TABLE OF CONTENTS

Resume / References

Portfolio

Professional Work

Bend!

Models

Modular Table

Academic Work

Nexus Masterplan

Nexus: Hive

Bronx Library

Zambia Clinic

Open-Air Theatre

Digi-fab Quilt

RESUME

Dorsa Naimi

Virginia Tech School of Architecture

B.Architecture 23

naimidorsa@gmail.com

703-989-4933

BACKGROUND

Passionate about design + design research; motivated with a willingness to learn. Background including interactive team situations, overcoming challenges and functioning effectively in diverse, fast-paced environments

REFERENCES

Parke MacDowell, AIA — manager + mentor

Associate Principle | Director of Fabrication pmacdowell@payette.com direct: 617-895-1131 | cell: 907-280-9497

Aki Ishida AIA, LEED AP — manager + professor

Interim Associate Director and Associate Professor aishida@vt.edu 917-514-1653

Kevin B. Sullivan, FAIA — manager + professor

President / CEO ksullivan@payette.com 617-895-1048

Sandrine Héroux— manager + mentor

Lead Fabrication Designer sheroux@payette.com 857-264-9465

WORK EXPERIENCE

Payette Associates: Design + Fabrication Intern, 01/22-08/22

• Operated machinery and equipment to fabricate and assemble models in various scales and materials, including using CNC machines for high-density foam sites and MDF mock-ups.

• Read and interpreted drawings to ensure precise fabrication and assembly, employing 3D printers and laser cutters for accuracy.

• Collaborated with team members to maintain efficient workflow and meet project deadlines.

• Conducted safety trainings to enforce safety protocols and practices.

• Communicated effectively with team members and stakeholders to achieve project objectives.

Naama Tsabar Studios; Assistant 10/23-current

• Collaborated with the artist to construct large-scale sculptures using diverse materials like polycarbonates, felt, deconstructed guitars, and piano strings.

• Aided in creating detailed technical drawings to visualize and fabricate projects effectively.

• Managed archiving and documentation of the build and design process, ensuring comprehensive records for future use.

• Coordinated logistics for art shows and installations, including transportation and setup.

• Expanded skill set by mastering new mediums like instrument deconstruction and integration into artistic endeavors.

Virginia Tech School of Architecture and School of Design: Social Media Coordinator, 2021-2023

• Developed and implemented comprehensive social media strategies to increase engagement and promote the School of Architecture and Design’s brand across all relevant social media channels.

• Created and curated compelling content, including written and visual assets, that aligned with the School’s messaging and goals, and published content regularly to maintain a consistent presence.

• Assisted with other communications projects as needed, such as creating marketing materials, and coordinating events.

ACKNOWLEDGMENTS

• OpenLab Boston Program : Payette

• Leader: DMCo (Digital Mentorship Collaborative)

Organize and initiate digital learning tools and skills for students by students

• Student Lecture Series Organization

• David & Cassandra Wagner Scholarship

• ICAT Student SEAD award

Initiated research to study bio-fabrication of Mycelium

SKILLS

• Adobe Suite : Ai, Ps, Lr, Ind, Ae

• Rhino : Grasshopper, V ray, Enscape

• Digital Fabrication: Cnc, 3d Printing, Laser Cutter

• Cinema 4d

• Autocad

• Sketchup

• Digital Photography

• Bilingual: Farsi/English

PAYETTE ASSOCIATES:

Beyond Walls - Bend

01/22 - 08/22

As a intern on the fabrication team I had the privilege of working on Bend! in collaboration with BeyondWalls; a community outreach project in Boston. My role in the project was to organize information from the Rhino model carefully, to create a labeling system to manage all the different parts of the final model. Additionally, to build the steel form, we cut, sanded, drilled holes and put in brackets to connect everything in-house.

Final form with wooden slats added and painted by local high school students.

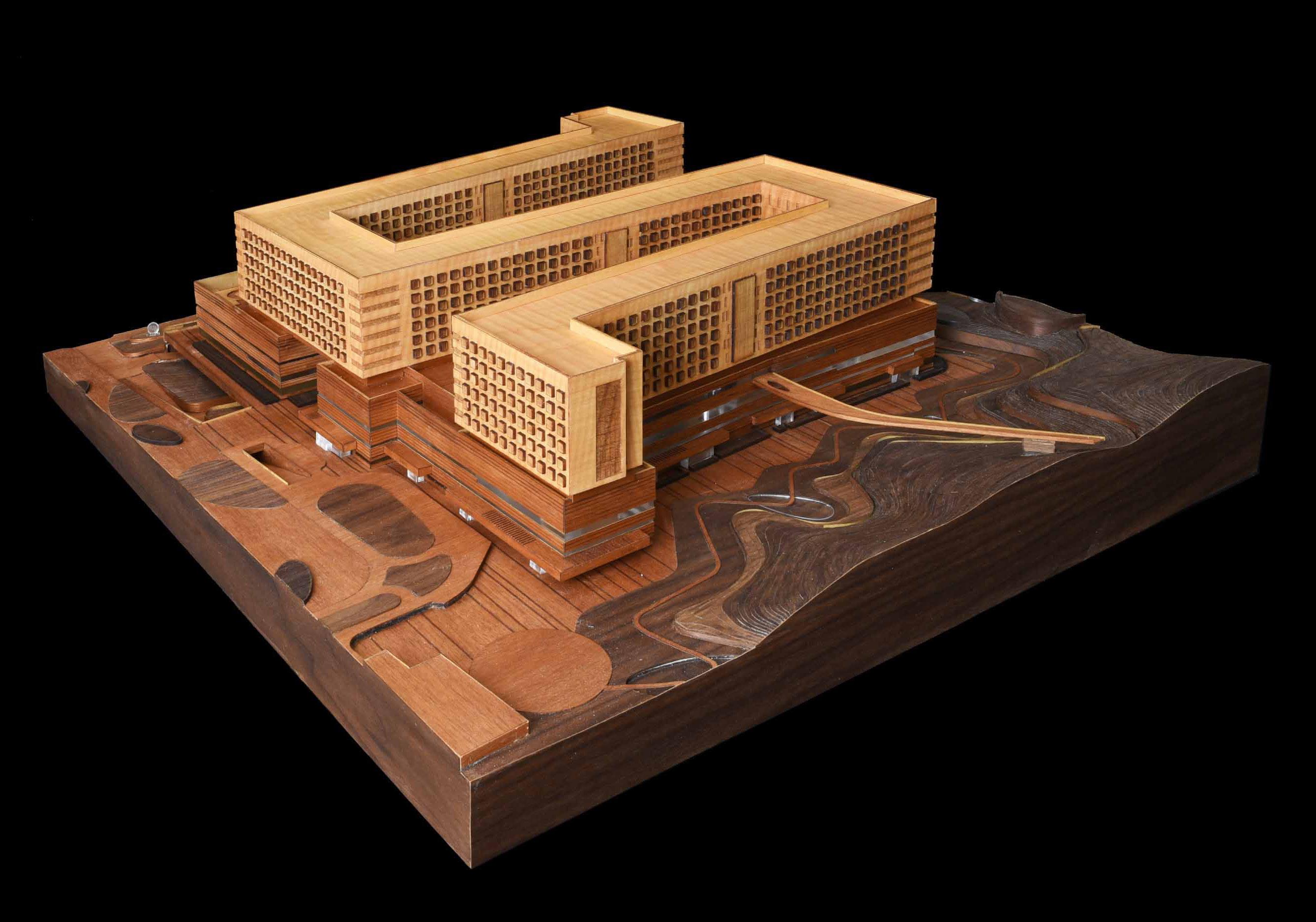

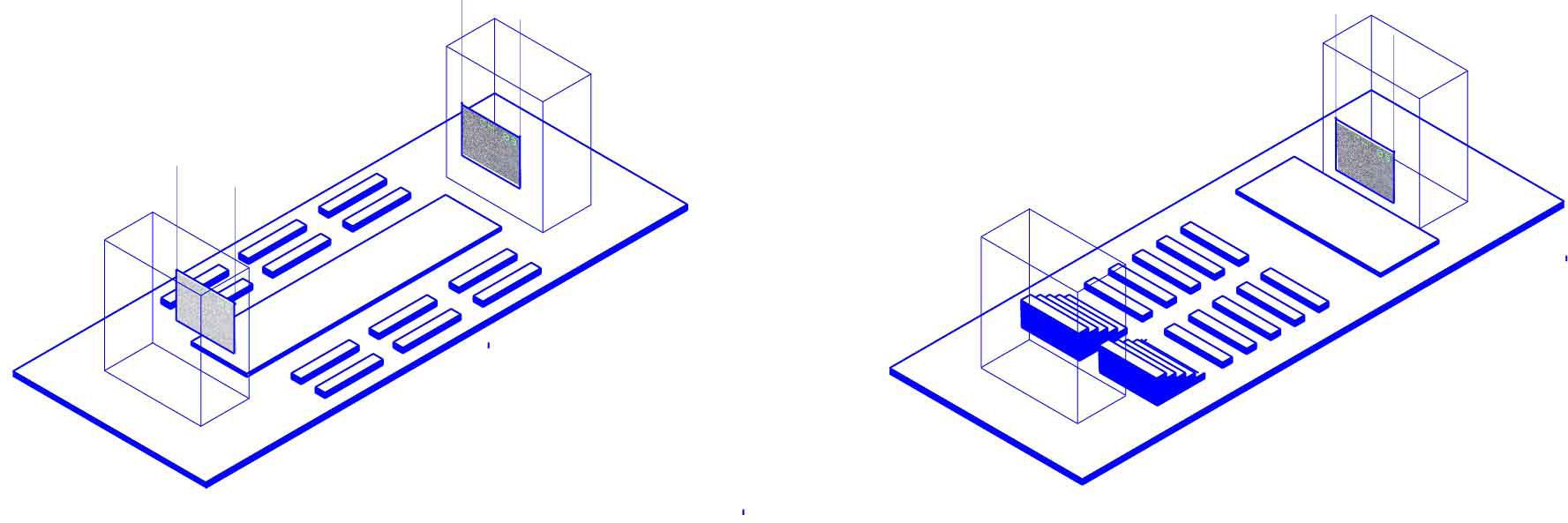

PAYETTE ASSOCIATES: Models

01/22-

08/22

As a team, we were assigned to produce several models of varying sizes and time-frames. We utilized CNC Mill, Laser Cutting, woodworking, and Rhino Modeling to complete the task. My role included gathering data to design a site model and collaborating with other teams to develop interview plans using Rhino. The fast-paced and collaborative effort of producing interview models demanded us to produce multiple models quickly.

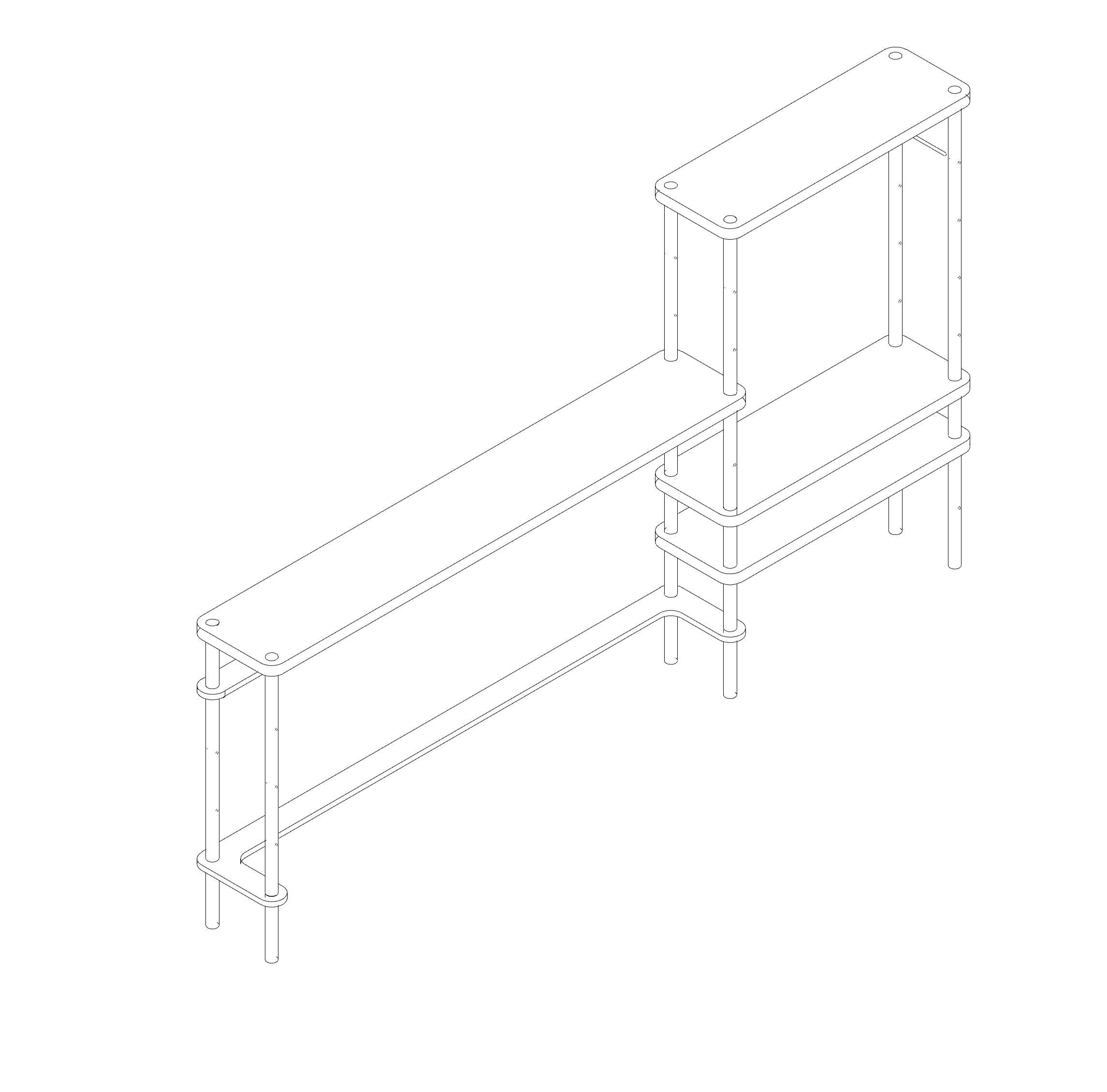

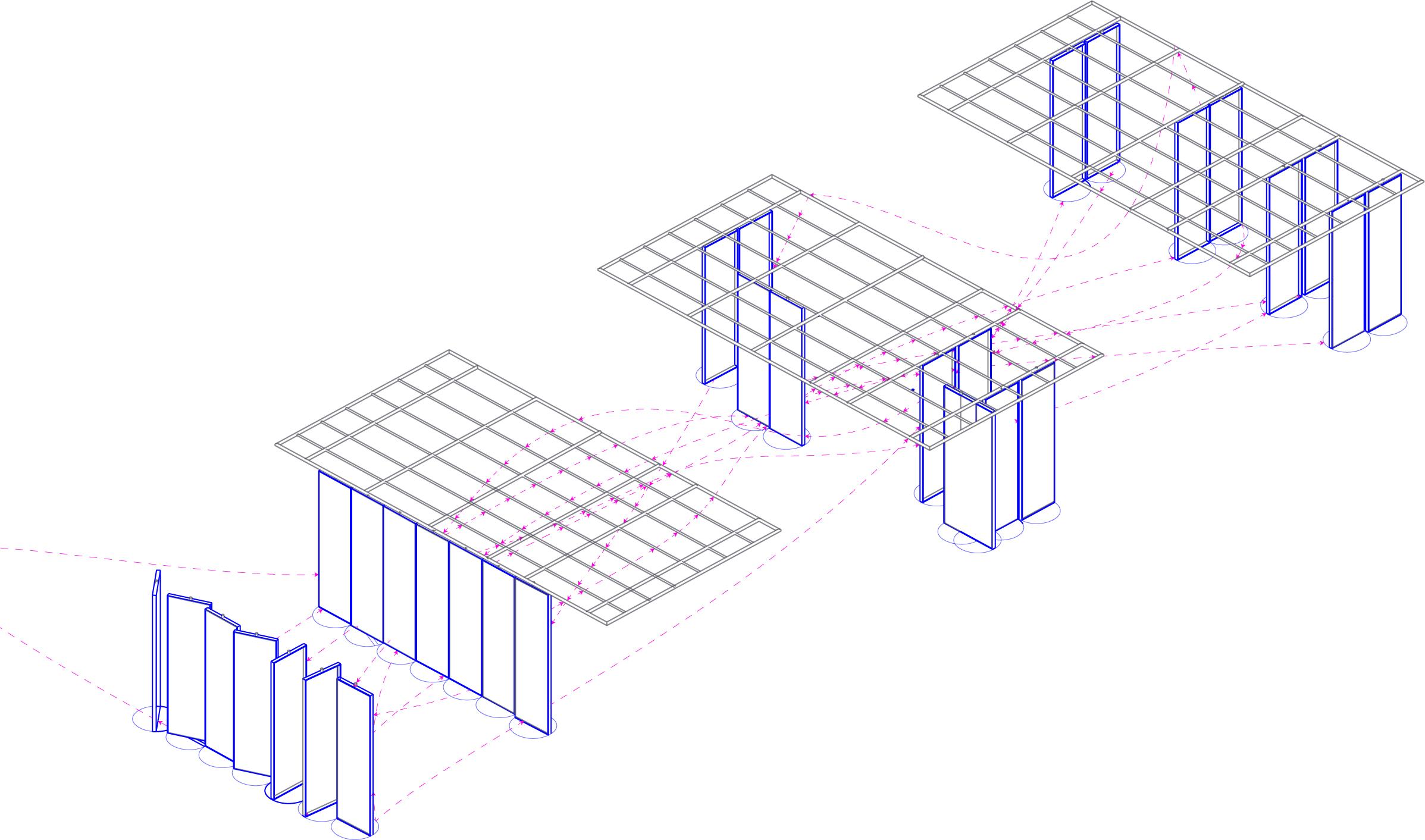

MODULAR TABLE

Brooklyn Coffee Shop

10/22-12/23

Partner: Shelby Greenburg

We worked together with Passionfruit, a local coffee shop located in Brooklyn, to create a versatile modular table. The design of the table was inspired by the playful and vibrant aesthetic of the space, and it serves the dual purpose of providing additional seating and a platform for displaying retail items. We ensured that the table could be easily assembled on-site, which made the installation process more convenient. Our collaboration with Passionfruit allowed us to design and build a piece that fulfilled their specific requirements and added to the lively atmosphere of the coffee shop.

Our main materials for the project included birch plywood and metal rods. The birch plywood was used for the table tops, providing a sturdy and durable surface. The metal rods were incorporated as accent pieces and support elements, adding an industrial touch to the design. Additionally, we used dowels for the legs, ensuring stability and easy assembly. This combination of materials resulted in a modular table that was not only visually appealing but also practical and functional, meeting both the client’s aesthetic preferences and their need for additional seating and retail display space.

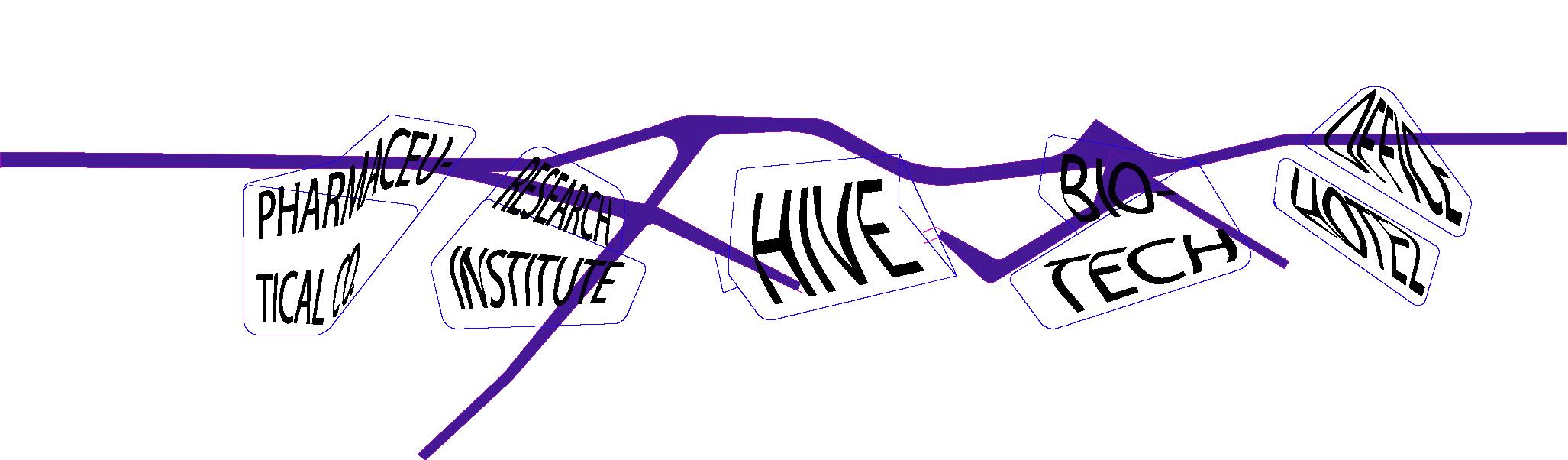

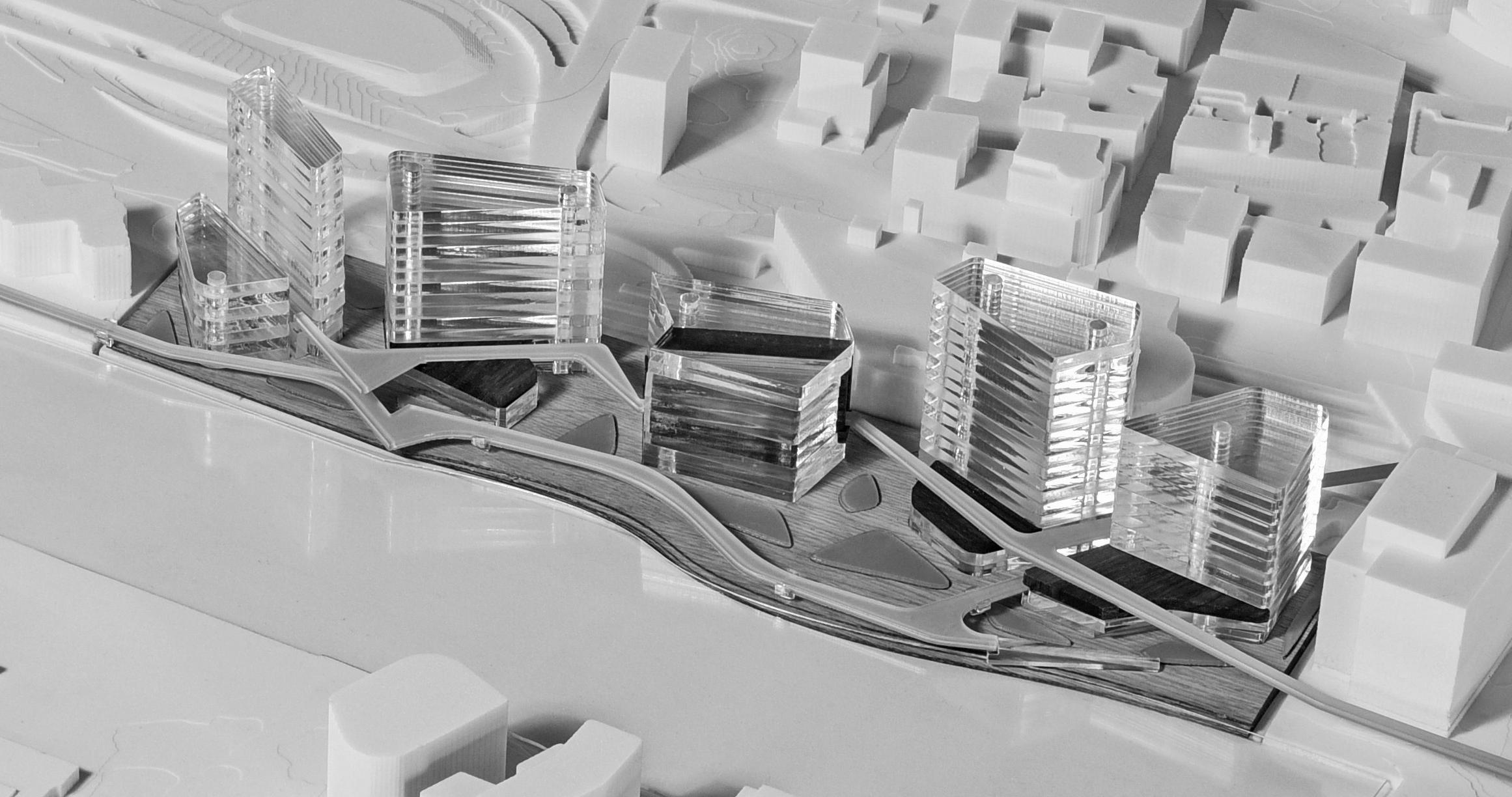

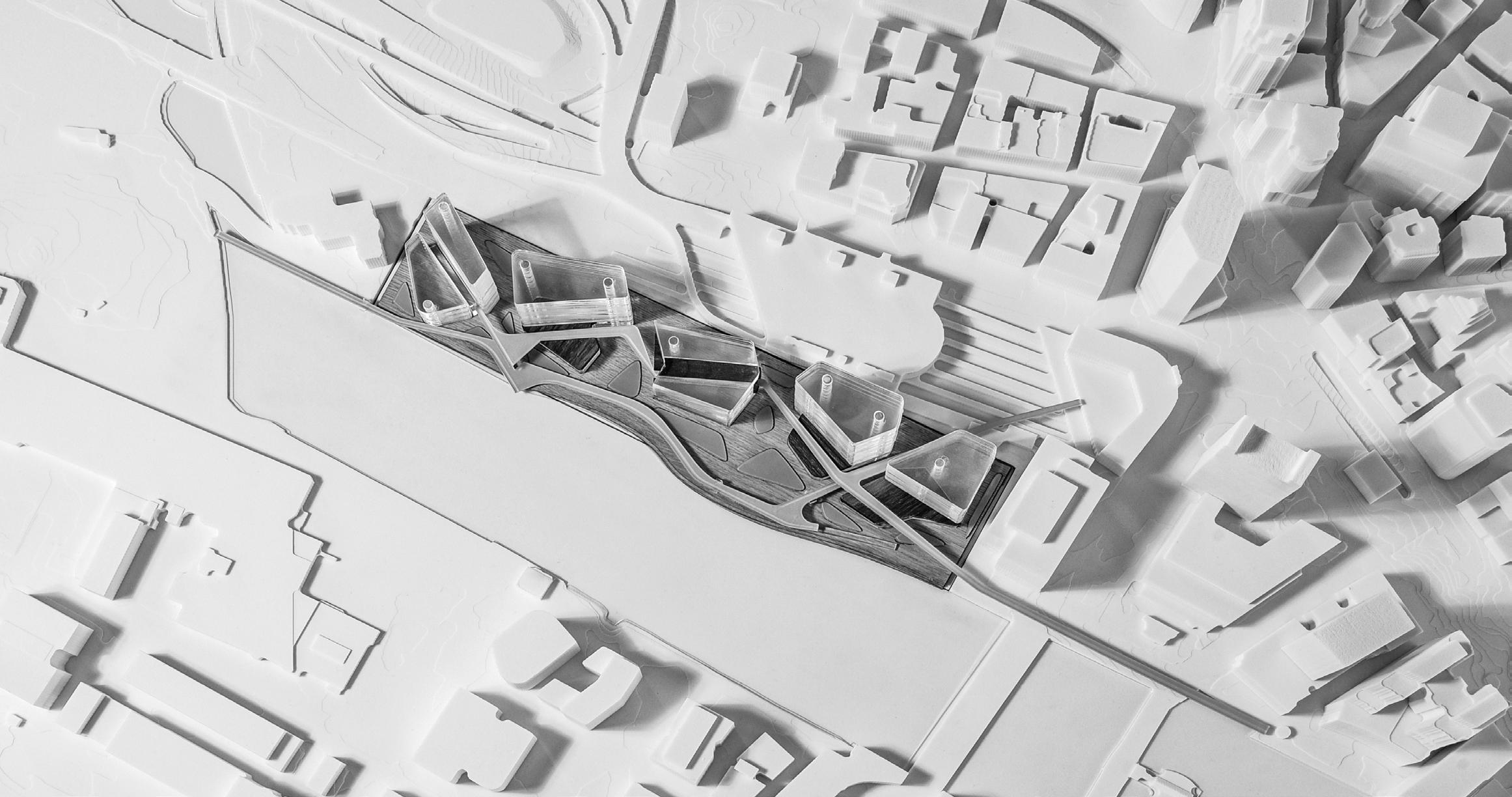

4TH YEAR STUDIO Nexus Master Plan

Selected Master Plans : 1/3 Entries Team: Aidan L. Lucas Y.

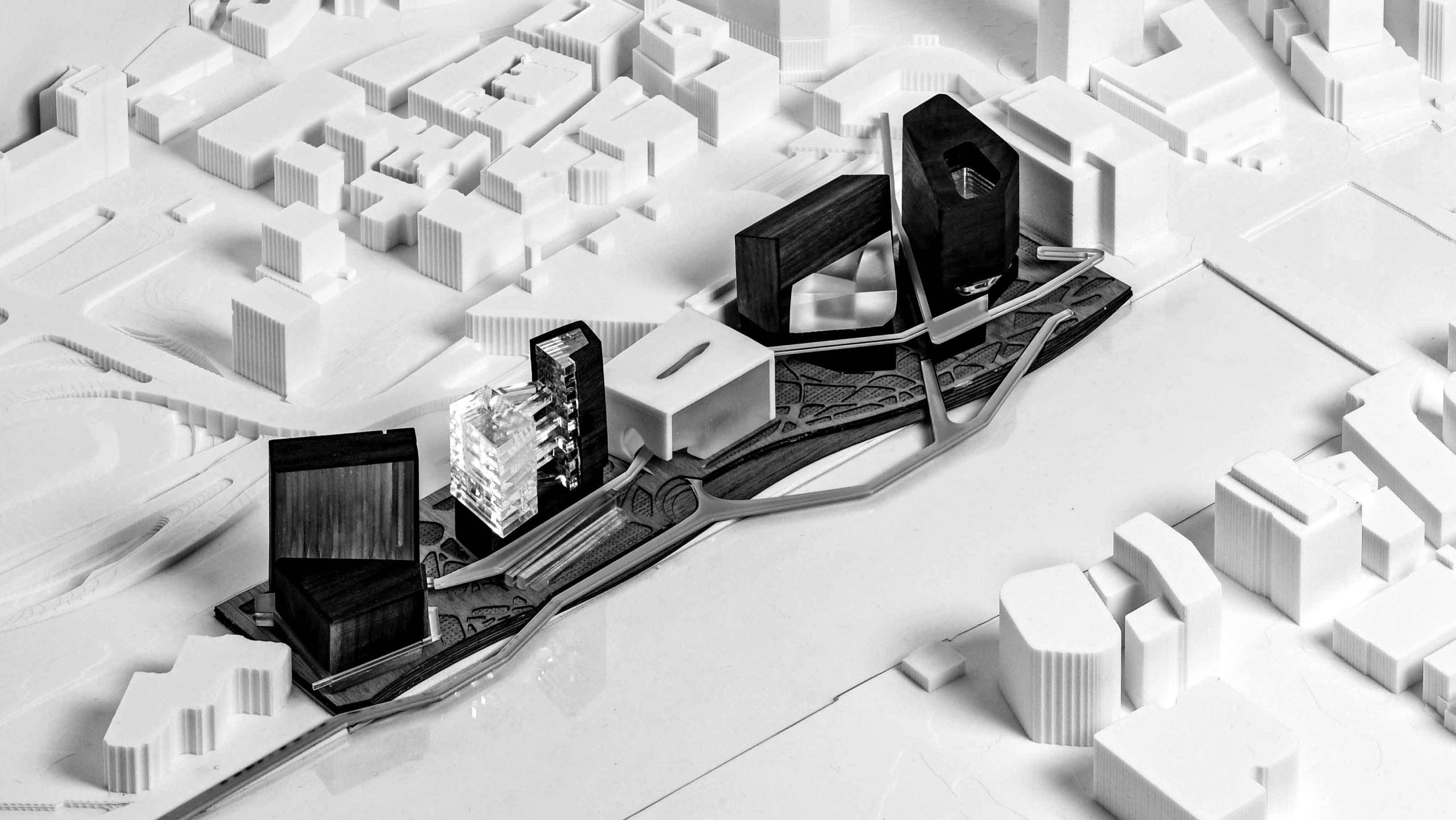

Teams were assigned to design a master plan for a new research and development campus moving to downtown Boston’s financial district, between the fort point channel and the south station.

Our team’s objective followed a goal to pursue an interactive public and private space. The master plan was formed through a bridging concept that connects the public to the surrounding site and the campus. The bridge stretches out from the commuter rails at South Station, directly connecting the buildings into the harbor- Allowing for a multi-level use of the bridge, a line that connects the commuter rail to the buildings’ public spaces, onto another line extending into the water, resulting in a unique experience with the harbor.

The final master plan model was built at a 1/16” scale. Materials consisted of acrylic, wood, and veneer. We had 3d modeled the form in Rhino and prepped files to create a cohesive template for physical modeling in a collaborative setting.

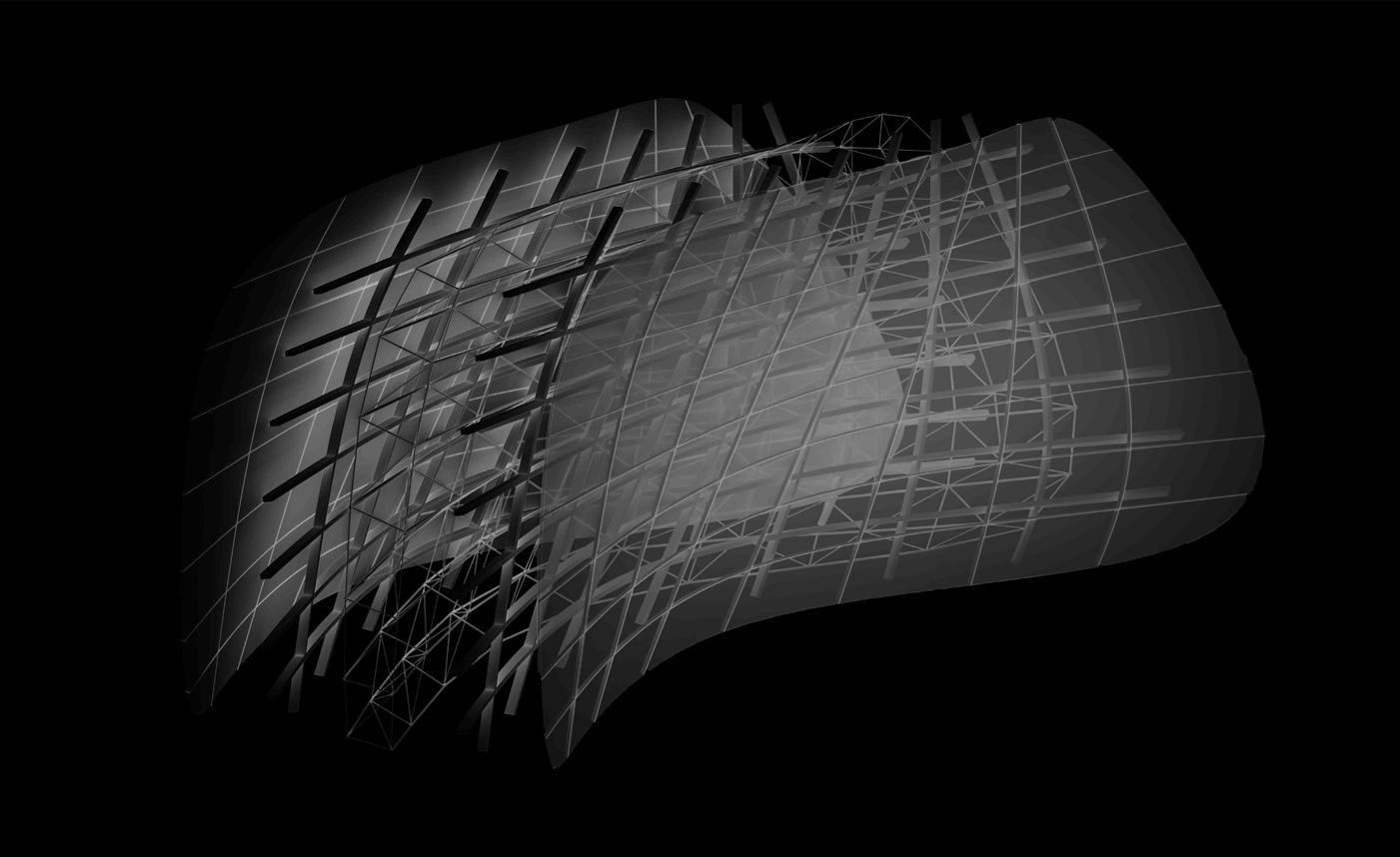

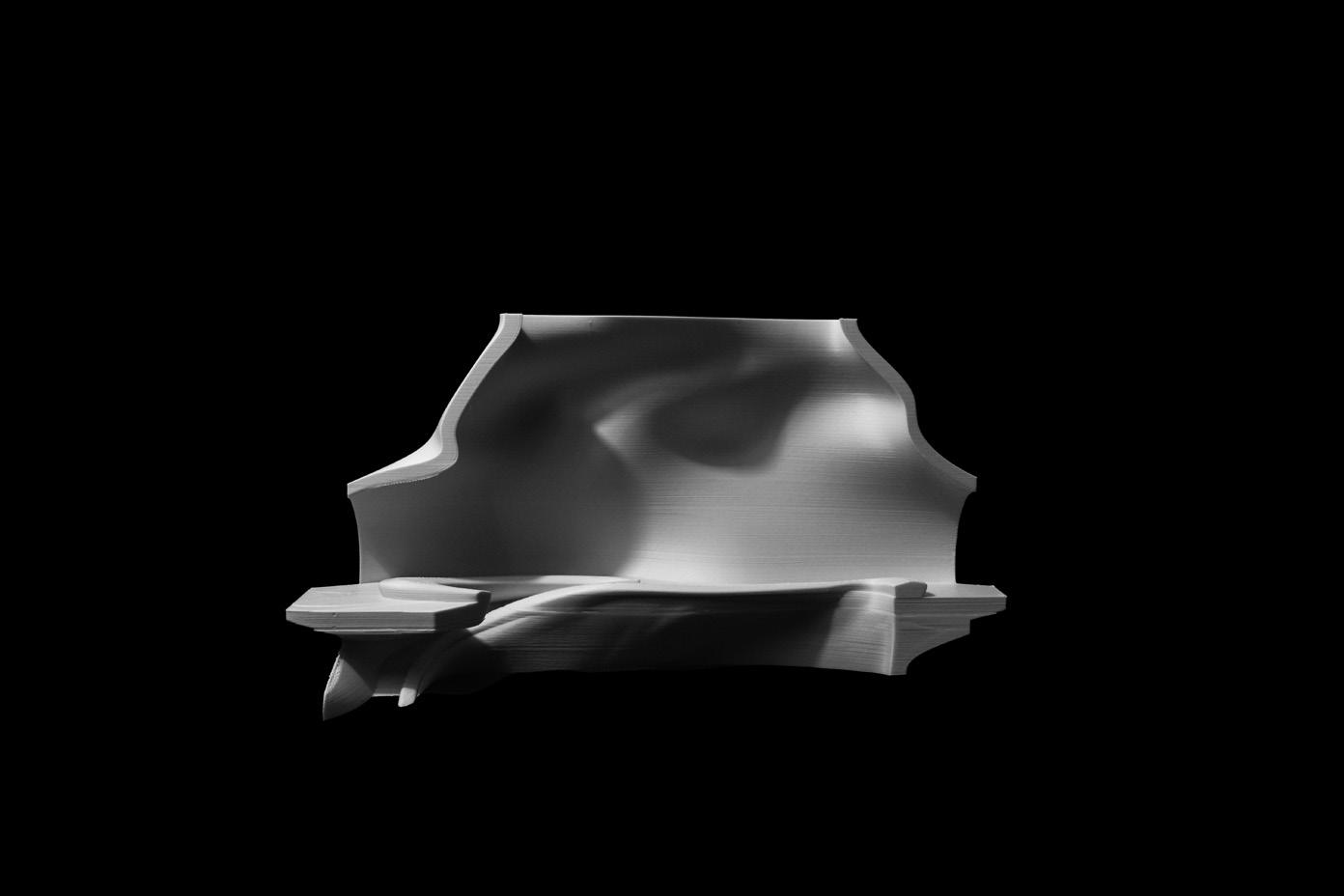

4TH YEAR STUDIO

Nexus: Hive

Team Member: Adam Alford

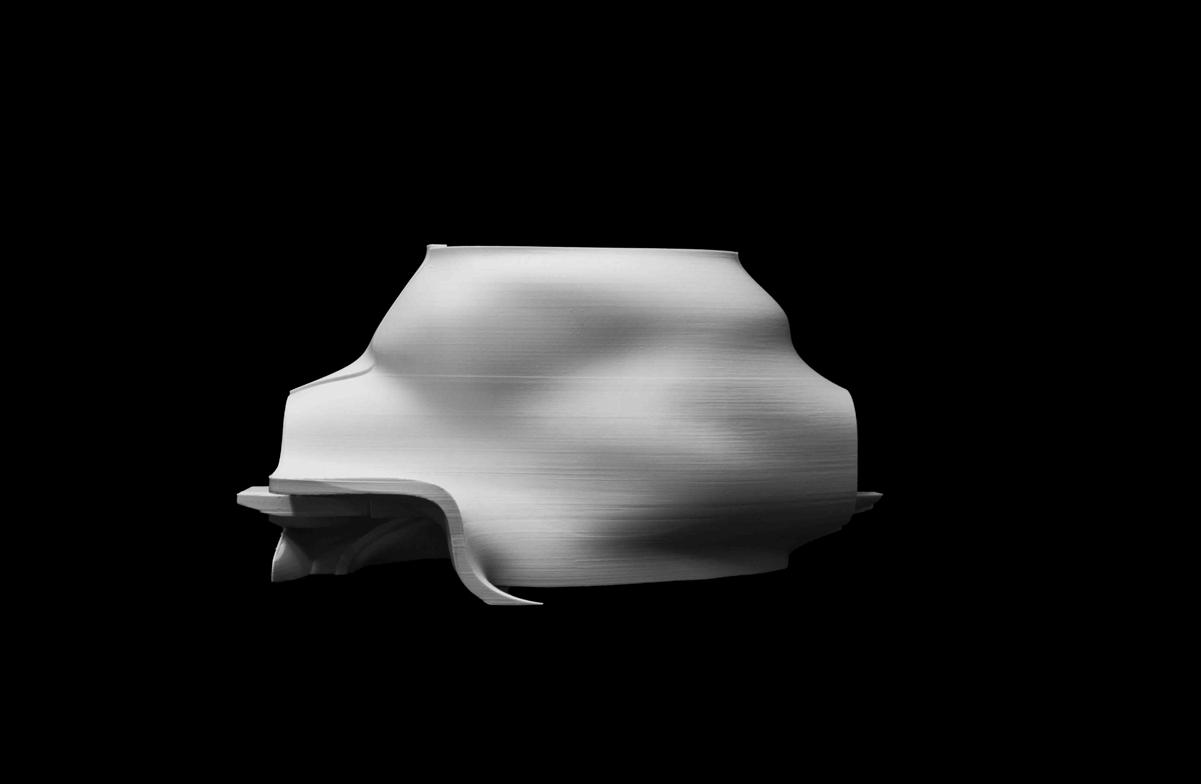

The Hive was a continuation of the Nexus master plan project.

We designed “The Hive” as a modern container that appears simple at first glance. However, it provides visitors with an immersive experience that showcases the dynamic relationship between the city and its inhabitants. The interior of “The Hive” is designed to represent controlled erosion, featuring fluid transitions that blur the boundaries between inside and out.

One of the defining features of “The Hive” is its strategic placement within the newly developed site, aimed at promoting connectivity and engagement with neighboring research and development buildings. As a bridge between the private sector and the public realm, “The Hive” is a catalyst for innovation and community empowerment. It hosts collaborative workshops, exhibitions, and informal gatherings to inspire creativity and meaningful dialogue.

4TH YEAR STUDIO

Hive : floor plans

4TH YEAR STUDIO

Nexus:

Hive

This was a partnered project where we explored the boundaries of form and design through mass modeling, primarily using 3D printing with PLA and resin printing. Our focus was on creating an organic and intricate design.

With a focus on detail and intricacy, we were able to showcase the potential of 3D printing and mass modeling as a means of creating sophisticated and complex designs.

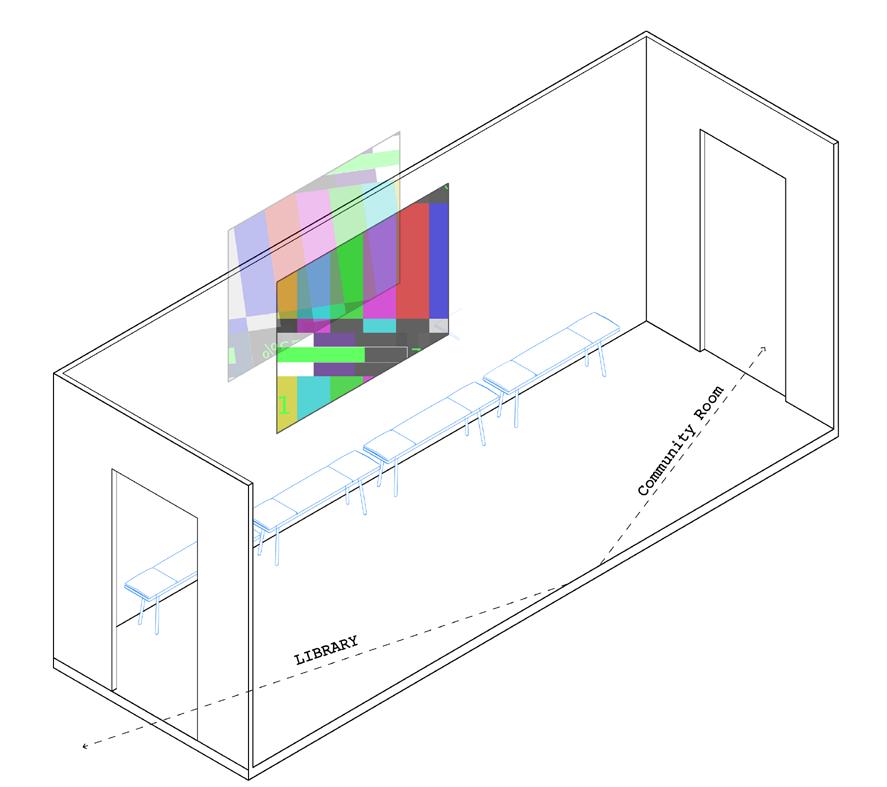

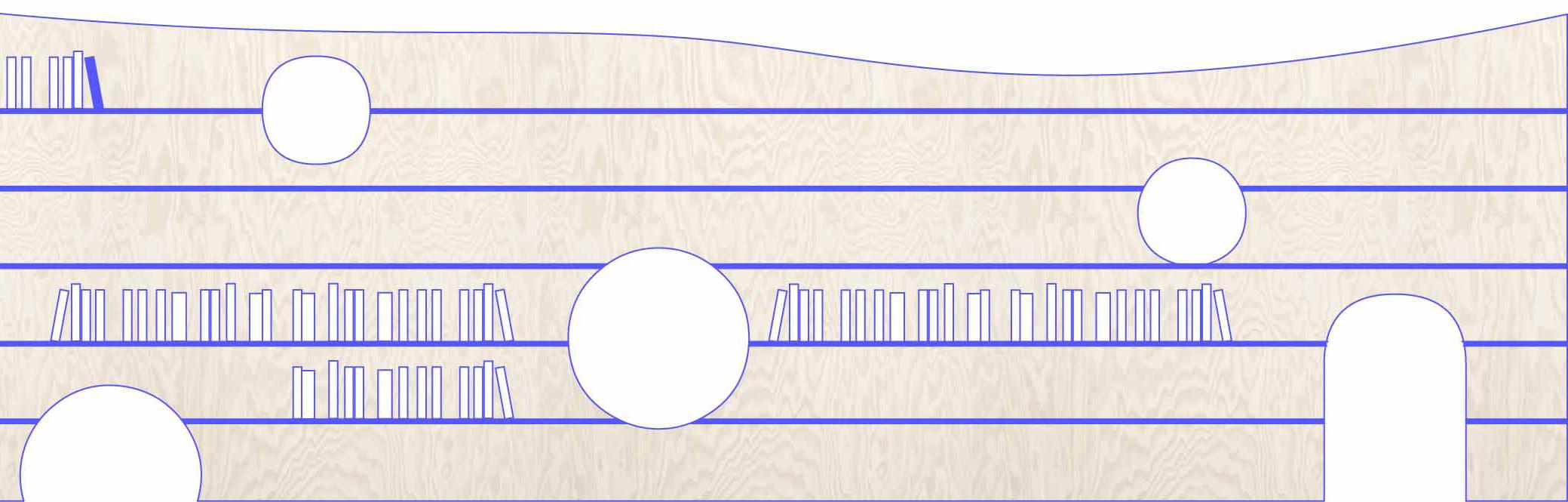

3RD YEAR STUDIO

Bronx

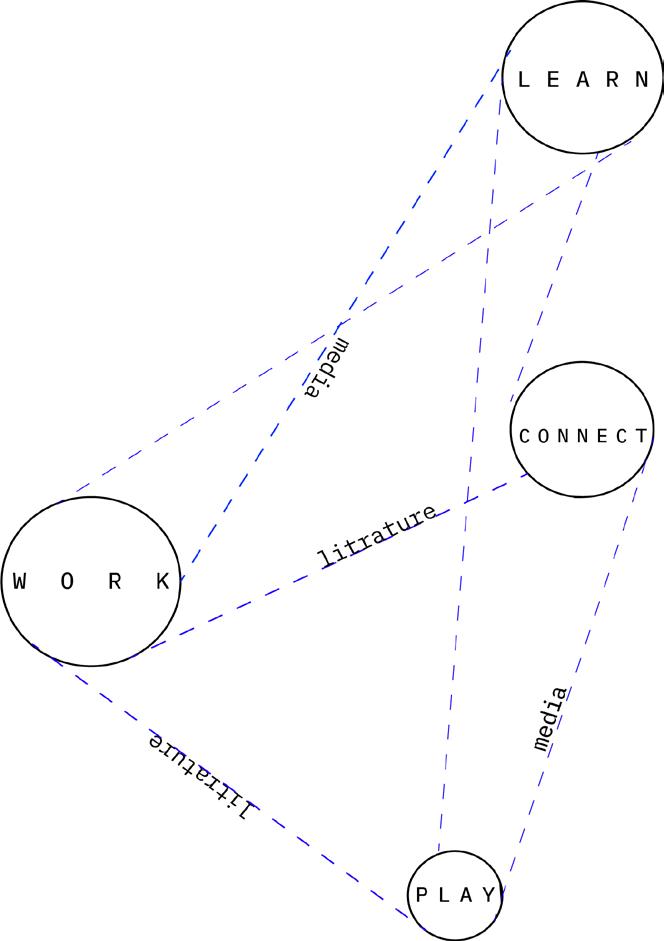

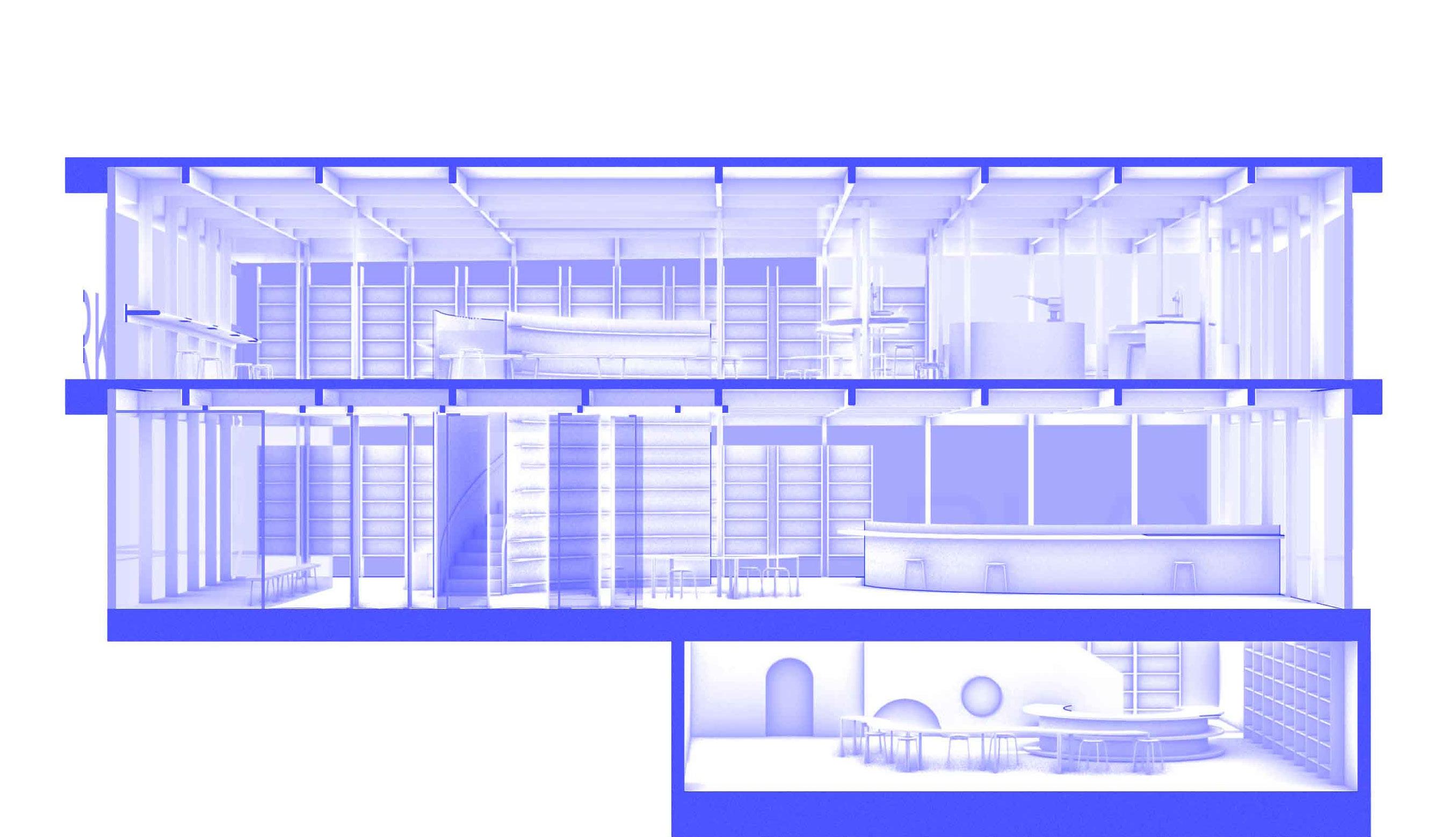

Library

This public library has been re-imagined to serve the growing community better. The main objective was to create flexible spaces beyond traditional book offerings. The library boasts areas dedicated to futuristic technologies and community spaces accessible around the clock. The final design aimed to create a hub for working, playing, learning, and socializing.

The adaptable spaces are made possible by custom-designed tables that can be linked or separated to create various seating options, from large groups to individuals. The tables interconnect and have the potential to expand, encouraging learning and growth that align with what libraries traditionally represent. The custom dividers also provide flexible spaces that the library can offer the public beyond books. Finally, the maker’s lab addition presents opportunities for the public to develop new skills.

Studying congregartion spaces (top left), educational buildings (top right), public gathering spaces with wifi accesbility (bottom left), and transit ie. buses, subway (bottom right)

Residential buildings

3RD YEAR STUDIO

Bronx Library- Floor Plans

00 : ground floor

01. ENTRANCE & 24/7 ENGAWA

02. ADJUSTABLE PUBLIC ROOMS.

03. FLOOR-TO-CEILING BOOKCASES.

04. FRONT DESK / INFO CENTER.

05. VIEWS TO CHILDRENS AREA

01 : top floor

06. PUBLIC ACCESS TO COMPUTERS

07. ROBOTICS ROOM

-01 : basement

08. CHILDREN/TEEN AREA

09. THEATRE SEATING + STAIRS

10. EXTRA STORAGE SPACES

3RD YEAR STUDIO

Bronx Library

24/7EngawaSpace

Customized modulartables

“DigitalBookcase”:

Introducing the use of screens to a typical bookcase for additional information; a new interpretation of the Dewey Decimal System..

Adjustable sliding/rotating walls for different needs. The modularity allows for several different size rooms: Private study spaces, conference rooms, voting booths etc.

Semi-transparent rotating screens with lock system

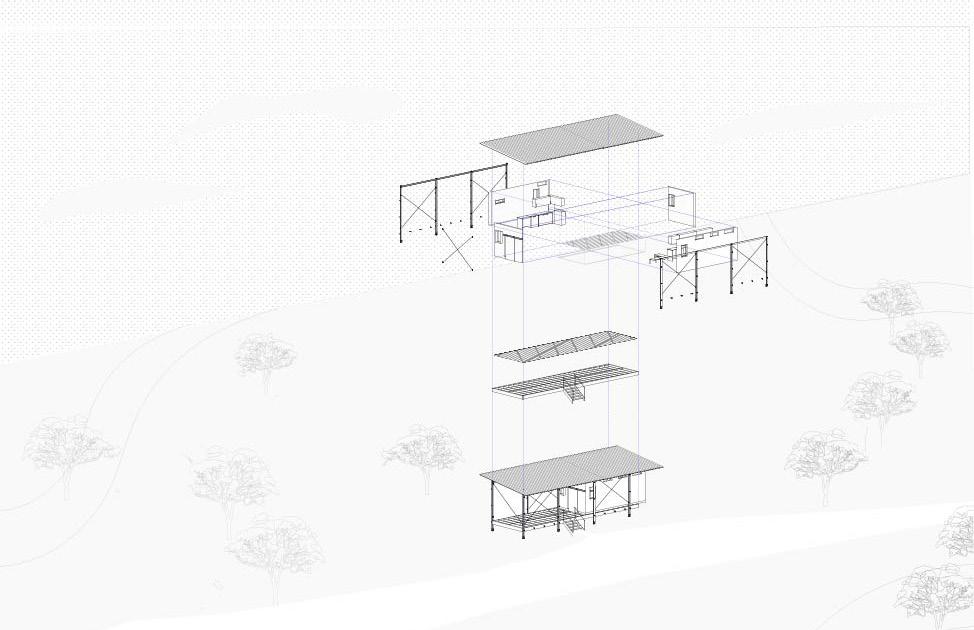

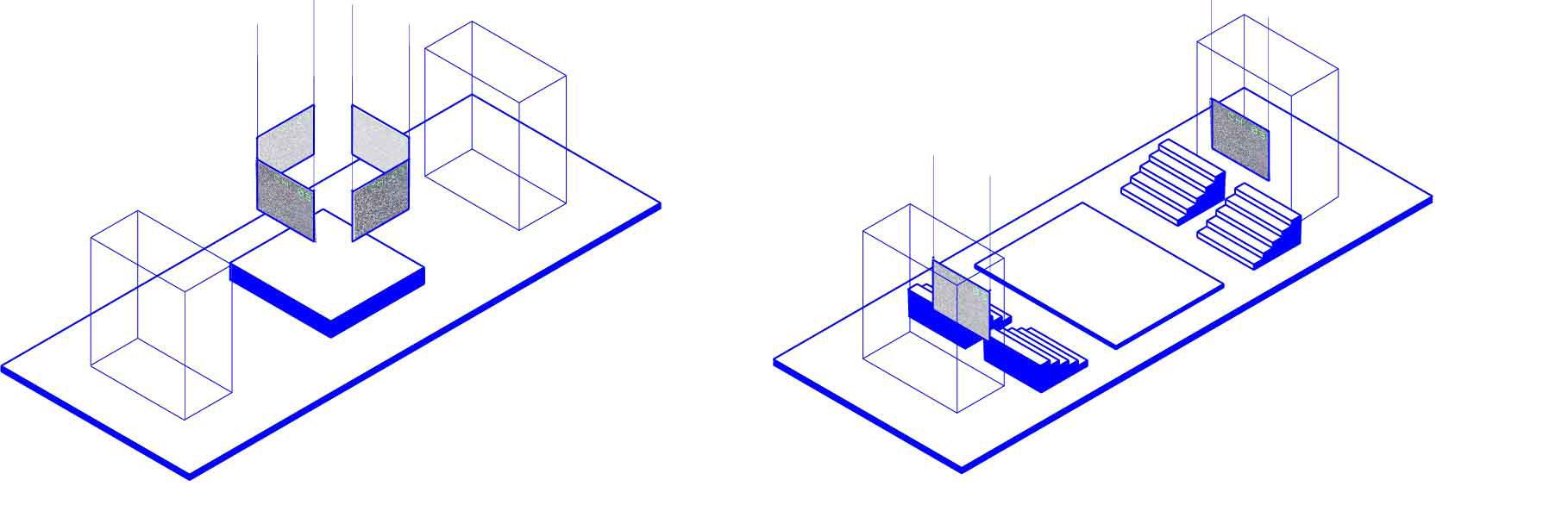

2ND YEAR STUDIO

Zambia Clinic

The Zambian government plans to build several health outposts across the country and has commissioned Virginia Tech to design these small clinics to accommodate a range of health professionals.

Located in rural SW Zambia, with a humid subtropical climate. The building stands out from its immediate surroundings to highlight its public character.

The architecture, reduced to a minimum, is logical + rational-a compact clinic, with a plan that facilitates efficient daily use for both patient + doctor-formulated out of universally available components organized into sets of modular assemblies defined by adjustable parameters.

The rationale of the form allows for flexibility- this ambition is a dominant mantra in the design.

3rd year competition

Open_ Air Theatre

Duration: 1 Week Project

The open-air theatre located at Virginia Tech was designed with the student population in mind, aiming to cater to a variety of events such as graduations, lectures, plays, concerts, and more. The primary design incentive was to create a flexible space, which is achieved through the implementation of a pulley system. This system facilitates seamless set transitions, ensuring that the space can adapt easily to the diverse range of events that it is intended to host.

Digital Fabrication Studio

Boston OpenLab:“digi-fab quilt”

Here I contributed to a “digi-fab quilt” by designing a unique 8x8” square that contributed to the final quilt. My square was inspired by organic landscapes and art forms, and aimed to push the boundaries of what digital tools can create. By exploring the balance between rigid design and natural form, my square was able to stand out as a unique representation of my creativity and design skills.

I gained valuable experience in digital decision-making and computational design methodology throughout this project. The project enabled me to link computational design methodology to physical fabrication processes, which empowered me as a digital decision-maker.

This three-part exercise leveraged our three primary digital fabrication tools: the laser-cutter, 3D printer and CNC router.