AI in Procurement: Detecting Supplier Risks Before They Impact Operations

How Strategic Procurement Leaders Use Artificial Intelligence to Build Supply Chain Resilience and Gain Predictive Visibility

The procurement function has rapidly evolved from a transactional service to a core strategic enabler of business continuity and competitive advantage Yet, as global supply chains grow increasingly fragile, procurement teams are exposed to unprecedented supplier-related risk, financial, geopolitical, environmental, operational, and reputational

Artificial Intelligence (AI) is redefining how organizations detect, assess, and mitigate supplier risks With real-time monitoring, predictive analytics, and cognitive insights, AI empowers procurement leaders to move from reactive issue management to proactive risk prevention

This blog outlines how AI transforms supplier risk detection and prevention It provides a comprehensive view of applications, use cases, organizational readiness factors, and future trajectories, all designed to guide procurement leaders, CIOs, and supply chain executives in embedding AI into the procurement ecosystem

Introduction

Global disruptions over the last five years, from the COVID-19 pandemic to regional wars, inflation shocks, ESG violations, and cybersecurity breaches, have exposed how deeply supplier risks can impact enterprise performance Gartner surveys indicate that 71% of Chief Procurement Officers (CPOs) now prioritize risk mitigation and supplier resilience as top strategic imperatives

Today’s procurement leaders are responsible for sourcing cost-effectively and also ensuring the continuity, ethical compliance, and security of supplier networks

As the scale and complexity of risk multiply, manual risk monitoring tools have become insufficient Artificial Intelligence, a set of technologies capable of detecting signals across fragmented data, identifying hidden threats, and providing timely, actionable insights

Why Traditional Supplier Risk Management Falls Short

Conventional supplier risk management frameworks are typically structured around static risk categories (e g , financial health, delivery delays, compliance audits) However, these systems suffer from several systemic limitations:

Traditional Approach

Periodic audits and questionnaires

Manual reviews and scorecards

Tier-1 supplier focus

Fragmented data sources

Siloed business functions

Key Limitation

Stale data; fails to detect evolving threats

Resource-intensive and inconsistent

Neglects multi-tier supply chain vulnerabilities

Inability to synthesize early warning signals

Risk decisions isolated from operational realities

A significant challenge lies in the latency between when a supplier issue arises and when it’s detected For example, by the time a supplier’s financial weakness is discovered via quarterly review, the damage from missed deliveries or breach of contract may already be underway

AI provides a paradigm shift from lagging to leading indicators, from periodic to continuous insight, and from anecdotal to data-driven decision-making

The Strategic Role of AI in Procurement

AI’s application in procurement is a strategic capability that enhances enterprise agility, governance, and resilience

Four Strategic Shifts AI Enables in Procurement

From Reactive to Predictive

Move from firefighting supplier issues to forecasting them in advance

From Gut Feel to Data-Driven

Replace subjective risk ratings with algorithmic scoring based on real-time data

From Tier-1 to Ecosystem Visibility

Expand monitoring to tier-2, tier-3, and subcontracted entities

Enable sourcing based on risk-adjusted total value, not just price and performance

According to a 2024 Gartner CIO survey, organizations that embed AI in procurement reduce supplier risk exposure by 45% on average and recover from disruptions 30% faster than peers

AI Capabilities for Supplier Risk Detection

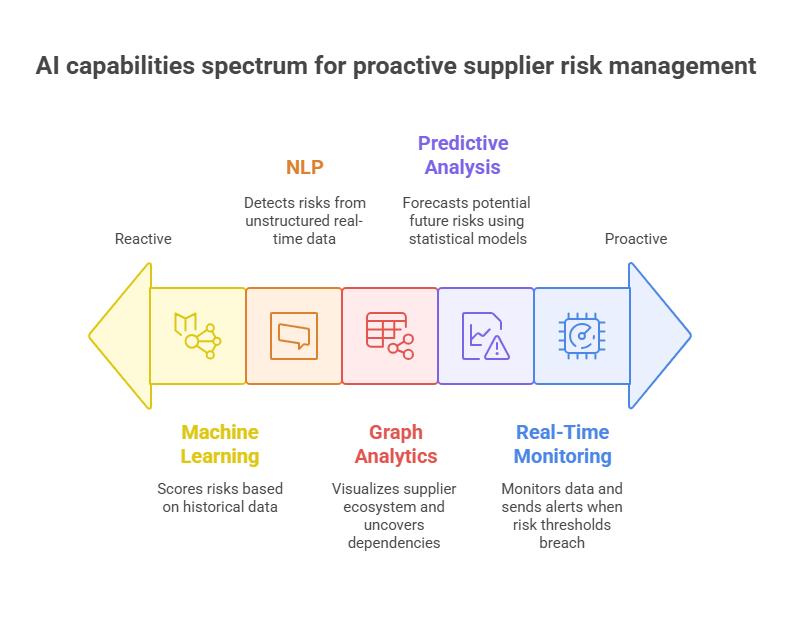

As supplier networks become more global and interdependent, procurement leaders are turning to artificial intelligence (AI) to transform how supplier risks are identified, assessed, and mitigated AI provides a multidimensional approach to risk management, synthesizing structured and unstructured data from across the enterprise and beyond The following five core AI capabilities are foundational to enabling real-time, predictive supplier risk detection:

Machine Learning (ML)-Based Risk Scoring

Machine learning algorithms process historical supplier performance data, procurement records, incident logs, and risk outcomes to build adaptive risk models

These models identify patterns that correlate with past disruptions, such as late deliveries, financial stress, or quality failures, and assign risk scores to current suppliers based on similar traits Over time, the system continuously learns from new data, refining its predictions and increasing accuracy

For example, if certain payment delays historically precede insolvency, the model will flag similar behavior as a predictive warning signal ML allows for nuanced, context-aware scoring that evolves alongside market dynamics and internal business shifts

Natural Language Processing (NLP)

NLP enables AI systems to ingest and interpret vast volumes of unstructured data, ranging from global news articles and social media posts to legal disclosures, regulatory updates, and NGO reports This capability is particularly valuable for identifying reputational, ethical, and geopolitical risks

For instance, NLP can detect early signs of ESG violations, lawsuits, or labor strikes involving a supplier, even if those issues haven’t yet reached formal reporting channels It then translates these signals into structured risk indicators that procurement systems can act upon

NLP broadens visibility beyond the confines of internal data, capturing sentiment and developments in real time

Predictive Analytics

Beyond detecting current issues, predictive analytics uses statistical and econometric models to forecast potential future risks across dimensions such as financial health, operational continuity, and compliance

These models incorporate leading indicators like macroeconomic trends, inflation rates, regional instability, and environmental changes to simulate disruption scenarios

For instance, predictive analytics can quantify the probability of shipment delays due to upcoming monsoons in a supplier’s region or rising input costs that could affect delivery schedules These foresights empower procurement teams to build contingency plans before risks materialize

Cognitive Search and Graph Analytics

This capability allows procurement teams to go beyond linear supplier relationships and visualize the extended supplier ecosystem using dynamic network graphs By mapping connections between suppliers, subcontractors, manufacturing sites, logistics partners, and geographic clusters, AI uncovers hidden dependencies and systemic vulnerabilities

For example, if multiple Tier-1 vendors rely on a common Tier-3 raw material supplier, disruptions at that node can have cascading effects Graph analytics helps detect these critical chokepoints and supports holistic risk mitigation planning across the value chain

Real-Time Monitoring and Alerts

AI-powered systems constantly monitor a combination of internal procurement data and external signals, such as shipment tracking, commodity prices, weather alerts, and geopolitical news, to detect anomalies

When risk thresholds are breached, the system sends real-time alerts to procurement and operations teams These alerts are contextual, actionable, and prioritized based on severity and potential impact

For example, a predictive AI model may flag a Tier-2 component supplier in Taiwan for a likely disruption due to upcoming regional elections and anticipated power grid instability With this early warning, the procurement team can initiate alternate sourcing or increase safety stock levels

Maturity Model for AI Supplier Risk Management

The adoption of AI in supplier risk management follows a clear maturity curve, reflecting an organization’s progression from manual, reactive practices to autonomous, AI decision-making This model helps procurement leaders benchmark their current capabilities and chart a strategic roadmap toward advanced resilience

Level 1 – Foundational

Organizations at this stage rely heavily on manual processes and static spreadsheets to assess supplier risk Evaluations are typically qualitative and limited to Tier-1 suppliers There is little to no real-time visibility, and responses to disruption are reactive rather than proactive Risk remains siloed within procurement with minimal cross-departmental coordination

Level 2 – Enabled

Risk management becomes more digitized, with supplier data housed in ERPs or procurement suites Dashboards provide visibility into key supplier KPIs, and early NLP tools may monitor for basic red flags However, analysis remains largely descriptive, with little automation or forward-looking insight Most large enterprises today operate within this stage

Level 3 – Intelligent

AI technologies begin to take root Machine learning models produce dynamic risk scores, predictive analytics forecast potential disruptions, and real-time alerts enhance responsiveness Organizations start shifting from hindsight to foresight, enabling faster, data-informed mitigation

Level 4 – Integrated

At this level, AI capabilities are embedded across finance, legal, logistics, and compliance, creating a unified view of supplier risk Decision-making becomes partially automated, with scenario modeling and advanced simulations informing procurement strategy

Level 5 – Autonomous

The most advanced stage features AI systems that autonomously execute mitigation plans, rerouting logistics, reassigning orders, or sourcing alternative suppliers without human intervention Dynamic risk resilience becomes a competitive advantage, observed in trailblazing sectors like aerospace, pharma, and high-tech

Maturity Stage Key Characteristics

Level 1 – Foundational

Level 2 – Enabled

Level 3 – Intelligent

Level 4 – Integrated

Level 5 – Autonomous

Manual risk assessments, Excel-based scoring, limited to Tier-1 suppliers

ERP integration, basic dashboards, and early NLP tools

ML-based risk scoring, real-time risk alerts, predictive insights

Cross-functional data integration (finance, legal, logistics), automated decision-making

AI-led risk mitigation actions (e g , auto-sourcing alternate suppliers), and dynamic resilience planning

Most organizations today operate at Level 2 or 3, with pioneers in aerospace, pharmaceuticals, and high-tech industries pushing into Level 4

Key Benefits of AI-Powered Supplier Risk Mitigation

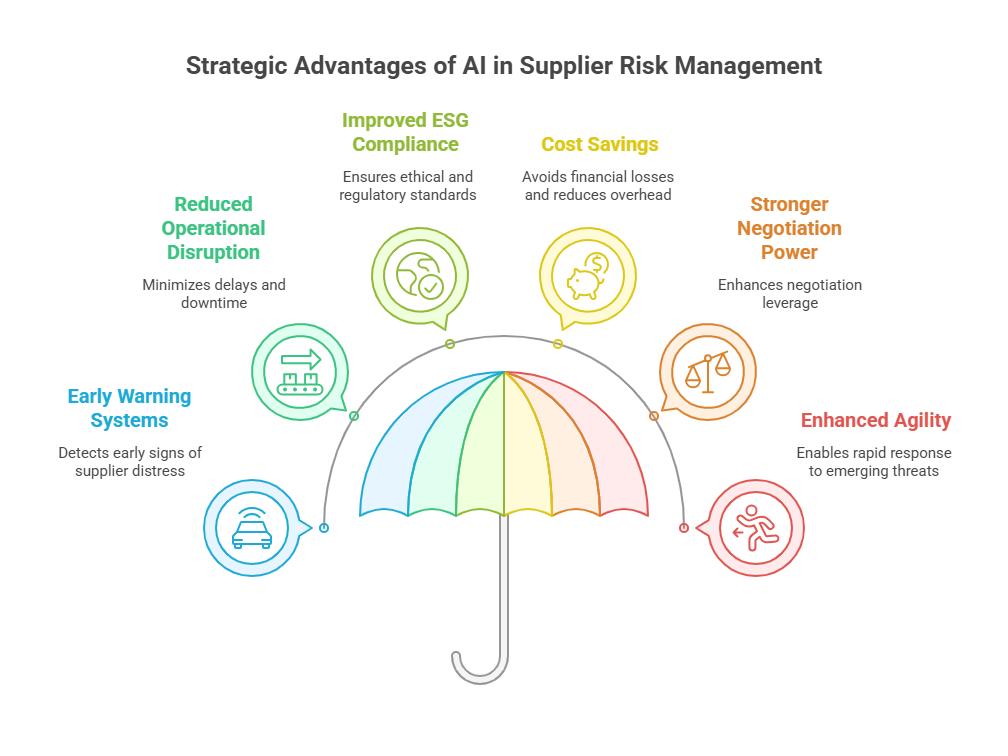

The integration of AI into supplier risk management delivers tangible value across procurement, operations, compliance, and finance By shifting from reactive damage control to proactive mitigation, organizations can protect business continuity while improving cost efficiency and resilience Below are six key benefits that define the strategic advantage of AI-powered supplier risk mitigation:

Early Warning Systems

AI excels at detecting subtle signals of supplier distress, long before traditional methods might raise concern Through predictive modeling and real-time data analysis, AI systems can identify early indicators such as payment delays, workforce instability, regulatory scrutiny, or reputational damage

For example, a sudden drop in shipment frequency or negative ESG-related news could trigger automated alerts well in advance of a formal supplier failure, allowing stakeholders to respond proactively

Reduced Operational Disruption

Timely intervention is key to maintaining operational flow With AI-generated alerts, procurement teams can initiate alternative sourcing strategies, adjust inventory levels, or reroute logistics before a disruption escalates This capability minimizes delays, reduces downtime, and safeguards production schedules, especially in industries where even a short supply chain interruption can translate into significant financial loss

Improved ESG Compliance

Environmental, Social, and Governance (ESG) standards are under growing scrutiny AI tools equipped with natural language processing continuously monitor global news, NGO reports, and regulatory databases for ESG violations or ethical lapses among suppliers

This ensures compliance is upheld across all tiers of the supply chain, and organizations can quickly disengage from high-risk or non-compliant vendors

Cost Savings

Preventing disruptions is significantly more cost-effective than reacting to them AI helps companies avoid financial losses associated with expedited freight, SLA violations, production halts, and emergency vendor onboarding

Additionally, automated risk monitoring reduces the manual effort required for risk audits and performance reviews, lowering administrative overhead

Stronger Negotiation Power

When procurement has access to transparent, data-driven risk profiles, supplier negotiations shift in their favor AI insights offer leverage to negotiate better terms, demand contingency planning from suppliers, or justify supplier diversification strategies

Enhanced Agility

In volatile geopolitical or environmental conditions, real-time visibility is critical AI enables rapid scenario planning and decision-making, ensuring procurement teams can pivot swiftly in response to emerging threats, whether it’s a trade embargo, cyberattack, or pandemic outbreak

Benefit

Early Warning Systems

Reduced Operational Disruption

Improved ESG Compliance

Description

AI detects signs of supplier failure before traditional methods

Proactive alerts lead to timely intervention (e g , alternate sourcing, inventory adjustment)

Automated monitoring ensures supplier adherence to sustainability standards

Cost Savings Prevention of disruption-related penalties, expedited shipping costs, and missed SLAs

Stronger Negotiation Power

Enhanced Agility

Organizational and Technical Considerations

Transparency into supplier risk strengthens procurement strategy

Real-time data enables faster response to geopolitical, environmental, or market changes

Adopting AI for supplier risk requires a strategic approach encompassing people, processes, and platforms

Organizational Readiness

● Data Governance: Clean, accessible, and structured data is foundational

● Cross-Functional Alignment: Involve risk, finance, ESG, logistics, and IT teams

● Leadership Buy-In: Executive sponsorship is critical for change management

Technology Enablement

● Tool Integration: Ensure compatibility with ERPs, SRM tools, and contract management platforms

● Cloud Infrastructure: Use scalable cloud-based AI services for processing large datasets

● Third-Party Providers: Partner with AI firms specializing in procurement intelligence

Ethical and Regulatory Considerations

● Avoid algorithmic bias in supplier scoring

● Ensure compliance with data privacy and transparency standards (e g , GDPR, CCPA)

Gartner predicts that by 2027, over 50% of procurement organizations will integrate AI-based supplier risk intelligence into sourcing and contract decisions

Strategic Recommendations for Operationalizing AI in Supplier Risk Management

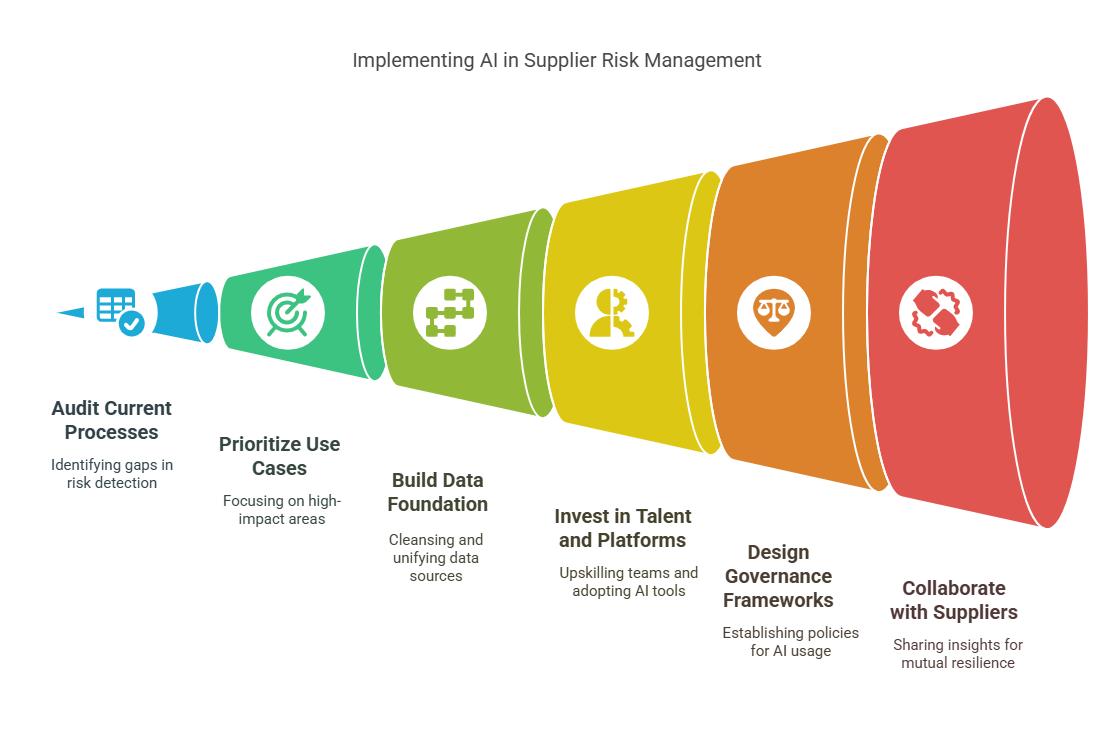

Adopting AI for supplier risk management requires more than just deploying new technology It demands a strategic, enterprise-wide shift in mindset, data governance, and organizational capabilities

For procurement leaders and CIOs seeking to embed AI into risk mitigation workflows, the following recommendations provide a practical blueprint to accelerate value realization and de-risk AI adoption:

Audit Your Current Risk Detection Process

Begin with a comprehensive assessment of your existing risk management practices Identify gaps in data visibility, response time, and risk scope across all supplier tiers

Are your current assessments manual, reactive, or siloed within departments? Do you lack real-time alerts, or are you overlooking key risk domains like reputational and geopolitical threats?

This audit sets the baseline and clarifies the critical areas AI must enhance, such as enabling predictive alerts, cross-tier visibility, and dynamic scenario modeling

Prioritize Use Cases with High Impact

To ensure early wins and stakeholder buy-in, prioritize AI use cases that deliver measurable impact Focus first on high-risk, high-cost domains like financial risk detection, shipment or lead-time variability, and ESG compliance monitoring These areas typically have abundant data, strong regulatory implications, and a direct influence on supply continuity and cost

Align these use cases with strategic business goals to demonstrate quick ROI and justify further investment

Build a Data-First Foundation

AI’s effectiveness hinges on high-quality data Begin by cleansing, unifying, and enriching your supplier, contract, and performance data Connect disparate data sources, including ERP systems, SRM tools, logistics platforms, and third-party risk databases, into a unified data lake or AI-ready warehouse The richer and cleaner the data, the more accurate and actionable your AI-driven insights will be

Invest in AI Talent and Platforms

Upskilling procurement professionals to interpret AI outputs is critical Equip teams with training in data literacy, risk modeling, and AI tool usage

Concurrently, evaluate and adopt AI-native platforms that offer modular integration, pre-trained models, and strong interoperability with your procurement tech stack Consider tools with built-in NLP, graph analytics, and alerting engines to accelerate deployment

Design Governance Frameworks

Operationalize AI by creating clear governance policies Define acceptable risk thresholds, escalation paths, decision-making authority, and ethical AI usage principles Ensure transparency, accountability, and traceability of AI-generated decisions, especially when automating mitigation actions or influencing vendor relationships

Collaborate with Strategic Suppliers

Treat AI risk management as a collaborative advantage rather than a compliance mechanism Share relevant AI insights with strategic suppliers to jointly assess vulnerabilities and co-create resilience plans This fosters trust, aligns incentives, and ensures mutual preparedness in facing disruption scenarios

Final Thoughts

AI is the linchpin of a next-generation supplier risk management strategy By adopting AI insights, procurement organizations can anticipate disruptions, protect revenue streams, and unlock competitive agility

The future of procurement belongs to those who can see risk before it hits With AI, that future is already here