HEAT TRANSFER FLUIDS FOR ANY APPLICATION

PROVIDING GLYCOL-BASED HEAT TRANSFER FLUID TO KEEP YOUR HVAC SYSTEMS AND PROJECTS RUNNING SMOOTHLY.

Thermal Charge® offers application-specific heat transfer fluids, innovative inhibitor technology, and industry-leading service and fulfillment so you can power through every challenge, need, and demand.

Visit thermalcharge.com to find the right heat transfer fluid for your application.

What mechanical engineers and building automation professionals need to know before investing their trust—and their reputations—into AI-driven systems.

Nathan Kegel

ITM Evolution: A preview of the 2026 edition of NFPA® 25, Standard for Inspection, Testing, and Maintenance of Water-Based Systems.

Terry Victor

Meeting in Ohio, boiler manufacturers’ group spent two eventful days focused on industry’s next generation.

Shaunica Jayson

This spring’s volatile business conditions have made it harder for firms to plan long term.

Rob McManamy

Now 25 years old, LEED has

Deisy Verdinez

Our interview with veteran engineers Jennifer Leach and Keith Hammelman about how to recruit and retain today’s independent, techsavvy and socially engaged young talent.

Rob McManamy

&

Pathfinding

‘Pause’ on Wind Power Create Room for

Larry Clark

HPAC Engineering (USPS Permit 464-930, ISSN 0039-0895 print, ISSN 1930-8957 online) is published 6x a year (Jan/Feb,,Mar/Apr , May/Jun, Jul/ Aug, Sep/Oct, Nov/Dec) by Endeavor Business Media, LLC. 201 N Main St 5th Floor, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI, and additional mailing offices. POSTMASTER: Send address changes to HPAC Engineering, PO Box 3257, Northbrook, IL 60065-3257. SUBSCRIPTIONS: Publisher reserves the right to reject non-qualified subscriptions. Subscription prices: U.S. ($ 111.25); Canada/Mexico ($ 123.75); All other countries ($148.75). All subscriptions are payable in U.S. funds. Send subscription inquiries to HPAC Engineering, PO Box 3257, Northbrook, IL 60065-3257. Customer service can be reached toll-free at 877-382-9187 or at HPACengineering@omeda.com for magazine subscription assistance or questions.

Printed in the USA. Copyright 2025 Endeavor Business Media, LLC. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopies, recordings, or any information storage or retrieval system without permission from the publisher. Endeavor Business Media, LLC does not assume and hereby disclaims any liability to any person or company for any loss or damage caused by errors or omissions in the material herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. The views and opinions in the articles herein are not to be taken as official expressions of the publishers, unless so stated. The publishers do not warrant either expressly or by implication, the factual accuracy of the articles herein, nor do they so warrant any views or opinions by the authors of said articles.

Navigating Uncertainty, with Economist Richard Branch

*NEW PODCAST* As tariffs, supply chain and labor issues continue to challenge our industry, one of its most respected economists returns with some updated insights. www.hpac.com/55287394

and Air Cleaners, Keys to

NOW ON DEMAND: Recorded 11/18, IAQ expert Dr. Bill Bahnfleth explains this revolutionary concept, redefining standards with new air cleaning technologies. www.hpac.com/55236601

Engineering eBOOK: The Best of Ken Elovitz, P.E.

An Engineer’s Notebook, 2021-2024. Dive into this collection of useful professional advice, laced with helpful legal acumen. www.hpac.com/55020330

2025: Our May Quiz!

*LIFE + SAFETY* Before the National Fire Protection Association meets next month, dive into the history of fire detection and suppression. Answer 5 questions for a chance to win a $25 gift card! www.hpac.com/55286091

us on Twitter at @HPACEng, as well as our sister publications, @Contractormag, and @ContractingBiz. Retweet our up-to-date content, send comments, questions. Expand your world of engagement with us, at no

EDITORIAL OFFICE 8001 Lincoln Ave. • Suite 720 Skokie, IL 60077 www.hpac.com

EXECUTIVE TEAM

CEO: CHRIS FERRELL

COO: PATRICK RAINS

CRO: PAUL ANDREWS

CDO: JACQUIE NIEMIEC

CALO: TRACY KANE

CMO: AMANDA LANDSAW

EVP, BUILDING, ENERGY & WATER GROUP: MIKE CHRISTIAN

EDITORIAL CONTACTS

MIKE EBY

Group Editorial Director meby@endeavorb2b.com

ROB MCMANAMY Editor-in-Chief rmcmanamy@endeavorb2b.com

DAVID ECKHART Art Director deckhart@endeavorb2b.com

SALES CONTACTS

MIDWEST BILL BOYADJIS 973-829-0648 bboyadjis@endeavorb2b.com

SOUTH & WEST RANDY JETER 512-263-7280 • Fax: 913-514-6628 rjeter@endeavorb2b.com

EAST BRIAN SACK 732-629-1949 bsack@endeavorb2b.com WEST ELLYN FISHMAN 949-239-6030 efishman@endeavorb2b.com

CLASSIFIEDS/INSIDE SALES

STEVE SUAREZ 816-588-7372 ssuarez@endeavorb2b.com

DIRECTOR OF SALES JOE AGRON 941-200-4778 jagron@endeavorb2b.com LIST RENTAL SMART REACH sr-assets@endeavorb2b.com effective PRODUCTION AND CIRCULATION

RITA FITZGERALD Senior Production Manager rfitzgerald@endeavorb2b.com

MELISSA MENG Ad Services Manager mmeng@endeavorb2b.com

JAMES MARINACCIO

Audience Marketing Manager jmarinaccio@endeavorb2b.com

Experience comfort and efficiency with Daikin's Light Commercial Packaged Rooftop Units, designed to meet the unique needs of building owners and tenants. Our 3- to 25-ton models, in 3 cabinet sizes, provide innovative HVAC technology and designs for low installation and operation costs with reliable performance, making them ideal for both new construction and retrofit projects.

» Hot Gas Reheat (Only available on Gas/Electric and AC models)

» Electric Heat

» Downflow Economizer

» Stainless Steel HX (Gas/Electric Units)

» Non-fused Disconnect Switch

» Powered Convenience Outlet

» Non-powered Convenience Outlet

» Low-Ambient Kits

» Phase Monitors

» Smoke Detectors (Return, Supply or Both)

» Daikin iLINQ DDC Controller

BY ROB MCMANAMY, EDITOR-IN-CHIEF

The news hit the wire just as we went to press. Several major U.S. daily newspapers in May had mistakenly put 10 AI-generated, fake book titles on their 2025 recommended summer reading lists. AI had paired real author names with plausible book titles... and no fact-checker anywhere caught it!

Embarrassing examples like that are one reason why most journalists and many industries are still treading gingerly into the artificial intelligence revolution, even as AI seemingly gains momentum every day. And that trend certainly includes design and construction. On May 13, the new Deltek Clarity Architecture & Engineering Industry Study published its latest report, based on responses from nearly 700 firms across the U.S. and Canada. A summary of its AI findings:

• AI adoption surged across the industry, with 53% of firms leveraging AI tools – up from 38% last year;

• Use cases include proposal development, project planning, business development, and data analytics;

• However, a gap remains between intent and full integration, as many firms are still heavily reliant on manual processes for core functions like accounting and resource management;

• Digital maturity is among firms’ top tech priorities, with 38% now rating themselves as digitally mature or advanced, and 74% expecting to be so within three years.

Starting on page 14 of this issue, contributor Nathan Kegel of IES Ltd. adds his insight. “AI has the potential to reshape how we design and operate buildings, but we are still in the early stages,” he writes. “Right now, the most successful applications are narrow, well-defined, and paired with strong human oversight... Engineers should remain curious, but skeptical.” So humans are still very much needed in this industry, and will be for quite some time.

Our cover story and June podcast dive into that next-generation talent pool with engineers Jennifer Leach and Keith Hammelman, who are both presenting this June at ASHRAE’s annual conference in Phoenix.

They both note that today’s young engineers are a different bunch, shaped by many factors including environmental issues, human rights and, of course, technology.

“This latest generation is focused more on a work-life balance,” says Leach, an associate principal at BR+A Consulting Engineers. “They aren’t as motivated by money as the generation before them... I like to refer to them as ‘modern hippies,’ because they’re very focused on rights, human rights and the environment, and things like that... This upcoming generation is more concerned about who they work with than what they do.”

Adds Hammelman, a principal at Cannon Design, “[They want to know] what a company is doing that goes beyond. Will it allow them to grow in helping the environment? Or in social justice? Anything of that nature. It goes beyond just straight doing architecture and engineering now.”

As the father of one child who is installing photovoltaic panels on a massive solar farm in downstate Illinois and another now monitoring greenhouse gas emissions for a building performance lab in New York City, I can relate. The next generation in and around this industry certainly seems plugged into the bigger picture.

And taking that long view for many also involves more career planning, even if money isn’t the biggest motivator now. Young engineers still want to see a pathway forward.

“When I started, I was told ‘You’re an engineer and you’re just going to do engineering.’ Well, in reality, there’s a lot of different ways that things are done within a firm and you need to create those career pathways because not everyone is the same,” says Hammelman.

For more insights from Leach and Hammelman, I encourage you to read our cover story and listen to our June episode of HPAC On The Air. Also check out our May episode, “Navigating Uncertainty, with economist Richard Branch.”

Indeed, there’s a heck of a lot going on in and around our industry this spring and summer. Our goal is to try to keep you abreast of what’s most important to your bottom line, whatever that might be.

William P. Bahnfleth, PhD, PE The Pennsylvania State University Glenn Barrett, PE DC Engineering

David W. Bearg, PE Life Energy Associates

Lawrence (Larry) Clark, QCxP, GGP, LEED AP+ Sustainable Performance Solutions LLC

Kenneth M. Elovitz, PE, Esq. Energy Economics Inc.

Charles E. Gulledge III, PE, HBDP, LEED AP, FASHRAE Environmental Air Systems LLC

Elise Kiland, PE, YEA Cambio.ai

Nancy Kohout, PE, LEED AP SmithGroup

Valentine A. Lehr, PE, FASHRAE Lehr Consultants International

Ginger Scoggins, PE, CEM, CxA, LEED AP, FASHRAE Engineered Designs Inc.

James P. Waltz, PE, CEM, ACFE Energy Resource Associates Inc.

Michael K. West, PhD, PE Advantek Consulting

Ron Wilkinson, PE, LEED AP Wilkinson Commissioning Management

Gerald J. Williams, PE, LEED AP 8760 Engineering LLC

This spring’s volatile business conditions have made it harder for firms to plan long term.

The economic news has been fast and furious this spring and more than a few headlines seem to be in conflict with each other. To make sense of it all, here we review the latest from Fed Chair Jerome Powell, plus industry voices at the American Institute of Architects (AIA), Associated General Contractors (AGC), Associated Builders and Contractors (ABC), Dodge Construction Network, and more. Taken together, they offer a clearer view of the road ahead for U.S. design and construction.

On April 30, the U.S. Bureau of Economic Analysis reported that U.S. GDP had declined 0.3% in the first quarter, the economy’s first negative quarter since 2022. If GDP declines again in the second quarter, then the U.S. economy would, by definition, be said to be in a recession.

Of course, that definition proved inaccurate in 2022, as the post-pandemic economy corrected course. And 2025 has its own unusual variables now that may yet stave off recession again.

Fed Chair Jerome Powell has been cautious about cutting interest rates in 2025.

On May 7, Federal Reserve Board Chair Powell said this year’s first quarter decline in GDP may well have been “reflecting swings in net exports that were likely driven by businesses bringing in more imports ahead of potential tariffs.”

With that in mind, the Fed is taking a ‘wait and see’ approach that Powell explained in his May press conference. Even in the face of mounting pressure from the White House to start cutting interest rates again, the Fed Chair announced that the Federal Open

Producer Price Index Monthly Percent Change (Inputs to Construction Industries — March 2017 through April 2025)

Source: U.S. Bureau of Labor Statistics

Market Committee had decided to leave the policy interest rate unchanged.

“The risks of higher unemployment and higher inflation appear to have risen, and we believe that the current stance of monetary policy leaves us well positioned to respond in a timely way to potential economic developments,” he said.

To further reassure the public, Powell added, “My colleagues and I remain squarely focused on achieving our dual mandate goals of maximum employment and stable prices for the benefit of the American people. Despite heightened uncertainty, the economy is still in a solid position. The unemployment rate remains low, and the labor market is at or near maximum employment. Inflation has come down a great deal but has been running somewhat above our 2 percent longer run objective.”

The Fed’s last rate cut was in December, but it has declined any further cuts while it waits to evaluate the impact of on-again, off-again trade tariffs that still remain in flux. Said Powell, “It’s not a situation where we can be preemptive, because we actually don’t know what the right responses to the data will be until we see more data.”

More data, of course, continues to roll in from several directions in our industry, and many are conflicting.

On May 15, the Bureau of Labor Statistics (BLS) reported that construction input prices decreased 0.1% in April compared March. Nonresidential construction input prices increased 0.2% for the month.

Overall construction input prices are 0.1% higher than a year ago, while nonresidential construction input prices are 0.2% higher. Prices decreased in all three energy categories in April.

“Construction input prices declined in April, but that was largely due to falling energy prices,” said ABC Chief Economist Anirban Basu. “Materials

Source: U.S. Bureau of Labor Statistics

directly affected by tariffs saw sharp price increases. Steel mill product prices rose 5.9%, while copper wire and cable prices increased 5%.”

“While recent developments have reduced tariff-related uncertainty, the 25% tax on steel and aluminum imports remains in place, and a sudden resumption in imports from China could cause an increase in shipping prices,” he added. Even so, Basu noted, 25% of ABC firms still expect their profit

margins to contract over the next six months, according to ABC’s Construction Confidence Index.

Meanwhile, on May 9, the Dodge Construction Network reported that its Dodge Momentum Index (DMI) grew 0.9% in April, boosted by a 3.3% increase in commercial planning during the month.

“Despite an uptick in April, the bulk of the DMI’s growth was driven by a surge in data center planning, while

momentum in other nonresidential sectors lagged behind,” said Sarah Martin, Dodge’s associate director of forecasting. “Owners and developers are navigating heightened economic and policy uncertainty, which likely bogged down much of the (April) planning activity.”

Indeed, “uncertainty” is the watchword, as highlighted in our May episode of HPAC On The Air, our online podcast with economist Richard Branch

“There will likely be trade and price disruptions in the months to come,” says Branch, now at FreeAgentEconomist.com. “That, along with a payback from the first quarter pre-spending, will result in much slower economic growth over the next six months.”

Even so, other positive signs continue to emerge, too.

According to BLS, the U.S. construction industry added 11,000 workers in April. And that growth came at “a faster clip than other sectors in April as the industry boosted pay more than other private employers,” said Ken Simonson,

The average project backlog at firms stands at a reasonably healthy 6.5 months, offering a bit of a buffer if future project work continues to remain soft.

— AIA Chief Economist Kermit Baker

AGC chief economist. “But uncertainty over tariffs and other policy reversals may cause a halt to many projects and employment gains.”

In March, national nonresidential construction spending decreased 0.5%,

Source: Dodge Construction Network

according to the latest figures from the U.S. Census Bureau.

“Data center investments are perhaps the only remaining source of industry momentum,” added ABC’s Basu. “Given unprecedented economic uncertainty, spending is unlikely to rebound in the coming months.”

For their part, design firms are also on edge. The latest AIA/Deltek Architecture Billings Index (ABI) dipped to 44.1 in March, as more firms reported a decline in billings from the previous month.

Since the ABI first dropped below 50 in October 2022, following the post-pandemic boom, billings have declined in 27 of the last 30 months. “Unfortunately, this softness is likely to continue as indicators of future work remain weak,” said AIA Chief Economist Kermit Baker, PhD. “Inquiries into new work declined for the second month in March, while the value of newly signed design contracts fell for the thirteenth consecutive month.

Clients are increasingly nervous about the uncertain economic outlook, and many remain wary of starting new projects at this time.”

However, backlogs at architecture firms remain reasonably healthy at 6.5 months, on average, which means that even though little new work is coming in currently, they still have a decent amount in the pipeline, notes Baker.

Looking ahead, Fed Chair Powell also said May 7th that U.S. negotiations with key trade partners will help to shape the economic outlook for the rest of the year. He added that the tariffs Trump implemented on April 2nd were “substantially larger than anticipated in the forecasts that I had seen and in our own forecasts. So it seems to me we’re entering a new phase where the administration is beginning talks with a number of our important trading partners and that has the potential to change the picture materially — or not,” Powell said. “It’s going to be very important how that shakes out.”

And in the meantime, our industry and the global economy, will continue to shake, as well.

Now in its 25th year, LEED has updated its tools to help high-performance buildings respond even more effectively to today’s most pressing sustainability challenges.

By DEISY VERDINEZ, U.S. Green Building Council

The U.S. Green Building Council on April 28 officially launched LEED v5, the latest version of its flagship LEED (Leadership in Energy and Environmental Design) green building program. LEED v5 builds on the 25-year legacy and global impact of LEED, updating and strengthening the most widely recognized sustainability standard for the building industry while providing userfriendly tools for building owners and teams to pursue certification through enhanced technology updates.

“Since its public launch 25 years ago, LEED has profoundly impacted millions of people in cities and communities around the world,” said Peter Templeton, president and CEO of USGBC. “LEED v5 raises the bar, further defining and evolving best practices and giving stakeholders across the building industry clear pathways to address today’s challenges to our health, climate and communities.”

The newest version of the LEED standard was developed with input from thousands of green building professionals to respond to today’s most pressing challenges and the significant opportunities at the intersection of sustainability and buildings. LEED v5 focuses on impact areas that touch decarbonization, human and ecological health, and resilience. It also further defines what it means to be a highperformance building today, creating even greater investment potential.

Decarbonization accounts for half of all points for LEED v5 certification

to confront current climate needs. The new rating system provides clear, actionable steps to deliver ultra-lowcarbon buildings by targeting emissions reductions across all aspects of the building life cycle, including operations, embodied carbon, refrigerants and transportation. All LEED v5 projects will complete an operational carbon projection and will be given tools to craft a comprehensive, long-term decarbonization strategy, creating pathways for sustainable transformation.

restore ecosystems, mitigate risks, and minimize business disruptions while protecting asset value—contributing to economic prosperity and safety across communities. Once projects conduct their assessments, LEED v5 offers a variety of strategies that can be incorporated at every stage of the life cycle to reduce risk and enhance resilience.

“Investors, owners, occupants and policymakers are asking for high-performing buildings that reduce emissions; mitigate climate risk; provide

Global demand for healthier and greener spaces has grown in recent years, with occupants increasingly demanding more transparency and accountability around sustainability and health in the built environment.

Resilience is another major theme across the rating system, addressing both human and natural systems to strengthen communities.

All LEED v5 projects will complete climate resilience assessments to enhance awareness of hazards, increase transparency of risks, reduce vulnerabilities, and ensure long-term safety and sustainability. These assessments equip projects to conserve and

healthy, productive spaces; positively impact communities; and protect natural systems,” said Sarah Zaleski, chief products officer of USGBC. “LEED v5 provides the best practices and accountability to drive performance across all these dimensions, delivering tangible benefits to building owners and their stakeholders.”

LEED v5 registration is now available for new construction, interior and existing commercial building projects through our online platform.

For more information or to register, visit usgbc.org/leed/v5.

What mechanical engineers and building automation professionals need to know before investing their trust—and their reputations—into AI-driven systems.

By NATHAN KEGEL, Vice President, IES Ltd.

Artificial intelligence” (AI) has reached peak buzzword status in the building sector. Promises range from faster design iterations and energy optimization to fully autonomous building operations. But how much of the hype is grounded in reality?

So what do mechanical engineers and building automation professionals need to know before investing their trust—and their reputations—into AI-driven systems?

First, it’s worth clarifying that not all tools labeled “AI” are created equal. What’s often marketed as artificial intelligence may, in fact, be advanced analytics, rule-based automation,

Nathan Kegel is Vice President, North America, for IES, a global climate tech company delivering innovative software solutions and consultancy services to decarbonize the built environment. In this role, he is focused on enabling the AEC sector to reduce the carbon emissions of the buildings they design, build and operate. Having previously worked for IES between 2011-17, Kegel rejoined as a Vice President in 2022. He gained additional professional experience as a Building Performance Analyst at integrated design firms, DLR Group & SmithGroup. A resident of Minneapolis, MN, he holds both a BA and Certificate of Construction Management from the University of Minnesota, as well as an MBA from the University of Phoenix.

or machine learning (ML). These distinctions matter, particularly in safety-critical environments like HVAC and building systems, where predictability, transparency, and traceability are essential.

In most current applications, what we’re seeing in the built environment is machine learning: algorithms trained on large datasets to identify patterns or predict outcomes. For example, an ML model might learn to predict a building’s heating load based on historical occupancy and weather data.

Current AI systems are typically designed for specific purposes (image recognition, language translation, etc.) and generally lack the understanding and adaptability that humans possess. In other words, complex reasoning is not yet something that current AI systems can undertake.

True artificial intelligence—systems that adapt autonomously and make complex decisions without human oversight—is still a theoretical concept. Some prognosticators believe this ‘artificial general intelligence’ (AGI) will be possible within five to 10 years, while others believe it will be more like one to four years. But it’s not here yet.

That said, there are several areas where AI and ML are beginning to add measurable value in engineering workflows:

In building automation, AI is increasingly used to refine

control strategies. Predictive models can optimize setpoints based on anticipated conditions rather than reacting in real time. For example, a chilled water system might preemptively adjust in response to forecasted outdoor temperatures and occupancy schedules, improving efficiency and comfort.

Some smart building platforms now incorporate reinforcement learning—a type of AI that learns from trial and error—to improve their performance over time. When implemented carefully and monitored closely, these systems can reduce energy consumption and operational costs.

AI-powered fault detection tools can analyze building system data in real time to detect anomalies, alert operators, and even suggest corrective actions. These tools reduce diagnostic time, improve maintenance planning, and help prevent small issues from turning into costly failures.

However, engineers must remain in the loop. Automated diagnostics are only as good as the data they’re fed, and as the assumptions behind the models.

Some software platforms are now using ML to support earlystage design. For instance, algorithms can predict heating and cooling loads based on historical project data or suggest equipment selections based on comparable building types. While this

isn’t a replacement for detailed simulation, it can streamline initial iterations and support concept development.

There is also potential for AI to improve building performance modeling by calibrating simulation models against real-world data. This could help bridge the persistent gap between predicted and actual performance, a challenge that continues to frustrate both engineers and building owners.

However, finding “good” data with which to train AI models for load calculations and energy simulation in the design of a new building is a real challenge.

Despite these promising use cases, there are significant limitations that engineers must be aware of before relying on AI:

1. Data Quality and Quantity

AI systems require vast amounts of clean, relevant data to function well. In many buildings, that data simply doesn’t exist, or if it does, is riddled with gaps, inconsistencies, and sensor errors. Poor data leads to unreliable outcomes, and engineers bear the consequences when systems don’t perform as expected.

2. Lack of Transparency

Many AI models operate as “black boxes,” meaning their internal logic is opaque. For engineers accustomed to physics-based modeling and deterministic outcomes, this lack of explainability is a problem, especially when regulatory compliance or liability is on the line.

3. Context Blindness

AI doesn’t understand context the way humans do. It may detect a correlation between outdoor temperature and energy use, but it doesn’t know about a broken damper, a recent tenant change, or a mechanical override. Human oversight remains essential, particularly in systems that control indoor environmental quality or safety functions.

4. Overpromising and Under-Delivering

In some cases, marketing claims outpace technical reality. Engineers should be cautious of solutions that promise “autonomous optimization” without offering transparency, audit trails, or clear ROI. Building owners are increasingly asking for accountability—not just automation.

5. Environmental Impacts

While AI holds a lot of potential and has already contributed significantly to improvements in medicine and biology, AI systems require a lot of resources to be manufactured and operated. The environmental impacts of the continued development and build-out of AI infrastructure are not yet fully understood, but include:

• Energy: AI is extremely power-hungry. The estimate reported by a Google AI search of how much power was consumed to train GPT-4o was 65,000 Mwh. This is enough electricity to power over 1.2 million U.S. homes for one hour or roughly 1,400 homes for an entire year. AI’s current power consumption is roughly the same as that of Japan;

• Water: According to one study, AI is on track to consume between 4.2 and 6.6 billion cubic meters of water per year by 2027. This would mean AI would consume 4-6 times the amount of water as the entire country of Denmark;

• Materials: According to the United Nations Environment Programme (UNEP), for every 800 kg of raw materials, only 2 kg ends up as useful materials. This puts the efficiency of manufacturing AI chips at 0.25%. In addition, many of the materials used are known to contain hazardous materials like lead and mercury.

Given the enormous environmental impact, more transparency is needed so design firms can make informed decisions about which tasks are worth the additional infrastructure which is required to “sustain” AI.

For mechanical engineers and system designers evaluating AI-based tools, here are a few considerations:

• Start with a clear use case. Identify a specific, highvalue problem to solve, such as peak load reduction or fault detection, and assess whether AI tools can address it better than conventional methods;

• Insist on transparency. If a model influences a design decision or control strategy, you should understand how it works and be able to verify its recommendations;

• Test before scaling. Pilot AI solutions in a limited, controlled environment to validate performance and build confidence;

• Keep the human in the loop. AI should support engineering judgment, not replace it.

AI has the potential to reshape how we design and operate buildings, but we are still in the early stages. Right now, the most successful applications are narrow, well-defined, and paired with strong human oversight.

Rather than expecting AI to automate entire design workflows or eliminate human operators, we should see it as a tool that can augment decision-making, improve accuracy, and free up time for higher-value work.

The future of building design and automation will likely involve a hybrid model: physics-based simulation and controls where transparency and precision are essential, and AI where data-rich, adaptive decision-making can offer an edge.

In the meantime, engineers should remain curious, but skeptical. Ask questions. Demand clarity. And above all, remember that while the tools are evolving fast, the principles of good engineering—rigor, accountability, and service to the end user—remain the same.

Our Podcast series offers unique and compelling industry insights for mechanical engineers in the HVACR and plumbing markets. Each month, we talk with engaging thought leaders and practitioners like ASHRAE’s Bill Bahnfleth and Legionella expert Dr. Janet Stout. Produced by HPAC Engineering magazine and hosted by Editor-in-Chief Rob McManamy, this series is just one of several exciting products, designed to enhance your HPAC multimedia experience.

In this post-pandemic, work-from-home world, company culture has never been more important for recruiting and retaining today’s socially engaged young talent.

Our June 2025 episode of ‘HPAC On The Air’ welcomed engineers Jennifer Leach and Keith Hammelman, who are both presenting at the 2025 ASHRAE Annual Conference in Phoenix. Their topic? Next-generation engineering talent. “How to get ‘em; How to keep ‘em.”

Leach is an associate principal at BR+A Consulting Engineers in the Washington DC area and a graduate of Penn State University. Hammelman is a principal at Cannon Design in Chicago and he holds a mechanical engineering degree from Iowa State University.

What follows is an edited transcript of our discussion...

HPAC : Jennifer and Keith, welcome. Please tell our audience a bit more about yourselves and the expertise you bring to this compelling topic.

Jennifer Leach: Thanks for having us. Keith and I are both members of the ASHRAE Technical Committee 1.7,

which is General Business Management and Legal Education. And as members of that committee, our primary source of educating ASHRAE membership is through seminars and such, typically at the annual conference in June, because they tend to have a soft skills or business-related skills track there. I have been a member of that committee since about 2009, and for a while I chaired it. I’m currently the program chair and I have co-authored the ASHRAE Online Ethics Learning module. Keith and I have been working together in that capacity for a few years now.

Keith Hammelman: As Jennifer mentioned, I am a voting member on the TC 1.7, but also I’m a principal at Cannon Design. I have been with that firm for 21 years and am now the leader of the mechanical discipline across the firm, which has employees spread throughout different offices. With that, we’re always looking at how we are able to bring in the talent and keep the talent, and continue

to develop them. So this was a very intriguing subject for us to start talking about and presenting at the ASHRAE conference

Leach: And it aligns well with the ASHRAE Presidential Theme this year: “Workforce Development.”

HPAC : Jennifer, let’s start with a preview of your presentation. I know you stress that culture is what attracts young engineers the most these days. Please elaborate on that.

Leach: Sure. It’s important to know who you’re hiring and most of the engineers graduating now are in Generation Z. So they are different. Different, particularly, from Gen Xers like Keith and me. We’re both children of Baby Boomers, so we’re workhorses. This latest generation really is focused more on a work-life balance. They aren’t as motivated by money as the generation before them, the Millennials. I like to refer to them as “modern hippies”, because they’re very focused on rights, human rights and the environment, and things like that. So it’s important to know who you’re hiring.

And then the flip side of that is it’s also important to know who you are. Particularly for this generation, because they’re going to do all of their research online beforehand. So any YouTube video, any social media post —whether it’s LinkedIn or Facebook or X, whatever you’re using— they’re going to investigate you. They’re going to see what you said about yourself on your website, and they’re likely going to challenge you on it.

So it’s important to know who you are and how that differentiates your company from the other engineering

firms. Because this upcoming generation is more concerned about who they work with than what they do. I think they want to work for a good engineering firm, but there’s lots of good engineering firms out there. So what distinguishes one firm from another? The answer to that is rooted in what your culture is and what you believe.

HPAC : Okay, Keith, so once you get them in the door and hire them, how do firms retain the engineering talent? How do you keep them happy and engaged at their firms?

Hammelman: One of the things you’re always looking at is what are people looking for? We bring them in. We tell them what is happening. But now we also want to show them this is what we’re actually going to do. So what do employees look for? What does the talent look for? Obviously tangibles: i.e. compensation, salary; benefits; PTO; remote, work-from-home policy; how flexible their manager is; being able to know who their manager will be; things like that. And they do really want to understand and be part of the culture of the firm.

When Jennifer and I started, that meant, “Great, we have a softball team.” But now it’s really what are the things that a company is doing that goes beyond? Will it allow them to grow in helping the environment, or in social justice, anything of that nature. It goes beyond just straight doing architecture and engineering now.

Another big focus is career and personal development. When I started, I was told I’m an engineer and you’re just going to do engineering. Well, in reality, there’s a lot of different ways that things are done within a firm and you need to create those career pathways because not everyone is the same.

What are these pathways going to look like? Is it going to be technical project management, discipline management, firm management? And then there’s the support roles that also

happen because there are engineers that move into marketing or other roles within the firm.

HPAC : So these new pathways may also lead in nontraditional directions?

Hammelman: One goal we’re actually seeing a lot, is how do people become owners? What does ownership look like? And what is a pathway to that style of ownership? Whether it’s an Employee Stock Ownership Plan (ESOP); whether it’s a publicly traded company; or whether it’s a private company that is owned by a series of officers; or if there’s just a couple owners... What does that mean for a new employee? Do they see a place for themselves today? And what does their place look like in the future?

One of the first questions I always ask is, “Have you taken your fundamentals of engineering exam?” If they haven’t, I always recommend highly that they take it as soon as they can. And consider what is their pathway to becoming a professional engineer? Some of the other stuff is just about communication. Reviews aren’t the only times to communicate with your manager and others within the firm, having that open door, as Jennifer mentioned. A younger generation really wants to be talking to not only their direct

managers and their peers, but they might want to even talk to individuals at a higher leadership level and make sure that they’re moving forward.

HPAC : Please talk about some of those culture changes at engineering firms. And how much is being driven by the demands of this younger workforce?

Leach: For sure. I mean, COVID changed everything. We have long had the ability to have online meetings, of course, but I think now it’s probably 50:1, online versus in-person meetings, because they are just so easy to do. So BR+A and Cannon are both large companies and we frequently work with people who are in other offices. So learning how to manage and be managed by somebody who’s not sitting in the same building as you, that’s a huge change and it takes a shift.

The world has changed, and we can’t stand firmly with our feet in the sand or else we’re going to be knocked over. In order to adapt, we have to recognize where things are going. It’s driven by young people and their need to embrace technology in all things. But it was also sort of for the rest of us who maybe weren’t as technology-driven. The owners of these companies tend to be baby boomers and Gen Xers. We

were kind of forced into it. So I think that ultimately it’ll be for the good, but it’s going to require some changes. It’s going to require checking in with people on a regular basis and having structured plans for mentoring and such, just to make sure we aren’t losing people along the way.

Hammelman: That’s a good synopsis. At Cannon Design, pre-pandemic, we were actually rolling it out in a formal process, allowing remote work where we have employees spread throughout the country and we have people who have offices in their homes already. But the pandemic accelerated all that, and the realization that you don’t need to be sitting next to someone to understand—five days a week, eight hours a day—that they’re working on stuff. People have lives and it’s okay for you to work and to have that focused time that you need at the local Panera Bread, for instance. They used to joke in the office, “Where’s Keith? Which Panera is he at today?” Because I would always just say, today, I’m going to work from home and then go over there.

But I think from that perspective, how this generation helped to accelerate it, how the pandemic did that at my firm. It was a flip of a switch when the pandemic hit. We all went home and it was no different from a mentorship perspective. We used a lot of instant messaging, Teams, picking up the phone, texting, etc. The conversations that we’re having back and forth now make sure that we’re having that mentorship not only of our younger generation, but also some of our older, more seasoned folks.

Actually, I personally think a lot of people, everyone has benefited, because it’s allowing you to have some flexibility in your life to deal with life challenges, and that’s what people are looking for. Not only the GenZers, but also us old Gen Xers are starting to say that, actually, we’re enjoying this.

Leach: I think it’s about seeing the person as a whole being, right? Because so much of who you are, you bring to work with you every day, you spend a lot of time there. But it’s important to respect and appreciate that life is challenging. It always has been, but it gets more and more challenging and the deadlines get crazier and everything else. So what are we doing to help each other along? And I think that that’s a big change in working in general is that we’re much more interested in the whole being of a person.

So I want to know what you did over the weekend. I’m interested in how your children are growing, or the new dog that you got, or whatever. Because if I know those things about you, I know your personality better. It’s easier for me to manage to that. So I think that those are all positive things, like Keith was saying.

Hammelman: Every person has a different story and a different pathway, and people are looking for an appreciation of that at work now, too. They want the ability to continue to grow and to grow in ways that a firm with a culture has. Whether that’s through the old softball team or volleyball team, or it could be displaying employee art and having art

shows, or even just get-togethers for colleagues to share what they’re doing in their personal lives.

HPAC : With so much of everything online and remote now, are you still doing campus visits for recruiting? How much of that has changed?

Leach: We still do lots and lots of college campus job fairs, etc., because you definitely need to meet people where they are. That’s an easy sort of get ‘em and hook ‘em because you still need that human connection, right? We have all of this technology and everything, but the human connection is important. And making that connection face-to-face is invaluable. So you’re going to get your best talent if you’re hiring young people out of college in that way.

Hammelman: We do the campus visits, too, but we’re also looking at what else can we as a firm give back to the campuses and the universities. So we’ll say, “Hey, we want to do a presentation to a class. Can we come in and give a talk, maybe meet with some professors, meet with some students?” Those types of additional collaborations can have a big benefit, too. (Especially) when some of the presenters are coming back in two years later from the school they just graduated from. That provides value.

HPAC : And how has team building within firms been affected by the remote aspects of everything now? How can you create the culture you want across offices in multiple cities?

Leach: At BR+A internally, we have our own company intranet where we share things that are happening either throughout the company or personally. So, ‘Congratulations to Joe for passing your PE exam’ or ‘Congrats to Bill and his wife Susie, who just had a little girl,’ or ‘Here’s the groundbreaking of this project.’ I think a lot of companies have that intranet that is really their own sort of social media platform. Plus, our firm does see the value in the team coming together collectively every few years. So they’ll bring everyone in for what we call a ‘One BR+A’ meeting, where we have people from different offices sharing what’s going on there, as well as the successes they’ve had since the last time we all met. And this year, probably in the fall, there will be a big one because BR+A is turning 50.

It’s important to feel connected with each other... And one of the important things to realize and to communicate, I think, is that everybody has their seat on the bus. They’re a cog in the machine, and no role is more or less important. You need them all. So we want to be able to manage to those strengths and ensure that people get what they need in order to succeed.

Firms also use site tours to engage engineering students.

Hammelman: For us, every office is a little individual on this. So we do have people come in on a regular basis. But we’ve not mandated that nor do I think we’ll ever mandate four days a week back in the office. People do come in and teams decide that, say, Tuesdays or Thursdays are their days that they come together and work side by side to get some of that collaboration. But that collaboration is also happening on a regular basis through the social media that we have internally in the firm.

We also have regular events called the Cannon Design Academy where people do get together and we ask them —whether it’s leadership or even staff— to start doing presentations for the entire firm. So they can learn how to do that and it starts building teamwork.

Leach: My favorite collaborations are once a month, when our construction administration folks will host our own internal ‘Lunch and Learns’. They’ll say, “Here’s all the great things that are happening, and here’s all the things you should never, ever do again.”

Hammelman: Yes! Those are always fun. On process improvement, I have weekly calls with all of my discipline leaders across the offices, and we go through staffing challenges, etc., and then I do breakout sessions with them. But they’re doing the same things with their teams in order to stay connected and to understand where the pinch points are, to understand where an individual is.

Again, it’s about how we need to communicate. The way we communicated back when I started in the mid-1990s was ‘You show up at 8 am, and you leave at 5 pm, and lunch is at noon.’ It’s a lot different how it is today. And just that whole process has changed. It’s actually been fun. So this change in culture was accelerated by the pandemic, but I still believe it was already going to happen.

ITM EVOLUTION: A preview of the 2026 edition of NFPA® 25, Standard for Inspection, Testing, and Maintenance of Water-Based Systems.

This article is reprinted with permission from NFPA Journal © 2025 NFPA®

By TERRY VICTOR, National Fire Protection Association

As a longtime member of the technical committee for NFPA 25, Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems, I’ve watched the standard undergo a lot of changes. Some have been small and intended to clarify the intent of the standard, while others have been more significant.

Of the proposed changes to the 2026 edition, five stand out. These are especially important for system owners who are responsible for complying with the standard, as well as the inspectors and technicians who perform many of the ITM tasks associated with those systems.

The purpose of NFPA 25, according to the standard itself, is to “provide requirements that ensure a reasonable degree of protection for life and property from fire through minimum inspection, testing, and maintenance methods for

The author is director of risk control services at Risk Suppression Partners LLC in Kimberton PA. He is currently a member of five NFPA technical committees, including NFPA 25.

The author, Terry Victor, will present this topic on June 17 at the 2025 NFPA Conference & Expo in Las Vegas.

water-based fire protection systems.” To that end, the NFPA 25 inspector should understand the scope of the standard, be familiar with its requirements, and be qualified to perform the required inspection and testing tasks.

The inspection, testing, and maintenance (ITM) requirements of NFPA 25 have always been based on the premise that the water-based fire protection system was installed correctly in accordance with “generally accepted practice” as stated in 1.1.3.

However, because many building owners and enforcers had unreasonable expectations for the inspector to be able to verify the adequacy and accuracy of the installed system, a specific statement to the contrary was added to paragraph 1.1.3.1. The intent of this statement has always been to make it clear that inspectors are not expected, or trained, to do more than inspect and test the system as installed. In the 2023 edition, paragraph 1.1.3.1 was changed slightly to clarify that along with the inspector not being responsible for verifying the accuracy of the design of the system, the inspector isn’t responsible for verifying the accuracy of the installation of the system, either. However, there are certain tasks within NFPA 25 that require the inspector to verify the accuracy of the design.

For instance, in Chapter 10, the inspector is required to consult NFPA 15, Standard for Water Spray Fixed Systems

for Fire Protection, and be knowledgeable about the design requirements to successfully inspect and test the water spray system. Because there are instances in NFPA 25 that require verification of the design, a proposed change to 1.1.3.1 would acknowledge those instances in the 2026 edition. Another change proposed for the 2026 edition addresses the qualifications of the NFPA 25 inspector. The 2023 edition lists three qualifications for personnel performing ITM functions. However, it was determined by the technical committee that it was not appropriate for NFPA 25 to dictate these prescriptive requirements. Instead, it should be left to the local jurisdiction through the legislative process to determine what the requirements are for qualified personnel. The qualifications in subparagraph 4.1.1.3.1 were deleted—they now reside in the annex to 4.1.1.3 as guidance—and paragraph 4.1.1.3 was modified to require the use of personnel qualified to perform specific ITM tasks.

A recent change in NFPA 13, Standard for the Installation of Sprinkler Systems, impacts the ITM requirements in NFPA 25. NFPA 13 now allows hydraulic calculations using a C factor of 120 for dry pipe and preaction systems when those systems incorporate certain corrosion inhibiting technologies.

The C factor describes the relative roughness of the pipe interior, which accounts for an average amount of corrosion in both wet and dry systems over the 20-year life of the system. The build-up of corrosion byproducts on the wall of a pipe has proven to be worse in dry systems than wet systems; therefore, different C factors are prescribed by NFPA 13. The higher C factor of 120 allows for smaller pipe sizes to be used when hydraulically calculating the system for the available water supply, and therefore a less expensive system.

However, an approved corrosion inhibiting technology must be maintained during the entire life of the system, or the system may become ineffective during a fire event because of the restriction in water delivery through the piping system caused by corrosion.

There are certain tasks within NFPA 25 that require the inspector to verify the accuracy of the design.

Because of the allowance of the higher C factor in NFPA 13 and the need to continuously maintain an approved corrosion inhibiting technology, the new edition of NFPA 25 has several proposed requirements to address that need. Previous paragraph 4.1.4.3 has been expanded from only referencing nitrogen as a corrosion inhibitor to create a new subsubsection 4.1.5 that includes all corrosion mitigation system technologies that must be maintained for the life of the system. If a corrosion mitigation system is not maintained, the dry or preaction system must be recalculated using a C factor of 100 and modified as necessary.

A related change was made to address the inspection, testing, and maintenance of corrosion-inhibiting systems with the addition of a new Section 13.11.

An impaired fire protection system is serious and requires immediate action. Some impairments are planned, as when system modifications are being performed or when performing certain inspections or tests. Others are considered emergency impairments, such as a control valve being found shut, having certain components failing an inspection or test, having an inadequate water supply, and many other conditions that prevent a system from functioning during a fire event.

Impairments require special action by the building owner and the assignment of designated personnel to coordinate impairment activities. Chapter 15 isdedicated to impairments, the establishment of an impairment coordinator, and the actions that need to occur until the impaired system is returned to service. However, the initial notification of an impairment to the AHJ, fire department, and alarm receiving facility was not emphasized in Chapter 4

A proposed requirement that reinforces the need for this initial notification of an impaired system was added to subsection 4.1.4, which already required notification for a system shutdown or system testing.

A new section was added to Chapter 4 that provides guidance for the building owner when water-based fire protection systems are no longer needed or are otherwise taken out of service. Earlier editions of NFPA 25 did not include guidance on what to do with the piping, valves, and other components of an inactive system. The building owner was left to decide if all or parts of the system could be abandoned in place or should be removed.

The ideal situation would be to remove all system piping and components that are taken out of service. In many cases, however, sections of piping are very difficult to remove in a cost-effective manner, and attempting to remove them could damage the building or other systems around it. NFPA 13 addresses what to do in those situations, but most of the other water-based installation standards do not. The text from NFPA 13 was extracted and added to Chapter 4 of NFPA 25 so it applies to all water-based fire protection systems and allows for pipe and control valves to be abandoned in place, with requirements for marking the pipe and removing the operating mechanisms in control valves.

However, all other valves and components must be removed when the system is taken out of service.

There have been many instances in recent years of waterbased fire protection systems freezing during extreme cold weather events. Immediate action is needed when ice is discovered in a system.

Ice in water-based fire protection systems is not a new problem, but until the 2026 edition, NFPA 25 has not provided guidance on what to do when this impairment occurs. A new requirement in Chapter 4 is short and direct: a system containing ice is to be considered impaired, which immediately initiates the additional requirements in Chapter 15–Impairments. The system is then required to be completely thawed out before being restored to service. Unfortunately, when a system filled with water freezes, damage to the system components usually occurs.

Sprinklers, valves, and other components can be damaged, fittings can break, and pipe can split. The annex to the new requirement provides steps that can be taken to restore the system to service, including completely thawing the ice in the affected parts of the system, identifying and replacing damaged piping and components, air and hydrostatically testing the repaired system, and restoring the system to service.

Meeting in Ohio, boiler manufacturers’ group spent two eventful days focused on industry’s next generation.

By SHAUNICA JAYSON, Vice President, American Boiler Manufacturers Association

The inaugural Emerging Leaders Forum took place April 8–9 at the Hilton Polaris in Columbus, Ohio, bringing together the “Boiler Industry Leaders of Tomorrow” (BILT) for two days of connection, learning, and growth.

With a strong focus on leadership development, networking, and deepening industry knowledge, attendees walked away with fresh insights and practical tools to bring back to their teams and workplaces.

ABMA’s 2025 Emerging Leaders Forum featured powerful keynote speakers, engaging peer roundtable discussions, a candid CEO Q&A session, hands-on interactive learning, and an exclusive tour of the National Board of Boiler &

The annual event features a host of insightful speakers, including trade expert Nate Bolin. For more, visit www.abma.com/summer-meeting.

Pressure Vessel Inspectors’ facility — all designed to inspire and equip the next generation of boiler industry leaders.

Speakers included:

Brent Falcone, VP of People and Culture at WARE, presented as the Keynote Speaker at the Tuesday Opening General Session sponsored by WARE.

Dr. Rick Marks, RelateWell, presented a valuable session on “Leading with Emotional Intelligence” at the Wednesday Morning Session sponsored by Rentech.

Dr. John Hillen, Strategy & Leadership Expert, presented as the Closing Keynote Speaker at Wednesday Afternoon Session sponsored by AUTOFLAME and LAARS

Other highlights:

In our “What’s Keeping You Up at Night?” session, participants broke into small groups to dived into real-world challenges and hot topics submitted through a pre-event questionnaire.

Each group tackled key issues that are top-of-mind for their peers, fostering candid conversations and shared problem-solving. The session wrapped up with each group reporting their key takeaways to the larger audience — sparking valuable insights, fresh perspectives, and a sense of shared experience across the industry.

Attendees had the unique opportunity to tour the National Board of Boiler & Pressure Vessel Inspectors’ state-of-theart Boiler Testing Facility and Pressure Relief Laboratory. The experience included informative sessions that offered an inside look at the National Board’s mission, the critical role of inspectors, and the process behind new construction inspections.

After the tours, attendees enjoyed a relaxed and fun-filled BBQ, followed by some friendly competition in “Minute to Win It” team games — a great way to build connections and end the day on a high note.

Joel Amato, Executive Director at the National Board of Boiler & Pressure Vessel Inspectors, joined us for an engaging session titled “Insights on Career & Identifying Future Leaders.”

Participants had the unique opportunity to ask Joel candid questions about his own career path, leadership philosophy, and the qualities he looks for in the next generation of industry leaders. The conversation provided valuable insights into how emerging professionals can position themselves for growth, build credibility, and make a lasting impact within the boiler and manufacturing industry.

It wouldn’t be an ABMA event without meaningful connection. The Emerging Leaders Forum created the perfect setting for attendees to build relationships, exchange ideas, and expand their professional networks.

For many, it was the first time meeting peers from across the industry — sparking conversations, collaborations, and connections that will last well beyond the event.

Before the official start of the Forum, WIBI hosted a Coffee Social on Tuesday morning — bringing together women from across the boiler industry to connect, share experiences, and learn more about ABMA’s Women in the Boiler Industry professional group.

It was a great opportunity to foster community, spark new conversations, and highlight the importance of supporting and empowering women in the industry.

Take an active role in shaping the future of the boiler industry. For more details about BILT and the Emerging Leaders Forum, contact Jordan Croson at jordan@abma.com.

Greenheck introduces factory-installed optics sensors as an enhanced option for its kitchen hoods. Model GKC kitchen ventilation controls feature hood-mounted temperature sensors as standard, which respond five times faster than ductmounted temperature sensors to modulate airflow. In addition, optics sensors can detect smoke and steam within seconds to trigger the exhaust fans. They can be included in an optional variable volume system capable of turning down fan speeds by up to 50%. The easy-to-use color touchscreen display precisely controls fans, makeup air, and lights. This touchscreen can now be added to each hood section, making individual hood light and fan zone control easier.

Greenheck Fan Corp.

The 80-gal. light-duty commercial electric water heater from American Standard Water Heaters features screw-in dual-heating elements manufactured with Incoloy and have low wattage density, a turbulenceinducing dip tube that reduces sediment build-up inside the tank, a heavy gauge steel tank and a magnesium anode rod that will prolong tank life, a DuraGlas-lined tank, factory-installed heat traps that reduce standby heat loss caused by heat mitigation to water pipe, automatic surface-mounted thermostats to enable easy temperature control, a manual energy cut-off to prevent overheating, and a terminal block for easy phase-in or operational conversions in the field.

American Standard Water Heaters

Fujitsu introduces its single-zone, wall-mounted AIRSTAGE Orion XLTH+ (Extra Low Temperature Heating Plus), the newest addition to its H-Series R-32 heat pump line. The cold-climate mini-split system is designed to ensure indoor comfort even at outdoor temperatures as low as -22° F while maintaining high efficiency with a SEER2 rating of up to 33.5 SEER2. Its compact outdoor unit, slim wall-mounted indoor unit, and extended line set lengths (up to 66 feet) simplify installation in almost any space. Available in three capacities: 9,000, 12,000 and 15,000 Btu/hr., with maximum heating capacities of 24,000, 27,300 and 28,000 Btu/hr., respectively.

Fujitsu General America

AERCO expanded its Innovation water heater line with 1,600 MBH and 2,000 MBH models. They feature a 65% smaller footprint compared to competitive offerings, allowing for zero side clearance installation, making them ideal for tight spaces. They mitigate risks of scalding and pathogen growth through lower set points, continual circulation and minimum-buffer water storage. The Advanced Edge controller with AERtrim O₂ technology self-adjusts and maintains optimal air-fuel ratios for peak efficiency, low emissions and maximum reliability. Integrated with AERCO’s Water Heater Management for multi-unit sequencing of up to 16 units to meet load requirements.

AERCO

Watts launches its SmartStream UV water disinfection system, designed to deliver highperformance water treatment for residential and light commercial applications. The system features built-in fail-safe protection, including an audible and visual alarm that alerts users when the ultraviolet lamp needs to be replaced or has failed. To streamline installation and operation, the system includes a ballast that functions as both the power source and the control center for the UV lamp. Available in three models: 2 gallons/minute (gpm), 8 gpm and 12 gpm.

Watts

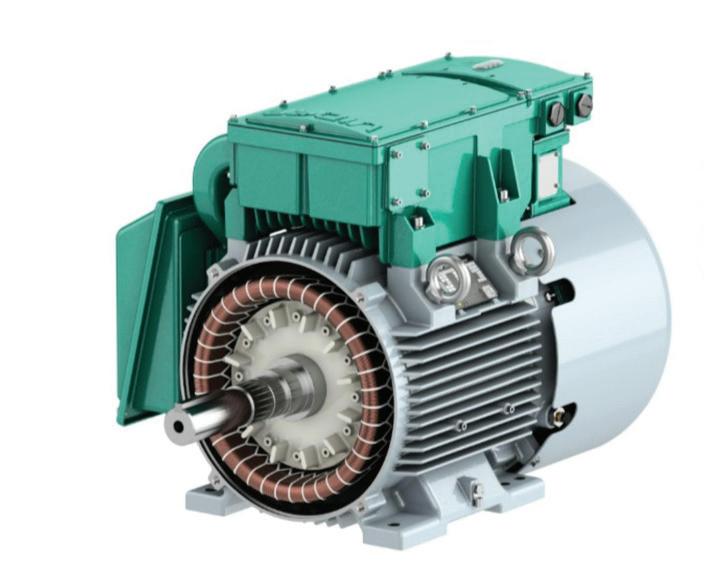

VIDAR is a new type of motor that embeds variable-speed intelligence directly into the motor to achieve new levels of performance, reliability and simplicity in industrial applications involving pumps, fans and fluid process systems. It eliminates the need for inefficient and failure-prone mechanical controls, such as throttled valves or dampers, and ensures consistent flow rates, improves product quality and seamlessly adapts to changing workloads. Its patented AC-Link technology replaces conventional AC-to-DC-to-AC variable frequency drive technology with a streamlined AC-to-AC approach. It reduces energy use and carbon dioxide emissions by up to 50% as compared to a fixed-speed motor and mechanical control.

VIDAR

Taco releases its SKV Series self-sensing vertical in-line pumps, integrating IE5 permanent magnet motors. They significantly reduce energy consumption, lower operating costs and support sustainability goals. The intelligent control system automatically adjusts the pump’s operation to system conditions, eliminating the need for external sensors. It precisely manages flow and head pressure, boosting system efficiency, reducing installation complexity and cutting commissioning time. The addition of the Oe Package makes the SKV Series even more intuitive, simplifying installation and operation for all users.

Taco

Comfort Solutions

Prima Power’s BCe sheet metal bending center offers the ideal solution for those working with single parts, small batches or mass production. Processing materials up to 3.5 mm thick (mild steel), this panel bender features flexibility, precision, high quality, a semi-automatic yet highly productive process, and 3D programming with integrated simulation of the bending cycle. The LUT table allows users to load the next part in masked time while the panel bender processes the current sheet to be machined. The angle correction database and servo-electric technology provide excellent bending quality. Easy manual loading allows users to process batches of any size, including kits and single parts.

Prima Power

ASC Engineered Solutions adds stainless-steel components to its SCI press fittings family for use in mechanical stainless-steel piping systems. The system includes couplings, elbows, tees, adapters, reducers, caps, unions and flanges, providing an alternative to conventional methods of welding and threading. Compatible with common pressing tools and jaws. Intended for use with ASTM A312 stainless-steel piping, Schedule 5,10 and 40, in sizes 1⁄2 in. to 2 in.

Color-coded insertion depth indicator lines provide quick visual reference for EPDM (green) and FKM (white) sealing element.

ASC Engineered Solutions

Rapid Locking System unveils its 3/8-in. and 5/16-in. reducer fittings. The body material is comprised entirely of refrigerant-grade copper and operates at a maximum rated pressure of 700 psi, ensuring peace of mind for contractors when moving from large to small bore piping. On average, press fittings reduce installation time by 60%, improving overall productivity with the connection work done in seconds. These fittings have been used in the field for more than 10 years and were specifically designed and engineered for use in high-pressure HVAC and refrigeration systems.

Rapid Locking System

Greenheck introduces Model RT rooftop units; designed for mixed air applications, they bridge the gap between traditional rooftop ventilators and dedicated outdoor air systems. Model RT simultaneously controls temperature and humidity to optimize indoor comfort. Energy-efficient features include inverter scroll compressors that modulate to deliver precise cooling and dehumidification performance while improving part-load efficiency. Direct drive supply and exhaust fans offer a wide performance range and standard modulation capabilities for variable air volume systems. Electronically commutated motors on condenser fans modulate to control head pressure and improve efficiency. Available in two cabinet sizes: RT-70 with airflow from 2000 to 7900 cfm, and RT-120 with airflow from 3500 to 13000 cfm.

Greenheck

Fellowes launches Array, a networked air purification system featuring building management system (BMS) integration via BACnet/IP. It provides continuous, real-time IAQ monitoring and automatic adjustments to ensure consistently clean, comfortable, and safe indoor air while reducing energy costs. Simple to install in both new construction and retrofit projects, requiring no ductwork connections. Its range of connected solutions seamlessly integrates into any space and can easily scale as building needs evolve. Its high-efficiency, 3-in-1 H13 True HEPA filters capture 99.95% of airborne contaminants down to 0.1 microns. Each air purifier continuously monitors occupancy density levels and air quality conditions in each zone. Fellowes

Rheem adds 3-to-5 ton models with two stages of cooling to its Renaissance packaged rooftop gas/electric and cooling lineup. Engineered for seamless replacements, the RACCYC and RGECYC units boast industry-standard footprints, common piping and electrical connections, field-convertible airflow and minimized weight for unmatched ease of installation. PlusOne HumidiDry hot gas reheat incorporates a variable frequency drive that operates at a lower speed on the first-stage cooling, saving energy, enhancing performance and increasing occupant comfort. PlusOne Velocifin is a patented, complete redesign of the heat exchanger tubing that increases heat transfer through to deliver better efficiencies. Full MicroChannel coils maximize reliability while reducing overall refrigerant weight.

Rheem Commercial

Weil-McLain’s Simplicity high-efficiency combination gas boiler features a 95% AFUE energy rating, an insulated stainless-steel firetube heat exchanger with a vertical “self-rinsing” orientation, a removable polypropylene collector base that prevents corrosion caused by acidic condensate. It can seamlessly integrate with a hybrid dual-fuel hydronic system. Available in sizes of 110 MBH, 150 MBH and 199 MBH, it can operate as a heat-only boiler or provide both heating and domestic hot water. An air inlet silencer provides whisper-quiet operation and a touchscreen display with user-friendly controls makes installation and navigation easy.

Weil-McLain

Sensaphone’s Sentry remote monitoring system replaces traditional landline-based auto dialer devices that are becoming obsolete. It supports up to five external sensors to monitor parameters, such as humidity, power outage, water detection and temperature with a sensing range of -109 F to 115° F. Users can access information and make system changes from any web-enabled device or a mobile app. The system displays all readings in the cloud for easy viewing; this cloud-based technology also lets operators manage multiple devices from one account.

Sensaphone

Sensaphone’s Sentinel PRO remote monitoring system is a powerful tool for facility managers seeking to enhance their maintenance plans through predictive and preventative maintenance. For predictive maintenance, the system’s real-time monitoring and alert features detect early warning signs of equipment malfunctions. It also identifies changes in conditions, such as temperature and humidity. It provides continuous remote monitoring of critical parameters, allowing teams to verify the condition of their equipment and confirm that scheduled maintenance is effectively preventing breakdowns.

Sensaphone

Airzone Control expands its Aidoo Pro HVAC control bridges line with three new models. The Aidoo Zigbee brings native HVAC integration to Zigbee 3.0 smart home platforms. The Aidoo Pro Smart Thermostat Interface is Wi-Fi based and designed for streamlined integration between smart thermostats and Inverter (VRF/mini-split) air-handling units. The Aidoo Pro Hub is a wired Ethernet controller for maximum reliability in critical applications. The line enables precise control over temperature set point, fan speed and mode from a smart home system, smart thermostat or building automation platform. Designed for efficiency, the devices enhance climate control automation while reducing energy consumption. Airzone Control

Dart Controls introduces the compact EZ VFD, an easy-to-use family of variable frequency drives for 1/4- to 2-hp applications. Dual-voltage input (115V/230VAC, single phase, 50/60 Hz) and 230VAC, three-phase, 0-60 Hz output allows use in a wide range of applications and installation. Built-in safety features include overload protection for current and temperature, anti-coast deceleration and motor braking. Four models are available with open chassis or NEMA 4X enclosures. They operate in a wide range of temperatures: from 14° F to 95° F for NEMA 4X models, and from 14° F to 113° F for chassis models. Ideal for conveyors, fans and blowers, pumps and compressors, and more.

Dart Controls

Greenheck’s eCAPS® online product selection program includes the Fan Energy Index (FEI) giving you a powerful engineering tool to select the best fan system for your application and help you select fans that meet or exceed ASHRAE 90.1-2019 and comply with state energy code requirements.

Our sustainability columnist ponders the possibilities of some new federal priorities.

Larry Clark

A regular contributor to HPAC Engineering and a member of its editorial advisory board since 2012, the author is a principal at Sustainable Performance Solutions LLC, a south Florida-based engineering firm focusing on energy and sustainability. Email him at larry@ sustainflorida.com.

Wind power, the electrical energy provided by wind turbines, has been blowing hot and cold for years. Recently it again has come to wider public attention due to two events: President Trump’s Executive Order in January temporarily “pausing” wind projects on federal waters and lands; and the new TV series, “Landman,” now streaming on Paramount+.

In the series’ third episode, actor Billy Bob Thornton plays the manager of an oil-drilling company who details the environmental downside of large wind turbines on a wind farm in West Texas. He points out all the energy – provided by fossil fuels – required to produce the concrete and steel used in the massive structure: the diesel fuel required to transport it to the site and to power the 450-foot crane needed to set it in place, plus the amount of oil required to lubricate it over its lifetime.

Although his conclusions regarding the carbon offset over the turbine’s 20-year lifespan are dubious, he still makes some valid points. Critics of wind farms frequently point to the economic and environmental penalty associated with the disposal of the turbines at the end of their useful life. They also cite the cost and environmental burdens, of which there are many, of transmitting the power from remote locations to the population centers where it is most needed.

If the new Administration’s intent is to develop policies that emphasize solar photovoltaic (PV) over wind, as the preferred source

of non-nuclear renewable energy in the U.S., then the ban may have some valid justification. Otherwise, the intent would appear to be purely political. In general, I do believe that PV has some significant advantages over wind.

They’re both clean and renewable, of course, although both have embedded energy penalties during manufacture, and disposal of PV panels also presents some environmental hazards. PV is quieter and less visually obtrusive, and does not kill or injure birds, bats, marine mammals, and fish on the magnitude of wind turbines. While both technologies, at utility scale, require a lot of real estate and are expensive to install – although PV is generally not located as far from the users as wind turbines – the solar PV is much less expensive to maintain.

Efficiency is also a consideration. Solar PV is a passive process of converting sunlight directly into electricity. PV panels typically have efficiencies of around 24%, so their efficiency is a function of wind speed and direction, Typical efficiencies for commercial scale wind turbines are 25-30%.

One would hope that the financial savings from pausing wind farm development would be applied to solar PV, and other alternative renewable energy projects, and that the new Administration will not abandon the funding of renewable energy, as many fear.

After all, even if America is now going to “drill, baby, drill,” like many proclaim, it must still continue to innovate, innovate, innovate!

August 20-21, 2025

Grand Sierra Resort & Casino

Reno, NV

September 30-October 1, 2025

Santa Clara Convention Center

Santa Clara, CA

October 29-30, 2025

Irving Convention Center

Irving, TX

Designed for fresh air.

AAON Delta Class has been dedicated from the beginning. AAON is always innovating. Learn more about our dedicated outdoor air systems (DOAS).