5 minute read

On the right channel... ...with the Great Lakes & St. Lawrence Seaway System

The Europe-North America trade route is a vital transportation link and is a long standing and vital link for continental trade. Vessel traffic between the European continent and North America via the St. Lawrence River and Seaway System serves as one of the world’s foremost two-way trade.

The Great Lakes–St. Lawrence Seaway System is a deep draught waterway extending 3,700km (2,340 miles) from the Atlantic Ocean to the head of the Great Lakes, in the heart of North America. The St. Lawrence Seaway portion of the System extends from Montreal to mid-Lake Erie. v Cargo shipments on the Great Lakes-Seaway system generate $45 billion of economic activity and 238,000 jobs in Canada and the US. v The binational St. Lawrence Seaway serves as the linchpin within the broader waterway, connecting the lower St. Lawrence River to the Great Lakes. Beginning in Montreal and extending to points west, the Seaway’s 15 locks (13 Canadian and two US) enable ships to climb a total of 168 metres from sea level up to Lake Erie.

Ranked as one of the outstanding engineering feats of the twentieth century, the St. Lawrence Seaway includes 13 Canadian and two US locks.

The Great Lakes and St. Lawrence River have been major North American trade arteries since long before the US or Canada achieved nationhood. Today, this integrated navigation system serves miners, farmers, factory workers and commercial interests from the western prairies to the eastern seaboard.

With economic output estimated at $6 trillion, the provinces and states bordering the Great Lakes–St. Lawrence Seaway System account for 30% of combined Canadian and US economic activity and employment. The region would rank as the third largest economy in the world if it were a country. Positioned at the core of this economic powerhouse, the Great Lakes–St. Lawrence Seaway System serves as a vital supply chain.

The Great Lakes/St. Lawrence Seaway was built as a binational partnership between the US and Canada, and continues to operate as such. Administration of the system is shared by two entities, the Great Lakes St. Lawrence Seaway Development Corporation (GLS) in the US, a federal agency within the US Department of Transportation, and the St. Lawrence Seaway Management Corporation in Canada, a not-for-profit corporation (ownership of the Canadian portion of the Seaway remains with the Canadian federal government).

About The Slsmc

The St. Lawrence Seaway Management Corporation is a not-for-profit corporation responsible for the safe and efficient movement of marine traffic through the Canadian Seaway facilities, which consists of 13 of the 15 locks between Montreal and Lake Erie. The Corporation plays a pivotal role in ensuring that the waterway remains a safe and wellmanaged system, which it shares with its

American counterpart, the Great Lakes St. Lawrence Seaway Development Corporation. The Corporation’s mandate promotes efficiency and responsiveness to the needs of shipping interests, ports, marine agencies, and provincial and state jurisdictions.

About The Gls

The Great Lakes St. Lawrence Seaway Development Corporation (GLS) is a wholly owned government corporation created by statute 13 May 1954, to construct, operate, and maintain that part of the St. Lawrence Seaway between the Port of Montreal and Lake Erie, within the territorial limits of the United States. Trade development functions aim to enhance Great Lakes/St. Lawrence Seaway System utilization without respect to territorial or geographic limits.

The mission of the Corporation is to serve the US intermodal and international transportation system by improving the operation and maintenance of a safe, reliable, efficient, and environmentally responsible deep-draught waterway, in co-operation with its Canadian counterpart. The GLS also encourages the development of trade through the Great Lakes Seaway System, which contributes to the comprehensive economic and environmental development of the entire Great Lakes region.

The GLS headquarters staff offices are located in Washington, D.C. Operations are located at the two U.S. Seaway locks (Eisenhower and Snell) in Massena, N.Y.

Slsmc Annual Summary

In his message prefacing the SLSMC’s Annual Summary, outgoing President and CEO Terence Bowles stressed the year’s theme of a Seaway that is resilient, predictable, and sustainable, noting that the System has the capacity to not only endure great challenges, but to get stronger in the midst of them.

The Seaway’s resiliency was witnessed through its negotiations of a renewed and modernized 20-year management, operation and maintenance agreement with the Federal Government.

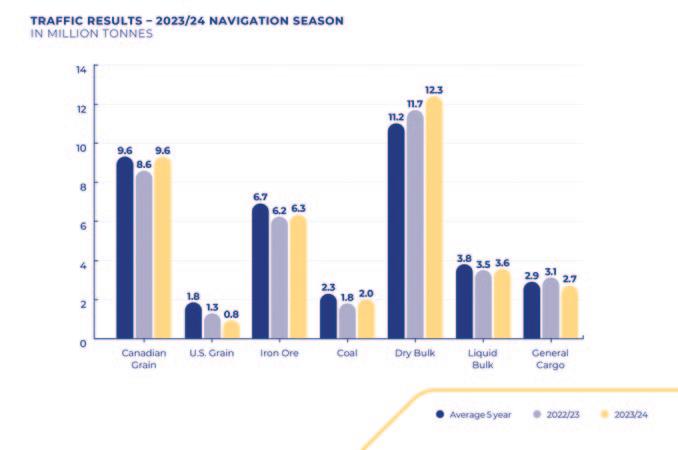

Economic uncertainty prevailed in 2023/24, with stubbornly high inflation. Despite this, tonnage increased 3.4% to 37.6mt (million tonnes), even with a brief shutdown in October due to a labour disruption — the first in 55 years. Clearing the impacted vessels took place in record time and allowed the Seaway and its stakeholders to return to normal operations in short order.

In terms of traffic results: overall, grain movements increased 5.0% vs. 2022 results; v Canadian grain movements have rebounded from the v drought-reduced results of 2022 posting an increase of 11.6%;

US grain exports remained subdued throughout the v navigation season due to continued competitive pressures.

The year ended 44.1% below 2022’s results; a record amount of other grain moved through the System v this year, up 462.9% vs. 2022; iron ore movements were slightly ahead of last year by 1.9; v coal movements returned to normal levels ahead of 2022 v by 14%; dry bulk movements showed an increase again this year, up v 5.4% vs. 2022. These results are attributable to record setting movements of both potash and cement, up 41.8% and 10.9% respectively. Movements of gypsum (up 13.4%) and stone (up 44.3%) also contributed to the improvement over 2022 results; and general cargo posted an 11.9% decline with lower iron & v steel shipments (down 16.4%) and fewer other general cargo movements (down 59.1%). This decline was partially offset by improvements in steel slab shipments (up 44.9%).

Infrastructure And Maintenance

As ever, the SLSMC has remained focused on infrastructure maintenance and improvements. It takes pride in maintaining and operating movable bridges that are integral to the daily functioning of adjacent communities.

The engineering team adopted a modern approach to eliminate the need to replace festoon cables on lift bridges (cable between the movable span and towers). This was achieved by installing remote input-output at ground level with fibre optic communication and upgrading the control panels to simplify the design, reduce complexity, and improve reliability. This innovative initiative reduced failures, thus reducing the maintenance team’s intervention time.

The maintenance teams worked in close collaboration to manufacture a template for the permanent installation of guard rails on the last stop log. The guard rail system underwent several modifications in recent years to improve both safety and technical aspects, aiming for quicker installation. However, complexities in the existing design, coupled with the new regulation on working at heights, led to a switch from a removable to a fixed guard rail system. Team collaboration played a crucial role in this innovation, as various employees involved in the stop log installation process, such as mechanical maintenance engineers, mechanical technical officers, welders, machinists, crane operators, and civil maintainers, contributed their insights and expertise. This collaborative approach facilitated the realization of an innovative idea in a short time frame. The new system not only saved time during lock emptying and filling but also ensured safe passage from the north to the south side of a lock. Additionally, it significantly reduced the time required for installing the guard rails.