Critical Role of Vacuum Feedthroughs in HighVacuum Systems

Ensuring Integrity in High-Pressure Environments

by Douglas Electrical Components

Ensuring Integrity in High-Pressure Environments

by Douglas Electrical Components

1 Defining High-Vacuum

High-vacuum systems operate at pressures far below atmospheric, requiring precise control of leaks and contamination.

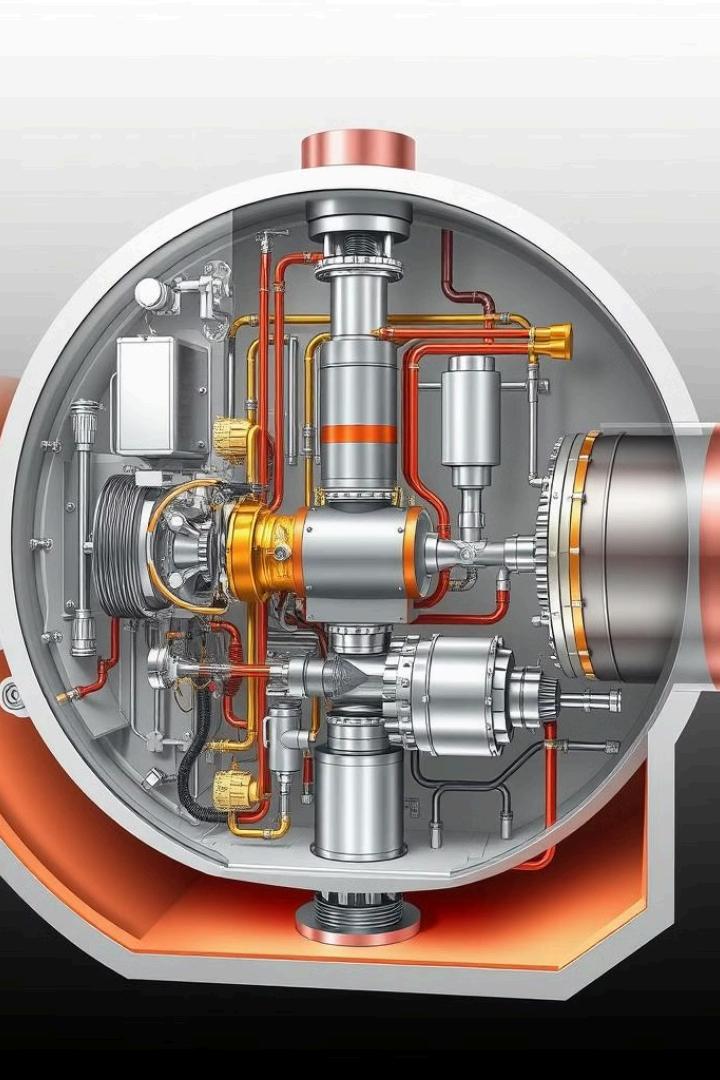

2 Critical Applications

Found in semiconductor fabs, space simulations, medical imaging, and scientific research, these systems are vital across industries.

3 The Role of Feedthroughs

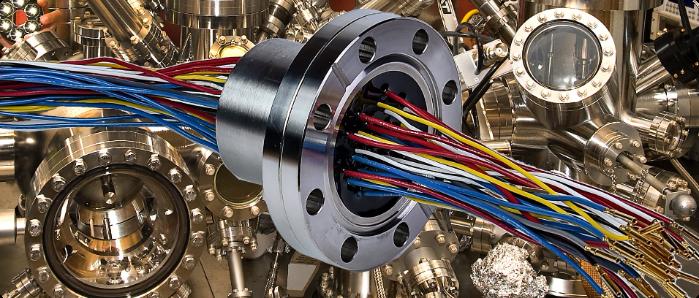

Hermetic sealing of all connections to the outside is essential to maintain a high-vacuum environment.

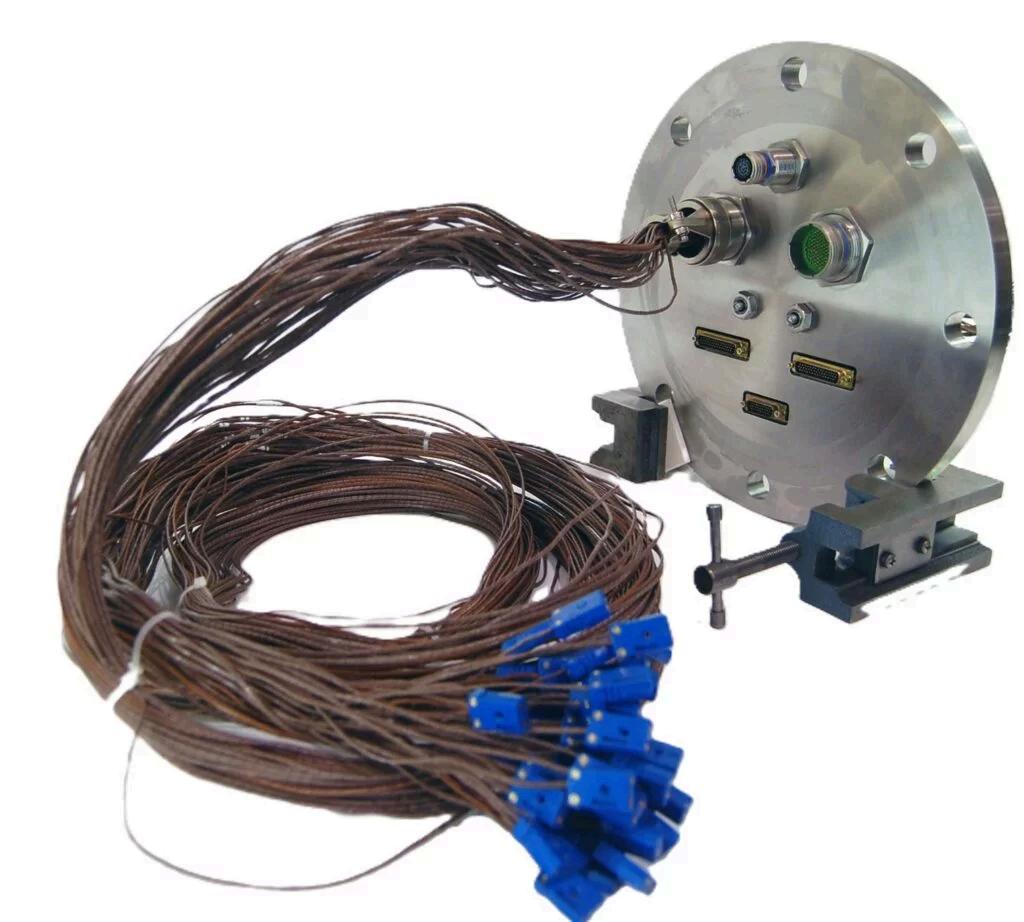

Feedthroughs are connectors that allow electrical, optical, or mechanical components to pass through the walls of a vacuum system without compromising the vacuum seal.

Electrical feedthroughs (power and signal)

Optical feedthroughs (fiber optic)

Fluid feedthroughs

Preventing gas leakage into the vacuum

Maintaining electrical and thermal insulation

Ensuring long-term durability under extreme conditions

Feedthroughs must be hermetically sealed to prevent any leaks, even under extreme pressure differentials.

Carefully chosen materials like stainless steel and glass-to-metal seals are essential to withstand thermal and mechanical stresses.

Their industry-leading hermetic feedthroughs are designed to meet the stringent requirements of high-vacuum systems.

Even the smallest leak can compromise vacuum integrity and introduce contaminants.

Components must withstand significant temperature fluctuations without failure.

High-vacuum systems are subject to intense mechanical forces that can lead to component breakdown.

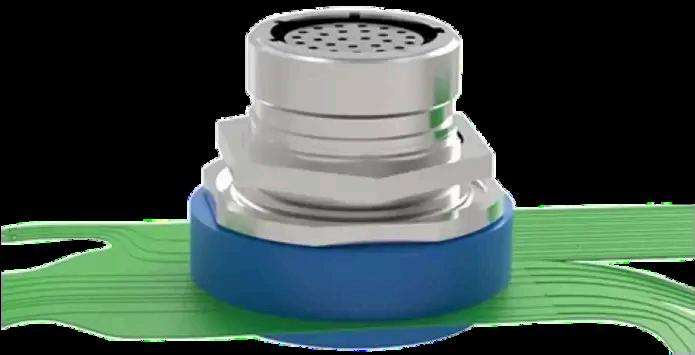

Hermetically sealed electrical connectors engineered for vacuum systems.

Expertly designed hermetic wire feedthroughs for reliable vacuum sealing.

Custom solutions through agile prototyping for unique system needs.

Ensuring contamination-free environments for precision semiconductor manufacturing.

Enabling the testing of aerospace components in high-vacuum conditions.

Maintaining vacuum integrity for advanced imaging and diagnostic tools.

Whether you need a standard or custom solution, Douglas Electrical Components delivers optimal performance, price, and reliability for your high-vacuum feedthrough requirements.