3 minute read

Improving the efficiency of mining operations with Quor Group’s QMS

One major challenge faced by the mining sector today is improving the efficiency of mining operations by harnessing the potential of technology, writes Ben Koch,Vice President of Bulk Handling Solutions at Quor Group. Organizations need extensive support in site automation control, quality management, and real-time integration to strengthen the robustness of their supply chain networks.

Effective quality management is of crucial importance in bulk mining operations due to multiple compelling factors. Bulk mining involves the largescale extraction and processing of dry bulk commodities often under challenging and variable conditions. The implementation of a Quality Management System (QMS) in these operations can yield substantial benefits.

The QMS is a critical feature of Quor Group’s stockyard management solution for mining operations and our warehouse management solution for agriculture. From small single pit mines to leading global mining groups with mines in Australia, Africa, Asia, and Central America, our customers use QMS extensively in their day-to-day mining operations.

Qms In Mining And Agriculture

The QMS is designed to support companies in the mining and agriculture sectors by ensuring that the grades of materials they ship meet contract specifications. This is crucial during operational planning to prevent penalties and optimize the blending process. The QMS provides accurate predictions of shipped grades, which is essential for fulfilling contracts and maintaining profitability.

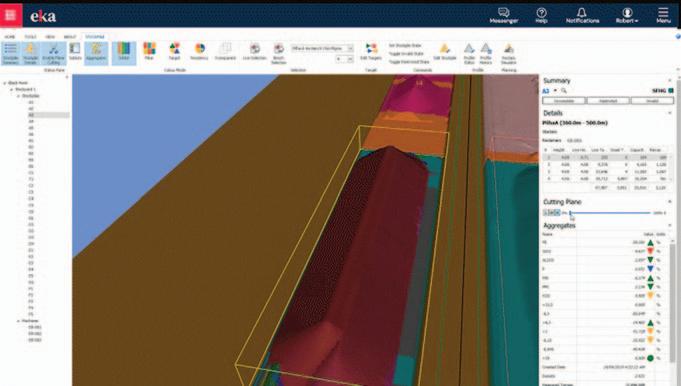

Advanced Digital Twins Of Stockyards And Terminals

The QMS leverages advanced digital twins, which are highly detailed, virtual replicas of physical stockyards and terminals. These digital twins are continuously updated in real time, reflecting the exact 3D placement of all bulk materials as they are stacked and reclaimed. This ongoing update ensures that the virtual model remains an accurate representation of the physical environment.

REAL-TIME 3D PLACEMENT AND MATERIAL TRACKING

In these digital twins, every material lot is tracked with precision. The QMS integrates with Laboratory Information

The implementation of a QMS in bulk mining operations can yield substantial benefits.

Management Systems (LIMS) to associate these material lots with their most recent laboratory results. This integration allows for accurate tracking of the quality and composition of the materials as they move through the supply chain, ensuring that companies can maintain quality standards and meet contractual obligations.

Precise Simulation Of Reclaiming Operations

One of the standout features of the Quor Group’s QMS is its ability to simulate reclaiming operations with high precision. These simulations use the 3D location data of materials within the stockyard to forecast the grades of the materials that will be shipped. Unlike basic weighted average forecasting methods, which might oversimplify the process, this simulation accounts for the real-world mechanics of stacker, reclaiming, and siloing operations. This allows companies to predict the quality of the shipped materials more accurately.

Superior To Basic Weighted Average Forecasting

Traditional methods of forecasting often rely on weighted averages, which can be less accurate because they do not account for the complex dynamics of material movement within stockyards. The QMS’s approach, which simulates the actual reclaiming process, provides a much more accurate forecast by considering factors like the exact 3D positioning of materials, the sequence in which they are reclaimed, and how these factors influence the final shipped grade.

Continually Updated Predictive Performance

The system continually updates its predictive performance statistics. This means that the QMS not only predicts outcomes but also tracks how accurate those predictions are over time. By understanding how close the predictions are to actual results, scheduling and logistics teams can make more informed decisions. They can confidently push the limits of contract specifications, maximizing value without risking breaches that could lead to penalties.

Optimizing Operations

Overall, this technology enables companies to fine-tune their operations to get as close as possible to contract limits without exceeding them, ensuring that they are not leaving potential revenue on the table. By optimizing blending and material handling, companies can enhance profitability while maintaining compliance with contractual obligations.

Quor Group’s QMS is a highly advanced system that far exceeds basic weighted average forecasting. It continuously updates its predictive data on performance using complex analytics. QMS helps users track and extract the desired quality in stockpiles with a true volumetric physical 3D stockpile model of material quality. The system equips operators to better match inventory quality specifications to sales quality specifications and increase throughput and site efficiency.

Quality management is not only crucial but also indispensable in bulk mining due to the scope and complexity of operations. An advanced quality management system (QMS) is essential for the success and sustainability of mining operations, as it provides the structure and discipline necessary to manage risks, enhance efficiency, ensure safety, and deliver consistent product quality.