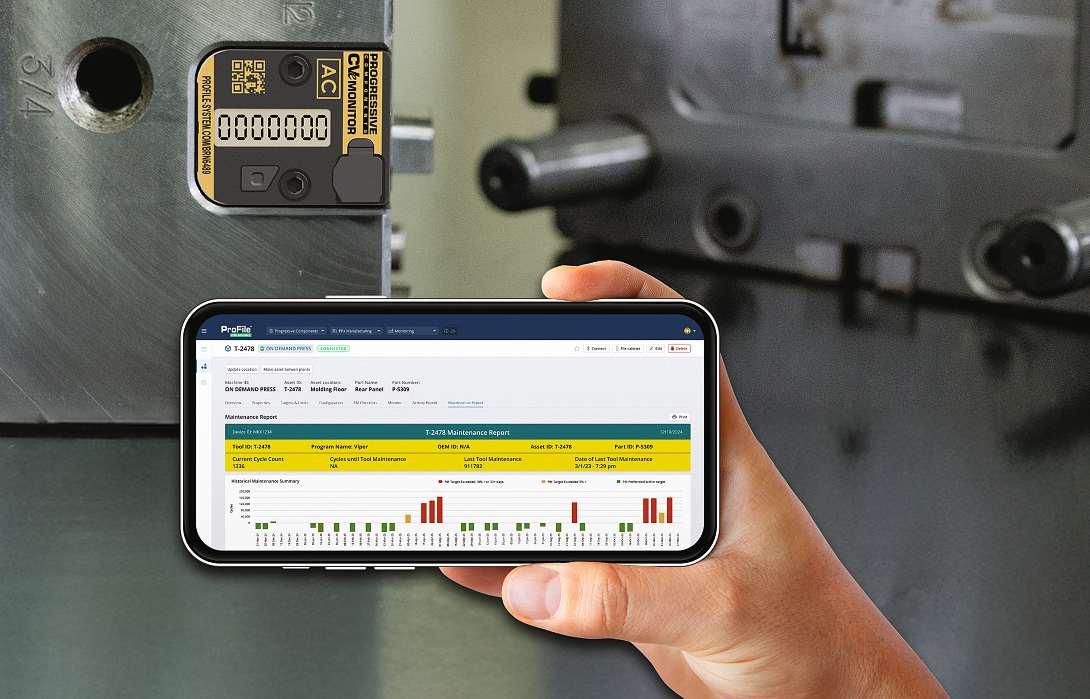

GAIN ACCESSTOYOUR TOOLS WITH THE CVeACMONITOR.

TOTAL MOULD CONTROL

Those responsible for theperformance of mouldsacrossmultiple locations can now access keydata through the new CVe AC:

•Historical cycle counts and timing data.

•Temperature and efficiency metrics.

•Noadded hardware,Bluetooth pairing with smartphones.

•Preventive maintenance tracking.

This innovation addstothe options fromthe ProFile Mould Management platform. Choose from AssetTags, Counters, and real-time Monitors to gain access and controlofyour fleetofinjectionmoulds.

One-sideddeal: Toolmakersunder pressure

For Europe’s machine and mould manufacturers, it is a blow that waswrittenonthewall:TheUSisintroducingflat-ratetariffsof 15 percent on all EU goods, supplemented by a continuing 50 percent levy on steel, iron and aluminium products In return, US exportstotheEUremainduty-free–aclearcompetitivedisadvantage that the EU has so far been unable to counter

The flat-rate nature of the tariff is particularly irritating While possible tariff quotas for steel products are at least being discussed, there is still a lack of clarity as to which industrial goods could be exempted Butonethingiscertain:highlyspecialisedmouldmakingin particular is coming under pressure – US customers will have to pay significantlymoreinfuture,eventhoughtheywillcontinuetorelyon European quality

ThefactisthataroundhalfofthemouldsusedintheUSareimported – many of them from Europe. The imported share for plastics processing machines is also around 70 percent Production in the US cannot meet demand on its own – certainly not in the quality and variety that European suppliers deliver. The tariffs jeopardise establishedsupplyrelationshipsandmakeplanningdifficultonbothsides of the Atlantic. Nevertheless, it is precisely this key industry that is now to be subject to tariffs

Despitethesechallenges,thereiscautiousoptimismintheEuropeanindustry.AstheVDWreportsintherun-uptoEMOHannover2025, themoodandexpectationsarebrightening.Investmentprogrammes andtechnologicalinnovationssuchasdigitalisationandautomation are providing positive impetus "Expectations and the general mood amongcompaniesinGermanyandEuropearenoticeablyimproving," says VDW Managing Director Dr Markus Heering

Transatlantic relations are being put to the test. Europe now needs tostandupforitsindustrialpolicyinterests,boostitscompetitiveness, and clearly commit to rket EMO 2025 nd i tant signal: medi crisis-proof –sert their rol

EDM-TECoHG stands forknow-how and highest productqualityinelectrical discharge machining. We areyourcontact forconsumablesintool andmouldmaking !

COVERSTORY

Meusburger digital portal p. 16

How Meusburger’s new digital portal enhances support for mould and die makers through advanced configurators and streamlined order management

Subscribe to our newsletter

▪ etmm-online/newsletter

▪ facebook.com/ETMMMagazine

Events

▪ etmm-online.com/events

Suppliers database

▪ etmm-online.com/suppliers

Photo galleries

▪ etmm-online.com/galleries

Industry news

▪ etmm-online.com

ETMM Media

▪ media.vogel.de/etmm

NEWS

BY

THE NUMBERS

6 Imports dominate as U.S. plastics machinery shipments fall

NEWS STORIES

8 New brand for plastics trade fairs

TRADE FAIRS

12 Global momentum builds ahead of EMO 2025

14 EMO 2025: Trade fair preview

REPORTS

MARKETS

10 EU drives circular reform in car design

HOT RUNNER SYSTEMS & COMPONENTS

20 KHS and Husky push PET bottle weight limits

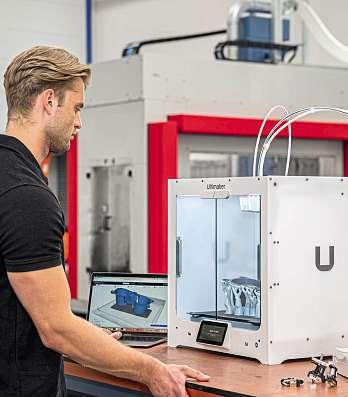

COMPONENTS

22 Smarter moulding with thin-film sensors

INJECTION MOULDING

24 HSK expands with 2.5 million euro investment

27 PMMA parts shine in Opel's new electric SUV

CAD/CAM & SOFTWARE

28 A brief history of simulation in CAM software

CUTTING TOOLS

32 Smarter tools for shorter cycles

MACHINING EQUIPMENT

34 Why CNC machining is still the gold standard

37 Ament Plastics optimises thermoset machining

38 Larger components produced a third faster in half the space

MACHINING ACCESSORIES

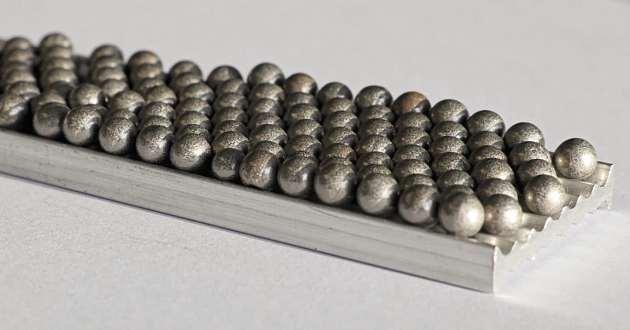

40 Cut the rattle: New material improves machine stability

ADDITIVE MANUFACTURING

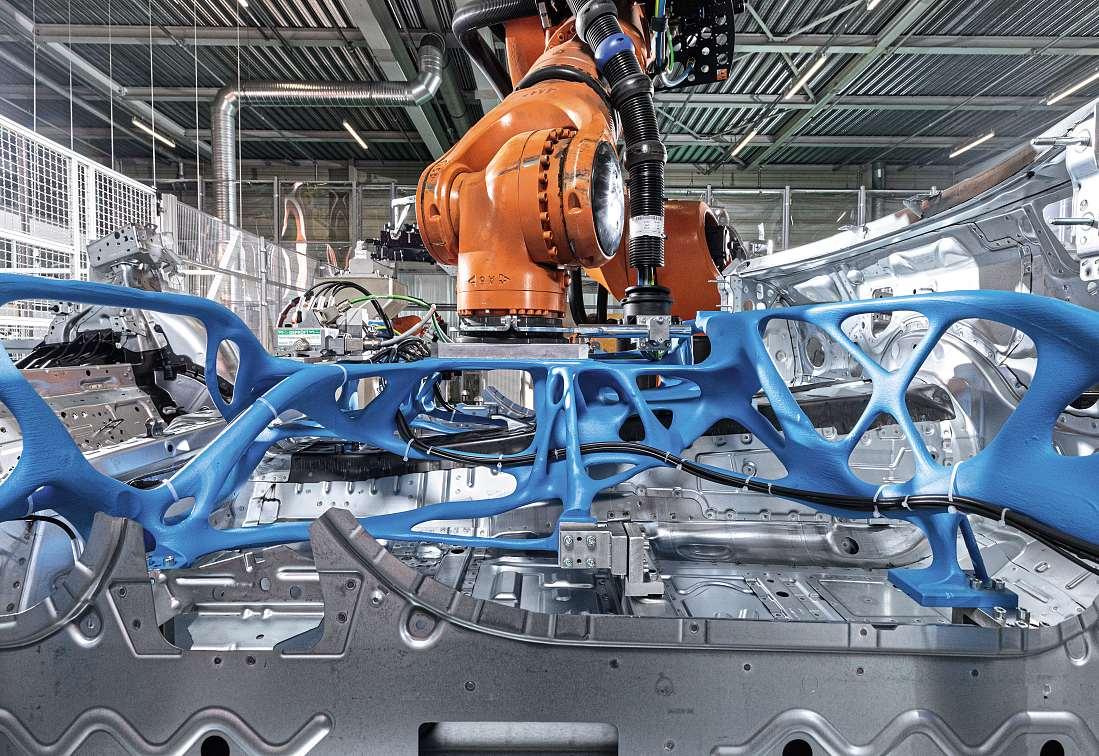

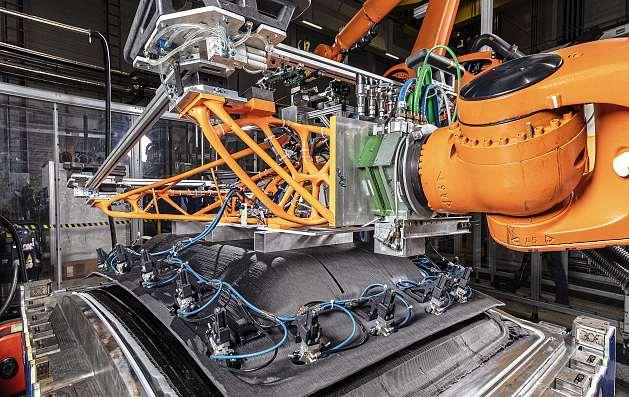

42 BMW scales up 3D printing in production

45 Ultimaker 3D printer for an affordable entry into additive manufacturing

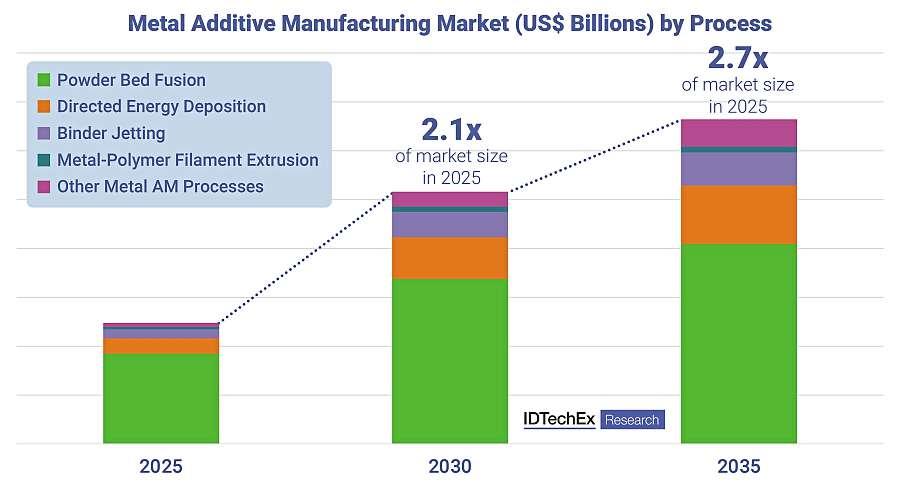

46 Trends impacting Metal Additive Manufacturing's future

QUALITY CONTROL

48 Precise surface inspection with AI-powered camera network

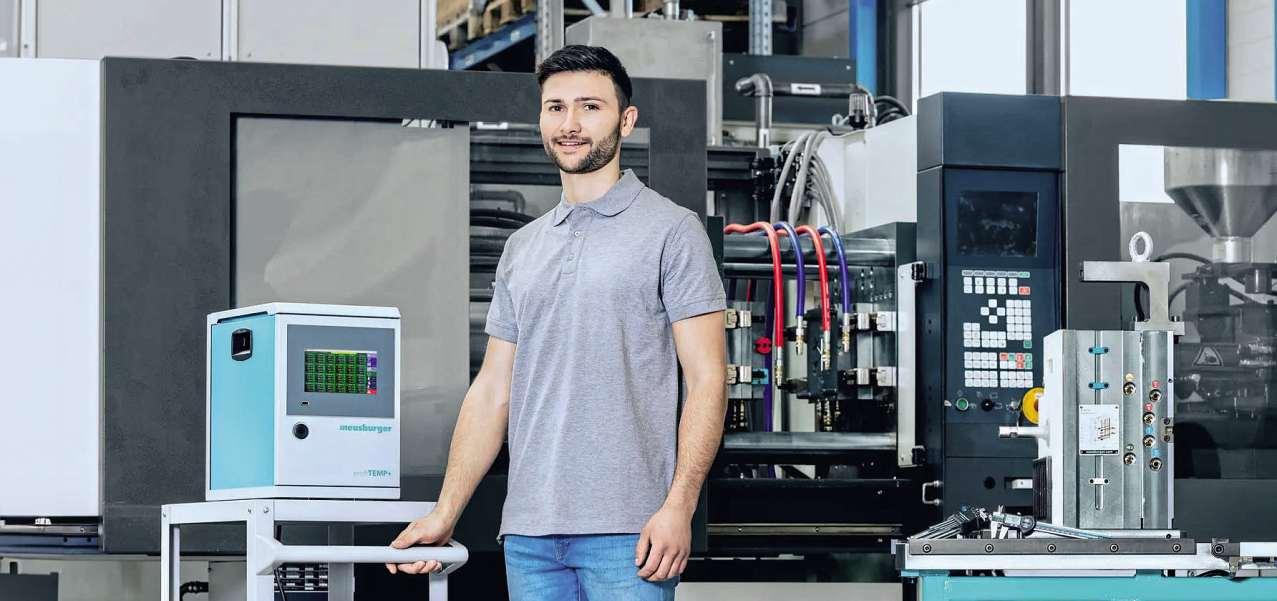

The range of Meusburger includes a broad spectrum of products that are specifically tailored to the needs of injection moulders.

3 Editor’sMessage 49 Masthead 50 ISTMAWorldNews Ranking June/July’s most-clicked articles on etmm-online.com

Additive Manufacturing: BMW scales up 3D printing in production

Machining Equipment: DMG Mori to present eight world premiers at EMO 2025

Machining Equipment: Vision laser replaces wire erosion in tool manufacturing

Hot Runners: KHS and Husky redefine lightweighting with ultra-light PET bottle 5. Machining Accessories: Cooled rack and pinion drives solve thermal challenges in machine tools

ImportsdominateasU.S.plastics machineryshipmentsfall

Trade tensions and tariff uncertainty are taking a toll: U.S. plastics machinery shipments dropped sharply in early 2025, while imports from Europe and Asia continued to dominate.

TariffuncertaintyweighsonUSplasticsequipmentshipmentsinearly2025

Plastics machinery shipments from US manufacturers declined for the second consecutive quarter in Q1 2025. The total shipment value was estimated at 252.1 million dollars, representing a 17.5 percent decrease from the revised fourth-quarter estimate and a 4.6 percent decline year-over-year

Source: Plastics

As of October 2024, U.S. plastics machinery imports year-todate were estimated at 2.9 billion dollars. The top five countries of origin — Germany, Canada, Austria, Italy, and Japan — accounted for 67.4 percent of total imports in 2024.

Source: Plastics

CREATING TOOL PERFORMANCE

walter-machines.com

PRECISION INSPECTION SOLUTIONS

LKMetrologyacquiresProconX-Ray

Best known as a manufacturer and global supplier of coordinate measuring machines (CMMs) and more recently laser scanning sensors, LK Metrology, based in Castle Donington, UK, announces the acquisition of Procon X-Ray, a specialist German manufacturer of computed tomography (CT) systems. With this strategic acquisition, LK Metrology broadens its portfolio of high-precision inspection solutions to include industrial CT imaging, strengthening its position as a long-established provider of metrology systems.

Foundedin2003,ProconX-RaydevelopsandmanufacturesmodularCTandX-rayinspectionequipmentforindustrialandscientific applications. Its systems are renowned for high-resolution focus X-ray technology, as well as customisable hardware and software. They are used worldwide in the automotive, aerospace, electronics, medicalandmaterialsresearchsectors.Throughthisacquisition,LK Metrology can now offer a wider range of products for inspection and measurement from a single source (ast)

K-ALLIANCE

Newbrandforplasticstradefairs

Messe Düsseldorf launches K-Alliance as new global brand.

In October 2025, more than 3,200 exhibitors from around theworldwillpresent a wide range of technologies for manufacturing, processing, and finishing at K in Düsseldorf At the previous edition three years ago, nearly 178,000 trade visitors from 167 countries attended the event to explore live demonstrations by machine manufacturers, raw material suppliers, and processors

Inadditiontothisleadingtradefair,whichtakesplaceeverythree years as a central platform for innovation in the sector, companies in the plastics and rubber industry rely on additional platforms to access growth markets directly. Untilnow, MesseDüsseldorf’s international trade fair activities in this field were grouped under the service brand Global Gate. This brand will now be replaced by the new umbrella name K-Alliance.

“The previous name especially emphasised Messe Düsseldorf’s functionasadooropenerforenteringpromisingsalesmarkets.The designationK-Alliancenowplacesaclearerfocusonthestrongpartnerships and alliances,” says Thomas Franken, Director of K (ast)

ONGOING MARKET WEAKNESS

Trumpf:Salesdown17percent

High-techcompanyTrumpfendedthefiscalyearasexpectedwitha decline in sales and order intake. According to preliminary calculations,inthefiscalyear2024/25(endingJune30,2025)thecompany generated sales of 4.3 billion euros (fiscal year 2023/24: 5.2 billion euros), with an order intake of 4.2 billion euros (previous year: 4.6 billioneuros).InitshomemarketofGermany,salesfellby15percent to around 700 million euros (previous year: 824 million euros). Germany thus remained the strongest single market in terms of sales. Trumpfalsorecordedadecline insalesintheUS Thesefellby 17 percent to approximately 660 million euros (previous year: 796 million euros). Despite a decline by 22 percent, China was still the strongest Asiansinglemarketwithsales of around 480 million euros (previous year: 615 million euros)

T rumpf

Trumpf CEO Nicola Leibinger-Kammüller said: “There were no signs of a real turnaround in the third consecutive year of crisis, either economically or geopolitically. Nevertheless, we believe that we have now reached the lowest point.” (ast)

ACCESS TO NEW MARKETS JSPacquiresGhepiandHapp

Japanese plastic foam specialist JSP has completed the acquisition of the remaining shares in Italian plastics manufacturer Ghepi and German firm Happ Both companies are now wholly owned subsidiaries of JSP According to the company, the acquisitions support a pan-European strategy to expand its injection moulding division.

The move is part of JSP’s long-term ‘Vision 2027’ strategy, which focuses on diversification and investment in new business areas, particularly injection moulding By extending its reach beyond established regional markets, the group aims to broaden its expertise in polymer materials and processing technologies.

Ghepi brings core competencies in the production of metal replacementcomponentsandisactiveinmarketspreviouslyuntapped by JSP Happ, meanwhile, is distinguished by its highly automated productionlinesandin-housemould-makingexpertise.Withthese acquisitions, JSP intends to enhance its enterprise value and drive growth across Europe. (ast)

A bench-top CT-Mini computed tomography (CT) system manufactured by Procon X-Ray.

Trumpf CEO Dr. phil. Nicola Leibinger-Kammüller Sour ce

JSP has acquired the remaining shares in Ghepi and Happ.

New EU regulation aims to boost reuse, recycling and recycled plastic content across the automotive sector

END OF THE ROAD, START OF A CYCLE

EUdrivescircular reformincardesign

The EU Parliament aims to boost circularity in the automotive sector with new rules on vehicle design and recycling. The proposal includes targets for recycled plastic, stricter end-of-life treatment, and clearer export rules.

WRITTEN BY

AlexanderStark

Managing Editor

In early July, the Environment (Envi) and Internal Market (Imco) Committees of the European Parliament adopted their joint proposals for a new EU regulation covering the entire vehicle lifecycle — from design to end-of-lifetreatment.Theobjectiveistoensurethatnew vehicles are designed to support reuse, recycling and recoveryfromtheoutset.Theregulationwouldapplyto cars and vans one year after it enters into force, with a longertransitionperiodoffiveyearsforbuses,heavy-duty vehicles, trailers, motorcycles, quads, mopeds, and minicars.Exemptionsareforeseenforcertaincategories, such as special-purpose vehicles and those of historical or cultural interest Additionally, vehicles built specificallyforthearmedforces,civildefence,emergencymedical services and fire services would be excluded.

The legislative review is part of the broader European Green Deal, which aims to promote circular business modelsbylinkingdesignwithend-of-lifetreatment.Under the proposed rules, vehicles would need to be designed for easy disassembly by authorised treatment facilities, enabling parts to be reused, recycled, refurbished or remanufactured.

MEPsarealsocallingforamandatoryminimumof20 percent recycled plastic in each new vehicle within six years of the regulation’s start. If sufficient recycled plastic is available at reasonable cost, this target should rise to 25 percent within 10 years to support long-term planning and investment.

Virginia Janssens, Managing Director at Plastics Europe, welcomed the 20 percent target but emphasised:

“WhilewewelcometheParliament’scallfora20percent recycledtargetinnewvehicles,webelievethattheCommission’s proposal of 25 percent is not only achievable but essential. A 25 percent target would help create the marketpullessentialforathrivingcirculareconomy,but reaching it requires urgent action: clear policies that attract investment in circular plastics, cut red tape, and ensureagloballevelplayingfieldforEuropeanindustry.”

PlasticsEuropealsoexpressedconcernovertheexclusion of bio-based plastics from the regulation’s targets.

“This is a missed opportunity A future-proof policy framework must recognise the role of plastics made fromsustainablesources,suchasbio-basedfeedstocks,” said Janssens. To support recycling efforts, the industry group proposes that bio-based and carbon capture–based plastics contribute no more than 5 percent to the overall target — “a balanced approach we hope to see reflected in the final legislation.”

Theproposedregulationintroducesextendedproducer responsibility for manufacturers, requiring them to coverthecostsofcollectionandtreatmentofend-of-life vehicles Italsosetsspecificrequirementsfortheremoval of fluids and components containing gases, refrigerants,orhazardoussubstancespriortoshredding MEPs arecallingonnationalauthoritiestostepupinspections oftreatmentfacilitiesandestablishtargetedinspection plans to combat illegal activities Used vehicles would

only be permitted for export if they do not qualify as end-of-lifevehicles.TheParliamentalsoproposesclearer criteria and documentation requirements to assist customs authorities in identifying ELVs

The European Automaker’s Association ACEA welcomed the Committee’s Report on End-of-life Vehicle Regulation as a significant step towards enhancing the autosector’scircularityandimprovingthemanagement of ELVs containing valuable and critical raw materials.

ACEA particularly welcomes the inclusion of pre-consumer plastics in the calculation of recycled content targets,thisensuresthattargetsremainachievableand aligned with manufacturing realities. Nevertheless, a phased-in approach is essential due to the current lack ofhigh-quality,safeandautomotive-graderecycledplastics on the market.

“The Parliament has made notable progress, particularlyonrecycledcontent,”statedSigriddeVries,Director GeneralofACEA.“Butcrushinglegalandfinancialrisks placed unfairly on truck and bus manufacturers, are a seriousconcernatatimewhenthesector’scompetitiveness hangs in the balance,” de Vries added. Clear rules and fair responsibility sharing would be essential to make this Regulation workable in practice, he added.

There are 285.6 million motor vehicles on EU roads and every year around 6.5 million vehicles come to the end of their lives. (ast)

ETMM-TIP

For the latest updates, exhibitor highlights and program details, visit the official EMO Hannover 2025 website at www emo-hannover.de

MANUFACTURING’S FUTURE ON DISPLAY

Globalmomentumbuilds aheadofEMO2025

From AI chatbots to climate-neutral factories: EMO Hannover 2025 is set to chart the future of manufacturing. As global challenges meet cutting-edge innovation, the trade fair signals a confident turnaround, driven by digitalisation, automation and sustainability.

Astheglobalmanufacturingcommunityprepares forEMOHannover2025,theleadingtradefairfor production technology is sending strong signals ofmomentumandoptimism.FromSeptember22to26, 2025, Hannover will once again become the focal point for international innovation, showcasing cutting-edge technologies in automation, artificial intelligence (AI), sustainability and competitiveness

The industry is facing numerous challenges, which it is tackling with technical innovations and globally oriented strategies. In the run-up to EMO, there are signs that the general conditions are improving again. “The current business situation is certainly difficult, but the

expectations and general mood among companies in Germany and Europe are improving,” says Dr Markus Heering, Executive Director of VDW, event organiser of EMO Newpolicysettings,federalgovernmentspending programs, support for investment, the resolution of the trade dispute with the USA and technological trends such as digitalisation and automation are having a positive impact on the investment climate. The machine tool industry is positioning itself confidently in this environment.

Againstthisbackground,theEMOorganiserisalready reporting high international engagement. Dr. Markus Heering recently concluded a world tour across three

EMO Hannover 2025 sets the stage for the next era of manufacturing technology.

continents, 27 countries, and 35 cities — where he met with industry leaders, exhibitors and journalists who shared their anticipation for EMO “Despite global uncertainties, we expect positive signals from EMO,” Heering said at the international preview event held in July in Frankfurt am Main.

Innovationsevery90seconds

EMOreflectsthecurrentmegatrendsofautomation,digitalisation, artificial intelligence (AI) and sustainability, explained Heering. This was also confirmed by the 26 exhibitors who were present at the preview. In 90-secondpitches,theydescribedtotheaudiencewhatvisitors can expect to see on their EMO stand in September An entertaining,thoroughlysportyforay,butonethatledto various in-depth discussions, also during the evening boattripontheRiverMain.Manyofthepitchesrevolved around new machines and features, tools, automation or quick-change systems (“time is money”). It was all about process optimisation and the use of robots with intelligentsoftwareorautonomoustransportsystemsin thefactory Sustainabilityconceptswerediscussed,with long-lasting machines and retrofitting for a second life, as well as the question of how the CO2 footprint of machines can be reduced. The topics of sustainability and energy efficiency were also to be addressed on the second day of the preview, during which a tour of the ETA factory in Darmstadt, a model factory of the Technical University, was on the agenda and where the focus was on research for the climate-neutral factory

The innovations presented in the three pitch rounds alsoaddressedsolutionstotheshortageofskilledworkers, for example machines with intuitive machine controls to show how easy high technology can be.

EconomicForumatEMO2025

VDWishostingtheEconomicForumforthefirsttimeat EMO 2025. The focus during the event held on September 9 from 2 to 4 pm will be on the prospects for top customerindustriesinmetalworking Ontheonehand,the developmentandintegrationofnewtechnologiesopens upadditionalmarkets.RolandSommer,HeadofShared ServiceProductionatmachinemanufacturerKronesin Neutraubling, Germany, says: “The intelligent use of automation and digitalisation in discrete manufacturing is more important than ever in today’s world Added value can only be generated through the right interactionbetweenthemachinetool,theemployees,thedata and the networking of processes.” On the other hand, a positive mindset can help drive positive outcomes. Eric Müller, CTO — High Pressure Die Casting at Italian automotive supplier Gnutti Carlo Group in Maclodio, emphasises: “As the world’s leading trade fair that brings together the world’s leading metalworking companies, EMO offers us the opportunity to bring European production back to the top!”

Infact,theagreementjustreachedinthetariffdispute betweentheUSAandtheEUcreatesareliableplanning foundationforinvestments,atleastintheshortterm “A flat-ratetariffof15percentwillofcourseraisetheprices ofmachinesandcomponents.Howthisaffectstheindividual customer industries will certainly be a topic of discussion at the EMO Economic Forum,” concludes Dr. Heering (ast)

Thecompact solution forversatile 5-axis machining–economical,progressive, convincing

Even thebasic versionofthe newmilling machineis designed foruniversal 5-axis millingwithpositioning, as well as for5-axissimultaneousmachining

•Versatile:for smallseriesproduction, dynamic 5-axis precisionmachining and training

•Generousswing circle of Ø500 mm offersspace forclampingdevices

•ModernHeidenhainTNC7control system with touchoperation

•Optimum visibility and accessibility

•Can be automatedwithpalletorparts handling

Discoverhow the PICOMAX550/550 PRO sets newstandards in 5-axis machining

SMART MACHINING SOLUTIONS

Automationmeetsprecision

Fehlmann Maschinenfabrik will showcase efficient solutions for modernmanufacturing The focus will be on innovative machine tools andflexibleautomation systems for single-part and small-batch production.

The new Picomax 550 PRO takes center stage at the booth. This compact, user-friendly, and versatile 5-axis CNC machine offers high precision, ease of use and powerful components. For the first time, it will be shown with an integrated automation solution: A fast, compact 6-axis robotic system automatically loads and unloads workpiece pallets. Both the CNC machine and robot are centrally controlled via the Fehlmann MillingCenterManager(MCM) Torquedrives,compactdesign,and intuitivecontrolmakethesystemhighlypreciseandspace-efficient. Thanks to the open system architecture of Fehlmann machining centers, they can be integrated into a wide variety of production environments–includingconnectionstocontrolsystemslikeErowa, Soflex, Promot, or barcode-based tool identification. www.fehlmann.com

DIGITALISED MANUFACTURING

Advancedworkholdingsolutions

Roemheld’s approach to Industry 4.0 is rooted in mechatronics. It involves enhancing existing hydraulic and pneumatic clamping devices with a powerful combination of mechanics, electronics and software. The innovative strategy ensures that even for applications demanding high clamping forces, where hydraulic solutionsremainthepreferredchoice,thebenefitsofdigitalisation may be fully realised.

AttheheartofthisphilosophyisStark.intelligence,asystemwith modular sensors designed to make hydraulically, pneumatically or mechanically operated zero-point clamping systems digital-ready. Each clamp is equipped with its own multi-sensor unit that continuously collects critical information, such as travel (position), temperature and pressure. The data is aggregated by a master unit and transmittedtovariousenddevicesviaanIO-Linkinterface,available inbothinductiveandwiredversions Stark.intelligenceoffersahigh degree of modularity and flexibility, allowing easy installation into machine tables or quick-release pallets. www.roemheld.de

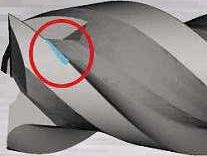

GOODBYE LONG CHIPS! Makingshortworkoflongchips

In metalworking, chip formation plays a central role in process reliability, tool life and surface quality, according to the company. Controlled chip formation is particularly important in the fine machining of unalloyed, alloyed and stainless steels. However, influencing thishasbeendifficultuntilnow.Butwiththedevelopmentofanew, standardised chip breaker geometry for its fine boring inserts, the cutting tool manufacturer Mapal from Aalen has now taken a decisive step in this direction. The innovation is expected to bring both technical and economic advantages when it comes to machining long-chipping materials.

Thenewdevelopmentcombinesapreciselydefinedrakeangleand chipanglegeometrywithoptimallycoordinatedcuttingvaluesand cutting depths This precise coordination perfectly influences chip formation and breakingbehaviour—even with demanding materials. Machinists benefit from optimal chip removal, reduced heat generationandsignificantly increased process stability The new approach to chip breaking will be presented at EMO Hannover 2025. mapal.com

SMART AUTOMATION Machinesforeveryproductionneed

Exhibitingunderthetheme‘Experienceinnovation,empoweryour future’, Mazak’s stand at EMO will highlight the benefits of a real partnership between machine manufacturer and user, with a stand thatplacescustomersuccess,smartautomationanddigitalintegrationattheheartofmodernmanufacturing Visitorswillexperience a comprehensive showcase of new machine tools, connected technologies and expert support services.

TheMazakstandwillhostatotalof20machinesthathighlightthe breadthofthetechnologiesavailable,from3-axislathesandvertical machiningcentresofferinganaffordableintroductiontotheMazak brand and the latest additions to the most sophisticated Integrex levelofMulti-TaskingandAutoGeartechnology.Thenewmachines on show will include the new Integrex j-200 NEO — shown for the firsttimeinEurope—whichcombinesoutstandingproductivityfor complex high-mix/low-volume batch work with an attractive price from the pioneers of Multi-Tasking machining www.mazak.com

LASER TECHNOLOGY

Visionlaserreplaceswireerosion

The latest Vision Laser laser processing machine from WalterMaschinenbauoffers laser technology for a wide range of applications for brazed tools in modern tool production. The design of the machine is based on the HelitronicVision,whichhas been tried and tested and reliable for decades. The laser technology used offers industry-proven reliability for the precise and efficient laserprocessingoftoolswith high quality requirements.

The Vision Laser enables efficient, contact-free processing of a variety of tool materials, including PCD (polycrystalline diamond), CVD (chemically deposited diamond), MKD (monocrystalline diamond) and carbide. It is ideal forapplicationssuchasendmills,ballnoseendmills,steptoolsand more. The Vision Laser ensures chipping- and crack-free cutting edges across a wide grit range, boosting performance and wear resistance. Even highly complex geometries — such as chip breakers and concave internal contours — can be produced with maximum accuracy Theprocessisresource-efficient,asiteliminatestheneed for consumables like cooling lubricants, filters or wires www.walter-machines.com

CUTTING TOOLS

Future-readytoolmanufacturing

One focus of Anca’s trade fair appearance is Ultra technology — a combination of high-precision axis control, intelligent servo algorithms and an integrated precision package consisting of innovative mechanical components, software and AI. This technology, which is made possible by Anca’s vertical integration, is designed to significantly improve accuracy, repeatability and productivity in grinding

Two new products based on this platform will be showcased: MicroXUltraisahigh-precisiongrindingmachinedesignedforseries productionofmicrotoolswithdiametersassmallas0.03mm.MX7 Ultrawillhighlightthefullyautomatedgrindingofindexableinserts withcomplexgeometries.Thismachineoffersexceptionalprecision and is ideally suited for high-performance insert manufacturing

The EPX-SF stream finishing machine celebrates its market premiere with several upgrades: improved gripper technology, easier drum changes, integrated coating solutions, 45 percent faster loading/unloading and intelligent process-based fine-tuning machines.anca.com

HIGH-TECH MACHINING DMGMoripresents8worldpremiers

Underthemotto‘ManufacturingtheFuture’,DMGMoriwillfeature inhall2morethan40high-technologyproductioncentres,eightof which will be world premieres Altogether, 33 automated manufacturing solutions will be on show.

There will be two new 5-axis machining centres, the new DMC 65 Monoblock2andtheDMU20linear3,bothvertical-spindlemodels, as well as a horizontal-spindle DMC 55 H Twin. The Ultrasonic 60 Precision will go one step further, offering 5-axis milling combined with ultrasonic-assisted machining and a positioning accuracy of 4 μm as standard.

Anew,universalturningmachineintheportfoliowillbethepowerful,versatileNLX2500|12502ndGeneration.Additionally,withits twin spindles and two B-axis tool carriers, the NZ DUE TC will combinethecharacteristicsofahighlyproductiveproductionlathewith turn-mill complete machining capability The DMV 200 and Sprint 420 lathes willalsobenewat the show. All of the world premieres may be automated to utilise their production capacity optimally. en.dmgmori.com

ADVANCED FUNCTIONS

AI-integratedmachiningsolutions

Artificialintelligence(AI)atmachiningcentremanufacturerHeller isalreadyareality,focusedonthecleargoalofraisingtheproductivityofitscustomers.Workingcloselywithpartners,thecompanyhas accumulatedtheexpertiseneededtointegratedigitalsolutionswith AI elements into machining cells and is already applying the technology across three platforms, intended to support machine operators, production planners and service personnel. The way in which these developments are delivering added value will be presented at the EMO 2025 exhibition in Hannover.

Visitors to the stand can witness live demonstrations on two Heller 5-axis machining centres, the HF 3500 and F 5000 Both models are be equipped with new automation solutions for workpiece and tool handling respectively The manufacturing cells enable automated production of complex components.

A new feature to be introducedatEMOprovides customers with an intelligent chat function, ASKme. This tool, integrated into the control interface, provides operators with a ChatGPT-like assistant. www.heller.biz Sour ce : Heller

ThenewMeusburgerportal—

functions,moreoptions!

With its newly expanded digital portal, Meusburger is enhancing support for mould and die makers through improved usability, advanced configurators, and streamlined order management.

Meusburger offers mould makers and injection moulders a wide range of high-quality components and accessories for their production and manufacturingtasks.Truetothemotto‘Everythingfrom onesource’,customersbenefitfromacompletepackage tailored to efficient processes, maximum quality and reliableresultsininjectionmoulding Thecompanyhas a finished goods warehouse of around 18,000 m2 and offers approximately 100,000 items, with 98 percent directly available from stock, which saves customers time and money when purchasing and operating

The standard parts manufacturer is meeting the currentchallengesinmouldanddiemakingwithastrategic combination of increased efficiency and greater digitalisation. Despite a general decline in market volume in theindustry,thecompanyismaintainingitspositionas market leader and focuses on innovative solutions to provide customers with optimum support even in difficult times

“We have been investing heavily in important digitalisation projects for years so that we can get a clear head start,”saysGuntramMeusburger.Thenewonlineportal plays a central role in this regard.

The Meusburger portal is designed to help customers reach their goals quickly and efficiently. Its intuitive interface makes designing easy, while a comprehensive support service ensures smooth operation. Accessible 24/7andavailablein20languages,theportaloffersflexibility and convenience worldwide.

Since its launch in 2024, the new Meusburger portal has continuously evolved through regular updates and functional enhancements. Each improvement aims to expand the digital possibilities for users, making the platform more intuitive, flexible and efficient. With optimised workflows and extended configuration options, the portal now offers even stronger support throughout the entire mould making and injection moulding process.

Meusburger plate configurator sets new standards

The Meusburger plate configurator enables customers to configure and order their plates quickly and easily. Maximum flexibility, short lead times and maximum planning reliability make the configurator a dependable solution, whether square or round plates are needed.

Wide range of possibilities

The plate configurator from Meusburger enables users to put together their desired plate step by step with the help of features such as a check of entered values in the background, a material selection wizard, and interactive selection tables with illustrations. Even the most demanding projects can be realised with the help of the plate configurator Drilled or non-drilled plates, the configurator covers all needs. Customers can also individually configure all plate types of the lengthwise and crosswise mould bases and flexibly adapt plates for die sets to their requirements.

Customised solutions

Meusburger offers eight standardised variations that are optimally aligned to the customers’ needs. The variations 1 to 8 cover a wide range of different predefined machining combinations. Requesting them is very easy. All available materials are heat-treated for stress relief Thanks to optimised production processes, users benefit from maximum quality and short lead times. Special plates are usually ready for shipping in three working days.

All advantages at a glance

The plate configurator provides instant information on price and shipment so that customers always have their projects under their control. A large stock of raw materials guarantees the continuous availability of the plates. In addition, the steel that has been heat-treated for stress relief ensures maximum process safety, as it guarantees reduced warping and enhanced smoothness during machining. The configurator sets new standards in terms of flexibility, speed and reliability in plate configuration and can be tested on the Meusburger portal: www.meusburger.com/plate-configurator.

Sour ce Meusbur ger

Meusburger’s portal helps users configure, order, and manage components with ease.

Time-savingdesign

ETMM-TIP

Discover the full range of functions and tools on the new Meusburger portal at www.meusburger.com/portal-en.

Organised and time-saving work is crucial when it comes to design. That is why the navigation in the new Meusburger portal was designed to be clear and user-friendlydespiteitssize.Designerscannowsavetheir partslistsbasedonthespecificprojectandindependentlyoftheshoppingcart,whichisidealforflexibleworking acrossmultipleprojects.Theresultisahighuseracceptance.Numerouscustomersarealreadyusingtheportal andareenthusiasticaboutthenewfunctions,including KummerWerkzeugbau.“Wehavebeenusingtheportal sincetheverybeginningandfinditeasytonavigate.The systemisclearlylaidoutandself-explanatory,”saysFelix Deutsch, Managing Director at Kummer The company fromOberaachinSwitzerlandhasbeenproducinginjection and die casting moulds in its own factory for more than 50 years and has relied on Meusburger as a supplier for several years.

MeusburgerhasalsosignificantlyimprovedCADdata handling ForFelixDeutsch,itisparticularlyconvenient that the CAD export can be started directly from the productdetailpages,withouthavingtoaddtheproduct to a parts list or the shopping cart first. In addition, the individual configuration of models is more user-friendly and offers direct access to downloads

Ontheproductdetailpages,userswillfindtablesand selection options specially developed for the industry andcustomisedtotheirindividualrequirements “After logging in, the net prices of the products are displayed immediately Thisway,wearealwaysuptodateandcan orderquicklyandeasily,”explainsDeutsch.SIMMeccanica from Ternate, Italy, for example, also benefits from this function The company was founded in 1980 and specialisesintheconstructionofprogressive,blockand transfer dies for the cold sheet processing as well as the construction of special machines “We have been working with Meusburger for a long time and are delighted withtheirextensiveproductrange.Wehavebeenusing the new portal for a few months now, which has considerably accelerated our ordering process,” confirms Mirko Tapparo, designer at SIM Meccanica

“Wehavebeeninvestingheavilyin importantdigitalisationprojectsforyears sothatwecangetaclearheadstart.”

Guntram Meusburger, Managing Director

A clearly structured and user-friendly design facilitates navigation and ensures a smooth user experience. The portal’s wizards and configurators, which offer customers a wide range of options, are particularly advantageous.Theycombinethetriedandtrustedadvantages with optimised and clearer functions

Oneexampledesignedtomakeproductselectioneasy for mould makers is Meusburger’s plate configurator It enables users to put together their desired plate step by stepwiththehelpoffeaturessuchasacheckofentered values in the background, a material selection wizard, and interactive selection tables with illustrations (see additional information in the box) In addition to the plate configurator and the wizards for mould bases and die sets, numerous other wizards and configurators are available in the portal.

Precisioncomponentsandpracticaltools formoulders

Apart from plates, the Meusburger portal offers quick access to a wide range of high-quality components and accessories for mould making The range includes a broadspectrumofproductsthatarespecificallytailored to the needs of injection moulders. In the field of temperatureregulation,thecompanyoffersreliableandsafe elementsthatensureperfectconditionsforhigh-quality injection moulded parts and smooth operation. A large selectionofready-to-useejectorsandcorepinsindifferent designs and materials is also immediately available fromstock.Additionally,aconfiguratorenablesthecustomised cutting to length of the pins

A comprehensive range of electrical components, includingindustrialconnectorswithvariouscombination options, matching cable ranges, proximity and limit switchesaswellasmagneticproximitysensors,thermocouples and pressure sensors, enables optimal process monitoring and secures production. Additional accessories are complementing the offer The range also includes a variety of marking stamps for individual marking of plastic parts in many versions, sizes and marking types, even with a fixed height and with latching function for highest process reliability

Reliable, high-precision guiding elements, also in self-lubricating versions or as ball guiding units, form theidealbaseforpreciseinjectionmoulds.Ready-to-use and interchangeable centring units in round and flat designsensurereliablefinalcentringofthemouldinthe split line face.

To complete the moulds, Meusburger offers a wide range of attachments, from lifting equipment to cycle counters, ensuring a safe operation and transport. This

Sour ce : Meusbur ger

The website brings all key functions together for faster and more efficient workflows.

Sour ce : Meusbur ger

The company is optimising its internal processes and focuses increasingly on automation and digitalisation.

offer is rounded off by an extensive range of workshop equipment with high-quality items for various applications in mould making

Selectingandpurchasingthoseproductsisnoweasier than ever.

Anoverviewofeverythingwith‘Myaccount’

The ‘My account’ area simplifies order processing considerably and gives customers quick access to all order data and receipts. The receipts are available just a few minutes after an order is placed. Customers can choose between different shipping methods (express shipping, standardshippingorself-collectioninGerman-speaking countries) and specify a desired dispatch date The delivery address can be conveniently selected via a dropdownmenu,andanewaddresscanbeaddedifrequired. Offers can also be ordered directly or requested again Felix Deutsch summarises: “Compared to the previous version,ordermanagementismuchmoreclearlyorganised and saves us a lot of time.” Marko Tapparo and his team at SIM Meccanica also use ‘My Account’ regularly. “Thecentralisedorderprocessingworksexcellently,and handling is very simple We can place our orders much more quickly than before. We also greatly benefit from the ability to evaluate product costs in real time,” says Tapparo.

To make the ordering process as efficient as possible, the item import in the portal is designed to be flexible: users can upload items as a group using Excel files or MEU files or enter them individually. Entering part of a term will automatically suggest matching items. In the

The range of Meusburger includes a broad spectrum of products that are specifically tailored to the needs of injection moulders.

‘My account’ area, customers not only benefit from simpleorderprocessing,theyalsohaveaccesstoalltheorder dataandreceipts.Inadditiontothecurrentorderstatus, customers can also track the location of the delivery A detailed support area provides answers to all the frequently asked questions

Quicklyandefficientlytothegoal

Meusburger prioritises getting customers to their goals as quickly and efficiently as possible. The search and filterfunctionsinthenewportalmakeiteasytofindand filter products or orders. On top of that, both the shopping cart and the parts lists are automatically saved all the time — so the customer is guaranteed to save time. Parts lists can also be conveniently forwarded.

If there are any challenges handling the portal, the extensive support area provides relevant and helpful information as well as the possibility to contact Meusburger via a form in the ‘My account’ area to make enquiries or requests on hot runner and control systems

The employees of Kummer Werkzeugbau AG have also benefited from this, as Felix Deutsch reports: “The transition to the new portal went smoothly and we quickly found our way around. In case of questions, both the personal contact Mr Oliver Jonischus and the support areaintheportalweretheretohelpus.”MarkoTapparo adds: “The transition was straightforward, we had no problemsatall.Thenewsystemisextremelyuser-friendlyandself-explanatory.”Thankstoitsresponsivedesign, the portal can also be used on mobile devices, which is ideal for use in the workshop

The Meusburger portal combines efficiency, user-friendliness and flexibility in one digital platform, providing the best digital support that creates tangible added value.

Partofacomprehensivedigitalisation strategy

Despite the current difficult market situation and although the full-range supplier did record a single-digit decline in turnover, Meusburger is able to maintain its position as the market leader for standard parts manufacturing in Europe. This is because the company is monitoringdevelopmentsinthemarketverycloselyand reactsflexiblytothechangingsituation.Inordertokeep abreastofcurrenttrendsandchallengesintheindustry, thecompanyhaslauncheditsownmarketbarometerin collaborationwiththeWBAToolingAcademy.Thefocus of all analyses is on serving customer needs even better in the future. This also includes the bespoke online service.

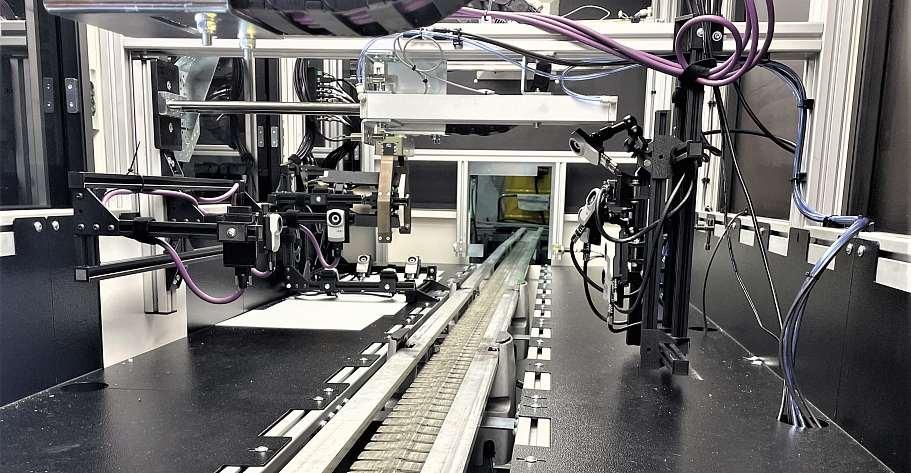

On top of that, the standard parts supplier is optimising its internal processes and focuses increasingly on automation and digitalisation. The aim of these measures is to continue to provide customers with optimum supportandtobethebestpartnerinmouldanddiemaking Examplesoftheoptimisationincludethenew‘Driverless Transport System’ (DTS), which was successfully put into operation in autumn. The packaging and picking processes were also optimised. Both measures help to further reduce lead times. “Ordered today, immediately dispatched” — with this aspiration, Meusburger wantstocontinuetoguaranteeitscustomersmaximum quality and short lead times (ast)

Meusbur

30 PERCENT LESS MATERIAL

KHSandHuskypushPET bottleweightlimits

In just four months, KHS and Husky Technologies have jointly developed one of the world’s lightest PET bottles for still beverages. The 5.89-gram “Factor 101” bottle sets new standards in material savings, top-load stability and line compatibility.

BydevelopingoneofthelightestPETbottlesforstill beverages,KHSispushingtheboundariesoflightweight packaging technology Under the working title of Factor 101, in close cooperation with Canadian-basedinjectionmouldingtechnologyequipmentand

services provider Husky Technologies, a container has been produced that uses just 5.89 grams of material to hold 591 milliliters of product. This is equivalent to the 20-ounce size common in the United States.

AtDrinktec2017KHSpresenteditsFactor100concept asafeasibilitystudythatfeaturedaPETbottleweighing approximatelyfivegramswithacapacityof500milliliters.Anumberofoptimisationshavenowbeenmadeto the further development, as KHS packaging designer Fabian Osterhold in Hamburg explains. “With such extreme lightweighting, what’s known as the top load is especially important. This value tells us how sturdy the bottle is from a vertical perspective It determines whetherthecontainercanbestackedornotandsurvive transportation undamaged.”

Extremelyrobustlightweight

To increase stability, the shoulder design of Factor 101 has been modified and the bottle body reinforced with functional webbing Moreover, Osterhold and his colleagueshavedevelopedabasewithapop-ineffect.Here, thebasepopsinwardstoacertaindegreewhenatopload isapplied,increasingtheinternalpressureandtherefore the stability of the bottle.

Twohundrednewtonsisacommontoploadthreshold in the industry; at 220 newtons, the Factor 101 exceeds this. In order to achieve this high value for a PET bottle used for still beverages, adapting just the container shape wasn’t enough “The preform design also needed to be developed further,” emphasises Osterhold. This is whyKHSjoinedforceswiththespecialistsatHusky The companyhasawealthofexpertiseasequipmentsupplier of PET preform injection moulding systems and services and has been in cooperation with KHS for many years. “Our joint aim is to produce a high-quality, high-performing, lighter weight result than either of us coulddoworkingonourown.Or,asIliketoputit:forus, oneplusoneisgreaterthantwo,”saysFrankHaesendonckx, Head of Stretch Blow Molding Technology at KHS

Challengingcoordination

Technically speaking, the stretching factors from blank to bottle and the resulting preform dimensions were especially important here. The relation of length to wall

thickness is particularly relevant to injection moulding In this context, KHS addressed the specifications and feasibilities of the stretch blow moulder and bottle design, while Husky made the necessary modifications to the preform. “The focus here was on the exact profiling ofthepreformmadepossiblebyKHStechnology,”Osterhold ascertains. “Focus lamps in the heater on our Inno-PETBlomaxSeriesV,forexample,makeforextremelyprecisetemperatureprofilingdirectlyunderthebottle neck ring This ensures that no material stays unstretched.Inturn,thisconsiderablyreducestheamount of plastic used.”

30percentlessmaterial

Compared to the standard lightweight PET container holding 500 milliliters of still water that usually weighs seven grams on the US market, the joint KHS/Husky product requires 30 percent less material. It can also be manufactured entirely from rPET.

However,bottlegeometryisjustonefactor “Linecompatibilityinthehigh-capacityrangeofupto90,000bottles per hour was a key challenge,” says Osterhold. “The

main issues here were conveying, labeling and the secondary packaging In the shrink tunnel, for instance, special attention had to be paid to the bottle shoulder —andthebottleofcourseshouldn’tfalloverduringconveying.”

“Not only the weight but also the time in which the project was implemented are possibly record-breaking,” Osterholdstates.Thankstothegreatteamworkbetween Husky and the many KHS departments involved in the development process, the project was successfully concluded in just four months.

Greatinterestinthemarket

Factor 101 was first presented live by Husky at the NPE 2024plasticstradeshowinOrlando,Florida,inMaylast year Theextremelightweightofthebottlewasmetwith great interest in the industry “The bottle in this form is of particular relevance to contract fillers who operate under great cost pressure,” believes Osterhold. The prime target markets are the United States, the Middle EastandSouthAmerica Thefirstprojectsarealreadyin preparation. (ast)

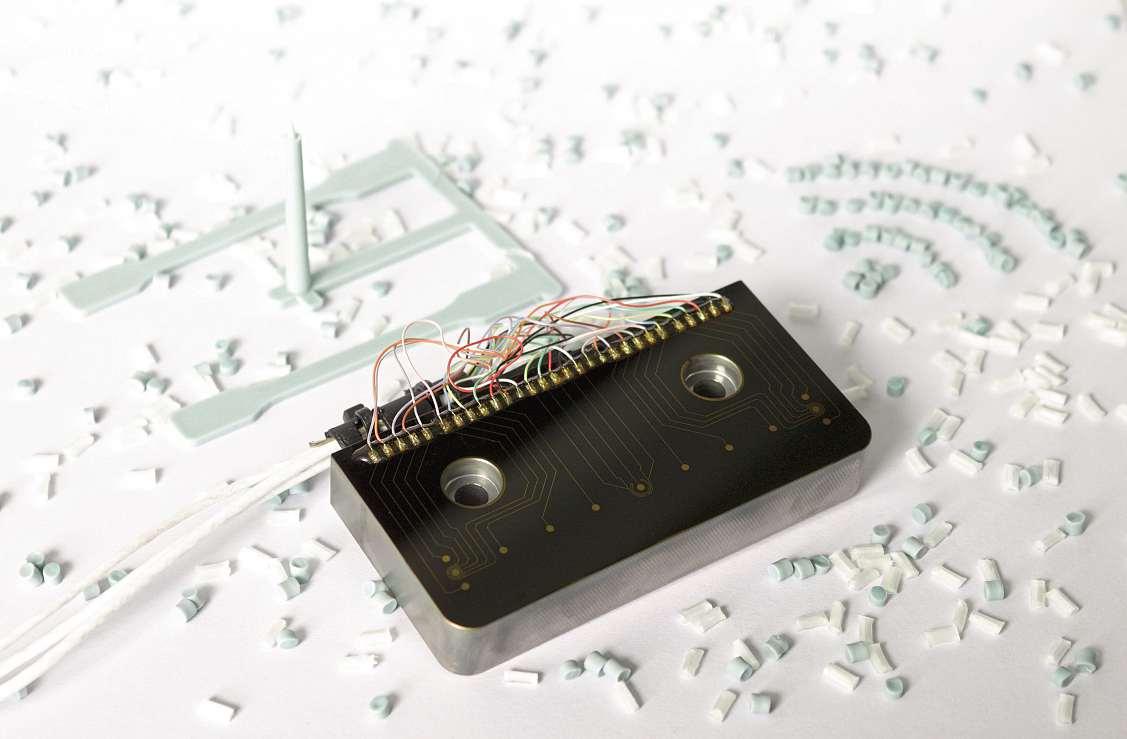

Smartermouldingwith thin-filmsensors

To make plastic production more efficient and sustainable, Fraunhofer IST has developed thin-film sensors that monitor pressure and temperature directly in the mould Combined with machine learning, the system enables real-time quality control and process optimisation.

For the resource-conserving and, at the same time, economicalproductionofplasticcomponents,the utilisation of intelligent, automated processes is crucial. In order to be able to monitor production processesautomaticallywiththeaidofAI,innovativesensor systems are required that provide, with the highest possible data quality, real-time information regarding the statusoftheproductandprocess.Inthe“AI-Net-Aniara” project,theFraunhoferInstituteforSurfaceEngineering andThinFilmsISTthereforeconductedworkonthedevelopment of innovative thin-film sensors

During the project, the Fraunhofer IST has developed an innovative sensor system that records process data such as temperature and pressure in real time — directly in the tool. The wear-resistant thin-film sensors and the adoption of machine learning methods enable pre-

cise monitoring, automated quality assurance and sustainableoptimisationoftheinjection-mouldingprocess.

Thepotentialofthin-filmsensortechnology

WithinthecontextofIndustry4.0,thepreciserecording andmonitoringofrelevantparameters,suchastemperatureandpressurecurvesinplasticinjectionmoulding, is essential.

The Fraunhofer IST has developed multifunctional thin-film sensors that are deposited directly onto the tool surface. These sensors enable spatially resolved real-time measurement of the temperature in the main stress zones of the injection-moulding process.

The thin-film sensor system was applied to an exchangeabletoolinsert.Thesensorsystemwasdeposited

Tool insert with thin-film sensors for plastic injection moulding.

on steel inserts by means of physical and chemical vacuumdeposition(PECVD),whichcanbeeasilyintegrated intothetool.Thebaselayerconsistsofathermoresistive andwear-resistantdiamond-likecarbon(DLC)layer An array of 13 electrode structures made of chromium was structuredontop,mappingtheflowfrontalongthecomponentgeometry.Thisisfollowedbytwoelectricalinsulation layers made of Sicon, between which the chromium-basedconductortrackswereproducedusingphotolithographic processes.

Machinelearningforimmediateprocess adjustments

Via a specially adapted electronic unit, the collected data are read out in real time and processed directly. With the aid of intelligent automation by means of machine learning algorithms on edge devices, it is possible to detectfaultsandweakpointsimmediately Thecomponent qualityisreliablydeterminedandisdisplayedasacolour signal even before the mould is reopened following the injection process. As a result, corrections and adjustments can be swiftly implemented.

The developed sensor system was tested on the injection-moulding machine at the Institute of Machine ToolsandProductionTechnology(IWF)attheTUBraunschweig As a sub-process of incremental manufacturing,digitalisedandintelligentmanufacturingstrategies fortheefficientmanufactureoffunctionalisedproducts in differing quantities were investigated with the aid of sensor technology It was found that as a result of the increased data availability in combination with the applicationofmachinelearningprocesses,individualised (intermediate) product states can be predicted and suitable optimisation strategies can be derived.

The high wear resistance of the thin-film system also enablesthemonitoringofprocesseswithahighproportionofglassfibersandrecyclates.Thisprovidesasignificantcontributiontowardstheutilisationofsustainable materials in production operations within the framework of the circular economy. (ast)

ETMM-TIP

Find out more about the AI-Net-Aniara project and its sensor innovations at www.ist.fraunhofer.de

ETMM-INFO

The Project

Within the framework of the EU research program AI-Net, research is being conducted into technologies that will accelerate the digital transformation in Europe. In a number of industry-led projects, the technology fields of communication networks and technologies for 5G and, prospectively, 6G, user-oriented data centers and artificial intelligence (AI) are being addressed. The German project consortium of “AI-Net-Aniara” focused on the application fields of sensor systems and production technologies.

The Fraunhofer IST contributed to Aniara with the development of a real-time-capable sensor system which can be integrated into existing infrastructures and utilised for data analysis with AI algorithms. By means of automated error detection and the derivation of virtual product properties, optimal operating strategies were developed.

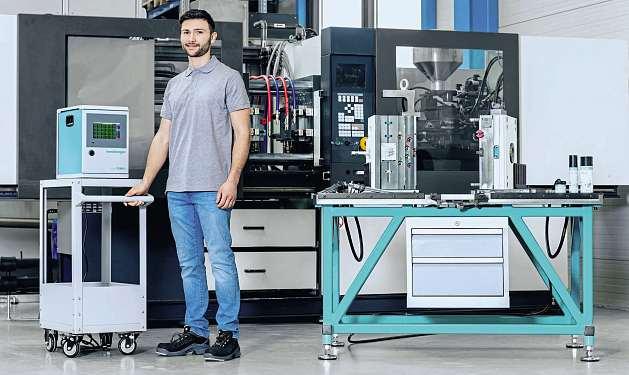

Left to right: Jürgen Burkert (Managing Director HSK), Mathias Grimm (Head of Plant 2 HSK), Ralf Schiefer (Head of Strategic Business + Product Development HSK) and Dr. Gerald Fiedler (sales engineer Sumitomo (SHI) Demag,) using an Intelect Multi 300 for 2K injection moulding

HSKexpandswith2.5 millioneuroinvestment

With a recent investment in all-electric multi-component moulding technology, HSK reaffirms its position in polymer processing.

Supported by nearly 150 machines from Sumitomo (SHI) Demag, the company is expanding globally.

NestledbeneaththeridgesoftheOremountainsin Germany are two plants manufacturing thousands of multi-material components for OEMs daily. With an additional site recently opened in SouthwesternOntario,Canada,HugoStiehlKunststofftechnik (HSK)investedin10injectionmouldingmachinesfrom the Sumitomo (SHI) Demag Intelect series. The latest installations include six advanced multi-component manufacturing cells comprising machines, peripherals and conveyors.

BringingtheirtotalnumberofSumitomo(SHI)Demag injectionmouldingmachinestonearly150,HugoStiehl Kunststofftechnik (HSK), which operates from four international sites, recently invested 2.5 million euros in multi-componentmouldingtechnology AsoneofHSK’s

longest serving machinery partners, Sumitomo (SHI) Demag Plastics Machinery delivered ten all-electric injection moulding machines from its popular Intelect series,withclampforcesrangingbetween750and1,800 kN (Multi).

Four of the systems have been installed at the company’s German HQ in Crottendorf, with six cells placed in Brantford Ontario in Canada — tested and certified to meet the regulatory safety requirements set by the Canadian Standards Association (CSA). “These machines were specifically commissioned to support the production and assembly of battery technology components withcomplexgeometriesusingourprecisetoolingtechnology,” explains Ralf Schiefer, Head of Strategic Business and Product Development at HSK

Sour ce :

Su mit

om o (SHI)

Demag

Two 2K machines Intelect Multi 180 and two Intelect 75 were installed at the Crottendorf site, with four Intelect Multi 180 and two Intelect 75 shipped to Canada. Asaprominentleaderinall-electricinjectionmoulding machines, as well as multi-component and 2K technologies,Sumitomo(SHI)Demaghandledtheentirecustomisation, technology integration and cell validation process.Thisincludedinstallingallofthesafety-relevant components, machines, peripherals and conveyor technology, reports Schiefer

Longstandingloyalty

Having supplied over 150 machines to HSK since 1990, Sumitomo (SHI) Demag was considered to be unquestionably the most reliable collaborative partner for this latest project “As a direct result of thesesuccessfulcooperations betweenbothcompaniesover threedecades,wewereideally positioned to respond to the exact project requirements. Our familiarity of the company also enabled us to pull forward production to meet the tight time frame specified by HSK,” says sales engineer Dr Gerald Fiedler who oversaw theentireprojectfromstartto finish.

Focusing on the value of this mutually cooperative partnership, Schiefer adds: “There are many factors that we appreciate in Sumitomo (SHI)Demagasapartner.The excellent customer support, themodularconceptsoftheir machines which increases thelongevityandflexibilityof our investments, familiarity of the control system, as well as the maintenance support which when combined results in some of the most efficient production cycle times.”

For the Saxon polymer processor, nearly 80 percent of the entire fleet now carries the Sumitomo (SHI) Demag badge.

Performance-wise,Schiefer has long appreciated the responsiveness of the toggle platformonthehydraulicmachines. This proven technology has now been applied to the all-electric Intelect series but now uses direct drives to achieve the most efficient yet repeatable performance required by manufacturers of safety components today.

Strongestadvocatesofall-electric

Eager to set the precedence for cleaner, less energy intensive production, HSK became one of the earliest adoptersofall-electricinjectionmouldingtechnologies. “Wechoseall-electricinjectionmouldingmachinesatan early stage because we always had our eye on ecology,” says HSK Managing Director Jürgen Burkert.

The Intelect series from Sumitomo (SHI) Demag quicklyfulfilledthecompany’srequirementsbydeliveringlowenergyconsumption,highprecision,repeatability, durability and a significantly less background noise Now, with 50 all-electric injection moulding machines

Special plates

Configurespecialplates

quicklyandeasily

Meusburger offers special plates in eight different standard variations, which are available in customisable dimensions and different materials, all in the usual high quality.

Howyoubenefit:

› More than 25 materials available

› Easy configuration of drilled and non-drilled plates

› Ready for shipping in three working days

operating in the clamp force range of between 500 and 3,500kN,HSKremainsoneofthemostenthusiasticsupporters of Sumitomo (SHI) Demag’s technologically advanced know-how. In particular the company’s prominent leadership in direct drive, inverter and control technologies, which for a mass manufacturer like HSK is considered to be state-of-the-art.

With a sustained history of responding to the latest trends, few companies possess the depth of processing expertise and technologies to match HSK’s wealth of experience and competence in 2K injection moulding Of the 31 2K Multi machines currently operating at HSK, overhalfareIntelectMultimachines.Equippedwiththe very latest multi-component technology, the large mould space combined with high tie bar clearance, optimisestheworkingenvelope.Thisprovidestherotation space to accommodate a large tooling estate, while simultaneously delivering maximum precision with parallel, dynamic movements, explains Fiedler

Early2Kadopters

Greater processing precision when using the Intelect Multi’scanbeattributedtothecompany’sservomotors which are designed and built by the Sumitomo Heavy Industries Group The dosing is fully electric to ensure thehighestdegreeofaccuracy Themachinedesignalso featuresauniqueautomatictie-barpullontheoperating side.Additionally,theservomotoroftheindexdrivehas been integrated into the control system, explains Dr Gerald Fiedler

ETMM-TIP

Looking to boost efficiency and precision? Explore all-electric multi-component moulding on sumitomo-shi-demag.eu.

“Thesemachineswerespecifically commissionedtosupporttheproduction andassemblyofbatterytechnology components.”

Ralf Schiefer, Head of Strategic Business and Product Development, HSK

HSK purchased the first 2K injection moulding machine produced in Wiehe in 1997 It was an Ergotech Multi 50-120H/80V with the production number 71440001, recalls Fiedler, providing additional assurance of the long-standing trust enjoyed between the two like minded and innovative companies.

Eager to maintain the company’s position at the forefront of polymer processing trends, managing director Burkert elaborates that by specialising in 2K injection moulding and IMD, and by transitioning to all-electric machines HSK continues to adapt to shifting demands.

“As a full-service manufacturer with an advanced machineryfleetandover400highlyskilledpeople,wecontinuetoobserveheighteneddemandforadvancedmanufacturing techniques. In particular an expansion of applicationsofferingveryspecificsafetyfunctionalities for battery housings.”

Similarly, Sumitomo (SHI) Demag continues to push the boundaries of innovation, particularly with regard to connectivity, interfaces and data exchange. The networked support service My Connect allows for remote support and rapid reactions to unplanned production disruptions. This variety of functionalities is especially beneficialformulti-sitemanufacturerslikeHSK,which with the opening of the Canadian plant in December 2024, as well as two plants in Crottendorf and another subsidiary in Dalovice in the Czech Republic, now operate across multiple time zones

Newmachinesformodernfacilities

Aspartofthecompany’srobustexpansionstrategy,HSK Canada commenced production in December 2024. ServingtheUSandMexicanmarkets,tosupporttheprocessing of hundreds of thousands 2K components daily ontheirnewIntelectmachinesandtohelpmaintainthe tightqualitycontrolparameters,thefacilityisequipped with the latest in assembly, camera and measurement technologies. Alongside 2K injection moulding, as a technical moulder HSK is also heavily involved in highly-specialistprocesses.Thisincludesinmouldlabelling, insert injection moulding, over moulding of textile and metal cables, and micro-injection moulding (ast)

The majority of the 140 injection moulding machines currently running at HSK, including plant 2 in Crottendorf (pictured) are supplied by Sumitomo (SHI) Demag

At the Hugo Stiehl Canadian facility, four Intelect Multi 180 and two Intelect 75 produce hundreds of thousands of components daily.

ILLUMINATED LOGOS

PMMApartsshineinOpel’s newelectricSUV

The new Opel Grandland Electric features illuminated Plexiglas moulded lettering in place of traditional chrome elements. Developed in collaboration with Röhm and Hella, the design reflects current trends in lighting technology and materials use.

The Opel “Blitz” lightning bolt glows white at the front, and brand name in signal red letters at the rear ThenewGrandlandElectricSUVisOpel’sfirst seriesmodeltofeaturethenewexteriordesignwithout chrome elements. Instead, the brand insignia are made fromPlexiglasandareilluminated.Withthisilluminatedlettering,parentcompanyStellantisistakingadefinitivestepinmodernisingandelectrifyingthistraditional German car brand.

Integrated into the slimline rear light strip that extends across the entire width of the vehicle, the Opel letteringisdiscernibleevenfromadistance Thelighting specialistsatHellaLightingproducethemulti-partrear light of the Opel Grandland Electric using Plexiglas moulding compounds, the brand polymethyl methacrylate(PMMA)fromRöhm “It’sawell-knownmaterial for us at Hella. We know and appreciate the properties,” says Samuel Tomka, head of the Optical Development Department at Hella Slovakia.

Thethree-dimensionalletteringisinjection-moulded in one piece. The letters are approximately 30 millimeters high and long, and 10 millimeters deep “The challenge is to achieve uniform thickness and avoid cracks and sink marks,” explains Tomka. “Plexiglas moulding compoundshavethepotentialtomitigatetheserisksto a minimum, so we can produce the lettering with the highest precision and ensure that the aesthetics and functionality meet the highest demands.”

Rafal Czokow, Senior Business Manager in Röhm’s MouldingCompoundsbusinessunit,describesthecharacteristics of the moulding compound used here: “This Plexiglas product is characterised by maximum optical purity and excellent light-guiding properties, as well as ahighheatdeflectiontemperatureandmechanicalstability,makingitagreatchoiceforuseinvehiclelighting components.Thankstoitswell-balancedmeltviscosity, themouldingcompoundisverywellsuitedforinjection moulding and offers great freedom of design.”

Targetedlightextractionatthesurface

Sincetheletteringispartoftherearlight,ithastocomply with the international regulations for vehicle lighting.ThisiswhytheOpelbrandnameisalsoilluminated insignalred,therequiredcolourforrearlights.Theoptical properties of the brand PMMA enable designers to create spectacular lighting effects: Thanks to a fine sur-

ETMM-TIP

Advanced materials enable sleek, regulation-compliant lighting designs. Learn more at plexiglas.de

All eyes on the brand — the Grandland Electric SUV is the first series model from Opel to feature an illuminated brand lettering

face structure, the red light of the LEDs is emitted only through the front of the otherwise crystal-clear letters. In daylight, the Opel lettering stands out beneath the rear light cover thanks to its elegant 3D effect.

HellaalsoproducesthetransparentcoverfromPlexiglas moulding compound. This is because, in addition to its high transparency, the material also has excellent UV and weather resistance, and does not turn yellow overtime.Asaresult,thesignalcoloursrequiredbythe relevant standards are reproduced perfectly, and the Opel brand name is highlighted with sharp and crystal-clear brilliance

InEurope,illuminatedemblemsandlogosonvehicle exteriors have only been allowed since 2023, and they aresubjecttostrictrequirementsintermsofdimensions andcolours.Whenitcomestovehicleinteriors,however, lighting designers have virtually free rein. In his role atHellaLighting,Tomkahasnoticedthatambientlighting is increasingly coming into focus in automotive design, and that both the showcasing of the brand and customisable lighting scenarios are set to play a major roleinfuture.“Thisopensupexcitingnewopportunities forus,andrelievesbondsfromcreativeminds,”saysthe newly appointed Head of Program Management for Interior Lighting in the International Segment. (ast)

COMPUTER AIDED MANUFACTURING

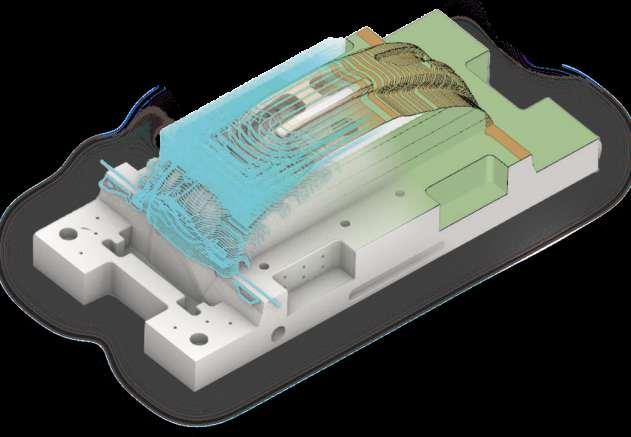

Abriefhistoryofsimulation inCAMsoftware

Simulation in CAM has evolved from a visual aid to a core pillar of safe, efficient manufacturing. This personal deep dive traces its transformation — from the early days of 5-axis backplotting to today’s real-time collision avoidance and GPUaccelerated material removal.

Intheworldofcomputer-aidedmanufacturing(CAM), simulation technology has evolved from a luxury to what many consider an essential component. In the landscapeofCAMsoftware,threequestionsconsistently emerge:IssimulationoftoolpathsinCAMtrulyamust haveormerelyanice-to-havefeature?Whatcapabilities should we expect from simulation in today’s modern CAM software and powerful hardware? And perhaps mostimportantly,whatdevelopmentscanweanticipate in the coming years?

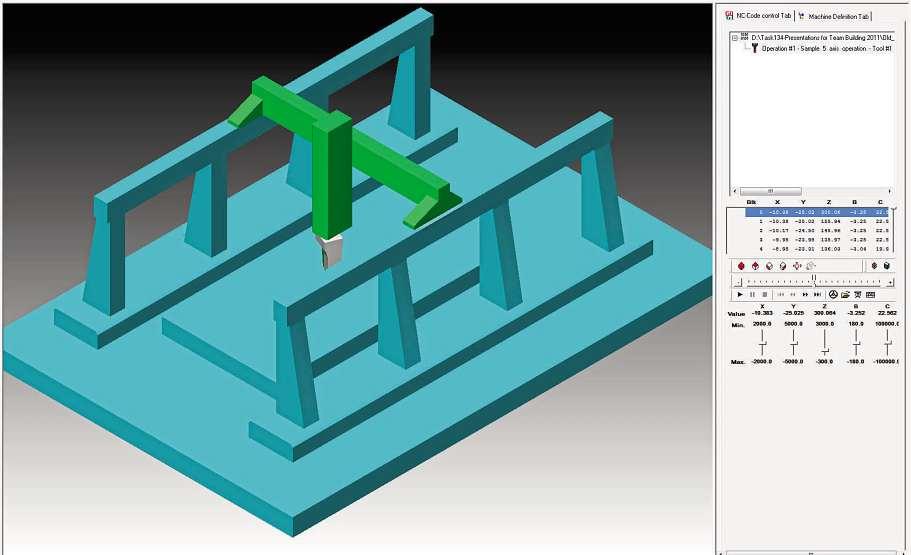

Thepioneeringphase:breakingnewground

In 1997, 3D CAM was still very new. The primary challenge was educating manufacturing companies about the necessity of CAM software, post processors, and data import capabilities from different CAM systems. Five-axis machining was an even smaller niche, and professionals used the term “True 5-axis machining” to describe the continuous motion of all five axes simultaneously. The majority of customers were performing

WRITTEN BY

Dr.Yavuz Murtezaoglu Founder & Managing Director Module Works

in CAM software has evolved from a luxury to a necessity during the past three decades.

whatwecalled“indexed”or“3+2axismachining”,where the machining direction remained fixed for each tool path operation.

Machine tool vendors were increasingly introducing 5-axisCNCmachinestothemarket,andcontrolmakers like Siemens and Heidenhain were enhancing their capabilities to support these advanced machines.

During this period, I was developing 5-axis tool path algorithms to overcome CAM software limitations, enabling customers to machine complex shapes across various industries. However, determining whether a tool path was safe presented significant challenges. The integrated simulation in CAM software utilised backplot technology to display the tooltip as a series of lines — effective for 2D or 3-axis machining but inadequate for 5-axis machining, where the tool tip could maintain its position on the line while the tool itself tilted.

The material removal simulation integrated into these systems effectively demonstrated how parts werecreatedfromstockmaterialbutfailedtoidentify potential collisions when all machine components were in motion. Dedicated standalone simulation software was available, but it required separate licensing, installation,andconsiderablepatiencetoevaluateeach program.

Themachinekinematicsrevolution

We recognised that the most significant risk in 5-axis machining was machine crashes To address this, we begansimulatingcompletemachinekinematics.Given the complexity of machine geometry, we focused on simplifying it, concentrating on critical components such as the table, work holding, and spindle while disregarding the housing and other less critical details.

We discovered that OpenGL, well-developed for gaming, could be leveraged to create fluid animations of machine movements for any 5-axis tool path The challenge was converting CAM software tool paths to machinemotion.Thesolutionlayinthepostprocessor:its roleistotransformthetoolpathfortheparttomachine kinematics, mathematically converting the tool axis vector in the workpiece coordinate system into rotary axis angle values for the specific machine. Since 5-axis

postprocessorswerescarce,wedevelopedourown.Our in-houseteamprovidedthekinematicmodel,whichwe linked to an OpenGL engine. The result was a fast, versatile 5-axis simulation capability, which we first demonstrated in the early 2000s — bringing complex toolpathstolifeonalargescreenwithimpressivespeed and precision.

Latestreleaseofmachinesimulation

While fast, this system initially didn’t report collisions. Nevertheless, it proved valuable. We termed it “Visual collision checking”, similar to tool path backplotting where users manually inspect the tool path. Operators could run the simulation, rotate the view with the mouse,andvisuallydetermineifcollisionswouldoccur Given the comparative slowness of computers at that time, this represented a pragmatic solution, offering instant simulation without waiting time. Users could navigate between the program’s start and end points simply by moving a slider bar with the mouse, visualising all motions.

We decided that our 5-axis tool path should be used in conjunction with this simulation and bundled them togethertopreventmachinedamageduetoinadequate simulation capabilities. While some customers purchased additional standalone simulation packages, most found our fully integrated simulation extremely helpfulsinceitutilisedthesamekinematicsolverasthe post processor they employed to operate the machine.

“SimulationinCAMhasevolvedfroma luxurytowhatmanyconsideran essentialcomponent.”

Dr. Yavuz Murtezaoglu, Founder & Managing Director of Module Works

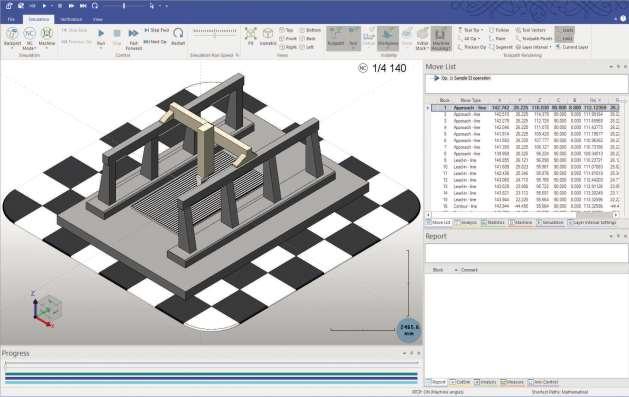

Fromvisualtovirtual:perfectingcollision detection

As computer hardware became increasingly powerful, ourambitionsgrew:whynotimplementactualcollision checking instead of merely visual collision checking? Encouraged by OpenGL’s success in gaming and how it facilitated our solution development, we explored furthergamingtechnologyandcollaboratedwithanexpert who had developed collision detection engines for the gaming industry After significant investment and adaptation to meet industrial needs, we achieved full collision checking, also known as “clash detection”.

ETMM-TIP

Want to learn how real-time collision avoidance works in practice? Visit moduleworks.com

Accustomed to instant simulation capability, we aimed to maintain similar speed levels even with collision checking This presented challenges, but we discoveredthatbyreducingthenumberoftrianglesinthe triangle mesh model, we could achieve satisfactory speeds.Additionally,wedefinedspecificcollisionpairs ratherthancheckingeverythingagainsteverything For instance, since a machine’s table would never crash against its housing, we eliminated that check. The outcome was extremely satisfactory and quickly became integral to our solution.

Simulation

CollisionAvoidanceSystem(CAS)ofModule Works

Atthisstage,however,wewereonlyaddressingmachine collisionsandgougesofthetoolandspindleagainstthe target workpiece geometry While we could guarantee thatthetargetpartwouldn’tbedamagedbythetooland no machine collisions would occur, we lacked material removal simulation, meaning unexpected cuts into unmachinedstockwentundetected,suchasarapidmotion crossing the stock. This required material removal simulation,sowedirecteduserstoruntheintegratedmaterial removal simulation engine within their CAM software, typically licensed from specialist companies providing such technology

We initially thought this would conclude our journey, as our primary objective was to help users run our 5-axis tool paths safely, and we had developed a working solution that satisfied our customers

Thedigitalchisel:revolutionisingmaterial removalsimulation

In 2005, at an academic conference, I met Dr Stautner fromDortmundUniversity,whohadcompletedhisPhD on material removal simulation technology and subsequently joined our team. We were receiving numerous customerrequestsforfullyintegratedmaterialremoval simulation within the machine simulator

Upon examining existing market technology, we found that most CAM software utilised a technology basedonmeshBooleans,wheretoolmotionisdescribed asameshsubtractedfromthestockmesh.Whileinitially quick, the process slowed dramatically as more Booleans generated increasingly more triangles. We adoptedthediscretemodeloriginatingfromDortmund Universitybutrecognisedthesubstantialworkrequired to ensure accuracy Though fast, making the results vis-

ually appealing and supporting technologies like turning and wire cutting presented significant challenges. Sincethen,we’veinvestedapproximately200person years in development, including quality assurance and productmanagement,tobringthetechnologytoitscurrent level — an achievement we’re extremely proud of Asdevelopers,wetendtoseekelegant,simplesolutions to complex problems, but this particular challenge demanded extensive effort since every detail is critical to avoidmisleadingusers.Thesolutionmustbeabsolutely safe, fast, user-friendly, and integrable.

Preventiveintelligence:real-timecollision avoidance

By 2015, our journey continued despite our satisfaction with our simulation technology, which had been integrated into numerous CAM software systems for material removal and machine simulation, with our market share growing steadily A new challenge emerged: how to run the simulation engine on an industrial PC adjacent to CNC control to prevent machine collisions in real time.

This exciting challenge came with the advantage of receiving information about future machine movements with a one-second look-ahead, providing data of the “future” one second in advance. Our task was to calculate collisions and material removal and stop the machine before any issues occurred. This necessitated significant optimisation of our calculation engine and required heroic efforts from our team to deliver timely solutions to partners

We named this technology CAS (Collision Avoidance System) and believe it could eliminate all machine tool crashes if widely implemented. With the rapid advancement of chip technology, accelerated by developments inArtificialIntelligence,weanticipatethatwithinafew years, even basic chips in CNC controls will have suffi-

Module Works’ first release of Machine Simulation in 2006.

cient performance, eliminating the need for additional industrial PCs.

Breakingbarriers:universalstandardsand GPUacceleration

WhileCNCmachinescanavoidcollisionsusingCAS,this requires proper definition of tool, holder, work holding, andstockgeometryforeachjobtoenableCASfunctionality ManyCNCmachinesdon’trequiresuchdatatocut parts, but it’s essential for collision avoidance Upon investigation,wedeterminedthatallthisdataexistswithinCAMsoftwarebutlackedastandardformatforexport to CNC machines - typically, only the NC program was transmitted

We initiated the development of MDES (ManufacturingDataExchangeSpecification)toenabletheexportof jobsetupdatafromCAMsoftwaretoCNCmachinesrunning CAS Working with approximately 90 % of major global CAM vendors and most CNC control makers and machine tool vendors, we secured substantial support fromkeyindustryplayers.Theadoptionofthisworkflow is progressing impressively To accelerate adoption, we’vemadethisspecificationfreelyavailableasanopen standard to prevent the proliferation of competing proprietary standards

RepresentationofaGPU

Thestorydoesn’tendthere.NVIDIA’ssuccesswithAIhas driven the development of powerful GPUs previously primarilyusedforgaming Withstabledevelopmentenvironments now available for industrial GPU applications like simulation, we’ve ported the most computationallyintensivepartsofoursimulationenginetoGPU While maintaining all features developed over the past 20 years, we now benefit from GPU power. The benchmarkresultsonamid-rangeGPUarefascinating:many tool paths with 1-3 million lines of NC code complete simulationatthehighestresolutioninunder10seconds I confidently assert that material removal simulation should never take more than 10 seconds, regardless of tool path size We’ve achieved this without compromis-

“Whiledevelopingcomplexalgorithms ischallenging,creatingindustry-grade complexalgorithmsissignificantly moredemanding.”

Dr. Yavuz Murtezaoglu, Founder & Managing Director, Module Works

ing quality or taking shortcuts to increase speed, maintaining the extensive detailed work we’ve invested (the 200 person years of effort since 2005). This approach facilitates straightforward retrofitting for all CAM softwarecompaniesusingoursolution,theyneedn’tchange anything for their users to enjoy this dramatically improved performance.