2 minute read

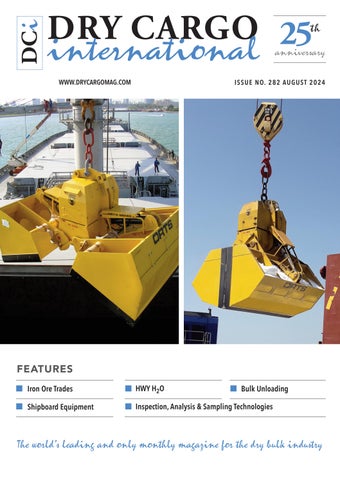

Haul aboard! Shipboard grabs and cranes

For 50 years now, ORTS GmbH Maschinenfabrik has been delivering grabs to customers all around the world. In 2024, these customers came from Southeast Africa, the near and middle East, eastern Mediterranean, North America as well as Sweden and of course Germany.

The main customers are shipping companies with their bulk carriers, which know that they can rely on the performance, speed and reliability of ORTS grabs for many, many years — even in the rough conditions experienced by sea-going vessels. Terminal operators, stevedore companies and heavy industry companies (for example steel works) also value the quality of ORTS grabs.

The complete range of grabs is offered, from electro-hydraulic grabs and radio controlled diesel-hydraulic grabs to mechanical rope grabs. Each grab is the constructed by ORTS Maschinenfabrik in its own facilities. This is visible at first sight, because of the unique construction design. It is not enough to just replace the block and tackle construction in the middle of a mechanical rope grab with a hydraulic cylinder, e-motor or hydraulic pump to get an electro-hydraulic grab. If you install a six-cylinder engine in a tractor, you don’t get a racing car.

Therefore ORTS electro-hydraulic grabs and the radio controlled dieselhydraulic grabs look different. And they do not only look different, they are different: The have a lower dead weight and higher closing force, while being fast and reliable. The construction surrounding the drive unit (hydraulic parts, e-motor, control block etc.) is easy and safe to reach for the service engineer/seaman. The escutcheons can be opened from two sides of the grab and used as a working platform right in front of all important parts of the grab.

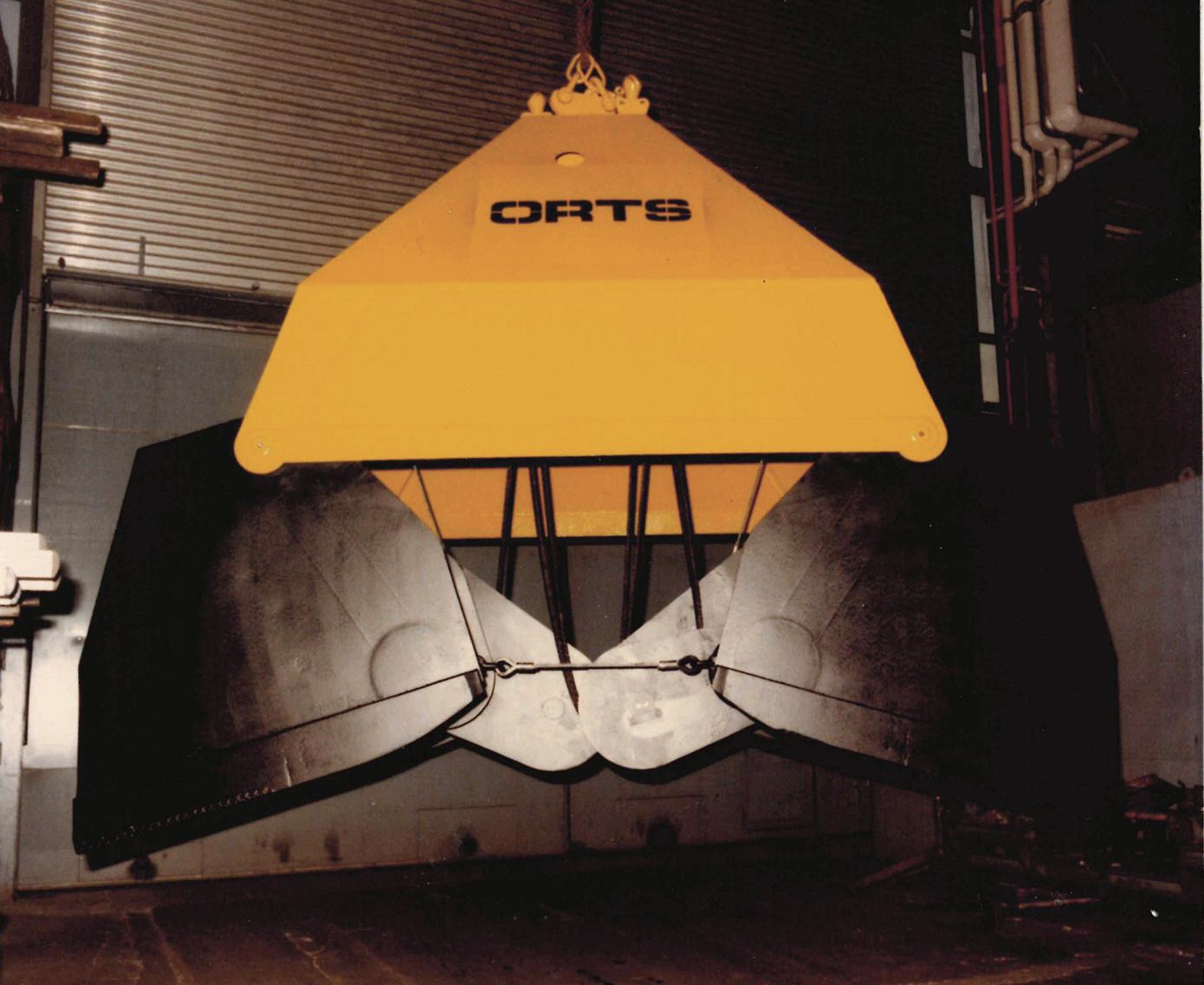

Unique and innovative grabs, like those that have radio controlled diesel-hydraulic technology, came from ORTS. The idea of this grab was born over 30 years ago in the technical offices of ORTS GmbH.

Since then, the radio controlled dieselhydraulic grabs from ORTS (type DHS-B, DHM and DHZ) have been manufactured in the workshop near Lübeck in Northern Germany.

No other grab maker has this kind of long-term experience with this specific grab type. Over the years, since 1995, the ORTS diesel-hydraulic grabs have become flexible, reliable and high-performance

‘workhorses’, thanks to continuous improvements in co-operation with the company’s customers. ORTS’ DHS-B (two- clamshell design) and DHM (orangepeel clamshells) are in operation on all continents, in all climate zones.

ORTS was also one of the very first grab makers to construct and build environmentally friendly grabs with enclosed clamshells in the 1980s, specifically to address environmental concerns.

All of the grabs by ORTS (dieselhydraulic, electro-hydraulic and mechanical ones) are well-known for their effectiveness (high discharge-rates), reliability and long lifetimes, handling millions and millions of tonnes.

The purchase price for a grab becomes less and less important, the longer the grab is working for the owner/operator. Quality, reliability and performance are more important and are the characteristics that really pay off over the years.

A cheap grab can become a very expensive grab very quickly: when the grab needs the first spare parts after only a short time of being in operation, has breakdowns during operation or takes more time for loading/discharge operations because the clamshells do not work at full capacity.

ORTS still supplies customers with spare parts for grabs, even when those are 25–30 years old. One of the first radio controlled diesel-hydraulic grabs is still functional now, after 25 years.

ORTS doesn’t only produce smaller grabs, bigger grabs with 50t (orange-peel dredger grab), 60t, 80t (two-clamshell dredger grabs) and 115t (salvage grab for ship wrecks) dead weight were also constructed and built by ORTS in the past.

In addition to grabs, special constructions like a self-floating oil-salvage grab, which is able to skim off oil from the water-surface after ship-accidents, and load-beams for up to 100t were constructed and built by ORTS.