2 minute read

VIGAN boasts wide expertise in pneumatic bulk unloading

Pneumatic unloaders are in a niche market, with only a few companies that play a significant role. One of the most important of these is Vigan, which started building modern pneumatic unloaders in 1968. Compared to the period before 1968 major differences could be observed when the Vigan unloaders entering the market: one elbow principle; v one large capacity pipe per machine; v multiple step turbines on the same v shaft (2-3-4 rotors per shaft); pulse regenerated filters using the v Venturi principle; luffing booms by hydraulic jacks; and v use of state-of-the-art wear-resistant v materials.

The result of these developments was an major improvement in energy efficiency, as well as a large capacity increase.

Further integrations of electronic components related to safety, steering, control and power brought the machines to the leading edge of technology.

Together with Vigan’s philosophy — to build every single machine under the same roof at its premises in Belgium — the company has a very important USP: it maintains full control and has a detailed overview of all specifications and features of every single machine. This approach has resulted in a very important cost consequence: to produce every single machine under the same roof one needs a lot of space.

When building its latest assembly hall some five years ago, most of Vigan’s workers

Handle bulk with efficiency and reliability

Pneumatic and mechanical ship (un)loaders

Up to 2500 tph for loaders and up to 1200 tph for unloaders.

Low noise & no dust emission thought that the company would host part of the next Olympic games. As we speak seven 800tph (tonnes per hour) pneumatic unloaders are on order for four customers — and one of these is a repeat order.

Turnkey solutions for cereals, soy flour, fertilizer, pellets and more...

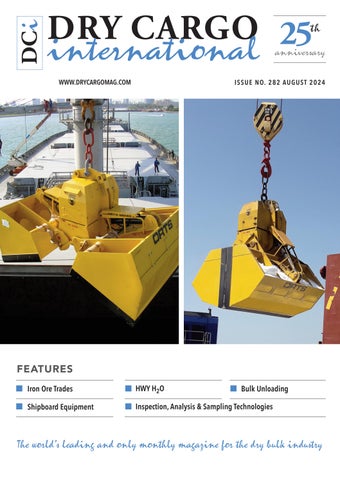

As can be seen from the pictures, Vigan will no longer even host the Badminton part of the games. Premounting its machines in the factory takes more time. But upon mounting at the customer’s site,

Vigan earns this time back many times over. Often, customers have congested quays and want no activities to interfere with their operations — or at least wants these activities to be minimized. Or they want to play safe, an all-in cost until the final operation. Vigan is prepared. Every single machine has been pretested, every single electrical motor, camera, etc., has been put into operation.

So Vigan has taken this philosophy to a very large scale — next level. Very soon, seven more 800tph machines from Vigan will be operating somewhere in the world. Between them, they can easily unload an annual capacity of 30 million tonnes of cereals, soybean or wood pellets. Vigan is proud to say it follows the ever-increasing need for bulk to be loaded and unloaded throughout the world.

Conclusion

Vigan Engineering has established itself as a cornerstone in the niche market of bulk handling equipment in sea ports. Since its inception in 1968, Vigan has been a pioneering force in the development of modern pneumatic unloaders. With a commitment to innovation and excellence, the company has consistently introduced cutting-edge technologies and engineering advancements that have set new standards in the industry. As one of the leading players in this specialized field, Vigan prides itself on producing high-efficiency, largecapacity unloaders, meticulously crafted under one roof at its state-of-the-art facilities in Belgium. This holistic approach ensures unparalleled quality control and precision, reinforcing Vigan’s reputation as a leader in bulk handling solutions.