4 minute read

Peak performance: how Bühler’s Performance Assessment Workshops can help clients in the ship loader/unloader sector to optimize their processes

The Performance Assessment Workshop (PAW) has long been a valued tradition within the Bühler Group, and has now been extended to shiploaders and shipunloaders after highly successful implementation in other parts of the business.

This new consulting service for this sector is designed to specifically address its key challenges. The workshops do this by enabling businesses to analyse their current operational processes, identify opportunities for improvement, and develop solutions that are tailor-made for their unique requirements. They allow organizations to maximize the efficiency of their existing installations, combining Bühler’s customized solutions with a structured and holistic methodology to optimize specific production goals.

MULTI-PHASE APPROACH

So what happens in a Performance Assessment Workshop? Experienced professionals evaluate the state of a company’s processes and systems through a multi-phase approach. First is the analysis phase, during which the current state of performance is thoroughly examined, with process data collected and analysed to identify bottlenecks and inefficiencies according to the 4M concept (‘Machine’ — condition, safety devices, parts availability, ‘Method’ — process, maintenance, recipe, quality control; ‘Man’ — knowledge, responsiveness, training, and ‘Material’ — quality, consistency, handling). The assessment evaluates the current situation according to various performance criteria such as performance, product quality, machine lifetime & safety and availability.

Based on the analysis results, a tailored action plan is developed to address the identified weaknesses. This planning phase is then followed by the final implementation phase, during which the measures are executed and continuously monitored to ensure the goals are achieved. This structured methodology means that all relevant aspects are fully considered for sustainable improvements and optimal performance.

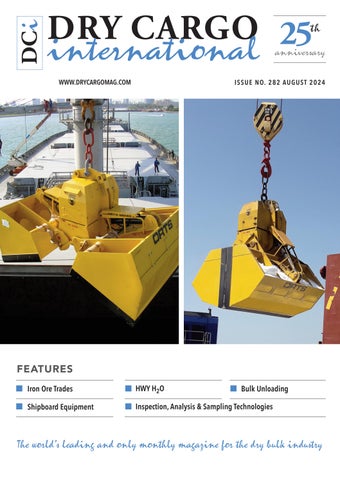

Bühler Portalink 600/100 mechanical ship-unloader in Trincomalee (all pictures)

Customer Benefits

PAWs have a wide range of benefits for customers, including efficiency improvements, cost reductions, and enhanced competitiveness. Identifying and eliminating bottlenecks and inefficiencies means that companies can accelerate their workflows, put their resources to more efficient use and, ultimately, reduce their operational costs. Continuous process improvements also help them to stay competitive and prepare for future challenges.

But PAWs are not about a top-down approach. The workshops operate through mutual engagement, with Bühler’s experts carrying out interdisciplinary analysis in full partnership with the customer. All relevant production factors — whether technical, technological or operational — are analysed to clearly demonstrate any potential for improvement.

Unlike a standard inspection, which would traditionally only cover areas like machine uptime and lifetime, the PAWs also encompass areas like capacity, product quality, technology, energy efficiency and workplace safety. They allow the customer to make targeted investments for its new processes, machines or workforce based on a transparent, objective assessment.

All PAW clients are provided with a full detailed report and customized action plan. This includes an executive summary and overview followed by full specifics about the methods used, a detailed breakdown of every finding — clearly spelling out its impact on performance factors — and a set of recommendations for improvement.

BOOSTING EFFICIENCY AT PRIMA CEYLON (PRIVATE) LIMITED

One Bühler customer to experience PAW’s benefits is Prima Ceylon (Private) Limited, located in Trincomalee. Built in 1980, the flour mill is the Group’s flagship Sri Lankan enterprise. Today, Prima Group operates one of the largest food conglomerates in Sri Lanka, encompassing flour milling, food production, and agro-food. Prima Ceylon (Private) Limited faced the challenge of modernizing its flour milling facilities while also boosting efficiency, and the workshop enabled a number of critical improvement areas to be identified.

Bühler’s recommended measures were seamlessly integrated into Prima’s production process, resulting in significantly reduced downtime and operational costs. What’s more, overall efficiency increased by approximately 20%, while maintenance and operational issues saw a reduction of up to 30%. These enhancements led to notable savings in power consumption and daily operational costs.

“The PAW conducted by Bühler has been instrumental in modernizing our older facilities while enhancing efficiency,” the company stated. “This type of longterm relationship is what makes our collaboration with Bühler unique.”

Increasing Sustainability

Efficiency is a key production target for quality losses such as waste and rejects, or energy consumption and losses in terms of (heat) waste. A Performance Assessment Workshop can be an essential tool for companies looking to optimize their processes and ensure long-term sustainability. By leveraging Bühler’s structured and holistic approach, businesses can significantly improve their efficiency, reduce costs, and stay competitive in a rapidly evolving market.

ABOUT PRIMA CEYLON (PRIVATE) LIMITED

PCL is Prima Group’s flagship Sri Lankan enterprise. When completed in 1980, the flour milling complex in Trincomalee was the world’s largest flour mill under one roof with a daily milling capacity of 2,200 metric tonnes of wheat. Located in the strategic Trincomalee harbour, the selfcontained complex has now expanded to 3,650 metric tonnes of wheat per day and a total silo space of 350,000 metric tonnes, with facilities for the movement of products directly onto and from the ships docking at the jetty. The fully integrated and automated milling process is connected by a modern transport network, with road, rail and sea access. On-site R&D facilities and residential living amenities exist within the complex for employees.

About B Hler

Bühler is driven by its purpose of creating innovations for a better world, balancing the needs of economy, humanity, and nature in all its decision-making processes. Billions of people come into contact with Bühler technologies as they cover their basic needs for food and mobility every day. Two billion people each day enjoy foods produced on Bühler equipment; and one billion people travel in vehicles manufactured using parts produced with Bühler solutions. Countless people wear eyeglasses, use smartphones, and read newspapers and magazines — all of which depend on Bühler process technologies and solutions. Having this global relevance, Bühler is in a unique position to turn today’s global challenges into sustainable business.

As a technology partner for the food, feed, and mobility industries, Bühler has committed to having solutions ready to multiply by 2025 that reduce energy, waste, and water by 50% in the value chains of its customers. It also proactively collaborates with suppliers to reduce climate impacts throughout the value chain. In its own operations, Bühler has developed a pathway to achieve a 60% reduction of greenhouse gas emissions by 2030 (Greenhouse Gas Protocol Scopes 1 & 2, against a 2019 baseline).

Bühler spends up to 5% of turnover on research and development annually to improve both the commercial and sustainability performance of its solutions, products, and services. In 2023, some 12,500 employees generated a turnover of CHF3.0 billion. As a Swiss family-owned company with a history spanning 164 years, Bühler is active in 140 countries around the world and operates a global network of 105 service stations, 30 manufacturing sites, and Application & Training Centers in 25 locations.