A Focus on People and Processes Pays Dividends for the Bob Maloney Collision Group PAGE 28 BREAK THE PAINT DEPARTMENT BOTTLENECK PAGE 22 BUILD YOUR SHOP WITH EVS IN MIND PAGE 36 REDUCE HESITATION AND CAPTURE THE KEYS PAGE 39 FENDERBENDER.COM / JUNE 2024 INVESTING WISELY Paying Dividends A strong business sense and highquality, OEMdriven repairs have grown the Bob Maloney Collision Group in Northwest Arkansas to a six-shop network with $22 million in annual sales.

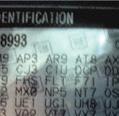

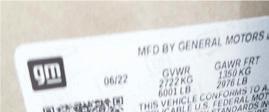

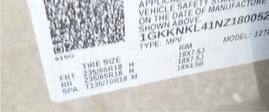

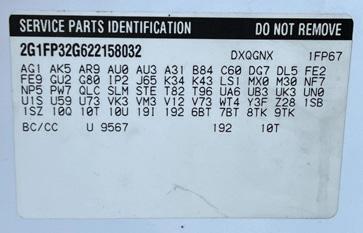

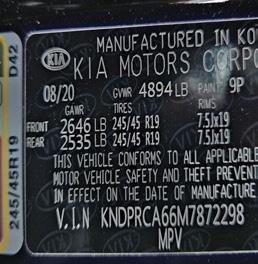

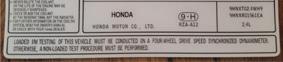

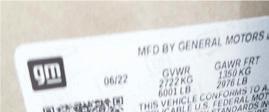

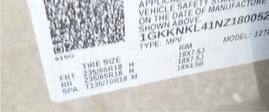

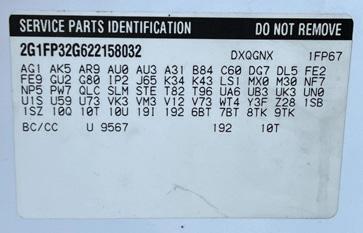

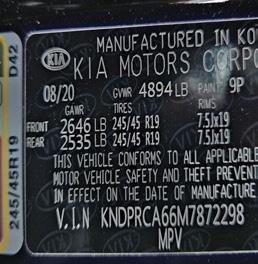

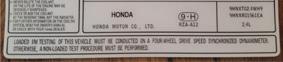

• Take photo without

• Check photo to avoid

• Capture the label from a straight-on angle to prevent distortion.

• Maintain a consistent distance to include the entire label in the frame.

• Avoid extreme zooming or cropping to maintain accuracy.

• Submit photos in JPEG or PNG format.

• Provide photos from different angles if the label has complex details.

• Ensure all relevant information is captured in the photo.

• Proof photos for clarity.

• Verify that all required details on the label are visible.

D.BYFORDMOTORCO.INU.S.A. ONFORMSTOALLAPPLICABLEFEDERALMOTOR HEDATEOF MANUFACTURE SHOWNABOVE. LB AT 30 240 kPa/35 REARGAWR: 1508KG P235/70R16SL 16X7.0J GVWR: 5880LB/2667KG WITHTIRESRIMS PSI COLD RIMS PSICOLD F0085 TIRE SIZE COLDTIREPR 303kpa 44psi 303kpa 44psi 303kpa 44psi The combined weight of occupants and carg P265/70R17 P265/70R17 P265/70R17 FRONT REAR SPARE SEATINGCA VEHICLE MFD .BY: TOYOTA MOTOR MANUFACTURING , GVWR ⁄233LB GAWR FR 2668LB RR 2668LB THIS VEHICLE CONFORMS TO ALL APPLICABLE FEDERAL MOTOR VEHICLE SAFETY THEFT PREVENTION STANDARDS IN EFFECT ON THE DATE OF MANUFACTURE SHOWN ABOVE . ⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄ KENTUCKY , INC . ⁄2 E N THE DAT 000000000000000 --NH737M --A --A D BYFORDMOTORCO.INU.S.A. RGAWR: 3325LB WR: 5880LB/2667KG WITHTIRESMS TIRE SIZE 303kpa 44psi 303kpa 44psi 303kpa 44psi The combined weight of occupants and cargo should never exceed 505 Kg 111 P265/70R17 P265/70R17 P265/70R17 FRONT REAR SPARE INFORMATION MFD .BY: TOYOTA MOTOR MANUFAC R FR 2668LB RR 26 RMS TO ALL APPL SAFETY , BUMPER , A IN EFFECT ON ABOVE . CAR KENTUCKY , INC . ⁄2 ⁄ ⁄⁄ RAL MOTOR VEHICLE SAFETYAND THEFT PREVENTION STANDARDS IN EFFECTON THE DATE OF MANUFACTURE SHOWN ABOVE.V.I.N.: 00000000000000000 STK A AA5 --NH737M --A --A MA C UR 668LBPLICABLE ER AND FOR ADDITIONAL INFORMATION ABOUT AUTO DATA LABELS: visit our website at www.AutoDataLabels.com email us at labels@AutoDataLabels.com | or call us at (631) 667-2382 ©2022 LKQ Corporation. Visit us at Portal.LKQcorp.com and LKQcorp.com IT’S AS EASY AS CLICK IT & STICK IT PPLICABL VE 0 0085 HE D QUALITY PHOTOS PRODUCE GREAT REPLACEMENT LABELS Quality of Lighting: Orientation and File Format: Angle and Distance: Multiple Angle Photo: Proof Photo Before Submission:

flash.

blurriness.

LINDSEY GAINER

BY JAY SICHT

LINDSEY GAINER

BY JAY SICHT

3 June 2024 fenderbender.com PROFILE 28 INVESTING WISELY A Focus on People and Processes Pays Dividends for the Bob Maloney Collision Group. BY

FEATURE 22 BREAKING THE BOTTLENECK Whether it’s your processes or your equipment that need replaced, here are tips to get the most from your paint department.

FenderBender (USPS Permit 25614), (ISSN 1937-7150 print) is published monthly by Endeavor Business Media, LLC. 201 N Main St 5th Floor Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI, and additional mailing offices. POSTMASTER: Send address changes to FenderBender, PO Box 3257, Northbrook, IL 60065-3257. SUBSCRIPTIONS: Publisher reserves the right to reject non-qualified subscriptions. Subscription prices: U.S. ($90 per year). All subscriptions are payable in U.S. funds. Send subscription inquiries to FenderBender, PO Box 3257, Northbrook, IL 60065-3257. Customer service can be reached toll-free at 877-382-9187 or at fenderbender@omeda.com for magazine subscription assistance or questions. Printed in the USA. Copyright 2024 Endeavor Business Media, LLC. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopies, recordings, or any information storage or retrieval system without permission from the publisher. Endeavor Business Media, LLC does not assume and hereby disclaims any liability to any person or company for any loss or damage caused by errors or omissions in the material herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. The views and opinions in the articles herein are not to be taken as official expressions of the publishers, unless so stated. The publishers do not warrant either expressly or by implication, the factual accuracy of the articles herein, nor do they so warrant any views or opinions by the authors of said articles. CONTENTS JUNE 06.24 | VOLUME 26 | NUMBER 06

As vehicles have evolved, so have the strategies for repairing them

NACAT marks 50th year of serving automotive educators, discusses July conference

Matte finish specifics discussed at CIC

The increasing repair cost of newer vehicles

The latest stories from around the industry

Massachusetts Shop celebrates 110 years in business, becomes MSO this year

Is Social Media Your Most Reliable Driver of Business?

Plan for EVs in Your New Shop Design COLUMNS

Removing Barriers to Customers

Handing Over the Keys

Checklist: Is Your Shop a Lean Operator?

Help correct archaic book times with your submission to the Database Enhancement Gateway.

What smaller or independent shops should consider for their

4 June 2024 fenderbender.com 18 36 STARTER QUICK FIX 07 DRIVER’S

SEAT

08

PAST THE PAGE

11

BREAKDOWN

16 NUMBERS

CONTENTS JUNE

14 LIGHT HITS

18 SNAP SHOP

34 THE SOP

36 OPERATIONS

20 SHOP PROFITS

BY GREG LOBSIGER 44 COLLISION COURSE

BY TIFFANY MENEFEE 46 DUE PROCESS

business climate. BY DREW BRYANT STRATEGY 39 CASE STUDY

ADAS equipment investment.

Use the right mindset to maintain your composure in a challenging

41 OPERATIONS

CLICK ON THE LOGO BELOW FOR PRODUCT INFORMATION

EDITORIAL

Matt Hudson Group Editorial Director

Jay Sicht Editor-in-Chief

Abdulla Gaafarelkhalifa Associate Editor

Kacey Frederick Assistant Editor

Emily Kline Special Projects Editor

Leah Marxhausen Special Projects Editor

Drew Bryant Contributing Writer

Tiffany Menefee Contributing Writer

Greg Lobsiger Contributing Writer

Noah Brown Contributing Writer

Lindsey Gainer Contributing Writer

Todd Kortemeier Contributing Writer

Steve Trapp Contributing Writer

EDITORIAL ADVISORY BOARD

Jordan Beshears Steve’s Auto Body

Sheryl Driggers Collision Advice

Frank Rinaudo Industry Consultant

Jason Mundy Mundy’s Collision Center

Stan Medina Certified Collision Works

SALES

Andrew Johnson Associate Publisher ajohnson@endeavorb2b.com

Mattie Gorman-Greuel Associate Sales Director

Cortni Jones Director of Business Development

Diane Braden Account Executive (National Accounts)

dbraden@endeavorb2b.com

Marianne Dyal Account Executive (National Accounts) mdyal@endeavorb2b.com

Chad Hjellming Account Executive (National Accounts) chjellming@endeavorb2b.com

Lisa Mend Account Executive (National Accounts) lmend@endeavorb2b.com

Martha Severson Account Executive (National Accounts) mseverson@endeavorb2b.com

Kyle Shaw Account Executive (National Accounts) kshaw@endeavorb2b.com

Sean Thornton Account Executive (National Accounts) sthornton@endeavorb2b.com

Ryan McCanna Administrative Assistant

ART

AND PRODUCTION

Mariah Straub Production Manager

Jen George Ad Services Manager

Mitch Bradford Art Director

ENDEAVOR BUSINESS MEDIA, LLC

CEO Chris Ferrell

President June Griffin

COO Patrick Rains

CRO Paul Andrews

Chief Digital Officer Jacquie Niemiec

Chief Administrative and Legal Officer Tracy Kane

EVP Endeavor Business Intelligence Paul Mattioli

EVP Transportation Kylie Hirko

VP and Group Publisher Chris Messer

HOW TO REACH US

Endeavor Business Media, LLC 571 Snelling Ave N Saint Paul, MN 55104 tel 651.224.6207 fax 651.224.6212

The annual subscription rate is $90 (U.S.A. only) for companies not qualified to receive complimentary copies of FenderBender.

LETTERS TO THE EDITOR editor@fenderbender.com

Opinions expressed in FenderBender are not necessarily those of Endeavor Business Media, and Endeavor Business Media does not accept responsibility for advertising content.

6 June 2024 fenderbender.com

CONTENTS ONLINE EXTRAS

LKQ Corporation

Axalta Coating Systems

SATA USA Inc.

Ford Motor Company

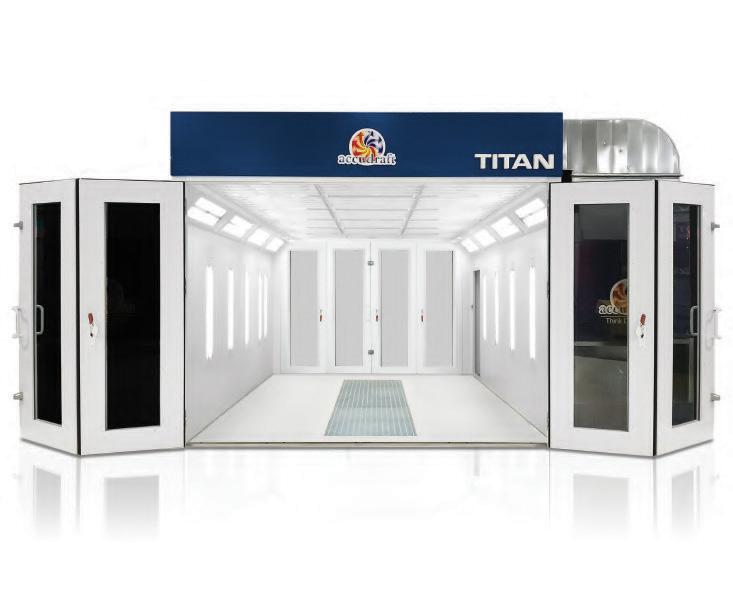

Accudraft Polyvance

Auto Data Labels

TOPDON USA ®

Motor Age Training

PPG Industries

AUTEL

Hunter Engineering

WHAT KEEPS YOU UP AT NIGHT?

As vehicles have evolved, so have the strategies for repairing them.

I’VE ALWAYS BEEN a gearhead at heart, fascinated at an early age with planes, trains, and automobiles (coincidentally, the 1987 John Hughes film, with Steve Martin and John Candy, is a favorite, too). For my fourth grade assignment to write a “book,” I chose “From Model Ts to dragsters,” which traced the development of the automobile from horseless carriages to the latest technology at the time.

More time than I’d like to admit has elapsed since then, but to cover the additional technology now found in today’s vehicles, my fourth grade book today would likely have to be three times as thick.

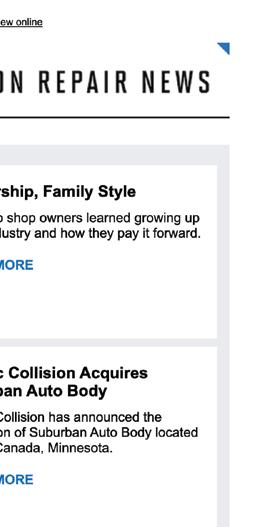

With ABRN, we continue to bring you the latest technical articles, product information, and training resources. In this month’s issue, learn from Hunter Auto Body Manager Kyle Motzkus, who speaks at training events around the country on repair planning, about how to us resources to efficiently research OEM repair information. Jeremy Winters, who was a collision repair/restoration painter for more than 18 years before joining the staff of Accudraft Paint Booths, gives painters tips for succcesfully repairing complex finishes, including tri-coats and quad coats. Veteran Contributing Editor Tim Sramcik guides readers how to determine the ideal solution for subletting their ADAS-calibration needs.

In FenderBender this month, Tiffany Menefee relates how her ADAS strategy has evolved with her shop’s experience to include more shop-owned equipment and remote assistance. EV Expert Dirk Fuchs fills us in on shop design considerations for EV repairs. And in my article on increasing booth ef-

ficiency, I call upon the expertise of Jeremy Winters and 3M’s Jason Garfoot, who help shop owners and operators and painters get the most refinish hours out of their paint department using the latest equipment and techniques.

Whether it’s vehicle technology, market consolidation, or billing challenges that keep you up at night, I hope you find assistance within the content of FenderBender and ABRN. And please drop me a line if there is a topic you’d like to see us cover.

JAY SICHT EDITOR-IN-CHIEF jsicht@endeavorb2b.com

JAY SICHT EDITOR-IN-CHIEF jsicht@endeavorb2b.com

7 June 2024 fenderbender.com DRIVER’S SEAT

CIC SHINES LIGHT ON MATTE FINISHES

MATTE FINISHES, once typically found under the hood of high-level custom car builds or low-visibility military applications, found a place in the mainstream market about 15 years ago with BMW’s “frozen” finish. Such low-gloss finishes can be finicky to care for (even bug splatters and their removal can burnish the finish) and in the refinishing process. But the customer has the same high expectations for the matte finish to be matched in color and gloss level as that of a six-figure German SUV or sedan. What’s a shop to do?

At the April Collision Industry Conference in Seattle, speakers at the Parts & Materials committee’s discussion provided some guidance for success.

The importance of sprayout panels

“Sheen is going to impact the color [match] a lot more than the color will impact the sheen,” said Brad Letourneau, regional trainer with BASF Automotive Refinish. ” Typically if we have a bad color match, we can blend that color out so the customer can’t see it. With the matte vehicle, we’re not blending the clear coat. We have to do a panel match.”

Both the sheen level (such as matte, semi-gloss, and medium gloss) and film build (in mils) affect the color match. Letourneau recommends that painters prepare sprayout (test) panels incorporating these variables, and those panels must be viewed at a 5° to 15° angle, not the typical 90° angle.

And for the test panels, Letourneau advised, painters need to be methodical in recording on the back of each card the equipment and materials used, such as the gun and fluid tip, which clearcoat, which hardener, the flash time, humidity bake time

and temperature, all of which contribute to the final outcome. To achieve the same result when refinishing the vehicle once the test panel color and sheen are matched, those variables must be reproduced.

Letourneau added that matte finishes are “simple to do once you do a handful of them,” and that shops repairing a high volume of Mercedes-Benz or BMW vehicles “have the repair process down to a science,” while larger MSOs may see fewer vehicles with the specialty finishes and may even refuse to take them in because of the extra time associated with them.

Booth considerations

Thorsten Alstede, technical consultant with AkzoNobel Vehicle Refinishes, agreed with Letourneau that matte finishes are not that different from others as long as the proper steps are taken and precautions are followed. Because matte finishes cannot be nib-sanded and polished, the “off-thegun” finish is what must be delivered. He went over best practices for spray booth operation to deliver a finish as dirt-free as possible. Painters should be able to identify what is the spray zone (determined by the airflow), what he calls “the booth within the box,” which is determined by the “invisible plans connecting the ceiling filters and floor exhaust.” Spraying within this zone provides the least turbulence and cleanest results.

Leave the booth running while loading and unloading to capture dirt and particles within the “invisible curtain.” For the least amount of contamination (for all finishes, not just matte), he recommends centering the vehicle and parts over the floor grates. It’s also critical to balance the pressure in the booth cabin during the spray and bake cycles for newer booths, and to calibrate for

a slightly positive pressure for booths older than four or five years old to compensate for worn seals.

When refinishing matte finishes, if drying equipment such as corner blowers are used, it’s critical to first purge the booth before they are turned on.

“There will still be overspray lingering outside your spray zone,” he said. “So, if you just wait a few minutes, you will have a way cleaner design in a flat-finish operation.”

High-tech and low-tech tips and tricks

Kye Yeung, owner of European Motor Car Works, added that his shop has learned a number of small tips and tricks for the matte refinishing process. His shop minimizes contamination by using dirt-trap materials (he recommends the one made by 3M), distilled water, and lint-free brass or stainless steel paint strainers. He also recommends purchasing a gloss meter, which measures gloss units from zero to 100, from matte to gloss, respectively, and measures the paint surface with three cameras at 20°, 60°, and 85° to differentiate the amount of gloss a human eye cannot. They can cost up to $5,000. But for refinishing purposes, a $400 model from eBay provides consistent results that can help avoid the need for redos, he said.

He also recommends using distilled water for the prewash, as minerals left after tap water evaporates can create a water spot in the finish. And another low-tech solution: applying cheap hairspray to the painter’s suit before going in the booth.

“That just basically glues the lint onto their body.”

around the collision repair industry.

8 June 2024 fenderbender.com PAST THE PAGE

VIDEOS | PODCASTS | WEBINARS | NEWS

Visit FenderBender.com/news for daily updates

@fenderbendermag fenderbender.com/linkedin fenderbender.com

from

The Daylight Solution

SATA trueSun

The amount of work caused by a wrong decision and the associated high costs of repainting the area leave no room for compromise when it comes to choosing the light quality.

In order to ensure that the correct color variant is selected during refinishing and the associated color shade can be determined, a light source that reproduces the entire color spectrum of visible light (daylight) as far as possible must be used. The specially developed SATA trueSun facilitates professional color retrieval and identification, even inside the bodyshop.

Best possible close to daylight reproduction of different color shades

Homogeneous light distribution across the entire illuminated area

Approx. 70 minutes at full light intensity

Uniform light intensity - independent from the battery's level of charge

Charging cycle time of only 50 minutes

Infinitely adjustable light intensity

www.satausa.com

INFO www.sata.com/truesun

SATA USA Inc. 1 Sata Drive • PO Box 46 Spring Valley, MN 55975 Phone: 800-533-8016 E-mail: satajet@satausa.com

Clear, on-screen step-by-step instructions make the ADASLink® diagnostic scan tool your gateway to ADAS calibrations

On-screen direction walks techs through calibrations for millions of vehicles

Comprehensive pre- and post-scans of installed systems and codes

Full diagnostic capabilities reveal trouble codes and other vehicle information

Code/pair new parts to the vehicle after installation

Follow guided processes to calibrate required systems after a collision

Scan or visit Sc an or hunter.com/adas It’s time to start doing this. We’ll help you.

NACAT: SUPPORTING AUTOMOTIVE EDUCATORS

Marking its silver anniversary, this organization helps make the transition from industry to education.

By ABDULLA GAAFARELKHALIFA

REACHING 50 YEARS OF AGE, the big 5-0, or a half-century, is a significant milestone for any person or organization. Automotive repair educators can certainly agree, as this marks the 50th year since the North American Council of Automotive Teachers (NACAT, pronounced “naycat”) was established. This will be a major theme at the upcoming 2024 NACAT Conference, July 22 to July 25 in Indianapolis.

‘Nay-What?’

If you’re not too familiar with the organization, no one could describe it better than NACAT President, Drew Barnes. “NACAT is an organization that was founded for automotive teachers by automotive teachers,” he said.

“As you transition from the industry into education, it’s a whole different world,” Barnes explained. “Much of the training provided by

school districts and universities doesn’t really cater to the automotive instructor.”

As the cars you see in your shop change in body, material, and even the types of engines, it’s imperative that educators are constantly updated before they teach a class to automotive students.

Their status in automotive repair circles is so well-respected that they even have people from outside North America attending and participating in training events.

Barnes emphasizes that the education teachers receive isn’t just about repairing the latest model vehicles. It’s also about things that instructors don’t often get training on anywhere else, such as classroom management.

11 June 2024 fenderbender.com QUICK FIX NEWS | IDEAS | PEOPLE | TRENDS

BREAKDOWN

PHOTO COURTSEY NORTH AMERICAN COUNCIL OF AUTOMOTIVE TEACHERS

When the Student Becomes the Master

Barnes says for those who might decide to enter teaching, “You might really understand how to work on a car, but you’ve never taught it. So, there are certain things from every ASE automotive area, from engines to transmissions to HVAC, and all the different topics that there are. And we try to provide a very wide variety of all the topics that are there.”

“I’ve been teaching for 15 years now, and there are still times that I want to go in and join in an engine performance training,” he added.

He also highlighted the popularity of EVs, ADAS, the technological advancements in engine management systems, and in automatic transmissions, which all make NACAT more important than ever.

These automotive repair topics will also play a big role in the upcoming conference as well.

“As an automotive technician, we always had training at our fingertips, but as a teacher, you kind of fall out of that loop a little bit and it’s hard to maintain a status of working with the manufacturers and other people to have access to that training,” Barnes said.

The Structure of NACAT

Barnes, as the NACAT president, is the chief executive officer and the “face” of the corporation, according to their website. Therefore, Barnes has control over NACAT’s general business affairs, property, assets, employees, officers, and others appointed to represent the corporation. He was elected last year and is in the middle of his two-year term.

Aside from his duties as president, like everyone else in NACAT, Barnes has been an automotive instructor at Vale High

School, in Vale, Oregon, for 12 of his 15 total years of teaching.

Before teaching, he worked as an automotive technician in a GM dealership and an independent automotive repair facility. Drew is a 2005 graduate of the General Motors ASEP program. He is an ASE Certified Master Technician and a current NACAT board member.

Barnes has been with NACAT since 2016 as a member and became president last year. The board of directors is a group of up to nine NACAT members who provide vision, direction, and advice to NACAT, according to the website. The board does not conduct the day-to-day business of the organization. The board monitors trends, offers guidance or suggestions, and discusses outcomes with the intent of helping NACAT grow and provide value to its members.

12 June 2024 fenderbender.com QUICK FIX

WE’RE

CONNECT WITH US ON YOUR FAVORITE SOCIAL MEDIA SITES WWW.FENDERBENDER.COM

SOCIAL

What Will Happen at the 50th Annual Conference?

On Monday, the event will take place at the Embassy Suites by Hilton Plainfield Indianapolis Airport. The day will commence with registration at 9 a.m., followed by a meeting for first-time attendees. The opening general session, keynote, and lunch will occur from 12 p.m. to 2 p.m. The afternoon will consist of training sessions, with breaks interspersed, and a trip to the Kemah Boardwalk for guests. The day will wrap up with a welcome reception at 6 p.m.

Tuesday’s activities will be held at the Pasadena Convention Center, featuring training sessions, a visit to the Space Center Houston for guests, and time allocated for exhibits. The day will culminate with valve cover races, a BBQ, and networking.

On Wednesday, training sessions will shift to San Jacinto College. Guests have the

option to visit the Houston Zoo or the Houston Museum of Natural Science.

Training concludes on Thursday at San Jacinto College, with a trip to Helen’s Garden or the League City Historical District for guests. The day will end with a cocktail reception and an awards dinner back at the hotel.

The Benefits of NACAT Membership

Attending the annual conference alone will enable educators of ASE Educational Foundation-certified programs to fulfill their programs’ requirements to complete 20 hours of professional development each year. Membership will also grant yearround access to a digital training library, among other benefits.

Members are awarded discounts, including $20 off a VISION Hi-Tech Training

& Expo Weekend or Four-Day Power Pass Registration, and a 20% discount on Motor Age Training products.

The benefits of NACAT extend beyond just members. Every year, NACAT awards the Larry Cotten Memorial Scholarship of $1,000 to a student training to become a collision repair technician.

“If you’re not a current NACAT member, explore the website and some of the benefits. Connect with people you may know who are NACAT members and see if it’s a good fit for you,” Barnes said.

“Back in 2016, I stumbled across the NACAT organization while looking for training,” he added. “I’ve been a member ever since, and now, as the current president, it’s truly been a fantastic organization.”

For more information on the benefits of joining NACAT, and to access the conference agenda, please visit www.nacat.org.

LIGHT HITS

FLORIDA MAN ARRESTED FOR DAMAGING HIS OWN CAR

The Lee County Sheriff’s Office in Florida arrested a Cape Coral man for insurance fraud.

According to court records, Ivan Antonio Gomez, 53, is facing one charge of knowingly making a false report of an alleged crime and one charge of making a false statement to an insurance company.

According to court records obtained by NBC2, Gomez claimed to have dropped his car off at a tire shop on Palm Beach Blvd for an oil change on February 24. Gomez then called the sheriff’s office about his car being ‘vandalized’ before he received a call back from the shop owner, who reported the same thing.

The Mercedes Benz had two smashed windows, a broken dashboard computer, and ripped seats. The only seat not destroyed was the driver’s side.

Later, detectives found cameras nearby that captured Gomez on video, dropping off the car and grabbing a metal rod to damage it himself.

During the investigation, law enforcement discovered that Gomez owed about $40,000 on the car, and after the damages, he filed an insurance claim, according to his arrest report. Four days after filing the claim, he withdrew it.

According to court records, Gomez was arrested on April 17 and released a day later after having paid $3,000 in bond.

CCG MAKES MAJOR ACQUISITIONS

Certified Collision Group (CCG) announced the acquisition of Square One Systems and Coyote Vision Group.

“CCG is excited to welcome Square One and Coyote Vision Group to our portfolio,” said Michelle Sullivan, CEO of CCG. “Square One has demonstrated over 40 years of innovative leadership in delivering effective solutions centered around analytics, collaboration, and accountability. Performance-driven groups

enhance top-performing, like-minded operators, ultimately elevating the entire industry. We are delighted to continue supporting Coyote Vision Group and Square One Performance group members as they optimize business performance, seize opportunities, and foster community growth.”

“This model has stood the test of time for many, many years in various industries, including automotive,” said Elaine Sachire, president of Square One Systems. “Square One’s focus has always been with the independent collision repairer to find solutions that assist its members to not just survive… but to thrive. Surrounding yourself with like-minded people is a simple recipe for success. This is where CCG and Square One together converge, resulting in like-minded people, like-minded resources, and like-minded strategies to help their members be the absolute best they can be.”

Erin Solis, senior vice president of Square One Systems, will lead the charge on behalf of the company. “I am so excited for the future of Square One and all the independent shop owners that are now and will become part of this journey,” said Solis. “As we embrace and honor Elaine’s core values and vision, we have big plans to expand our program, enabling us to help more shops grow and thrive in today’s ever-changing landscape.”

Certified Collision Group is a member network platform that serves independent collision repair operators across the U.S. and Canada. They provide access to carrier relations, fair pricing, and operational support.

FEW SMALL SUVS EXCEL IN NEW IIHS FRONT CRASH PREVENTION TEST

The Insurance Institute for Highway Safety (IIHS) has introduced a more rigorous vehicle-to-vehicle front crash prevention test. The Subaru Forester was the only small SUV

to earn a good rating in the first round of evaluations. The new test addresses highspeed crashes and those involving motorcycles or large trucks.

IIHS President David Harkey emphasized the importance of this update, stating that automatic emergency braking, now standard in most new vehicles, prevents up to half of all front-to-rear crashes. The Honda CR-V and Toyota RAV4 received acceptable ratings, while the Ford Escape, Hyundai Tucson, and Jeep Compass were rated marginal. The Chevrolet Equinox, Mazda CX-5, Mitsubishi Outlander, and Volkswagen Taos were rated poor.

The updated test includes trials at higher speeds and examines performance with different targets, reflecting a larger proportion of police-reported front-to-rear crashes. IIHS Senior Research Scientist David Kidd noted that higher-speed crashes are more dangerous, often involving large trucks or motorcycles.

In the new evaluation, multiple trials are conducted with different targets at various speeds. Both the forward collision warning and automatic emergency braking (AEB) systems are evaluated. Points are awarded for timely warnings and substantial speed reductions. The Forester performed well in all tests, while the CR-V provided a timely warning and stopped or nearly stopped in most trials. Even vehicles with a marginal rating demonstrated a higher level of performance than required in the original evaluation. However, the four poor-rated vehicles fell short in multiple scenarios.

WINNERS OF THE NABC LONE STAR CHANGING AND SAVING LIVES GOLF FUNDRAISER

The National Auto Body Council announced the winners of the NABC Lone Star Changing and Saving Lives Golf Fundraiser, held on Wednesday, April 10, 2024, at the Texas Star Golf Course in Dallas, according to a news release.

14 June 2024 fenderbender.com

QUICK FIX

More than 125 players, sponsors, and industry members gathered for the second tournament of the NABC season. The day featured the presentation of an NABC Recycled Ride to deserving U.S. Army veteran Kijafa Adams prior to the shotgun start. In addition, the National Auto Body Council presented two vehicles the day before at the PPG Conference to U.S. Army veteran Nathan Burrows and single mother Walnisha Stevenson.

After a round with threatening skies and windy conditions, the winners put together solid rounds to take the signature NABC crystal trophies.

• 1st – Darren Huggins, Tom Wolf, David Powoli, and Gene Kozash, who came in -19 under at 52 (shown below)

• 2nd – Tim Bates, Patrick Hickory, Ernest Salady, and Mike Malliton, who were -18 under at 53 and won a scorecard playoff

• 3rd – Kyle Drob, Tracy Carpenter, Logan Payne, and Travis Rilat, who were tied at -18 under with a 53

The men’s closest to the pin and longest drive went to Brian Wilkinson, while Alyssa Theis took home the ladies’ closest to the pin and longest drive honors.

“Congratulations to our winners and thank you to all of our players and sponsors for supporting today’s event. The real winners are those who we support through our programs – the families in need, military members, veterans, and first responders. We’re honored to be able to give back to them and their communities through the collective work of the collision industry,” said Scott Sampley, chairman of the National Auto Body Council.

The NABC Changing and Saving Lives Golf Fundraisers provide an opportunity to join industry colleagues and customers for great golf and support the NABC. There is also the opportunity to win bragging rights on the course, great raffle prizes, and auction items. Through the foundation, proceeds will benefit families in need, military members, veterans, and first responders, and help fulfill the mission of harnessing the power of the collective membership of the collision repair industry to positively impact communities across the country.

The new Changing and Saving Lives Foundation is a 501(c)3, making sponsorship and golf donations taxdeductible for companies and participants. It will also continue to offer the popular multi-event sponsorship program, making it more affordable and more efficient to be a partner in the NABC golf events.

June 2024

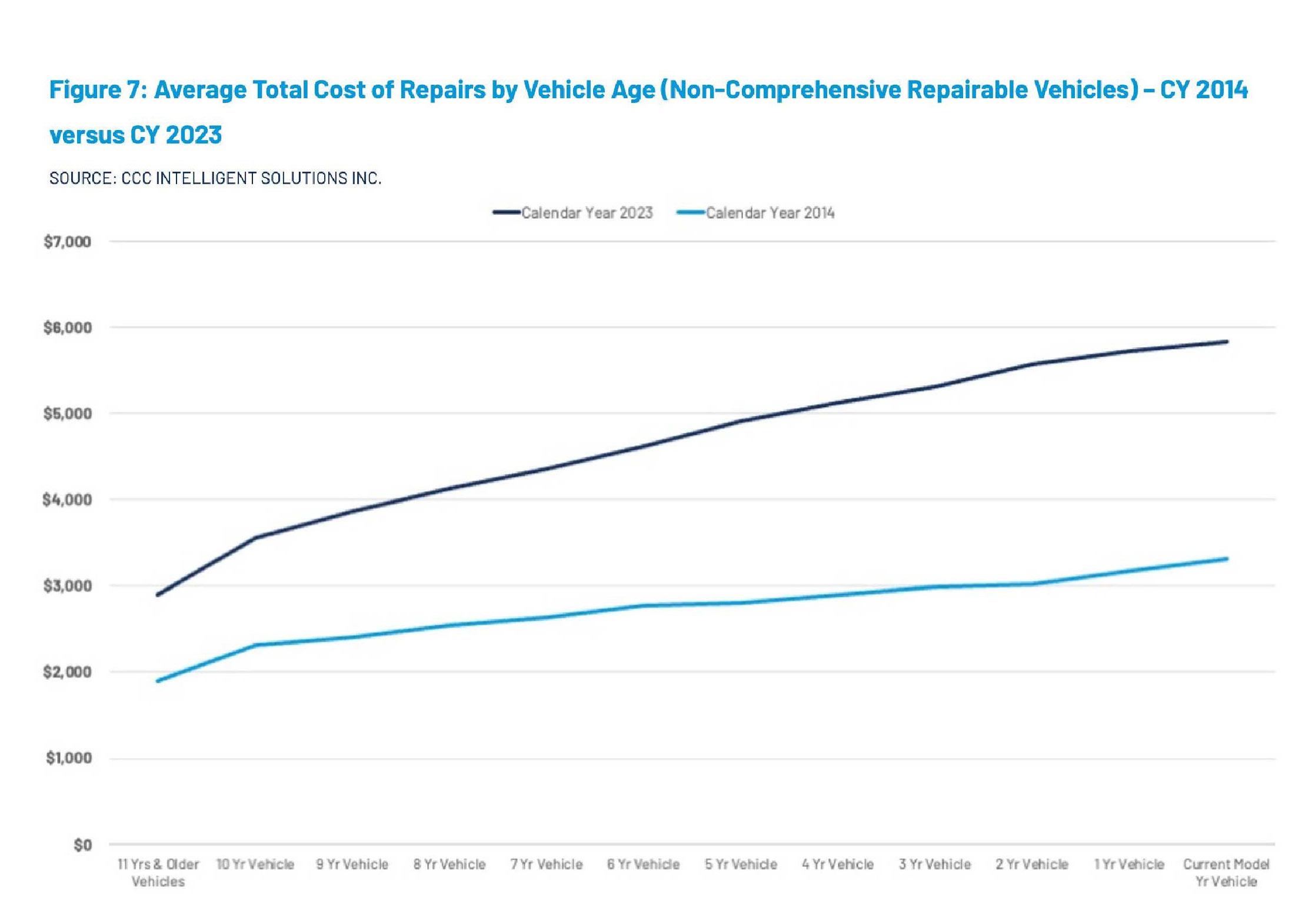

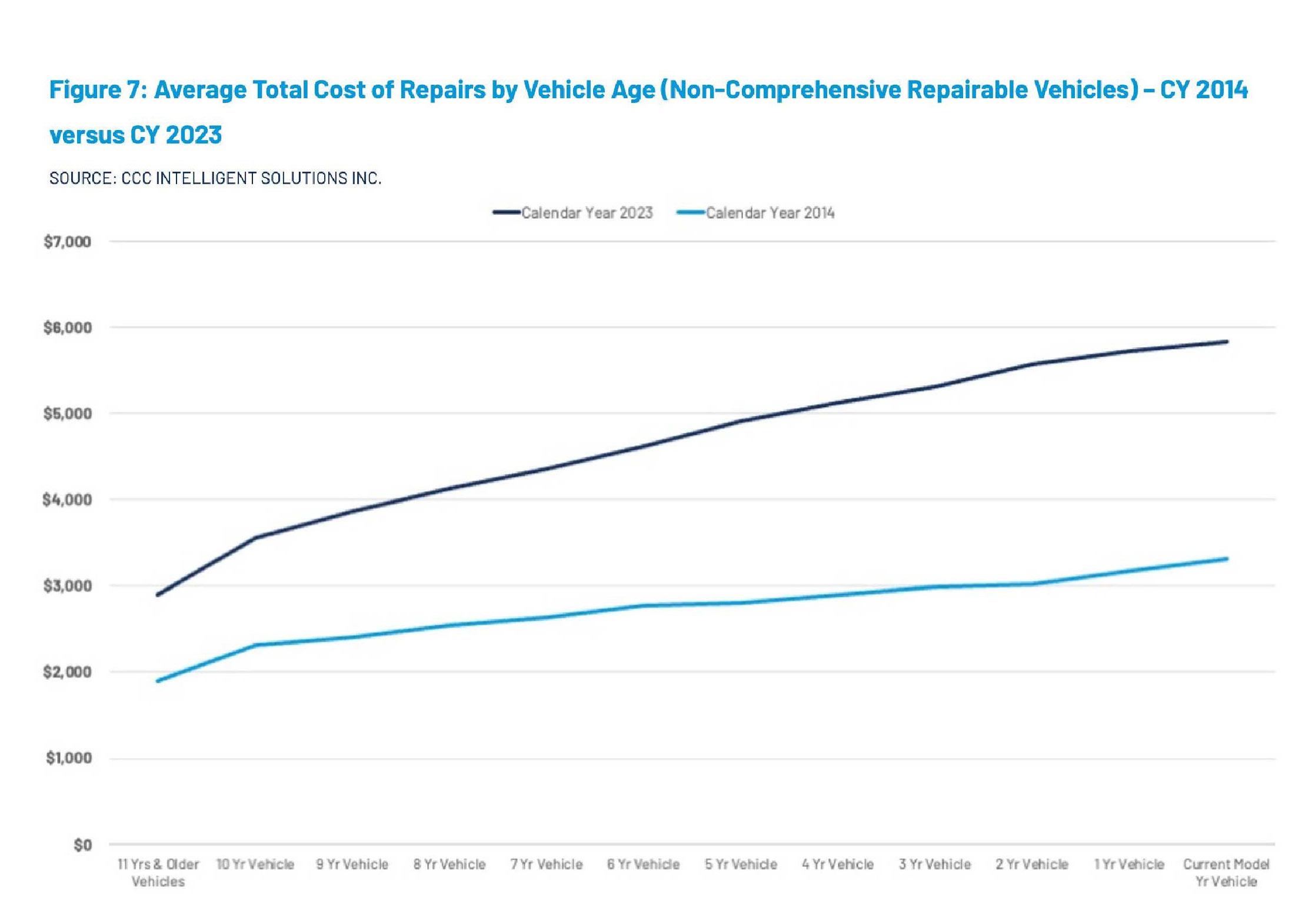

THE INCREASING REPAIR COST OF NEWER VEHICLES

WITH LATE-MODEL VEHICLES GROWING IN COMPLEXITY using more lightweight, advanced materials and complex electronic modules and sensors for advanced driver assistance systems (ADAS) and creature comfort, it’s not unexpected that repair cost severity is up for newer vehicles.

According to CCC Intelligent Solutions’ Crash Course report for the first quarter of 2024, the cost differential between repairing older and newer vehicles has increased over the past 10 years.

As an example, the cost of non-comprehensive repairs of the oldest repaired vehicles (11 years and older) and the current model year in 2014 was a little under $2,000 and less than $3,500, respectively, a 75% difference. But in 2023, the repair cost for older vehicles was less than $3,000 and current model year vehicles was nearly $6,000, a 101.3% difference. The report goes on to explain the delta between old and new repair costs will decrease as the complexity for older and newer vehicles becomes more consistent.

16 June 2024 fenderbender.com

NUMBERS

QUICK FIX

Efficiency, sustainability, and ease of use – these are just three of the reasons why PPG’s Envirobase High Performance waterborne paint system is the trusted choice for more than 40,000 body shops around the globe.

But the benefits don’t stop there. The Envirobase High Performance paint system supports fully digitalized repair processes and is compatible with every tool in the PPG LINQ™ digital ecosystem, making it the perfect solution for modern collision centers.

The refinish industry is always evolving. Our PPG experts continue to develop new products that enhance the core Envirobase High Performance waterborne system and help body shops meet changing demands and challenges.

SAME SYSTEM. SAME GREAT RESULTS. MORE FLEXIBILITY. PPG ENVIROBASE® HIGH PERFORMANCE

For more information visit envirobase.com The PPG Logo and Envirobase are registered trademarks and PPG LINQ is a trademark of PPG Industries Ohio, Inc. © 2024 PPG Industries, Inc. All rights reserved.

FULLER’S COLLISION

MASSACHUSETTS

FROM HORSE-POWERED TO HORSEPOWER

“Fuller’s has been a name in auto repair since 1914,” says Joshua Fuller, CEO of Fuller’s Collision Group. As the name might suggest, Fuller’s is a family business.

Aside from collision repair, they also offer auto and tire services in a separate building.

The Fuller’s legacy began with Joshua’s great-grandfather, Willis Fuller, who made the remarkable transition from working on horsedrawn buggies to working on the ignition wiring of Ford Model Ts.

Today, Fuller’s Collision holds 10 OEM certifications. “We focus on our major brands, what our market demands,” Fuller said. The focus is heavily skewed towards domestic brands like Ford, GM, and Stellantis. They also accommodate more popular foreign brands like Infiniti, Nissan, and Subaru. “Tesla is on the radar,” he added.

He said OEM certifications often tie you to use certain brands of products, so for paint and coatings, you’ll find Axalta and BASF products.

“We’re also big on Car-O-Liner and we’re big into Pro Spot.”

Something that Fuller takes pride in is not just the physical tools used by his staff, whom he refers to as stakeholders, but also the software, particularly RepairLogic and Revv ADAS.

“Both those tools are phenomenal as far as identifying proper repair procedures, single-

18 June 2024 fenderbender.com LOCATION: AUBURN,

OWNER: JOSHUA FULLER SIZE: 20,000 SQUARE FEET STAFF: 30 AVERAGE MONTHLY CAR COUNT: 100 AVERAGE REPAIR ORDER: $5,000 ANNUAL REVENUE: $6M

B y A BDULLA GAAFARELKHALIFA Photos FULLER AUTOMOTIVE COMPANIES Submit Your Shop Proud of your shop and want to show it off to your peers? Tell us about it at NEWS@FENDERBENDER.COM SNAP SHOP QUICK FIX

use items, and potential calibrations based on what the vehicle is doing,” Fuller said.

THE PERKS OF HAVING WALLFLOWERS

Something that strategically catches the eye when looking at Fuller’s Collision Center, or at least when looking at their website, is the decorative flowers on the outside walls of the facility.

“A lot of our stakeholders spend more time here than they do with their families sometimes, so the way we look at it is, ‘How do you want your house to look?’” Fuller said.

He also mentions that this aesthetic sets the expectation for customers who often seek their services during challenging times.

“The collision experience is like going to the dentist,” Fuller explained. “Nobody wants to do it, and you really can’t plan for it. You’re fearful of the unknown because you don’t know how it will disrupt your life. We try to mitigate that by providing a setting where customers can let their guard down.”

THE MSO CLUB

On March 8, Fuller’s acquired Woody’s in Spencer, Massachusetts.

As of late March, Woody’s Auto Body will be renamed Woody’s Collision Center.

“But it’s not a rebrand,” Fuller said. “It’s a refresh.”

“At week three since the integration, we already started the front office redo, and we’re comparing spaces for flowers.”

19 June 2024 fenderbender.com

Are you leaving money on the table?

Help correct archaic book times with your submission to the Database Enhancement Gateway.

Recently, I was preparing for a presentation and was doing some research on ways to increase gross sales to increase profitability. I have written on this previously, but one of the easiest ways and most profitable ways is with better estimating.

Over the years, many of us have been approached by one of our technicians with a work order in hand with a complaint like this: “There is no way 9.2 hours is the correct time to R&R the radiator support!”

Fewer than 2% of labor times include time studies?

The latest figures I have heard are fewer than 2% of the labor times are time-studied in CCC, Audatex & Mitchell. It’s sad to think this is true, when car technology is multiplying each year and with the high monthly subscription cost to the shops. Unfortunately, I totally believe it to be true, and let me explain why. Since I am a third-generation owner, I have a few things from our history. One of them is the old large Mitchell Collision Estimator books from the late 1960s and early 1970s. Let’s take a look at a 1969 Chevy half-ton pickup fender replacement. For the RH fender, the R&R time was 2.0 hrs., plus .4 for antenna and .3 for moldings, for a total time of 2.7 hrs. I then opened CCC and looked up a 2018 Chevy half-ton, and the fender R&R time was 3.4 hrs. OK, the times are improving. Then I looked at a 2023 Chevy half-ton fender, and now it regressed to 2.1 hrs.! Granted, these two fenders have different designs. Let’s take a frame replacement. For the 1969 truck, the book time was 24.3, plus power steering 1.0, power brakes .7, and automatic .2 or a total of 26.2 hrs. The 2023 Chevy truck book time in CCC was much higher (sarcasm here), at whopping additional .8, or a total of 27 hrs. Just FYI: A properly written frame replacement estimate for today’s trucks could be nearly 100 hours when adding all the not-included operations.

It seems obvious the time studies that were done 50+ years ago by the information providers (IPs) are still paying them dividends. They are basically just throwing them up against the wall in the current software to see if shops will let them stick. Last I looked at my calendar, this is 2024. The vehicles of today are much more complex than those from OVER a half-century ago, and thus the book times should be adjusted accordingly.

A solution to effect change

So, what can the shops do about these archaic labor times? It’s called the Database Enhancement Gateway, or DEG, and it’s found at degweb.org. This is an organization that was created by AASP & SCRS over 15 years ago. One of the founders was the late March Taylor, a collision repair industry advocate and shop owner from Hawaii. The DEG’s online platform is a public place for shops to submit inquiries to CCC, Audatex, and Mitchell. These inquiries can range from questioning specific labor times to missing parts, P-page clarification, and more. Not only can any shop in the country submit an inquiry, but they can view all the prior “inquiries.” These can be printed and used when insurers deny labor times for, example, Clarifying Ppage not-included items.

On the first page of the Database Inquiries, I was reviewing the submitted inquiries that had IP changes and here are just a few examples:

1. Nissan Armada radiator support R&R time was changed from 7.9 hrs. to 13.1. That’s an additional 5.2 hrs., or a 40% increase in labor.

2. 2017 Honda Accord rocker panel R&R went from 11 hrs. to 15 hrs., or an additional 4 hrs!

3. 2019 Chevy Silverado LKQ hood refinish time went from 3.8 hrs. to 4.8.

Here’s the deal: does every inquiry result in an IP change? No, but only by submitting an inquiry in the first place will they change. According to our government’s Bureau of Labor Statistics, there are over 200,000 folks employed in collision shops. After reviewing the DEG’s submitted inquiries, there are on average eight inquiries submitted per day. In 2024, there are approximately 255 working days. And with eight inquiries per day, that’s 255 x 8, or 2,040 per year. Sadly, only 1% of employees from the shops submit inquiries to DEG.

So, the question each one of us needs to ask ourselves is, “Do we want to be part of the solutions to our industry or part of the problem?” If every employee of America’s body shops would take just five to eight minutes once per year to submit a DEG inquiry, that would equal nearly 800 inquiries per day vs. the current eight per day. Change starts with us, folks, and that’s all there is to it. So, the remaining 99% of the shop owners, managers, estimators, and technicians need to get off their butts and help improve the industry by submitting DEG inquiries. A rising tide lifts ALL boats!!

LOBSIGER

Lobsiger has owned Loren’s Body Shop in Bluffton, Indiana, for over 23 years. He has been a member of Mike Anderson’s groups for ten years and had extensive lean manufacturing training. EMAIL: greg@lorensbodyshop.com ARCHIVE: fenderbender.com/lobsiger

20 June 2024 fenderbender.com COLUMNS SHOP PROFITS JOSIE SMITH PHOTOGRAPHY GREG

Greg

WATERBORNE MADE EASY

With a waterborne basecoat that’s easy to mix, match and apply and that uses the same coat flash application you’ve already perfected, Cromax® EZ makes an exceptional finish feel effortless. Discover how easy an outstanding finish can be.

axalta.us/ez

AXALTA COATING SYSTEMS

Cromax® EZ

Copyright © 2024 Axalta Coating Systems, LLC and all affiliates. All rights reserved.

Whether it’s your processes or your equipment that need replaced, here are tips to get the most from your paint department.

By JAY SICHT

22

Photo: 3M Automotive Aftermarket Division

THE PAINT DEPARTMENT CAN OFTEN BE A PRODUCTION BOTTLENECK.

Perhaps, as you suspect, a booth replacement or an additional prep deck or booth is what is needed. But before you make a significant capital equipment investment, evaluate if your paint department is already operating at maximum efficiency with your existing equipment and footprint.

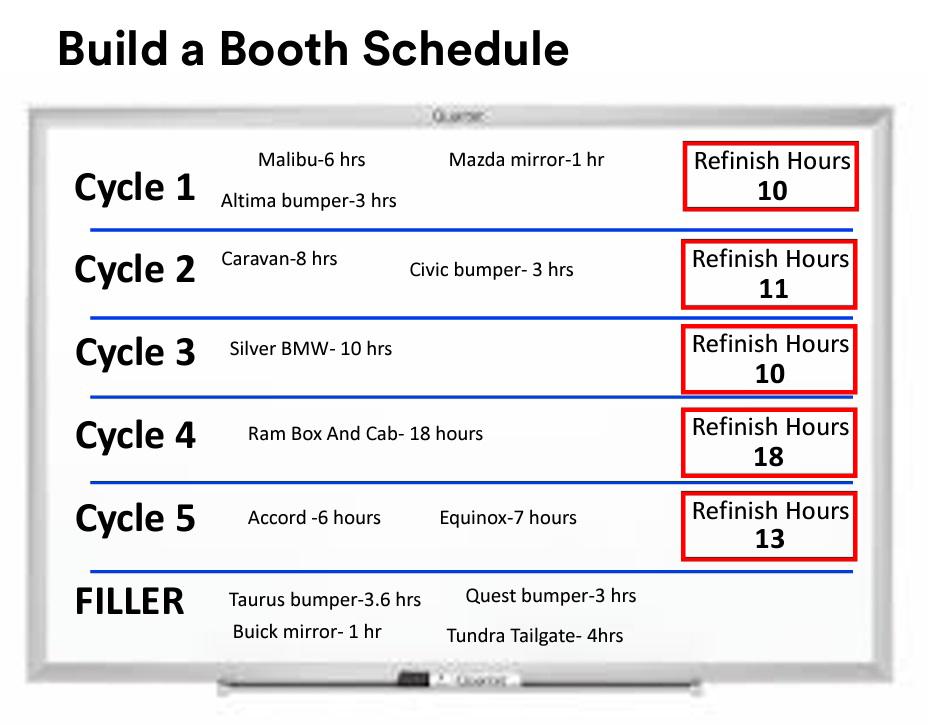

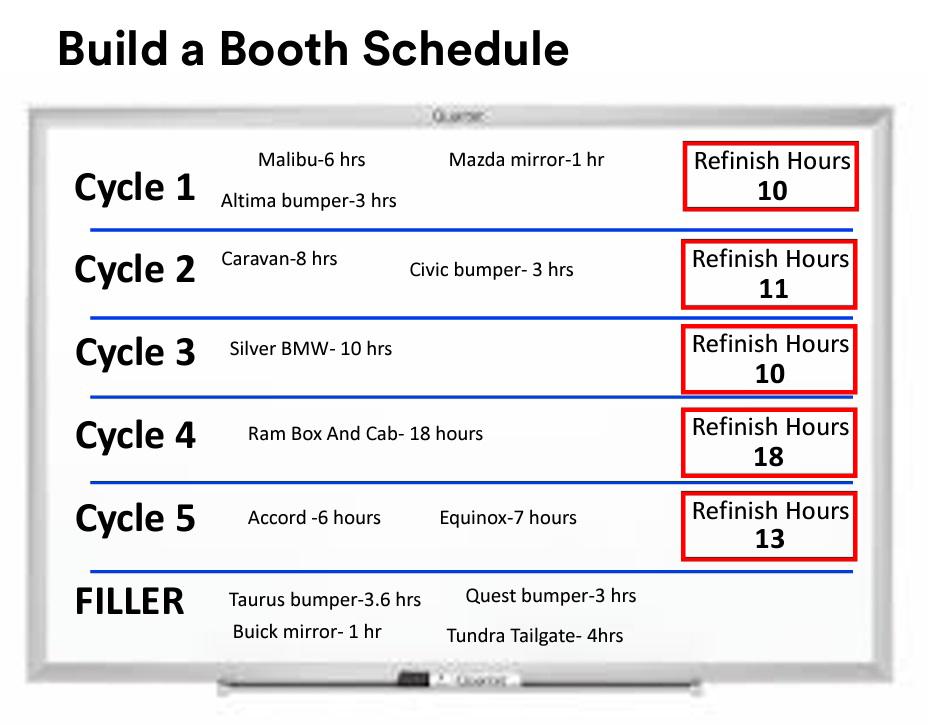

“One of the key things to look at is how many refinish hours per day you’re getting out of your spray booth,” says Jason Garfoot, senior application engineer at 3M Automotive Aftermarket Division. In his previous role at Global Finishing Solutions (GFS), he had worked with consultant Steve Trapp, who at the time was at Axalta. (Trapp, a contributor to FenderBender, is now senior process consultant for L.E.A.P. LLC.) The two analyzed data from all over the United States and Canada and determined the most efficient painters and body shops averaged about 12 refinish hours per booth cycle, which trans-

lates to between 48 and 72 refinish hours per spray booth per day.

“So for a week, they should be getting a minimum of 240 hours out of their spray booth,” Garfoot says. “If they’re not, they don’t need [an additional] paint booth. If you’re not already maximizing the throughput of your booth, there’s no point in eating up the floorspace of the shop that could be used to work on more cars."

It's a common mistake he sees made by body shop owners and operators.

"First, they loaded up based on what they want to produce, but they don't realize how much a paint booth should produce, and now they've basically cut off the workspace for the body tech’s side to load that booth in the first place.”

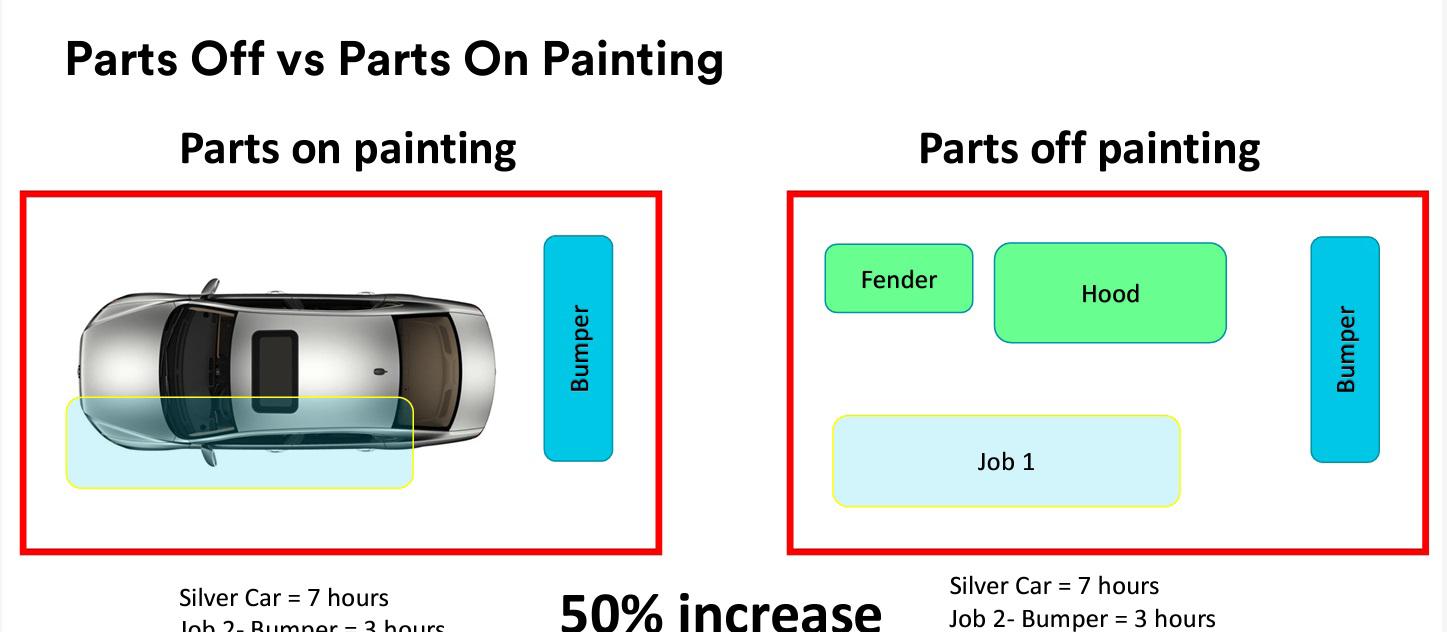

IMPLEMENT A PARTS-OFF PAINTING STRATEGY

Many shops are adopting a “one-touch system,” in which panels are test-fit, disassembled, painted, and reassembled before being sent to the booth, which maximizes booth loading.

Jeremy Winters, content creator at Accudraft Finishing Systems, says the traditional, less-efficient process often means a car needing a fender replacement is in the booth just to blend the door. But painting the door off the car allows for more efficient booth-loading. This recommended process allows the bolt-on panels — such as a door or fender — to be cut in at the same time, since the panels are affixed to stands that allow them to be positioned where needed in the booth.

“It seems like more work up-front, but it actually saves everybody time because the parts don’t have to go to the paint shop, come back for fitment, and then go back to the paint shop for the outside to be painted,” he says.

Although the shop can’t bill for the removal and installation time of this process, the “one-touch” system is more efficient for both the painter and the body technician, who no longer must wait for a fender to be cut in before he or she can hang it on the car, says Winters, who until 2-1/2 years ago was a painter in a collision repair shop.

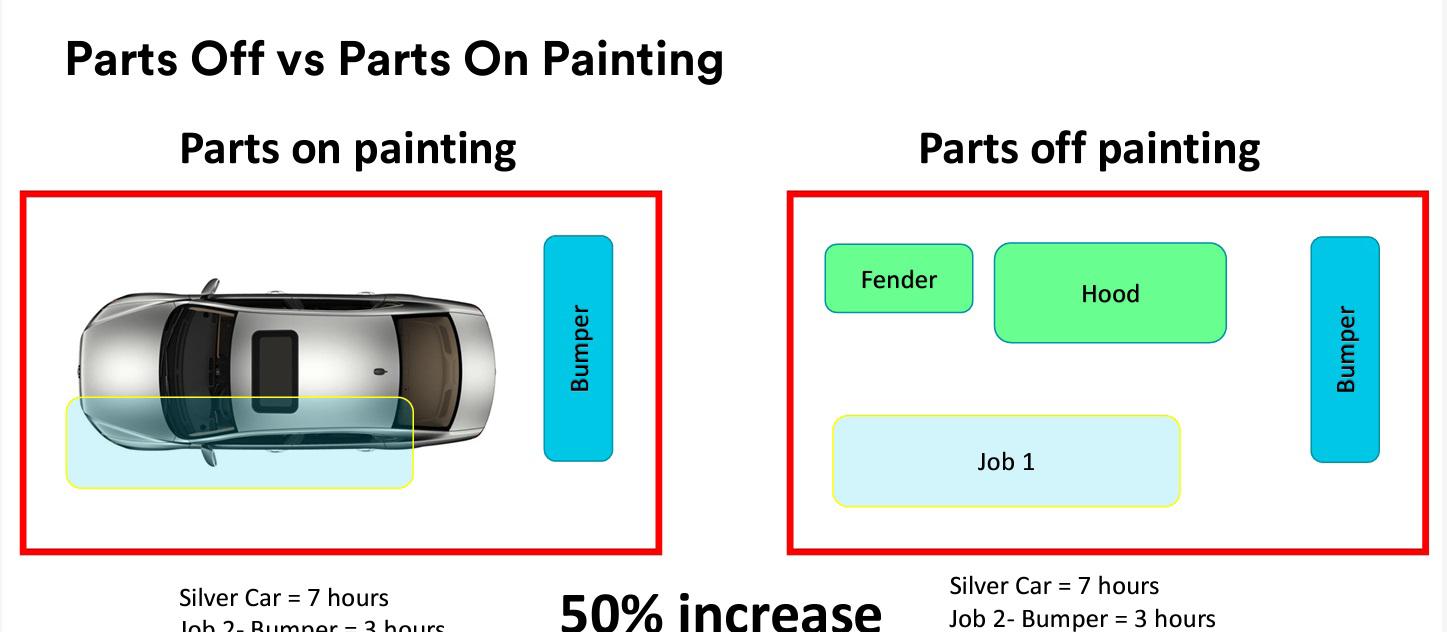

50% Efficiency Increase for parts-off painting With parts-off painting, two additional panels to be loaded in the booth. In this example, there are seven refinish hours for the silver car plus three hours for the bumper, a total of 10 hours in parts-on painting. With the parts removed from the silver car, an additional fender (one hour) and hood (four hours) can be loaded in the booth for a total of 15 hours, a 50% increase.

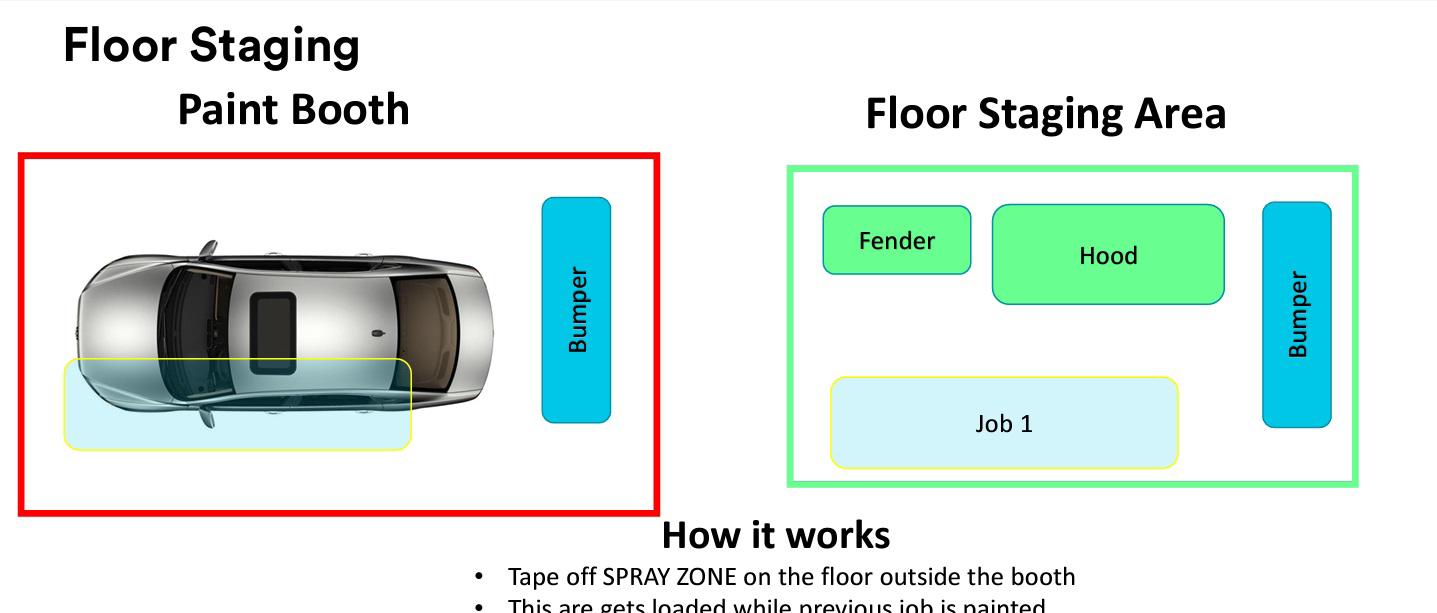

Stage For Efficiency

While the booth is in use, a taped-off or painted-line staging area the same size as the booth’s spray zone footprint allows painters and preppers to set up the panels on stands to quickly and efficiently load the booth in the next cycle. To minimize the risk of color-changing overspray, some rules of thumb to follow are to keep one feet between panels of the same color, three feet between panels of similar colors, six feet between different colors, and to spray solid colors last.

24 June 2024 fenderbender.com

BREAKING THE BOTTLENECK

3M AUTOMOTIVE AFTERMARKET DIVISION

“With one prepper and me, every week I would turn, on average, 225 hours every week. And that is going in and starting work at 7:00, 7:30, and knocking off at 5:30. (I would work late, occasionally, like everybody else)," he says.

Garfoot also recommends the practice in the three-day Paint Prep & Refinish Training class he teaches each month at the 3M Skills Development Center in St. Paul, Minnesota. The latest industry company data shows the average work order nationwide includes about eight and a half refinish hours, he notes. So to get to the benchmark 12 hours per cycle, a shop should strive to load the booth with an average of one and a half repair orders (R.O.s) per cycle by including a bumper cover or other part from another job.

ADDRESS CONCERNS ABOUT DAMAGE AND R&I TIME

With the extra parts handling required, it’s probably natural that painters and body technicians may be worried about parts

being scratched. But it’s a fear that’s blown way out of proportion, Garfoot says.

“In all my years as a painter, I painted maybe two or three panels that got damaged, and it usually wasn’t from normal reassembly. Something happened: somebody bumped a stand into the car, or they weren’t paying attention, and they dropped the door as they were trying to bolt it on. As painters after we paint something, we're absolutely terrified that body techs are going to damage the parts when we give them back to them. But they’re very careful with painted parts.”

Technicians may also be concerned about being paid for the time it takes to remove and install panels, even though adopting the practice will prove to save them time and make them more productive, Garfoot says. But to introduce them to the concept, one strategy is for the shop to pay the technician an extra hour for pulling the rear door and a fender for a blend (in the case of a front door repair).

Low-Tech Solutions

A dry-erase board can be used to plan booth cycles to efficiently plan how it will be loaded. Some considerations: Plan four cycles but add a fifth in case you have time; save for the end of the day the big jobs that require a lot of tape time or if the vehicle won’t be assembled the same day. Try to average 12 hours per cycle, and look for where you can add filler work. Separate solids and metallics (and especially tri-coats) as much as possible. Before going home, load the booth and/or staging area and build the next day’s schedule.

“And then it’s easier for them to want to do it because they’re getting paid for it. But it’s worth it to the shop owner because they’re going to get twice the refinish hours out of their booth. If I’m a body shop owner, I’ll give up on hour all day long to get four or five more out of it. You’re increasing your efficiency without having to add other employees, without having to buy a bunch of products without having to change all this stuff in your shop. It's just giving them time to remove panels that insurance won't pay for.”

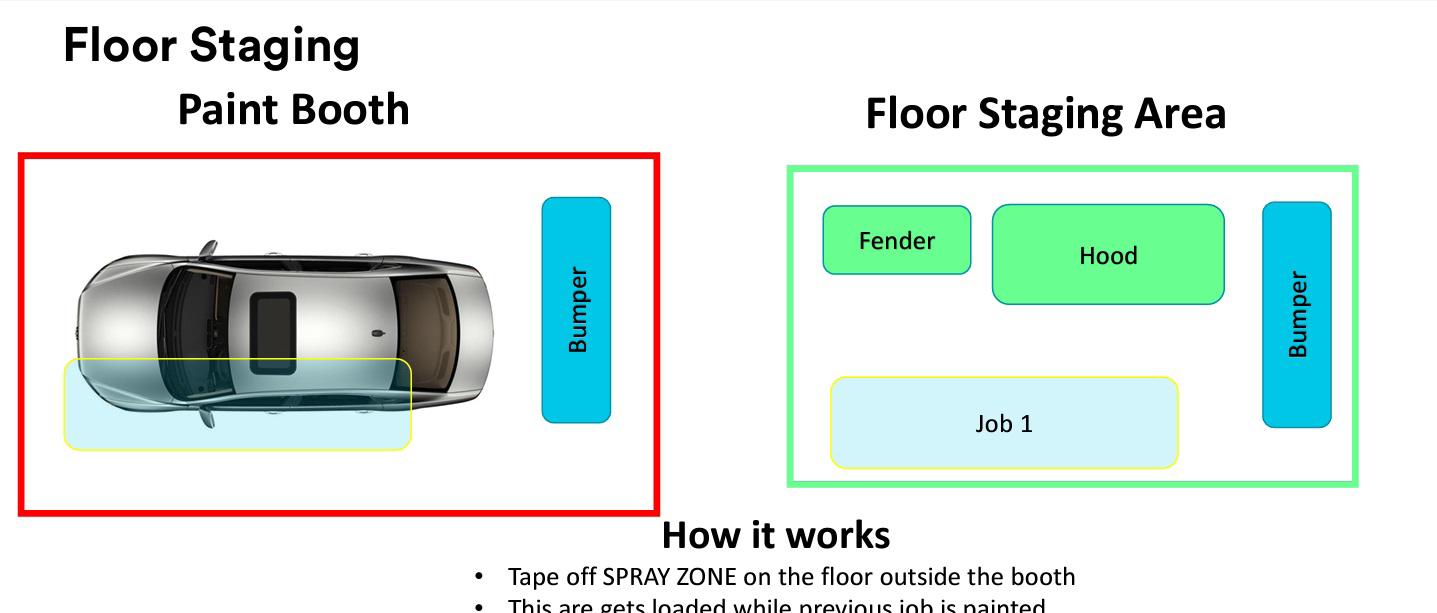

PLAN FOR PRODUCTION WITH PRE-STAGING

While the booth is filled with parts flashing or baking, Garfoot recommends that the next load for the booth be pre-staged in an area near the booth. The area includes lines tapedoff or painted in the same footprint as that of the booth and helps the painter or prepper visualize how much capacity the booth has, allowing for quick loading.

“Some of the best shops I’ve consulted with, if they know they’re doing four cycles a day, have four staging areas. They’ll load each staging area as they’re completing the prepping of those vehicles. They’re not having to unload the staging area and then reload it with something else. They can stack them there for the day, and the painter knows which one they’re going to pull from next.”

For shops more limited in space, Garfoot points out, they can still implement a floorstaging area and use a dry-erase board to schedule each booth load.

BOOTH AIRFLOW CHARACTERISTICS

DICTATE HOW IT SHOULD BE LOADED

Painters do need to be aware of the airflow characteristics of their booth, Garfoot says, noting that once, when he was a collision repair shop painter limited to using a semidowndraft (ceiling intake, rear exhaust) booth, it could easily cost him a cycle per day.

“I would typically have to stay a little bit later to get four cycles out of it, and it was mainly because I had to be careful how I positioned things.”

If the blend panel is positioned toward the rear exhaust filters, overspray from paint being

25 June 2024 fenderbender.com

3M AUTOMOTIVE AFTERMARKET DIVISION

sprayed on the refinished panel will land on the blend panel, causing a color-match issue.

“So, blend panels have to be placed toward the intake side. You’re a little bit limited on positioning.”

For the same reason, he points out, “effect”/metallic color panels also need to be placed toward the exhaust side.

Even when spraying in a downdraft environment, the painter needs to be careful of where the overspray will land, which will dictate how many, say, different-color bumpers can be loaded in the booth and sprayed at once. But keep in mind, he says, the parts are on stands that can be easily rolled in and out of the booth to avoid color contamination.

“Once they’re dry, they’re dry. Throw a sheet of 36 over them or drape plastic over them.”

Winters recalls pushing through eight bumpers in one cycle during a particularly urgent production day.

“I sealed everything the same color and as I sprayed one, I slid it to the back corner and threw plastic over it and I did the next one.”

Once all color was applied and flashed, the bumpers were cleared in one batch.

MATCH COLORS BEFORE THE BOOTH IS LOADED

Painters should verify the color match before the booth is loaded, Winters says.

“Yes, there’s color-corrected lighting. Yes, we pride ourselves on being able to see in the booth, but if you’re matching color in the booth, it’s too late. If you have other cars lined up and this car is giving you a problem matching the color, don’t ever pull it into the booth. You can tape it up and have it sitting, ready to go. But pull it to the side and keep cars coming through so you can work on getting the production done. In between, you can be working on matching that color.”

CONSIDER A SWITCH TO WATERBORNE

Compared to traditional solvent-based paint systems, waterborne systems offer faster color matching, quicker drying times, and improved turnaround, albeit at higher product cost and the need to upgrade equipment.

“Dry times for water vs. solvent, especially for two-tones even for basic collision repair

jobs, are astronomically faster,” Winters says. “Yes, there is the upfront cost of adding blowers, the fan systems, handheld blower stands, and whatnot; there’s a bunch of different options for it, along with retrofitting spray guns, if the shop is supplying spray guns to the painters. But water has a lot of advantages of being able to speed up the cycle time.”

Winters says one can expect to cut 30 minutes of time needed for application and color-match on each job.

“Let’s say you do four rounds through the booth every day. That’s two hours that gets added onto the end of the cycle that you now gain. If you were doing four rounds in a booth as a solvent painter, now maybe you’re doing five rounds. That’s one extra job a day, one extra flow of parts.”

At the end of the year, the numbers in that example add up to an additional 240 jobs moved through the booth. So, it’s easy to see what the potential is, Winters says, but an owner or operator should examine what improvements may be needed before pulling the trigger on a new booth purchase.

“If they’re tapped out – if they’re already using water, they know they have good painters, and they can see the metrics on that and they need to improve and they’re just busting at the seams and they cannot do any more, yeah; it’s time to add a booth.”

A shop may also not need to add another painter to its staff, Winters points out, even when installing an additional booth.

“One thing I enjoyed about having two booths is I could offset things and keep going. I could seal this one and get this one into color, and while this one is flashing, I could jump over to the next booth because my prepper already had the car taped up. I wiped it down

and then threw it into sealer. Now, I go over here and clear this, and that one’s ready to go.”

It’s a constant back-and-forth to keep the work flowing, Winters says, noting that Accudraft offers double booths that offer a smaller footprint than two separate booths but a larger cabin workspace for parts-off overall refinishing or multiple jobs, with custom options for height and mechanicals such as where the air makeup unit is installed.

WHEN AN INVESTMENT IN NEW TECHNOLOGY MAKES SENSE

Owners or operators often expect a 20 or 30-year-old booth being used every day to still produce as it did the first year it was installed. But Winters likens them to a car with 250,000-300,000 miles on it.

“We’re dealing with stuff that’s mechanical, and at the end of the day, it’s not if it’s going to break; it’s when it’s going to break. Even with inspections, once stuff gets the miles on it, it’s going to go down. If you’re spending more time having to fix things, if problems arise and you’re having a harder time accessing parts, those need to be considered.”

Recalling what he advised about parts placement and added time needed for nondowndraft booths, Garfoot says some purchases can be pennywise and pound-foolish.

“There are a lot of companies that make good-quality booths; it’s just making sure you’re buying the right one for your shop. Don’t hurt your production. Body shop owners, if they haven’t painted before or very much, should get the input of the painter when they’re making that buying decision. Saving $80,000 up front may cost you $250,000 to $1 million a year in production.”

26 June 2024 fenderbender.com

BREAKING THE BOTTLENECK

PPG REFINISH

Color Match First Painters must not wait until the vehicle is in the booth to match colors, when it can be better used in production.

www.passthease.com #1 TRUSTED SOURCE FOR ASE TEST PREP YOU PASS OR YOU DON’T PAY! THANKS TO OUR TRAINING SUPPORTERS

INVESTING WISELY

A Focus on People and Processes Pays Dividends for the Bob Maloney Collision Group.

BY LINDSEY GAINER BRANCH PHOTOGRAPHY

PROFILE

28 June 2024 fenderbender.com

Owners

Bob Maloney, Robert Maloney, & Kenny Davis, alongside minority owners Matt Schroeder and Damon Wetzel, are in the business of investing…not only in properties and buildings, but more importantly, in their employees and customers.

It’s their focus on relationships—coupled with a strong business sense and high-quality, OEM-driven repairs—that’s taken the Bob Maloney Collision Group in Northwest Arkansas from one shop—netting just under $1 million a year—to a six-shop network that brought in $22 million in 2023, only 14 years after its founding.

Here, Davis and Schroeder offer a glimpse into what makes the group so successful. When Bob Maloney Collision Group began in 2010, it was a single-shop operation based in what was previously a Ford dealership owned by Bob Maloney. That shop is now the flagship of the group, the Bob MaloneyRogers location.

Investing in Expansion

From there, expansion happened quickly, literally within 20 minutes in the case of their second location, says Davis, which the group leased from a local Chevy dealer who lost his franchise and body shop manager. Bob Maloney-Springdale was born.

The momentum kept building from there.

“We knew we could run two and felt confident we could run three. So, we purchased the third shop, Kenny Davis Collision. Then came the fourth, Westside Collision. Both of those shops were existing buildings. And then we built shop five — Bob Maloney-Pea Ridge — from the ground up. It opened January 1, 2023, and made $260,000 in the first month…that’s in a town with no stoplights, with two four-way stops.”

Shop six came in November 2023 — Bob Maloney-Siloam Springs. The owners heard it was for sale, looked at it, and purchased it. A no-nonsense deal, just like the rest.

The team doesn’t overthink things, says Davis, and the organization operates without debt, so when they need to move quickly, they can.

Business is certainly booming in all locations. Collectively, the shops occupy a total of 56,000 square feet, employ 118 people, and brought in $22.5 million in sales last year.

Investing in People

The effort the group has put into acquiring additional locations is impressive, no doubt — but it pales in comparison to the energy they direct toward their team and customers.

In their shops, employees are never just a number; hard work is rewarded, and talent is noticed, appreciated, and developed.

“We are teammates here,” says Davis. “If someone has a problem, we’ll be there as a group to get them through it.”

Day in and day out the owners are on the floors of their shops, building relationships, understanding the team’s strengths and weaknesses, and giving them the tools and training they need to succeed.

They offer excellent benefits, too, and a work/life balance that’s hard to beat.

“We do not work 45 or even 41 hours a week,” says Davis. “We’re a 40-hour-a-week business. We want our employees to be with their families as much as possible.”

Management conducts quarterly “pulse” meetings with employees as well, just to check in and see how they’re doing.

“We have some of the best technicians in Arkansas, maybe even the country,” Schroeder proudly states, which makes it easy for management to train and grow their organization from within.

Schroeder himself is the perfect example.

“We can’t say enough about guys like Matt,” Davis adds. “He’s going to be one of the greats.”

Back To Pre-Loss Condition

There are two goals for every car that leaves the shop: 1) a return to pre-accident condition and 2) a safe repair that meets OEM standards.

Schroeder first came to Bob Maloney Collision 12 years ago as an intern before working his way up to managing his own shop by the time he was in his early 20s.

“Kenny and I opened the Kenny Davis location together — it was just him and me for several months,” reminisced Schroeder. “Piece by piece it grew.”

Under Schroeder’s leadership, the location went from netting $65,000/month to $400k+.

“Matt is tenacious,” says Davis. “He gets things done. You don’t have to ask him twice. Often you don’t have to ask him at all. Everyone loves working with Matt, but Matt doesn’t mess around.”

Davis admires that he earned the respect of everyone working with him at such

30 June 2024 fenderbender.com PROFILE

a young age — the people who work alongside him trust him, he says, for good reason.

Now, at just 31 years old, Schroeder is a junior owner and regional manager, overseeing the group’s northern stores.

“Before I was even a minority owner in the business, I was given the keys to treat it like it was mine. I felt empowered from the beginning working here.”

His advice for others with similar aspirations?

“Always go above and beyond. Don't just do the required next step, and don't just do it one time. Do it 100 times. Do it till it’s exhausting. If you have a good leader, they'll notice and reward that.”

That’s certainly true in the Bob Maloney Group. The men provide numerous other examples of upward mobility…detailers who are now painters, techs and estimators who are now managers. The list was long and the message clear — if you put in the work, your efforts will be rewarded in their organization.

“If you come to work for Kenny and you work, he will be one of the best you’ve ever worked for,” says Schroeder. “At the end of the day, I've never seen somebody take care of so many people and genuinely care. When he says he has all our employees phone numbers and knows them personally, that’s the truth.”

That genuine care for people is shared by all the owners, they say, and especially Bob Maloney.

“Bob is the most genuine, honest, wonderful person you will find on the face of the Earth,” Davis says. “We can’t speak highly enough of him. To work with that man and to be mentored by that guy is where all this comes from. None of us could have done this without being mentored by Bob.” Schroeder couldn’t agree more.

Not only is Bob one of the smartest businessmen either have encountered, they say, but he also legitimately loves the business and the people who work for him, they say; and it shows.

“We have extremely low turnover. Even employees who have left often return, and that's a testament to us as a company, to our virtues and standards.”

Investing in Operations

Cars are the second largest investment most people ever make, reminds Davis.

“What we might think of as ‘just a Ford Taurus’ is probably somebody's pride and joy. You have to think about that when you're repairing the car, keep that perspective in mind.”

31 June 2024 fenderbender.com

Getting The Color Right:

A painter checks the color-match of a sprayout card at Bob Maloney Collision in Rogers.

Repaired By The Book OEM repair procedures are pulled for every repair, which is how each is fixed, says Matt Schroeder.

“We work hard to ‘own the customer,’ we like to say,” he added. That means the whole team prioritizes the customer’s journey through every step of the repair process and communicates updates to them regularly.

“Every repair may be different, but every car goes through the exact same process, and every customer has the same experience,” says Schroeder. Nexsyis Collision management system helps them run lean; they also use OEC’s estimateIQ and RepairLogic, adasTHINK, and asTech for scans.

There are two goals for every car that leaves the shop: 1) a return to pre-accident condition and 2) a safe repair that meets OEM standards.

“We want the customer to be proud of their car, and we want the car repaired according to OEM procedures — we pull those on every single vehicle. We're going to fix it the way the manufacturer said to fix it every time. Our OEM parts percentage is high — 98%.”

They also utilize local dealerships for ADAS calibrations, and all repairs come

with a lifetime warranty. The group boasts a laundry list of manufacturer certifications as well, and they’re on track to be the first certified Rivian repair shop in the state.

They’ve also been investing heavily in documenting their processes this past year.

“We didn't prepare enough for SOPs and process,” Davis says, given how quickly the organization has grown. “Every shop has the same processes, but we needed to document them.”

It’s already paying off and is getting everyone “on the same playing field.” Plus, he says, the insurance companies are pleased to see it. “It's the consistency that we want. We were always doing it; we just didn’t have it written down.”

Like many of the business practices they’ve implemented in the shops, this one was born from a framework laid by their Sherwin-Williams 20 group, an invaluable resource to the organization in countless ways…especially in honing their damage analysis process and management techniques.

“We could not have gotten to the point we're at without Sherwin-Williams,” Davis

states categorically. “You don’t know what you don’t know, as they say. You think you know everything, and then you go to a 20 group and realize, man, I never thought about that.”

Davis advises everyone — including competitors in his local market — to join a 20 group to gain unique insights into their business.

“You’ll never realize your full potential if you don’t.”

The 20 group led them to Mike Jones’ Discover Leadership program as well — a class that’s proven immensely helpful to dozens of Bob Maloney teammates.

“We’ve probably put 25 to 30 employees through that class,” Davis says. When asked what his biggest takeaway was, Schroeder pauses and answers thoughtfully, “Don’t let a bad minute or two ruin the entire day.”

“They teach you that there’s 86,400 seconds in a day. Why let 60 seconds of that shape your whole day? Why let it control you? In this industry stuff changes all the time, sometimes it feels like every five minutes. It can be hard. This really helped me put things in perspective.”

Check the conversation you're having with yourself in your head, too, he says, and ask yourself, “Is this really how I want to act, how I want to come across and be known to my team?”

As for what’s to come, Davis estimates sales will continue to grow as the group refines their processes, likely doubling in the next ten years. But their focus extends far beyond profit alone. As a team, they’ll continue investing in the right people, the right locations, the next technology, and the next training to constantly better themselves.

They’re living proof that the right investments pay dividends.

32 June 2024 fenderbender.com

PROFILE

Original fit and function

Identical size and thickness

Seamless camera integration

Structural rigidity

Noise deafening

Recalibration ready

Forward thinking. Not reverse engineering.

The use of OEM glass over alternatives is key to providing customer peace of mind. Same as the factory part, Original Ford Glass is designed to integrate with today’s advanced windshield safety systems, maintain structural integrity, and more.

Joining the Ford Certified Glass Network (FCGN) gets you access to not only the right parts but also exclusive Ford procedures, training, and support — helping you properly install and calibrate glass in any Ford vehicle you see.

Learn more about the benefits of joining at ford.com/fcgn-fb.

IS

By Carol Badaracco Padgett

EVEN IF AN AUTO BODY SHOP’S Facebook and Instagram pages crash, its online business presence must stay on track.

Think it’s highly unlikely the social platforms could hit a brick wall? Accidents do happen, the most recent being this spring on March 5, 2024, when both Meta vehicles stalled for more than two hours.

So, shop owners will want to be certain that potential customers with immediate collision repair needs can locate them online,

34 June 2024 fenderbender.com

SOCIAL

YOUR MOST RELIABLE DRIVER OF BUSINESS? A business website that runs consistently means

body shop is always ready to roll.

MEDIA

your

STRATEGY THE SOP

PEXELS, SANKETMISHRA18610082

quickly and through a simple, direct route. According to Daniel Burkholder, founder of BodyShop Marketing, based in Miami, Oklahoma, that route is your website.

A Reliable Vehicle

The market expert says that with a business website that runs consistently—one that’s fast, mobile-responsive, and contains all the necessary information—your shop is always ready to roll.

“Professional business websites and Google business profiles are vital for auto body shops to grow and dominate in today’s market,” as Burkholder puts it.

Social media pages, like Facebook and Instagram, are rented platforms, in comparison.

“Your website is something your shop can own, and you can build a lot of strong assets and content there,” he stresses.

The idea is to speak to your customers where they are—and right away when they need you.

“If you are a collision repair shop, then speak to someone who has just been in an accident,” Burkholder says. “If you are a restoration shop, then speak to that person who is looking for the perfect shop they can trust with their baby.”

Even though large corporate chains may have the benefit of their own marketing teams to maintain a website that ranks well on Google and Google maps, sometimes the smaller independents have the unswerving personal connection—referral-based and highly trusted.

“There are many benefits to being an independent shop, such as connection to community,” Burkholder says. “There’s a large element of people who like to visit a local family-owned business. That’s kind of a movement.”

Top Tools

Automobile marketing specialists like BodyShop Marketing can give independent businesses the same tools the big chains use to generate online visibility.

“We can develop a fast, mobile responsive website that loads quickly and looks friendly,” Burkholder notes.

Some of those tools are blogs and other content creation, pushed out onto the web like press releases, that improve website rankings and push independent shops near the top of prospects’ online searches.

“We can also generate Google reviews by sending texts to customers who just got service,” he adds.

Marketing specialists can also help independent shop owners decide on the best overall online approach for their individual auto body business.

“If you are in a town of 3,000 people and there are two small auto body shops in town. spending a ton to rank No. 1 on Google is a waste of money and time,” Burkholder notes as an example.

But if an independent shop has a good deal of square footage, like one Burkholder works with that has 100,000 square feet and employs 45 people in a town of about 16,000, they may need a larger customer base that reaches beyond their hometown.

“So, we are building an aggressive online strategy to help them dominate the 100 miles surrounding their shop,” the marketing specialist says.

High-performance Components

The smoothest running websites will give customers exactly what they need. Warranty information and clear communication about services are several examples that Burkholder gives.

“I would also mention that you work for the customer and not the insurance company,” he advises. “Onsite rental—‘keys for keys’ —can also be a great feature to highlight.”

Some customers who visit your website will care about your certifications, Burkholder notes, and so that’s another good thing to include.

“Some will have done a great deal of research and will want to know about your equipment,” he suggests. “Make it clear you use only new OEM parts and follow OEM procedures.”

Marketing co-op funds can sometimes be available from certain vendors whose supplies you rely upon, which is worth checking

into. For example, a paint company might help pay for a body shop’s marketing if the business uses their brand.

A surefire component to add to any shop’s website is customer reviews, which provide visitors with social proof of a business’s competence and reliability. These reviews—along with all other profiles posted on a shop’s site—should be optimized with main keyword phrases that help customers find you online.

Top keyword phrases include terms like “body shop,” “auto body shop,” and “collision repair.”

In addition, Burkholder notes, “I think a great ‘About’ page is good to include, and that’s where you can tie community into the website.” As part of that page, shops are advised to emphasize selling points such as the fact that they’re locally or family owned.

The marketing specialist also suggests creating and maintaining a Facebook page as a reinforcement to a body shop’s website. Something else that’s critical to remember: information on a shop’s website and social pages will be most effective when it’s fresh and relevant.

“To build authority with Google, you need to keep creating content for your website,” Burkholder stresses.

Forward Momentum

Even though they’re clearly critical to a business’s success, the marketing specialist says websites aren’t always front-of-mind for body shop owners.

“A lot of businesses have been very busy the past two to three years,” Burkholder says. “But now when they’re busy is a good time to do the marketing, instead of waiting until it’s slow.”

While it may be tempting for a body shop that’s slammed to focus on social media as its go-to marketing maneuver, that’s not always smart.

As the marketing specialist drives home his point: “When a shop owns their website, they can build a lot of strong assets and content there. So, even if Facebook goes black, they still have a very strong online presence.”

35 June 2024 fenderbender.com LEARN | GROW | WORK SMARTER

BUILD WITH ELECTRIFICATION IN MIND

Planning a new shop? Ensuring you can repair EVs could be a worthwhile investment.

By Noah Brown

ARE YOU MAKING extensive upgrades to your shop – or even planning a new facility? If so, have you considered how to allow for repairs of electric vehicles (EVs)?

36 June 2024 fenderbender.com

STRATEGY

TECH+TOOLS

PHOTO BY JAY SICHT

There are around 275 million registered vehicles in the United States. Just under 3.5 million of those – roughly 1.25 percent –are EVs.

Despite that relatively low number, there is data to suggest that EVs are continuing to pick up momentum and continue to embed themselves in the mainstream. According to Edmunds, around 1.07 million new EVs were sold last year – more than four times as many since 2018 – and EVs accounted for 7.5 percent of all new vehicle sales in the U.S. in 2023.

There are also pockets of the country where EVs are much more popular. California, Texas, and Florida account for roughly a third of the country’s total EV population.

Adoption of electric vehicles is happening, slowly but surely, and if you are thinking about or are already in the process of building a new collision repair shop, it may be a wise long-term investment to design it with EVs in mind.

Dirk Fuchs, founder and owner of Electric Mobility Consulting and a leading expert in the EV space, says getting into EV repair now – if it makes sense for your shop – can open up a lot of opportunities in the future.

“There are new EV manufacturers coming out it seems every month,” Fuchs says. “EV upstarts are going to need a repair network in the future – that could be a good opportunity.”

When designing a new space, there are a few considerations that should be made to ensure the short-term success and long-term vitality of your shop.

Making Space

EVs are, structurally speaking, very similar to ICE vehicles when it comes to collision repair. In fact, EVs have fewer moving parts than ICEs, which makes them simpler to repair in terms of mechanical work.

However, there are some special considerations that need to be made.

“The first thing I would consider when you build a shop layout is to determine where you would like to repair EVs,” Fuchs says. “Most places aren’t going to go 100-percent EV repair. It’ll probably be a mixture of EVs and ICE vehicles, but as your repair more EVs, more EVs will come in.”

Fuchs says you have to decide where you’re going to do your “clean” work and your “dirty” work. EV batteries and electrical circuits are incredibly sensitive and susceptible to contamination – Fuchs says he’s heard several horror stories of shops doing a good job on a repair but didn’t cover the electrical components very well.