LSP, MBH, Trimac share stories of award-winning success Pages 16-31

Tequila hauler puts family first Page 38

Trailer spec’ing for optimal ROI Page 42

Study: Tank segment to outpace GDP through 2029

Advisory firm expects growth in bulk shipments to uplift prices and revenue.

BulkTransporter.com/55289338

Mack targets bulk haulers with all-new Anthem

New tractor offers enhanced efficiency, and driver comfort for tank fleets. BulkTransporter.com/55300271

Bulk Transporter

Market Leader

Commercial Vehicle Group – Dyanna Hurley dhurley@endeavorb2b.com

Editorial Director – Kevin Jones kjones@endeavorb2b.com

Editor – Jason McDaniel

jmcdaniel@endeavorb2b.com

Associate Editor – Alex Keenan akeenan@endeavorb2b.com

Marketing/Advertising – Dan Elm delm@endeavorb2b.com

Art Director – Eric Van Egeren evanegeren@endeavorb2b.com

Production Manager – Patricia Brown pbrown@endeavorb2b.com

Directories/Listings – Maria Singletary msingletary@endeavorb2b.com

Audience Development Manager –Laura Moulton, lmoulton@endeavorb2b.com

Endeavor Business Media, LLC

CEO Chris Ferrell

COO Patrick Rains

CRO Paul Andrews

CDO Jacquie Niemiec

CALO Tracy Kane

CMO Amanda Landsaw

EVP Transportation Group Chris Messer

Bulk Transporter Volume 122, Issue 5, is published six times per year by Endeavor Business Media, LLC, 201 N Main St, 5th Floor, Fort Atkinson WI 53538. Postmaster: Send address changes to Bulk Transporter, PO Box 3257, Northbrook, IL 60065-3257. Send inquiries to Bulk Transporter, PO Box 3257, Northbrook, IL 600653257. Customer service can be reached toll-free at 877-382-9187 or at bulktransporter@omeda.com for magazine assistance or questions.

Printed in the USA. Copyright 2025 Endeavor Business Media, LLC. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopies, recordings, or any information storage or retrieval system without permission from the publisher. Endeavor Business Media, LLC does not assume and hereby disclaims any liability to any person or company for any loss or damage caused by errors or omissions in the material herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. The views and opinions in the articles herein are not to be taken as official expressions of the publishers, unless so stated. The publishers do not warrant either expressly or by implication, the factual accuracy of the articles herein, nor do they so warrant any views or opinions by the authors of said articles.

Corporate Office: Endeavor Business Media, LLC, 30 Burton Hills Blvd, Ste. 185, Nashville, TN 37215 USA; 800-547-7377

Jason McDaniel Editor

Follow us at:

@bulktransporter

linkedin.com/in/ jason-mcdaniel-BT

facebook.com/bulktrans

As

regulatory burdens ease, tank truckers are free to redirect overtaxed resources to the industry’s No. 1 priority

I first heard of a “rolling recession” two years ago. I’m not sure if we ever exited this recession, we’re just about to enter it, or, really, what’s going on at this point—it depends on who you listen to—but I do know plenty of good news has been rolling in for tank truckers lately. In the previous issue of Bulk Transporter, we celebrated the revocation of CARB waivers and elimination of duplicative security screening. Now we’re reveling in FMCSA’s withdrawal of proposed speed-limiter mandates and, most recently, the potentially landscape-shifting removal of the Environmental Protection Agency’s ability to regulate greenhouse gases.

EPA Administrator Lee Zeldin revealed the agency’s proposal to rescind the 2009 endangerment finding, which set the groundwork for modern GHG standards for heavy-duty trucks, in July.

“With this proposal, the Trump EPA is proposing to end 16 years of uncertainty for automakers and American consumers,” Zeldin said. “If finalized, rescinding the endangerment finding and resulting regulations would end $1 trillion or more in hidden taxes on American businesses and families.”

American Trucking Associations quickly praised the decision to “rescind the disastrous GHG Phase 3 rule” and the Clean Freight Coalition, of which National Tank Truck Carriers is a founding member, also voiced its appreciation. “CFC members have consistently opposed the unattainable targets included in this rule that would cause tremendous harm to the trucking industry, jeopardize the supply chain, and result in higher prices for goods across our country,” said Jim Mullen, CFC executive director.

“The CFC supports all feasible and sustainable technologies that reduce trucking emissions. The rescission of GHG Phase 3 will allow the industry to develop and adopt the best technology to support the movement of our nation’s freight.”

A new Department of Energy report, also released in July, supports this assertion, concluding that “carbon dioxide (CO 2 )-induced warming appears to be less damaging economically than commonly believed—and that aggressive mitigation strategies could be more harmful than beneficial.” Critics will say the report’s brought to us by the fossil fuel industry, but I’m pretty sure it was paid for by taxpayers—as are all our government’s activities—and I’m certain it contains an interesting review of long-held assumptions by a group of doctoral “experts.”

I can’t predict how all these regulatory revisions will play out, in court or on our highways, and the latest round of tariff announcements injected fresh uncertainty into the market in August. But I’m convinced any money fleets save on dubious emission technologies and alternative vehicles, and compliance with overburdensome regulations, could be better spent on the adoption of advanced transportation and learning management systems, and the pursuit of the tank truck industry’s most pressing priority—safe operations.

This issue spotlights three bulk haulers that leveraged the latest in equipment and technology, including IMMI RollTek seats, Storyboard hands-free communications, and Netradyne video telematics, to deliver award-winning results in NTTC’s North American safety contest. And, unlike much of today’s social-governance virtue signaling, safety investments deliver real-world benefits amid challenging operating conditions, reducing incidents, saving lives and money—and showing employees, customers, and insurers safety comes first.

So, if death and taxes are the only certainties—and both are pretty grim—any opportunity for trucking companies with razor-thin margins to mitigate both must be good for everyone. Right?

Now, someone please tell me if we’re in a recession or not. BT

PREMIUM QUALITY. EXPERT DESIGN. TRUSTED FOR OVER 50 YEARS.

• 3-A SANITARY

• DOT-407 CHEMICAL

• FOOD GRADE

• ASME

• DOUBLE CONICAL

CALL TO SCHEDULE A TOUR OF OUR BRAND NEW 400,000+ SQ. FT. STATE-OF-THE-ART, ADVANCED MANUFACTURING FACILITY

Eagle Transport Corporation is expanding into Louisiana with a new terminal in St. Gabriel, located just outside Baton Rouge, that grows the carrier’s capabilities within the chemical transportation industry.

With a long history in petroleum transport, Eagle established its foothold in chemical transportation in 2011. Building on existing chemical-focused terminals in Kingsport, Tennessee, and Houston, Texas, which focus entirely on chemical product transport, St. Gabriel, strategically bridges the gap, the company said.

Eagle’s growing presence in St. Gabriel begins with an operations supervisor, Tyrone Elphage, who oversees the day-to-day operations of this location, which has three drivers and aims to bring on more team members in coming months.

“We believe that having Tyrone on site at this early stage will enable us to grow the terminal and better serve our current customers,” Bobby Vaughn, Eagle director of

chemical operations, said in a news release. “Tyrone brings a wealth of experience, and we hope he will be able to hire and train all the new drivers on-site.”

Initial products transported include amines, primarily for the Eastman plant, and Eagle plans to expand services to other chemical companies in the area over the next year, the company reported. The long-term goal is to develop the location into a standalone site similar to its terminals in Kingsport and Houston.

The Kenan Advantage Group was named Bulk Carrier of the Year during Uber Freight’s annual recognition program, which celebrates carriers across Uber Freight’s expansive logistics network.

Photo: KAG

Each year, Uber Freight honors standout carriers that demonstrate exceptional service, operational excellence, and commitment to innovation in the past year.

KAG Specialty Products was selected for its outstanding performance, valued partnership, and commitment to innovative solutions. Selections were based on quantitative performance metrics, including loads hauled, miles traveled, tender acceptance, check call compliance, and ease of doing business, among other data points.

“We value our partnership with Uber Freight and remain committed to being a reliable, go-to carrier that consistently delivers for our shared customers,” John Rakoczy, KAG Specialty Products EVP, said in a news release. “This award is a testament to the hard work of our team and our working relationship with Uber Freight.”

With the addition of the St. Gabriel terminal, Eagle continues to grow its footprint in the chemical transportation sector.

“The expansion reflects Eagle’s long-term commitment to operational excellence, customer service, and strategic growth,” the company stated. “Looking ahead, the Eagle Transport team remains focused on building strong local partnerships, expanding its workforce, and delivering safe, reliable transportation solutions across the East Coast, Gulf Coast, and beyond.”

Quantix recently opened a new location in Port Allen, Louisiana, that features a state-of-the-art tank cleaning facility and a full-service maintenance and repair shop for wash customers. The new Port Allen site, located at 1737 Highway 190, broadens the chemical supply chain services company’s already expansive network.

“Expanding our network to better serve our customers is always front of mind for us at Quantix,” John Labrie, Quantix president and CEO, said in a news release. “The key success metric for our customers has always been access to locations and services that allow them to move their products safely and efficiently.

“This location’s tank wash allows just that by reducing turnaround time for trailing assets.”The opening of the facility adds 15 local jobs and unlocks the capacity to wash over 30 trailers a day for Quantix’s fleet and carriers outside of its network, the company reported. The cleaning facility is equipped to provide tank wash services for general chemicals and more.

“The moment we started working together and building a relationship, we knew this was a great fit. Premier’s values, goals, and work ethic align perfectly with the Longhorn brand.”

Wfi’rfificonfifinufingfifiofiofffirficufifiomfizfidfiprofificfifionfifindfirfifik-fihfirfingfiopfifionfififorfi fifirgfifi&fimfidfiumfiflfififififi,fifindfipfindfinfificonfirficfiorfi,fifindfimorfififi

Quantix recently changed the name of Pennsylvania-based CLX Logistics and its subsidiaries, which the chemical supply chain services company acquired last year, to Quantix Managed Solutions.

In addition to providing TMS, benchmarking, managed transportation, and supply chain consulting, Quantix Managed Solutions also includes capacity solutions, providing outsourced transportation options specific to the chemical industry, the company reported.

“The CLX Logistics acquisition has proven to be of great benefit to our customers,” John Labrie, Quantix president and CEO, said in a news release. “By leveraging the incredible, chemical-specific data that the team collects, our customers are saving money on everything from fuel costs to transportation costs and maintenance. Beyond that, we’re improving their customers’ experience through white-glove delivery.”

Quantix Managed Solutions boasts $24

billion in lifetime freight spend within its Gravity database, all ingested from chemical-specific companies, Quantix added. One-third of that data is from liquid bulk alone.

“Many providers in this space lump the chemical industry into the ‘specialty’ bucket but the reality is the challenges they face simply cannot be compared to a car hauler, for example,” said Zack Novak, Quantix Managed Solutions senior vice president and general manager. “Quantix Managed Solutions offers everything from support for long haul and hazmat to moving bulk shipments with 24-hour notice.”

reported then, they formed a platform with more than $2 billion in logistics spend, with approximately 5,400 owned assets, over 40 distribution centers and rail terminals, and 3,300 partner-carrier relationships.

The newly named Managed Solutions business was managing $500 million worth of freight annually when Quantix acquired it in April 2024. Collectively, the companies

“Quantix Managed Solutions understands our business completely,” said Brad Crocker, president and CEO of Trecora, a Quantix Managed Solutions customer. “They’re an extension of our team in a sense and the trust we place in them reflects the quality they provide.”

• Tool-free Installation

• Reduce Downtime

Introducing the new Repairable J560 Connector. Now repair your damaged connector with a twist of the wrist and get back on the road.

12’

• Maintain Cable Length • Corrosion Resistant • Increased Driver Satisfaction

13.5’

15’ Straight to Straight MS60-7022-02

15’ Straight to Angled MS60-7023-01

20’ Straight to Straight MS60-7022-03

20’ Straight to Angled MS60-7023-02

National Tank Truck Carriers recently recorded another regulatory win.

Thanks to the efforts of Patrick Usher, Usher Transport executive vice president of corporate governance and NTTC Energy Services committee chair, and a group of NTTC leaders, Doraville, Georgia, no longer will require drivers to obtain a city-issued ID to access local fuel terminals.

The Doraville City Council approved the change to Section 6-14 of the city’s ordinances in a May 21 vote.

“Hazmat carriers and their drivers are among the most highly regulated and thoroughly trained professionals in the transportation sector,” Usher said in a news release. “The now-repealed Doraville ordinance placed an undue burden on these essential workers, created inefficiencies, and opened the door to a patchwork of conflicting local requirements.

“The city’s decision brings necessary clarity and relief to carriers operating in this critical region.”

The ordinance requiring local identification cards for petroleum and propane drivers dated back to the 1970s, NTTC reported.

While originally enacted following a tragic fire near a fuel terminal—unrelated to tank truck drivers—the regulation imposed additional background checks, fees, and administrative steps for drivers already fully vetted and regulated under robust federal hazardous materials transportation laws. These redundant requirements conflicted with federal preemption standards under the Hazardous Materials Transportation Act (HMTA), which seeks uniformity and safety through consistent national regulations.

“This is a significant victory for regulatory common sense and the safe, efficient transportation of fuel,” said Ryan Streblow, NTTC president and CEO. “Doraville’s action aligns local law with long-standing federal preemption principles, eliminates duplicative burdens on professional drivers, and enhances interstate commerce. We applaud the city council for recognizing the need to streamline regulations in a way that supports both safety and economic vitality.”

Doraville is home to a major fuel terminal hub serving the Metro Atlanta area and Southeastern United States. Removing the permit requirement ensures unimpeded

access for qualified hazmat drivers, enhances supply chain fluidity, and helps prevent regulatory confusion and delays that could impact fuel delivery and public safety.

“This decision is a model of smart local governance,” said David Price, UPT executive vice chairman and NTTC chairman of the board. “We commend Doraville’s leadership for recognizing that national safety standards must remain consistent and for acting decisively to ensure that professional tank truck drivers can perform their vital work without unnecessary local interference.”

Pennsylvania-based PGT Holdings recently established Southern Pines Cryogenics as an independent asset-based carrier providing bulk cryogenic transportation solutions for the industrial gas industry.

Southern Pines Cryogenics previously operated as a division of PGT subsidiary Southern Pines Trucking, which was founded in 2000. Now as its own entity, Southern Pines Cryogenics is positioned for continued growth, safely transporting vital gases across North America to service the construction, healthcare, chemicals, food and beverage, and other industries, the company reported.

“As an independent company, Southern Pines Cryogenics will focus exclusively on the safe transportation of industrial gas products,” owner Pat Gallagher said in a news release. “We offer a close-knit community of drivers and staff who are committed to providing exceptional customer service. Southern Pines Cryogenics

Southern Pines Cryogenics previously operated as a division of PGT subsidiary Southern Pines Trucking.

Cryogenics

is the trusted partner for industrial gas transportation.”

With a fleet of late-model Peterbilt 579 tractors and bulk cryogenic trailers equipped with the latest safety technology, Southern Pines Cryogenics provides flexible solutions

to meet customers’ diverse transportation needs.

Southern Pines Cryogenics is led by Darren Coast, who serves as president. Coast started his transportation career at PGT after graduating from Westminster College. He now has over 30 years of multi-modal experience in transportation and logistics. Coast also is a member of several trucking and industrial gas associations, including ATA, TCA, NTTC, TMC, PMTA, CGA, and GAWDA.

“We are excited to announce the formation of Southern Pines Cryogenics as its own entity and expand on the great service offerings, customer service, and reliability that our customers have known from us over the years as a division of Southern Pines Trucking,” Coast said. “With safety and service at the forefront, we look forward to expanding our business and continuing to meet and exceed the needs of our valued customers, drivers, and staff.”

Girard has been on the forefront of Chemical Transportation Industry. We live by the mantra that it’s not enough to keep up with change, as leaders we must progress and move it forward; always mindful of ways to improve product design for our customers.

The International Liquid Terminals Association recently recognized outstanding individuals and companies during the ILTA 2025 Safety and Leadership Awards Breakfast in Houston.

Each year, ILTA presents the Safety Excellence Awards to member companies that demonstrate exceptional performance and a deeply rooted commitment to workplace safety during its annual conference and trade show. To be eligible, ILTA members must complete a straightforward reporting process aligned with U.S. OSHA Forms 300 and 300A. Companies that go above and beyond in reducing incidents and promoting a culture of safety are recognized with this award—a reflection of the industry’s shared commitment to protecting workers and operating responsibly.

“ILTA congratulates all of the 2025 award recipients and thanks them for leading the way in safety, service, and operational excellence,” the association said in a news release.

Safety Excellence Award recipients

■ Advario North America

■ Benchmark River and Rail Terminals

■ BWC Terminals

■ Canal Terminal Company

■ CITGO Petroleum Corporation

■ Colonial Pipeline Company

■ Delek Logistics Partners

■ Enbridge US Gulf Coast Terminals

■ Energy Transfer

■ Flint Hills Resources

■ Howard Energy Partners

■ Intercontinental Terminals Company

■ Jefferson Energy

■ Kinder Morgan

■ LBC Baton Rouge

■ LBC Freeport

■ Marathon Petroleum Company

■ Martin Midstream Partners

■ MIPC

■ Motus Energy

■ Murphy Oil USA

■ ONEOK

■ Saudi Aramco

■ Shell Pipeline Company

■ Stolthaven Terminals Houston

■ USD Group

■ Vecenergy

■ Vopak North America

Viking Transport, which runs a propane delivery fleet in Mississippi, recently deployed BeyondTrucks’ AI-powered, multi-tenant transportation management system in an effort to modernize processes.

Previously, Viking’s operations relied on disconnected systems that required manual data entry across multiple platforms and spreadsheets. The fleet needed an integrated TMS that could handle its unique and complex operational processes while optimizing the balance between internal and external transportation movements to improve utilization, the companies reported.

“We’ve decided to migrate our TMS to the BeyondTrucks solution,” Todd Russell, Viking general manager, said in a news release. “As we have expanded, using a mixture of spreadsheets and manual processes in combination with our legacy TMS has not served our needs. BeyondTrucks allows us to automate our processes, which results in higher productivity, reduced errors, and better visibility into real-time data.

“We are also seeing improved customer service experiences for both internal and thirdparty loads.”

With the BeyondTrucks platform, Viking now has several new capabilities for streamlining business processes and improving utilization, including:

■ Driver workflow tools for standardizing operating procedures at the driver end

■ Integrations with Cargas (ERP) and Sage (payroll) systems for maintaining crucial records and information and reducing manual data entry

■ Automated rating and payroll calculations for both internal and external transactions

■ Real-time data visibility reporting for quicker decision-making

■ Driver mobile app with an offline mode for use in remote areas without cell reception

“We’re seeing more companies like Viking looking to modernize their transportation

The Platinum Safety Award is ILTA’s highest safety honor. To receive this distinction, companies must achieve an average total recordable incident rate (TRIR) of 0.5 or less per 100 employees and submit a detailed description of their company’s safety programs. Submissions are reviewed by a panel of peer safety professionals who evaluate both safety performance and the strength of a company’s safety culture.

Safety Award winners

■ Small company:

Howard Energy Partners

■ Large company:

Marathon Petroleum Company

In addition to safety excellence, ILTA also recognized outstanding individual contributions through its annual leadership awards.

Outstanding Young Professional Award recipients

■ Marissa Karl, Buckeye Partners

■ Distinguished Service Award recipient

■ Harold Laurence, Trinity Consultants

Viking Transport recently deployed BeyondTrucks’ AI-powered, multi-tenant transportation management system in an effort to modernize processes.

management systems,” BeyondTrucks CEO Hans Galland said. “Our platform can address fleets’ unique and complex processes with its highly configurable, real-time workflow capabilities. We’re proud to count Viking Transport among our newest customers and look forward to helping position them for continued growth in the energy sector.”

Bill Marchbank fumed in disbelief. He’d just finished digesting a highly critical third-party assessment of Trimac Transportation’s safety culture following the June 2018 explosion of a fuel tanker at a maintenance facility—and couldn’t stomach the report’s assertion. “Trimac [already a two-time National Tank Truck Carriers safety champion at that point] doesn’t operate safely?” he wondered incredulously.

“Everyone involved was so mad they wanted me to fire the consultant,” recalled Marchbank, then chief operating officer. “I said, ‘Hold on, let me read it again.’ So I read it again that night, and I was still angry. Then I read it the next morning, and again at noon, and finally I called Matt [Faure, Trimac president and CEO] and said, ‘I know this is inflammatory, and it’s got our blood boiling,

but if you scratch out all the provocative language, he’s not wrong.

“He is absolutely right about the way we need to go about making changes.”

Marchbank’s receptiveness, however reluctant it was initially, precipitated a safety renaissance for Trimac, which overhauled its safety program using a socio-technical approach in the aftermath of that “triggering event,” as Faure

describes it. Soon thereafter, the family-owned carrier went on to claim its first NTTC safety championship in 12 years; and now Trimac is celebrating its fourth win since 2002 by further refining its signature safety program, better utilizing existing tools and technology, and pursuing continuous improvement through innovation.

Alex Guariento, then vice president of safety, accepted Trimac’s 2024 Harvison-division Heil trophy—which goes to a for-hire carrier with more than 15 million miles—during this year’s NTTC Annual Conference in Tampa. “We don’t do safety to win trophies,” Faure emphasized. “We do it because we want to be the safest company in this industry. We want to bring everybody home every

day. That’s why we do safety. The trophy is a cherry on top. It’s the icing on the cake to be recognized by our peers for all the amazing work that everybody is doing.”

This victory is even sweeter for Guariento and Marchbank.

Guariento retired in June, at which point Marchbank—now the SVP of mergers and acquisitions integration— relinquished safety oversight to Ryan Collinge, who succeeded him as COO in 2023.

“It’s nice to go out as a champion,” Marchbank grinned.

“But what I’ve enjoyed most is watching the growth of everyone in this company. It’s been wonderful to see people embrace our ‘Rooted in Safety’ program.”

Three people were injured in the 2018 explosion in Newfoundland, Canada, which investigators attributed to the

sparks from a welding torch igniting the fumes in a tanker while it was in the shop; but, miraculously, everyone survived, including the mechanic who was repairing a vapor recovery pipe under the trailer. “By the grace of God—nobody died,” said Guariento, who

teamed with Trimac in 2020 after a long career in transport safety, including 14 years at Greyhound.

“But it caused us to really take an introspective look at how we do safety. How did this happen? What enabled it to happen? And what came out of that

was we had very thorough procedures, but they were so complex they took too long, so people weren’t following them.

“They looked good on paper, put in practice, they didn’t work.”

Robert Beach, who retired in 2021, initiated the Rooted in Safety makeover, stepping in as VP of safety and risk management in July 2018 after more than 30 years in Trimac operations. The proactive program cultivates a safety-centric environment by encouraging employees to identify potential hazards before they spark sobering near misses. Key elements include studying the psychology behind safe behaviors; acknowledging the role managers and factors outside drivers’ control play in on-highway incidents; focusing on high-consequence events; and conducting investigations based on direction, competency, opportunity, and motivation (DCOM).

“Basically, there are three legs to the stool—sensitivity to operations, organizational mindfulness, and measurable learning outcomes,” Marchbank summarized.

Guariento took the program to the next level, simplifying processes with employee feedback, reforming driver interactions—including how leaders differentiate mistakes from willful noncompliance—utilizing modern technology, and elevating safety above all other considerations. “His willingness to take the brunt of what comes with that, whether it’s from a customer, driver, or operator—in the name of safety progress—is a truly commendable trait,” Collinge said.

The organization’s inspirational reward is a DOT-recordable accident frequency that steadily improved each of the last five years—while Trimac expanded rapidly through 14 acquisitions—culminating with a company-record rate of 0.196 accidents per million miles in 2024. Stated more impressively, Trimac last year traveled 149 million miles while transporting nearly 700,000 liquid and dry bulk loads across seven time zones, often in snow, rain, or heavy traffic, in a fleet of 2,100 tractors and 4,200 tankers—with only 16 DOT-preventable accidents.

“Safety is the No. 1 priority here,” Guariento said. “There’s no doubt in my mind, from the top down in this company, nothing supersedes safety.”

Continuous improvement Service with safety is a founding principle that remains a core value at Trimac

under the leadership of Jeff McCaig, Trimac’s chairman of the board, and the grandson of Jack McCaig, who founded the company in 1945. His passion for safety filters down to Faure, Collinge, and the rest of Trimac’s executive team—whose unwavering support fuels constant advancement.

“If your leaders don’t expect safe operation, then you’re not going to get solid safety performance,” said Lance Hagler, who was selected to succeed Guariento as VP of safety in July. “One thing I respect about Matt and Jeff is how they push us. They don’t come to the safety department and say, ‘What do we need to do next to stay safe?’ They have ideas. They read articles, they look at what other people are doing, and they ask complex questions. That ensures we’re being progressive, looking ahead, and not resting on how we did things 20 years ago.”

At far left, Trimac organized a convoy that cruised by former driver Roger Beauchemin’s house in Montreal to celebrate his 100th birthday in 2021. At left, driver Edward Stasyshyn was selected as Trimac’s first Champion Finalist in NTTC’s Driver of the Year contest in 2020.

Ongoing safety efforts include enhancing leadership and driver training, clarifying procedures for weather-related work stoppages, boosting hazard ID rates, and expanding technology investments and proficiency. Trimac now uses Q4 Leadership training to develop senior leaders’ people skills, and Avatar for LLLC (Look ahead, Look around, Leave room, Communicate) defensive-driving instruction and customized product stewardship videos delivered to drivers’ Isaac Instruments electronic-logging devices (ELDs). Following a rollover last winter, it also formalized a process for parking trucks that leverages its Lytx camera system’s Road View feature, which allows dispatchers to monitor road conditions in real time. “If we feel it’s not safe to drive, we’ll shut down the lane and tell the customer we’re going to be late,” Guariento said. “There’s absolutely no reason for a driver to get caught in a storm we know is coming.”

Trimac, which first began halting operations due to weather conditions in 2020, preemptively shut down lanes 150 times last winter after refining the decision process, Guariento shared. At the same time, employee-reported, high-consequence hazards jumped from

220 IDs in 2020 to 4,200 in 2024—both of which combine to further reduce risk. “When you have that kind of focus on proactive action and not just the number of accidents, then you’re out there with your eyes wide open, looking for what could go wrong,” Hagler said.

Technology-wise, Trimac is rolling out Storyboard’s software for handsfree communications across its fleet; spec’ing new tractors with IMMI’s airbag-equipped RollTek seating to increase survivability, and spray-reducing EcoFlap splash guards to boost visibility; and trialing wearables that provide soloworker health alerts. “As we improve, the tools we’re evaluating are increasingly unproven, because nobody out there is doing what we’re doing,” Hagler said. “So the decisions are harder, and we have to ask tough questions about the things we’re trying—which may not be in use anywhere else in the industry.”

Award-winning results Hagler couldn’t contain his joy upon hearing Trimac revealed as a 2024 Heil champ, immediately jumping out of his chair and rushing on stage to celebrate with Guariento. “I tried to say, ‘Hey Lance, come back,’ but he was so excited,” Faure laughed. “So I was super happy for the team.” Hagler grinned as he reflected on his reaction, admitting he was simply overwhelmed by seeing the company’s drivers and managers— who’ve collectively decreased Trimac’s accident frequency by 64% since 2020— recognized for their achievements.

“We put a lot of effort into safety, and it’s everybody—from our drivers to the CEO,” Hagler said. “But you rarely get rewarded for the things you do well in safety. Typically, you’re measuring the things that go wrong. You’re talking to

customers about issues and investigating incidents.

“So this award is a huge honor. Winning it is a big deal.”

For Faure, merely entering NTTC’s safety contest is significant. “It’s critical for us,” he enthused. “Every year, we try to improve the application we put forward. And how do you do that? Well, you can’t improve just with words. You must improve with actions. So it forces us to constantly innovate, try new things, and strive to do something that makes a difference.” And when those efforts pay off with a safety championship, the benefits are bountiful. The largest shippers seek out the most reliable carriers, top insurers support the safest fleets—and Trimac is one of Great West Casualty’s loss-run leaders among fleets with over 1,000 trucks—and elite drivers stick with carriers that are committed to their protection.

“The ideal outcome with recognition like this is first-class drivers who want to work in a safe environment, take care of their families, and go home at the end of the day will choose Trimac,” Collinge said.

“Maybe they didn’t think about us before, but now they will.”

With Collinge and Hagler leading the way, Trimac’s approach to safety won’t change. Hagler, mentored by Marchbank and Guariento, boasts new energy and enthusiasm, and Collinge brings a datadriven mindset to his new role. “We have the capacity to handle more data now than ever before, and that’s going to lead us in new directions,” Collinge predicted, vowing they’ll remain curious while growing more formulaic in their ongoing pursuit of safe operations.

“I can leave here proud of what we’ve accomplished, confident the company is in great shape,” Guariento concluded.

“I know they’re going to continue improving.”

Marchbank—whose fury has long since turned to delight—couldn’t agree more.

“It’s been an amazing ride for us, and I’ll tell you this—we are going to stay focused squarely on the socio side of that socio-technical model, because that’s about 80% of the lift. If you can get an organization to where people are comfortable saying, ‘We’re doing this wrong,’ and reporting it, then you have a chance to fix the problem before someone gets hurt.

“That’s where we’re truly trying to go.” BT

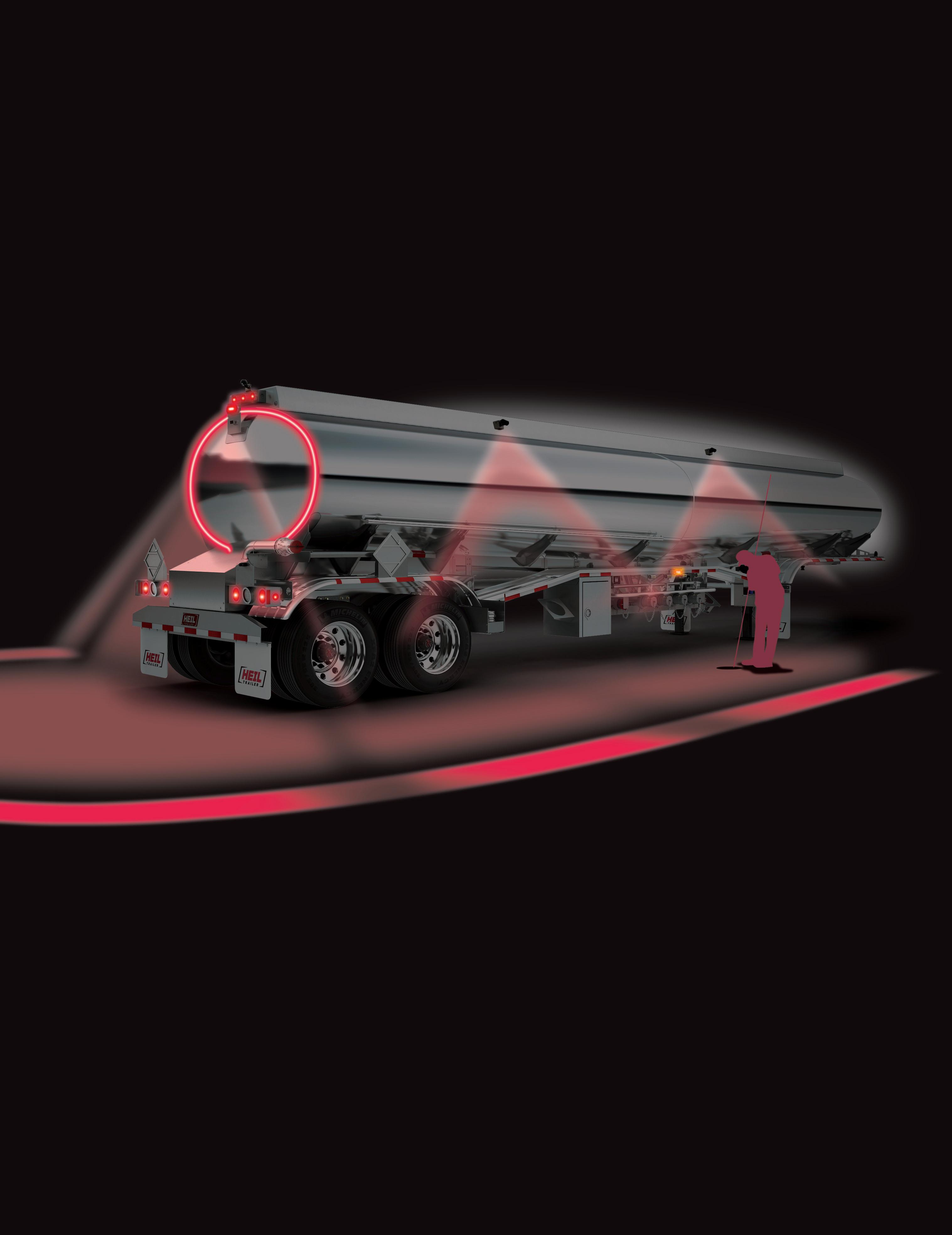

CivaCommand makes life easier for drivers like Ronnie Carnes with Lott Oil Company. He can prevent crossover, obtain real time overfill and retention status and more because the easyto-use CivaCommand Smart Tank System digitizes and integrates all loading and unloading functions.

Why make things harder for drivers? Scan the QR code or visit: opwglobal.com/civacon/civacommand

opwglobal.com/civacon/civacommand

MBH secures its place among the safest bulk fleets

by Jason McDaniel

Brian Hitchcock, founder and CEO of MBH Trucking, still pilots his fully customized Peterbilt 379 at 64 years old. Yes, he enjoys it. His father and grandfather also drove trucks, so it’s in his blood. But, more pertinently, he’s determined to do whatever it takes to preserve the family business amid growing challenges, like rising equipment costs and worker shortages.

“I used to drive for fun,” he said. “Now I do it because we don’t have enough people.”

MBH does, however, have a growing reputation for operational excellence that today includes a Heil trophy, a legacy-boosting honor Hitchcock hopes will help him secure the company’s future for his sons—MBH general managers Rick and Jordan Hitchcock—by attracting first-class customers and employees who stick with them. The Webberville, Michigan-based bulk hauler collected the prestigious award in April at

National Tank Truck Carriers’ 2025 Annual Conference in Tampa, Florida, where it emerged as the North American safety champion in the Sutherland division for for-hire carriers with less than 15 million miles.

“For generations, our family has wanted to be known as the best, and this safety award makes me feel that way,” Brian beamed. “We’ve done the best job we could for many years to get to this point—and we’re only one second away from everything changing—so we’re very grateful.”

MBH, which transports fertilizers, liquid sweeteners, and diesel exhaust fluid to seven Midwest states and Ontario, Canada, with 24 trucks and 40 tank trailers, didn’t have a dedicated safety director before Susan Sanderson, HR and safety manager, arrived in 2009. Now it’s in its third consecutive year without a DOT-recordable accident thanks to Brian’s steadfast commitment to steadily expanding its safety processes and procedures, maintaining elite equipment, and utilizing Samsara cameras and alerts to coach up its safety-conscious professional drivers.

“It was a goal of mine to help Brian win this award, so I got emotional when he gave me the news,” Sanderson shared.

“It was really quite awesome.”

Brian founded MBH in 1998. But the family’s transportation story started much earlier. Lyman B. Hitchcock, Brian’s grandfather, began hauling

bagged fertilizer in 1953; and Allen and Dorothy Hitchcock, Brian’s parents, founded A&D Hitchcock Trucking in 1960. Brian worked with his parents, and then his brother, Brad—who still operates Hitchcock Trucking in Webberville—before venturing off on his own with two trucks and two tankers to haul liquid fertilizer for a local plant.

“As the need for liquid bulk transportation grew, we grew with it, and it’s been a good business,” Brian said.

Brian’s sons joined MBH as soon as they graduated from high school. Rick, 42, gravitated toward operations, and now oversees dispatching, billing, and payroll; and Jordan, 39, who always preferred working with the equipment, now manages maintenance and repair activities, and truck and trailer purchasing and spec’ing. Brian’s third son, Ryan, 33, is not directly involved with MBH but serves as project coordinator, and his excavating company recently installed 5 million gallons of tank storage for MBH’s sister operation, Chloride Solutions, which provides liquid calcium chloride for local dust control and ice management.

“Ryan took care of everything involved with that project,” Rick said. “That was huge for us.”

MBH downsized during the Covid-19 pandemic, primarily due to complications with international trade and

transportation. But the company has been “very fortunate” during the lingering freight recession and tariff-induced economic uncertainty, Rick said, maintaining steady business by providing safe and reliable service to loyal customers— and a family-first environment for its dedicated drivers and office personnel.

“The Hitchcock family is wonderful— every single one of them,” Sanderson attested. “They’re down-to-earth people, and they want to keep their employees happy because they want them here for the long run.”

Steady improvement

Safety is paramount to happiness, and long-term job satisfaction, and

Sanderson has labored tirelessly to build out MBH’s safety program since arriving 16 years ago. “Brian had never had a safety person, so he brought me in to get the safety department up and running, and develop written policies or procedures. None of that was set up yet,” Sanderson recalled.

“They gave me the opportunity to come in and start from scratch.”

The trucking veteran went to work immediately, leaning on her experience as safety and environmental manager at Davis Cartage to begin establishing MBH’s safety program, including creating a manual for drivers, recording rules for cross-border transportation, and championing inward- and

outward-facing Samsara cameras— which Brian first piloted in his own vehicle to encourage driver buy-in— for alerts and liability protection. She also keeps MBH informed of changing regulations and helps conveys that information to drivers in a way that makes sense, Jordan added. “Since she came on, every year, every six months, every quarter, we’ve gotten a little bit better,” Rick agreed. “And it hasn’t always been easy. Sometimes, it’s painful.

“You can’t just write up a policy and say, ‘Yup, we’re safe now.’ It doesn’t work that way.”

Samsara’s system, which also enables post-incident coaching and hands-free communication through drivers’ electronic-logging devices, has played a critical role in MBH’s safety improvement, Sanderson said. But nothing is more impactful on highway safety—and MBH covered 1.9 million miles with a .000 accident frequency in 2024— than expertly educated, highly capable humans who care about their customers, equipment, and each other, Brian insisted.

MBH utilizes online training supplied by its auto and health insurance providers, and thoroughly vetted prospects first ride and then drive with trainers until they’re comfortable on their own.

“Everybody wants a .000 accident ratio, and fortunately we’re one of the few carriers who’ve done that,” said Brian, who’s on the Michigan Truck Safety Commission and a past president of the Michigan Trucking Association. “But staying safe in today’s society is a never-ending process, especially with some of the new technologies that are eroding common sense.”

How does MBH encourage its 25 company drivers to appreciate their equipment? By supplying them with clean, well-maintained trucks and tank trailers that don’t break down on the roadside—or frustrate them at shipper facilities—boosting driver retention and dependability. “There’s a level of comfort for customers when the same drivers are

coming in, they have nice equipment, and they’re not struggling, or sitting there, unable to load, because their trailer has an issue,” Rick said. “That doesn’t happen at MBH. We’re going to be there, ready to work.

“That’s been our signature for years.” MBH maintains two two-bay facilities for vehicle maintenance and cleaning. The shop includes one bay for service and repairs and another for trailer prepping, and the wash rack boasts bays for external truck and internal tank cleaning. The carriers’ three-man maintenance team can diagnose powertrain

and aftertreatment issues with OEM software, and upfit tanks with auxiliary equipment, like the spray systems on Chloride Solutions trailers; and DVIR updates delivered via Samsara devices keep them apprised of any problems. “We’re an hour away from the closest dealers, so we had to get into doing a lot of things ourselves,” Jordan said.

Trucks are mostly Peterbilt sleeper cabs sourced from JX Truck Center and Reefer Peterbilt, along with a handful of Western Stars from D&K Truck. MBH equips a few Ranger positive displacement pumps for high-viscosity products

like molasses, but most trucks feature MP Flomax 15 self-priming pumps. “They can move fluids at 260 gallons per minute, and that’s crucial for us,” Jordan said.

“Our guys want to be in and out of places in 45 minutes.”

DOT 407 stainless-steel tankers by Polar Tank, Wabash (Brenner), and MAC LTT—and sourced from Superior Tank— vary in length, capacity, and configuration. MBH runs pups, 11,000-gallon double conicals, heavy-duty eight-axle units, and doubles in Michigan, where the carrier can legally scale up to 110,000 lbs. of payload. Most trailers feature hydraulic lines, Hendrickson suspensions and tire pressure monitoring systems, Michelin and Yokohama super-single tires, Bendix air disc brakes, and additional rear lighting from Grote or Truck-Lite—and they all sport regularly replaced reflective tape.

“If there’s an issue, we address it immediately,” Rick confirmed.

Safety-focused service MBH leaders put people first, emphasize continuous safety improvement, and run first-class equipment. That’s why it’s a 2024 NTTC safety champ.

Brian grew emotional while accepting the Heil trophy, and Sanderson was equally overcome receiving the news she’d hope to hear since MBH first started entering the North American safety contest in 2021. “I was surprised, to be honest,” Rick said. “We’re just a needle in a haystack, so I was definitely taken aback.” Jordan, however, wasn’t shocked. “I know everybody here works very hard to stay safe,” he said. “But it’s a pretty sweet accomplishment.”

The championship isn’t MBH’s first NTTC honor. It also won personnel safety awards in 2021 and 2023 and Grand awards in 2023 and 2024. But it is the sweetest, especially for the drivers, many of whom have stopped to admire the trophy. “They’ll say, ‘Wow, this really is cool,’” Sanderson said. “And I tell them, ‘You guys won that. We have it because of your safety—so thank you very much.’”

MBH already is incorporating the championship logo into emails, bills of lading, and clothing, and contemplating the additional benefits of an award-winning safety reputation yet to come. Rick hopes it helps MBH convince insurers he can successfully train less experienced drivers. “One of the first things we did after winning was compile an email chain with the logo and send it off to our insurance company, like, ‘Hey, we’re not so bad after all,” he said. The company also continues to grow and evolve, recently implementing Toro’s transportation management system while considering upgrading video-safety telematics and searching

for new ways to keep veteran drivers involved, and younger people interested. And Brian—whose father still helps deliver bagged fertilizer part-time in his custom Peterbilt 389—is determined to stick around as long as it takes to make sure his family’s trucking legacy is safely secured in the next generation’s hands, even if that means never fully hanging up his keys. “It has been an amazing journey that I could not be any more grateful for, and the spinoffs of everything we’ve done so far will be even greater,” he predicted.

“I have 11 grandchildren coming up, and the platform is there for them to do anything they want to do.” BT

The B630: Your new, lightweight, and economical way to move product.

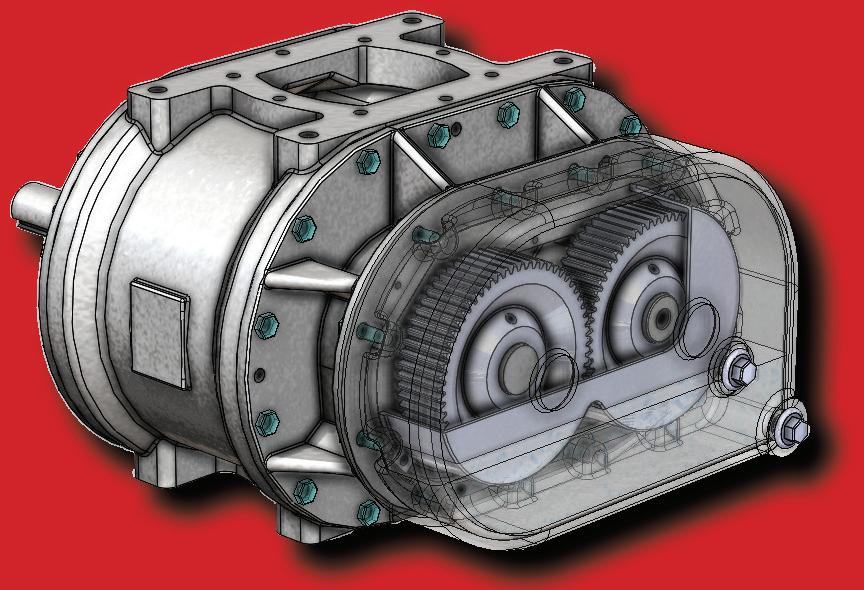

Introducing the B630 Truck Blower from HR Blowers, engineered specifically for the U S powder market and available exclusively through Werts Welding and Tank Service

Designed to move dense powders like cement and fly ash, the B630 combines quality, performance, and efficiency. Weighing in at just 265 lbs., it's the lightest lobe blower available in the United States, making it ideal for operators looking to reduce overall weight without sacrificing durability or output. Engineered for convenience and built to last, the B630 comes with the longest warranty in its class, a testament to the exceptional quality and craftsmanship that define HR blowers

HR Blowers, based in the UK, have been manufacturing premium truck blowers for over 40 years

Werts Welding and Tank Service, headquartered in St. Louis, has proudly supported the US transport industry since 1957

LIGHTER

ECONOMICAL

Better Bottom Line

SIZE / CAPACITY

• Flow from 306 - 718 cfm

• Continuous Pressure to 16 Psi

• 265 Lbs dry weight

APPLICATIONS

• Truck mounted for tank offload

• Conveying fine to dense powders

LSP wins second Heil trophy—its first in NTTC’s new category by

Jason McDaniel

LSP Transport (LSPT) made history four years ago as the first private-fleet operator to win a championship in National Tank Truck Carriers’ long-running North American safety contest, previously dominated by for-hire carriers.

Two years later, NTTC added a third Heil trophy exclusively for private fleets.

“We kind of felt responsible for that,” joked Ross Pendergast, LiquidPower Specialty Products (LSPI) director of operations and LSP Transport general manager, who joined the LSPT team in 2021.

Now LSP Transport is celebrating its 10th anniversary as the private fleet of Berkshire Hathaway-owned LSPI with its second NTTC safety championship,

and first in the new private-fleet category, which Gemini Motor Transport controlled the first two years. The bulk hauler secured its initial trophy in the contest’s Sutherland division—now reserved for for-hire carriers with less than 15 million miles—and bagged its second trophy with an accident frequency of 0.180—nearly 50% lower than in 2020. “They’re both satisfying,” said Joe Maple, LSPT safety manager. “It’s hard to win this thing. Darn hard. But

LSP Transport’s safety-conscious crew secured its first private-fleet division Heil trophy with a 0.180 accident frequency.

the reality is, despite all the growth that’s taken place in the last four years, including personnel changes and facility expansions, we never altered our mindset. It’s still about operating safely and taking care of customers.

“So this win is particularly gratifying for us.”

Maple, Pendergast, and the rest of the LSPT team, which includes Gary Coulter, LSP Transport terminal operations manager, and Jake Politakis, LSPI vice president of supply chain, credit their new AI dashcam and telematics provider, a renewed emphasis on Smith System training, and newly empowered lead operators for their safety achievement

at the 2025 NTTC Annual Conference in Tampa, Florida, where Politakis accepted the trophy.

“Everything starts with safety at LSP Transport,” Politakis said.

“When we talk about reliability with customers, we can’t deliver if we’re not a safe organization. Whether it’s outof-service time on equipment, drivers who are unable to work because they’re injured, or those factors causing people to leave, these things aren’t good. So we want to approach everything with a safety mindset. That’s our foremost commitment.”

With support from LSPT’s leaders and ownership group, and the buy-in of its 72 company drivers, that safety-first approach is ingrained in LSPT’s culture—and the results are remarkable. LSPT drivers traveled 5.5 million miles without a preventable accident in 2024; and, more impressively, the company’s last preventable occurred way back on Oct. 2, 2019—a date Maple recalls easily. It was approaching 30 million miles without a preventable this summer.

“That means people aren’t getting hurt,” Maple beamed.

They aren’t getting cited either. LSPT drivers haven’t received a compliance, safety, accountability (CSA) violation in more than a year, a feat Maple credits to the six mechanics charged with maintaining the company’s highly specialized

fleet of 82 trucks and 192 tank trailers. Most tractors are Kenworth T680 72-in. sleepers with advanced driver assistance systems and compressors for pumping off LSPI’s viscous product. New stainless-steel Wabash tankers are insulated DOT 407s with automatic tire inflation, disc brakes, and roll stability. “We toot maintenance’s horn all the time in safety meetings because they’re an integral part of what we do,” Maple said. “They ensure we operate safely by showing drivers what to look for in pre- and post-trip inspections, and making sure vehicles are in working order before

they leave, instead of saying, ‘Well, it’ll be alright until it gets back.’

“We don’t operate like that. We fix problems before we get on the road.”

New hourly compensation rates encourage drivers—many of whom come from oilfield operations that pay by the mile—to stay safe on pickups and deliveries, no matter how long they take. And with elite equipment, safety-focused managers, and policies that align with careful practices, LSPT drivers are sticking around, perpetuating safe operations. LSPT’s turnover rate is at 5% after reaching 25%-plus three

years ago. “It would have been nearly impossible to grow and maintain a high safety standard with that kind of turnover,” Pendergast said.

The industry’s top trade organization is taking notice.

LSPT has won an award every year since it started entering NTTC’s safety contest in 2019, including five Grand awards. It also owns five personnel safety awards—and now two North American safety titles.

“This one feels even better to me,” Coulter said. “It proves the first one wasn’t a fluke.”

LSPT didn’t repeat by relaxing. The company switched telematics vendor, doubled down on Smith System education, and created a new class of lead operators guided by former driver Chad Moore, now head of services and training, further strengthening its “all-encompassing” safety ecosystem. “Yeah, we paid a lot of attention to safety when we won before, and we did the best we could,” Coulter attested. “But we’ve improved across the board since then.”

The fleet’s previous video safety technology was more punitive than preventive, or “more stick than carrot,” as Coulter says. LSPT’s camera-aided approach rewards drivers for safe behaviors, gamifies improvement, and enables self-coaching through real-time in-cab alerts. “It gives drivers audible alerts inside the truck if they make a mistake, or they’re following too closely or something like that, and gives them a chance to recognize and fix it themselves,” Maple said.

“That has been instrumental in helping drivers change their habits.”

One veteran driver had a long list of things he hated about cameras when LSPT started piloting its new system three years ago, Coulter relayed. But a few weeks in, he realized he had more bad habits than he cared to admit, and self-correction was making him better. Now LSP equips every tractor with outward-, inward-, and side-facing cameras that provide invaluable

liability protection for drivers and the company while improving performance in multiple ways, in one case enabling LSPT to identify and eliminate a rash of dropped trailers.

“We’re getting better at all the things that help us avoid incidents, so the system is tremendously beneficial,” Maple said.

Smith System’s crash-avoidance keys reinforce safe driving habits. LSPT now has six certified instructors who teach

the system during introductory and ongoing training. “It’s more ingrained now,” Pendergast said. “We have more people trained in Smith System, who are qualified to train others, we have some in-house capability to teach trainers, and our cameras complement it.” Orientation lasts eight days. Then new drivers head out with a lead operator until they’re ready to drive safely on their own— whether it takes three weeks or three months.

From coast to coast, we’ve got you covered.

KAG offers nationwide tank wash facilities for both food and chemical tanks designed with drivers in mind. With after-hours scheduling, Kosher certification, and a 99.75% industry-leading acceptance rate, we make sure your tank is clean, compliant, and ready to roll.

Schedule your tank wash today. thekag.com/kag-tank-washing/

LSPT considers all its drivers operators, because they also must perform safely inside customer facilities, and lead operators are driver trainers with even greater responsibility. Leads meet regularly to ensure training is uniform across all locations, and set an example for other drivers, including establishing a precedent for using cones to reduce fixed-object collisions.

“They’re a mentor and coach,” Coulter said. “They’re a sounding board, and they filter information out to our terminal managers.”

Safe expansion

Coulter and Maple contributed to the first NTTC safety championship. Pendergast and Politakis joined them shortly thereafter to spearhead the rapid growth of LSPI’s private-fleet business while keeping a close eye on safety. Over the last three years, LSPT grew its driver pool and fleet; and increased throughput by an even greater amount—with only a slight increase in miles traveled, Pendergast said—by regionalizing operations to enhance efficiency and give drivers more home time.

“When we started this mission four years ago, we quickly realized the value a private fleet gives us—with our customers, and by positioning us with the ability to grow,” Politakis shared. “That’s why we really leaned into figuring out what we needed to do to facilitate this growth,” Politakis said.

That work includes expanding LSPI’s rail car fleet and its facilities.

The bulk transporter is relocating its Bryan, Texas, terminal closer to its LSPI manufacturing facility, currently about 12 miles away, in a 2026 move that will double shop capacity to eight pull-through bays and increase yard space by 40%, Pendergast said. It’s also relocating and expanding its West Texas terminal; adding a maintenance facility in Chickasha,

Above, LSPT drivers haven’t received a CSA violation in more than a year after the company ‘upskilled’ its maintenance team and capabilities. At left, a driver awaits his next load in a lounge that features one of LSPT’s two Heil trophies.

Oklahoma; nearly doubling its yard space in the Lower Midwest; and building out a new site in the Upper Midwest. LSPT also maintains a terminal in the Dakotas, and a drop yard in the Southeast U.S.

“We’re not shy about giving these guys the resources they need,” Politakis said.

“I haven’t said no to any of Ross’ requests in my three and a half years. We’ll see how long the streak continues, but it’s very helpful to have our parent company’s support, and access to capital to make the proper investments in people, tools, and technology it takes to be bestin-class, and I think we’re seeing that with all our safety programs and everything we have in our toolbox.”

Ongoing investments also convey leaders’ belief in LSPT’s continued growth potential, Politakis said—and ensure LSPT will be contending for safety championships for years to come.

Pendergast’s goal is to have a trophy for every terminal, at least.

“If we don’t change anything, and everything continues to go right, we ought to be in the running ever year,” Maple predicted. BT

OUR TANK CLEANING SOLUTIONS REMOVE EVEN THE MOST STUBBORN RESIDUES FROM EVERY TANK SHAPE AND LENGTH.

Cloud-Sellers 360

Fluid-Driven Tank Cleaner shown mounted on the Manway Horizontal Nozzle Assembly with virtual depiction of tank cleaning

CLOUD-SELLERS® 360

FLUID-DRIVEN TANK CLEANER

Industry standard for use with large smooth bore tankers

Available with dual- or triple-nozzle fluid-driven hubs, sealed lubricated units and flow-through gearboxes, this high-impact, high-efficiency tank cleaner offers consistent cleaning over the entire pressure range.

TANKJET® AA190

MOTOR-DRIVEN TANK CLEANER

Low-flow, high-pressure unit designed for bulkhead and baffle tankers.

WE OFFER FAST, COST-EFFECTIVE PERIODIC MAINTENANCE AND REPAIR SERVICES

Choose from multiple authorized repair centers.

48 hour turnaround on periodic maintenance service for just $525.

TANKJET 50 TANK CLEANING NOZZLES

High-pressure unit designed for IBC tote cleaning.

UNLOCK UP TO 25% IN SAVINGS WITH OUR TRADE-IN PROGRAM

by Jason McDaniel

NTTC’s

National Tank Truck Carriers will continue to celebrate its 80th anniversary at Tank Truck Week 2025 by tackling the issues of today, exploring the solutions of tomorrow, and reconnecting with members from yesterday, including Altom Transport, which recently rejoined the association after a long hiatus—and is bringing a brandnew Polar Tank trailer with it to Kansas City.

“This year’s Tank Truck Week embraces yesterday, today, and tomorrow—and part of that is welcoming members who’ve come back,” said Ryan Streblow, NTTC president and CEO. “We’ve had an amazing year with fleets and carriers coming on board, and not just Altom, but Breckenridge Trucking, Maverik Logistics, Energy Transport, Sprint Transport, and more. So we have a great group already, and commitments from a variety of carriers that aren’t members now but have heard about the progress we’ve been making over the past three to five years.

“We’re a recognized name on Capitol Hill, we’re fully embedded in the regulatory environment, and we’re laser-focused on improving the tank truck industry’s image—and that’s really starting to resonate.”

Tank Truck Week is set for Oct. 5-8 at the Kansas City Convention Center in Kansas City, Missouri.

Thomas Warren Jr., executive vice president at Altom and Al Warren Oil Company, is planning to attend for the first time in several years. And he’ll go as a member for the first time since 2013 after rejoining the association last fall. “We’re

part of an insurance captive, and a bunch of members were talking about the great things they’re doing,” Warren said. “Our terminal network is growing, and our safety department is growing along with it, so we started taking a look at the resources NTTC is offering, and I thought, ‘This probably is a good time to return.’

“There’s new leadership in place—and we feel they can help us grow the company.”

The group’s combined fleet, including sister companies Altom Canada and Excel Environmental Services, now boasts over 450 tractors, with 75 tank wagons, and 1,000 tank trailers. And their recent growth includes new Midwest terminals in Monroe, Michigan, which opened in June, and Harrison, Ohio, on the northwest side of Cincinnati; and 40 2026 Polar tankers added this year—just in time to display one at Tank Truck Week, a right reserved for members.

“It’s the opportunity of the year to showcase marquee brands,” Streblow said.

Altom still was prepping its show trailer when Bulk Transporter went to press, but the carrier planned to send a 7,000-gallon DOT 407 chemical tanker. The insulated, stainless-steel, double-conical trailer will feature center unloading; “3-o’clock” safety rails; Betts Industries ground-level vapor recovery; Hendrickson axles, disc brakes, and tire pressure monitoring; Truck-Lite lighting—including Super 44 LED strobes—and Michelin super-single tires. “Our trailers aren’t the run-of-the-mill units you see other carriers pulling,”

Sunday, Oct. 5

• 4-6 p.m.: Cargo Tank Risk Management Committee (CTRMC) meeting

• 4:15-5:15 p.m.: Young Executives and first-time attendee event

• 5:30-7 p.m.: Political Action Committee (PAC) reception

Monday, Oct. 6

• 8:30-9:30 a.m.: Dry Bulk and Food Grade Committee meeting

• 9:45-10:45 a.m.: Chemical Committee meeting

• 11 a.m.-noon: Workforce Development Committee meeting

• 1-2 p.m.: Energy Services Committee meeting

• 2:15-3:15 p.m.: Advocacy Committee meeting

• 3:30-4:30 p.m.: General session—Opening remarks from Art Fleener, Fleener Consulting; and an OEM panel featuring EnTrans International, Hendrickson, and Kenworth

• 4:30-6:30 p.m.: Exhibit hall open, ACT 1 grand opening reception

Tuesday, Oct. 7

• 8:30-9:30 a.m.: Regional Safety and Security Council meetings

• 9:45-11:30 a.m.: General session and keynote speaker

• 11:30 a.m.-2 p.m.: Exhibit hall open

• 2-3 p.m.: Board of Directors meeting

• 3:15-4 p.m.: Educational sessions—“First Steps in Hazmat Compliance: A Beginner’s Guide for the Tank Truck Industry” with Art Fleener; “Zero Trust in Motion: Enhancing Cybersecurity in the Trucking Sector” with Dr. Louis DeWeaver; and a tank wash and maintenance session

• 4-4:45 p.m.: Educational sessions—“Prevention and Intervention: Combating Human Trafficking through the Trucking, Bus, and Energy Industries” with Micah Larsen; and tank wash and maintenance session, and an operational session

• 4:30-6:30 p.m.: Exhibit hall open

Wednesday, Oct. 8

• 9:45-10:30 a.m.: Educational sessions—A safety and security session, a tank wash and maintenance session, and an operational session

• 10:45-11:30 a.m.: Educational sessions—“Bulletproofing Your Business: Surviving in Today’s Legal Environment” with C. Stephen Setliff; a tank wash and maintenance session; and an operational session

• 11:30 a.m.-1:30 p.m.: Exhibit hall open

• 1:30-2:30 p.m.: Tank Maintenance and Cleaning Council meeting

• 2:45-3:45 p.m.: Safety and Security Council meeting

• 6-8:30 p.m.: Annual Safety and Security Council banquet (Reception 6-6:30 p.m., Dinner and awards 6:308:30 p.m.)

Warren said. “We take a lot of pride in what we do, so we make them as driver and shipper friendly as possible.”

A unique experience

Tank Truck Week, which last year brought more than 1,000 industry stakeholders to Charlotte, North Carolina, once again will feature expert speakers—including an appearance by former NTTC president and Bulk Transporter editor John Conley—committee meetings, and educational sessions on safety and security, tank wash and maintenance, and operational topics. Day 1 includes an event for first-time attendees and a Political Action Committee reception on the Loews Kansas City Hotel rooftop, Day 2 boasts an OEM panel led by NTTC Chairman David Price and the ACT 1 grand-opening reception, Day 3 includes a keynote by NFL Hall of Fame quarterback Terry Bradshaw, and the week concludes with the annual Safety and Security Council awards banquet.

Finally, the exhibit hall, which opens Monday, Oct. 6, will spotlight new tank truck equipment and technology from more than 80 vendors and suppliers spread across nearly 200,000 sq. ft. of space.

“Tank Truck Week is a unique experience,” Streblow said. “It attracts C-suite executives; operations, purchasing, and financing personnel; and safety, security, and maintenance professionals—and offers something for everybody across the board as the week progresses.” BT

No matter if you need bottom-loading, gravity-unloading, standard or air-actuated product returns, single-, dual- or triple-bank manifolds, get exactly what you need, built to your specifications, with Betts-engineered proven modular design.

• Up to 10 compartments

• 11-inch or larger on-center distance

• Standard or air-actuated product returns

• Methanol/ethanol-resistant sight glass

• Multiple seal options available, including fluorosilicone, FKM BLT and FKM

“GFLT-S”

Visit BettsInd.com/AirManifold and use our SmartSpec™ Custom Air Manifold Configurator to easily generate a custom product number for your specific application.

(See

Familial bonds buoy bulk tequila hauler’s international business by

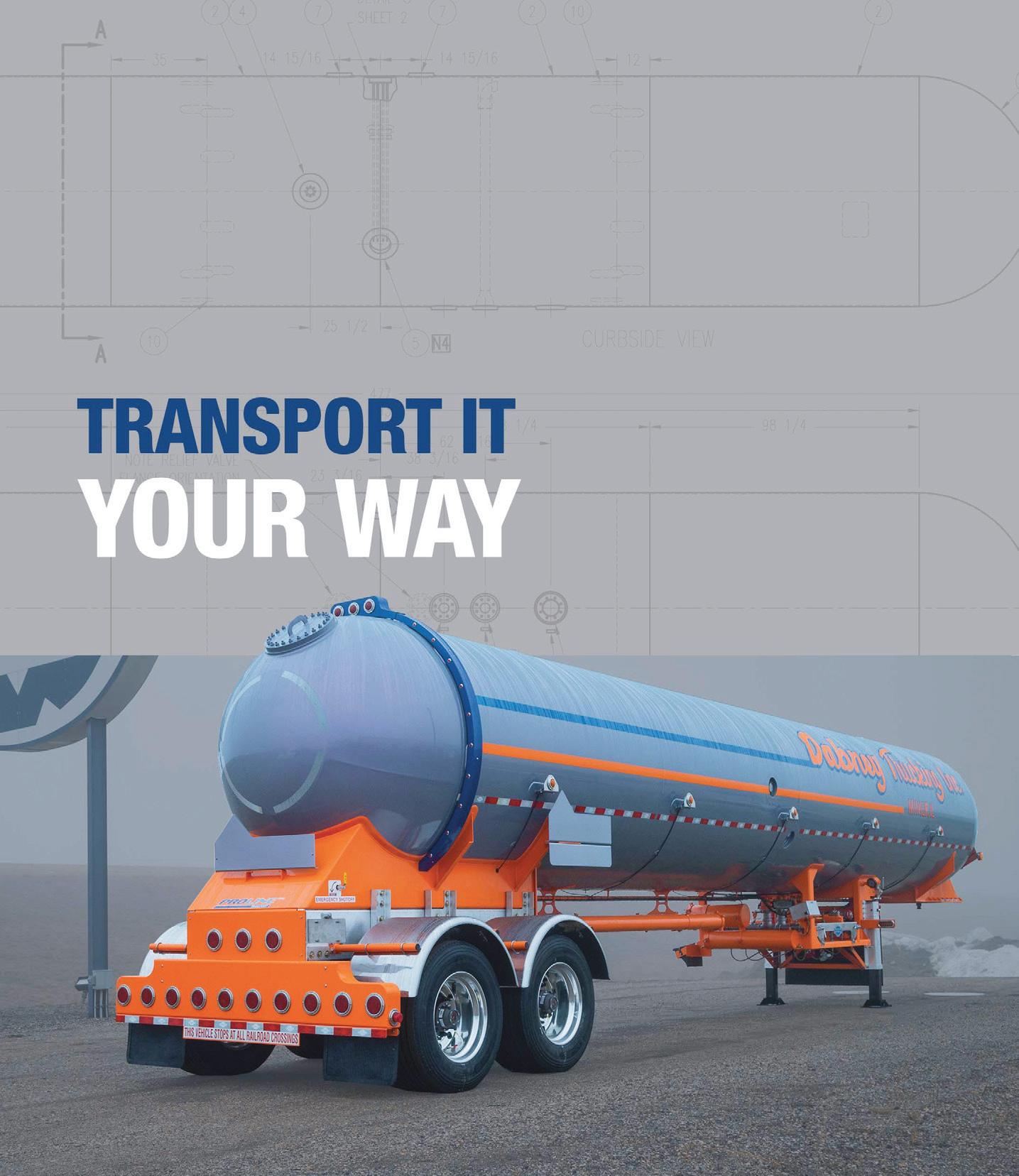

In Mexico, “la familia es todo.” For non-Spanish speakers, that translates to family is everything, and this idea is exemplified in Transnational Lines’ relationship-oriented approach to growing the Angels’ tank truck business on both sides of the border, from partnering with Mexican trailer manufacturer Retesa to develop the first bulk tequila tankers for cross-border transport, to expanding its U.S. chemical-hauling division with transload partner Ventura Transfer Company—both family-owned operations.

“Our customers are the world’s largest petrochemical companies, and they’re very particular, especially the German ones,” said Randy Clifford, Ventura chairman and CEO, and recent past National Tank Truck Carriers chair. “They’re very detail oriented. They want things done in a specific way, on a very precise schedule. Mexican carriers, in general, don’t function quite like that.

For them, it’s more of a relationship than a strict business arrangement.

“[Transnational CEO] Santiago [Angel Gutierrez] wants to work with the Cliffords—as opposed to Ventura Transfer.”

By putting people “primero,” Transnational—founded in 1979 by Santiago’s father, Jorge Angel Rosales, in Guadalajara, Jalisco—today is the

largest exporter of bulk tequila into the U.S. and Canada, and a growing hauler of liquid sweeteners and chemicals in the States. And by leveraging its unique supply chain expertise, including specialized food-grade equipment and Kosher-certified tank cleaning facilities in Mexico, Transnational is fending off market challenges, including tariff uncertainty and new English language-proficiency requirements for drivers.

The international bulk hauler currently is testing Scania trucks in Mexico and a new terminal location in Laredo, Texas.

“We feel good about our position,” Santiago said. “We have another business, Agave Azul, that has been growing agave plants since my great

grandfather’s time, so we know the tequila business, and food-grade transportation, very well. We’ve always been tightly connected to the key players, and we understand what’s going on in the industry and how it’s evolving.”

Family-owned, tequila-driven Santiago’s father started out transporting “tequila a granel,” or bulk tequila, for the Beckmann family, majority owners of Jose Cuervo tequila, from their factory to Tijuana as Transportadora de Liquidos JAR. Then he branched out, hauling wine for L.A. Cetto and tequila for other major producers, like Sauza and Orendain. Santiago and his brother, Jorge Angel Gutierrez, Transnational chief operating officer, joined the business in the mid-1990s, around the same time the company first ventured into the U.S. through a partnership with Oakley Transport.

“My father was focused on Mexico, but my brother and I wanted to do more in the U.S. because we saw it was a bigger market,” Santiago shared. “So we bought the U.S. business from him and started Transnational Line [in 2001].”

Cargill was the brothers’ first big U.S. customer. Today, Transnational also hauls sweeteners, concentrated juices, and liquid yeast for leading manufacturers like Coca-Cola, ADM, Bimbo, and Zucarmex; and tequila and alcohol for AB InBev, Cutwater Spirits, and Maestro Dobel, with a fleet of 300 trucks and 400 tankers. “We’re exporting 80% of the over-the-road bulk tequila that goes into bottles in the U.S.,” said Luis Huerta, Transnational director of operations. Santiago estimates that equates to about 500,000 liters per week—or 6.9 million gallons annually.

The Angel family still operates their original transport company in Mexico, along with several other businesses, including their 800-hectare agave farm; Anguz Transportation, which runs 50 trucks, 50 dry vans, and 30 refrigerated trailers in Mexico; and Premium Tank Wash (PTW). Transnational is headquartered in San Diego and maintains U.S. sites in Los Angeles, and El Centro,

Transnational Line is headquartered in San Diego, California, and also maintains Mexican terminals in Guadalajara, Tijuana, Mexico City, Mexicali, and Hermosillo.

California (with Ventura); and Mexican terminals in Guadalajara and Tijuana— where the PTW wash racks are located— Mexico City, Mexicali, and Hermosillo.

“There aren’t many carriers who do what we do, and no one who does it like us,” Huerta asserted.

Inspiration for bulk innovation

Transnational’s fleet now includes tank trailers from Polar Tank and West-Mark, and Mexican manufacturers Elk Tanks and Retesa—which built the first tequila trailer for cross-border transportation in 1995. “Before that time, you could transfer bulk tequila at the border to a U.S. trailer, which would take it to its final destination,” Santago explained. “But then the CRT [Consejo Regulador del Tequila], which regulates the industry in Mexico, prohibited transloading tequila, so you had to load one tank that also made the final delivery.”

The Prietos, who own Retesa, and Angels worked with CRT to design the first 407s that comply with U.S. Department of Transportation and Mexico’s Secretariat of Infrastructure, Communications, and Transportation (SICT) regulations. Retesa delivered the first 10 units within six weeks, and Transnational made the first door-todoor delivery of bulk tequila—which, at 50-55% alcohol is both food-grade and

flammable—from Mexico to a San Josearea bottling facility operated by Diageo, owner of Don Julio tequila, soon thereafter. Retesa’s modern tequila tanks are 40-ft., 25,000-liter (6,604-gallon) stainless-steel units Transnational pairs as doubles in Mexico, where vehicle weight limits are higher, and splits into two truckloads at the border. “We like developing tanks with our customers,” said Rene Prieto Jr., Retesa general manager, and son of founder Rene Prieto Sr., the company’s chairman.

“Our engineering department is very specialized, we’re highly involved in every aspect of the design process, and my father still helps a lot.”

Retesa has sold 50 tankers to Transnational since 2010, Rene Jr. estimated, and sanitary trailers now are a key offering in the OEM’s diversified product line, which includes chemical, fuel, and dry bulk tanks increasingly available in the States. Retesa added Littlejohn Tank and Equipment as a U.S. dealer earlier this year. “Our top goal is to continue selling trailers to long-term partners. We don’t want to sell to them once. We want customers for life.”

Mexico’s spirit, distilled Life-long business relationships are equally important to Transnational, and Ventura Transfer—a 156-year-old

carrier the Cliffords acquired in 1957. They chose to partner with the Angels in 2017 after Greg Clifford, Ventura chief operating officer, and Randy’s brother, visited Transnational’s Guadalajara location. “He came away very impressed,” Randy relayed. “He said he hadn’t seen a terminal facility in the United States that was better than the one he saw there.”

In El Centro, Ventura receives products in tank cars and transfers them into trailers Transnational delivers to “maquiladoras” like Rheem and Ureblock in Mexico. The carrier now hauls 20-25 loads of poly oils and other chemicals out of the facility every week, Huerta said. “Sometimes they preload their tankers, and we pick up and deliver them, and sometimes we bring our tankers in to get loaded, depending on the customer and the process required,” he said.

Transnational currently dedicates 15 trailers to the partnership. And, in the Long Beach area, Ventura also is providing its specially designed drop-center chassis to Transnational, which uses them to haul ISO tanks in and out of ports. “They opened a whole new channel of business for Transnational Line, because we never had any thoughts of working with chemicals.

“It’s been quite a lovely journey.”

The connection is a two-way street. Ventura can offer dependable service to Mexico, thanks to Transnational’s contacts and ability to expedite border crossings; and while most of Ventura’s existing consignees are just across the border, it now has a trusted partner who’s willing and able to take the family’s business much farther south. “We have a better relationship with them than any Mexican carrier we’ve worked with previously,” Randy said. “They’re great people.”

Transnational’s bonds with long-standing customers, transportation partners, and equipment suppliers are enabling growth amid ongoing complications, including tariffs and English-language requirements.

Tariff uncertainty, which only increased in August, decimated Transnational’s export business for about a month earlier this year before the Trump administration issued various delays and exceptions. “It was difficult,” Santiago said. “Many of our clients couldn’t plan ahead because they didn’t understand the impact, but it’s gotten much better.” He still worries about future impacts, but for now, bulk tequila—unlike Mexican beer—isn’t subject to additional taxes. “From what I hear, the products we handle aren’t the focus of Trump’s tariffs,” Santiago said. “He’s more focused on the automotive and steel sectors than commodities.”

The Federal Motor Carrier Safety Administration’s push to enforce English-language proficiency (ELP) requirements is another concern Huerta fears will have “a huge impact” on binational drivers. But Transnational already implemented a training program and created a manual for drivers. “We’re

Transnational Line hauls chemicals from El Centro, California, to ‘maquiladoras’ in Mexico with help from transload partner Ventura Transfer Company. The international bulk hauler also is the only carrier in Mexico with Kosher-certified tank washes, at left, in Guadalajara and Tijuana.

trying to give them the tools they need to answer basic questions,” Huerta said. Meanwhile, the company is moving forward, testing new tractors in Mexico and a new location in the U.S. Transnational mostly runs Kenworth T680 mid-roof sleepers in Mexico, and Freightliner Cascadia and International LT trucks with dual license plates in the U.S., but it’s now testing 10 Scania cabovers in Mexico. “They offer very good fuel economy,” Huerta said. “And comparing them to our conventional trucks is giving us good perspective on what’s coming next.” The carrier also recently sent its first load of increasingly popular agave nectar to Laredo, where it’s aiming to establish a presence in the busiest U.S. port of entry—starting with 20 trucks stationed at a family friend’s facility.

“We’ve had many offers over the years, but we didn’t go because we were so busy on the West Coast,” Santiago concluded. “But now, I think, it’s time.” BT

by Ellie Gabel

Expanding a tank trailer fleet is not as simple as merely purchasing new trailers. Choosing the wrong equipment will lead to a slower return on investment (ROI) and may introduce more issues than benefits. Careful spec’ing is key to making the most of these purchases, but which specs deserve the most attention isn’t always clear.

Manufacturers may heavily market some trailer features that ultimately have minimal impact on the bottom line. Conversely, some specs fly under the radar but can make a considerable difference. While the most critical specifics may vary between fleets, here are some general considerations with heavy ROI implications to look for when spec’ing a new tank trailer.