3 minute read

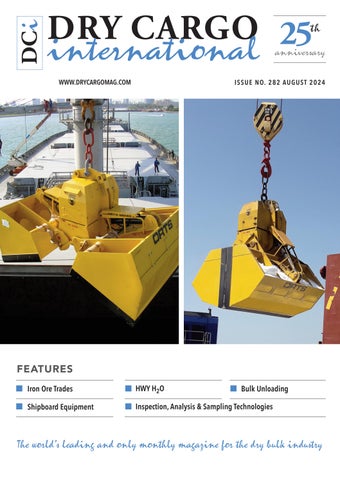

Elevating transshipment efficiency: keys to effective loading and unloading cargo ships

Transshipment plays a big role in the seamless operation of the global supply chain, enabling bulk goods to reach their final destinations through strategic intermediate stops. However, the process is filled with operational, technical, and financial challenges, from avoiding port congestion and demurrage costs to maintaining operations under harsh sea conditions and navigating market pressures.

In this article Nemag dives into these challenges and discusses optimization strategies that are essential for enhancing the efficiency and cost-effectiveness of transshipment operations. Nemag illustrates how strategic practices and the right equipment choices — specifically in crane and grab technology — can significantly improve productivity even in geographically challenging conditions.

A good example of a transshipment situation is in Sierra Leone, West Africa, where SMT Shipping has achieved significant transshipment advancements. (see page 21 of the June 2024 issue of DCi) This region presents a unique challenge due to its shallow shores, extending 10 to 20 metres in depth for up to 10 miles. To be profitable, you will have to ship your cargo with colossal ore carriers.

The Definition Of Transshipment

Transshipment refers to the process where goods or dry bulk cargo are transported to an intermediate destination before reaching their final destination. This logistical strategy serves various purposes, including the consolidation of multiple smaller shipments into a single larger one, enhancing efficiency and reducing transportation costs. Conversely, large consolidated shipments can also be divided into smaller packages (deconsolidation).

The Best Crane And Grab For Loading And Unloading Cargo Ships

Many high-performance marine transshipment hubs are equipped with fourrope (grab) slewing cranes. The reason for choosing four rope cranes is the significantly higher efficiency offered, compared to, for instance, slow-moving, single line derrick cranes equipped with slow-operating remote-controlled or electro/hydraulic grabs.

In most cases, these four-rope cranes are standardized to a high degree with specific speeds and accelerations, depending on the make and type. Within these constraints, the productivity of any transshipment crane depends entirely on the productivity of the grab.

Any grab, regardless of type or brand, will have a given deadweight and payload. The general idea is that the lower the grab’s deadweight, the higher the payload and the higher the productivity. When selecting the best grab, operational speed and the weight of the material are generally the most important aspects. When it comes to transshipment, maintenance is a key factor that affects the choice of grab. Generally, both the clamshell grab and the NemaX are suitable, but the choice is as follows:

CLAMSHELL GRAB:

A clamshell grab is highly versatile. It can handle almost every material and is an excellent all-rounder. It can handle soybeans, grain, fertilizers, iron ore, bauxite and more. A single clamshell grab can manage different materials, which is advantageous given the limited number of grabs (usually two or three) a pontoon can carry. Additionally, its ability to close completely is beneficial for environmental containment.

NEMAX:

However, if the material is compatible, the NemaX grab emerges as a better option. Its revolutionary design translates to lower dead weight, faster opening and closing, and its also simplifies maintenance — an essential consideration in remote transshipment locations. With fewer moving parts, the NemaX’s maintenance needs are reduced compared to a clamshell. In addition, this grab can be accessed from the ground when open, which also facilitates easier maintenance. However, the NemaX is not universal across all materials yet. The major streams of material in transshipment are coal, bauxite and iron ore, for which the NemaX is suitable.

How To Improve Transshipment

Improving transshipment efficiency depends significantly on the optimization of crane and grab operations. Productivity, defined as the product of payload capacity and the number of cycles per hour (productivity = payload x cycles per hour), underscores the importance of matching the optimal grab with the crane and material being handled. Since different materials require specific grabs for efficient handling, having a selection of grabs tailored to the various materials being transshipped is crucial. In fact, less productivity can also lead to demurrage costs.

The cycle time, which significantly influences productivity, is determined by the sum of the crane’s hoisting and slewing times, along with the grab’s opening and closing times. The speed at which the crane’s winches operate affects the grab’s closing time, which in turn depends on the length of the grab’s closing cable withdrawal. It is essential to note that a crane can only begin slewing once the grab is fully closed and lifted out of the cargo, making the grab’s opening and closing speed a critical component of overall productivity. This is particularly true for operations requiring small slewing angles, where operators aim to minimize cycle time for maximum efficiency. Therefore, investing in grabs that can open and close rapidly, without compromising on payload capacity, can significantly enhance transshipment productivity by reducing cycle times. This not only boosts throughput but also reduces the risk of demurrage costs by ensuring an efficient transfer of cargo, emphasizing the need for precise equipment selection and operation in optimizing transshipment processes.

Navigating The Future Of Transshipment With Strategic Insights

Transshipment is an integral component of the global supply chain, enabling the strategic movement of bulk goods through intermediate stops to their final destinations. Yet, it is a process filled with operational, technical, and financial challenges — from mitigating port congestion and demurrage costs to ensuring seamless operations under challenging sea conditions and overcoming market pressures.