SIDEAIRBAG GONFLABLELATÉRAL

⁄O⁄⁄O⁄⁄⁄⁄⁄⁄O⁄⁄⁄⁄J⁄⁄YO⁄⁄⁄⁄⁄H

•⁄o notlean againstthedoor⁄

•⁄o not use seat coversthat block side airbagdeployment⁄

⁄ee owner’s manualfor moreinformation⁄

WARNIN AVERTISSEMENT

Order Labels From Our Easy To Use App Download By Scanning Below! New and Improved ADL App Now Available!

⁄O⁄⁄É⁄⁄⁄⁄⁄⁄⁄⁄B⁄⁄⁄⁄⁄⁄⁄⁄ ⁄⁄⁄⁄⁄⁄O⁄⁄O⁄⁄⁄⁄⁄⁄⁄⁄

•⁄e vousappuyez pascontrelaporte⁄

•⁄’utilizez pas un couvre⁄siège qui p tbloquerledéploiementdu cou blelatéral⁄ ⁄oirle n cteur pour depl n nts⁄

ConformU.S.EPAclass/s Californiaclass/ d : P Group: FGMXV Evap: FGMXR0 SFI/HO2S/TWC, OBD:II

i peutbloq ussingonflablelaté l u conducteur gneme

TOTAL 4

REAR 2

FRONT 2

SEATINGCA

Thecombinedweightofoccupantsandcarg o d everexceed 352 kg or 776 lbs. EOWNER’S TIREANDLOAD RMATION

And

ONCONTROLINFORMATION

Conforms ations: 2016 MY Not for sale in states with California emissions standards TWC/HO2S/WR-HO2S/CAC/TC/DFI 2.3 p:GFMXV02.3VJW No adjustments Fuel: Gasoline ABZ

Simplify your body shop processes today.

The 3M OEM Match Family of seam sealing products are engineered to help technicians of all skill levels more easily replicate the appearance and function of a vehicle’s original factory seam sealer.

The system includes our line of seam sealer matching tips and the 2K 3M™ OEM Match Epoxy Seam Sealer in 4 colors – allowing you to replicate the most common OEM seams with one simple application.

Learn more about the 3M OEM Match Family

As

BY JAY SICHT

Headed to

Celebrating the 5th anniversary of Hood Master in Nashville

The

Here are some suggestions to make the most of your week.

AS THE DAYS GROW SHORTER and the first leaves fall on the lawn, it’s still hard to believe it’s already that time of year to prepare for the SEMA Show. If there’s one constant in Las Vegas, it’s change. I’ve been many times (not every year in the beginning) since 2000, back when one could hail a taxi curbside at the Las Vegas Convention Center. It’s since grown to add another hall and total 4.6 million square feet. Fortunately, most of the collision repair-oriented training events and exhibits are centrally located in the upper South Hall. Part of a $600 million renovation is now complete on the South Hall, which includes a Grand Lobby between the North and Central halls with natural light (as is found in the newer West Hall). If you’re making the long walk between exhibits in the North and South Halls, there is now a climate-controlled interior concourse. Still, making the most of your time at the show requires careful planning and a good bit of strategy. To help you make the most of your time and travel investment, I humbly offer some suggestions. Pre-run the show by referring to our SEMA Show guide within this issue, which includes a training schedule for I-CAR and SCRS Repairer Driven Education sessions. Also, check out the semashow.com website, where you can map out the vendors you want to visit and their locations. Paper maps are available at the show, but the mobile app can not only guide you as you navigate the expansive halls and outdoor exhibits;

you can scan products in the New Products Showcase to get more information and find the manufacturers’ booths. To cover the most ground possible while you’re there, one must be strategic.

Still, it’s easy to regularly walk seven miles a day. Wear two pairs of comfortable and broken-in shoes and alternate them. It’s the desert, so don't forget to pack saline nasal spray and lip balm. It’s noisy inside the halls, so don’t forget a mint or chewing gum.

I hope to get the chance to say hello to many of you there. See you soon!

JAY SICHT EDITOR-IN-CHIEF jsicht@endeavorb2b.com

Chris Jones Group Editorial Director

Jay Sicht Editor-in-Chief

Abdulla Gaafarelkhalifa Associate Editor

Kacey Frederick Assistant Editor

Emily Kline Special Projects Editor

Leah Marxhausen Special Projects Editor

Drew Bryant Contributing Writer

Tiffany Menefee Contributing Writer

Greg Lobsiger Contributing Writer

Noah Brown Contributing Writer

Lindsey Gainer Contributing Writer

Todd Kortemeier Contributing Writer

Steve Trapp Contributing Writer

Jordan Beshears Steve’s Auto Body

Sheryl Driggers Collision Advice

Frank Rinaudo Industry Consultant

Jason Mundy Mundy’s Collision Center

Stan Medina Certified Collision Works

SALES

Chris Messer VP/Market Leader - Vehicle Repair Group

Andrew Johnson Associate Publisher ajohnson@endeavorb2b.com

Mattie Gorman-Greuel Associate Sales Director

Cortni Jones Director of Business Development

Diane Braden Account Executive (National Accounts) dbraden@endeavorb2b.com

Marianne Dyal Account Executive (National Accounts) mdyal@endeavorb2b.com

Chad Hjellming Account Executive (National Accounts) chjellming@endeavorb2b.com

Lisa Mend Account Executive (National Accounts) lmend@endeavorb2b.com

Martha Severson Account Executive (National Accounts) mseverson@endeavorb2b.com

Kyle Shaw Account Executive (National Accounts) kshaw@endeavorb2b.com

Sean Thornton Account Executive (National Accounts) sthornton@endeavorb2b.com

Ryan McCanna Administrative Assistant

ART AND PRODUCTION

Mariah Straub Production Manager

Jen George Ad Services Manager

Mitch Bradford Art Director

ENDEAVOR BUSINESS MEDIA, LLC

CEO Chris Ferrell

President June Griffin

COO Patrick Rains

CRO Paul Andrews

Chief Digital Officer Jacquie Niemiec

Chief Administrative and Legal Officer Tracy Kane

EVP Endeavor Business Intelligence Paul Mattioli

EVP Transportation Kylie Hirko

HOW TO REACH US

Endeavor Business Media, LLC

571 Snelling Ave N Saint Paul, MN 55104 tel 651.224.6207 fax 651.224.6212

The annual subscription rate is $90 (U.S.A. only) for companies not qualified to receive complimentary copies of FenderBender.

LETTERS TO THE EDITOR editor@fenderbender.com

Opinions expressed in FenderBender are not necessarily those of Endeavor Business Media, and Endeavor Business Media does not accept responsibility for advertising content.

Embrace innovation and comfort like never before. y ?

Stay tuned for the unveiling of our latest design

THE LKQ REFINISH TEAM and the Collision Repair Education Foundation (CREF) recently celebrated the 5th anniversary of the Hood Master event in Nashville, Tennessee. This event has evolved from an industry painting challenge to a platform for co-hosting PiN Master, a student painting contest facilitated by CREF. It serves as a fundraiser to support collision repair programs that partner with CREF and has become a unique industry community event.

The Hood Master challenge is more than just a contest; it’s an exciting platform where painters and refinishers push the boundaries

of their creativity and unparalleled talent. Participants create artwork on mini car hoods, which are judged in person by a

panel of industry experts, hand-selected by sponsors. This year’s contest categories included airbrush, graphics, pinstripe, wild card, and online crowd favorite, with prizes totaling well over $26,000.

The first through third-place winners, along with the honorable mention winner, received prizes to help prepare for the start of their careers in the automotive industry. Prizes included tools and equipment donated by Hood Master sponsors and supporters of CREF.

The event took place at 5 p.m. on Thursday, August 29, at the Bell Tower in Nashville.

Earn

Trax

Looking at a collision repair association in a large area taking its first steps.

By ABDULLA GAAFARELKHALIFA

THE OXFORD DEFINITION of an association is “an official group of people who have joined together for a particular purpose.”

There are many reasons why collision repairers would want to join. The industry is constantly evolving through technology, often lacking the training or educational tools to maintain success through these changes, and facing a shortage of young professionals entering the field.

Collision repair associations across the country help meet those needs.

FenderBender had the chance to speak to Megan Mueller, the founder of the Mountain States Collision Repair Association (MSCRA) as well as the president for their board. She

is also the co-owner of Ozzie’s Body Shop in Loveland, Colorado. She shared insights into the formation and vision of the association.

The MSCRA was officially founded over a year ago. Initially, it was the idea of a few current board members who laid the groundwork. The association opened its doors to potential members about four months ago, aiming to support the collision repair industry in Colorado and Utah.

“We want to offer support to people in the collision industry both in the state of Colorado and the state of Utah right now,” Mueller said. The association aims to foster a community where members can share experiences and learn from each other.

“We’re still in our baby steps, for sure, but we’re super excited to see where it goes,” she added. The goal is to create a robust network of collision repair professionals who can collaborate and support each other.

“It’s been a grassroots effort, and we’re grateful for the support we’ve received so far.”

The association is considering expanding to Idaho and Wyoming, Mueller said. “We have some extremely rural shops that are really far away from technology and from dealers,” Mueller explained. The association aims to bridge this gap by offering resources and education to these remote locations.

“With the ability to hold monthly Zoom meetings, we can provide educational content to members regardless of their location,” she said. This approach allows the association to offer valuable resources to shops that may not have access to in-person training and support.

One of the significant challenges faced by the association is the diverse needs of shops in densely populated cities versus those in rural areas. “We want to provide education that can be used by

everybody,” she said. The association aims to connect rural shops with the right resources to help them perform proper and safe repairs.

After being open to membership for only four months, as of August 22, MSCRA has a member count of 31.

“I love the idea of there being a community of people that everybody can reach out to within their state or within the two states,” she said. Granted, it can be hard for repairers separated by the rural/urban divide.

“Performing proper and safe repairs is more of a challenge in rural areas where you don’t have the resources,” Mueller said. The association aims to provide these shops with the tools and knowledge they need to succeed.

During the MSCRA infancy, the organization has had many industry heads be featured in their monthly meetings and speak on important topics such as:

Danny Gredinberg with the DEG (Database Enhancement Gateway) and Collision Advice about the DEG and Repair Planning.

Sam and Richard Valenzuela with National Autobody Research, Billable Genie, and Labor Rate Hero about inflation, market approvals, market rates, etc.

Erin Solis with the Society of Collision Repair Specialists and Square One Coyote Vision Group about post repair inspections.

As of August, Mueller shared that she plans to have Greg Peeters with Car ADAS and Keith Egan with Betag North America.

Running an auto body association can still come with challenges despite having numbers comparable to a single state auto body association. In the far future, Mueller would like to see each state represented in chapters under the MSCRA.

Mueller addressed the challenges previous collision repair associations in Colorado and Utah faced.

“One of the main things I heard from other people was that getting support is crucial,”

she said. “It’s a lot of work to run an association, so having the support is a huge thing.”

“They would get together and complain about what was wrong with the industry rather than putting resources in front of people to meet those challenges,” she explained. “We want to be 100% positive and solution-focused.”

The Utah Auto Body Association website is offline, and their Facebook shows that their last post came in 2021. The only existing state association in Colorado was Automotive Service Association (ASA) Colorado, but as Mueller explained, it’s more mechanically oriented.

“We didn’t want to reinvent the wheel,” Mueller said. “We have all these other associations that are incredible, and we can learn from them.”

Mueller shared her personal journey in the collision repair industry. Growing up in her family’s shop, Ozzie’s Body Shop, she developed a deep passion for the industry. Despite

her father’s initial reluctance, Mueller eventually took over the business and has been instrumental in its growth and success.

“I grew up at the shop, running around cleaning in the summers,” she recalled. “I really wanted to be involved in the industry.”

Mueller’s journey is a testament to her dedication and hard work. She left her career as a dental hygienist to join the family business full-time in 2017. Since then, she has been focused on growing the business and adapting to the rapidly changing industry.

“My dad is one of my best friends, and he’s always called me the boy of his three girls,” she said. “He’s been incredibly supportive and has helped me navigate the challenges of the industry.” It’s no wonder why support access is important to Mueller.

“None of us have to feel alone in this industry anymore,” she said. “I want to say a huge thank you to everybody that’s been involved with helping all of us get the Mountain States Collision Repair Association going.”

The amount of work caused by a wrong decision and the associated high costs of repainting the area leave no room for compromise when it comes to choosing the light quality.

In order to ensure that the correct color variant is selected during refinishing and the associated color shade can be determined, a light source that reproduces the entire color spectrum of visible light (daylight) as far as possible must be used. The specially developed SATA trueSun facilitates professional color retrieval and identification, even inside the bodyshop.

Best possible close to daylight reproduction of different color shades

Homogeneous light distribution across the entire illuminated area

Approx. 70 minutes at full light intensity

Uniform light intensity - independent from the battery's level of charge

Charging cycle time of only 50 minutes

Infinitely adjustable light intensity

Registration for the 13th annual MSO Symposium is now open, according to a news release.

The event, tailored for multi-shop operators of all sizes, independent collision repair facility owners, and their business partners, will be held on Monday, November 4, in Las Vegas, just before the start of SEMA/AAPEX.

The one-day conference will commence at 9 a.m. PT with a light breakfast, followed by numerous networking breaks throughout the day.

“The camaraderie in our industry is appreciated and it leads to ongoing improvement for our customers and the market,” said advisory board member Mike DeFrancesco, vice president of strategic accounts at CollisionRight. “I value hearing from and speaking with my peers regarding what’s working and the challenges we face.”

The 2024 event will feature presentations and panel discussions on

various topics, including the economy, consolidation trends, AI influences, data breach concerns, and future industry outlooks. Attendees will also have the chance to network during a plated luncheon, an afternoon break, and a post-event reception from 5 to 7 p.m.

“The MSO Symposium’s uniqueness has made the conference a staple for owners, managers, and executives leading collision repair facilities in the North American market,” said Roy Schnepper, owner of Butler’s Collision in Michigan, highlighting the symposium’s significance.

Interested parties are encouraged to register their teams promptly, as seating is limited and early registration discounts are available for a limited time. Please note that this is a closed meeting with specific attendance requirements.

For more information and to access early registration rates, visit the MSO Symposium’s website at msosymposium. com/register. Media personnel and equipment or service providers may attend, but space is limited.

For registration inquiries, contact Jennie Lepore or Brian Nessen, or visit msosymposium.com.

Quality Collision Group announced the acquisition of Hance’s Uptown Collision Center, according to a news release. Serving Plano, Richardson, Allen, McKinney, Frisco, and surrounding areas since 1955, Hance’s is renowned for luxury auto body repair, specializing in brands like Tesla, BMW, and Mercedes.

Owner Rob Mays purchased the collision repair landmark with his family in 1995, 40 years after it opened its doors. With ASE and I-CAR Gold accreditations and multiple OEM certifications — including Tesla, Ford/Lincoln, Nissan/Infiniti, FCA and Kia/Hyundai — Hance’s consistently earns the trust of vehicle owners by ensuring repairs are done with manufacturerapproved parts and procedures.

“We are thrilled to welcome Hance’s to Quality Collision Group,” said Matt Robbins, COO of Quality Collision Group. “Rob and his team have set a high standard for collision repair in Texas, perfectly aligning with our commitment to quality and OEM excellence.”

For nearly thirty years, owner Rob Mays—a self-described ‘life-long car guy’—has upheld the traditions and values of the storied Hance name. Today, the shop offers a full range of services, from collision and auto body restoration to paint refinishing and unibody repair.

“Becoming part of Quality Collision Group is an exciting development for

us,” said Mays. “With their expanding network and operational expertise, the Hance’s team is well-positioned to continue delivering exceptional results for our clients.”

PSE Group has acquired RMS Pro Finishes, a provider of high-quality automotive refinish and associated products.

This acquisition marks PSE Group’s continued expansion efforts in the United States.

“We are thrilled to welcome RMS Pro Finishes into the PSE Group family of companies. This acquisition represents our commitment to strategic partnerships that further enhance our offerings and expand our service geography,” said Patrick Mayette, president and CEO of PSE Group.

Founded in 1981 and headquartered in Charleston, W.Va., RMS Pro Finishes is the leading multi-location automotive refinish coatings distributor for the tri-states of West Virginia, Ohio, and Kentucky. The company’s commitment to quality and customer satisfaction aligns with PSE Group’s focus on being the best coatings solutions provider in the United States.

“Partnering with PSE Group opens many new and exciting opportunities for RMS Pro Finishes,” said Terry Midkiff, president of RMS Pro Finishes. “We look forward to enhancing our serviceability to our customers with additional tools and resources available through PSE Group. This was certainly a great fit for all RMS employees.”

With this acquisition, PSE Group enters its 16th state, further expanding its footprint in the automotive refinish segment and opening growth opportunities in specialty coatings.

PartsTrader, a Chicago-based leader in automotive parts procurement solutions, today announced the appointment of Kyle Schmitt as Group Chief Financial Officer (CFO).

In this key executive role, Schmitt will be responsible for steering PartsTrader’s financial strategy and operations, with a focus on driving growth and enhancing profitability. His proven track record in strategic planning and execution will be instrumental in guiding PartsTrader through its next phase of expansion.

Schmitt shared his enthusiasm about his new role, stating, “I have witnessed firsthand the incredible potential and dedication of our team. I look forward to continuing my contributions to the growth and success of PartsTrader and helping to drive our mission forward.”

Schmitt, who previously served as Chief Strategy Officer at PartsTrader, brings over 15 years of global experience in both finance and SaaS operations with executive roles in investment banking, financial institutions, M&A (London), property & casualty auto claims, insurtech and autotech.

“We are thrilled to welcome Kyle to the role of Chief Financial Officer,” said PartsTrader CEO Steve Messenger, “Kyle’s extensive experience and strategic insights have already made a significant impact on our organization. We are confident that his leadership will further strengthen our financial operations and contribute to our long-term success.”

Global investment firm The Carlyle Group, which purchased Axalta Coating Systems in 2013 and later took it public, has agreed

to purchase automotive parts wholesale distributor Worldpac, Inc., from Advance Auto Parts, Inc. The $1.5 billion cash transaction is expected to close before the end of the year.

Worldpac generated approximately $2.1 billion in revenue and approximately $100 million in EBITDA over the last twelve months at the end of the second quarter of 2024.

“We are pleased to announce the sale of the Worldpac business,” said Shane O’Kelly, president and chief executive officer in a press release. “The sale enables our team to sharpen their focus on decisive actions to turn around the Advance blended box business. Proceeds from the transaction will provide greater financial flexibility as we continue our strategic and operational review to improve the productivity of the company’s remaining assets and better position the company for future growth and value creation. On behalf of everyone at Advance, I would like to thank the more than 5,000 Worldpac team members for their dedication over the last ten years.”

“We are excited to partner with Worldpac, a great business operating in attractive markets,” said Wes Bieligk, a partner, and Katherine Barasch, a senior member of Carlyle’s Global Industrials investing team. “Our proven track record in executing complex carve-outs position us uniquely to support Worldpac and its team as an independent company.”

According to the release, Carlyle’s investment in Worldpac builds on the firm’s extensive carve-out experience in the Industrials sector, having invested $13 billion in industrial carve-outs over the past two decades, including in such companies as Nouryon, Atotech, Signode, and Allison Transmission.

Carylyle acquired Axalta, formerly known as DuPont Performance Coatings, in February 2013 and took the company public in late 2014.

Visit Booth #37101 at the SEMA Show to experience the future of cordless performance.

Our tools deliver the pneumatic power you trust in a durable cordless form, so performance is always in your hands. Trusted Heritage. Purpose-Built.

The LKQ Refinish Division is a leading distributor of Automotive Refinish Paint, Fleet & General Industrial Coatings and associated refinish products throughout the US and Canada. This division was formed by joining our well-known Keystone Automotive Paint, Body and Equipment business with our recently acquired FinishMaster business. Our experienced team is dedicated to providing the products and services necessary to help grow your business.

• Abrasives

• Body Repair

• Detailing

• Refinish & Coatings

• Safety

• Tools & Supplies

Whether you have a collision repair business or a restoration project, we carry all of the brands you trust to get the job done.

The need to perform ADAS calibrations continues to grow. However, this year’s respondents reported a very slight loss in the percentage saying they do in-house calibrations.

Despite the decrease, the percentage of surveyors reporting that they perform ADAS calibrations in-house is still significantly higher than the 2021 survey, which was only 21%.

In this year’s survey, 84% of surveyors who said “no” say they either sublet or use a mobile service for ADAS calibrations.

By Abdulla Gaafarelkhalifa

Photos Courtesy SHANNON’S AUTO BODY, SPANESI

When you think of greater Minnesota, what comes to mind? Snow, recreational vehicles, people camping in motor homes, perhaps the accent from the movie “Fargo?” Well, the repairers at Shannon’s Auto Body would say, “Yeah! That’s about right.” They built their shop for standard cars like sedans, SUVs, and minivans back in 1996. However, their location has another set of demands, as it is a popular destination for campers who want to visit with their big and bulky motor homes or drive in with a boat strapped to their trailer. So, in a sense, they do it all.

In the last decade or so, they’ve been doing less and less work on recreational vehicles because the demands of being a normal day-to-day collision repairer for standard vehicles has required more of their production space. They needed to add more equipment for ADAS calibrations and diagnostics.

“Not everything is just hammering stuff out anymore,” explained General Manager Josh Shaw.

The space may have disappeared, but not the demand. That’s why in July 2023, they opened a new location devoted to collision repair, while their original location is devoted to recreational vehicles.

“So now, instead of referring that work out, we can capture more in-house,” Shannon Christian, owner of Shannon’s Auto Body, told FenderBender. “And now that we’re doing it, we’re getting outside work beyond our own customers that we previously had.”

Continuing to serve the community with their recreational needs is quite lucrative because it’s the work is less complicated than it is for standard vehicles.

“I would just say the amount of electronics in the new [passenger] vehicles versus at least on the boat side is very

limited and most of that is aftermarket addon,” Shaw said.

The shop that’s dedicated to recreational vehicles will become more useful as the shop prepares to take on EVs, although that might be a while. You might find more albino squirrels than Teslas in greater Minnesota.

“For us, the Tesla traffic is only on the weekends,” Shaw said. “Once September hits, you may not see another Tesla appear for a month or two. We’re trying to stay with where our customer base is.”

But we’re not here to talk about boating or RVing. Summertime is over, kids. Instead of gazing at the lakes and trees, gaze upon the clean white floors, equipped with a Spanesi side-loading system for the prep station and spray booth, also from Spanesi.

“They make it a heck of a lot easier to move the cars around,” Shaw said.

This feature is not common in a typical American auto body shop, but make no mistake, Shannon’s prides itself on being meticulous about certifications, equipment, and tools.

“Based on what the OEM requirements are, after we started pursuing a lot of certifications, a lot of our equipment decisions are now based on the manufacturer,” Shaw explained. “It doesn’t pay to buy a piece of equipment that you can’t actually use or isn’t going to give a certified repair.”

“The industry is changing fast,” Christian said, even for a place where it seems that time is moving slowly.

The changing industry in the rural area makes Shannon’s proud to be working with no DRPs. “[This] allows us the freedom to just truly work for the customer and fix the car the right way,” Shaw said.

“We’re a family-owned business serving our community,” Christian said. “We put our community first.”

Prevent safety issues for every vehicle that leaves your shop and improve profitability at the same time.

Over the years, I have made probably 30 10-day long fishing trips to Canada with family and friends. Each trip always comes with much preparation and excitement. For most of us, planning for our vacations is usually half the fun of the trip. After so many of these trips, I pretty much know what equipment, clothes and supplies to take. The trouble is, if I forget just one crucial item, it could ruin my week, as we go to very remote locations and I can’t just hop in the truck and run to town. The way I prevented forgetting anything was by creating a list of items to take. These items ranged from a passport, plenty of socks, fishing tackle, or how about even a black marker and tape to label the fish we bring home? “What does the even have to do with collision repair?” you ask. Please keep reading.

In the past year, I have flown on a commercial airplane several times. Has everything gone just perfectly each time? Well, no, but I always arrived at my desired destination and most importantly, safely. From 1968 to 1977, airplane passenger boardings resulted in 1 fatality out of every 350,000. From 2008 to 2017, the numbers improved to 1 in every 7,900,000. Even better yet, in 2018 to 2022 it’s 1 in every 13,700,000. Obviously, air travel has become much safer over the years. Otherwise, air travel since 2022 has become 39 times safer than back in 1968. FYI: Currently, we are 48 times more likely to get injured in a car accident than on a commercial airplane.

Obviously, technology has helped improve air safety, but there is also another seemingly small but crucial underlying factor. For most folks who have flown in an airplane with a window seat, you have probably observed the pilot outside walking around the airplane. If you are anything like me, I have asked myself, “What all is he/she even looking at?” Well, the pilot is inspecting the nose cone, landing gear, wings, flaps, engines, tail section for any damage, and more. Most commercial city hopper planes are flown multiple times per day and therefore have visual inspections multiple times per day. These inspections seem very redundant, along with a waste of time and money, right?? Ha-ha well, whether it be you or me on that next flight, that airplane had better have been inspected before taking off, EVERYTIME!!!!

Before pilots take off in an airplane, they are following a preflight check, which includes an exterior visual inspection. In layman’s terms, it’s a “checklist.” Similarly, in hospitals before the first incision is made

on a patient undergoing a surgery, a surgical safety checklist is to be followed. It might include things like:

A. Have all team members introduce themselves by name and role.

B. Does the patient have any allergies?

C. Is it the right or left leg?

D. Has an antibiotic been administered?

E. What is the anticipated blood loss?

F. Do we have ample blood available?

Whether we are piloting an airplane with 350 souls on board, performing an open-heart surgery on a patient, or repairing a vehicle that has been involved in a collision, following a checklist is crucial.

As collision repairers, we are ultimately responsible for the safety of the passengers in every vehicle we repair. Not only are we responsible for the SRS components and structural integrity of the vehicle after pulling/welding, but have we done the basic checks of door and hood latches or that the lug nuts were tightened?!

By following checklists, we can prevent safety issues for every vehicle that leaves our shops. But we can even improve profitability by lowering our costs.

Every day in nearly every shop across the country, at least one vehicle in the build department must stop for some type of problem. Either we missed a broken part, missed damage, received a left foglamp instead of a right, a new mirror cap wasn’t painted, etc. These costs are nearly incalculable.

Many problems can be fixed just by following a simple checklist. You can very easily create your own and they can even be by departments.

Here are just a few examples of a car entering the body department:

A. Pull car and parts into correct bay.

B. Review estimate and repair procedures.

C. Complete measuring & pulling if required.

D. Complete all mechanical work etc.

E. Take photos of all body work etc.

You get my point here. Checklists are applicable to every department and crucial to preventing firefighting & chaos. FYI: 80% of all plane crashes are from pilot error!! This is no different for collision shops and employee errors.

Here is a great book on this subject that I would highly recommend: “The Checklist Manifesto How to get things right,” by Dr. Atul Gawande.

GREG LOBSIGER

Greg Lobsiger has owned Loren’s Body Shop in Bluffton, Indiana, for over 23 years. He has been a member of Mike Anderson’s groups for ten years and had extensive lean manufacturing training.

EMAIL: greg@lorensbodyshop.com

ARCHIVE: fenderbender.com/lobsiger

As vehicle technology continues to advance, the need for capable technicians and tools has never been more important.

LIGHTWEIGHT MATERIALS, sensitive calibrations, and OEM repair procedures all mean today's vehicles need more care than ever in how they're repaired.

Keeping pace with the technology requirements for tools, equipment, and technician training continues to be a concern for those who responded to our 2024 FenderBender Industry Survey.

“This is a specialized business. We don’t repair vehicles the way we used to. Just because a body shop exists, it doesn’t make them able to repair a vehicle properly,” answered one respondent to the question “What’s the biggest misconception about the collision repair industry?” “Certifications, training, and equipment are necessary to repair a vehicle correctly, and not everyone is willing to invest in their business like others. So, not just every shop is going to give the same quality of repairs.”

The technician shortage was cited as the greatest challenge – 36% of survey respondents – facing collision repair shop operators. “I find that the general public doesn't realize how technical repairs are,” noted one survey respondent, “not to mention the amount of knowledge and tools the techs need to have.”

Stan Medina, owner of Certified Collision Works in Corpus Christi, Texas, and a member of the FenderBender editorial advisor board, focuses on repairs that don’t require major structural repairs. So, he’s been able to grow his staff of six in part through apprenticeships. He also coaches fellow shop

owners, specializing in those getting a start in the business.

“Usually what I tell guys, especially those who are just getting started, is if you're going to hire a helper, don't expect to hire someone who knows how to paint already or knows how to do body work,” he says.

He says ads on Indeed.com for apprenticeships work well, and to have the greatest chance of success, he advises hiring younger applicants, say, age 18 to 25, and give them a structured timeline of activities for them to complete as they learn new skills as a helper. Otherwise, they may stand around waiting for instructions.

The majority of survey respondents, 61%, reported they have an annual budget for equipment. Don Putney, president of Collision Equipment Experts in Elgin, Illinois, advises shop owners and operators to look ahead when planning their equipment needs.

“You need to look at not only what you are fixing now, but what you are fixing in the future.”

Spray booths are just one example. “Last mile delivery” vehicles are becoming more prevalent, and they require taller and longer booths.

“I'm doing more 30 foot and 32-foot-long booths,” he says. “Because if you get a Sprinter van in there, it chews up 28 feet really fast.”

If an owner or operator is looking toward OEM certification, some of those also require taller spray booths, Putney says, and if one is not in the shop, a sublet provider must be specified who has one.

Smart control panels and LED lighting are trends that can pay off with less maintenance, he notes.

EV repairable claims reached a record 2.26% of all claims in the first quarter of 2024, with a total loss rate of 9.93%, similar to the 9.51% rate for vehicles with internal combustion engines.

A projected 243.3 million drivers were on the road in 2023 after an all-time high of 232.7 million in 2021.

Source: Mitchell International

As of April, the consumer price index for motor vehicle insurance increased 22.6% from 2023 and 41.8% since April 2022.

41.7% in Two Years

In Q4 2023, a decrease of one day from Q4 2022

40% 243.3 Million 75%

17.7 Days

Source: Collision Advice and the Federal Highway Administration

Year-over-year through May, total loss % has increased 1.6% for all loss categories and 1.5% for non-comprehensive.

21%

Source: CCC Crash Course Report

The percentage of shops regularly paid for total loss processing by the eight largest U.S. insurers is increasing.

“An LED light tube lasts 15 years, but a ballast will last a year or two,” he says, so look for a spray booth with ballast-free LED lighting.

The reporting capabilities of smart control panels do allow for operators to monitor the number of booth cycles they can push through, but for Putney, the big advantage is the ability to monitor their performance and minimize downtime.

“If there's failure code if something happens, you know rather than having to wait for a service tech. It will tell you what the issues are. The fault code 1 or whatever is, would indicate my prefilters might be plugged. Now, you can pull your prefilters out and put new ones in rather than having to call a service technician and wait for him to get there to pull your filters out.

So to me, that’s more important than the number of booth cycles I’m getting through. But different shop operators are going to have different feelings on that.”

When looking at purchasing a new booth, operators need to consider what their needs are so they can select a booth with a spray zone with the airflow optimized to their needs. For downdraft booths from most companies, there are options for the size of the pit: single-row, two-row, and three-row.

“Each of them has a different application, and more and more I'm seeing people paint parts off a car. And if you do that, you want to have your parts in the spray zone, which means where the pit is. So, if you're doing a lot of parts-off painting, you should have a three-row pit, or at a minimum a two-row pit so that you have room to have all those parts on the pit.”

A longer booth also makes sense to provide more room to paint parts off the car, he says.

“So, I tell people 27/28 foot at a minimum.”

The narrower the pit, the higher is the air velocity, which allows for benefits such as quicker through-cure, Putney explains.

But outside of the pit area, the airspeed is lower and results in dirtier paint jobs. It follows that a shop painting only vehicles and no parts would best use a single-row pit, and the two-row pit is best for a shop doing a lot of complete vehicles and some loose parts.

“Also talk to the distributor who’s going to install the booth and service the booth. Find a distributor who can help you find the right equipment for you and help you find the right location for installation.”

A slight increase from the 2023 survey, to 83%, of 2024 survey respondents reported having the capability and equipment to repair aluminum components. Putney says pulse MIG/MAG welders set up for aluminum, steel, and silicon bronze welding remain most popular.

“They’re a smart welder; that makes it nice. The biggest thing is I tell people look for something that has dual pulse, because more and more as we weld aluminum, dual pulse works better than single pulse does.”

It’s important to buy from a distributor who can assist with training how to set up and adjust the welder is important, Putney advises.

Smart spot welders, which help set up test welds to ensure proper penetration, are the trend.

“But there are new features now such as when you put the arm in, it automatically senses all the arms. You don’t have to tell it which arm you have on. Some of them will automatically do the water jacket so you’re not having to mess with separate water lines and stuff like that. To be brand-specific for GYS and Chief, the boom is actually adjustable and goes up and down. So if you’re working on a rocker panel, you lower that boom way down. Or if you’re doing a windshield up on a frame rack, you can raise that boom way up high.

An Organized Workplace Stan Medina says his shop is fully equipped at the moment and the shop has a focus on organization, helping smooth operations but also to enhance its “show-ready” public image.

So there are some nice features now that some of the other manufacturers are coming out with.”

For dent pulling, drawn arc technology using keys is a popular trend, Putney says.

With earlier technology, screw-on eyelets welded to the panel required a ¾” gap between each stud.

“So, you didn’t pull that dent out 100%. Well, now with drawn arc capabilities and with keys, you can put one right up against another and pull that whole dent out a lot better.”

The drawn arc technology uses an argon shielding gas, places the key then slightly retracts it to create an arc to weld the key directly to the panel.

“The nice thing is then when you’re done, you can twist it and pull it off, and then you can reuse that key again.”

The percentage of survey respondents reporting no OEM certification programs rose a couple points this year to 46.52%. One respondent gave his reason for not renewing those programs:

“We did have several of them, but we had zero ROI. Now, there are third-party companies that we source our info from. All of it comes straight from the OEM and it’s a tenth of the cost.”

Others reported they needed to direct their marketing more to leverage the brand recognition and other advantages of an OEM certification program.

For those considering a particular program, Putney advises to carefully examine their equipment requirements.

Some European manufacturers allow only certain welders,” he says. “And sometimes, you have to buy it through their program; you can’t buy it locally.”

For example, Putney sells a welder that is practically identical to the one specified for the Audi-certified program.

“But even though it’s the exact same spot welder, it’s not gray and it doesn’t have a VAS part number on it.

The tools and equipment needed to repair today’s vehicles have become as high-tech as they have. We asked survey respondents to evaluate how these tools and equipment fit in their budget.

Asked what percentage of their annual revenue is reserved for

tool, and equipment purchases, a majority said they

perform

How many OEM scan tools does your business own?

Does your shop utilize a third-party service for scanning services? Does your business have challenges being reimbursed for diagnostic scans?

The number of shops able to repair aluminum components has jumped by nearly 20% while carbon fiber is up 6%.

Does your business have the capability and equipment to repair aluminum components?

Does your business have the capability and equipment to repair advanced structural composites or carbon fiber components?

Does your business use an OEMapproved refinishing system?

of

is used in your shop(s)?

So it’s important to research the vehicles you’re going to fix.”

With the increase in thinner materials, high strength steels, and aluminum, it’s probably no surprise that Putney reports glue pulling is probably the hottest thing out there,” in part due to the high-strength glues available.

“We had a car on a frame rack on which we were pulling the rocker panel with the frame machine. And we had to anchor it because the car was sliding. If you follow the process, it works well.”

It eliminates the majority of weld-on attachments needed, such as pins, studs, and wiggle wire, Putney says, and results in a higher quality repair.

“And it’s an easier repair for the technicians. It’s easier to see [the progress of removing the dent] because it's easier to see it on paint than bare metals. So I would tell anybody who’s out there looking for their equipment budget to include this.”

Respondents to our 2024 survey reported a few percent fewer (28%) doing advanced driver assistance system (ADAS) calibrations in-house. Those who said “no” reported either

delivering the vehicle to a sublet provider or using a mobile service.

Putney has decided not to sell ADAS calibration systems. He says he has concerns about liability, partly from his current experience in performing audits and inspections for OEC.

“My opinion on ADAS is that the OEMs are still going to ask for them to be done by a certified Ford, GM, or whomever facility.”

For shops performing calibrations inhouse, he’s seen inexperienced staff such as detailers pressed into service to double as calibration technicians, which raises questions for him about their competency and safety. And for mobile providers, he doesn’t see many shop environments that are prepared for ADAS calibrations.

“Most of these shops don't have the right lighting, the right level floor, and all that, and I just see that as an issue until more things done.”

He’s also concerned about talk of some OEMs talking of dynamic or self-calibration in the future.

Medina says he doesn’t plan any capital equipment purchases in the coming year. But he, too, coaches shop operators to take a

Production-Ready

Production boards keep operations running smoothly at Certified Collision Repair.

hard look at the return on investment before committing to a purchase of, say, six figures’ worth of structural measuring, holding, and pulling equipment. And before they do, he also advises them to first build a banking relationship and establish a credit history of responsibly paying for purchases of increasing value.

He has added more parts carts and LED lighting to present his best image when he’s posting on social media.

“One thing that we kind of pride ourselves on is really having an organized shop. So we're investing in more of a social mediaappearing shop. The shop looks cool. The shop looks trendy.”

“A lot of things I read and talk with other shop owners about is fear that the industry is not progressing and is stagnant,” wrote another survey respondent. “But our shop has continued to remain very profitable, growing by 15-20% year over year, even into our 4th generation and over 75 years in business.

“We continue to stay up to date on current tooling, training, and whatever is needed to remain relevant. That is vital in today’s collision repair industry, and shops not willing to do so will fall behind and have to close down, but shops that are willing to stay up to date can thrive.”

See it at our booth #31017 upstairs, South Hall

SATA is introducing a liner cup system into the market, with one decisive advantage: when used with SATA spray guns, there is no need for an adapter.

Favorable center of gravity, easier cleaning, and lower weight.

Particle free premium strainers that click into the lid before painting.

Lids offer a quadruple bayonet safety system that show at a glance whether all tabs are locked in place.

Hard cup, liner and lid are made with high quality materials.

Complete and detailed scale system with an upside-down scale showing remaining quantity during painting.

LCS: .40 liter, .65 liter, .85 liter

In 2023, the SEMA Show came back with a vengeance, reaching a record attendance of 2,200 exhibitors and approximately 160,000 attendees. In 2024, thousands of vendors, hot rodders, and enthusiasts will again travel to the Las Vegas Convention for SEMA’s 57th show, November 5 to November 8.

Where else can collision repairer shop owners, managers, and technicians check out the latest product innovations, catch up on the latest education,

and experience the latest custom vehicle trends? Get a first look at the cutting-edge technology in action on the show floor.

The SEMA Show floor is massive, so FenderBender is here to guide you through this year’s highlights. The 2024 SEMA Preview highlights available educational seminars and featured vendors. All show information is subject to change, so please visit semashow.com for all updates and information.

The SEMA Show New Products Showcase, located in the North Hall, is the world’s largest display of new automotive aftermarket products. It is the top buyer and media destination at the show, featuring thousands of the hottest products in the industry.

Use the SEMA Show mobile app’s “Product Scanner” feature to scan and download product photos and exhibitor information that will remain on your SEMA Show app long after the 2024 show has ended.

By

Take a look around the showcase to view products you have heard of but never seen, and discover products new to you.

Either scan products using the SEMA Show’s app or a provided scanner to acquire information.

Access production descriptions, images and exhibitor booth numbers through the app or through printouts.

For more information on what exhibitors and products will be showcased, visit semashow.com

the show, we'll be able to reach more people and educate them on all the great things that our industry does. At the same time, live streaming will be an awareness campaign, where people will start to come to the show in even greater numbers. It's going to increase the value of what we're doing on-site as well.

We’ve also added a few new events. One of them is going to be an industry night and have a concert attached to it. It’s going to allow people an opportunity to gather and network. The bands that we have lined up for that are the Goo Goo Dolls, O.A.R., and Reignwolf.

FB: The quote: “The more voices we have, the more SEMA can do to protect your freedom and our passion,” is posted on SEMA’s website. Can you tell me how this message is incorporated into the SEMA Show?

TG: There are regulations right now in different states and at different levels of our government that feel like electric vehicles must be mandated.

SEMA believes that electric vehicles are an answer but doesn't feel like they're the only answer. There's incredible innovation happening in different areas of the industry with synthetic fuels and other forms of propulsion right now. We feel that the marketplace is smart enough to decide what's going to be best for their needs. We're able to showcase these innovations in our FutureTech Studio area at the show.

We'll also have good representation from our team in Washington, D.C., at the show. There will be opportunities where you can connect with that group or even within groups like I-CAR and CREF (Collision Repair Education Foundation) that do similar things. You'll be able to feel part of a community that is making

sure that all the voices and options are heard and be able to participate in that firsthand.

FB: What do you hope attendees' main takeaways from this year's show will be?

TG: I would say community would be a big one. When you walk through the Upper South Hall —which is our collision repair and school section — you’ll feel that community. It's just incredible that we have these people who have worked together for years and years, and they have new jobs, and they're maintaining relationships throughout their whole career.

I would also say the innovative products that we have. All the new tech and new ways to do things. When you come to the show, and then you bring what you discovered back to work. The products and processes are cutting-edge and will assist you in selecting better products for your end user, and your customer.

The third thing is being able to educate yourself in the industry. We've got a lot of different education sessions. There are a lot of different tracks and there are some specifically geared to the collision repair industry that are hosted by CREF and I-CAR.

FB: Any last remarks that you would like our readers to know about the 2024 SEMA Show?

TG: This is going to be our best show ever. So, if someone's thinking about whether this is the year they want to come to the SEMA Show, I would say that undoubtedly this is going to be one of the best shows if not the best we've ever had. For those who have been to our show in the past, we've got a lot of new things happening, and I think they're going to be surprised with all that they're going to be able to see and learn.

During the SEMA Show, there are a number of don’t miss offerings. Here’s a look at some of the seminars that are available from I-CAR and SCRS. As sessions and times are subject to change, please visit semashow.com for the latest information and to learn more about these seminars and events and more! All times in Pacific Time (PT).

I-CAR’s 2024 Seminar Lineup

SCRS Repairer Driven Sessions

The SEMA Show holds many other educational sessions. Below are some other tracks of seminars available during the week. Further information on the sessions within the tracks can be found on the SEMA Show website.

Aftermarket Updates and Future Trends

Inside the Shop

Leadership Essentials for Today, Presented by Dale Carnegie

Legislative and Regulatory

Main Stage Experience

Sales and Marketing

Small-Business Strategy

TIA

Vehicle Technology and Electric Vehicles

Wednesday, Nov 6

9:00 AM — 12:00 PM

9:30 AM — 11:00 AM Repair Planning with Precision

Industry Realities of Restoring ADAS Safety Systems, and Consumer Confidence, Through Calibration The Benefits of Ceramic Coating for Your Customer, and Your Collision Center

12:00 PM — 1:30 PM AI is Here: How Others are Leveraging AI Interactions with Automotive Consumers

Lateral Tension & Push Tools are Taking GPR to a New Level Efficiency Unleashed: Rethinking Roles in Collision Repair

1:00

Booth #33071

accudraftpaintbooths.com

This year at the 2024 SEMA show, Accudraft will display several of our products for the automotive repair industry. The showcase piece being our TITAN booth, perfect for any refinishing that your shop will do. The TITAN comes standard with 15HP motors, the ability to move 20,000 CFM, as well as produce 1.5 million BTU of heat through its direct fire AMU. Also on display is the newest standard features to the booth: Vetrino glass doors, Accudraft LIVE Control PanelTM, and Accudraft LIVE TM

Also being showcased is our cloud-based Accudraft LIVE TM program, which is a musthave for any shop owner. Accudraft LIVE TM transforms the way collision repair shops operate by providing real-time analytics and insights into YOUR paint booth’s performance. This innovative, cloud-based, software solution offers many benefits that can significantly enhance a shop’s efficiency, productivity, and overall profitability.

The new LIVE Control Panel TM gives ultimate control over your booth and its data. The new panel features an easy to navigate 15” full color touch screen controller with all important booth data such as mode, temperature, humidity, alarms, pressure, and more, being shown on an easy to follow display. With the ability to store nearly 1000 unique programs, the end user has total control in how the booth operates and can make custom programs for individual products with the ability to fine tune as they go with a tap on the screen.

At Accudraft, we firmly stand behind saying that we have a solution for every industry.

Booth #31213

AirProDiagnostics.com

AirPro Diagnostics is the leader in remote diagnostics, scanning, programming, and cost-effective ADAS calibration solutions for the collision, glass, and mechanical repair industries.

The AirPro tool and calibration devices meet rigorous vehicle manufacturer requirements by having OEM licensed software and multi-brand diagnostic applications resident and directly connected to the vehicle. ORION, AirPro’s cloud-based diagnostic management system, is the hub by which all services are delivered within the company’s 10-Minute Response Pledge. AirPro Diagnostics is backed by a team of uniquely skilled brand specialists who provide reliable, efficient, and accurate scanning, diagnostic, and ADAS calibration solutions that meet the highest quality and safety standards.

AirPro Diagnostics Auggie mobile FFC calibration system has met the National Highway Traffic Safety Administration (NHTSA), Euro NCAP, and Insurance Institute for Highway Safety (IIHS) standards.

Booth #33201

asTech®, based in Plano, Texas, is the leading global provider of comprehensive diagnostic, calibration, and programming solutions for the automotive aftermarket. We deliver cuttingedge, certified, and AI-driven repair solutions using OEM and OEM-compatible tools to ensure safe and accurate repairs based on OEM data-driven procedures.

Our patented Rules Engine and proprietary software enable us to offer virtual ASECertified Master Technician services, warrantied and accessible directly to customers in 44 countries. We also exclusively manage Launch Tech and Autel remote service offerings.

asTech’s virtual ASE-Certified Master Technicians provide remote solutions for vehicle trouble codes and real-time support to shop technicians as needed. With the asTech All-In-One, we have developed the most comprehensive single-device solution for remote and on-site diagnostics, calibrations, and programming in the global aftermarket.

Booth J10138

Elitek.com

Elitek Vehicle Services, an LKQ company, is the premier sublet provider for mobile and remote diagnostic services. Elitek is the largest independent mobile service company providing major mechanical services, automotive diagnostics, OEM programming, re-flash: module update/replacement/ sensor calibrations (as necessary), OEM pre/in-process/post scans, A/C Services – 1234YF on site, electrical/electronic, wiring harness and connector repair/ replace, and ADAS calibrations. Elitek has the equipment and skills to restore vehicles to the manufacturer's settings safely. The Mobile Team currently serves over 100 major metropolitan areas in 41 states, Calgary, and the Greater Toronto Area. Its best-in-class team members provide dealer-level services at your location. The Elitek Remote Device empowers repair facilities to deliver efficient, accurate, and customer-centric services, with a variety of services utilizing OEM scans instead of the aftermarket equivalent.

Booth #34183

fujisprayauto.com

When it comes to spray finishing equipment, Fuji Spray Auto is a name you can trust.

Fuji Spray Auto is a leading manufacturer of advanced spray finishing equipment, based in Toronto, Canada.

Built on the base of 35+ years of spray expertise we are dedicated to pushing the boundaries of innovation, consistently delivering solutions that meet the rigorous demands of the automotive sector.

Every Fuji Spray Auto product is a testament to our unwavering commitment to quality. Backed by decades of experience and crafted with precision, our equipment is trusted by professionals who demand authenticity and excellence in every detail.

We understand the challenges of achieving high-quality results in a fast-paced environment. That’s why our equipment is not just designed to meet industry standards— it’s crafted to exceed them, offering the performance, reliability, and consistency that professionals require to stay ahead.

Innovation is at the heart of everything we do. We continuously refine our products to stay ahead of industry trends and advancements, providing the tools necessary for professionals to excel in their craft. Whether it's through improved efficiency, enhanced control, or superior durability, our spray systems are built to deliver outstanding results every time.

Choosing Fuji Spray Auto means choosing a company committed to excellence in every aspect of automotive finishing. Our products are trusted by professionals who demand nothing but the best in performance and reliability, helping them maintain a competitive edge in a dynamic industry.

Goliath Carts, LLC is a pioneering company that has been at the forefront of providing innovative solutions for the collision industry. Founded in 2010 by automotive and technical industry experts, Goliath Carts recognized the need for improved organization and efficiency within collision repair shops. Their vision led to the development of customized point of use carts, which revolutionized the way tools, equipment, and supplies were accessed by technicians, minimizing downtime and optimizing workflow.

At the heart of Goliath Carts' offerings are their comprehensive range of point of use carts, which are meticulously designed and constructed to provide maximum functionality, durability, and organization. These carts feature specialized compartments, drawers, and holders to securely store tools, supplies, and equipment, ensuring easy accessibility for technicians during the repair process. Additionally, Goliath Carts provides customizable workstations, mobile storage solutions, and specialized racks designed for paint and body shops, further enhancing productivity and streamlining processes.

One of the standout offerings from Goliath Carts is their award-winning mobile self-powered workstations. They provide technicians with a portable solution for various tasks in production, blueprinting, and diagnostics. These workstations allow technicians to operate computers, printers and other devices directly from the cart, eliminating the need for separate power sources. This keeps your workers on task and double output, right out of the box! Come visit us at the 2024 SEMA Show in Booth #34087 or online at www.goliathcarts.com to find out how our carts can help improve your bottom line. Together let’s drive forward!

Booth #42017

Hunter.com

At SEMA 2024, Hunter Engineering Co. will once again exhibit a wide range of high-tech wheel and tire service equipment, designed and built in the U.S. and ready to drive productivity and profitability.

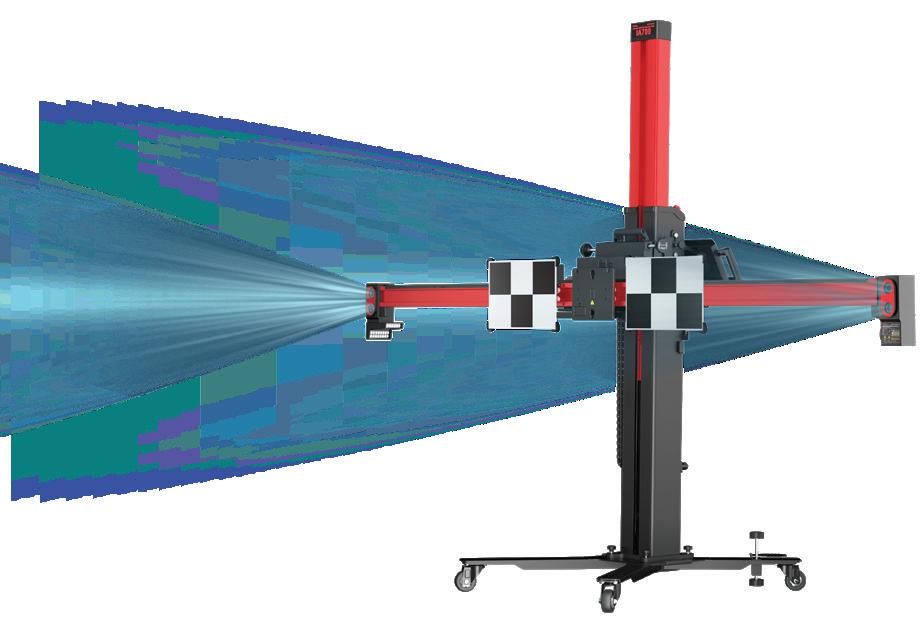

That equipment will include Ultimate ADAS®, Hunter’s innovative method of eliminating error-prone manual layouts common to static ADAS calibrations. Ultimate ADAS® debuted with great success at SEMA 2023.

Now available on a widespread basis in 2024, the new system will have particular interest for collision shops looking to begin or increase ADAS calibration work.

Ultimate ADAS® combines Hunter alignment technology with an efficient and easy-to-use guided target placement system for aroundthe-vehicle coverage. Gimbal-mounted lasers are the key component, replacing the inexact guesswork of strings, plumb bobs and tape measures to cut setup time by 70 percent for some procedures.

The vast majority of ADAS calibrations involve forward-facing cameras and radar, which generally require only 10 to 20 feet in front of the vehicle. This is space that every collision shop has available.

Ultimate ADAS® significantly simplifies and speeds up the calibration process.

The gimbals and onscreen guidance make target placement much more precise by automatically compensating for non-level floors, monitoring for placement errors, and confirming accuracy with laser measurements each step of the way. Easily decipherable paper and digital confirmation of targets and placement is included and available via the HunterNet®2 customer portal.

“We named it Ultimate for a reason,” says Ryan Gerber, ADAS Product Specialist. “It’s the fastest and most precise ADAS calibration system available.”

KECO Body Repair Products is a leader in the auto collision repair industry, specializing in Glue Pull Repair (GPR) and Paintless Dent Repair (PDR) tools and training. Based in Oklahoma City, KECO leverages over 60 years of manufacturing expertise to provide innovative and high-quality products designed to make collision repair more efficient and less invasive.

At the core of KECO's offerings is their flagship L2E GPR Collision System, a comprehensive work cell that streamlines the repair process from roughout to a flat finish. This system is complemented by a range of tools that exemplify KECO's commitment to delivering superior performance and versatility. These tools enable technicians to achieve clean and efficient repairs while preserving the vehicle’s original structure and finish.

KECO’s product lineup includes an extensive array of glue tabs, lifters, and other tools and accessories, all meticulously designed to meet the varying needs of auto repair professionals. In addition to providing top-tier tools, KECO places a strong emphasis on education and support, offering advanced training programs and unrivaled postpurchase support to ensure technicians can utilize KECO tools to their fullest potential.

KECO empowers technicians to stay informed about the latest advancements in GPR and PDR by fostering a collaborative community and providing a wealth of resources. Their dedication to innovation and quality positions KECO as the gold standard in the industry. For those seeking the pinnacle of auto repair technology, KECO Body Repair Products represents excellence in every aspect of collision repair.

Maximize Paint Profitability with Pro-Stat Quantum: Visit Us at SEMA 2024, Booth #33259

Discover how Pro-Stat Anti Static Gun and Quantum can help your body shop increase profitability by making your paint booth more efficient and effective. Debuting at SEMA 2024, these complementary solutions combine the power of Pro-Stat’s advanced static control technology with Quantum’s integrated direct billing system, allowing you to boost your bottom line with every paint job.

Pro-Stat ensures flawless, even finishes on all surfaces—metal, plastic, and fiberglass—by eliminating static electricity. By reducing dust inclusions, preventing uneven coverage, and improving metallic laydown, Pro-Stat helps you cut down on rework, saving time, labor, and materials. This static removal technology focuses on enhancing the overall quality of the paint job by minimizing contamination.

Quantum, on the other hand, is the tool that turns your paint booth into a larger profit center than ever before. With no upfront cost, Quantum is billed directly per repair order with paint and material time, creating a consistent new revenue stream for your shop while improving efficiency. By integrating Quantum into your process, you add financial benefits while Pro-Stat focuses on quality.

Visit Pro-Stat at Booth #33259 for a live demo and learn how these solutions together can help you get more profit out of every paint job. See how Pro-Stat cuts down on dust and dirt by up to 90%, increases paint transfer efficiency, and ensures perfect coverage— even on difficult edges and corners. Take advantage of exclusive SEMA offers and a free trial to see how Pro-Stat and Quantum can transform your paint booth and drive new revenue to your shop.

Unlock new profits from your paint work with Pro-Stat and Quantum—your next step to better finishes and bigger earnings.

quantum.prostat.com/sema

Booth #31017

SATAusa.com

All new spray gun coming from SATA.

SATA GmbH, Kornwestheim-based specialists for wet coating technologies recently introduced the highly anticipated jet X premium spray gun. At first glance, you can see that it has a new look: what stands out is the simple, elegant exterior in matte black with red accents.

According to SATA, the most important innovations are of a technical nature. An innovative nozzle technology is intended to set new standards in atomization: The labyrinth system invented by SATA guides the air in the nozzle so that it exits free of turbulence and pulsation. This ensures that the material is atomized extremely fine and homogeneously. The spray pattern is said to be particularly easy to control with optimized material distribution and clearly defined fade-out zones.

The jet X also has several other clever features, such as a trigger that can be removed in no time, with an integrated wrench for the fluid tip. The jet X is ergonomic and lighter weight than ever before with fewer components, the maintenance is quick and easy.

There will be four options to choose from to fit your needs. The jet X Basic and jet X Digital Ready will be available in January 2025. Due to regulatory requirements the jet X Digital and jet X Digital Pro will be available upon UL approval of the digital device. The RP will be available but if you fall under transfer efficiency mandates, please note that there are NO current SCAQMD or EPA approvals.

See these products in our booth at SEMA #31017 Second floor South Hall.

Booth #32278 Symach.com

At Symach, we integrate advanced repair and refinish technologies into your body shop, providing a qualitative and competitive edge in space optimization and repair efficiency. As the only equipment producer conducting extensive research on paints and drying technologies, we offer precise, user-friendly drying technology with high quality results.

Symach operates from our 170,000 sq. ft. facility in Bologna, Italy, producing toptier equipment and offering professional bodyshop design consultancy. Using client specific requirements, we design your repair process first, followed by the body shop layout, delivering insights on repair costs, ROI, and technician roles. Our design process significantly reduces engineering and construction costs, getting your project from concept to open doors as efficiently as possible.

Pioneering drying technology, we invented and perfected the FixLine model, a revolutionary solution for in-line car repair.

Our customers benefit from staff training and ongoing support with access to our REMO tech-assistance platform. REMO provides online training and detailed tutorials for every technician, painter, and manager. Our paint booths transmit data to this platform, offering productivity reports and maintenance alerts, ensuring exceptional efficiency and reliability.

Symach is the global leader in building efficient collision repair shops. Our FixLine process, featuring patented DryTronic and UV-LEDTronic technologies, boosts productivity by 30% and reduces energy consumption by over 80%. These innovations are vital as our industry shifts toward electric vehicles, carbon management, and energy cost savings. Imitations can't match our results, and competitors' products may not be as cost-effective.

Contact us for solutions tailored to your business needs: info@symach.com

Visit: https://www.symach.com/

Accudraft Paint Booths Booth #33071 accudraftpaintbooths.com

AirPro Diagnostics Booth #31213 AirProDiagnostics.com

asTech®️ Driven by Repairify™️ Booth #33201 astech.com

Elitek Vehicle Services Booth J10138 Elitek.com

Fuji Spray Auto Booth #34183 fujisprayauto.com

Goliath Carts Booth #34087 goliathcarts.com

Hunter Engineering Co. Booth #42017 Hunter.com

KECO Body Repair Products Booth #33221 kecotabs.com

Pro-Stat Quantum Booth #33259 Pro-Stat.com

SATA USA Booth #31017 SATAusa.com

Symach Booth #32278 Symach.com

With a waterborne basecoat that’s easy to mix, match and apply and that uses the same coat flash application you’ve already perfected, Cromax® EZ makes an exceptional finish feel effortless. Discover how easy an outstanding finish can be.

axalta.us/ez

Introducing collision careers to high school students can put them on a trajectory to success at a young age.

WHEN YOU THINK BACK to how you first became interested in the automotive industry, what stands out? What sparked your curiosity? How old were you? How did you learn more about it?

For many, it happened in high school… often in shop class. But not all schools offer shop these days, and even if they do, there’s

no guarantee collision is part of the conversation, says Jim Byron, owner of Byron’s Patterson Auto Body in Patterson, New York.

It’s up to industry pros to change that, in his estimation.

“Every shop in America — MSO, nonMSO, it doesn’t matter — they can get involved at the high school level to introduce these kids to collision at a young age.”

Whether spotting talent in the classroom or in the employees at his own shop, Byron is a firm believer that interest and strengths are best identified early…when they are, it can result not only in a rewarding career but a long-term employee for you, too.

As told to LINDSEY GAINER

For 25 years, I worked with the Boards of Cooperative Educational Services (BOCES) program in New York, advocating and representing the collision industry to high school kids. They’d pair a paint/equipment vendor with a representative from a collision repair shop, and we’d talk to the students about the jobs available to them.

I understand we work tirelessly in our business — and adding a commitment like this on top of that is asking a lot. But it allows you to interact with the educators, the actual teachers who are instructing these young people, and to better understand their situations with budgets and what they’re able to offer. Working with local schools lets us all be part of the solution to end the tech shortage by encouraging students to consider automotive programs, apprenticeships, or vocational school.

Let’s be honest — high schoolers are unlikely to listen to a 60-minute lecture. But if you engage them and ask questions to get them involved in the conversation, talk to them on their level, their response is quite positive.

Get them thinking cars…start with something vague, “Who here likes cars?” That kind of thing. “What kinds of cars do you like?” I’m an old guy, so I say, “What’s the hottest thing out there right now?” In more recent years it’s been things like the Subaru WRX and the Honda Civic Si’s. Back in the late ‘80s it was Monte Carlos with 350’s, or the Buick Grand National. And they all know the Corvettes. You get kids thinking about cars, then move on to questions like, “What do you think happens to one of those cars when it gets into an accident; how does it get fixed? Do you think you just throw it away, part it out? The fender is crumpled. What would you do?”

Bring props with you — something like a headlight assembly — and ask them what they think it came from, what kind of car, and show them how it attaches to the structural member. Get them thinking about what would happen if it got hit in an accident… would it break or would the structural member become distorted? Keep the questions and the conversation flowing. Then move into talking about paint and that side of the business. You can tell pretty quickly who might have an interest in collision work, then encourage them to keep exploring it.

If you have the opportunity to bring students into your shop, make sure you pair them with your shop’s “personality.” We all have one…the people person who loves to do this kind of thing. We have that guy in our shop, and we make it part of his job… he works with all the young people, and he knows how to warm up to them quickly and get them to warm up to him quickly. Make it an easy, interesting experience for them.

The amount of experience someone has when they first walk through my door isn’t what’s going to determine their success. Work ethic and passion is what truly matters. Whether it’s a high school kid or an adult, that holds true. You put a kid out on a one- or two-week train-

ing program in a collision repair shop and it’s going to be obvious to an educator whether it’s something they may want to pursue. You can then continue honing and engaging their skills and interests, play to their strengths.

Same goes for the adults working for you — you have to recognize and capitalize on people’s strengths for them to feel truly fulfilled in their jobs.

When you think about the reasons people stay in a job, it’s not because of the money — they stay because they feel needed, they feel like they’re an integral part of your operation. They need an environment they can prosper in…that they feel they’re a part of, that they fit into.

Look at your current employee pool first when there’s a void to fill in the shop. Is there someone on your payroll whose strengths would fit the bill? Would they be interested in trying something new?

Just last year I pulled one of my gas station attendants into the collision business because I saw he was great with people and had an interest in something more. Always keep your eye out for opportunities like that.

I’ve been here for 42 years, and I have people that have been with me since the beginning… and 80% of my workforce has been here for over 25 years.

How do I get employees? How do I build my business? How do I keep my employees? By creating a great working environment…a real one. This is a people business, first and foremost, after all. You’ve got to make it an environment that people who want to be in this industry want to work in.

I know when I step aside next year and my son, James, and his wife, Stephanie, take over, they’ll continue building on the foundation I’ve laid.

It all boils down to one basic principle: processes do not drive people. People drive the processes.

Sometimes trying to do too much means you’re not able to do enough.

By TODD KORTEMEIER

THERE’S A FEELING THAT shop owners sometimes get: “Is my shop doing enough?” They look around the shop some days and see a capacity for more work, while other days they can’t handle the workload they currently have. Helping turn feelings into results is where David McCreight comes in.

“People say, ‘Well, I always thought I could do more because I knew benchmarks or whatever would tell me I should be able to,’” says McCreight, owner and president of Collision Resources Inc., a provider of scheduling and estimating software and consulting services.

“‘But I never could figure out how to do it; we tried more employees, we tried different pay plans.’ And it comes back to how you load the shop, the mix of work that you load in the shop, and then just managing that work in process as it goes through the flow.”

McCreight sought to solve this problem through software, and it’s generated positive

results for many, many customers. In that process, he’s identified numerous pitfalls that shops run into when it comes to scheduling work, working efficiently, and increasing revenue.