PRO-LINK+, built for servicing a complete range of commercial vehicles, makes Benny more than just a pitstop technician - it makes him an efficiency expert.

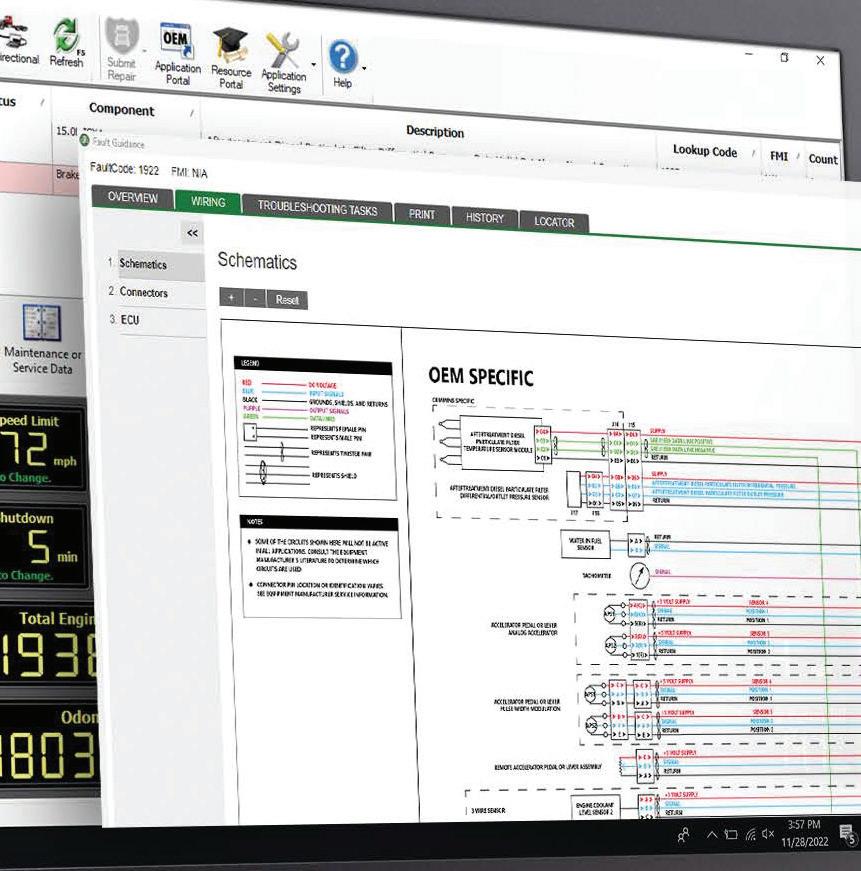

Under the hood, PRO-LINK+ delivers:

• OEM-specific coverage for engines, transmissions, chassis, and brakes

• Code-specific information with detailed testing procedures, component photos and wiring diagrams

Take control with over 200 special tests and 600 user-configurable parameters. Built tough for medium and heavy-duty trucks, PRO-LINK+ is your essential diagnostic companion.

Shop Operations

Measuring success in the shop

Helping your maintenance department achieve higher standards starts with tracking the right KPIs.

What are the Metrics?

We’ve compiled all the vital benchmarking and industry data you need to succeed.

Equipment

p.15 Demographics

p.16 Equipment

p.18 Engines, Oils, & Fuel

p.20 Tires & Brakes

p.21 Technology

In the Bay

p.22 Shop Stats

p.24 Technician Shortage

p.25 Compensation

p.26 Training

Artificial Intelligence

Eight ways AI is changing the shop

Shops have plenty of options when it comes to AI tools, from speeding data entry to troubleshooting.

Here’s a few of the interesting

Brandon Thompson

Visit the official website of Fleet Maintenance for more information from stories in this issue, plus online exclusives on pertinent topics in the fleet maintenance management industry.

Data is the new diesel fueling fleet efficiency Trimble’s Brian Mulshine shares how fleets have used AI to build high-performance maintenance programs and predicts the top trends for 2026. FleetMaintenance.com/55332703

Remembering Paul Cigala: 1966-2025 Few, if any, better represented the “expert” part of Subject Matter Expert than Paul Cigala, who died Nov. 4 and was laid to rest on Nov. 11. FleetMaintenance.com/55329396

How to protect your SCR and secure your DEF in cold weather

When the temperature drops, fleets need to be ready to avoid issues caused by frozen DEF and cold SCR components. Some options include active heating elements and component insulation, plus a robust maintenance program. FleetMaintenance.com/55329898

Talking veteran issues with Nick Smith, a U.S. Marine turned International sensation

In this episode, Fleet Maintenance’s resident vet John Hitch sat down with International’s Nick Smith, a Marine who completed two tours in Iraq, to discuss the many benefits veterans bring to trucking, from leadership to grit, and how International sets its vets up for success. FleetMaintenance.com/55329288

The Fleet Lead podcast features EndeavorB2B’s CV journalists and aims to help fleet managers and trucking professionals navigate the industry. It covers topics like new technology, efficiency, and regulations with expert analysis and realworld insights.

When the terrain gets rough, Continental Truck Tires deliver. Our construction lineup is built to take on the most demanding conditions with the strength and reliability fleets count on.

Our Gen3 construction tires are engineered for mixed-service performance—offering superior traction, cut-and-chip resistance, and extended tread life to keep your trucks rolling through rock, mud, and everything in between.

From coast to coast, Continental helps build the roads, bridges, and cities that keep America moving.

Is your fleet’s maintenance program exceeding the competition or falling behind? You can find out with the right data and tools.

By John Hitch Editor-in-chief

“How much do you bench?” has long been a common question in certain testosterone-filled circles, a quick way to size up the competition’s strength and validate the person asking. This is not where the term “benchmark” came from, mind you. It dates back hundreds of years to how surveyors measured elevation. The term was popularized in the business world by Xerox, which wanted to copy—and surpass—the success of its Japanese rivals. Over there, continuous improvement was already ingrained into the culture, with kaizen practices and kanban boards that visualized progress, helping their auto manufacturers add efficiencies and reach new heights since the 1940s and ’50s.

Over time, benchmarking has become crucial to help fleets and shops grow in strength and maintain a competitive edge.

According to Samantha Thompson, vice president of customer success and fleet telematics at Penske Truck Leasing, 80% of transportation professionals rely on some version of benchmarking.

And in that spirit, we’ve made this entire issue about the data and analytics tools to help your operation grow. We start with a guide to help sort out what data and KPIs contribute to that cause (Pg. 8). Above all, the main lesson is ensuring the quest for improvement does not diminish safety.

Just under that, make sure the data translates to real-world improvement. Politicians may cherry-pick numbers to make themselves and their policies look better, but this industry doesn’t have that luxury. Every change-management initiative must be backed by evidence of what is and isn’t working.

“Any goals must be measurable and attainable in some way, otherwise you won’t see improvement,” efficiency expert Peter Cooper explained.

You can—and should—benchmark metrics such as technician efficiency, but not at the expense of doing the job the right way. For example, production lines at manufacturing facilities have used digital kanban screens for at least a decade to show real-time progress: green screens are good and red ones bad. But in a shop bay, where work rarely repeats the same way twice, that kind of pressure could encourage corner-cutting and inaccurate repairs. A slight bump to the bottom line is not worth the risk to your drivers.

That feature by Gregg Wartgow offers plenty of ways to safely measure and improve tech metrics, so give it a look. We also threw in some ways to help managers measure their own strengths and weaknesses, which could help as you set your 2026 resolutions. For some high-level benchmarking, for both your business and the overall industry, turn to our annual data report on Pg. 14, which compiles survey results from our audience and external research to provide a snapshot of both the equipment and shop trends shaping the industry.

We also must note that knowing where you stand among your peers from year to year could soon become antiquated. With the rapid adoption of AI, it won’t be long before every fleet can get all the benchmarking data they need minute to minute.

It already exists for Penske customers with the introduction of Catalyst AI, a benchmarking tool that combines the logistics and maintenance provider’s troves of fleet data with machine learning and data

analytics. Thompson showed it to me at the American Trucking Associations’ Management Conference & Exhibition, cycling through a sample fleet’s fuel efficiency and unplanned repair metrics, and how those stack up to comparable fleets.

“Catalyst AI is a decision engine behind the scenes that allows us to aggregate information across the data in our ecosystem to do a couple of cool things,” Thompson explained. “First and foremost, [Catalyst AI] identifies a unique fleet, applies a similarity score to that fleet, and then finds all the other fleets that look like it, and then does a comparison about performance.”

You can instantly gauge how you should be doing based on the standard means, and even likely root causes for why you are or are not excelling. The dashboard also color codes with red or green and assigns a numerical value. Think of it as your fleet’s GPA.

A user can also filter down to hub and individual asset performance and use the “Fantasy Fleet” option to check their fleet against the theoretical gold standard.

The patent-pending algorithm sorts for around 30 different data points and amalgamates those into a benchmark fleet. Those competitors are anonymized, so their identity is safe. Thompson said guessing a specific fleet from the data would be “equivalent to winning the lottery 32 times in a row.”

But you win every time, because you can easily identify core strengths and areas that might need to be bulked up. While it only exists for Penske, it’s hard to imagine their competitors won’t Xerox this continuous improvement tool. It’s likely that in a few short years, benchmarking tools will be as important for fleet managers as scan tools are for techs, alerting leadership to faults in operations and suggesting troubleshooting methods.

But that’s the future. And the important thing is to survive the next year, a feat made easier by not hiding from underperforming metrics.

“What gets measured gets improved, right?” Thompson offered. “Data and facts are stubborn things. Once you put it front and center, you can’t unsee it.”

Her advice for 2026?

“Start where you have the most pain or the most opportunity to gain, focus in on that, set some small but achievable goals, and then start chipping away at it,” she concluded.

Helping your maintenance department achieve higher standards starts with tracking the right KPIs.

By Gregg Wartgow

To

fi nd out if a fleet or shop's maintenance team is truly living up to its potential, there’s one critical thing management has to do, according to no-nonsense eciency consultant Peter Cooper.

“Shop leaders need to manage with facts, not feelings,” he asserted.

e former director of operations for Iowa-based Merx Truck & Trailer—and present CEO of Ascend Consulting —expounded on this maxim with the hypothetical employee “Technician Jim,” who he said “might be a great guy who shows up on time with a positive attitude, but he may also be the guy who takes three hours to do a one-hour job.”

On the fl ipside, imagine a tech who routinely beats standard repair times, but exudes toxic vibes that poison your shop culture.

In both cases, facts—not feelings—must guide your assessment of their value, and more importantly, how to train them up on the hard and so skills they lack.

And to do that, the best method is to focus on the key performance indicators that actually matter to your shop’s defi nition of success, not the ones that make you feel good.

Each shop has di erent priorities, but the KPIs that matter should lead to more uptime and profitability. But whatever area you want to improve, make sure you can capture and analyze the related data.

“Any goals must be measurable and attainable in some way, otherwise you won’t see improvement,” e ciency guru Cooper said.

Next, because this is a team e ort, you have to make sure everyone involved understands the full picture and how the data relates to success.

“It’s essential for fleet maintenance departments to understand what they’re measuring and why,” said Ernest Acevedo, fleet maintenance director at DPV Transportation, a specialty passenger transportation company based in Everett, Massachusetts. “I’ve honestly been in rooms with other fleets where someone says, ‘We’re this percentage in this certain area.’ Okay, so now what? How are you going to use that measurement to make your shop better?”

If they can’t answer, it just might be the sort of esoteric data that feels good to boast about to colleagues, but won’t sway your C-suite or lead to success. e top brass want proven results that bring in more revenue, and the facts explaining how that did or did not happen.

We also want that for you, so we canvassed several experts to fi nd out which KPIs will help you get your facts straight—and lead to a highly successful 2026. And that starts with a trio of technician metrics that serve as the engine for your shop health.

Before we get into the three KPIs, remember that although you want your technicians to service vehicles as quickly as possible, the quest for speed can’t come at the expense of accuracy and safety.

“As a company, our philosophy is that we’d rather take our time and get it right,” said Amanda Schuier, strategic maintenance director at Jetco Delivery, a Houston-based freight carrier. “So we never want to push our technicians too hard. On the other hand, we obviously don’t want people milking the clock.”

Schuier, who is also the immediate past chair of the Technology & Maintenance Council (TMC), pointed to TMC Recommended Practice RP 545, which can help fleets start the process of measuring technician performance. It goes beyond standard repair time and comprises three main metrics to accurately measure tech performance.

Direct vs. indirect labor compares a technician’s time spent working on vehicles to their time spent on non-vehicle-related tasks, like cleaning bays, performing maintenance on tools, and attending training. RP 545 recommends that a fleet’s indirect labor should never exceed 30% of total labor.

Steve Saltzgiver, lead strategic consultant at fleet management software provider RTA, agrees that 25-30% indirect labor is a fair amount of wiggle room to afford technicians. “You can’t

Most fleets have two overarching directives for their maintenance departments: keep vehicles safe on the road and maintenance costs under control. To that end, there are a handful of important KPIs fleet maintenance directors can keep an eye on to help gauge how their shop-level managers are doing.

Scheduled vs. unscheduled maintenance

“Trucks just showing up can be very disruptive to production flow and technician productivity,” said John Whittet, chief customer officer at Fullbay, a provider of fleet maintenance and shop management software. “Sometimes it’s a matter of the shop manager making sure PMs are getting done right and on time.”

RP 545 dictates that no more than 30% of total maintenance costs are derived from unscheduled PMs.

Maintenance resulting from DVIRs

RP 545 also advises that no more than 17% of a fleet’s total maintenance costs should result from things drivers report on their DVIR. If it’s more than 17%, the quality of the fleet’s PM inspections should be reviewed.

PM completion rate

As an extension of the above KPI, the percentage of PMs completed on time is key.

“Our goal is 98%,” said Wayne Skinner, senior

expect a technician to perform direct labor when they don’t even have a wrench in their hand,” Saltzgiver said.

Cooper said independent shops should be a little more ambitious in their quest for direct, billable labor.

“For a shop as a whole, 80% billable is a good goal. That said, I would never expect a lead technician to bill more than 75% of their clocked hours. That’s because they should be spending some time mentoring the shop’s more inexperienced technicians.”

But if your best tech is mentoring 40-50% of the time, you might be better off hiring a full-time trainer, because you could be leaving that or much more on the table through lost billable hours.

Labor productivity by job, which some refer to as technician efficiency, is equally important. It compares how long it takes a technician to perform a specific job to the standard repair time. RP 545 recommends a ratio of 0.9, meaning that the technician is slightly beating the SRT. For instance, completing a 3-hour brake job in 2.75 hours is a ratio of 0.9166 (2.75/3).

The lower that number, the more valuable your tech is. This metric is naturally incentivized with flat rate, but hourly shops could consider productivity bonuses to drive this down more (though don’t gamify without guardrails; make safety part of the equation).

vice president of fleet, maintenance, and procurement at Summit School Services, a provider of student transportation. “I don’t think 100% is realistic because there could always be a bus that was in an accident and is in a body shop when the PM comes due. Shop managers can’t do much about that.”

Aged work orders

Skinner also likes to keep an eye on work orders involving non-PM work, such as recalls. Any work order over 90 days is flagged because it should have been addressed during that vehicle’s 90-day PM cycle.

Summit School Services had a software program custom-built for this KPI. Drivers and technicians can flag vehicles as out of service for various reasons. Techs are also able to place vehicles back into service if they discover that a reported issue isn’t safety-critical. A dashboard is automatically updated every 15 minutes, allowing shop managers to take a quick view of what’s out of service and why. This near-instant visibility helps ensure that issues are resolved as quickly as possible.

RP 545 recommends that vehicle uptime should be at least 97%, essentially for 29 days in a 30-day month.

Summit School Services has made accidents and injuries its own KPI for shop managers.

Obviously, the goal is zero. Skinner said making this a KPI makes it clear that leadership is focused on safety, which keeps maintenance managers focused on it, too.

Another part of a maintenance manager’s job is to ensure that technicians are receiving the right training at the proper pace. Skinner said video-based training is now built into the company’s LMS (learning management system). “If technicians are behind on their training, that shop loses points on its KPI,” Skinner said.

Congratulatory badges

Summit's LMS also has functionality that allows managers to issue “congratulatory badges” when technicians and other employees deserve recognition. Skinner said each maintenance manager is required to issue a certain number each month. When someone falls behind, it’s highlighted on a dashboard within the fleet management software.

For the abovementioned KPIs, Skinner said they must be visible to everyone at all times in order to have their intended effect. “Nobody can be scrambling in the dark,” Skinner advised. “Our managers and teams are able to see how they’re performing, which enables them to fix their own destiny.”

Along those lines, tracking Repeat repair rate is absolutely vital to indicating the service quality you want. As Schuier touched on earlier, speed can’t come at the expense of accuracy. Tracking this KPI helps shine a spotlight on quality issues, which enables shop managers to intervene before things get out of hand.

“Repeat repairs, or comebacks, should never exceed 2% of the total repairs being done,” Saltzgiver said. “If a shop or certain technician is seeing more than 2%, there could be a serious problem.”

Once a maintenance director or shop owner has a way to record and measure all of these technician KPIs, is it simply a matter of looking at the data and deciding if "Technician Jim" gets a raise or gets shown the door? Not at all. While numbers are never supposed to lie, they can sometimes be misleading, failing to tell the whole truth.

“I was working with a shop owner who was concerned that a good technician’s direct labor had slipped down to around 60%,” Cooper said. “So I went to the shop one morning to observe. I noticed that the technician clocked in at 8 a.m., but then had to walk all the way across the shop floor, past six bays, to get to the service window. Then he had to stand there for at least 10 minutes while the service advisor was on the phone. By the time he was handed his first job and walked back to his bay, 20 minutes had flown by. That’s not the technician’s fault. That’s a problem with the process.”

Similarly, a technician’s low direct labor rate could be due to unorganized scheduling or parts management failures. “A technician can’t finish a PM on time if he has to wait for an oil filter to be delivered,” said John Whittet, chief customer officer at Fullbay, a provider of fleet maintenance and shop management software.

On the other hand, if a technician is constantly disorganized, outside smoking, or fiddling with their phone, that’s obviously a different story.

A low labor productivity (or technician efficiency) KPI could also be misleading. Cooper said the No. 1 goal is to make sure your shop’s SRTs are accurate and fair. Secondly, there could be unique circumstances causing a tech's actual time to exceed the standard repair time, such as having to deal

» Summit School Services says real-time out of service is one of several important KPIs to help measure shop manager performance.

We don’t ask for your trust, we earn it. Apollo guarantees the best cost per mile, or we pay the difference. Add in a 7-year warranty, 3 retreads, and road hazard coverage, and you’ve got the only tire brand that turns promises into paybacks.

with a lot of rust, road salt, seized hardware, etc. Finally, it’s the shop manager’s job to ensure that service advisors are doing a good job with their initial diagnosis, so techs aren’t set up to fail right out of the gate.

In other words, shop managers shouldn’t go blaming the technician until they’re able to put any given KPI into the proper context.

“ e job of the manager is to fi nd out the root cause of why a technician isn’t meeting their KPI goal,” Saltzgiver said. “Shop managers should be having one-on-ones with their technicians at least once a month, preferably every two weeks. en they can go through the metrics together and make sure everyone understands what’s really going on.”

Data-driven KPIs, as previously described, are an important part of measuring technician performance. But those metrics alone cannot be the measure of success.

“ Shop managers should be having one-on-ones with their technicians at least once a month, preferably every two weeks. Then they can go through the metrics together and make sure everyone understands what’s really going on. ”

Steve Saltzgiver, lead strategic consultant, RTA

And though Cooper went on about facts over feelings, he never said to completely ignore feelings. Some feelings, like employee attitude, can be measured and therefore quantifiably improved.

“Much like marketers use net promoter scores to measure how consumers feel about their brand, shops can measure how their technicians feel about their jobs and co-workers,” he explained.

To do so, he suggested managers send out quarterly surveys to techs asking if they receive enough support from leadership and if they get along with co-workers.

“ is type of data is more subjective, but provides valuable insights into how individual technicians and the shop as a whole are performing,” Cooper added.

Acevedo noted that a tech’s psychology is a big part of their overall value to a shop. is refers to behavioral traits like hustle, follow-through, and genuine care. Overachieving technicians are focused on productivity, but are also careful to avoid cutting corners. Overachievers treat drivers with respect and are pleasant to be around in the shop.

» If you are lucky enough to have an overachieving tech, you will notice they excel under the hood and face-to-face with colleagues and customers. To get all shop employees closer to that level, you will need the data to troubleshoot their deficiencies.

“ ose are the things that don’t show up in maintenance so ware,” Acevedo said. “A shop manager needs to observe how their technicians act in the shop. All you have to do is watch a person work to see if they care, are sloppy, or have no sense of urgency. ese things don’t show up on a time clock, but can cost a fleet dearly.”

As shop-level managers observe these traits and behaviors, Acevedo said their fi ndings should be documented in a technician’s personnel fi le. en, when the time comes to conduct an o cial performance review or simply have a one-on-one meeting, the information is there to be discussed. is helps keep everyone focused on meeting the set standards.

But shops must have clearly defi ned roles and expectations if they expect technicians to meet certain standards. What skills, trainings, certifications, and behaviors should a technician possess? Every shop must figure this out for itself—and communicate it to its technicians.

Schuier has been working on this very thing at Jetco Delivery. For a Level 1 technician, it’s about attitude and ambition as much as anything else.

“We want our Level 1s to have certain skills, of course,” Schuier said. “We also want them to show up on time, ask questions, gladly help clean the shop when asked, etc.”

As for a Level 2 technician, Schuier said measuring success depends on the situation. Some Level 2 technicians have no interest in rising to a management-type role. at’s okay. “Here I like to fi nd other ways of challenging and motivating them,” Schuier related. “Maybe they would like to attend some training on electrical or diagnostics so they can help with more complex jobs that a Level 3 technician would do. On the other hand, they might be content just doing what they’re doing, even if it’s just PM-related work. at’s okay too, as long as they’re doing a good job with a good attitude.”

As for the most experienced Level 3 technicians, Schuier wants them to help build Jetco’s culture of growing from within.

“I’m looking for technicians who provide leadership and have others look up to them,” Schuier said. “I’m also looking for an attitude where they’re able to see the bigger picture and are willing to stay late to fi nish a job, for example. ey should also be good at maintaining excellent communication with our operations team.”

In other words, Schuier likes to see her experienced technicians begin exhibiting the qualities of a good shop manager. at way, she knows when these technicians are ready to rise from generating KPIs to analyzing them, making their shop a more e cient, productive place.

Shop managers have plenty of concrete KPIs to meet to succeed at their job. But what about some of the “nonquantifiable” traits a good maintenance manager needs to possess? How can fleets gain visibility into that? A good place to start is by asking the technicians being managed, as long as their feedback is honest and accurate.

“Technicians are a unique bunch of people in that they hate to badmouth their bosses,” said Ernest Acevedo, fleet maintenance director at DPV Transportation, a specialty passenger transportation company. “At the same time, fleet maintenance directors need their technicians to respect their shop leaders. Maintenance directors have to find a way to encourage honest feedback from those technicians.”

Amanda Schuier, strategic maintenance director at Jetco Delivery, has found a way to do that. “We’ve begun doing what we call 360-degree reviews for our managers,” she said.

What is a 360-degree review? Each manager is reviewed by their shop team. To help ensure open and honest feedback, Jetco uses a platform that anonymizes responses. And Schuier and the president of the company attend one of the shop’s huddle meetings prior to a 360-degree review process getting started. They stress how vital technician feedback is when trying to accurately assess manager performance.

if three technicians said the shop manager has a bad attitude every other morning, that’s something we can address privately with the shop manager to fix what might need fixing.”

That’s the entire purpose of KPIs in general—to measure performance and identify what needs fixing. That goes for the hard data a software platform can provide as well as observational data that

helps provide deeper insights into an employee’s behaviors and characteristics. When it all comes together, that’s when fleets can truly understand how their maintenance teams are performing.

“We did our first 360-degree of a manager earlier this year and got 100% participation from the technicians,” Schuier said. “We look for themes in the feedback. For example,

Find out with our maintenance benchmarking survey results.

By John Hitch, Alex Keenan and Lucas Roberto

e live in a world where we are told only the data matters. And we entrust machines to gather it all for us. From the pedometer you wear to discern if you have traveled enough steps that day to the accelerometers on your trucks that warn if your drivers are going too fast or stopping too abruptly. Soon we may even measure how fast technicians turn wrenches. You can fall down a rabbit hole chasing all the numbers, but that data is only part of managing a fleet or shop. You also need to know how your company compares to the rest of the industry—if your decisions and leadership put you ahead of the curve or behind the pack.

To help you on this journey of self-discovery, we’ve compiled equipment and shop data taken from our own survey, as well as several industry sources. Unlike in the Matrix, we suggest you ingest both the red (equipment) and blue (shop) data. But similar to Morpheus, our intention is to o er the truth—no more. What you do with it is up to you.

2023:

2024:

2025:

2026:

OEM

What alt-fuels are you using or considering for the next three years?

How have the recent policy changes by the EPA to reduce trucking-related regulations impacted your business?

We will continue with ICE only/not invest in

or

Our business will continue to explore different “green” options due to corporate sustainability goals

Do you agree with EPA’s proposal to update engine software to eliminate power loss due to diesel exhaust fluid issues?

FOR BETTER ERGONOMICS**

Equalization System

Failsafe mechanical system delivers equal lifting and a stable, level vehicle for operators.

Extended Height

The extended-height top beam on 192 models provides greater clearance.

Hydraulic Cylinders

Dual-drive hydraulic cylinders deliver smooth operation and rise higher than those in comparable lifts.

UHMW Polyethylene Load Bearings

Evenly distribute radial and axial forces during operation.

Column Safety Locks Placed every four inches in the columns and engage automatically when lifting.

Safety Lock Failsafe mechanisms secure the lifting carriages and arm assemblies during operation.

A versatile choice for mixed fleets, BendPak’s new 16AP and 20AP Series super-duty two-post lifts easily take on Class 1 through 5 vehicles, from passenger cars to commercial trucks and vans. They reach further, lift higher and deliver greater stability than other lifts, all while protecting technicians with unmatched safety systems and ergonomics. With fewer moving parts, they’re easier to maintain, less prone to wear, and more cost-effective to operate. Maximize your uptime and efficiency with BendPak’s super-duty lifts — delivering superior performance and unmatched value. To learn more or to shop now, visit bendpak.com or call us at 1-800-253-2363

Multi-face Metal Columns Innovative design better withstands twisting and biaxial loading forces to minimize movement for greater stability.

Lift Dampener

Precision controls allow operators to manage descent speed.

Large

A customer health audit by Velociti found in one fleet 500 out of its 3,000 total dash cam systems, or 16.7%, were non-functioning.

Using 2021-2024 data, Velociti also found 20% of a fleet’s on-board technology will fail annually

135

Source: Marathon Strategies

Hiring techs was the top issue for shops (61%) and second biggest issue for fleets (48%), according to Noregon Research's 2025 Survey.

65% of shops surveyed by ATRI said they were understaffed. Those shops had a 18% turnover rate, while fully staffed shops reported a 7.8% rate.

Source: Addressing the Shortage of Qualified Diesel Technicians” 2025 report

Almost two-thirds of techs surveyed by WrenchWay reported that they would NOT recommend the industry to a friend.

All 11 of technicians we asked at TMCSuperTech 2025 said they would recommend the industry.

2023 Postsecondary diesel completions: 11,310 total

7,646 graduated from 307 public schools/institutions

3,664 graduated from 44 private schools/institutions

Source: IPEDS database

Shops reported one-third of graduates were unqualified in 20 core skill areas.

94% of techs surveyed by FM in July were in favor of a 4-day work week. 27% said they had implemented it and it was successful. 6% said they tried and went back to five days.

Over half of shops/ managers surveyed offer technician training at least once a month.

The 11 TMCSuperTech competitors we surveyed said they have mentored or are currently mentoring, and all agreed that it was a rewarding experience.

Only 26% of diesel techs agreed their shop does a good job of teaching new techs and compensating mentors, down from 41% in the previous year.

Are you

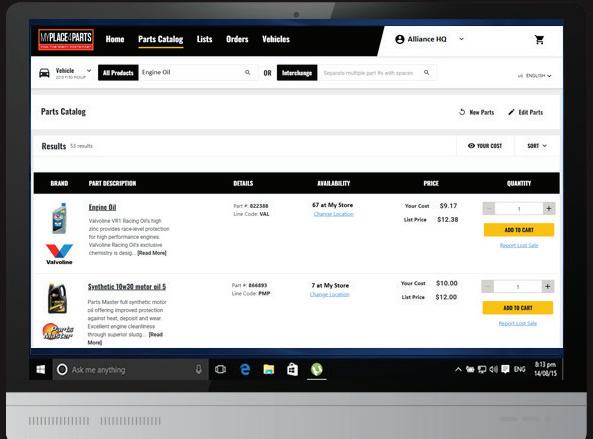

In Noregon Research's 2025 Survey, 54% of fleets cited accurate and effective troubleshooting/diagnostics as their top issue.

Professional Power in Your Hands

“Access to live data, tests and calibrations for all makes of engines, transmissions, brakes and body control systems is critical today with everything being electronic. The comprehensive coverage and ability to go from code to diagnostic procedure, component location and wiring diagram make PRO-LINK+ the best diagnostic system I’ve ever used.”

Frankie Mendoza

Owner

Frankie’s Truck Repair Nogales, AZ

Shops have plenty of options when it comes to AI tools, from speeding data entry to troubleshooting.

By Seth Skydel

Artificial Intelligence is no longer a concept or a technology for the future. It’s being used across the transportation industry right now, with plenty of solid maintenance use cases to boost shops’ eciency quotient. From predictive maintenance and troubleshooting to budgeting and record-keeping, AI is rapidly improving how fast trucks and trailers are serviced and repairs are managed.

AI is a broad term, and many applications fall under the subset of machine learning. But even in these nascent cases, the data on AI’s transformative e ect is compelling—while future iterations that could take over shop management are both exhilarating and terrifying.

Either way, the technology demands a closer look, so here are some of the primary areas where AI is making its mark.

Today’s predictive maintenance tools, based on historical and real-time repair data, focus on providing more profitability and uptime, identifying which assets, systems, and components are likely to fail and when.

“Fleets and service shops using these tools already see time savings through automated uploads of service records that extract asset details, repair types, and costs from any format,” noted Brianna Perry, product marketing manager at Fleetio. “Beyond convenience, richer data becomes the foundation for smarter service practices.”

At the heart of these AI systems is the ability to

merge telematics, service histories, and diagnostic and inspection results to deliver more complete repair recommendations before issues become expensive breakdowns. But they stop short of prescribing next steps, Perry said.

“ e next generation of AI tools will go further by interpreting unstructured data like scanned invoices or technician notes to pinpoint why failures occur,” she added.

AI models can also analyze fault codes and identify issues before they cause downtime, leading to the opportunity to fi x them before they happen, explained Paul Maida, sr. product manager at Geotab.

For example, Geotab’s predictive measurement tool Electrical System Rating (ESR) scores the health of a vehicle’s electrical system on a scale from 0 to 100 every day, and assigns a value of Good, Fair, Caution, or Poor to predict potential battery failures. is allows managers to proactively schedule maintenance or repair. Geotab said one fleet reported a 28% reduction in on-road battery replacements using ESR.

In traditional workfl ows, much of the repair process is bogged down by the need to create, review, and authorize repair orders. AI is streamlining these tasks by digitizing and interpreting service documents automatically.

Trimble’s Brian Mulshine, senior director of

We’re

product management, is spearheading two AI initiatives that illustrate this shi . e fi rst, Advanced Road Call, is an AI chatbot that gathers basic information, codes the issue (using VMRS System codes such as a 017 for tires), and can integrate the information, including vehicle location, into a live agent’s workflow.

“Large carriers can have thousands of road call events monthly,” Mulshine said. “Our AI chatbots retrieve critical information and fi nd the nearest approved vendor automatically, reducing administrative work and getting the driver back on the road faster.”

Trimble’s second project, an invoice-scanning AI solution, eliminates the manual entry of outside repair invoices into the TMT Fleet Maintenance and TMT Service Provider systems. is eliminates data entry errors and greatly enhances the accuracy of cost reporting and warranty tracking, he said.

“Fleets spend countless hours entering invoice data for outside repairs,” Mulshine said. “With AI, you can drag a multi-page invoice into the system, and it automatically captures totals, vendor names, VINs, unit numbers, parts, and labor. e system can even interpret handwritten invoices.”

e bigger the fl eet, the larger the gains. Mulshine posited that a fleet with 3,000 tractors—each averaging four service events annually—and 12,000 trailers with two events per unit totals 36,000 total shop visits per year. Figuring that 30% are outsourced, this means a fleet processes 46 external vendor invoices a day.

“Capturing this data is time consuming or all data is not captured; each invoice takes about fi ve to six minutes each,” said Mulshine, who added automating the process improves on that time by 80%.

Of all the AI use case low-hanging fruit, diagnostics is arguably dangling on the bottom branch. Traditional fault code analysis provides limited insight, requiring technicians to manually interpret issues in context. AI can now combine

that data with historical repairs, vehicle usage, and other conditions to suggest root causes, as well as perform fault code analysis and use machine learning to identify risks and trends. AI-enabled diag tools can also forecast when components and systems will likely fail.

Geotab Ace, the company’s generative AI chatbot, takes it further by allowing users to query real-time fault code data in plain language. “We’re fi nding new ways to use AI to summarize and consolidate diagnostic data,” Maida said. “ e key is to keep humans in the loop. e system can rank the top fault codes by severity, but a technician still reviews them before making the fi nal call.”

Opus IVS is also pioneering diagnostic intelligence with its Blueprint Copilot, an AI-enhanced repair planning assistant built on the company’s ADAS MAP platform. “For the fi rst time, shops can generate repair blueprints that account for complex vehicle systems,” said Frank Terlep, VP of ADAS Solutions at Opus IVS. “It ensures safe, profitable, and correct repairs.”

Brian Herron, CEO of Opus IVS, added, “Our vision is to simplify complex vehicle repair with AI that assists, not replaces, technicians.”

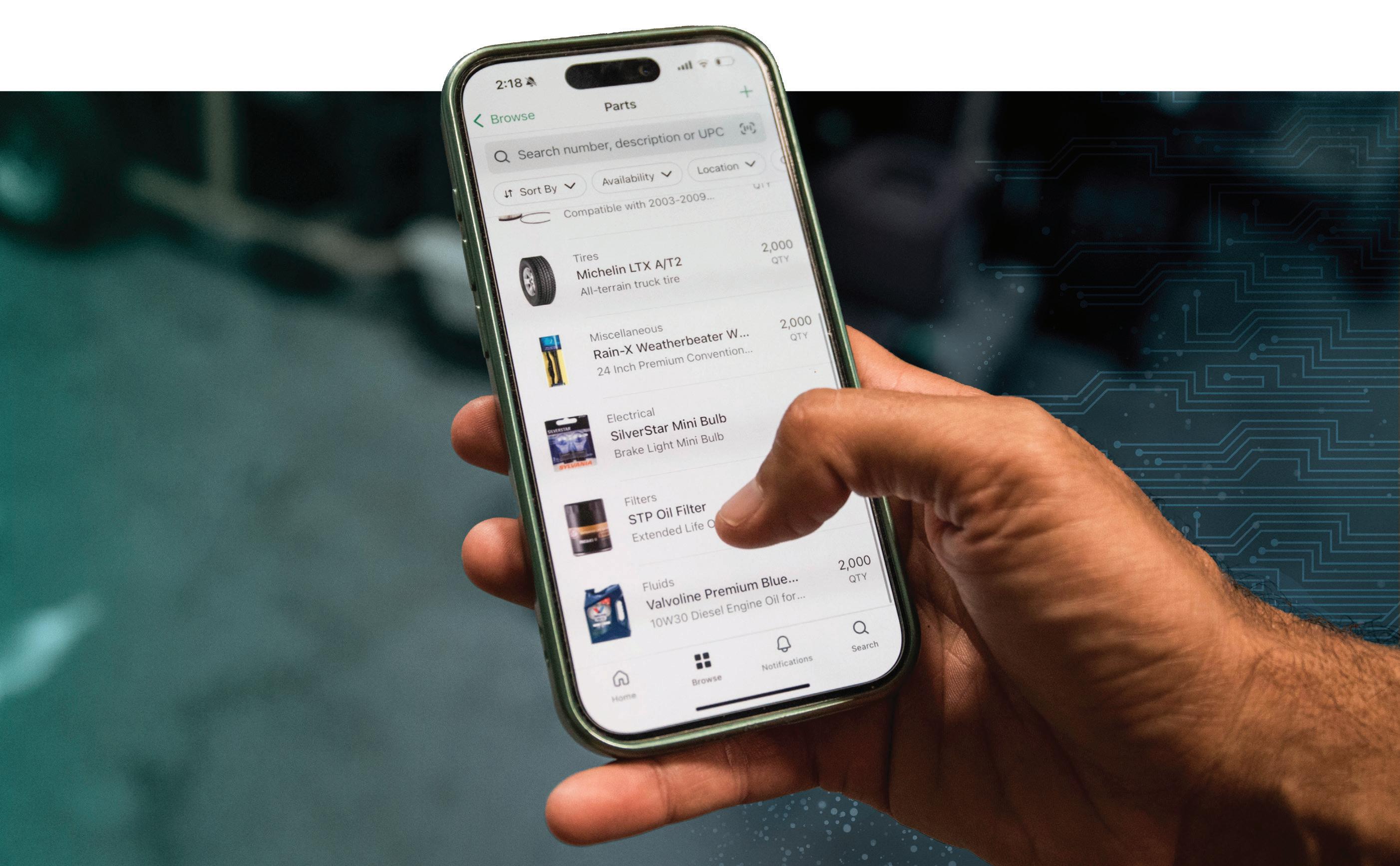

AI’s role in parts inventory management is quickly becoming one of the most practical benefits for maintenance operations. The same insights used to manage repairs can anticipate parts needs.

“Over time, AI insights will feed inventory models that adjust stocking levels automatically,” Fleetio’s Perry said. “ e shop still makes the call, but AI keeps the shelves and workflows one step ahead.”

As AI learns from past repairs, it can forecast demand for fi lters, sensors, or components associated with specific fault codes or maintenance intervals. By linking telematics data to parts usage, AI ensures that critical components are available before they’re needed, eliminating delays waiting for shipments and the cost of emergency sourcing.

For shops managing hundreds of part numbers

and multiple vendors, AI-driven automated inventory forecasting is not just a convenience— it’s a strategic advantage that helps prevent downtime and keeps technicians productive.

As experienced technicians retire, the knowledge gap widens. AI o ers a way to capture and replicate the best practices of veteran techs across entire organizations.

“ e shortage of qualified technicians in shops has been a serious challenge for years,” Pitstop CEO Shiva Bhradwaj said. “AI can help address that core problem.”

Bhardwaj likens AI to a digital mentor that can “guide a technician step-by-step through diagnostics and repairs,” he said. “It o ers entrenched knowledge, mimicking a human mentor but at a much faster pace. Each job becomes part of a continuous learning process. at’s how you build e ciency across every bay.”

e Pitstop fleet management platform deploys AI agents to put this in practice. Features include:

Ü Mechanic Assistant to leverage diagnostics and sensor data to pinpoint root causes, guide repair decisions, and predict failures.

Ü Data Entry Assistant uploads documents in minutes.

Ü Maintenance Optimizer tracks PM e ectiveness by analyzing service visits and enables more e ective maintenance strategies.

Ü Analytics AI delivers actionable reports on costs, parts, and vehicle availability.

Bhardwaj said Pitstop’s AI has a 95%+ accuracy rate. e technology also reduces complex vocational fleets’ downtime (measured as unplanned repeat service visits) by 74% on average. e platform also improves time to repair by 30% because of vehicle repair insights gleaned prior to intake, allowing for higher throughput.

Maintenance budgeting has traditionally relied on spreadsheets and historical averages. AI is turning that process into a dynamic, data-driven exercise.

Motive’s AI Answers platform shows how large language models can revolutionize fl eet analytics. e tool allows managers to ask plain-language questions such as, “What was our average vehicle downtime last month?” and receive instant visualizations drawn from maintenance, safety, and fuel datasets.

“Something that used to take months to put together is now something we can do instantly,” said Michael O’Neil, project manager at Reliable Carriers, an auto hauler using the solution.

“ ere’s no longer that pain point of having to dig through spreadsheets. Anybody can access and understand the data.”

Hemant Banavar, chief product officer at Motive, added, “Truck service operations need fast, actionable insights but static reports and hard-to-reach data across disconnected tools make that nearly impossible. AI Answers delivers those insights instantly, so data isn’t a bottleneck.”

By eliminating manual data searches, Motive said AI Answers allows fleets to act faster on key insights, improving productivity and operational e ciency. For shops managing multiple systems and datasets, it o ers a simpler, unified way to keep both performance metrics and maintenance decisions aligned.

While AI adoption is growing, in a multi-national and multi-cultural industry like trucking, that o en comes with the need to translate documents, notes, video and audio fi les, and other information. Smartcat, a provider of AI enterprise translation so ware, is already seeing results in the automotive market, where it is providing AI translation, AI voice-over, AI dubbing, instantaneous subtitle translation, and more, in any language.

“ e impact of AI translation on speed is substantial,” said Alex Conza, senior strategic marketing manager at Smartcat. “A welltrained workforce is essential for efficiency and product understanding. Localizing technical

documents, user manuals, and industry-specific eLearning is critical. AI translation and localization platforms make this process faster and more cost-e ective.”

Each of these AI innovations points toward a more connected and autonomous future for fleet maintenance operations.

Current and developing technologies connect systems, automate workflows, and ensure information flows where it’s needed most.

At its core, AI is about enabling people in truck and trailer service operations to do what they do best—solving problems, making informed decisions, and keeping trucks moving.

e coming years will defi ne how deeply these systems reshape shop operations. But one thing is clear: the era of the AI-powered shop is here.

LAS VEGAS—In November, we walked through nearly all of AAPEX’s 560,000 sq. ft. of exhibit space, and a fair amount of the SEMA Show’s 4.6 million sq. ft. Here’s a few of the interesting people and products we saw at the world’s largest automotive aftermarket event, with more coverage on the way in 2026.

» Clarios, fresh off the launch of its Battery Manager health monitoring software, was at AAPEX with a custom Pac-Man style video game where a truck gobbles up batteries for a power boost.

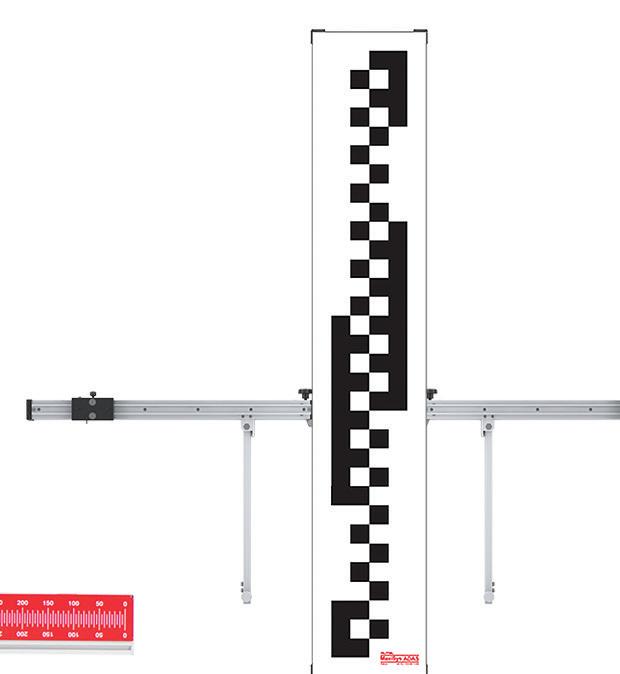

» Rotary displayed its XA14 Alignment

Lift, which has a 14,000-lb. capacity, is 34% more narrow than four-post lifts, and provides a larger area for techs to operate.

» Come to Fullbay’s Whac-a-Mole game to win a stuffed animal and stay for a demo of its platform’s AI-powered Service Orders, which automatically cleans up unclear text, captures hands-free dictation, and speeds up approval time.

» M-tek drew attention to its custom spray booths for cars and trucks with this immaculate 1965 Chevy Corvette Stingray.

» After 15,000 miles, carbon builds up on the GDI valve, slowly diminishing your engine’s combustion efficiency and power. BG Products’ Platinum Service introduces chemicals to clean the valve and restore performance. In addition, BG’s Rev-It tool attaches to the wheel and pedal, using shop air to rev the engine every 45 seconds to ensure proper flow without tech intervention.

» LocknLube showed off its X Series grease pumps, which run on shop air, fit up to 55-gal. drums, and cut greasing time by 40% (bottom left). The company will also release four new inflator gauges in 2026, including a preset inflator perfect to use with tire cages (top right).

Fleets can fine-tune their

oil

drain intervals and better manage their assets with oil diagnostic data, but only if they’re willing to listen.

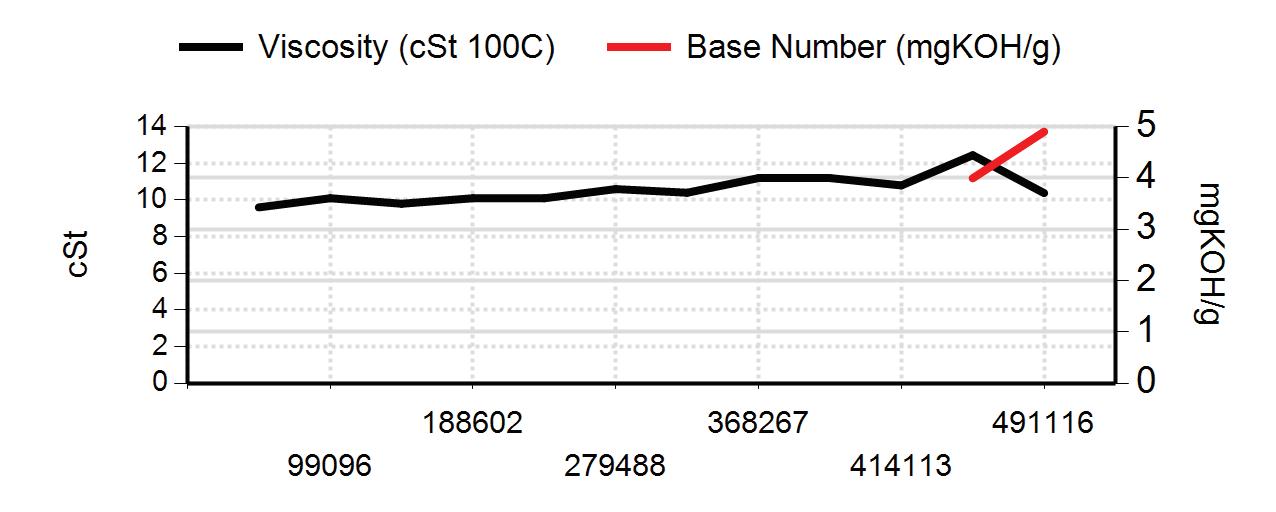

In the world of fleet maintenance, data has become one of the most valuable tools in driving both performance and profitability. One of the most impactful—but often underutilized— sources of that data is oil analysis. As a lubrication expert, I’ve seen firsthand how diagnostic oil data transforms fleet operations by replacing outdated mileage-based oil change inter-

By Brandon Thompson PRODUCT MARKETING MANAGER, LUBRICANTS, CITGO PETROLEUM CORPORATION

Brandon Thompson is the product marketing manager, Lubricants at CITGO Petroleum Corporation. With 19 years of experience across lab operations, product development, and compliance, he is passionate about driving success for CITGO’s brands while leveraging his deep expertise in the lubricants industry. He holds a Bachelor of Science in Chemistry from Xavier University of Louisiana and a master’s in public health from A.T. Still University.

vals with condition-based strategies rooted in real engine health.

The result? Fleets gain better control over maintenance planning, reduce unnecessary service costs, and avoid catastrophic failures— all by listening to what the oil is telling us.

Engine oil is much like the blood in our bodies—when tested, it reveals vital information about overall health. In engines, that means insights into wear, contamination, and the overall health of the system.

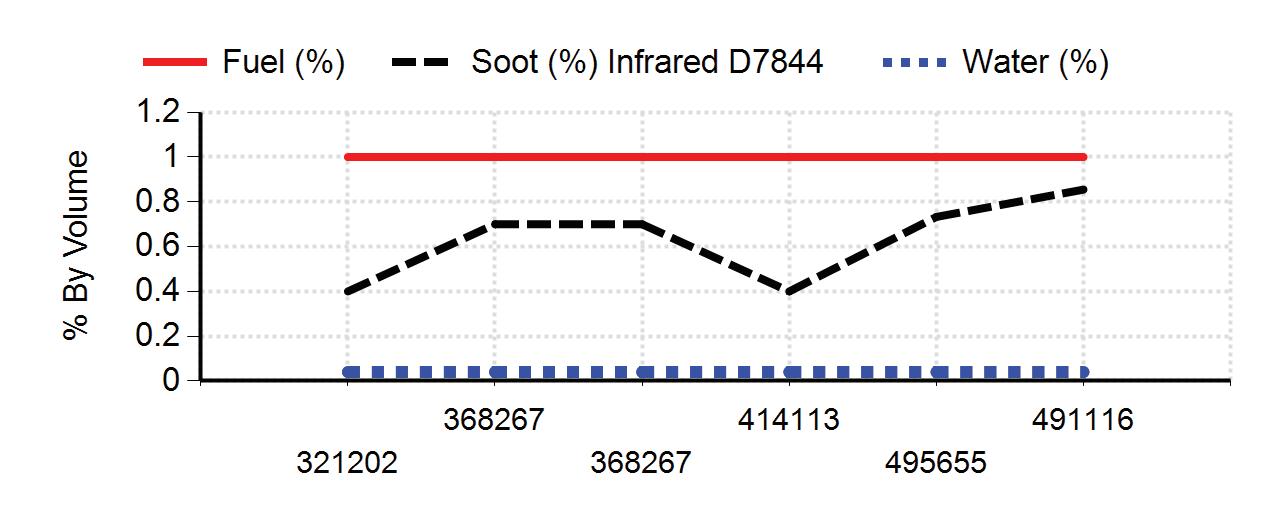

For years, fleets have relied on fixed oil schedules, the good-old “every X miles” approach. While this approach is simple, it doesn’t account for real-world variables like load weight, driving conditions and habits, fuel quality, or engine type. Two trucks might travel the same distance, and yet their oil conditions can greatly differ based on how and where they operate.

That’s where oil analysis comes in. By shifting to a condition-based interval approach, oil changes are guided by actual oil health— not just mileage. This allows fleets to safely extend oil intervals, reduce unnecessary maintenance (scheduling smarter, not harder), and make more informed and cost-effective decisions.

Of all the benefits oil analysis brings to fleets, the ability to safely extend drain intervals (ODIs) has the biggest operational impact. Understanding the true condition of the oil allows teams to determine the optimum drain interval—one that maximizes oil life without risking engine damage. This directly translates to cost saving by reducing oil change frequency, labor time, and downtime. And when every mile matters, extending ODIs is a clear win.

From a fleet perspective, the shift to oil diagnostic data brings multiple benefits:

Ü Reduced downtime

Ü Labor savings

Ü Trend-based adjustments

Ü Improved cost efficiency across the fleet.

New to oil diagnostics? No problem. Getting started with oil analysis is simpler than many believe. Here’s how:

Ü Register all tracked equipment with your lab’s system.

Ü Submit a sample of unused oil to establish baseline reference values.

Ü Begin sampling at regular intervals, compare results, and make data-informed decisions. Just a few samples can often reveal early issues or confirm oil quality, turning a skeptic into a true believer.

Here’s how I recommend fleets approach oil sampling and diagnostics:

Ü Start with OEM or Oil Supplier Guidelines as your baseline.

Ü For your initial sampling, always take a sample of new oil to establish a clean reference point. Follow that with a sample at the normal drain interval.

Ü Then adjust your ODIs based on trends. If results are stable, extend oil change intervals by 5–10% and keep monitoring. If results show issues (like metal spikes or contamination), shorten the next interval until the issue is resolved.

Ü Many fleets test every oil change. For high-value or high-mileage assets, a mid-interval sample can provide early warnings.

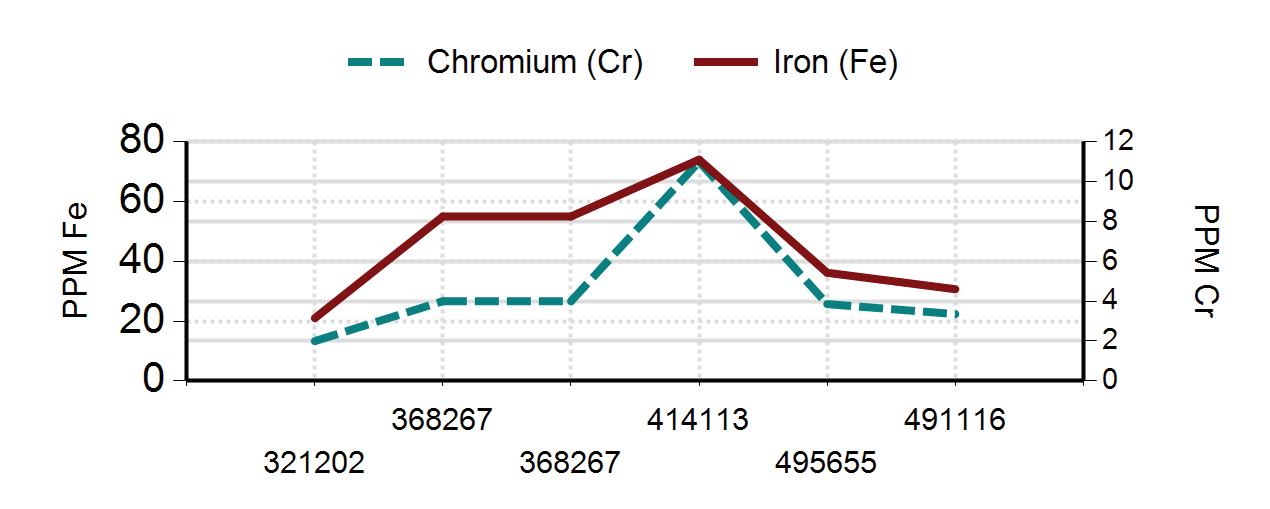

To make the most of their oil analysis, fleets and technicians should watch for the following warning signs in oil analysis reports:

» To start an engine sample program, fleets send in a sample of unused oil for benchmarking. Then they can look for changes like fuel dilution or metal spikes.

Ü Coolant intrusion: Sodium, potassium, and water content suggest a possible head gasket or cooler leak.

Ü Fuel dilution: A drop in viscosity may mean unburned fuel is entering the crankcase.

Ü High soot/oxidation: Oil thickening points to potential sludge or deposit formation.

Ü Metal spikes:

• Iron + Chromium = piston ring or cylinder wear

• Copper = bearing or cooler issues

• Aluminum + Iron = piston scuffing These issues, when fleets catch them early, can prevent serious and costly engine damage.

While basic oil reports are valuable, modern fluid condition monitoring services are being used for predictive and preventative equipment maintenance. State-of-the-art tools, like CITGO LubeAlert, are used for predictive and preventative equipment maintenance. These fluid condition monitoring services are used for predictive and preventative equipment maintenance and help elevate data into an integrated maintenance solution by:

Ü Detecting early signs of wear, fuel dilution, or coolant leaks

Ü Tracking trends to extend drain intervals or flag issues sooner

Ü Prioritizing repairs with clear severity ratings

Ü Automating work orders via system integration

Ü Measuring ROI through reduced downtime and oil use

There is no way around it: Oil diagnostic data has become an essential part of modern fleet management. It offers fleets more than just a

snapshot of engine health – it provides a pathway to safer, smarter, and more sustainable maintenance. From extending oil drain intervals to catching wear before it becomes failure, oil analysis empowers fleets to make proactive decisions grounded on real data. Whether you’re just starting your oil analysis journey or looking to get more value from your program, just let the oil do the talking—and make sure you listen closely.

REESE ’s 16K fifth wheel hitches mount to in-bed rails and are rated up to 16,000 lbs. towing capacity and up to 4,000 lbs. pin weight capacity. The hitch’s dual jaw locking system completely surrounds the kingpin for significantly reduced wear, while side-to-side pivot action better accommodates hook-ups on uneven ground. Built with wide-stance one-piece legs, the hitches are easy to remove when done towing, providing full access to the bed of the truck.

For more information visit FleetMaintenance.com/55329851

Lytx ’s Dynamic Risk suite of monitoring features combines data from real-time machine vision and AI-powered road imagery with environmental sensors and National Oceanic and Atmospheric Administration (NOAA) weather data to help fleets prepare for hazards on the road. Using these tools, Dynamic Risk automatically tags road events with weather such as low visibility, snowy roads, wet roads, and more. The system also includes features such as Pedestrian Detection, which lets drivers know when a pedestrian is in their path, and will eventually include a Dynamic Risk Index for driver coaching and In-Cab Weather alerts.

For more information visit FleetMaintenance.com/55329599

Netradyne ’s Driver•i D-810 is a 360-degree fleet safety and performance platform that combines edge-based AI processing with up to eight cameras for full vehicle visibility. The system captures activity around the cab, sides, rear, and trailer, helping reduce blind spots and collisions while supporting in-cab alerts and real-time driver coaching. Its on-device intelligence enables instant analysis and continuous operation without depending on the cloud, improving reliability and data security even in low-connectivity areas. Compact windshield cameras and an optional in-cab display also enhance driver awareness, while managers gain searchable video and insights to streamline investigations, reinforce safety culture, and reduce operational costs.

For more information visit FleetMaintenance.com/55329011

Eberspaecher ’s Coolant Heater is a compact and powerful alternative to PTC technology, according to the company. It features a thick film element (TFE), which applies to a metal plate through a screen-printing process, providing a high heat output with a smaller installation footprint. The 800-volt system achieves up to 12 kW of output and delivers enough output even at 400 volts. For added safety, the coolant heater features multiple sensors and an independently operating second shutdown path. The heater works for passenger cars and trucks, and will begin production in 2027.

For more information visit FleetMaintenance.com/55328665

Bosch Mobility Aftermarket has expanded its heavy-duty portfolio with the HCV Air-Disc Brake Pads , designed for Classes 6–8 vehicles. Engineered to deliver OE-level friction stability and reduced rotor wear, the pads are available in two segments: Long Haul, for tractor-trailer applications, and Severe Service HD, optimized for refuse, bus, and other high-heat operations. Each kit includes four pads and a hardware set, offering a complete brake job solution. Tested to meet FMVSS 121, the pads provide consistent performance across varying loads, temperatures, and driving conditions.

For more information visit FleetMaintenance.com/55329538

The Tractor AeroKit with Flex Fairing from FlowBelow features flexible wheel fairings that can return to their original shape after impact, a redesigned rear fairing, and a lighter dynamic center fairing. All are built from aluminum to decrease weight and increase corrosion resistance. It also includes telescoping center mounting bars to make it easier to reach the fifth wheel, remove fairings, and install chains. More easily transferable from one truck to another, the flexible fairings and lowered rear hanger option let fleets that pull pups or intermodal containers use this aero kit. Comes with a fiveyear, 500,000-mile warranty.

The Stainless-Steel Rear Hitch , No. X7506S, from Torklift is designed for the 2022–2026 Ford F-150 Lightning with Rear Lift Gate. The rear hitch is custom-engineered for the electric truck and includes a stainless-steel receiver designed to resist corrosion and floor stains. The hitch also has a 10,000lb. towing capacity and a 1,000-lb. tongue weight rating at the trailer ball, and can be bolted on to the truck. Durable and designed not to interfere with lift gate hardware, the hitch is ideal for contractors, fleet vehicles, and work-ready electric trucks, according to the company.

For more information visit FleetMaintenance.com/55323046

For more information visit FleetMaintenance.com/55323559

Prestone ’s EVX line of electrified vehicle thermal management fluids is engineered for both light- and heavy-duty EVs, offering low electrical conductivity, corrosion resistance, and stability under high-voltage conditions. Tested to meet accelerated global standards, including China’s GB29743.2 and ASTM D8566, the fluids help OEMs ensure safety, compliance, and performance. Available in phosphate-, silicate-, and non-ionic formulations, the EVX fluids are designed for battery-electric applications, fuel cell vehicles, and more.

For more information visit FleetMaintenance.com/55329170

increased cycle life for CVs

The ODYSSEY Evolution ODV31 battery from EnerSys features AGM2 technology and Absorbed Glass Mat (AGM) power with Thin Plate Pure Lead (TPPL) technology. Providing over 650 charge/recharge cycles, the battery is designed for mediumto heavy-duty trucks with hotel loads, EAPUs, or other equipment. The ODV31 offers up to a 10-year service life and works with the ODYSSEY Connect battery monitoring system.

For more information visit FleetMaintenance.com/55324856

give fleets reliable comfort and efficiency on every route. Airtronic air heaters keep cabs and bunks warm without idling, lowering fuel use and boosting driver comfort, while Hydronic water heaters prewarm engines for faster starts, less wear, and reduced emissions. Together, they deliver dependable performance that keeps trucks and crews moving in any climate.

OTR ’s AI-powered TreadIQ platform allows OTR’s engineers to input customer preferences for tread styling and performance, and then the system will generate functional 3D tire concepts, according to the company. Along with the 3D model, TreadIQ also creates trade-off analyses to allow performance comparisons between various tread patterns, and assess traction, ride quality, handling, and other tire characteristics. Plus, customers can see how their branding fits on tire models in real time.

For more information visit FleetMaintenance.com/55329472

Kooner Fleet Management Solutions FleetIQ platform combines predictive analytics, automation, and real-time communication to give fleets a unified view of vehicle health and maintenance operations. Designed for both back-office and on-the-road use, FleetIQ uses component-level predictive maintenance to anticipate failures, automates technician dispatch and routing, and integrates with ERP, CRM, and telematics systems for streamlined workflow management. The mobile-first interface supports technicians in the field while improving visibility for fleet managers.

For more information visit FleetMaintenance.com/55329005

The SPARQ AI Diagnostics System is a plug-in OBD-II device integrated with an AI-driven mobile app, designed to deliver diagnostic insights and vehicle health monitoring. It scans over 50,000 generic and OEM-specific fault codes across engine, transmission, electrical, drivetrain, suspension, braking, and tire systems. Technicians can use it to identify and prioritize maintenance issues, track service history, and plan for upcoming repairs. The system also enables remote data capture and real-time health scores. SPARQ is available through a one-time purchase model with no subscription fees.

For more information visit FleetMaintenance.com/55329847

Motive ’s AI Dashcam looks for high-risk behavior and sends in-cab alerts to drivers to help them adjust in real time. It comes with AI detection models that look for unsafe driving actions such as distraction or phone usage, and then provides both audio and visual dash cam alerts to the driver. The camera records at 30 fps, with a 150-degree field of view on the road-facing side and 180 degrees on the driver-facing side. The camera can also capture HD video even when the engine is off or power is lost due to loose cables, and stores footage from the last 55-230 hours. Up to 60 minutes of HD footage is available with every request.

For more information visit FleetMaintenance.com/55312729

Transtex ’s EDGE CABFLEX is a patent-pending aerodynamic cab extender fairing designed to replace OEM cab extenders. Weighing 70 lbs., the fairing is light, durable, hinge-free, and built to reduce the damage caused by jackknifing while minimizing downtime and operational costs, the company said. Additional features include strong turning angles, same-point OEM replacement, reinforcement from thermoplastic and stainless-steel materials, and customizable wrap options.

For more information visit FleetMaintenance.com/55329846

The ARI-hetra 36,000-lb. BatteryPowered Wireless Mobile Column Lift System is designed to deliver precise, synchronized lifting through its ball-screw technology. The hydraulic-free design means no fluids, seals, or leaks, according to the company. It is fully selfpowered with four deep-cycle batteries per column for long-lasting performance and quick 110V charging from any standard outlet. Its compact, slim design is intended to enhance maneuverability, positioning, and visibility around vehicles, making it ideal for tight service bays. Additional features include continuous mechanical locking and redundant safety systems, as well as compatibility with adjustable carriages and cab-off adapters. This lift is ALI-certified.

For more information visit FleetMaintenance.com/55324857

Adding coverage for MY2026 vehicles

Bosch Diagnostics has released software updates 6.11 and 6.12 for its ADS X series scan tools, adding coverage for the first 2026 model year vehicles and expanding support for 2024 and 2025 models. The updates include nearly 6,000 new special tests, 450 additional system applications, and new ADAS calibration coverage for RAM, Chevrolet, and GMC vehicles. The updates also add two-step SGW unlock for Stellantis platforms, enabling more seamless diagnostics. Monthly updates ensure ADS X users stay equipped to diagnose and service the latest vehicle systems efficiently.

The JohnDow Industries Centralized Fluid Evacuation System is built directly into the service facility, designed to provide a cleaner and safer work environment, faster service turnaround, and higher customer satisfaction. This system is permanently installed with direct lines to the waste-oil tank and requires no compressor, which means reduced noise, wear, and maintenance. Designed for high-volume, multi-bay operations.

For more information visit FleetMaintenance.com/55329511

Designed for high-volume tire and

The ProBalance Diagnostic Wheel Balancer No. E900, from Coats is a high-performing direct drive wheel balancer with new diagnostics. It’s up to 10 times faster than non-direct drive balancers and is backed by a 10-year warranty on the motor. Featuring a touchscreen interface, it uses a diagnostic roller and ProMatch feature to measure radial runout, note wheel and tire shape, and detect issues. Its maximum tire weight is 160 lbs. and maximum diameter is up to 44”.

For more information visit FleetMaintenance.com/55323567

For more information visit FleetMaintenance.com/55329168

Narrow knurled tips provide extra grip

The Lisle Corporation 90-degree Electrical Connector Pliers , No. 38030, feature angled tips for easier access to hard-to-reach connectors. Designed to remove many single and double connectors found on cars, trucks, and heavy-duty vehicles, the narrow knurled tips provide extra grip when removing connectors in tight spaces. The pliers may also work on fuel lines, EVAP lines, and DEF fittings with tabs that must be depressed to disengage. The tool is 7” long and made from forged carbon steel for extra strength and durability. The pliers feature dual-material grips for additional comfort.

For more information visit FleetMaintenance.com/55329191

The Portable Jump Starter and Air Compressor, No. SL1686, from Schumacher Electric is a compact, lithium-powered, multi-function device designed for automotive, outdoor, and emergency use. It delivers 1,800 peak amps for 12V jump-starting and features fast-charging USB-C and USB-A ports, a three-mode LED worklight (SOS, strobe, flashlight), and a high-efficiency air compressor with a maximum pressure of 150 psi. The compressor includes four inflation modes and a custom setting, with automatic shutoff at the preset pressure.

For more information visit FleetMaintenance.com/55329190

The Launch Tech USA TSAP3 is designed to simplify and streamline TPMS service, and features over 11 different TPMS functions for performing diagnostics on most aftermarket sensor brands, with constant over-the-air updates to ensure the most up-to-date vehicle coverage. According to Launch Tech, the TSAP3 can perform complex relearns in under two minutes. Additional features include guided relearns with step-by-step instructions for all relearn procedures, the ability to diagnose and reset TPMS systems on both domestic and import vehicles, standalone operation, and LTR sensor compatibility.

For more information visit FleetMaintenance.com/55329518

Brass Knuckle Spike Glasses provide both long-lasting anti-fog performance and UV protection with BK-Anti-Fog+, a molecularly fused layer that resists heat, humidity, and repeated cleaning, exceeding the EN 166/168 anti-fog standard by 45 times and blocking 99.99% of UVA and UVB rays with UV 6 protection. Fit is highly adjustable, including a fivestep ratcheting temple, flexible rubber tips, a floating reinforced-rubber nosepiece, and a soft integrated brow guard, allowing technicians to wear them comfortably all day while maintaining clear vision in harsh conditions.

For more information visit FleetMaintenance.com/55329178

Ideal for damaged chrome-capped lug nuts

The 4-Piece Half Size Metric Flip Socket Set from Cal-Van Tools is designed for removing inflated, damaged, or warped chrome-capped style lug nuts found on many domestic and import vehicles. Each double-sided, 6-point flip socket features deep wells for secure engagement and fits a 1/2” drive. Made from durable chrome molybdenum steel with a corrosion-resistant black oxide finish, the sockets are impact-rated for use with power tools. The set includes a 3” extension bar and comes in a molded plastic carrying case for organized storage and easy transport.

For more information visit FleetMaintenance.com/55329175

The Rotary Lift XA14 Alignment Scissor Lift has a 14,000-lb. capacity and is designed for shops where floor space is at a premium. Over 34% narrower than a standard four-post lift, it allows for recessed or surface-mount installation to maximize shop layout flexibility. The open front and rear design provides unobstructed access to vehicle adjustment points, making wheel alignments and repairs easier for technicians. The lift features two 7,000-lb. rolling jacks, adjustable turning radius gauges, air-actuated rear slip plate locks, and longer ramps. With 72” of vertical rise, it supports comfortable access for repair work while minimizing bay space requirements. For more information visit FleetMaintenance.com/55329573

Continental ’s Vantage hose line includes two lightweight, flexible options: Vantage Nitrile and Vantage EPDM. Built for reliable performance in air and multipurpose applications and available in 200 and 300 psi working pressures, both are designed for easy handling and installation in daily shop or industrial use, from pneumatic tool operation to general air flow management. The Vantage EPDM features a durable synthetic rubber tube and cover for use with air, water, and light chemicals, while the Vantage Nitrile provides ARPM Class A high oil resistance with aramid reinforcement. Non-conductive and built for demanding environments.

For more information visit FleetMaintenance.com/55329532

The BendPak RWS-200WL Battery-Powered Wheel Lift eliminates the physical strain of wheel service, protecting technicians while delivering greater uptime. Unlike airpowered models that must stay tethered to an air supply, this rechargeable battery-powered lift is truly mobile for use throughout the shop. With double the power of 12V units, the RWS-200WL delivers faster lift speeds, superior torque, and a 200-lb. capacity to easily handle oversized wheels and tires. By reducing technician fatigue and lowering the risk of strainrelated injuries, the RWS-200WL can help reduce workers’ comp claims, support OSHA-compliant safety practices, and even contribute to lower insurance premiums over time.

For more information visit FleetMaintenance.com/55329521

WEDNESDAY

Kick up your heels at this lively bash on Wednesday evening at the Gaylord, packed with live music, line dancing, games and good ol’ fashioned fun. No ticket required.

Join us in Grapevine, Texas this January to make sure you’re leading with confidence and staying in control as you face the road ahead. Explore the latest heavy duty aftermarket products, connect with your industry and learn how to improve your operations using data-driven solutions.

JANUARY 19-22 GRAPEVINE, TEXAS See the Signals. Make Your Move. | hdaw.org