Dynemech Vibration Technology

MODERN PRECISION MACHINERY MOUNTING SYSTEM

Shock Mounts

DXOSeriesAnti-VibrationMounts

Heavy-DutyVibrationReductionandStability

Features:

Designed for Heavy Machines: Ideal for applications requiring robust stability and significant vibration reduction.

High Performance: Provides exceptional vibration isolation for very heavy industrial machines.

Applications:

Heavy Power Presses

Forging Presses

Gen Sets

All Types of Heavy Industrial Machineries

Benefits:

Enhanced Stability: Ensures secure mounting and stability for large, heavy equipments.

Effective Vibration Reduction: Minimizes vibrations to protect machinery and improve performance.

Dynemech Vibration Insulation Plates

Insulation Plates

Premium Anti-Vibration Sheets for Industrial Excellence

Features:

High Grade Composite Material: Built for durability and effectiveness in vibration control.

Varied Load Capacities: Available in different thicknesses to match specific load requirements.

Custom Frequencies: Designed to suit various industrial applications with different natural frequencies.

Chemical Resistance: Resistant to water, oils, lubricants, and fuels commonly found on shop floors.

Non-Deforming: These Insulation plates maintain their shape and effectiveness under the specified maximum load.

Thicknesses:

Screw Support Mounts

Dynemech Screw Support Mounts

Precision Levelling and Vibration Isolation for Industrial Machinery

Features:

Design: Circular mounts placed between machine feet and the floor for effective vibration isolation.

Elastomeric Insulation Plate: Specialized plates tuned to different natural frequencies, ensuring excellent vibration damping.

Benefits:

Flexible Shop Floor Layout: Easy machine relocation and permanent mobility.

Extended Equipment Life: Reduces wear, tear, and noise, mitigating costly downtime and maintenance.

Enhanced Production Efficiency: Prevents vibration-induced failures, ensuring smoother operations.

Stable Machine Levelling: Ensures precise machine alignment, enhancing overall performance and preventing misalignment issues during operation.

Rubber Air Springs

Dynemech Rubber Air Springs

Advanced Vibration Control for Industrial Machineries

Features:

Vibration Control: Effectively removes unwanted vibrations, protecting sensitive laboratory equipment and machinery.

Versatile Applications: Suitable for both active and passive vibration control.

Models Available:

Series DRAS

Series DLPM

Performance:

Natural Frequencies: 2.5-6.0Hz.

Load Capacity: Ranges starting from 25Kg, making them ideal for bo foundations.

Advantages:

Enhanced Prec ment from vibrations.

Effective for Va de range of applications

Wedge Mounts

Wedge Mounts for Precision Levelling and Vibration Damping

Key features include:

Adjustable Bolt Mechanism: Allows easy height adjustments for precise machine levelling.

Large Contact Surface: Ensures enhanced stability and vibration contr l

For vibration damping, specialized elastomeric insulation plates:

Custom Damping Capabilities: Absorb vibrations tailored to specific frequencies.

Versatile Vibration Control: Suitable for various machine needs.

Applications:

Ideal for heavy CNC machines and power presses.

Features

Robust Construction: Supports Heavy Machineries with optimal coverage.

Precision Engineering: Ensures exact levelling and vibration control, boosting performance and durability.

Foundation Isolation

Isolated Foundation for Vibration Damping

Active and Passive Vibration Isolation

Applications:

Active Damping: Power presses, forging hammers, engine test rigs.

Passive Isolation: Machining centers, grinding machines, testing equipment, laser cutters, microscopes.

Purpose:

Active Isolation: Reduces shock/vibration using insulating materials.

Passive Isolation: Prevents vibration transfer to sensitive equipment.

Construction Guidelines:

Excavate foundation pit, ensure smooth surface.

Secure damping plates with adhesive, seal joints.

Waterproof with PVC and fiber board, seal overlaps.

Pour concrete in layers, set each one.

Separate foundation block and tub, seal gaps, and level the machine.

Anti-Vibration Table

Dynemech Anti-Vibration Tables

Precision Vibration Control for Testing Laboratories

Ideal For:

Laboratories near industrial units with high vibration from machines like presses, hammers, VMCs, etc.

Analytical and laboratory balances, control scales, etc.

Features:

Granite Surface Plate: Grade-1 accuracy for critical measurements.

Dual Vibration Damping:

Below the granite top.

At the bottom with leveling feet and insulation plates.

Damping Options: Elastomeric, Pneumatic, or Spring-Based depending o vibration levels.

Applications:

Analytical Balances

Hardness Testers

Spectroscopes

Microscopes

Roughness Testers

And more.

Dynemech Anti-Vibration Solutions

Spring Isolators

Spring Isolators are ideal for applications that require excellent vibration control. They are perfect for isolating heavy machinery and equipment that produce significant vibrations, such as:

Press Machines

HVAC Systems

Centrifuges

Forging Hammers

Textile Machines

Features:

High-Grade Springs: Made from top-quality wire and finished with protective coatings for durability.

Viscous Damping: Limits excessive movement, especially during slow start-ups or impacts in rotating machines.

Advantages:

Superior Vibration and Shock Isolation

Enhanced Structural Safety

Improved Worker Health: Reduces fatigue and creates a better working environment.

Versatile Installation: Accommodates both sensitive and heavy machinery in the same workshop.

Shop Floor Flexibility: No foundation needed for small/medium machines; reduced depth required for heavy machines.

Extended Machinery Life: Simple installation and reliable performance

Jackup Mounts

Dynemech Jackup Mounts

Your Premier Choice for High Load Capacity and Precision Leveling

Versatile Solutions:

High Load Capacity: Designed to support heavy mac

Precision Leveling: Offers exceptional leveling capab

Non-Skid Design: The bottom ensures stability and p

Key Features:

Effective Vibration Isolation: Provides superior passi surroundings.

Durable Construction: Built for heavy-duty use and l

Easy Installation: Quick setup for a variety of industr

Advantages:

Maintains machine stability and alignment, even und Enhances machine performance by minimizing vibra

Improves operational safety and reduces maintenan

Maximize Machine Performance:

Suitable for machine tools, textile machines, graphic

Ensures optimal leveling and vibration isolation, exte efficiency.

Machinery Raiser Damping Blocks

Dynemech Machinery Raiser Damping Blocks

Your Premier Solution for Vibration Damping and Machine Levelling

Effortless Installation and Versatility:

Quick Setup: Facilitates easy and fast installation for CNC machines and other equipme

Height Adjustment: Elevates machines for improved access during cleaning and repairs.

Integrated Vibration Damping: Insulation plates effectively reduce vibrations

Key Features:

Dual Functionality: Combines precise leveling and vibration control with machine height adjustment.

Durability: Engineered for long-lasting performance in heavy-duty applications.

Total Productive Maintenance (TPM) Friendly: Supports TPM practices by enhancing reliability and reducing breakdowns.

Ideal Applications:

CNC Turning/Machining Centers, Cylindrical & Centreless Grinding Machines, Precis Machine Tools.

Advantages:

Improves machine reliability and reduces life cycle costs.

Enhances stability and minimizes vibration transmission to structures. Ensures proper machine height (100-200MM), aiding in maintenance and cleaning.

Dynemech Stud Mounts

Compact and Efficient Vibration Dampers for Versatile Applic

Versatile Solutions:

Effective Vibration Damping: Dynemech Stud Mounts provide superio absorption across a range of industrial and commercial applications.

Compact Design: Engineered for space efficiency without compromis performance.

Key Features:

Compression Load Applications: Ideal for handling loads in compressi stability and vibration reduction.

Durable Construction: Built for long-lasting use in demanding environments.

Ideal Applications: Compressors, Pumps, ID & FD Fans, Motors, Machine Tools, Gensets, Electric P

Air Conditioners, Measuring & Testing Equipment, Material Handling Equipmen Laboratory Instruments.

Advantages:

Reduces noise and vibration transmission, protecting machinery and surround structures. Enhances operational safety and prolongs equipment life.

Easy installation.

Dynemech Mac Level Mount

Precision Mounting for High-Speed Rotating Machines

Tailored Solutions:

Optimized for High-Speed Machinery: Dynemech Mac Level M designed specifically for machines with high rotational speed axial forces.

Precision Levelling: Ensures accurate and stable machin performance.

Key Features:

Vibration Control: Effectively reduces vibrations, enhancing during high-speed operations.

Durable Design: Built to withstand the demands of fast-mov

Ideal Applications:

High-speed rotating machines with minimal axial force requ

Advantages: Increases machine precision and operational stability. Reduces wear and tear, extending machinery life. Simple installation and low maintenance.

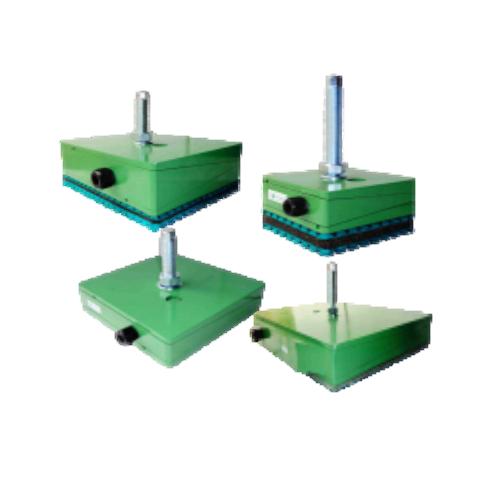

Dynemech Sandwich Mounts

High-Performance Vibration Control for Heavy Compressive Loads

Innovative Design:

Elastomer Bonded Structure: Dynemech Sandwich Mounts consist layers of elastomer bonded to flat steel plates, providing exception and load-bearing capacity.

Slim Profile: Designed with a compact and slim structure, offering efficient vibration damping without taking up excess space.

Key Features:

High Compressive Strength: Engineered to withstand very high compressive loads, ensuring stability and longevity.

Large Support Surface Area: Provides excellent support and distributes loads evenly

Stackable for Customization: Can be stacked to achieve lower natural frequencies fo enhanced vibration isolation.

Ideal Applications:

Heavy machinery requiring superior vibration control under high compressive forces

Advantages:

Effectively reduces vibration transmission, protecting equipment and structures.

Customizable performance by stacking mounts for lower frequencies. Slim design allows for installation in space-constrained environments.