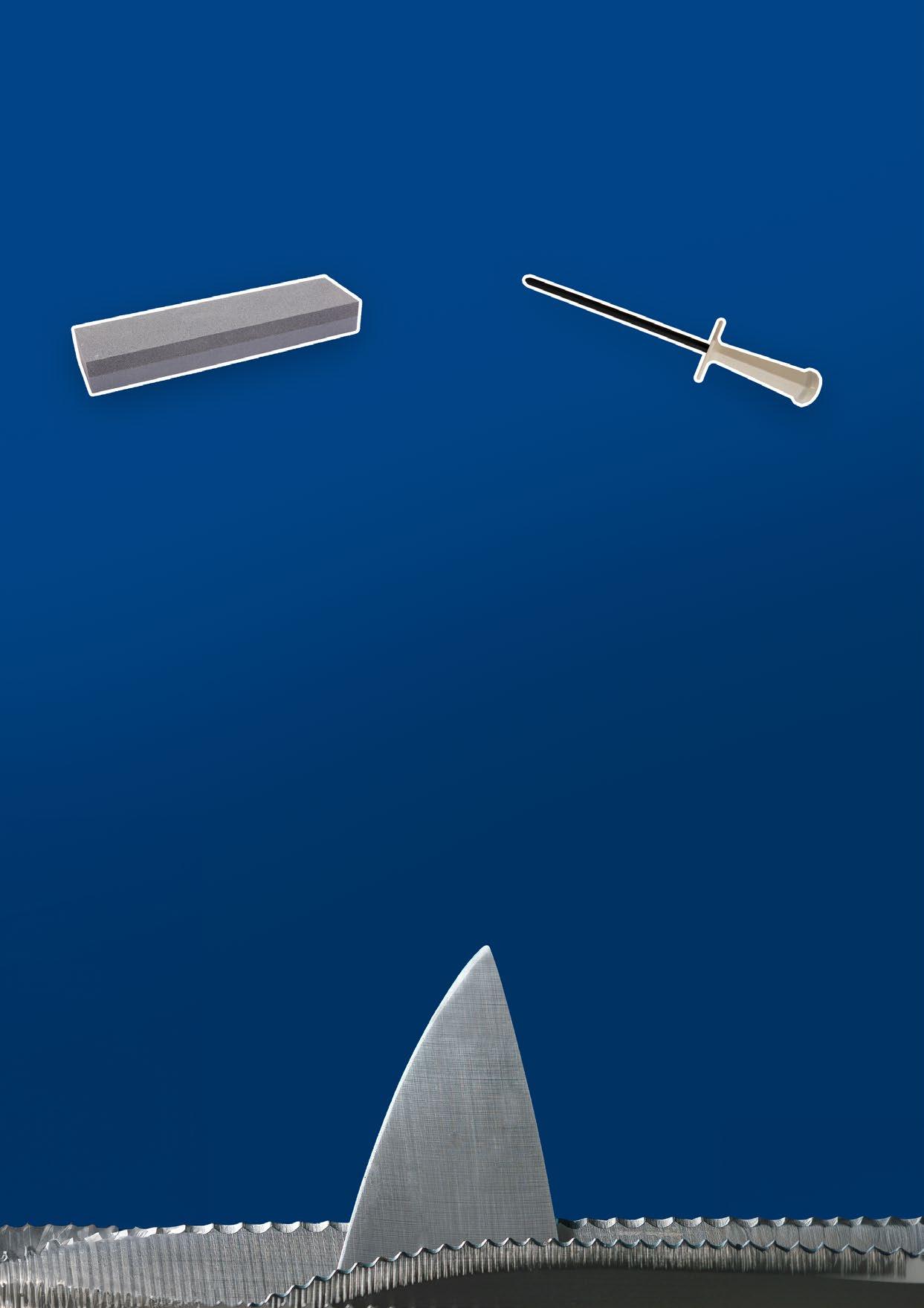

Sharpening

Stones FINE

Everyday maintenance of the cutting edge. Once you have your knife sharp you use the fine stone to maintain that cutting edge, Move to a medium grit once the fine no longer brings the edge up to the required sharpness.

MEDIUM

When your knife is “dulling” off quickly and the fine stone is no longer bringing the edge back to the required sharpness.

COARSE

For resetting the edge. Such as changing the angle of the shoulder of the knife or if the edge has been damaged (chipped).

Coarse stones are very hard on the knife and most knife steel will perform a lot better once used on a coarse stone is brought up with a medium and then fine.

KEY POINTS:

• Using light pressure and more strokes rather than more pressure and less strokes

• Too much pressure or inconsistent pressure can cause the stone to “scallop” and then needs resurfaced to be flat and preform correctly again

• Always use lubrication to stop the stone from clogging up

• Clean stone regularly to ensure all stone dust and knife filings are removed so stone will perform at its best every time

SHANCFB8

Stone Norton

SHANCMJB8

SHANFJB8

SHANPAIB8

Fine FB8 Oil

Stone Norton Crys Med MJB8

Stone Norton Crys Med Fine Oil

Stone Norton Alum Combi Med/Fine Non Oil

SHANCAKS100 Norton Crystolon - Water KS108

SHANCKS100 Norton Crystolon - Oil KS108

SHAA220400 Wet Atlantic

SHASS035237SS Super Stone

SHASS035637SS Super Stone

SHASS035837SS Super Stone

Grit

Grit Fine

SHANIKWT iKON Stone Water Combination medium/fine

SHASTC30 Sun Tiger Combination 30 -

SHASTD1080 Sun Tiger Delux D1080

SHADF Diekensen Comb

SHADO Diekensen Oil

Cambrian Engineering was established in 1925 in New Plymouth, on the west coast of New Zealand. Cambrian product a range of knife sharpening steels, manufactured completely in-house using time honored traditional techniques. Cambrian steels have a reputation of second to none for quality reliability and longevity.

Slip resistant handle with fingerguard helps avoid accidental slips and cuts in the kitchen

Black Rhino Cambrian Dexter DIAMOND & OVAL Victorinox NO WORK

High quality Victorinox sharpening steel diamond coated and an ergonomic plastic handle and hanging ring.

OVAL STEELS

Ideal for quickly restoring a dull edge. Safety is ensured through high-quality fittings; all handles are attractive and ergonomically formed.

Dick knives and steels are a long established, proven brand that are used within the meat and food processing sector. Their high quality materials ensure a long life and excellent performance, while their handles are designed to offer users a safe and comfortable grip.

ROUND STEELS

Give your knives the care and attention they need to perform at a consistently high standard with this knife sharpening steel from Dick. Featuring a round sharpening steel with regular serrations to create a smooth and razor sharp knife edge, you'll be able to prepare ingredients faster and more efficiently.

This knife steel is extremely longlasting and wear-resistant, delivering exceptional value for money. It is also fitted with an easy-to-grip polypropylene handle for maximum control over your strokes, and features a convenient ring for easy storage.

Dick

FLAT STEEL

Provides ample surface area for honing various sizes of knives, Its fine cut surface is finely grooved to realign the blade’s edge. The ergonomic handle offers a comfortable grip.

SQUARE STEELS

Complete with a galvanic coating, this tool features a breakproof, tough core and efficient surface protection, making it ideal for quick and effective steeling.

Egginton

ROUND, OVAL, SQUARE

Egginton Sharpening Steels are made from high carbon chrome vanadium steel, hardened to 64° Rockwell C and hard chrome plated.

STEG992431 Butcher’s Steel Black Round 31

STEG992225 Chef Cut Steel Fine Black Round 25

STEG992031 Chef Cut Steel Fine Black Oval 31

STEG21996531 Primeline Black/Grey Round 31

Stone Dia-Sharp Bench Fine D6f

SHADX07920EDGE1 Dexter Edge1 Hand Held

Ergo Primedge Steel III

Acusharp E/S 120

Electric Chefs Choice KE198

Improves the sharpness and edge retention of your knives with the very finely sharpened and specially coated sharpening steel blade

Various Sharpeners

STONE DIA-SHARP BENCH

Fine diamond to hone a razor sharp edge. Sharpens faster than conventional stones.

DEXTER EDGE1 HAND HELD

Tungsten carbide cutting heads for precision sharpening. Three or four strokes and it’s sharp. Protective handle grip for either left or right hand sharpening.

ERGO PRIMEDGE

The Ergo Steel III is an edge maintenance tool used on the production floor. Throughout the day, as a knife edge dulls.

ACUSHARP

Sharpen knives (even serrated knives), cleavers, axes, machetes, and many other cutting tools. The large ergonomic handle fits either hand safely and securely.

ELECTRIC CHEFS CHOICE

Three stage electric knife sharpener. Applies an ultra sharp edge to 20 degree knives.

SHADSD6F

SHAEHES3

KNISA

SHAEES120

STEELS

“Keep your knives sharp... RAZOR SHARP!”

Various Sharpeners

ELECTRIC NIREY - KE198

The KE-198 is not designed for continuous commercial use. The everyday user profile would be a recreational hunter or fisherman or keen amateur chef.

ELECTRIC NIREY - KE280

The intended purpose of the Nirey KE-280 is for commercial use ideally suited to butcher shops, restaurants and commercial catering purposes.

IKON HAND SHARPENER

Protective handle grip.

MASTER HYPER DRILL

Extendable handle, easy to hold. Keep your knives exceptionally sharp. Quick and easy operation steel guide, no plastic fragments.

DICK MAGNETO HYPER DRILL

Magnetic knife guides keep your knife straight for the perfect honing angle. Plate made of stainless steel.

CARIBOU AUTO

The Caribou standard automatic steel is ideal for operators seeking a mounted automatic steel option (mount sold separately).

GIESSER SHARP EASY

Perfect honing and polishing. Including table bracket, sharpener can be exchanged easily (without tools).

GIESSER MAX

With the option of 30 or 40 degree angles, this quality German made precision sharpener has most knives covered.

SHAGMAX9990

WHAT’S THE EDGE?

Stone vs. Steel

Sharpening Stones

(also known as Whetstones)

Function

Sharpening stones are used to grind and hone the edges of knives. They physically remove material from the blade to create a new, sharper edge.

Types

Whetstones come in various grits (coarse, medium, and fine).

Coarse grits are used for repairing chips and reshaping edges, while finer grits are used for honing and polishing.

Use

To sharpen a knife with a stone, the blade is drawn across the stone at a consistent angle, usually between 15° to 20°. Water or oil is often used as a lubricant, depending on the type of stone.

Outcome

Stones sharpen the knife by creating a new edge, making them essential for knives that are dull or have damaged edges.

Sharpening Steels

(also known as honing steels)

Function

Honing steels are used to realign the edge of the knife, rather than sharpening it. Over time, the edge of a knife can bend or fold over with use. A honing steel straightens this edge without removing significant material.

Types

Steels can be smooth or slightly abrasive (ceramic or diamondcoated steels). The abrasive types can have some sharpening effect, but their primary purpose is still to hone.

Material: Traditional steels are made of hardened steel, but ceramic and diamond-coated steels are also common for more abrasive honing.

Use

To hone a knife, the blade is drawn along the steel at a consistent angle (usually 20°), using a sweeping motion from the base of the blade to the tip.

Outcome

Honing steels maintain the edge of the knife between sharpenings. They do not actually sharpen the knife but keep it in good working condition by straightening the edge.