoid seams. This option is typically used for doors, panels, and countertops that require extended lengths. Keep in mind that nonstandard / larger sizes of material / components will incur extended lead-times as well as premiums for product, crates, and freight.

Recycled Leather Veneer (RLV™) Colors

Our standard RLV™ colors / patterns begin on pages 20-22. These 22 colors / patterns are based on trends and popularity as well as longevity. By creating a standard palette, we can create efficiencies that result in consistent lead-times and cost savings for you. Over time, the standard color palette will evolve as all trends do—please keep this in mind as you plan.

EcoDomo® is also capable of matching colors on any of our embossed textures. Many of our commercial clients utilize this feature for aligning with brand standards, and of course designers will use this when they have specific color needs. This option is available through a Custom Request and will incur premiums and extended lead-times. See SECTION 7: Custom Requests for more information.

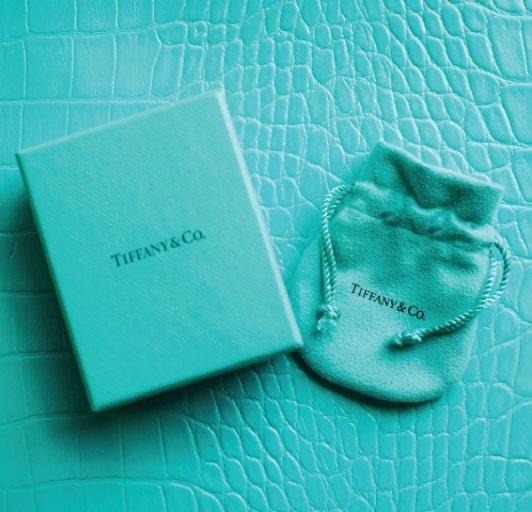

Sample Custom Color Match

Sample Color Match: Leather and RLV™

Component Program

SECTION 2: Product Specifications

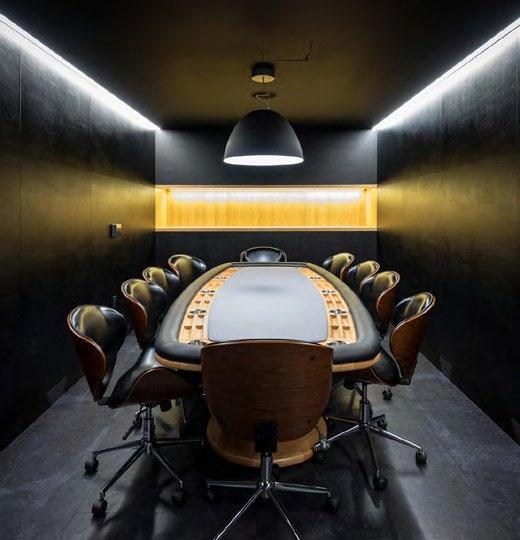

RECYCLED LEATHER VENEER (RLV™) PERFORMANCE

Millions of square feet of RLV™ have been installed in a wide range of commercial and residential applications in more than 25 countries since 2005. The same high-performance, chemical-resistant finish is used for cabinetry and floor applications. EcoDomo® RLV™ can be found in hotels, prominent luxury brands, law firms, and in over 2,500 Starbucks locations worldwide on floors, casework, furniture, and more. Anywhere wood is used, RLV™ has been used on projects of all sizes.

The examples below showcase RLV™ performance over years of wear. Contact Sales@EcoDomo.com for additional information.

TECHNICAL PERFORMANCE CHARACTERISTICS

Light Stability Test (ASTM F-1515)

Resistant to Chemicals (ASTM F-925-24)

(24 hours for surface attack, dulling, or color change)

Staining and Color Transfer to Adjacent Surface (ASTM F-1861-02)

Class 4

No change

None

Fire: Single-Flame Source Test (ISO 11925) Pass

Fire: Tunnel Test (ASTM E-84)

Class C – Class “A” available

Static Load Limit (ASTM F-970) (100 pounds PSI) .0005 inch

Brewery Tables – Coal Buffalo – 2008

Brewery Tables – 12 Years Later

SECTION 2: Product Specifications

RECYCLED LEATHER VENEER (RLV™) PERFORMANCE: REAL LIFE EXAMPLE

The best testimonial remains the wear and tear in a real-life application. These pictures show the use of our doors in a kitchen environment for a decade. Photos were taken after one (1) year and after ten (10) years. The kitchen features all doors and drawers in recycled leather veneers combined with a leather floor in a Toffee Buffalo from our Echelon Collection of leather floor tiles.

Infinity Doors and Drawers in Antique Black Walrus RLV™ – Photos by Seanie Blue. Toffee Buffalo Leather Floor

Component Program

Infinity Doors and Drawers in Antique Black Walrus RLV™ – Photos by Andrea Stein Toffee Buffalo Leather Floor.

SECTION 2: Product Specifications

MADE IN USA, FORMALDEHYDE USAGE, GREEN PRINCIPLES

Are EcoDomo® products made in the USA?

All EcoDomo® cabinetry components are built in the USA using substrate material sourced from sustainably managed North American forestlands. Keeping production here in the USA creates thousands of jobs, supporting both local communities and the domestic economy. We have been American-owned and operated since our founding, and we take pride in our continuing commitment to American workers and American EcoDomo’quality. s recycled leather veneers are an innovation in an industry driven by a combination of sustainability and luxury. We’re actively contributing to the revival of the domestic leather industry with a sustainable product.

Does EcoDomo® use formaldehyde?

EcoDomo® makes a difference with our products by partnering with suppliers to ensure continued environmental stewardship. We select materials manufactured to meet or surpass current regulatory requirements, including low formaldehyde emissions.

All the woods we use comply with TSCA Title VI / CARB formaldehyde emission standards. (See more on LEED qualifications on following page.) Our recycled leathers are made using vegetable-tanned remnants only and do not contain any added formaldehyde.

Are EcoDomo® components green?

EcoDomo’s Mission is To Create Beautiful Opportunities through Biomaterials. EcoDomo® was founded on the principle of developing sustainable, natural materials, and all our products and our corporate culture focuses on creating a sustainable future today with a commitment to people, products, and the planet.

• Our products use recycled leathers and CARB-compliant HDF.

• Our recycled leather is made from leather remnants diverted from landfills.

• Our colors are derived from natural pigments, ensuring great UV resistance.

• Our leather finishes are all water-based.

• Our packaging is made from recycled materials.

• Our workplace is designed to empower employees

See the following page for more information or contact us for our environmental policy.

Component Program

ENVIRONMENTAL AND LEED SCORING

Environmental Stewardship

SECTION 2: Product Specifications

EcoDomo® uses only TSCA Title VI / CARB TSCATitleVI / CARB–compliant Recycled Leather Veneer (RLV™), HDF, and substrate cores which meet or exceed the highest standards for air quality.

California Air Resource Board (CARB) governs regulations for formaldehyde emissions from composite wood products in the state of California. The US EPA adopted these emission levels effective June 1, 2018, making them a national requirement. These are the toughest emission standards in the world.

What does this mean to you and your customer?

You can use EcoDomo® cabinetry components with confidence, knowing we use U.S.-made plywood and HDF that comply with formaldehyde emissions standards. Your customer will receive the highest-grade materials and know their product meets the highest standards for air quality.

You will be assured that EcoDomo® will continue to source U.S. materials and be an industry leader in implementing products that improve quality, strength, and sustainability.

Are EcoDomo® cabinet components LEED certified?

EcoDomo® is a responsible manufacturer utilizing sustainable processes that may contribute toward LEED points, as outlined below. In 2005, we were one of the first companies to become a member of the United States Green Building Council. Only entire buildings can obtain LEED certification by using products that contribute LEED points. Products on their own are not LEEDcertified.

Visit the U.S. Green Building Council website for more details at usgbc.org.

LEED Specifications

EcoDomo’s Recycled Leather Veneer (RLV™) may contribute to LEED in the following categories:

MR 4.1 / 4.2

IAC 4.2 / 4.3

Local 5.1 / 5.2

Renewable 6.0

Recycled content (pre-consumer)

Low-emission adhesive and product

500-mile radius of manufacturing

Rapidly renewable resource and material

EcoDomo® is a member of the US Green Building Council and other professional organizations. We believe that paying for carbon credits, wind-generated electricity, and recycled materials is as essential as paying for rent and other utilities. Visit www.EcoDomo.com for more details.

SECTION 2: Product Specifications

RECYCLED LEATHER VENEER (RLV™) CLEANING AND CARE

EcoDomo® Recycled Leather Veneer (RLV™) Cabinet Components (Doors, Drawer Fronts, etc.)

After cabinet installation, remove large sawdust / construction debris with a soft-bristled household vacuum on both the interior and exterior of cabinets. Then remove fine dust by lightly wiping cabinets with a clean, damp cloth, followed immediately by a wipe with a separate, clean, dry cloth. Be careful not to scratch the surface with cleaning tools or by inadvertently embedding debris.

• Regular exterior and interior cleaning require only wiping with a clean, damp cloth and then drying. Remove oil, grease, or general soil using a clean cloth dampened with a mild cleaner such as Bona AllPurpose Cleaner. Rinse with a clean, damp cloth, then dry thoroughly. It is important to wipe spills immediately. Prolonged exposure to spills may cause permanent discoloration or damage to the leather and substrate.

• Avoid using harsh detergents, strong soaps, abrasive cleaners, and self-polishing waxes. All these items can damage the factory-applied protective finish.

• Avoid using your dishcloth to clean or dry cabinet exteriors. It may contain remnants of detergents and grease that will be transferred to the RLV™

• For long-lasting beauty, treat RLV™ as you would fine furniture. Excess moisture is the enemy of any finish. Sink, range, dishwasher, oven, and baseboard areas are most susceptible to moisture damage. Immediately dry surfaces where there is moisture or where water may have spilled using a clean, dry cloth. Never hang damp towels over cabinetry to dry. Excessive moisture will cause the wood substrate to expand and may damage thefinish.

• Do not spray cleaner of any type directly on RLV™.

Aluminum-Framed Recycled Leather Veneer (RLV™) Doors

• Use soap or mild detergent and warm water on a soft cloth to clean the aluminum frame.

• DO NOT use an abrasive cloth to clean aluminum.

• Avoid spraying cleaner directly on aluminum.

• Follow care and cleaning listed above for RLV™ surfaces.

Glass Door Inserts within Recycled Leather Veneer (RLV™) Doors, RLV™ Shelving, and RLV™ Countertops

• Spray an ammonia-free glass cleaner on a clean, soft, lint-free cloth or paper towel, and clean only the glass area.

• Avoid spraying cleaner directly on the glass as overspray may cause damage tothe RLV™ or aluminum frames.

• Follow care and cleaning listed above for all other RLV™ surfaces.

Component Program

SECTION 2: Product Specifications

HUMIDITY IN THE HOME WITH RECYCLED LEATHER VENEER (RLV™)

EcoDomo® leather components are made of wood substrates wrapped with a leather finish. The same guiding principles for cabinetry made from wood apply to our products: Humidity and moisture will affect our leather components the same way they affect wood cabinetry. Our doors and drawer fronts are made of exceptional, high-density, cabinet-grade HDF which, by design, is more resistant to moisture. (Please read below for our recommendations for you and your leather cabinetry components.)

Healthy Environment

Home maintenance and medical experts advise homeowners to monitor and control indoor humidity levels to maintain a safe and healthy home environment. As it turns out, the humidity levels that are healthiest for people are also ideal for cabinetry. Indoor relative humidity levels of 40% to 50% are ideal; uncontrolled extremes above 80 percent or below 20% are likely to cause problems.

Humidity Imbalance

Wood and leather products absorb moisture and swell or expand in high-humidity conditions. Wood and leather products release moisture and shrink or contract in low-humidity conditions.

Some expansion or contraction of wood and leather products may be noticeable when the cabinetry is moved from one location to another or when humidity conditions change.

Wood and Leather Products and Humidity Considerations

Expansion or contraction of cabinetry fronts is most likely caused by improper humidity conditions during site storage, installation, or use. Our finishing process slows expansion and contraction but cannot prevent it entirely in extreme high or low humidity. These extreme conditions can cause shrinkage or loosening of the RLV™ and / or warpage of the substrate.

Some remodeling or construction activities greatly increase moisture content within a home and can be harmful to wood and leather cabinetry if precautions are not taken. For example, drywall taping adds a lot of moisture to a home if the area is not properly ventilated. Homes that are not used year-round still require climate control to avoid wood or leather issues due to extreme high or low humidity levels.

Examples of humidity imbalance include swollen doors or drawer fronts, but doors which no longer close properly, door and drawer front-panel expansion or contraction, joint separation (especially in mitered doors), and bowing of stiles or rails. Mitered doors need low, stable moisture.

Cabinetry stored in unfavorable humidity conditions should be allowed to acclimate to the surrounding environment for a period prior to installation. This minimizes the degree to which wood doors may swell, bind, shrink, or warp upon installation. Once our doors have been installed in climate-controlled conditions, they will naturally revert to their original dimensions.

Humidity and Warranty

Our warranty is written with the expectation that the product(s) will be stored and installed in a climate-controlled environment; the warranty is void if the cabinetry is stored or installed in extreme temperatures or humidity levels. With proper maintenance of humidity levels, the new cabinetry will be a long-lasting, durable, and beautiful enhancement to any home.

SECTION 2: Product Specifications

WARRANTY

LIMITED WARRANTY AND LIMITATION ON DAMAGES

COVERAGE: EcoDomo® warrants its leather cabinetry components to be free of defects in material and / or workmanship under normal residential usage to the original purchaser of the cabinetry for as long as they own their home or one year, whichever comes first.

GENERAL WARRANTY INFORMATION: EcoDomo® Leather cabinetry components – hide and RLV™ – are expected to have color variation due to the organic nature of the product. The warranty does not cover damage caused by improper installation, excessive humidity, or extreme temperature variations.

Mistreatment of any kind, including mechanical impacts, scuffing caused by hard objects, water damage, plumbing leaks, fire damage, inadequate maintenance, or improper usage will void this limited warranty. Further excluded are problems due to extreme humidity, heat or cold, sunlight, stains, discoloration, rips, tears, gouges, and indentations. Normal wear and tear are expected, as with any other component for cabinetry application. Variations are considered the natural characteristics of the material in relation to their environment and are not covered under these warranties. We reserve the right to substitute discontinued products with the most similar styling and color available at the time your claim is submitted. No warranty is extended unless installation instructions and maintenance are followed.

WARRANTY REMEDY: EcoDomo® will furnish comparable leather components of similar color, pattern, and quality for either the repair of the defective area or the replacement of the defective product at the sole option of EcoDomo®

CONSEQUENTIAL OR INCIDENTAL DAMAGES EXCLUDED: Our obligation under these warranties shall be limited to the repair or replacement of any part or parts that prove defective as determined by our review. These warranties do not cover the cost of installation, removal, subsequent damage, or transportation of the defective product, regardless of who performs the work.

IMPLIED WARRANTIES: There are no implied warranties including warranties of merchantability and fitness for a particular purpose or use extending beyond the limited warranty noted above. No representative, employee, or agent of EcoDomo® is authorized to modify or change the limited warranty or limitation on damages as stated herein.

HOW TO MAKE A CLAIM: Promptly contact the dealer or manufacturer in writing and include: name of product purchased, quantity, cost, date purchased, installer, and installation date. The authorized EcoDomo® Cabinetry dealer or manufacturer will arrange for an inspection. A dated sales receipt as proof of purchase is required to obtain benefits from the warranty. If a dealer is unavailable, please write to: Warranty Department, EcoDomo®, at the address below, with a complete explanation of the defect.

We will review and resolve the claim within 60 days after the claim is filed with EcoDomo®. Our address is 630 East Diamond Avenue, Suite M, Gaithersburg, MD 20877.

Component Program

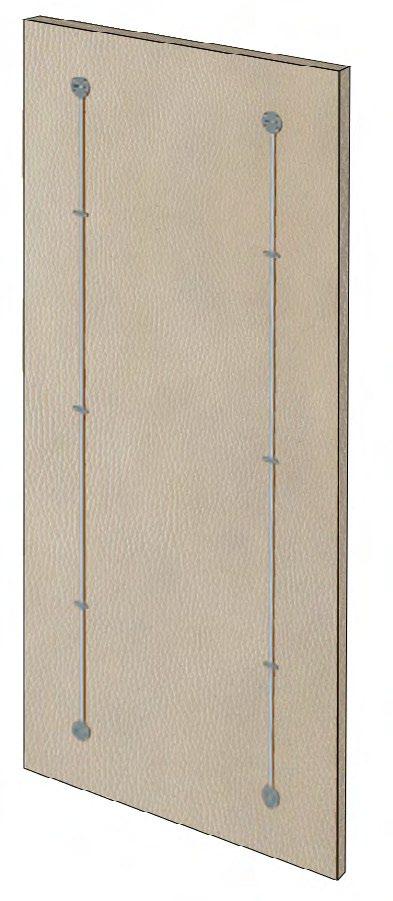

LIMITED WARRANTY FOR DOORS OVER 72” HIGH

SECTION 2: Product Specifications

EcoDomo® includes a door-straightening mechanism on all doors over 72” high. Two mechanisms will be included when such a door is also greater than 27” wide. For standard installation, the mechanism is visible on the back side of the door. For Infinity wrapped doors, there is an option to hide the bar. Please ask for pricing. This mechanism is primarily countersunk into the door, though attachment plates are used which protrude slightly. Decorative hardware / drilling may be affected. If the client chooses to waive the inclusion of this mechanism, warpage and other issues may occur, subsequently making the warranty invalid.

>27” wide

Anti-Warp Door Mechanism (visible option)

The option exists for Infinity wrapped doors to completely dissimulate the anti- warp mechanism (not shown).

SECTION 2: Product Specifications

RECYCLED LEATHER VENEER (RLV™) PATTERN OVERVIEW

Our Component Program includes three standard RLV™ patterns available in distinct colorways:

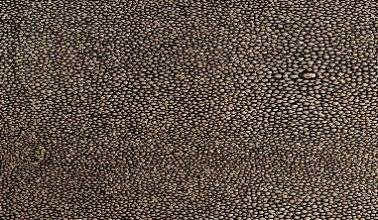

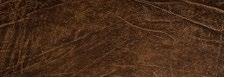

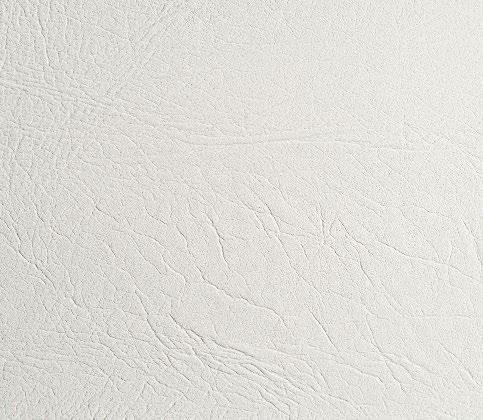

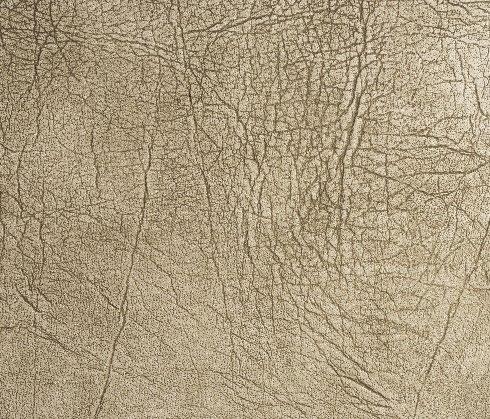

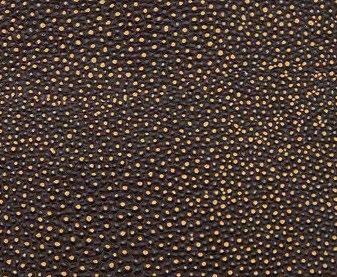

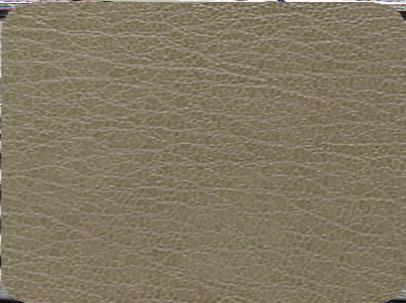

BUFFALO

The Buffalo pattern represents our most popular and most familiar leather pattern, thanks to its use in the furniture industry. Aesthetically, this pattern is variable and non-repeating, with embedded details that replicate hair grains and fat wrinkles. Its 70% leather content mixed with texture gives it the feel of natural leather. Buffalo shown in Gold Grey Metallic

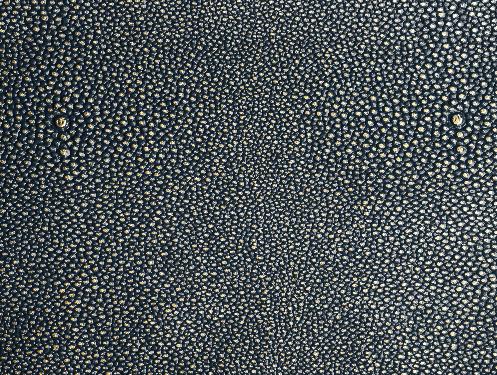

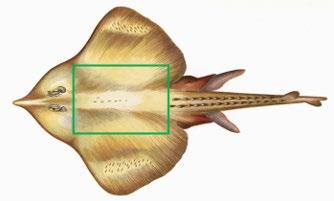

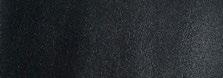

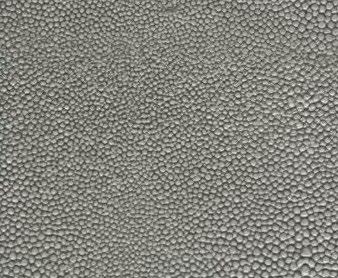

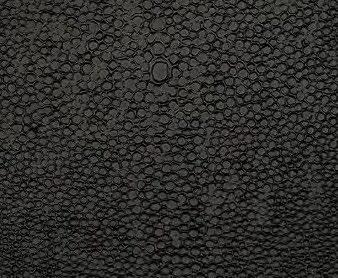

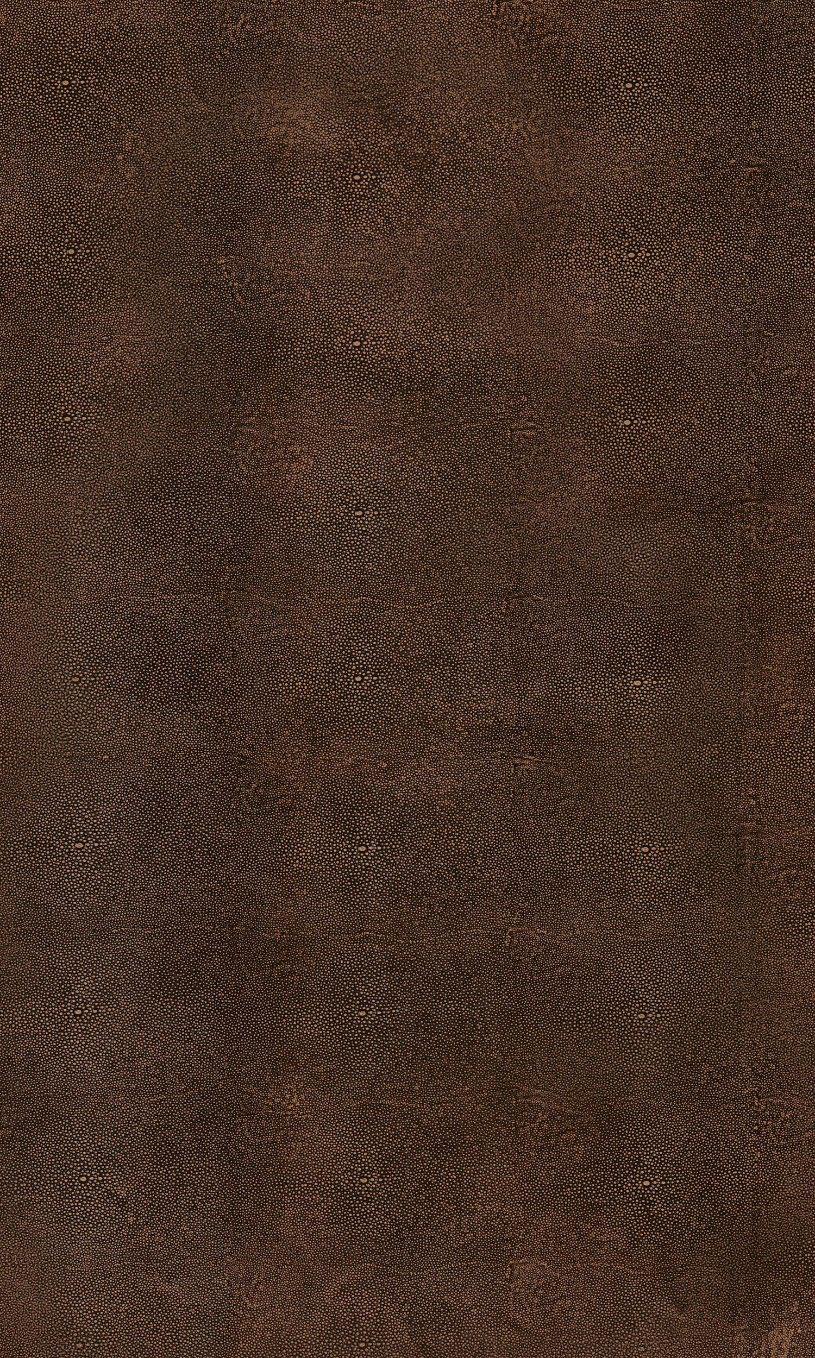

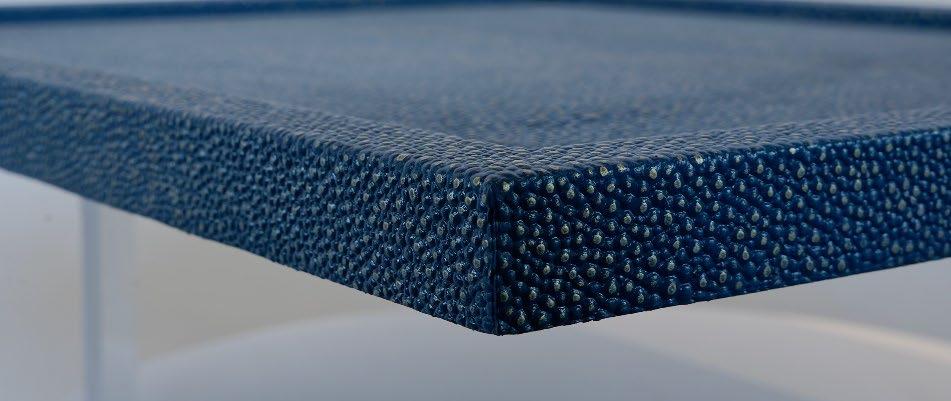

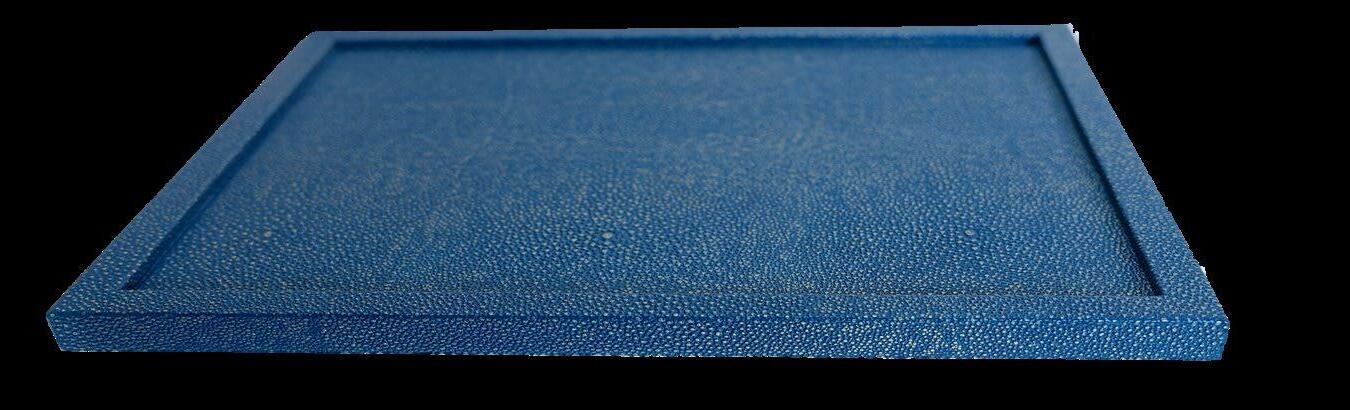

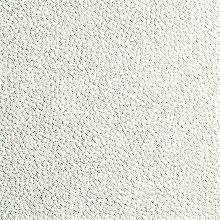

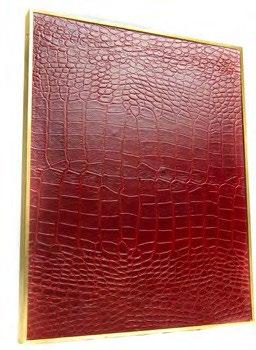

SHAGREEN

The Shagreen pattern is known for its smooth, pebbly texture and small scale with the “ eye” which appears at regular intervals. The Shagreen texture has a repeat pattern which is not pronounced. It’s typically associated with luxury, as its natural counterpart was taken from a very small sections of stingray that required a particular skill necessary to prepare and ultimately inlay them.

Shagreen shown in Newbury Port Blue

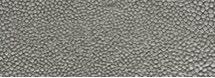

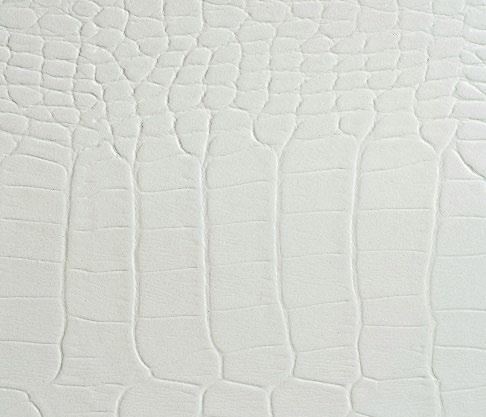

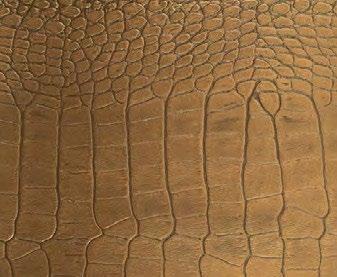

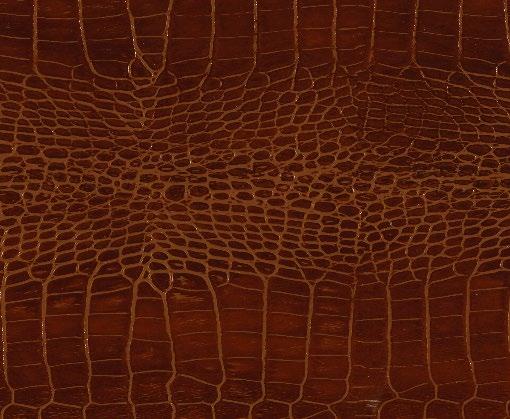

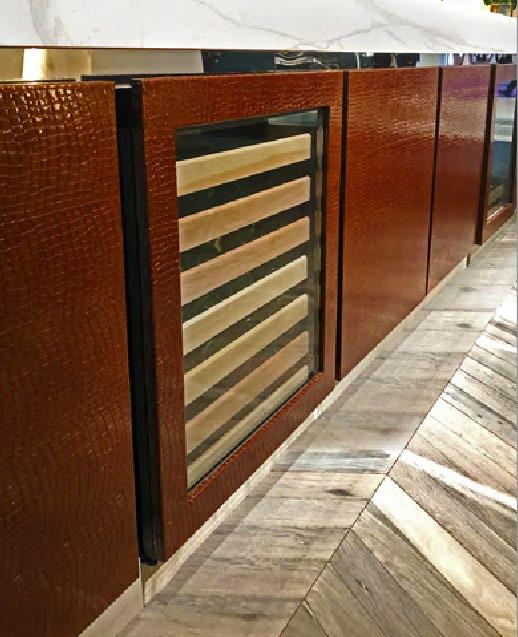

CROCODILE

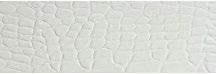

Unlike Buffalo and Shagreen patterns, Crocodile has a larger, more pronounced pattern, which we sequence match for each order. As with exotic woods, like wenge or zebrawood, by sequence matching we can produce a more aesthetically pleasing result. For this pattern, we require plan and elevation drawings to use as references during production. See the following page for examples.

Crocodile shown in Antique Grey

Component Program

SECTION 2: Product Specifications

RECYCLED LEATHER VENEER (RLV™) COLOR / TEXTILE PALETTE – STANDARD OFFERING

Buffalo Colors

Colors Crocodile Colors

SECTION 2: Product Specifications

BUFFALO – STANDARD RECYCLED LEATHER VENEER (RLV™) COLORS

Bright White

Gold Grey Metallic

Paloma Grey

Grey Umber

Cocoa

Maple

Coal

Component Program

SECTION 2: Product Specifications

SHAGREEN – STANDARD RECYCLED LEATHER VENEER (RLV™) COLORS

White

Grey Stone

Coco

Newbury Port Blue

Pebble Chocolate

Black Night

Black

SECTION 2: Product Specifications

CROCODILE – STANDARD RECYCLED LEATHER VENEER (RLV™) COLORS

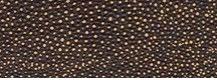

NOTE: For orders in the Crocodile pattern, EcoDomo® will sequence match the entire layout when multiple components are ordered. Floor plan and elevation drawings must be submitted with your part list. These will serve as a reference as we plan for production to provide the most pleasing aesthetic for your design. See pages 28-30 for details.

Bright White

Paloma Grey

Antique Grey

Casino Royal

Mahogany

Coal Fire

Component Program

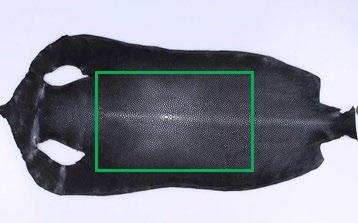

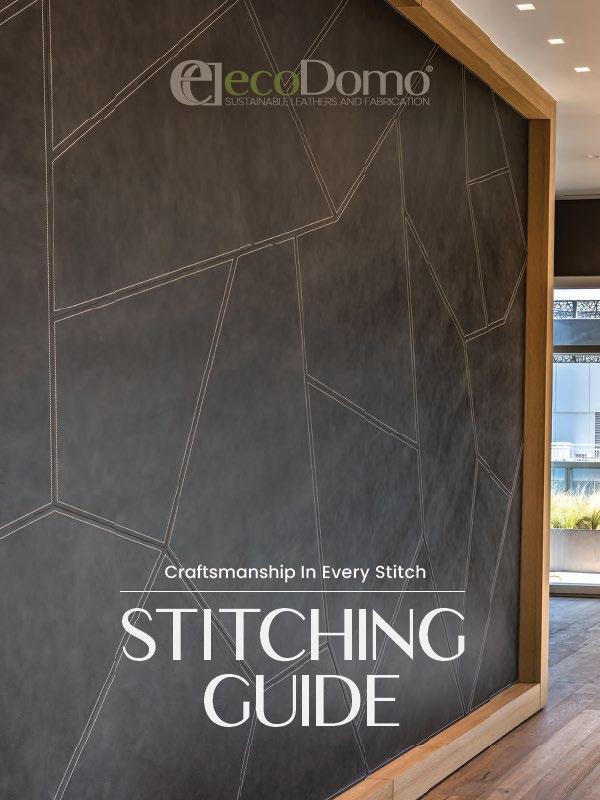

EMBOSSING AND PLATE LINES – SHAGREEN

SECTION 2: Product Specifications

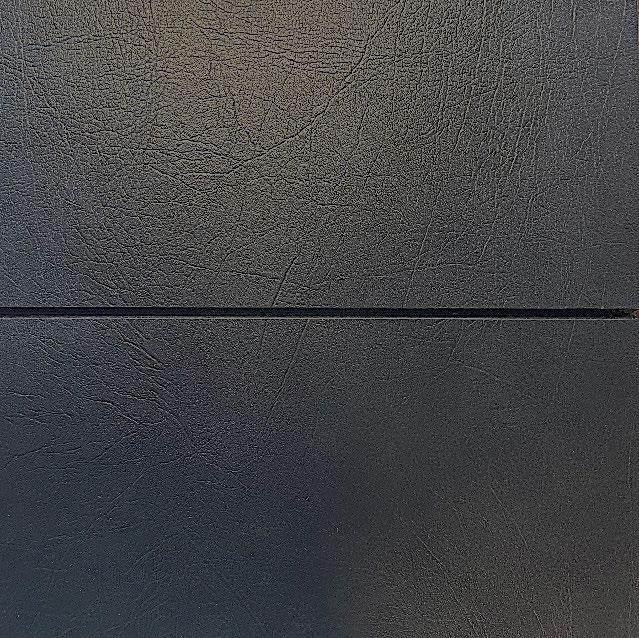

All our Recycled Leather Veneer (RLV™) patterns (Buffalo, Shagreen, and Crocodile) are created through an embossing process using steel plates that are 24” wide. The pattern appears on a flat, rectangular plate that is carefully placed on top of the RLV™ material. Using a combination of heat and pressure, the pattern from the plate is pressed into the material. The plate is then moved to another area of the RLV™. This process is repeated until the pattern appears over the entire sheet. For the Shagreen RLV™ pattern, plate lines are an inherent element visible on doors and panels that are larger than 24” x 44”.

The photo below shows a sheet of RLV™ in Shagreen with a plate line. The plate lines’ visibility will depend on the color, finish, and stock available at the time of order. Shagreen finishes are done by hand with multiple touches leading to variation in color, depth of finish, and the visibility of plate lines. There are no refunds on any products with a shagreen finish due to plate lines.

Plate Line

Plate Line

Plate Line

SECTION 2: Product Specifications

Embossing and Plate Lines – Shagreen (continued)

The default process includes the plate lines; if multiple panels and doors are involved, EcoDomo® will align the plate lines across the entire installation for the best aesthetic overall.

Alternatively, our artisans can create a discreet seam in the material – a “Magic Seam”. The “Magic Seam” is practically invisible as artisans line up the grain from one leather piece to another. This option will be highlighted for quotes which involve multiple doors which are larger in size. The seam issue usually presents itself only with large-scale installations.

The photos below show a sheet of RLV™ in Shagreen with a seam integrated vs a plate line

Photo Courtesy of The Tailored Closet – San Diego

Plate lines indicated with red arrows on photos above

Countertop in Pebble Shagreen showing Plate Lines

Magic Seam Plate Line

Desktop in Black Knight Shagreen showing Plate Lines

Photo Courtesy of The Container Store

Component Program

Embossing and Plate Lines – Shagreen (continued)

SECTION 2: Product Specifications

The photo below shows infinity shaker style architectural doors finished with Pebble Shagreen RVL and accented with a flax stitch manufactured by EcoDomo®. The plate lines are visible on the doors every 24”.

Plates lines are a standard feature of shagreen leather due to the embossing. Shown on the right is the detail of the plate line on Pebble Shagreen RLV™ Not all Shagreen colors show the same way as this is a handmade, hand-wiped finish.

Design by Gail Davis Designs. Photos by Andrea Stein.

SECTION 2: Product Specifications

CROCODILE – DIRECTIONAL SPECIFICATION REQUIREMENT

EcoDomo’s Crocodile pattern is offered in either a vertical or horizontal direction. Please indicate your preference on your order. The default orientation is vertical.

VERTICAL CROC PATTERN: 46” max height. Width parameters follow specific components.

HORIZONTAL CROC PATTERN: Width and height parameters follow specific components.

Left: Example of a custom crocodile color on appliance panels with the backbone laid horizontally.

Design by Cory Keiser - Photo by Andrea Stein.

Right: Example of a custom crocodile color on an island with infinity doors and panels with the backbone laid vertically. The default orientation is vertical.

Design by Jennifer Gilmer Kitchen and Bath – Photo by John Cole

Component Program

SECTION 2: Product Specifications

CROCODILE – SEQUENCE MATCHING

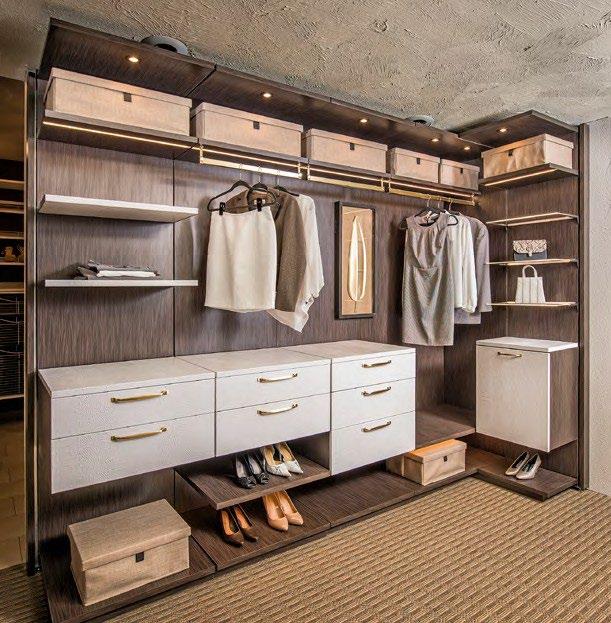

BELOW: Closets illustrating the sequence alignment.

EcoDomo® products shown in photo at left:

• Shelving

• Countertop

• Kensington Style drawer fronts

As shown below, the Crocodile RLV™ pattern aligns vertically for each drawer front within the stack and will match a counter above. We consider the entire landscape of your design to achieve the best possible look.

SECTION 2: Product Specifications

Crocodile – Sequence Matching (continued)

A Kitchen Island in

Fire Crocodile Illustrates the Sequence Alignment Design by Jennifer Gilmer Kitchen and Bath – Photos by John Cole.

Penta

Component Program

Crocodile – Sequence Matching (continued)

SECTION 2: Product Specifications

Vertical Sequence Matched Doors in Coal Crocodile

Vertical Sequence Matched Drawers and Back Panel

Photo from Yacht Design

Photo from California Closets

Vertical Sequence Matched Countertop, Drawers, and Drawer Inserts in Coal Crocodile

Photo courtesy of The Container Store

Component Program

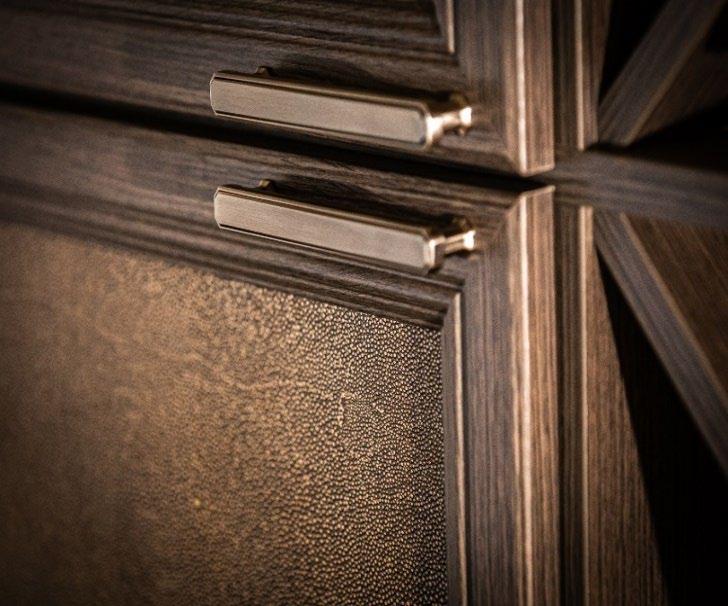

SECTION 3: Doors and Drawer Fronts

RECYCLED LEATHER VENEER (RLV™) DOOR AND DRAWER OVERVIEW

RLV™ door and drawer fronts are available in four standard door styles: Penta, Infinity, Shaker, and Slim Shaker Penta and Infinity are both slab designs. Our Shaker Style follows typical styling and includes an outside frame with a recessed center panel. The Slim Shaker has a narrow frame applied to the perimeter of the door which adds thickness to the overall door size. Our Shaker doors are also available as a Shaker Frame – see page 44.

100% Leather Coverage Leather / Melamine Back 100% Leather Coverage 100% Leather Coverage

All four door styles are available in our standard RLV™ patterns:

Each pattern is available in a standard array of colors outlined on pages 20-23.

Infinity

Penta Shaker

Slim Shaker

Buffalo

Shagreen

Crocodile

Buffalo in Grey Umber

Shagreen in Black Knight

Crocodile in Coal

SECTION 3: Doors and Drawer Fronts

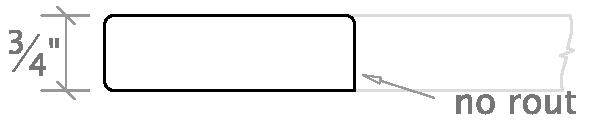

SLAB DOOR SPECIFICATIONS

INFINITY

DOOR SPECIFICATIONS

• Substrate thickness: 3/4”

• Slab design with face, back, and edges wrapped in Recycled Leather Veneer

• Furniture-grade HDF substrate.

• Size parameters for doors and drawer fronts:

o Minimum: 4-1/2” x 4-1/2”

o Maximum: 48” x 96”

• Doors taller than 72” receive an anti-warp mechanism; see page 18 for details.

• Specify width and height to the nearest 1/16”.

• Available in RLV™ colors listed on pages 20-23

Additional Information

• Hinge boring for doors is available; see SECTION 6: Interior Components for details.

• Larger door sizes will be considered on an individual basis.

• Framed doors use the Shaker Frame door style.

• Pairs with Infinity or Kensington Drawers.

Infinity Leather doors in a residential kitchen -Antique Black Walrus RLV™ –

Photos by Seanie Blue Infinity Front

Component Program

Slab Door Specifications (continued)

PENTA SPECIFICATIONS

Section 3: Doors and Drawer Fronts

• Slab design with face and edges wrapped in Recycled Leather Veneer.

• Back finished in black or white melamine.

• Substrate thickness: 3/4”

• Furniture-grade HDF substrate.

• Size parameters for door and drawer fronts:

o Minimum: 4-1/2” x 4-1/2”

o Maximum: 48” x 96”

• Doors taller than 72” cannot receive an anti-warp mechanism.

• Specify width and height to the nearest 1/16”.

• Available in RLV™ colors listed on pages 20-23

Additional Information

• Hinge boring for doors is available; see SECTION 6: Interior Components for details.

• Larger door sizes will be considered on an individual basis

• Framed doors use the Infinity Shaker Frame. Penta is not available in any other door style.

Penta doors and drawers in Coal Walrus in a commercial office space. Photos Alex Hoffman.

Penta Front

Penta Back

SECTION 3: Doors and Drawer Fronts

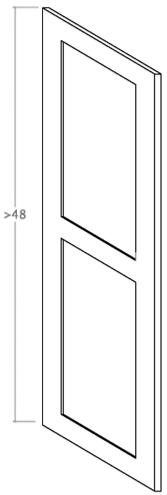

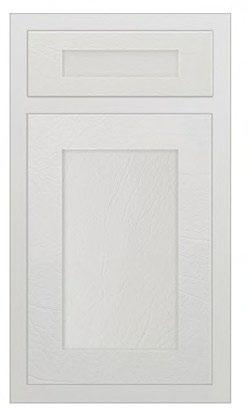

“5-PIECE” DOOR SPECIFICATIONS

SHAKER DOOR SPECIFICATIONS

• Substrate thickness: 3/4”

• Outside frame with recessed center panel on front; back is solid sheet of RLV™ / slab.

• Face, back, and edges wrapped in RLV™

• Furniture-grade HDF substrate.

• Size parameters listed on page 121.

• Doors taller than 72” receive an anti-warp mechanism; see page 18 for details.

• See pages 39-40 for drawer details.

Additional Information

• Hinge boring for doors is available; see SECTION 6: Interior Components for details.

• Doors >48” high have a center rail unless the client signs-off specifying otherwise.

• Larger door sizes will be considered on an individual basis.

• Framed doors use the Shaker Frame door style.

• Pairs with Infinity, Kensington, and/or Shaker Drawers

Shaker Back

Tall Shaker Frame

Shaker Front

Stile / Rail Section

Component Program

“5-Piece” Door Specifications (continued)

SECTION 3: Doors and Drawer Fronts

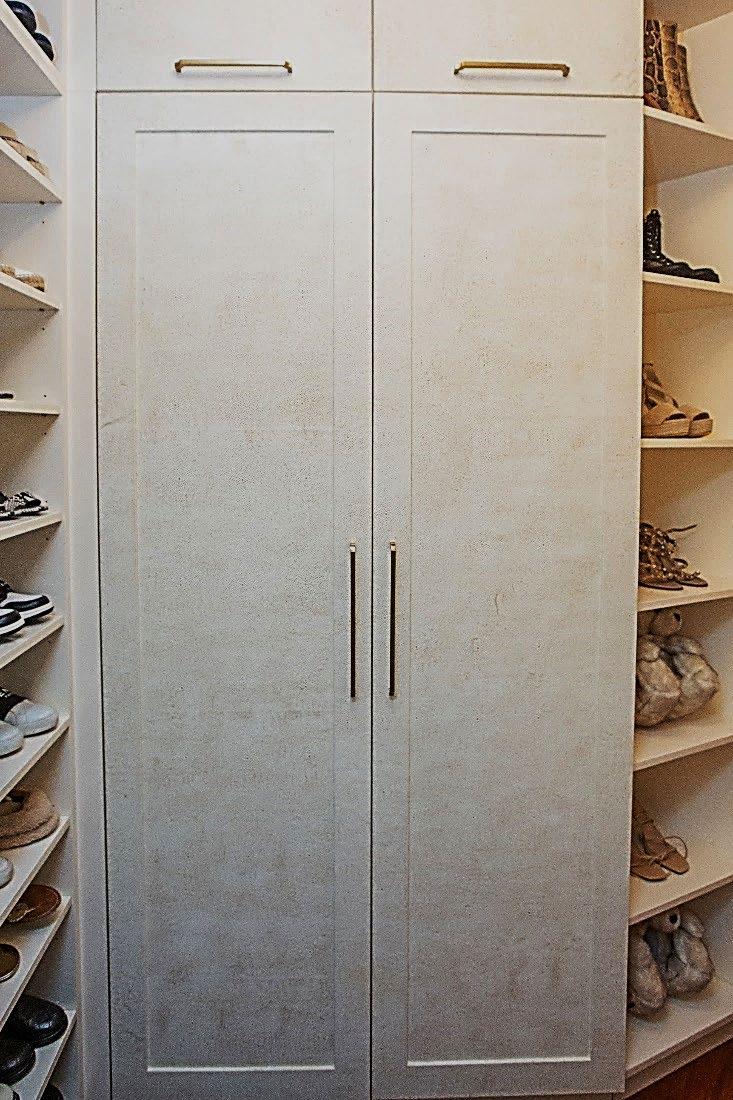

Photos illustrating shaker doors in Coal Crocodile (left) by Couture Closets. Note that the crocodile grain is book matched across the stiles, rails and center panel. On the right is a White Shagreen Shaker Door - without the center rail - designed by P Miller Luxury Closets.

SECTION 3: Doors and Drawer Fronts

SLIM SHAKER DOOR SPECIFICATIONS

• Substrate thickness: 1”

• Narrow (5/8” wide) outside frame with recessed center panel on front; back is solid sheet of Recycled Leather Veneer / slab.

• Face, back, and edges wrapped in RLV™

• Furniture-grade HDF substrate

• Size parameters listed on page 121.

• Specify width and height to the nearest 1/16”.

• Available in RLV™ colors listed on pages 20-23

• Doors taller than 72” receive a visible anti-warp mechanism; see page 18 for details.

• See page 42 for drawer details.

Additional Information

• Hinge boring for doors is available; see SECTION 6: Interior Components for details

• Larger door sizes will be considered on an individual basis.

• Framed doors use the Shaker Frame door style.

• Pairs with Slim Shaker Drawers

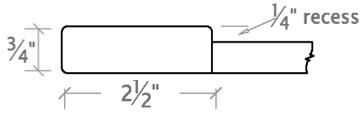

5/8” Width

Side View of a Slim Shaker in Newberry Port Blue Shagreen

Stile / Rail Section View

Component Program

SLAB DRAWER FRONT SPECIFICATIONS

• Substrate thickness: 3/4”

• Slab design.

• Furniture-grade HDF substrate

• Size parameters for doors and drawer fronts

o Minimum: 4-1/2” x 4-1/2”

o Maximum: 96” x 44”

• Specify width and height to the nearest 1/16”.

• Available in RLV™ colors listed on pages 20-23.

INFINITY

• Face, back, and edges wrapped in RLV™ PENTA

• Face and edges wrapped in RLV™.

• Back is black or white melamine.

KENSINGTON (AVAILABLE IN DRAWERS ONLY)

• Face and edges wrapped in RLV™

SECTION 3: Doors and Drawer Fronts

• Back is partially wrapped 2” with exposed HDF (typically this area will be hidden by a drawer box).

Additional Information

• Framed drawers use the Shaker Frame door style.

• Pairs with Infinity or Penta Doors; can be mixed as a Slab accent with Shaker doors

Kensington Drawer in an Installation

Kensington Drawer fronts offer the best value. Typically, the raw HDF on the back gets covered by the drawer box.

Infinity Front Infinity Back

Penta Front Penta Back

Kensington Front

Kensington Back

SECTION 3: Doors and Drawer Fronts

Drawer Illustrations

A single pair of drawers has a disproportional visual impact on a cabinet design for often the same additional cost of an accessory or specialty decorative item. A small amount of leather elevates the entire cabinet. Shown below are examples of this concept in a bar in Coal Crocodile and a closet in Moon Shagreen.

Photo courtesy of Closet Envy.

Photo courtesy of The Container Store.

Component Program

SECTION 3: Doors and Drawer Fronts

“5-PIECE” DRAWER FRONT SPECIFICATIONS

SHAKER DRAWER VARIATIONS (3/4” THICK)

• Substrate thickness: 3/4”

• Outside frame with recessed center panel on front; back is solid sheet of Recycled Leather Veneer / slab.

• Face, back, and edges wrapped in RLV™

• Furniture-grade HDF substrate.

• All stiles are 2½” wide; rail widths vary per below.

• Specify width and height to the nearest 1/16”.

• Available in RLV™ colors listed on pages 20-23 Shaker (3/4” thick)

• Stile and Rail framing is 2-1/2” (matches Shaker door).

• For drawers ≥7-1/2” high.

Small Shaker (3/4” thick)

• Stile width is 2-1/2” (stiles match Shaker door).

• Rail height is 2”.

• For drawers 6” to 7-7/16” high.

Extra Small (XS) Shaker (3/4” thick)

• Stile width is 2-1/2” (stiles match Shaker door)

• Rail height 1-1/2”.

• For drawers 4-1/2” to 5-15/16” high.

Extra (XS) Small Shaker Front

Extra (XS) Small Shaker Back

Small Shaker Front Small Shaker Back

“5-Piece” Drawer Front Specifications (continued)

Specification Guide

SECTION 3: Doors and Drawer Fronts

Shaker Drawer Front Sizing Based on Drawer Height

Rail dimensions apply to Shaker and Shaker Frame.

Typical Configuration for Base Cabinet (18” w x 30” h) Frameless Inset

Drawer / Door Full-Height Door

DESIGN NOTE:

Drawer / Door Full-Height Door

• Consider placement of drawer fronts next to full-height doors, as the rails may not align. This is shown in configuration examples above: Rail heights on drawer fronts are Small (frameless) and XS (inset).

• The Infinity style will be substituted for door / drawer fronts smaller than the minimum size listed above.

Component Program

SECTION 3: Doors and Drawer Fronts

“5-Piece” Drawer Front Specifications (continued)

The photos below illustrate Shaker Doors and Drawers in White Shagreen in a Texas closet.

Photos courtesy of The Container Store

“5-Piece” Drawer Front Specifications (continued)

SLIM SHAKER DRAWER SPECIFICATIONS (1”

THICK)

SECTION 3: Doors and Drawer Fronts

• Standard thickness: 1”

• Narrow (5/8” wide) outside frame with recessed center panel on front; back is solid sheet of Recycled Leather Veneer / slab.

• Face, back, and edges wrapped in RLV™.

• Furniture-grade HDF substrate

• Specify width and height to the nearest 1/16”.

• Available in RLV™ colors listed on pages 20-23.

Slim Shaker Front Slim Shaker Back

Slim Shaker Drawer featured in Newburry Port Blue Shagreen

Component Program

SECTION 3: Doors and Drawer Fronts

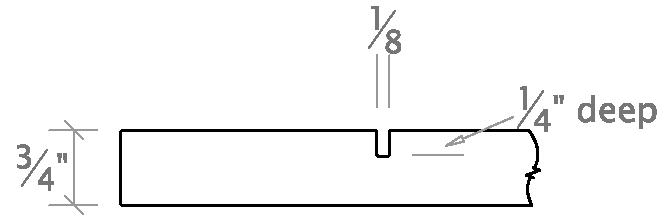

MOCK DOOR / DRAWER OPTION (FOR 3/4” THICK INFINITY DRAWERS)

• Standard thickness: 3/4”

• Matches Infinity door / drawer with specified kerf locations that mimic the look of multiple doors or drawers

• Kerf sizing is 1/8” wide x 1/4” deep

• Kerf grooves are available in horizontal and / or vertical positioning.

Kerfs are wrapped in RLV™ as are the backs of doors / drawers.

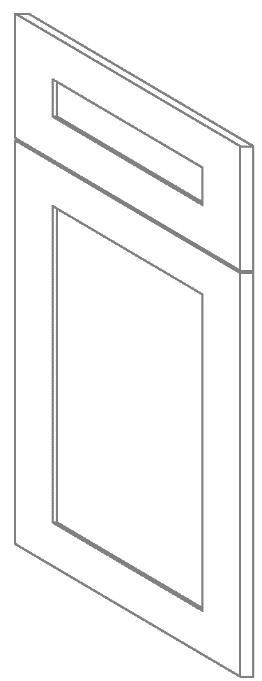

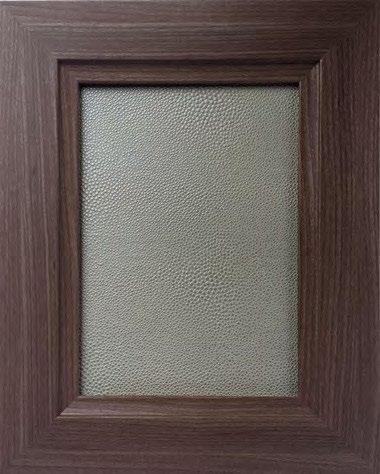

DOOR / DRAWER FRONT OPTIONS

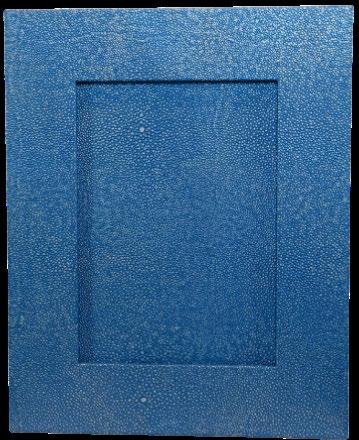

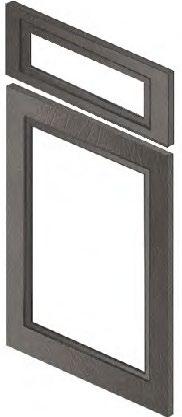

SHAKER FRAME SPECIFICATIONS

• Substrate thickness: 3/4”

• Frame only; center area for field-install of glass or other decorative material.

• Backside frame options:

o Frame only, no prep for glass.

o Frame prepped for glass.

o Frame prepped for glass with retainer strip.

• Face, back, and all edges wrapped in RLV™.

• Doors >48” high have a center rail unless the client signs-off specifying otherwise.

• Furniture-grade HDF substrate.

• Size parameters listed on page 121.

• Specify width and height to the nearest 1/16”

• Available in RLV™ colors listed on pages 20-23

Additional Information

Specification Guide

SECTION 3: Doors and Drawer Fronts

• Hinge boring for doors is available; see SECTION 6: Interior Components for details.

• Larger door sizes will be considered on an individual basis; see SECTION 7: Custom Requests for details.

• This is the default door style for all framed doors.

Shaker Frame Shown with Clear Glass Insert on Right in Pebble Shagreen Design by Gail Davis

Shaker Frame Front Shaker Frame Back Frame Frame Prepped for Glass

Frame Prepped for Glass with Retainer Strip

Component Program

SECTION 3: Doors and Drawer Fronts

Door / Drawer Front Options (continued)

DOOR / DRAWER INSERT PANEL

• RLV™ faced panel for installation into frame of customer-provided door / drawer front

• Wood door styles require routing in back for panel; it is similar to ordering and installing decorative glass.

• Panel face is finished in RLV™; edges will show core material.

• Back is finished in melamine color similar to RLV™ selected

• Furniture-grade HDF substrate

• Substrate thickness: 1/4”

• Specify width and height to the nearest 1/16”

• Size parameters for panels:

o Minimum: 4” x 4”

o Maximum: 48” wide x 96” high

• Available in RLV™ colors listed on pages 20-23

AVAILABLE FROM DOOR MANUFACTURERS

Multiple door companies offer EcoDomo® insert panels as an option within their existing lines of products, including but not limited to:

• Canary Closets and Design

• Conestoga Wood Specialties

• Element Designs

• J.B. Cutting

• And others Contact EcoDomo® or your preferred door manufacturer for more information.

Insert Panel Shown in Coco Shagreen

Door / Drawer Front Options (continued)

APPLIANCE FRONT / DOOR

• Available in Slab, Shaker, Slim Shaker, or Shaker Frame (for refrigeration with glass door).

• Backside DOES NOT include dado for glass insert unless specified

• Suitable for refrigerator, wine unit, dishwasher, and face panel for built-in oven .

• Constructed to specifications per appliance manufacturer (Sub-Zero, Monogram, Perlick, etc.).

• Face and edges wrapped in RLV™; back includes 2” overlap; finished / non-RLV™ areas receive a clear coat to seal core material.

• Specify width and height to the nearest 1/16”.

• Size parameters for appliance fronts:

o Minimum: 4-1/2” x 4-1/2”

o Maximum: 48” wide x 96” high

• Available in RLV™ colors listed on pages 20-23

SECTION 3: Doors and Drawer Fronts

Left Door: Slab; Right Door: Frame with Opening; RLV™: Mahogany Crocodile

Monogram Appliance Panels with Custom Patent Hide Leather Design by Richard Anuszkiewicz

Section View

Component Program

SECTION 3: Doors and Drawer Fronts

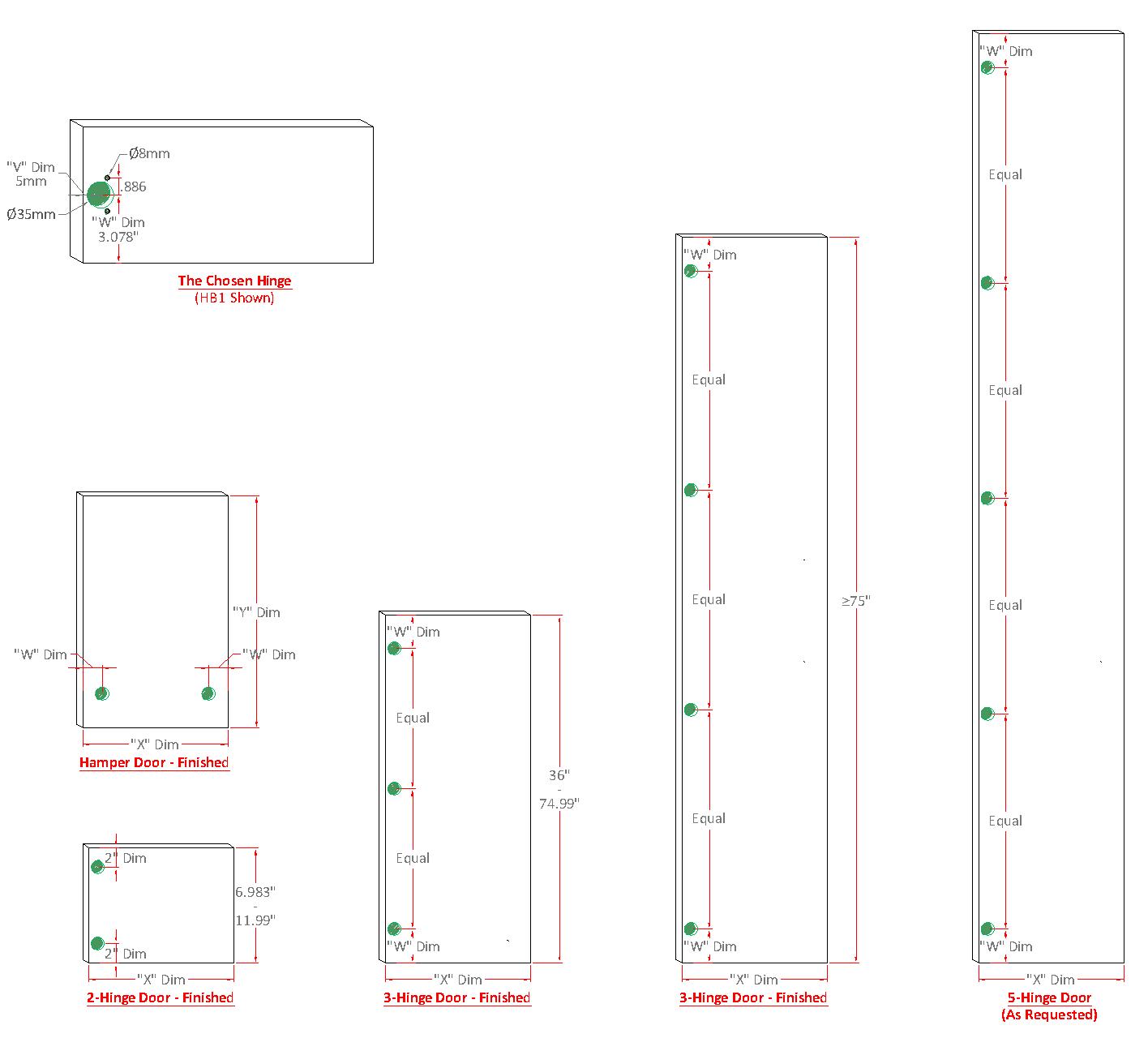

HINGE PREP

• This add-on allows for customized hinge boring for cabinet doors.

• Client must supply actual hinge along with a diagram indicating the quantity and center placement for each hinge boring.

See EcoDomo’s YouTube channel for demonstrations on cutting, hinge boring, and more with Recycled Leather Veneer.

Hinge boring is the same as with any other wood or melamine door using a hinge press machine or drill with a guide.

Photo of a Blum hinge press in action on RLV™

Typical result of a hinge drilling

Door / Drawer Front Options (continued)

Hinge Prep (continued)

SECTION 3: Doors and Drawer Fronts

DIAGRAM EXAMPLE: Hinge Boring Detail

Component Program

(LEFT BLANK INTENTIONALLY)

Component Program

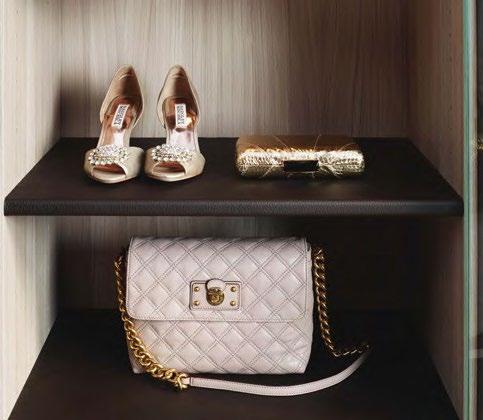

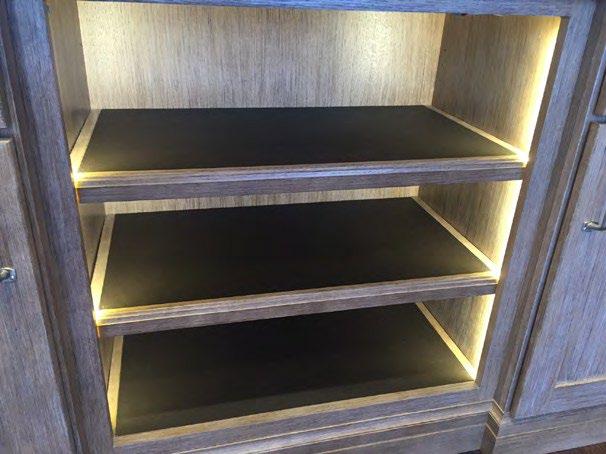

SHELVING

• Constructed from HDF / particle board core; RLV™ is applied in a continuous manner to top, front edge, and bottom.

• Finished ends must be indicated.

• The standard shape for shelving is a rectangle / square; for other shapes or configurations, a Special Request and diagram must be submitted.

• Specify dimensions to the nearest 1/16”.

• Size parameters for shelving:

o Minimum: 6” long x 6” deep

o Maximum: 94” long x 44” deep

• Standard thickness options: 3/4” and 1-1/8”.

• Client is responsible for providing support for shelves over 36” long.

• Available in RLV™ colors listed on pages 20-23.

Additional Information

• Shelving enhancements, such as stitching, embellishments, and cut-outs / notches are available; see Section7/Custom Embellishments for details.

SECTION 4: Complimentary Items

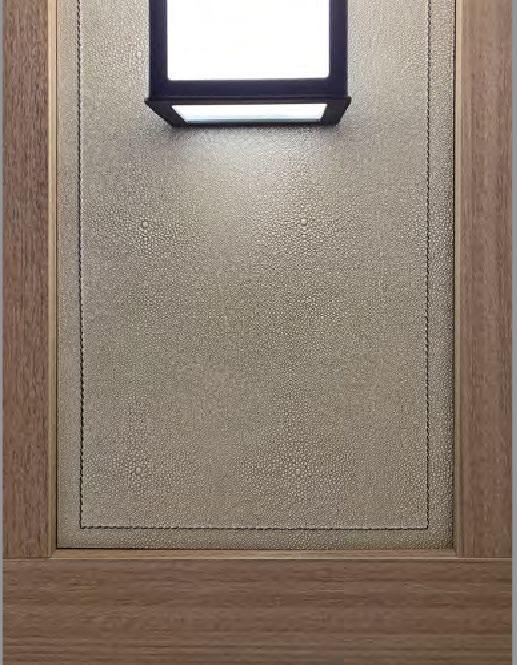

Pebble Shagreen Back Panel and Shelves Designed by Marina Porl

Coal Crocodile Shelves in 3/4” Thickness Showcasing How the Crocodile Grain Matches from One Shelf to Another

SECTION 4: Complimentary Items

Shelving (continued)

FLOATING SHELVES

• Constructed from HDF with RLV™ applied to top, bottom, face, and both ends; square profile with seams between faces

• Specify dimensions to the nearest 1/16”.

• Size parameters for floating shelves:

o Minimum: 6” long x 6” deep

o Maximum: 94” long x 18” deep

• Standard thickness: 3”. Thicker options are available by custom request.

• Available in RLV™ colors listed on pages 20-23

• Includes a mounting-rod system, detailed below

Mounting Rods for Floating Shelves

The Mounting-rod system includes:

• Solid steel rod with welded backplate for every 18” of shelf length (all floating shelves receive a minimum of two rods)

• Heavy duty screws / wall anchors per rod

EcoDomo® provides pins for the shelves. The minimum is two pins, the ratio with pins is as follows:

• Brackets:

o 1 to 3 feet = 2 pins

o 3 to 5 feet = 3 pins

o ≥5 feet = 4+ pins

Specification Guide

Supports up to 80 pounds per linear foot* when attached into a stud, concrete, or other solid structure; the use of wall anchors in lieu of studs is not recommended, unless only lightweight items are being displayed.

*Weight capacity for shelves up to 10” deep; shelves deeper than 10” reduce the load capacity; rod is 8” long

Component Program

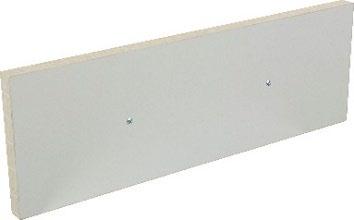

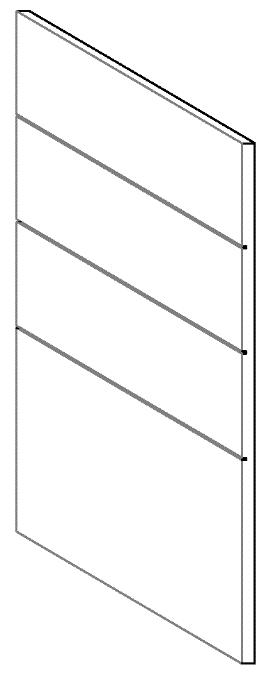

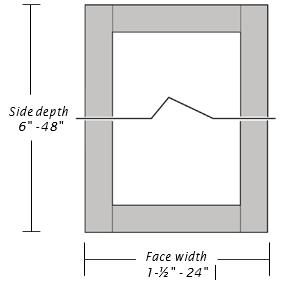

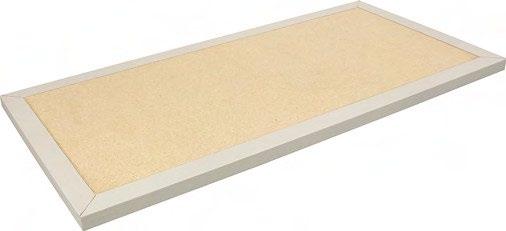

PANELS

• Constructed from HDF / particle board core.

SECTION 4: Complimentary Items

• Recycler Leather Veneer (RLV™) is applied in a continuous manner to surfaces as specified.

• Up to five surfaces may include RLV™; see guide below for submitting your order

• Specify dimensions to the nearest 1/16”.

• Size parameters for shelving:

o Minimum: 6” wide x 6” high

o Maximum: 44” wide x 94” high

• Standard thickness options: 1/4”, 3/4”, and 1-1/8”.

NOTE: 1/4” thick panels may receive RLV™ applied to face / back; RLV™ does not wrap onto edges.

• Available in RLV™ colors listed on pages 20-23

Additional Information

• Panel enhancements, such as stitching, embellishments, and cut-outs / notches are available; see SECTION 7: Custom Requests for details.

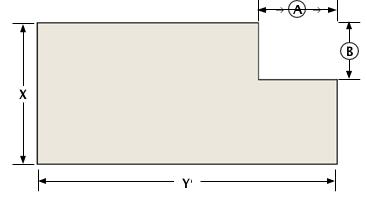

PANEL SPECIFICATION GUIDE (EXAMPLE)

Panel

Finished Edges(s) (Maximum of five Surfaces with RLV™)

Left side, front and bottom edges

Example

SECTION 4: Complimentary Items

Panels (continued)

RLV™ Surface Location Identities

• 1/4” Panels:

o Front, Back

o Front and Back

• 3/4” and 1-1/8” Panels:

o Left Side

o Right Side

o Both Sides

o Top Edge

o Bottom Edge

o Back Edge

3/4” Panel Shown in Coal Shagreen (This color and aluminum framed door are available through Special Request.)

Left: Back Panel used in a home office made with O/S Pebble Shagreen RLV™ Photo courtesy of California Closets.

European Wall System with 1/4” Panels in Backsplash Framework (This can be ordered as individual pieces or as a large sheet to be cut in the field.)

Component Program

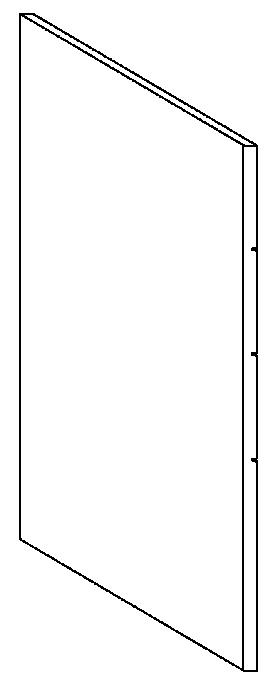

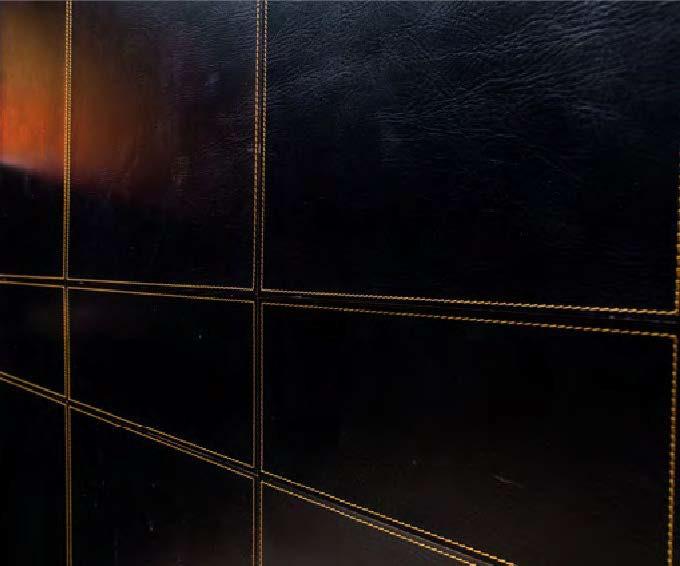

WALL PANELS

• Constructed from HDF / particle-board core

• RLV™ is applied to face and edges with a 2” overlap onto back.

• Specify dimensions to the nearest 1/16”.

• Size parameters for shelving:

o Minimum: 4” wide x 4” high

o Maximum: 44” wide x 94” high

• Standard thickness options: 1/2” or 3/4”.

• Available in RLV™ colors listed on pages 20–23.

SECTION 4: Complimentary Items

Panel enhancements, such as stitching, embellishments, and cut-outs / notches are available. See SECTION 7: Custom Requests for details

Rectangle Wall Panels in Custom 4’ x 12’ Maximum Size (Shown in Coal Buffalo)

Library Wall Panels in Custom Coastal Crocodile Designed by Village Handcrafted Cabinetry

Rectangual Wall Panel in Brick Pattern (Shown with Custom Stitching)

Wall Panel Detail Face View Back View

SECTION 4: Complimentary Items

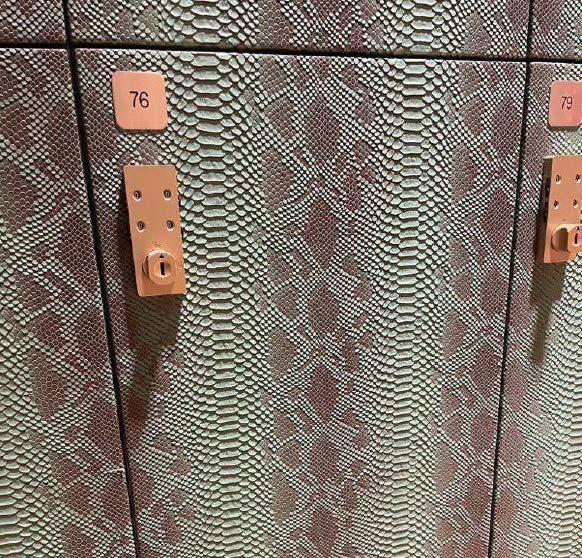

BOX COLUMN

• Constructed as a four-sided box from 3/4” HDF; with RLV™ applied to side, top, or bottom as specified

• Maximum of five sides include RLV™.

• Specify Left, Right, or Both for inclusion of RLV™ on sides

• Specify Front or Front and Back face for inclusion of RLV™ on front and back faces.

• Specify Top, Bottom, or Top and Bottom for inclusion of RLV™ on top and bottom faces.

• Unfinished exterior areas are sealed.

• Specify dimensions to the nearest 1/16”.

• Size parameters for box columns:

o Minimum: 1-1/2” wide x 6” deep x 6” high

o Maximum: 24” wide x 48” deep x 96” high

• Available in RLV™ colors listed on pages 20-23

Box Column Shown in Pearl White Shagreen (custom color)

Box Column Top View

Design by Lisa Martin

Box Column 1: RLV™ Applied to Front, and Left Side

Box Column 2: RLV™ Applied to Front, Left Side, and Top

Component Program

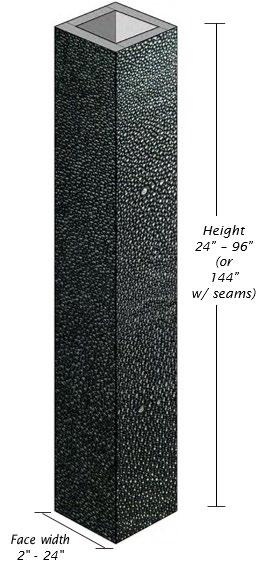

SQUARE COLUMN / LEG

SECTION 4: Complimentary Items

• Constructed as a four-sided square column from 3/4” HDF; RLV™ is applied to all four sides.

• Specify dimensions to the nearest 1/16”.

• Size parameters for square columns:

o Minimum: 2” length x 2” width x 24” high

o Maximum: 24” length x 24” width x 96” high*

• Up to 144” long available with seamed RLV™

• Available in RLV™ colors listed on pages 20-23

Component Program

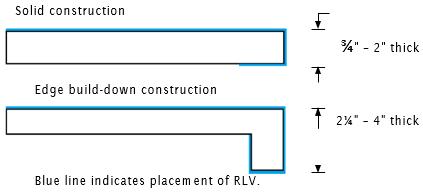

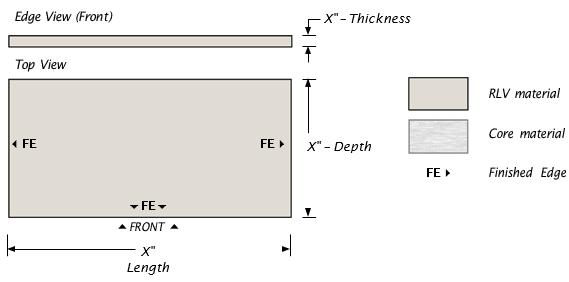

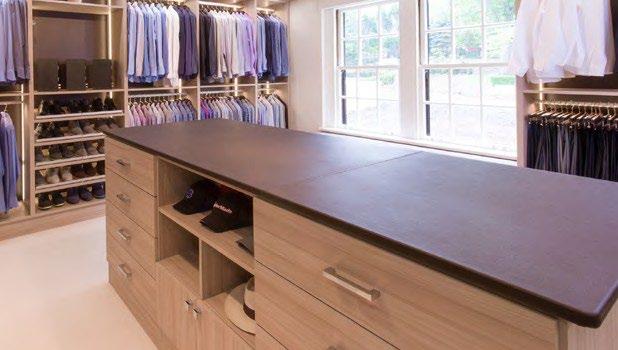

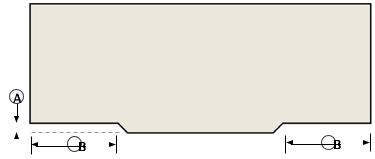

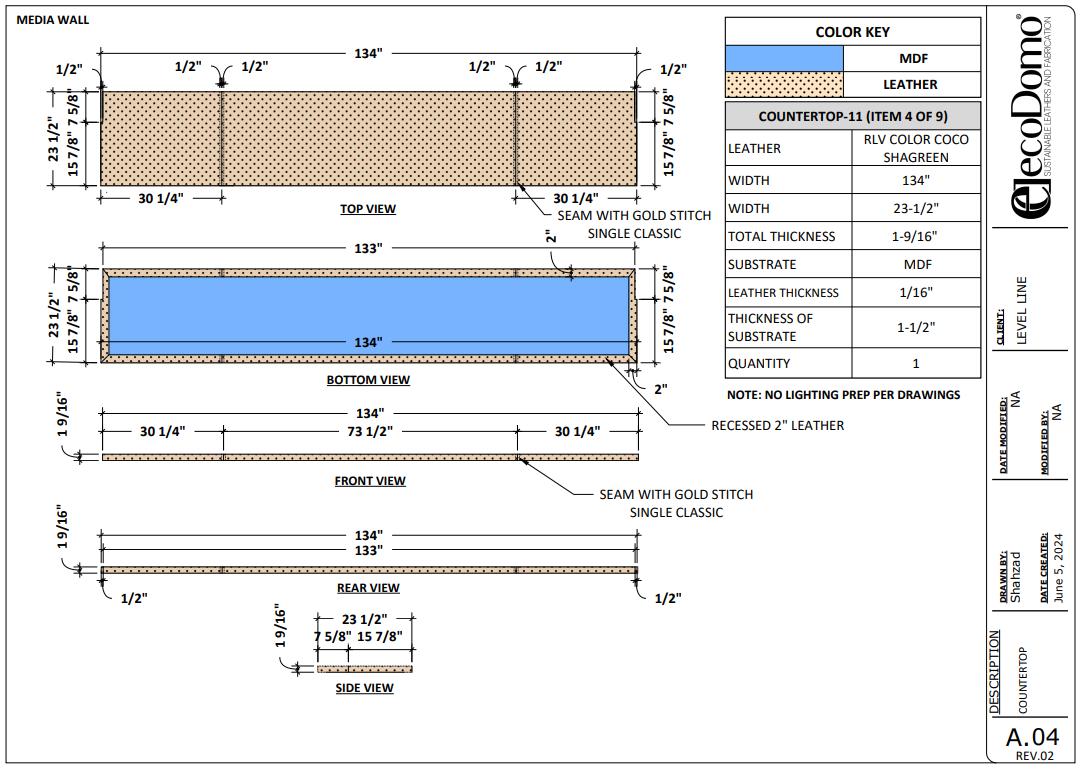

COUNTERTOP OVERVIEW

• Constructed from HDF / particle board with RLV™ applied in a continuous manner to top and edges, as indicated; RLV™ continues to bottom side, up to 2”.

• Finished edges must be specified and may include all four edges on a rectangular top.

• Rectangle-shaped countertops are standard: however, other typical countertop shapes are available; see SECTION 7: Custom Requests for details.

• A diagram must be submitted for all countertop orders.

• Specify dimensions to the nearest 1/16”.

• Size parameters for countertops:

o Minimum: 9” long x 9” deep

o Maximum: 94” long x 44” deep

• For countertops longer than 94” (up to 144”) separate sections are prepared at factory for joining in the field; options for seams are shown on the following pages.

SECTION 5: Countertops

• Edge thickness must be indicated. Specify to the nearest 1/4”:

o Minimum: 3/4”

o Maximum: 4”

• See detail on the next page for edge build-down specifications.

• Available in RLV™ colors listed on pages 20-23.

Additional Information

• Countertop enhancements, such as waterfall sides, stitching, embellishments, and cut-outs are available; see SECTION 7: Custom Requests for details.

• All edges and corners are square; radius shapes are available with limitations in RLV™; you may elect to use Hide Leather (SECTION 7: Custom Requests) if radius / arch is necessary in your design.

• Installation is like laminate or wood countertop. Tops can be pre-drilled to accept biscuits and butterfly clips to secure on-site counter joint.

SECTION 5: Countertops

Countertop Overview (continued)

Countertop Edge Detail (Side View)

Sample Butterfly Clip to Join Tops

Countertop fastener kit includes:

(1)Hex wrench

(10)5/16” x 3-1/2” x full threaded studs

(20)Special 5/16” hex nuts

(20)Special 5/16” curved washers

Ask for complete installation instructions from EcoDomo® or visit www.EcoDomo.com for installation instructions.

Designed by Wendy Scott from Timeless Closets and Cabinetry

Featured in the Home Section of The Wall Street Journal in January 2024

Island Countertop in Pebble Shagreen

Component Program

Countertop Overview (continued)

Countertop: Top Side

Diagram Example for Countertop Above

SECTION 5: Countertops

Countertop: Bottom Side

Bottom View (factory provided example)

SECTION 5: Countertops

COUNTERTOP BACKSPLASH

Specification Guide

• Constructed from HDF / particle board with RLV™ applied in a continuous manner to face and all edges with a 1” overlap on back.

• Indicate on countertop diagram location / inclusion of backsplash

• Backsplash ships separate from the countertop.

• Specify dimensions to the nearest 1/16”.

• Size parameters for backsplash:

o Standard height: 3”

o Standard thickness: 3/4”

o Minimum: 9” long

o Maximum: 94” long

• For countertop / backsplash longer than 94” (up to 144”) separate sections are prepared at factory for joining in the field; options for seams are shown on the following pages.

• Available in RLV™ colors listed on pages 20-23.

Additional Information

• Recommended installation: Apply directly to clean drywall with PL-4000 adhesive

Note that the

Coal Crocodile 2” Countertop with Overmount Sink Cut- Out and Backsplash

crocodile texture of the backsplash is book matched with the top.

Component Program

Countertop Backsplash (continued)

ISO View

SECTION 5: Countertops

Countertop with Backsplash along Back and Continuing Around Column / Notch Plan View

Backsplash

SECTION 5: Countertops

COUNTERTOP SEAM OPTIONS

SEAMED RLV™ WITH CONTINUOUS SUBSTRATE

• RLV™ is seamed on surface while substrate material runs entire length as specified.

• Allows for single shipment of lengths up to 144” (with a maximum width of 44”).

• EcoDomo® utilizes a magic seam. This process book matches the embossing pattern from one sheet to another, making the seam a lot less visible. EcoDomo® will determine placement of seam based on best aesthetic; note that this option looks best with Shagreen or Crocodile RLV™ due to the patterns.

Coal Crocodile Countertop

(12’ Long on Bar Top with Sink Cut-Out)

Magic Seam

Magic Seam – Edge Detail

Magic Seam is in this Location and is Virtually Invisible

Component Program

Countertop Seam Options (continued)

BUTT JOINT (FIELD ASSEMBLY)

SECTION 5: Countertops

• Each section of countertop is prepared with finished ends to be joined together in the field.

• Submit a countertop diagram indicating the desired location of the seam(s).

Preparation of the countertop underneath and toggle boats designed for countertops may be requested when ordering a countertop in multiple pieces for tighter seams.

SECTION 5: Countertops

Countertop Seam Options (continued)

INTEGRATED MITER

Specification Guide

• A mitered seam is pre-built at the factory to allow for joining multiple countertop sections in the field.

• Submit a countertop diagram indicating the desired location of the mitered seam(s).

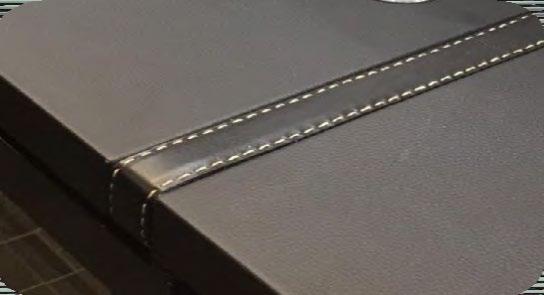

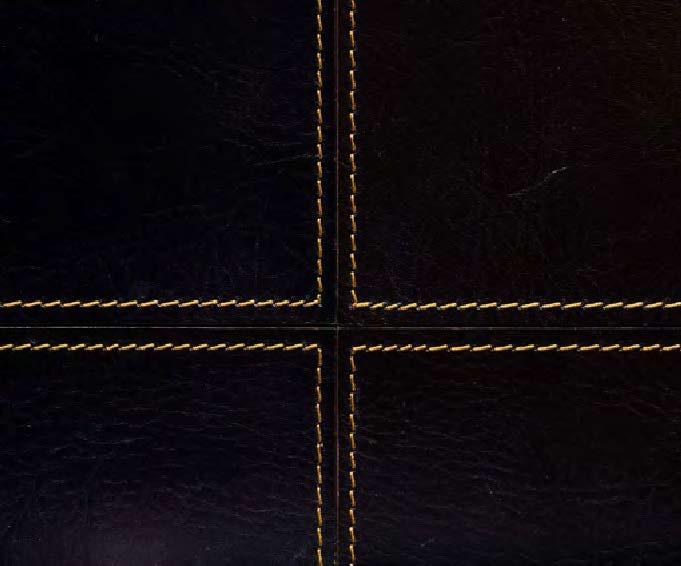

STITCHED RLV™

• Stitching in specified color is added to both sides of a seam

• Submit a countertop diagram indicating the desired location of the seams as well as the color of the stitching.

• See Section 7, pages 101-103, for details on stitching colors.

Oversized Countertop with Stitched Leather Pieces

Stitch Detail is Suitable for Residential Tops Only

Photo courtesy of California Closet

Component Program

Countertop Seam Options (continued)

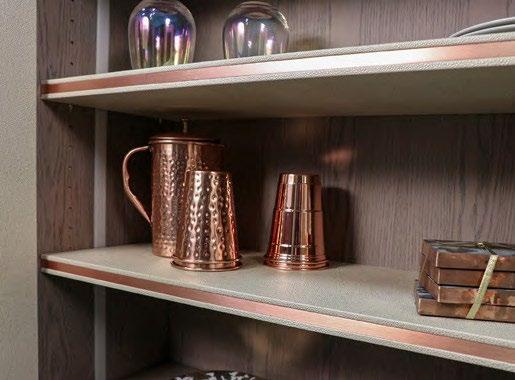

INTEGRATED DESIGN ELEMENT

SECTION 5: Countertops

• Elements such as EcoDomo® belts, or customer-supplied wood framing, can be designed into a countertop to integrate seams in an aesthetically pleasing manner.

• Available for lengths less than or greater than 94”.

• Submit a diagram with dimensional details for desired layout, seams, and design elements.

RLV™ Countertops within Customer Supplied / Assembled Wood Frame for Bar Seams

We recommend an acrylic sealer to be used around the edges. Photo taken by Andrea Stein after five years of wear. The RLV™ is Mahogany Buffalo.

The designer, Grizzform, opted to place a discreet copper metal bar in between the tops as a design element.

RLV™ Pebble Shagreen Countertop in a Mexican Restaurant with a 2” Edge Build Down

SECTION 5: Countertops

Countertop Seam Options (continued)

Integrated Design Element (continued)

EcoDomo® Beltstrips within a 10’ Countertop

EcoDomo® Beltstrips within a 20’ Countertop

Component Program

COUNTERTOP OPTIONS

CUT-OUTS

SECTION 5: Countertops

• Standard cut-outs are available for panels, shelving, and countertops; other components require a custom request.

• Typical cut-outs include grommet holes, notches for obstacles, and sink cut-outs.

• Client must supply a diagram indicating width, depth (or diameter), and placement of cut-out(s) on specified part.

• See options below and on the following pages.

TOP-MOUNT CUT-OUT

• Available in any shape, this cut-out typically is used for top mount sinks and faucets.

• EcoDomo® provides a precise cutout, which means this option can also be used for vessel sinks and grommet holes.

NOTE: Core material will be visible.

Please submit a detailed dimensional diagram and any applicable templates with your order

Bar Island Countertop with Rectangular Cut-Out for Beverage Dispenser Drip Tray

Island Countertop in Closet with Grommet Hole in Center for Electronic Charging Station

Vanity Countertop with Circular Cut-Outs for Vessel Bowl and Faucet

SECTION 5: Countertops

Countertop Options (continued)

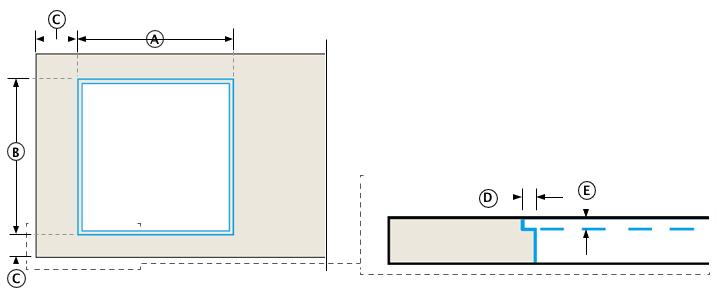

UNDERMOUNT CUT-OUT

• This cut-out includes a wrapped RLV™ edge at the cutout to allow for installation of an undermount sink or another similar accessory.

CUT-OUT FOR DROP-IN GLASS

Specification Guide

• A square / rectangular tiered cutout is provided with RLV applied to all surfaces / edges visible from the top side. Client should provide a detailed drawing indicating width platform and cut-out size / location.

Diagram Example for Specifying Cut-Out

Include the following dimensions:

• Overall cut-out size (A, B)

• Distance to start of cut-out (C from end, C from edge)

• Width of notch (D)

• Height of notch (E)

Square Undermount Bar Sink Cut-Out with Top-Mount Faucet Cut-Out

Component Program

Countertop Options (continued)

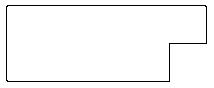

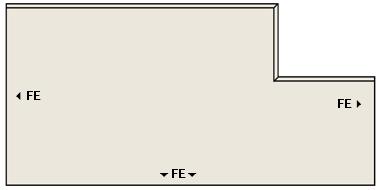

NOTCH

• This cut-out is typical for architectural obstacles. Examples include:

o Structural chase for plumbing / electrical

o Column / pillar

o Overhead soffit

• Include the following dimensions with your diagram:

o Distance from end of counter to start of notch

o Length and Depth of notch (A, B)

SECTION 5: Countertops

SECTION 5: Countertops

CONFIGURATION MODIFICATIONS

COUNTERTOP OPTIONS

Specification Guide

• Standard configuration modifications are available for shelving and countertops. Other components require a custom request.

• Client should supply a diagram indicating desired configuration and specifications.

• Maintain minimum / maximum overall sizing as indicated for specified component.

• See examples below and on the following pages for standard configurations.

45º CLIPPED CORNER(S)

• Include overall dimension of clipped corner. Dimensions of clip must be equal; for example: 3” x 3”.

Countertop with Left Clipped Corner

NOTE: Radius corners, arched ends or circular shapes are not available with RLV™ material. See Section 7, Full Hide Leather, if your design requires these shapes.

Bump-Out with 45º Clipped Corners

Component may include one or two clipped corners. Include the following dimensions in your diagram:

• Dimension of projection (A)

• Dimension to start of clip(s) (B)

• Left and right of bump-out if applicable

Countertop with Center Bump-Out and Both Corners Clipped Buffalo Leather Countertop with Bump-Out Design by Lobkovich Kitchen and Bath

Component Program

Configuration Modifications (continued)

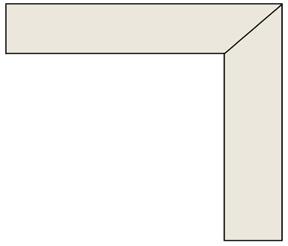

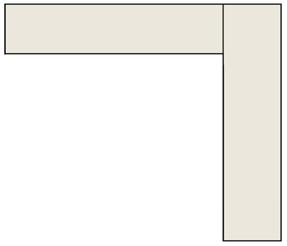

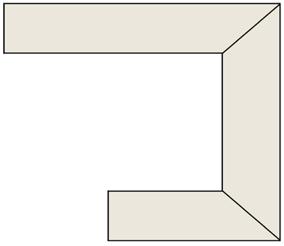

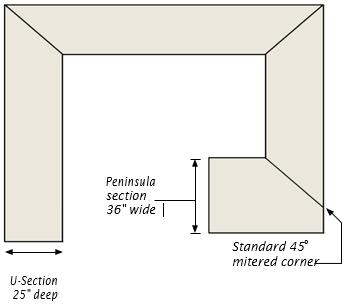

MULTI-SECTION COUNTERTOPS WITH 45º MITERED CORNERS

Includes: L-SHAPE, U-SHAPE, AND G-SHAPE COUNTERTOP CONFIGURATIONS

SECTION 5: Countertops

The 45º angle is maintained regardless of countertop depth on each section. Alternatively, countertops may be joined in the corner at a 90º angle using a Butt Joint, as shown on page 65. Examples below.

L-Shape Countertop

L-Shape Countertop with Butt Joint

U-Shape Countertop

G-Shape Countertop

SECTION 5: Countertops

Configuration Modifications (continued)

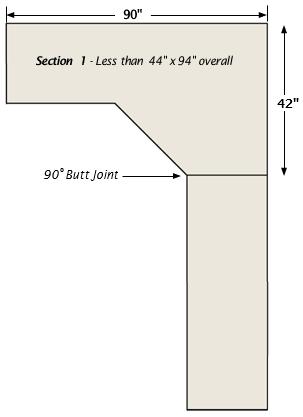

MULTI-SECTION COUNTERTOPS WITH 45º DIAGONAL FRONT

Specification Guide

Applicable to: L-SHAPE, U-SHAPE, AND G-SHAPE COUNTERTOP CONFIGURATIONS.

Available with 90º back corner or 45º angled back to follow front. Joint areas are dependent on overall size of each section:

• If less than 44” x 94”, a section will be made in one piece. (See example below labeled Section 1.)

• If greater than 44” x 94”, sections will be configured as either a 22.5º mitered joint or 90º joint as indicated upon ordering.

L-Shape Countertop with 45º Diagonal Front, 90º Back Corner

L-Shape Countertop with 45º Diagonal Front and Back (0verall size is greater than 44” x 94”; three sections are required)

Component Program

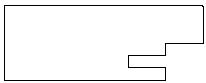

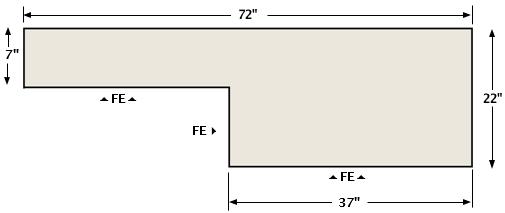

COUNTERTOP CUSTOMIZATION

BANJO SHAPE / DEPTH CHANGE

SECTION 5: Countertops

Allows for varied depths in one single component, with RLV™ applied to edges indicated below. (Ends and back edge may also include RLV™ as indicated.)

Due to the nature of RLV™, the inside 90º corner will have a slight triangular cut-shape in the material, which is then filled using a matching color by our artisans. The difference is only slightly visible.

Countertop with Banjo Shape / Depth Change

Countertop with Banjo Shape and Matching Cushion in Mink Cordova Leather in a Gentleman’s Closet

SECTION 5: Countertops

Countertop Customization (continued)

WATERFALL COUNTERTOP

• Waterfall sides and four-sided wrap / countertop assemblies are available in standard RLV™ materials as well as Hide Leather. See examples below.

• Parameters, pricing, and lead-time are quoted by project.

• Follow instructions for measuring and installation.

Vanity ensemble featuring:

• RLV™ Gold Grey Metallic Buffalo Infinity drawer fronts and matching cubby.

• Countertop wraps vanity / cubby; shown in Paloma Grey Buffalo.

• Wall behind vanity in Camo Green Canvas by Lord Fabrik.

Antique Grey Buffalo RLV™ Island Countertop with Waterfall Design on Both Sides Design by P. Miller Luxury Closets

Component Program

Countertop Customization (continued)

CURVED COUNTERTOPS

SECTION 5: Countertops

• Countertops are available in specialty shapes and configurations in RLV™ and other materials. Below is a circular countertop with special notching, waterfall sides, and mitered seams using Cordova in Nigrine.

• Parameters, pricing, and lead-time are quoted by project.

Photos below show mitered seam between countertop surface and waterfall side at the EcoDomo® HQ.

Radius Shape, Notch Cut-Out (Bottom Left Area) and Seam on Surface

Mitered Seam Detail (View from Edge)

SECTION 5: Countertops

COUNTERTOP EXAMPLES

Design by California Closets

U-Shape Countertop with Mitered Corners

White Shagreen Countertop with Matching Drawer Fronts Finished with an Aluminum Trim Detail

Design by Wendy Scott

Coal Crocodile and Coco Shagreen Countertops with Matching Bank of Drawers

Design by Wendy Scott

Component Program

Countertop Examples (continued)

SECTION 5: Countertops

Countertop in Pebble Shagreen Used as a Bench

Countertop with Waterfall Sides in a Kitchen

Coal Crocodile with Cut-Out

Cocoa Buffalo in a Typical Mudroom

Component Program

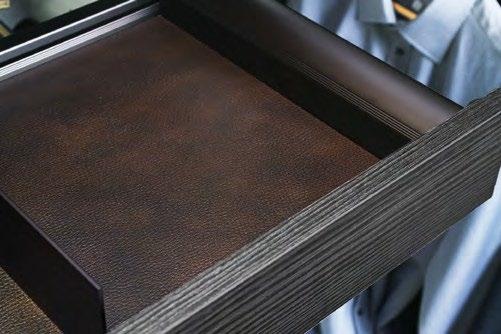

DRAWER LINER

• Drawer liners drop into the floor of a drawer or roll-out tray and provide an upscale aesthetic as well as sound dampening, while also protecting the drawer box from scratches. NOTE: This is not a loose sheet of RLV™!

• Constructed from phenolic layered material, similar to the core of laminate, with RLV™ applied to one side; total thickness is 2mm (slightly less than 1/8”).

• Specify size to the nearest 1/8”.

• Size parameters for liners:

o Minimum: 4” long x 4” deep

o Maximum: 94” long x 44” deep

• Available in RLV™ colors listed on pages 20-23.

SECTION 6: Interior Components

Drawer Liner in Antique Black Walrus

Drawer Liner in Paloma Grey Crocodile

Detail / End View of Phenolic Backer with RLV™ Surface

SECTION 6: Interior Components

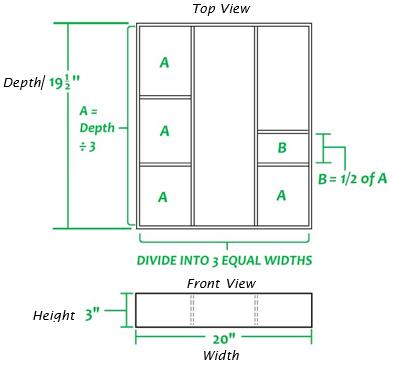

DRAWER DIVIDER INSERT

• The Drawer Divider Insert is constructed from HDF with RLV™ applied to interior and top edges; it is designed to drop into existing drawer box.

• Configuration and quantity of dividers must be indicated in a diagram and submitted with order; see example below.

NOTE: Center dividers are 1/4” thick

• Specify width, depth, and height to the nearest 1/8”.

• Size parameters for Drawer Divider:

o Minimum: 3” wide x 6” deep x 3” high

o Maximum: 36” wide x 24” deep x 9” high

• Available in RLV™ colors listed on pages 20-23.

DESIGN NOTE:

Guide

• These inserts are holders to set objects in and keep them separated and organized.

• The opening, drawer, or shelf that these are placed on may need additional clearance height to accommodate your glasses, objects, and collectibles.

Diagram for Drawer Divider Insert in Photo at Left

Example of Drawer with Dividers

Component Program

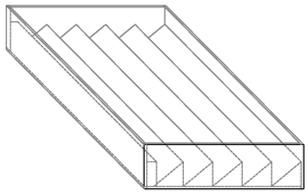

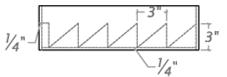

TIERED DRAWER INSERT

• The Tiered Drawer Insert includes four sides and tiered bottom. Constructed from HDF with RLV™ applied to interior, top edges, and exterior sides. Drops into existing drawer box.

• Angle and dimension of tiered rows are pre-set, and total number of rows is determined by depth of insert.

• Specify width, depth, and height to the nearest 1/8”.

• Size parameters for Tiered Insert:

o Minimum: 12” wide x 12” deep x 3” high

o Maximum: 36” wide x 24” deep x 9” high

• Available in RLV™ colors listed on pages 20-23.

DESIGN NOTE:

SECTION 6: Interior Components

Three Dividers Left to Right, and Three Dividers Front to Back

• These inserts are holders to set objects on and keep them separated and organized.

• The opening, drawer, or shelf that these are placed on may need additional clearance height to accommodate your glasses, objects, and collectibles.

Top View Side View

Component Program

ARCHITECTURAL COMPONENTS

CUSTOM CONFIGURATIONS

SECTION 7: Custom Requests

• This option allows EcoDomo® to source / manufacture requests for custom pre-built components using standard RLV™ or Special Request materials.

• Anything wood made in wood, EcoDomo® can finish the item in leather.

• Parameters, pricing, and lead-time are quoted by project.

• Examples include Shelving / Display Units, Cabinets, Freestanding Islands / Greeting Counters.

Single Wall Unit with TV Display Area and Cubbies Below Shown in Paloma Grey Crocodile Design by Suzanne DeRusha

Leather Boxes with Leather Pulls Design by Lobkovich Kitchens and Bath

Credenza Wrapped in Leather on all Sides with Coco Shagreen

EcoDomo® offers fully wrapped custom furniture and components.

Design by Fedi Gezcki

Dumbell Rack Finished with Cordovo Mink Leather with a Custom Stitch Detail in Henna Design by Jenn Paolino

SECTION 7: Custom Requests

Architectural Components (continued)

HOODS

EcoDomo® has a successful history of partnering with designers and architects on extensive applications. We will work closely with you to accomplish your unique creations. Whether you’re dreaming up an innovative design for a client, or are seeking alternate materials or colors, there is not much we cannot do. The following photos provide a sample of materials, designs, and special component configurations.

Please visit our website to see more options or contact us to discuss your project needs.

Leather hoods are readily available custom by project, your millworker using EcoDomo® pre-made panels, or from Trade Winds, a supplier to Viking, La Cornue, Aga and other high end appliance manufacturers.

Component Program

Architectural Components (continued)

CUSTOM COLOR REQUESTS

SECTION 7: Custom Requests

Discover the endless possibilities with our Custom Leather Color Offering at EcoDomo®. Since individuality and personalization are key when it comes to leather products, our Custom Leather Color Offering is designed to bring your unique vision to life. All fees associated with the match are applied against the order of that color.

Here’s How

• Share your swatch with us, whether it’s a fabric scrap, a paint sample, or a leather piece. EcoDomo® can color match any Benjamin Moore or Sherwin Williams paint color.

• Pick your preferred texture.

• Send us your reference piece for a perfect match.

• Wait 14 to 21 days and see the results.

SECTION 7: Custom Requests

Custom Color Requests

(continued)

A sample project with a custom color matching a Benjamin Moore Color in crocodile RLV™ for doors, appliance panels and drawers. Design by Kori Keyser Designs.

Kensington Style Drawer which gets the Raw HDF the Center Covered by the Drawer Box

Component Program

ALTERNATE MATERIALS

GENERAL OVERVIEW

SECTION 7: Custom Requests

EcoDomo® has a successful history of partnering with designers and architects on extensive applications. We will work closely with you to accomplish your unique creations. Whether you’re seeking alternate materials or colors, or are dreaming up an innovative design for a client, there is not much we cannot do. The following pages provide a sample of materials, designs, and special component configurations. Please visit our website to see more options or contact us to discuss your project needs.

Applications and Process

• Available for: standard / custom panels, countertops, shelves, and floating shelves as well as custom pre-assembled configurations and components.

• Requires minimum order quantity (MOQ) and is quoted per project.

• Mock-up sample order is generated for each project.

• Lead-time is established and varies based on material / size / complexity of project.

• EcoDomo® can also work with client-sourced leather, suede, and most fabrics MOQ applicable.

Material Options

Full Hide Leather

Hair-on-Hide

Suede

Canvas

Vinyl

SECTION 7: Custom Requests

Alternate Materials (continued)

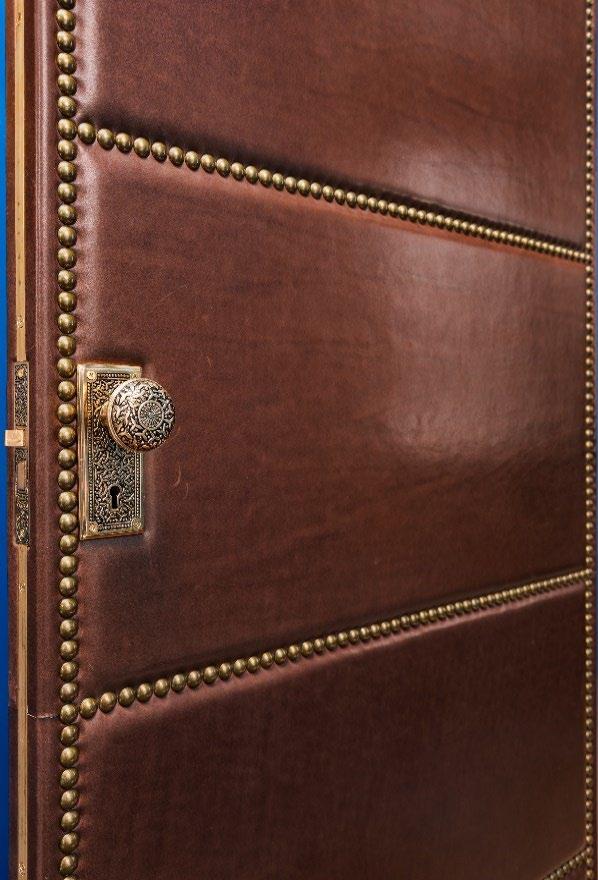

FULL HIDE LEATHER

• Hide leather has inherent color and texture variations due to the organic nature of the material. While every effort is made to use only the suitable parts of a hide, a few bumps or indentations may appear within the surface from time to time. This is true for all hide leathers from any supplier.

• Available in six standard colors in the Cordova Hide Collection as well as custom colors and clientsourced material (COM). All COM leather is subject to approval, as some hides have excess oil which prevents proper adhesion.

• The Cordova collection is made of premium leather hides which are larger in size, feature a pebble grain finish, and are designed to be resistant to liquids and abrasion.

• Seamless hide size is 48” x 72”. The 20” x 80” size is possible when cutting through the larger hide in a diagonal format. The cost of these items is higher as this type of cut generates a lot of waste.

• Seams can be integrated into the design through stitching, folding, mitered edges, and the addition of design elements recessed into a door, countertop, or panel. Examples include belts and wood framing.

Standard Cordova Collection Colors

Winter Denim Nigrine Pewter Oyster

Mink

Doors and drawer fronts in Full Hide Leather are limited to the Infinity door style and include a separate panel which is attached to the back side as shown below.

Infinity Door in Cordova Pewter

Photo of a cabinet with C.O.M. leather – Courtesy of Halcon

Component Program

Alternate Materials (continued)

Full Hide Leather (continued)

SECTION 7: Custom Requests

Don’t fear leather for countertops, doors, and architectural components! Like the leather used in furniture and automobiles, it is inherently resistant to wear and tear. It is also treated with EcoDomo ’s proprietary finishes to further enhance and extend its life for years to come!

Appliance Panel Fronts Using Patent Leather Sourced Outside of EcoDomo® Design by Richard Anuszkiewicz

Cordova Mink Countertop with Belt Accents and Drop--In Sink / Faucet Cut-Outs

Cordova Mink Shelving in Closet

SECTION 7: Custom Requests

Alternate Materials (continued)

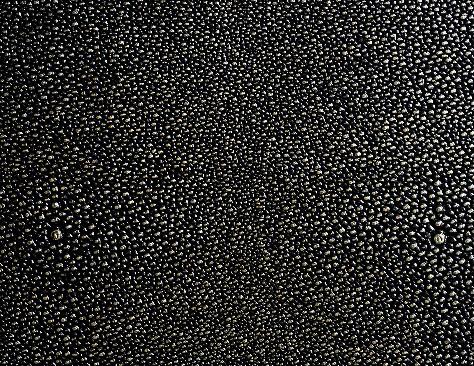

HAIR-ON-HIDE

• This material is an authentic leather hide with the hair fibers intact. It can be used in its natural state of appearance or dyed to an opaque color. EcoDomo® can work with almost all Hair-on-Hide materials.

• Applications include components within the standard offering, as well as rugs, furniture, and other architectural / interior applications.

• Sizes of hides vary but typical usable area has a maximum size of 48” x 70”.

• Hides may be seamed together to obtain greater overall size.

• Client may also source hide material for EcoDomo® to apply onto desired component.

Black Hair-on-Hide Countertop with Belt Accents

Appliance Paneled Fronts