Project New Wave Textiles

The hobby of Calvin te Vaarwerk

Product development From J-Beam to OB Profile

4 6 14

Preface

Project New Wave Textiles

The hobby of Calvin te Vaarwerk

Product development From J-Beam to OB Profile

4 6 14

a customer and also have the opportunity to visit our own factory and connect with colleagues. I’m really looking forward to it. We’re incredibly proud of what has been achieved in Shelbyville over the past two years, thanks in large part to the excellent collaboration between our Czech and American teams. It’s something we’re proud to showcase to our customers.

Especially in these times of trade tensions (tariffs), it’s crucial that we have the ability to produce in multiple locations. Risk diversification was one of the key reasons we embarked on the USA venture back then, though we couldn’t have predicted just how relevant that would become.

As for our business, the situation remains somewhat volatile. While the outlook for storage system construction is generally positive, we have to work hard to secure sufficient volumes. The European market in particular is still weak.

That’s why we’ve made changes to our organization. It’s essential to operate as decisively as possible, both in the market and internally. Since September, we’ve been working within the new structure, though of course several changes still need to be fully embedded.

At the Warehouse & Rack Solutions BU level, changes have also been implemented, and the appointed functional leaders are gradually rolling out their activities. It’s great to see that our collaboration with sister company voestalpine Krems Finaltechnik GmbH is becoming increasingly close. This has already led to some promising market opportunities and orders. We’re also entering the next phase of the TORRI integration, which includes the implementation of SAP.

Plenty to look forward to. But for now, I wish you all a wonderful holiday season with your family and friends!

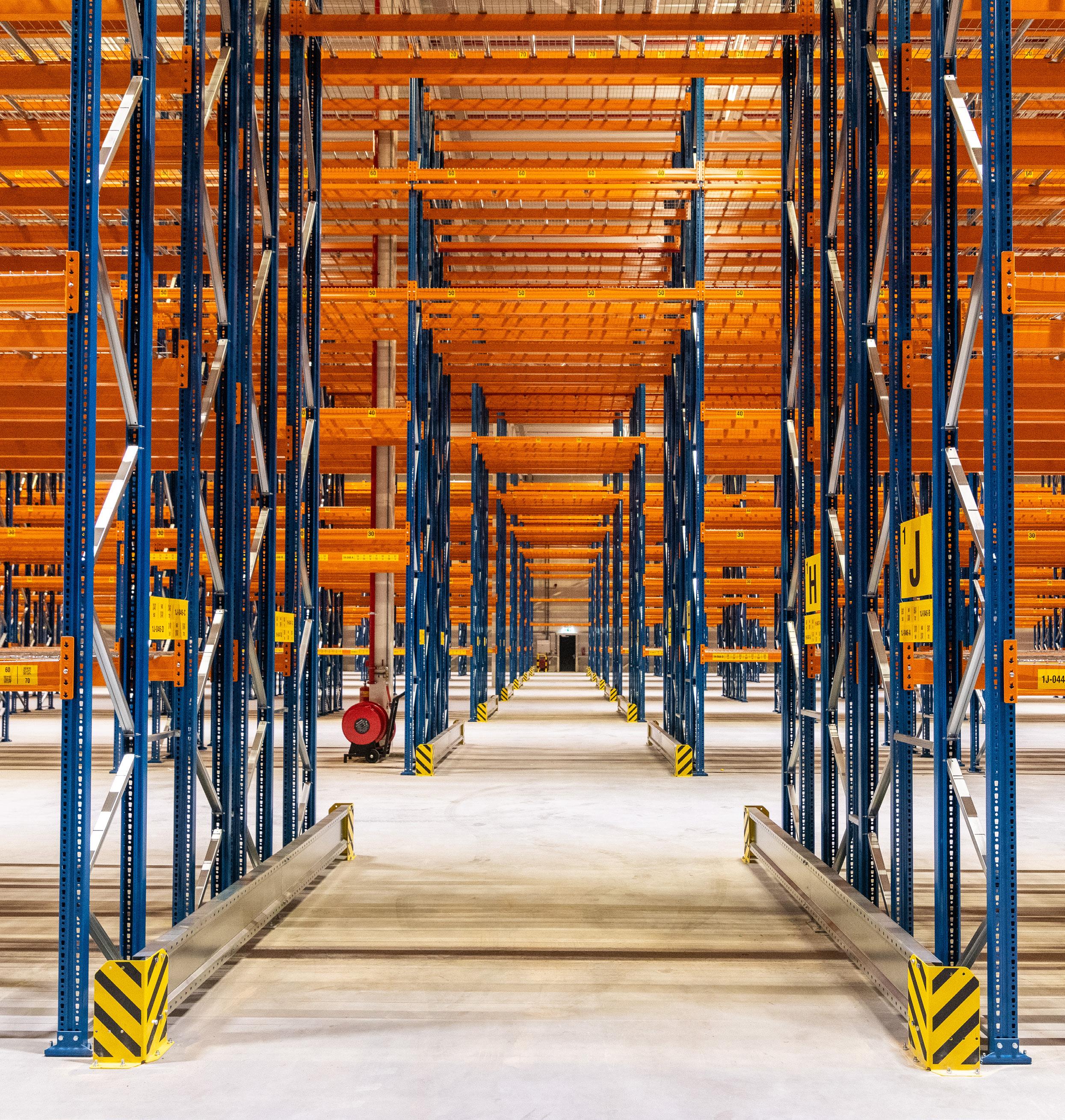

New Wave Textiles is a leading company focused on service-driven distribution of a wide range of textile products, including promotional wear, corporate wear, sportswear, workwear, and custom designs within the Benelux.

Its portfolio features carefully selected brands such as Clique, Craft, Cutter & Buck and Jobman, complemented by tailor-made solutions through its in-house business unit “Make Your Own Design,” which develops unique outfits.

The company serves dealers across a broad value chain, providing various markets with high-quality and suitable textile products.

question

How can we increase our storage capacity at the existing location, streamline our operations and prepare for our next growth phase, without compromising on service?

Working on a solution together

For New Wave Textiles, we developed an advanced automated storage solution in collaboration with robotics supplier HAI Robotics, based on our ROBORACK system.

The racking, specifically designed for robotic applications, is fully tailored to HAI’s robots and enables triple-deep storage of over 132,000 boxes.

With 16 large (ACRs) and 30 smaller (AMRs) robots, the system ensures fast and error-free order processing. Because of its scalability and compact design, this solution is a future-proof replacement for manual picking and replenishment processes, without requiring major renovations to the existing facility.

Navigation via QR codes

The floor and racking are equipped with QR codes, allowing robots to precisely locate themselves, identify the correct box and determine its destination.

Smart click-in boxes

The boxes easily click together, so when one is retrieved, the ones behind it automatically slide forward. This ensures the front position is always accessible, significantly boosting system efficiency.

Scalability for future expansion

The system is designed with growth in mind. In the next phase, the manually operated section of the warehouse can be seamlessly converted into a fully automated robotic environment by simply adding more rows of racking and robots.

storage density

Because of the triple-deep storage and smart space utilization, significantly more goods can be stored within the same square footage. This boosts capacity without requiring any expansion of the building.

Project details

Over 132,000 storage locations for various box sizes

46 autonomous robots (16 ACRs and 30 AMRs)

5 conveyor pick stations with put-to-light walls

3 inbound conveyor stations

An advanced robotic system with over 132,000 storage locations, delivering maximum storage density and fast, error-free order processing.

Customer quote

„Alongside HAI’s robots, we were looking for a European racking supplier known for their commitment to sustainability and quality. Through HAI, we found NEDCON and we are extremely satisfied with the collaboration and the final result.“ – Pieter van Barneveld (Deputy Director)

Can you briefly tell us something about yourself?

I’m Calvin te Vaarwerk, 24 years old and recently moved in with my girlfriend in Dinxperlo.

I’ve been passionate about technology and fuel-powered sports from a young age. Besides my job at NEDCON, I also work as a freelancer. I focus on repairs, assembly and metalworking. I also have a passion for photography, especially capturing razor-sharp action shots. Photography is a small hobby I enjoy on the

side. Together with friends, I like working on various projects and in the evenings we enjoy a drink together.

How did you end up at NEDCON at the time?

When was this exactly?

During my Mechanical Engineering studies, I was looking for a graduation project. I found one at NEDCON: the crossing system for Vanderlande. I started in February 2024 and the six months flew by. I successfully completed

the project. Toward the end of my internship, I was asked if I enjoyed working at NEDCON and whether I’d be interested in joining the company. That’s how I ended up at NEDCON.

What roles have you held at NEDCON so far? I started as an Engineer. After about nine months, I stepped into the role of Senior Engineer. Since September 1, 2025, I’ve been working as a Product Developer.

How did you get into motocross and how old were you when you first rode a dirt bike?

My interest in motocross started early. At the age of three, I rode a quad in my grandparents’ garden. My younger brother also started on a quad. Later, we rode a sidecar together. But soon we had a problem: no one wanted to be the passenger. My mom wasn’t thrilled at first, but my dad decided to cut off the sidecar. From then on, we rode dirt bikes. At age five, I was able to get a license to ride on a motocross track. The first track I rode on was in Halle at HALMAC, where I also competed in my first race.

Do you own your own bike?

Yes, owning your own bike is a must. I have two GasGas MC 450F Factory Editions. One is for training and the other is my race bike. Technically, they’re identical, but the race bike has fewer hours on it and stays fresher for important moments.

What’s involved in maintaining your bike?

Maintaining a bike is manageable. When you buy a new one, you get instructions on how to maintain it. After each training session or race, it’s wise to spray it clean so you can spot any issues quickly. My dad and I handle the following maintenance ourselves: changing air filters, oil changes, replacing chains and sprockets, changing tires, swapping grips and replacing clutch plates. We leave tasks like installing a new piston, adjusting valves and servicing the front and rear suspension to Mellendijk Motor Parts (MMP).

How often do you train and where?

I train about once a week, usually at the MACL track in Lichtenvoorde. You can train at any motocross track in the Netherlands and I occasionally do. In recent years, I’ve also spent time in Spain in December, enjoying the sun while riding. In the near future, I’ll be riding less due to renovations on our house. With limited free time, motocross is taking a bit of a back seat.

Which competitions have you participated in?

I’ve competed in various championships, including:

•Club races (at different clubs)

•Regional races (in the Achterhoek)

•Exchange races (UMX in the Achterhoek and Twente)

•MX-Cup (German races in North Rhine-Westphalia)

•Zwarte Cross Open (qualifiers with the final at Zwarte Cross)

•Dutch Championship (races throughout the Netherlands)

•Dutch Masters of Motocross (international race series in the Netherlands)

The Dutch Masters of Motocross is the highest level I’ve competed at. These international races in the Netherlands attract many foreign riders. You must qualify among the fastest 40 riders during time trials to participate in the races later that day.

What has been your greatest achievement so far?

My best achievement was at the last Dutch Masters of Motocross in Markelo 2024, where I finished 19th in the second moto. It was extra special because several world championship riders were competing.

What do you feel when you‘re at the starting line of a race?

Before a race, I always feel a healthy dose of tension. I’m not nervous, but I’m driven to be the first into the first corner.

What makes this hobby so special to you? Motocross is special because it allows you to fully unleash yourself. Even though it may seem like you’re just sitting and accelerating, it’s a physically demanding sport. While riding, you can clear your mind and forget everything else. The beauty is that the rider makes the difference. If you’re not the fastest, you need to look at yourself first.

What’s the next race in 2026 where we might see you?

It’s not yet clear which races I’ll compete in during 2026. Most likely, I’ll participate in the Zwarte Cross Open and club races at MACL in Lichtenvoorde.

Do you have any goals or dreams in motocross?

The time when I dreamed of becoming as good as Jeffrey Herlings has passed. My goal remains: to have fun and enjoy the ride.

Is there anything I forgot to ask that readers should definitely know?

For those curious about what it’s like: you can find various videos on my YouTube channel Calvin te Vaarwerk.

If you have any questions, feel free to reach out!

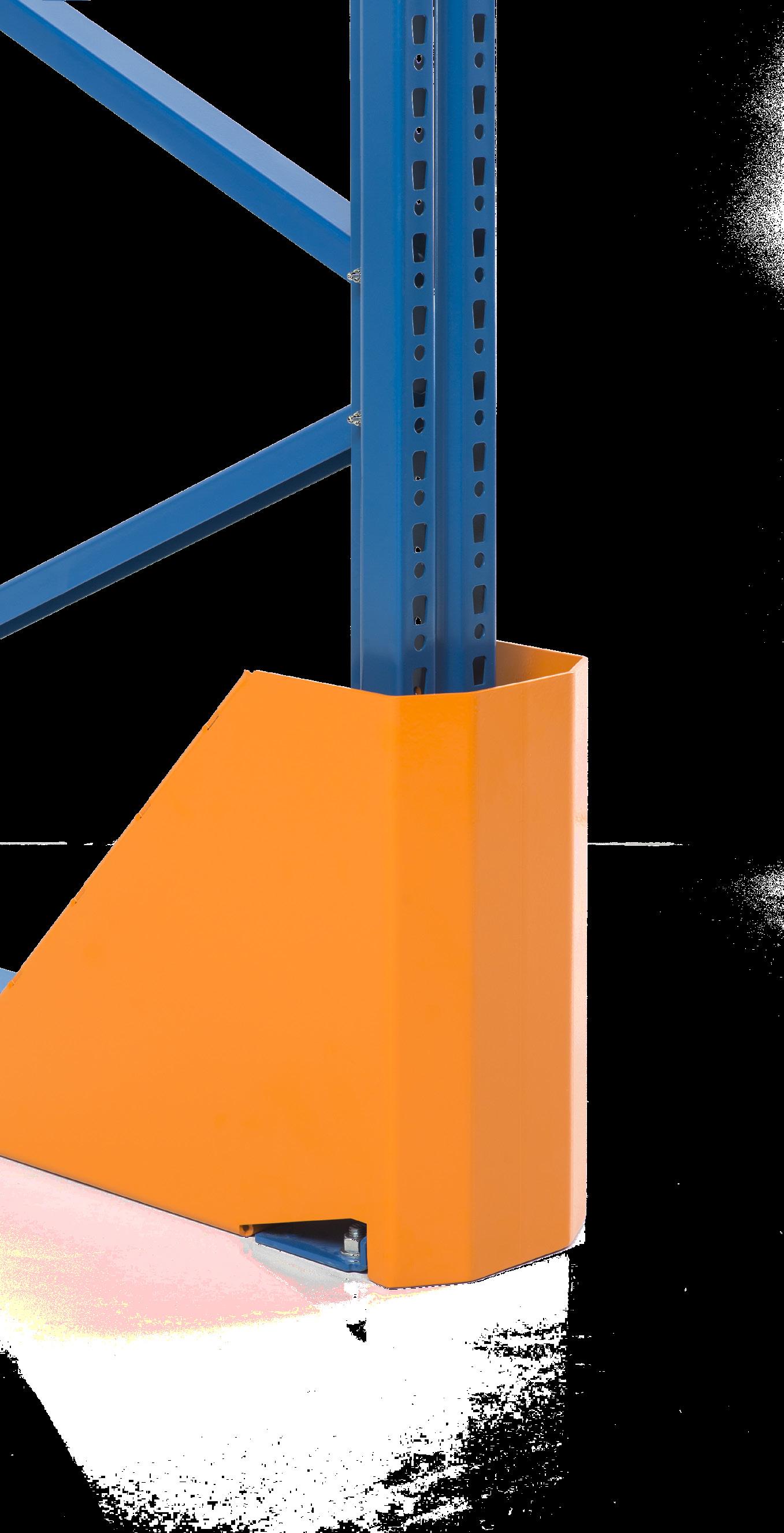

During an inspection by our colleague Helmut Scholten at our customer Simon Loos, it was found that 100 damaged uprights needed to be replaced. The costs were rising, so the decision was made to install DEFENDERS to protect the uprights.

This year, after installing the DEFENDERS, only 4 damaged uprights needed to be replaced. 3 of which were located in areas where no DEFENDERS had been placed!

Watch the project video here!

About Enexis

Enexis Netbeheer is one of the largest grid operators in the Netherlands, responsible for the installation, management and maintenance of electricity and gas networks. With over 5,000 employees, Enexis contributes daily to a reliable energy supply for millions of households and businesses.

The challenge

How can we create a flexible warehouse layout for a location where both new and reusable materials need to be immediately deployable?

The result

A future-proof and efficiently organized warehouse that enables Enexis to respond quickly to outages or maintenance work on the energy network. The solution includes heavy-duty pallet racks for large-scale materials and shelvings for small items and consumables. A mezzanine floor maximizes the use of vertical space, ensuring optimal storage density.

The smart and safe layout makes this warehouse a reliable link in Enexis’s logistics chain.

Project details / figures

2,996 pallet positions

708 shelves

2 weeks installation time

Key features

Durability: Heavy-duty pallet racks with extra-deep frames (1,400 mm) for safe storage of generators and cabinets.

Safety: All racks are equipped with Defenders and reinforced wire mesh panels to ensure warehouse safety.

Innovative 3D-tooling: Using our CSA tool, the entire warehouse was configured in 3D. Because of the modular design, the system can be easily adapted to changing storage needs.

Working on a solution together

For the new site in Best, we developed a custom racking system in close collaboration with Enexis, tailored to their logistics processes. This location stores generators, small materials and PICs (Product Deployment Components) used during outages or scheduled maintenance.

Throughout the design process, we made extensive use of our CSA tool. This tool allowed us to visualize various configurations, quickly respond to feedback and arrive at a wellsupported design. This approach accelerated decision-making and ensured efficient preparation and flawless execution.

Smart optimization within the ML7K System

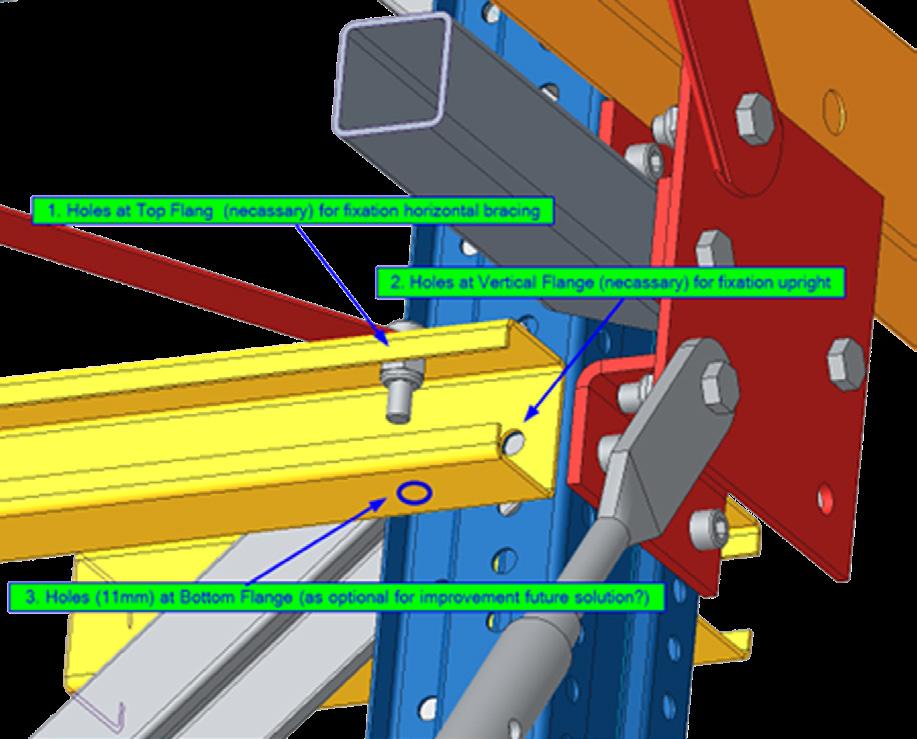

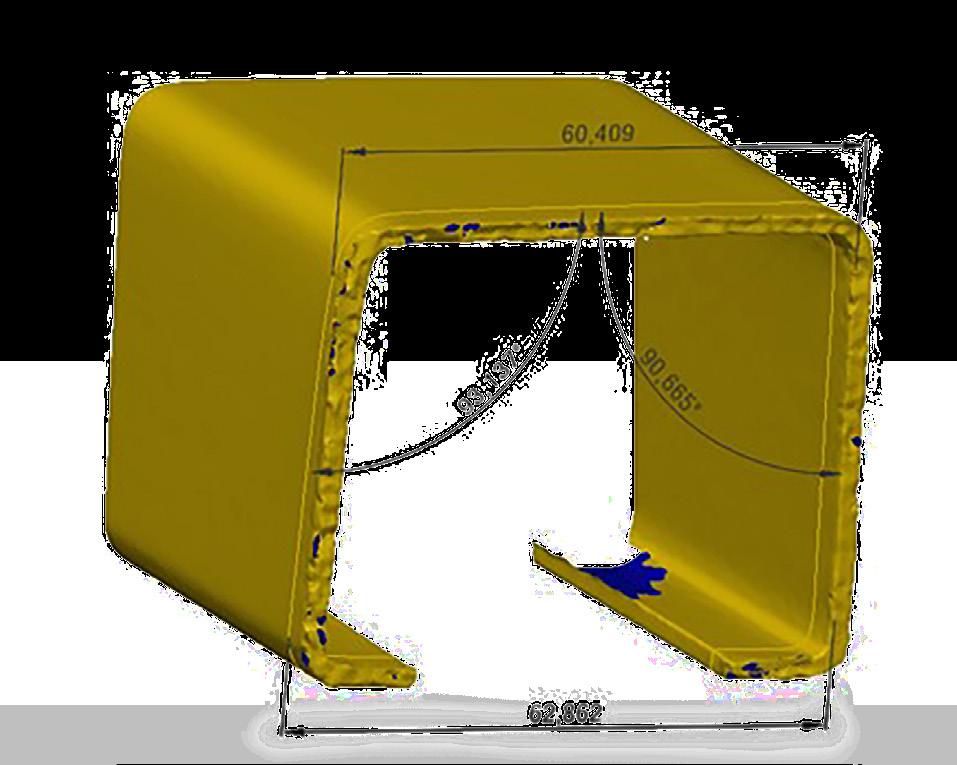

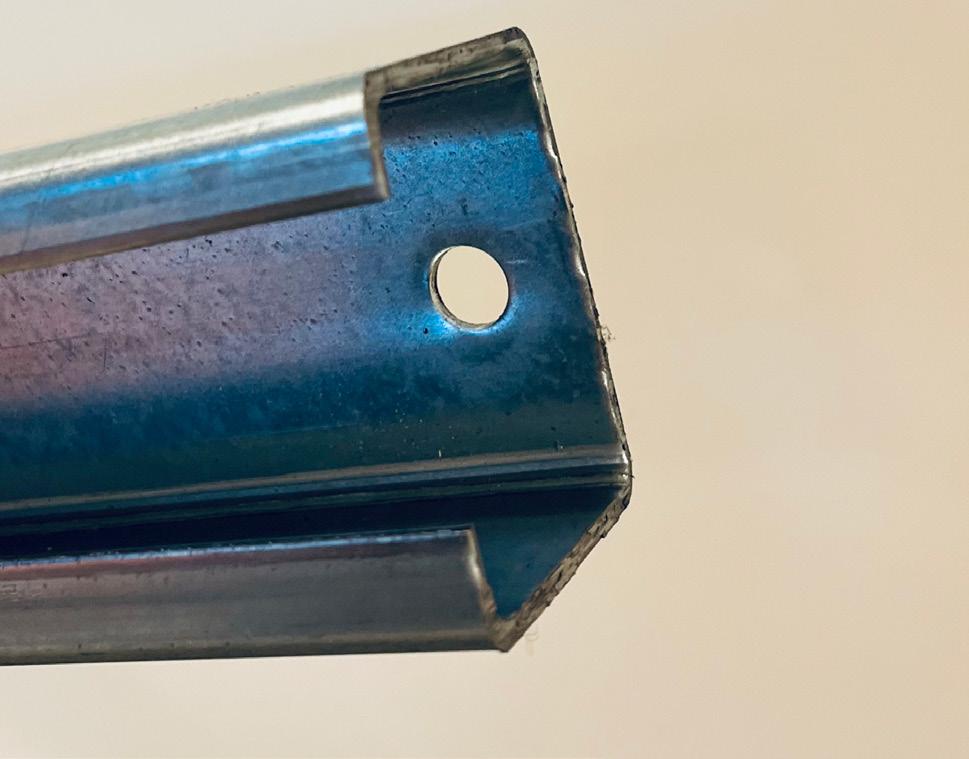

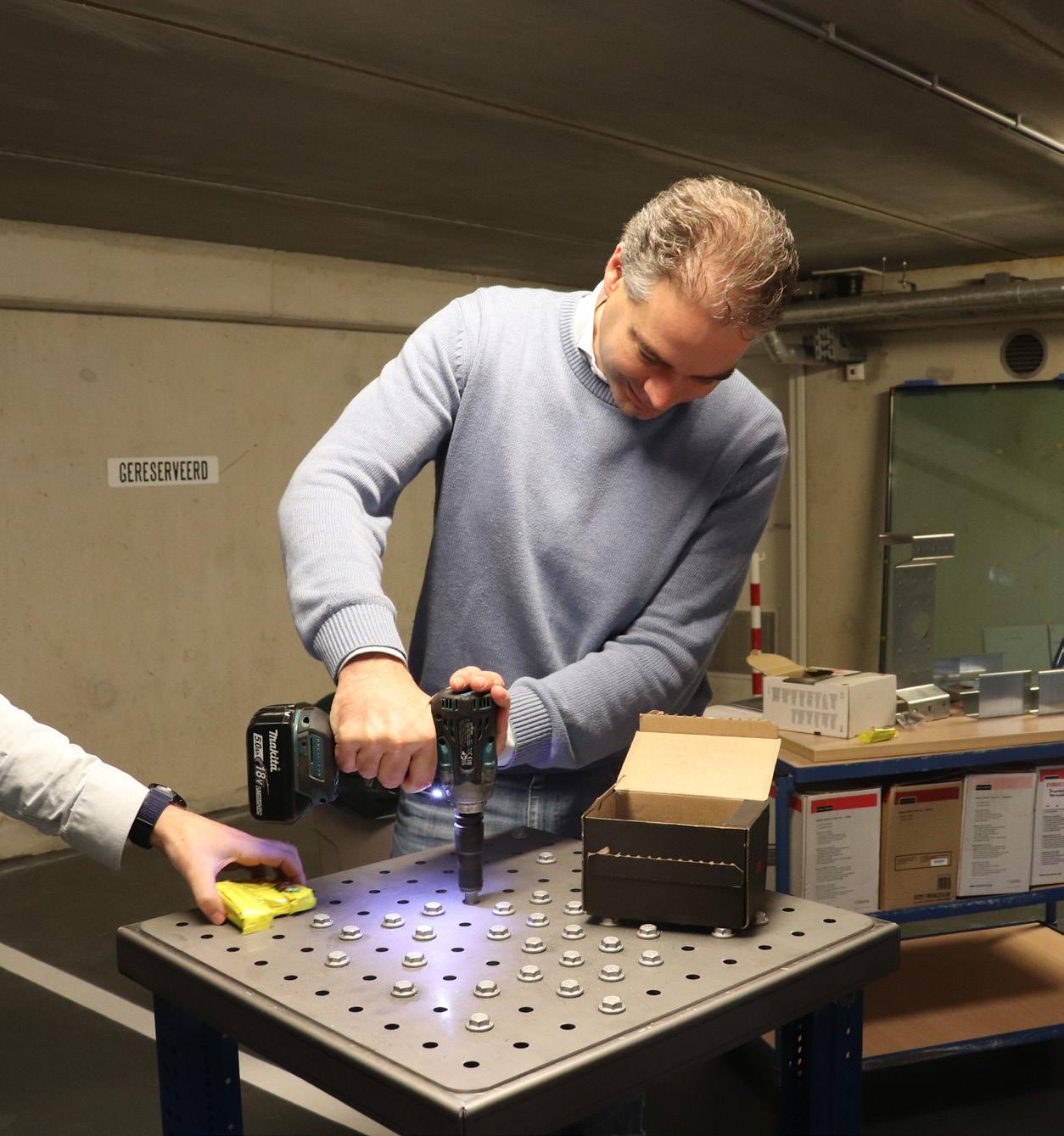

Innovation doesn’t always have to be grand or dramatic. Sometimes, progress lies in the details. In product development, we’re always exploring new technologies and clever solutions. But it’s often the small adjustments that deliver surprisingly big results. A great example is the recent optimization within our ML7K system, also known as the KNAPP Evo shuttle rack.

The J-Beam: Small component, big role

In this system, the so-called J-beam plays a key role. This J-shaped profile supports the

grating floors used by maintenance technicians, contributes to the overall stability of the rack, and provides mounting points for the sprinkler system. Because of its multifunctional purpose, the profile has a specific shape and hole pattern.

Until now, the J-beam was produced externally: first laser-cut, then bent into shape. A laborintensive process, especially considering the scale at which we operate. On average, 150 kilometers of this profile are used annually, with peaks reaching up to 600 kilometers. That volume presented a clear opportunity for improvement.

The KNAPP development team at NEDCON set out to find an alternative that could be produced in-house. The solution was found in the existing Open Box profile (OB profile), which is roll-formed in our own factory. But would this profile meet the technical requirements of the system?

Calculations and tests followed:

Is the profile strong enough?

Does it fit within the height structure?

Can the hole pattern be adapted for various applications?

Each time, the answer was yes.

One of the main challenges was the hole pattern, particularly for sprinkler mounting. In practice, different variants are needed: sometimes one hole, sometimes two. By designing modularly, we now apply a standard pattern with multiple holes, making all options available. We’ve also anticipated future applications by including additional hole positions.

Our production department was closely involved throughout the process. While the profile may seem simple at first glance, its execution proved quite complex. Thanks to strong collaboration and technical alignment, the green light was given.

After development, the OB profile was incorporated into the NEDCON standard, including 2D drawings, 3D models, SAP configurations, production routing, and sales tooling. A meticulous process, ensuring everything was critically reviewed and properly implemented.

Soon after, a project emerged where the new profile could be applied immediately. Thanks to the dedication of the entire team, the profile was quickly available and ready for use.

The result speaks for itself: we now produce the profile in-house, achieving a cost reduction of over 15% compared to the J-beam. For an average project, this translates to a savings of around 0.5%. That may seem modest, but in absolute terms, it’s more than worthwhile and it helps NEDCON stay competitive in the market.

About Apollo Tyres Limited

Apollo Tyres is an Indian multinational company that has been active in the production and sale of tires for passenger cars, trucks, and two-wheelers since 1972. The company operates multiple factories worldwide, including in India, Hungary, and the Netherlands. In 2009, Apollo acquired the Dutch brand Vredestein, including its factory in Enschede. However, this location with a history spanning over 100 years will close in the summer of 2026. Key reasons include high energy costs and inflation in the Netherlands, prompting a shift in production to Hungary.

How can we store our green tires* in a costefficient way within a compact, existing hall?*

*Green tires are tires in an intermediate stage of the production process. They have not yet been vulcanizedandarethereforesoftandsensitiveto deformation and contamination.

Working on a solution together

The initial solution proposed by Siemens was based on previous Apollo projects and came with a significantly higher price tag than the alternative developed by our RD&P department. By carefully listening to the needs, constraints, and concerns of both our direct client and the end customer, we were able to convince all parties of our tailored solution. The substantial cost savings became a key incentive for Siemens to choose NEDCON.

The request originated from our sales department: could we develop a solution for the temporary storage of green tires during the tire production process at the Hungarian site? The challenge involved individual semi-finished car tires weighing between 5 and 25 kg each.

An earlier proposal was based on an overengineered design, using thick, folded corner profiles. After feedback from the customer, our Product Development department was asked to explore potential cost-saving alternatives.

During development, we investigated how to create a more cost-conscious configuration using existing NEDCON standard profiles from our own production. The new solution features a U-profile mounted within the frame, onto which standard NEDCON horizontal ties are attached. These ties support the customer’s plastic blocks, which hold the green tires.

The key difference from the initial design is the lighter material usage and the fact that the new version is largely manufactured using roll-formed profiles from our own factory, resulting in a significant cost reduction.

The design was thoroughly tested by our in-house Test Department to ensure it meets all required specifications.

To safeguard the concept and intellectual property, the design has been formally documented in a whitepaper, securing ownership for NEDCON.

solution

A great bonus: the new solution nearly doubled the pre-calculated EBIT!

Thanks to our custom-designed system, Apollo Tyres Limited achieves significant savings on the purchase of the racking system. Even more, this solution introduces a completely new storage method for green tires. Previously, these tires had to be placed on special trays within the racks. Now, they can be stored directly using 14,000 plastic blocks integrated into the racking system.

This direct storage method not only reduces handling costs but also optimizes the use of available space a smart innovation with both operational and financial benefits.

Installation

On September 8, 2025, our supervisor Ladislav Takac, together with a team from Jasopa, traveled to Hungary to start the installation. Despite some initial uncertainties, the project got off to a strong start.

After a somewhat challenging launch phase, the project is now progressing smoothly. It involves several components that must be installed at height including fire baffles, horizontal elements, and plastic blocks, making the assembly labor-intensive.

The total construction time was planned for eight weeks — and by the time you read this, the project has been completed.

Project details

4 aisles of racking

9 levels high and 25 bays wide

Double-deep storage 14,000 plastic blocks

result

An ML1 system with a storage capacity of approximately 3,600 tyres.

Sustainability in this project

Sustainability plays a key role. Siemens is providing a full report on the project’s CO₂ emissions and is working closely with our Sustainability Officer, Jan Rensen, to ensure transparency and accountability.

At NEDCON, employment relationships tend to be long-term, and many of you reading this have been with the company for quite some time. When I talk to colleagues about their careers, two things often stand out: some left and later returned, while others started here as interns and chose to stay as employees.

Compared to other companies, we perform above average in this area. In recent years, nearly 20% of all interns at NEDCON have joined the company after completing their internship.

But is hiring the only reason we offer internships at NEDCON?

Definitely not. Providing internship opportunities brings many additional benefits. First and foremost, it encourages innovative thinking within teams. Students often approach challenges from a different perspective than colleagues who have been with NEDCON for a longer time. This fresh outlook leads to new insights.

Moreover, mentoring students offers valuable learning experiences for our colleagues as well. Both in terms of human skills and exposure to new techniques. In many cases, it’s a win-win situation. And last but not least, we offer young people a meaningful work and learning experience that helps them grow. It gives them valuable tools to take their next steps in society.

Why do students choose an internship at NEDCON?

We often hear from students that they choose an internship at NEDCON because of our approach to

guidance. At our location in Doetinchem, we offer students two types of supervisors. First, a theoretical supervisor who supports them in carrying out their work. In addition, they are assigned a process supervisor who helps with planning the internship or graduation project and with submitting documents to their university or college. Students also receive an internship allowance, plus a lunch allowance.

Within the steering group that oversees internships, we regularly evaluate whether we’re achieving our goals. At the time of writing, we’re exploring the possibilities of offering international internships at NEDCON. Early findings suggest that there are promising opportunities ahead.

Do you have an exciting challenge that could be suitable for an intern? Let our internship coordinator know via stage@nedcon.com.

Roel van Leeuwen

Based in Groenlo, It’s all about Christmas has been the specialist in Christmas products since 1988. Their core business focuses on selling a wide range of Christmas products online, including baubles, artificial Christmas trees and Christmas lights. Through multiple international webshops, they supply countless customers with everything needed for a festive holiday season. In addition to their strong online presence, they also boost their seasonal success with various pop-up stores during the holidays.

How do you create an efficient warehouse solution for a new distribution center while considering the storage needs for both e-commerce and retail setup?

Working on a solution together First, we mapped out all the basic requirements, taking into account the layout of the new building. Once the needs were defined, we initiated the next phase by developing a 3D model based on previous layouts.

Thanks to our advanced CSA-Tool, we were able to create a detailed 3D configuration right from the design phase. This tool automatically generates the safest and most optimal configuration based on our standard product range. It also allows us to quickly adapt to any required optimizations. This resulted in a solution where functionality and efficiency are perfectly aligned.

Storage for 4,772 pallet spaces.

Our CSA-Tool enabled us to develop a highly detailed 3D configuration while allowing quick adjustments for optimizations.

All racking systems were coated in red and anthracite grey, matching the company’s branding.

We successfully delivered a large-scale pallet racking project, creating space for 4,772 Euro pallets. The warehouse was fully customized to meet the client’s needs and executed in their corporate colors of red and anthracite grey.

This project is a great example of how we elevate warehouse storage solutions using the innovative technology of our CSA-Tool and tailored solutions.

You may have already encountered the term AGV in the past. The abbreviation stands for Autonomous Guided Vehicle. At first glance, it looks like a standard forklift truck, but it is equipped with scanners, sensors, and navigation and warning devices. Their interaction with the control system allows transport operations to be carried out in a fully autonomous mode.

For couple of weeks now, you can see such a vehicle in the NEDCON production plant in Pardubice. There were several motivations for implementing AGV. The primary ones included assisting FLT drivers in performing routine transport activities and installing additional equipment incorporated in Industry 4.0. Another significant incentive was a long-term interest in learning about the world of robotic transport. NEDCON has been working for years with strategic partners who ensure the integration of similar AMR robotic technology into our racking systems.

Autonomously guided vehicles generally show maximum efficiency when used in repetitive transport activities, especially when long distances must be covered. The biggest limitation for AGV is the type of load being transported. Ideally, it should be a compact, solid, dimensionally standardized package stored on a standard pallet.

At the beginning of the project, it was essential to determine what kind of handling the AGV should perform. Based on detailed research, the transport of SF shelves from the production line to the adjacent warehouse was selected. The form of the final product of the line played a significant role – stable stacks of shelves on conventional wooden pallet. The decision to deploy the vehicle at the WEMO line output then emphasized the high degree of automation of this production technology.

The next step of the project was to choose storage locations for the transported goods. This helped to define the exact trajectory that the AGV would follow

during transport. The final step in defining the handling activities was to determine the additional operations. These are in form of warehouse stock optimization. If necessary, pallets in the warehouse can be rearranged or relocated. The aim of these operations is to simplify the subsequent manual picking of orders.

The result of the tender process identified Toyota Material Handling as the suitable supplier of this autonomous technology. Their SAE160 vehicle was the only one that met all the requirements for transport activities, pallet stacking, and operational safety. Basic AGV parameters: electric drive, load capacity of 1.6 tons, and lifting height up to 4.7 meters. A special feature of the vehicle for NEDCON is its telescopic mast, which ensures proper guidance during transport activities. This is only the second installation of this specific navigation system for Toyota worldwide.

The AGV uses laser distance measurement for its navigation. The vehicle emits a beam that is reflected

from the surfaces of the installed reflectors. The received signal is then evaluated by the control unit, which accurately determines the current position of the vehicle. For the proper navigation function, it is necessary to have at least 3 reflectors within visible distance. For this reason, a total of 57 reflectors were installed along the track in 39 different locations.

The navigational rotating laser is mounted on the previously mentioned telescopic mast. In the production hall, the telescope is in the lower position so that the vehicle can pass under the crane track without colliding and then through the tunnel connecting the production and storage halls. As soon as the AGV enters the warehouse, the telescope extends to the upper position. This allows the laser to reach the height at which the reflectors are attached - above the stored products. This procedure ensures the continuous functionality of the navigation system.

Charging the vehicle is a completely autonomous process. The AGV home station, located behind the WEMO line, is equipped with a charging station. When the vehicle moves into this position, the connector arm swings out and then locks into the charging port. No assistance from personnel is required.

One of the most important aspects of autonomous transport is ensuring operational safety. The AGV control system continuously evaluates data obtained from the following safety features:

front and rear transport scanners front height obstacle detector

side scanners for obstacle detection side scanners for safe turning upper obstacle detector at laser level pedestrian detector load movement sensor on forks

The vehicle is also equipped with an acoustic and light warning system to alert forklift drivers and pedestrians in the area. In the event of an imminent collision with a foreign object, the AGV‘s speed is reduced, and the vehicle is then brought to a complete stop. If any non-standard situation arises, the autonomous vehicle can be switched to manual mode at

any time and operated as a hand-controlled forklift truck. In extreme cases, an emergency stop is available in the form of buttons and mechanical stops at the ends of the forks.

For safety reasons, scanners have been installed in the tunnel between the production and storage halls and in the main corridor in the warehouse. The task is to monitor the presence of pedestrians and manual forklifts in these areas. Considering the current occupancy, the AGV control system activates light signals and controls the transport activities of the vehicle in the given segment of the track. The scanners thus contribute significantly to the safety and smooth flow of traffic.

Although all these features and devices contribute to better safety situations, they are not all-capable. To achieve maximum operational safety, it is necessary for everyone who encounters the autonomous vehicle to cooperate. It is important to respect the specific nature of AGV operation and prevent any hazardous situations.

The final phase of AGV implementation is currently underway. Defined handling activities are being tested in a completely autonomous mode of operation. At the same time, AGV operator training and safety training for forklift drivers and for other employees are in progress.

The first months of operation will also serve to gain experience with AGV operation. Future integration of the SAP system is planned, which should contribute to an even higher degree of operational autonomy. At the same time, discussions are already going on regarding the potential expansion of the vehicle‘s application for other handling activities within the production plant.

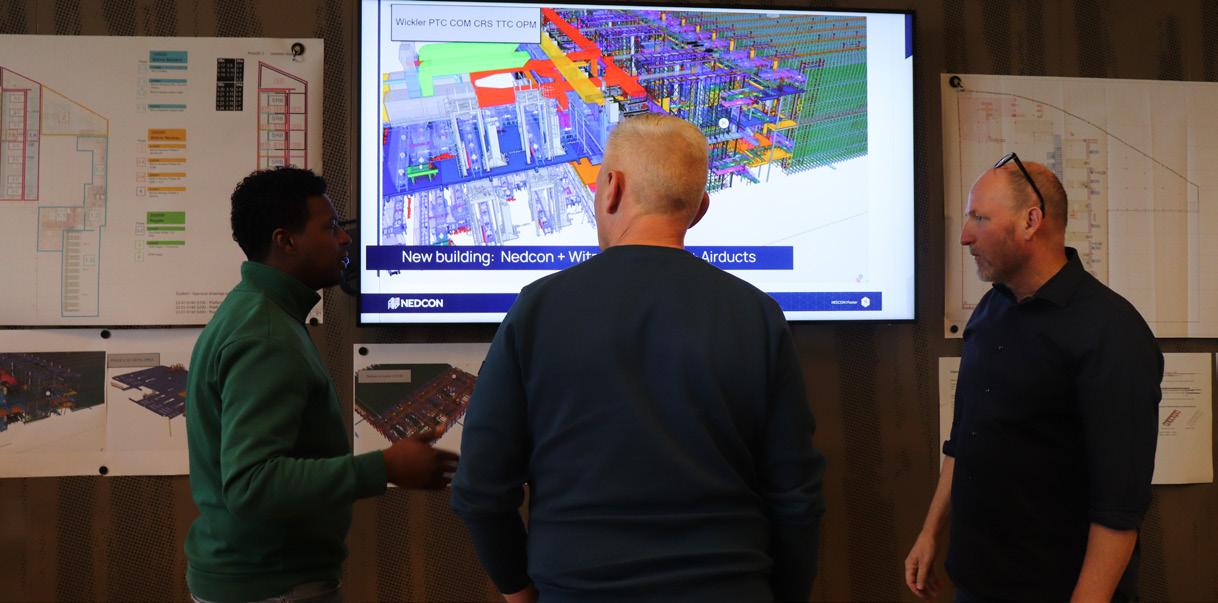

Changes within our organization are happening at a rapid pace. To share these developments and learn from one another, we organized an internal news market on November 6, 2025, as part of the NEDCON Academy, held at our headquarters in Doetinchem. It was an informal, accessible, and interactive event where each department was given the space to inform colleagues about current activities and initiatives.

With this news market, we aimed to:

Increase visibility of projects and initiatives

Foster understanding of each other’s work and challenges

Collaboratively build a future-oriented organization

Each department was asked to present at least one topic in a format of their choosing. The result was a diverse and engaging range of subjects. During the two-hour event, colleagues could walk past the various booths, ask questions, and engage in conversations.

To close the event, Lodewijk van der Borg, CEO of Royal Kaak, gave a presentation on his company’s vision for integrating Artificial Intelligence (AI) into business processes. His message was clear: AI adds value across all disciplines, provided it is applied thoughtfully. He emphasized the importance of critically reviewing AI-generated output, just as you would review a colleague’s work. Ultimately, human judgment remains essential.

At the time of writing, the feedback survey is still open, but initial results show that 100% of respondents are in favor of organizing another edition. We will carefully review all suggestions and incorporate them wherever possible.

A thank you to all colleagues for your contributions. Your enthusiasm and dedication at the booths made this a successful and inspiring afternoon. The strength of the news market lies in the commitment of our people and that was clearly visible.

To be continued!

Where were you born?

I was born in Belfast, Northern Ireland August 21, 1971. I moved to the United States in 2019 for work and was getting married.

What is your family situation like?

This is my 2nd marriage. Both my wife and I have 2 children from previous marriages. 4 children in total (2 girls aged 20, 1 girl 23, 1 boy 17) blended family.

What is your best trait?

Listening, dependable, showing kindness and compassion to others.

What is your worst trait? I can be stubborn.

What is your favorite food?

Steak! I like to go to Losanti in downtown Cincinnati for special occasions, but otherwise we usually have steak at home. I like my steak medium rare.

What kind of music do you like to listen to?

I like all types of music, but I tend to be drawn to alternative and jazz. On the alternative side, I enjoy listening to Depeche Mode, The Killers and The Black Keys. For jazz, I appreciate artists like Chet Baker, Miles Davis and Ella Fitzgerald.

What are your hobbies?

Hiking, walking on the beach, reading (audibles), solving NY times mini crosswords daily and cooking.

What can we wake you up at night for?

Whatever you want. I will get up for it. I am actually a really light sleeper.

Who would you like to eat a biscuit with?

Winston Churchill or Matthew McConaughey. I would like to discuss topics with them such as resilience, change, personal struggles, leadership and family.

Do you have a motto or slogan you would like to share with your colleagues?

“Focus on improving, not proving”

What dream do you most want to see come true?

Going to Manchester United football match in Manchester England.

What do you like to do on weekends?

Rest, catch up with friends and family and watch sports. I enjoy watching English football, American football, hockey and baseball.

What news from the past six months has impressed you the most?

The first fully functional 3D printed human heart successfully bio printed.

What is your favorite vacation destination or activity?

Where I have our other home in Hilton Head SC. I usually go there during vacation or major holidays! For an activity I like kayaking and walking on the beach.

What achievement of yourself or of NEDCON are you most proud of?

For NEDCON having one of its best revenue years last year.

Can you tell something about how you came to work at NEDCON?

I was approached by a recruiter and had asked me if there was interest in the current position I am in. Thought my skills and experience would be a great fit. And as they say the rest is history.

What employer did you work for before NEDCON and what position did you have there?

I worked for Dexion North America as a VP of Sales. Dexion North America operates as part of Gonvarri Material Handling, a global leader in storage and material handling solutions. Their core business is providing industrial storage and shelving solutions through selective pallet racking, automated systems and shelving.

What is your biggest challenge at NEDCON? Getting to learn the “NEDCON way” while adapting to the US market.

What other role within NEDCON would you like to spend a week doing?

On site supervisor, because I want to experience what it would be like to be on site working with the installation team.

If you were the director of NEDCON for one day, what would you do or change?

Embrace more of current AI and sales tools to help streamline and build on new business for the company.

What will NEDCON look like in 5 years? What is the biggest change you predict?

More dominant player in the US with full manufacturing/production capabilities.

And I would like to ask

the

What are the most important product development priorities/innovations we should explore to meet evolving market demands and improve our competitive edge?

This year we again celebrated our long-term employees at NEDCON. We want to thank them for devoting 10, 12 ½ , 20, 25 or 40 years to our company.

Find the first names of our long term-employees of this year in the word search below!

40 years

Birgit Ruiter

30 years

Pavel Martan

Miroslav Kocman

Hana Vokáčová

Roman Bleha

Roald Sjouken

25 years

Erik Lansink

Jerry Lauers

Fabian Tuender

Christiaan Koch

E B A N M P E T R C V S W D F O M G A D H O D G A F R H A Í G A V É D A Ř V E R U Á E R I K V Ř L A H C I M

R U P B P W Z A T G A I Á E P I Z J K

T E Í J N B Í R E L J L V O B N R Š G

Edwin Rauwerdink

Marianne Douma

Robert van Beek

Milan Tezner

Pavel Píša

Martin Šilhánek

Robert Šlor

Tomáš Mašata

Tomáš Klička

Michal Smetánka

Bronislav Kříž

Vilém Novotný

I Š V F I Á R K S W W É F M Ř E J E H

N U Z C T A N O F G D M N I W D E Z P A É T G R F R J A J U B E I A V R K A

V E S U A I B V F L I S G U T J R E V

S N O P M I L A N Ř D V E W U R Y R E W N I C K Z D C K R R P N Í S T A A L

P A V E L Š T J R O B E R T Z W A M S

20 years

Daniela Mach

12.5 years

Anne Wissink

10 years

Martin Franěk

Marek Svatoň st.

Jiří Vacek ml.

10 years

Jaroslav Vosmanský

Martin Kubec

Martina Novotná

Petr Naď

Course:

Cuisine:

Preparation time:

Cook time:

Servings: Main course Italian & French 30 minutes 1 hour 4 people

• 600 grams of pork tenderloin (or more)

• 200 grams of streaky bacon

• Pepper

• Salt

Optional: spices of your choice such as paprika powder, garlic powder, Italian herbs

Ingredients Italian style

• 1 jar of green pesto

• Sun-dried tomatoes

•

•

Ingredients French style

•

•

Additional equipment

• BBQ with direct and indirect heat zones

• Butcher’s twine

• Meat thermometer

Let’s get started!

Step 1: Take a sharp knife and trim the ends and any excess fat from the pork tenderloin. Butterfly the meat by slicing it open so it can be filled later.

Step 2: Weave a bacon mat for each tenderloin. Season both sides of the meat with steak rub and place it on the bacon mat.

Step 3: We’ll prepare two different fillings: one inspired by Italian flavors, the other by French cuisine.

Step 1: Spread pesto on the inside of the pork tenderloin.

Step 2: Add sun-dried tomatoes.

Step 3: Sprinkle over the toasted pine nuts.

Step 4: Lay a few slices of Serrano ham on top.

Step 5: Roll the tenderloin tightly in the bacon mat and secure it with butcher’s twine.

Last step: Heat your BBQ to 120–150°C using an indirect setup. Cook the pork tenderloin until it reaches an internal temperature of 60°C.

Then grill it briefly over direct heat to crisp up the bacon and give it a nice color. Your stuffed tenderloins are now ready!

To complete the dish, serve with:

Enjoy your meal and have a wonderful Christmas! Pom Duchesse or potato croquettes Green beans wrapped in bacon, grilled on the BBQ Stewed pears

Step 1: Slice the brie and place it inside the pork tenderloin.

Step 2: Add walnuts.

Step 3: Drizzle a bit of honey over the filling (you can also add the honey after grilling, when serving).

Step 4: Roll the tenderloin tightly in the bacon mat and secure it with butcher’s twine.

This September, Cotap proudly celebrates 85 years of expertise and dedication as a leading flooring specialist. Cotap offers a wide range of floors, including laminate, PVC, carpet and parquet. With their broad product range, Cotap serves over a thousand specialized stores, such as home and parquet specialists, providing their customers with high-quality and sustainable flooring solutions. As a family business, Cotap is known as the sustainable partner for Dutch retailers and project designers. With a broad portfolio of brands like Ambiant, Floorlife, Co-pro and Straq, Cotap delivers new flooring collections and unique floor concepts tailored to consumer needs.

challenge

How do we design our new distribution center as efficiently as possible to support future growth?

Working on a solution together

After a successful project in 2023, where NEDCON supplied pallet racking for Cotap, the family company approached us again. Cotap, a leading flooring specialist for the retail sector, is preparing for a major next step in its development: relocating its headquarters from Genemuiden to a brand-new distribution center in Zwolle. Together with our partners Montac and Magazijnplein, we started working on this project for Cotap again. In this second phase, we not only supplied new pallet racking but also shelving systems. The new distribution center, including headquarters, located just behind the existing building in Zwolle, will become the heart of Cotap’s logistics operations, especially for Intergamma.

23,952 pallet locations 950 shelving boards 10 weeks installation time

& capacity

The pallet racking with 6 beam levels is designed to support heavy loads of up to 3,750 kg per beam level. They provide a safe and stable solution for heavily loaded pallets.

For this project, we developed a special solution with two narrow frames in depth, totaling 1,600 mm deep. This ensures that we can store five different pallet sizes.

The result

A future-proof storage solution that matches Cotap’s growth ambitions. Thanks to the collaboration between Cotap, NEDCON, Magazijnplein and MonTac, the foundation is laid for safe and efficient logistics at the new facility in Zwolle. And the next project request has already been initiated. This is a clear sign of trust and a great continuation of a pleasant partnership.

For this project, we collaborated with MonTac BV from Zwolle, Marc-Willem ten Duis, and our reseller Magazijnplein.

When our colleague Jack Boh was asked to share something about his workdays at NEDCON his creative spirit took over.

Curious to see working at NEDCON through Jack’s eyes? Read his poem!

One Day, Today - Col. Jack E. Boh

Jack got up, he went to see To see just what the time might be.

Oh me, oh my! Is he the guy?

The one up first? Is he the guy?

He is, at least, on paper! It seems The one named Max, he no longer dreams. But sings to himself a sweet little ditty, “Somebody once told me the world is gonna roll me”

“He’s up, but he’s happy”, Jack sighs with a grin, Who has not one hair on his chinny chin chin. So he forgoes the razor and hops in the tub. But the water starts cold! Therein lies the rub!

But lucky for him, the water heater’s there, To put on a show of affection, of care. At the flash of a candlestick, Jack’s all freshly cleaned, Then clothed and alone, he exits the scene.

He wakes his son Lukas, who’s all but aware, That today’s a school day, oh the horror, the terror!

“It’s not all that bad”, Jack says with a smile.

“But you get to go to NEDCON for a while!”

“And I have to sit in a classroom, quite sane, And have facts and ideas squeezed into my brain

For I am but a child”, Lukas states rather proud, “and are children not meant to go play and be loud?”

Jack answers “and just what do you think I do When I go into work for an hour or two?

Well, it’s longer than that, but you know what I mean. I spend almost 8 hours in front of a screen”

“Except to grab coffee, to chat with a friend. Or to go for a walk before break’s at its end. For sales are important, but friendship and health Will carry the team, and there’s the true wealth.”

“As a Sales Engineer, I help NEDCON to grow But through humor and friendship, I let everyone know, What I do with my time here is not merely make cash But to go make a difference, while having a bash.”

“So go to first grade, and then on to the next, So one day you too can join NEDCON’s group text. Where outside work hours we share all sorts of things. Camaraderie, not sales, is just what it brings.”

“And remember, tomorrow might feel like the same, But tomorrow’s tomorrow might not be so lame. So always work hard and someday you’ll be Privileged to work here at NEDCON like me.”

Here are my two sons, Lukas (6) and Maximilian (3), while hiking at our local park. We like to go to England-Idlewild Park in Burlington, Kentucky on the weekends to ride bikes/scooters and hike on the trails.

Honey Nut Cheerios are my favorite snack! Come to the US office, and you’ll find me eating them on an hourly basis. When I die, my gravestone will be sponsored by General Mills.

Here I am, playing my new guitar in the NEDCON USA office at lunch. I’m lucky that none of my coworkers are musicians, otherwise they would’ve called me out on all my mistakes! I shopped for almost an entire year before colleagues Dennis and Sarah convinced me that this guitar was the one! And they were right! Every evening, once the kids are in bed, I play guitar for an hour or so.

Here’s the whole family over the summer. Given how often we get our pictures taken, it sure feels like a daily activity…

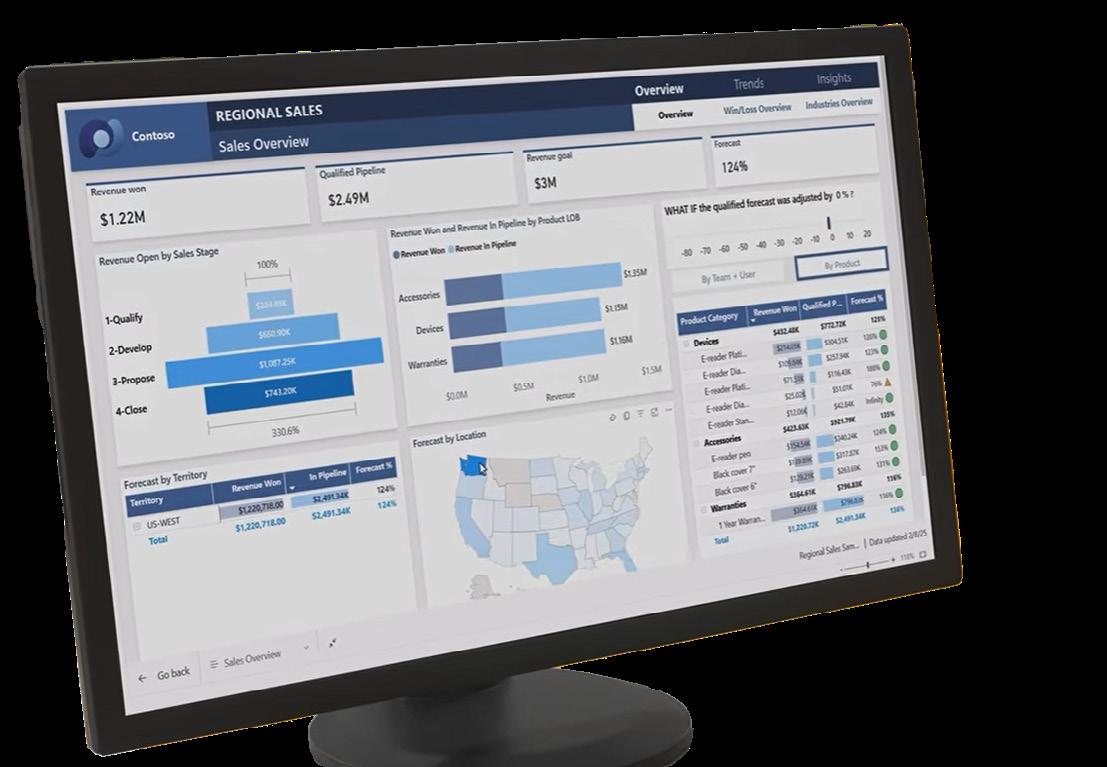

In a world where data drives decisions, our organization is taking a bold step forward with a strategic Business Intelligence (BI) initiative. A project was initiated to guide us through this process. In this article, we would like to give you some insights into this project.

Focused initially on our sites in Doetinchem and Pardubice, this project lays the foundation for a data-driven culture, where reliable insights are always within reach. At the heart of this transformation is Power BI, our central tool for reporting and analysis. Built on a robust technical infrastructure using Microsoft Azure and Microsoft Fabric, we’re creating a scalable, secure environment for collecting, managing, and visualizing data across departments.

To make this happen, we focus on three core streams:

Technical infrastructure: Azure provides a cloud-native platform for large-scale data collection and processing. Fabric integrates data engineering, science, and real-time analytics into one cohesive system.

Data management: Clean, structured data is essential. By promoting awareness and ownership of data quality, we ensure that our dashboards are trustworthy and actionable.

Power BI dashboards: Once the technical and data foundation is in place, Power BI transforms raw data into clear, interactive dashboards. Accessible to everyone, from shop floor to boardroom. These insights help us optimize processes, improve quality, and make informed decisions at every level.

The core team

This project is made possible thanks to the dedication and expertise of a multidisciplinary core team. Here’s an overview of the project members:

Michel van Dijk – responsible for establishing the Data Management Framework and leading the team.

Ilona Klinker & Bhavya Villangat – leading the technical implementation and architecture.

Carmen Raben & Johan Schapendonk –translating business needs into concrete Power BI use cases.

Jaap Bakker – providing IT technical support.

Jaroslav Nedobity & Jiri Raab – offering temporary support from our production site in Pardubice; long-term successors are being sought.

Good collaboration is essential to bridge the gap between IT and business, ensuring our BI solutions are both technically robust and practically valuable. We’re also grateful for the input and support we receive from all levels of the organization, because your involvement is key to making this a success.

We expect to complete these initial steps by Q2 2026, with a small number of official dashboards up and running. From there, the rollout will expand across all levels, from strategic to operational. This process will take time to connect all departments and use cases, but it is so worth it!

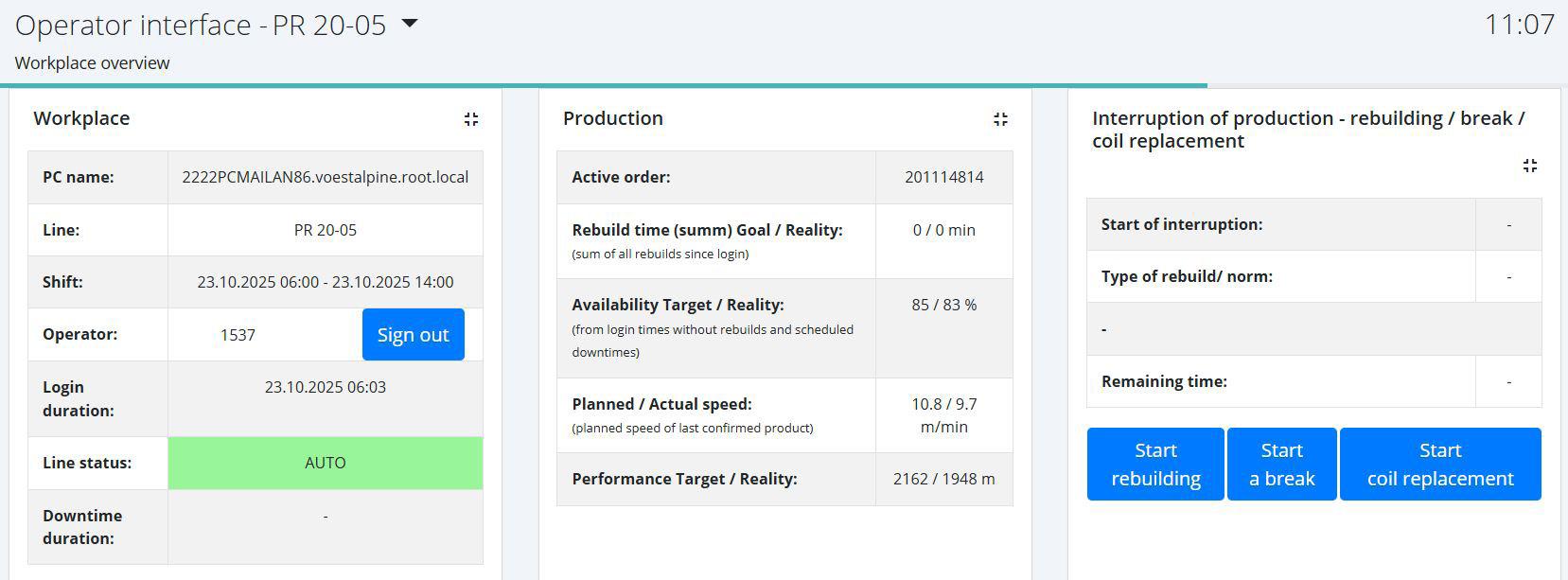

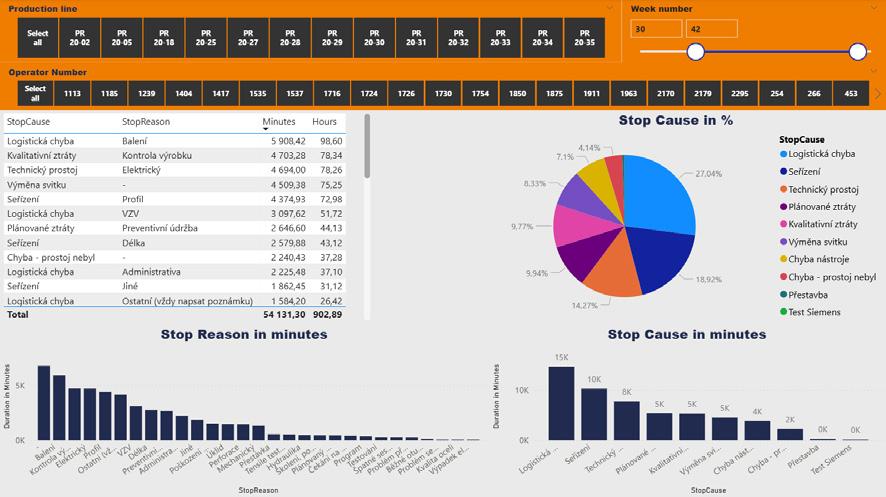

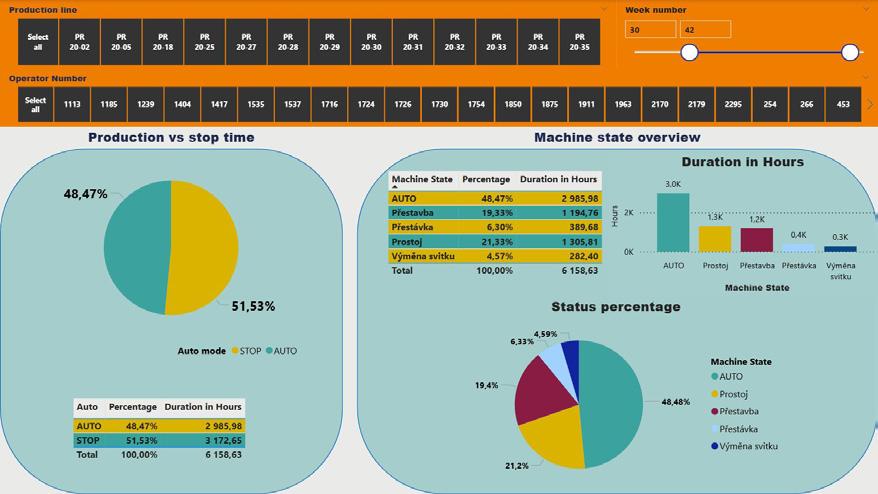

OEE Siemens business case

One standout example is our OEE (Overall Equipment Effectiveness) dashboard. This cross-site collaboration between Doetinchem and Pardubice shows how machine data can be visualized in real time to improve production quality. It measures how well our machines convert planned production time into high-quality products.

OEE measures:

Availability: Shows if the machine is running when production is scheduled. When it stops for more than 30 seconds, the operator needs to record the reason for this stop: Rebuilding, Break, Coil exchange, or other Standby (specified with an additional Stop code).

Performance: Provides important information on whether the machine is working at the right speed. Data from SAP brings the planned speed, and we compare it with the actual.

Quality: Shows if we are producing defect-free items. We compare confirmed good products against consumed raw material.

These metrics are combined into a single score that highlights efficiency. With Power BI, operators and managers can monitor performance live, identify bottlenecks and take action quickly.

It helps us to analyze key pain points. Our current focus is on:

Stop-code overview: Collects reasons why our machines do not work or why they stopped Rebuilding analysis: Points to downtimes due to machine adjustments and compares suggested and actual durations.

Work order analysis: Shows the difference in production performance from SAP against the actual performance during the production shift.

Most metrics are calculated automatically and visualized in dashboards accessible to operators and managers for daily online shop floor control. OEE helps us see where we lose efficiency and guides us to make production more reliable and cost-effective.

Our goal: increase line availability from 45% to 55% by year-end.

Insight into trends and long-term numbers is given to us thanks to the connection of the OEE database to Power BI. After two months of working with this business intelligence tool and delivering a few long-term dashboards, we can say that our decision to use it was completely right.

From dashboards to Automation & AI (Artificial Intelligence): Making data work for us

Tools like the OEE Siemens dashboards and Power BI help us visualize and understand what’s happening, from performance indicators to operational trends. These insights support teams in identifying opportunities and making more informed choices.

We recognize, however, that we’re not ready to take every step toward automation and AI all at once. Legacy systems and existing infrastructure present real challenges. That’s why every improvement, whether small or large, contributes to the bigger picture. By using the data tools we already have, we can take practical steps toward systems that help us work smarter and respond more quickly.

Automation and AI are not separate from BI, they are a natural next step. As we continue to grow in data maturity, we’ll begin exploring practical use cases that add value, such as automated alerts, data-driven recommendations, and predictive insights. It’s a journey, and each step forward helps us unlock more potential from the data we already collect.

Curious what BI, OEE and/or AI could mean for you/ your team? Feel free to reach out to us!

Michel van Dijk (Project BI)

Jiri Raab (Siemens OEE)

Bram te Woerd (Automation & AI)

In the previous edition of our NEDCONNECT magazine our colleague Joe Seither gave us a glimpse into his life beyond the office. He is a passionate stand-up comedian.

So welcome to our new column Joke with Joe!

Tragedy struck late last night, as a man fell from the roof of a 20-story nightclub. Eyewitnesses confirm he was not a bouncer.