THERE

IS A

TEARDOWN ANALYSIS DIMENSIONAL ANALYSIS

NON-GENUINE TURBO COMPONENTS

ComponentMeets Specifications Risk Level

Turbine Housing*No High

Journal BearingsNo Medium

Thrust BearingsNo Medium

Speed SensorNo Medium

Thrust BearingsNo Medium

Bearing HousingNo Low

Inlet StudsNo Low

*TURBINE HOUSING

Risk Level: High

Meets Specifications: No

NON-GENUINE TURBO COMPONENTS

ComponentMeets Specifications Risk Level

Journal Bearings* NoMedium

Thrust BearingsNoMedium

Nozzle RingNoMedium

Diffuser NoLow

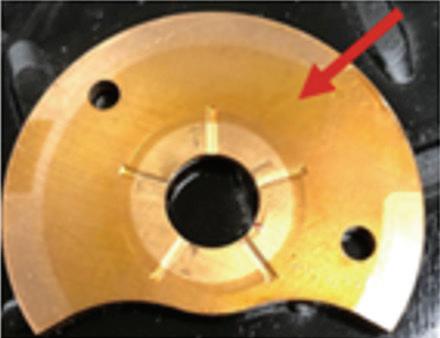

*JOURNAL BEARINGS

Risk Level: High

VG mechanism was gritty and restricted movement. The shroud plate was reused, and cleaning abrasive was found inside.

■ Potential Impact: Damage to turbine wheel and binding in VG mechanism could render turbo inoperable.

reused, and they failed to meet roundness and straightness specifications.

■ Potential Impact: Diminished performance and early failure

NON-GENUINE TURBO COMPONENTS

*THRUST BEARINGS

Risk Level: Medium

Meets Specifications: No

TESTING

NON-GENUINE TURBO COMPONENTS

■ Potential Impact:

The high-risk results we found from functional testing could lead to a number of possible negative outcomes: increased cost to recalibrate, additional hours of service support, and reduction of turbo life.

Diffuser No

Journal Bearings No

Thrust Bearings*No

Nozzle RingNo

Material composition incorrect (high levels of aluminum, lead, zinc, silicon, phosphorus and sulfur with low bismuth)

■ Potential Impact: Diminished service life and potential early failure.

Type of Test Pass / Fail

Actuator StepAll FailedHigh

Leak TestHalf FailedHigh

Functional TestAll FailedHigh

Speed SensorAll PassedN/A

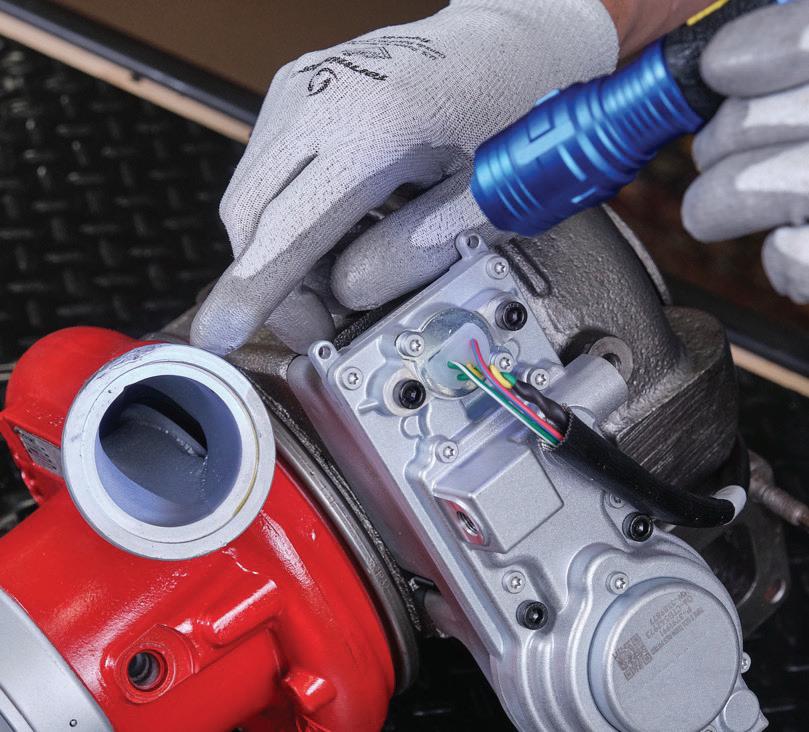

ACTUATOR ANALYSIS

NON-GENUINE TURBO COMPONENTS

Issue Observed

Low-grade replacement components in circuit board assembly

Added wiring and heat dissipator causing pinched wiring

Added heat dissipator pressing on electronic chip (could crack chip)

Lack of vibration dampening in circuit board compartment

■ Impact:

Teardown High

Teardown High

Teardown High

Teardown High

VG unable to reach 100% of commanded position Electronic InterfaceHigh

Every issue listed above could cause reduced durability, decreased performance, fault codes and EGR issues. These are only the most severe issues observed from testing non-genuine actuators.

TESTING THE DIFFERENCE

THERE’S NO SUBSTITUTE FOR GENUINE QUALITY

OBJECTIVE

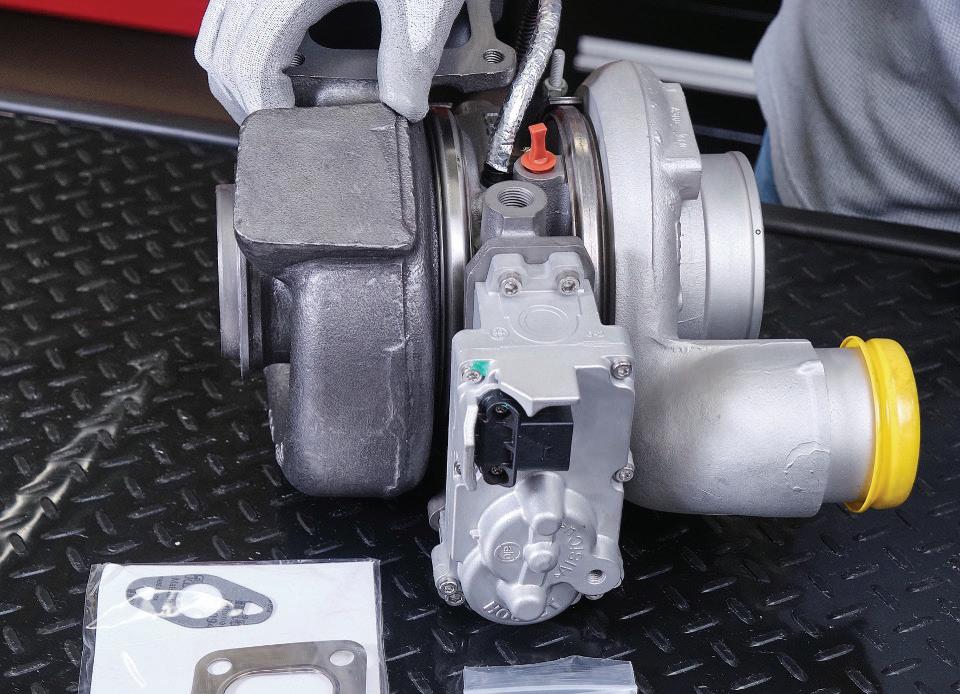

Cummins engineers conducted lab testing on non-genuine remanufactured turbochargers that competitors sold as replacements for ISX and ISB engines.

BACKGROUND

The non-genuine turbos and actuators were placed through engine performance testing, teardown and thorough component analysis to see how they faired against the requirements put on Genuine Holset Reman turbochargers.

The non-genuine turbos and actuators displayed issues that could result in reduced service life of the turbos, as well as progressive damage and engine failure.

■ Remanufactured to same standards as new turbos using a 5-step process (disassembly, cleaning, inspection, restoration and testing) ■ Durable and efficient turbo operation ■ Prolonged engine life

Inadequate material composition

Reuse pivotal components that Cummins requires to be replaced with new

■ Potential for turbo failure leading to catastrophic engine damage