4 minute read

NEUERO continues to develop its unloading systems and expertise

Bulk handling equipment manufacturer NEUERO has particular expertise in pneumatic and mechanical unloading systems. Below, the company details some of its notable unloading projects and expertise.

Recent Contracts

San Miguel Malt Unloader

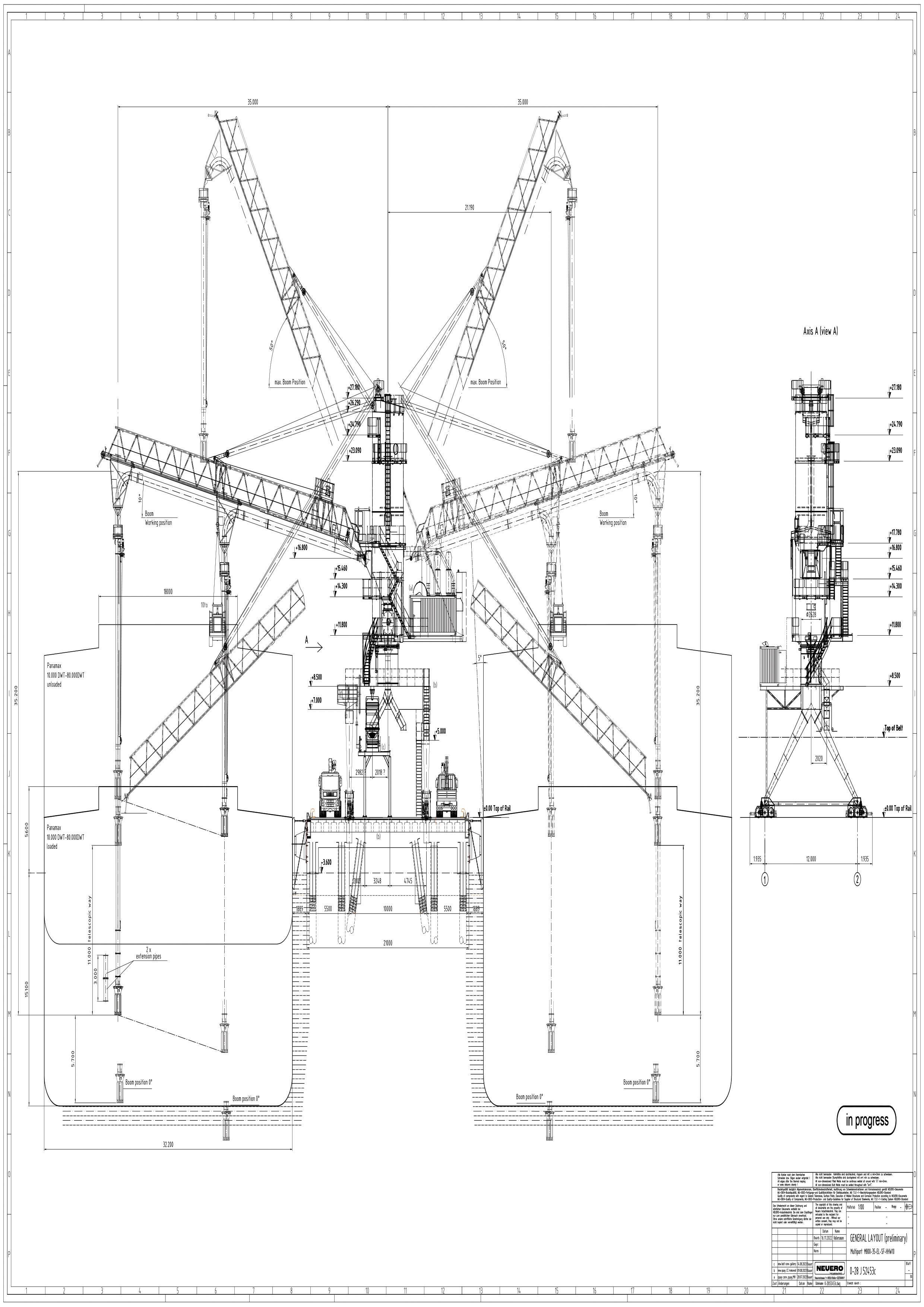

The general design is a NEUERO Multiport - 35 newest generation (for more details, see ‘current installations’ below) for Capesize ships or, as in this case, the shipunloader is designed to unload on both sides of the jetty.

This unloader is equipped with a 35metre boom, 19m horizontal telescopic range and a payload winch with a lifting capacity of 10 tonnes (12, 15 or 16 tonnes are also available as an option). The ability to lower the boom to the ground facilitates inspection and maintenance and provides additional protection in extreme weather conditions such as typhoons with wind speeds of up to 300km/h and earthquakes.

The Multiport M800 is specially designed for gentle malt handling, ensuring high capacity and efficiency. To further improve malt handling, the unloader is equipped with the latest generation of Belt-

* See details at technological developments.

Airlock*, which minimizes leakage and wear while eliminating the common problem of blockage of conventional airlocks by foreign objects. This advanced airlock system also includes automatic belt tracking for improved reliability.

For even greater efficiency and capacity, NEUERO offers the ADS (Auto-Dipping System*) along with a remote control to adjust the airflow of the suction nozzle* to optimize the unloading process.

Mariveles Grain Terminal

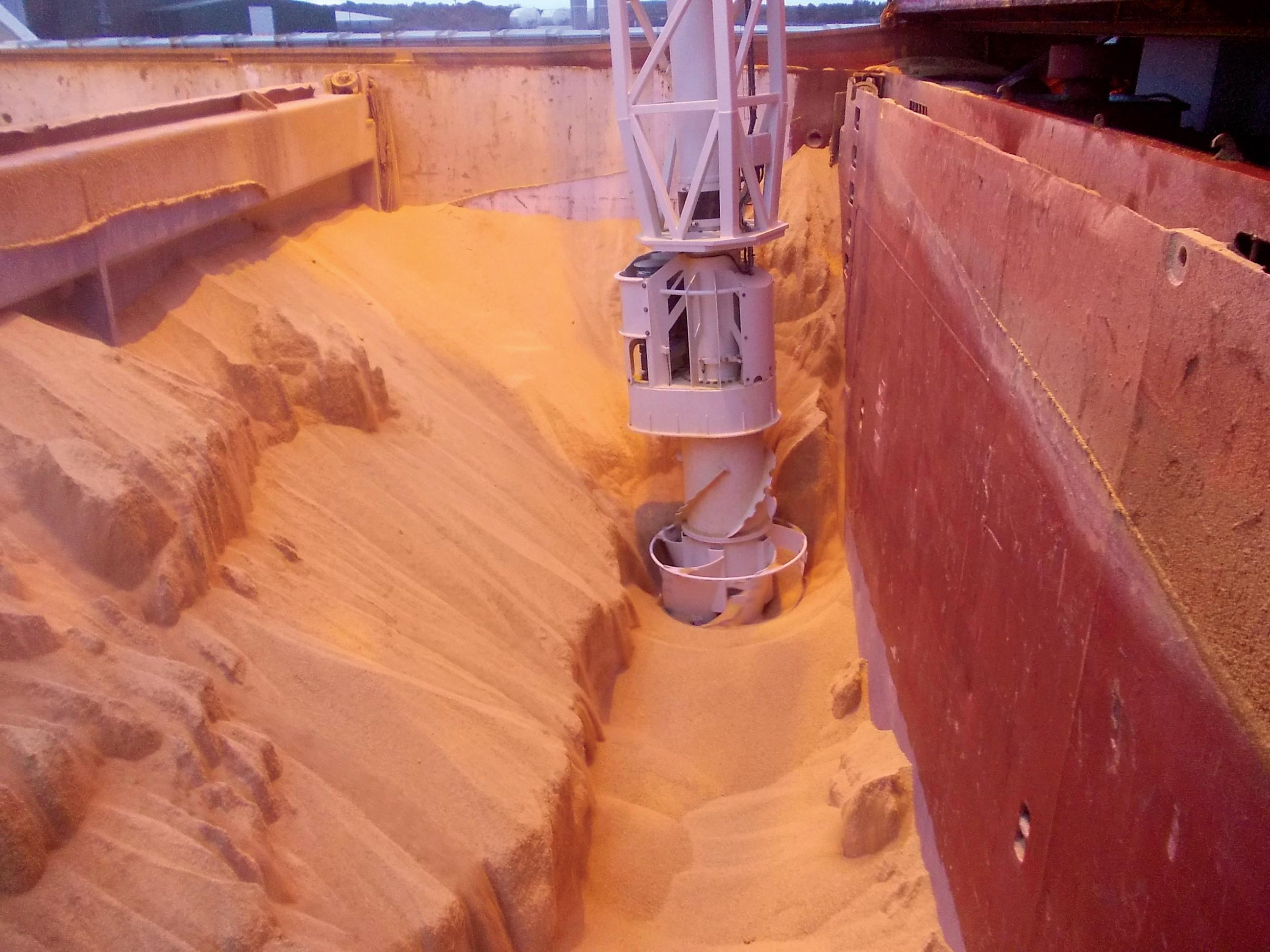

Mariveles Grain Terminal is one of multiple companies that have recently placed orders for the NEUERO Flexiport design unloader. The Flexiport, with a capacity of 800tph (tonnes per hour), combines the best of pneumatic and mechanical technologies, and is designed with a special rotating feeding/digging nozzle to efficiently unload non free flowing material such as soyameal, fishmeal, etc., etc.. Clients see the benefit of the NEUERO design compared to mechanical-only unloaders that require bulldozers in the ship’s hold to break up the material and push the material to the feeder. The Flexiport design can efficiently unload non-free-flowing material without the use of bulldozers — saving manpower and additional equipment costs.

Mariveles Grain Terminal has placed a recent order for a NEUERO Flexiport unloader, which combines the best of pneumatic and mechanical technologies.

CURRENT INSTALLATIONS

NEUERO MULTIPORT NEW GENERATION

Several units of this model, designed to unload Cape size vessels, have been ordered by customers in the Middle East.

The main characteristics of these shipunloaders include:

M600, 600tph (tonnes per hour)** — v 2 x 250kW direct drive turbo blowers with steel impellers; M800, 800tph** — 2 x 330kW direct v drive turbo blowers with carbon fibre impellers*; 35m working boom length — v measured from centre vertical pipes to centre slewing boom; auxiliary winch of 10 – 12 – 15 – 16 v tonnes; all are equipped with the NEUERO v scavenging filter (no need for compressed air); all have the ability to lower the boom v to the ground; New joint sealing between the v horizontal pipe and the main receiver filter means no wear, and no leakage; airlock standard, or advanced Belt Airlock; v Auto Dipping System; and v Suction Nozzle Airflow Regulation. v

TECHNOLOGICAL DEVELOPMENTS

One major development is the belt airlock new generation with improved automatic self-alignment belts. The biggest advantage of belt airlock is the ability to avoid blockages caused by foreign material and grain chopping caused by sharp edges between the rotor tip and airlock body.

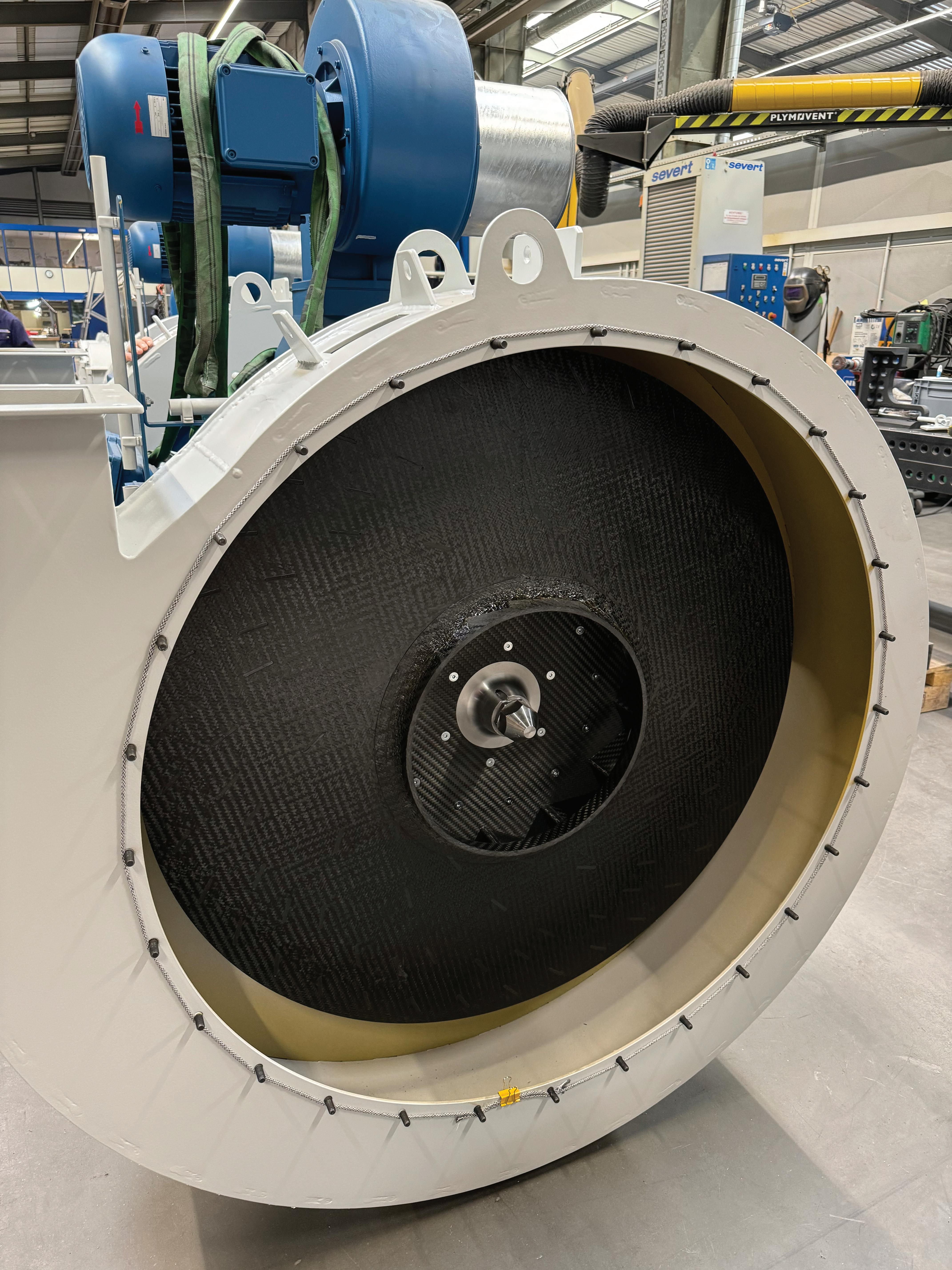

The turbo blower impeller is a new development. The first generation of carbon fibre impellers is for NEUERO’s largest 330kW turbo blowers. The impellers have a much lower weight and are more resistant, resulting in higher speeds with possible higher vacuum.

The Auto Dipping System Automation positions the suction nozzle at optimal material penetration. The optimal suction nozzle penetration is helps to maintain best capacity. The operator is given the ability to set the machine to capacity — energy-efficient operating point.

The Suction Nozzle Airflow Regulation Automation positions the air entrance at the suction nozzle. This is an excellent alternative to manual mode, where the operator needs to go inside the ship. The goal is to find the optimal Material X Air relation. This optimal relation varies according to the specific product characteristic. The operator is able to set the air opening remotely, to find best capacity — energy-efficient operating point and does not need to enter the ship. The air opening is done by an electric actuator and opening and closing a slide grid. The best setting is given at the machine operating manual.

** Based on wheat 750kg/m3 standard capacities.

Case Studies

RETROFITTING OLD PNEUMATIC UNLOADERS

What can you do if an old rotary piston blower has a failure? To replace the system with a similar like-for-like unit often involves long delivery times, and generally complex designs with motor-clutch — gearbox — blower. Additionally, the gearbox and blower need a hydraulic unit for lubricating and cooling.

At ADM in Hamburg Germany NEUERO was able to replace the old system with new turbo blowers, offering the same capacity as the previous system. These blowers have advance protection to identify vibrations or temperature increases and adjustable speed with frequency inverters. The blower and the motor have a common shaft that has no mechanical loss that is common in belt or gearbox designs.

An ageing pneumatic ship-unloader: NEUERO replaced the failed roots blower (bottom, right) with its new high-tech turbo blower (bottom, left).

An additional benefit, besides energy savings, was the noise reduction of the unloader; the characteristic low frequency of a rotary or piston blower is difficult to insulate. This was solved with the high frequency of a turbo blower.

“Amazingly quiet, I feel like I’m in my living room,” was the first testimonial from Michael Siebels, Silo Manager.